Thick-film type limited current hydrogen sensor and preparation method thereof

A limiting current and sensor technology, applied in the direction of instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve problems such as affecting promotion and application, unstable sealing of reference electrodes, etc., to avoid dimensional changes and blockages, improve work performance, ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

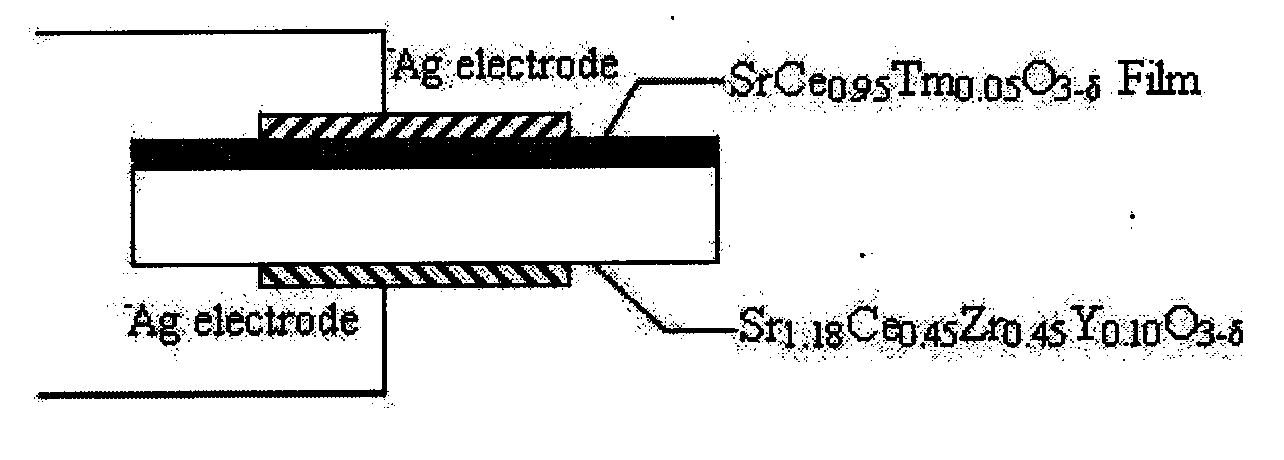

[0026] Press Sr 1.18 Ce 0.45 Zr 0.45 Y 0.10 o 3-δ and SrCe 0.95 T m 0.05 o 3-δ Weigh the corresponding reagents according to the stoichiometric ratio, and mix the raw materials, ZrO 2 Balls and absolute ethanol were mixed according to the mass ratio of 1:2:0.5, then put into a polytetrafluoroethylene ball mill jar, milled for 10 hours, and the ground slurry was naturally dried and then put into a resistance furnace. Pre-burn at ℃ for 10 hours, and then set aside after cooling down to room temperature.

[0027] SrCe 0.95 T m 0.05 o 3-δ Preparation of slurry. SrCe pre-fired at 1300°C 0.95 T m 0.05 o 3-δ The powder was mixed with terpineol containing 6%wt ethyl cellulose at a ratio of 45:55, added an appropriate amount of absolute ethanol and ball-milled on a ball mill for 3 hours, and then put into a sealed jar for later use.

[0028] Weigh about 1g of proton conductor Sr pre-fired at 1300°C 1.18 Ce 0.45 Zr 0.45 Y 0.10 o 3-δ Powder, pressed into a circle at 1...

Embodiment 2

[0032] Press Sr 1.18 Ce 0.45 Zr 0.45 Y 0.10 o 3-δ and SrCe 0.95 T m 0.05 o 3-δ Weigh the corresponding reagents according to the stoichiometric ratio, and mix the raw materials, ZrO 2 Balls and absolute ethanol were mixed according to the mass ratio of 1:2:0.5, then put into a polytetrafluoroethylene ball mill jar, milled for 10 hours, and the ground slurry was naturally dried and then put into a resistance furnace. Pre-burn at ℃ for 10 hours, and then set aside after cooling down to room temperature.

[0033] Sr 1.18 Ce 0.45 Zr 0.45 Y 0.10 o 3-δ Preparation of slurry. Precalcined Sr at 1300°C 1.18 Ce 0.45 Zr 0.45 Y 0.10 o 3-δ After the powder was mixed with terpineol containing 6%wt ethyl cellulose at a ratio of 45:55, an appropriate amount of absolute ethanol was added and ball milled on a ball mill for 3 hours, and then put into a sealed jar for later use.

[0034] Weigh about 1g of mixed conductor SrCe pre-fired at 1300°C 0.95 T m 0.05 o 3-δ Powder, p...

Embodiment 3

[0038] With the above-mentioned proton conductor BaCe 0.90 Y 0.10 o 3-δ The sheet is used as the substrate, and the surface is coated with mixed conductor SrCe by screen printing technology. 0.95 T m 0.05 o 3-δ The uniform film was dried in a vacuum oven at 105°C for 5 minutes to evaporate the solvent. Then apply a new layer of film and re-dry, and repeat this process. After repeating 10 times, take out the substrate and sinter at 1550°C for 6h. Polish both sides of the wafer clean, coat with silver paste, and bake at 800°C for 1h. A limiting current hydrogen sensor with a dense diffusion barrier layer was prepared.

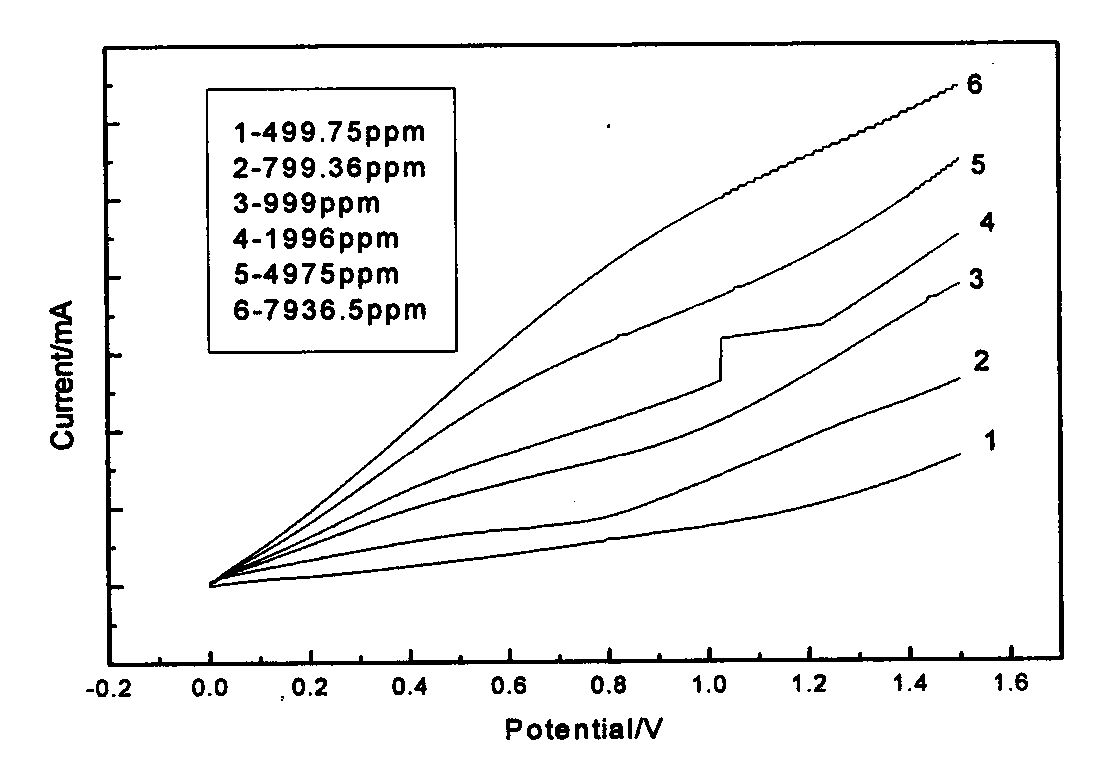

[0039] The performance test of the hydrogen sensor at 750°C shows that at a voltage of 0.8V, the hydrogen concentration has a linear relationship with the limiting current (see Figure 7 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com