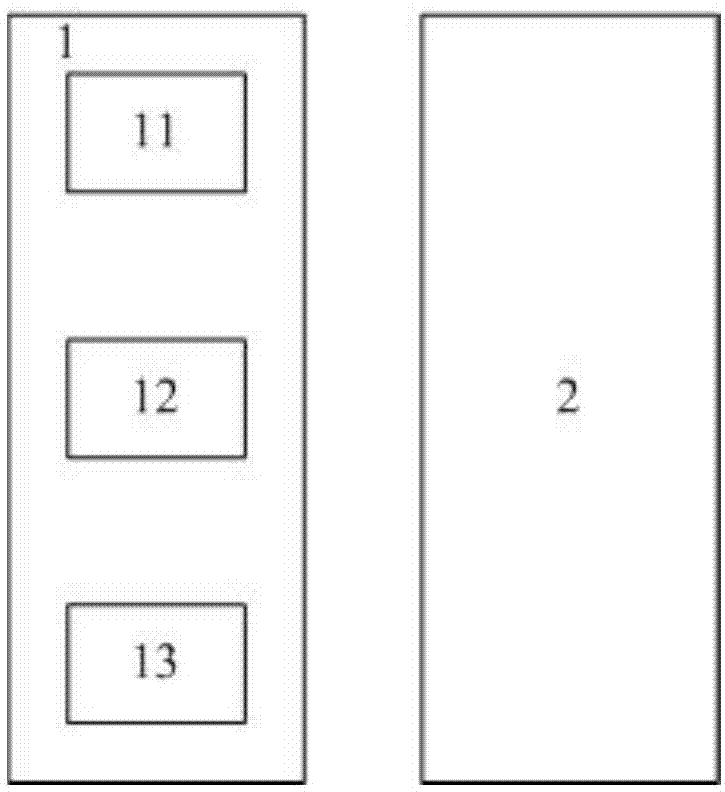

Patents

Literature

104results about How to "Avoid problems such as clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

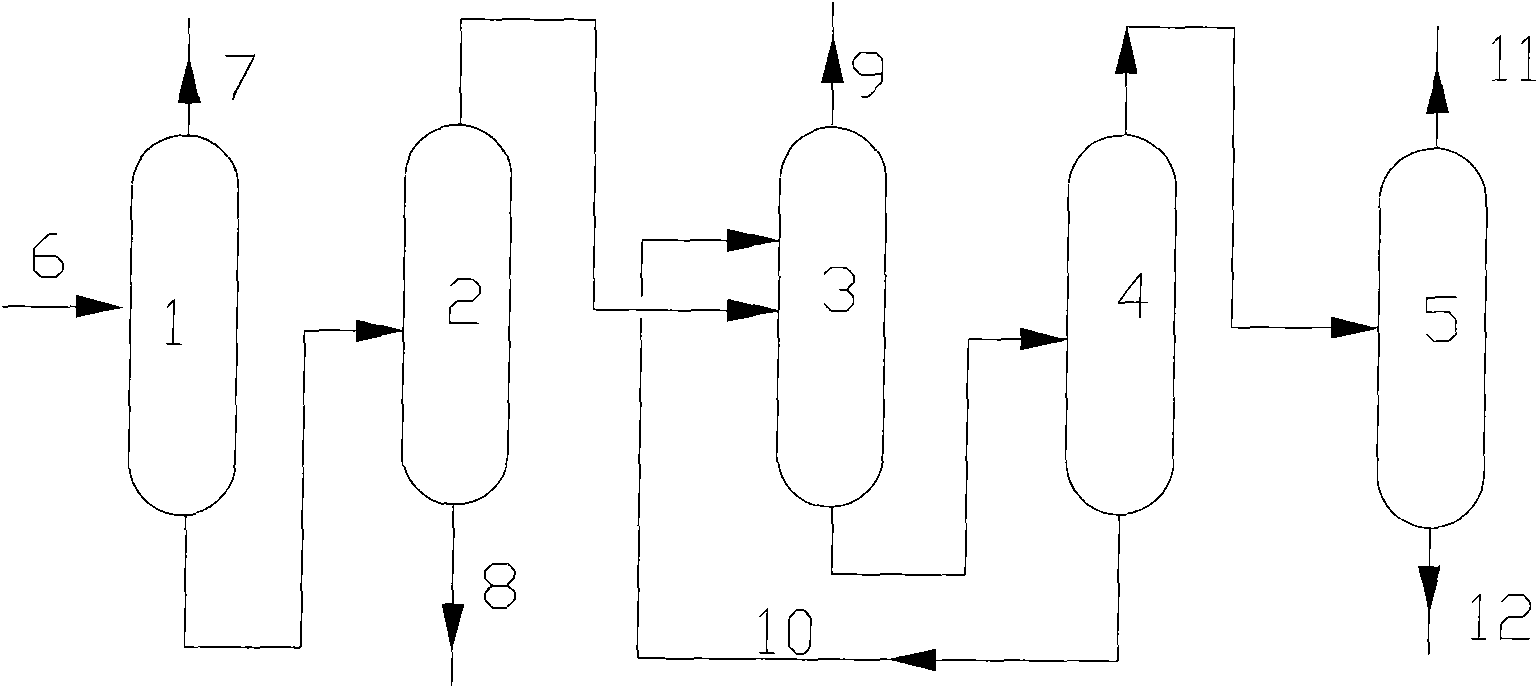

Method for hydrotreating high-sulfur and high-metal residual oil

ActiveCN101519603AHigh porosityReduced inactivation rateRefining to eliminate hetero atomsNaphthaHydrogen

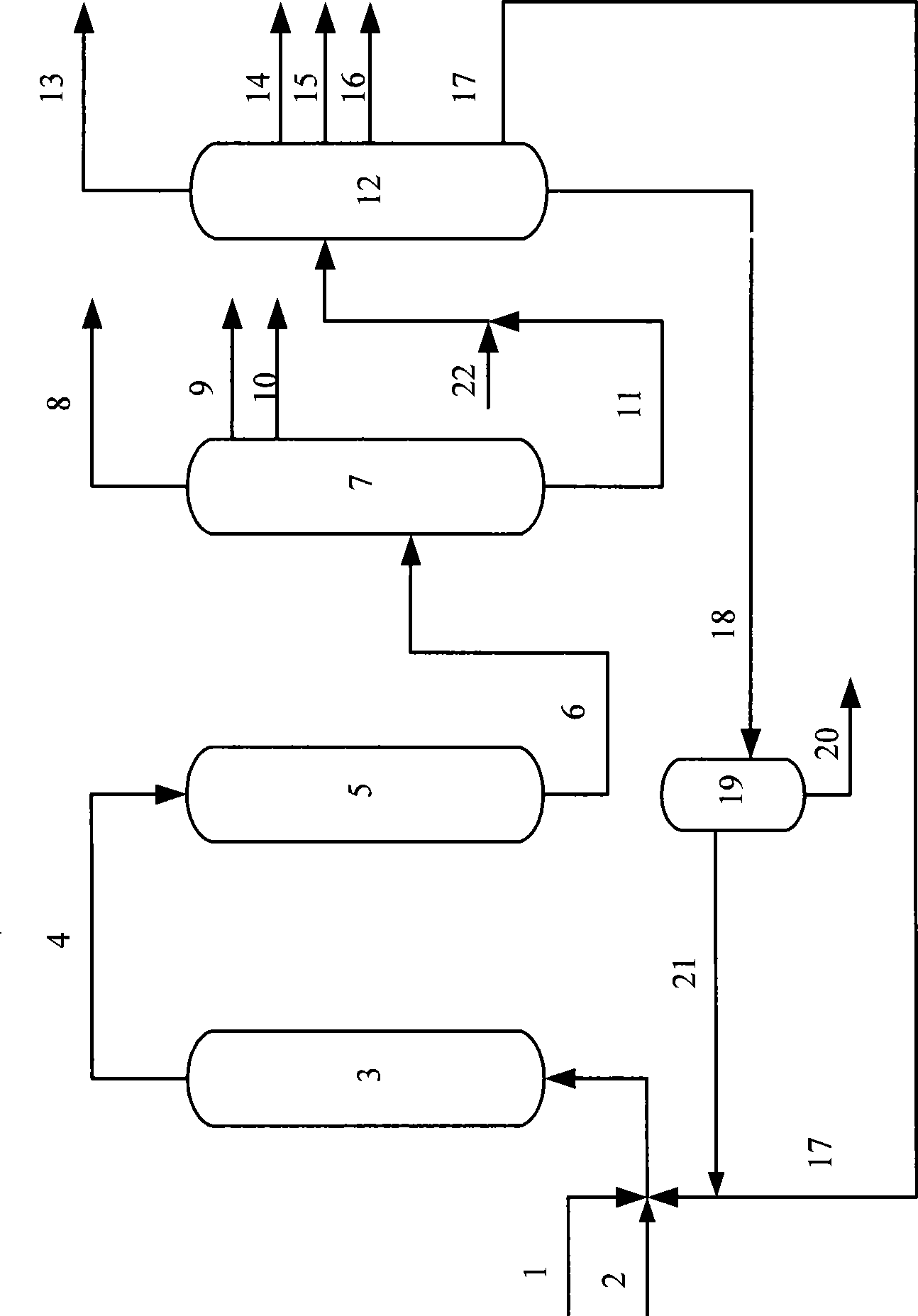

The invention provides a method for hydrotreating high-sulfur and high-metal residual oil, which comprises the following steps: the residual oil and catalytic cracking recycle oil are in contact with a residual oil hydrogenation catalyst in the presence of hydrogen gas and under the hydrotreating reaction condition so as to carry out a hydrotreating reaction; the reaction product is separated to obtain gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil. The residual oil hydrogenation catalyst is a combination of at least two catalysts, namely, an up-flow reactor catalyst and a fixed-bed hydrogenation catalyst and the two catalysts are respectively put in an up-flow reactor and a fixed-bed reactor; the ratio of the up-flow reactor catalyst and the fixed-bed hydrogenation catalyst is 30:70 to 70:30. The method can treat the high-sulfur and high-metal residual oil and effectively slow down the ascending speed of the pressure drop of the fixed-bed catalyst bed, thus realizing the long-term running of the device. Besides, the method can combine the residual oil hydrotreating and catalytic cracking more effectively and has better implementation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

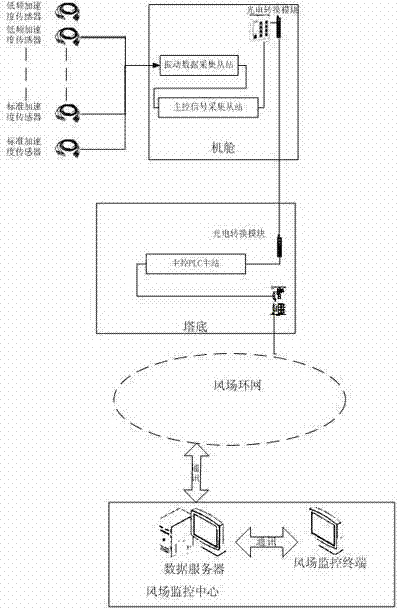

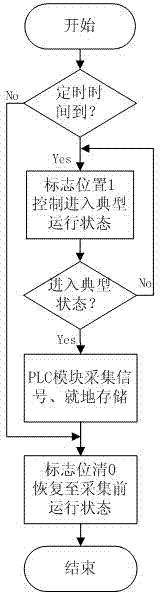

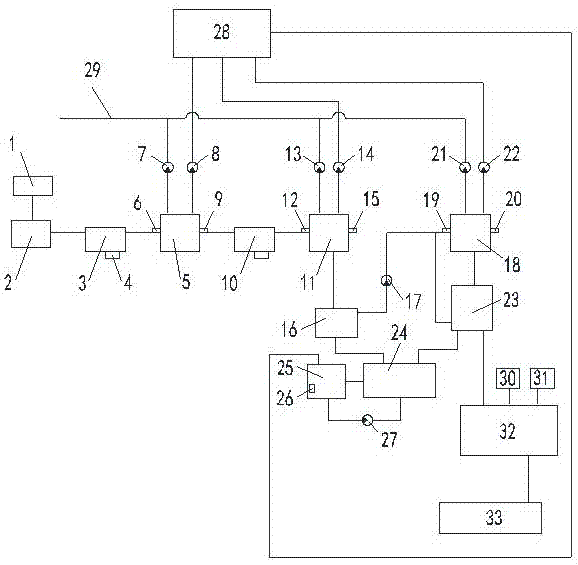

On-line state monitoring and fault diagnosis method integrated into master control system for wind turbines

ActiveCN104329222AImprove compactnessReduce occupancyWind motor controlMachines/enginesStable stateControl system

The invention discloses an on-line state monitoring and fault diagnosis method integrated into a master control system for wind turbines. According to the data acquisition requirement of a state monitoring system, the master control system controls the wind turbines in a set operating state, and then acquires vibration data. Under a stable state, the vibration data acquisition method can help to decrease the difficulty of data processing and increase the accuracy of data analysis. Meanwhile, under the same operating state, the acquired data facilitate the horizontal comparison of analysis results of the different units and the vertical comparison of historical data of the same unit, and also contribute to the construction of an automatic diagnosis system database. Finally, the integration of the two systems can increase the compactness of a control cabinet and reduce cost.

Owner:NARI TECH CO LTD +3

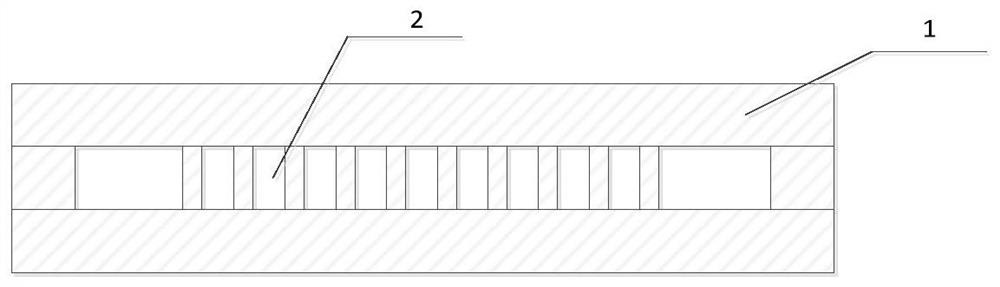

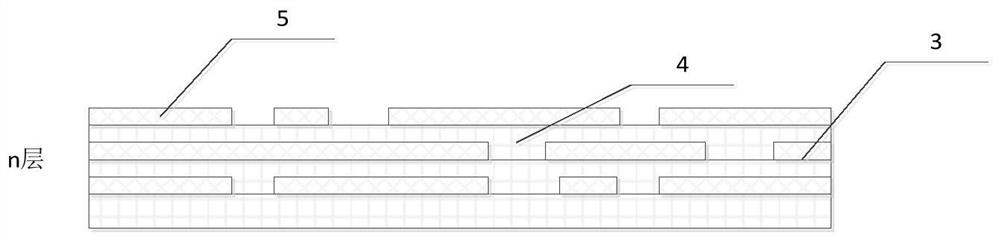

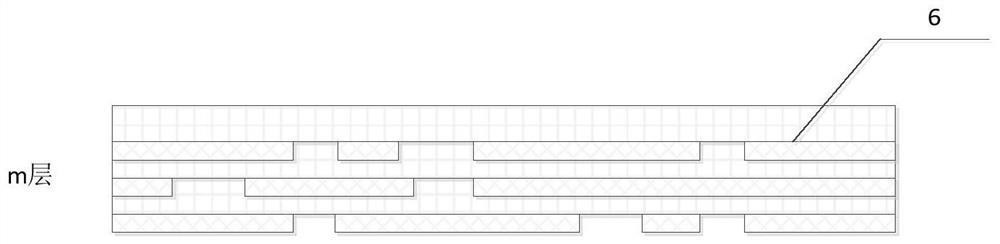

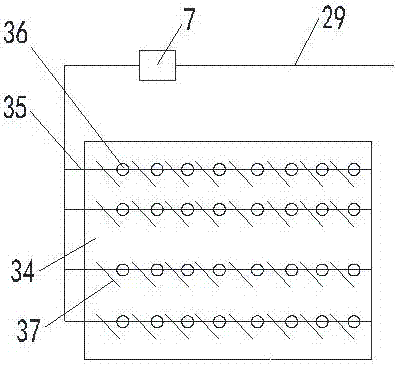

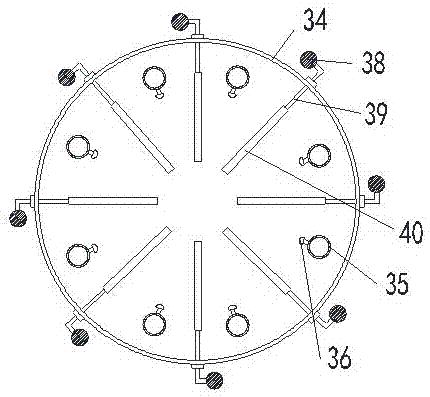

Printed circuit board with embedded micro-channels and preparation method of printed circuit board

ActiveCN113056087AAchieving Density CoolingImprove cooling effectPrinted circuit aspectsPrinted circuit manufactureHigh densityEngineering

The invention discloses a printed circuit board with embedded micro-channels. The printed circuit board comprises an embedded micro-channel metal core plate, wherein the top part of the embedded micro-channel metal core plate is provided with n wiring layers I, the bottom part of the embedded micro-channel metal core plate is provided with m wiring layers II, and the printed circuit board is provided with a liquid inlet and a liquid outlet which are communicated with the micro-channel. The structure has efficient heat dissipation capability, can realize transmission of high-density electrical signals, and meets the application requirements of high-density integrated high-power electronic devices.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

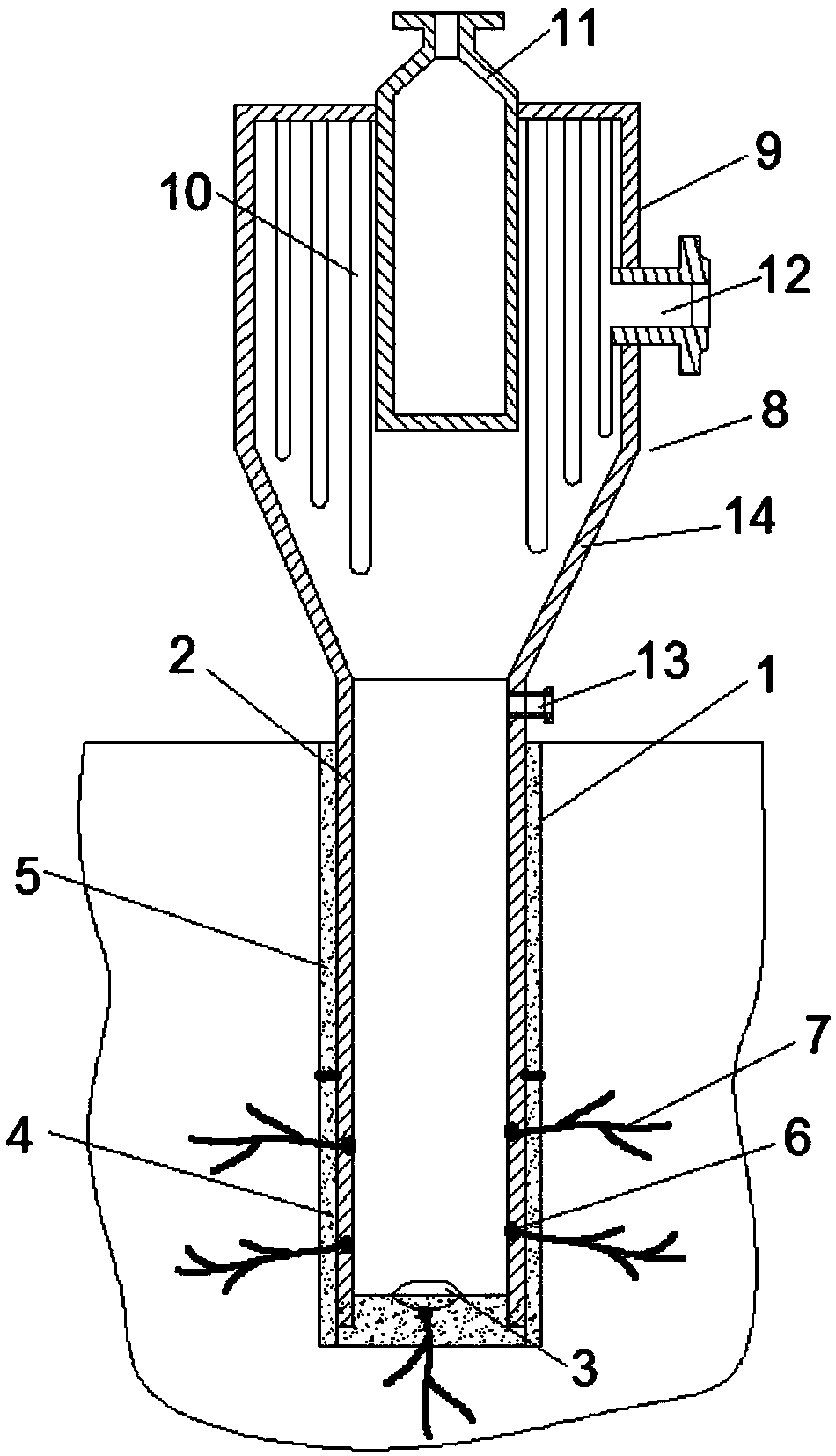

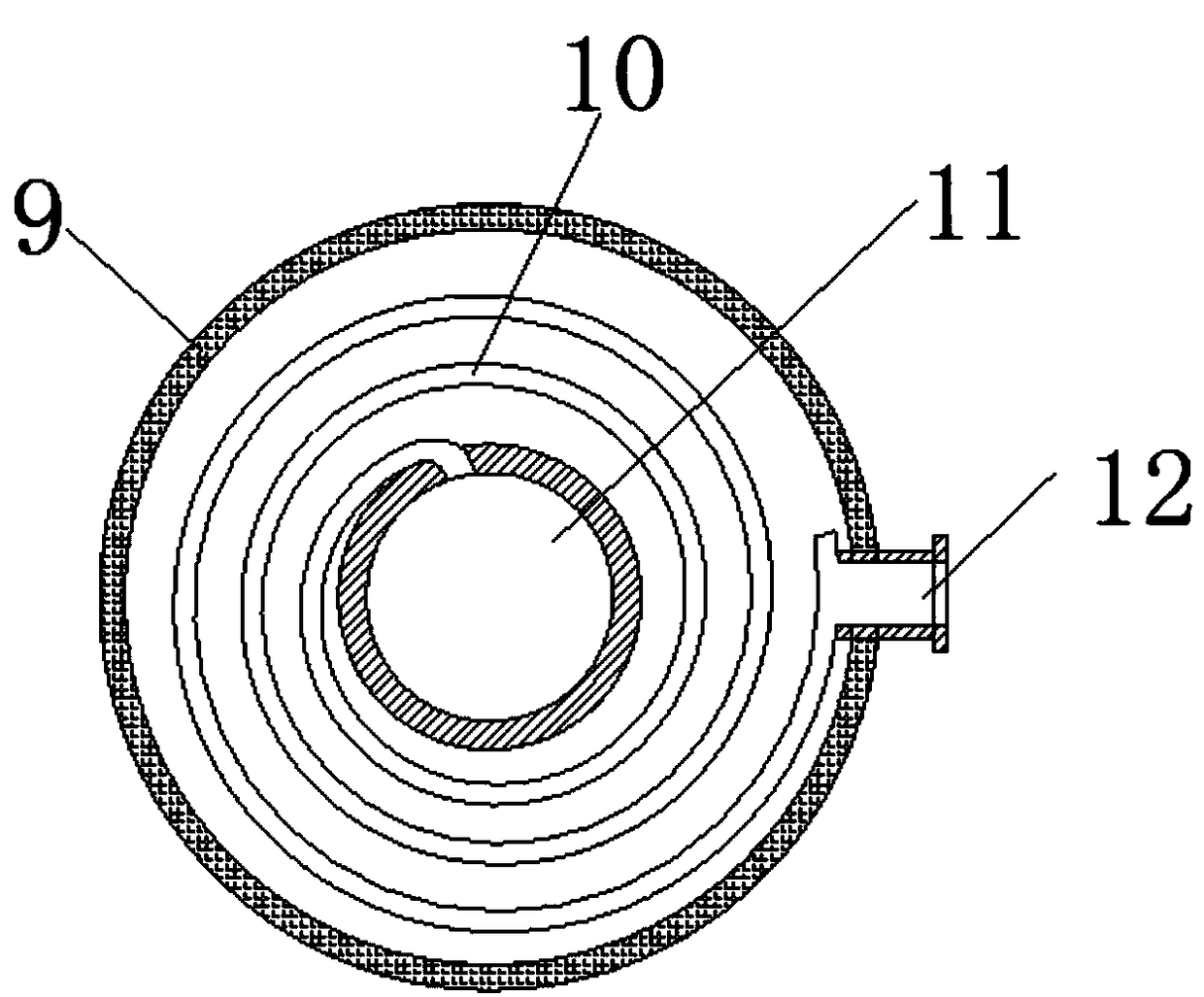

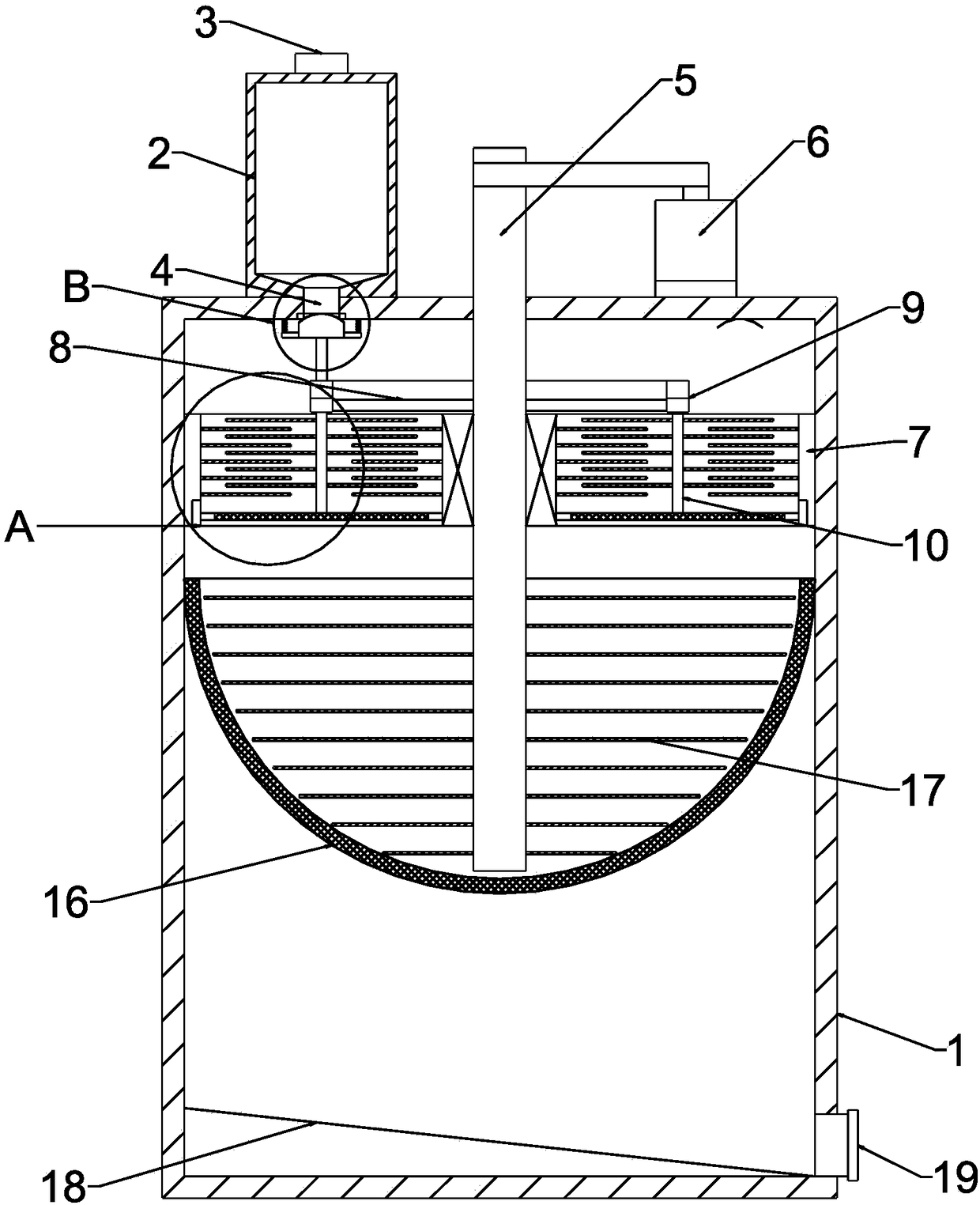

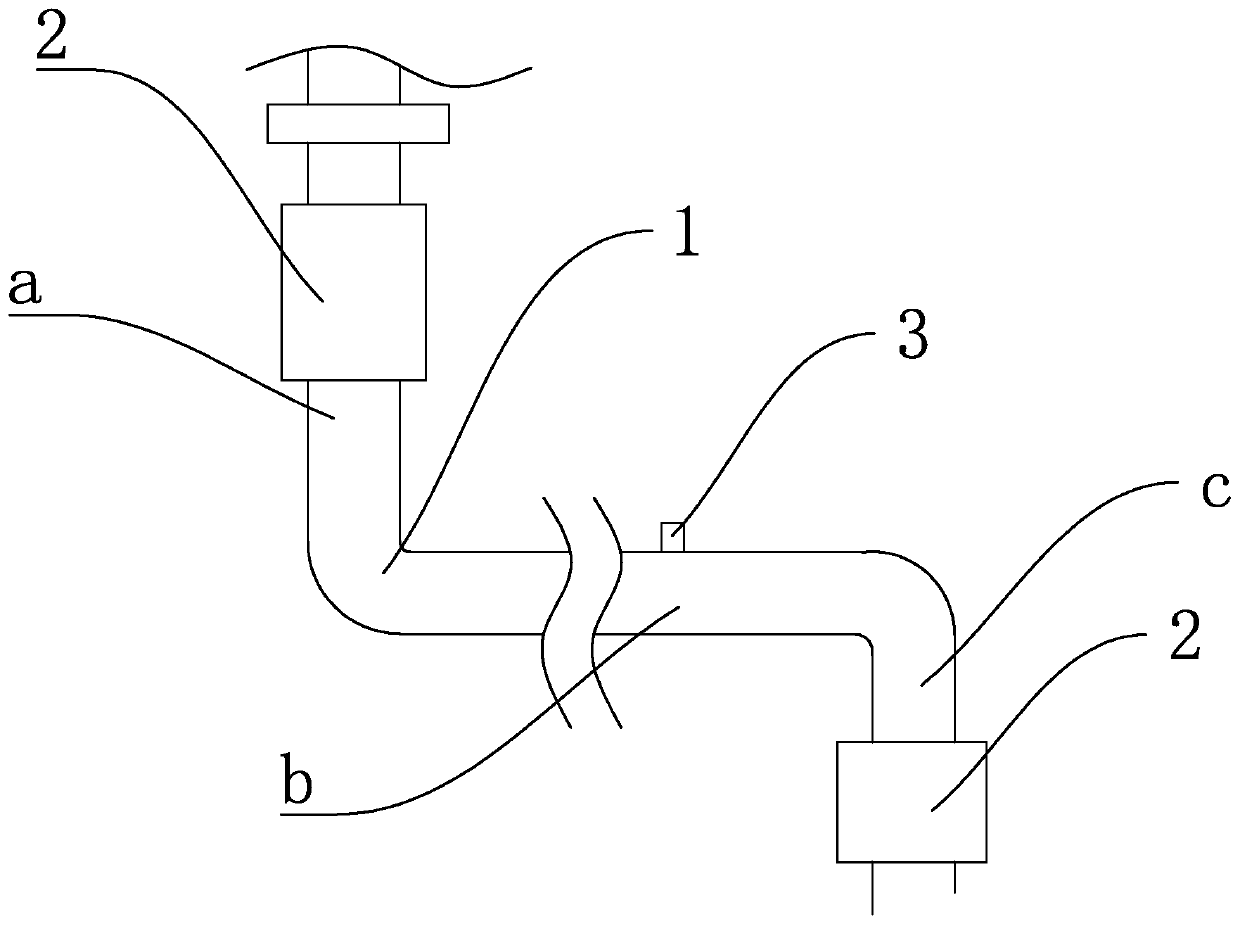

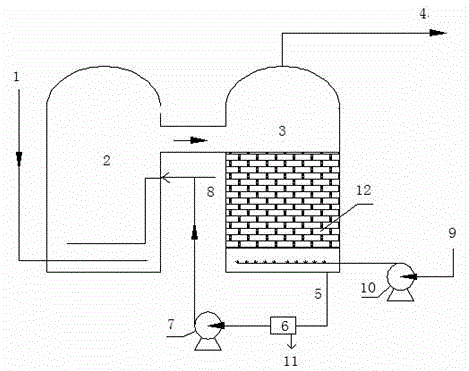

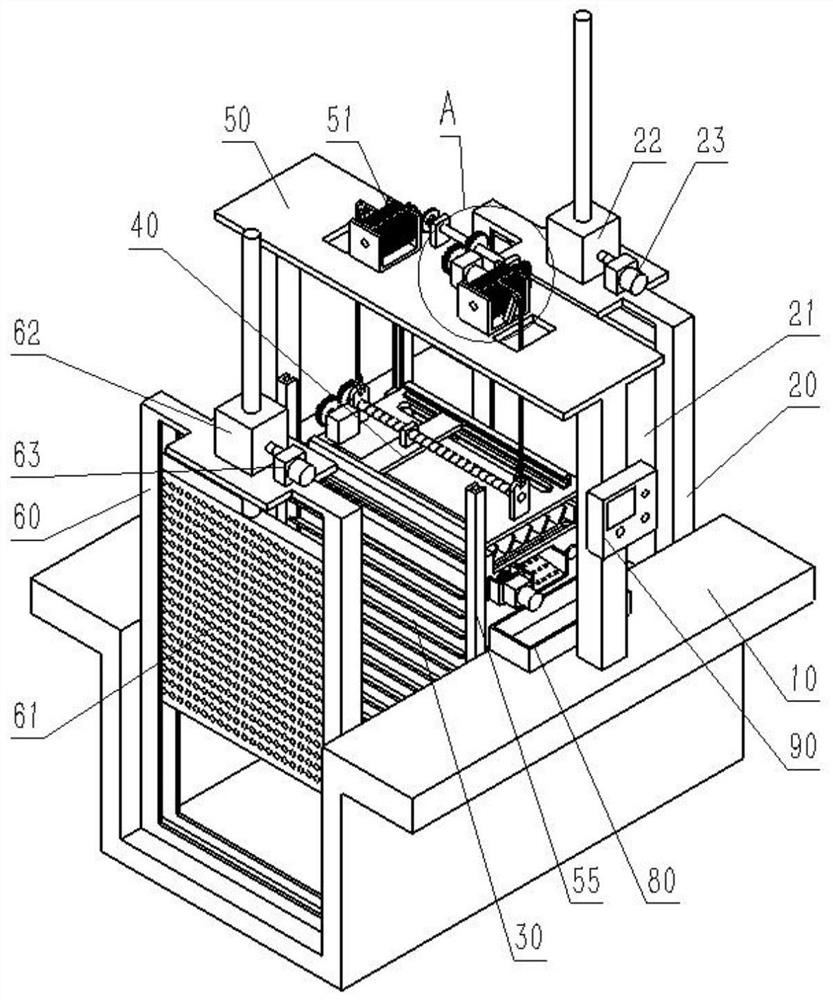

Technology for improving heat production capacity of geothermal wells

ActiveCN109403917AImprove efficiencyIncrease heat productionGeothermal energy generationFluid removalThermal insulationWell cementing

The invention relates to the technical field of geothermal energy development, in particular to a geothermal well novel technology. The technology improves the ability of leading geothermal energy inrock strata into geothermal wells through a heat conduction well cementing technology and a enhanced conductivity fracturing technology, and achieves high efficiency heat taking and heat transferringusing through spiral plate type condensing section gravity heat pipe heat exchanger. The technology comprises the following concrete process that after completing drilling a geothermal well and casinga sleeve pipe, the heat conduction well cementing is carried out, that is, thermal insulation cement slurry is injected in the low temperature section of the formation, and heat conduction cement slurry is injected into a stratum high temperature section to complete well cementing; after solidification of the heat insulation cement slurry and the heat conduction cement slurry of the well cementing, subsection perforation fracturing is carried out in the sleeve pipe of the stratum high temperature section, cracks are produced in high temperature strata, and heat conduction material is filled into the cracks to form a heat guiding belt extending from the sleeve pipe to the stratum; and finally, the condensing section of gravity heat pipe heat exchanger connected with the sleeve pipe is installed on the ground to form a high-yield geothermal well system in which rapid heat transfer in the stratum and high efficiency heat transfer in a well cylinder finally.

Owner:田振林

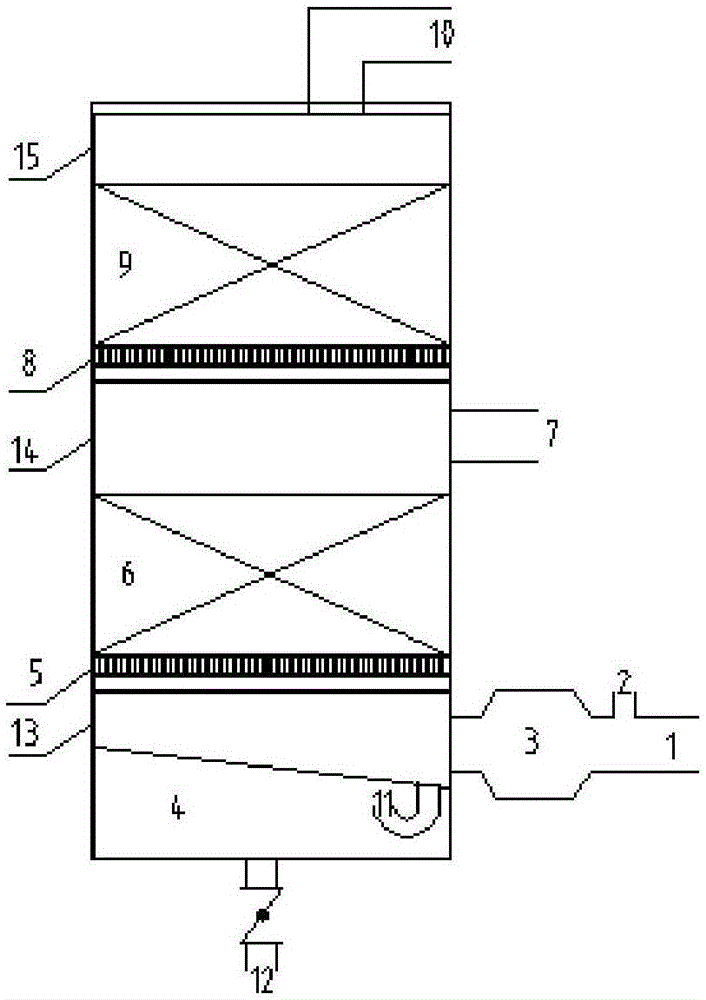

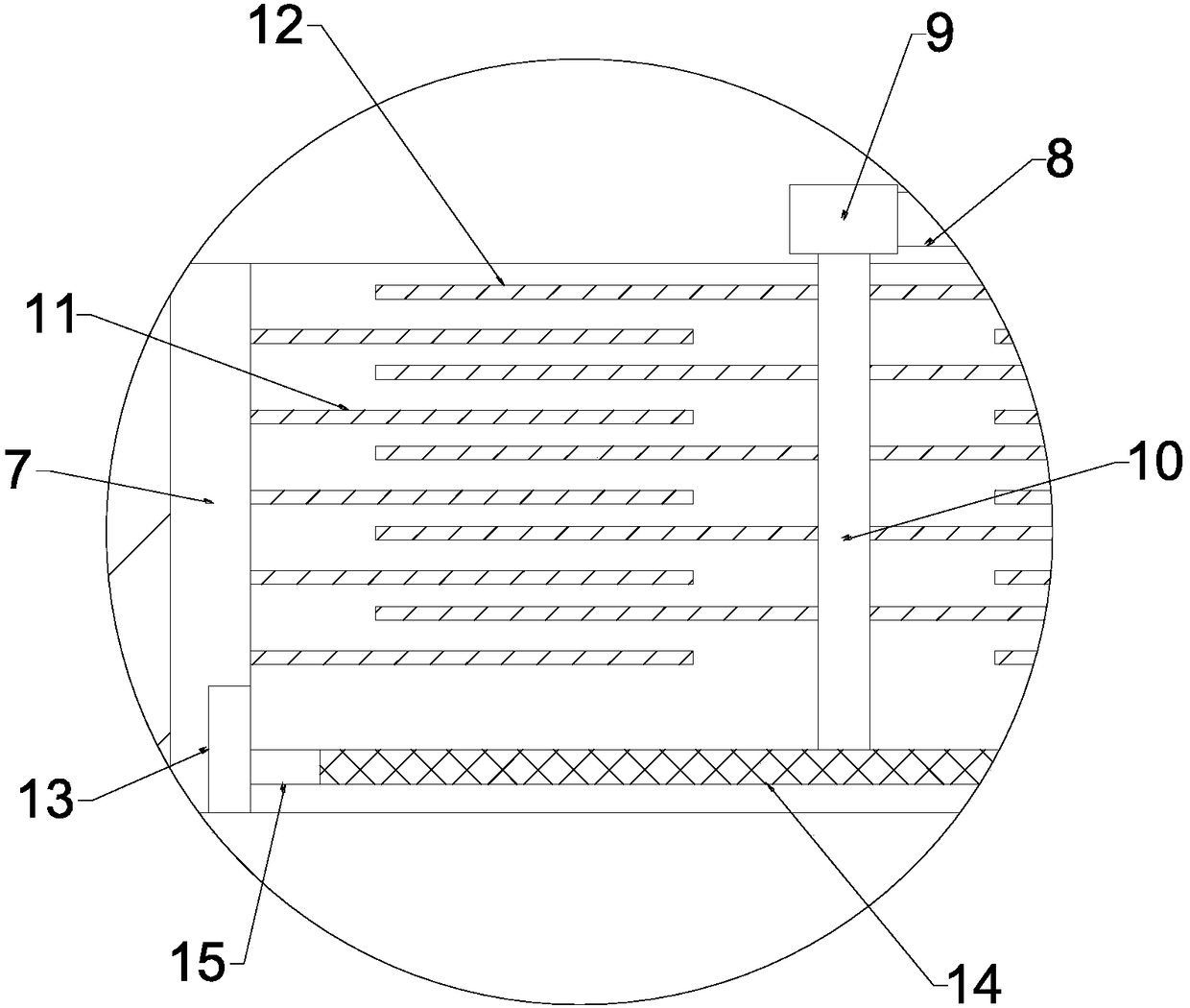

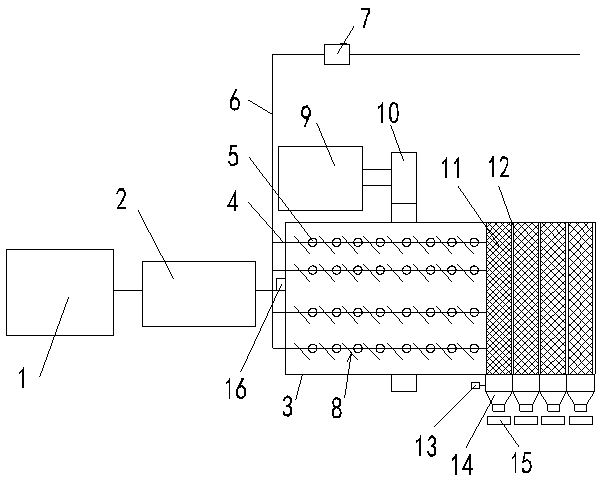

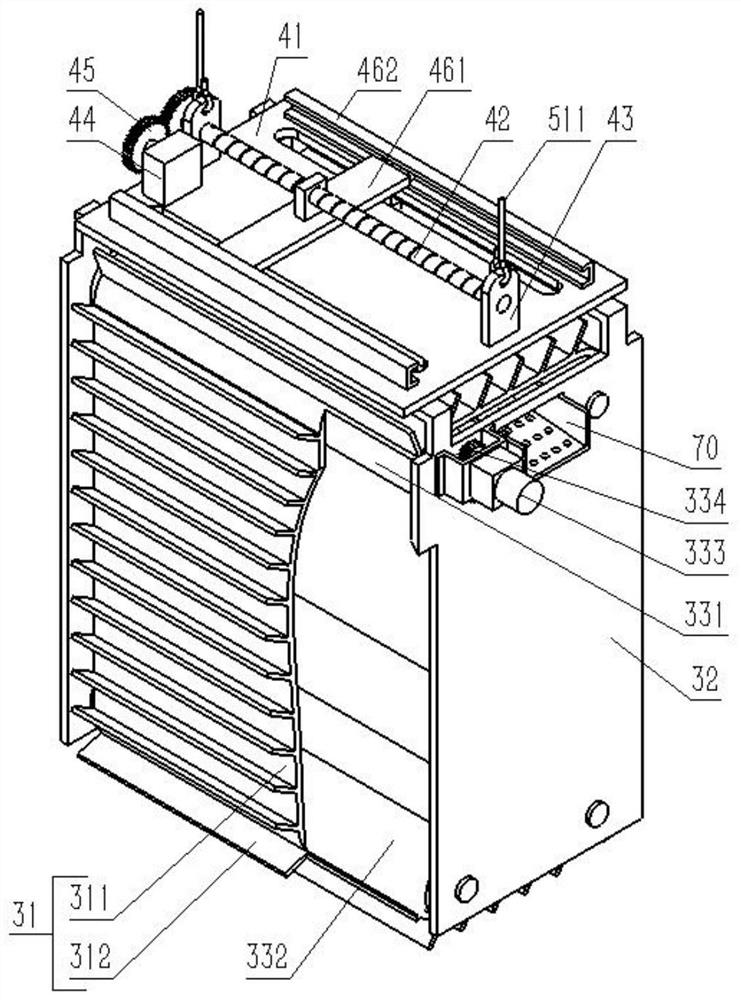

Active carbon fiber-based industrial flue gas desulfurization and denitrification device and method

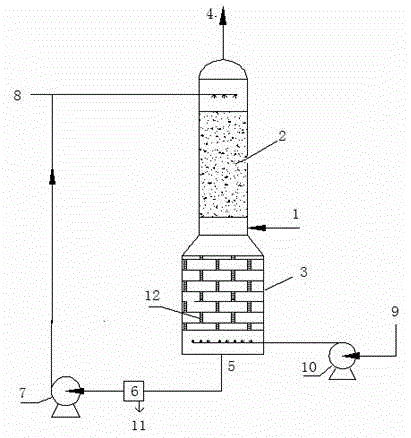

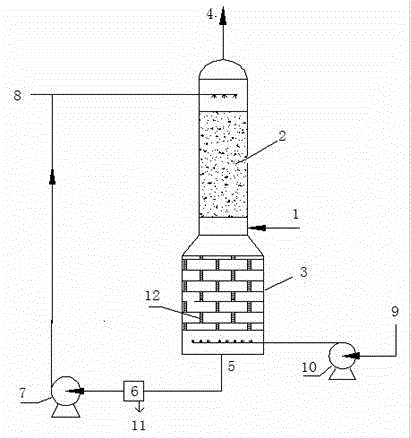

InactiveCN106823785ANo entryHigh economic valueGas treatmentDispersed particle separationFiberGrating

The invention discloses an active carbon fiber-based industrial flue gas desulfurization and denitrification device and method. The device comprises a reaction tower body, wherein a sulfuric acid collection device, a gas feeding region I, a grating I, a desulfurization region, a gas feeding region II, a grating II, a denitrification region and a gas discharging region are arranged in the reaction tower body in sequence from the bottom to the top; a gas feeding pipe I and a gas feeding pipe II are further arranged on the side wall of the reaction tower body; a gas outlet is formed in the top of the reaction tower body; the desulfurization / denitrification region is an active carbon fiber desulfurization / denitrification catalyst reaction bed layer. The method is realized through the device; flue gas passes through all regions in the reaction tower body in a way of entering from the bottom and leaving from the top, so that sulfur dioxide and nitric oxide in the flue gas are respectively turned into sulfuric acid and nitrogen / water. The desulfurization and denitrification device provided by the invention is simple in structure, easy to operate, small in occupied area and low in cost; the method is simple and convenient in technological process, high in desulfurization and denitrification efficiency and worthy of being popularized in the industry.

Owner:成都中祥天宇环保科技有限公司

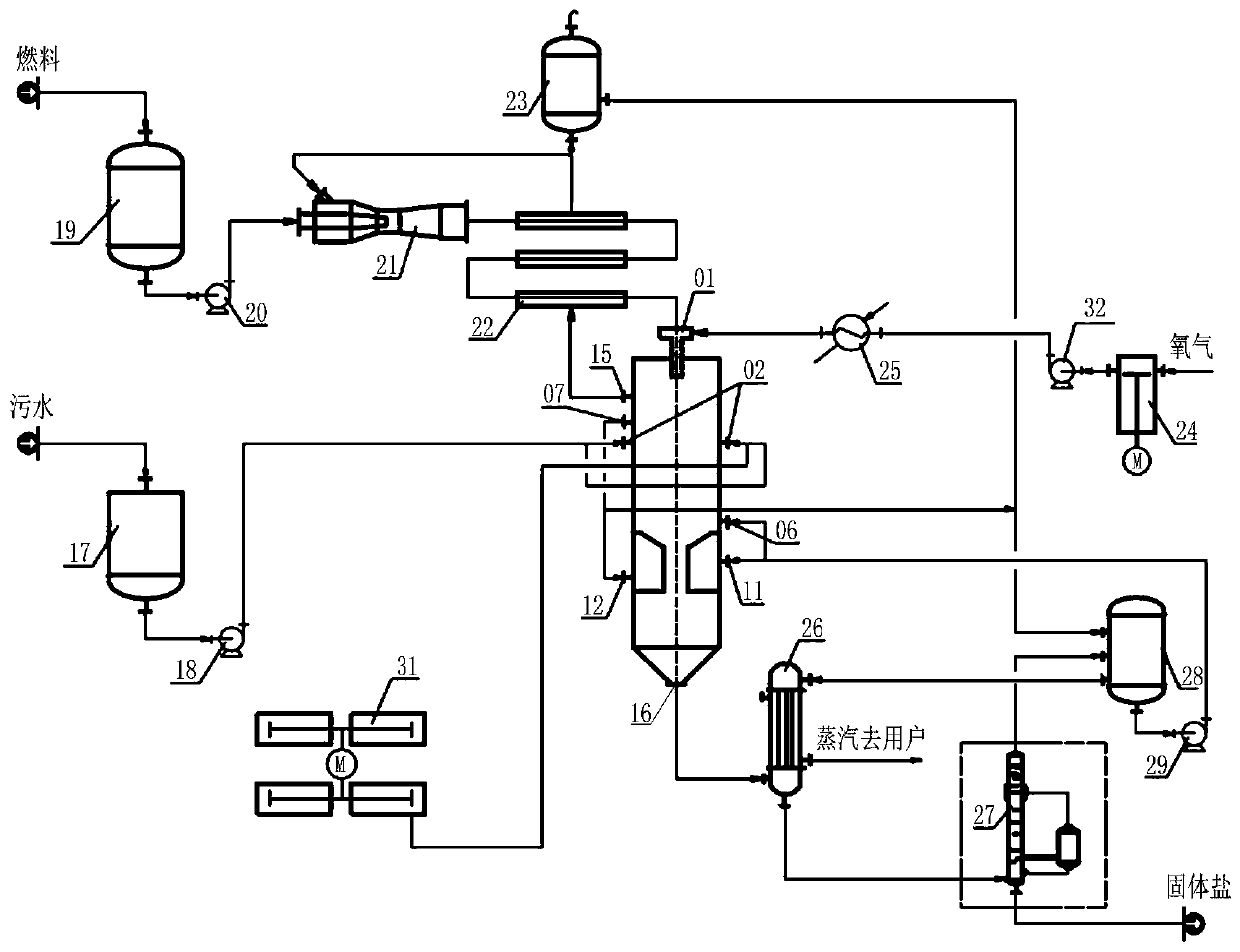

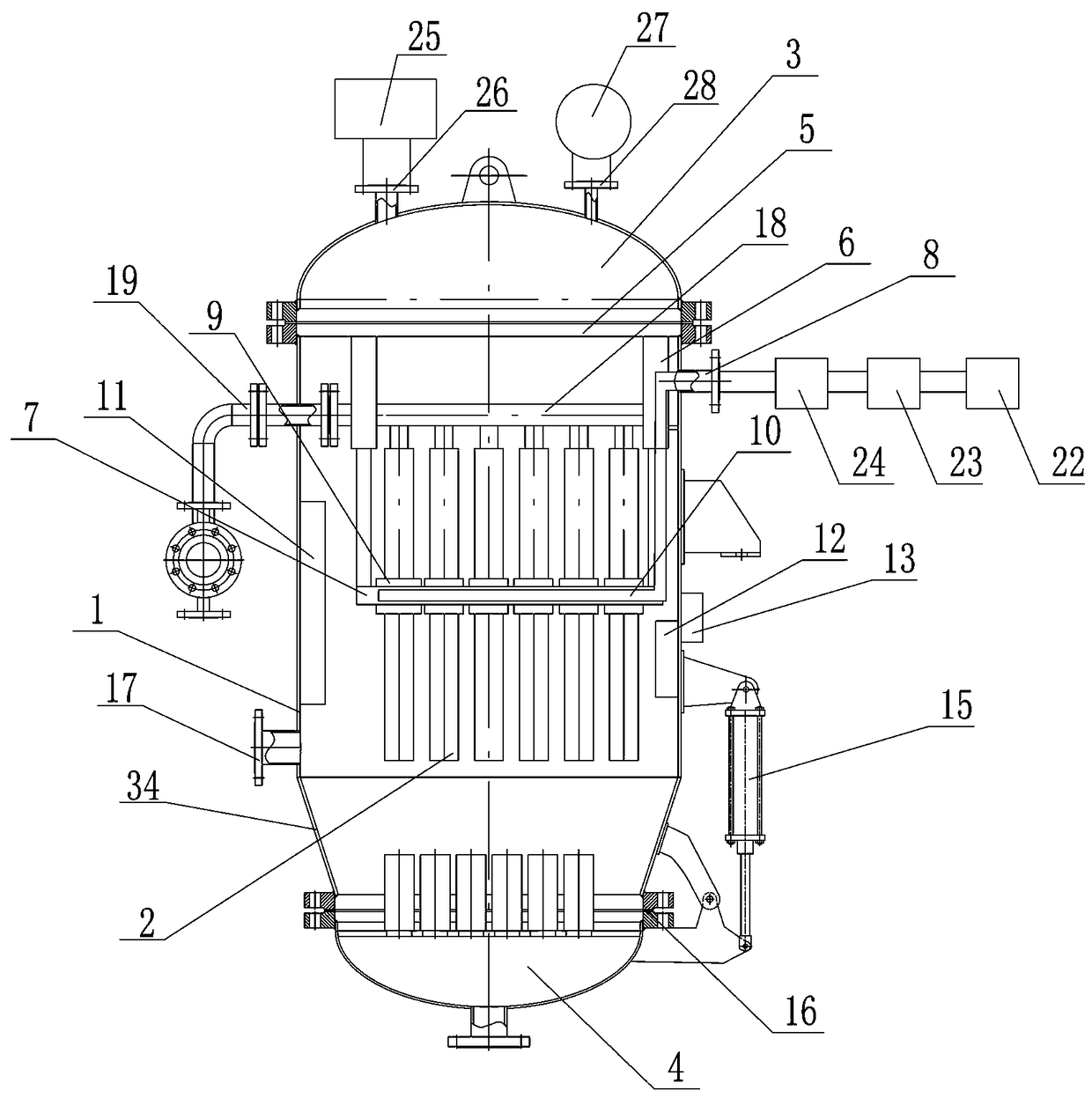

Supercritical hydrothermal combustion reactor for recovering salt from organic wastewater and application thereof

PendingCN111470559ASolve corrosiveSolving Salt Deposition ProblemsWater contaminantsMultistage water/sewage treatmentSaline waterSalt water

Owner:成都九翼环保科技有限公司

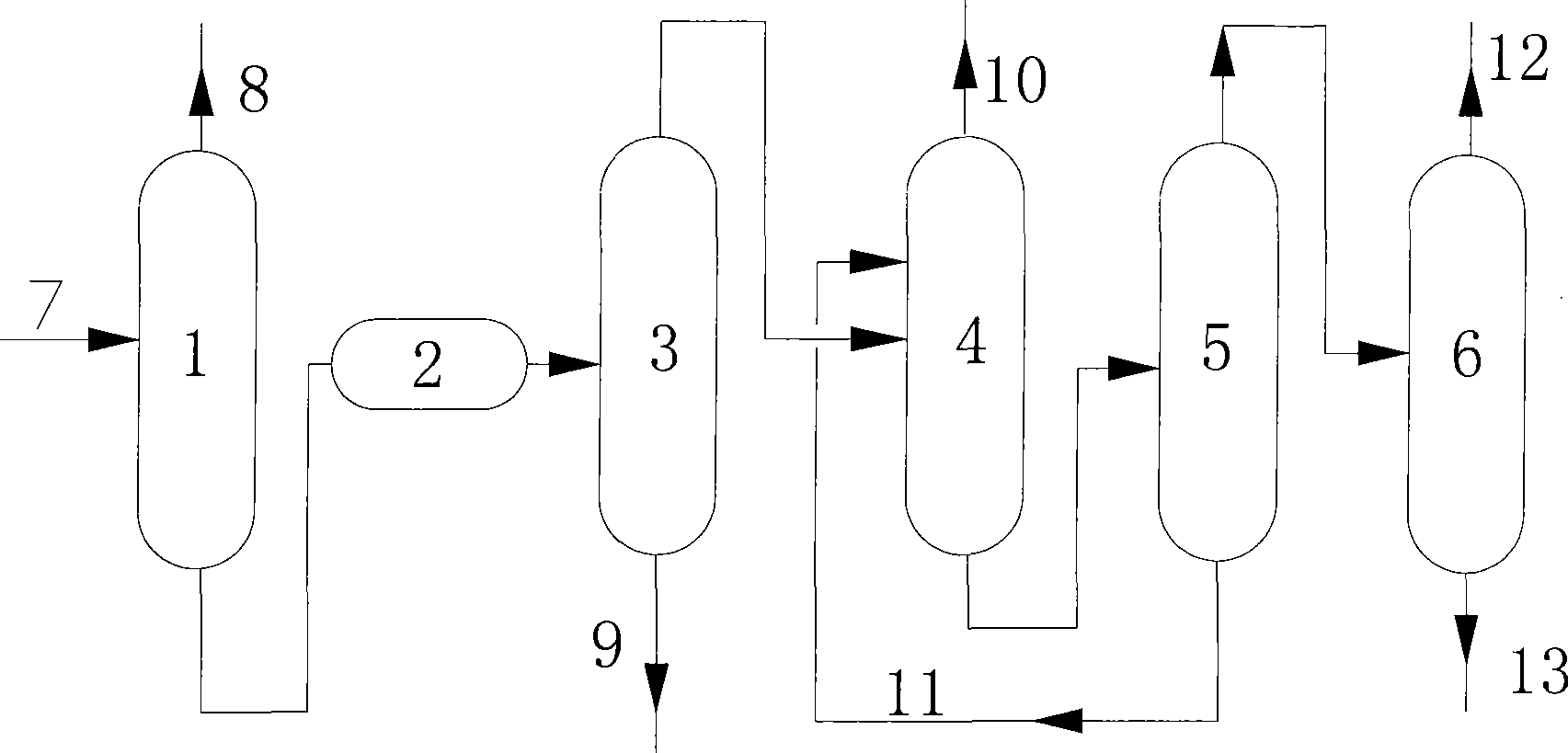

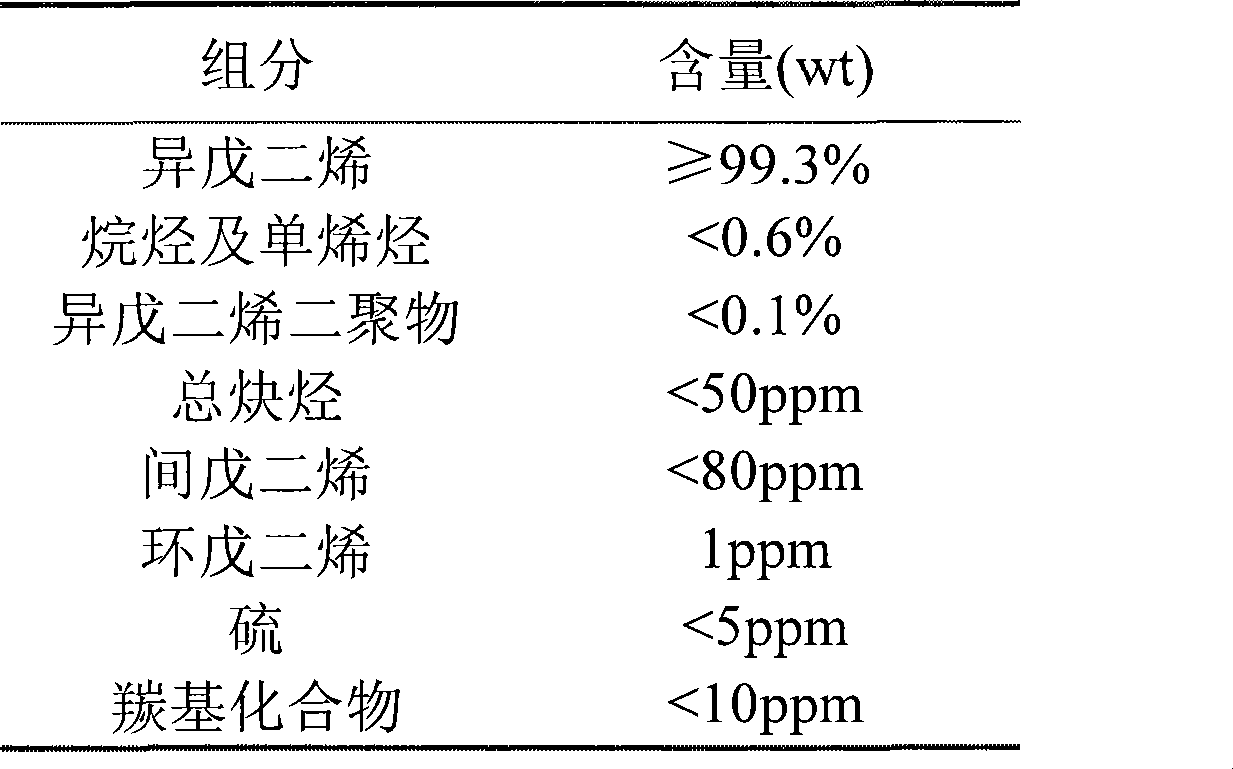

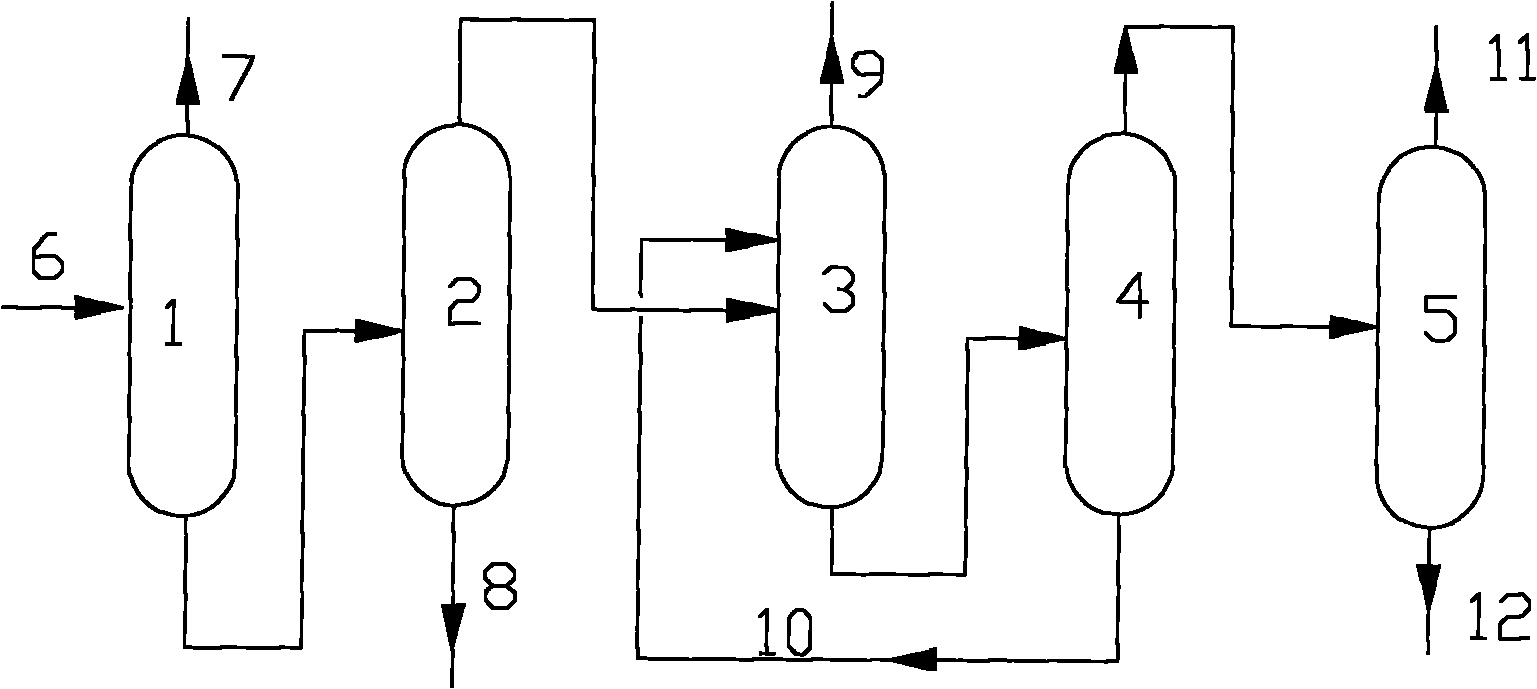

Method for separating carbon 5 fraction by NMP method and one-stage extraction and rectification

ActiveCN101423450AAvoid corrosionAvoid problems such as cloggingHydrocarbon purification/separationHydrocarbons from unsaturated hydrocarbon addition2-methylbutaneDehydrogenation

The invention discloses a method for separating C5 fraction through first-stage extraction rectification by a NMP method. The method comprises the steps of dehydrogenation, dimerization reaction, deheavy, extraction rectification, steam stripping and refining, wherein isopentane is utilized to take most of acetylene hydrocarbon away from the tower top in the dehydrogenation step; and a mixed solvent of NMP and a saline solution is adopted as an extracting agent in the step of extraction rectification. The method improves the extracting agent, increases the selectivity of the extracting agent, cancels a two-stage extraction rectification unit, and reduces the using amount and the regeneration amount of the solvent, thereby reducing operating cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

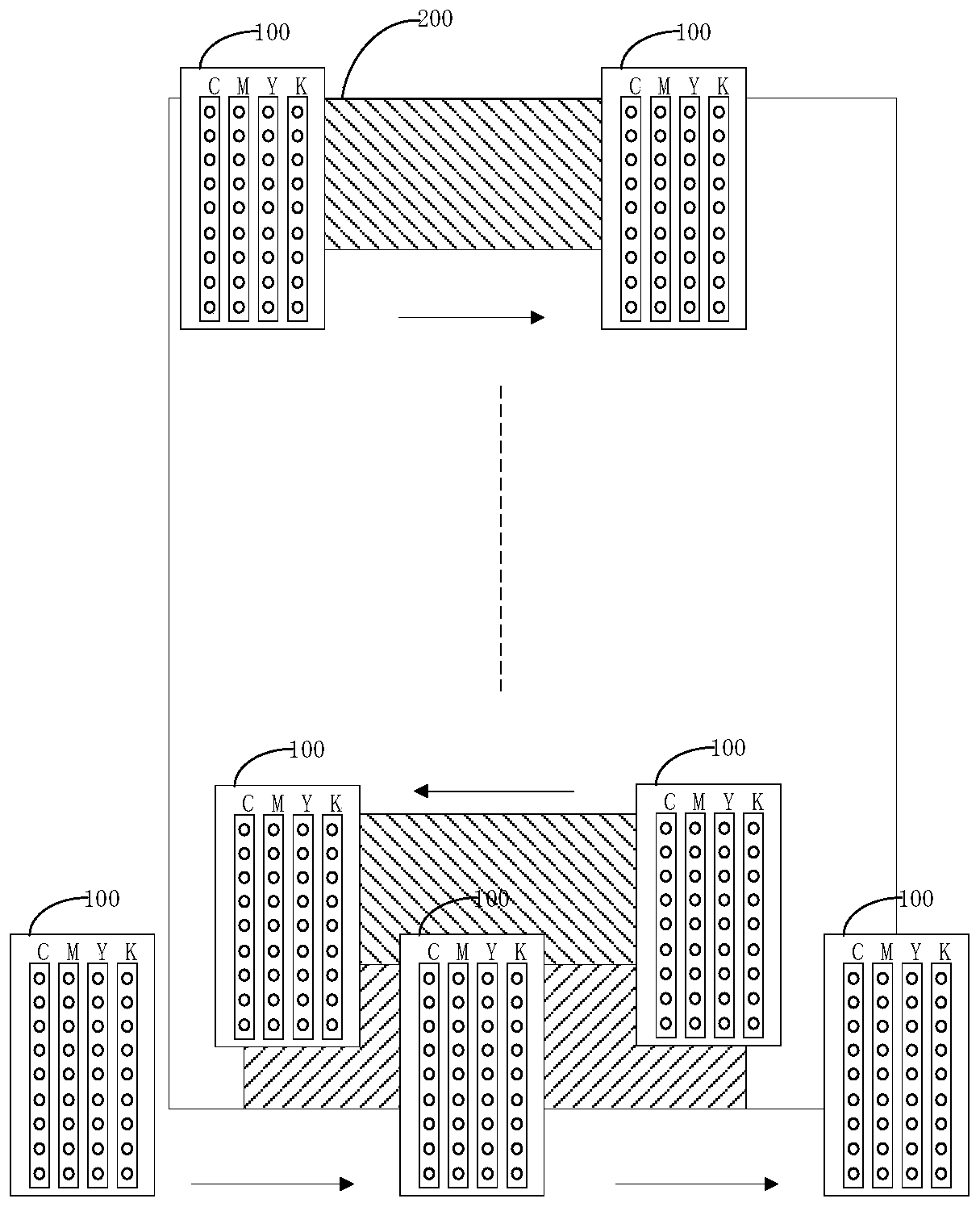

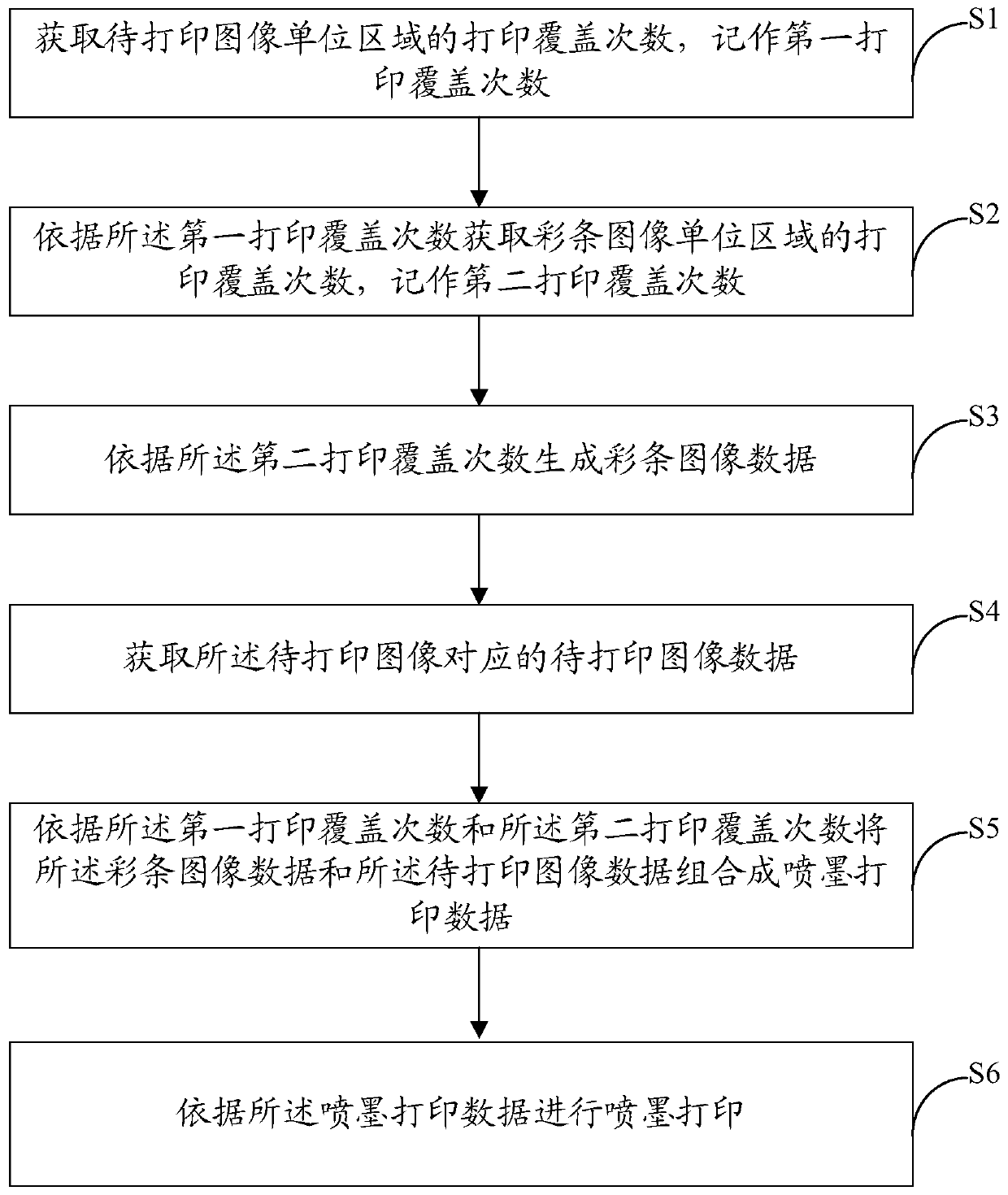

Moisturizing and printing control method, device and facility for sprayer, and storage medium

The invention discloses a moisturizing and printing control method, device and facility for a sprayer, and a storage medium. The moisturizing and printing control method for the sprayer comprises thesteps that the number of times of printing coverage of a to-be-printed image in unit area is acquired and is recorded as a first number of times of printing coverage; the number of times of printing coverage of a striped image in unit area is acquired according to the first number of times of printing coverage and is recorded as a second number of times of printing coverage; striped image data aregenerated according to the second number of times of printing coverage; to-be-printed image data corresponding to the to-be-printed image are acquired; the striped image data and the to-be-printed image data are combined to form ink-jet printing data according to the first number of times of printing coverage and the second number of times of printing coverage; and ink-jet printing is carried outaccording to the ink-jet printing data. By the adoption of the moisturizing and printing control method, device and facility for the sprayer, and the storage medium, the problem that a nozzle does not discharge ink for a long time and consequentially, becomes dry or is blocked is solved; the problems of low printing efficiency and ink waste caused by excessive printing of striped images are solved, and the printing cost is reduced.

Owner:SENDA SHENZHEN TECH CO LTD

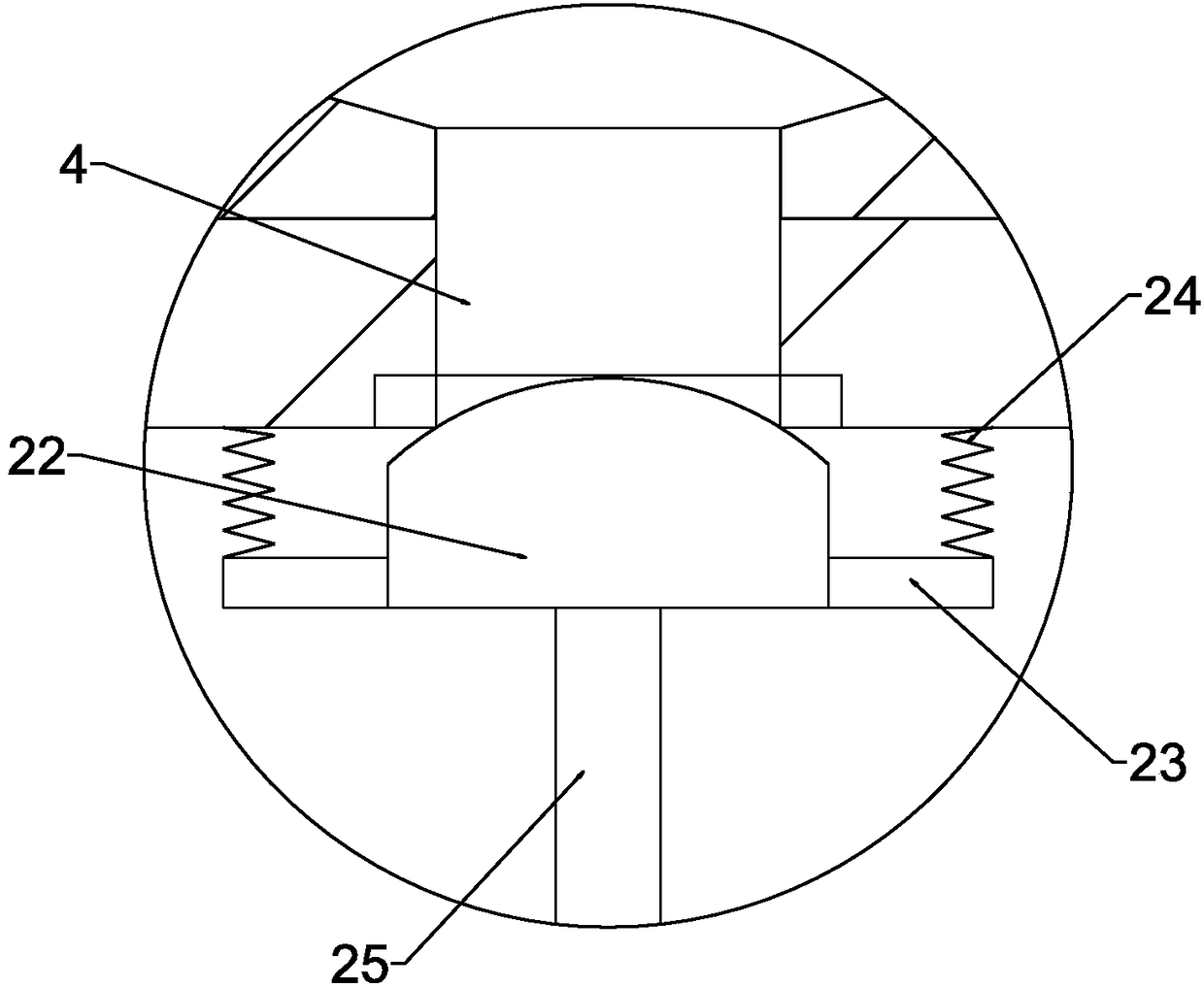

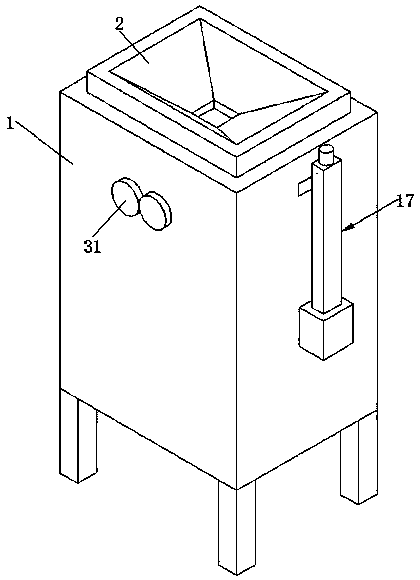

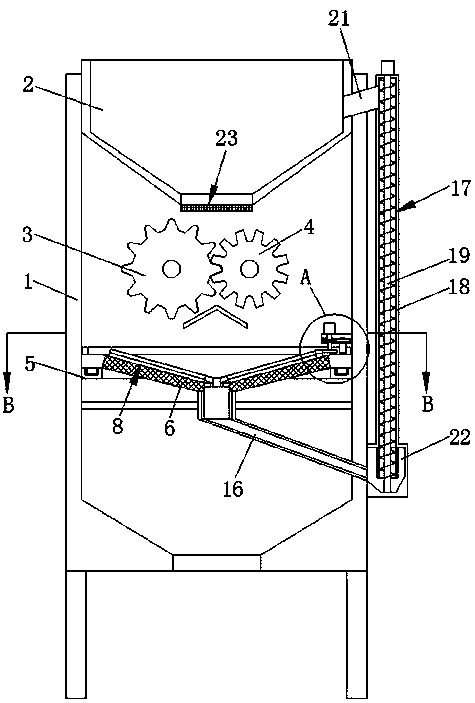

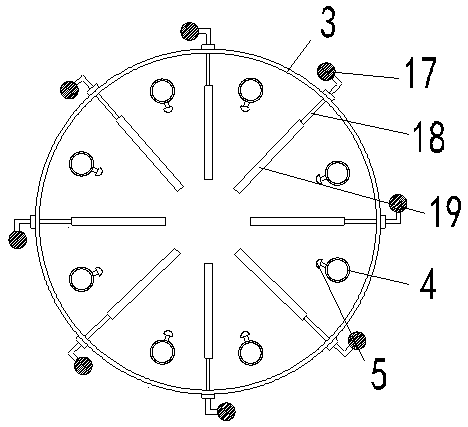

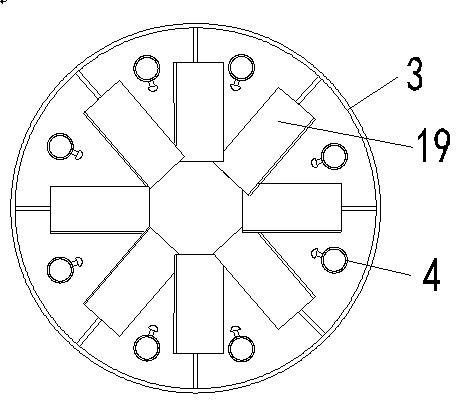

Multi-directional fodder crushing and filtering device with constant-speed intermittent feeding function

InactiveCN108187840AImprove processing efficiencyAvoid problems such as cloggingFeeding-stuffGrain treatmentsMachiningMulti directional

The invention discloses a multi-directional fodder crushing and filtering device with the constant-speed intermittent feeding function. The multi-directional fodder crushing and filtering device comprises a shell; a storage cavity is formed in the shell, and a motor is arranged on the shell; a material injection pipeline and a feeding pipeline are arranged on the material storage cavity; a stirring shaft is arranged on the upper wall of the shell; an annular groove is formed in the upper part in the shell, and an inner gear is arranged at the upper part in the shell; fixed blades are arrangedin the annular groove; a rotating connecting rod, a rotating sleeve, an auxiliary rotating shaft, first rotating blades, a filter screen plate and a transmission gear are arranged on the periphery ofthe stirring shaft; a filter screen cover is arranged in the middle of the inner wall of the shell; a plurality of sets of second rotating blades are arranged on the periphery of the stirring shaft ina welded mode; an annular plate is arranged at the upper end of the rotating sleeve, and a wave groove is formed in the upper end of the rotating sleeve; and a plug, wing plates, connecting springs and a push rod are arranged at the lower end of the feeding pipeline. According to the multi-directional fodder crushing and filtering device, the crushing working efficiency is improved by means of multi-stage crushing, so that machining can be rapidly and stably guaranteed; and by means of the clearance fit of the wave groove and the push rod, the plug can be continuously pushed to be matched with the feeding pipeline so as to form intermittent feeding.

Owner:吴烨程

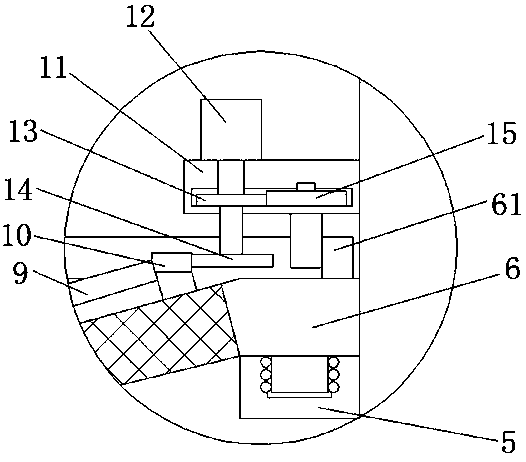

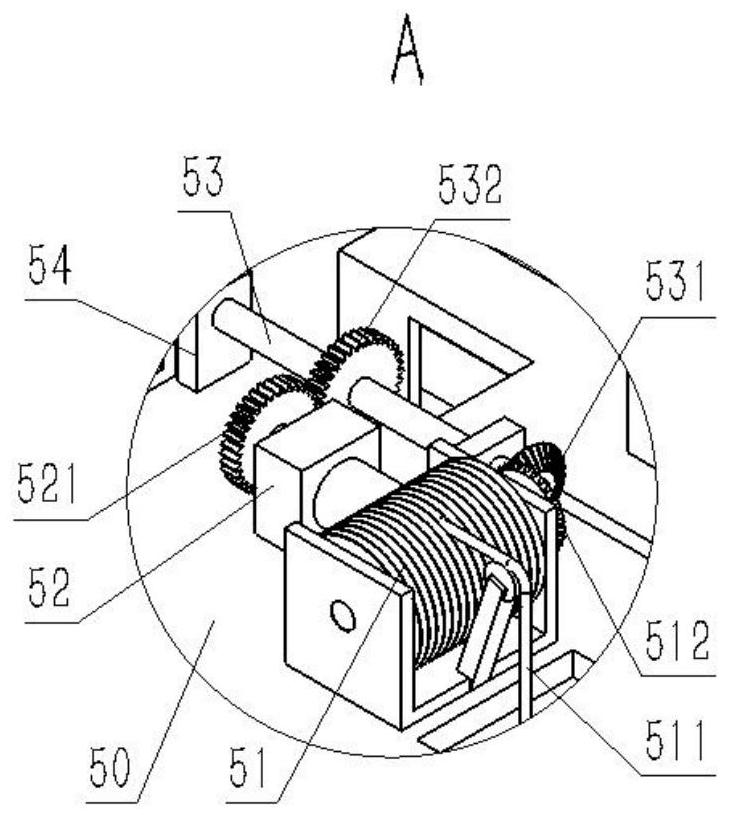

Caking zinc sulfate scattering device and using method thereof

ActiveCN110787867AAvoid mesh cloggingReasonable designSievingScreeningProcess engineeringStructural engineering

The invention discloses a caking zinc sulfate scattering device. The device comprises a box body, a collecting funnel, a screening net, a cleaning device and a conveying device. The interior of the box body is hollow, the top of the box body is fixed with the collecting funnel, a limiting valve is mounted at the bottom of the collecting funnel, a first crushing roller and a second crushing rollerare symmetrically arranged under the collecting funnel, the screening net is rotatably arranged on a mounting ring, and the screening net is in a funnel shape. The fixing frame is provided with the cleaning device, the cleaning device comprises cleaning rods and a transmission box, the four cleaning rods are obliquely and symmetrically fixed to a group of rotating shafts, and a transmission box isarranged on the portion, above the screening net, on the inner wall of the box body. The caking zinc sulfate scattering device is reasonable in design, the screening net can be effectively cleaned, the screening net is effectively prevented from being blocked, meanwhile, unqualified products can be crushed again, and the device is suitable for being used and popularized.

Owner:HUNAN LIHONG NEW MATERIAL TECH CO LTD

Auxiliary drainage structure and building drainage system

InactiveCN110005035AAvoid problems such as cloggingNovel structureGrain treatmentsSewer pipelinesButt jointEngineering

The invention relates to the technical field of drainage, in particular to an auxiliary drainage structure and a building drainage system. The auxiliary drainage structure comprises a shell, an innertube and a reaming and cutting device. A first butt joint structure and a second butt joint structure are correspondingly arranged at the upper end and the lower end of the shell. The inner tube is disposed in the shell. The reaming and cutting device is disposed on the inner wall of the inner tube, and the reaming and cutting device comprises reaming and cutting tracks and reaming and cutting blades. The reaming and cutting tracks are fixedly disposed on the inner wall of the inner tube, and each of the reaming and cutting tracks is provided with at least one reaming and cutting blade and thereaming and cutting blades are movable on the reaming and cutting tracks. An excitation structure is further disposed between the inner tube and the shell, and the excitation structure includes a plurality of sets of excitation teeth. The auxiliary drainage structure can ream and cut and break solid wastes in a drain pipe through the reaming and cutting device, and occurrence of problems such asblockage of the drain pipe can be avoided; and the building drainage system is convenient to use, intelligent and efficient, can effectively monitor the entire drain pipe, and can prevent blockage andraise an alarm in time.

Owner:SHAOXING UNIV YUANPEI COLLEGE

Purification method for hydrogen sulfide containing gas

ActiveCN104548906ARemarkable effect of energy saving and consumption reductionAvoid problems such as cloggingDispersed particle separationCombustionProcess equipment

The invention relates to a purification method for a hydrogen sulfide containing gas. The purification method comprises the following steps: introducing hydrogen sulfide-containing gas into an absorption reactor, contacting and reacting with an absorbent, and then emitting the reacted up-to-standard gas; absorbing the reacted rich absorption liquid into a regenerative reactor, contacting a regenerant for regeneration reaction under the existence of an oxygen-containing gas, to obtain a regenerative absorption liquid and an elemental sulfur mixture, filtering and separating through a powdered sulfur filter, separating elemental sulfur and the regenerative absorption liquid, recycling the regenerative absorption liquid in the absorption reactor, collecting the elemental sulfur and feeding the elemental sulfur into a storage tank. According to the purification method for a hydrogen sulfide containing gas, normal-temperature recycling is carried out, the hidden safety hazards of technology equipment plugging, bed layer combustion, fog and froth entrainment of exhaust gas and the like can also be avoided, secondary pollutants generated during regeneration can be absorbed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Leaching treatment method and system for heavy metal pollution bottom sediment in ephemeral stream

PendingCN107285584AGive full play to the functional advantagesFully consider self-control requirementsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesParticulatesSoil science

The invention discloses a leaching treatment method and system for heavy metal pollution bottom sediment in an ephemeral stream. The method includes the following steps that 1, the bottom sediment is broken apart; 2, leaching is performed with clean water through a cylinder stone-washing machine; 3, bottom sediment components with the particle size being 2.36 mm or below are subjected to sand-washing treatment; 4, bottom sediment components with the particle size being 1.18 mm or below enter a precipitation pool and are lifted to a vibrating sieve to sieve fine sand with the particle size being 0.075-1.18 mm; 5, bottom sediment components with the particle size being 0.075 mm enter a sedimentation pool, and sludge after sedimentation and separation is treated; 6, the bottom sediment in the precipitation pool and the sedimentation pool is treated and then discharged after meeting discharging standards. A stone-washing system, a sand-washing system, the vibrating sieve, a water supply pipeline and a chemical dissolving device are involved in the method, and the stone-washing system, the sand-washing system and the vibrating sieve are connected with the water supply pipeline and the chemical dissolving device. The method is easy to operate and convenient to implement, solves the problems that big and small particulate matter of the bottom sediment adhere to one another, and sticky blocks are large in quantity, and improves the sieving efficiency of the bottom sediment.

Owner:山东省环科院环境工程有限公司

Method for one-stage extraction, distillation and separation of C5 fractions by using reactive distillation N-methyl pyrrolidone (NMP) method

ActiveCN101838177AAvoid corrosionAvoid problems such as cloggingChemical industryDistillation purification/separationExtractive distillationReactive distillation

The invention discloses a method for the one-stage extraction, distillation and separation of carbon 5 (C5) fractions by using the reactive distillation NMP method. The method comprises the following steps of: light components removal, heavy components removal, extractive distillation, gas stripping and purification, wherein in the step of light components removal, most alkynes are removed from atower top through isopentane; in the step of extractive distillation, the mixed solvents of the NMP and salt solution serve as an extracting agent; and in the steps of light components removal and heavy components removal, the process of reactive distillation is used. The method has the advantages of improving the extracting agents and the selectivity of the extracting agents; saving a two-stage extractive distillation unit, and reducing the using amount and regeneration amount of the solvents, thereby reducing the operation fee.

Owner:CHINA PETROLEUM & CHEM CORP +1

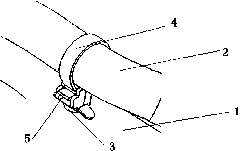

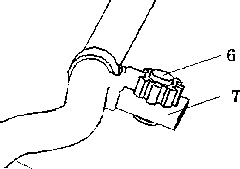

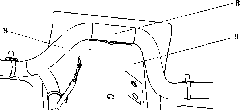

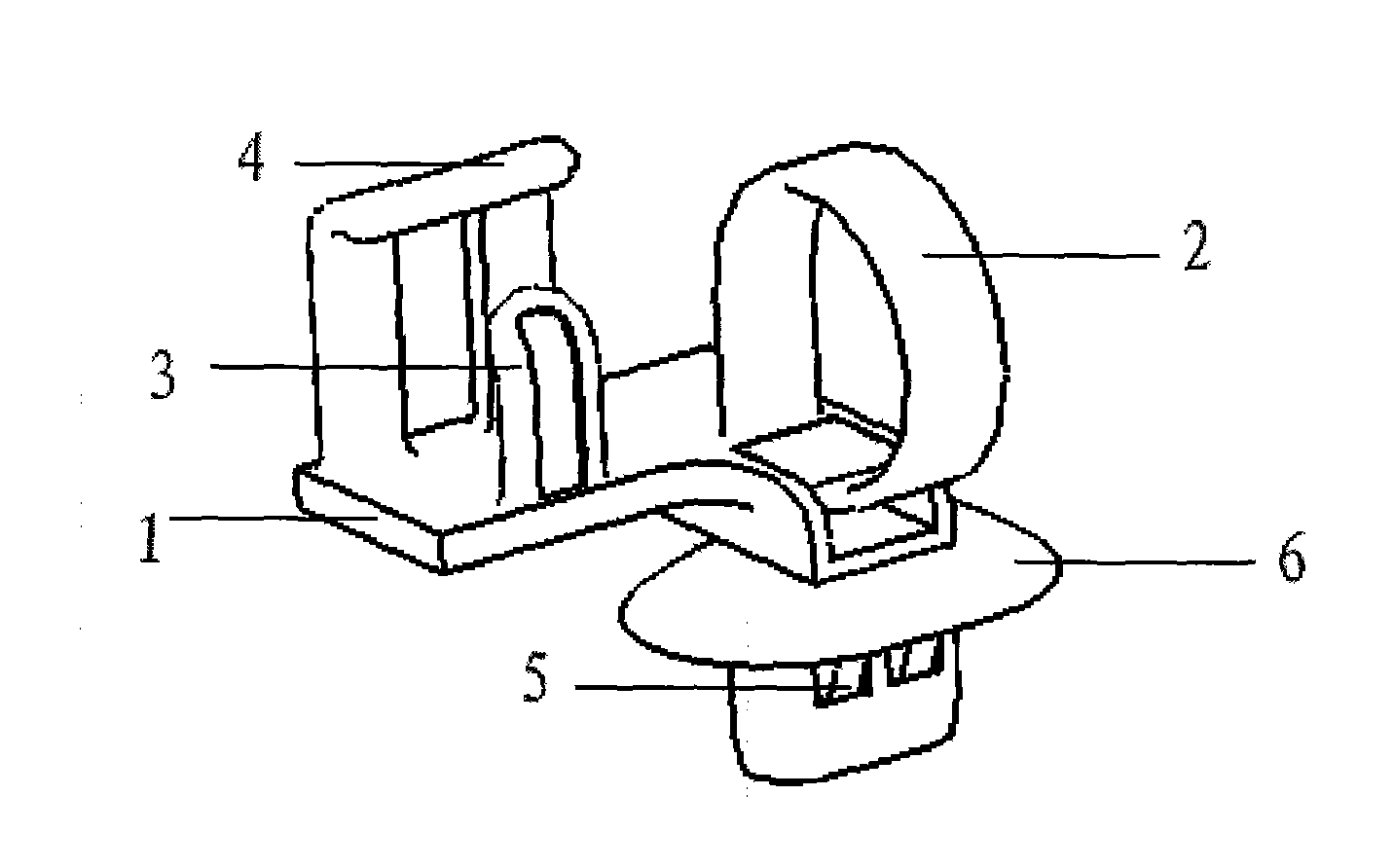

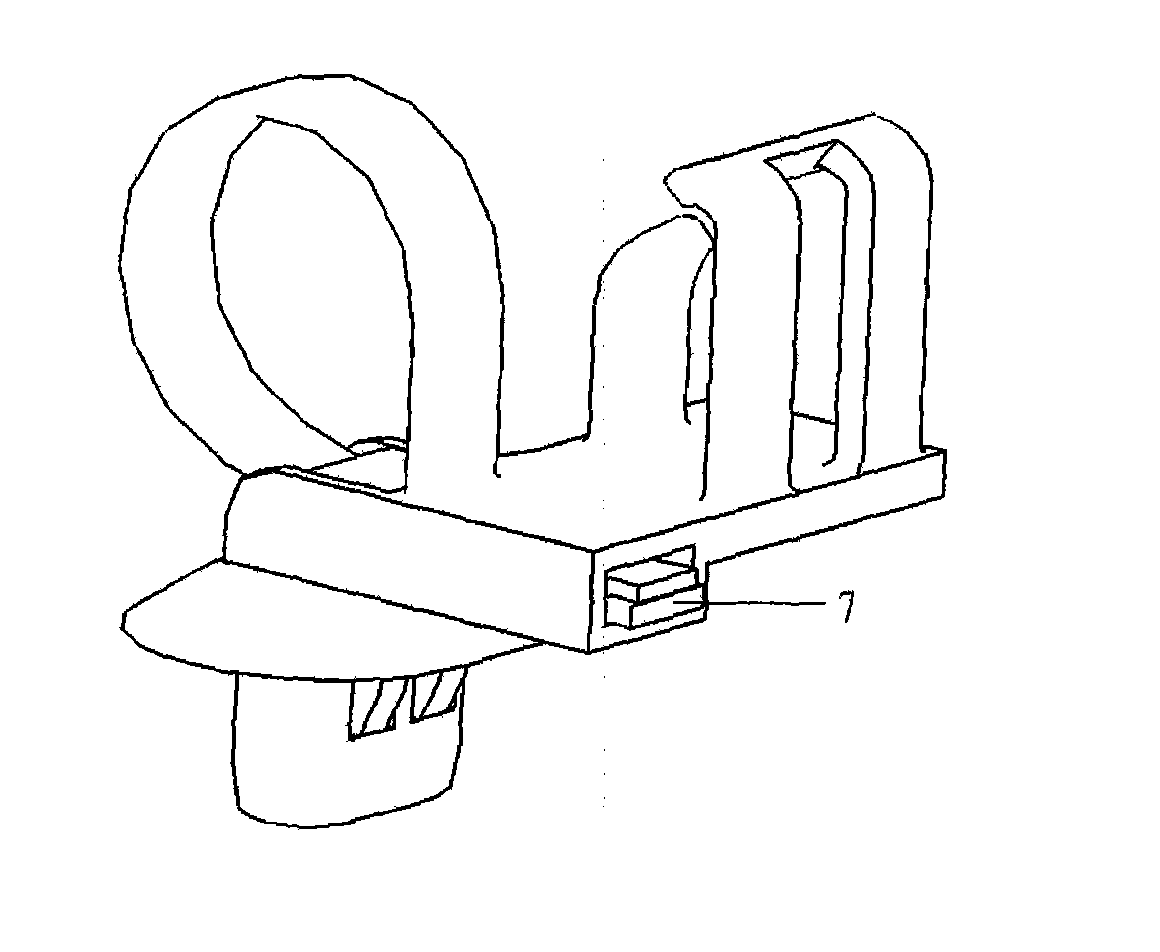

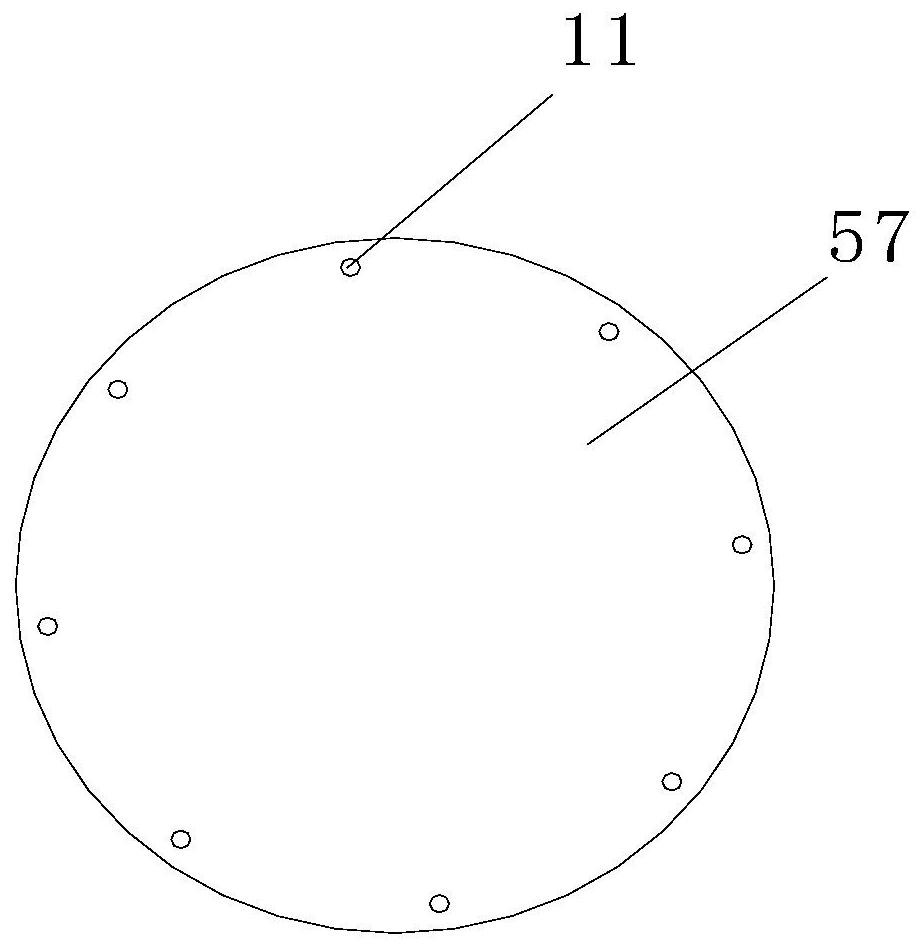

Multi-purpose fastening bracket and mounting method thereof

ActiveCN101826709ASmall diameterReduce the height of the occupied spaceElectrical apparatusEngineeringMechanical engineering

The invention relates to a multi-purpose fastening bracket and a mounting method thereof. The multi-purpose fastening bracket comprises a bracket body (10), a clamping groove (11), a baffle clamping structure and a bracket clamping structure. The clamping groove (11) is arranged inside the bracket body (10) in a downwards concave form and is used for accommodating wiring harnesses and / or pipelines in a vehicle; the baffle clamping structure is arranged on the bracket body (10) and can seal and open the clamping groove (11); and the bracket clamping structure is arranged the other side of the bracket body (10) opposite to the baffle clamping structure and is used for fixing the multi-purpose fastening bracket in a sheet metal hole.

Owner:CHERY AUTOMOBILE CO LTD

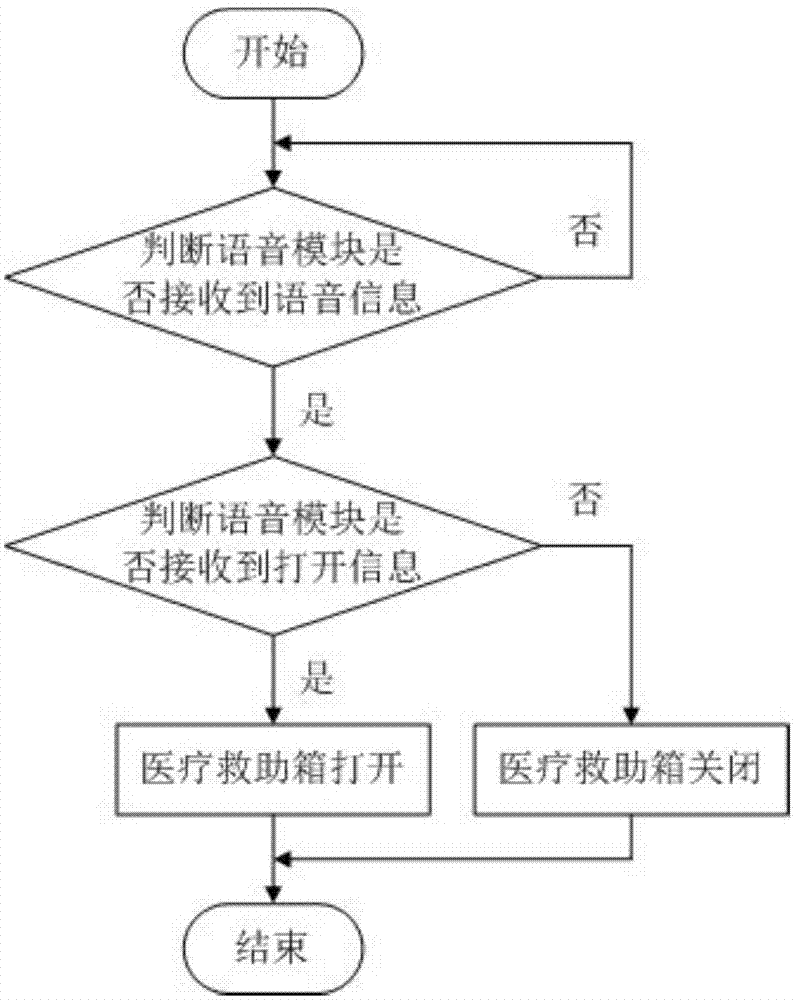

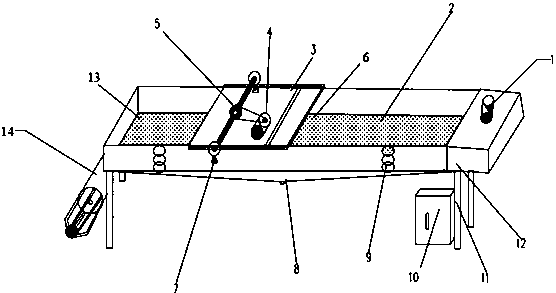

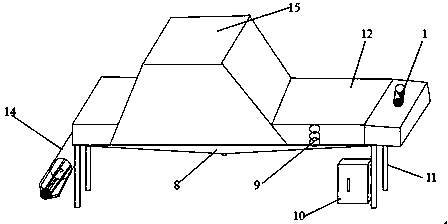

Small rotor flying robot for medical assistance

InactiveCN103792947AReduce shipping costsImprove flight stabilityAttitude controlPosition/course control in three dimensionsMedical treatmentHeavy traffic

The invention discloses a small rotor flying robot for medical assistance and belongs to the technical field of robots. The small rotor flying robot for medical assistance is used for transportation of medical assistance medicine and medical instruments in heavy-traffic cities or remote mountainous areas. The small rotor flying robot for medical assistance comprises a machine body, an autopilot system and a medical assistance system, wherein the autopilot system comprises a sensor subsystem, a flight control computer and a servo power system, the flight control computer is connected with the sensor subsystem and is used for processing data obtained by the sensor subsystem, and the flight control computer is connected with the servo power system and is used for controlling work of the servo power system and adjusting the flight speed and flight attitude. The small rotor flying robot for medical assistance has the advantages of being low in cost, fast and accurate in positioning.

Owner:HARBIN WEIFANG INTELLIGENT SCI & TECH DEV

Vibrating solid-liquid separator

InactiveCN104667607AEasy to separateAvoid cloggingFiltration circuitsMoving filtering element filtersWastewaterEngineering

The invention discloses a vibrating solid-liquid separator. The vibrating solid-liquid separator comprises a water inlet, a screen, a vibrating device, an elastic assembly, a rack and a discharging hole, wherein the water inlet is formed in one end of the rack, the discharging hole is formed in the other end of the rack, the elastic assembly is assembled below the rack, the screen is installed in the rack, the vibrating device driven by a motor is also assembled at one end, which is close to the discharging hole, of the rack, and pendulums are installed on two sides of the vibrating device. According to the vibrating solid-liquid separator disclosed by the invention, the pendulum vibrating structure is ingeniously designed to be matched with the elastic assembly, the vertical and horizontal vibration of the screen is achieved by utilizing different weights of the pendulums on the two sides or different installation positions of the pendulums, a separation mode of vertical and horizontal swing for separating coarse particle objects of a manual screen is simulated, night soil can be effectively separated from wastewater sufficiently, the problem of blocking of meshes of the screen can be effectively avoided, and the separator is simple in overall design structure, and is moderate in volume, effectively avoids the problem of blocking of the meshes of the screen and the like, so that the working efficiency is relatively high, and the manufacturing cost and the use cost of equipment are relatively low.

Owner:ZHANGZHOU LIANNANQIANG ENVIRONMENTAL PROTECTION TECH CO LTD

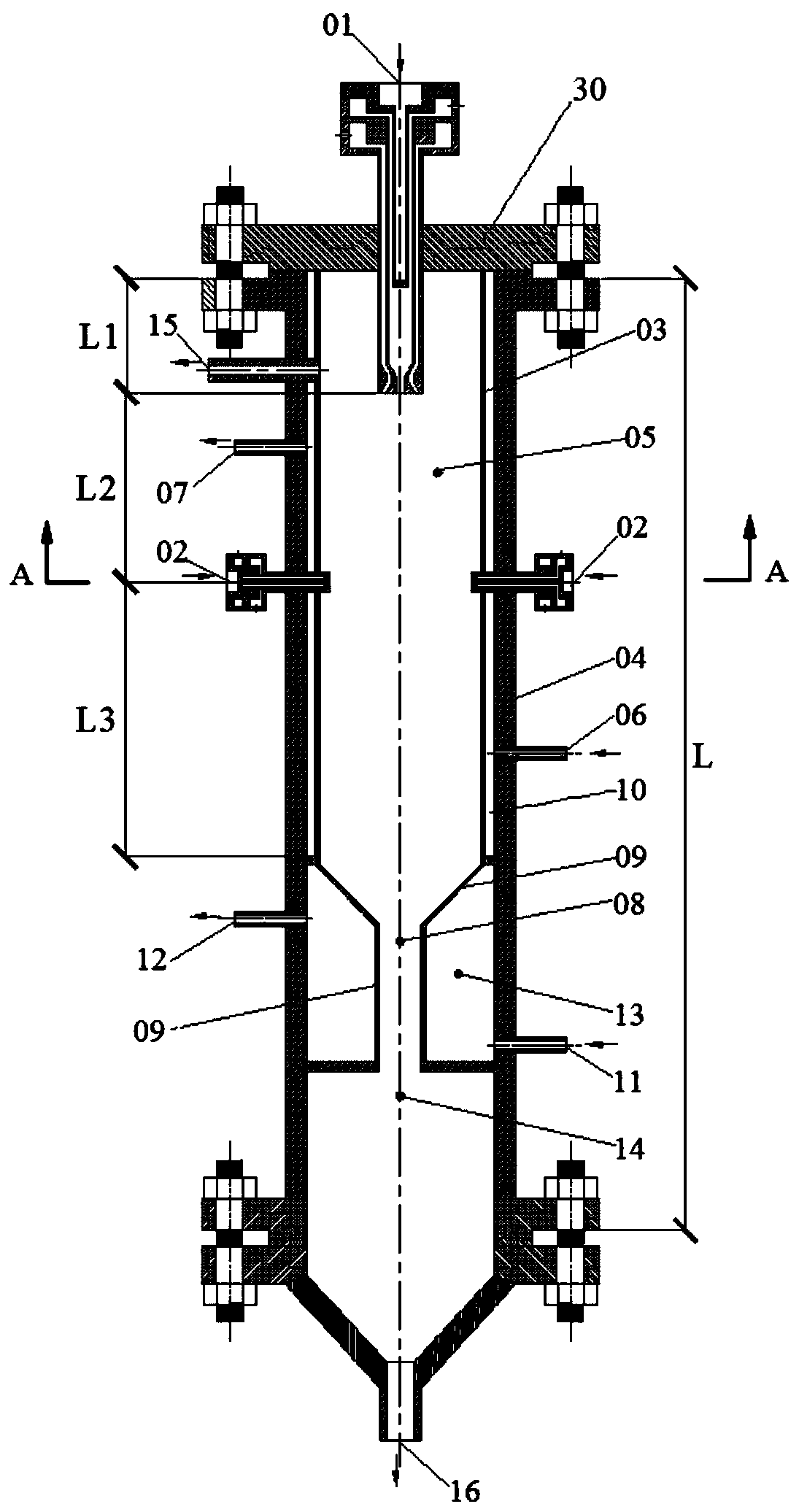

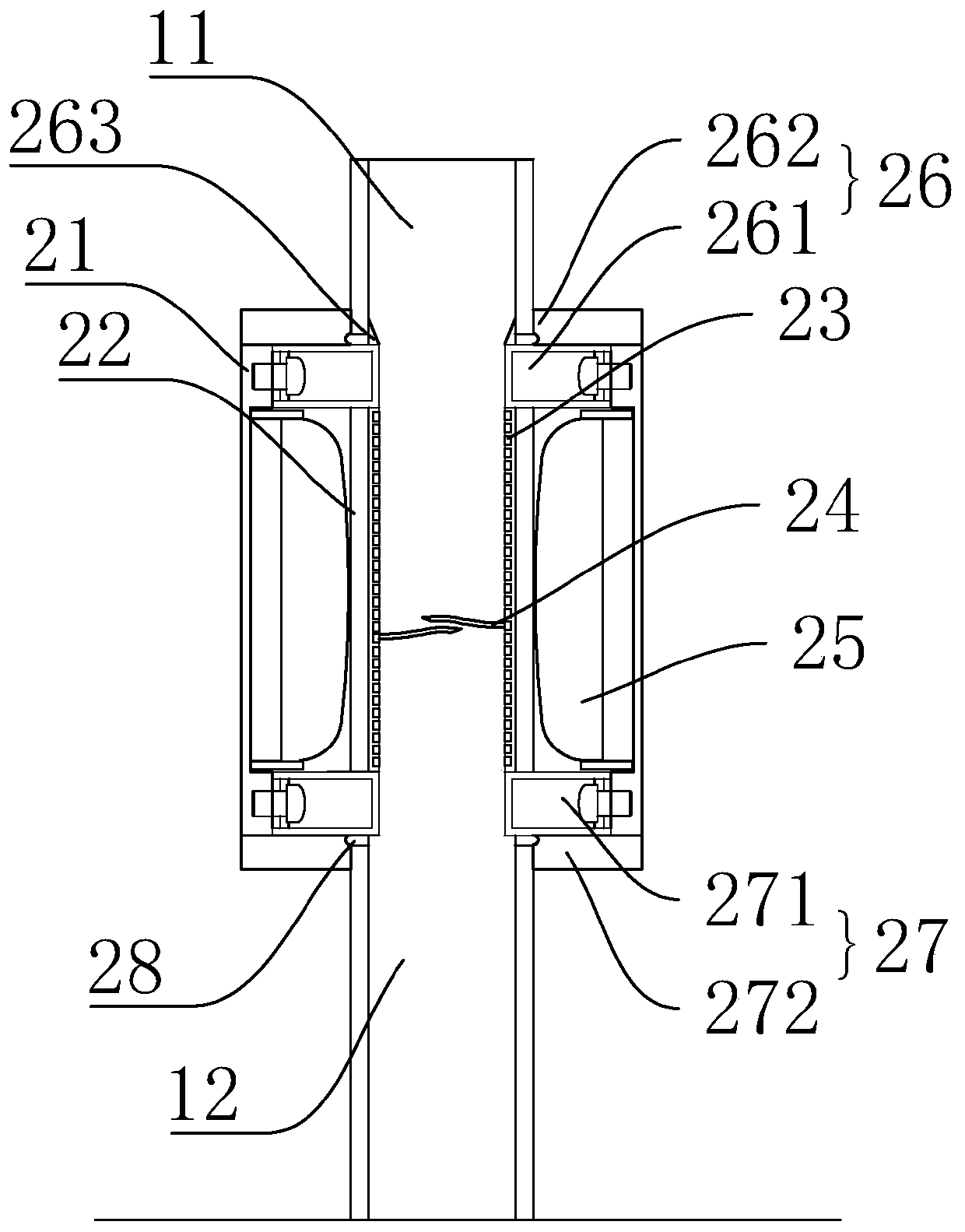

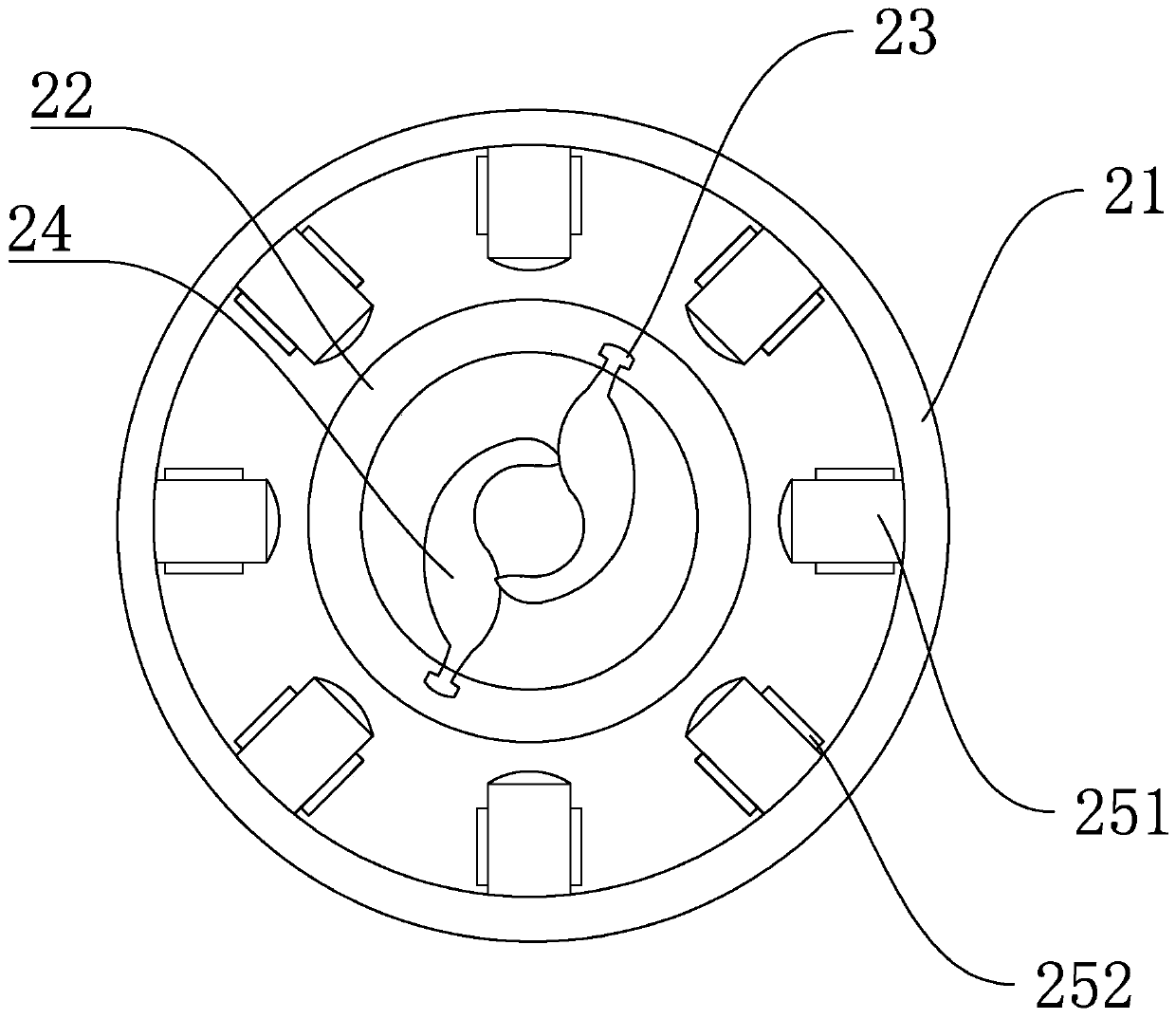

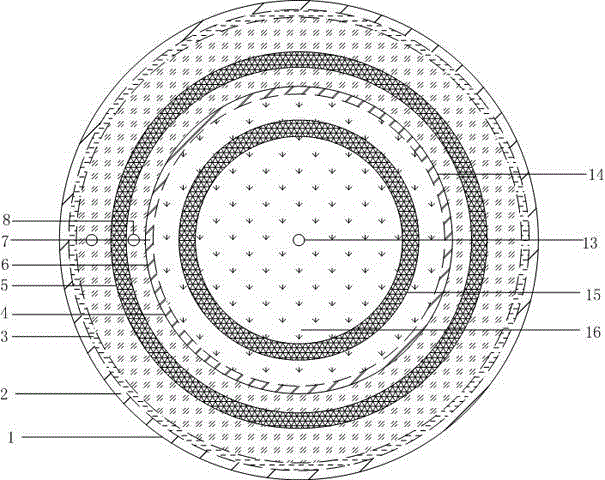

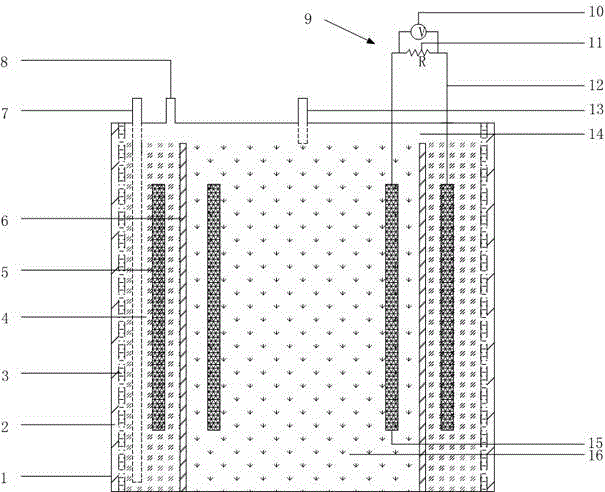

Microbial fuel cell for in-situ remediation of nitrate pollution of underground water

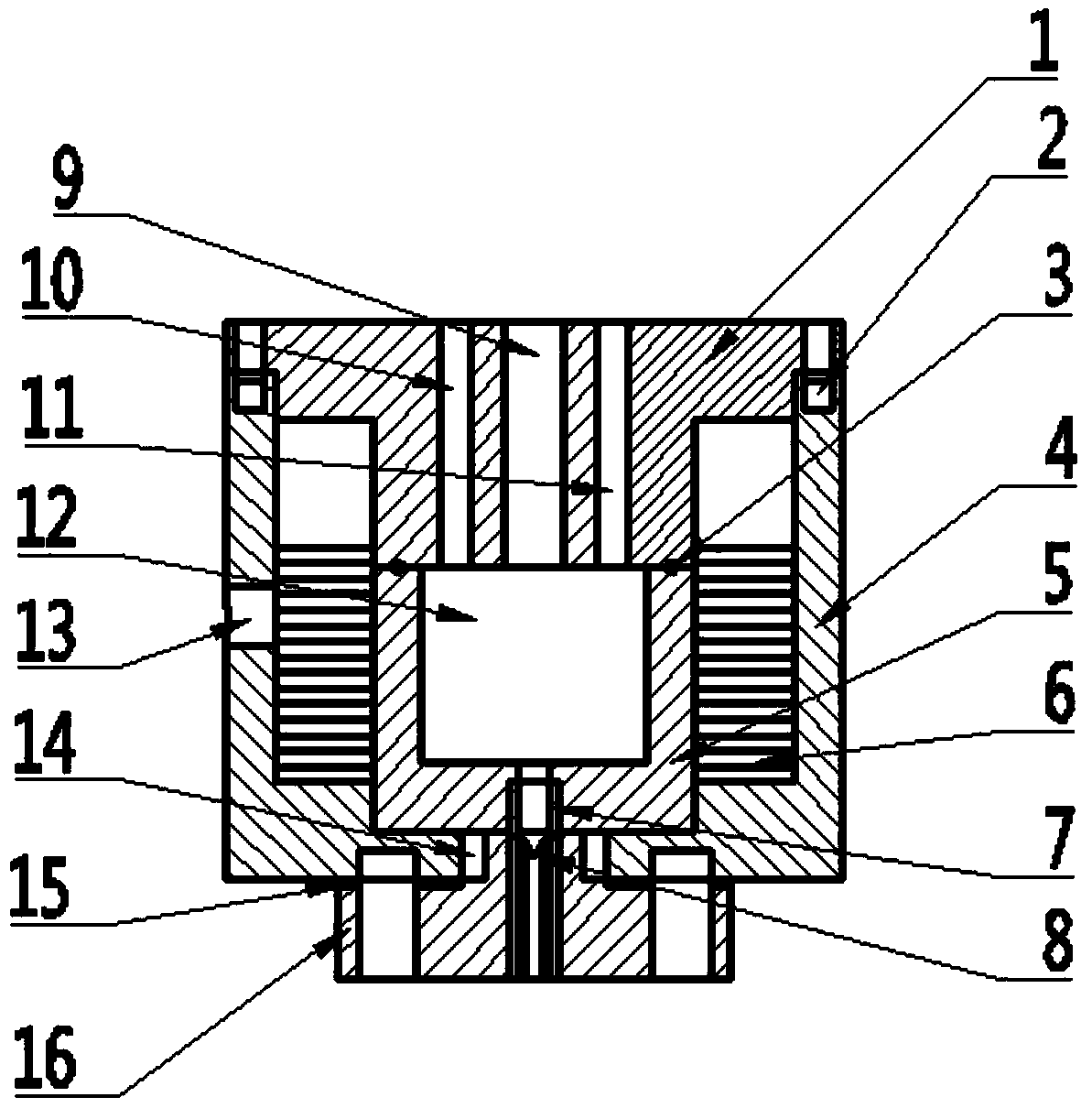

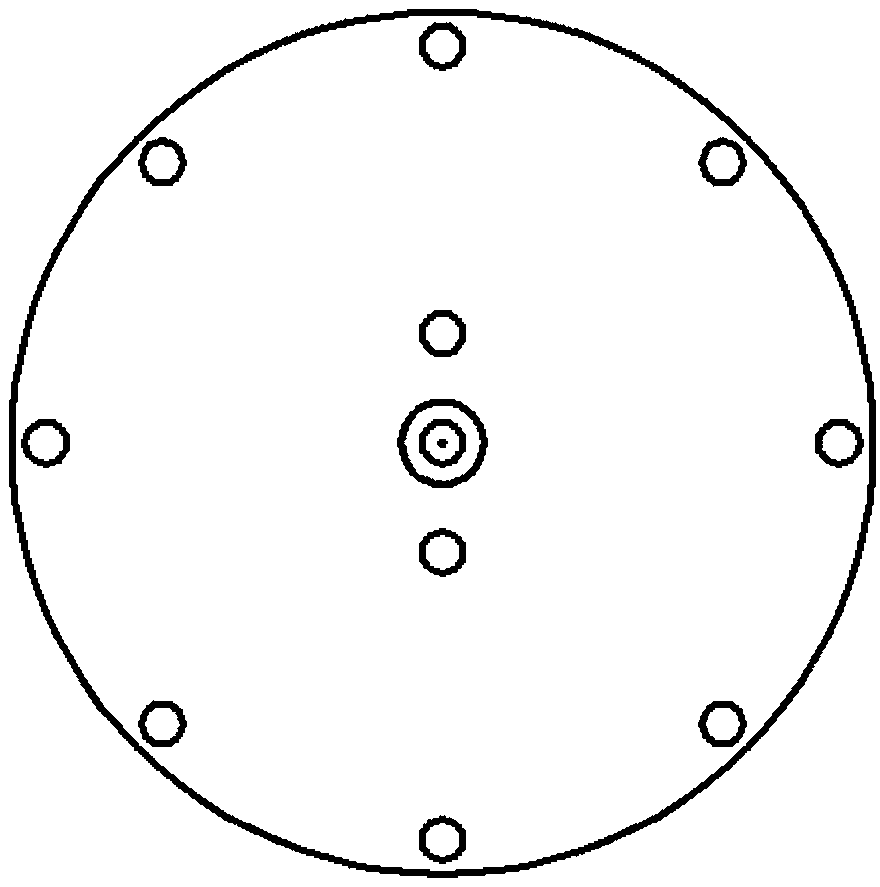

ActiveCN104681844AAchieve continuous operationAvoid problems such as cloggingBiochemical fuel cellsBiological water/sewage treatmentExhaust pipeDenitrification

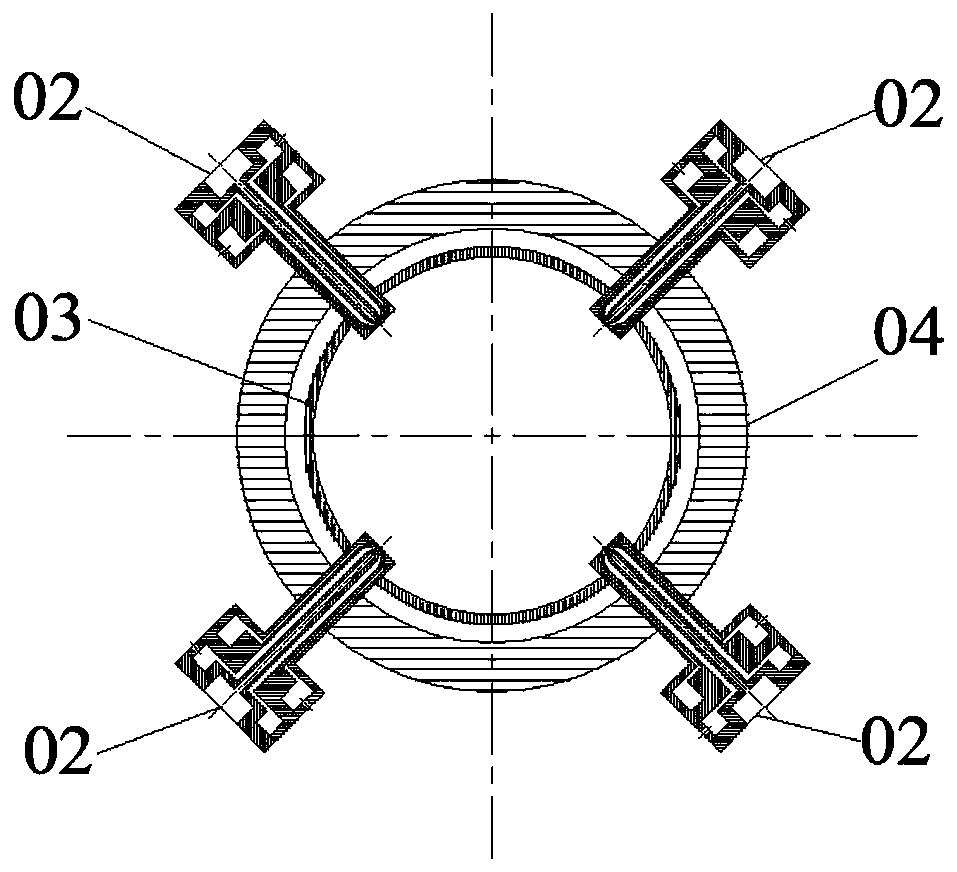

The invention discloses a microbial fuel cell for in-situ remediation of nitrate pollution of underground water. The microbial fuel cell is in an integral cylindrical structure and comprises an anode chamber, a cathode chamber, an anion-exchange membrane assembly and an external circuit system, wherein the anode chamber is externally arranged at the outer side of the cathode chamber in a sleeving manner, a water inlet pipe and an exhaust pipe are arranged on the top of the anode chamber, a biological anode is arranged in the anode chamber, anaerobic electricity-generating microorganisms are attached to the biological anode, the anode chamber is filled with an anode liquid and the anode liquid is organic wastewater; a water outlet pipe is arranged on the top of the cathode chamber, a biological cathode is arranged in the cathode chamber, electric active denitrification microorganisms are attached to the biological cathode, the cathode chamber is filled with a cathode liquid, and the cathode chamber is inoculated with efficient anaerobic denitrification microorganisms; the anion-exchange membrane assembly comprises an anion-exchange membrane and a carrying layer; the external circuit system comprises an external circuit, a lead and an electric signal collecting recorder. The microbial fuel cell disclosed by the invention has triple functions of removing organic wastes, generating electricity by the microorganisms and carrying out the in-situ remediation on the nitrate pollution of the underground water, is simple and compact in structure, is economic and efficient, and can continuously and stably operate.

Owner:OCEAN UNIV OF CHINA

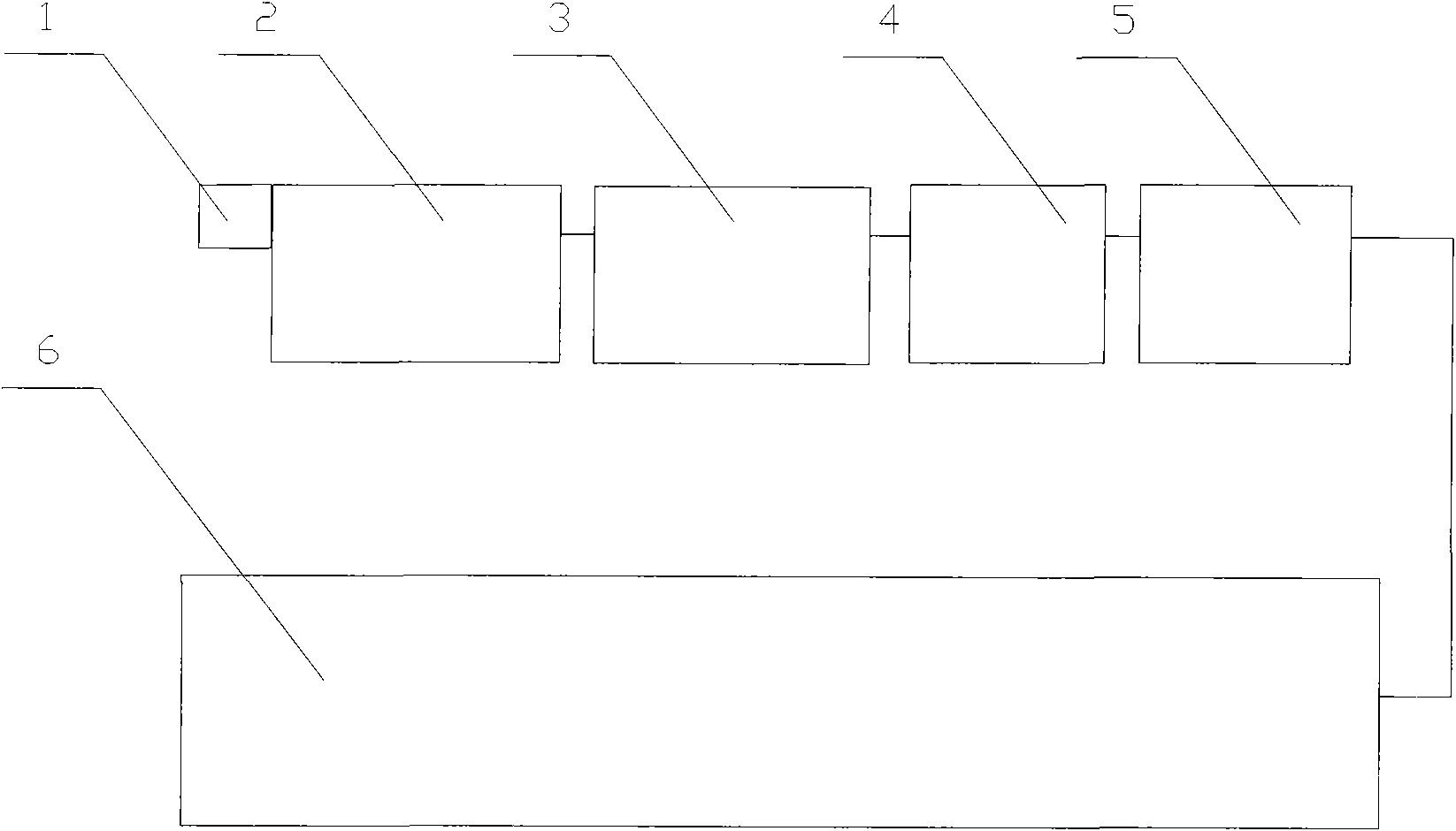

Sewage treatment system for artificial wetland primarily

InactiveCN101585642AEliminate bulky materialReduce areaMultistage water/sewage treatmentSustainable biological treatmentConstructed wetlandSlag

The invention relates to a sewage treatment system for an artificial wetland primarily, which comprises a bar screen, a water-collecting tank, a flocculation drug mixing tank, a sedimentation tank, an aeration tank and the artificial wetland connected in turn, wherein the base material of the artificial wetland comprises one or more of sand soil mixture, crushed stone, zeolite, limestone, coal slag, steel slag, blast furnace slag, crushed stone, porcelain granules, melon seed piece and pebble; the water outlet of the sedimentation tank is provided with an overflow weir for yielding water; and a stirring paddle is arranged in the flocculation drug mixing tank. The sewage treatment system greatly reduces the concentration of pollutants entering the sewage in the artificial wetland, and certain pollutants difficult to perform biochemical treatment can also be taken out in a mode of flocculation sedimentation, thus the content of the pollutants entering the sewage in the artificial wetland is reduced so as to reduce the area of the artificial wetland, reduce the sedimentation of the pollutants in the artificial wetland, and avoid the generation of the problems of blockage and the like. The sewage treatment system is mainly adapted to domestic sewage and other similar organic sewage.

Owner:HAISIBOTE BEIJING SCIENE & TECH

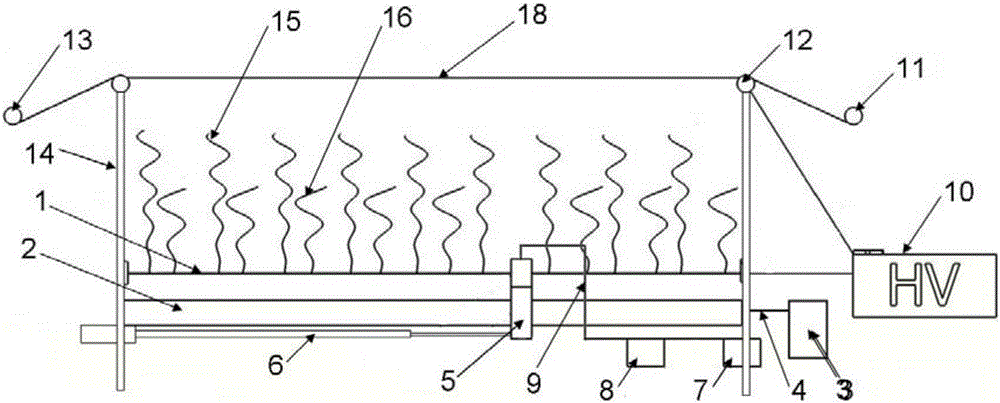

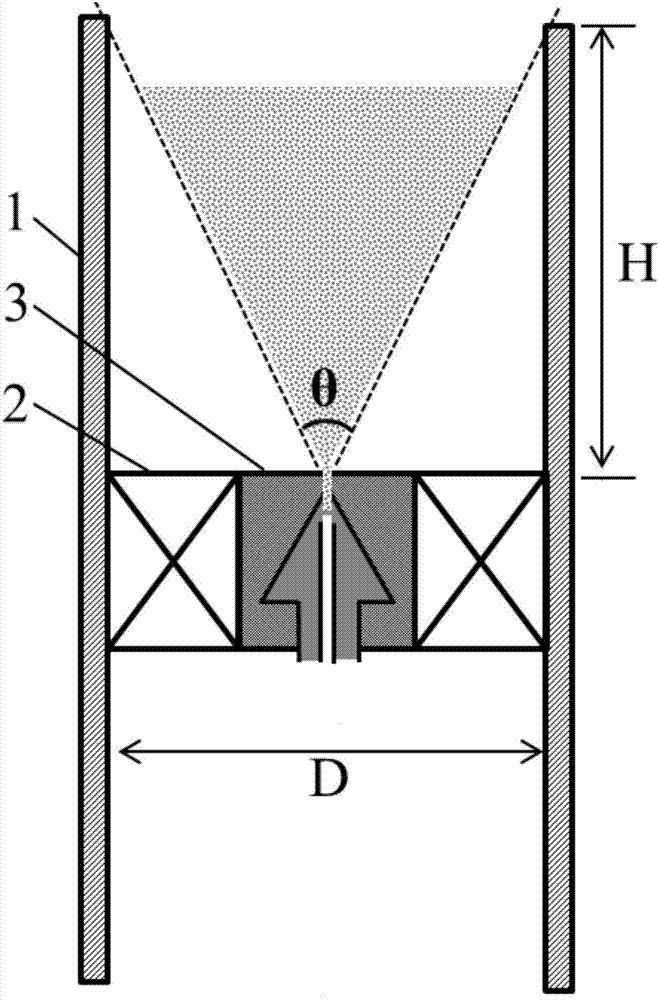

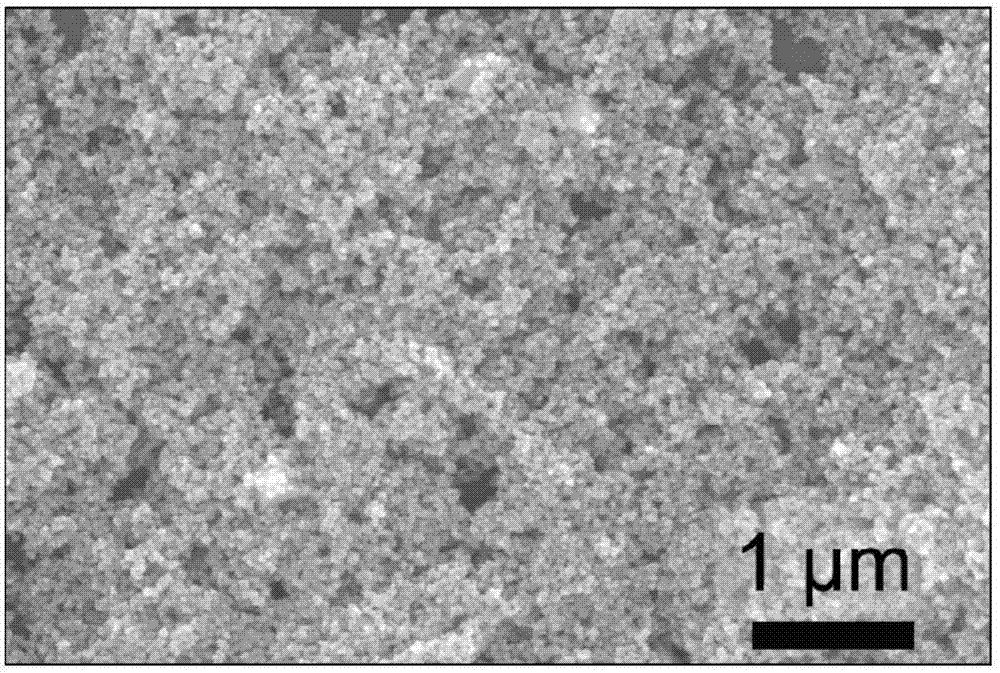

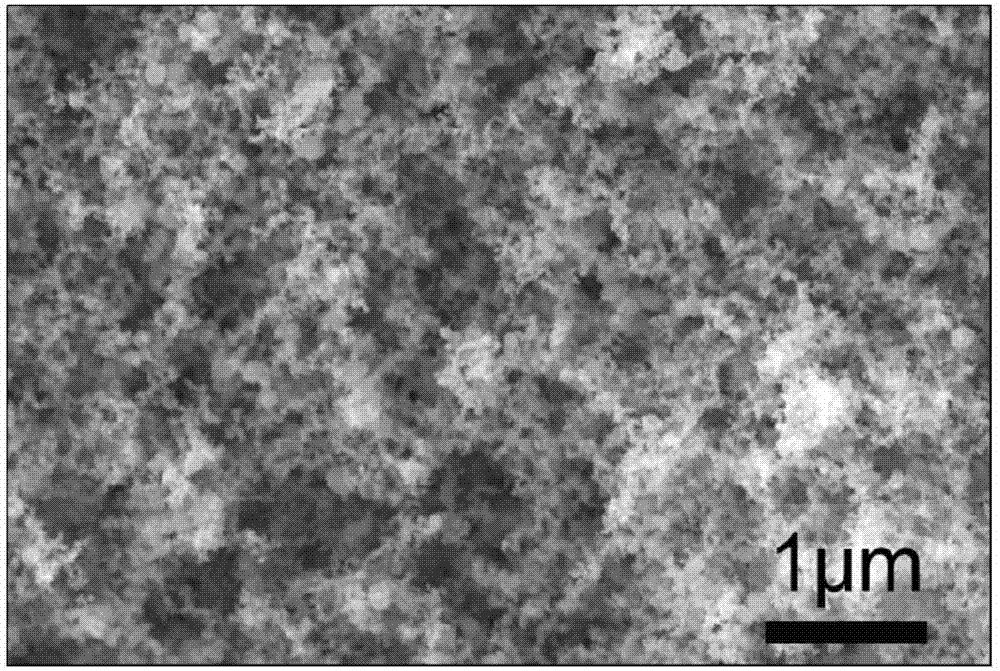

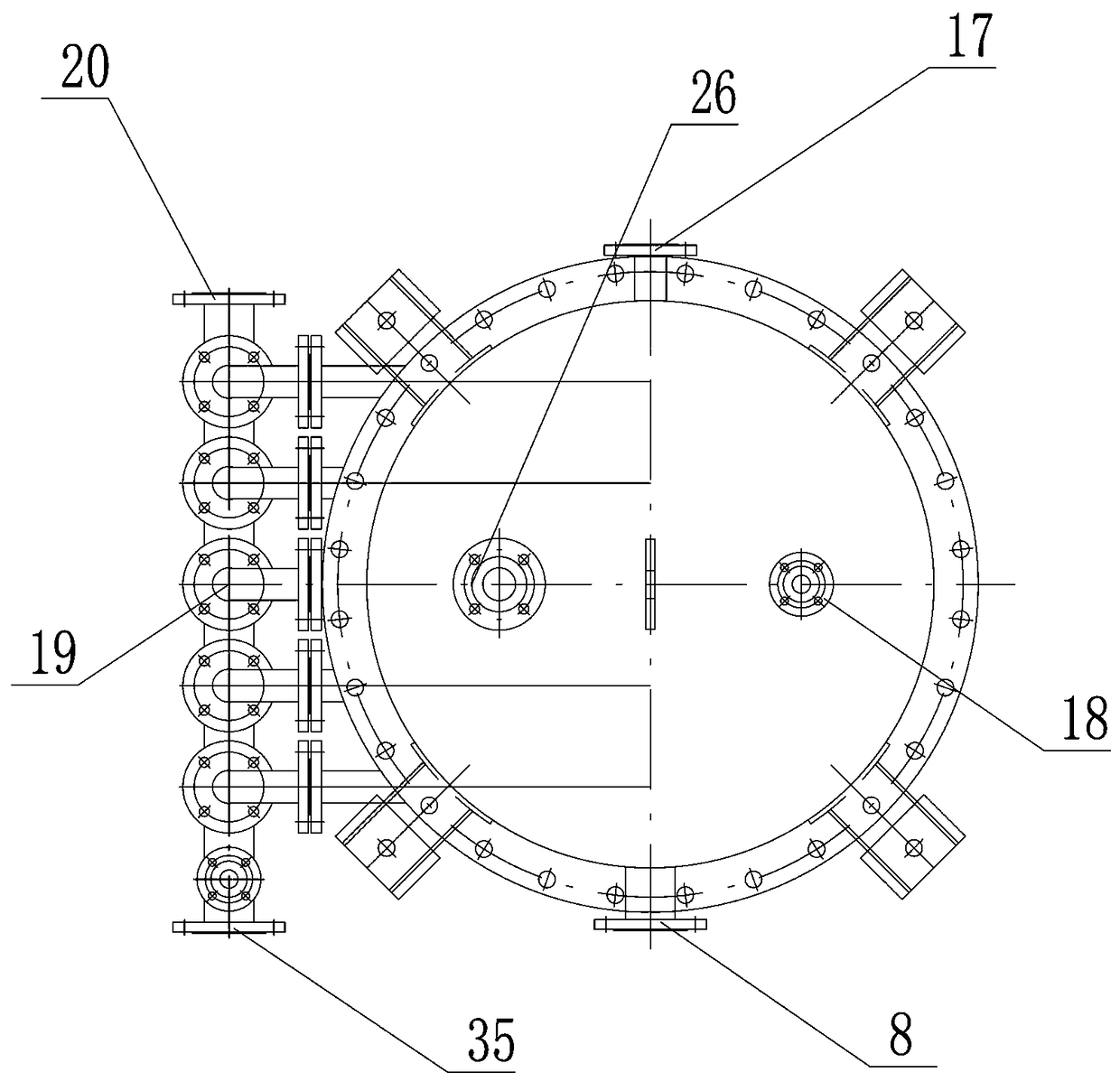

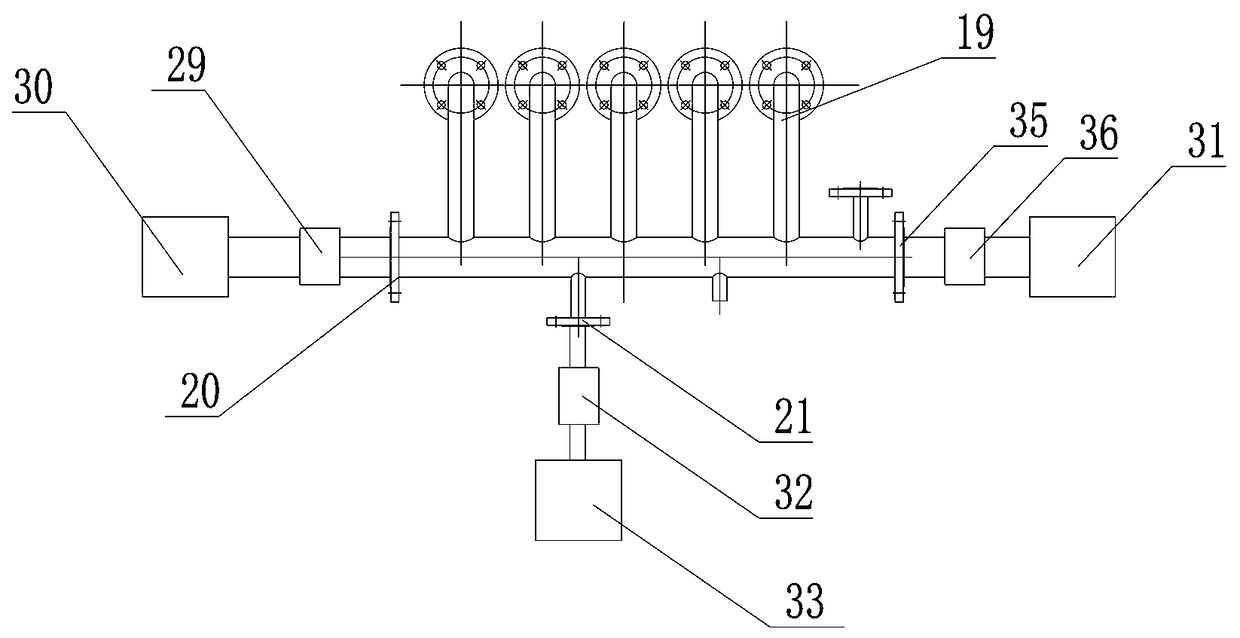

Electrostatic spinning device for preparing nano-fibers on large scale

The invention discloses an electrostatic spinning device for preparing nano-fibers on a large scale. According to the electrostatic spinning device, a straightened metal chain serves as a fiber emitting electrode, the metal chain is connected with a positive electrode of a high-voltage direct current power source, a collector is arranged over the metal chain, the collector is connected with a negative electrode of the high-voltage direct current power source or grounded, a power supply system for jetting airflow upwards is arranged under the metal chain, and a liquid supply system for applying a spinning precursor solution to the metal chain is arranged on the metal chain. The device is simple in operation, the electrospinning fiber efficiency can be remarkably improved, electrospinning fibers with the uniform diameter are obtained, and large-scale production of the micro-nano fibers is achieved.

Owner:聚纳达(青岛)科技有限公司

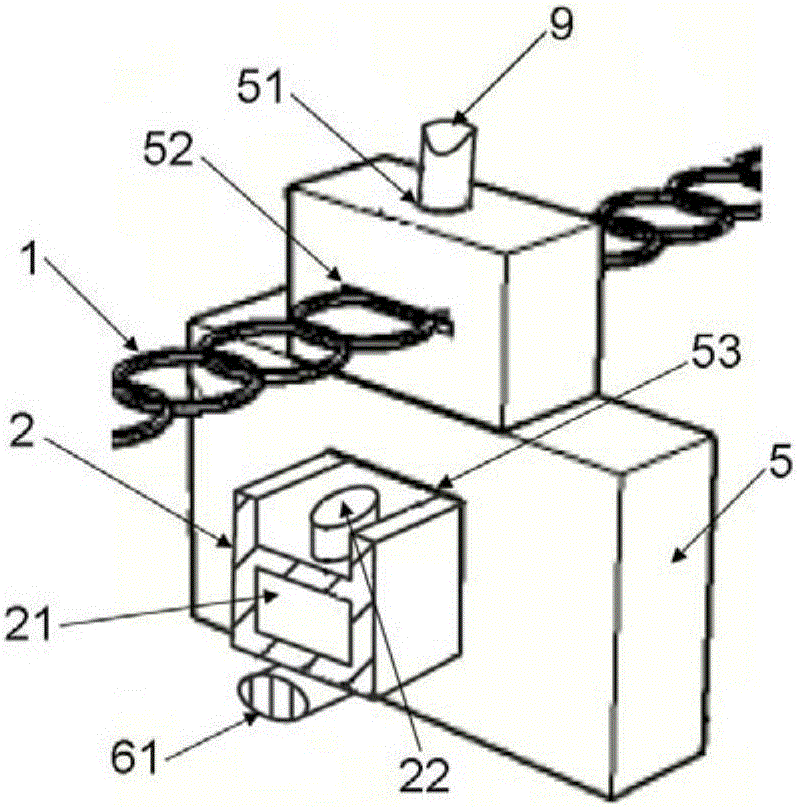

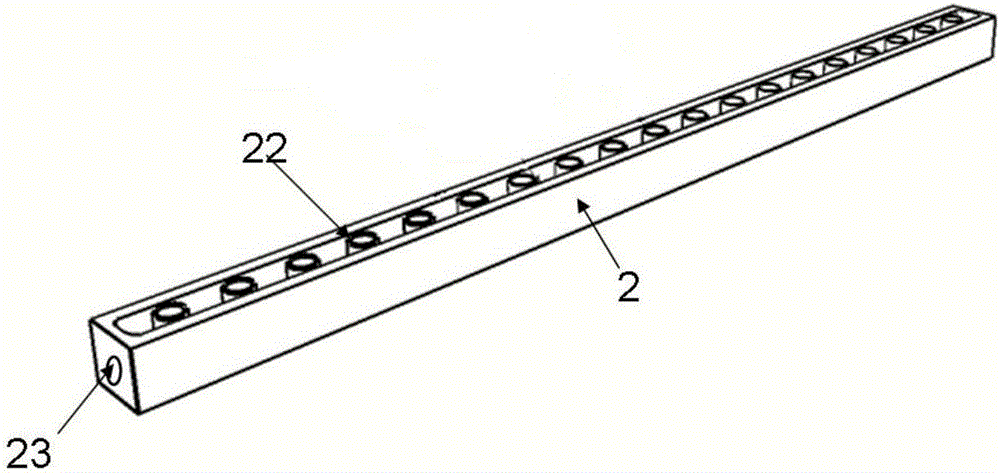

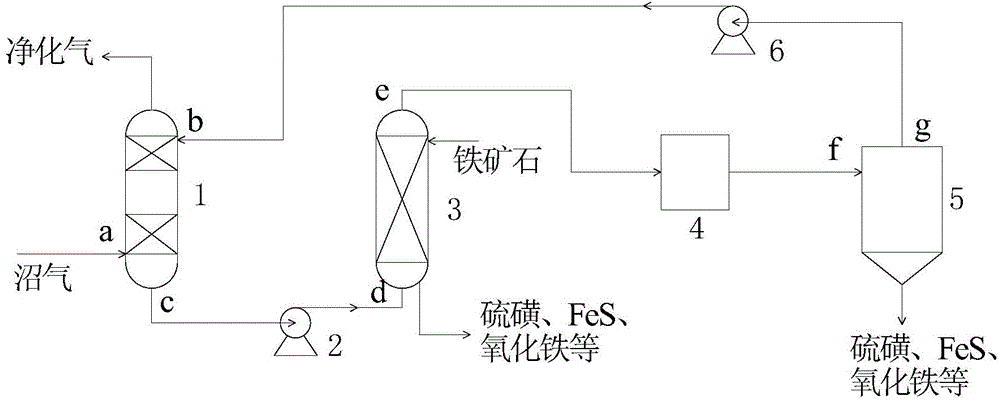

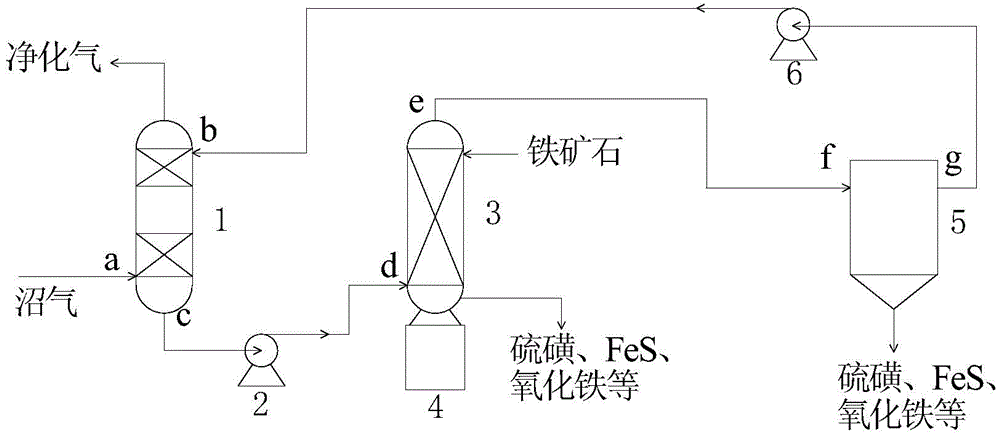

Method and device for removing hydrogen sulfide by methane

ActiveCN103952200AAvoid cloggingRestore alkalinityGaseous fuelsDispersed particle separationIron saltsIronstone

The invention relates to a method and a device for removing hydrogen sulfide by methane. The method comprises the following steps: (1) washing for absorbing methane by using Na2CO3, K2CO3 or a mixture of Na2CO3 and K2CO3 as a sulfur removal absorption solution; (2) performing replacement reaction on the sulfur removal rich solution obtained in the step (1) and solid particles which have the particle size of 1-30mm and contain iron oxide or iron element, and regenerating to obtain regenerated Na2CO3 or K2CO3; (3) performing sulfur recovery and sulfur removal barren solution recycling on a product obtained in the step (2). According to the method, the alkaline liquor absorption and the iron ore replacement regeneration are carried out by unit, so that the problems of deposition, blockage and the like of sulfur in an absorption tower caused by high iron ion concentration during synchronous adding of alkaline liquor and iron ore is avoided; the iron ore replaces iron salt and is cheap and easily available, so that the sulfur removal cost is remarkably reduced; simple equipment is provided for purifying carbon dioxide-rich sulfur-containing gas.

Owner:湖州旧馆頔南污水处理有限公司

Auxiliary airflow type pneumatic on-demand sprayer for reducing diameter of metal droplet

ActiveCN109047767AHigh forming precisionGuaranteed original performanceAdditive manufacturing apparatusSpray nozzleAirflow

The invention discloses an auxiliary airflow type pneumatic on-demand sprayer for reducing diameters of metal droplets, which belongs to the technical field of additive manufacturing. The auxiliary airflow type pneumatic on-demand sprayer comprises three parts: a heater, a sprayer, and an auxiliary air circuit device. The heater is mainly composed of a heating ring; the sprayer is mainly composedof an alloy casing, a nozzle casing, a nozzle, an end cover and the like; the auxiliary airflow device is mainly composed of an auxiliary airflow disk. In 3D printing, the on-demand sprayer can reducethe diameters of the droplets by adjusting the airflow of the auxiliary air circuit for a situation that the diameter of the nozzle cannot be continuously reduced, and can also be used for adjustingsome special cases that it is easy to oxidize when special metals are sprayed and the like; the forming precision is effectively improved, the original performances of the materials are ensured, and the working requirements under different conditions are satisfied.

Owner:BEIJING UNIV OF TECH

Method and device for fixing automotive wiring harness and washing pipe

ActiveCN101640394ASmall diameterReduce the height of the occupied spaceElectrical apparatusElectric/fluid circuitBandageMechanical engineering

The invention relates to a method and a device for fixing an automotive wiring harness and washing pipes, aiming to fix parts such as the wiring harness, the washing pipes and the like more reasonablyand reliably. The invention adopts the technical scheme that the method for fixing the automotive wiring harness and the washing pipes is characterized in that a main body of a fixing bracket is a flat plate with a wiring harness bandage, the wiring harness is fixed with the bracket by the harness bandage; the flat plate is provided with a washing pipe fixing clamp, the washing pipe is fixed withthe bracket by the fixing clamp, a buckle at the lower part of the flat plate is buckled in an automotive metal plate hole so as to fix the fixing bracket with the automotive metal plate.

Owner:CHERY AUTOMOBILE CO LTD

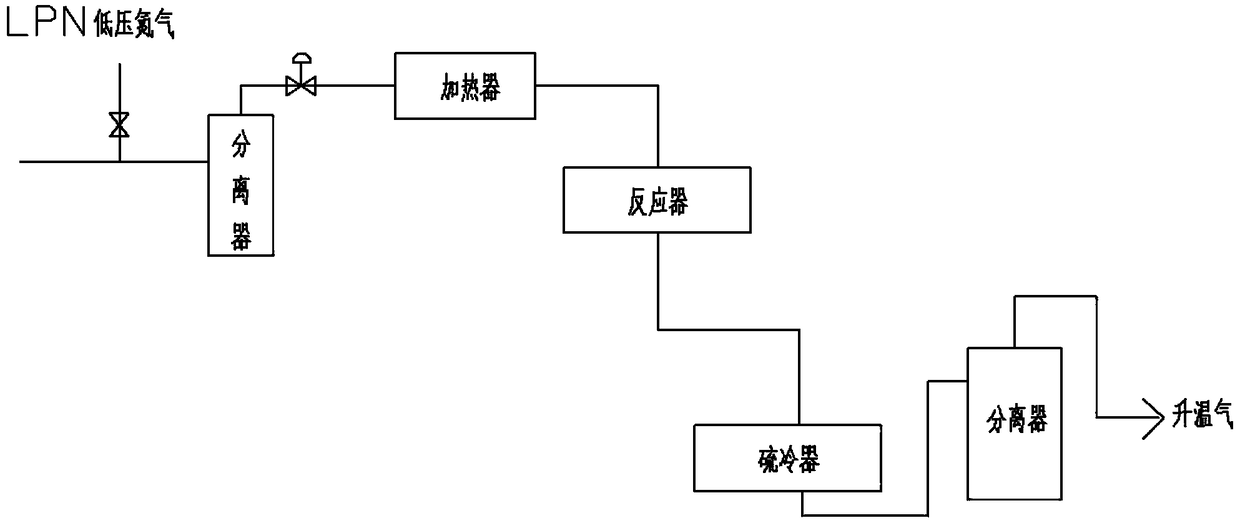

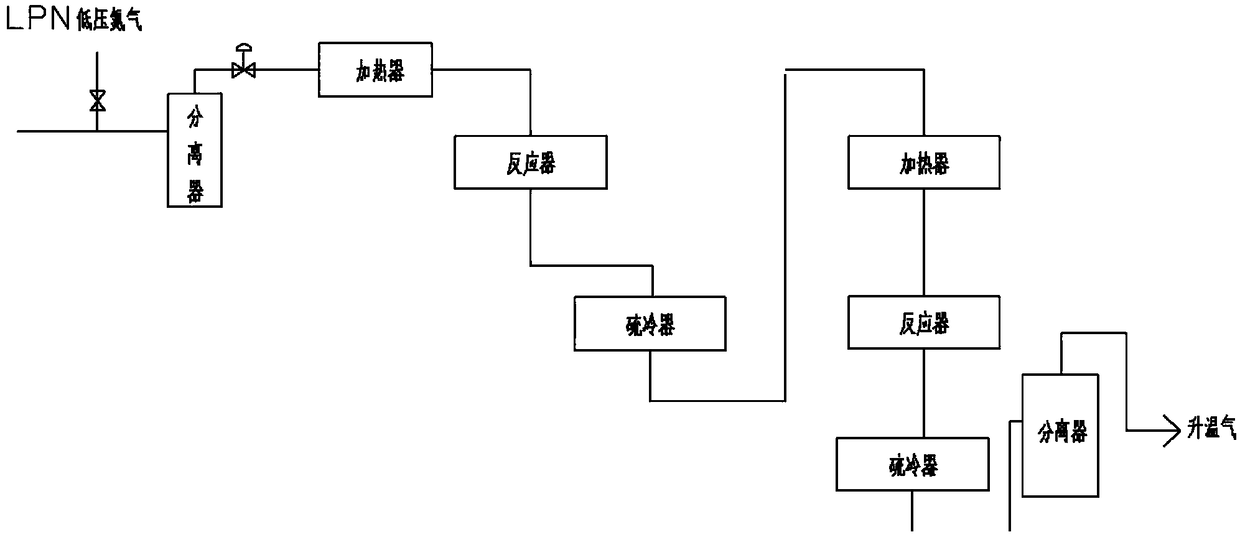

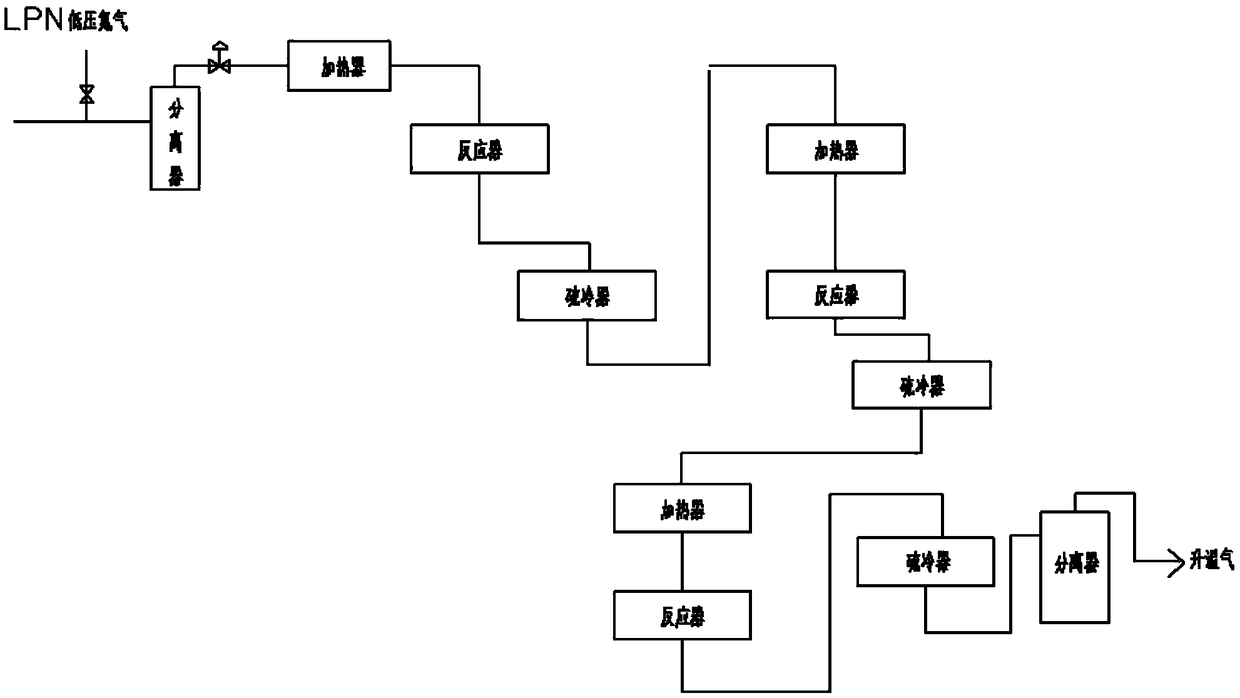

Recovery process for purifying sulfur with coal-to-methanol synthesis gas

ActiveCN109485018AAvoid overheating inactivationSmooth temperature changeSulfur compoundsEnergy inputWater vaporCarbon deposit

The invention provides a recovery process for purifying sulfur with coal-to-methanol synthesis gas. The process comprises the following steps: performing replacement on a reactor and a system nitrogentemperature rise system, and heating a sulfur recovery catalyst bed by adopting nitrogen; clearing sulfur after stopping sulfur recovery, controlling the temperature of a heater at the inlet of the reactor, heating by medium pressure steam, ensuring the temperature of the inlet of the bed to be 120-260 DEG C, and clearing sulfur while controlling the bed temperature to 120-260 DEG C. The volume content of H2S and S at the outlet of the bed is less than 0.01%, and when no liquid sulfur is discharged during drain recovery of a system condenser, the operation of clearing sulfur with nitrogen isended. According to the process disclosed by the invention, catalyst starting can be completed, the activity temperature is met, and in the processes of raising the temperature of the sulfur recoverycatalyst and stopping sulfur clearing, incineration side-reactions are fundamentally avoided, so that the influences of carbon deposit and water vapor on the catalyst activity can be eliminated. In addition, the inert gas nitrogen is taken as the sulfur-clearing carrier, so that unsafe factors brought by leakage are fundamentally eliminated, and intrinsic safety is realized.

Owner:HENAN LONGYU COAL CHEM

Interlock-controlled sediment eluting and screening system and eluting and screening method thereof

PendingCN107555739ATo achieve the purpose of classification processingControl Stirring IntensitySievingSludge treatmentPhysical chemistryEngineering

The invention discloses an interlock-controlled sediment eluting and screening system and an eluting and screening method thereof. The system comprises an eluting device, a screening device and a variable-frequency spraying pipeline, wherein the eluting device comprises a eluting roller, a material transmitting device and a speed control driving device, the eluting roller is connected with the speed control driving device, and the material transmitting device is arranged in the eluting roller; the screening device is connected to an outlet end of the eluting roller; the variable-frequency spraying pipeline is arranged in the eluting device. The eluting and screening method comprises the steps as follows: (1) sediment is scattered and fed; (2) the sediment is eluted; (3) the sediment is screened; (4) the eluting roller rotates reversely and the material stirring and eluting time is prolonged; (5) chemical eluting is started and performed through the variable-frequency spraying pipeline,or chemical eluting and clear water eluting are performed alternately. Accurate eluting is realized, energy consumption is reduced, blockage of screen meshes is effectively avoided, and the eluting efficiency is improved; eluting and separation of sediment components with different particle sizes and heavy metal content are realized, and classified treatment of the sediment is realized.

Owner:山东省环科院环境工程有限公司

Sluice with garbage intercepting and sweeping functions

PendingCN112627126AImprove the efficiency of interception operationsImprove efficiencyBarrages/weirsCleaning using toolsWater flowHydraulic engineering

The invention relates to the technical field of water conservancy projects, and particularly relates to a sluice with garbage intercepting and sweeping functions. The sluice comprises a first fixing frame, a gate plate, a blocking net device and a sweeping device. The first fixing frame is arranged in a water channel; the two sides of the gate plate are in sliding connection with two first sliding grooves formed in the two sides of the first fixing frame correspondingly, and the water channel is opened or closed through a first hoisting assembly; the blocking net device is used for intercepting garbage in water flow; the sweeping device is arranged above the blocking net device and used for sweeping the garbage intercepted by the blocking net device; the blocking net device comprises a blocking belt, supporting plates and a drive assembly; the two supporting plates are symmetrically arranged on the two sides of the blocking belt; the drive assembly is connected with the blocking belt; and after the blocking belt intercepts the garbage in the water flow, the blocking belt is driven by the drive assembly to lift the garbage to the position below the sweeping device. The sluice solves the problems that in the prior art, manual work continuity is poor, the work efficiency is low, and the intercepted garbage cannot be cleared away in time.

Owner:大同市水旱灾害防御中心 +1

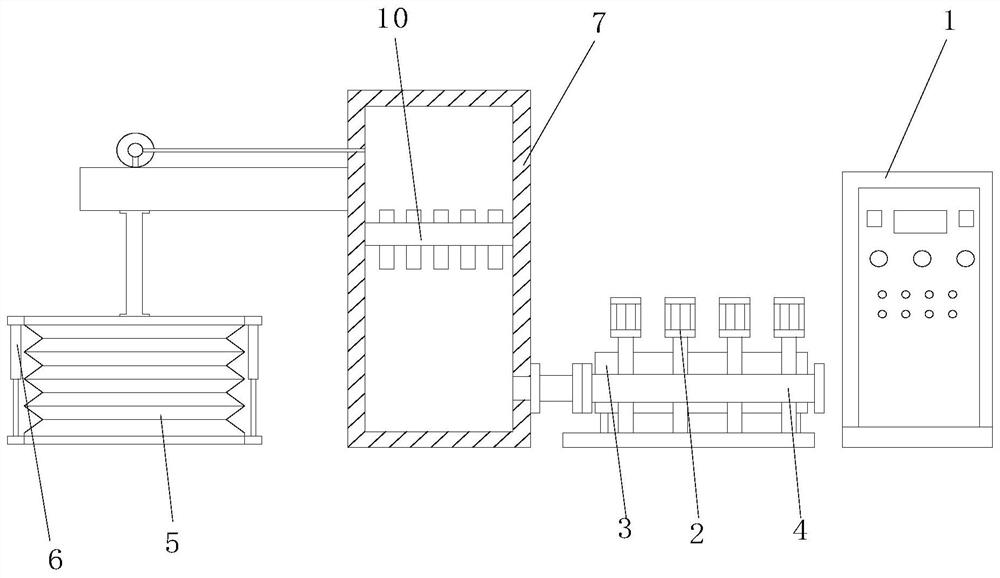

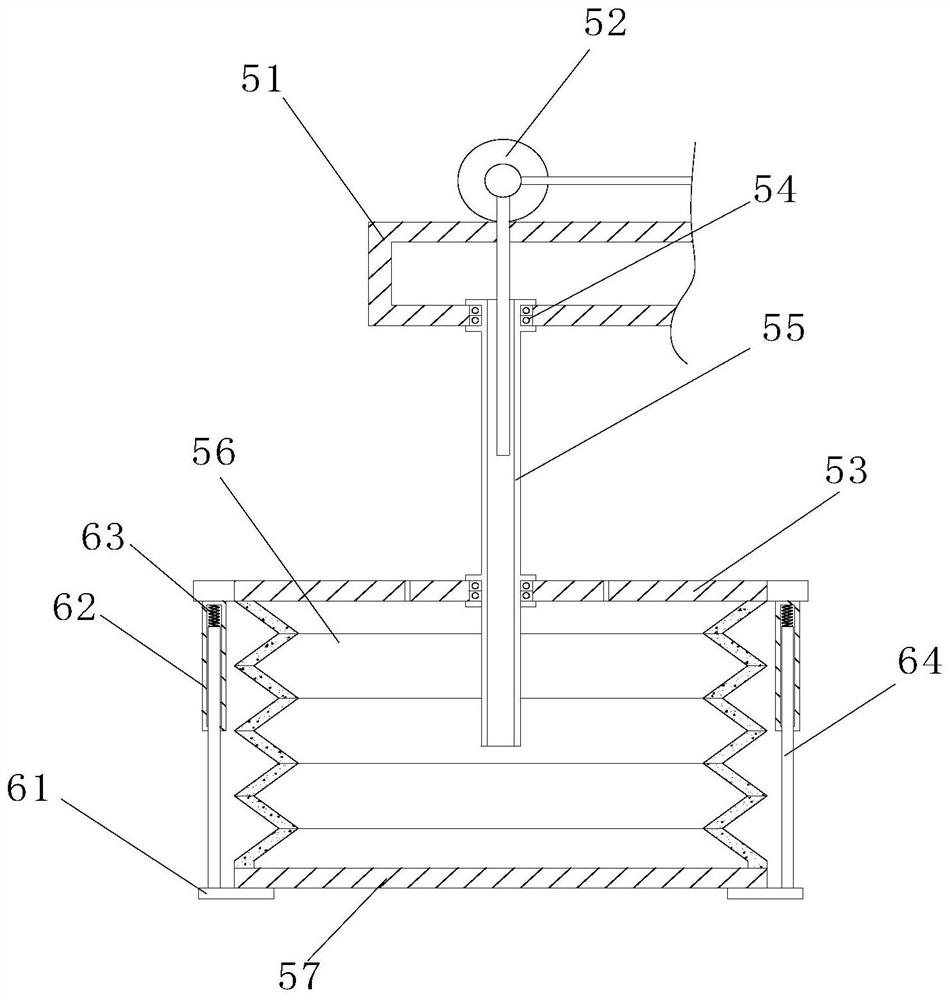

A frequency conversion constant pressure water supply component

The invention relates to the technical field of water supply, and discloses a variable frequency constant pressure water supply assembly, including an electric control cabinet, a water pump group, a pressure tank, a water supply pipe, a water collection mechanism, a telescopic mechanism and a water storage tank, and the inside of the electric control cabinet is fixedly installed with The electric control system, ABB frequency converter, water pump unit, air pressure tank and water supply pipe are all arranged on the left side of the electric control cabinet. The water inlet end of the water supply pipe is fixedly connected and communicated with the water storage tank, and a filter mechanism is fixedly installed inside the water storage tank. The filter mechanism adopts the reverse osmosis membrane filter mechanism. The water collection mechanism is fixedly installed on the left side of the water storage tank. It sinks, thereby expanding the water collection space, and its deformation range can be freely changed according to the strength of the external water pressure, which has the effect of automatically balancing the internal and external pressure. Compared with the existing water collection mechanism, it can avoid external water pressure Added the benefit of being too large to cause damage to the water collection mechanism.

Owner:SHANGHAI BANGPU INDAL GROUP

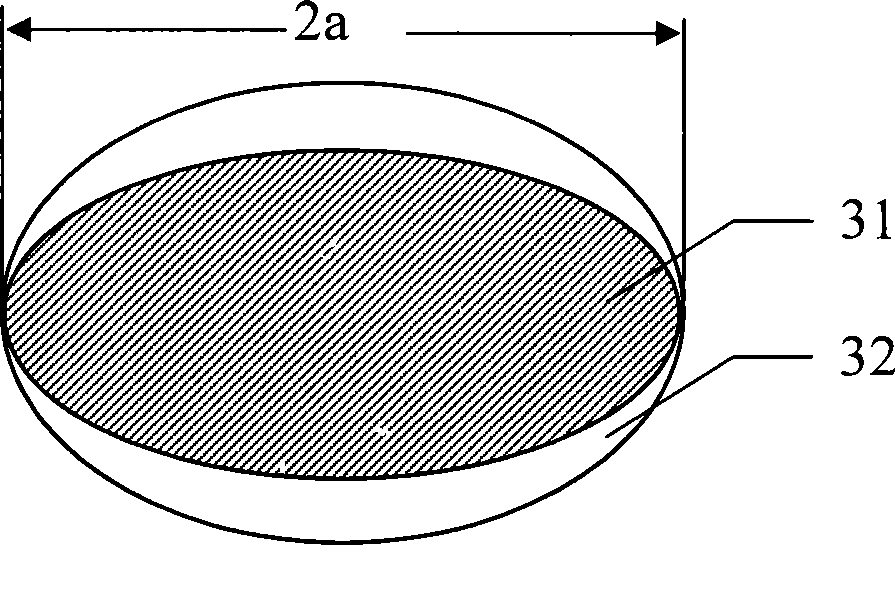

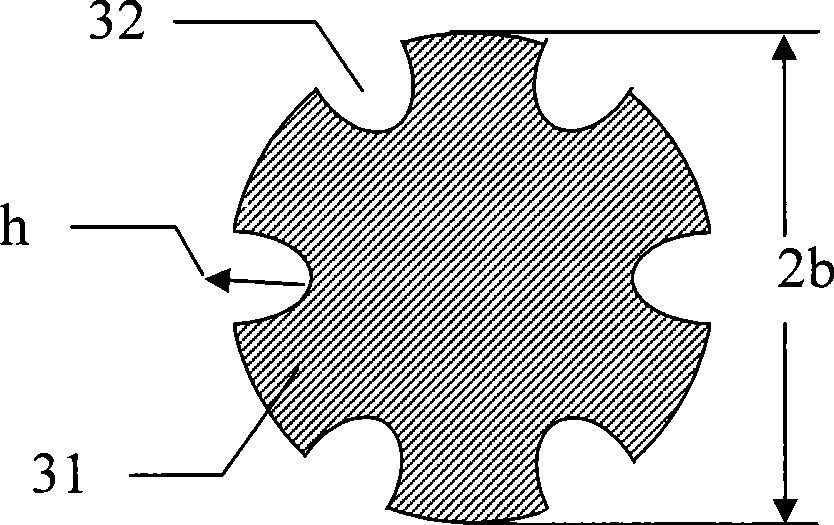

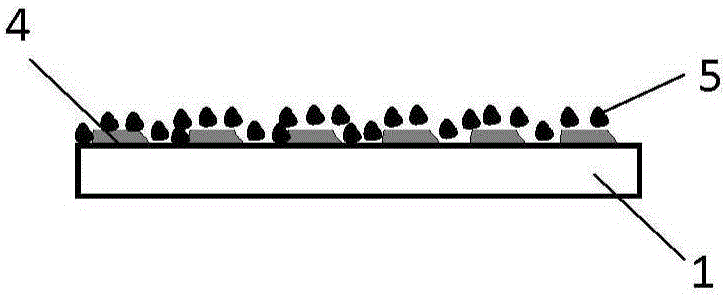

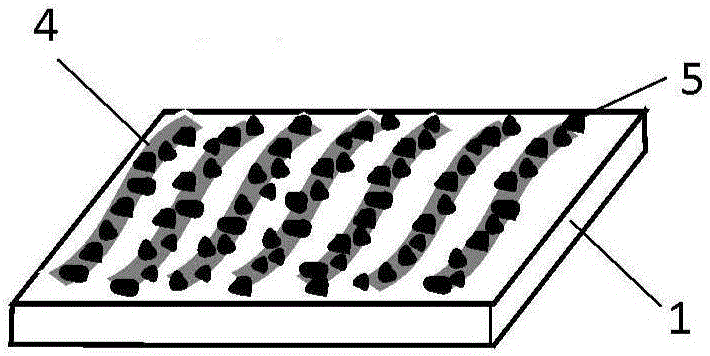

Method for manufacturing abrasive pattern arrangement brazed grinding wheel based on laser pre-fusion covering

ActiveCN106312849AAchieve preparationAvoid Contour Insufficient DefectsGrinding devicesNumerical controlOptoelectronics

The invention discloses a method for manufacturing an abrasive pattern arrangement based on laser pre-fusion covering. The method includes the steps that firstly, a work face of a grinding wheel base body is coated with binding agents; secondly, a laser focusing spot is driven to conduct scanning and fusion covering heating on the binding agents according to the abrasive arranged patterns, and therefore the binding agents heated by lasers are melted and form a fixedly-connected fusion covering layer with the grinding wheel base body; thirdly, the binding agents not heated through laser fusion covering are removed, the upper surface of the fusion covering layer is cut to be flat, and therefore the thickness of the fusion covering layer is consistent; and fourthly, abrasives are scattered and planted on the work face of the grinding wheel base body, the grinding wheel base body is subjected to heating, heat preservation and cooling in sequence, the abrasives located on the fusion covering layer are bonded to the fusion covering layer, and finally the abrasives not bonded to the fusion covering layer are removed. The advantage that numerical control is used for driving the lasers to conduct local selective fusion covering is sufficiently utilized so that manufacturing of grinding discs with complex abrasive patterns arranged can be achieved; melting and connecting of diamond are achieved through the fixed-thickness binding agent fusion covering layer, and therefore the grinding characteristic of the grinding wheel is effectively improved; and the problem about positioning and the problems of mesh blocking and the like generated during template and screen method implementation are solved, and the manufacturing efficiency is greatly improved.

Owner:HUAQIAO UNIVERSITY

Spraying combustion device and method for compounding metallic oxide powder by spraying

ActiveCN106976845AImprove product added valueShape is easy to controlOxygen/ozone/oxide/hydroxidePyrolysis reactionsCombustible gasSpray nozzle

The invention relates to a spraying combustion device and a method for compounding metallic oxide powder by spraying. The device comprises a gun body, a flow guiding component and an atomizing nozzle; the flow guiding component is arranged in a hollow chamber of the gun body, is capable of sliding relative to the hollow chamber and is connected with a gas inlet of a combustible gas; the atomizing nozzle penetrates through the flow guiding component and can slide along the hollow chamber following the flow guiding component. The spraying combustion device can realize the optimal matching of spraying and combustion, and meanwhile, the problem of chamber blocking caused by the liquid drops and particles attached to the walls in the spraying combustion process can be effectively avoided, the operation is simple and convenient and the technological process and the preparation time are shortened. The method comprises the step of spraying an aqueous solution containing metal salt into a warm area at 800-2500 DEG C, thereby acquiring the metallic oxide powder. According to the invention, the aqueous solution containing metal salt is selected for replacing a precursor containing organic components in the traditional technology, the production cost is lowered, the technology safety is promoted and the prepared powder product is controllable in morphology and size, high in quality and high in additional value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Backwash filter

ActiveCN109260822AImprove filtering effectAchieve sprayingStationary filtering element filtersHydraulic cylinderEngineering

The invention discloses a backwash filter comprising a housing, a microporous filter cartridge fixedly disposed inside the housing, an upper sealing cover disposed on the upper portion of the housingand a lower sealing cover disposed on the lower portion of the housing. The upper side of the housing is provided with a filter aid inlet, and the inner side of the filter aid inlet is communicated with a filter aid pre-coating device. The filter aid pre-coating device includes a cross rod disposed on the upper side inside the housing, two hydraulic cylinders fixedly disposed below the cross rod,a connecting cross rod fixedly disposed at the top ends of hydraulic cylinder shafts and a precoating port communicated with the filter aid inlet through a connecting hose. The precoating port is fixedly disposed on the connecting cross rod and disposed corresponding to the microporous filter cartridge. The backwash filter has the advantages of high filtering speed, wide application range and highautomation degree.

Owner:石家庄一通过滤器设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com