Method and device for removing hydrogen sulfide by methane

A technology for removing hydrogen sulfide and biogas, which is applied in the field of desulfurization of carbon dioxide-rich sulfur-containing gas and biogas desulfurization. The effect of blower, simplified process equipment, and avoidance of sulfur blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

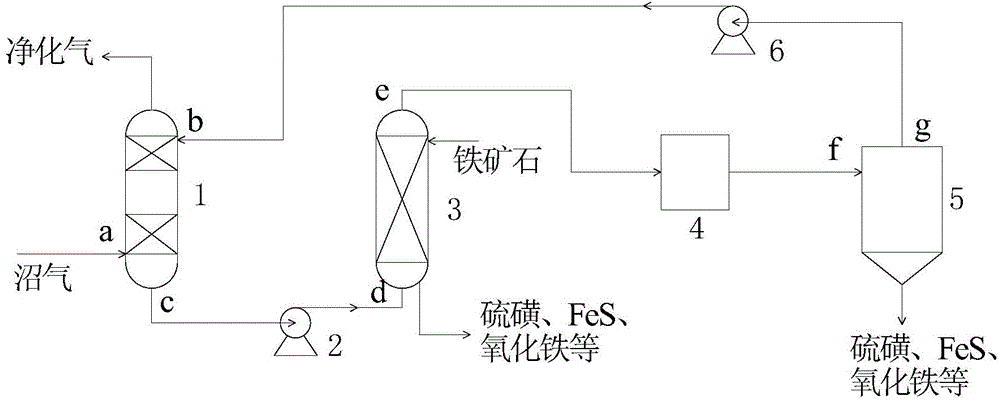

[0025] like figure 1 In the biogas purification and hydrogen sulfide removal method shown, the biogas enters the absorption tower 1 from the bottom a, and injects Na with a pH of 8.5 into the upper inlet b. 2 CO 3 Alkaline countercurrent contact, absorb the H 2 S, the desulfurization efficiency is up to 99.9%, and the purified biogas is discharged from the top of the tower; the rich liquid that has absorbed hydrogen sulfide enters the inlet d of the regeneration tower 3 through the rich liquid pump 2, and is fed from the upper part of the regeneration tower with a particle size of 1-5mm Iron ore, contacting with the rich liquid countercurrently produces a displacement reaction, so that the lye can be regenerated; the regenerated desulfurization liquid is first subjected to the action of the ultrasonic instrument 4 to enhance the stripping of the product sulfur, FeS and other precipitates from the lye, and then enters the precipitation separation The device 5 stands still to ...

Embodiment 2

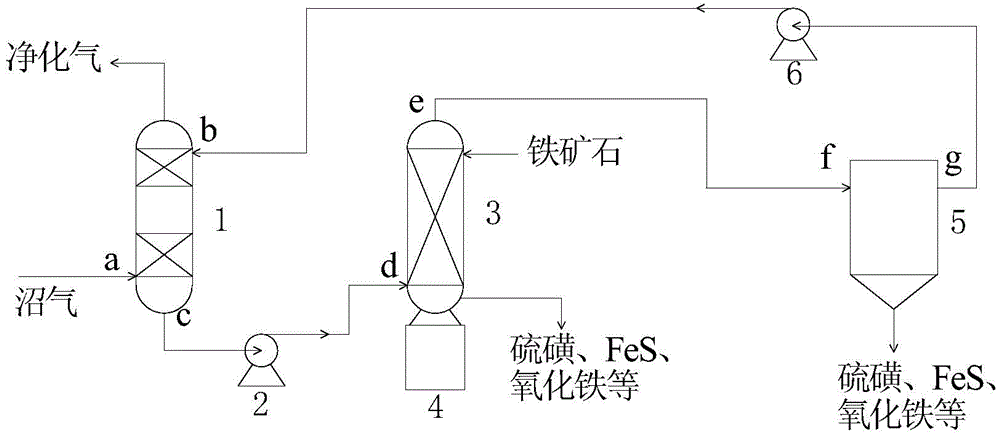

[0027] like figure 2 In the biogas purification and hydrogen sulfide removal method shown, the biogas enters the absorption tower 1 from the bottom a, and is sprayed into the K with a pH of 9 from the upper inlet b. 2 CO 3 The lye is contacted in countercurrent to absorb the hydrogen sulfide in it, the desulfurization efficiency reaches 99.99%, and the purified biogas is discharged from the top of the tower; the absorbed H 2 The rich solution of S enters the inlet d of the regeneration tower 3 through the rich solution pump 2, and iron ore with a particle size of 5-10mm is put in from the upper part of the regeneration tower 3, and an ultrasonic device 4 is installed at the lower part of the regeneration tower 3 to give The continuous action of ultrasonic waves accelerates the replacement reaction between iron ore and rich liquid, so that the alkali liquor can be regenerated; the regenerated desulfurized liquid enters the precipitation separation device 5 from f to stand sti...

Embodiment 3

[0029] This example is the same as Example 1, except that the desulfurization solution used is Na with a pH of 8. 2 CO 3 with K 2 CO 3 Mixed lye, the desulfurization efficiency is 99.8%; the particle size of the iron ore used is 20-30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com