Patents

Literature

292 results about "Gaseous oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gaseous Oxygen. Oxygen is a colorless, odorless, and tasteless gas at normal atmospheric temperatures and pressures. It transforms into a liquid at –183 °C (its boiling point). Oxygen combines readily with most elements and numerous compounds. This combining is called oxidation.

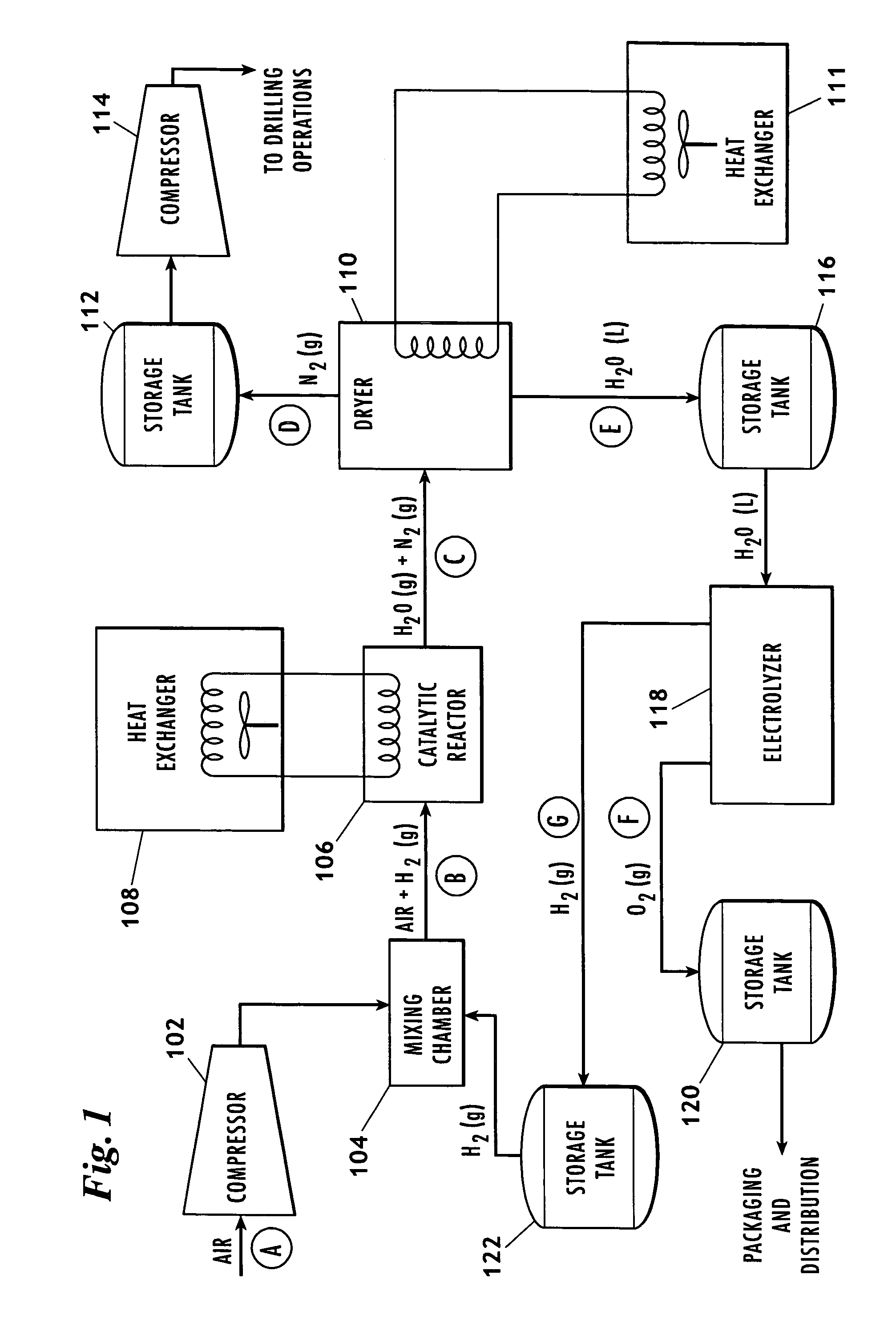

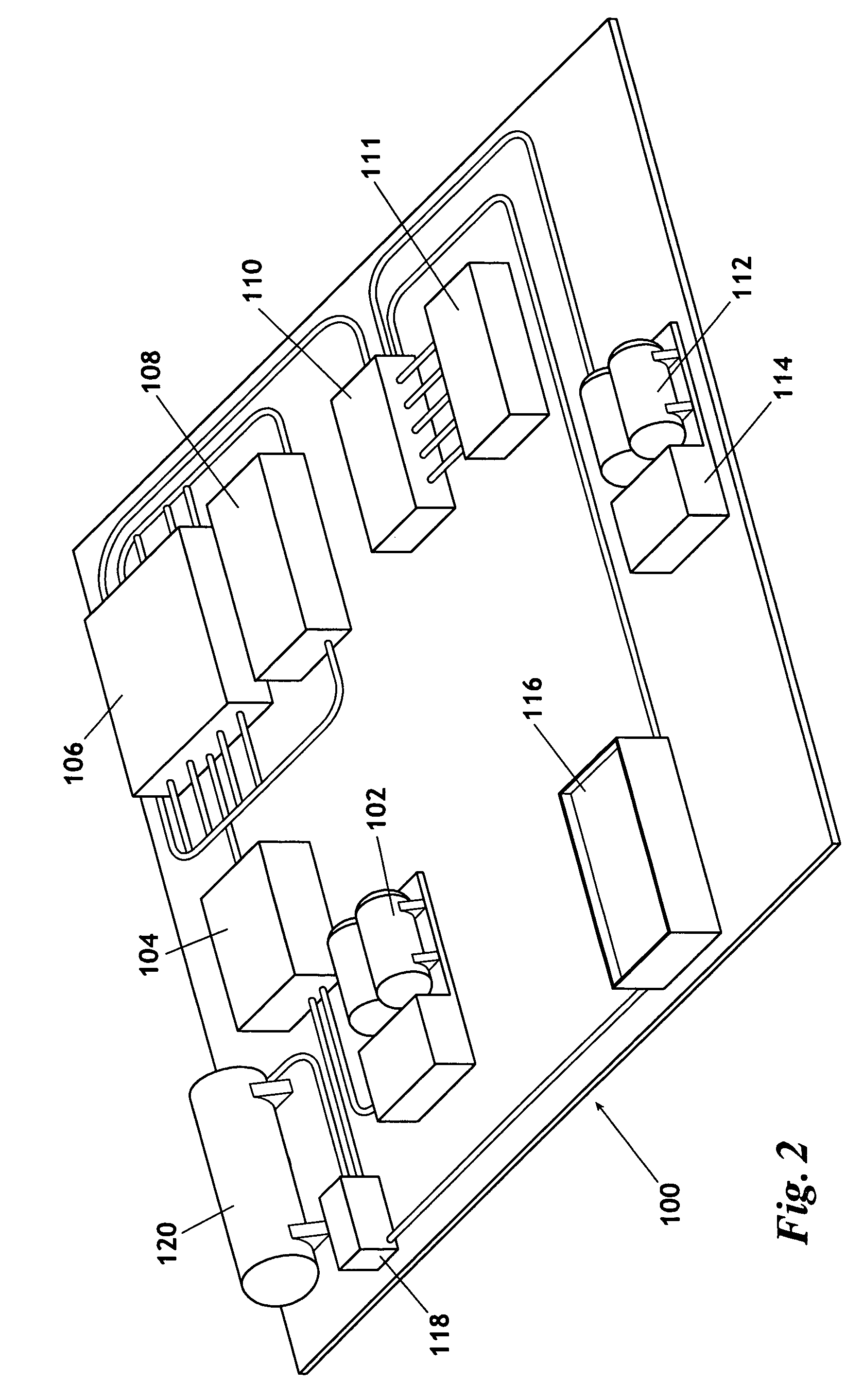

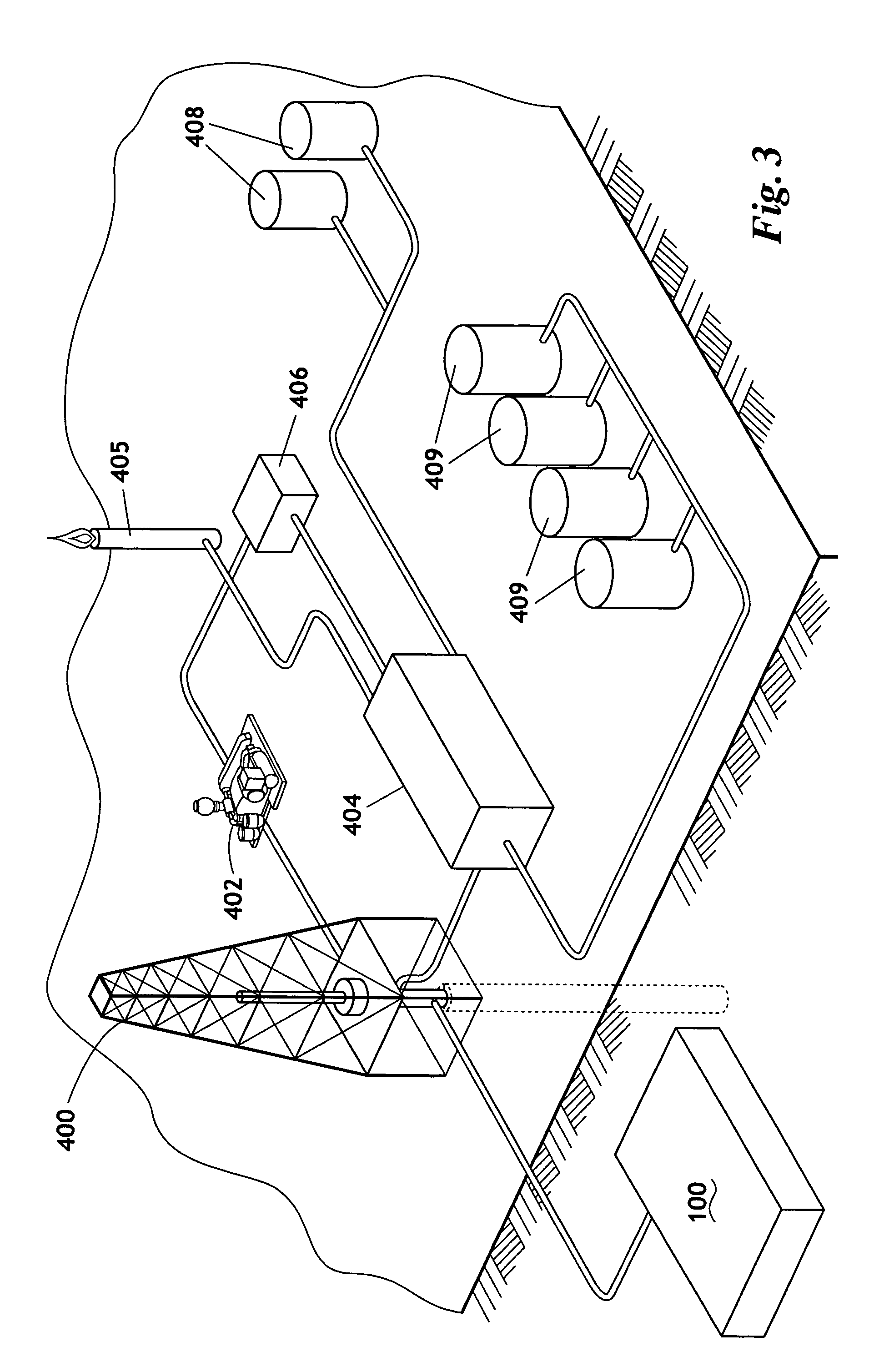

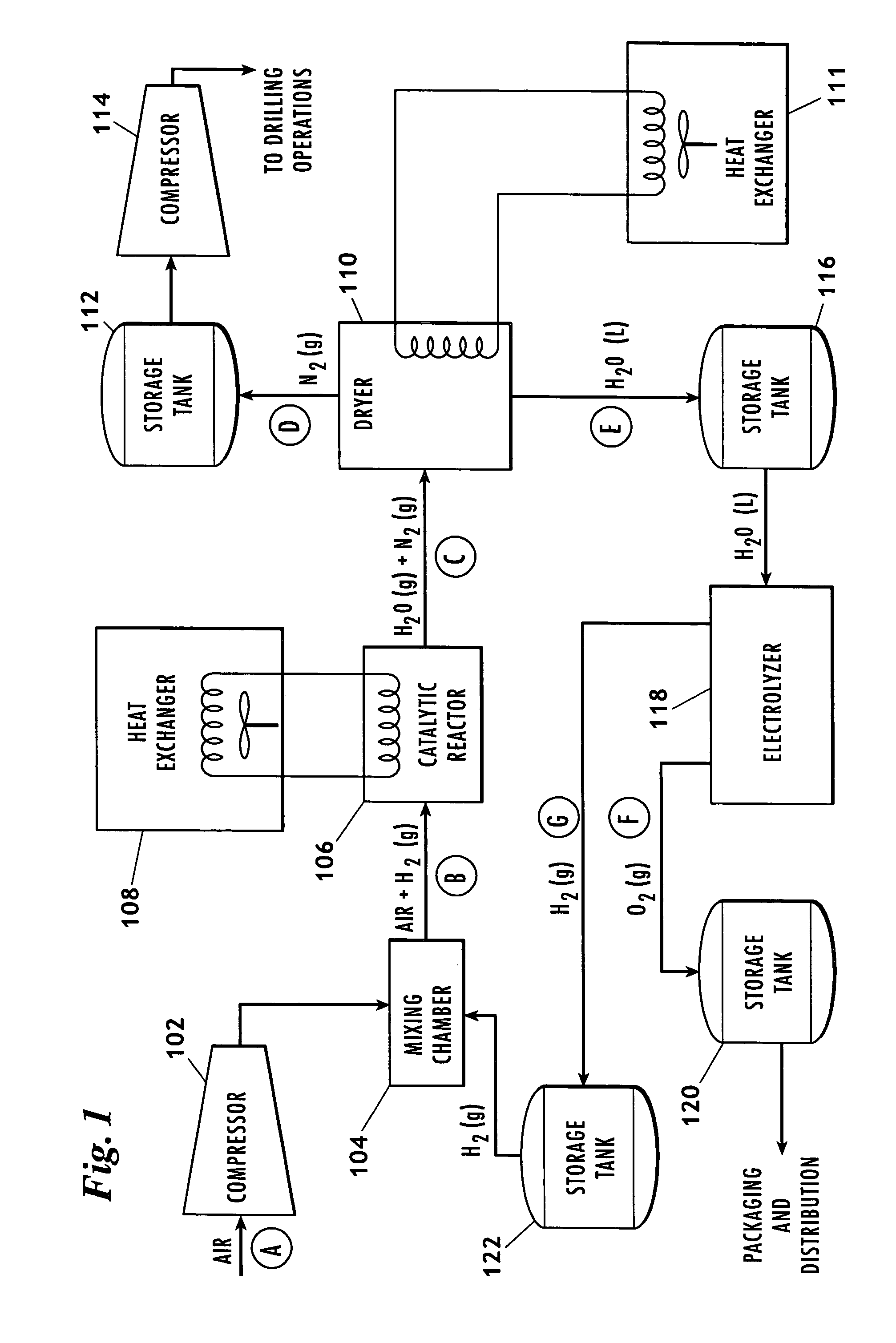

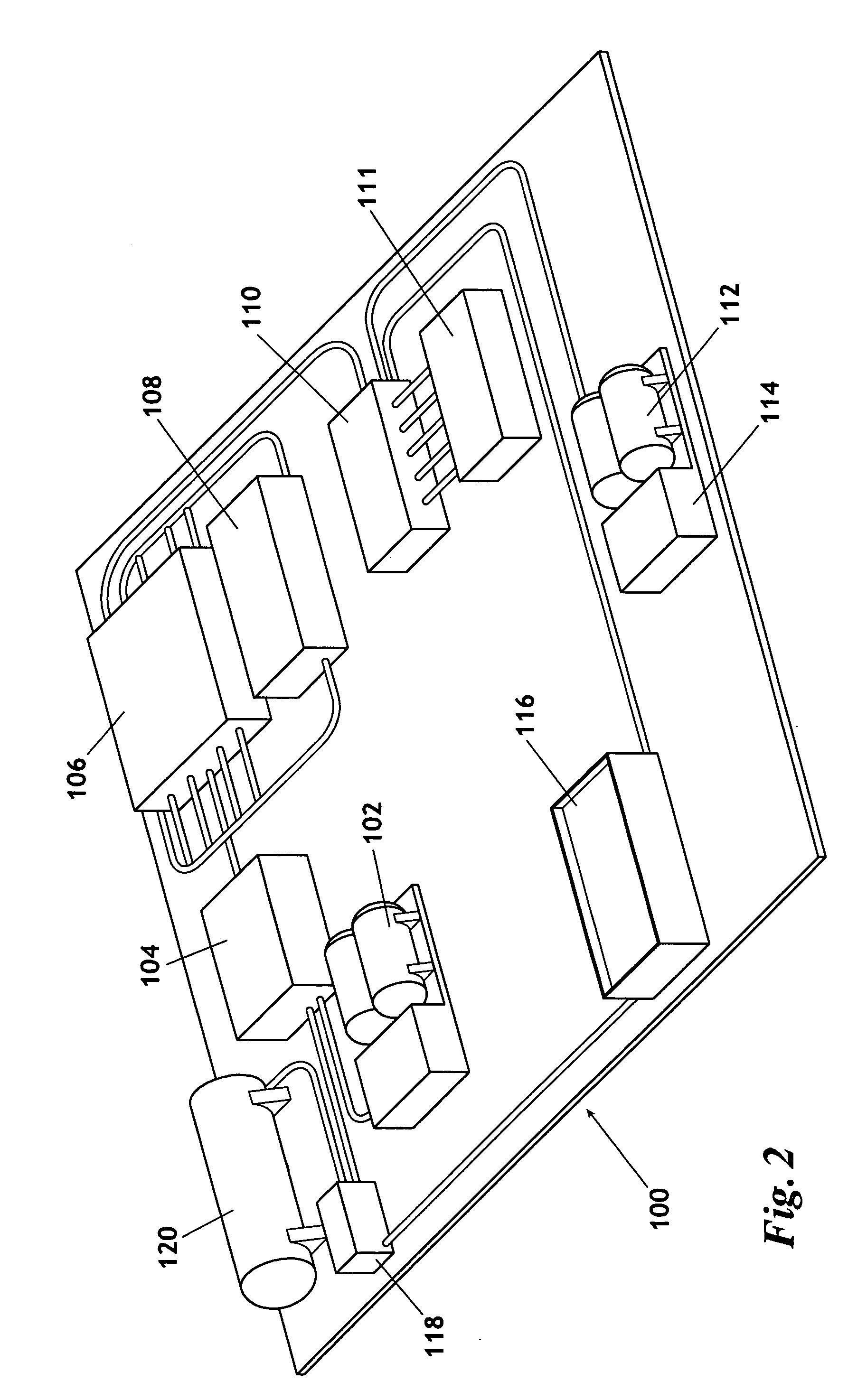

Method for producing nitrogen to use in under balanced drilling, secondary recovery production operations and pipeline maintenance

InactiveUS7468173B2Offsetting costsNitrogen purification/separationDispersed particle separationElectrolysisAtmospheric air

The invention uses a feed of atmospheric air and mixes the air with hydrogen. The hydrogen and air mixture is fed into a catalytic reactor where a deoxygenation reaction occurs. The deoxygenation reaction uses a platinum catalyst to produce water from oxygen and hydrogen. The nitrogen passes through the catalytic reactor without reacting with the hydrogen, the oxygen, or the water. The water is separated from the nitrogen in a dryer. The nitrogen may then be used in drilling and production operations. The water is fed into an electrolyzer where an electrolysis reaction occurs. The electrolyzer passes an electrical current through the water to produce gaseous oxygen and hydrogen. The hydrogen is recycled back to the catalytic reactor and the oxygen may be vented or sold.

Owner:SUNSTONE TECH

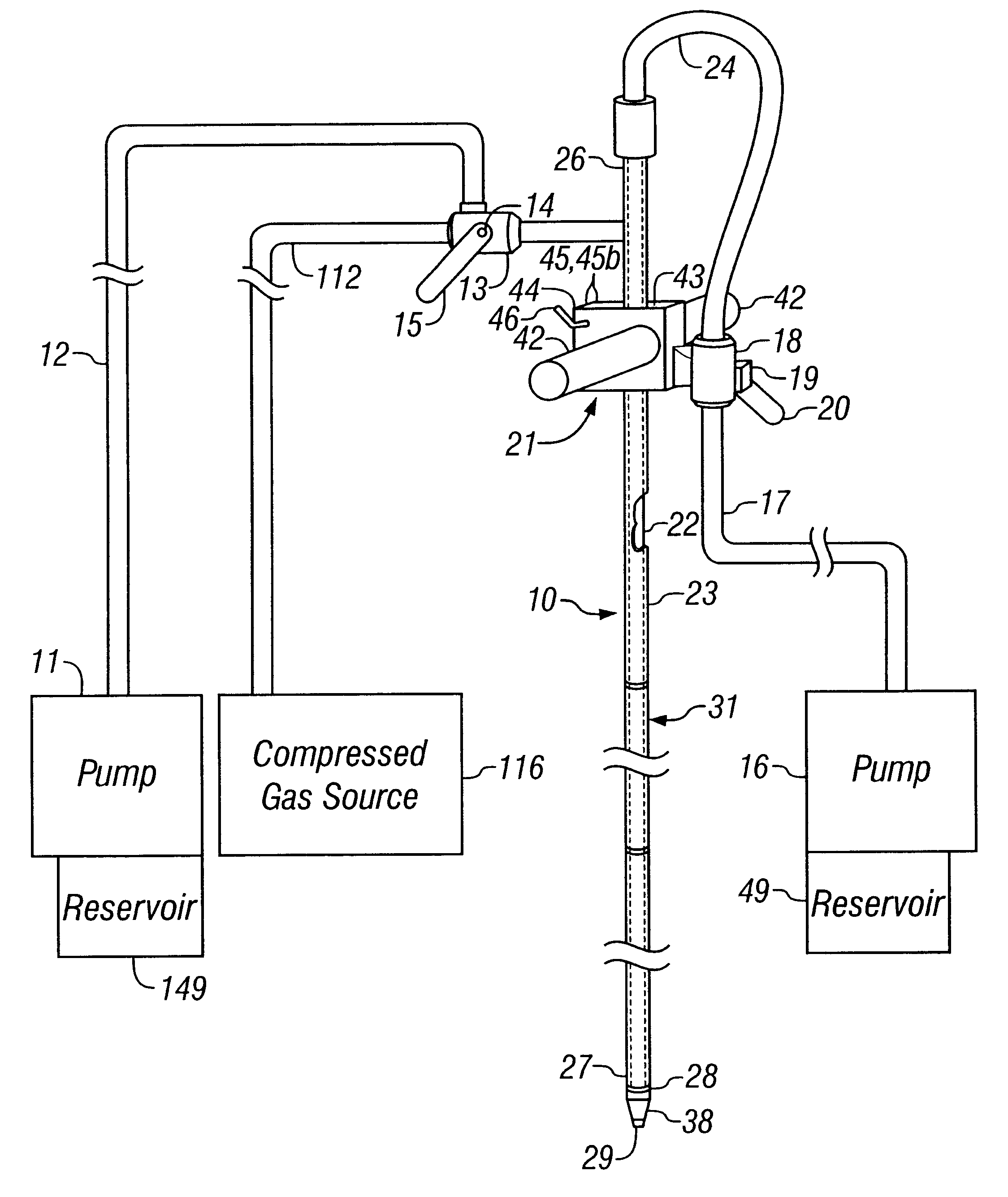

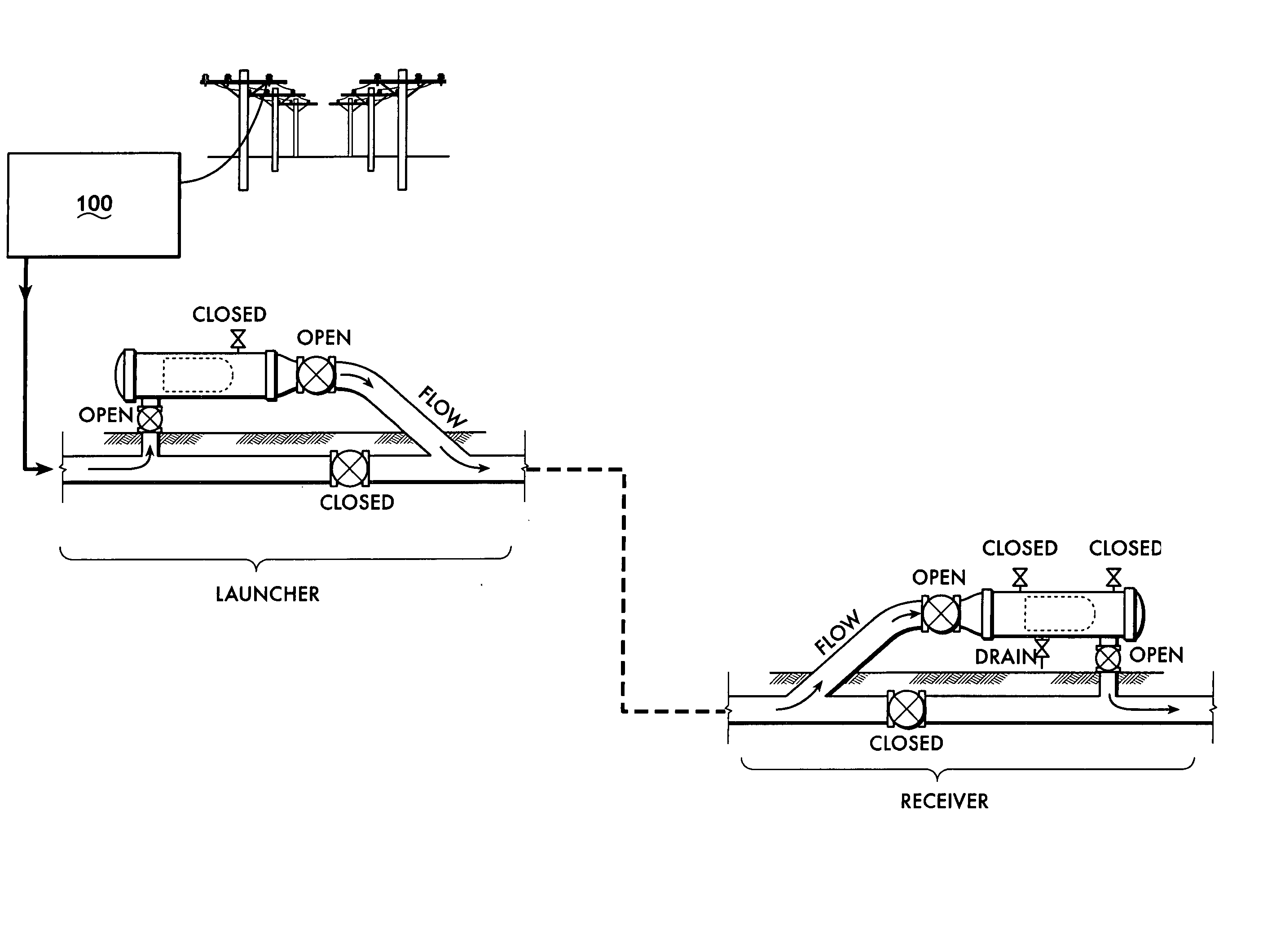

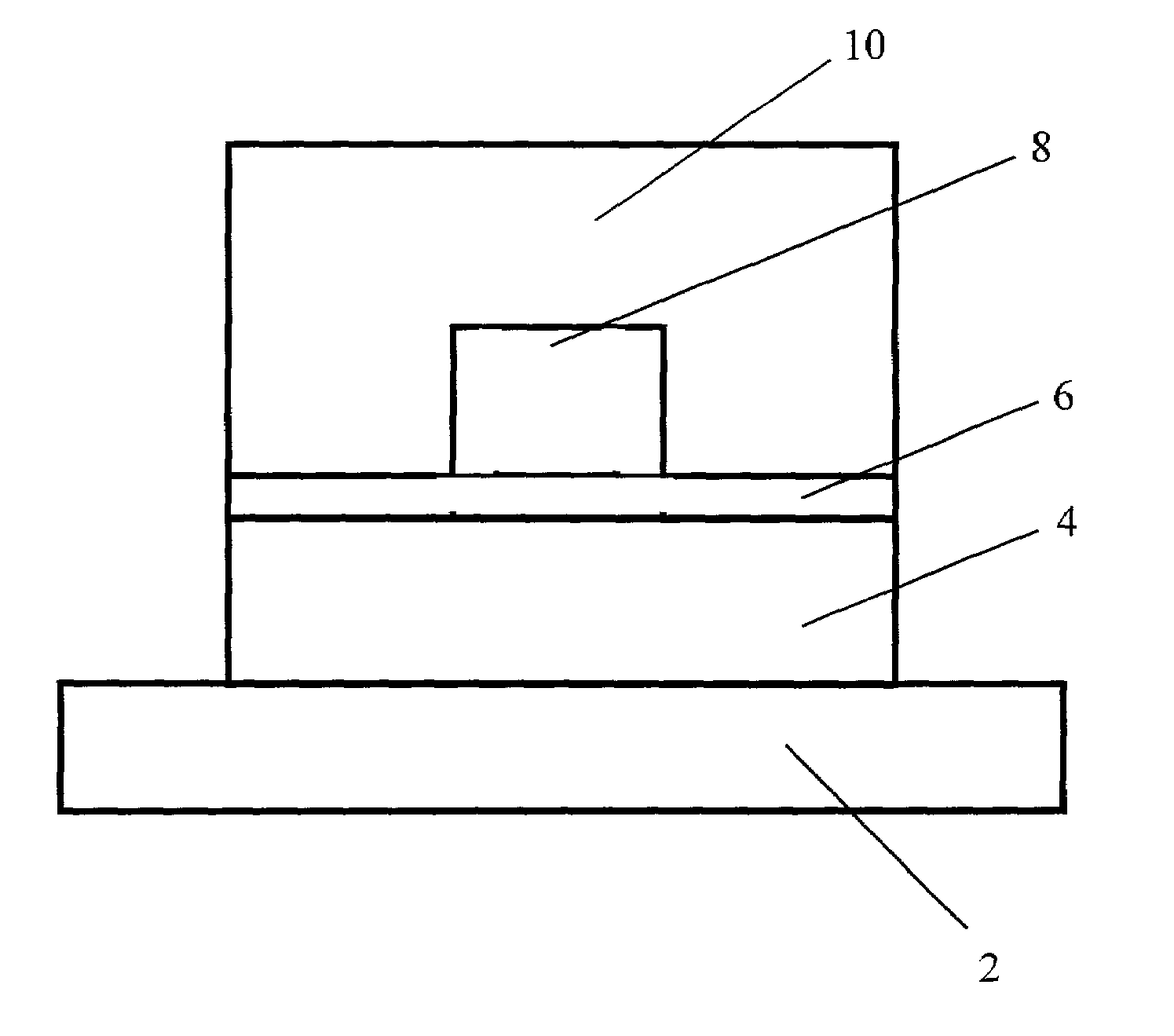

In-situ deep remediation injection system and method

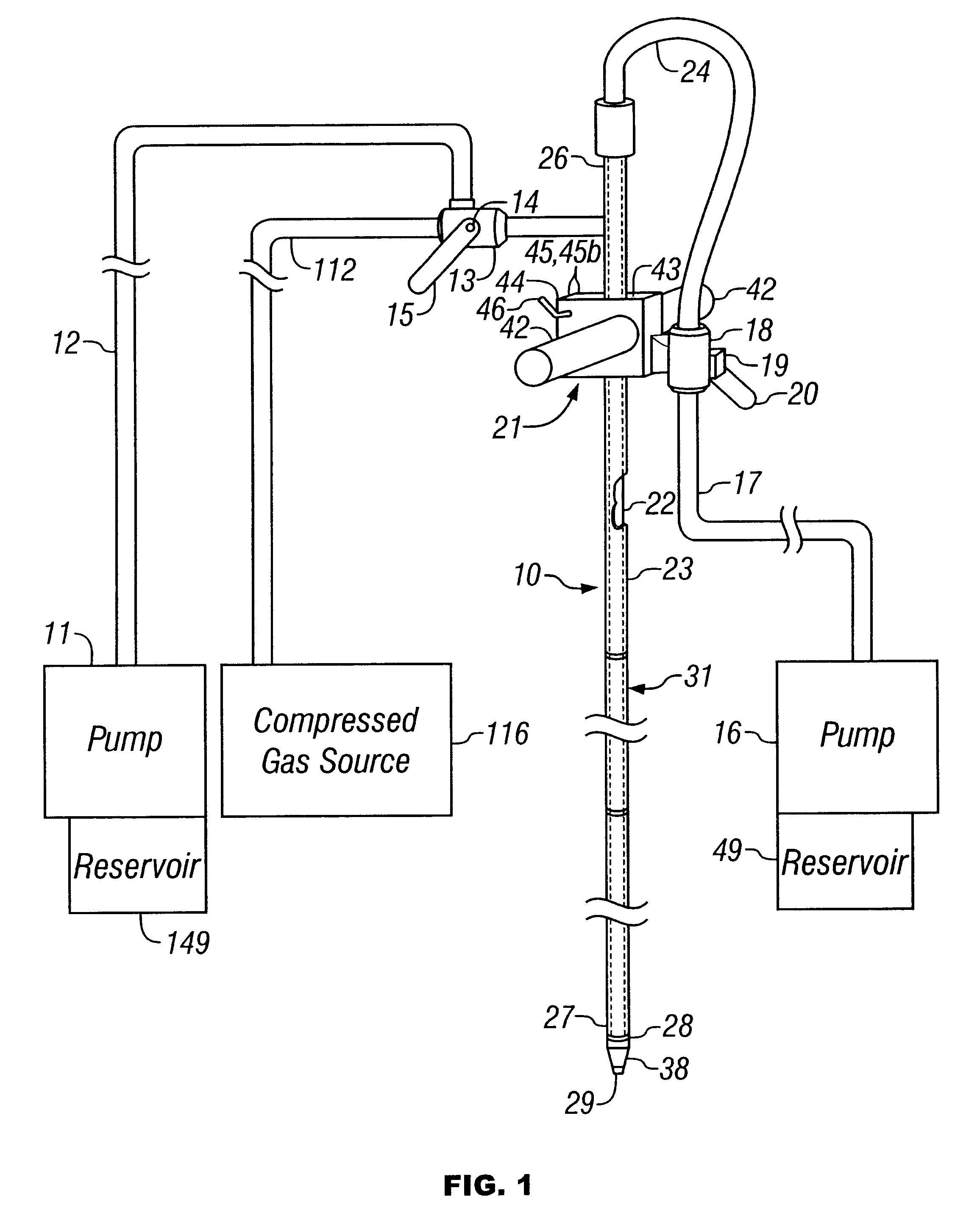

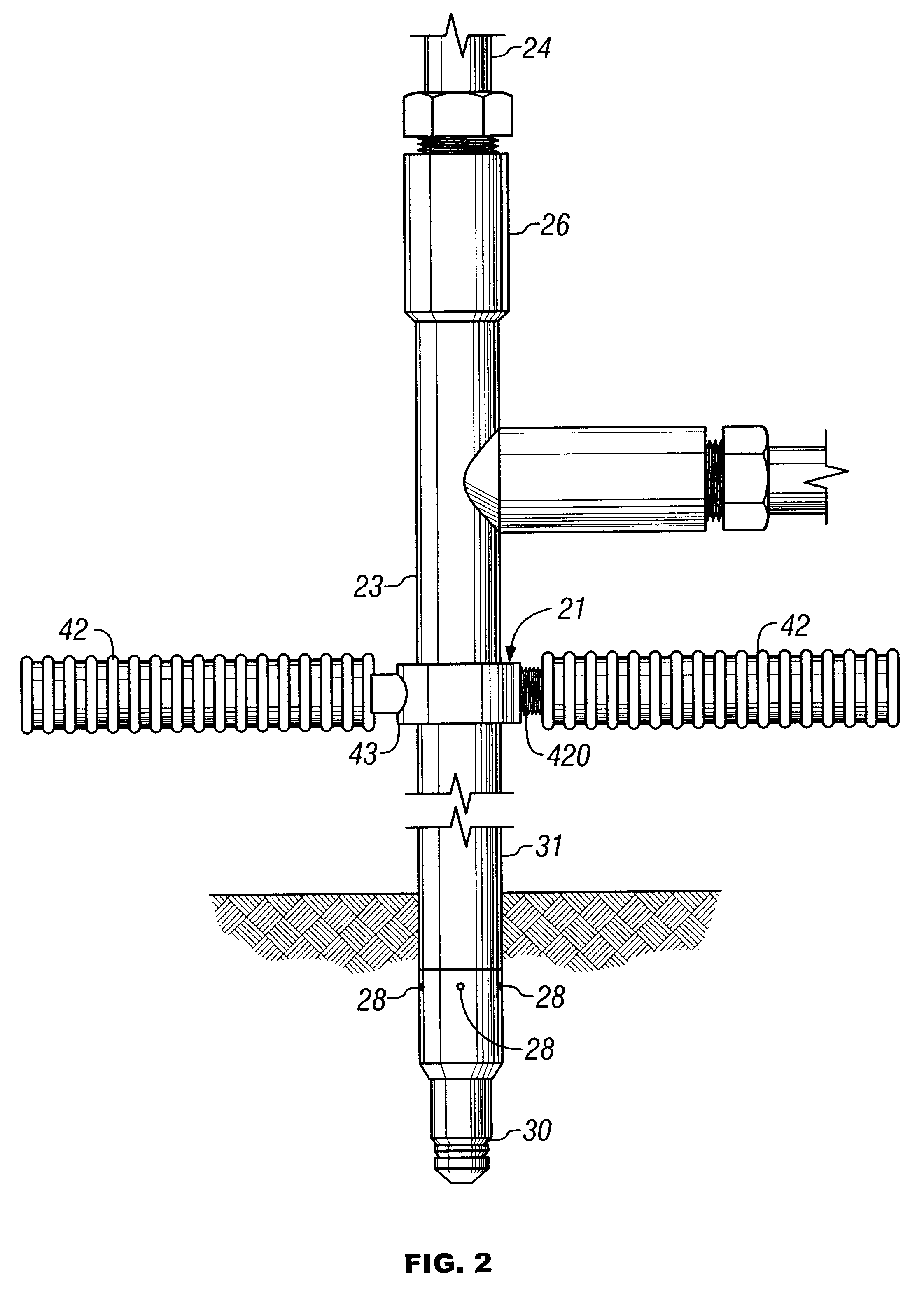

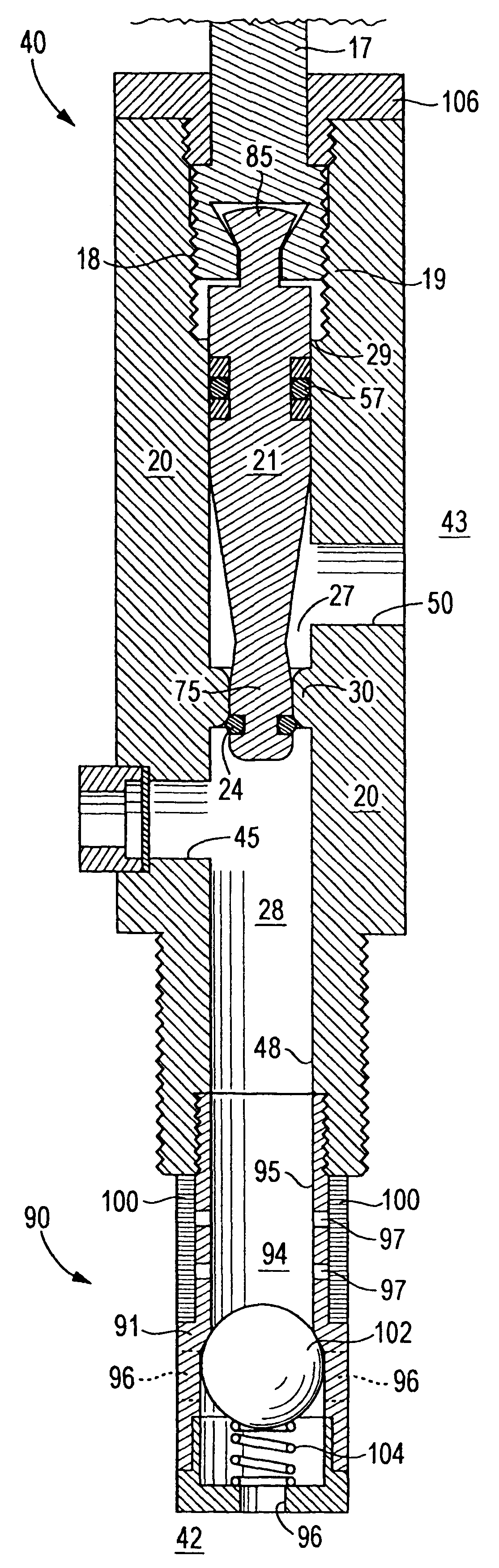

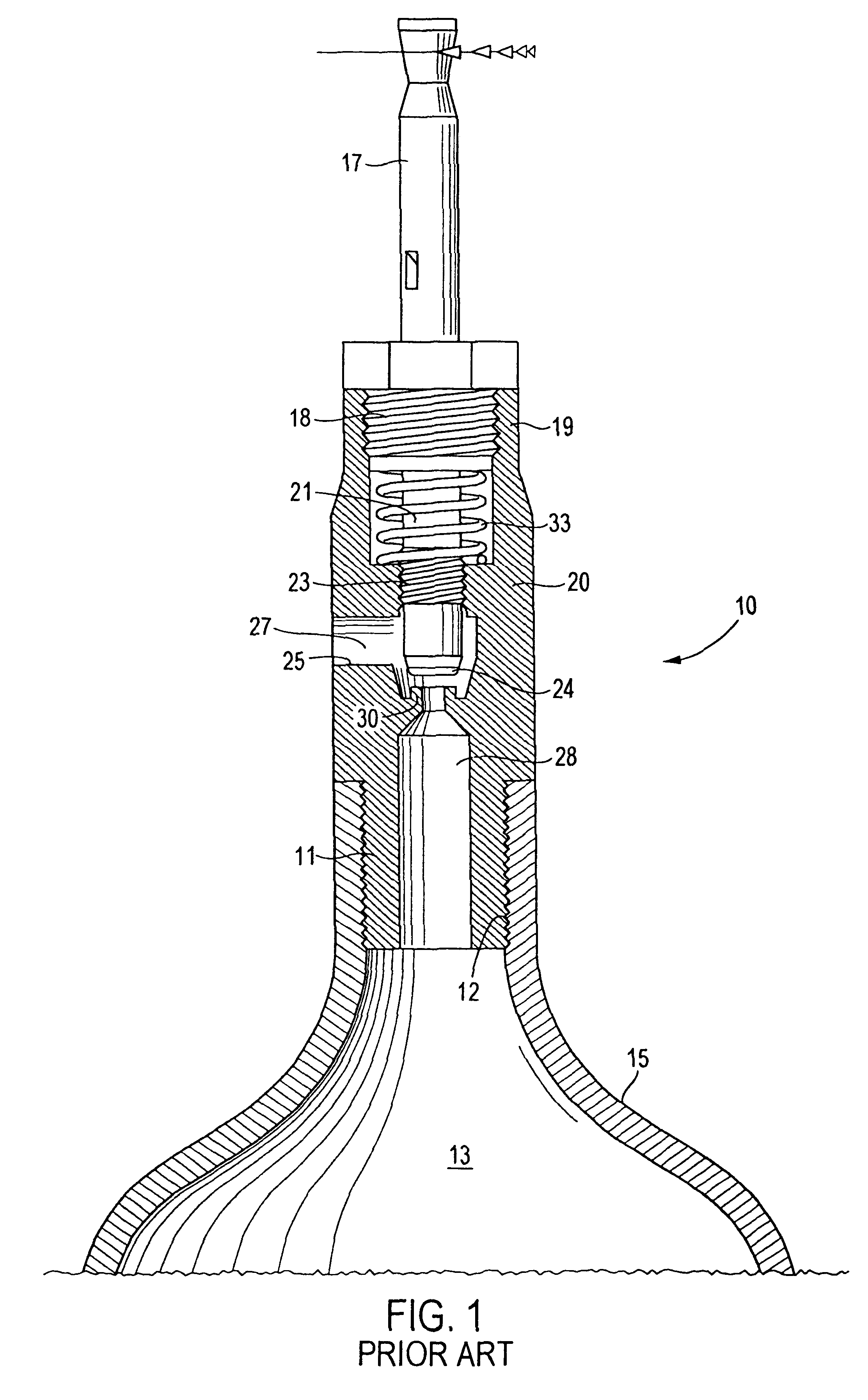

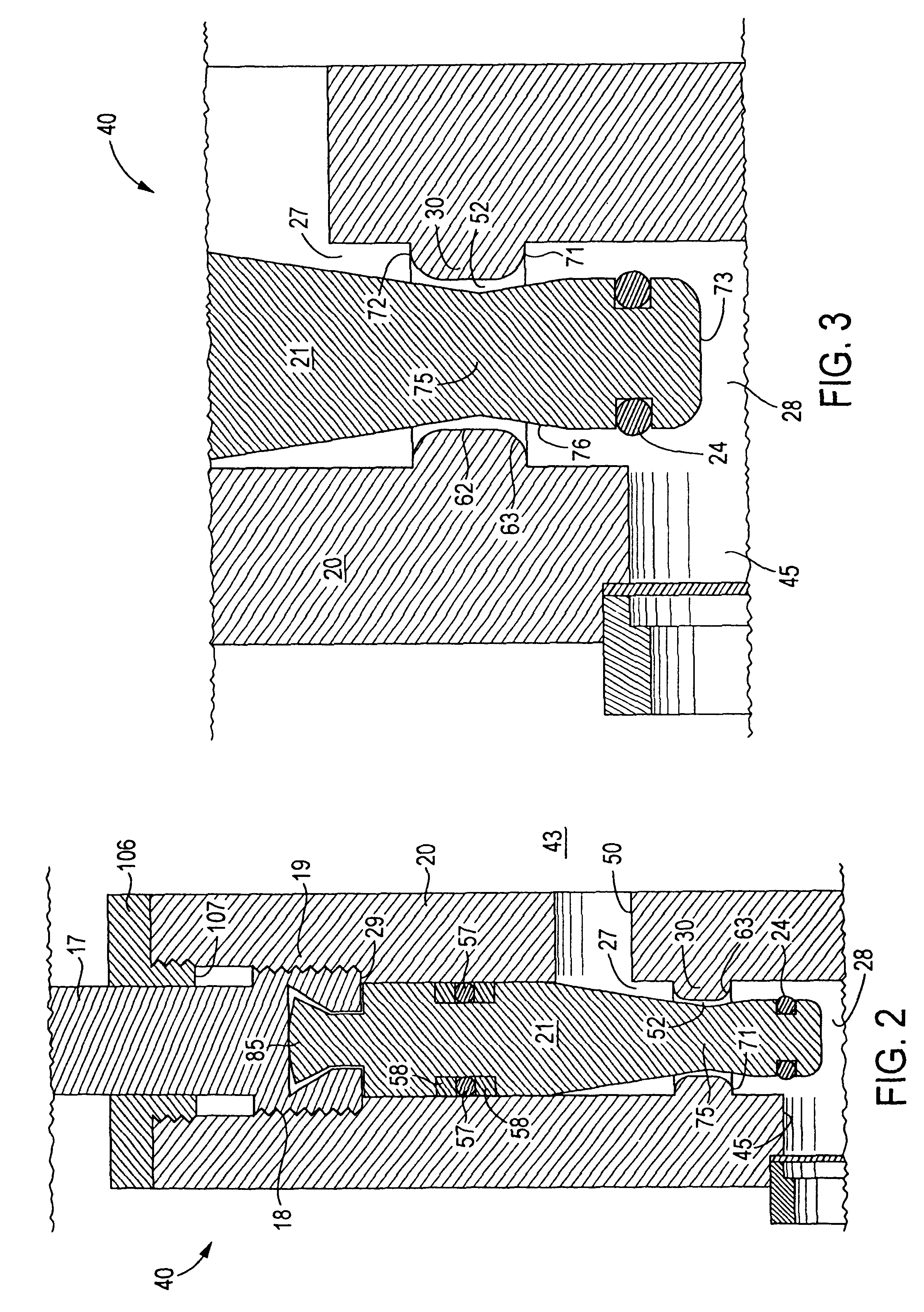

An improved deep remediation injection system for in-situ remediation of contaminated soil and ground water. The system includes a soil penetrating lance for injecting at least two different highly-pressurized fluids taken from the group of air, gaseous oxygen, ozone, oxygenated liquid, hydrogen peroxide, surfactant-containing liquid, catalyst-containing liquid and suspended biologicals-containing liquids, or a liquid containing other chemicals, into said contaminated soil as said soil penetrating lance is inserted for penetration therein. The soil penetrating lance has at least an upper set of injection ports, the upper set of injection ports being generally radially spaced-apart on said lance, and at least one lower set of injection ports, the lance having an average width in the vicinity of the upper set of injection ports. The lance further includes substantially fluidically-independent first and second conduits leading, respectively, to the lower set of injection ports and the upper set of injection ports so as to permit delivery of separate pressurized fluid streams to the upper and lower sets of injection ports and then into the soil. The upper and lower sets of injection ports are spaced apart from each other on said lance a distance no farther than about three times the average width of said lance in the vicinity of the upper set of injection ports.

Owner:NICKELL JERRY D

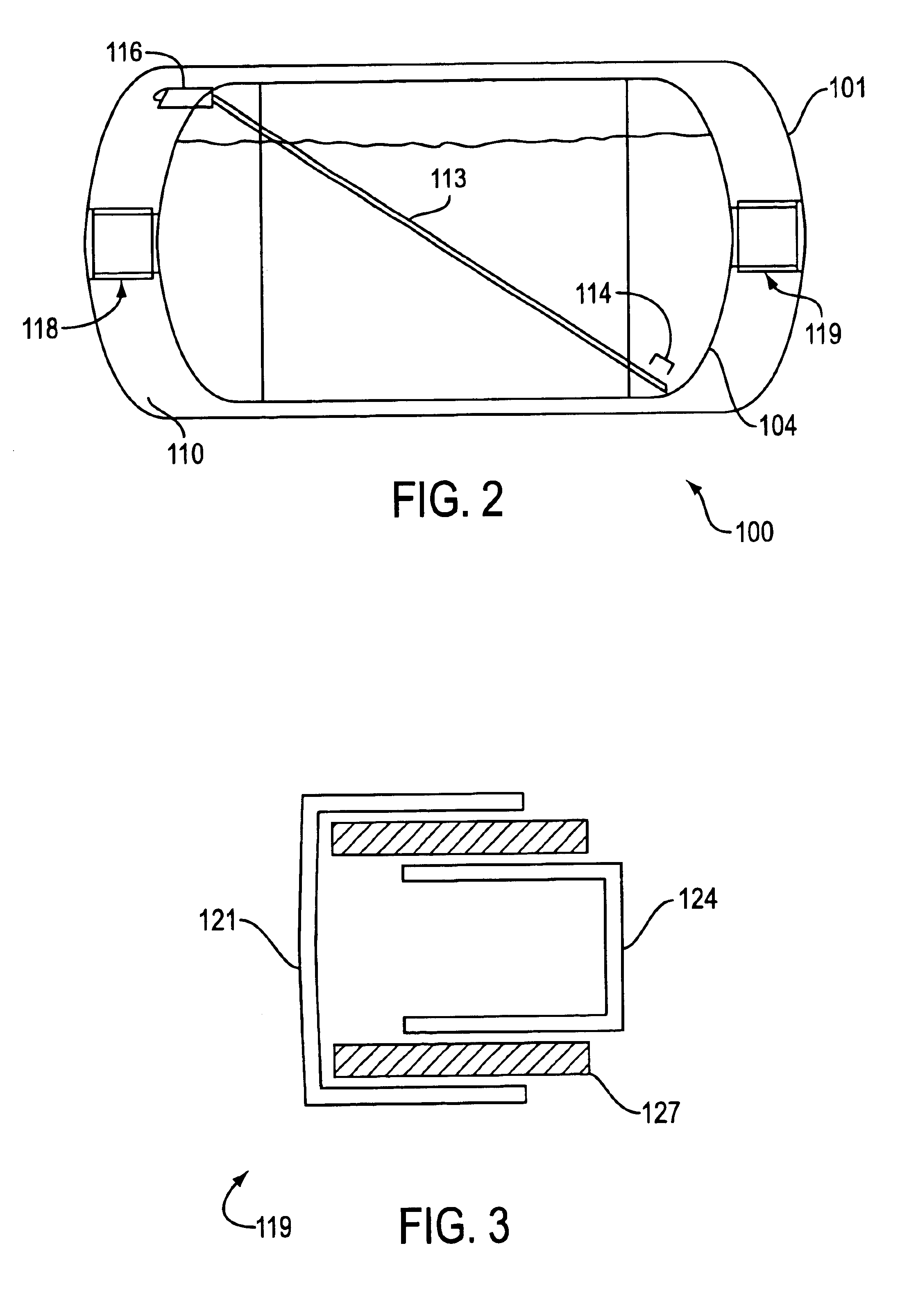

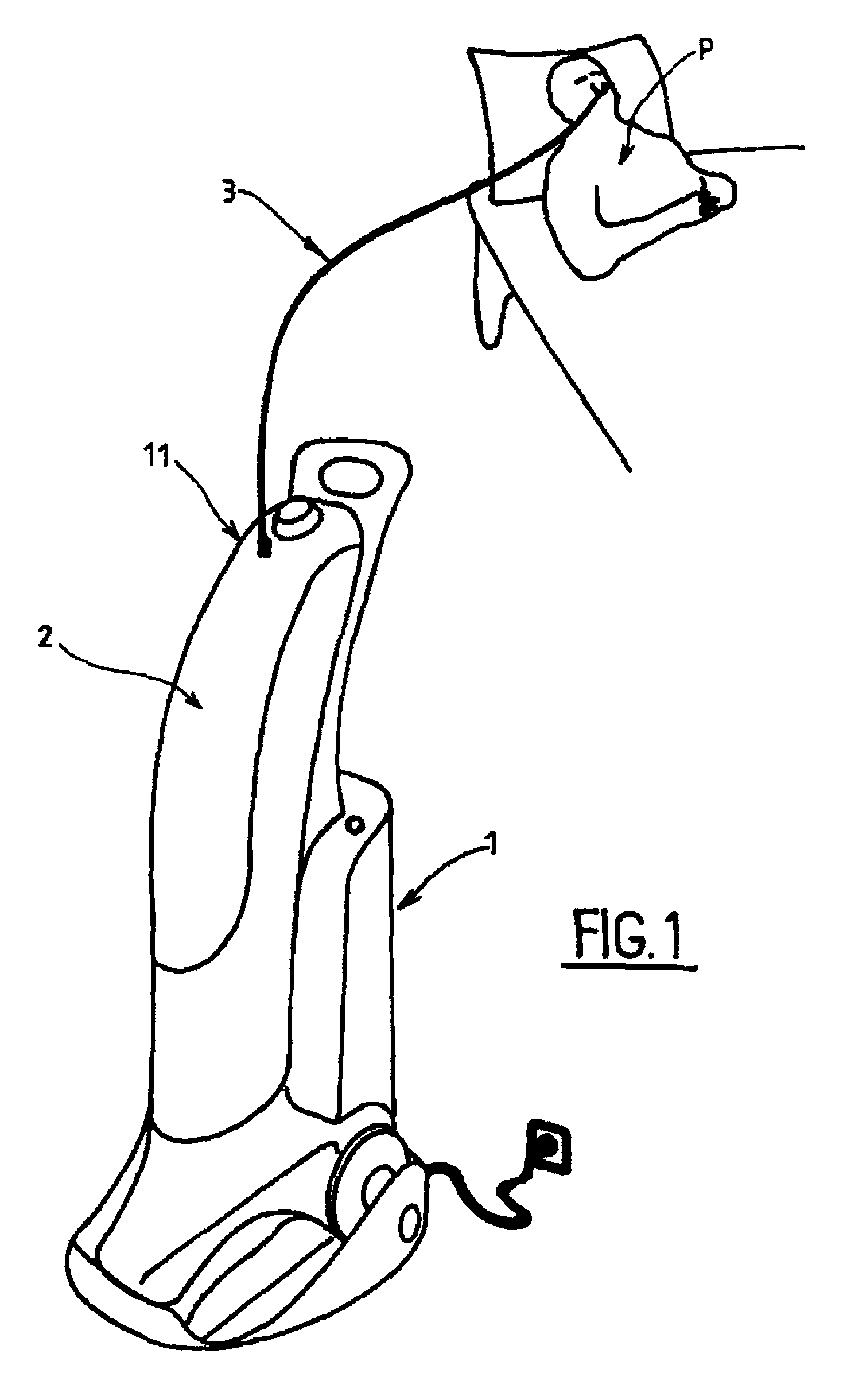

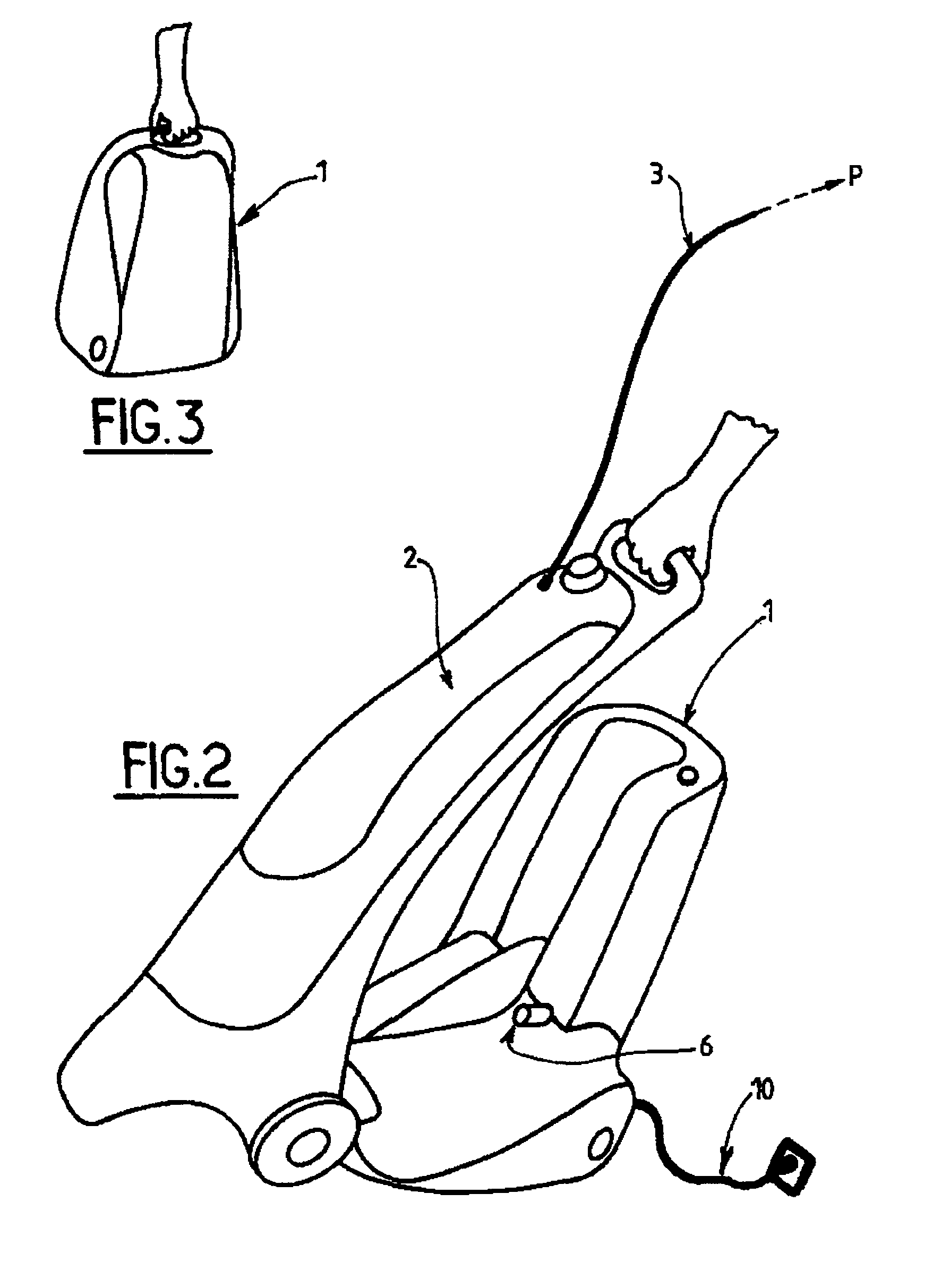

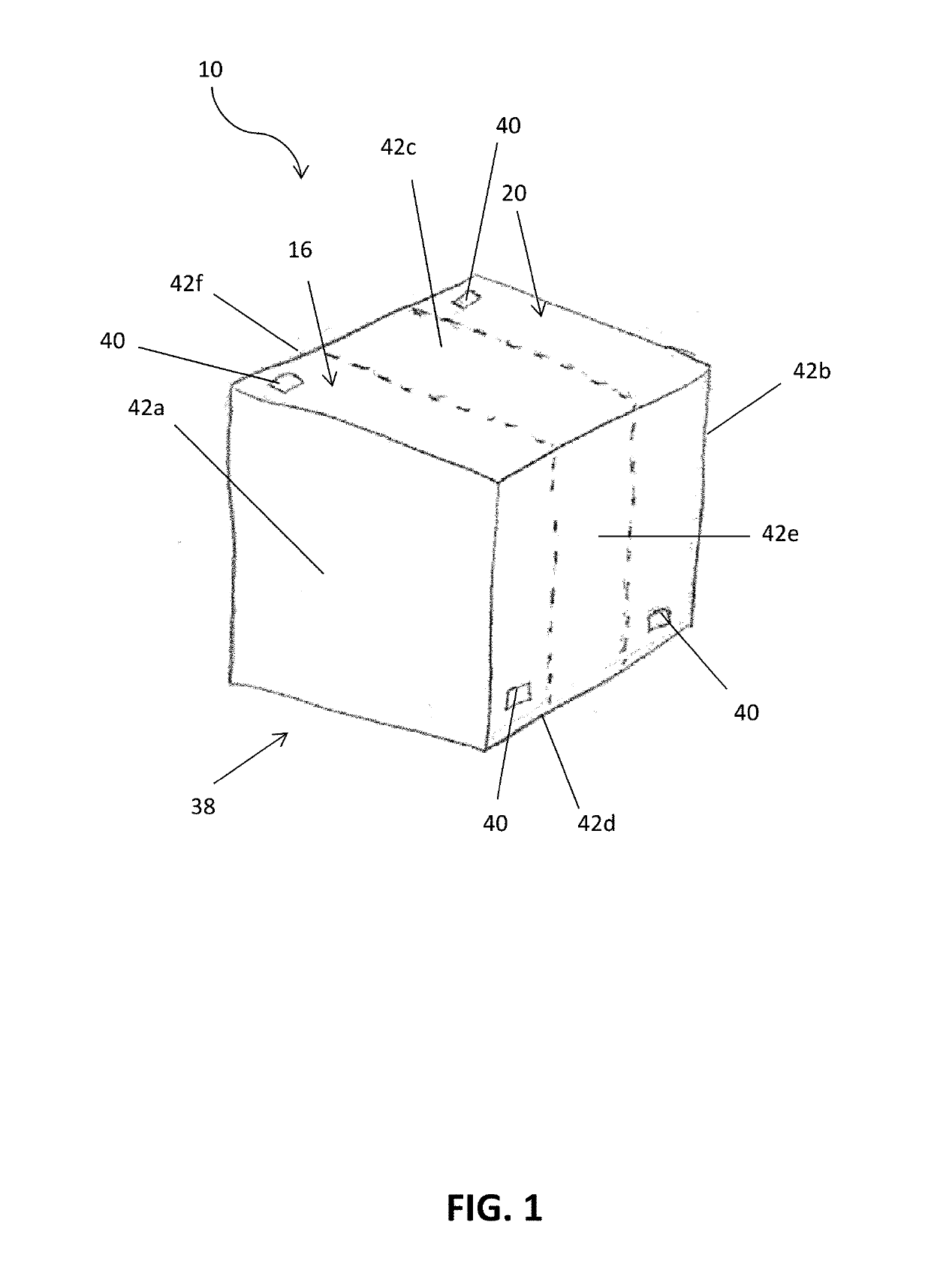

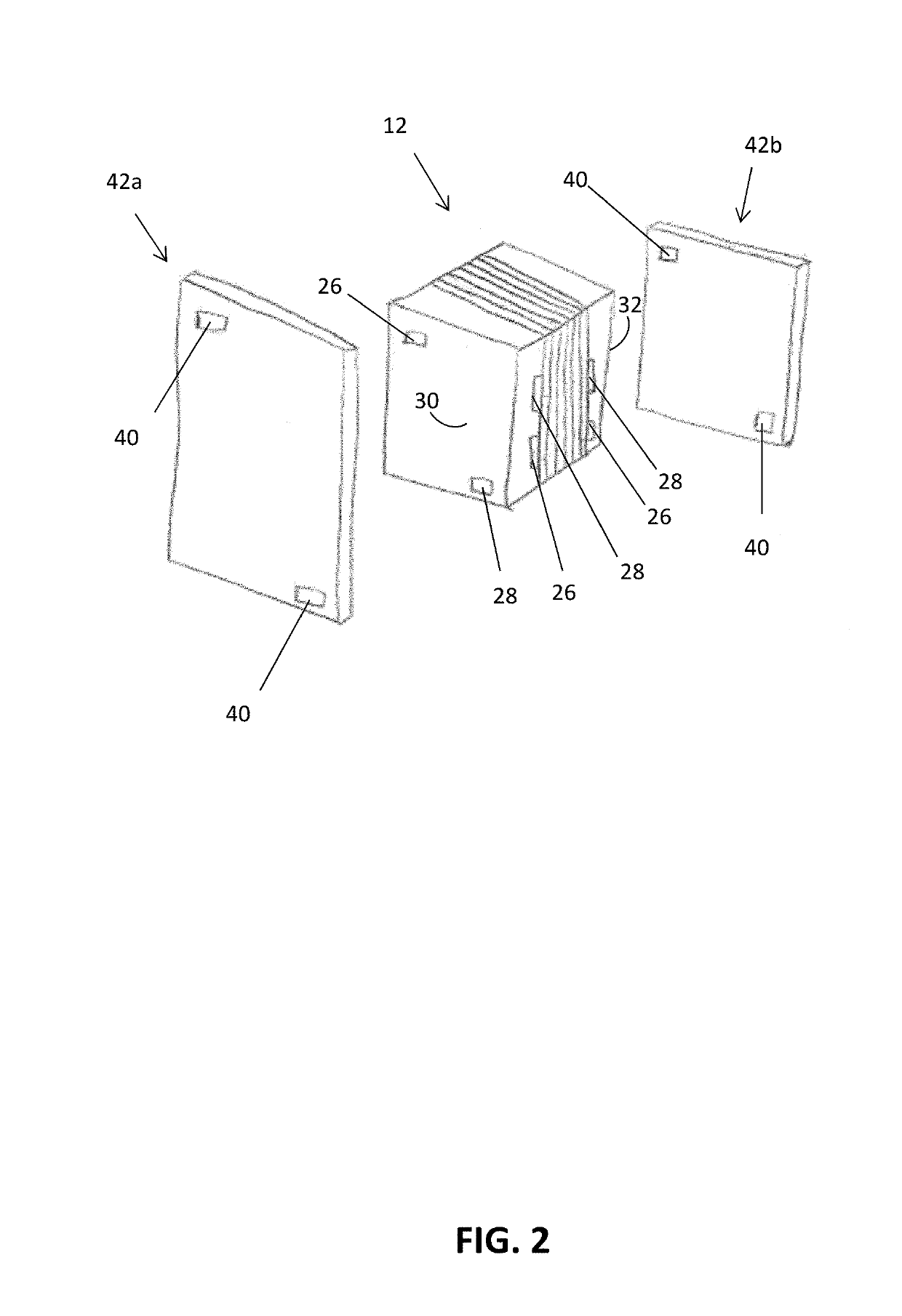

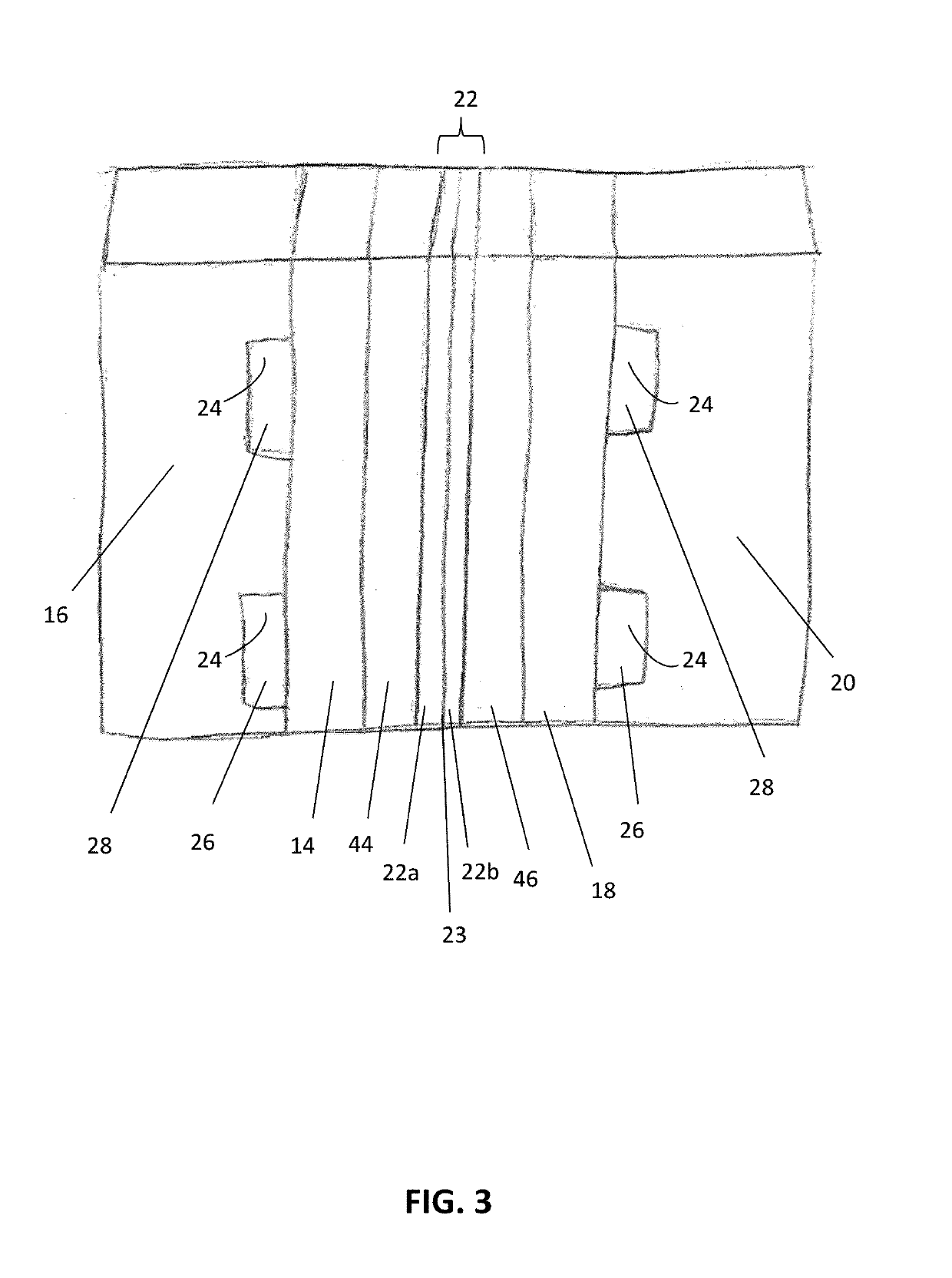

Portable liquid oxygen unit with multiple operational orientations

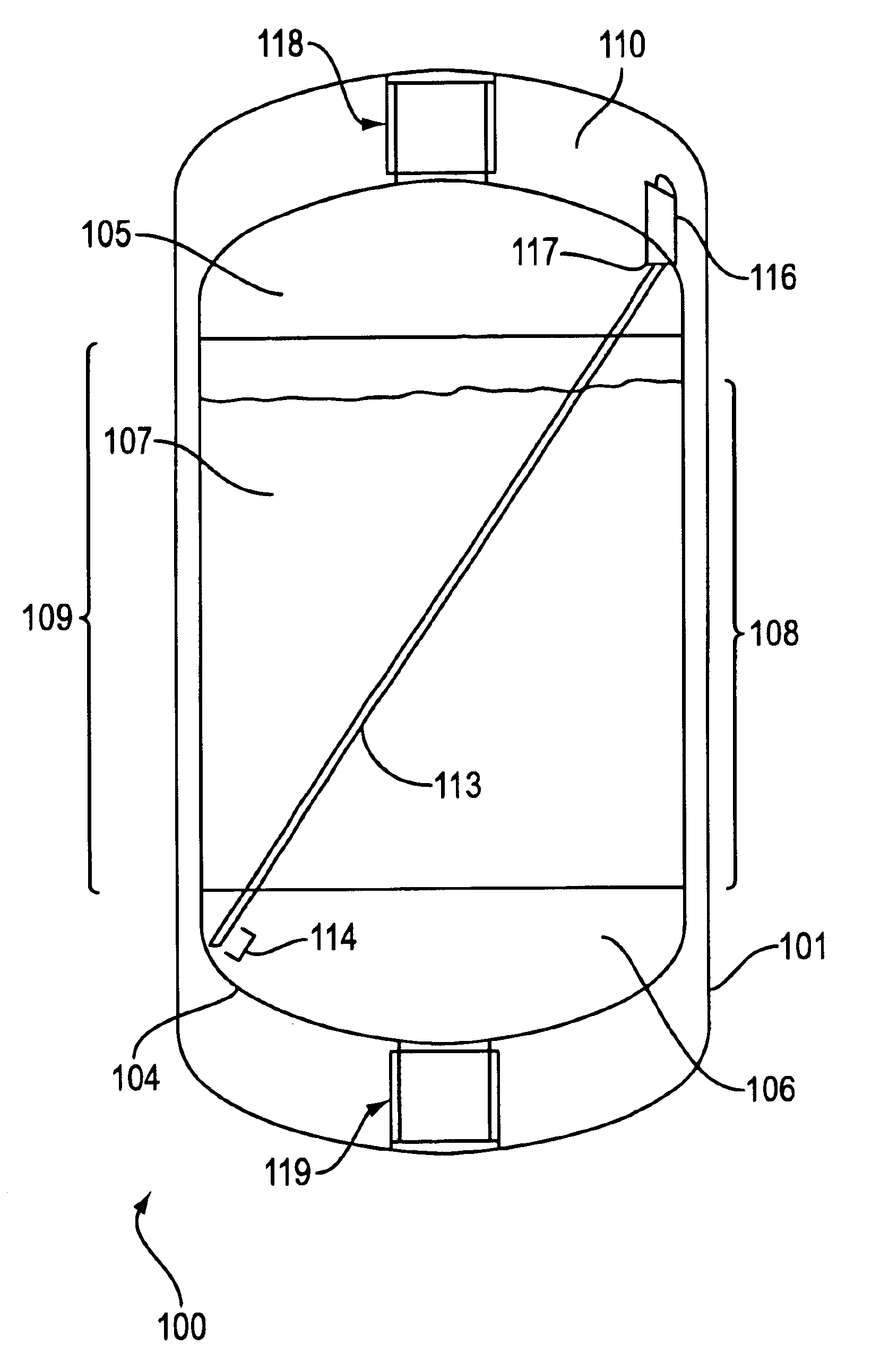

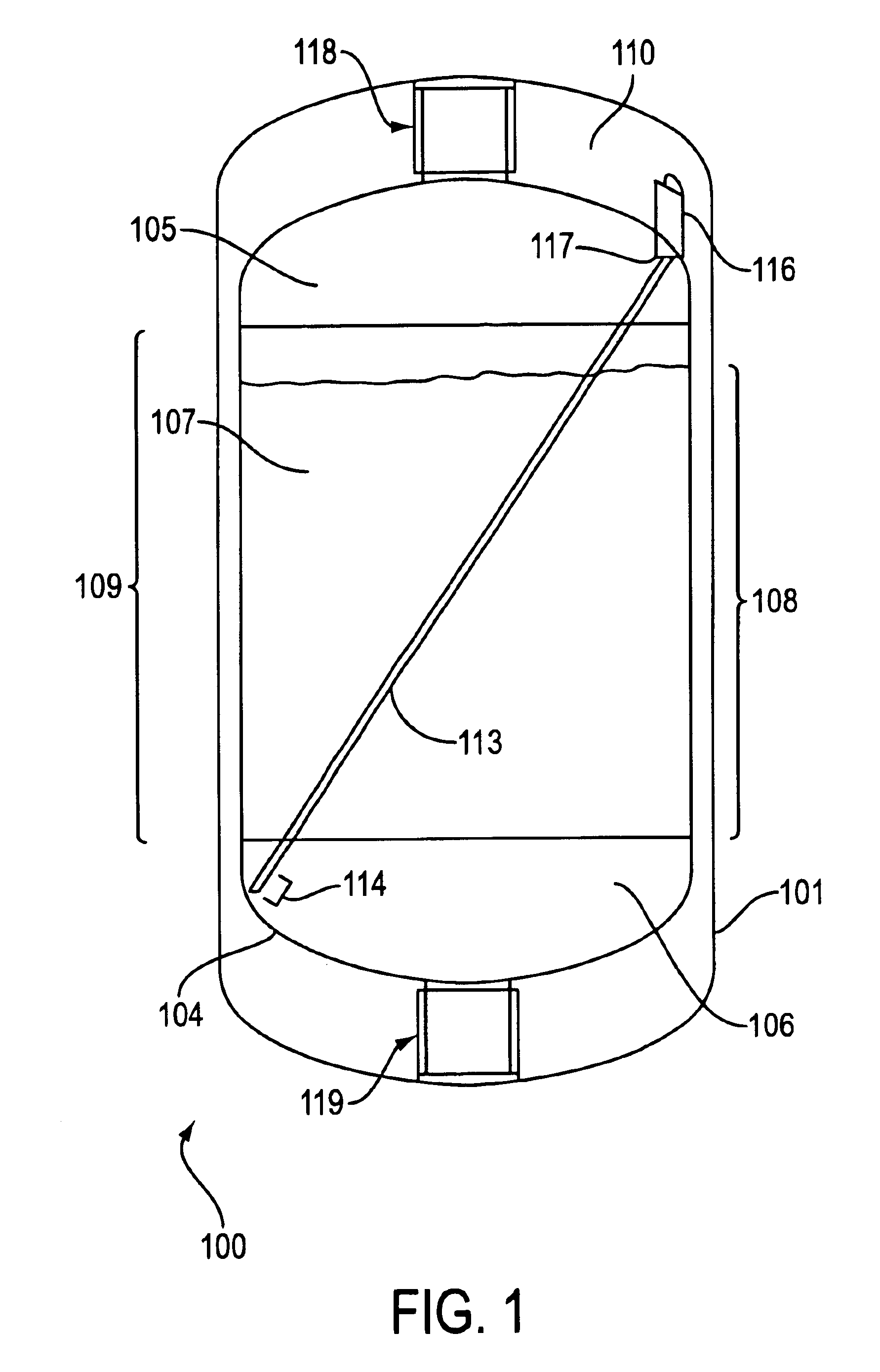

A portable liquid oxygen (LOX) storage / delivery apparatus is provided, including an insulated LOX container having an interior, a top portion, bottom portion, and sidewall, the sidewall including a first and second side portion, both extending between the top and bottom portion, and a port system in communication with the interior for charging the container and for withdrawing LOX and gaseous oxygen. The gaseous oxygen is withdrawn from the container through a first outlet and LOX is withdrawn from the container through a second outlet when the container is positioned in a first orientation with the sidewall vertically oriented, as well as when the container is positioned in a second orientation with the second side portion oriented downwardly and with the first side portion upwardly and overlying the second side portion, and any position in between.

Owner:CAIRE

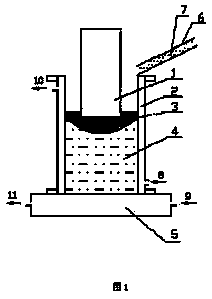

Apparatus for electrolysis of molten oxides

The invention provides improved electrodes for electrolytic cells operating with molten salt electrolytes. Nonconsumable iridium-based anodes of the invention facilitate the release of gaseous oxygen from oxide-containing melts, for example in the electro-chemical production of liquid or gaseous reactive metals from oxides. Cathode substrates of the invention are constructed of a tungsten-based alloy and enable deposition of an overlying liquid-metal cathode. Incorporation of the anode and cathode substrate of the invention into molten-oxide cells establishes a novel method for electrolytic extraction of titanium and other reactive metals.

Owner:MASSACHUSETTS INST OF TECH

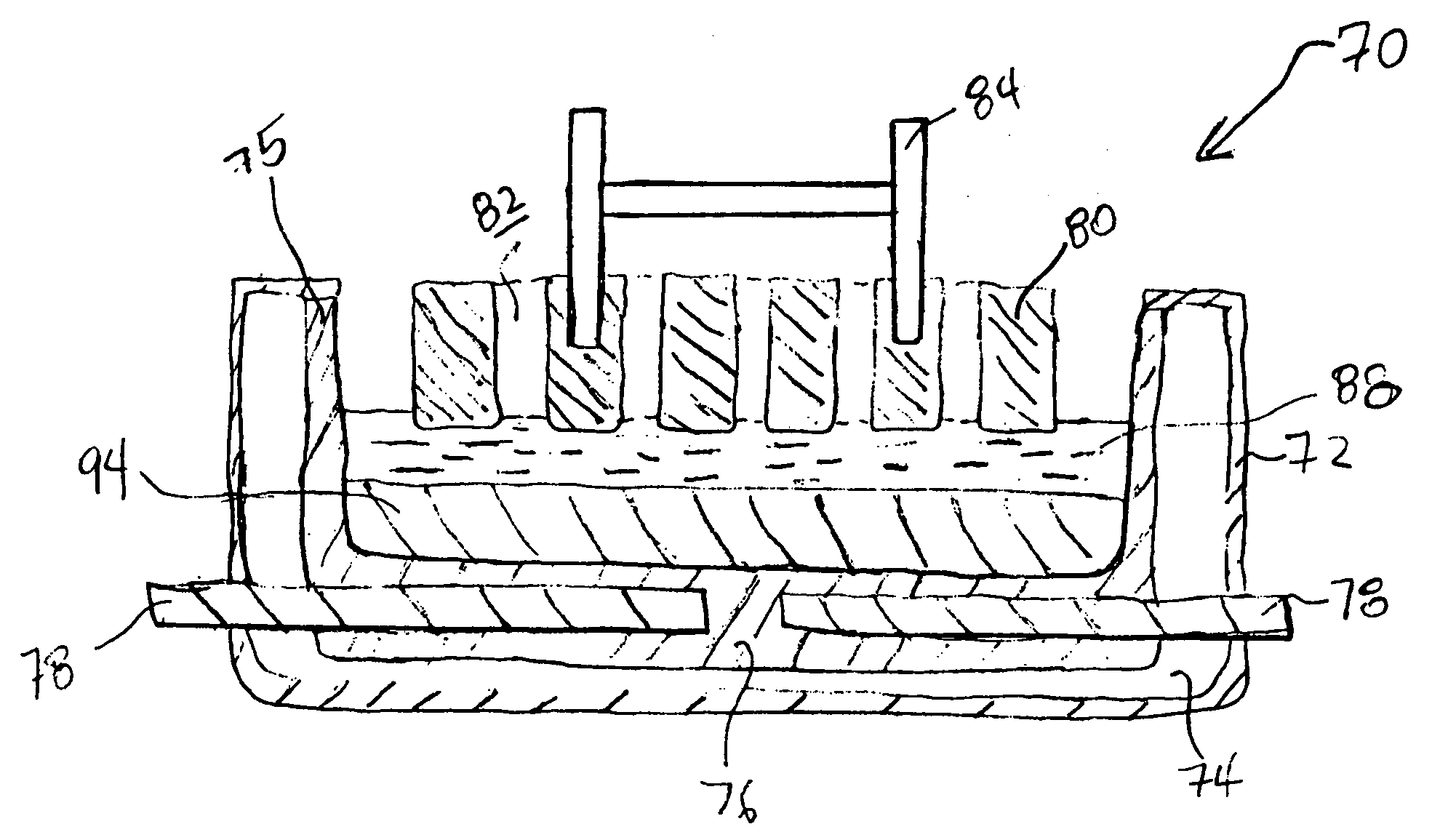

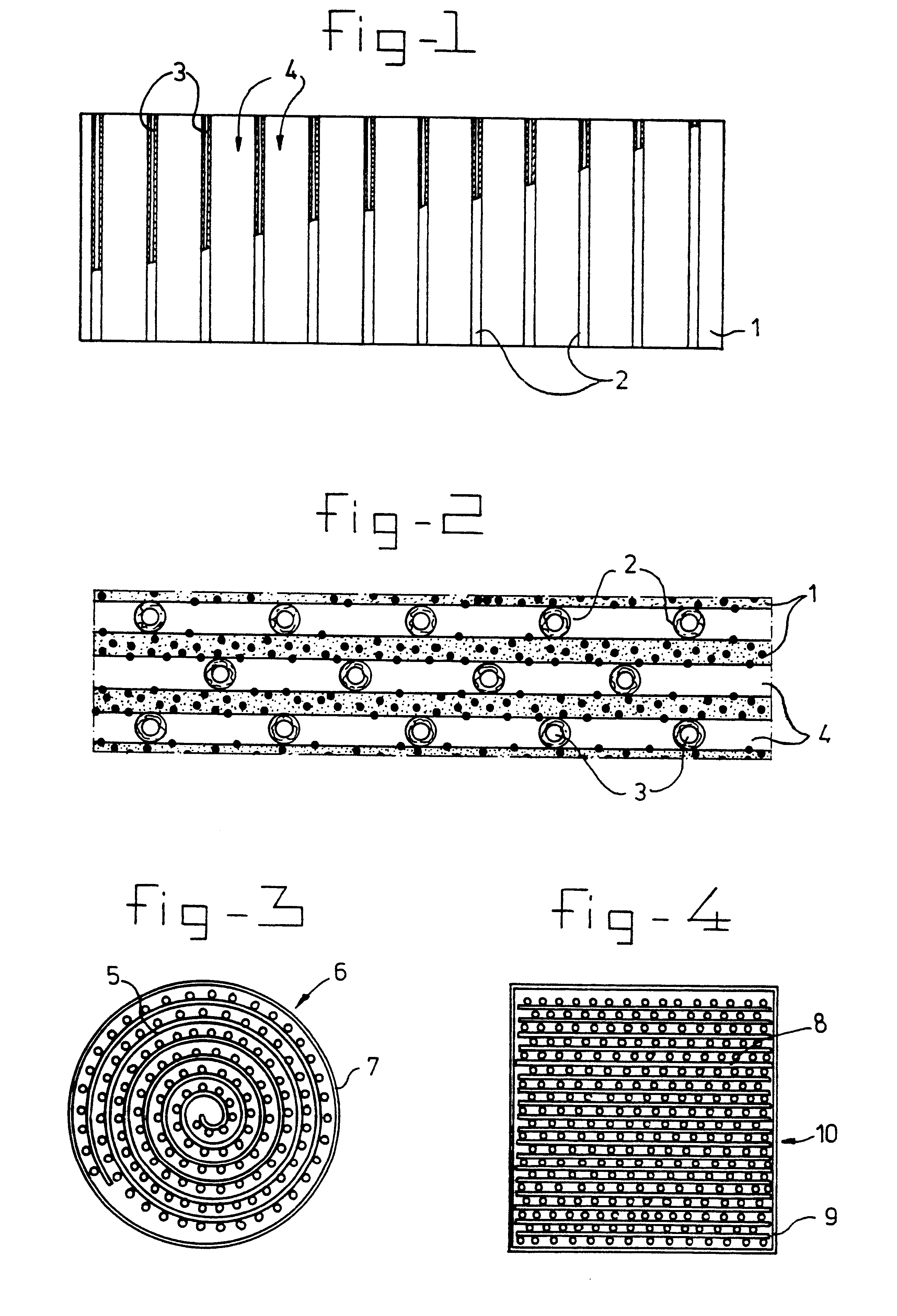

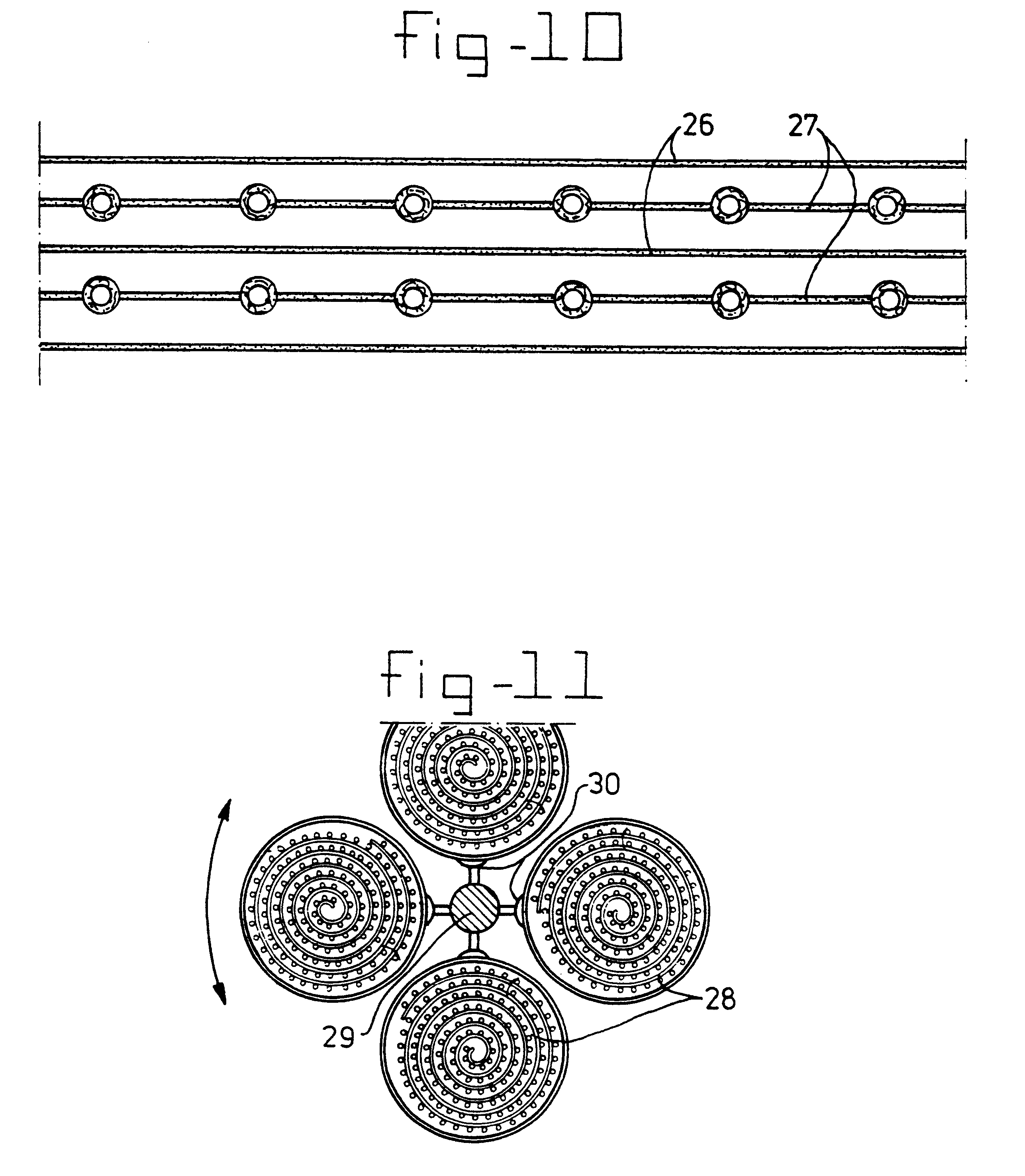

Bio-artificial organ containing a matrix having hollow fibers for supplying gaseous oxygen

InactiveUS6372495B1Practical to useBioreactor/fermenter combinationsBiological substance pretreatmentsHollow fibreFiber

A bio-artificial organ system is provided comprising a wall surrounding a space which has a solid support for cell cultivation. The space includes a there dimensional matrix in the form of a highly porous sheet or mat and including a physiologically acceptable network of fibers or an open-pore foam structure; hydrophobic hollow fibers permeable to gaseous oxygen or gaseous carbon dioxide evenly distributed through the three dimensional matrix material and arranged in parallel running from one end of the matrix material to the other end of the matrix material. Cells obtained from organs are present in the extra fiber space for culture wherein the cells are provided with sufficient oxygenation and are maintained as small aggregates with three dimensional attachment.

Owner:ACADEMISCH ZIEKENHUIS BIJ DE UNIV VAN AMSTERDAM ACADEMISCH MEDISCH CENT +1

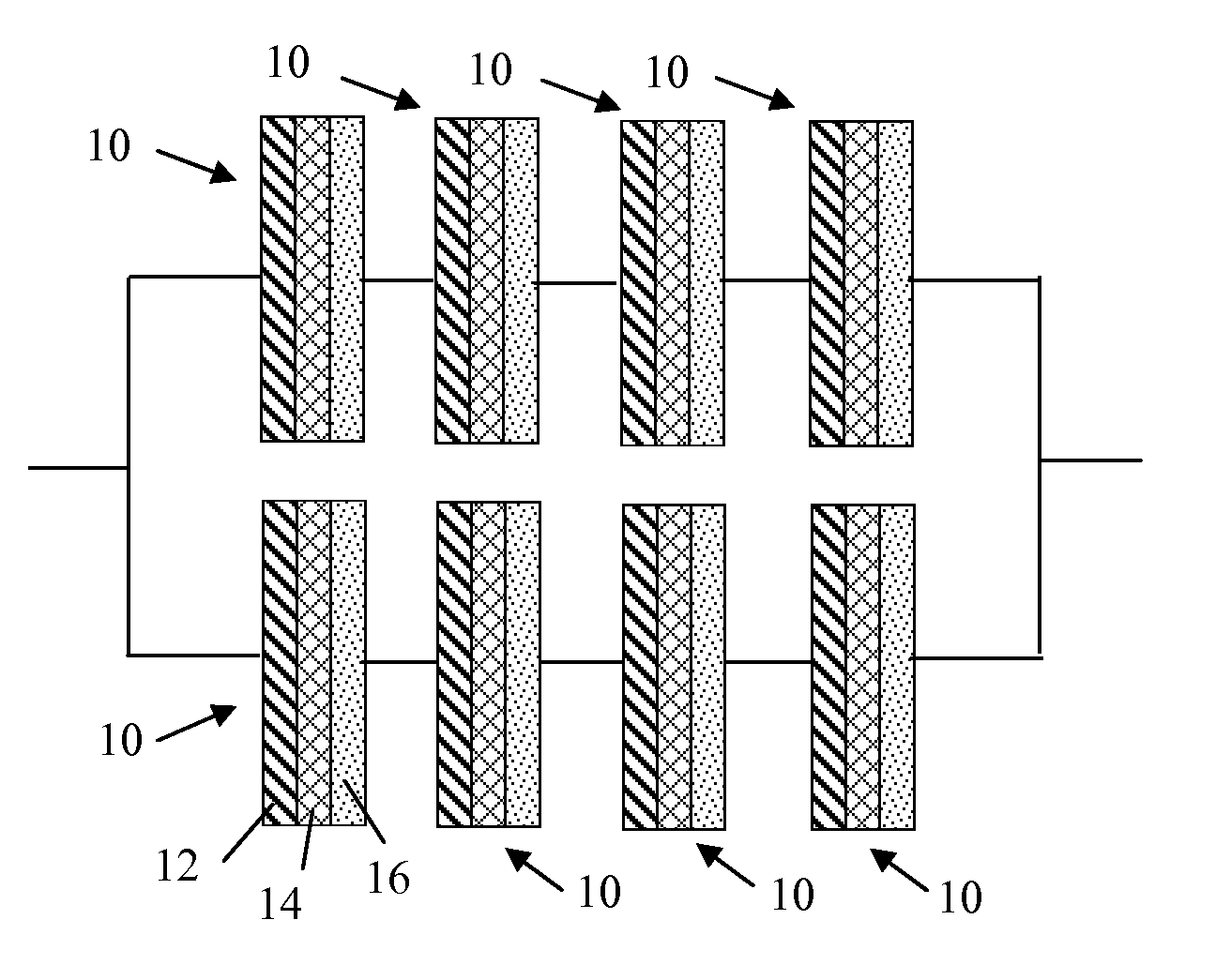

Lithium-oxygen electrochemical cells and batteries

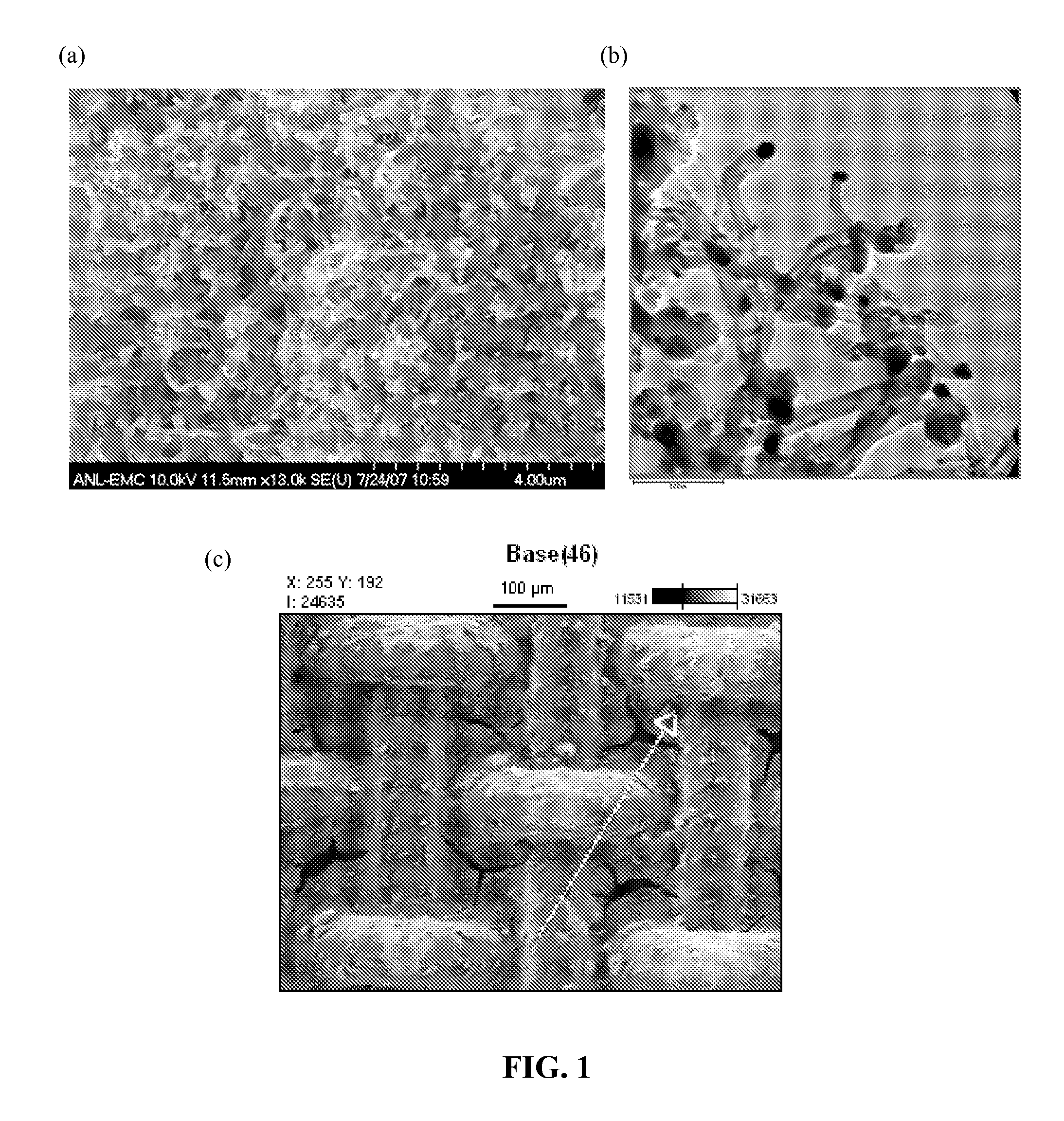

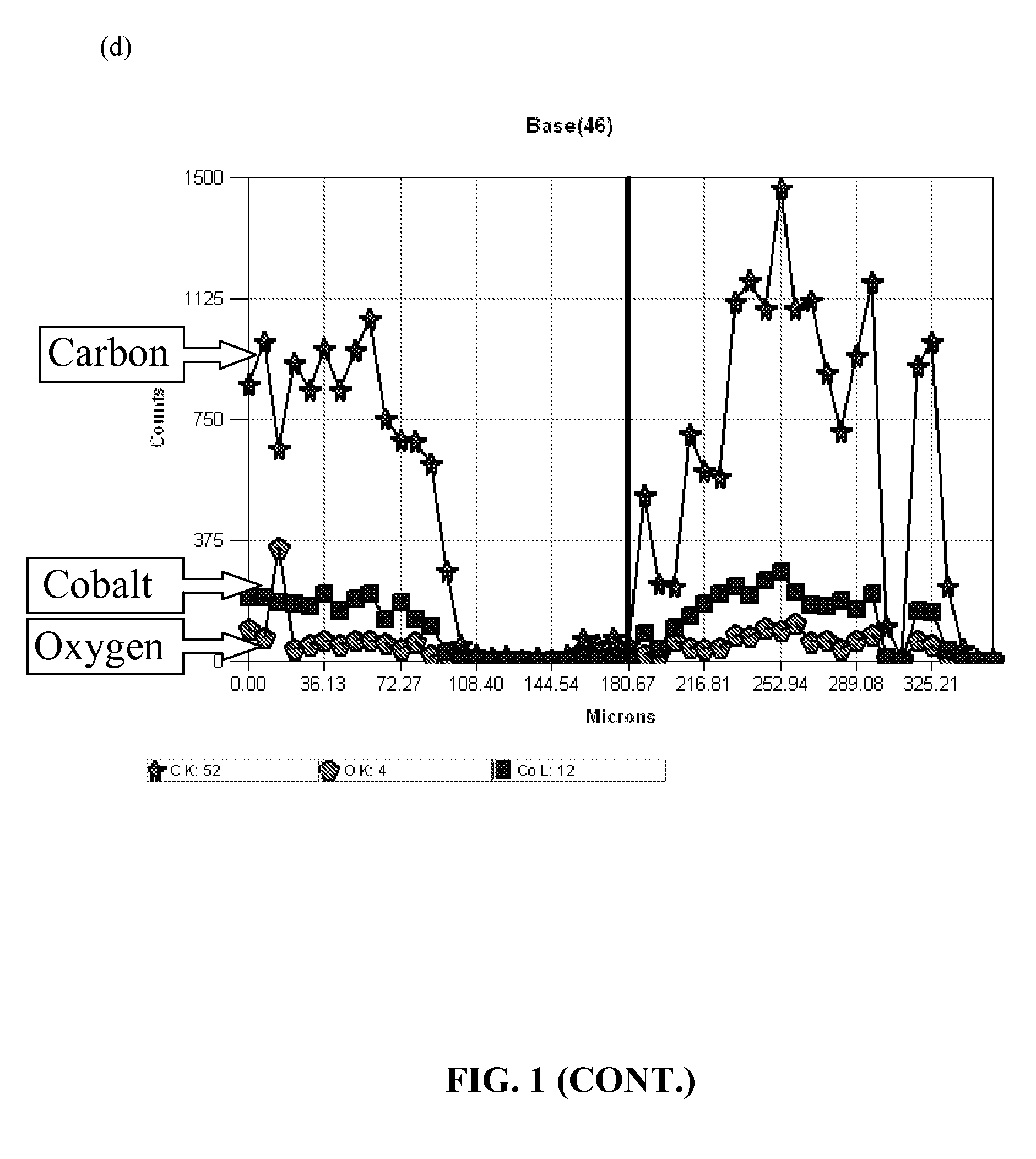

InactiveUS20110104576A1Facilitate reversible interconversionMaterial nanotechnologyFuel and primary cellsElectrical batteryNanoparticle

A lithium-oxygen electrochemical cell of the invention comprises a lithium-containing anode, an oxygen-permeable cathode, a non-aqueous electrolyte comprising a lithium salt in a non-aqueous liquid between the anode and the cathode, and a source of gaseous oxygen in fluid communication with the cathode; the cathode comprising an oxygen-permeable support bearing carbon nanotubes having at least one open end. In some embodiments, the cell is rechargeable and the cathode includes a nanoparticulate catalyst in contact with the carbon nanotubes; wherein the catalyst is adapted to facilitate the reversible interconversion between oxygen gas and an oxygen anion e.g., oxide ion, peroxide ion, or a combination thereof, during charge and discharge of the cell.

Owner:UCHICAGO ARGONNE LLC

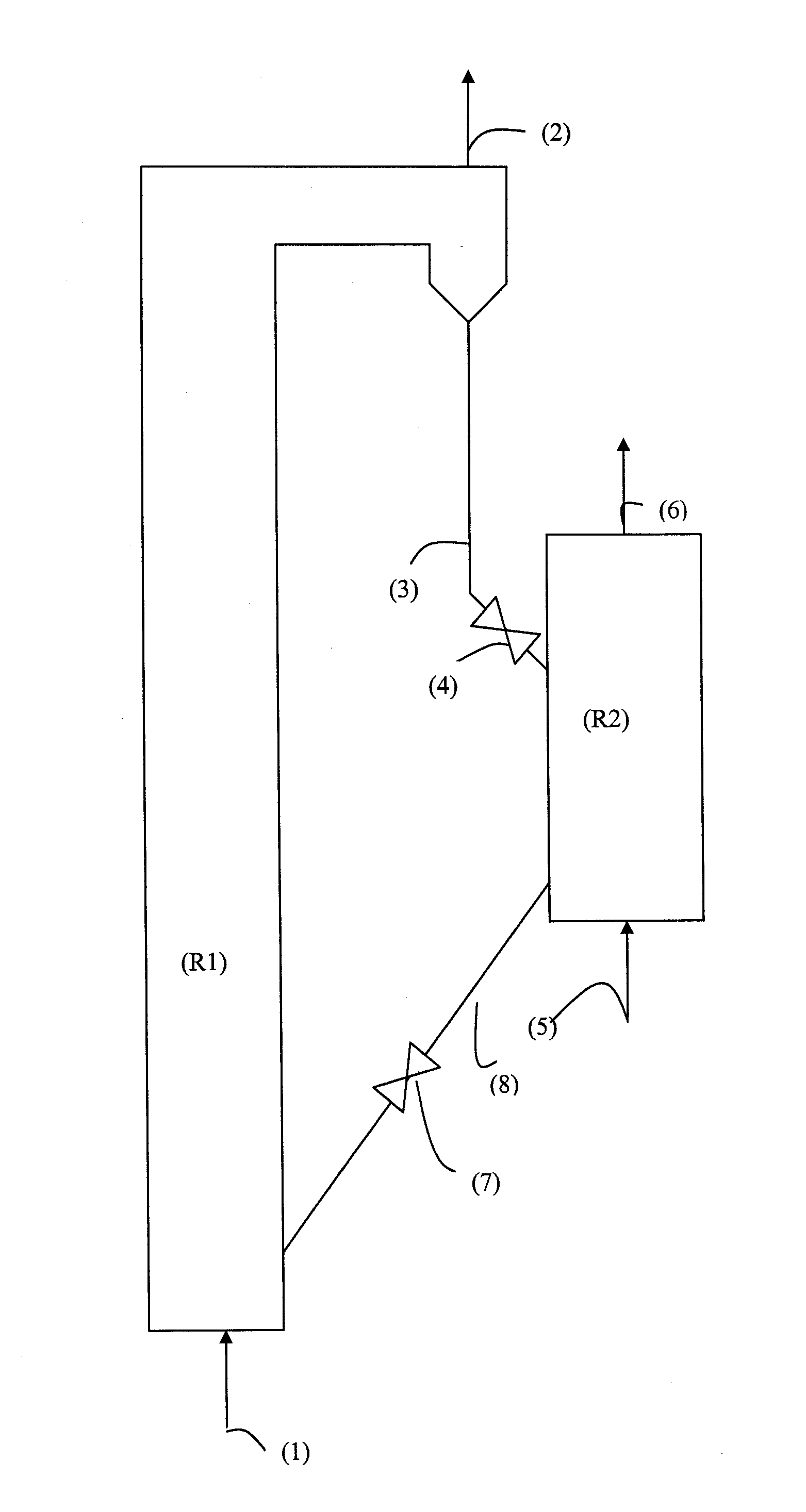

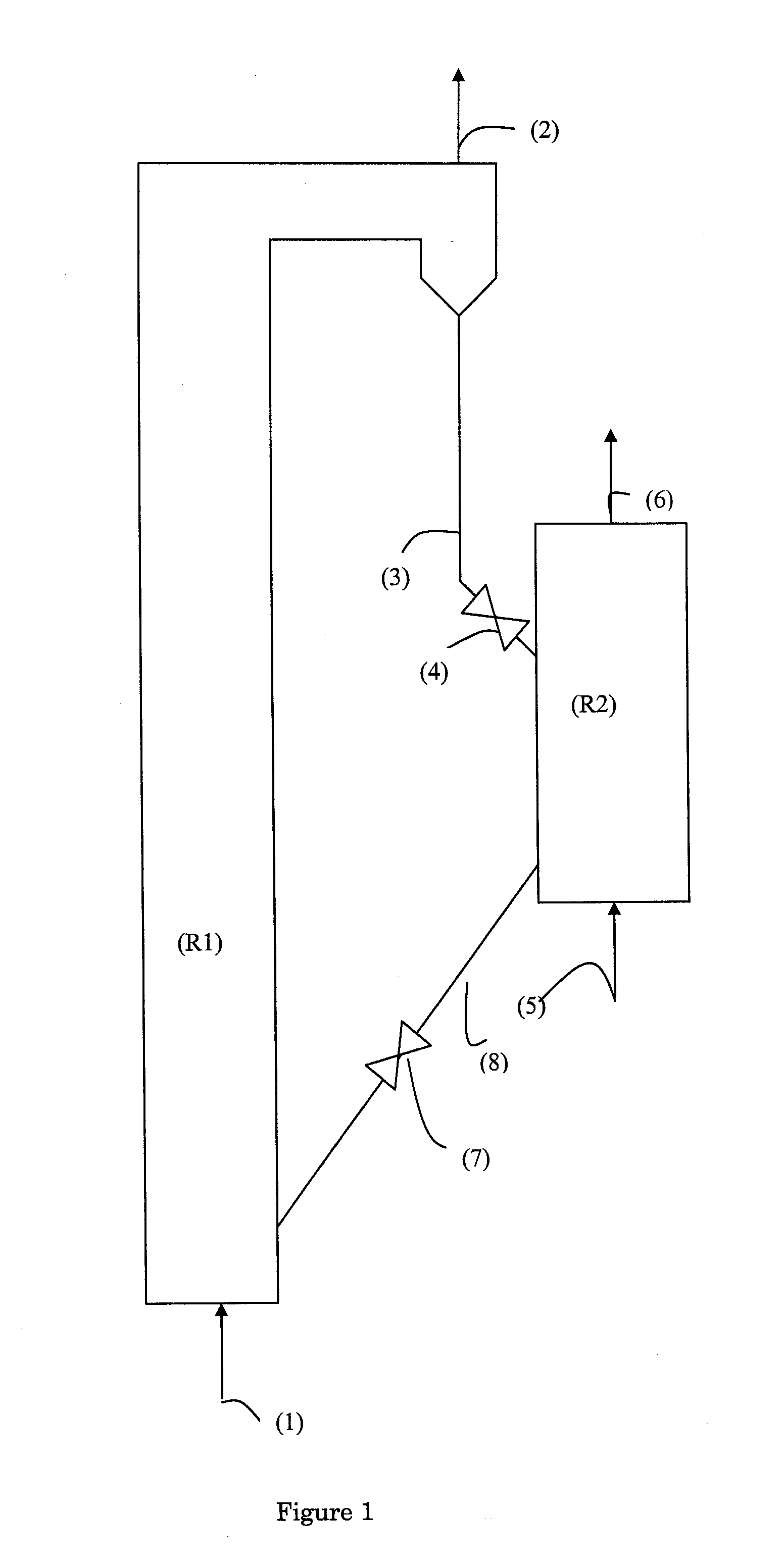

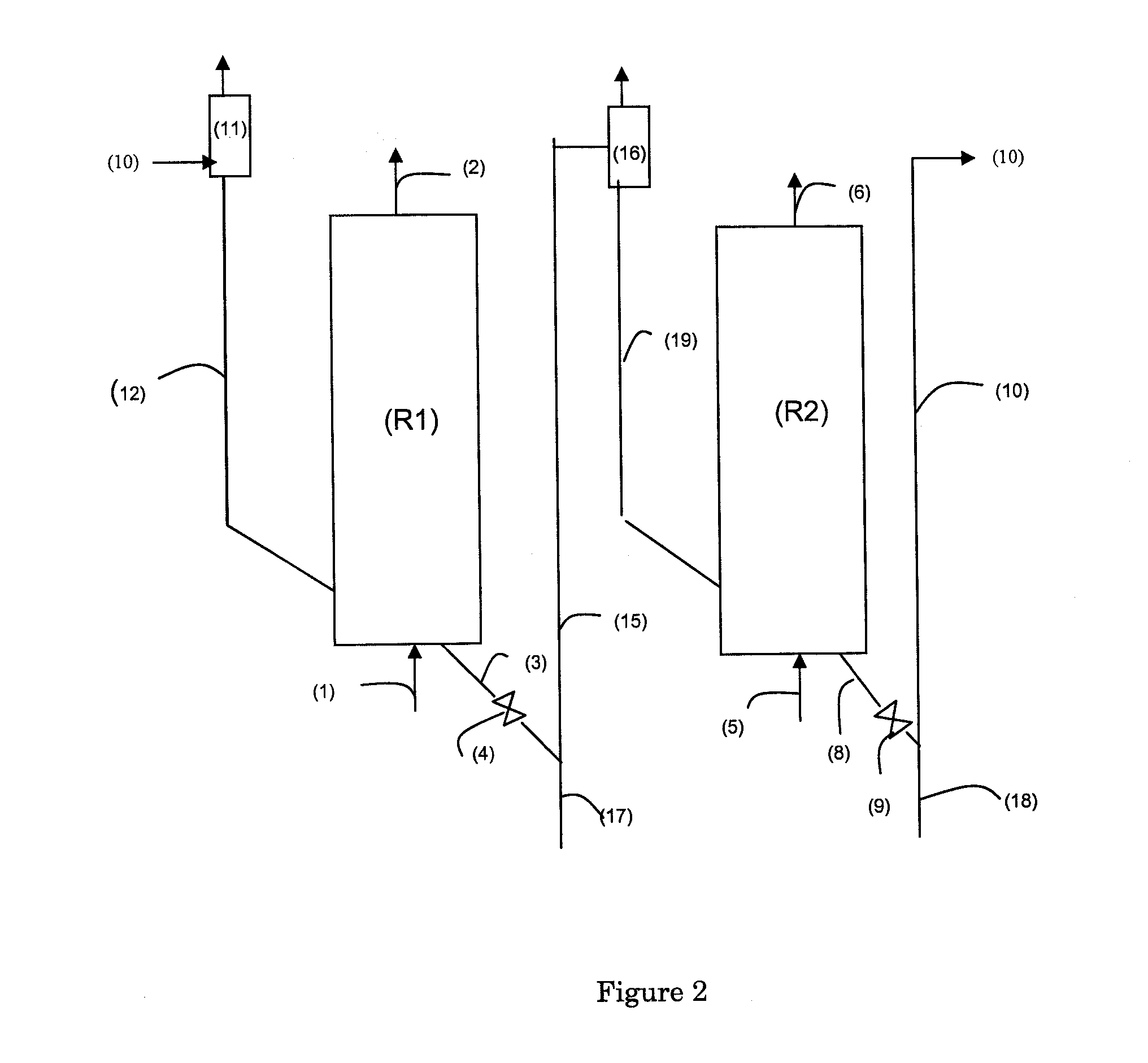

Oxygen production method and plant using chemical looping in a fluidized bed

The invention relates to a method and to a plant for producing high-purity oxygen, said method comprising a chemical loop wherein circulates a fluidized bed material having the capacity to release gaseous oxygen through oxygen partial pressure lowering, at a temperature ranging between 400° C. and 700° C. The oxygen thus produced can be used in applications such as oxycombustion methods, production of syngas under pressure or FCC catalyst regeneration.

Owner:INST FR DU PETROLE

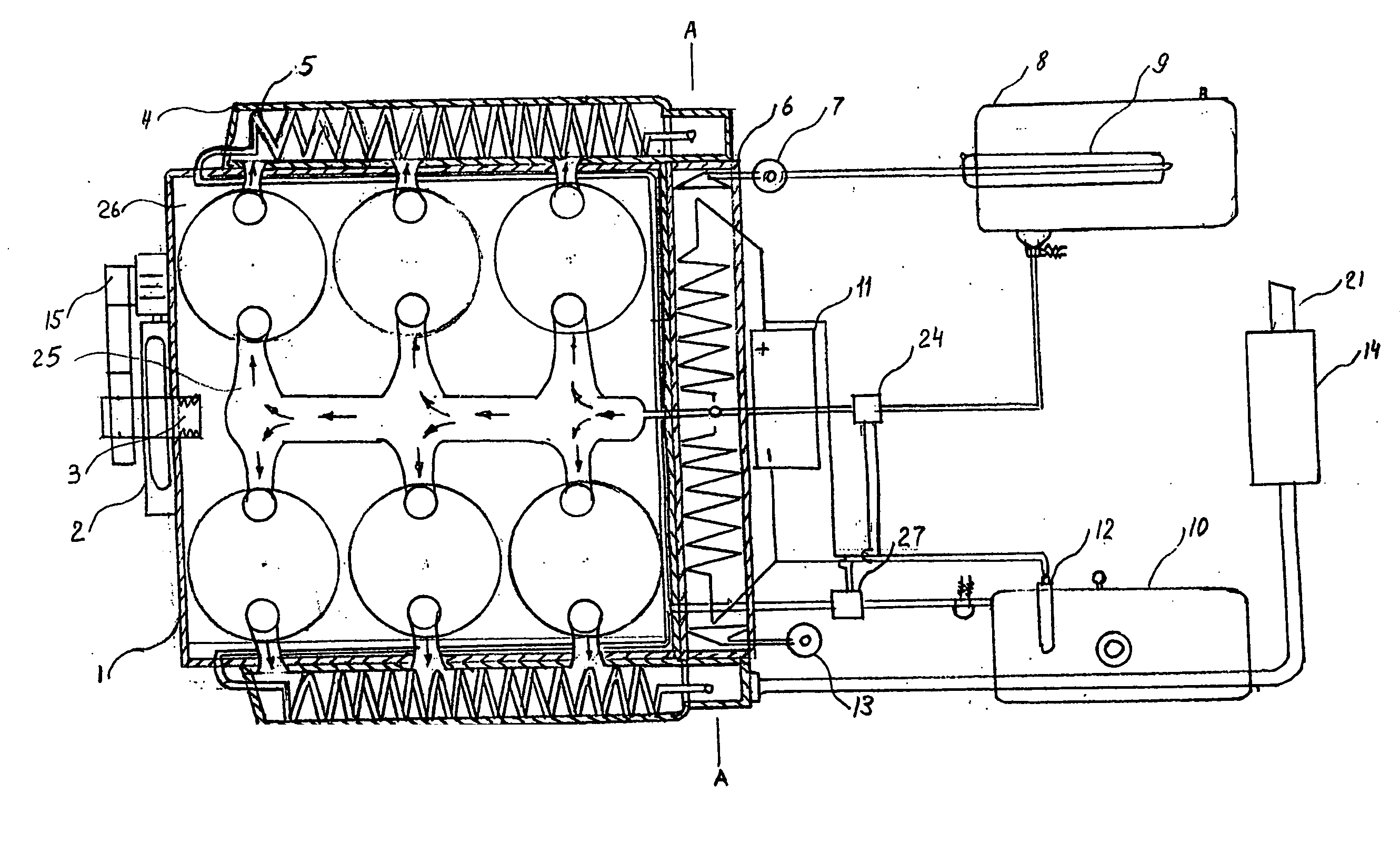

Hydrogen and oxygen production and accumulating apparatus including an internal combustion engine and method

An apparatus, including an internal combustion engine, produces hydrogen fuel from water to power the engine, comprises water supply means, fuel storage means, controlling means, a collector receiving combustion products output from engine's operation, a transformer utilizing thermo-impact of the combustion products and decomposing supplied water into hydrogen and oxygen, an ion divider electrically separating hydrogen and oxygen ions into gaseous hydrogen, further directed into the fuel storage means and controllably fed substantially into engine's cylinders, and gaseous oxygen. It also includes exhaust means outputting exhaust products from the collector into the atmosphere, on their way out heating water in the water supply means. The fuel storage means contain initial hydrogen or another predetermined fuel. Electrolyzer means are provided to supplement hydrogen and oxygen ions production. Recommended temperature and parts size ranges for six-and eight-cylinder engines are disclosed. A truck engine usable embodiment is also illustrated and described.

Owner:YATSENKO YURIY

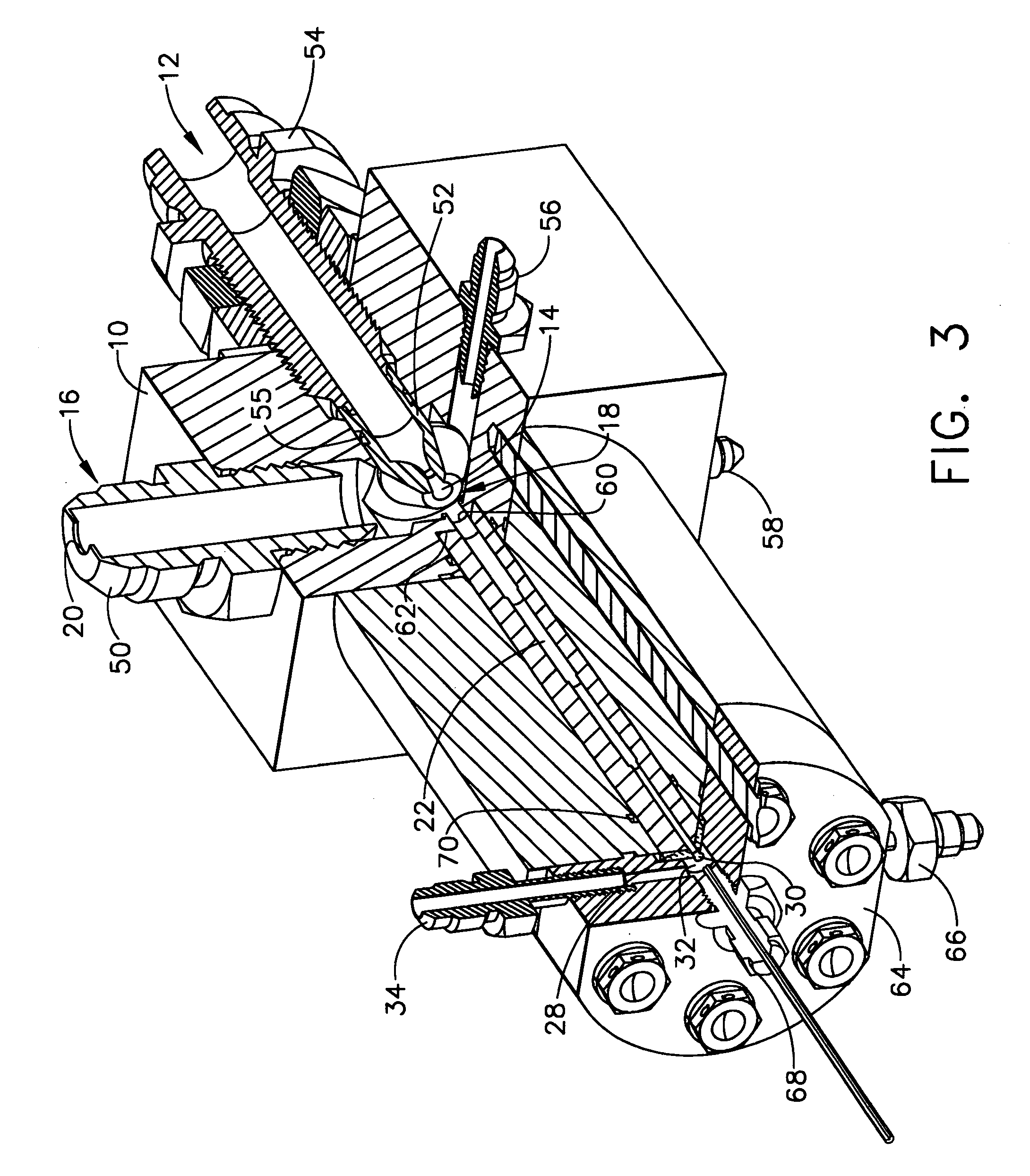

Cylinder valve and bayonet check-filter with excess-flow protection feature

InactiveUS6607007B1Reduce the risk of fireLower potentialFunctional valve typesContainer filling methodsOxygen systemHigh pressure oxygen

A valve apparatus especially well-suited for use in gaseous oxygen delivery systems. A valve apparatus is provided that substantially reduces the risk of fire in high-pressure oxygen systems. The apparatus is particularly well-suited for use as a plug valve on ordinary cylinder containers, but may be beneficially used in any pressurized gas system, particularly oxygen systems such as those encountered in many industrial facilities. The wetted portion of the valve is isolated from threaded portions to prevent particulate contamination of the gas stream. The valve seat is located to protect it from direct impact of high-velocity gas streams. The inventive valve, and its associated inventive check-filter and excess-flow prevention features, reduces the potential for hazardous combustion at valve points within oxygen delivery systems.

Owner:LUXFER INC

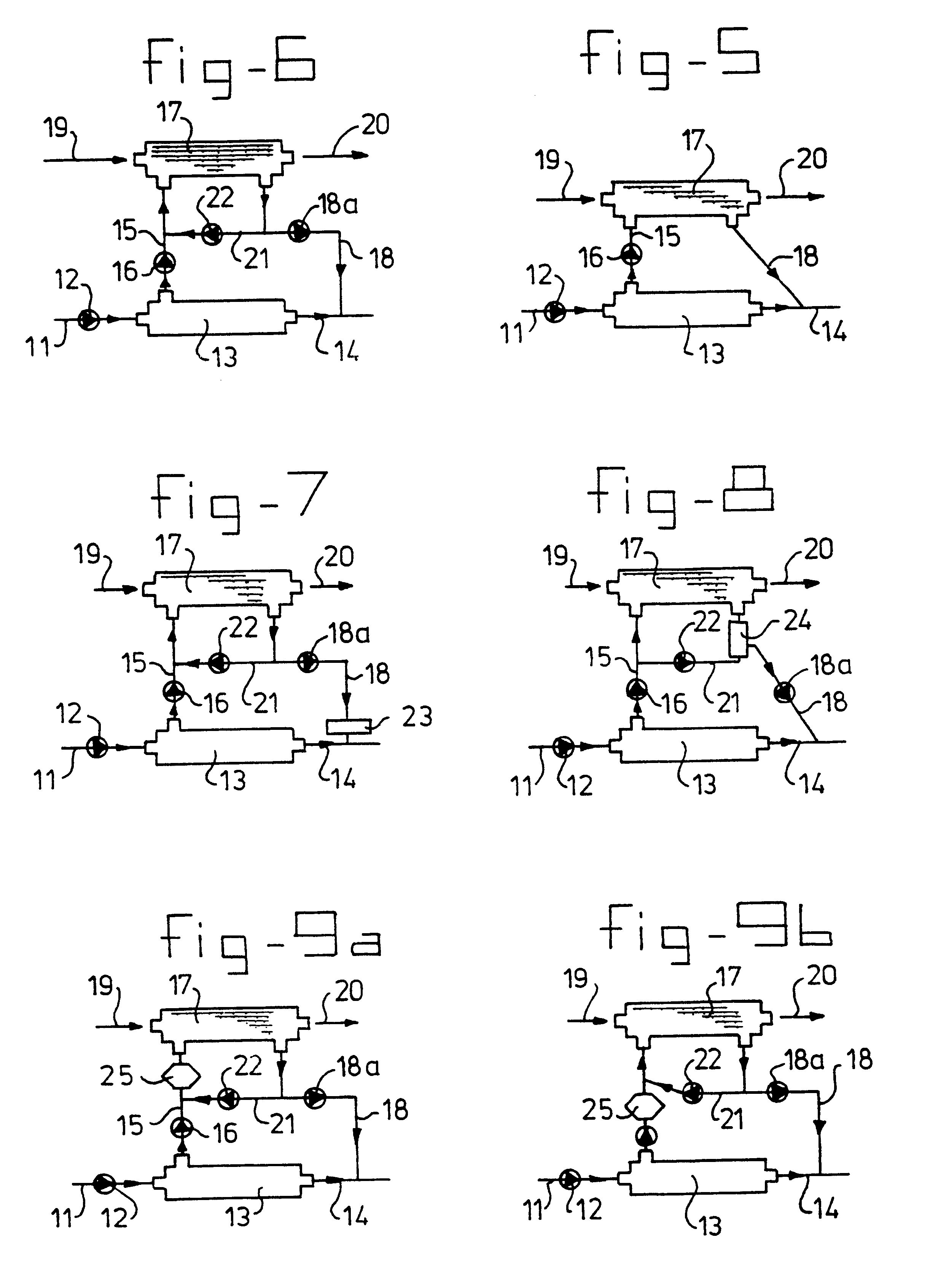

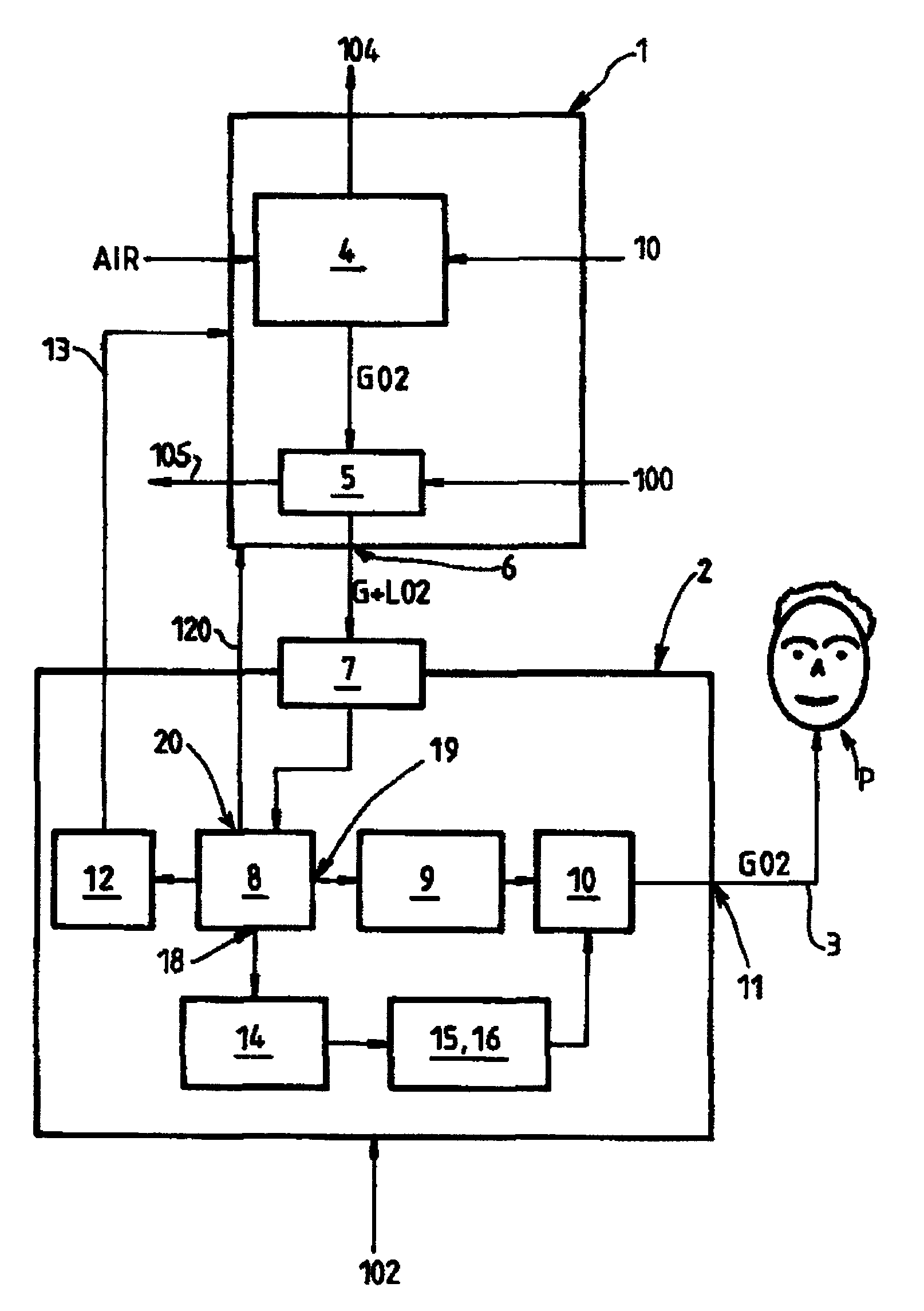

Device for supplying domiciliary and ambulatory oxygen

Device for supplying domiciliary and ambulatory oxygen, comprising an oxygen filling station and a portable oxygen reserve that can be selectively connected to the filling station, the filling station comprising an oxygen concentrator intended to isolate gaseous oxygen from the air, a liquefier connected to one outlet of the concentrator to receive the isolated gaseous oxygen so that it can be liquefied, a transfer connector connected to one outlet of the liquefier and intended to be connected to an inlet connector of the reserve, the reserve comprising a tank connected to the inlet connector so that liquid oxygen can be transferred from the filling station to the tank, a delivery system comprising members for tapping off, heating and regulating the flow of the oxygen from the tank so as to deliver gaseous oxygen to a patient.

Owner:CRYOPAL

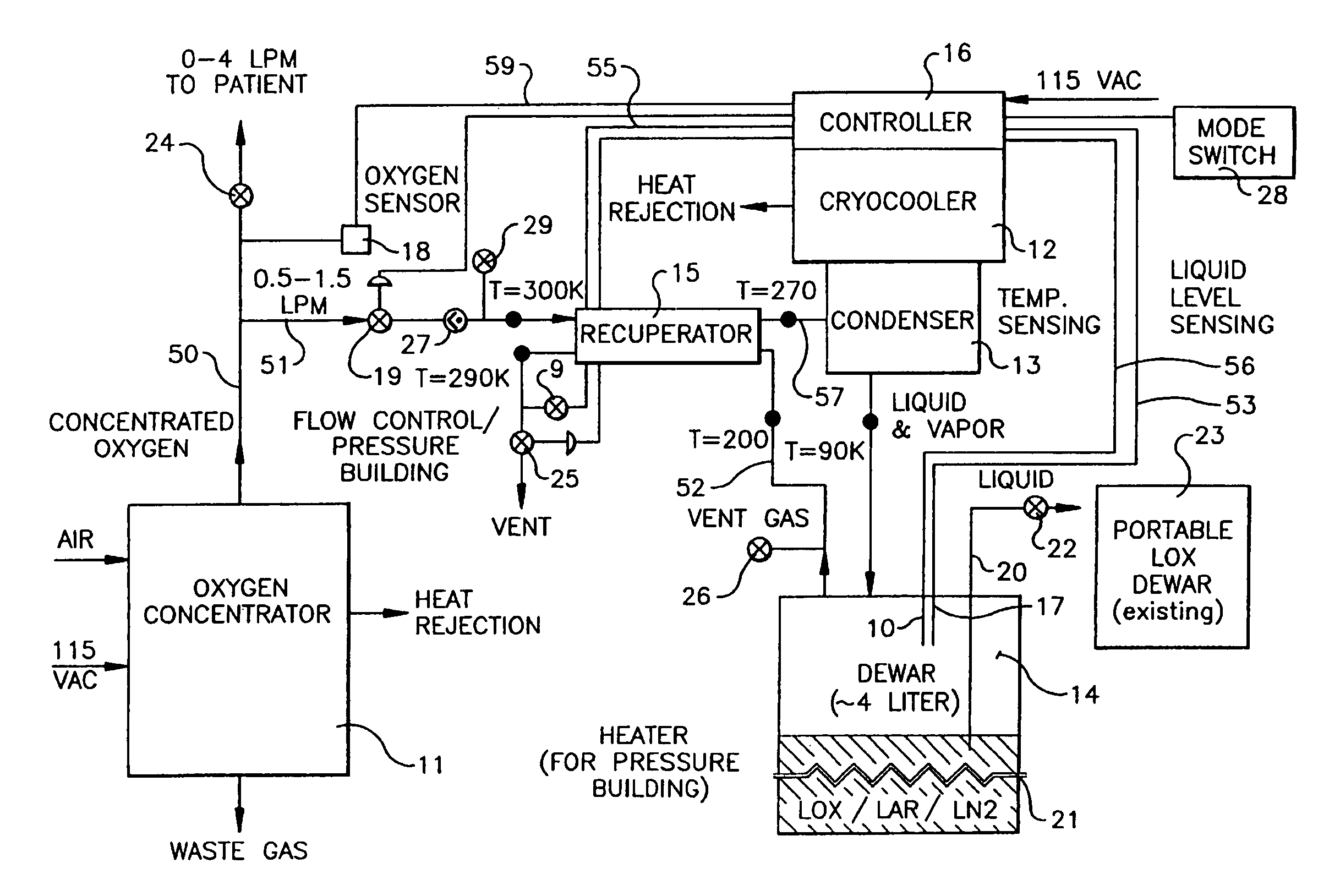

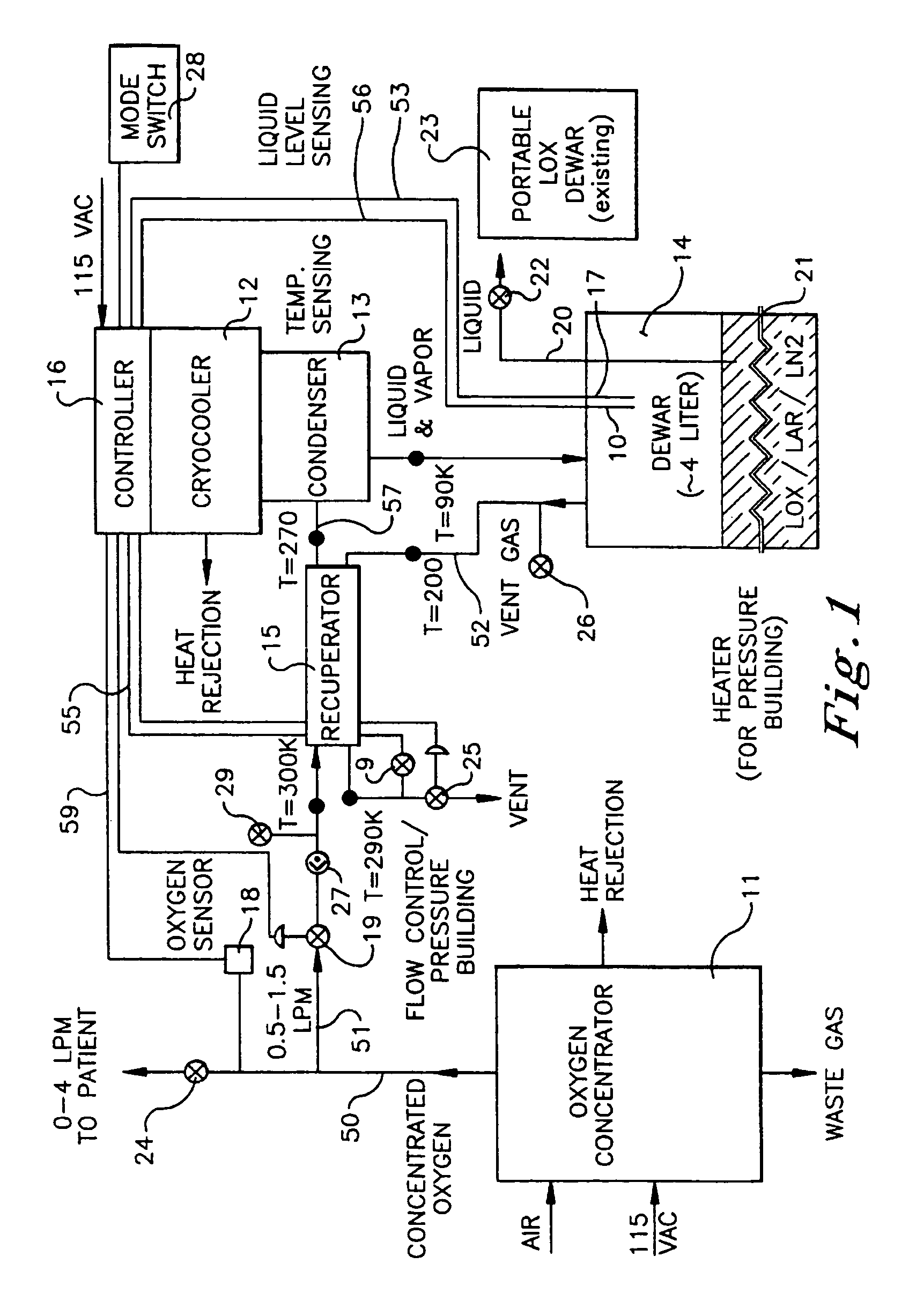

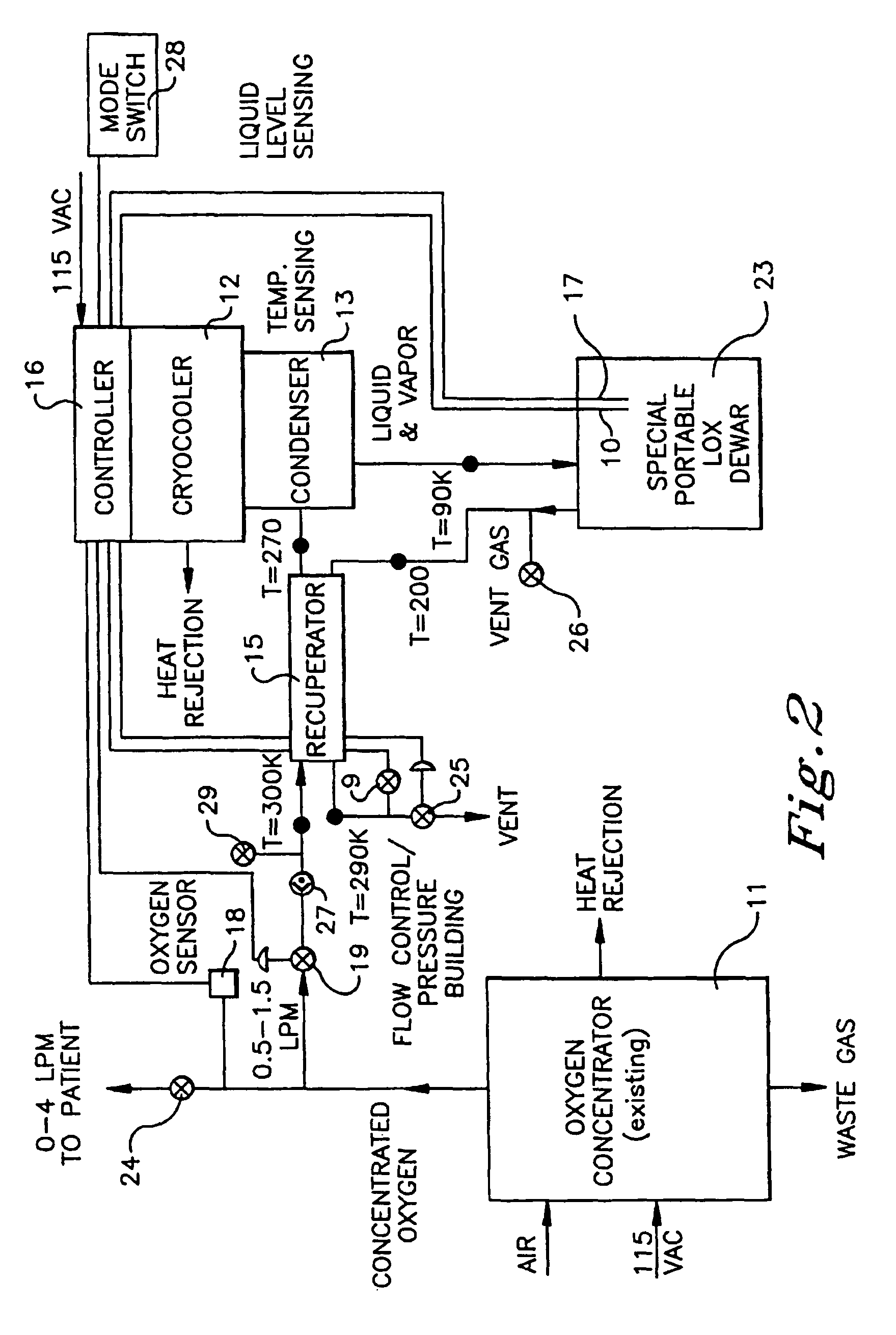

Methods and apparatus to generate liquid ambulatory oxygen from an oxygen concentrator

InactiveUSRE43398E1Increase condensation rateIncrease the areaLiquefactionOther heat production devicesAmbulatory systemCryocooler

Owner:RESPIRONICS

Method for producing nitrogen to use in under balanced drilling, secondary recovery production operations and pipeline maintenance

InactiveUS20050186130A1Offsetting cost of projectEconomically feasibleNitrogen purification/separationDispersed particle separationElectrolysisPtru catalyst

The invention uses a feed of atmospheric air and mixes the air with hydrogen. The hydrogen and air mixture is fed into a catalytic reactor where a deoxygenation reaction occurs. The deoxygenation reaction uses a platinum catalyst to produce water from oxygen and hydrogen. The nitrogen passes through the catalytic reactor without reacting with the hydrogen, the oxygen, or the water. The water is separated from the nitrogen in a dryer. The nitrogen may then be used in drilling and production operations. The water is fed into an electrolyzer where an electrolysis reaction occurs. The electrolyzer passes an electrical current through the water to produce gaseous oxygen and hydrogen. The hydrogen is recycled back to the catalytic reactor and the oxygen may be vented or sold.

Owner:SUNSTONE TECH

Atomic layer deposition processes

InactiveUS20100227476A1Easy to control accuratelyGood step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemisorptionThin membrane

This invention relates to method of forming a thin film on a substrate in a reaction chamber by an atomic layer deposition process comprising a plurality of individual cycles. The plurality of individual cycles comprise at least two groupings of individual cycles. The individual cycles comprise (i) introducing a gaseous metal containing precursor into the reaction chamber and exposing the substrate to the gaseous metal containing precursor, wherein at least a portion of the metal containing precursor is chemisorbed onto the surface of the substrate to form a monolayer thereon, (ii) stopping introduction of the metal containing precursor and purging the volume of the reaction chamber; (iii) introducing a gaseous oxygen source compound into the reaction chamber and exposing the monolayer to the gaseous oxygen source compound, wherein at least a portion of the oxygen source compound chemically reacts with the monolayer; and (iv) stopping introduction of the oxygen source compound and purging the volume of the reaction chamber. The method involves repeating the individual cycles until a thin film of desired thickness is obtained. The method also involves carrying out at least two groupings of individual cycles at different process conditions. The methods are useful for producing a thin film on a semiconductor substrate, particularly metal containing thin films for electrode applications in microelectronics.

Owner:PRAXAIR TECH INC

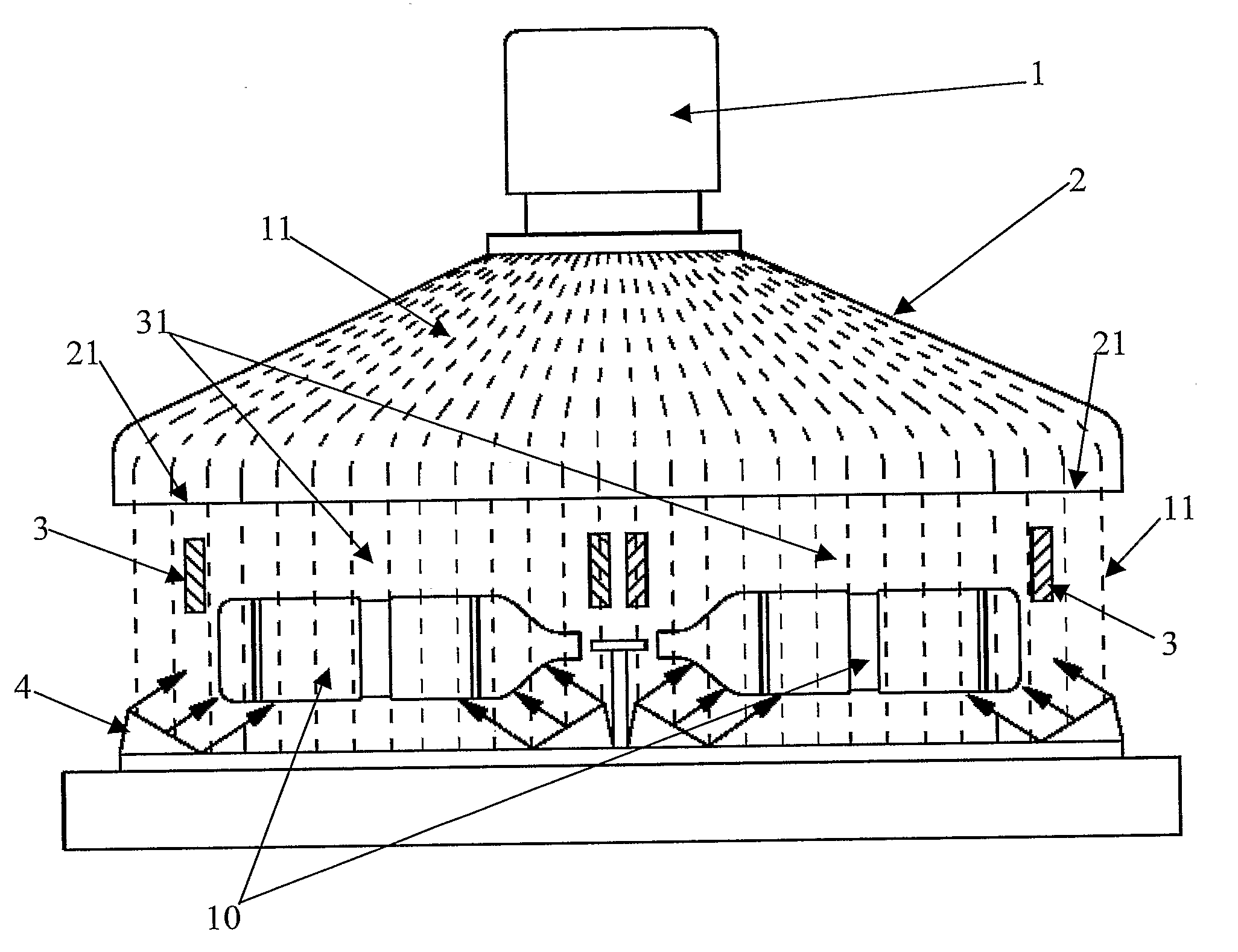

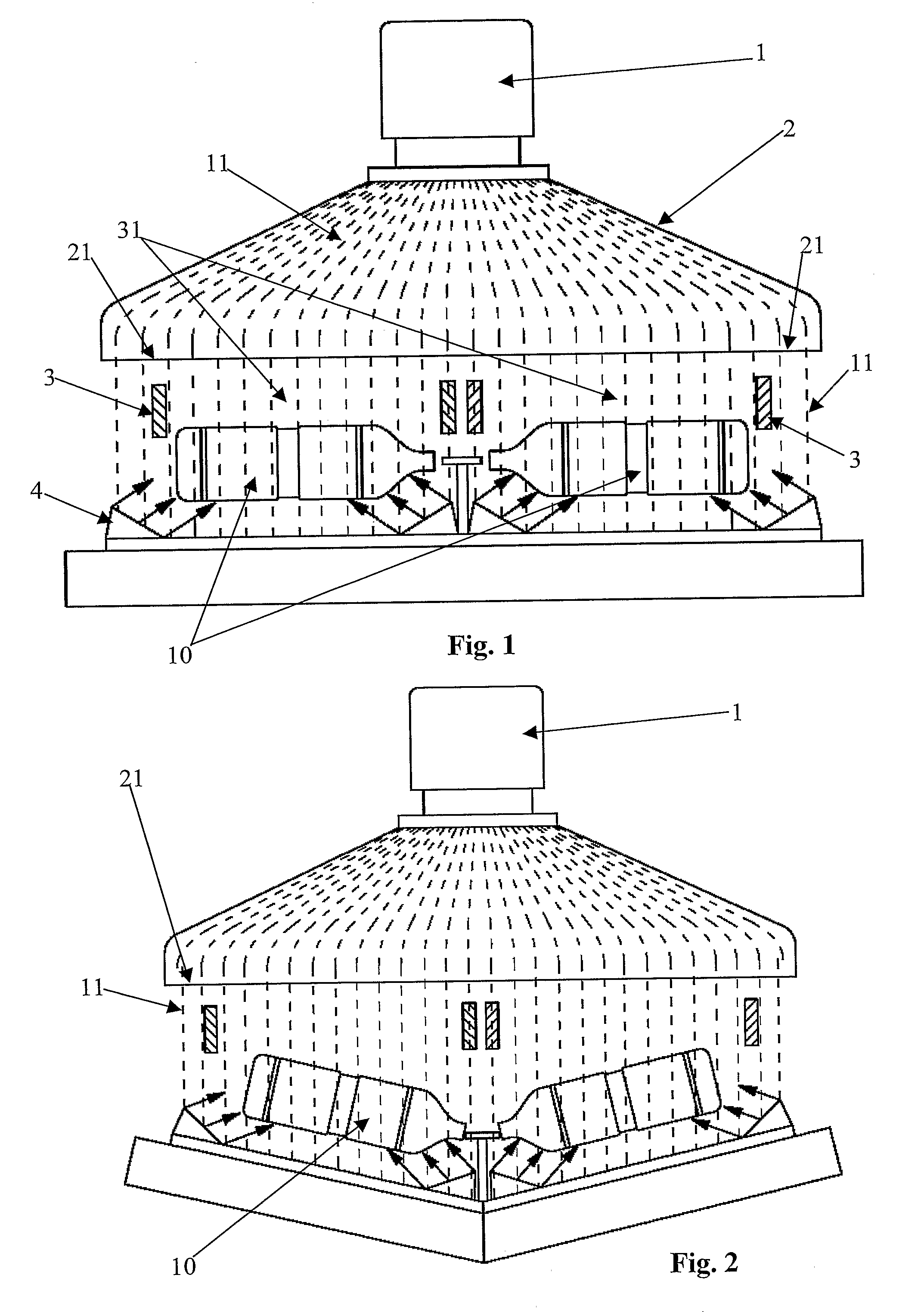

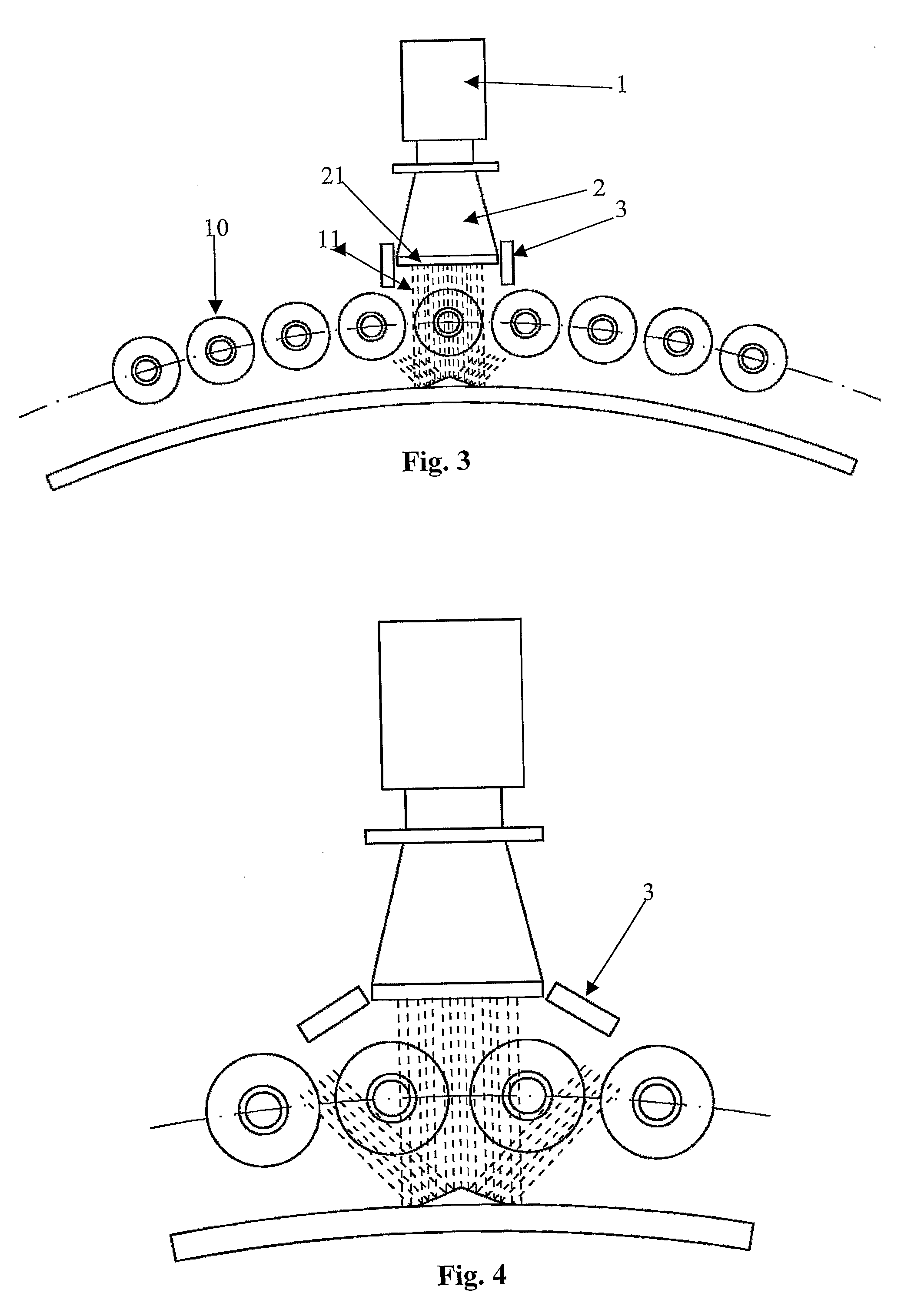

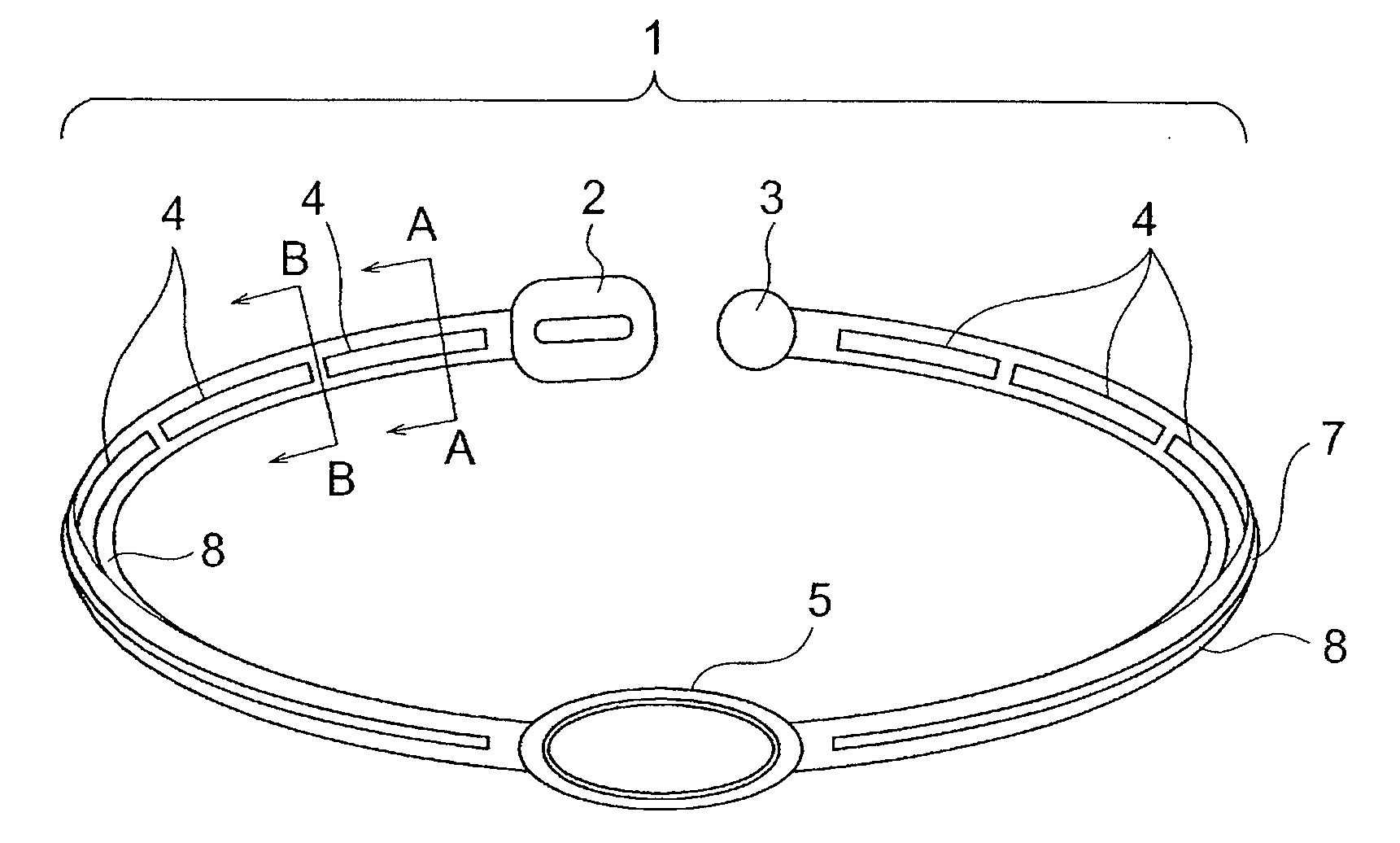

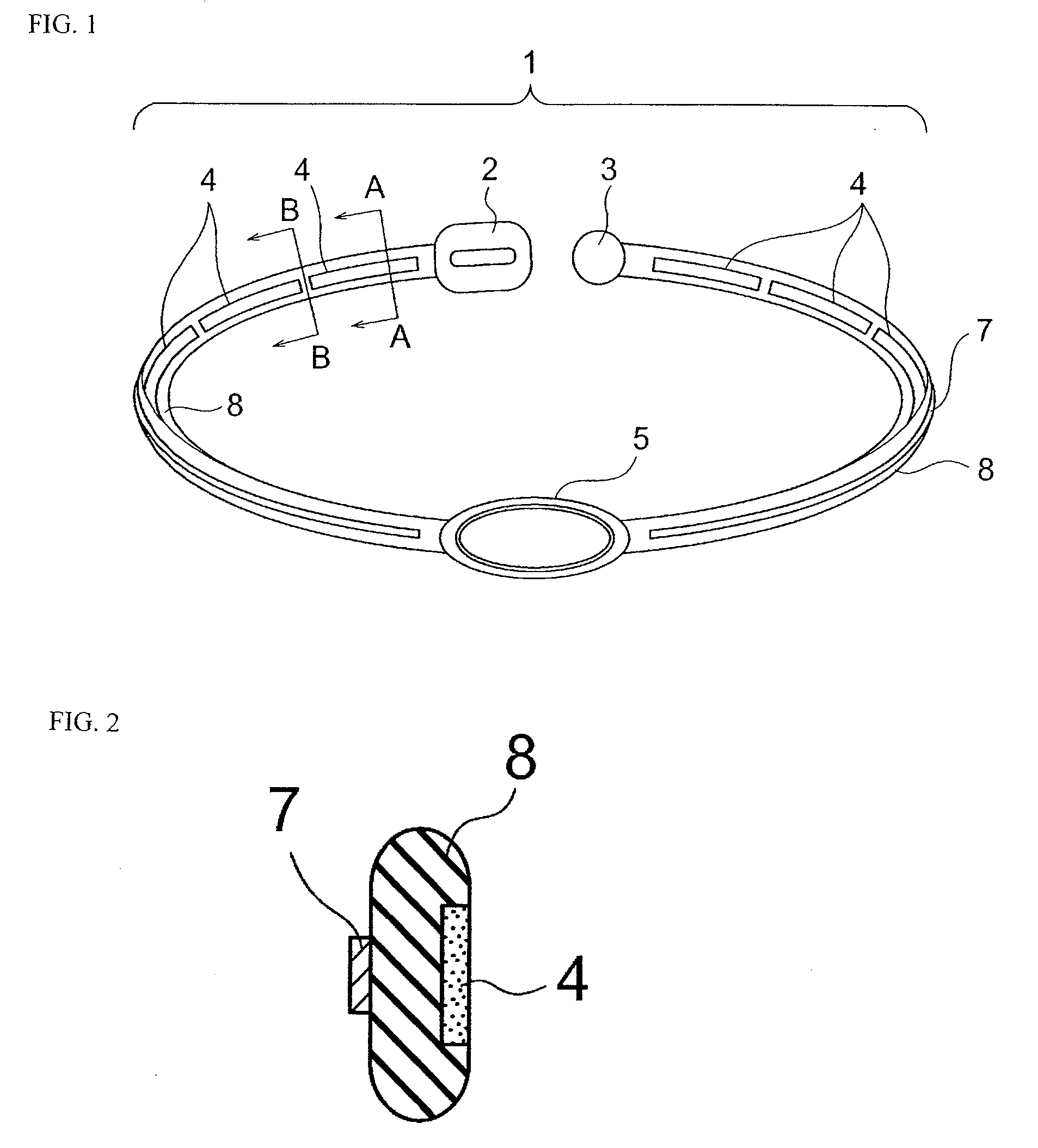

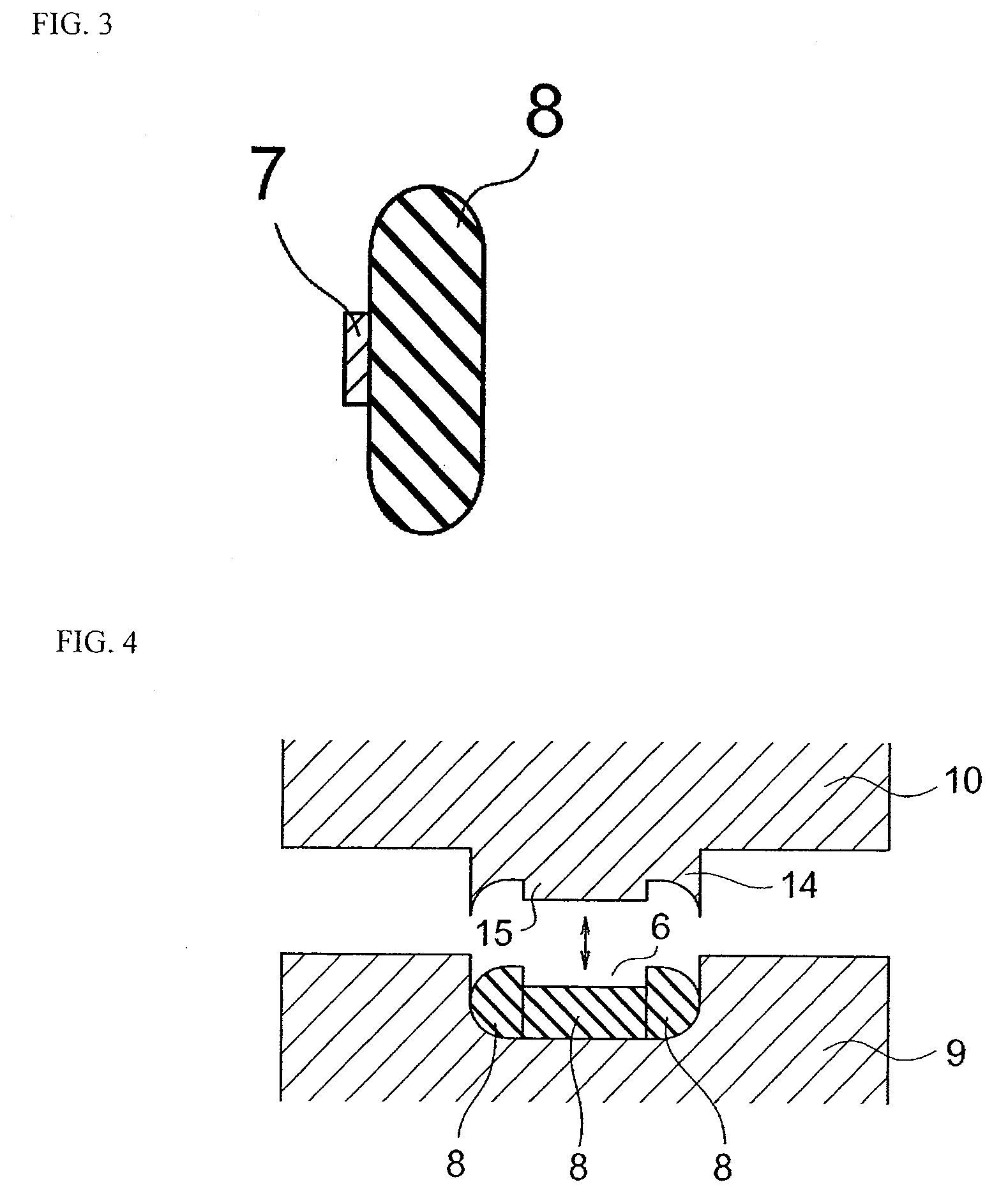

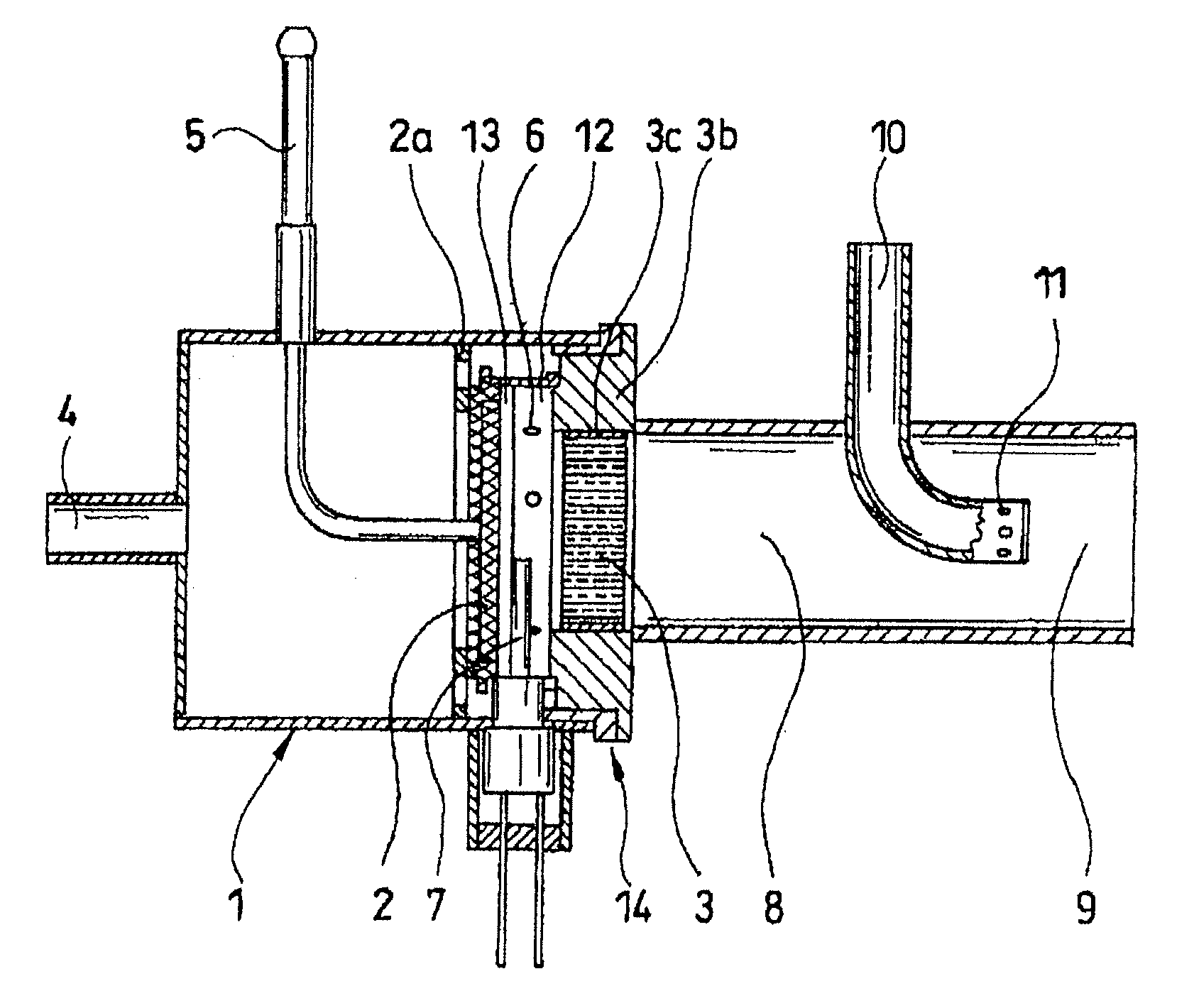

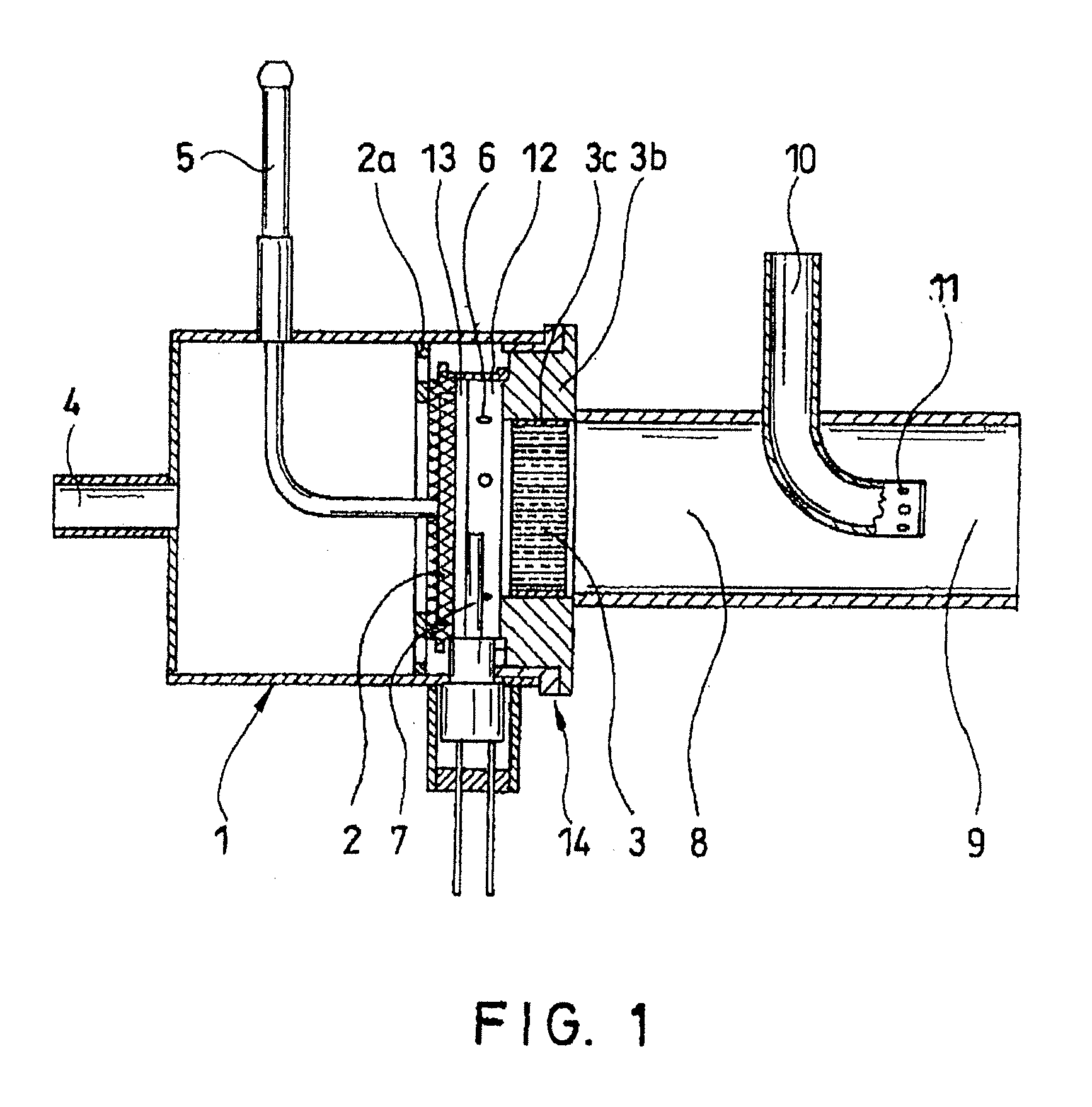

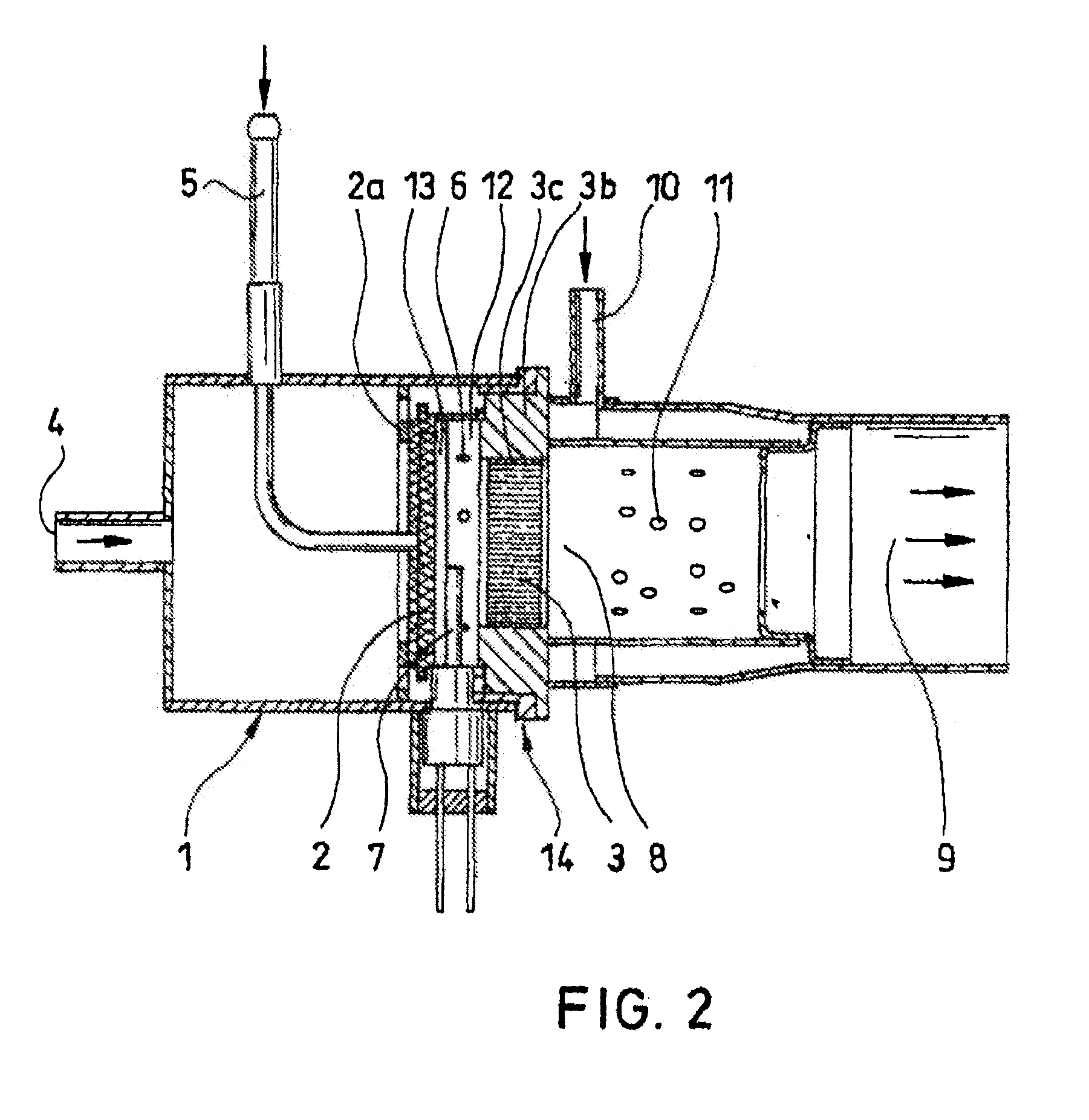

Sterilization system for pet containers and bottles

ActiveUS20100209290A1Solve problemsPackage sterilisationLavatory sanitoryElectron radiationElectron flow

A sterilization system for PET containers and bottles including at least one electron flow generator 1, a scan gun 2 and at least one target 4 preferably made of heavy metal, so that when a part of the electron radiation hits said target a reflected X ray radiation is generated, which contributes to the sterilization of the containers. A certain amount of liquid or gaseous oxygen which upon collision with the electron radiation is converted to ozone is also exposed to the radiation, thus further contributing to the sterilization.

Owner:SIPA SOCIETA INDUSTRIALIZZAZIONE PROGETTAZIONE E AUTOMAZIONE SPA

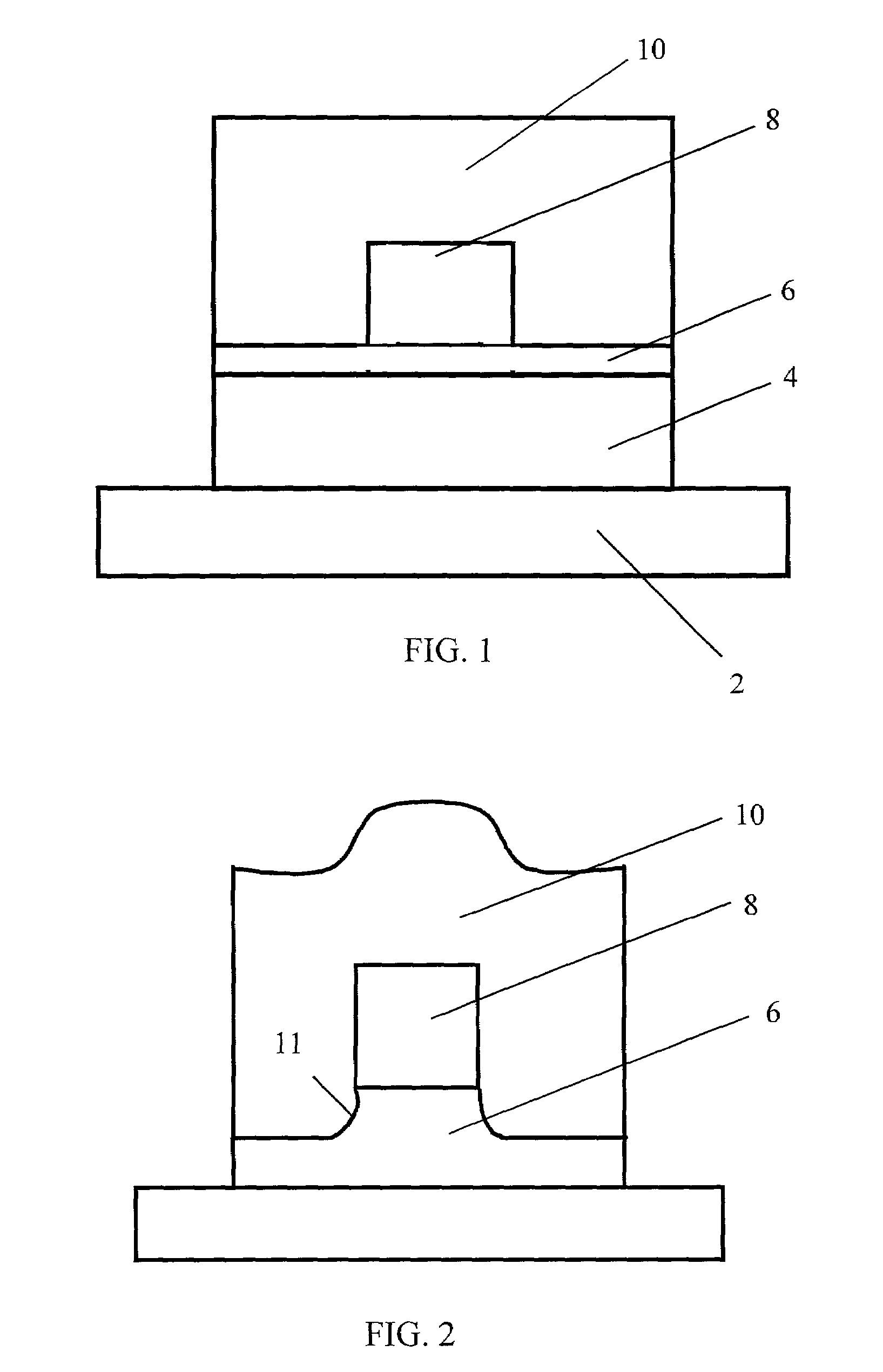

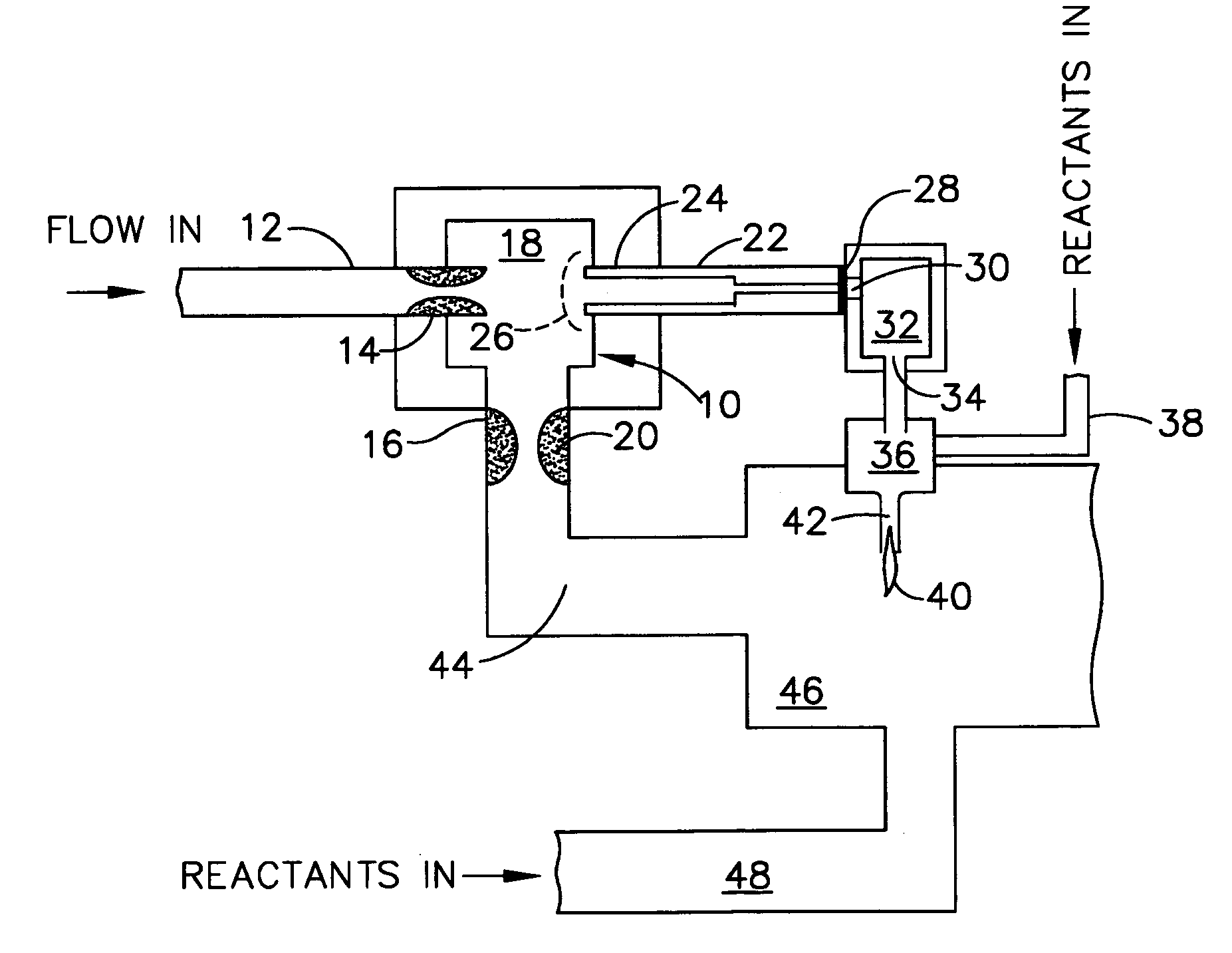

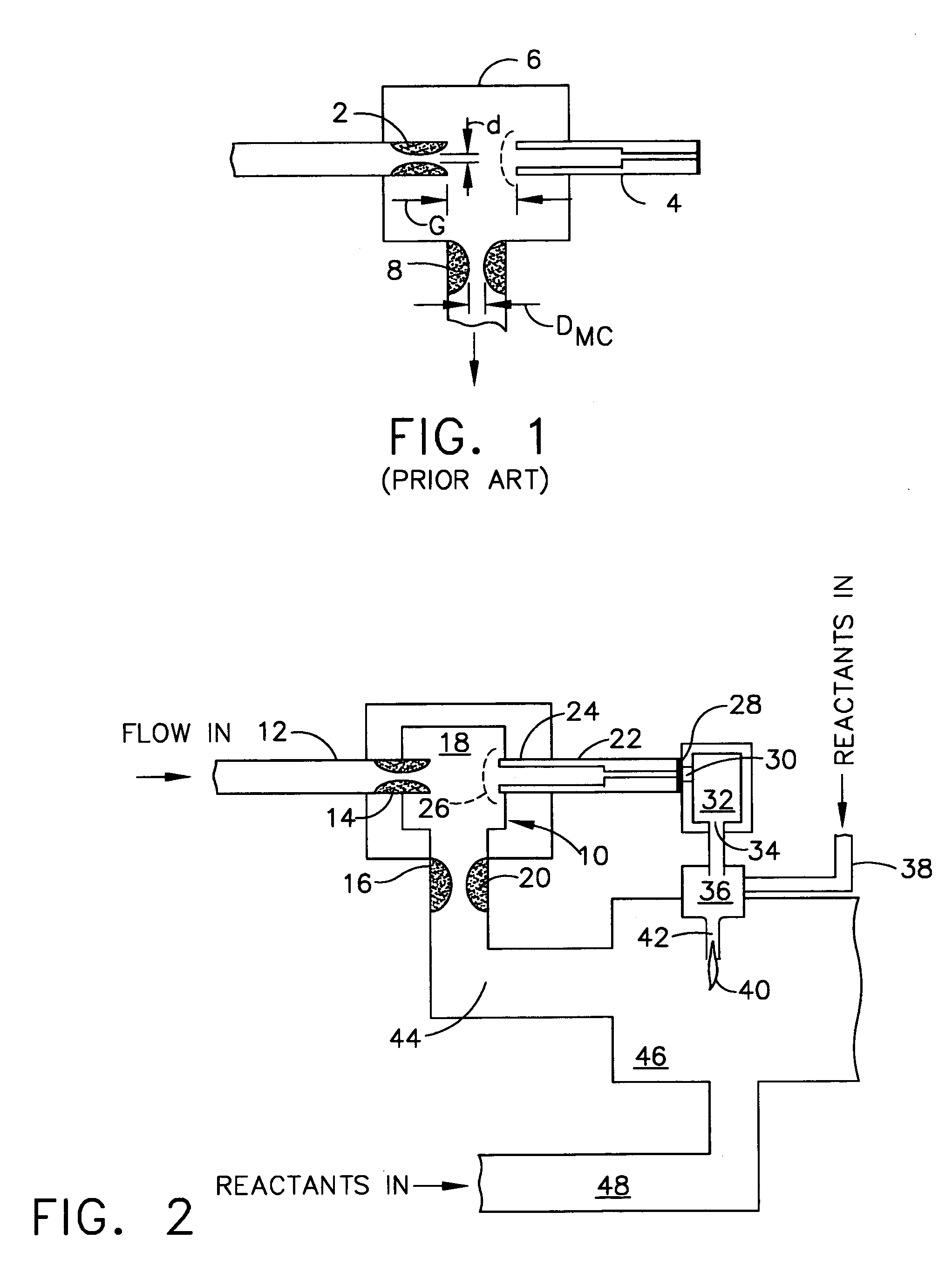

Polymer waveguide fabrication process

InactiveUS7011932B2Improve manufacturabilityMaintain good propertiesCladded optical fibrePhotomechanical apparatusGaseous oxygenOragene

The invention relates to a process a process for forming single-mode, organic waveguides employing organic polymeric materials. The process reduces dissolved and gaseous oxygen content to very low quantities, resulting in production of waveguides having superior properties and manufacturability. Also provided is a process for preventing loss of light due to cores having flared ends. A waveguide is produced by sequentially a layer of a liquid, photosensitive buffer and clad composition to a surface of a substrate; deoxygenating under vacuum; overall exposing under an inert gas actinic radiation to partially polymerize the compositions below a full curing. Coating a photosensitive core composition to the clad composition; deoxygenating under vacuum, covering with an inert gas atmosphere; positioning a photomask above, but not in contact with the core layer; imagewise exposing the core through a photomask pattern to actinic radiation to partially polymerize the core composition; developing core; coating a photosensitive overclad composition over the image areas of the core composition; deoxygenating under vacuum; overall exposing the overclad composition, under inert gas to actinic radiation to substantially fully cure the optional buffer composition, the underclad composition, the core composition and the clad composition.

Owner:ENABLENCE TECH USA

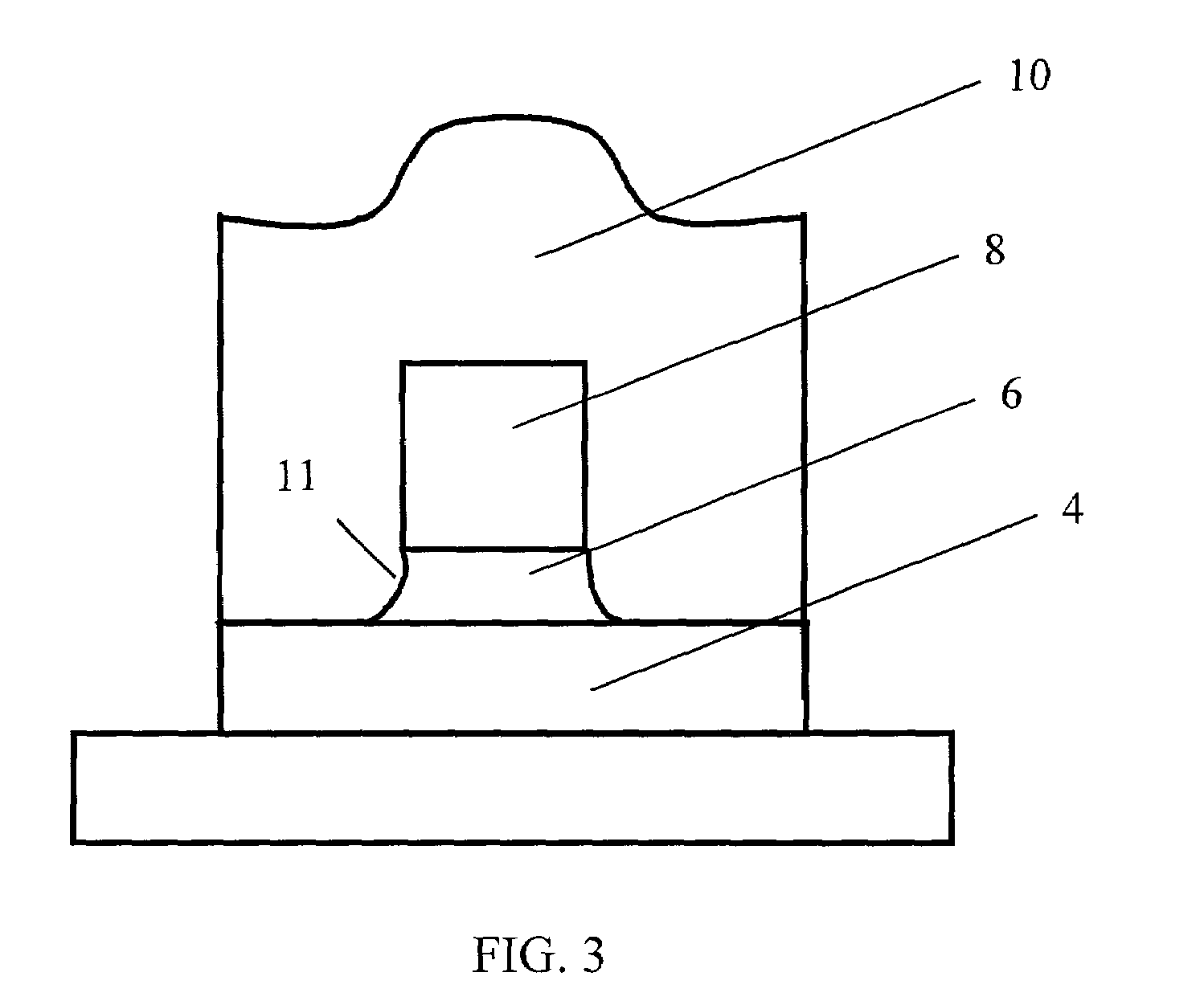

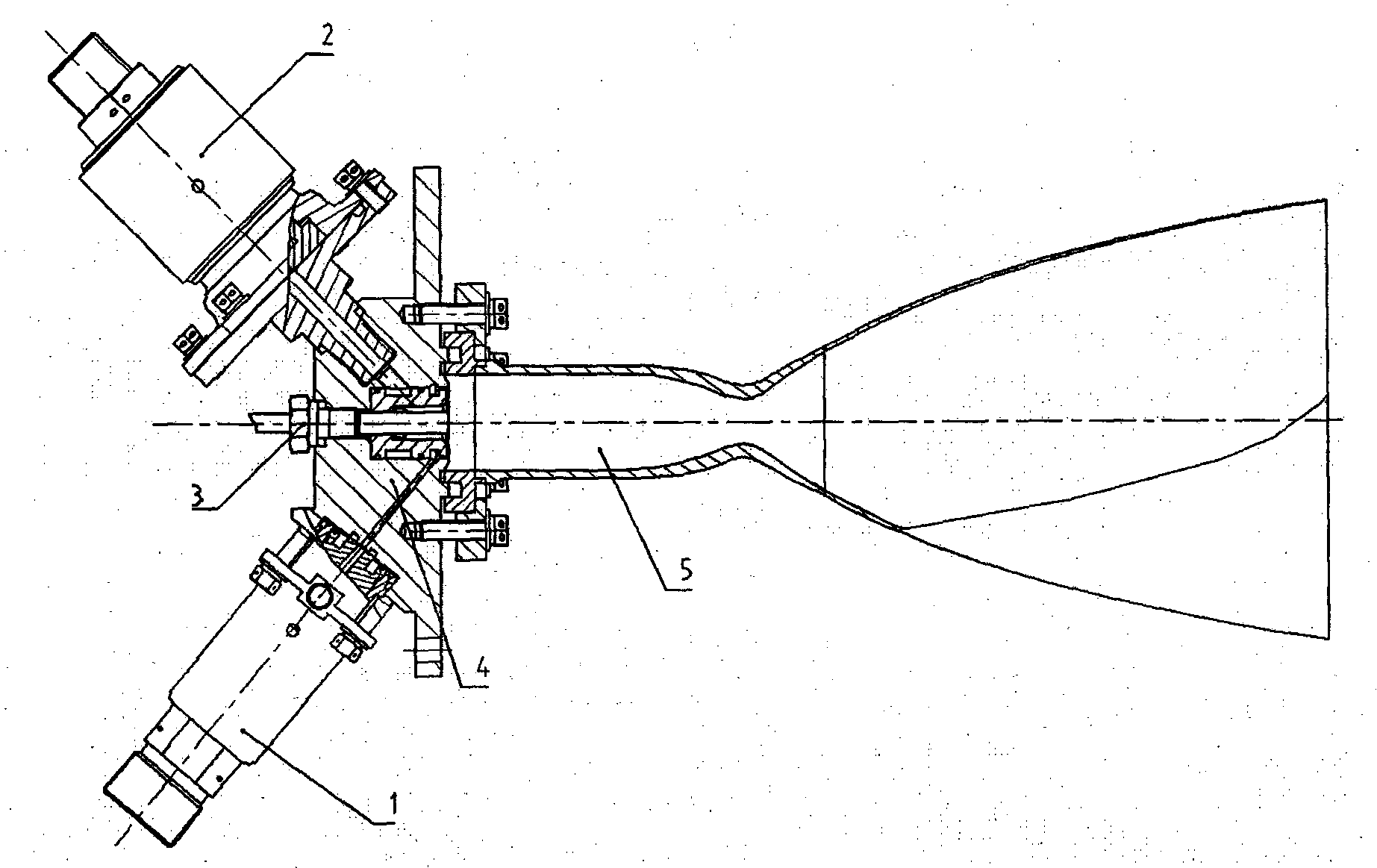

Gaseous hydrogen/gaseous oxygen eddy current cooling thrust chamber injector

InactiveCN102207043AImprove stabilityImprove cooling effectRocket engine plantsCombustion chamberThrust chamber

The invention provides a gaseous hydrogen / gaseous oxygen eddy current cooling thrust chamber injector, which comprises an injector head, a turbulent flow disc, an injection panel, a combustion chamber, a gaseous oxygen injection ring and an injection pipe. The injector has a simple structure, and a gaseous oxygen nozzle inclines upwards along the inner wall surface of the combustion chamber, so that the stability of external eddy current and the cooling effect are improved; the problem that the cooling effect is unsatisfactory because the wall surface temperature of the combustion chamber is high is solved; and the gaseous hydrogen / gaseous oxygen eddy current cooling thrust chamber injector can be applied to a thrust chamber with the thrust of 3,000N and the pressure of the combustion chamber of 2MPa.

Owner:BEIHANG UNIV

Health Jewelry Utilizing Silicone Elastomer and Process for Producing the Same

InactiveUS20080041099A1Process economyPromote blood circulationCurling devicesBraceletsHydrogenSkin contact

The present invention provides a body accessory which can formed into a ring shape, comprising a silicone elastomer body having a silicone elastomer layer mixed with fine titanium powder, which contains titanium powder obtained by burning a gaseous oxygen-hydrogen mixture in high-pressure water, fusing metallic titanium using the resultant burning gas and precipitating the product in water at least as a major component, on the skin contacting side and the silicone elastomer decorative continuous protrusion on the exterior side. The present invention also provides a process for manufacturing the body accessory, which comprises a silicone elastomer accessory body having a silicone elastomer layer mixed with fine titanium powder on the skin contacting side and a silicone elastomer decorative continuous protrusion on the exterior side and can be made into a ring, said process comprising the first step of forming a continuous concavity on a silicone elastomer accessory body; the next step of embedding a silicone elastomer layer containing fine titanium powder; the further step of separately forming a silicone elastomer decorative continuous protrusion; and the final step of placing the accessory body thus obtained on said decorative continuous protrusion and curing with heat for integration.

Owner:PHILD CO LTD

Electrolyzer for gaseous carbon dioxide

InactiveUS20190127865A1Improve shipping rateEliminate needCellsOrganic diaphragmsElectrolysisGaseous oxygen

An electrochemical device and method can include techniques involving bipolar membrane electrolysis to transform an input product into an output product. Some embodiments can include a gas-diffusion electrode as a cathode, a bipolar membrane configured to facilitate autodissociation, and an anode that can be configured as a liquid-electrolyte style electrode or a gas-diffusion electrode. In some embodiments the electrochemical device can be configured as a CO2 electrolyzer that is designed to utilize input product including carbon dioxide gas and water to generate output products that can include gaseous carbon monoxide or other reduction products of carbon dioxide and gaseous oxygen or the oxidation products of a depolarizer such as hydrogen, methane, or methanol. Embodiments can be utilized in the production of fuels or feedstocks for fuels and carbon-containing chemicals, in air purification systems, flue gas treatment devices, and other machines and facilities.

Owner:PENN STATE RES FOUND

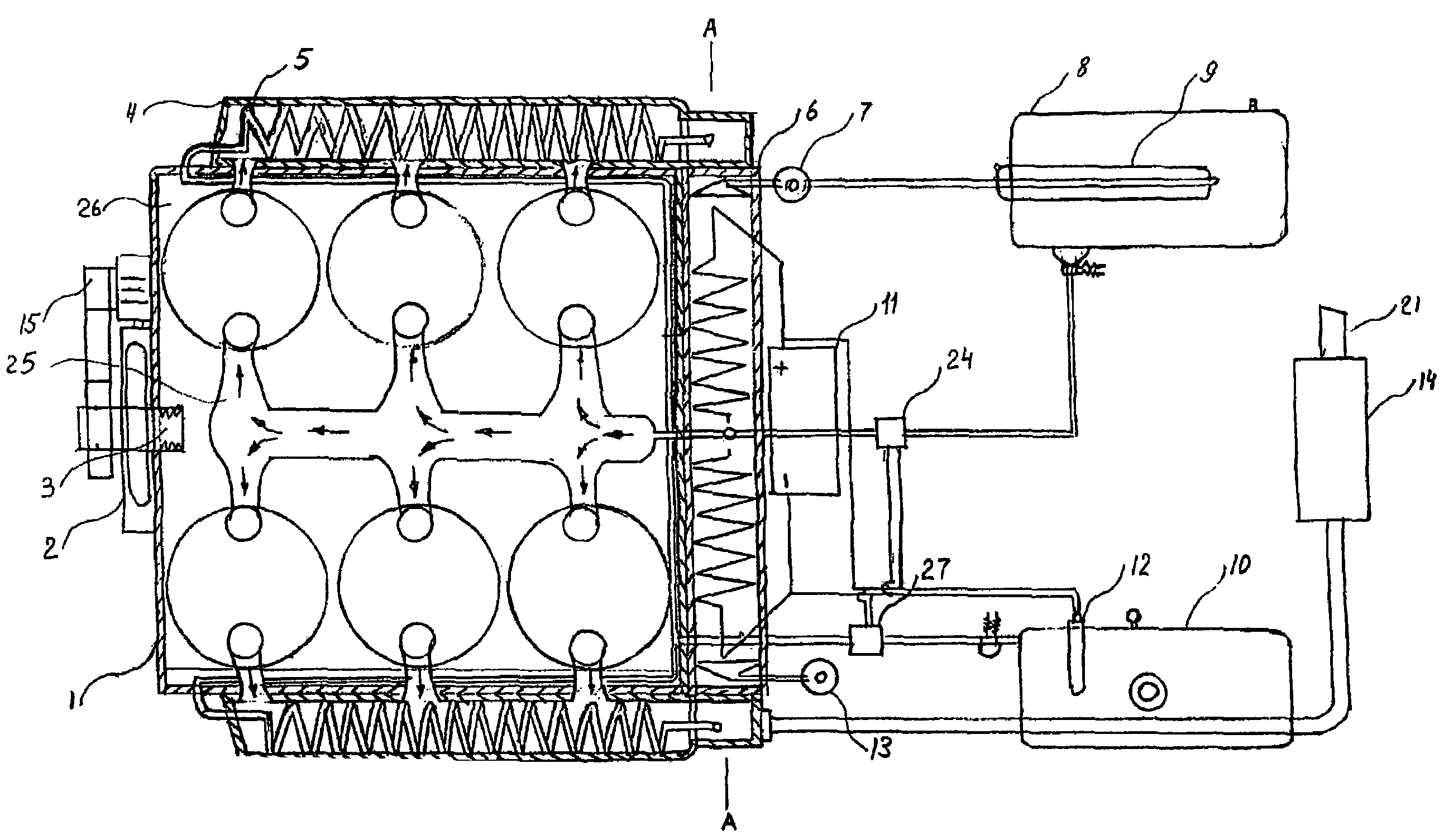

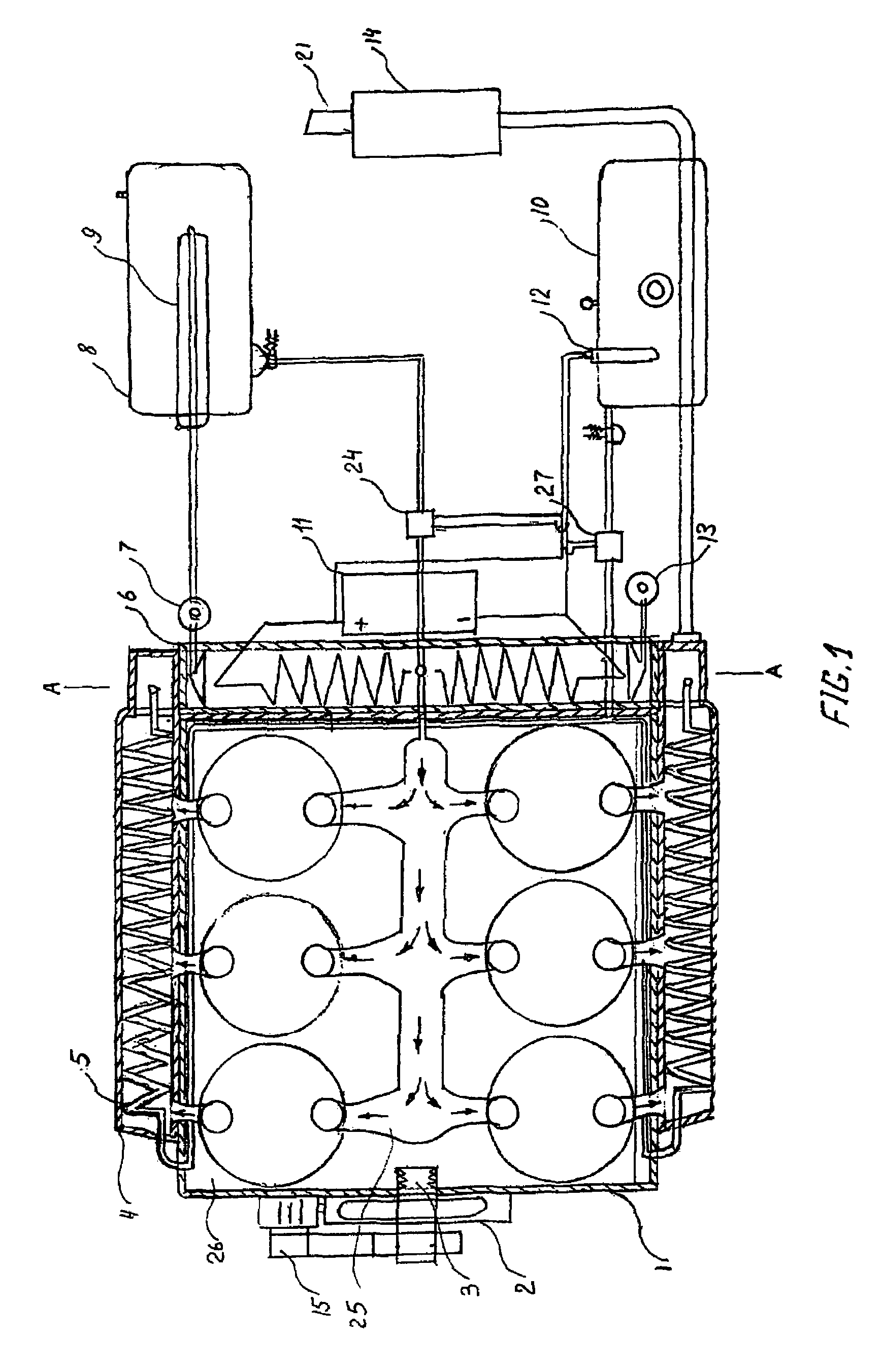

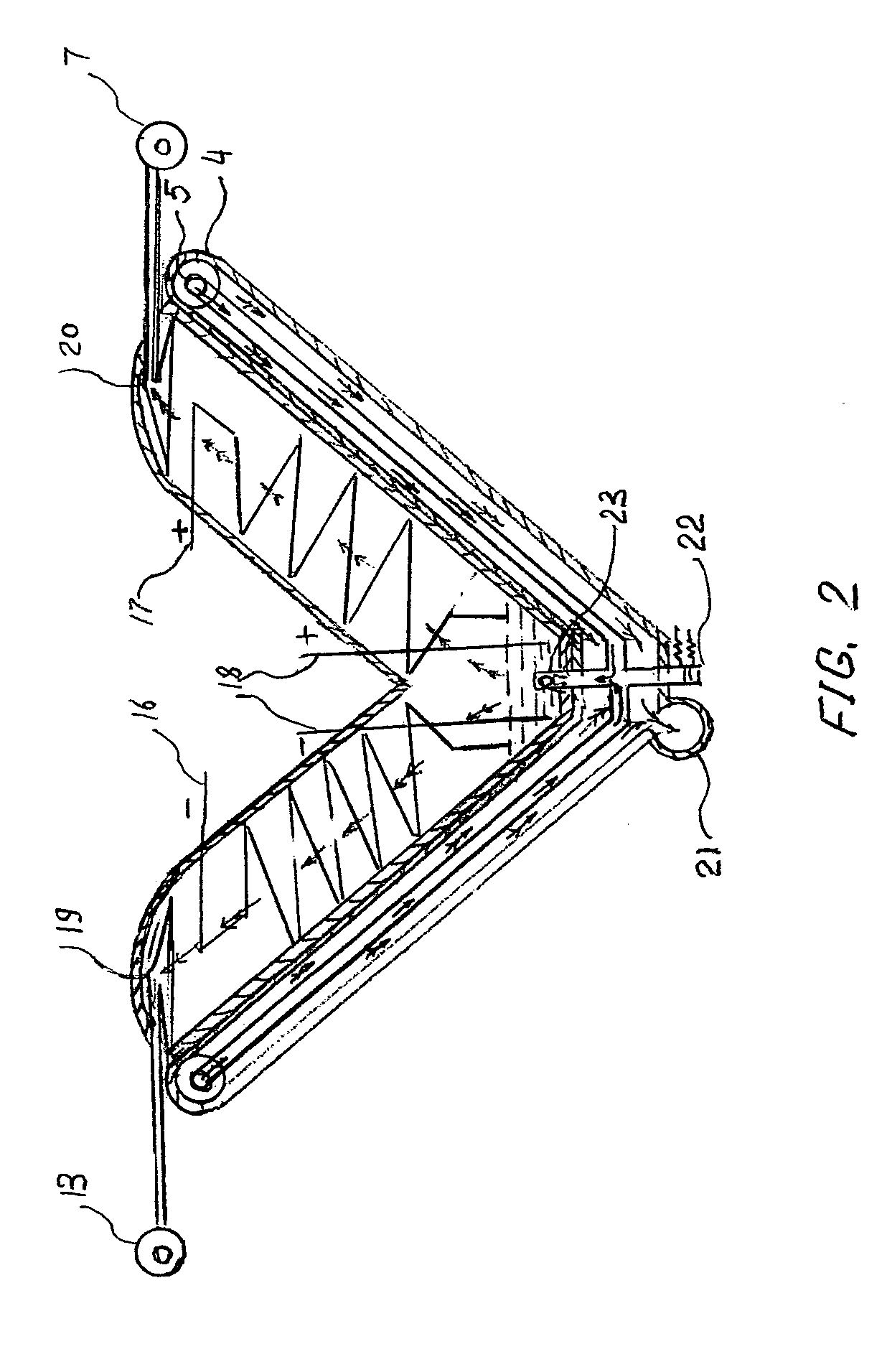

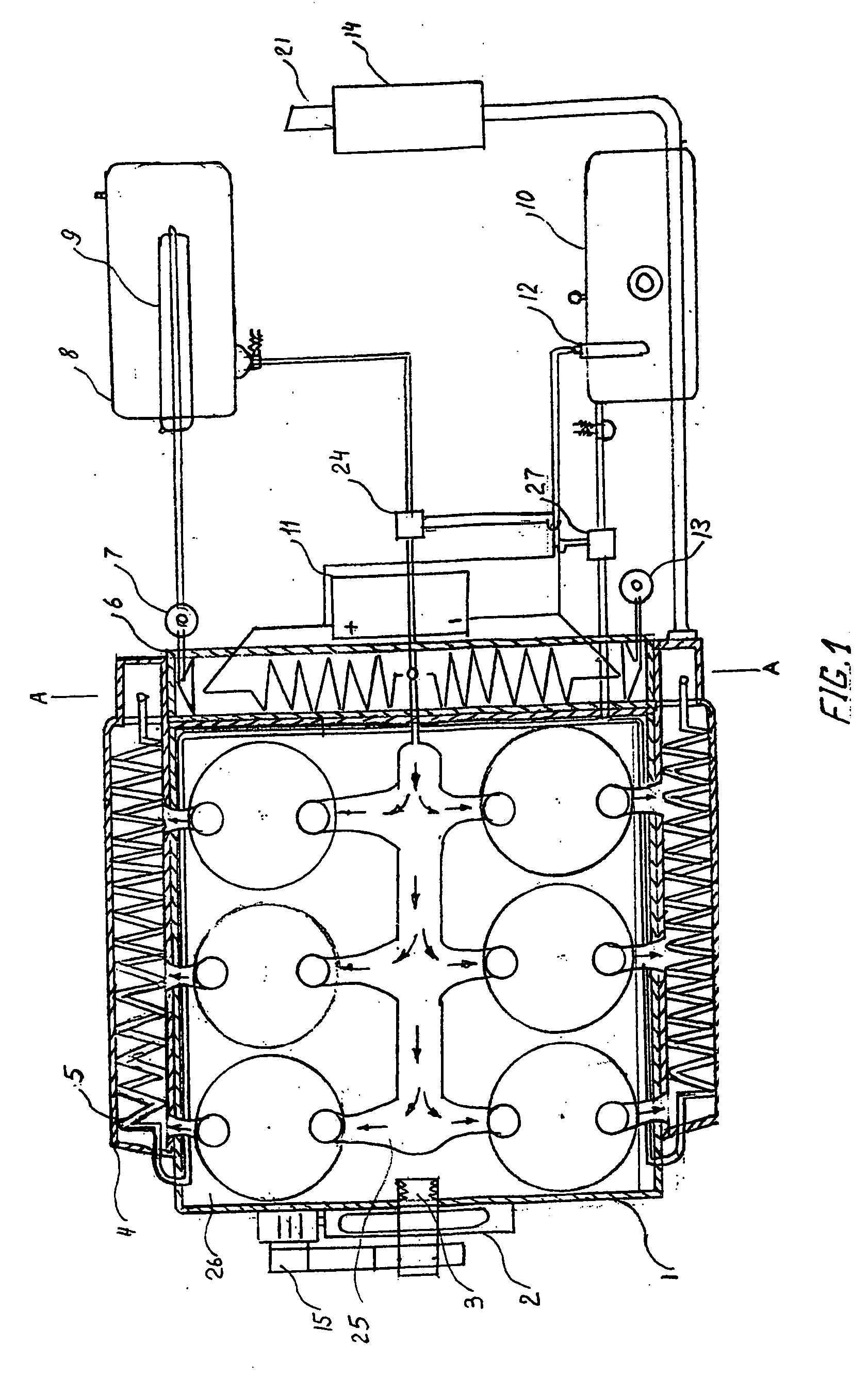

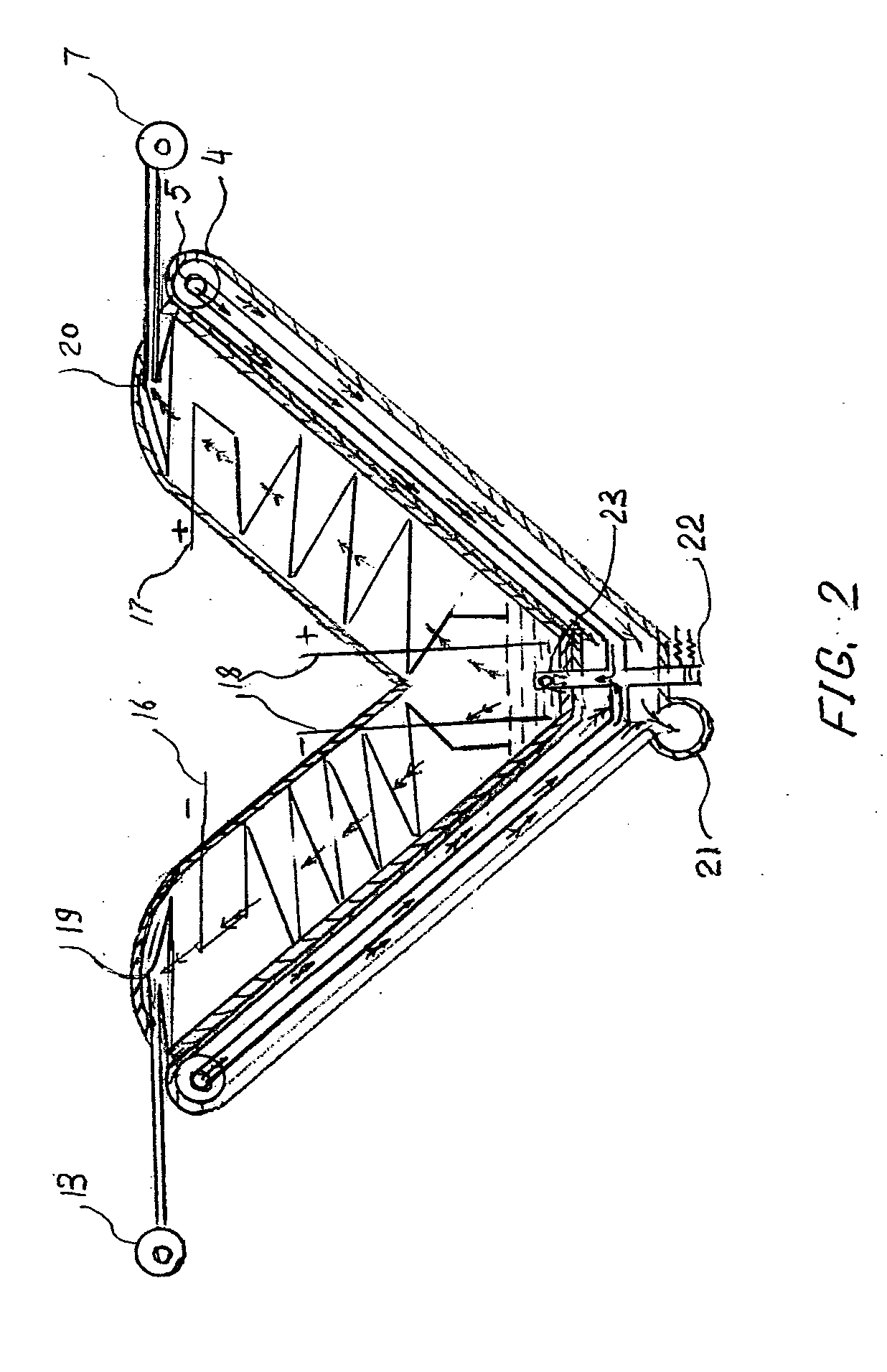

Hydrogen and oxygen production and accumulating apparatus including an internal combustion engine and method

InactiveUS20070215070A1Easy to operateHydrogenInternal combustion piston enginesElectrolysisTransformer

An apparatus, including an internal combustion engine; for powering the engine the apparatus produces hydrogen fuel from water, and comprises water supply means; fuel storage means; controlling means; a collector, receiving combustion products output from engine's operation; a transformer, utilizing thermo-impact of the combustion products and converting supplied water into ionized hydrogen and oxygen; an ion divider electrically separating hydrogen and oxygen ions into gaseous hydrogen, further directed into the fuel storage means and controllably fed substantially into engine's cylinders, and gaseous oxygen; exhaust means outputting exhaust products from the collector into the atmosphere, on their way out heating water in the water supply means. The fuel storage means contain initial hydrogen or another predetermined fuel. Electrolyzer means are provided to supplement hydrogen and oxygen ions production. Recommended temperature and parts size ranges for six- and eight-cylinder engines are disclosed. A truck engine usable embodiment is also illustrated and described.

Owner:YATSENKO YURIY

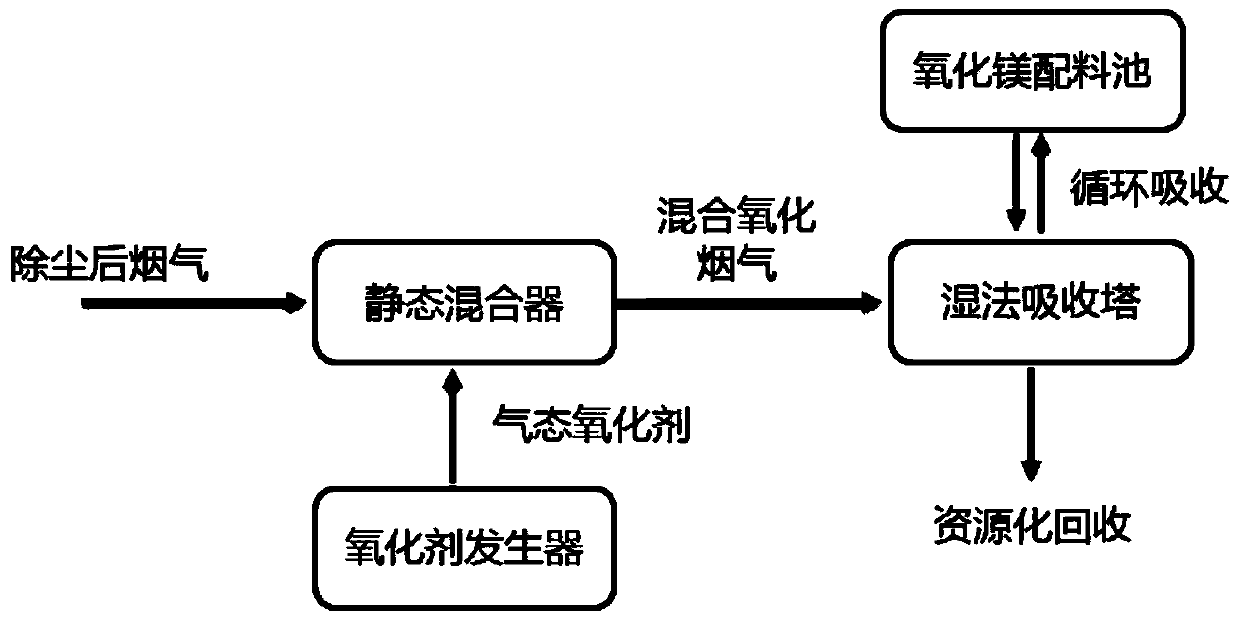

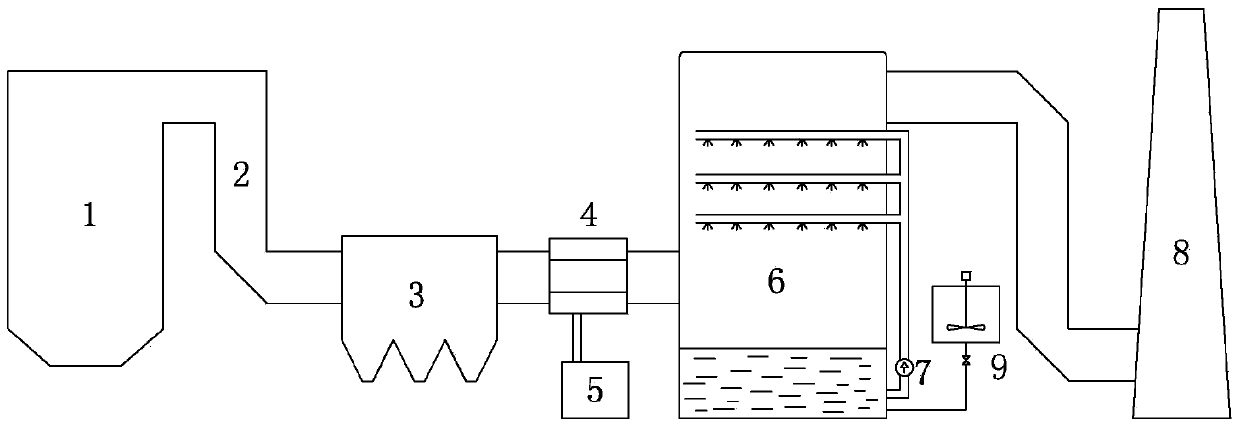

Flue gas treatment method and flue gas treatment device capable of simultaneous desulfurization, de-nitration and mercury removal through magnesium oxide

InactiveCN103736373AFully oxidizedPrevent oxidationDispersed particle separationFlue gasDust control

The invention discloses a flue gas treatment method and a flue gas treatment device for simultaneous desulfurization, de-nitration and mercury removal through magnesium oxide. The flue gas treatment method comprises the following steps: (1) removing dust from boiler flue gas and then transmitting the boiler flue gas into a static mixer, spaying ozone into the static mixer at the same time, mixing and oxidizing the boiler flue gas with the ozone; (2) transmitting the mixed and oxidized mixture gas into an absorbing tower from the bottom part of the absorbing tower, circularly spraying magnesium oxide solution in the absorbing tower; and (3) exhausting the sprayed-absorbed flue gas from the top of the absorbing tower through a chimney. Due to the adoption of combination of oxidization with a gaseous oxidizing agent and absorbing with magnesium oxide solution, the effect of simultaneous desulfurization, de-nitration and mercury removal in one tower is realized, and furthermore, the effects of simultaneous desulfurization, de-nitration and mercury removal are all good.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

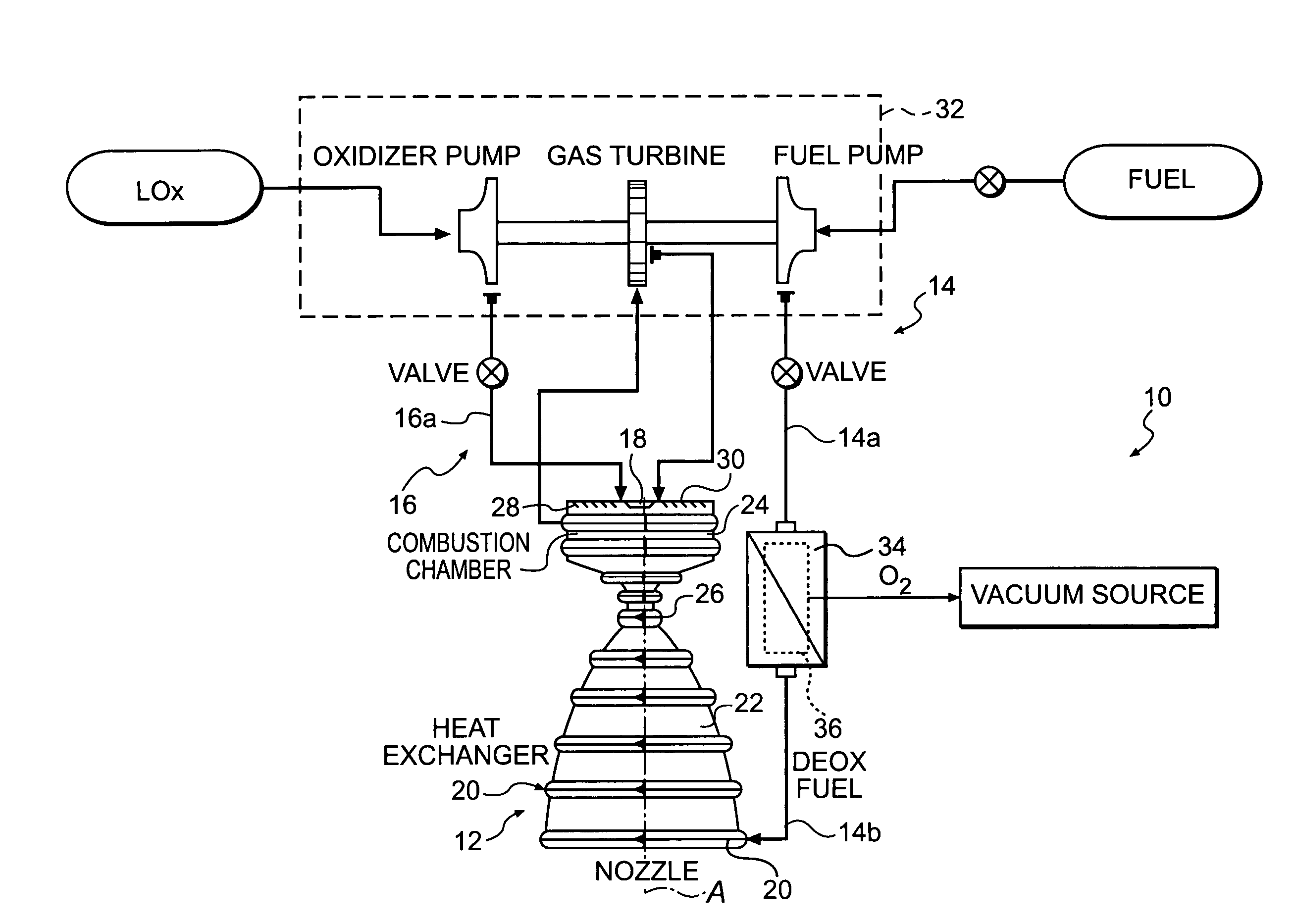

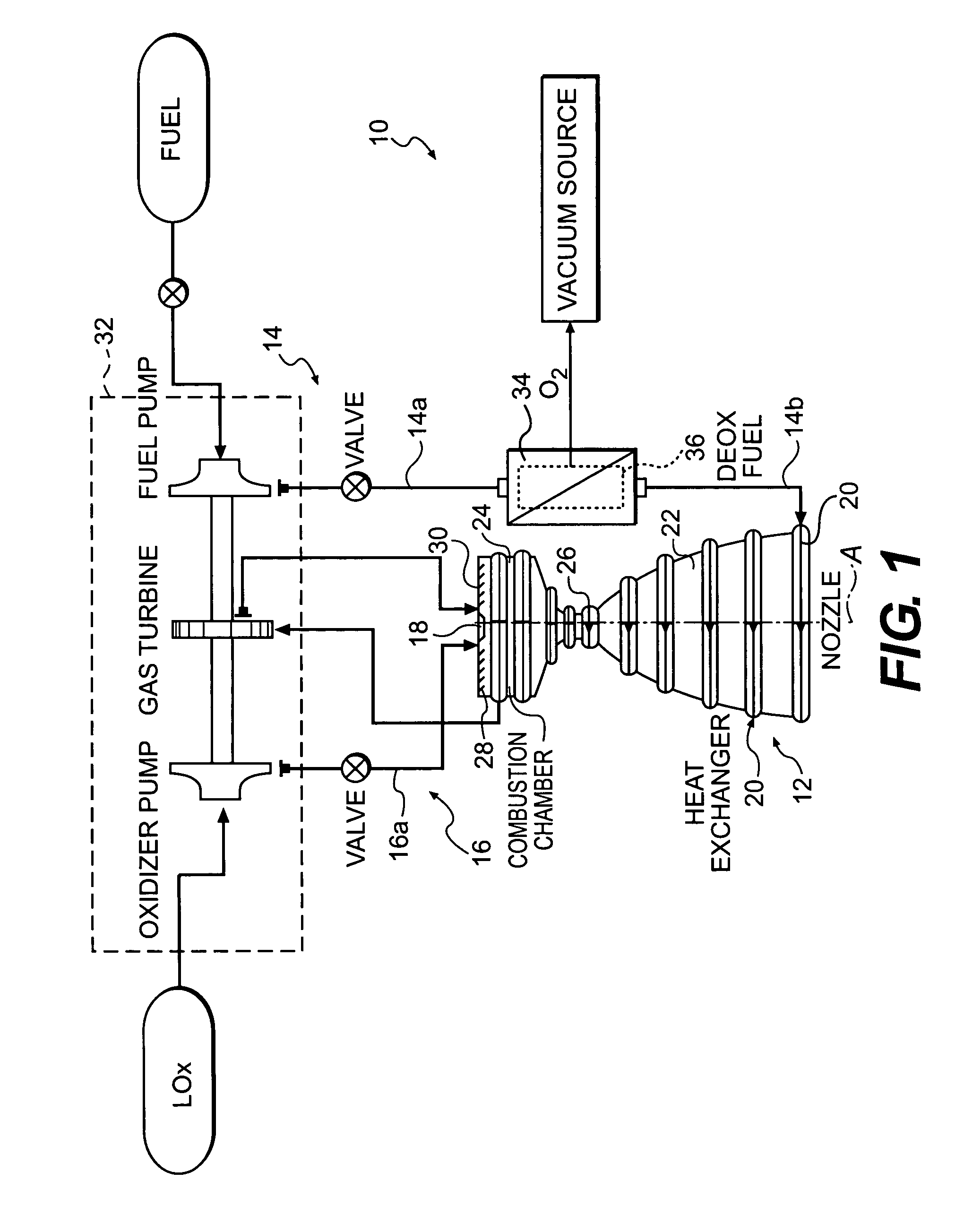

Hydrocarbon-fueled rocket engine with endothermic fuel cooling

InactiveUS20100257839A1Improve combustion stabilityImprove mixing efficiencyCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberKerosene

A rocket engine utilizes a kerosene-based fuel in a supercritical state which is catalytically converted to lighter hydrocarbons with heat from a thrust chamber assembly which operates as a heat exchanger. This process is facilitated by a fuel stabilization deoxygenator system which removes dissolved oxygen and / or by inerting the internal surfaces of the fuel-cooled combustion chamber wall passages by applying a zeolite-based catalyst coating to permit the fuel to be heated beyond normal temperature ranges. The supercritical kerosene-based fuel is passed through a turbine and injected into the combustion chamber to burn with the gaseous oxidizer. An increased mixing efficiency between the gaseous components results in an increase in combustion efficiency and increased stability of combustion.

Owner:UNITED TECH CORP

Gaseous oxygen resonance igniter

A gaseous oxygen resonance igniter includes a body with a first inlet for gaseous oxygen incorporating a supersonic nozzle. An outlet from the body incorporates an orifice of predetermined size to maintain a desired pressure in the body. An aperture in the body opposite the first inlet provides a port to a ceramic resonance cavity. A ceramic bleed disc is engaged at a second end of the resonance cavity. An end cap incorporates a plenum adapted to receive high temperature oxygen flow from the resonance cavity through the bleed disc. An exhaust port is connected to the plenum for the high temperature oxygen which flows to a mixing chamber which introduces pilot fuel for ignition as a combustion initiation torch.

Owner:UNITED TECH CORP +1

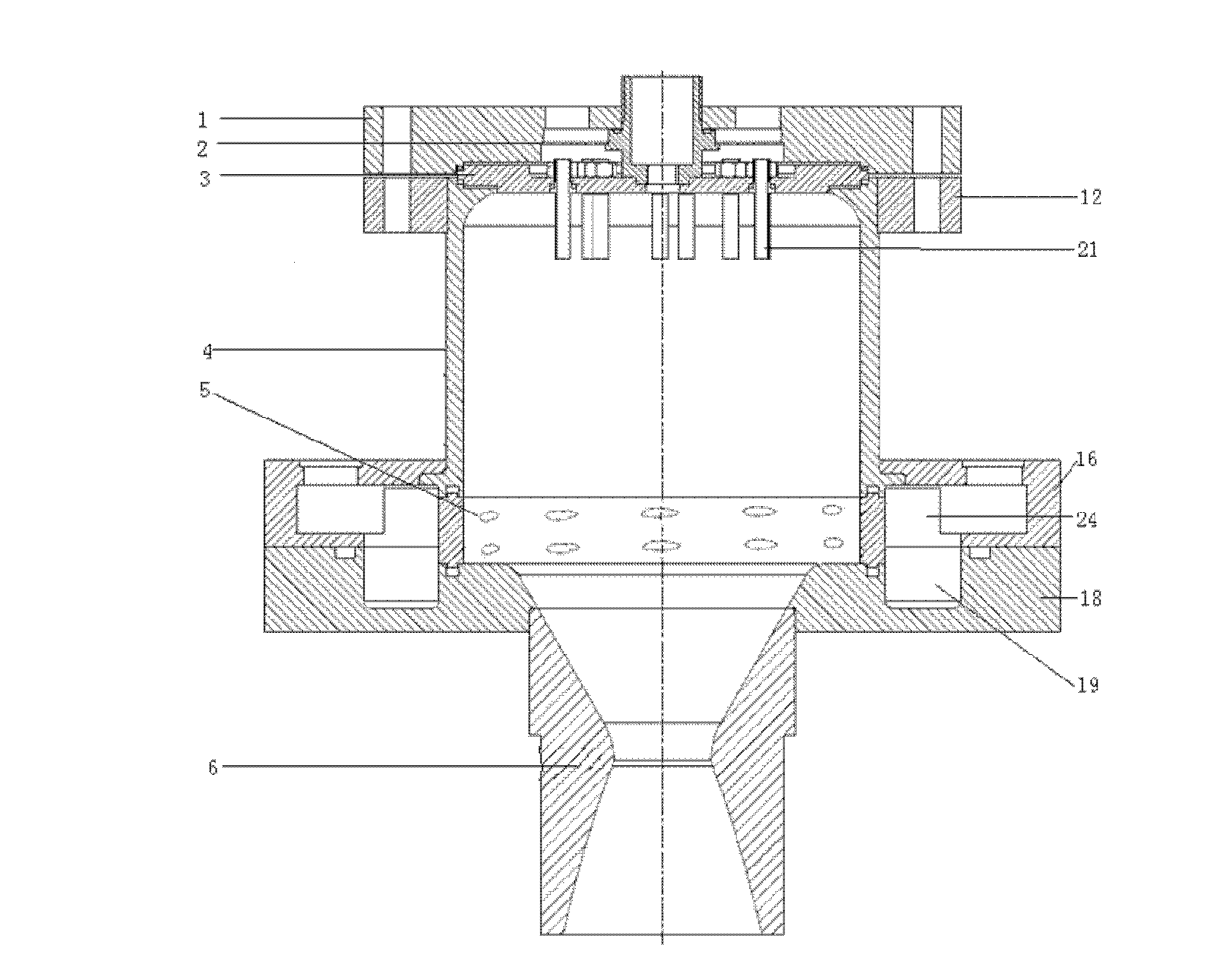

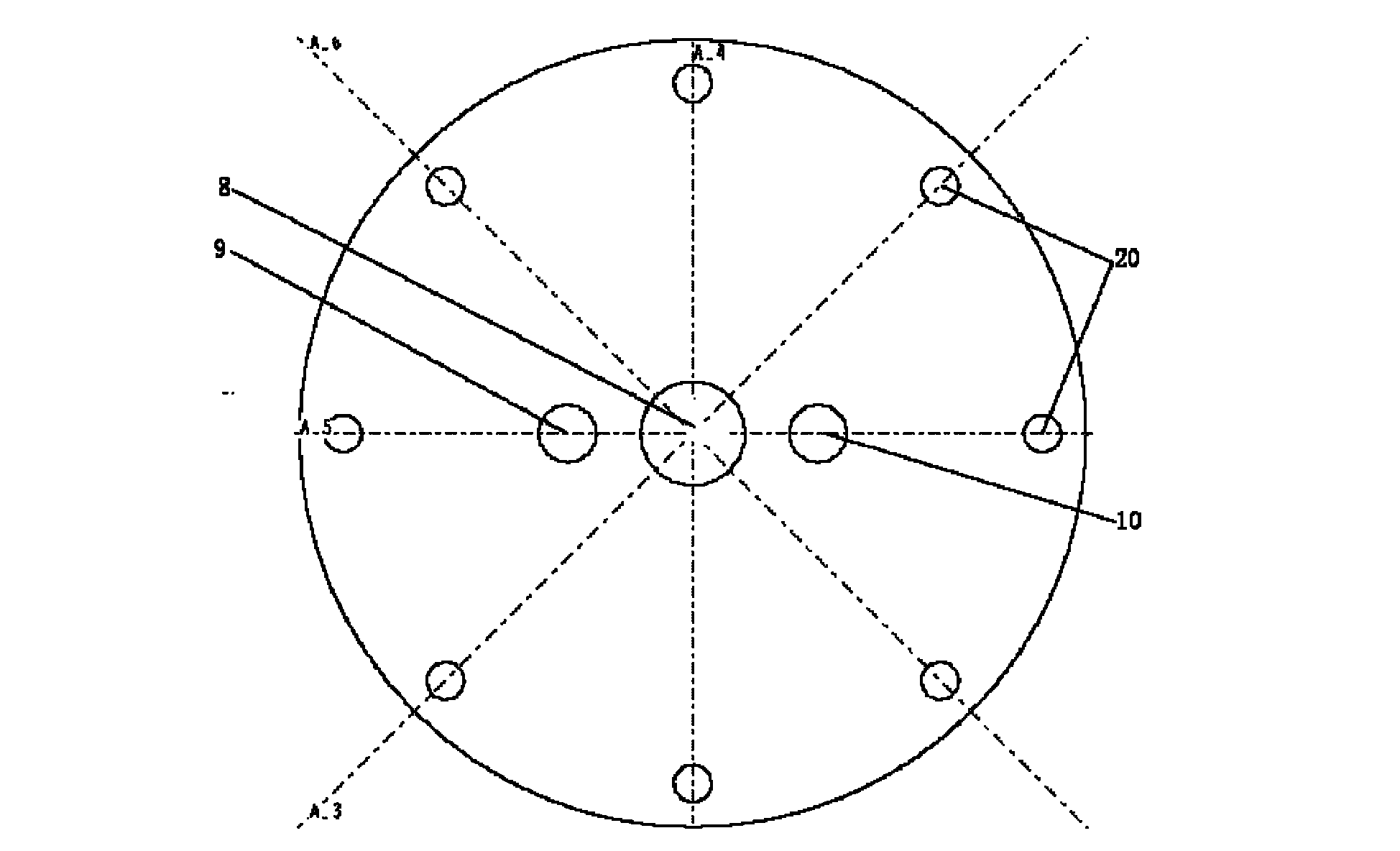

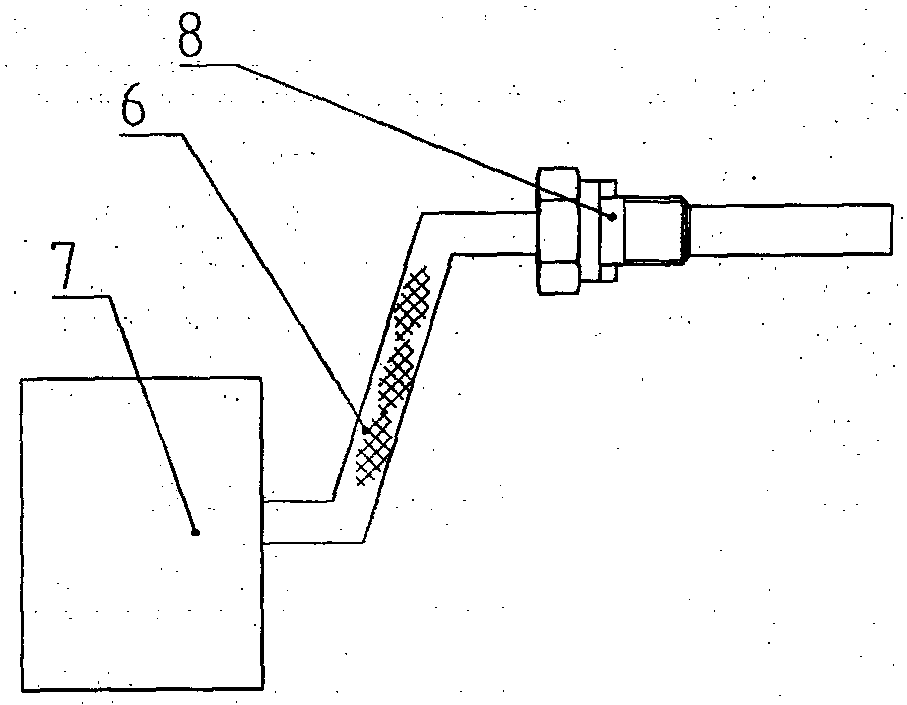

small thrust rocket engine

ActiveCN106134417BTo achieve non-toxicImprove performanceElectric spark ignitersRocket engine plantsCombustion chamberKerosene

The invention discloses a small-thrust rocket engine applied to aerospace vehicles, which comprises a fuel valve (1), an oxygen valve (2) connected with an injector (4), and transports kerosene and gaseous oxygen to the injector (4) respectively ; The tail of the injector (4) is provided with an electric igniter (3); the injector (4) is connected with the thrust chamber body (5); the thrust chamber body (5) is composed of a combustion chamber and a nozzle The electric spark generated by the igniter (3) directly ignites the propellant gas mixture near the injection surface of the injector (4), and the gas is discharged from the nozzle to generate thrust. The invention uses gas-oxygen / kerosene as a propellant, solves the environmental pollution problem of the existing toxic spontaneous combustion propellant engine, and achieves beneficial effects such as non-toxic, non-polluting, high performance, fast response, and adaptation to steady-state / pulse dual working modes. .

Owner:SHANGHAI INST OF SPACE PROPULSION

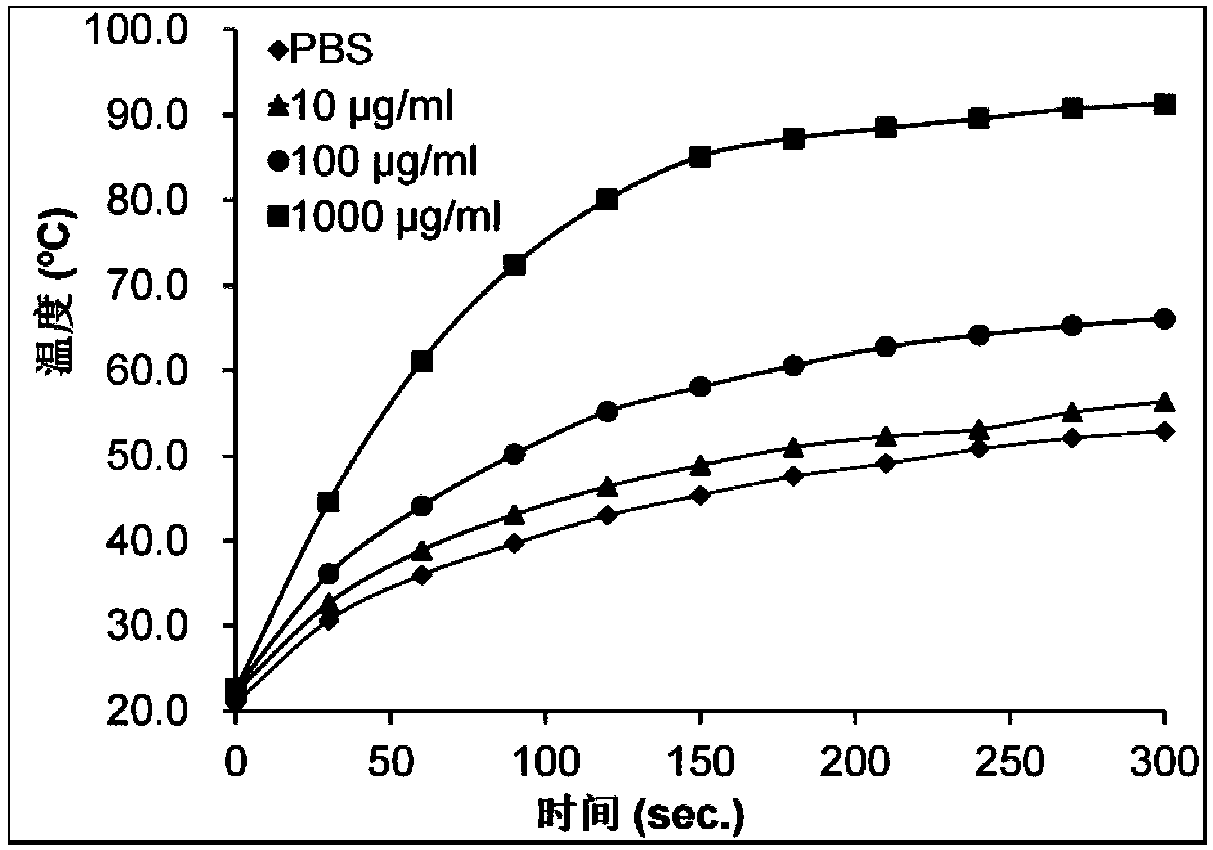

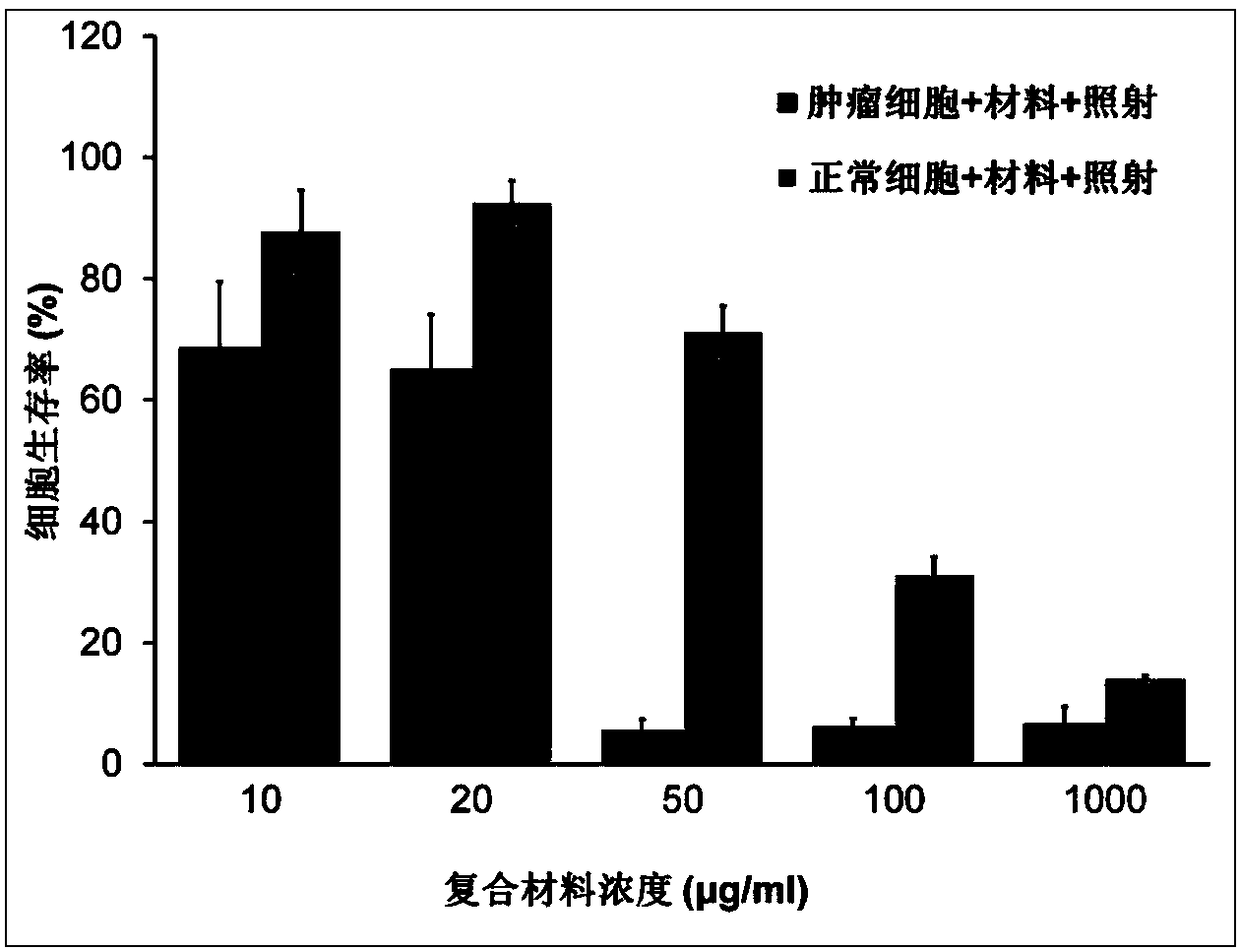

Preparation method and application of composite nanometer material for combined treatment of tumor by optothermal and active oxygen

ActiveCN108273059AStrong selective killing effectReach killPhotodynamic therapyAntineoplastic agentsBiocompatibility TestingTherapeutic effect

The invention relates to a preparation method and an application of a composite nanometer material for the combined treatment of tumor by optothermal and active oxygen, and belongs to the technical field of medicines used for treatment. Nanometer iron is prepared through an ethylene glycol method, a catechol group on a dopamine molecular is oxidized under the condition of alkaline solution and oxygen, dyhydroxy benzpyrole or a semiquinone free radical is formed to generate rearrangement or coupling crosslinking auto polymerization reaction, a polydopamine layer coats the outer surface of the nanometer iron, the active group of the polydopamine is used for realizing covalent linkage with glucose oxidase to prepare a nanometer iron / polydopamine / glucose oxidase (nanometer iron / PDA(propane diamine) / GOx(gaseous oxygen)) composite nanometer material, and the composite material of the inorganic nanometer material modified by biomacromolecules and biomimetic materials is constructed. The prepared material has the advantages of obvious treatment effect, high biocompatibility, no toxicity and no pollution. The preparation technology has the advantages of simpleness and low cost and is suitable for scale production and clinical medical care.

Owner:SHANDONG UNIV

Reduction of carbonized particles in a poly(arylene ether)-polyamide composition

Owner:SABIC INNOVATIVE PLASTICS IP BV

Electrocatalytically active non-carbon metal-based anodes for aluminium production cells

InactiveUS6103090AReduce consumptionImprove responseMachining electrodesIsotope separationOxygen ionsRare earth

A non-carbon, metal-based high temperature resistant anode of a cell for the production of aluminium has a metal-based substrate coated with one or more electrically conductive adherent applied layers, at least one electrically conductive layer being electrochemically active. The electrochemically active layer contains one or more electrocatalysts fostering the oxidation of oxygen ions as well as fostering the formation of biatomic molecular gaseous oxygen to inhibit ionic and / or monoatomic oxygen attack of the metal-based substrate. The electrocatalyst can be iridium, palladium, platinum, rhodium, ruthenium, silicon, tin, zinc, Mischmetal oxides and metals of the Lanthanide series. The applied layer may further comprise electrochemically active constituents from oxides, oxyfluorides, phosphides, carbides, in particular spinels such as ferrites.

Owner:MOLTECH INVENT

Device and Method For Preparing a Homogeneous Mixture Consisting of Fuel and Oxidants

InactiveUS20080134580A1Diminish sooting tendencyReduce thermal stressHydrogen/synthetic gas productionMixing gases with gases/vapoursReaction zoneLiquid fuel

A device for providing a homogenous mixture of fuel and oxidant including an arrangement (5) for feeding liquid fuel to an evaporator, an arrangement (4) for feeding gaseous oxidant into a mixing zone (12) downstream of the evaporator, and a reaction zone downstream of the mixing zone in which a packed structure (3) is arranged. The packed structure can be a ceramic cylindrical molding having a diameter in the range 25 to 35 mm and an axial length in the range 15 to 50 mm or it can have flow conduits that are square in cross-section and have a cell density in the range 400 to 1200 cpsi.

Owner:EHNERDEJ GMBKH

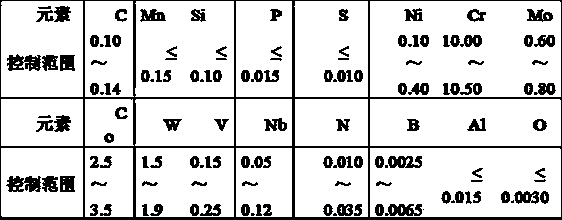

Method for manufacturing steel ingots through ultra-supercritical steam turbine blade steel electro-slag remelting

The invention discloses a method for manufacturing steel ingots through ultra-supercritical steam turbine blade steel electro-slag remelting. Specifically, a smelting method adopting an electric-arc furnace, LF,VOD / VHD, double-supporting-arm electro-slag furnace remelting is adopted, components Si, Al and B of a consumable electrode is strictly controlled, the adding amount of Al powder or Fe-Si powder mixture is strictly controlled in the electro-slag slagging process, the oxidation burning loss of elements in the electro-slag remelting process is reduced by evenly and strictly controlling the adding amounts of the Al powder and the Fe-Si powder in a slag bath in the remelting process of the consumable electrode, and even and uniform integral chemical components, gaseous oxygen content and purity degree of electro-slag ingots are ensured. The method is suitable for smelting of common electro-slag furnaces, device input is reduced, and smelting cost is reduced. The low-Si, low-Al ultra-supercritical steam turbine blade steel gaseous oxygen content obtained by means of the method is smaller than or equal to 30*106, and non-metallic inclusions conform to assessment stipulations of ASTM E45 standard A law and accordingly meets the blade steel purity degree requirement for an ultra-supercritical steam turbine.

Owner:FUSHUN SPECIAL STEEL SHARES

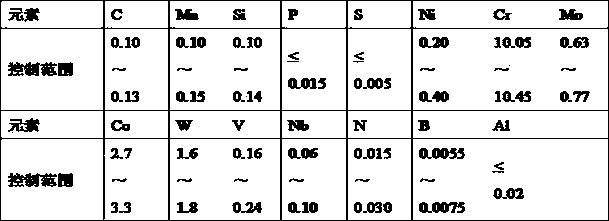

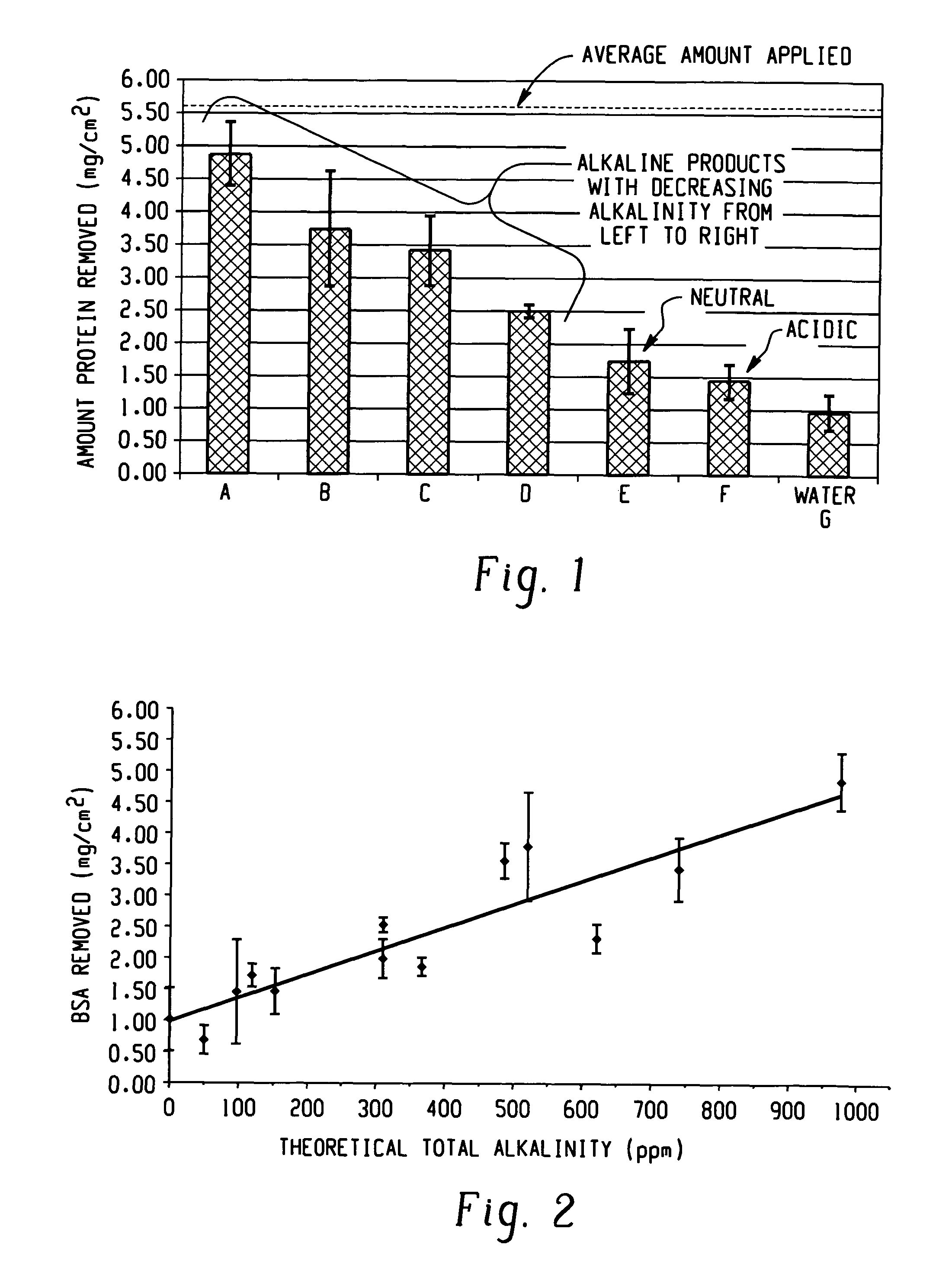

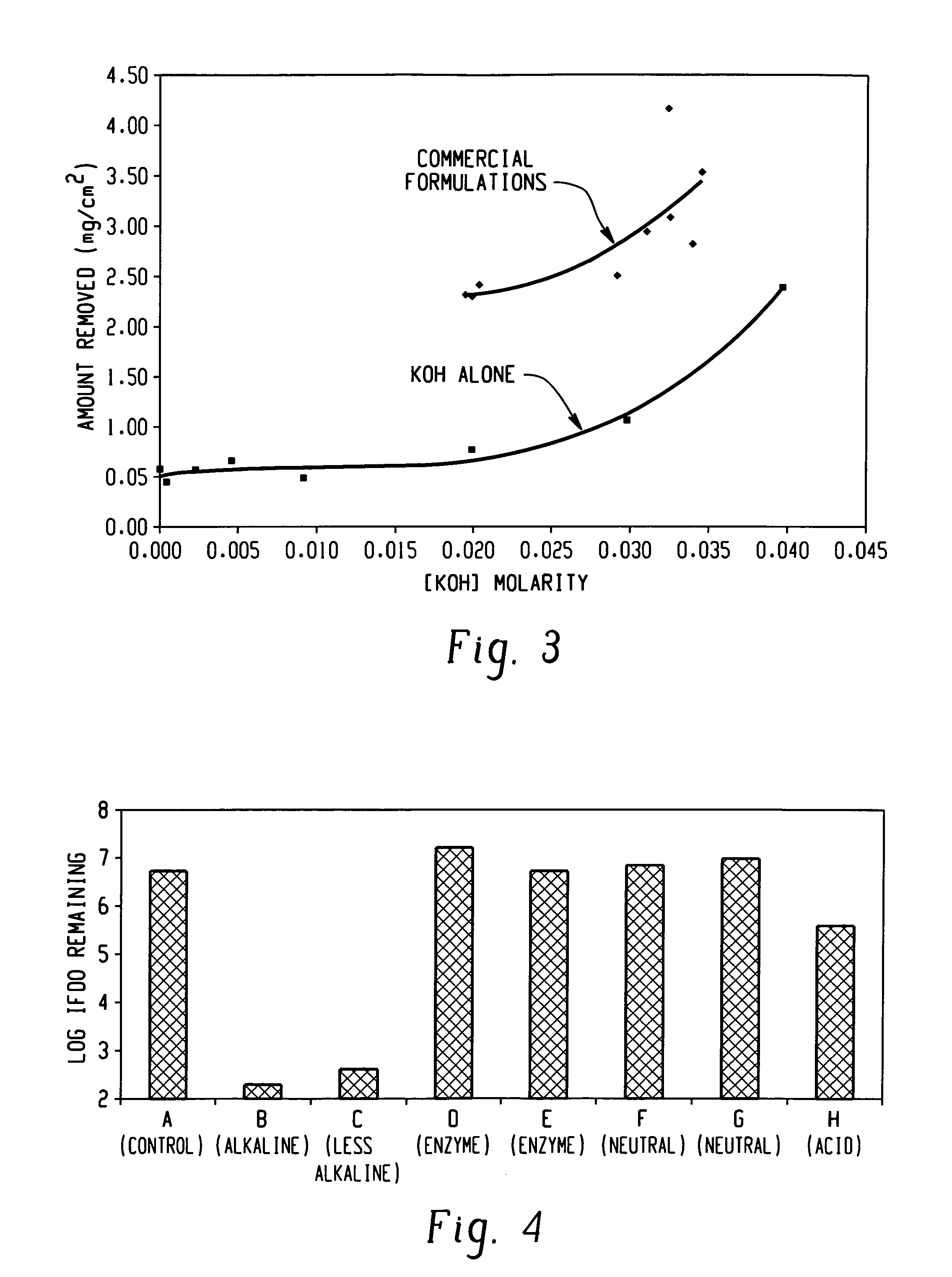

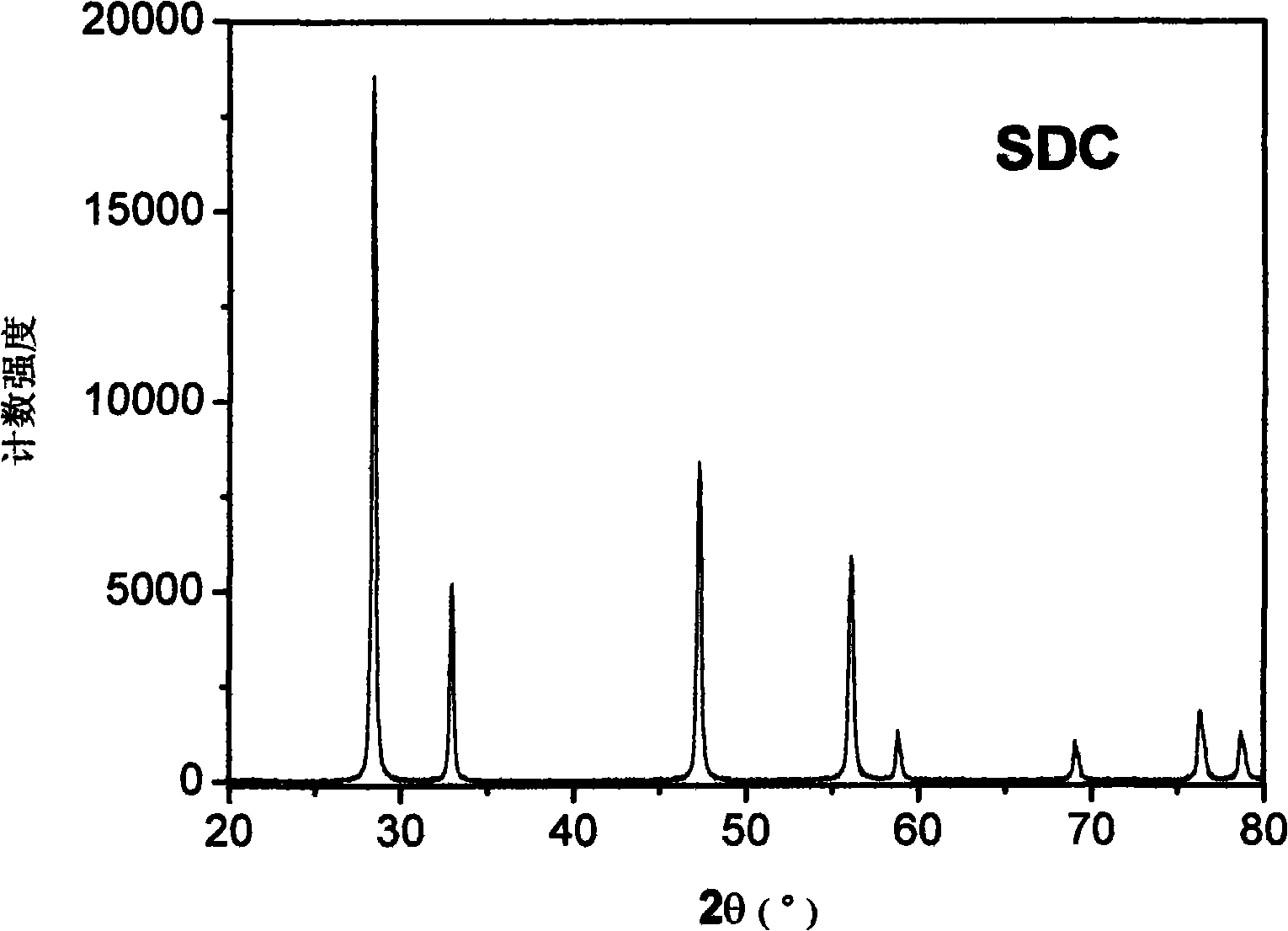

Decontamination of surfaces contaminated with prion-infected material with gaseous oxidizing agents

ActiveUS7803315B2Gentle processThe process is fast and efficientInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsProtein materialsCleansing Agents

A surface which carries a material which is infected with prions is cleaned with an alkaline cleaning solution to remove as much proteinaceous material as possible from the surface. The solution contains an alkaline cleaning agent which attacks prions remaining on the surface and which attacks prions removed from the surface during the cleaning step. After the cleaning step, the surface is exposed to a strong gaseous oxidant, preferably hydrogen peroxide vapor. The hydrogen peroxide or other strong oxidant attacks the prions, particularly the unclumped prion strands, deactivating the prions.

Owner:AMERICAN STERILIZER CO

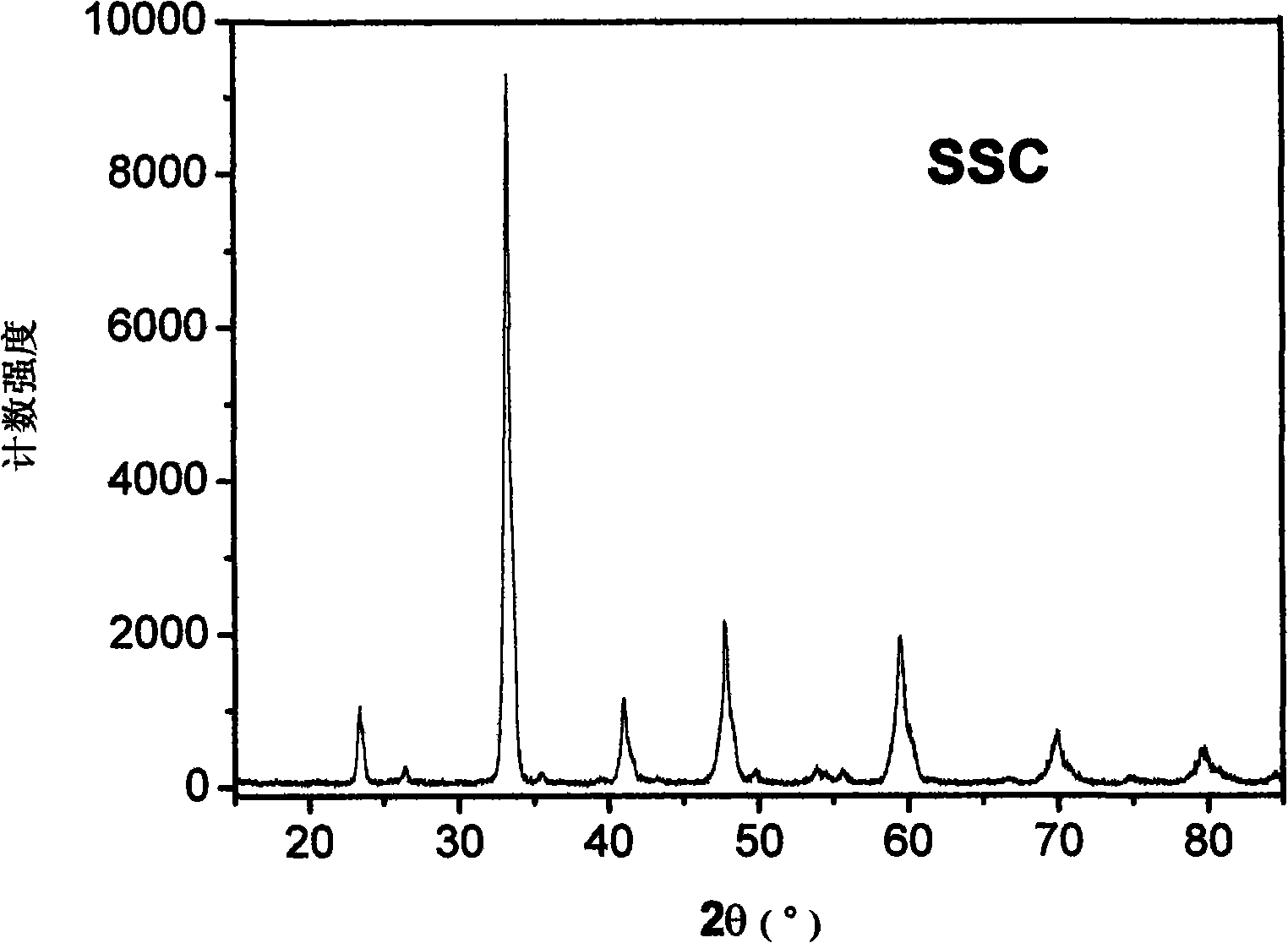

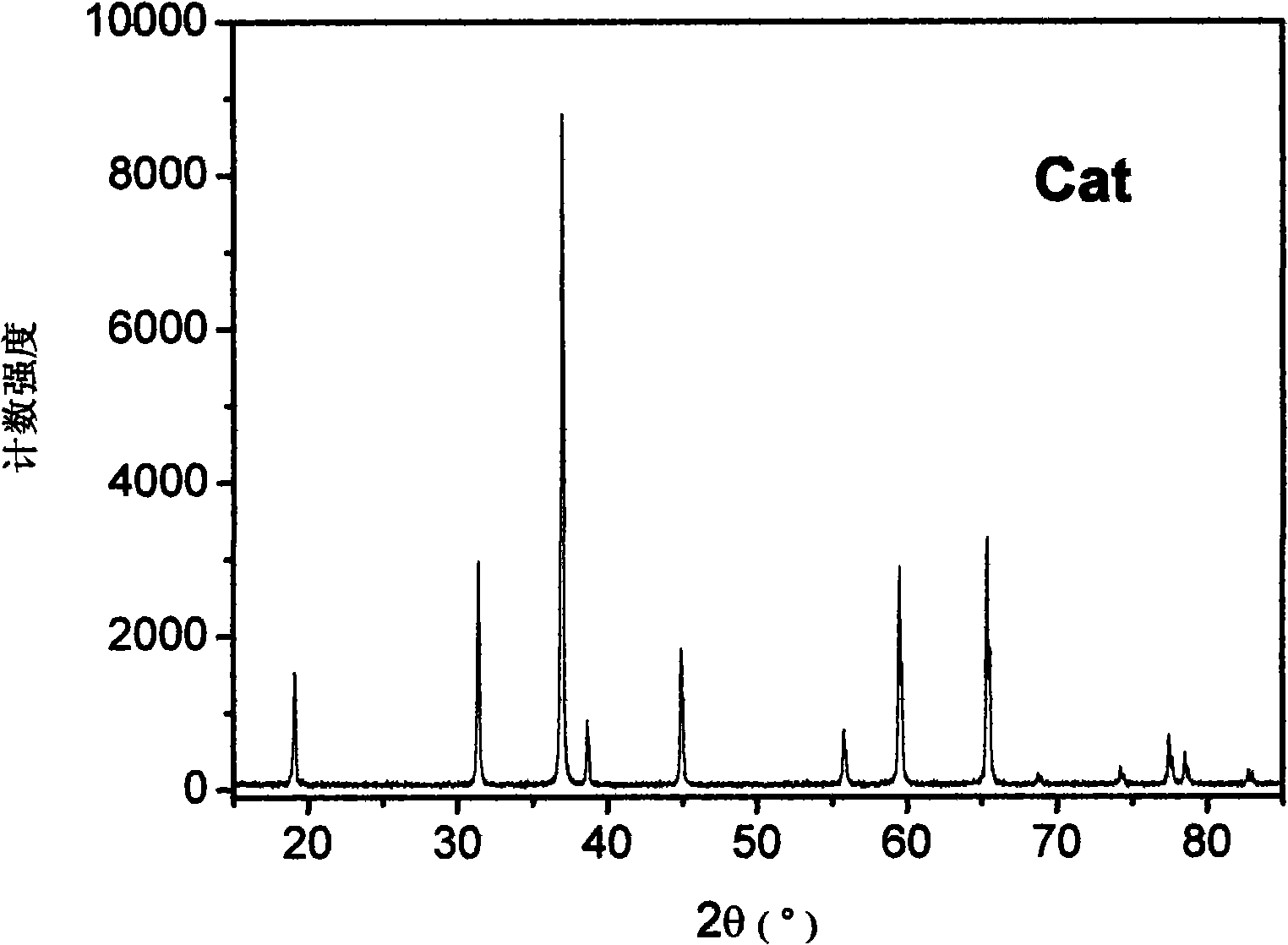

Ternary complex cathode material of intermediate/low temperature solid-oxide fuel battery

InactiveCN101295791AGood chemical stabilityImprove structural stabilityCell electrodesFuel cell detailsElectrical conductorActive matter

The invention discloses a novel ternary composite cathode material for a medium and low temperature solid oxide fuel cell, which comprises an oxygen ion conductor oxide, an electronic-oxygen ion mixed conductor oxide and an oxygen catalytic reduction active matter. The material is characterized in that: the cathode material taking perovskite structured oxygen ion and electronic mixed conductor as the main body has the main function of catalytically reducing the gaseous oxygen at the surface as oxygen ions and transmitting the oxygen ions in an manner of bulk phase to the interface between an electrolyte and the cathode; the conductivity of the oxygen ions is improved by adding the oxygen ion conductor, thereby improving the bulk phase transmission speed of the oxygen ions; the speed of the surface oxygen exchange of the cathode material is obviously increased by adding the oxygen catalytic reduction active matter, thereby greatly enhancing the catalytic activity of the surface oxygen of the cathode material. All effective components of the ternary composite cathode material are synthesized by adopting nitrate by an EDTA-citric acid complex method. Shown in single cell tests, the ternary composite cathode material shows not only excellent comprehensive performance but also excellent compatibility among all the effective components.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com