Ternary complex cathode material of intermediate/low temperature solid-oxide fuel battery

A solid oxide and cathode material technology, applied in fuel cells, fuel cell parts, battery electrodes, etc., can solve problems such as gaps, easy carbon deposition and deactivation of nickel-based anodes, and achieve high structural stability, The effect of good chemical stability and excellent electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

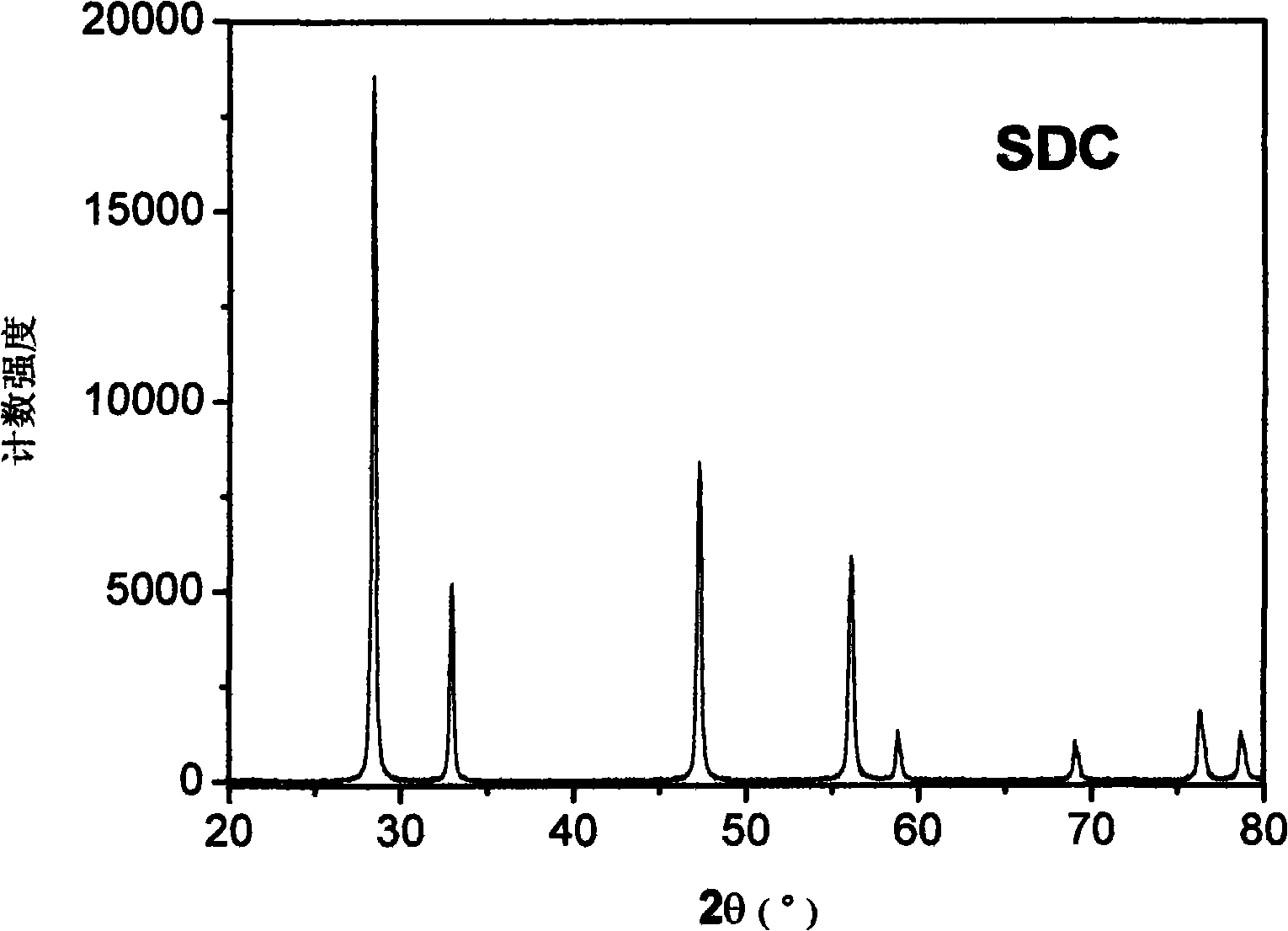

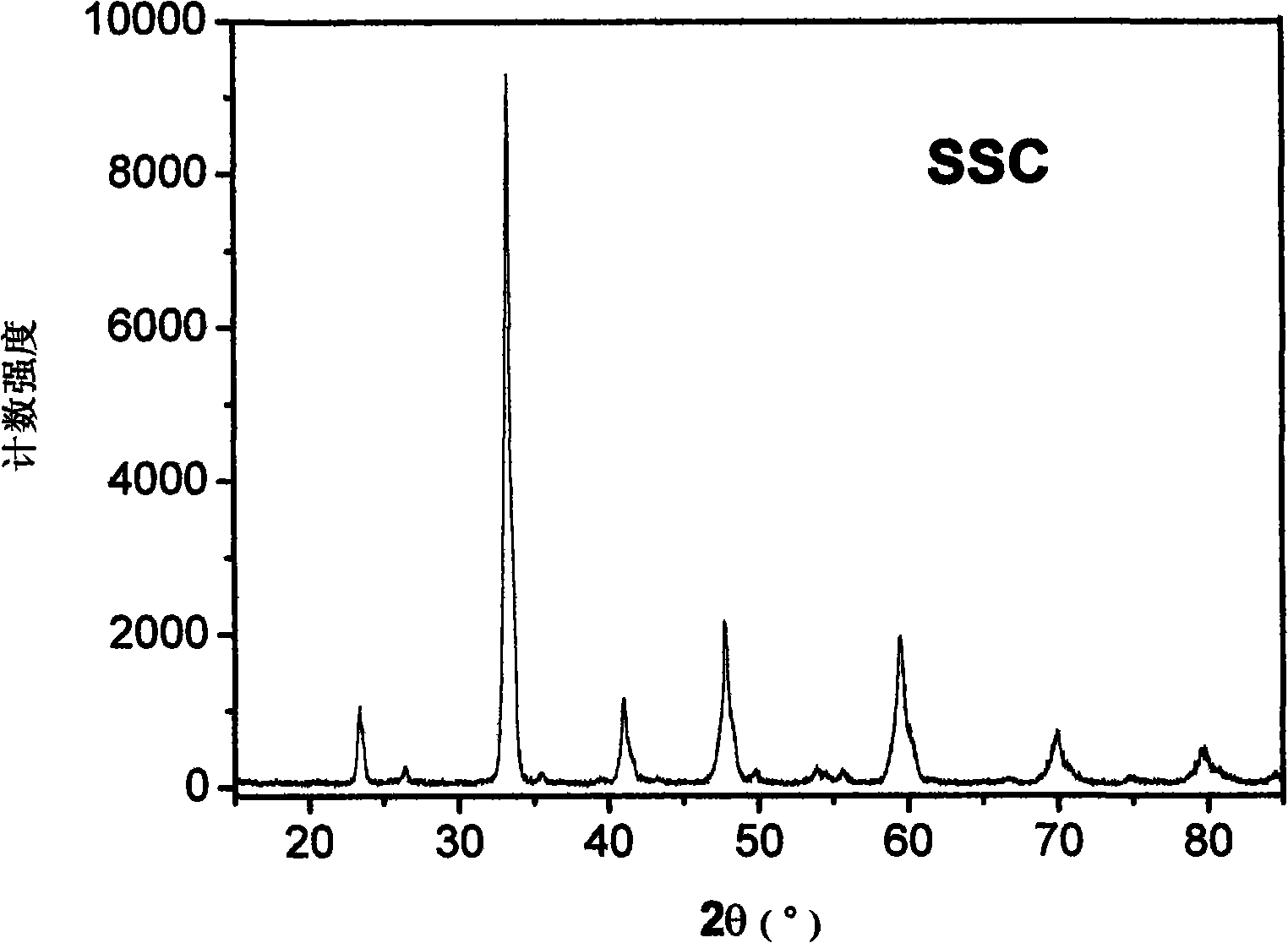

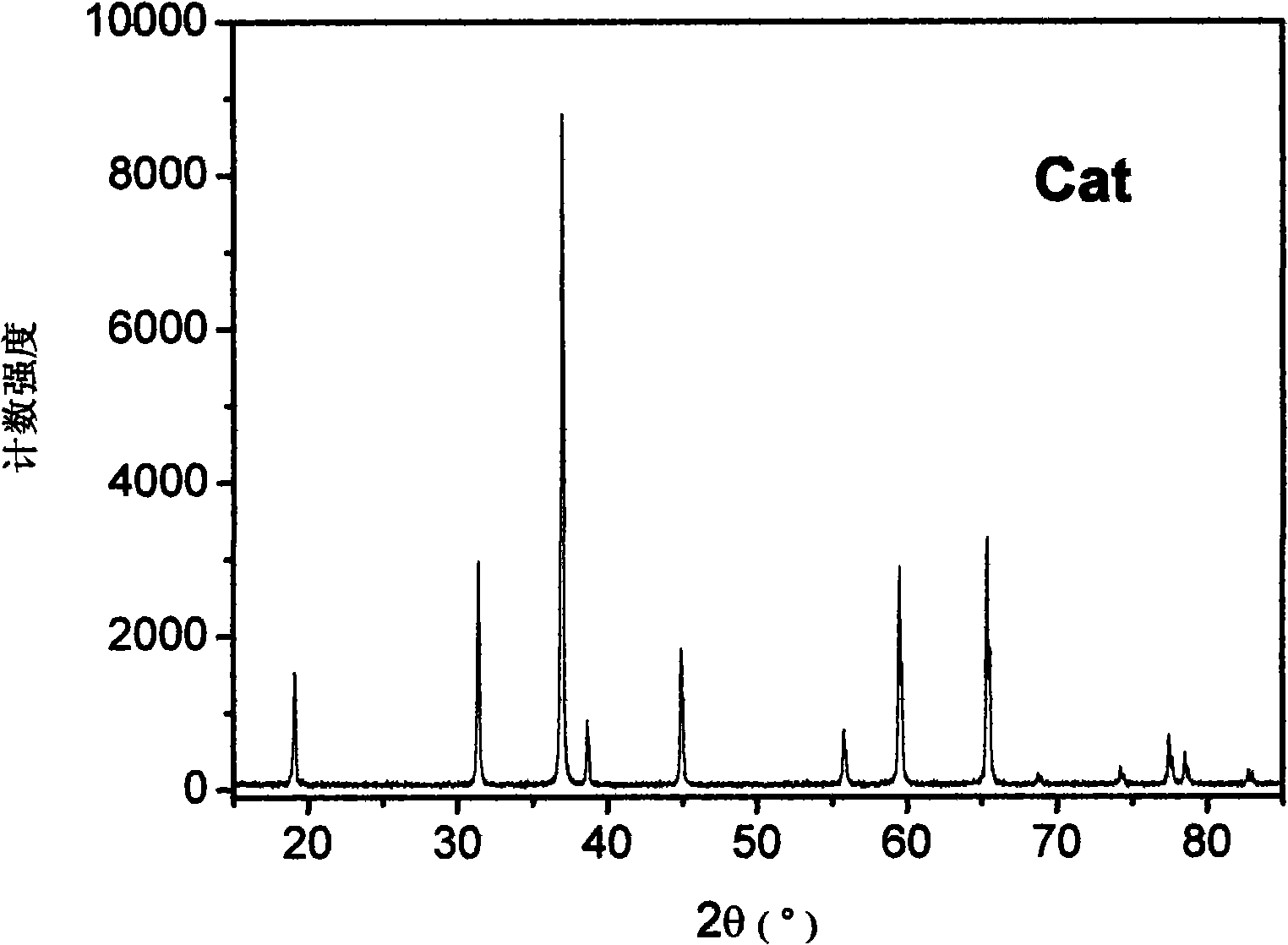

[0045] Oxygen ion conductor Sm 0.15 Ce 0.85 o 2-δ (SDC), Gd 0.20 Ce 0.80 o 2-δ (GDC) and La 0.25 Ce 0.75 o 2-δ (LDC), an oxygen ion-electron mixed conductor La 0.70 Sr 0.30 CoO 3-δ 、Sm 0.50 Sr 0.50 CoO 3-δ and Gd 0.60 Sr 0.40 CoO 3-δ , the oxygen catalytic active material Cat is synthesized by EDTA-CitricAcid complexation method with nitrate as the starting material. According to the molar ratio of various metal ions in the oxide to be synthesized, pipette the corresponding stoichiometric metal ion nitrate solution and the beaker, and add an appropriate amount of EDTA and citric acid therein, that is, the ratio of EDTA and citric acid to the total metal ions The ratios of the amounts of substances are 1:1 and 1:1.5, respectively. Then use NH 3 .H 2 O to adjust the pH of the solution to 7.0, heat and stir the solution at a constant temperature of 80°C, transfer it to an evaporating dish after the solution is highly concentrated, place it on an electric furnac...

Embodiment 2

[0047] According to the ratio of 1:1, weigh the appropriate amount of NiO and GDC powder respectively and put them in the mortar, add an appropriate amount of absolute ethanol after fully grinding, and grind again in a fluid state to maximize the uniform mixing of the two powders , after drying with an infrared lamp, in order to improve the tableting performance of the powder, add an appropriate amount of anhydrous ethanol solution of polyvinyl butyral (PVB), aqueous solution of polyvinylpyrrolidone (PPD) and polyethylene glycol (PEG), etc., mix again and dry. Weigh 2g of powder and place in In the 22 mold, it is preliminarily formed under a pressure of 100Mpa, and then 40mg of SDC powder is evenly spread on it, and finally formed under a pressure of 250Mpa. The above-mentioned plain sheet was treated at 1400°C for 4 hours to obtain an anode-supported anode-electrolyte complex.

Embodiment 3

[0049] Weigh an appropriate amount of SSC and SDC powders according to the mass ratio of 7:3, add appropriate amount of terpineol, polyethylene glycol, and dibutyl phthalate to prepare ink form; also weigh according to the mass ratio of 1:1 Take an appropriate amount of SSC and Cat powder, add an appropriate amount of terpineol, polyethylene glycol, and dibutyl phthalate to prepare an ink shape. The SSC&SDC layer is coated on the anode supported by the anode and the electrolyte side of the electrolyte complex by the DoctorBlade scraping method. After pre-fired at 600°C, the SSC&Cat layer is coated with the same method, and then treated at 950°C for 3 hours to obtain a double electrode Single cell configuration: NiO-GDC / .SDC / SDC&SSC-SSC&Cat. Figure 4~7 SEM photographs of different functional components of the single cell after electrochemical testing. in Figure 4 is the general view of the cathode surface, Figure 5 is the cross-sectional view of the cathode, Figure 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com