Distillation method and apparatus

a technology of distillation method and apparatus, which is applied in the direction of lighting and heating apparatus, refrigeration and liquid storage, and solidification. it can solve the problems of increasing electrical power consumption, inability to produce constant product slate of liquid and gaseous products from air separation plants, and inability to meet the needs of liquid and gaseous products. it achieves a high production rate and the effect of increasing the expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

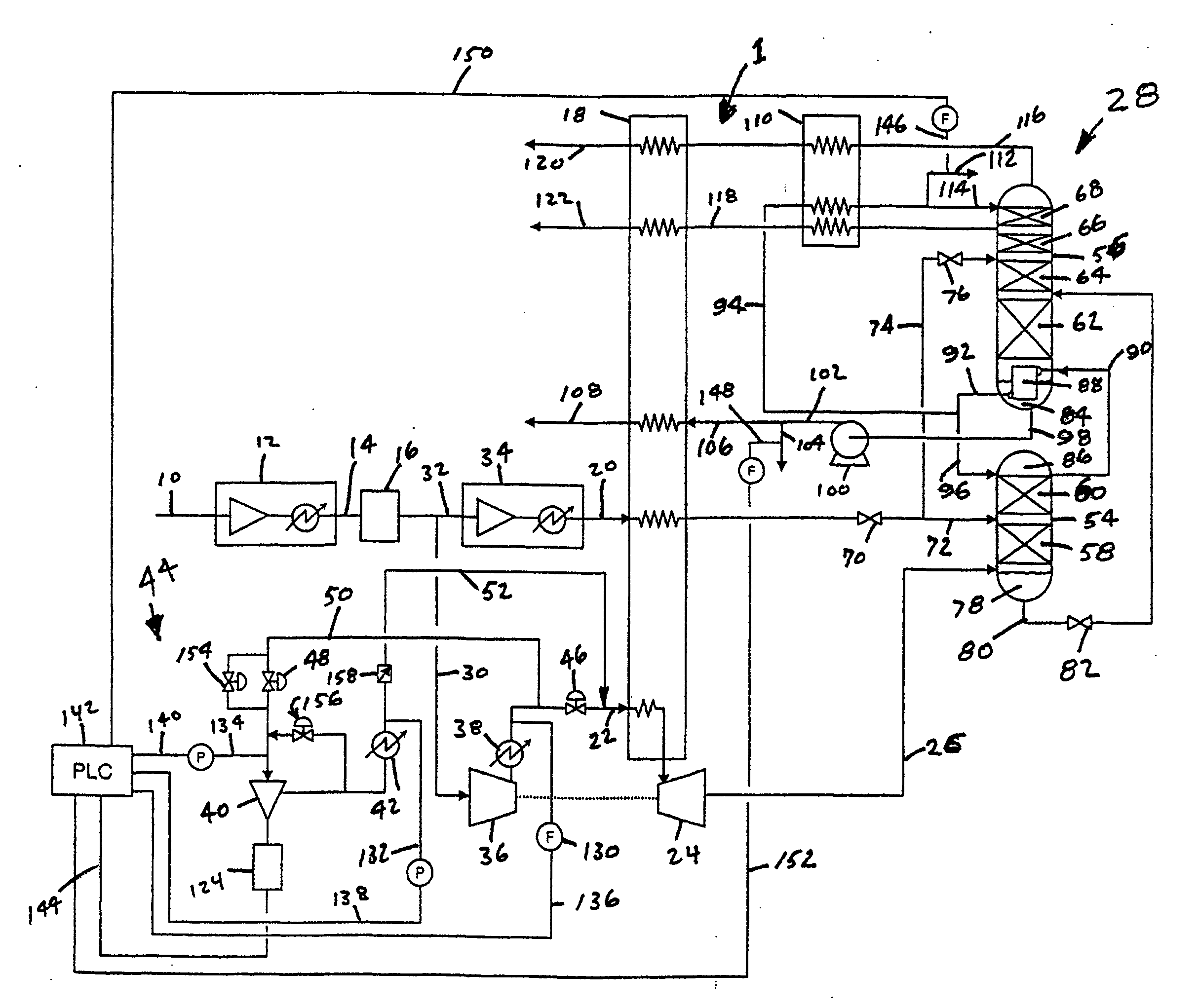

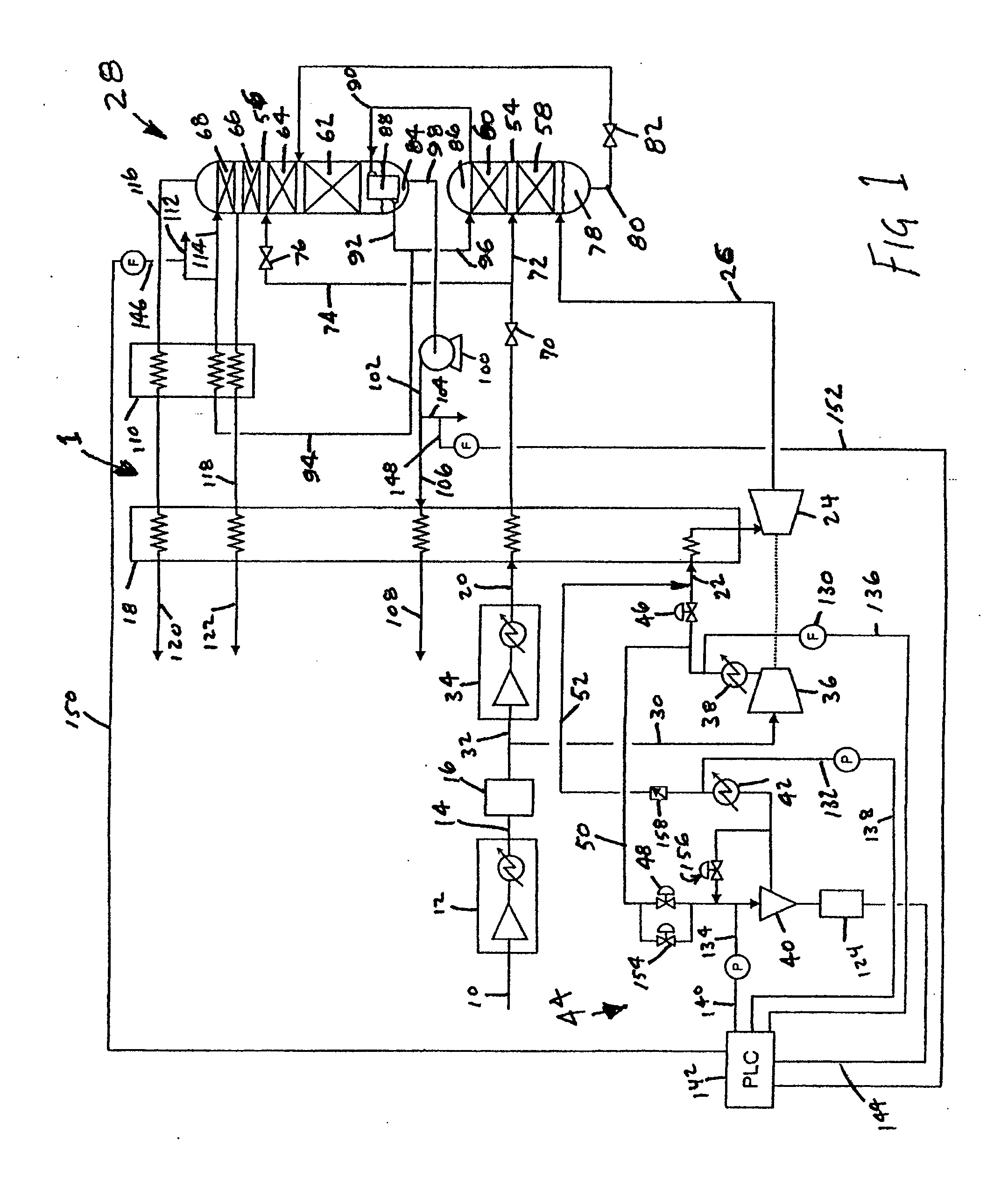

[0030]A feed stream 10 containing oxygen and nitrogen, for instance air, is distilled within a distillation apparatus 1 in accordance with the present invention. Distillation apparatus 1 is designed to produce gaseous and liquid oxygen products as well as gaseous nitrogen and liquid products. It is understood, however that this is for purposes of illustration only and the present invention has applicability to a distillation apparatus in which only a single column is used to produce gaseous and liquid nitrogen products such as in a nitrogen generator as has been described above. Additionally, although not illustrated, a distillation apparatus and method in accordance with the present invention might also include other columns that, for example, are specifically designed for argon and rare gas production.

[0031]Feed stream 10 is compressed within a base load compressor 12 that may be an intercooled, integral gear compressor with condensate removal. The resultant compressed feed stream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com