Patents

Literature

204 results about "Mixed conductor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed conductor which is known as mixed ion-electron conductor (MIEC) refers to a single-phase material which has a significant conduction ionically and electronically. Due to the mixed conduction, a formally neutral species can transport in a solid and therefore mass storage and redistribution are enabled. Mixed conductors are well known in conjugation with high-temperature superconductivity and are able to capacitate rapid solid-state reactions.

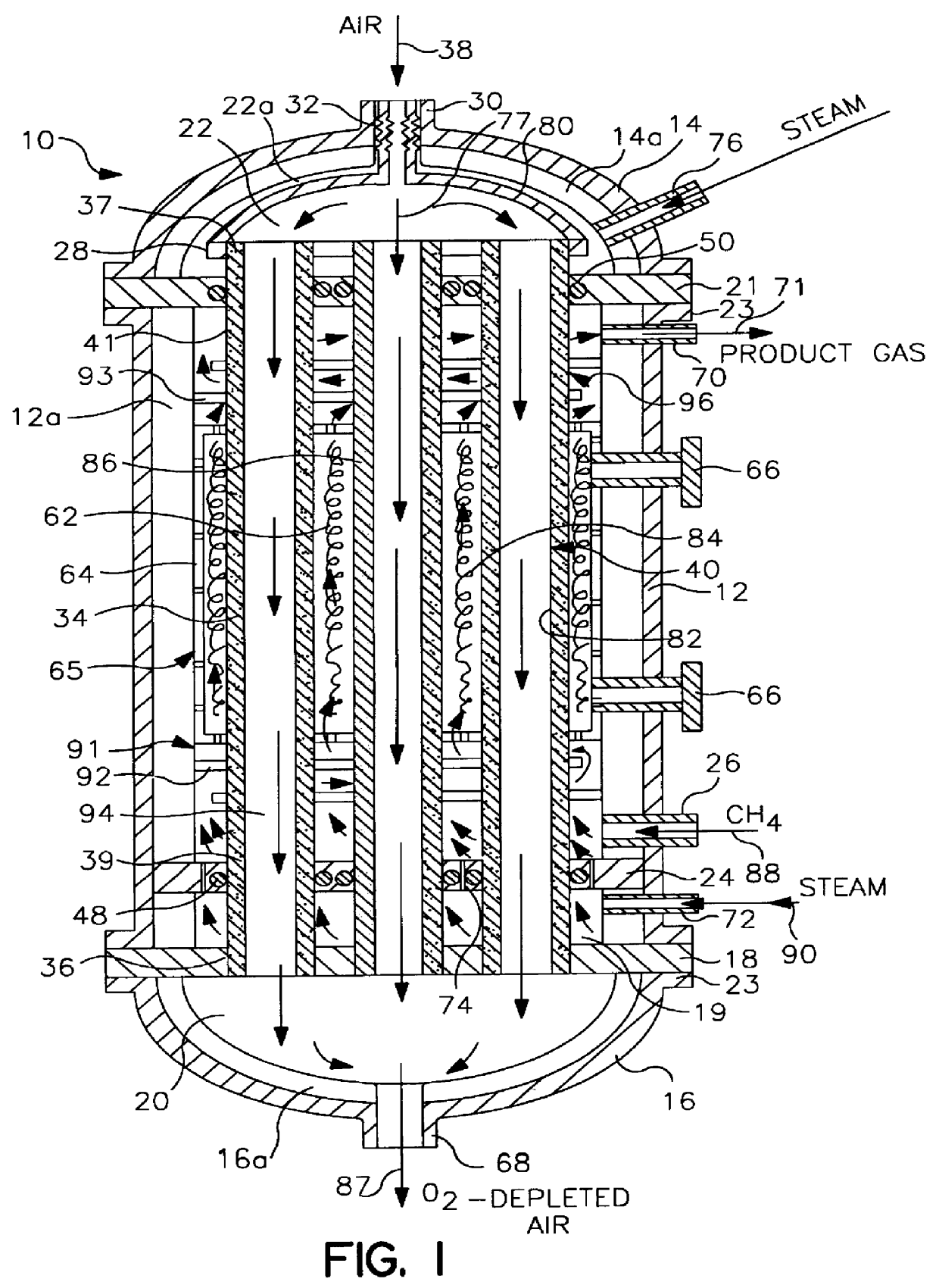

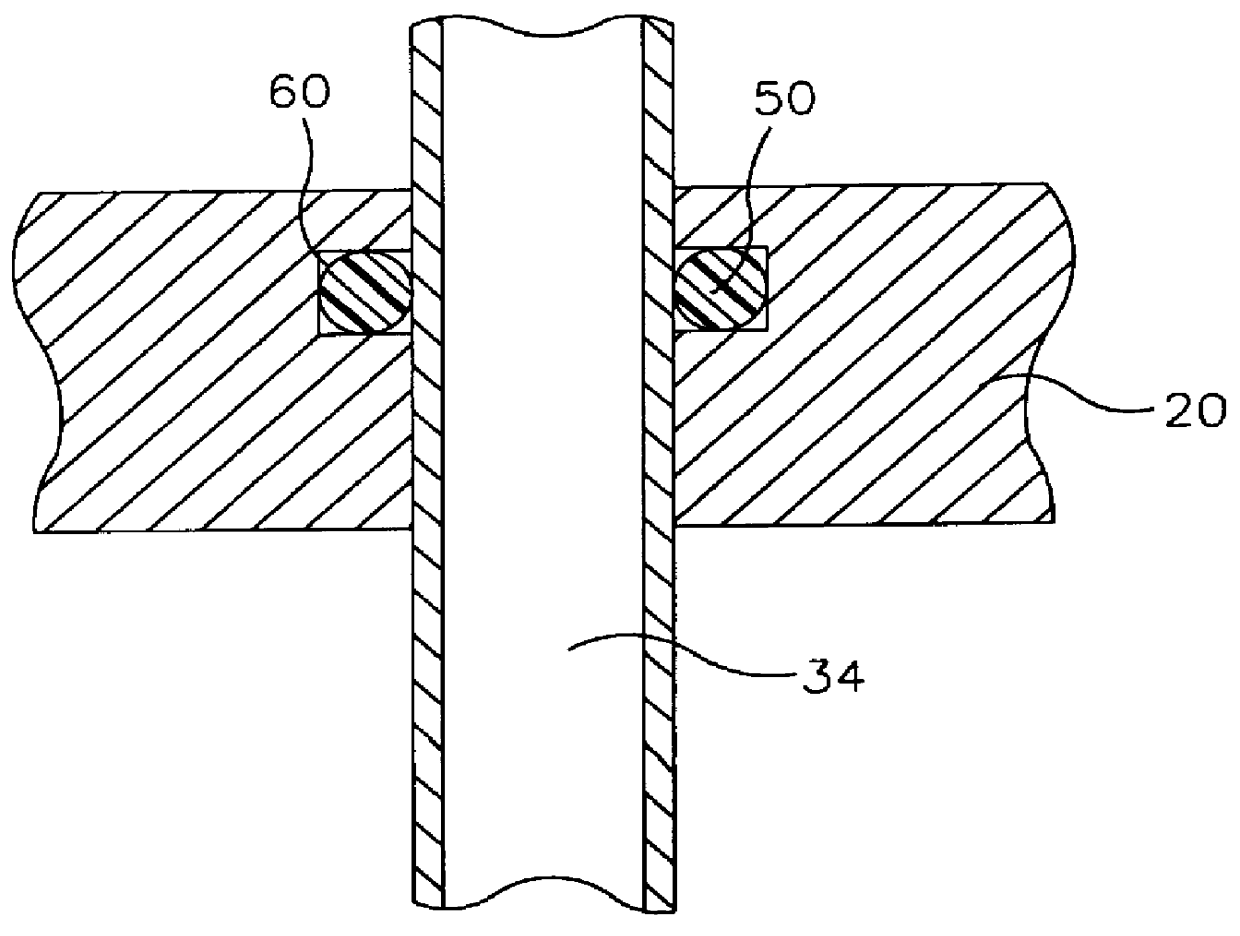

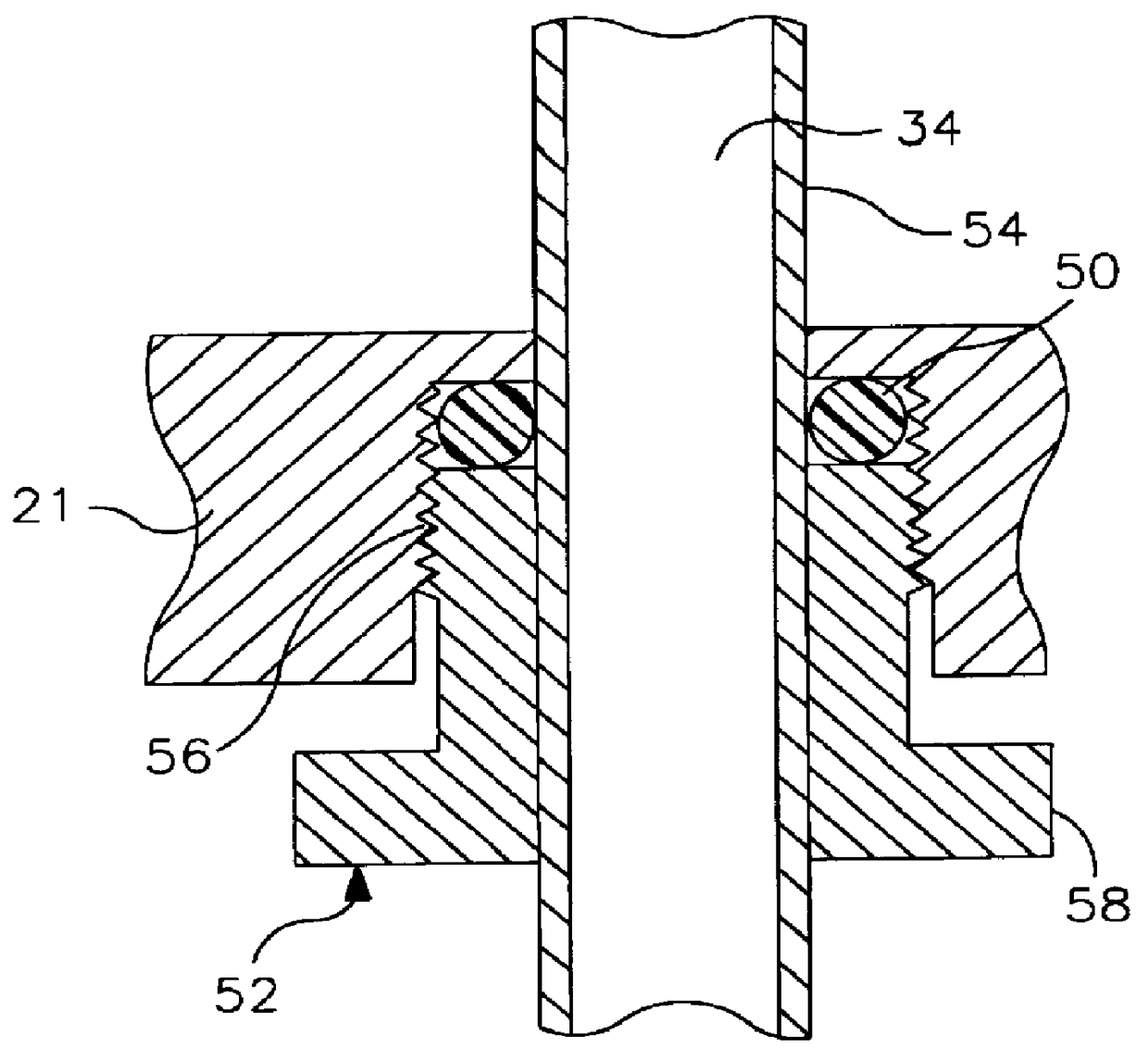

Tube and shell reactor with oxygen selective ion transport ceramic reaction tubes

InactiveUS6139810AIncrease oxygen fluxDecreasing anode side partial oxygen pressureIsotope separationHydrogen/synthetic gas productionPtru catalystElectrical conductor

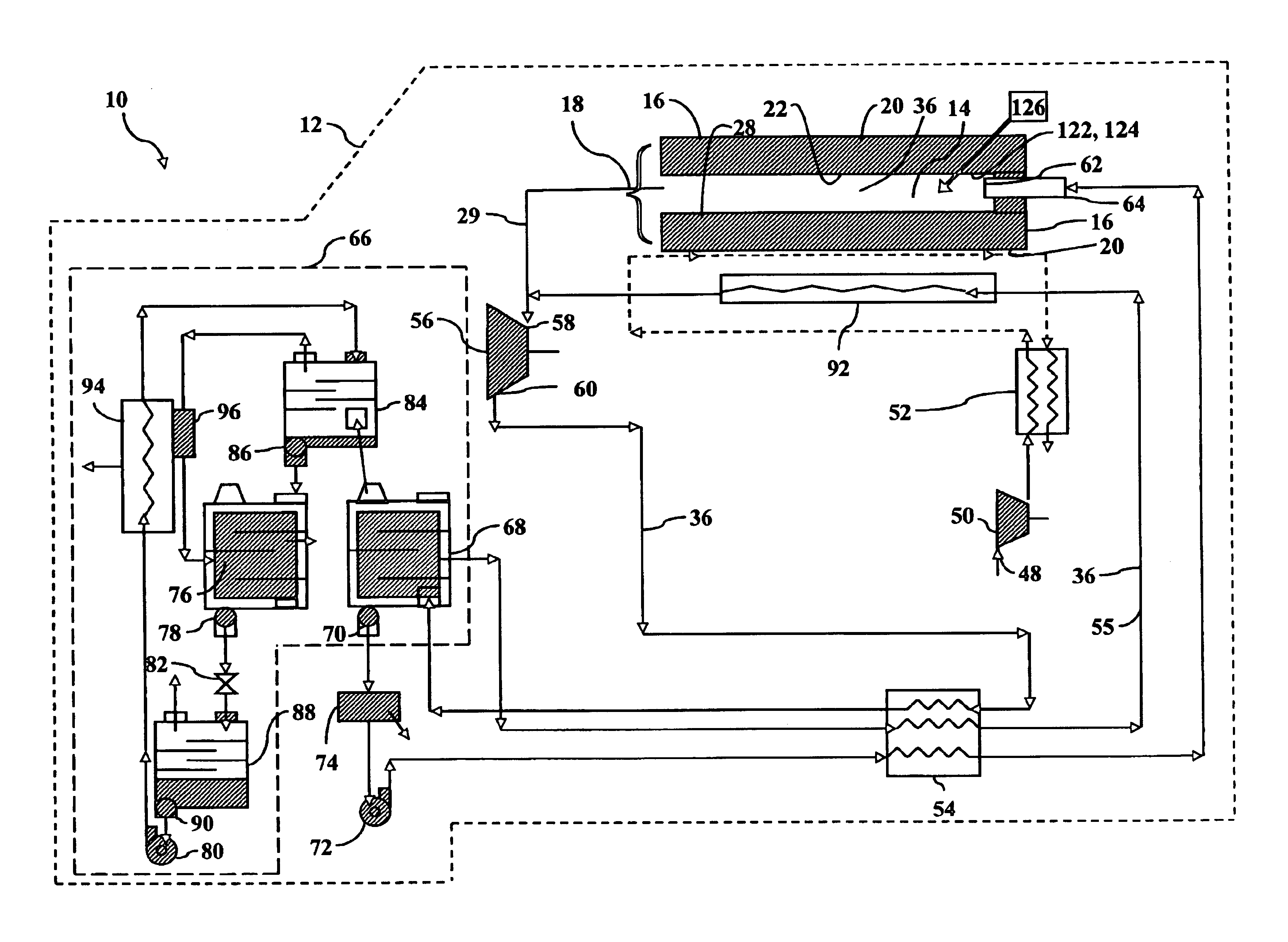

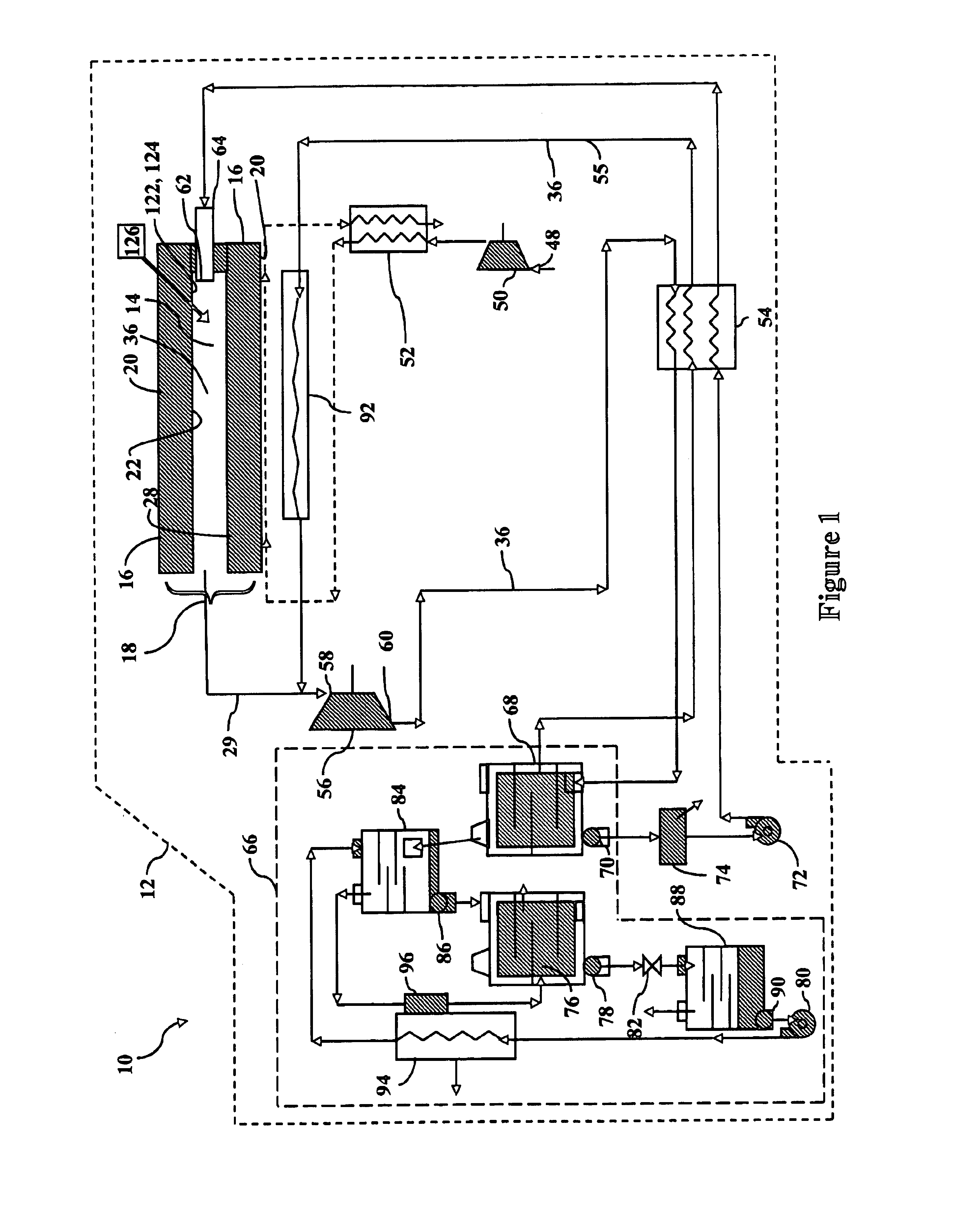

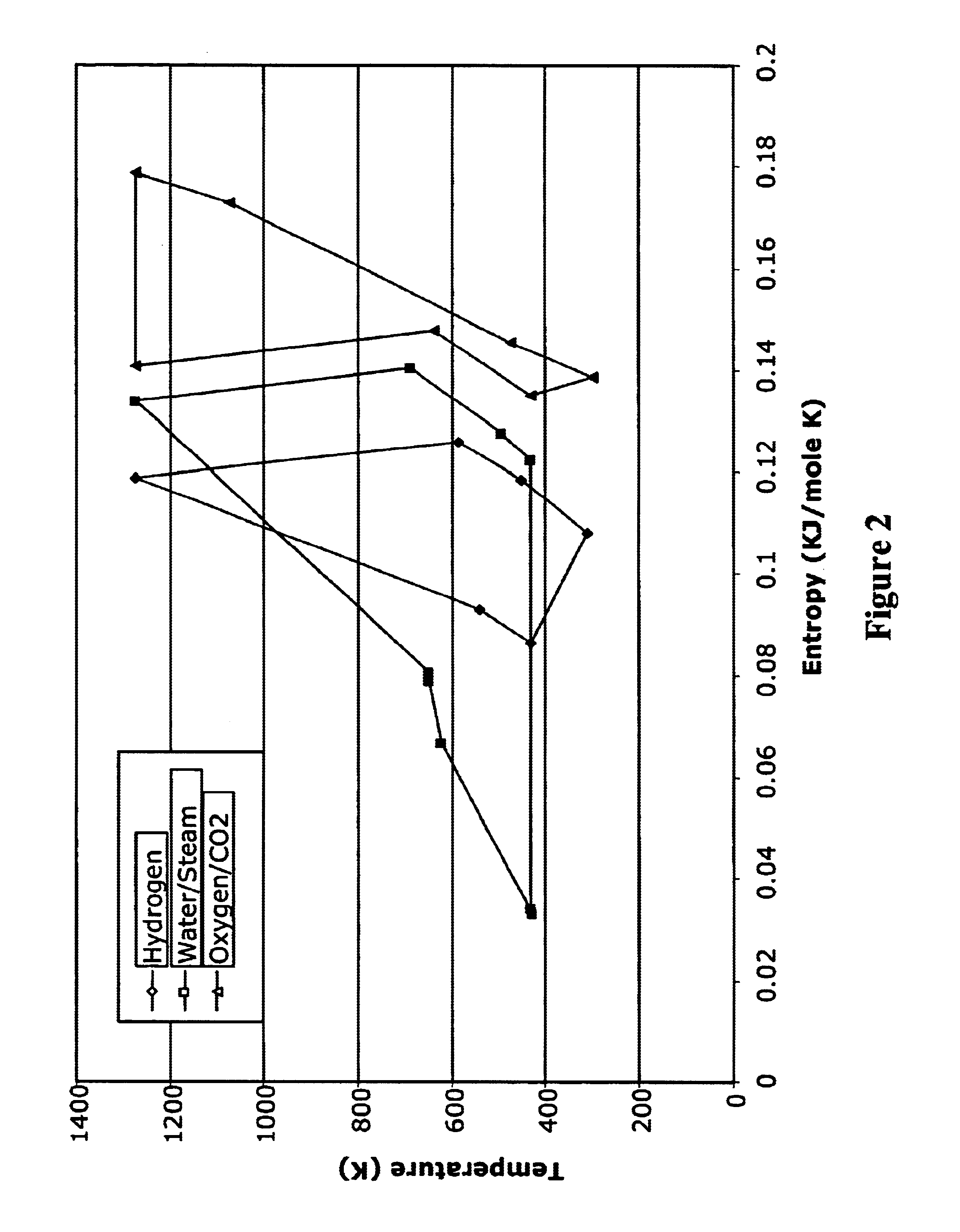

A reactor comprising: a hollow shell defining a hermetic enclosure; a plurality of tube sheets disposed within said hermetic enclosure, a first one of said plurality of tube sheets defining a first chamber; at least one reaction tube each having a first end and an opposing second end, said first end being fixedly attached and substantially hermetically sealed to one end of said plurality of tube sheets and opening into said first chamber, the second end being axially unrestrained; each of said reaction tubes is comprised of an oxygen selective ion transport membrane with an anode side wherein said oxygen selective ion transport membrane is formed from a mixed conductor metal oxide that is effective for the transport of elemental oxygen at elevated temperatures and at least a portion of said first and second heat transfer sections are formed of metal; each of said reaction tubes includes first and second heat transfer sections and a reaction section, said reaction section disposed between said first and second heat transfer sections; a reforming catalyst disposed about said anode side of said oxygen selective ion transport membrane; a first process gas inlet; a second process gas inlet; and, a plurality of outlets.

Owner:STANDARD OIL CO +1

Hybrid Conductors and Method of Making Same

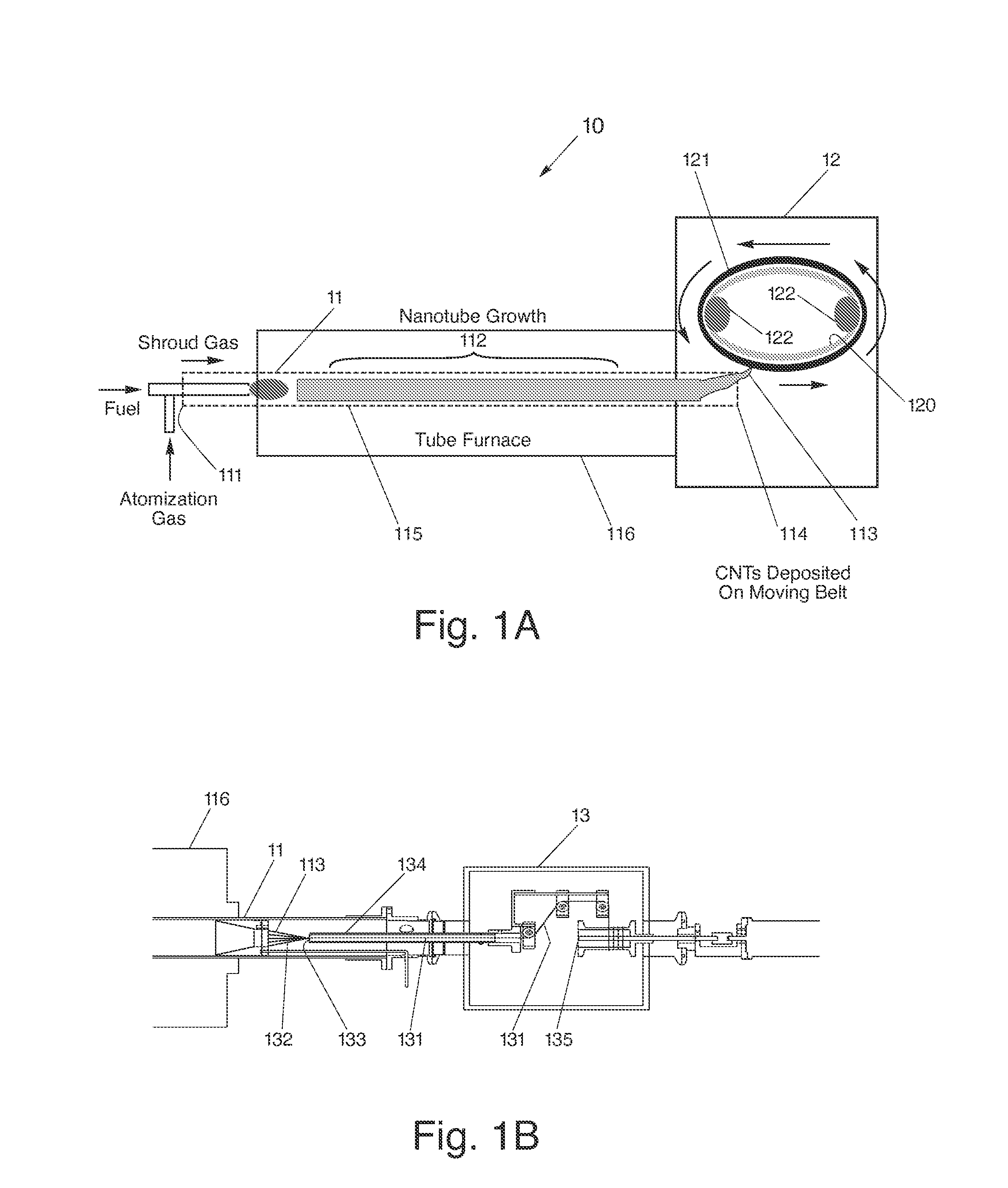

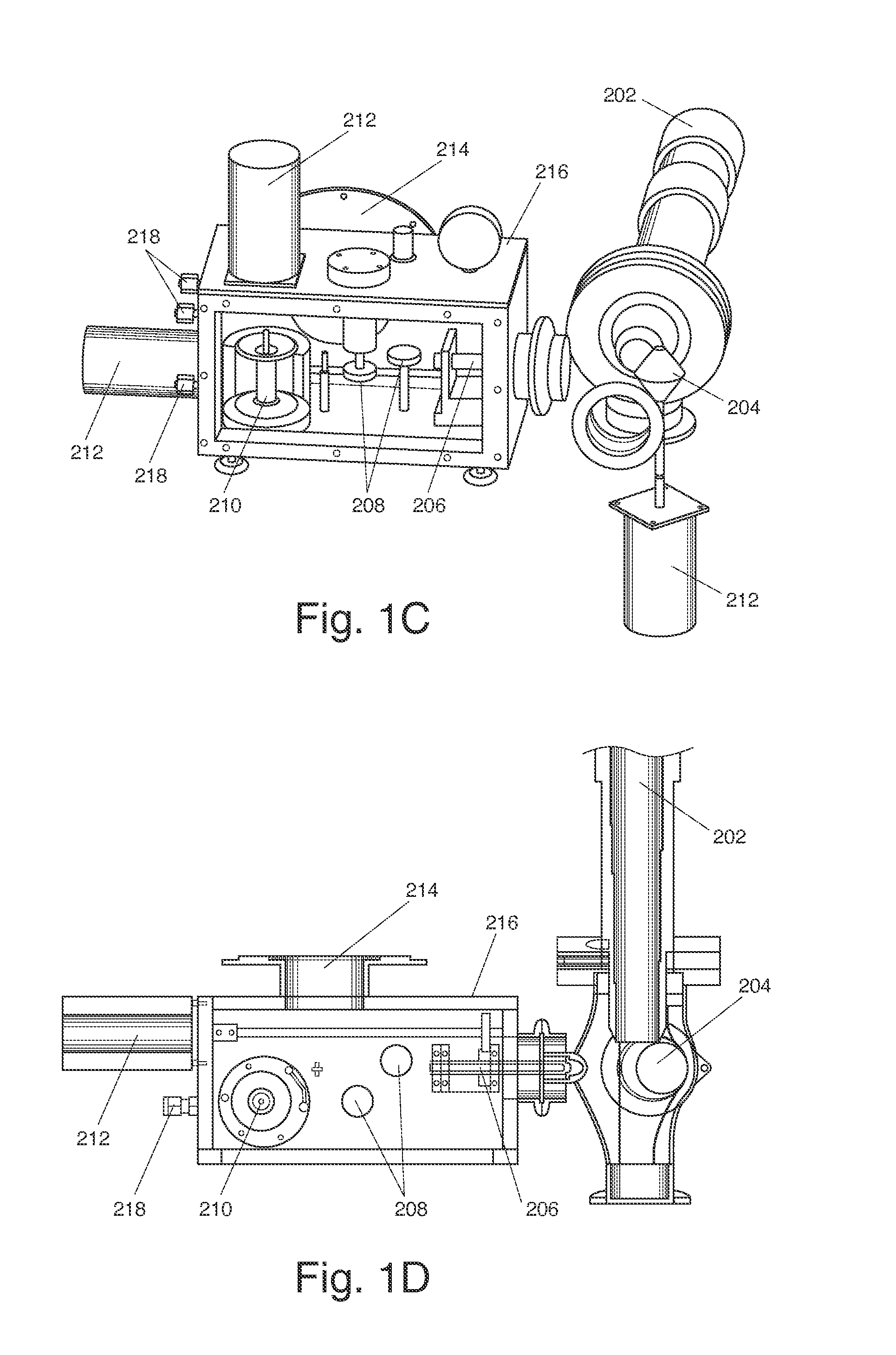

ActiveUS20110005808A1Improve conductivityLow resistivityNon-insulated conductorsConductive materialElectrical conductorCarbon nanotube

Hybrid conductors capable of achieving enhanced conductivity and current capacity over a wide range of frequencies are disclosed. The hybrid conductors may be used in electrical or thermal applications, or combinations of both. One method of fabricating such hybrid conductors includes complexing conductive metal elements (e.g., silver, gold, copper), transition metal elements, alloys, wires, or combinations thereof, with carbon nanotube materials. In the alternative, the hybrid conductors may be formed by doping the carbon nanotube materials in salt solutions.

Owner:NANCOMP TECHNOLOGIES INC

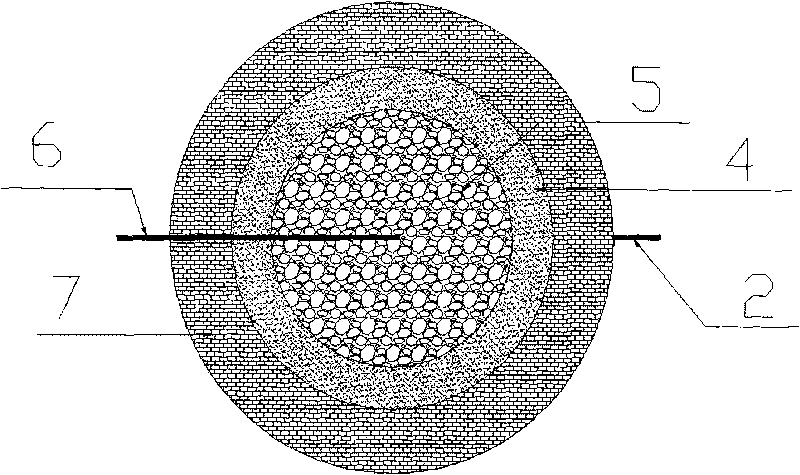

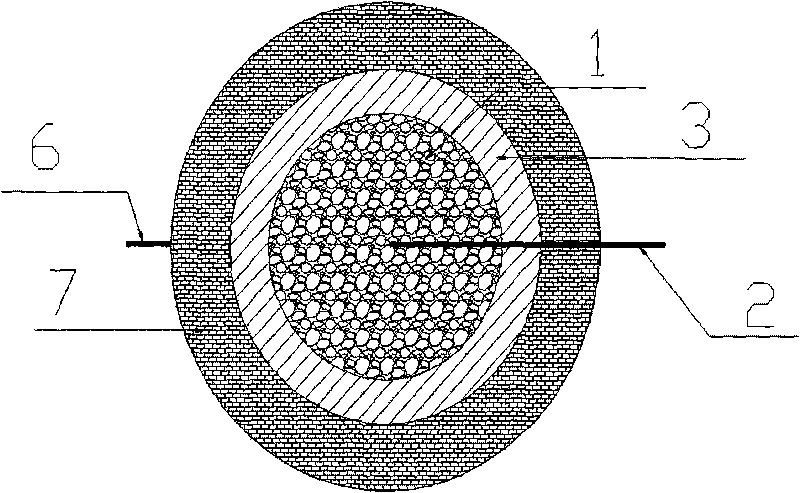

Composite oxygen ion transport element

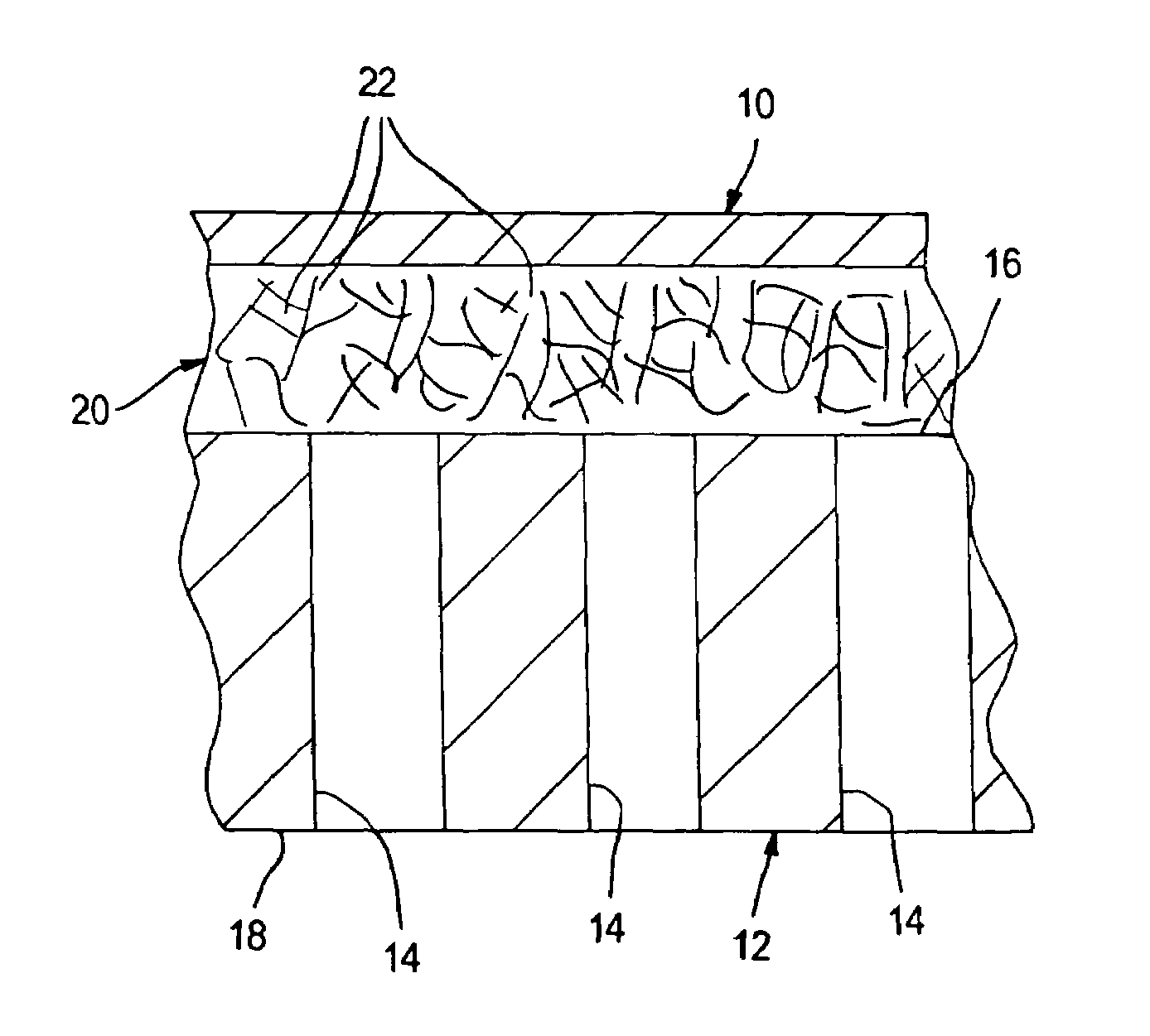

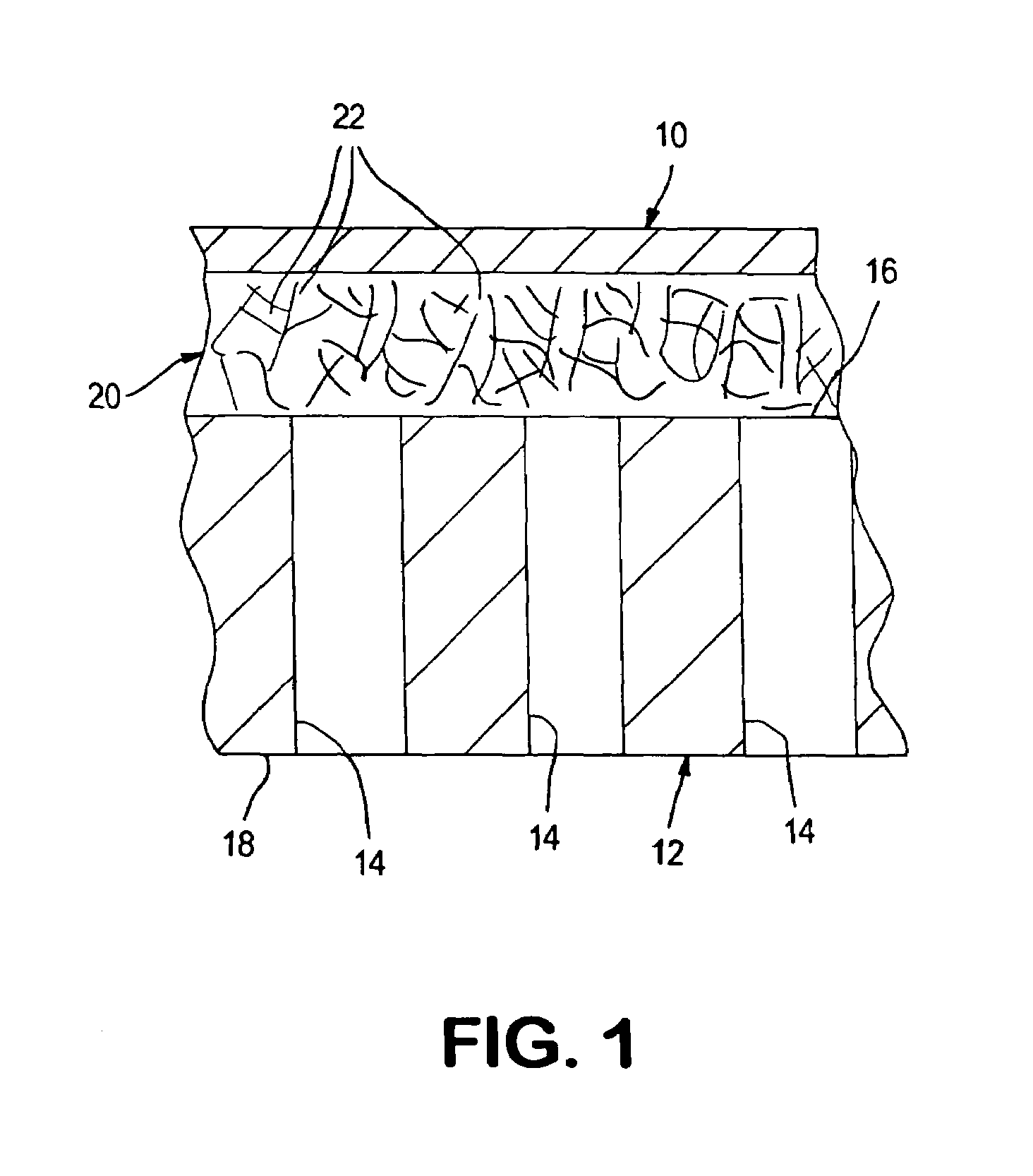

ActiveUS7229537B2Improve flux performanceImprove toughnessLayered productsIsotope separationElectrical conductorDiffusion resistance

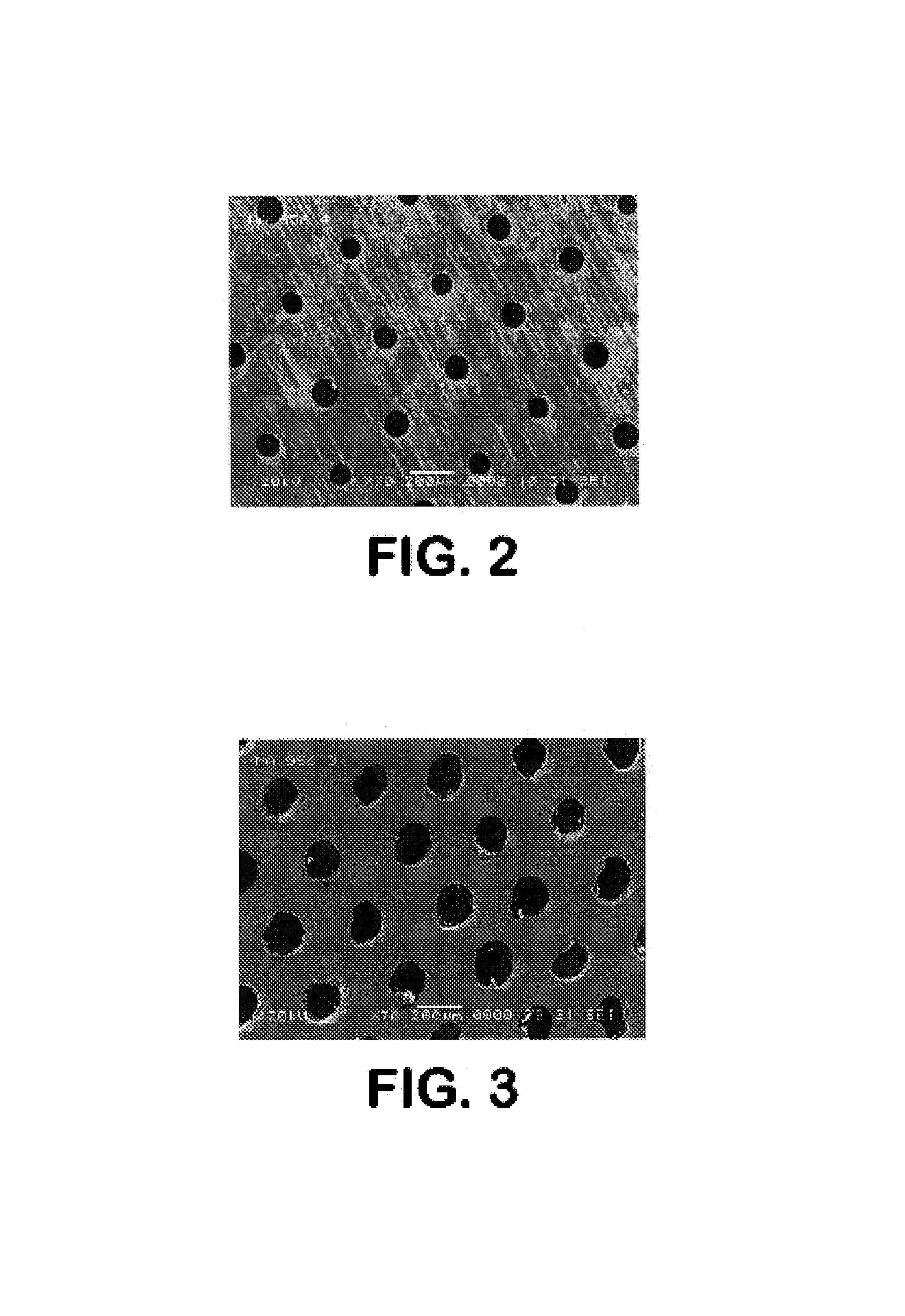

A composite oxygen ion transport element that has a layered structure formed by a dense layer to transport oxygen ions and electrons and a porous support layer to provide mechanical support. The dense layer can be formed of a mixture of a mixed conductor, an ionic conductor, and a metal. The porous support layer can be fabricated from an oxide dispersion strengthened metal, a metal-reinforced intermetallic alloy, a boron-doped Mo5Si3-based intermetallic alloy or combinations thereof. The support layer can be provided with a network of non-interconnected pores and each of said pores communicates between opposite surfaces of said support layer. Such a support layer can be advantageously employed to reduce diffusion resistance in any type of element, including those using a different material makeup than that outlined above.

Owner:PRAXAIR TECH INC +1

Combusting hydrocarbons excluding nitrogen using mixed conductor and metal hydride compressor

InactiveUS6951111B2Control rateIncrease vapor pressureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberHydride compressor

Provided is a combustion engine having a combustion chamber. The combustion engine comprises an engine housing having an air intake port, a mixed conductor, a water intake port, an exhaust turbine and a hydrogen compressor assembly. The air intake port provides air to the mixed conductor which provides an oxygen-pure fraction of air to the combustion chamber by conducting oxygen ions in the air from a retentate side to a permeate side when the oxygen partial pressure on the permeate side is less than that on the retentate side. The water intake port provides water to the combustion chamber for combustion with hydrocarbon fuel and the oxygen-pure fraction of the air to produce exhaust fluid. The exhaust fluid expands in the exhaust turbine causing the turbine rotor to rotate producing mechanical energy. The hydrogen compressor assembly extracts hydrogen from the exhaust fluid and provides hydrogen to the exhaust turbine.

Owner:CHENTEK

Composite film material for lithium battery and preparation method and application thereof

ActiveCN107591511AReduce manufacturing costEasy to operateLi-accumulatorsCell component detailsElectrical conductorComposite film

The invention provides a composite film material for a lithium battery. The composite film material comprises a polymer film and a conductor particle layer coating the surface of the polymer film in one side. The conductor particle layer contains one or more of particles of an ion conductor material, particles of an ion-electron mixed conductor material and particles of an electron conductor material. The invention also provides a preparation method of the composite film material and an application of the composite film material in a rechargeable metal lithium battery. The invention provides aliquid metal lithium battery and solid metal lithium battery containing the composite film material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

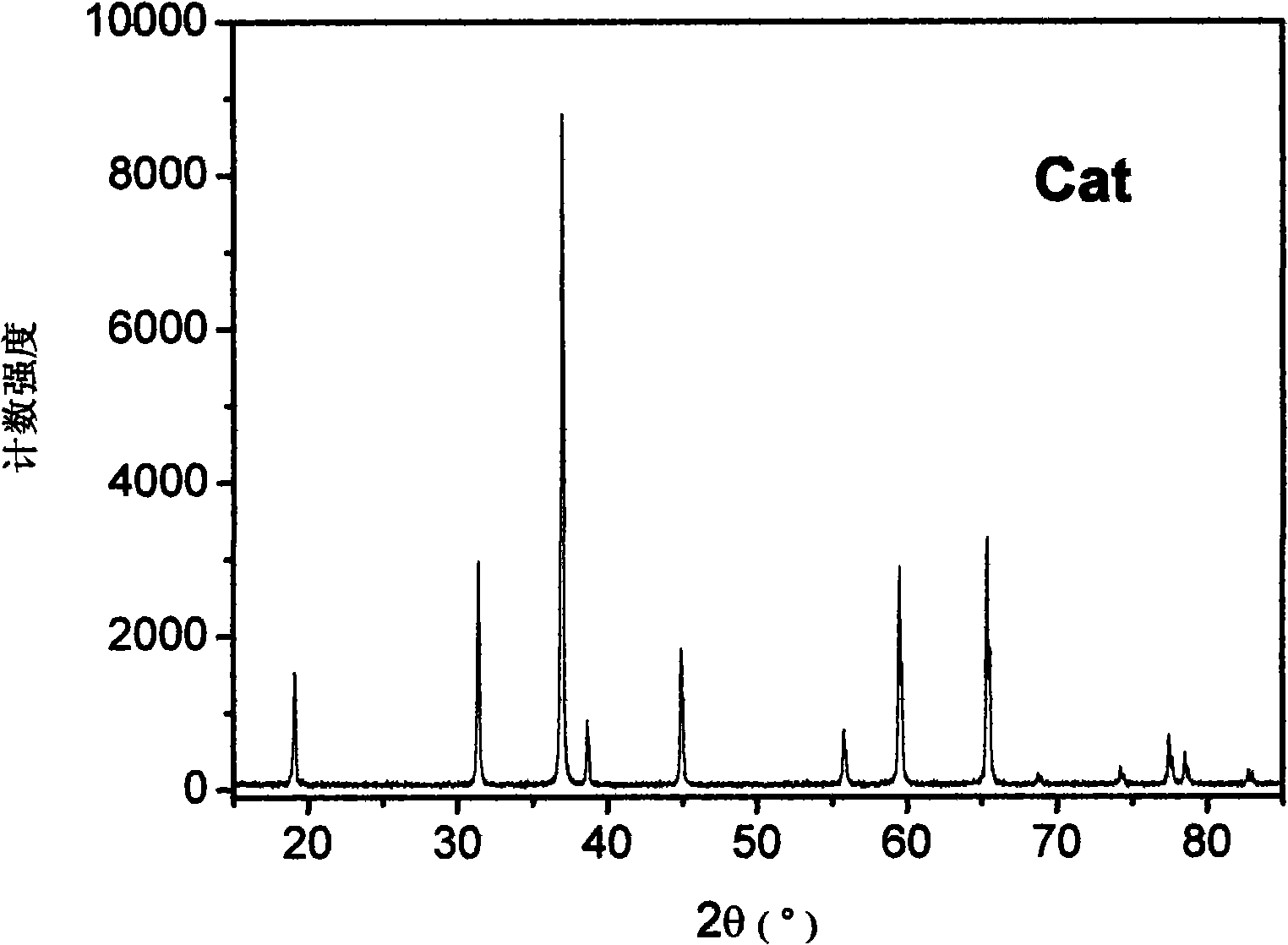

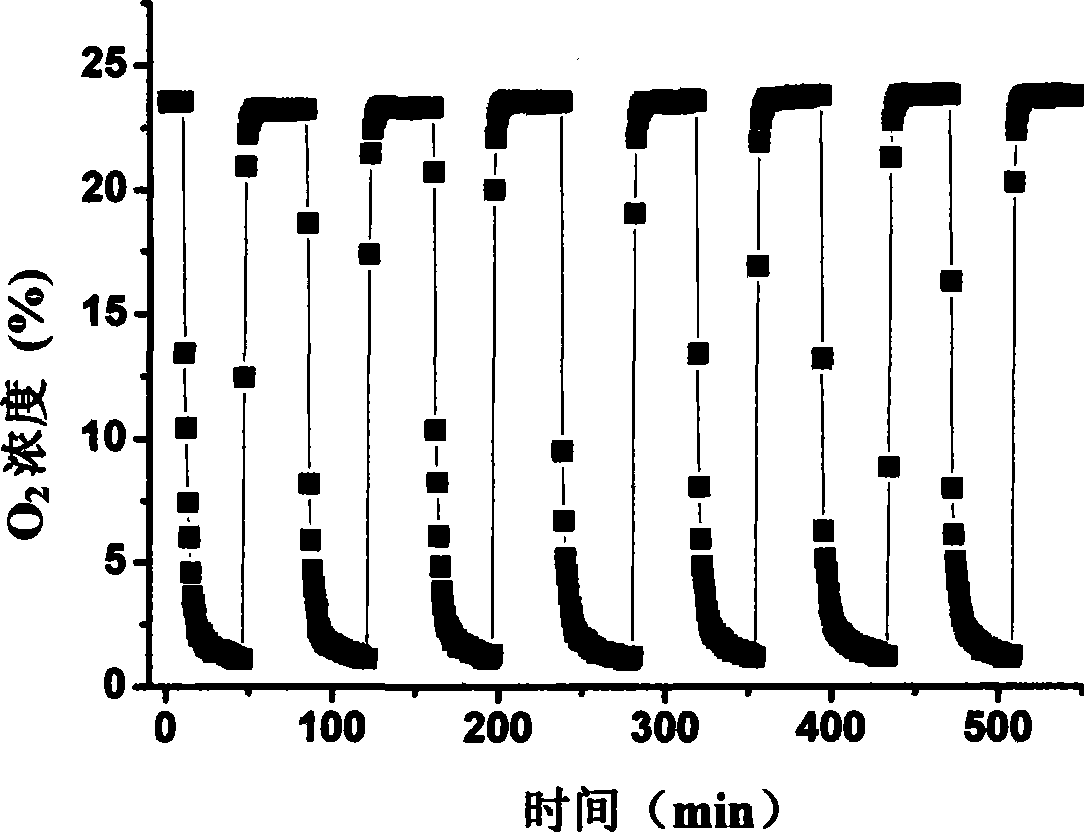

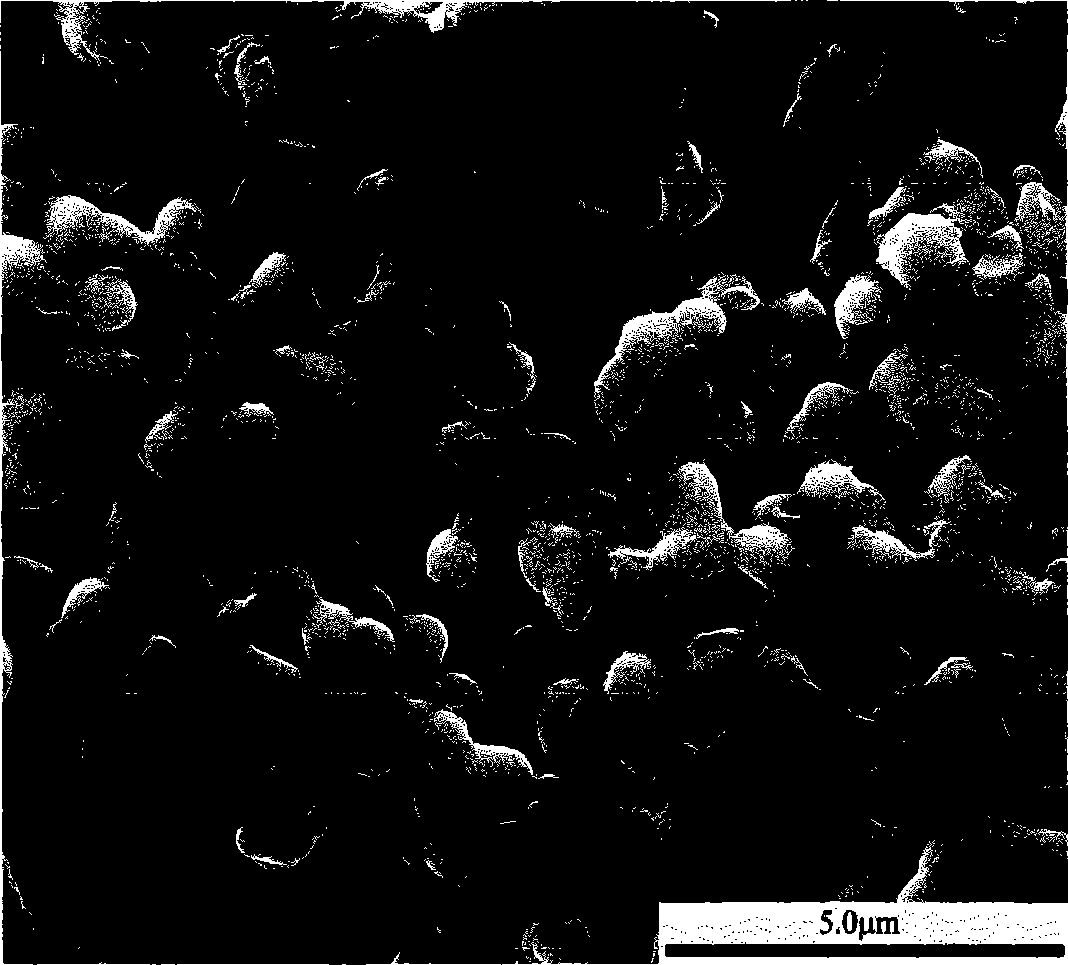

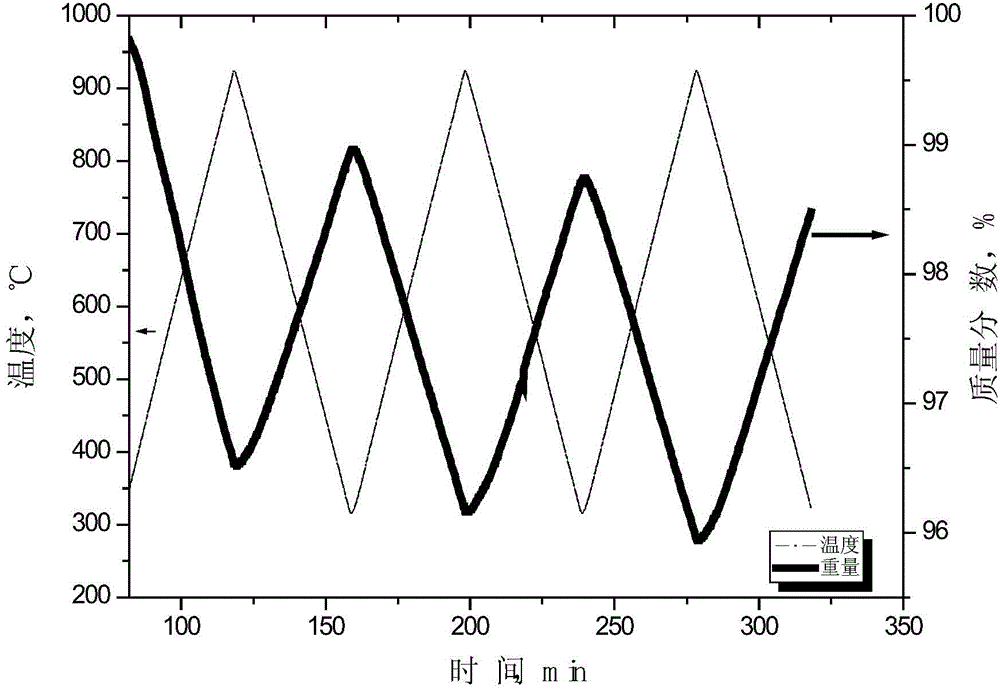

Oxygen adsorbent, preparation method and application thereof

InactiveCN101837278AHigh purityHigh oxygen adsorption capacityOther chemical processesDispersed particle separationElectrical conductorOxygen vacancy

The invention provides an oxygen adsorbent, a preparation method and application thereof. The oxygen adsorbent material is a mixed conductor ceramic material which has oxygen (O2) selectivity and is subjected to chemical oxygen adsorption and deoxygenation by using oxygen vacancies (or gap oxygen positions) in crystal lattices; and the oxygen adsorbent only absorbs oxygen in air flow, but not absorbs any other non-oxygen components. The preparation method comprises the following steps of: mixing soluble salt solution of all metal ions forming a composite oxide uniformly; and preparing multi-metal composite oxide powder by using an organic acid complexing method and a concentrating and gelatinizing method. The novel oxygen adsorbent is used for high-temperature variable-pressure oxygen adsorption or variable-temperature oxygen adsorption so as to perform air separation, or remove impurities from trace oxygen, or be used as an oxygen-storing material. The novel oxygen adsorbent has the advantages of high oxygen adsorption capacity, high oxygen adsorption rate and extremely high oxygen selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing solid oxide fuel cell and entire cell thereof at low temperature

InactiveCN101577341ANot easy to warpLower sintering temperatureCell electrodesSolid electrolyte fuel cellsElectrical conductorEntire cell

The invention discloses a method for preparing a solid oxide fuel cell and an entire cell thereof at low temperature, which comprises the steps of: firstly conducting tape casting layer by layer for three times or stratified tape casting co-decompression, then obtaining a porous membrane / dense electrolyte / porous three-layer membrane by co-firing at low temperature, and then impregnating anode materials at one side and cathode materials at the other side, and finally obtaining the entire cell by sintering at low temperature. The relative density of a YSZ / GDC dense electrolyte in the three-layer membrane is higher than 96 percent and the porosity of the porous layer is greater than 60 percent. The impregnating mass fraction of the composite anodes of a NiO / CuO isoelectronic conductance phase and a doped ZrO2 / CeO2 plasma ion conductance phase reaches 40-70wt percent; and the impregnating mass fraction of the composite cathodes of an ion-electron mixed conductor or ion and electron reaches 40-60wt percent. The preparation method has the advantages of fewer processes, wide application of technology to the industry, low cost and good industrial prospects. The intensity of the obtained entire cell is relatively high, and the shape and size thereof are stable and reliable in preparation process and running.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

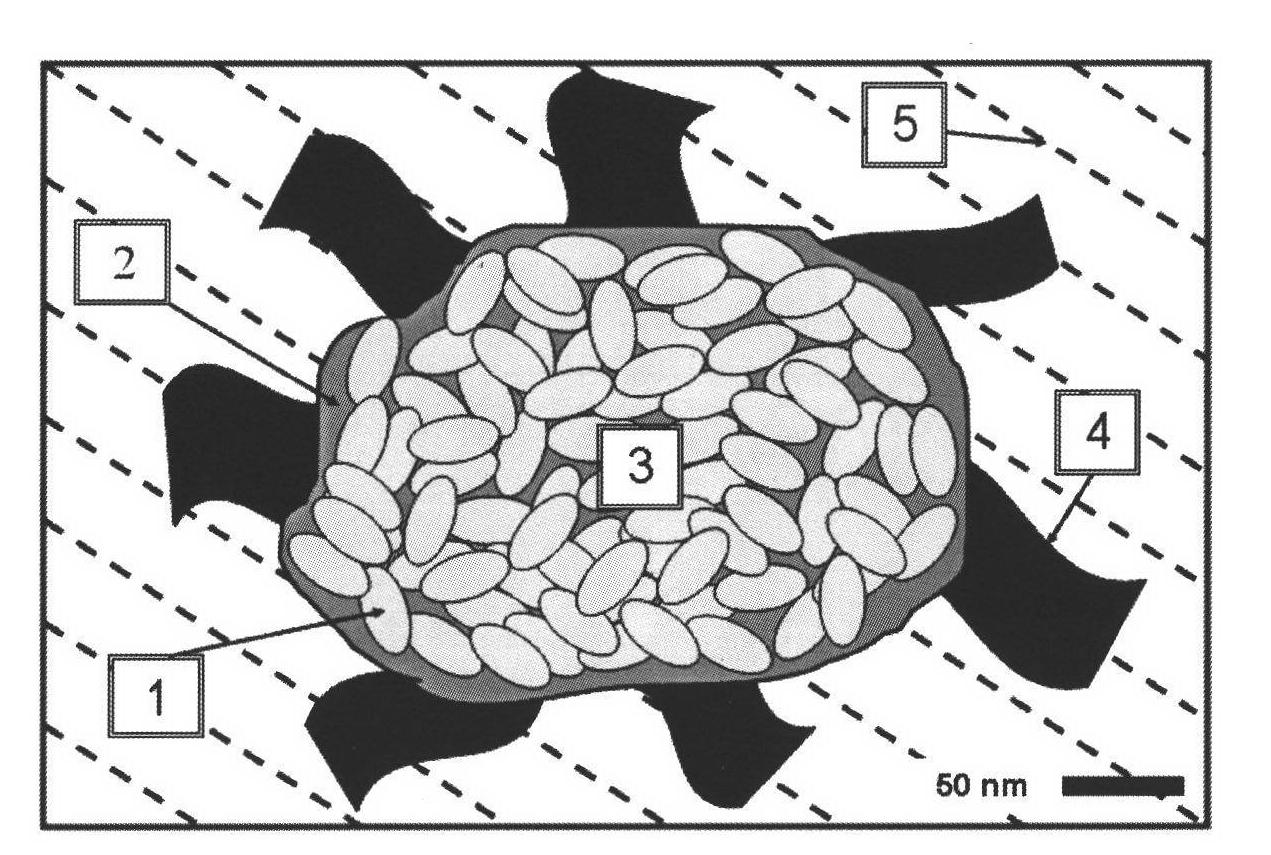

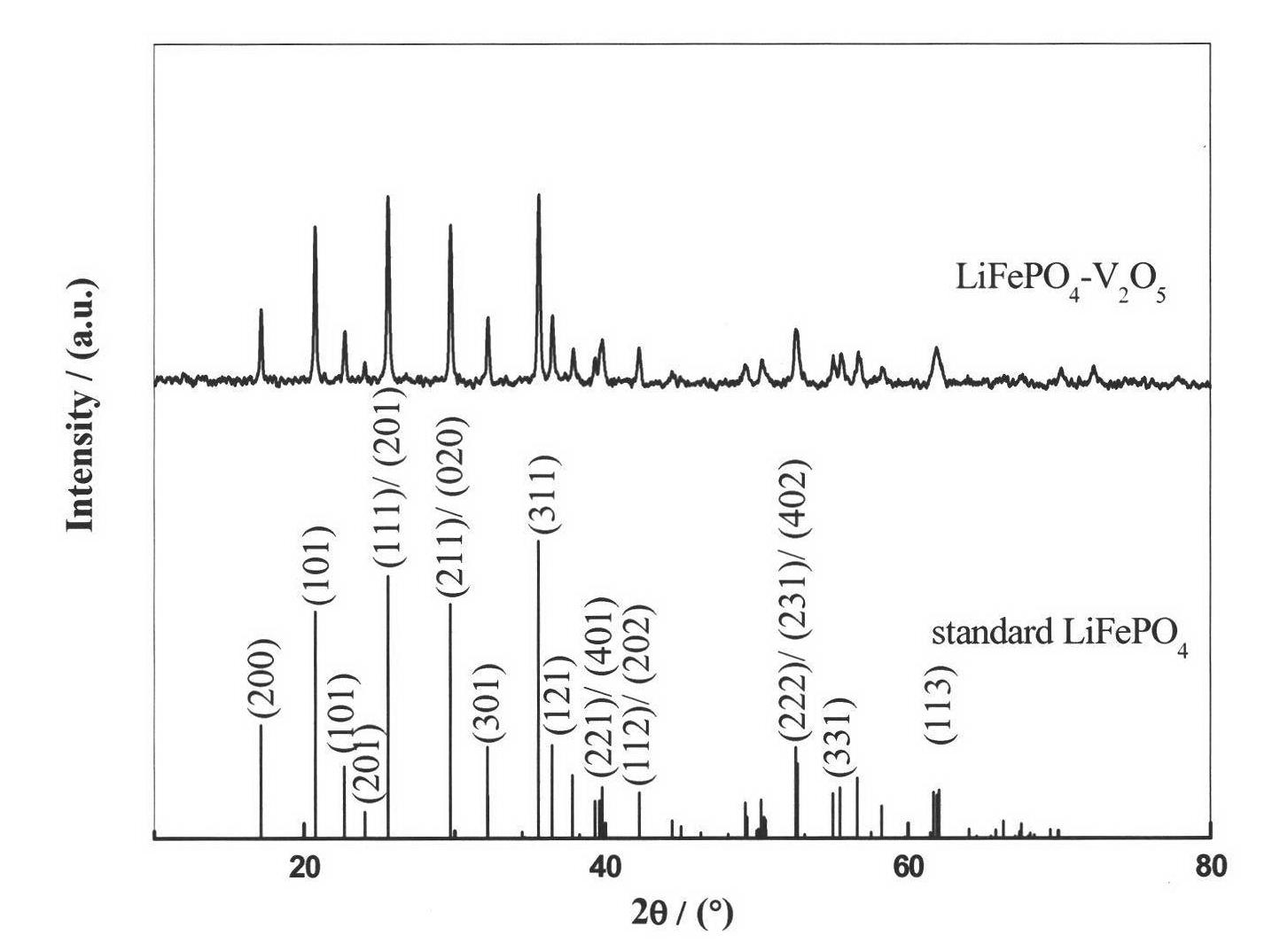

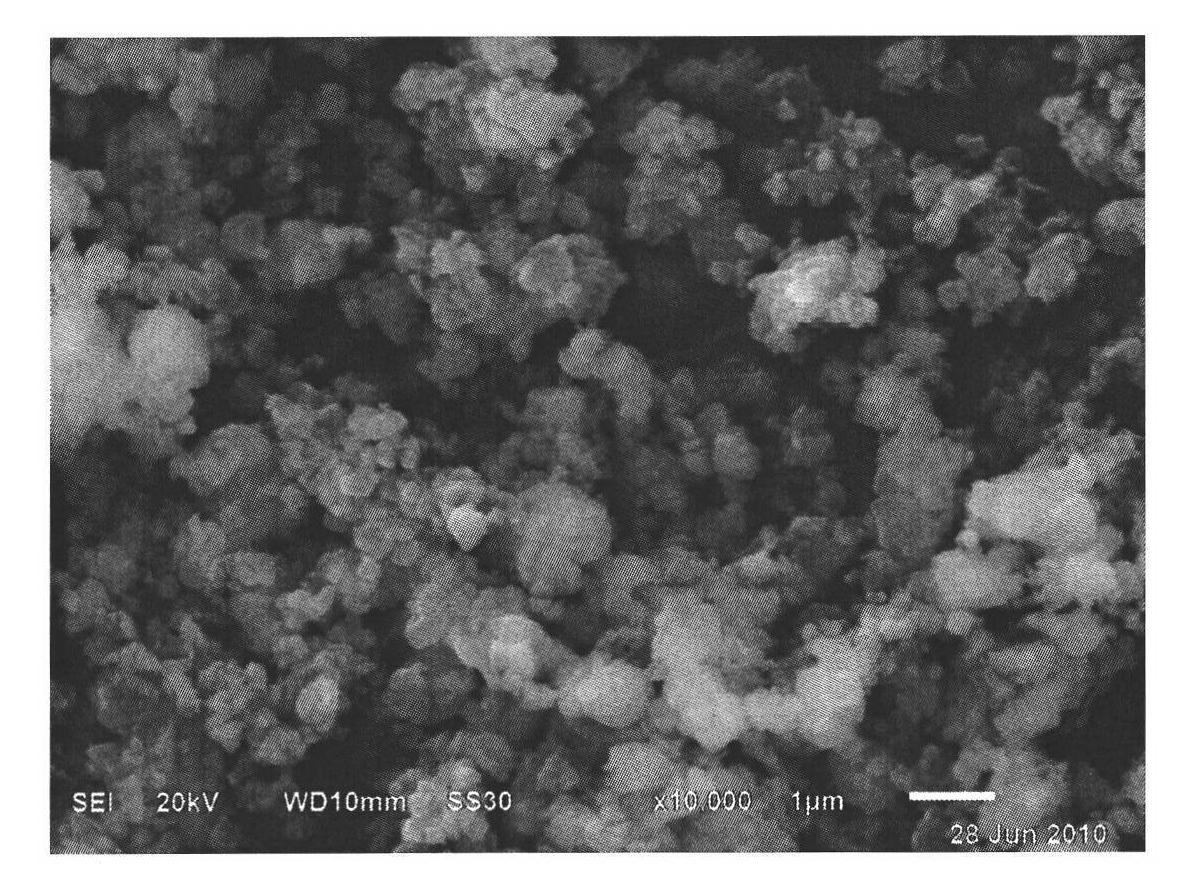

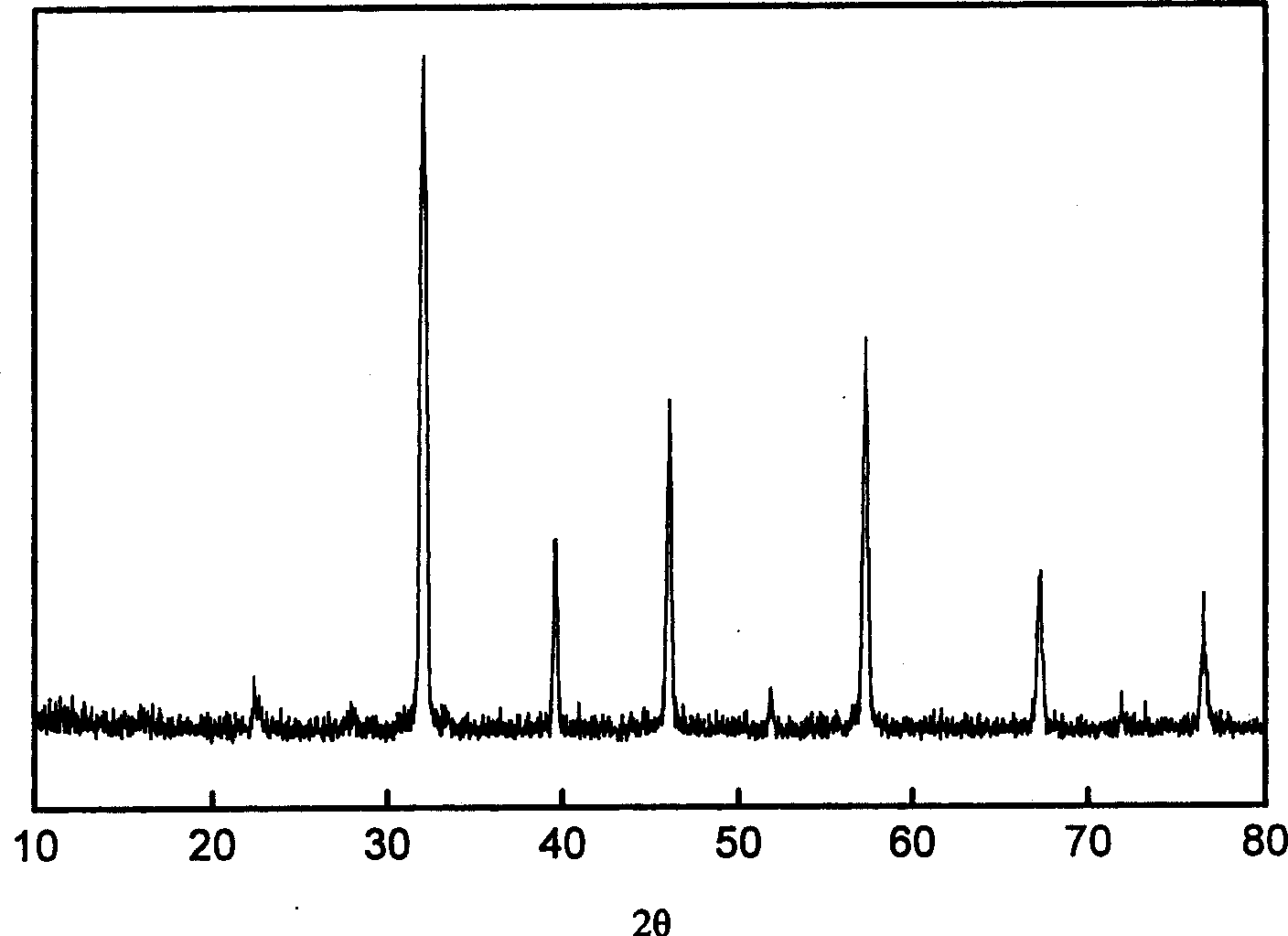

Mixed conductor composite material LiFePO4-MXy and preparation method thereof

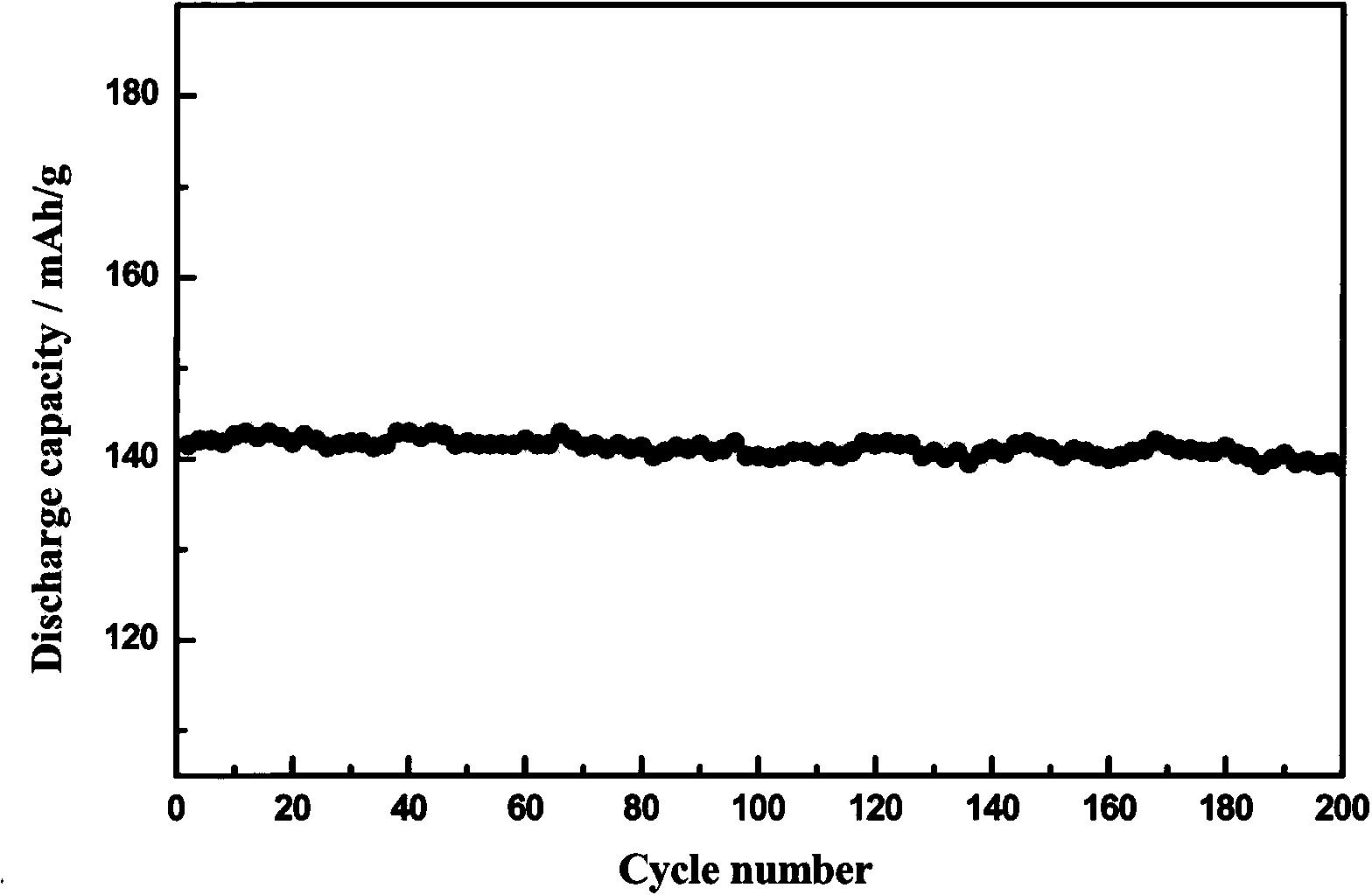

InactiveCN102427134AHigh tap densityImprove discharge stabilityCell electrodesElectrical conductorHigh rate

The invention discloses a mixed conductor composite material LiFePO4-MXy. The mixed conductor composite material LiFePO4-MXy is prepared by synthesizing LiFePO4 from the oxides or sulfides of transition metals by a solid state method, and performing high-energy ball-milling and annealing on the transition metals to obtain the mixed conductor composite material LiFePO4-MXy. In the mixed conductor composite material (MCM) LiFePO4-MXy, MXy is not only a conductor of lithium ions but also a conductor of electrons, LiFePO4 particles are uniformly dispersed in the MXy, and the surface of the mixed conductor composite material in a lithium ion battery comprises a carbon material which is added in size mixing and electrolyte which is impregnated in the carbon material. The LiFePO4-MXy has the advantages of high electron conductivity, high ion conductivity, high high-rate charge and discharge capacity, high cycle performance, relatively higher tap density, simple and practical production process, cleanness, no pollution, low cost and the like, and is suitable for large-scale production.

Owner:XIANGTAN UNIV

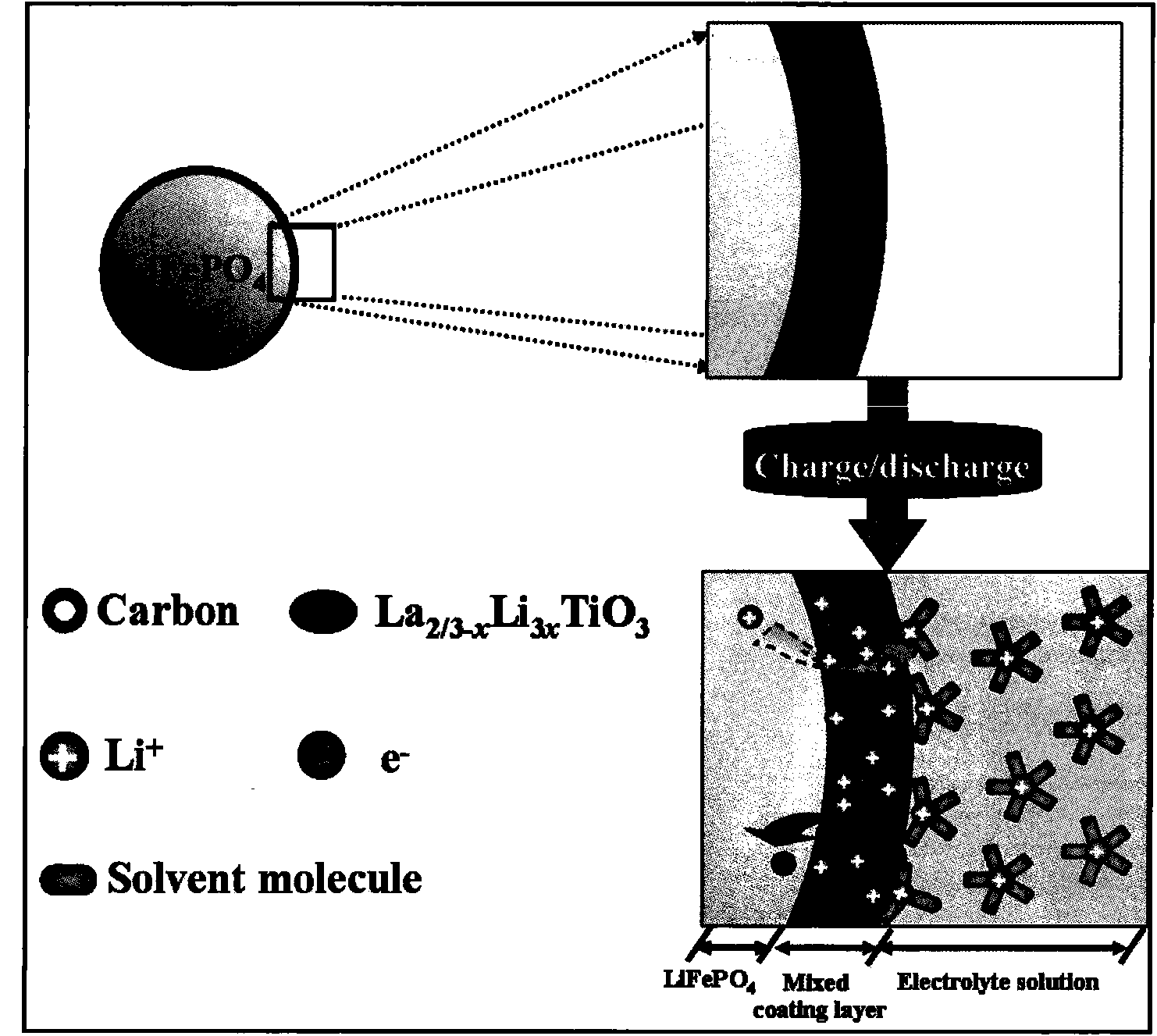

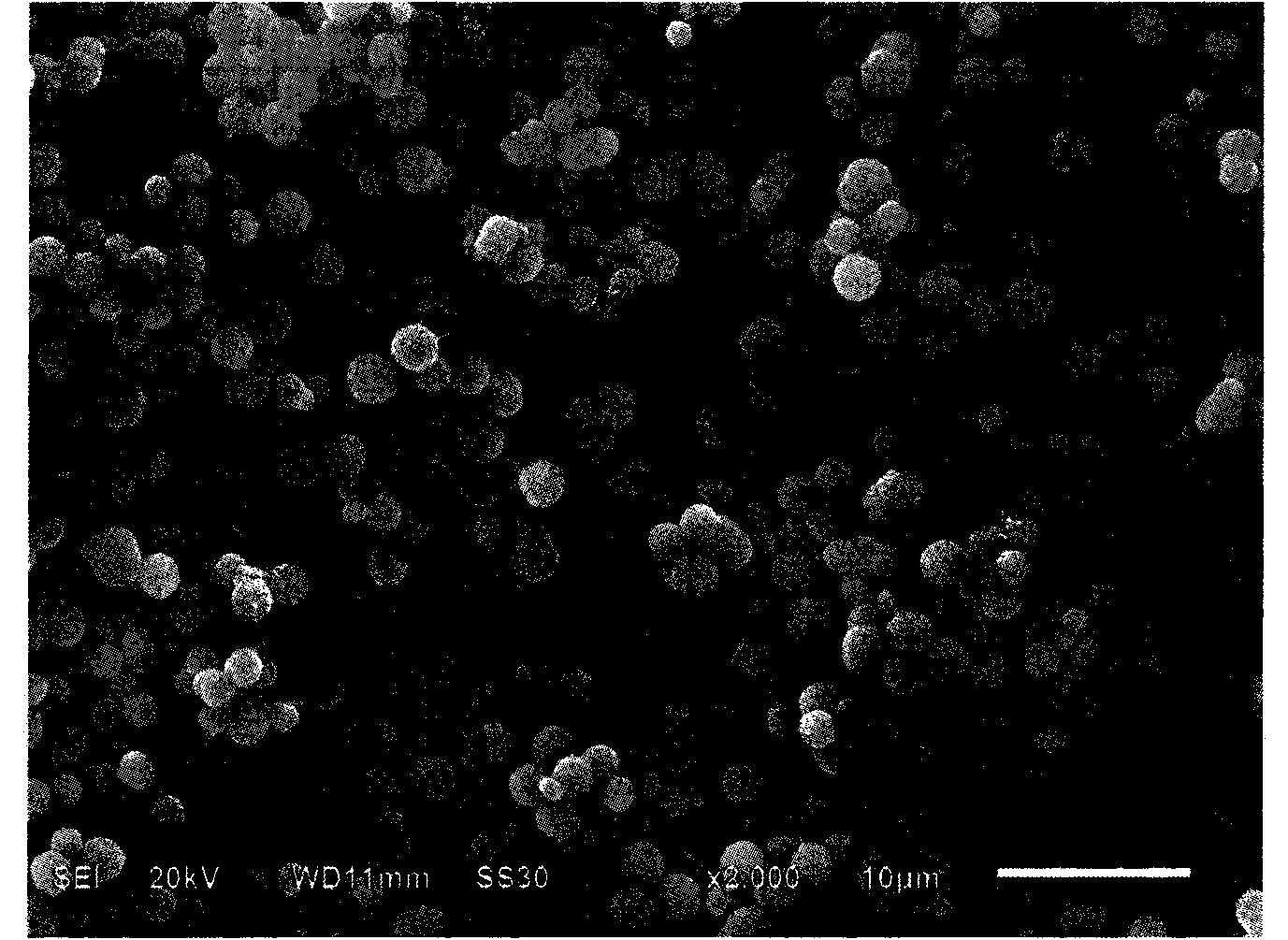

Spherical LiFePO4/(C+La2/3-xLi3xTiO3) composite anode material and preparation method thereof

InactiveCN103400962ALower internal resistanceInhibition of dissolutionElectrode manufacturing processesChemical/physical/physico-chemical processesSpherical shapedElectrochemistry

The invention discloses a spherical LiFePO4 / (C+La2 / 3-xLi3xTiO3) composite anode material. According to the composite material, carbon (C) serves as an electron conductor, and La2 / 3-xLi3xTiO3 serving as a fast lithium ion conductor is uniformly mixed and coated on the surface of spherical LiFePO4 so as to form a mixed conductor layer. The mixed conductor layer not only can conduct electrons and lithium ions, but also can prevent an electrolyte from corroding an active material and inhibit Fe from dissolving, so that the improvement on the electrochemical performance of the material is facilitated. The spherical LiFePO4 / (C+La2 / 3-xLi3xTiO3) composite anode material disclosed by the invention has high conductivity and lithium ion diffusion rate, excellent high-magnification performance and high tap density, and is applicable to power type lithium-ion batteries; and the preparation method is simple, feasible, clean and pollution-free, is low in cost and is applicable to industrial scale production.

Owner:XIANGTAN UNIV

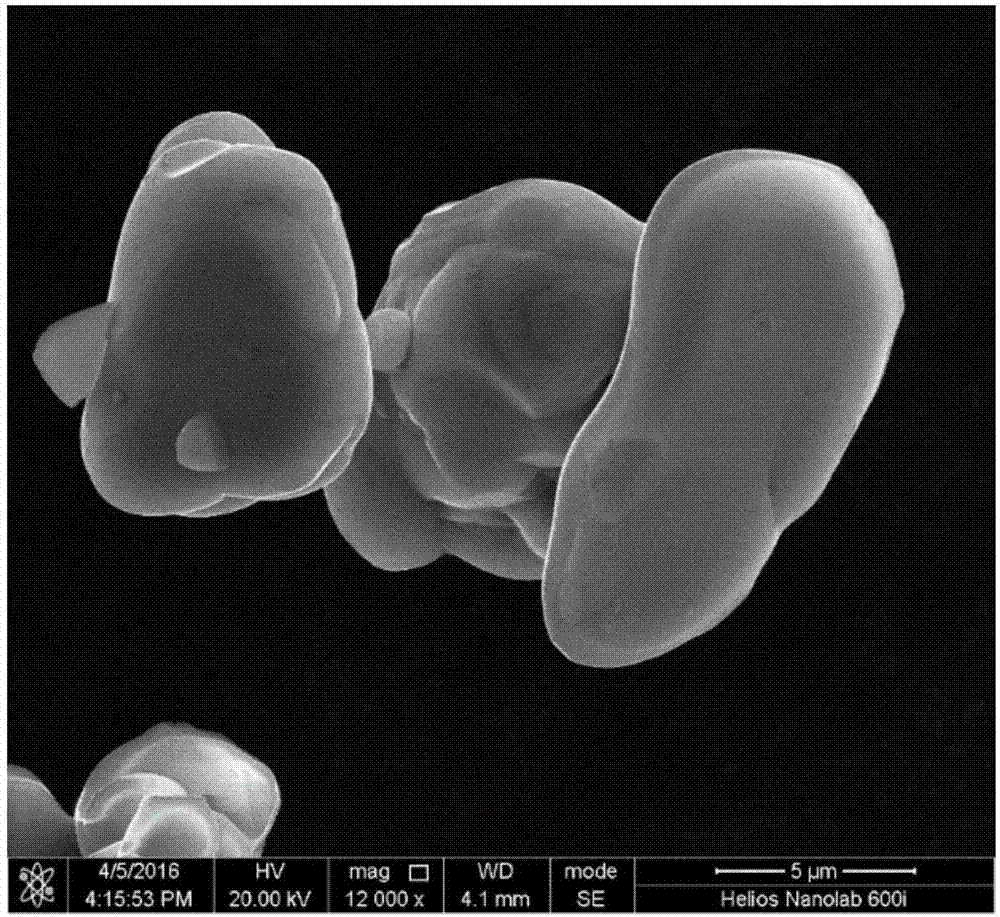

Fluorophosphate lithium ion-electron mixed conductor modified lithium cobaltate composite material and preparation method thereof

ActiveCN106920947AAvoid decompositionReduce erosionCell electrodesSecondary cellsPhosphoric acidSlurry

The invention discloses a fluorophosphate lithium ion-electron mixed conductor modified lithium cobaltate composite material and a preparation method thereof, and relates to the fields of lithium ion battery positive electrode materials and preparation methods thereof. The technical problems to be solved in the invention are poor cycle performance, poor rate performance and poor compatibility with an electrolyte of lithium cobaltate positive electrode materials under a high voltage of 4.55V. The composite material is a lithium cobaltate positive electrode material coated with a layer of lithium-containing fluorophosphate, wherein the coated lithium cobaltate positive electrode material is a layered material and has chemical formula is LiCo1-xMxO2, x is not less than 0 and not more than 0.2, the chemical formula of the coating layer material is LiM'PO4-yF1+y, and y is not less than 0 and not more than 1.2. The method comprises the following steps: 1, preparation of a coating layer material solution; 2, preparation of a slurry; 3, drying; and 4, sintering. The preparation method has the advantages of simplicity, low cost, and easiness in industrialization realization. The fluorophosphate lithium ion-electron mixed conductor modified lithium cobaltate composite material is used for making lithium ion secondary batteries.

Owner:HARBIN INST OF TECH

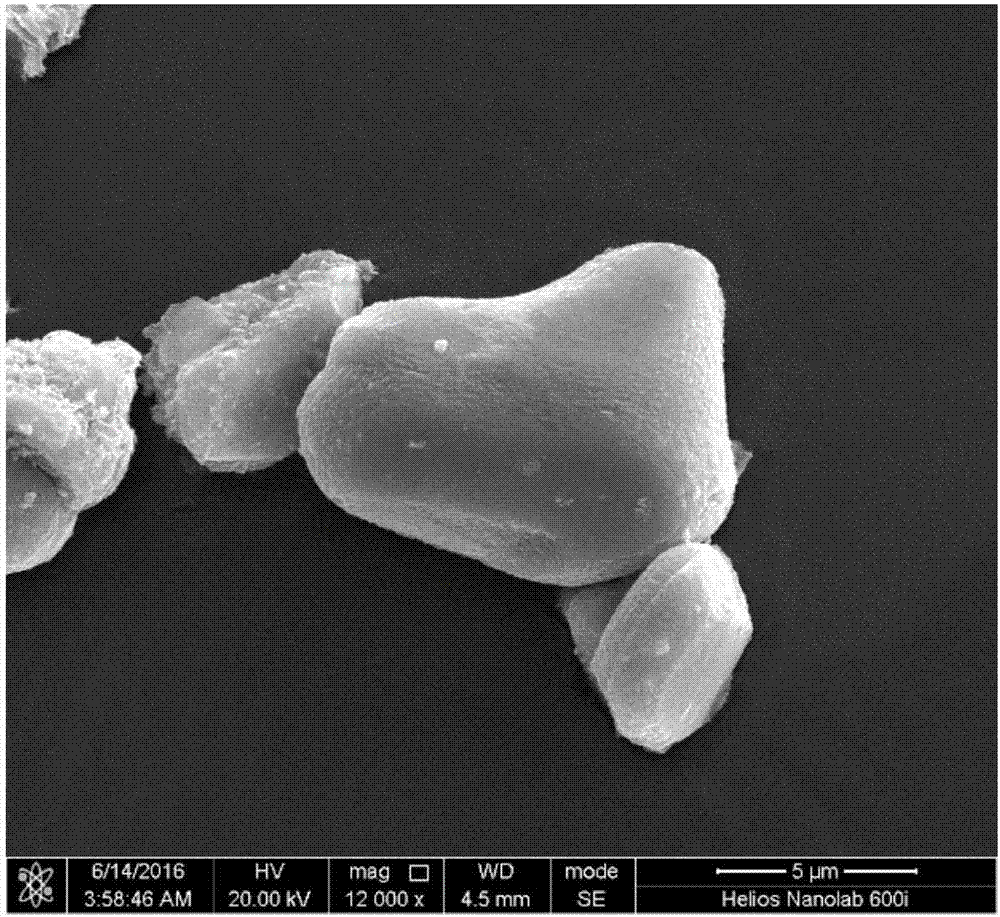

Lithium ion-electron mixed conductor modified ternary anode material and preparation method

InactiveCN108091857ALithium ion conductivity is goodImprove electronic conductivityPhosphatesCell electrodesElectrical conductorPhosphate

The invention discloses a lithium ion-electron mixed conductor modified ternary anode material and a preparation method. A layer of lithium-containing phosphate is arranged on the surface of the ternary anode material, a main ingredient magnesium lithium phosphate of the coating layer serves as a lithium ion conductor material and has better lithium ion electric conductive performance, and electronic conductivity of the coating layer can be improved by doping trivalent and tetravalent metal ions or F ions; thus, the coating layer has better lithium ion and electron conduction performance at the same time. The modified ternary anode material can work under higher voltage and remarkably improve battery capacity; furthermore, cycle performance, rate capability, overcharging performance and safety performance of the modified ternary anode material are greatly improved.

Owner:桑顿新能源科技(长沙)有限公司

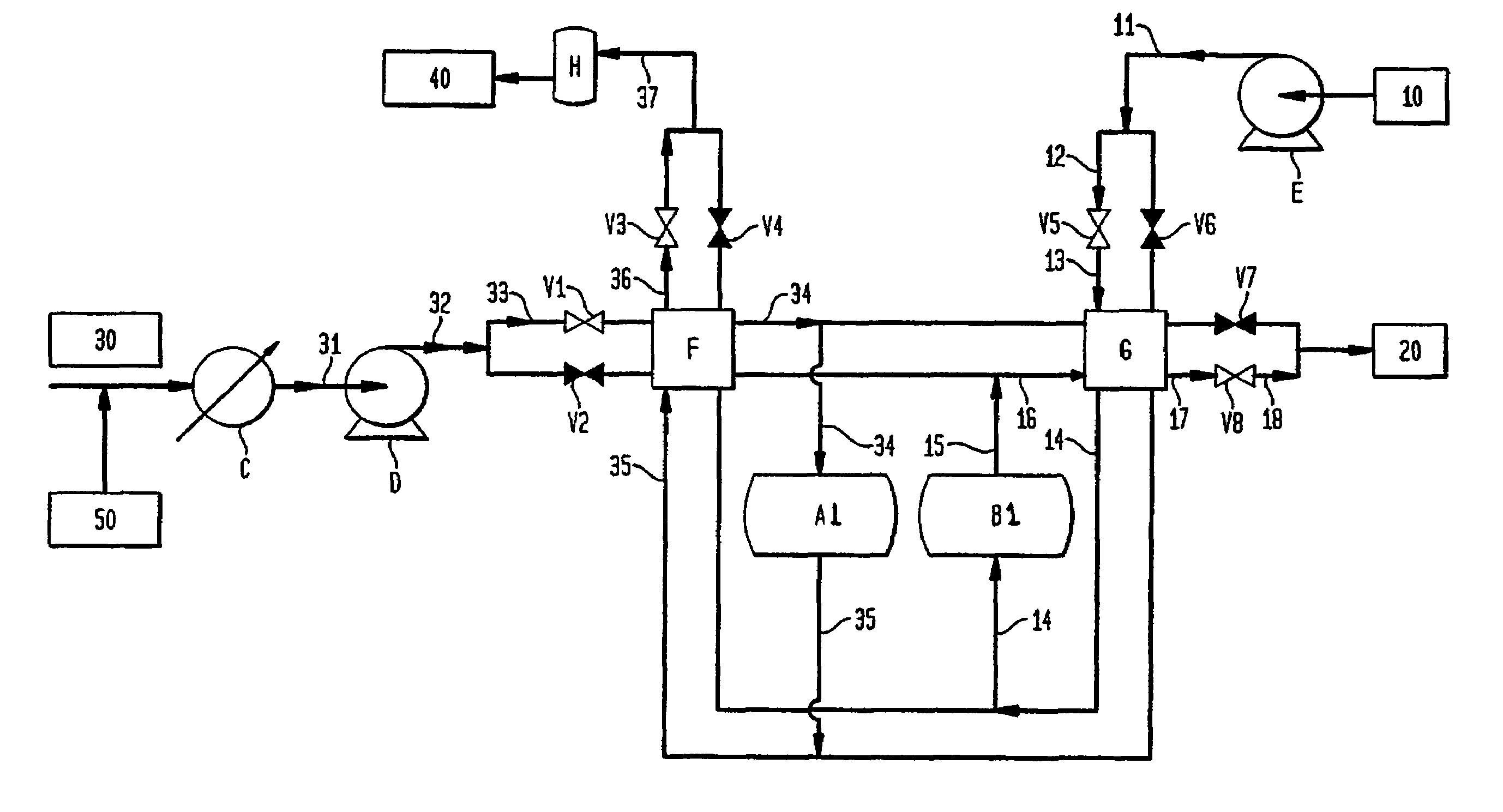

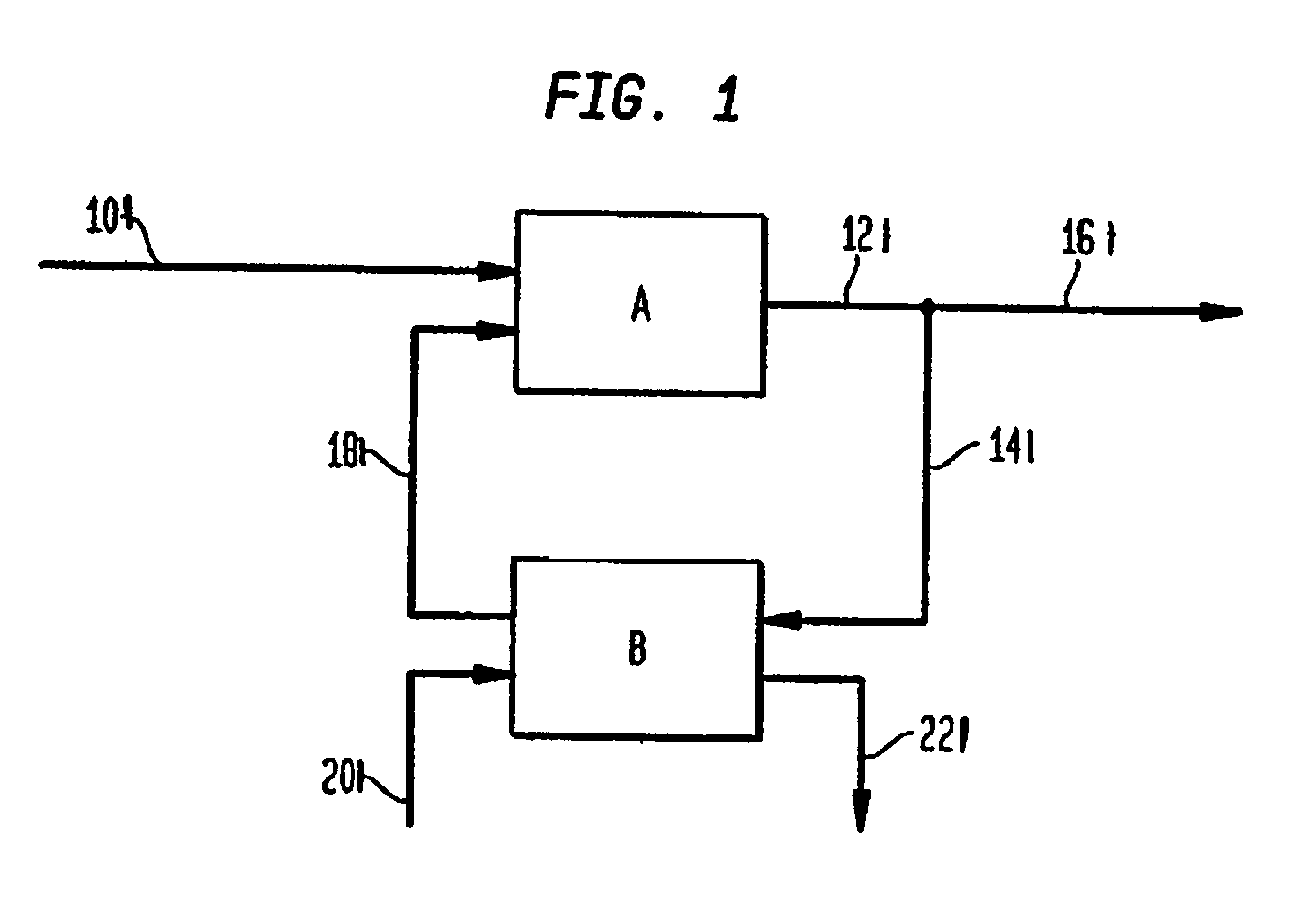

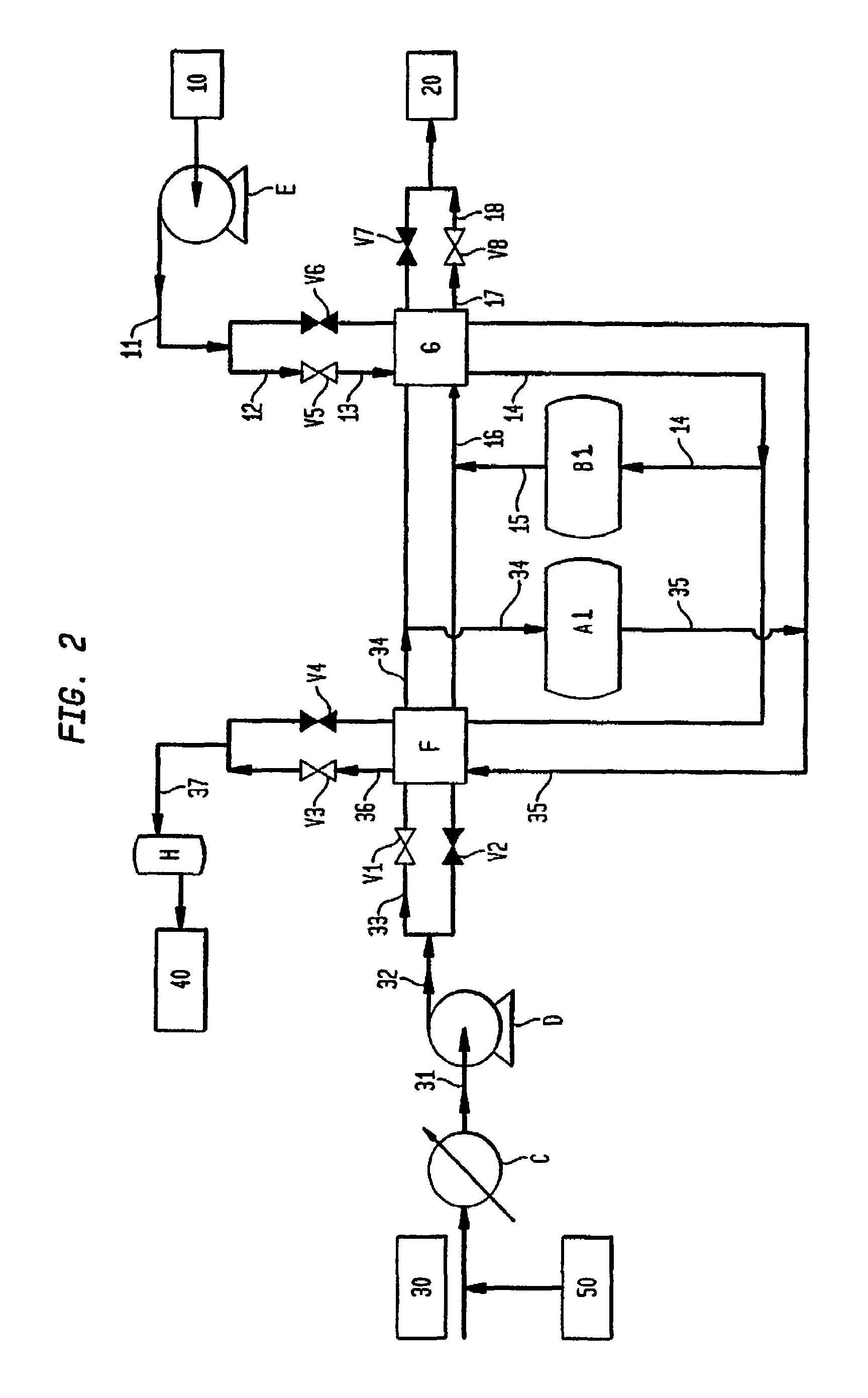

Oxy-fuel combustion process

Production of oxygen-enriched gas streams is disclosed herein. Air streams contact an oxygen-selective mixed conductor particularly a perovskite material whereby oxygen is retained or adsorbed on the perovskite and can be employed in a variety of processes such as in combusting a fuel gas, heat recovery and boiler related operations.

Owner:BOC GRP INC

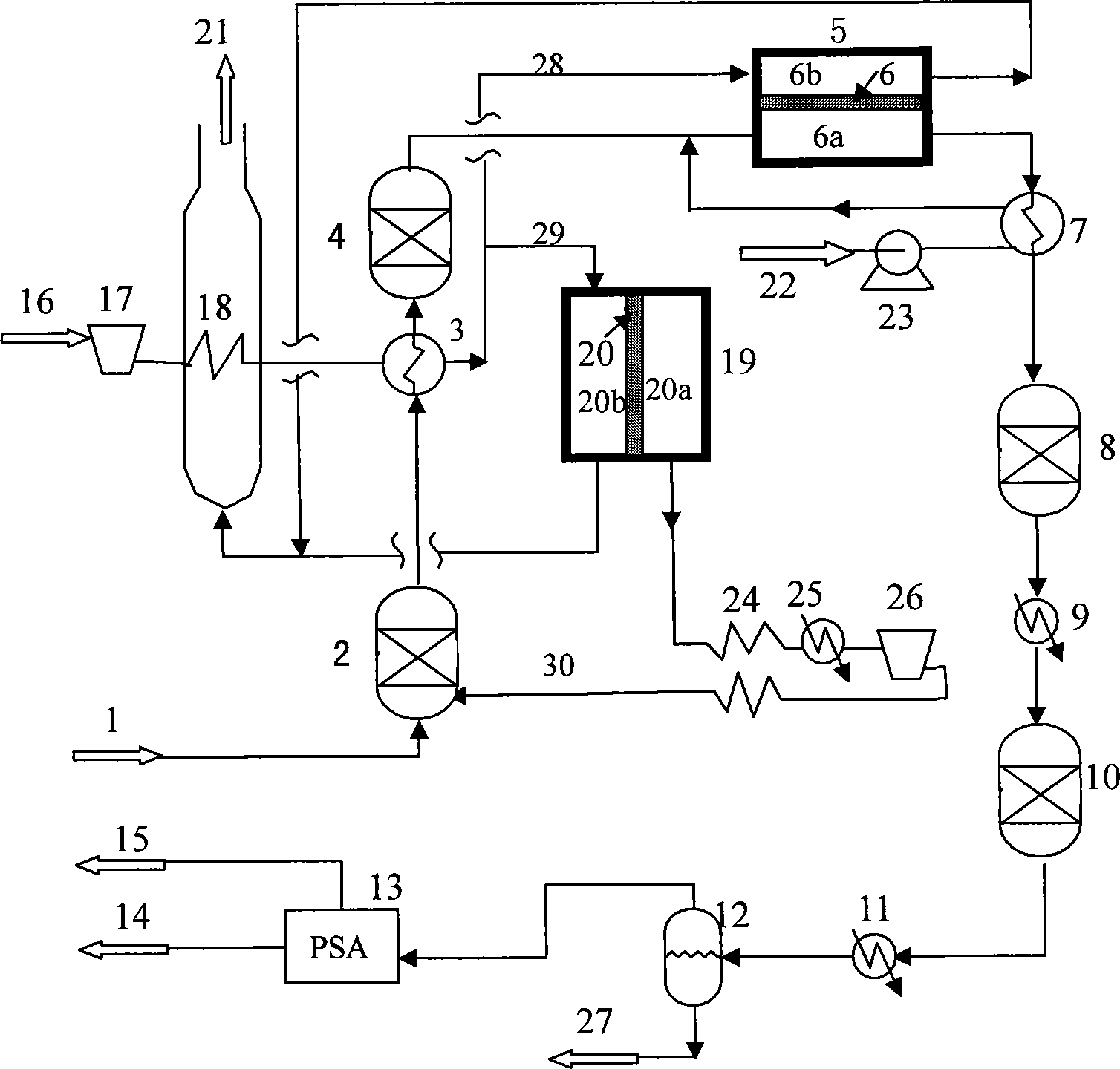

High temperature coke oven crude gas hydrogen generating system device and technique

InactiveCN101239702AReduce the amount of solutionLess investmentHydrogenEnergy inputElectrical conductorWater vapor

The present invention provides a system device of hydrogen preparing by dried gasification of the easy condensation component, high temperature desulphurization purification and part oxidation and reforming of low carbon hydrocarbon using high temperature coke-oven raw gas as raw material and its process, belonging to coke-oven raw gas hydrogen production process field. The hydrogen preparing system device of high temperature coke-oven raw gas is mainly adopts drying gasification furnace, high temperature desulphurization device, mixed conducting oxygen-permeable membrane reactor and mixed conducting oxygen-permeable membrane oxygen separator. The system device of the invention includes a high temperature coke-oven raw gas supplying system, an oxygen supply air supplying system, a high temperature vapor supplying system, a drying gasification furnace oxygen supplying system, a high temperature desulphurization system and a coal gas reforming reaction product output system. The advantages of the hydrogen gas system is that the high physical sensible heat and the high chemical energetic component of a mass high temperature coke-oven raw gas generated in the course of coal carbonization is fully converted to a oxygen as possible; since oxygen supplying by adopting dried gasification, high temperature desulphurization and mixed conductor oxygen-permeable membrane, the system has a high efficiency of hydrogen preparing, and an improved amplitude.

Owner:SHANGHAI UNIV

High-stability high-permeability compact ceramic oxygen-permeation membrane and preparation method thereof

InactiveCN104492278AImprove stabilityHigh mechanical strengthSemi-permeable membranesDispersed particle separationElectrical conductorOxygen ions

A disclosed high-stability high-permeability compact ceramic oxygen-permeation membrane is composed of, in percentage by volume, 75-92% of an oxygen ion conductor phase and 8-25% of an ion-electron conductor phase; the oxygen ion conductor phase is a doped CeO2 porous matrix, and the ion-electron mixed conductor phase is a perovskite structure oxygen ion-electron mixed conductor and is disposed in a connected pore channel of the matrix. Additionally, the invention also discloses a preparation method for the above high-stability high-permeability compact ceramic oxygen-permeation membrane. The technical scheme effectively solves the problem that a ceramic oxygen-permeation membrane cannot simultaneously possess the long-term stability and the high oxygen permeation flux in the prior art. The oxygen permeation flux is improved, and also the high-stability high-permeability compact ceramic oxygen-permeation membrane has good long-term working stability.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Ternary complex cathode material of intermediate/low temperature solid-oxide fuel battery

InactiveCN101295791AGood chemical stabilityImprove structural stabilityCell electrodesFuel cell detailsElectrical conductorActive matter

The invention discloses a novel ternary composite cathode material for a medium and low temperature solid oxide fuel cell, which comprises an oxygen ion conductor oxide, an electronic-oxygen ion mixed conductor oxide and an oxygen catalytic reduction active matter. The material is characterized in that: the cathode material taking perovskite structured oxygen ion and electronic mixed conductor as the main body has the main function of catalytically reducing the gaseous oxygen at the surface as oxygen ions and transmitting the oxygen ions in an manner of bulk phase to the interface between an electrolyte and the cathode; the conductivity of the oxygen ions is improved by adding the oxygen ion conductor, thereby improving the bulk phase transmission speed of the oxygen ions; the speed of the surface oxygen exchange of the cathode material is obviously increased by adding the oxygen catalytic reduction active matter, thereby greatly enhancing the catalytic activity of the surface oxygen of the cathode material. All effective components of the ternary composite cathode material are synthesized by adopting nitrate by an EDTA-citric acid complex method. Shown in single cell tests, the ternary composite cathode material shows not only excellent comprehensive performance but also excellent compatibility among all the effective components.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

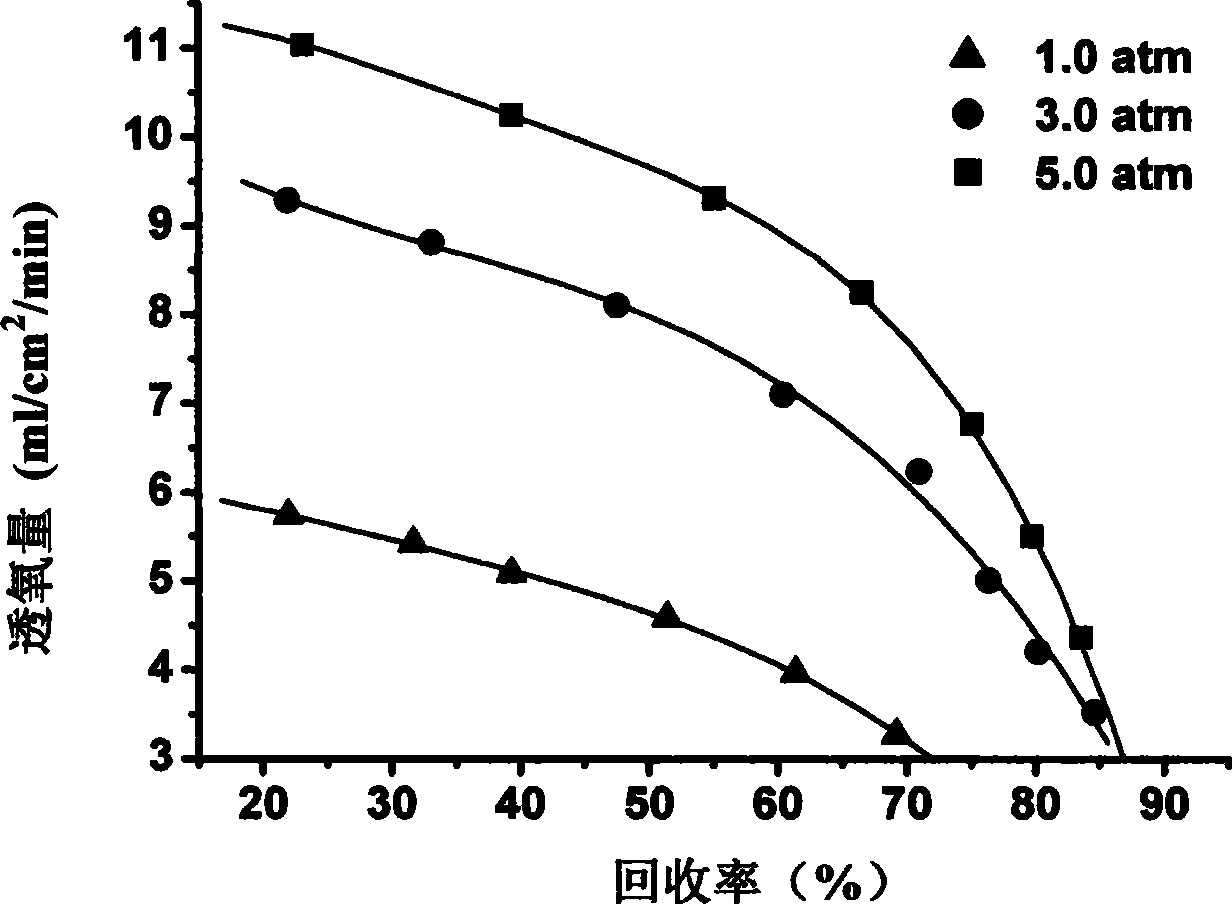

Method for preparing oxygen and nitrogen by air separation

InactiveCN101450792AEfficient separationSeparation and energy savingNitrogen purification/separationChemical industryElectrical conductorSorbent

The invention provides a method for producing oxygen and nitrogen through air separation. The whole process is carried out on a platform consisting of a mixed-conductor oxygen-permeable ceramic membrane separator and a pressure swing adsorption separator taking complex metal oxide as oxygen absorbent. The process comprises the following concrete steps: most oxygen in the air is adsorbed by a mixed-conductor oxygen-permeable ceramic membrane; the remained air is oxygen-deficient air; the pressure swing adsorption separator taking the complex metal oxide as the absorbent adsorbs oxygen in the oxygen-deficient air; and the oxygen is desorbed under the lower pressure between 1 Pa and 100 kPa to ensure that the remaining gas after adsorption is mainly nitrogen, so as to obtain high-purity nitrogen. The method has the advantages that the method can efficiently separate the oxygen from oxygen-containing gas and separate oxygen and nitrogen from the air in an energy-saving way.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

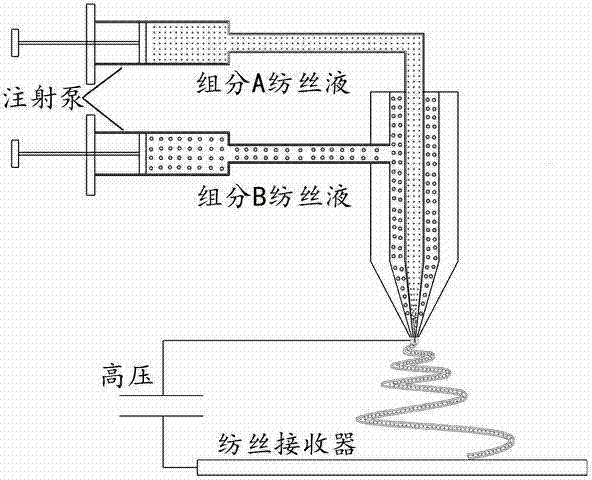

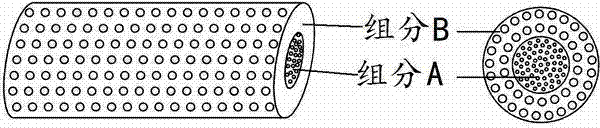

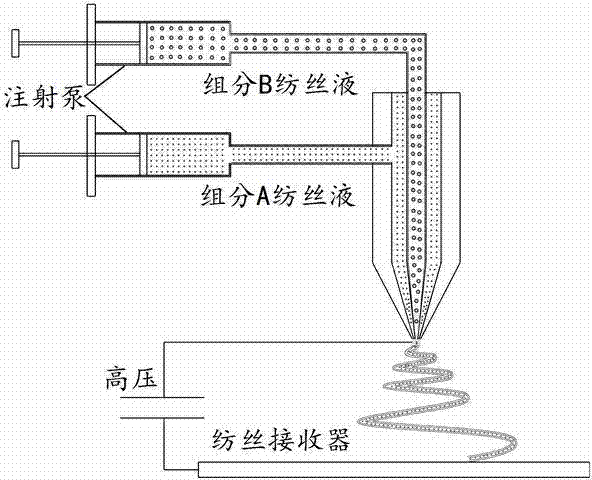

Low-temperature solid oxide fuel cell cathode in core-shell nano fiber structure and electrostatic spinning preparation method thereof

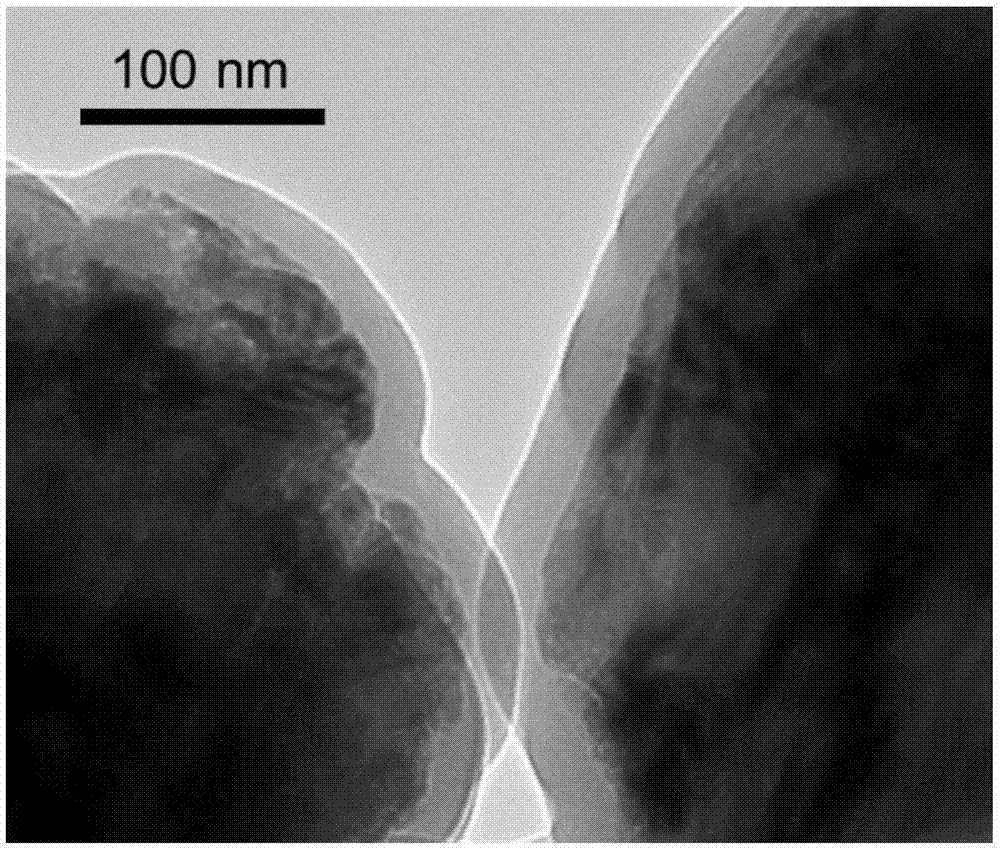

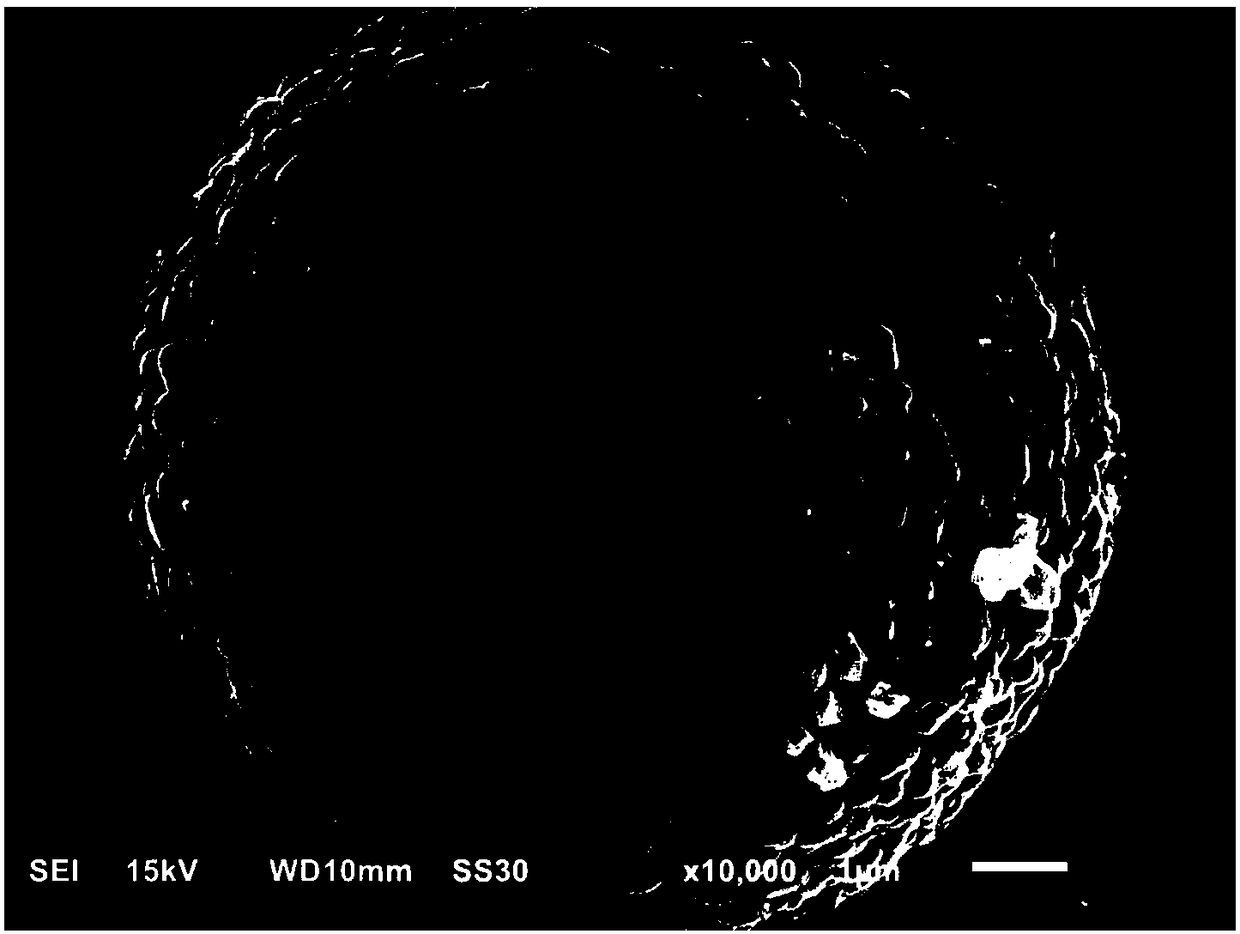

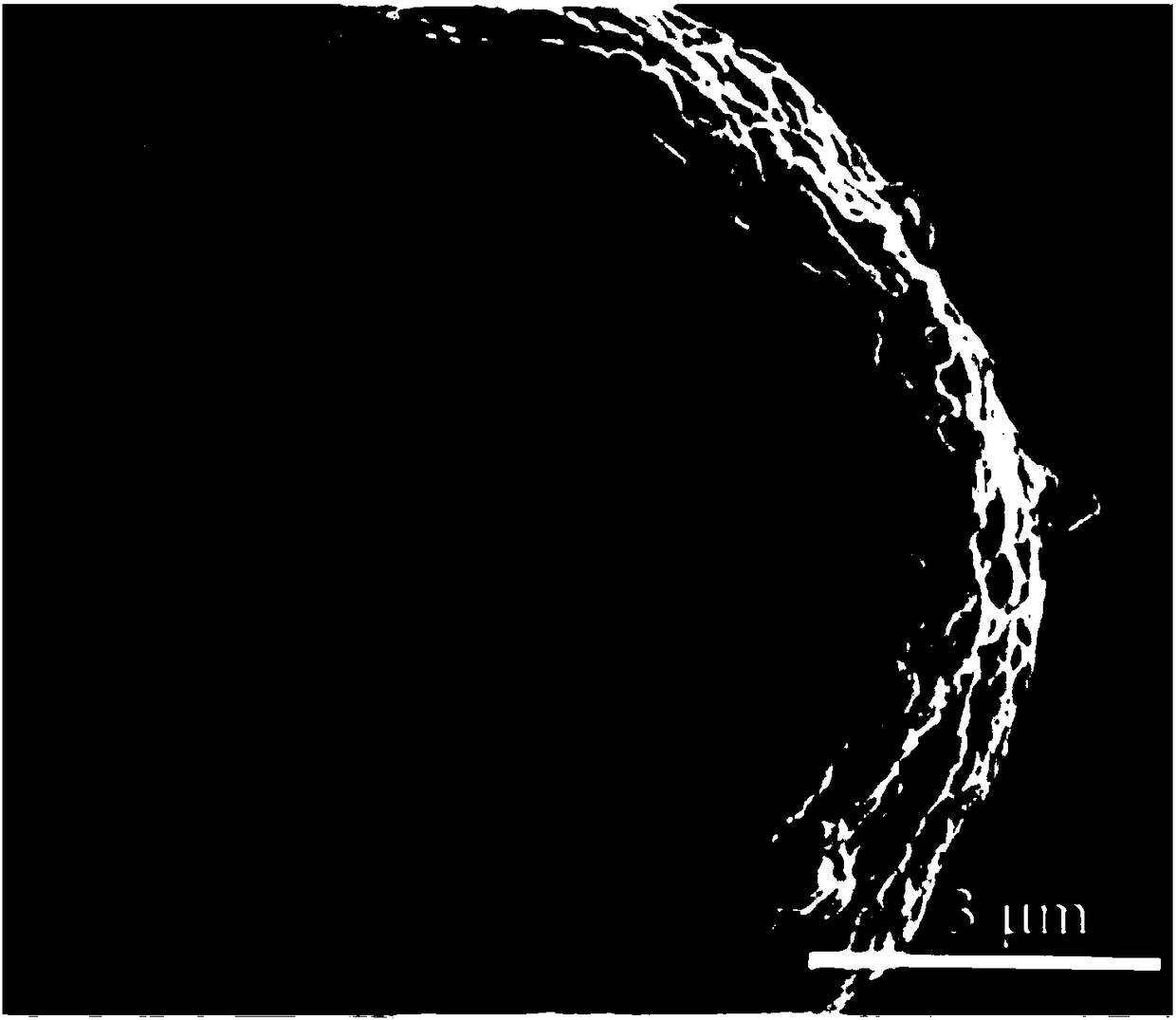

InactiveCN104752734AHigh catalytic activity for oxygen reductionSmall coefficient of thermal expansionMaterial nanotechnologyCell electrodesElectrical conductorOxygen ions

The invention relates to a low-temperature solid oxide fuel cell cathode in a core-shell nano fiber structure and an electrostatic spinning preparation method and belongs to the field of functional materials. The core-shell nano fiber structure cathode consists of a nano fiber core and a nano shell layer, wherein the fiber core and the shell layer respectively consist of a perovskite structure ion-electron mixed conductor component A and an oxygen ion conductor electrolyte component B or consist of opposite components; the core-shell nano fiber cathode is prepared in an electrostatic spinning manner, a component A before-spinning precursor solution and a component B before-spinning precursor solution are respectively prepared and then are respectively injected into an inner-layer spinning passage or an outer-layer spinning passage so as to carry out the spinning, and composite fibers are dried and sintered at a high temperature to obtain the core-shell nano fiber structure cathode material. By adopting the core-shell nano fiber structure, the oxygen reduction catalytic activity, anti-CO2 surface adsorption toxicity capacity and structural and performance stability of the low-temperature SOFC cathode are improved; moreover, the process is simple, and the cost is low.

Owner:DALIAN UNIV OF TECH

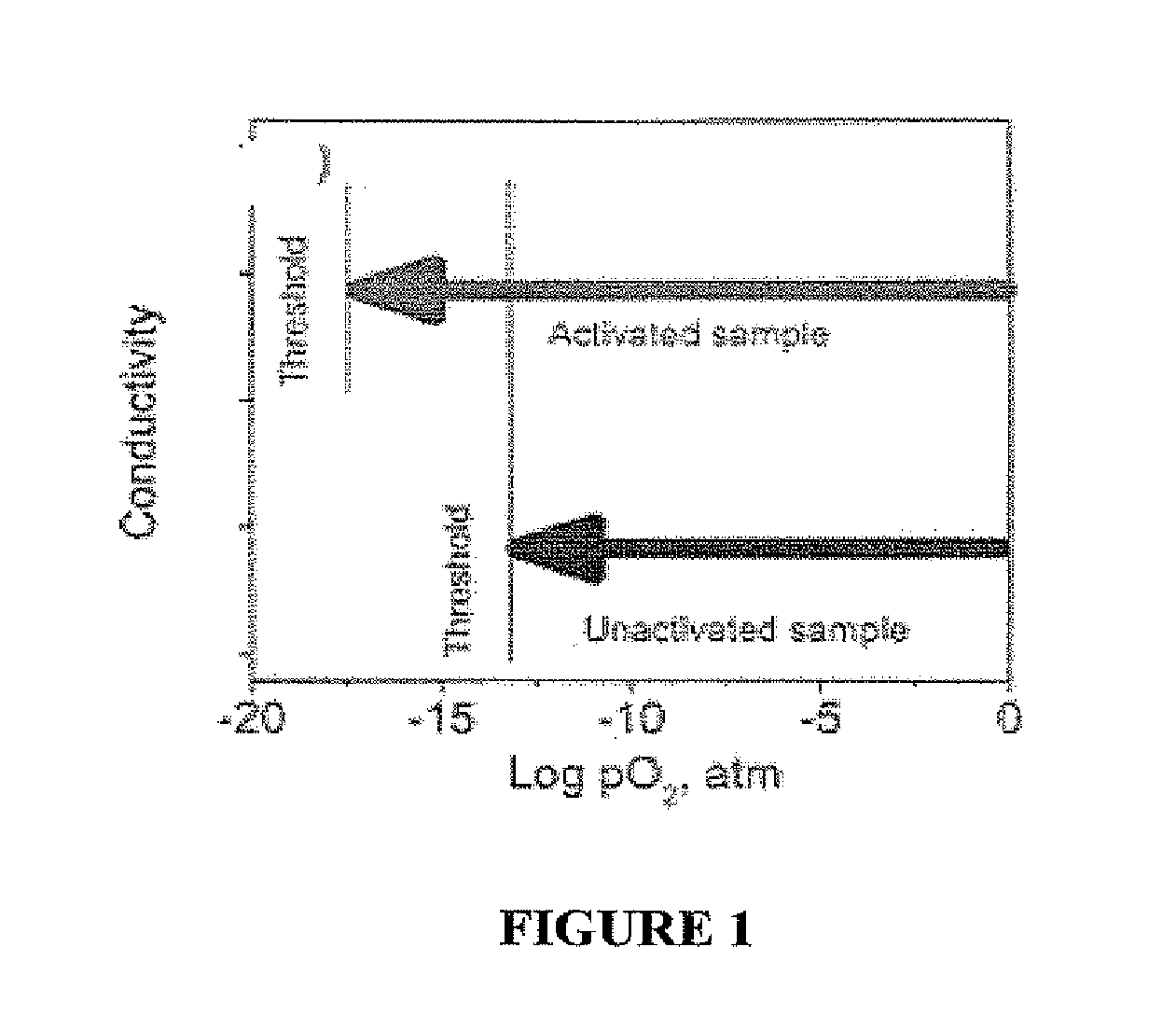

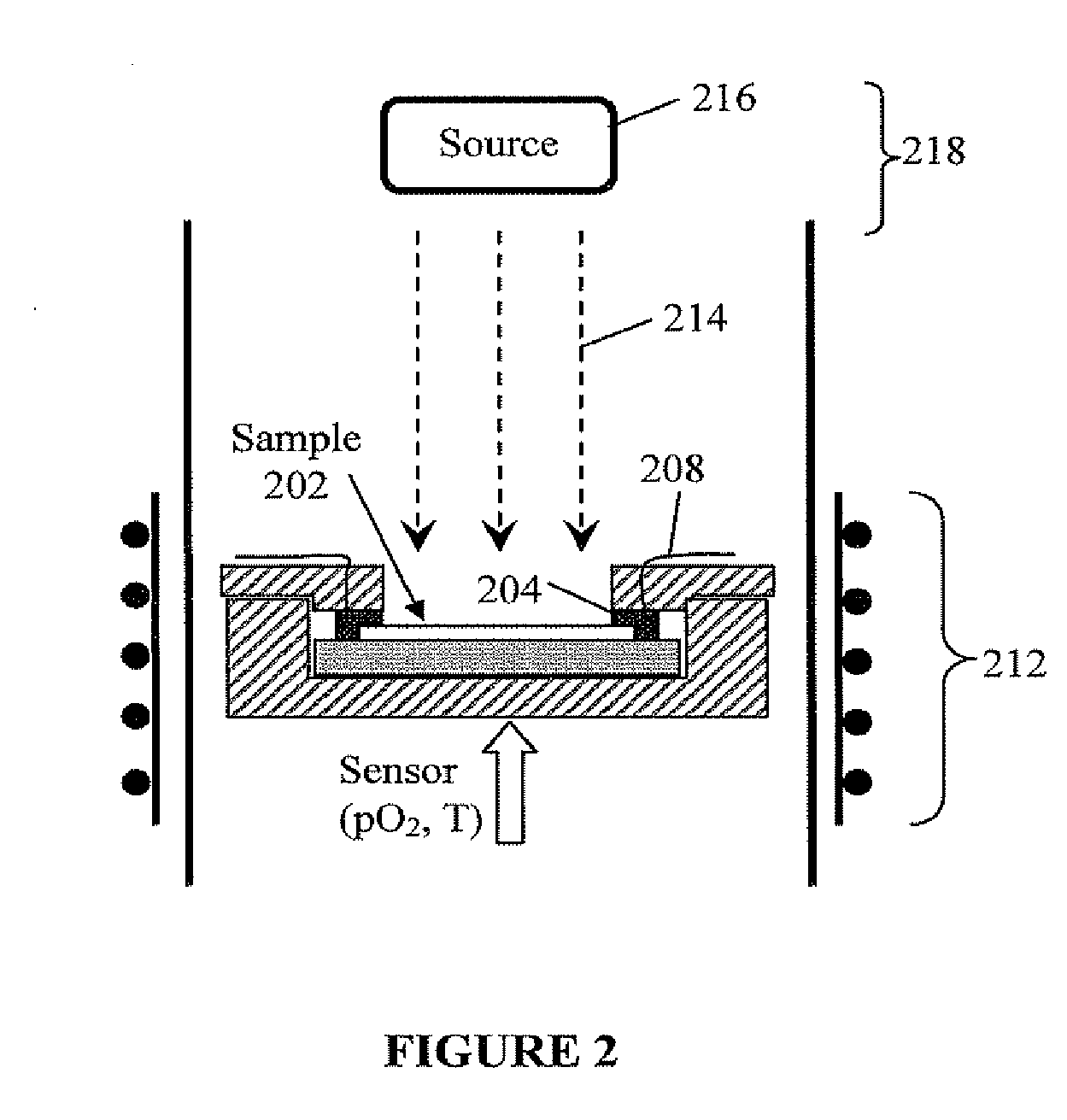

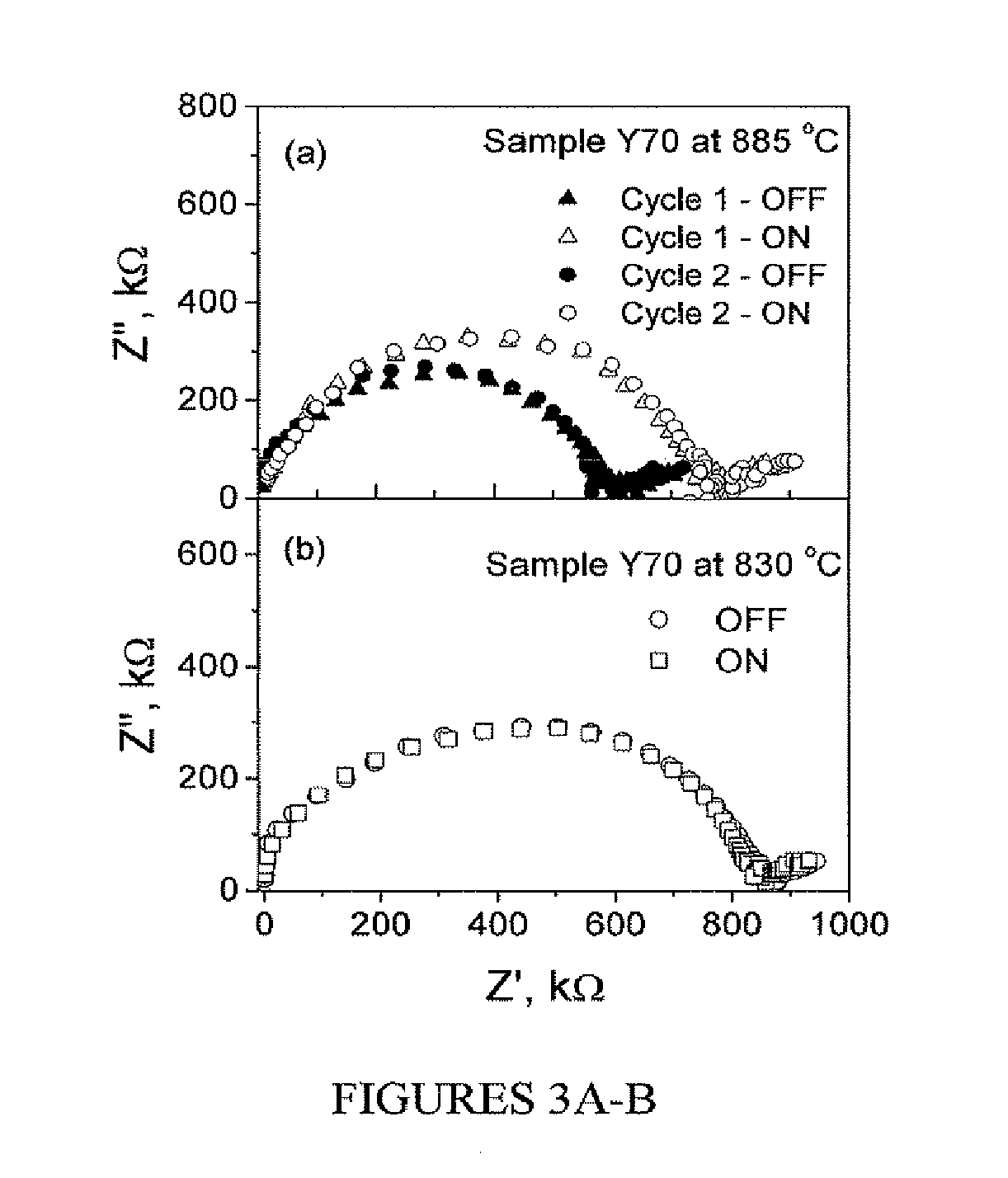

Photo-activation of solid oxide fuel cells and gas separation devices

InactiveUS20100255387A1Modulating electrical conductivityDecreasing conductivity of oxide ionSolid electrolytesFinal product manufactureElectrical conductorOxygen ions

In various aspects, provided are methods for: (a) improving oxygen incorporation in a solid oxide layer less than about 1000 nm thick; (b) extending the on-set of mixed conduction in a solid oxide layer less than about 1000 nm thick; (c) modulating the electrical conductivity of oxide ion conducting layer less than about 1000 nm thick; (d) decreasing the conductivity of an oxide ion conducting layer less than about 1000 nm thick; (e) improving the performance of a solid oxide fuel cell; and (f) improving the performance of a gas separation device. In various embodiments, the methods comprise exposing oxygen to light having one or more wavelengths in the range between about 100 nm to about 365 nm and contacting the layer with the oxygen so exposed. In various embodiments, the methods provide the potential for tailoring the surface catalytic activity of oxygen-ion and mixed conductors used in various solid-state devices.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

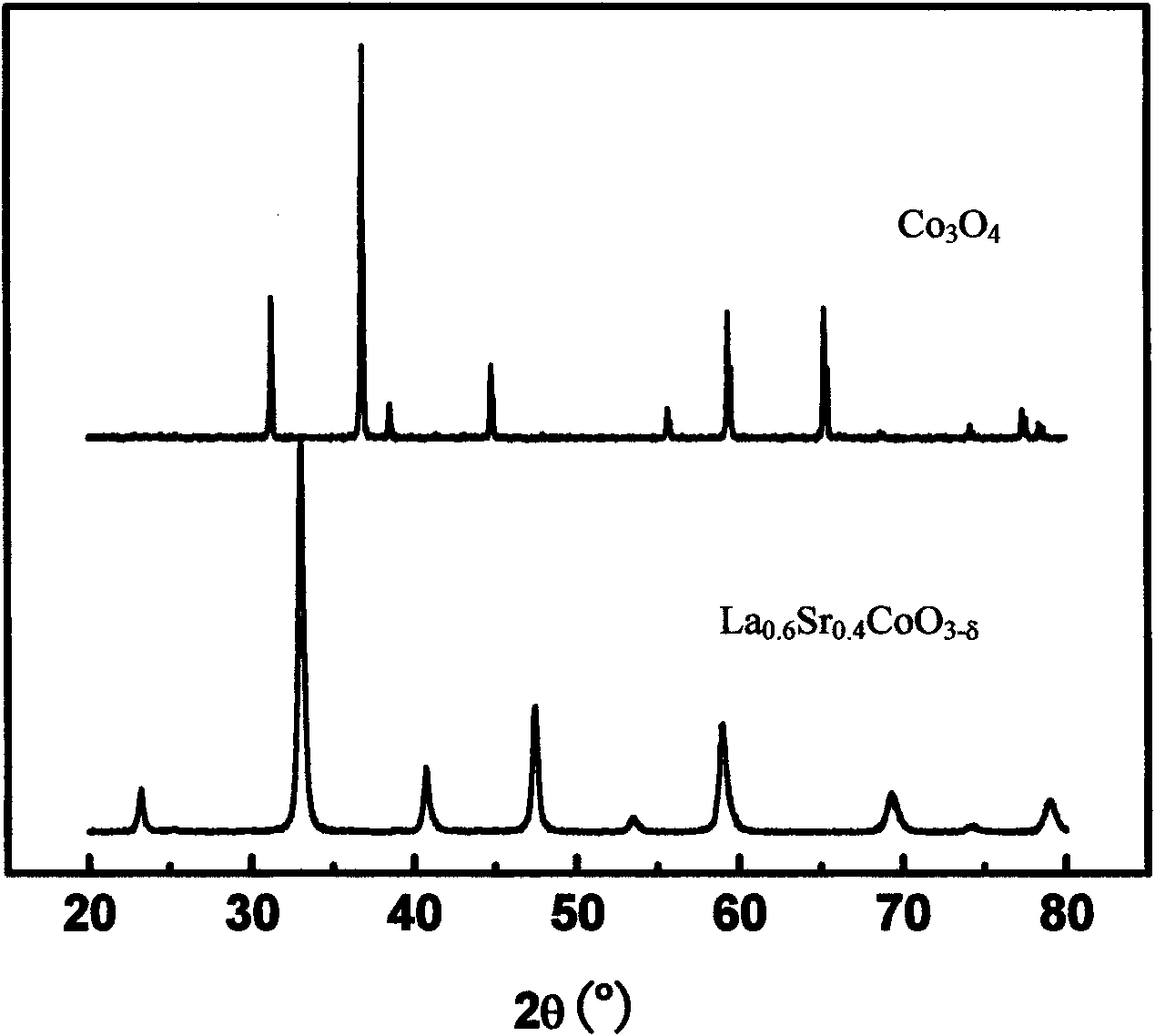

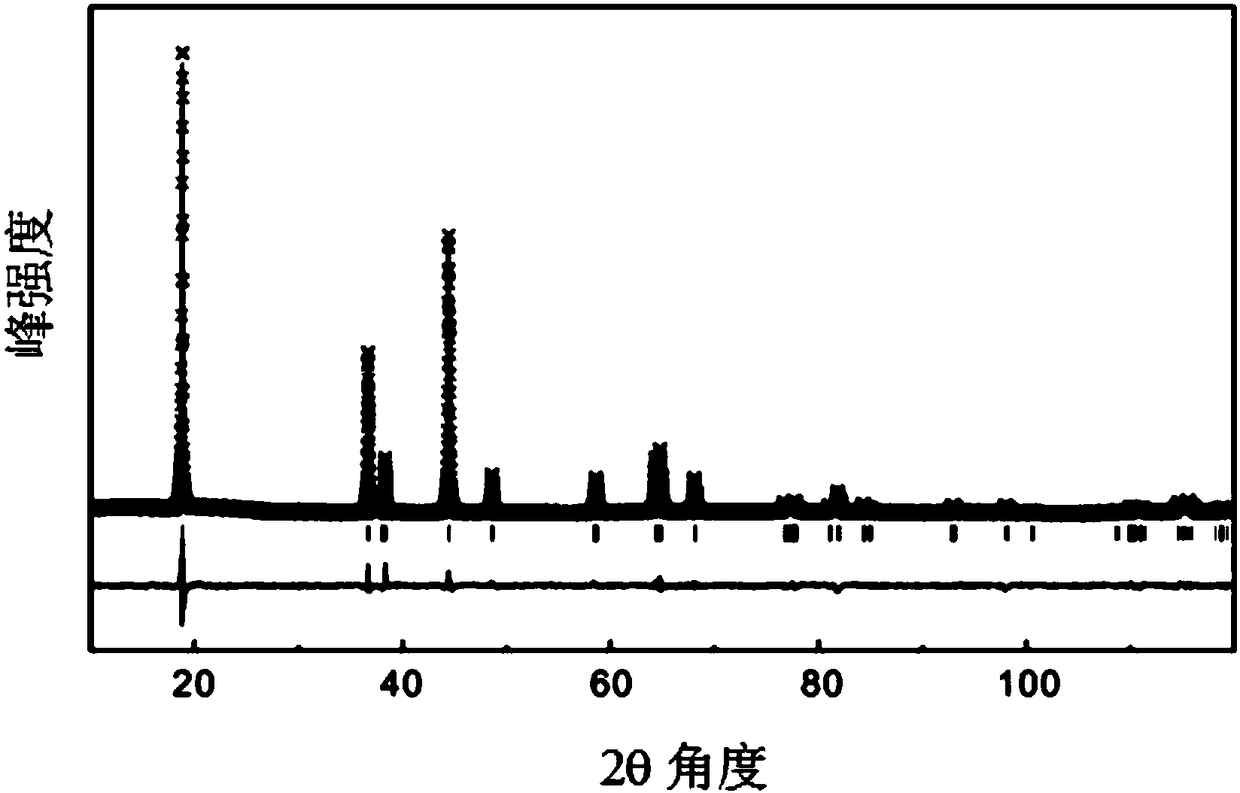

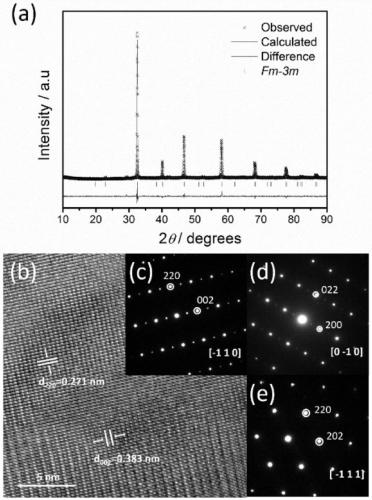

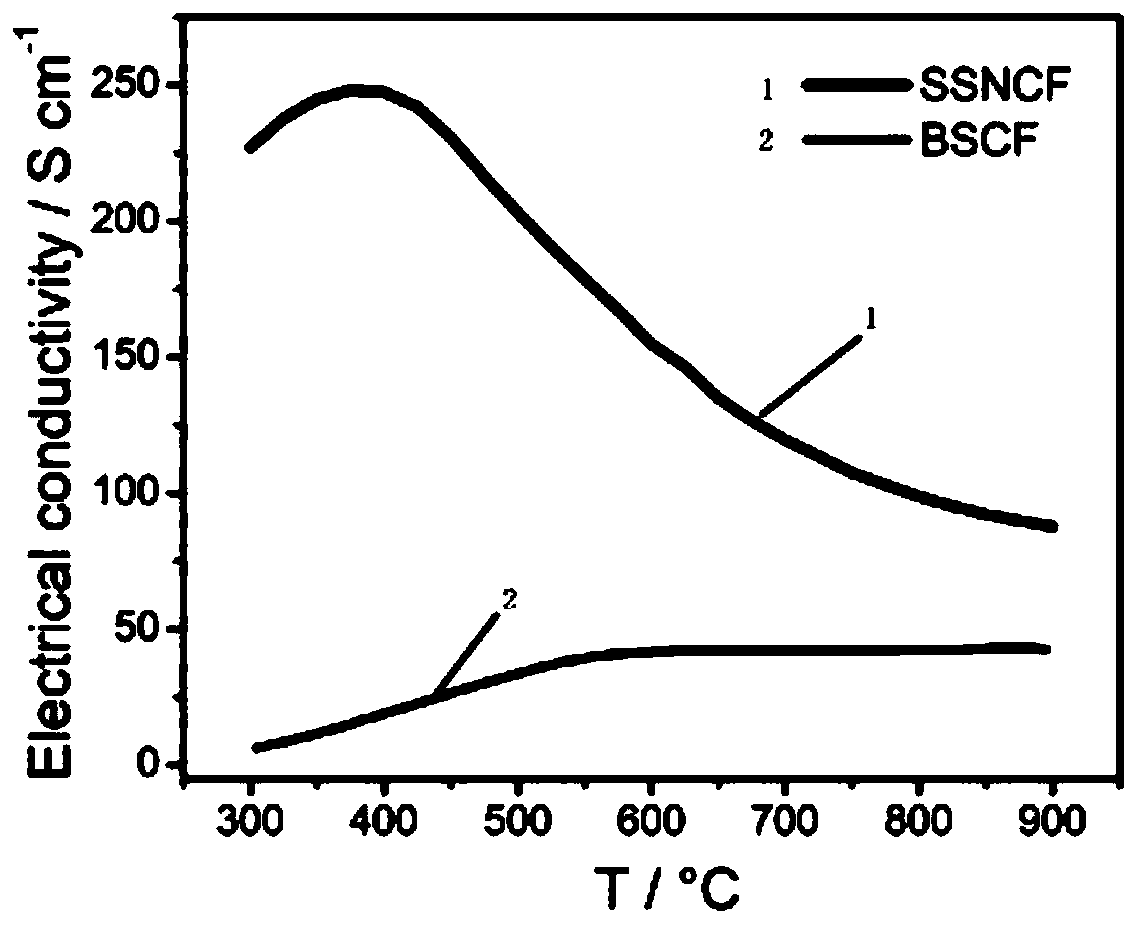

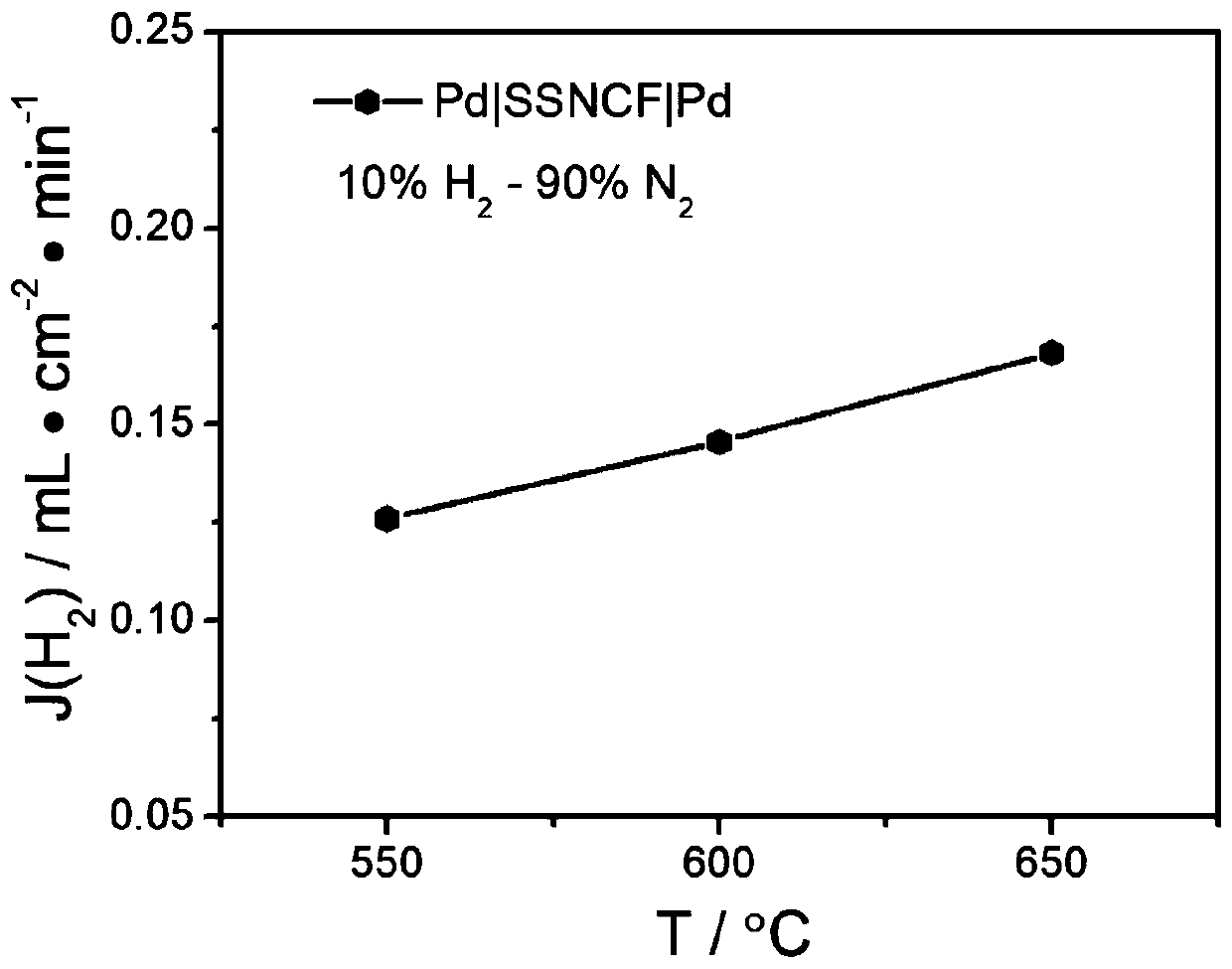

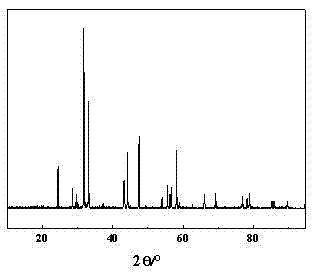

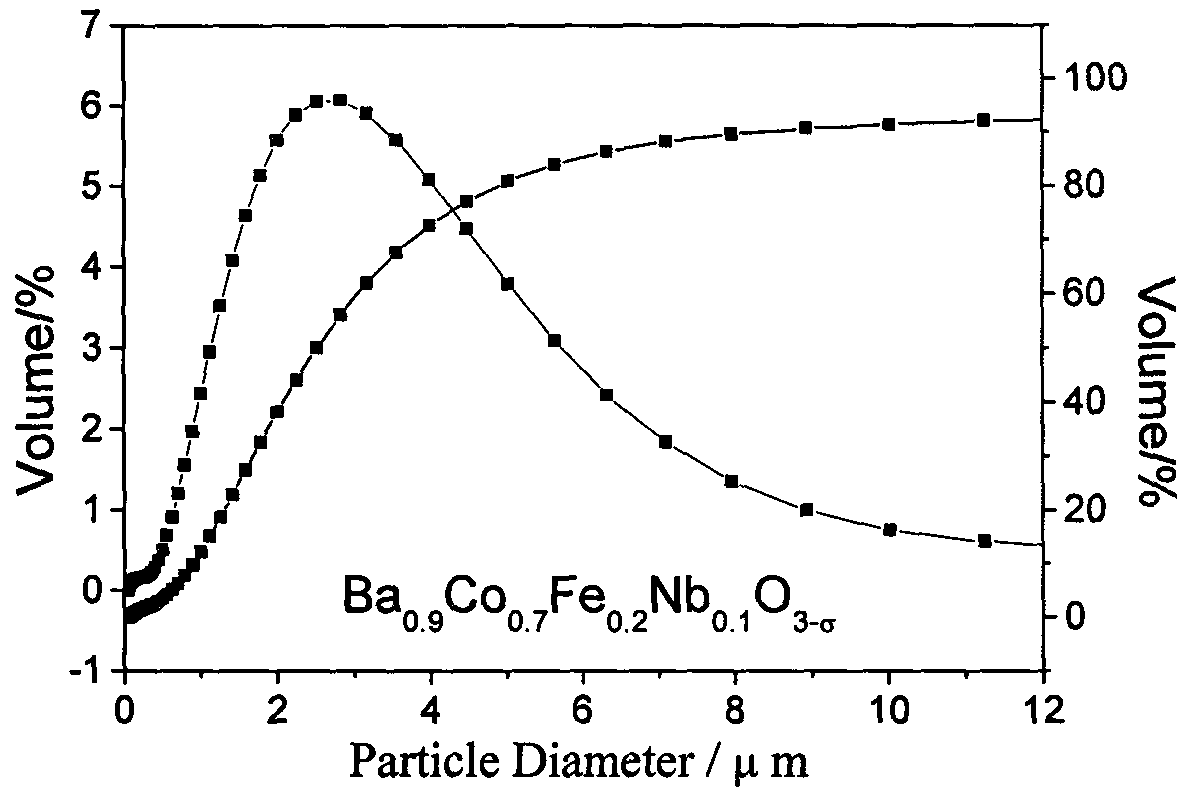

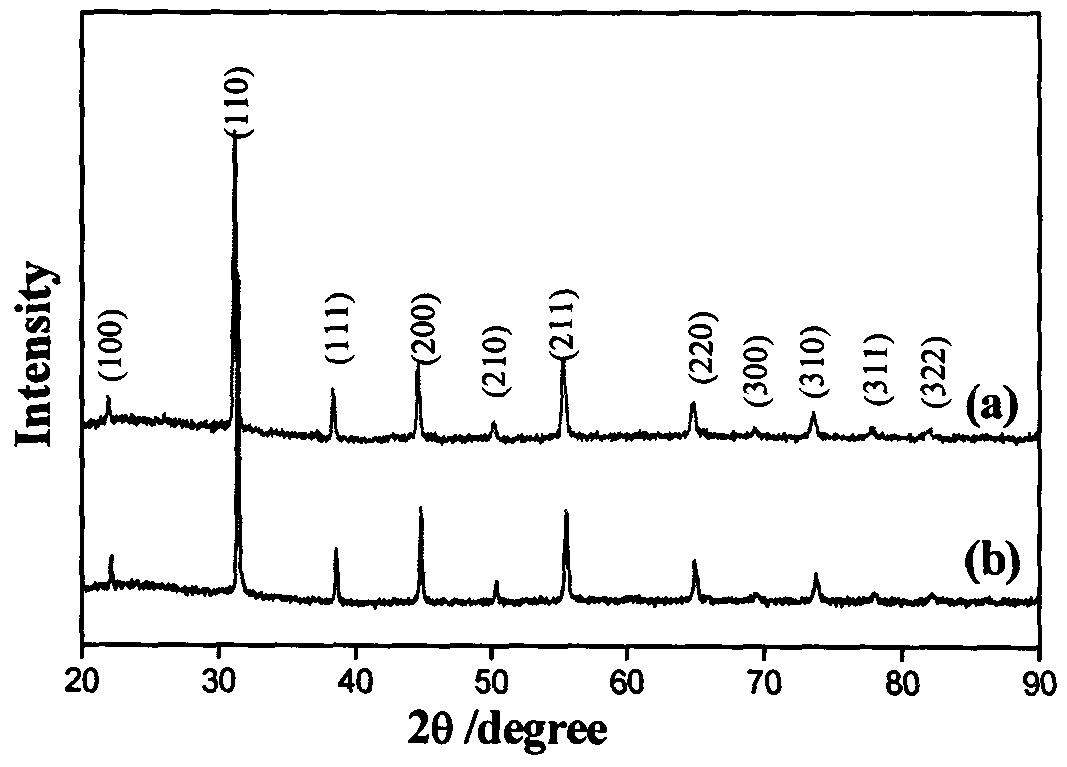

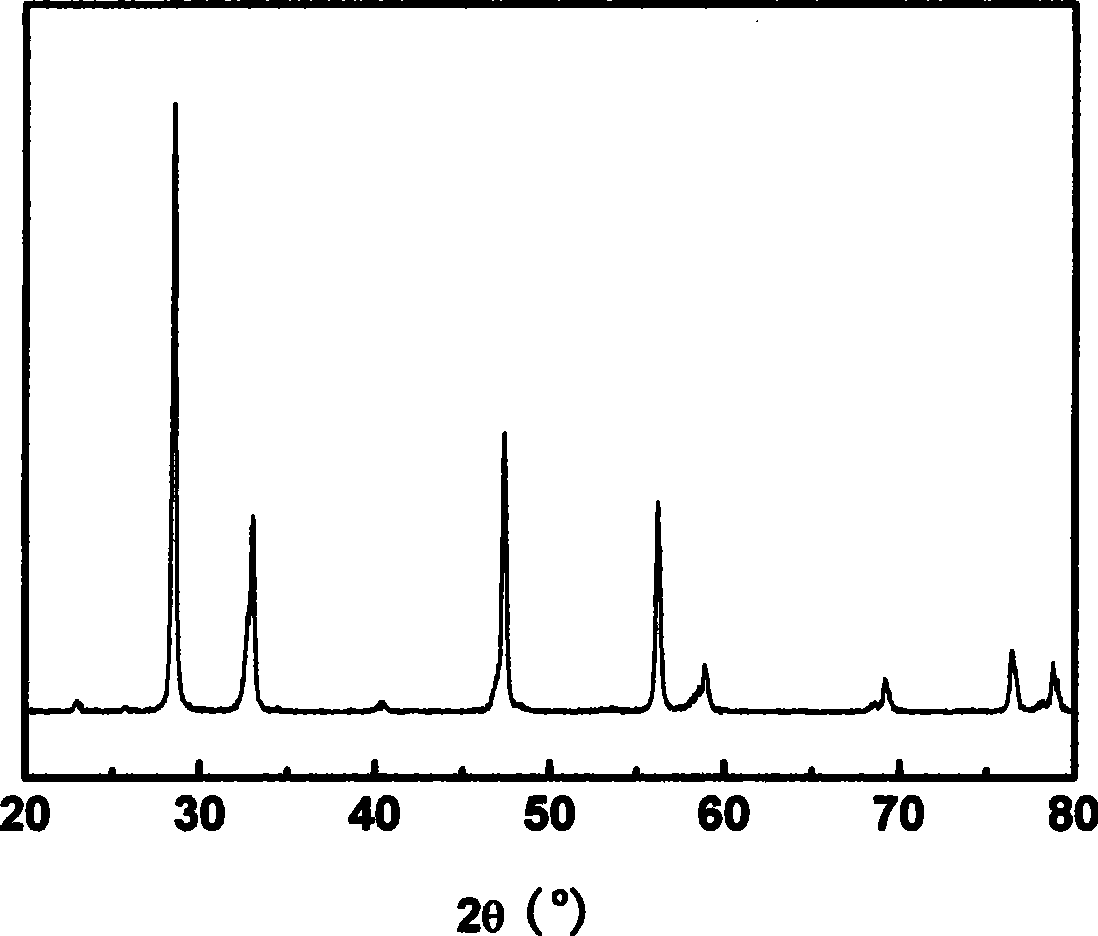

Perovskite mixed conductor material and preparation method thereof

ActiveCN109817997AImprove output performanceCell electrodesCobalt compoundsElectrical conductorOxygen vacancy

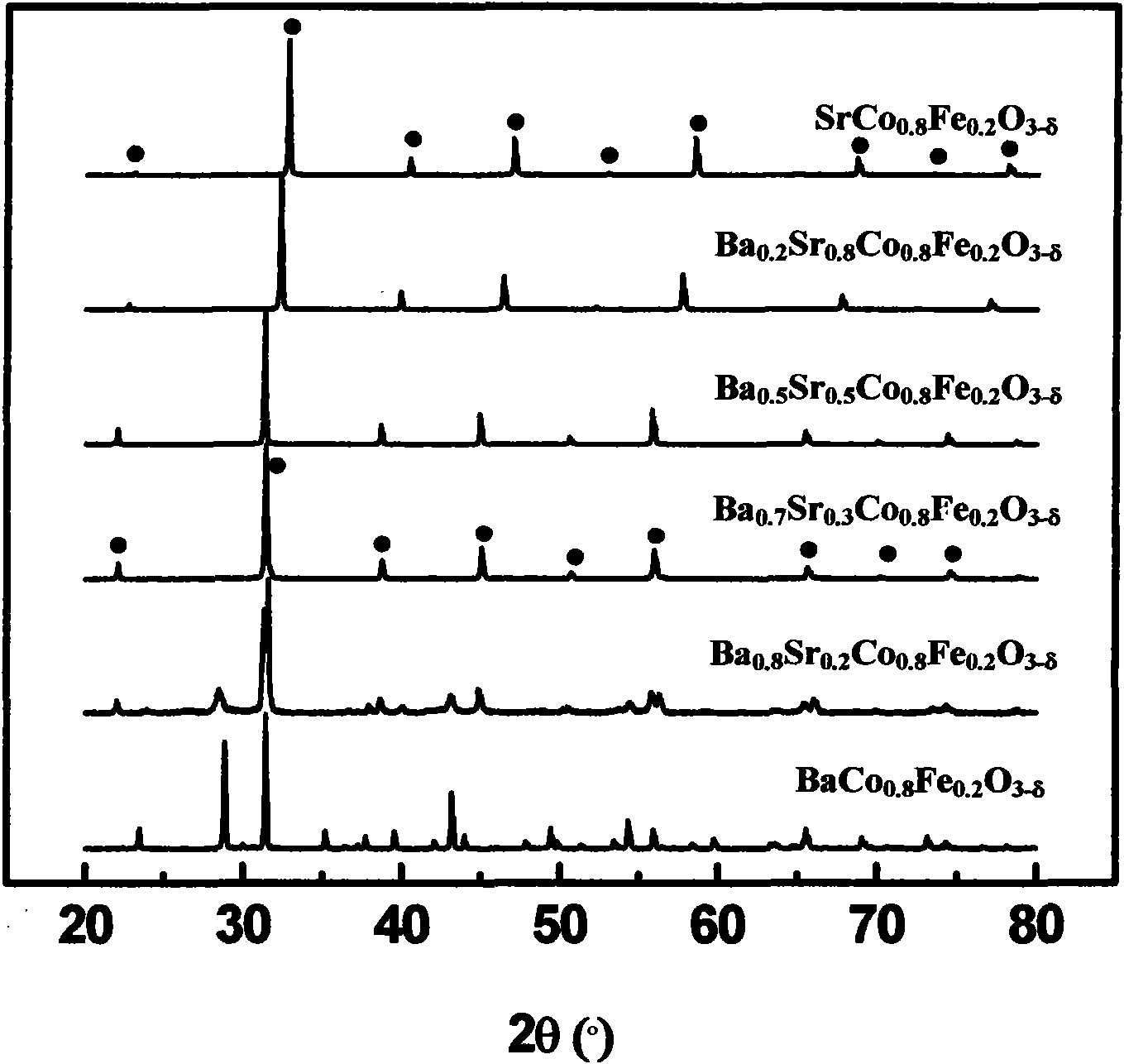

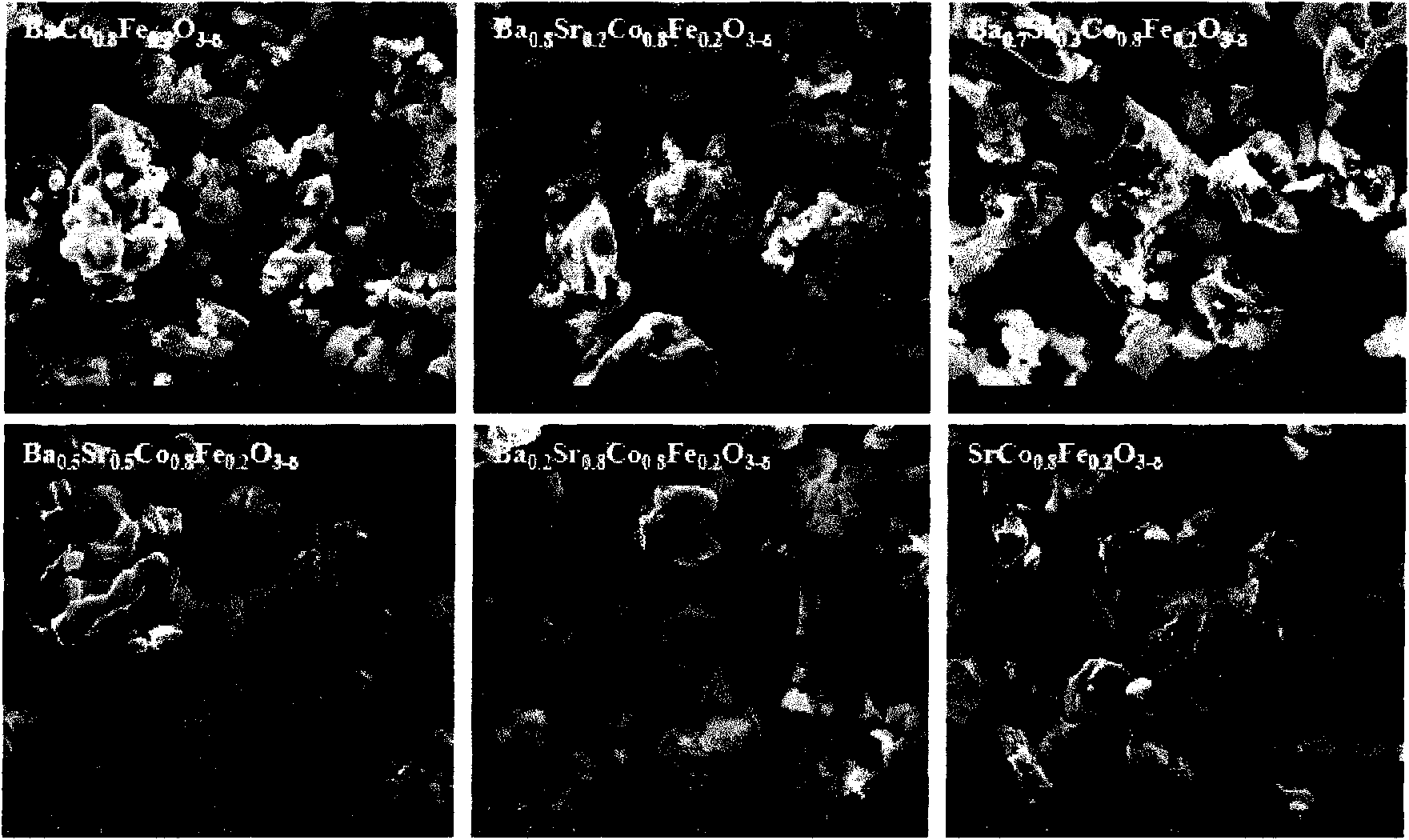

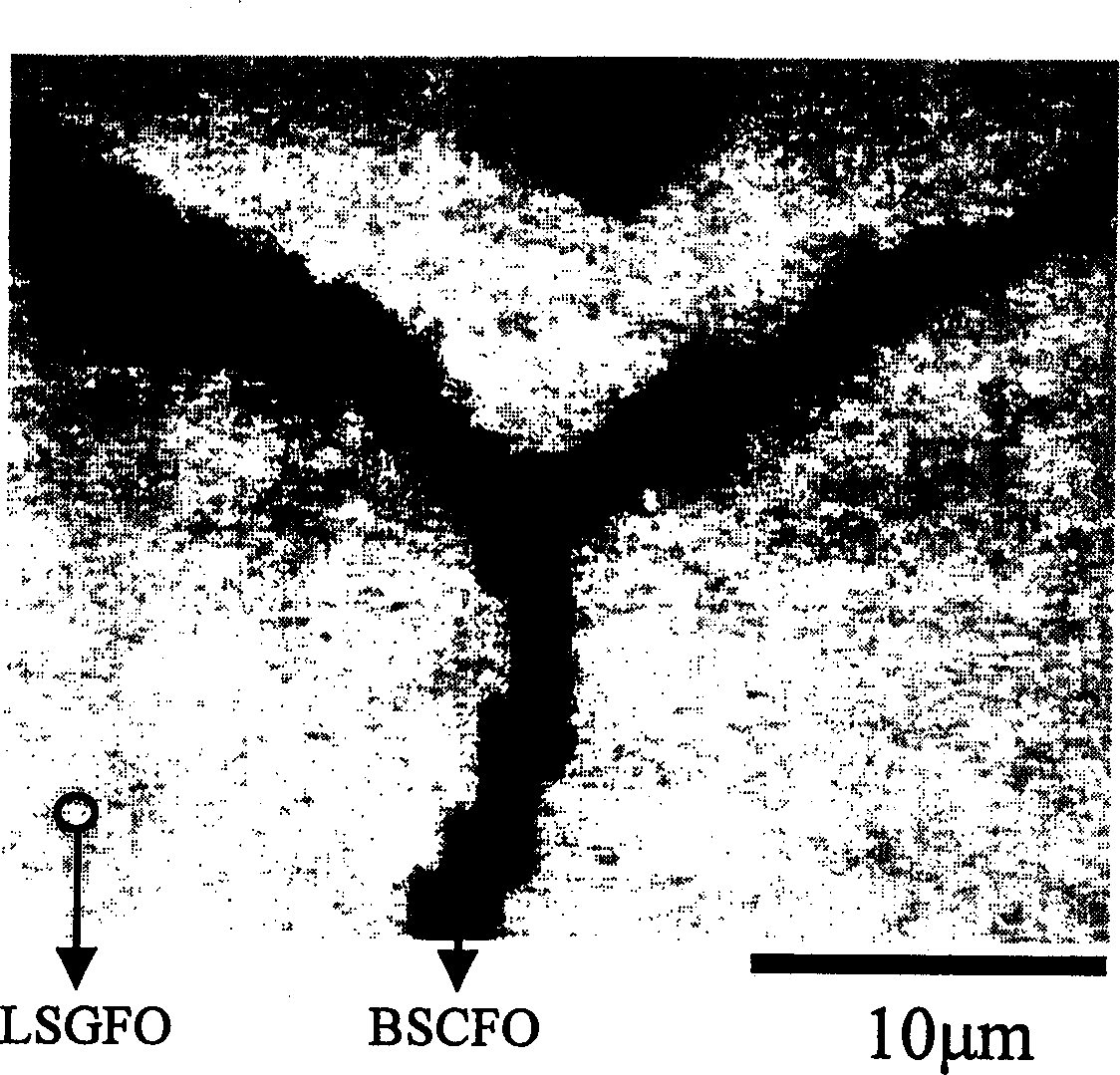

The invention relates to a novel oxygen ion, proton and electron mixed conductor solid oxide fuel cell cathode material. The composition molecular formula of the cathode material is Sr2Sc0.1Nb0.1Co1.5Fe0.3O<6-delta> (SSNCF), wherein [delta] represents the content of oxygen vacancies, and the invention belongs to the field of solid oxide fuel cell cathode materials. The cathode material also has excellent proton conductivity under the condition that the cathode material has certain oxygen ion and electron conductivity. The cathode material has proton, oxygen ion and electron mixed conductivity,so that the SSNCF has excellent electrochemical performance on a proton conductor, and correspondingly, the maximum output power at 650 DEG C is up to 840 mW.cm<-2>. Meanwhile, through a hydrogen permeation method, the hydrogen permeation performances of the two materials (SSNCF and Ba0.5Sr0.5Co0.8Fe0.2O<3-delta> (BSCF)) are compared by using an experimental method, the proton conductivity of thetwo materials is compared, and the proton conductivity of the two materials is estimated.

Owner:NANJING UNIV OF TECH

Deoxidant body

The present invention relates to one kind of deoxidant body. The deoxidant body includes a casing with opening, an opening plug and stuffing inside the casing. The casing consists of mixed conductor of stable zirconia mixture 80-85 wt% and high temperature resisting metal 15-20 wt%, the said stable zirconia mixture consists of zirconia 92-98 wt% and magnesia and / or yttrium oxide 2-8 wt%; and the high temperature resisting metal is metal Mo or metal Ni. The casing of the deoxidant body has concurrent oxygen ion conduction and electronic conduction of the mixed conductor as well as excellent thermal vibration resisting performance without burst during deoxidation and pollution.

Owner:BAOSHAN IRON & STEEL CO LTD

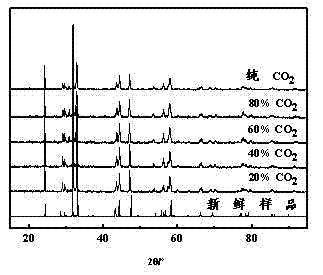

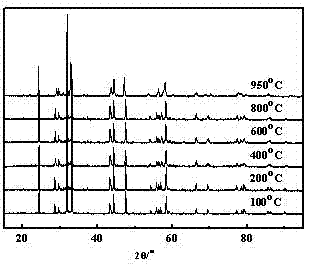

Anti-CO2 mixed conductor oxygen permeable membrane, preparation method and application thereof

InactiveCN102775134AImprove anti-CO

<sub>2</sub>

performanceOvercome the disadvantages of easy lossMixed conductorPyrolysis

The invention discloses an anti-CO2 mixed conductor oxygen permeable membrane, a preparation method and application of the anti-CO2 mixed conductor oxygen permeable membrane. The chemical formula is A2BO4+delta, wherein delta is oxygen nonstoichiometry, A is one or more of La, Ce, Pr, Nd, Pm, and Sm, B is one or more of Mn, Ni, Cu, Zn, Ga, Al, Fe, Mg, and In. The preparation method is as follow: dissolving nitrate or acetate solution of each metal element in polyfunctional organic acid, calcining and grinding the pre-powder obtained by pyrolysis to obtain powder, performing compression molding on the powder, and sintering the powder to obtain the mixed conductor oxygen permeable membrane. The mixed conductor oxygen permeable membrane obtained by the invention has high oxygen permeation flux and good anti-CO2 performance, overcomes the defects of pyrolysis of a traditional perovskite material in the CO2 atmosphere, and can be used for selectively separating oxygen from an oxygen-containing mixer and catalysis reaction, and also can be used for producing electrodes of low temperature solid oxide fuel cells and solid electrochemical sensors.

Owner:SOUTH CHINA UNIV OF TECH

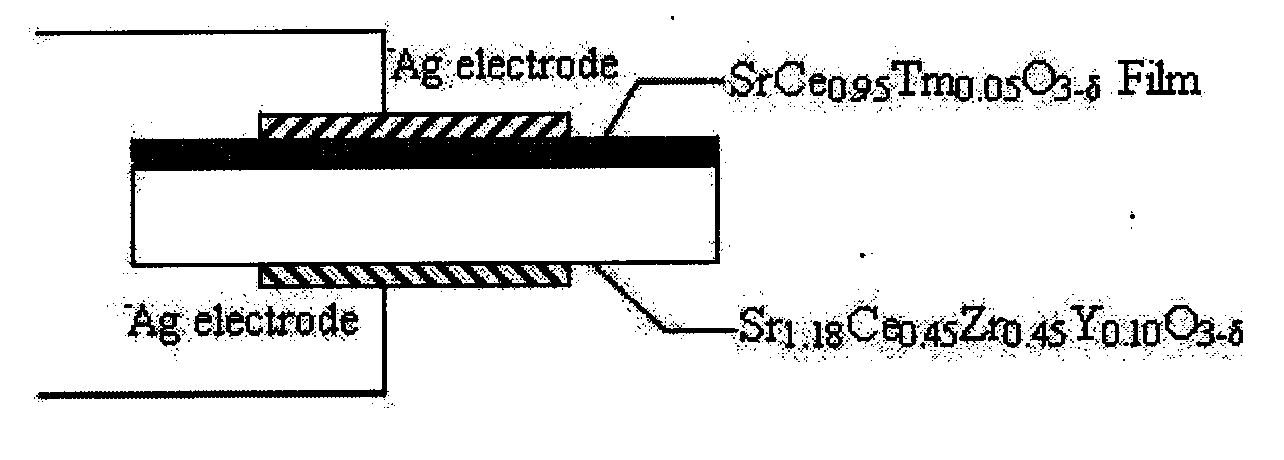

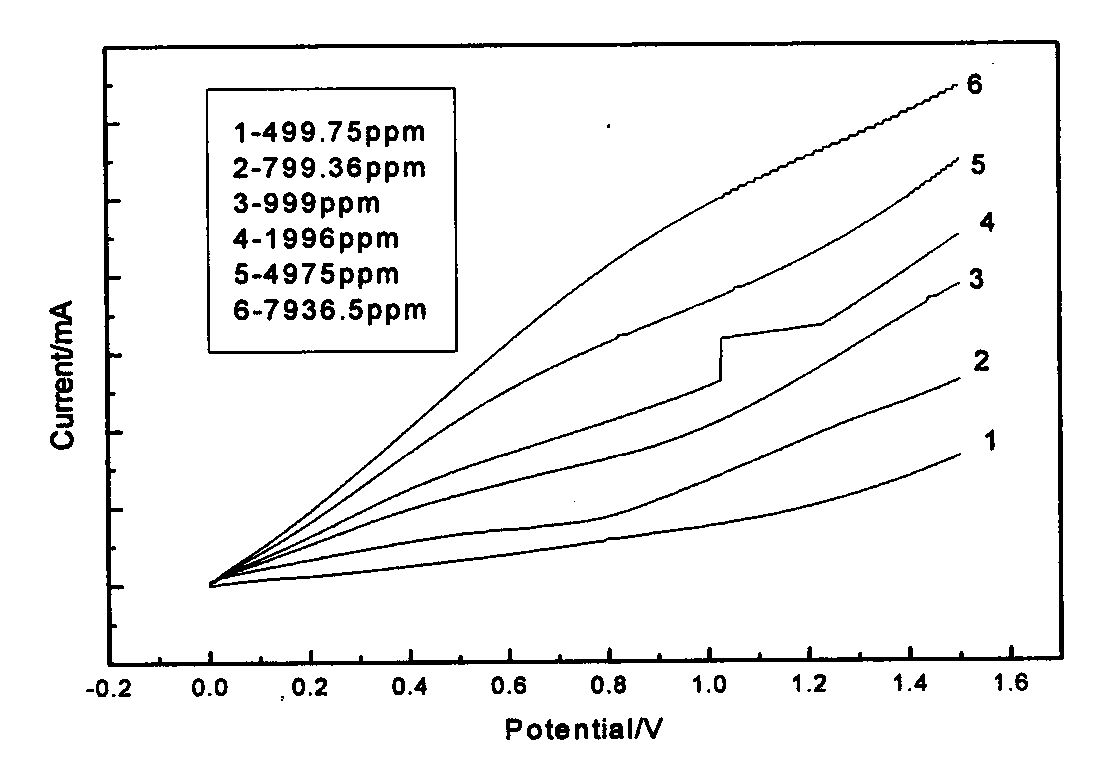

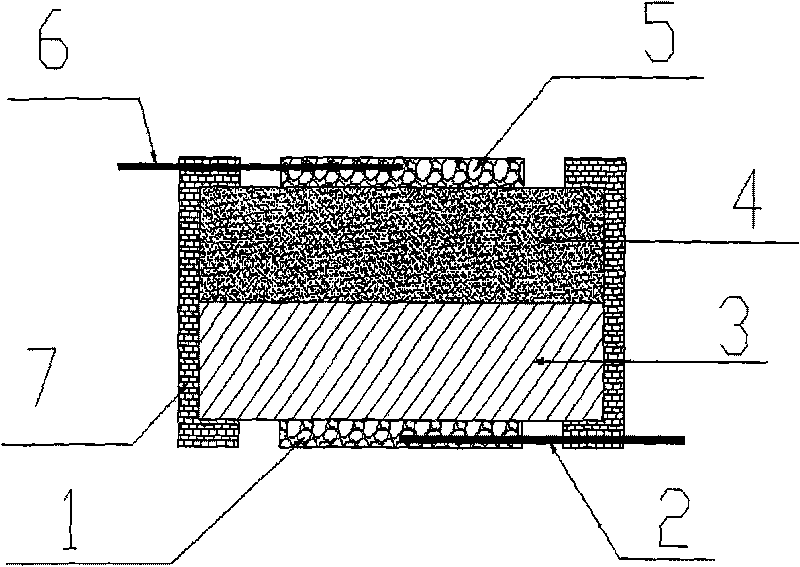

Thick-film type limited current hydrogen sensor and preparation method thereof

InactiveCN101625335AImprove work performanceAvoid sizeMaterial analysis by electric/magnetic meansElectrochemical gas sensorElectrical conductor

The invention relates to a thick-film type limited current hydrogen sensor and a preparation method thereof, belonging to the technical field of electrochemical gas sensors. The sensor consists of dense proton conductor slices and dense proton / electron mixed thick conductor films or dense proton / electron mixed conductor slices and dense thick conductor films. The composition of the proton conductor slices is AB(1-x)RxO(3-delta)(x is more than or equal to 0 and less than or euqal to 0.3), wherein A is Ca, Sr or Ba; B is one or more of Ce, Zr, Nb and Ti; and R is one or more of Sc, Y, La, Pr, Nd, Dy, Ho, Er, Lu, Gd and In. The composition of the proton / electron mixed conductor slices is AB(1-x)R'xO(3-delta) (x is more than or equal to 0 and less than or euqal to 0.3), wherein A is Ca, Sr or Ba; B is one or more of Ce, Zr, Nb and Ti; and R' is one or more of Sm, Eu, Tb, Yb, Tm, Mn and Ti. The preparation method of the sensor comprises the following steps: preparing two kinds of conductor powder; preparing the dense proton conductors and the dense proton / electron mixed conductor slices; preparing thick films by a screen print technology; and assembling the sensor. The sensor is suitable for the detection of hydrogen in gas.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing mixed conductor dense diffusion barrier-type oxygen sensor

InactiveCN101718743AFine grainImprove bindingMaterial electrochemical variablesMixed conductorElectrolyte

The invention provides a method for preparing a mixed conductor dense diffusion barrier-type oxygen sensor. The prepared oxygen sensor comprises an electrolyte layer, a dense diffusion barrier layer, an encapsulation layer, porous positive and negative collectors and the like. The electrolyte layer is made of a zirconia material; the dense diffusion barrier layer is made of a mixed conductor material consisting of zirconia and La1-xSrxMnO3; the encapsulation layer is made of glass glaze; the electrolyte layer and the dense diffusion barrier layer are formed by direct sintering through spark plasma sintering technology; porous positive and negative collector layers are formed by directly printing the positive and negative collectors on upper and lower surfaces of a composite material through screen printing and sintering the printed positive and negative collectors; and the encapsulation layer is coated at the edge of composite multi-layer ceramic. Due to the adoption of the spark plasma sintering technology, the prepared sensor solves the problems of turn-up, cracking and the like, has the characteristics of good repeatability, stable performance, simple preparation process, shortpreparation period, small volume, quick response and the like, and is suitable for the detection of wide oxygen concentration.

Owner:NINGBO UNIV

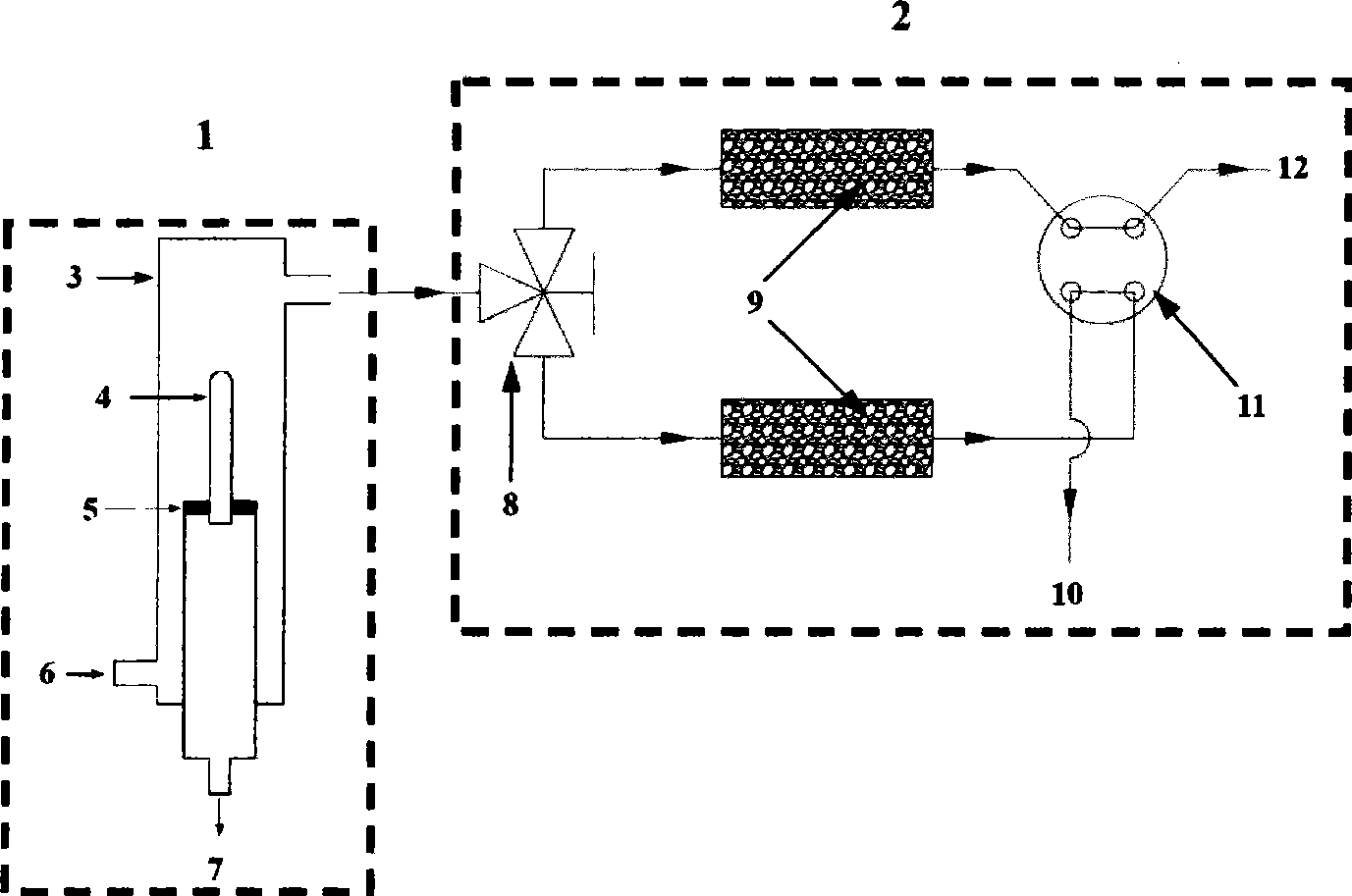

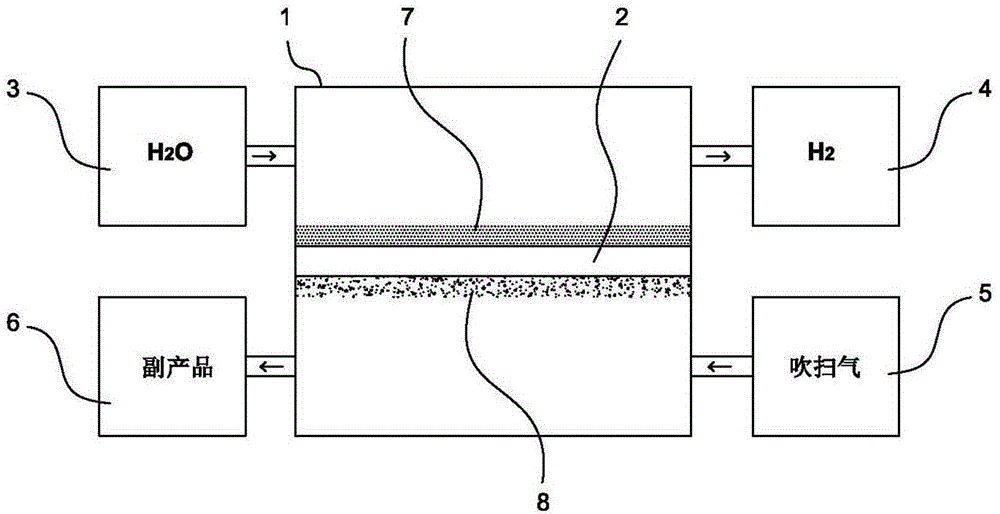

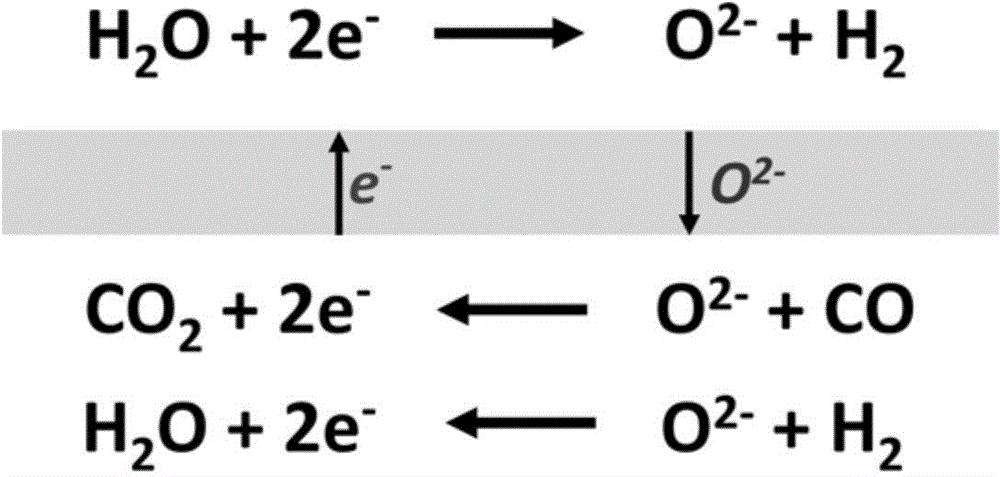

A system for preparing high-purity hydrogen and a method therefor

InactiveCN105692549ANo hydrogen embrittlementImprove stabilityHydrogen productionElectrical conductorWater vapor

A system for preparing high-purity hydrogen and a method therefor are provided. The system comprises a membrane reactor, an oxygen permeable membrane sealed in the membrane reactor, a catalyst moduleI disposed at one side of the oxygen permeable membrane, a catalyst module II disposed at the other side of the oxygen permeable membrane, a gas feeding device I used for feeding raw material gas intoone side of the oxygen permeable membrane, a gas feeding device II used for feeding purge gas to the opposite side of the oxygen permeable membrane, water vapor adopted as the raw material gas and low-purity hydrogen adopted as the purge gas. The method includes separating a raw material that is the low-purity hydrogen in the mixed-conductor oxygen permeable membrane reactor to obtain the high-purity hydrogen. The hydrogen separation rate and purity of the hydrogen prepared by the method are comparable with those of a palladium membrane. A membrane material used in the method is easily prepared and low in cost, and is hoped to replace the expensive palladium membrane to prepare the high-purity hydrogen.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

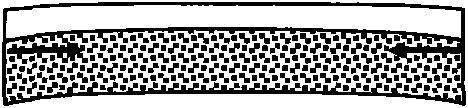

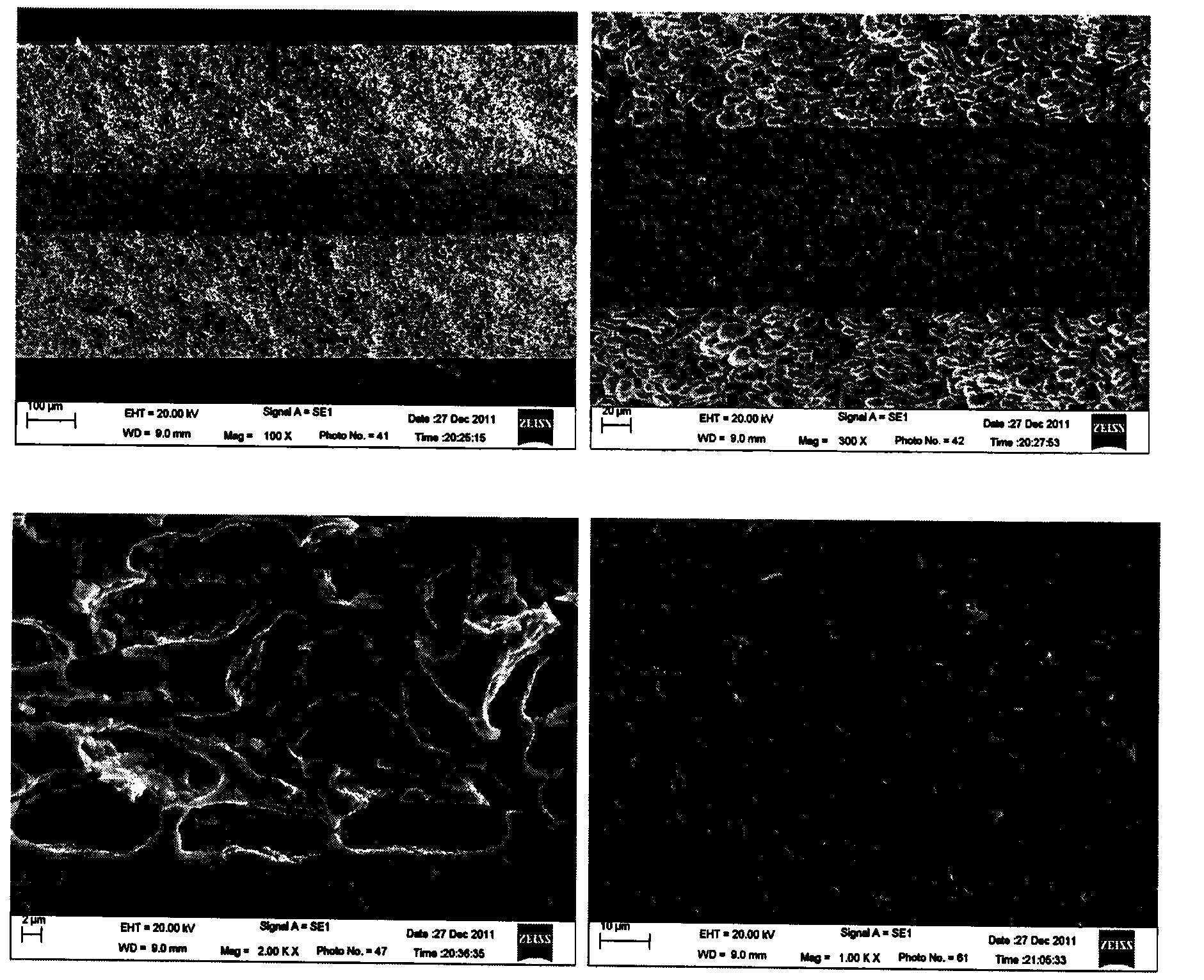

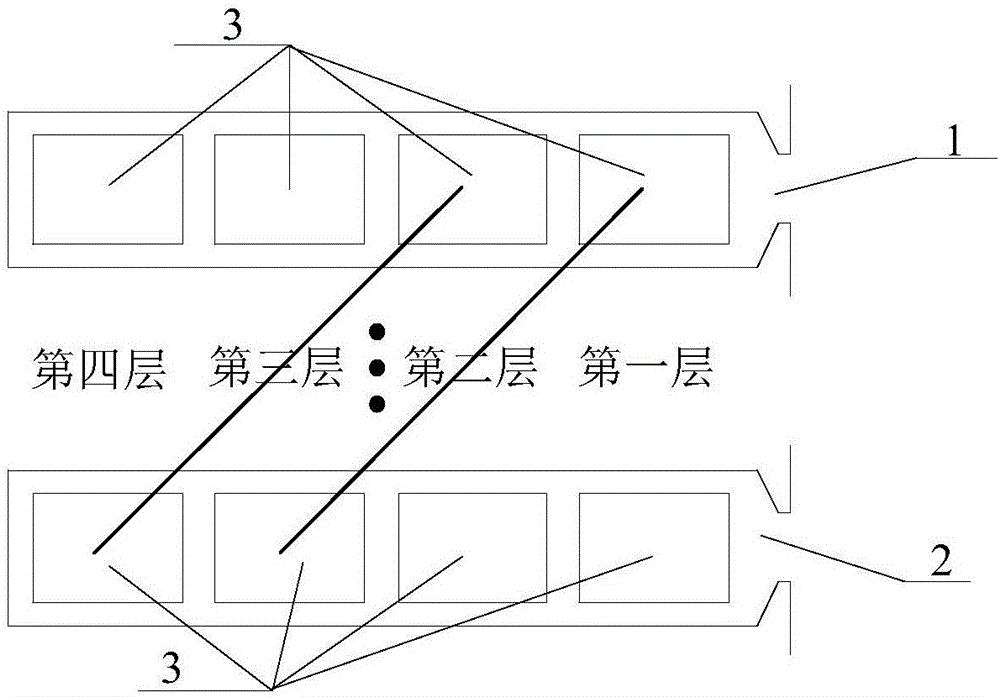

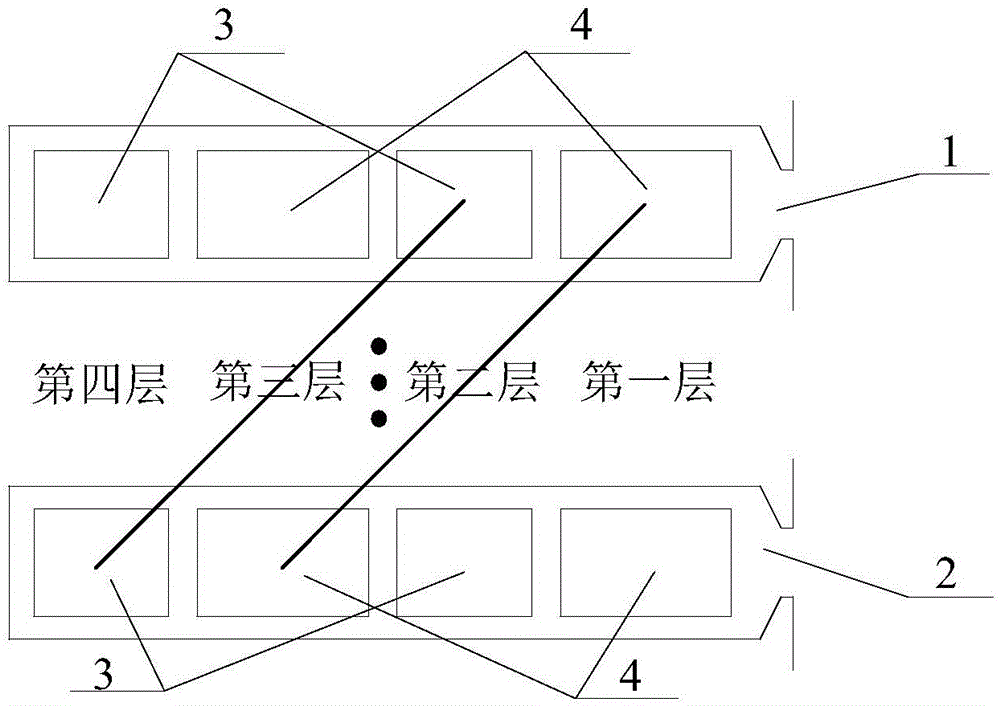

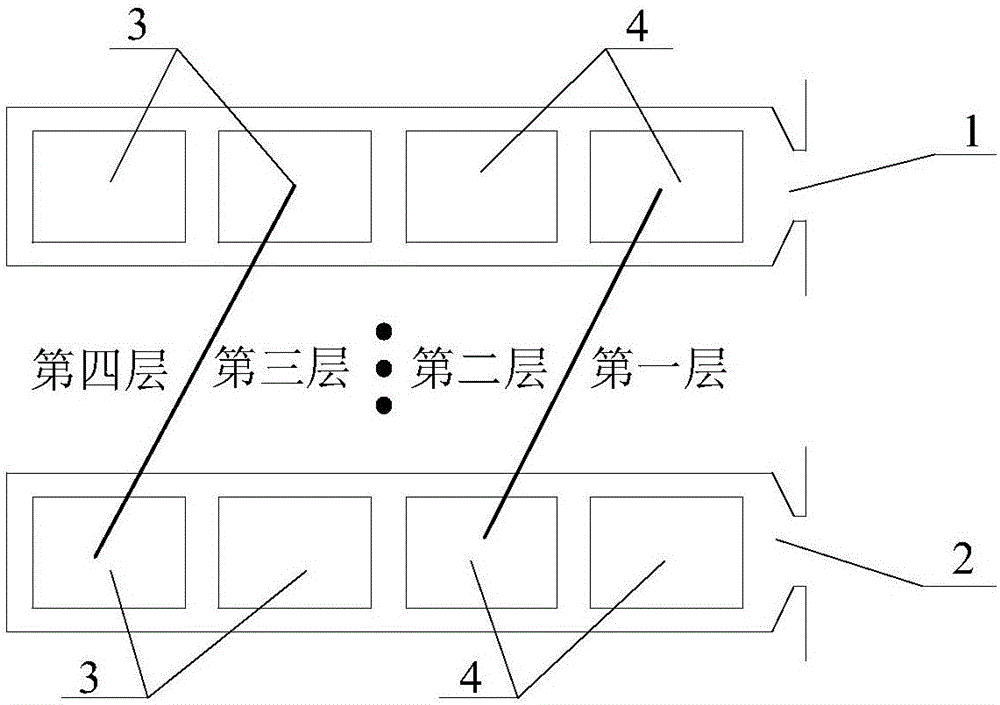

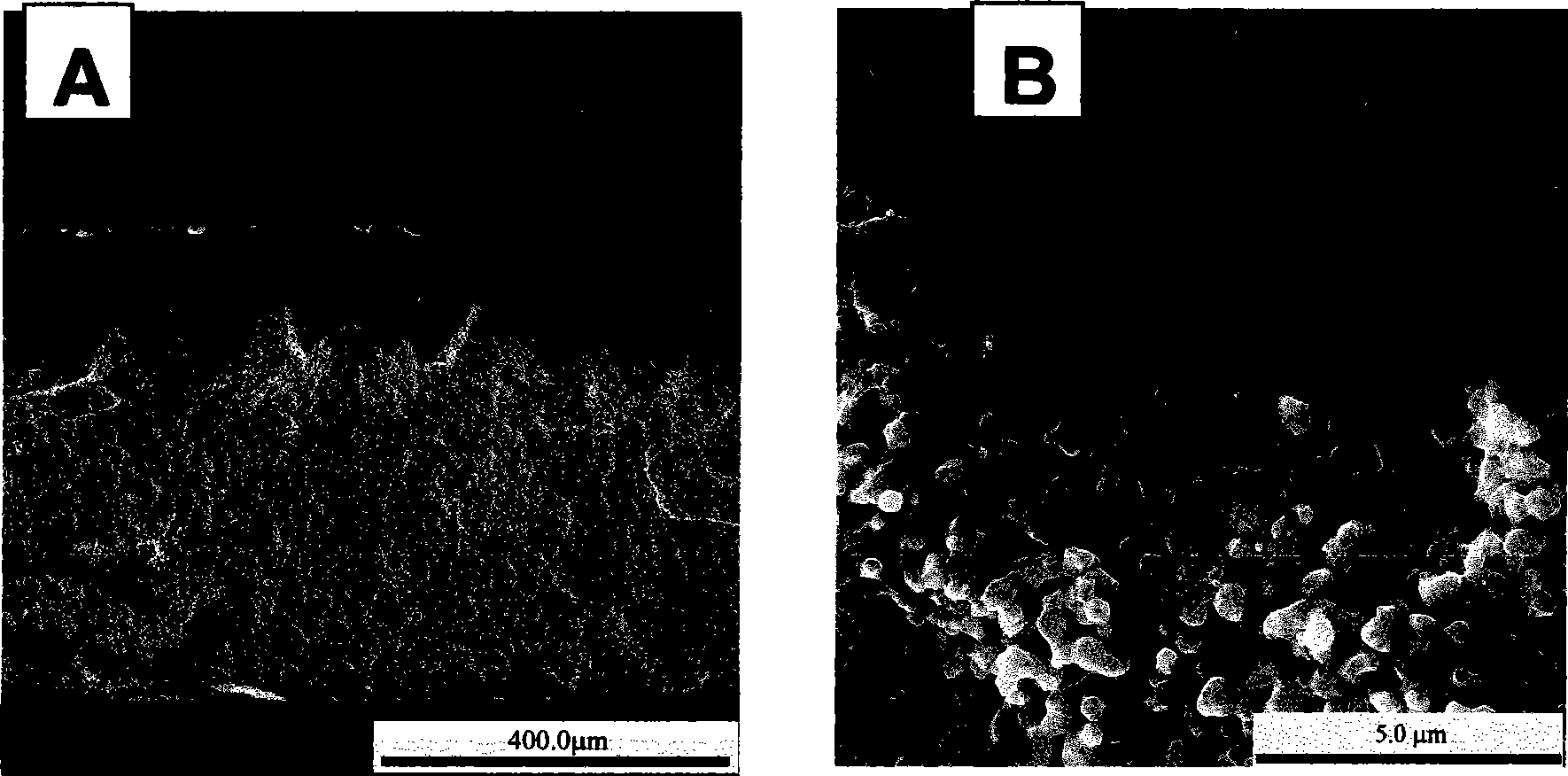

Preparation method and application of integrated three-layer structural inorganic oxygen permeating membrane

The invention provides a preparation method and an application of an integrated three-layer structural inorganic oxygen permeating membrane. The preparation method comprises the steps of (1) preparing a mixed conductor oxygen permeating material by adopting a traditional solid-phase synthesis method; (2) mixing the oxygen permeating material powder with binder, plasticizer and solvent to prepare casting slurry; (3) respectively preparing compact layer green bodies and porous layer green bodies of the mixed conductor oxygen permeating membrane through a casting method; (4) stacking the green bodies together according to a sequence of porous layer, compact layer and porous layer, and pressing the stacked green bodies in a constant-temperature static pressing machine with temperature of 80DEG C to prepare an integrated three-layer structural oxygen permeating membrane precursor; (5) sintering the three-layer structural inorganic oxygen permeating membrane precursor to obtain the integrated three-layer structural inorganic oxygen permeating membrane. The integrated three-layer structural oxygen permeating membrane can be used for high-efficiently and selectively separating the high-purity oxygen from the oxygen-containing mixed air.

Owner:TIANJIN POLYTECHNIC UNIV

Hybrid conductor winding structure and motor with same and application of hybrid conductor winding structure

InactiveCN106787335AReduce DC copper consumptionSuppresses AC lossElectric machinesWindings conductor shape/form/constructionElectrical conductorLow speed

The invention discloses a hybrid conductor winding structure, which comprises low-resistivity conductors, high-resistivity conductors and an end part connection ring, wherein the low-resistivity conductors and the high-resistivity conductors are bent into a hairpin form separately and then inserted or embedded into stator slots (1 and 2), wherein the low-resistivity conductors are arranged in notches of the stator slots (1 and 2) and the high-resistivity conductors are arranged at the bottoms of the stator slots (1 and 2); and the end part connection ring is used for achieving fixed connection of the end parts of the low-resistivity conductors and the high-resistivity conductors, thereby forming the hybrid conductor winding structure. The invention further discloses a motor with the winding structure. The invention further discloses an electric automobile with the motor. AC losses of conductors in the notches when the motor runs at a high speed can be effectively reduced, the local temperature rise of the conductors in the notches is reduced, the problem of a high DC loss when the motor runs at a low speed is taken into account and the operating efficiency of the motor is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

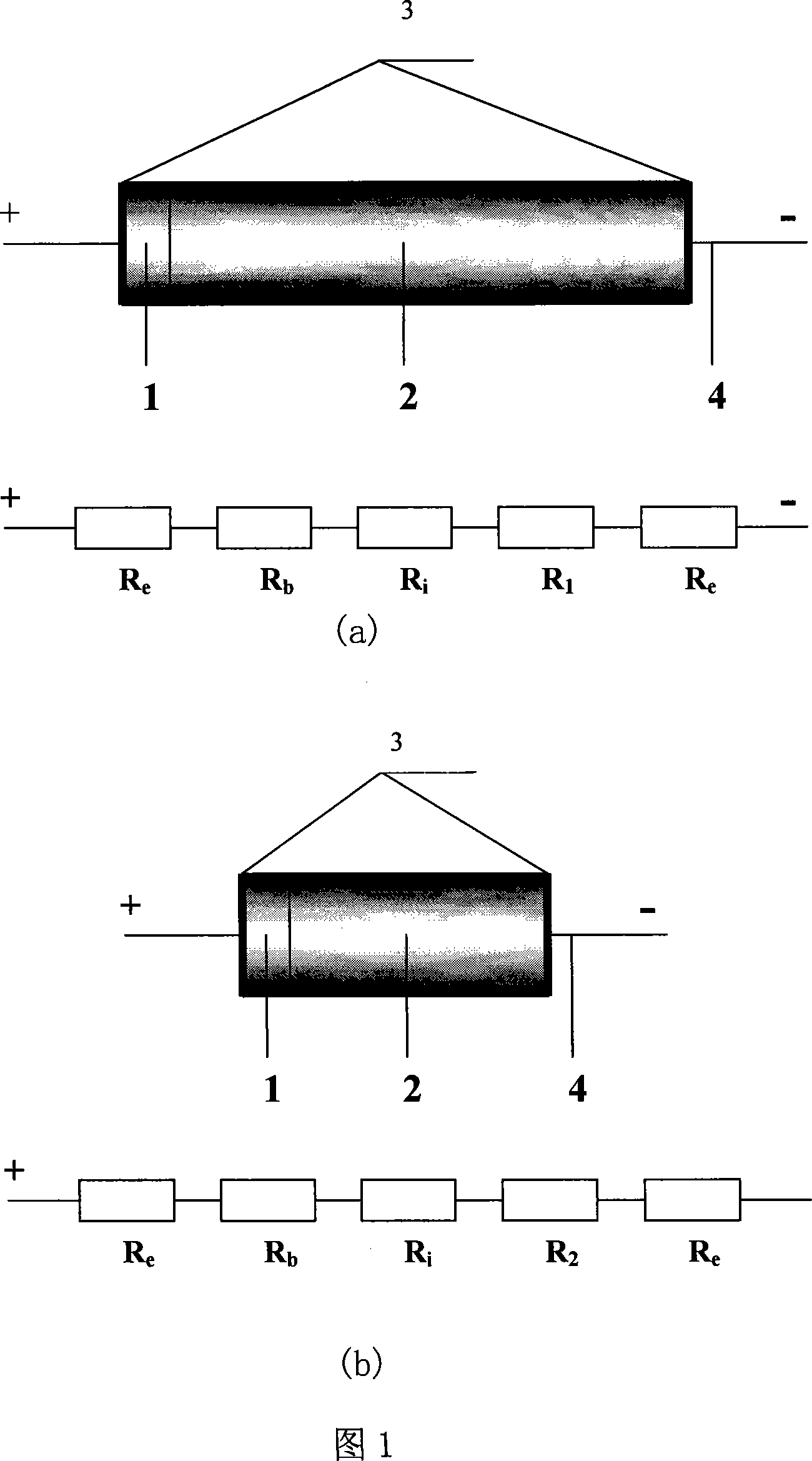

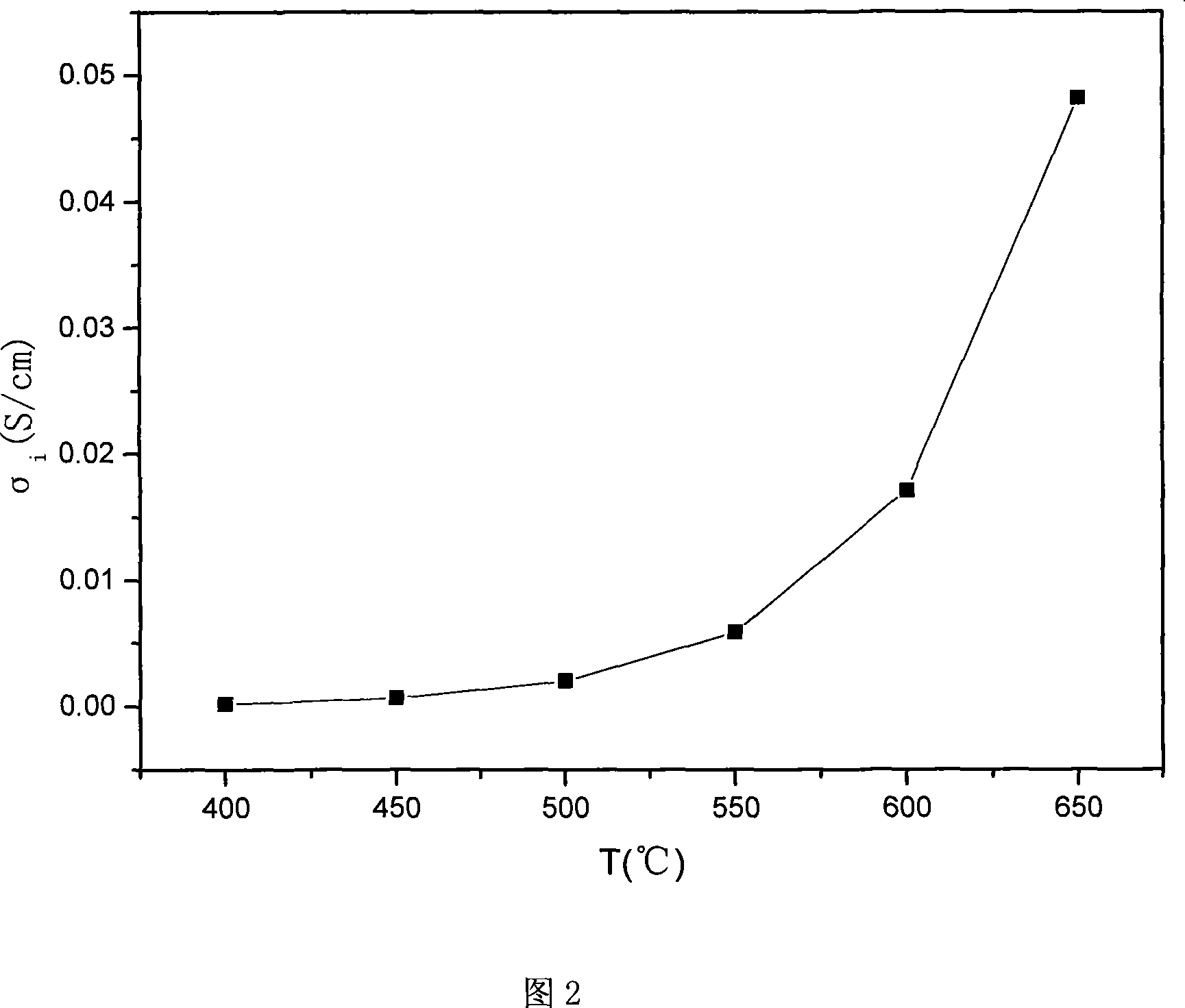

Oxygen ion-electron mixed conductor ion electric conductivity measuring method

InactiveCN101101271ASimple structureAvoid errorsMaterial impedanceSpecial data processing applicationsElectrical resistance and conductanceElectrical conductor

The invention relates to measuring method of the oxyanion hyphen electron mixed conductor material ionic conductivity. The mixed conductor is a ceramic material which has oxyanion and electron conduction power. The characteristics of measuring method is that it calculates and gets the ionic conductivity resulting the changes of resistance with the change of needed detection mixed conductor sample geometry after the electron block; because the tangent condition has not any changed before and after of mixed conductor block electrode, not considering the interfacial resistance, block electrode resistance and Pt electrode resistance, avoiding the error from this. The calculating formula of mixed conductor ionic conductivity is sigma i= (L1-L2) / [S*(R-R')].The measuring method of this invention is simply and convenience, the structure of measuring battery is simplify, reducing the factors of importing error.

Owner:SHANGHAI UNIV

Method for preparing unsymmetrical biphase composite oxygen permeable membrane

ActiveCN101450861AExcellent oxygen permeabilityGood chemical stabilityVoid ratioElectrical conductor

The invention provides a method for preparing an asymmetrical two-phase composite oxygen permeation membrane, which comprises the following processes: performing grinding, leveling, supersonic cleaning and drying on a two-phase composite oxygen permeation membrane which consists of an oxygen ion conductor and an oxygen ion-electron mixed conductor; protecting one surface of the oxygen permeation membrane, making the other surface of the oxygen permeation membrane exposed and placing the other surface of the oxygen permeation membrane into 1.0 to 50 percent of acid solution for soakage, wherein the soaking temperature is between 10 and 80 DEG C, and the soaking time is between 10 and 360 hours; and forming the asymmetrical two-phase composite oxygen permeation membrane. A porous carrier of the prepared asymmetrical two-phase composite oxygen permeation membrane has high voidage and centralized pore size distribution, and a porous carrier layer and an oxygen permeation membrane layer can be well fused and not separated. The asymmetrical two-phase composite oxygen permeation membrane has high oxygen permeability, and has high chemical stability and structural stability under reducing atmosphere. An asymmetrical composite oxygen permeation ceramic membrane prepared can be used for selecting and separating oxygen from oxygen-containing gas mixture and for converting natural gas into synthetic gas in a membrane reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Two-phase mixed conductor oxygen-breathable film

InactiveCN1465429AAvoid breakingReduce manufacturing costSemi-permeable membranesElectrical conductorOxygen ions

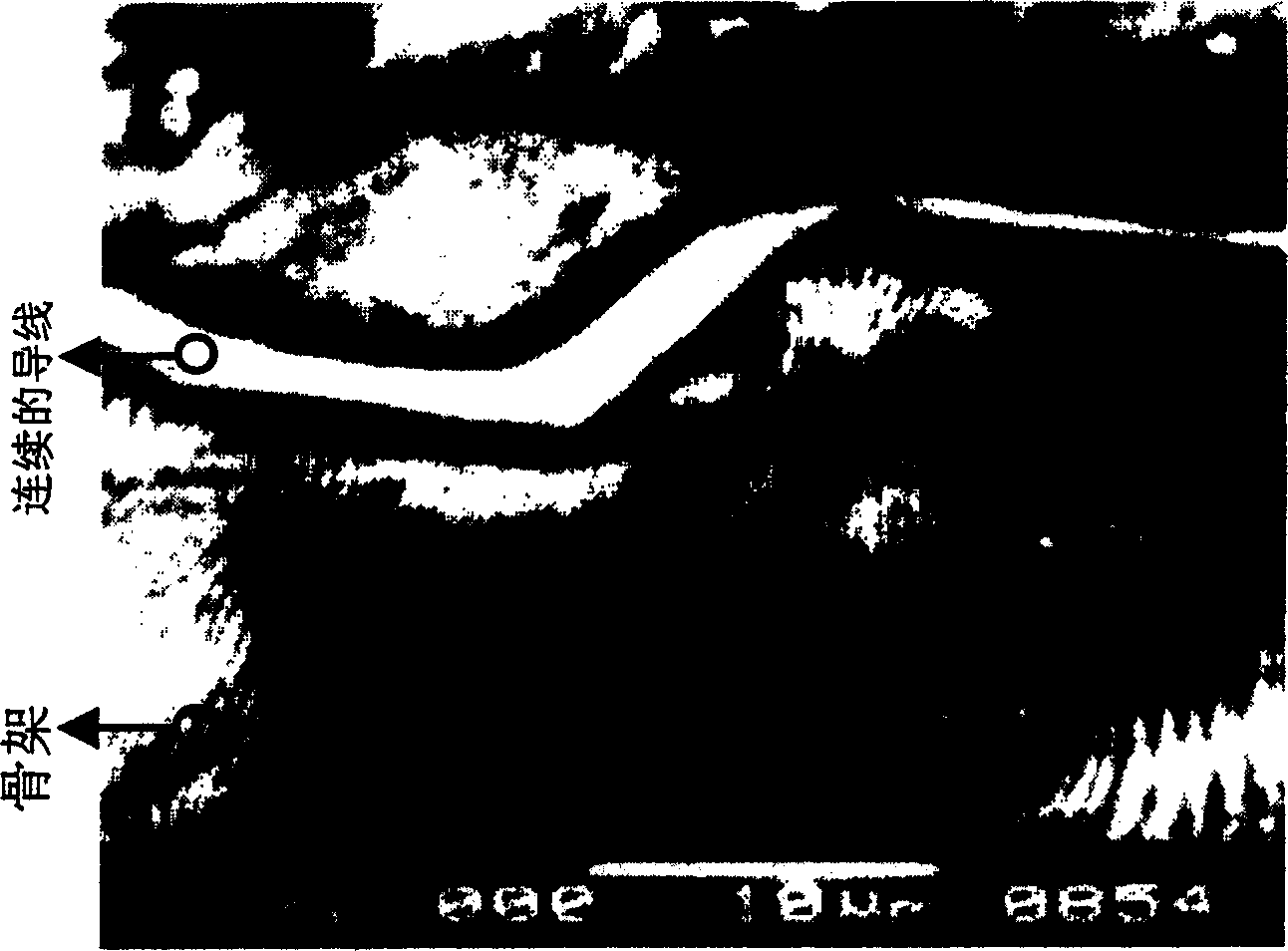

The present invention relates to a two-phase mixed conductor oxygen-permeating membrane, formed from oxygen ion conductive phase and electronic conductive phase. The described oxygen ion conductive phase and electronic conductive phase are made of perovskite, finally the two-phase mixed conductor oxygen-mermeating membrane with simple perovskite structure can be formed, in whch the oxygen ion conductive phase is formed into its skeleton, and the electronic conductive phase as a continuous conductor wire is passed through the skeleton. Said invention provides the molecular formula of the perovskite, and the application of said oxygen-pemeating membrane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-performance oxygen adsorbent and preparation method thereof

InactiveCN104857911AOther chemical processesDispersed particle separationElectrical conductorDesorption

The invention relates to a high-performance oxygen adsorbent and a preparation method thereof, wherein the oxygen adsorbent material is a mixed conductor ceramic material having oxygen selectivity, and provides extremely high oxygen selectivity by using lattice oxygen vacancy to carry out chemical adsorption and desorption on oxygen when the temperature is increased or decreased. The production method comprises: uniformly mixing raw materials according to a ratio, calcining for a certain time at a high temperature to prepare large-particle oxide powder, and carrying out double ball milling to refine the particles so as to prepare the multi-metal composite oxide powder. The novel oxygen adsorbent of the present invention can be used for temperature changing oxygen adsorbing and has high oxygen adsorption.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com