Patents

Literature

684 results about "Ironstone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ironstone is a sedimentary rock, either deposited directly as a ferruginous sediment or created by chemical replacement, that contains a substantial proportion of an iron compound from which iron can be smelted commercially. This term is customarily restricted to hard coarsely banded, nonbanded, and noncherty sedimentary rocks of post-Precambrian age. The Precambrian deposits, which have a different origin, are generally known as banded iron formations. The iron minerals comprising ironstones can consist either of oxides, i.e. limonite, hematite, and magnetite; carbonates, i.e. siderite; silicates, i.e. chamosite; or some combination of these minerals.

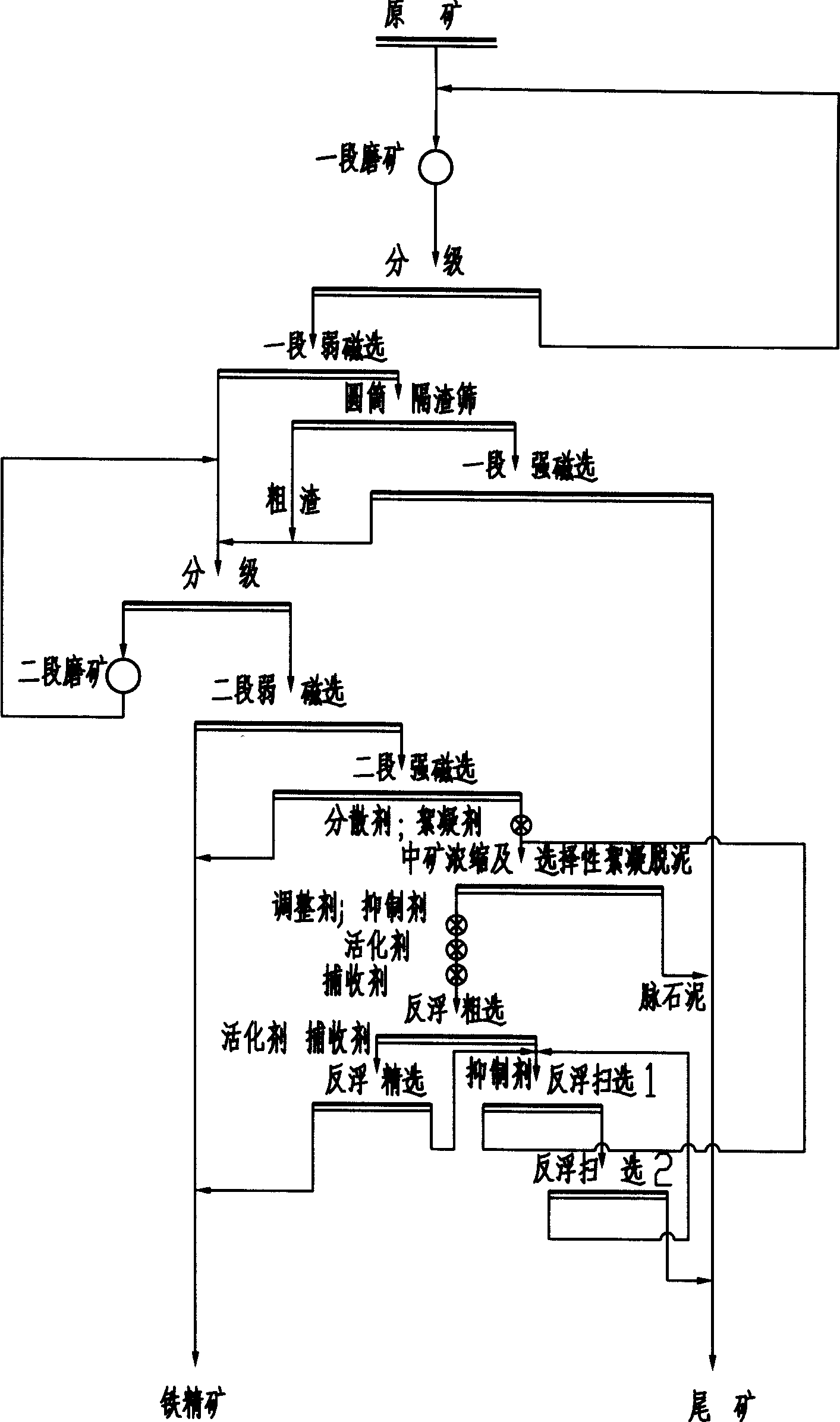

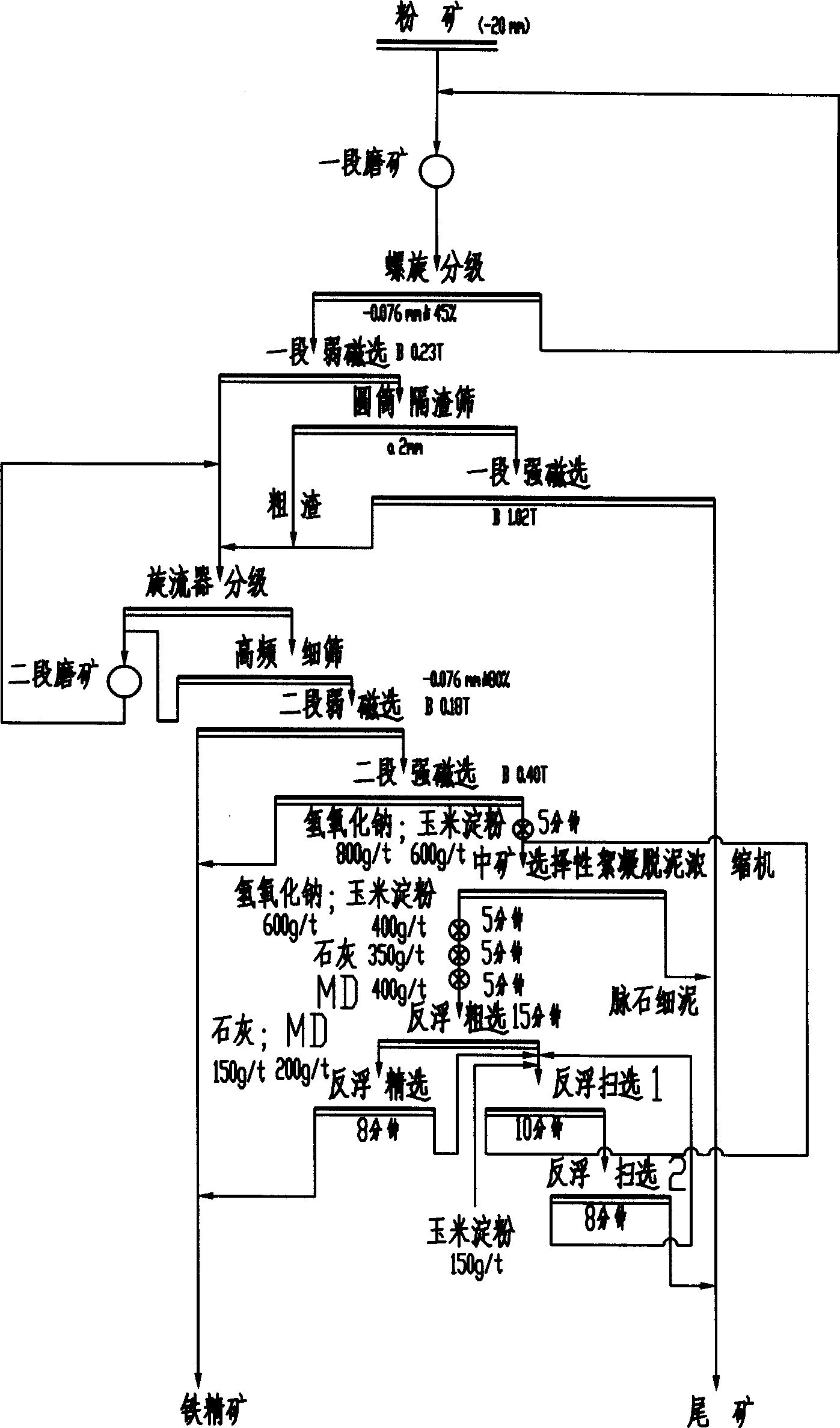

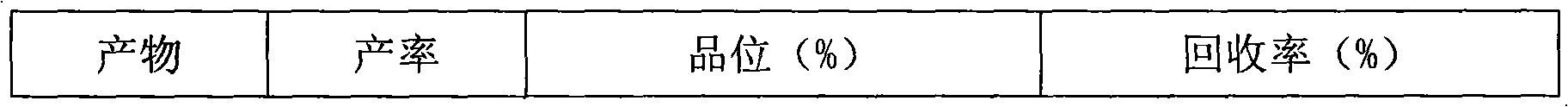

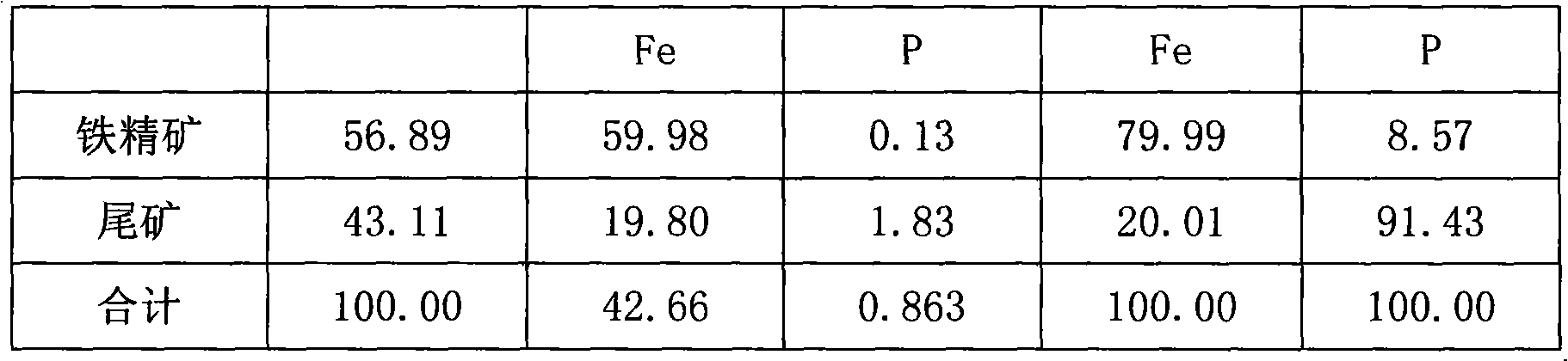

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

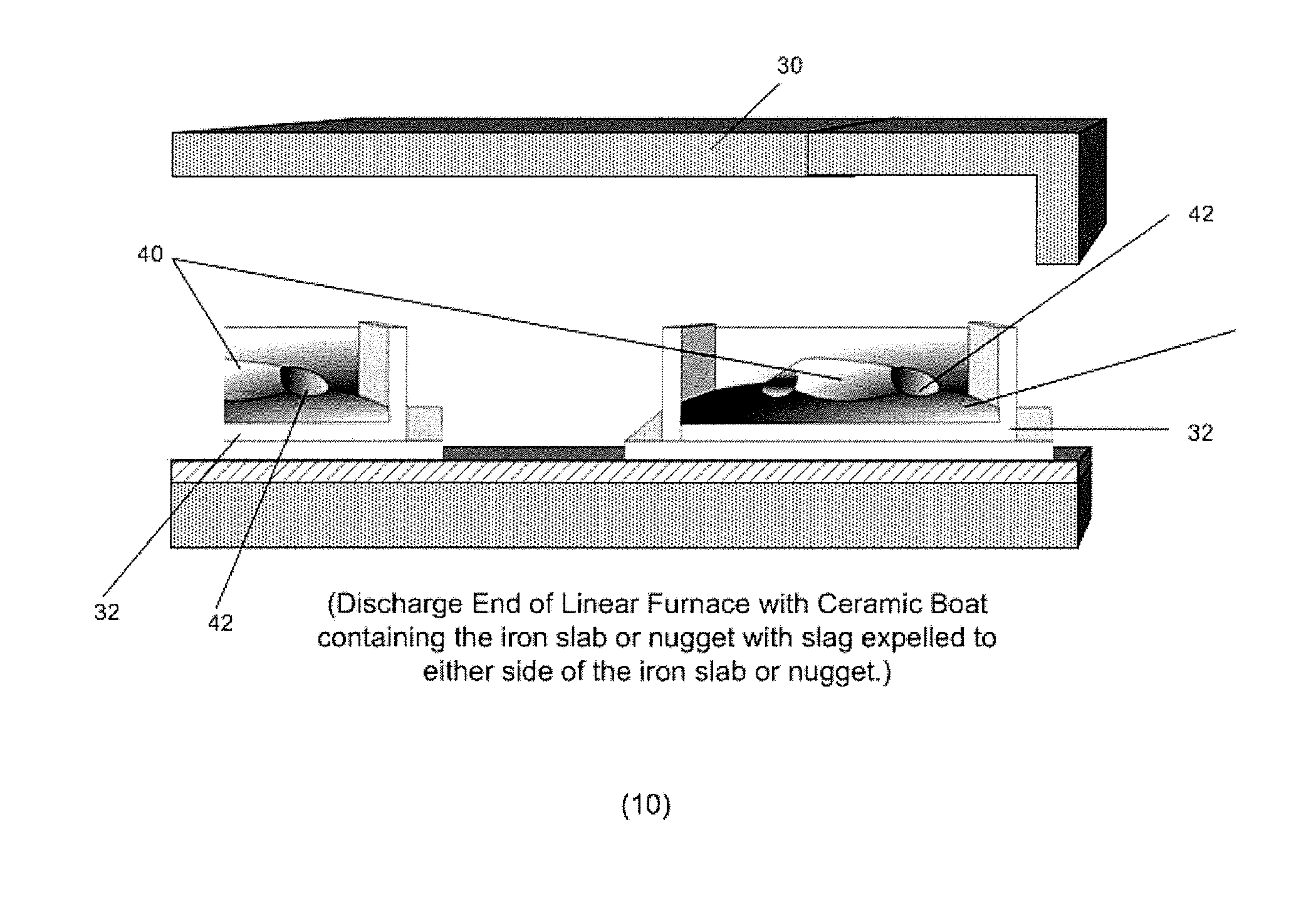

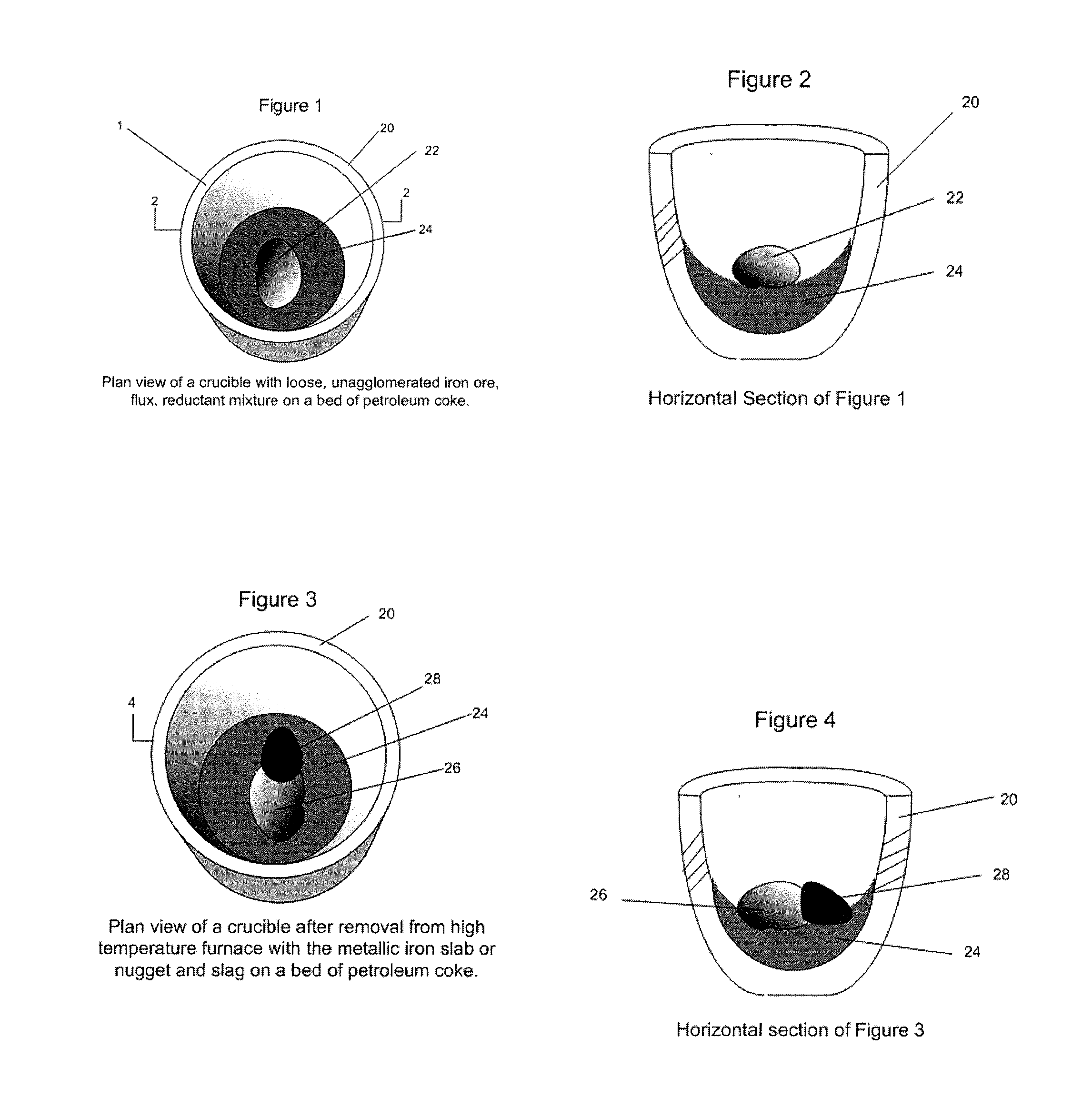

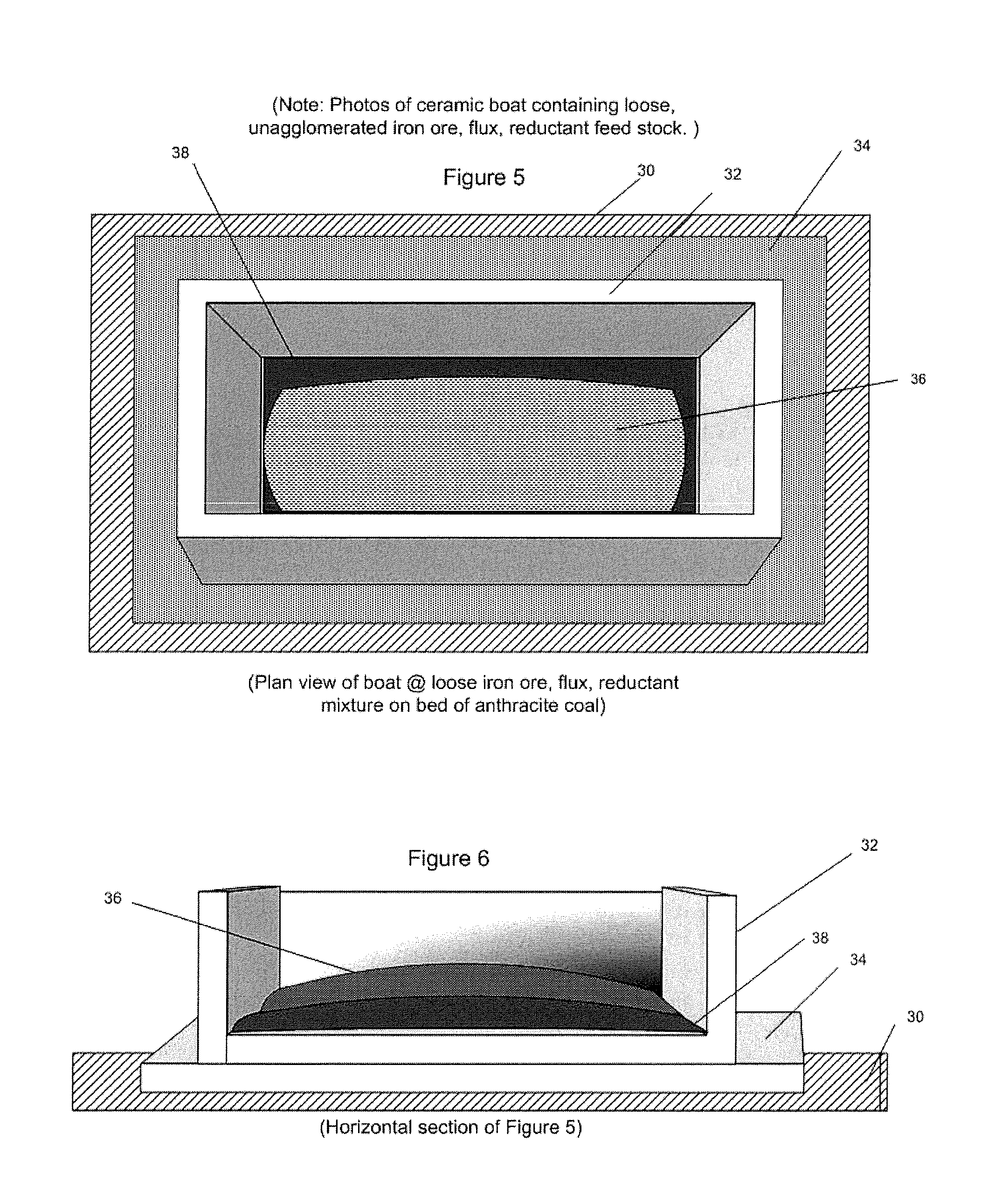

Direct Production of Iron Slabs and Nuggets From Ore Without Pelletizing or Briquetting

ActiveUS20130081516A1Lower cost of capitalReduce operating costsExhaust gas handlingGas emission reductionParticulatesIronstone

Metallic iron is produced from a composition formed from a mixture of iron ore particles and particles of a reductant made of a biomass material, a coal or coke in a particulate form together with a flux and is processed in a loose, un-agglomerated non-pelletized, non-briquetted form in a reducing furnace to produce metallic iron directly from the ore. An excess of biomass or coal or coke reductant can be used to provide CO and H that can be recovered as a synthetic gas and converted to electrical or other energy. Metallic iron nuggets or slabs can be produced from manganiferous ores or concentrates. Manganese can be caused to enter the nugget or slab or the slag by adjusting the furnace temperature. Titaniferous ores or concentrates can be used to produce metallic iron slabs or nuggets and a titanium-rich slag.

Owner:SIMMONS JOHN J

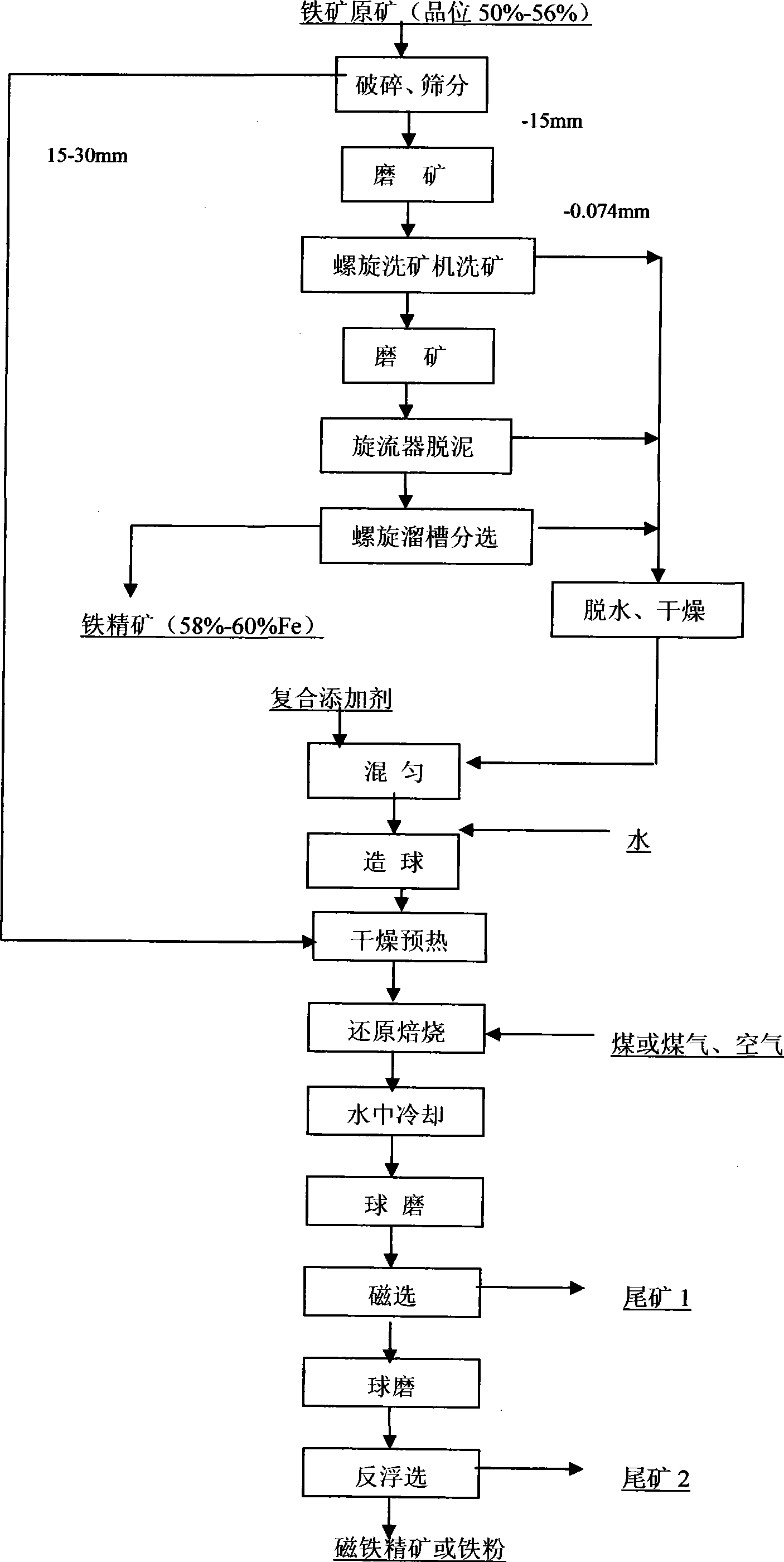

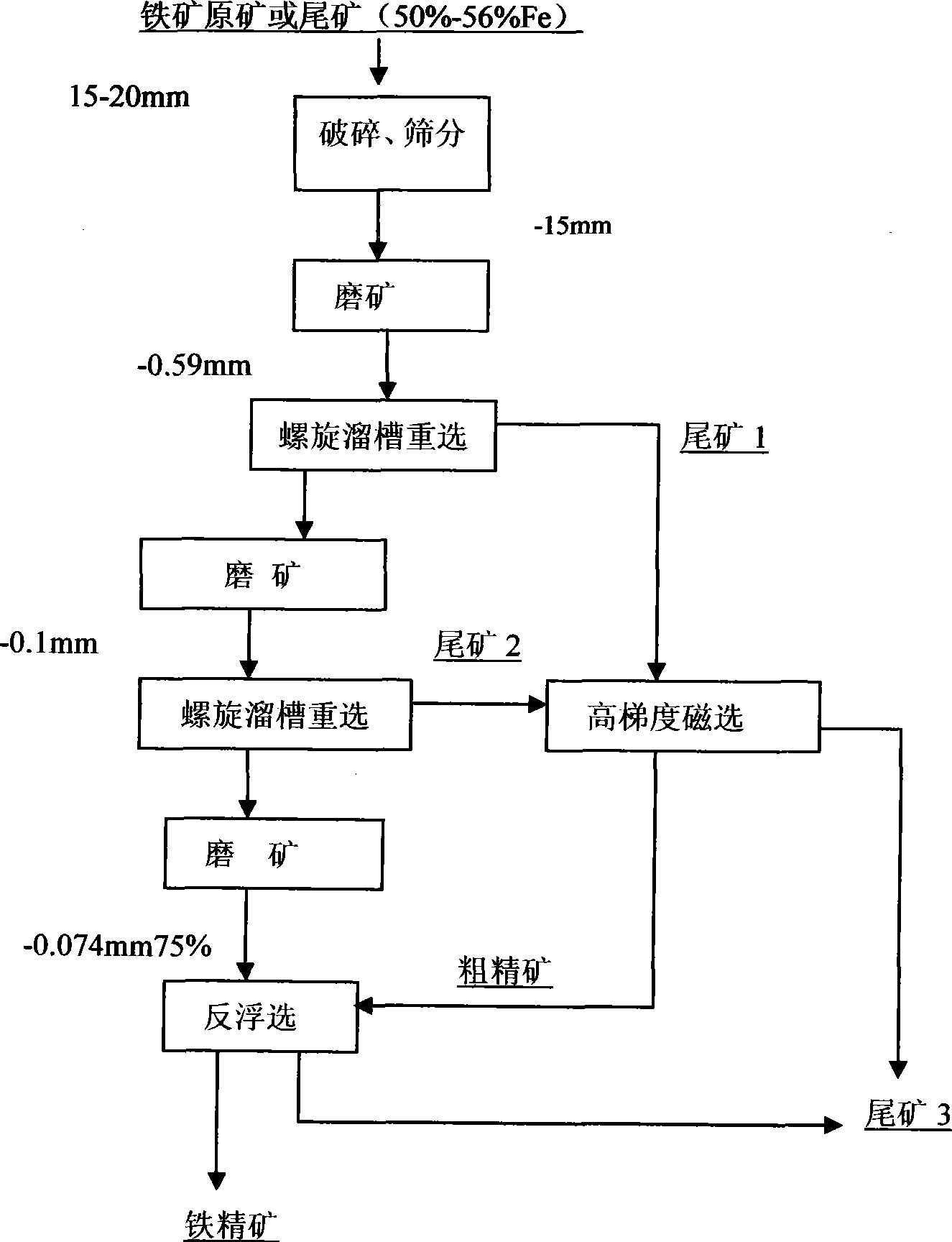

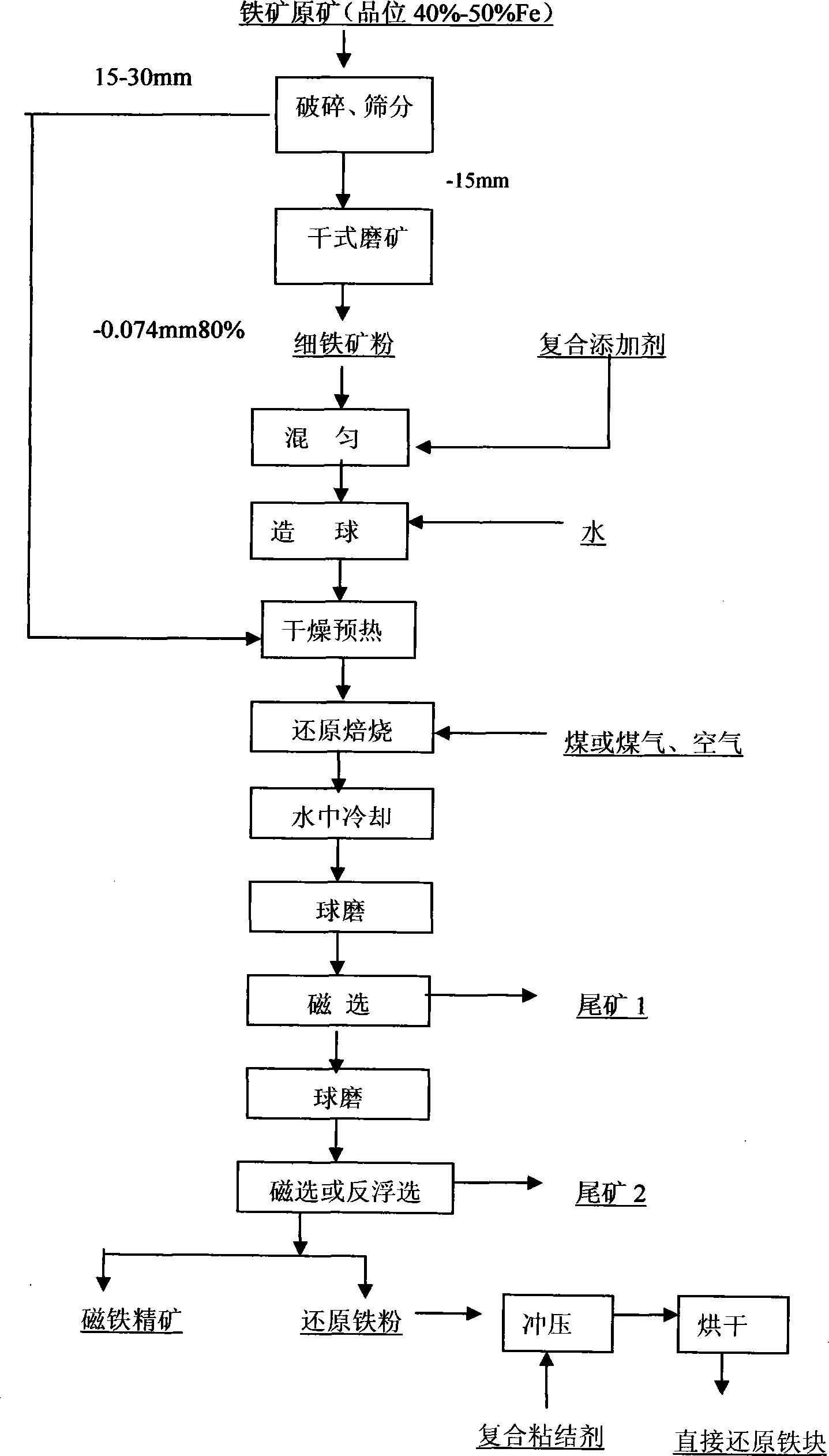

Method for efficiently separating low-ore grade and complicated iron ore

ActiveCN101413057ALow grain sizeHigh content of water of crystallizationProcess efficiency improvementIronstoneIron powder

The invention provides an efficient separation method for low-grade and complex iron ores. The method is characterized in that the complex iron ores of different grades and species are classified, so as to obtain lump ores and mineral powder which are balled, dried and preheated; reduction roasting, cooling, ball milling, magnetic separation, ball milling and magnetic separation or reverse flotation are performed in turn, so as to obtain iron ore concentrate or reduced iron powder; classification treatment is to crush and screen the iron ores with iron-containing grade between 50 and 56 percent and then dry and preheat obtained ores; fine-grained mineral powder is ground, washed, ground, deslimed and separated so as to obtain the iron ore concentrate and slime containing 58 to 60 percent of iron; the slime which is washed, deslimed, and separated is dewatered and dried and is added to and well mixed additives, so as to be balled then; the iron ores with the iron-containing grade between 40 and 50 percent are crushed and screened so as to obtain the lump ores which are directly dried and preheated, while the fine-grained mineral powder is obtained through dry-type grinding and then is added to and well mixed the additives so as to be balled then; and the iron ores with the iron-containing grade between 25 and 40 percent are crushed and screened so as to obtain the lump ores which are dried and preheated, while the fine-grained mineral powder is subjected to grinding, gravity separation or high-gradient magnetic separation and reverse flotation, so as to obtain coarse iron concentrate powder which is added to and well mixed with the additives and then is balled.

Owner:CENT SOUTH UNIV

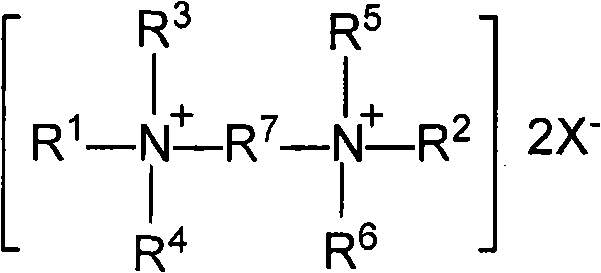

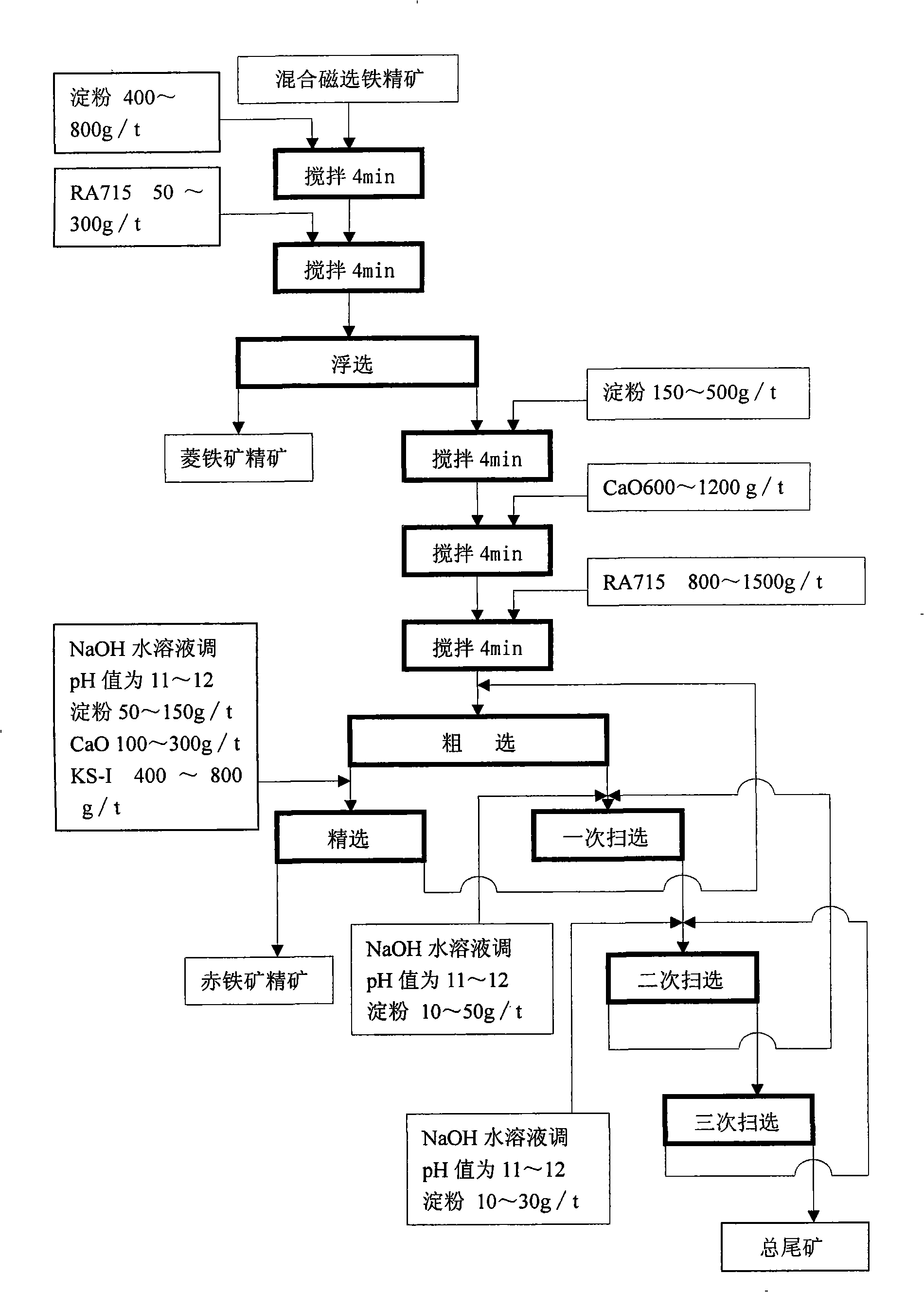

Use of quaternaries compound in floating silicate mineral

The invention relates to the field that biquaternary ammonium compounds are applied in silicate mineral flotation, and discloses a collector which applies the biquaternary ammonium compound with the constitutional formula shown as the formula I in bauxite or ironstone reverse flotation desiliconization. In the formula I, R<1> and R<2> are alkyls with 6-18 carbon atoms; R<3>, R<4>, R<5> and R<6> are respectively methyl, ethyl, -(CH2CH2O)nH, or -(CH(CH3)CH2O)nH, wherein, n is equal to 1-6; R<7> is alkylene with 2-6 carbon atoms; and X is Cl, Br or I. The collector of the invention has strong ability to collect quartz, kaolinite, illite and pyrophyllite, and is applicable to the silicate mineral separation from the bauxite or ironstone by reverse flotation, the suitable pH range of the flotation pulp is 5-13, and the dosage is equal to 50-500 g / t according to the content change of the silicate mineral in ores.

Owner:CENT SOUTH UNIV

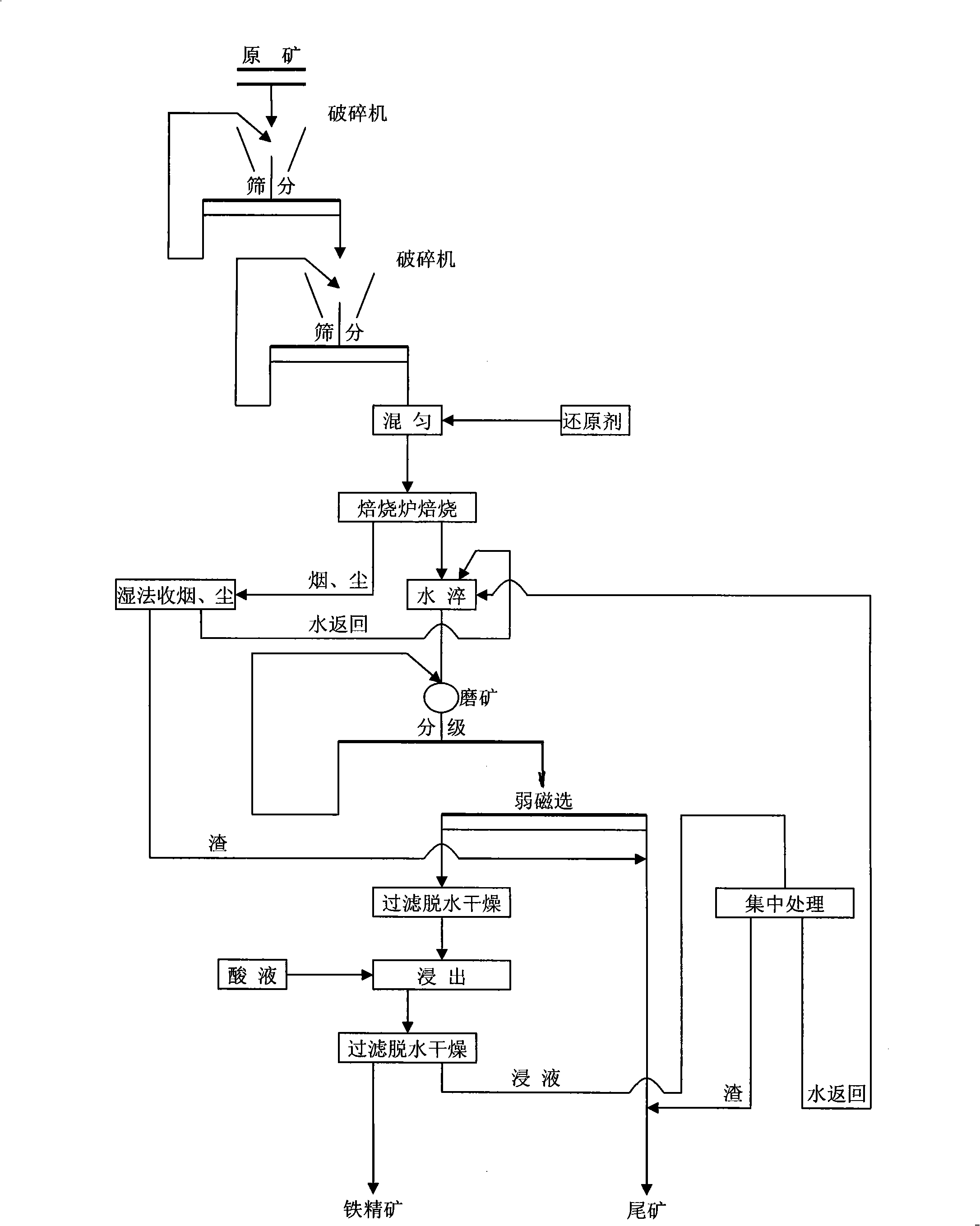

Method for reducing phosphorus in high phosphorus haematite or hematite and limonite ore by magnetization roasting-leaching method

InactiveCN101338361AReduce phosphorus contentProcess efficiency improvementMagnetic separationIronstoneMagnetization

The invention relates to a high phosphorus hematite-hematite-limonite magnetic roasting-extraction phosphorous reduction method, in particular applicable for an extraction phosphorous reduction method for the iron ores which mainly include the hematite-hematite and the limonite and accompany with magnetite, pyrrhotite, iron pyrites, etc. The method of the invention adopts magnetic roasting-wet extraction to reduce phosphorous; after carrying out modifying on high phosphorus iron ore, muriatic acid or vitriol is selected to carry out extraction phosphorous reduction on the iron concentrate obtained by a weak electromagnetic separator which not only can obtain the iron concentrate with an iron grade to be larger than 56 percent; simultaneously the content of the phosphorous in the iron concentrate is lower than 0.30 percent.

Owner:昆明晶石矿冶有限公司

Cyclone suspension flash magnetized roasting-magnetic separating method for refractory ferric oxide ore

The present invention relates to a cyclone suspension flash magnetizing roast-magnetic separation method for difficult-separable ironoxide ore. Its concrete steps are as follow: firstly, roasting the powdered difficult-separable ironoxide ore granules or fire-ground strong-magnetically-separated chats in the separation process under the condition of high-temperature reduction atmosphere and cyclone suspension fluidized state to make them be quickly dynamically reduced into magnetite within 5-100 sec. then adopting weak magnetic separation process to obtain high-quality acceptable iron headings.

Owner:湖南长拓高科冶金有限公司

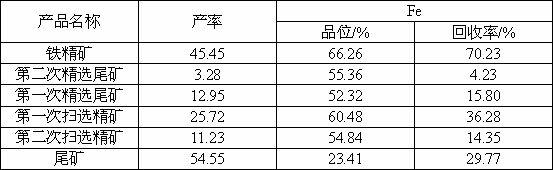

Stepped-flotation separation method for iron ore containing carbonas

InactiveCN101274302ANo difficulty returningImprove flotation environmentFlotationMagnetic separationIronstoneHigh intensity

The invention discloses a flotation and separation method of carbonate-bearing iron ore which has fractional steps and is characterized in that the carbonate-bearing iron ore is milled by a ball milling method and pre-separated by adopting low-intensity magnetic separation and high-intensity magnetic separation, and iron ore concentrate that is obtained from the mixed magnetic separation is separated by the flotation technique with fractional steps, which comprises the following steps: in the first step, siderite concentrate is selected under neutral condition by adopting the direct flotation technique; in the second step, the hematite concentrate is selected under strong basicity condition by adopting the reverse flotation technique. The flotation and separation method of the carbonate-bearing iron ore of the invention has smooth process running, the siderite selection in the first step improves flotation environment, and the hematite selection in the second step can finally obtain the hematite concentrate with the iron grade of over 66 percent and the recovery rate of over 62 percent. The flotation and separation method of the carbonate-bearing iron ore of the invention provides an exploiting method of the domestic potential iron ore resources with low iron grade and has important significance to the economical and reasonable exploiting of the carbonate-bearing iron ore.

Owner:ANSTEEL GRP MINING CO LTD +1

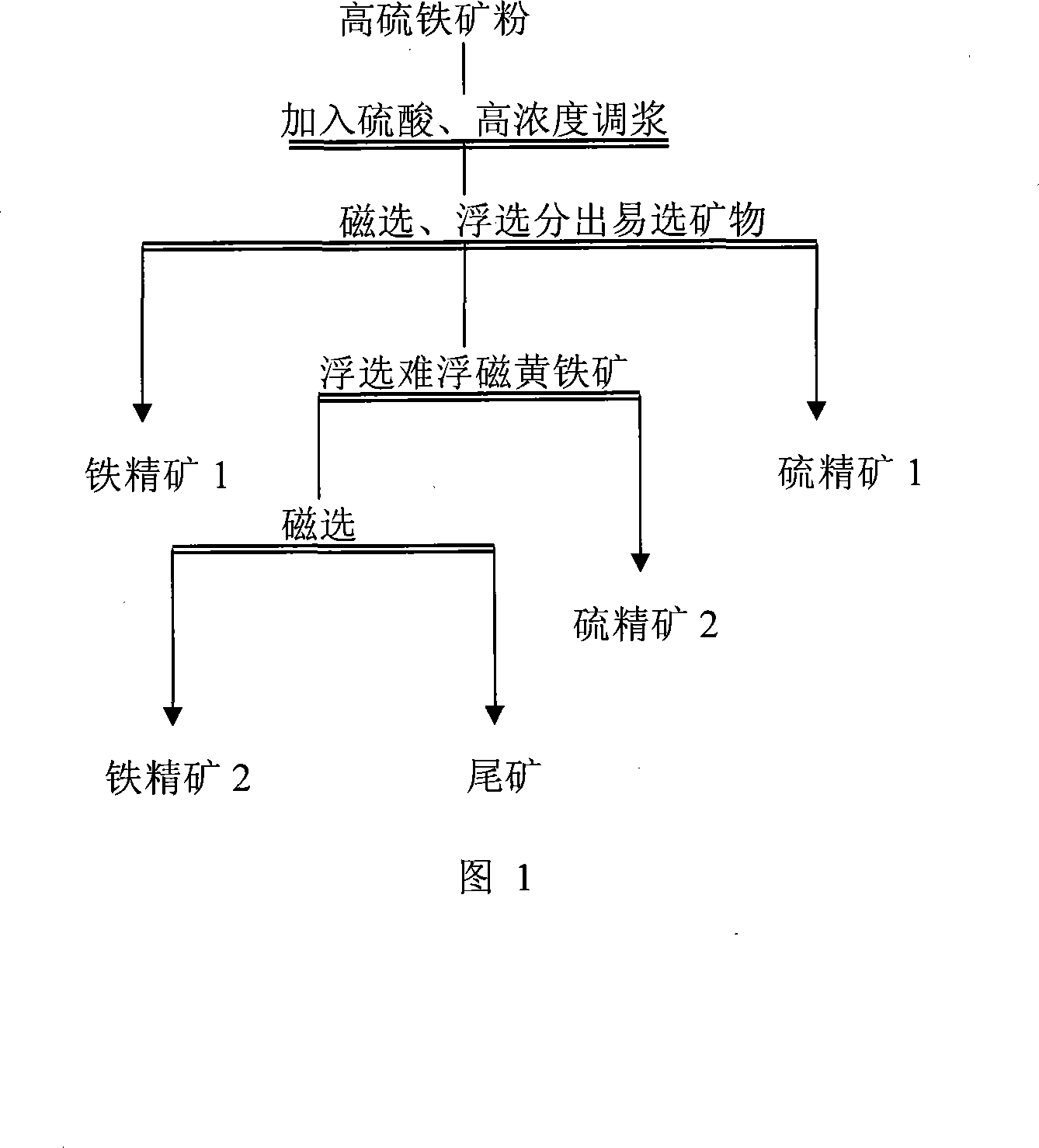

Desulfuration method for high sulfide pyrite powder

ActiveCN101157979ASimple process structureLow costFlotationProcess efficiency improvementIronstoneSulfur

The invention relates to the desulfurizing method of high-sulphur iron ore power, in particular to the iron ore power recycled by using sulfurous iron ore, pyrites and floatation gangue. When the content of sulphur of the iron ore concentrate, which is mostly magnetite, reaches over 15 percent, by adopting the principle of asynchronous size classification, the iron ore concentrate can reach over 65 percent, wherein the content of sulphur is reduced to less than 0.3 percent, and the rate of desulphurization reaches more than 90 percent. The method has the advantages of the simple system of medicament, slight acid-causticity for equipment, and low cost of operation.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

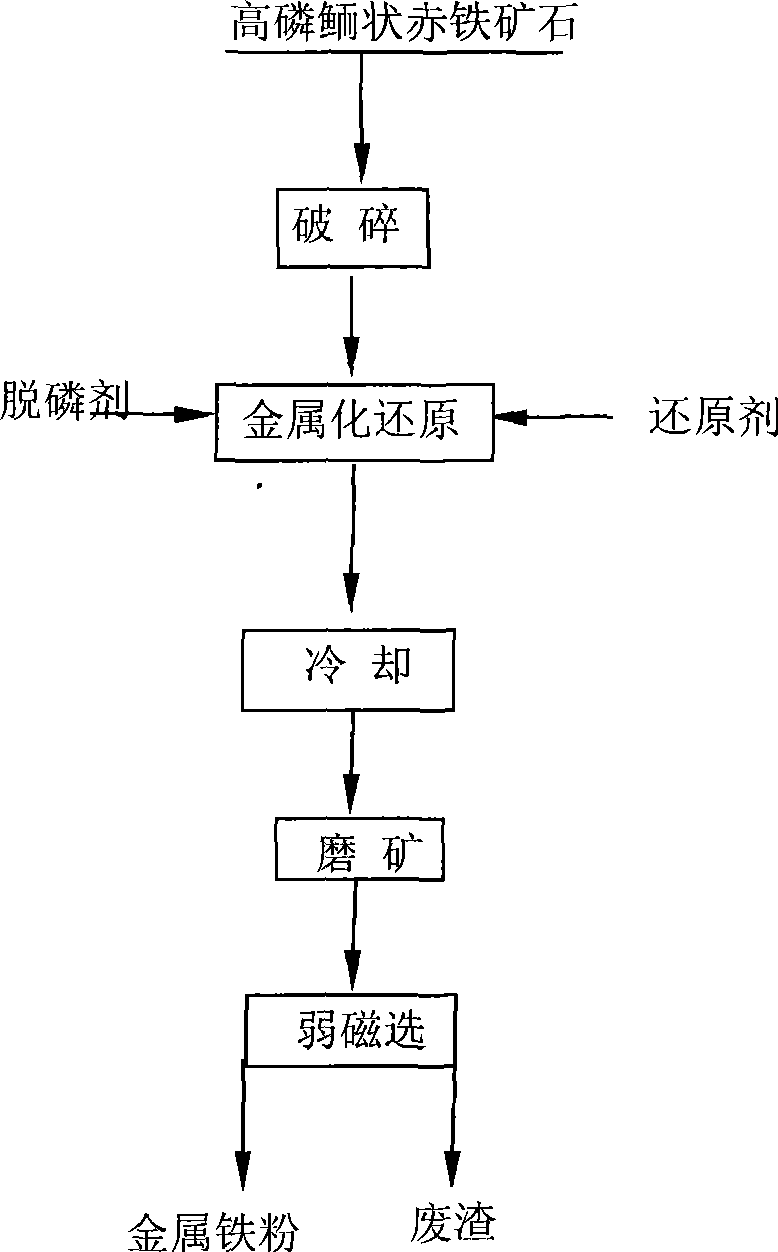

Technological process for directly producing spongy iron from high-phosphor oolitic hematite

InactiveCN101487068AAvoid pollutionEmission reductionProcess efficiency improvementIronstoneResource utilization

A technique method for directly producing spongy iron by using high phosphorus oolitic hematite belongs to the iron making field, and is characterized in that the high phosphorus oolitic hematite is added with a dephosphorizing agent and then is subjected to direct metallization reducing roast by taking coal as a reducing agent, low intensity magnetic separation for raising iron and reducing phosphorus is carried out, thus obtaining the substance with more than 90 percent of iron metal and phosphorus less than 0.08 percent. The invention has the advantages as following: (1) the utilization rate of resource is high, thus shortening the process flow of making raw steel material from iron ore, avoiding from polluting environment in concentrated ore sintering, pelletizing and blast furnace ironmaking in other methods, and having obvious environmental benefits, energy-saving and consumption reduction effects; (2) the technique method is simpler than other methods, the iron raising process and phosphorus reducing process can be completed simultaneously; and (3) coal power with low cost is directly taken as the reducing agent instead of the expensive coke, thus saving the cost in coking process and avoiding from polluting environment; the varieties are simple, the source is rich, the discharging amount of pollutants in the method is less than that in other methods and the pollutants are easy to deal with.

Owner:UNIV OF SCI & TECH BEIJING

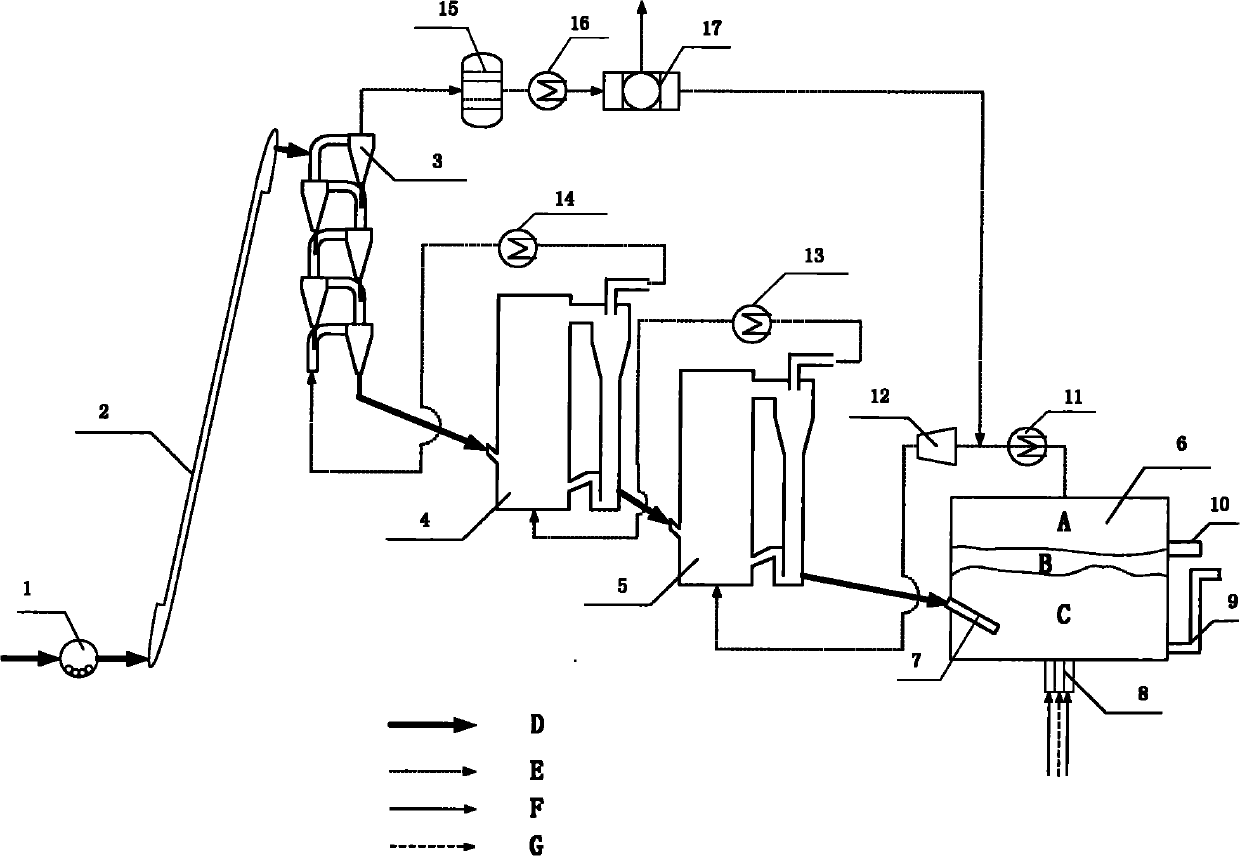

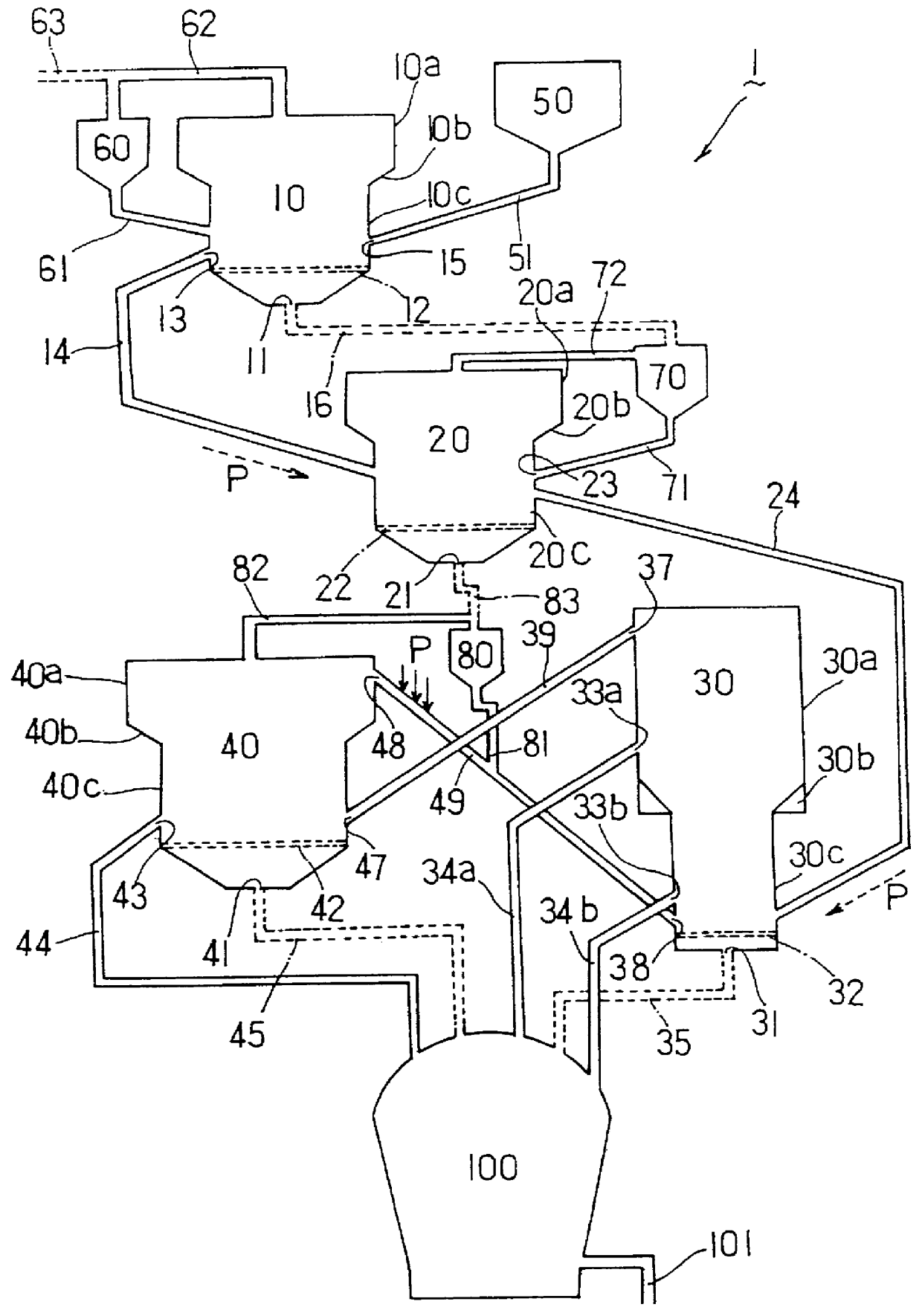

Direct steelmaking process by using fine ores, coal and oxygen

The invention discloses a direct steelmaking process by using fine ores, coal and oxygen. Coal dust and oxygen are blown into a high-temperature melt to produce reducing gas; by utilizing the advantages of gas phase suspension preheating of fine iron ore and high speed and high efficiency of gas phase reduction, the fine iron ore is preheated and reduced respectively in a cyclonic preheater and a recirculating fluidized bed; and the obtained pre-reduced fine iron ore with the metallization rate of over 90 percent is blown into the high-temperature melt to form molten steel. Due to the reduction at lower temperature, the generated pre-reduced fine iron ore achieves less carburization, and less decarbonization is achieved when the finished product molten steel is obtained. The direct steelmaking process simplifies the steelmaking production flow essentially. The direct steelmaking process has the advantages of high productivity, low energy consumption for each ton of steel, equipment and capital investment conservation, full simplification of physical distribution, no temperature loss in the molten iron transporting process, and easy implementation of production continuity and automatic control.

Owner:LAIWU IRON & STEEL GRP

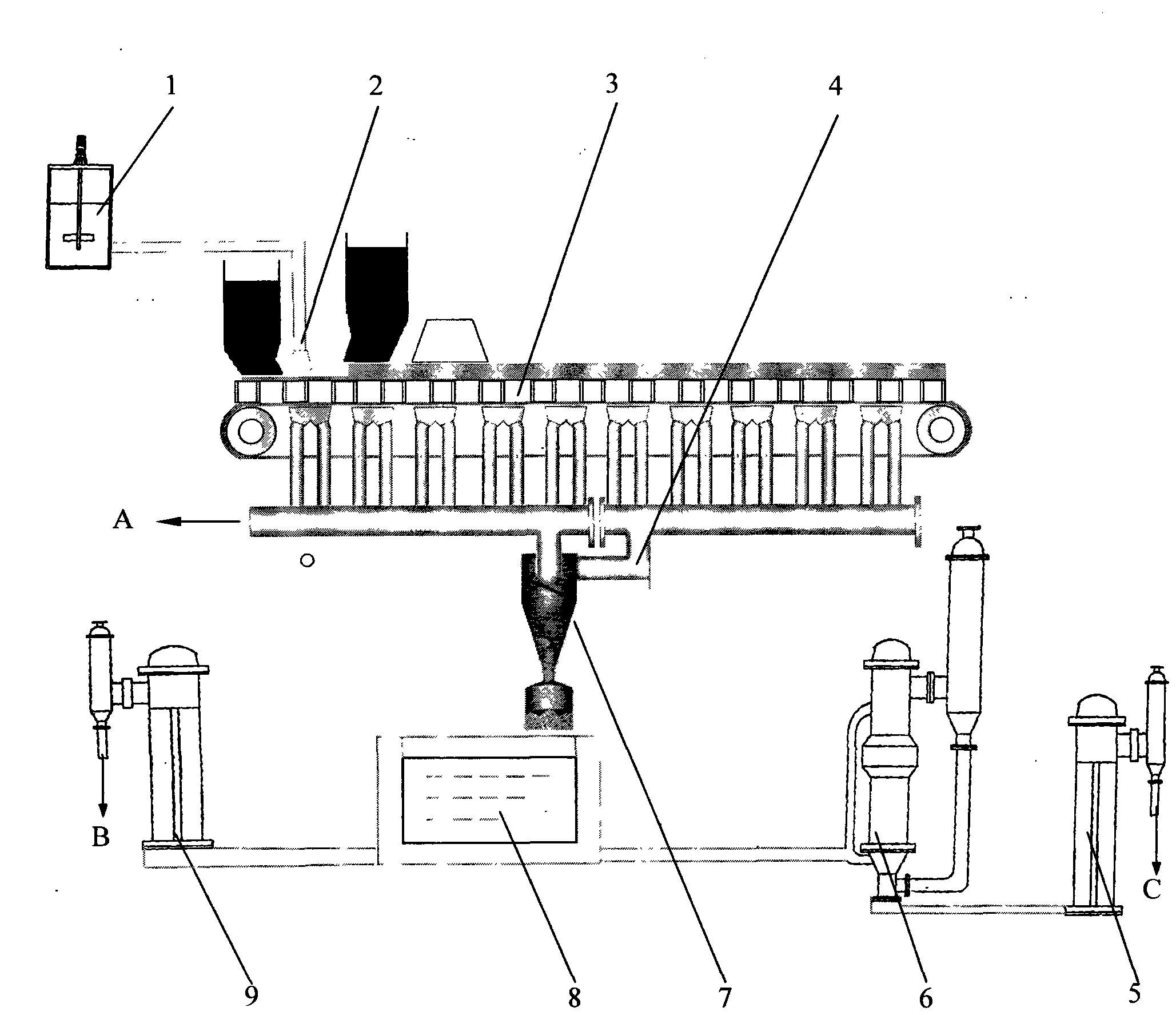

Inhibitor addition-based desulfurizing method in iron ore sintering process

ActiveCN102068887AConcentrated emission concentration is highImprove desulfurization efficiencyDispersed particle separationIronstoneFiltration

The invention discloses an inhibitor addition-based desulfurizing method in the iron ore sintering process, and aims to provide a desulfurizing method in the iron ore sintering process, which has the advantages of low investment cost, low operation cost and high desulfurization efficiency. In the method, an ammonia-containing compound is added into a bedding material layer at the bottom of a sintered material layer, ammonium sulfate generated in the reaction of ammonia which is decomposed from the ammonia-containing compound and sulfur oxide in the sintering process is adsorbed to dust and taken away by flue gas; ammonium sulfate-containing dust in the flue gas of an air bellows on the rear half part of a sintering machine is collected by a cyclone dust separator; and the collected dust is washed, filtered and dried to form dry dust, and the filtrate after filtration is concentrated, crystallized and dried to form ammonium sulfate.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

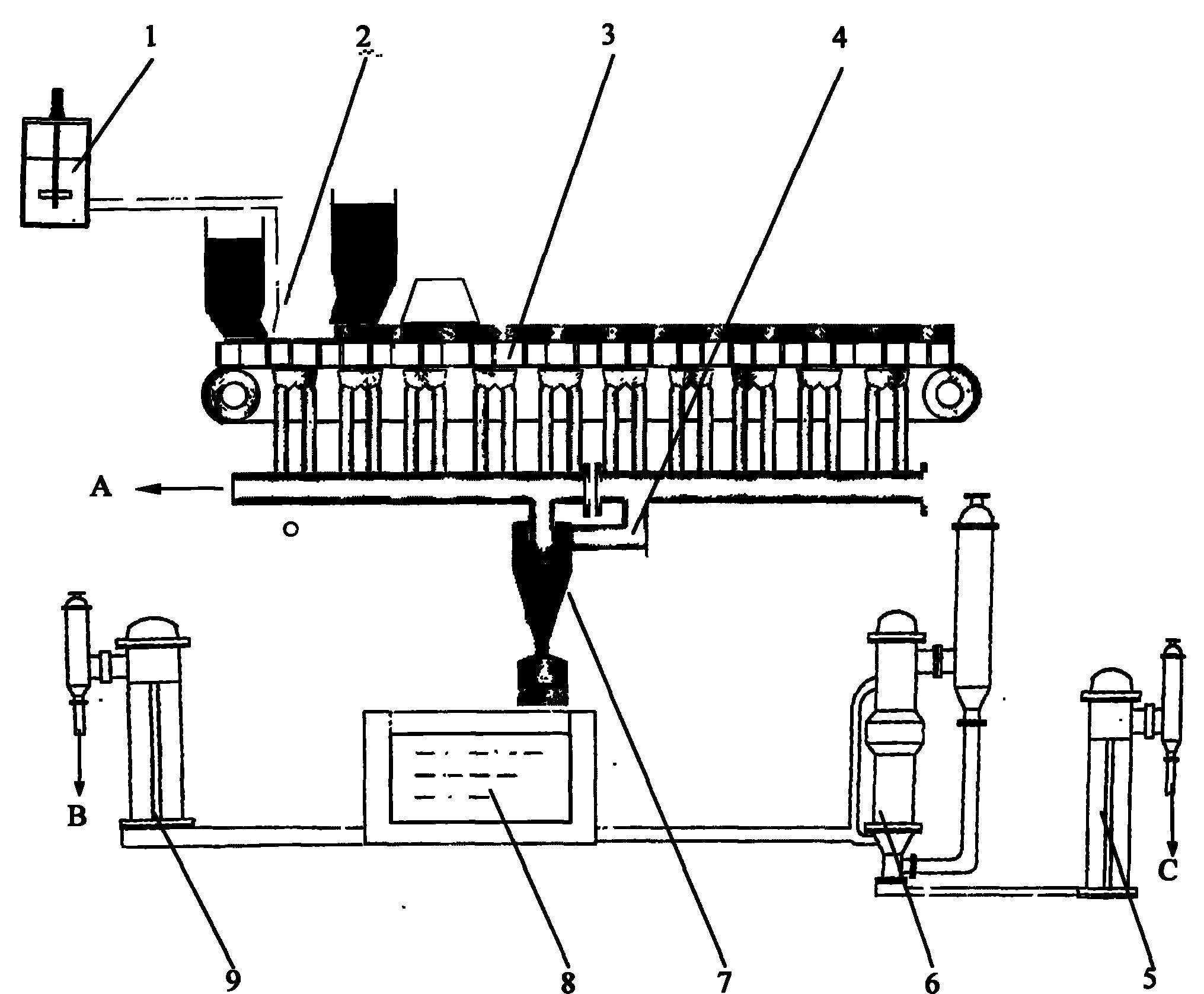

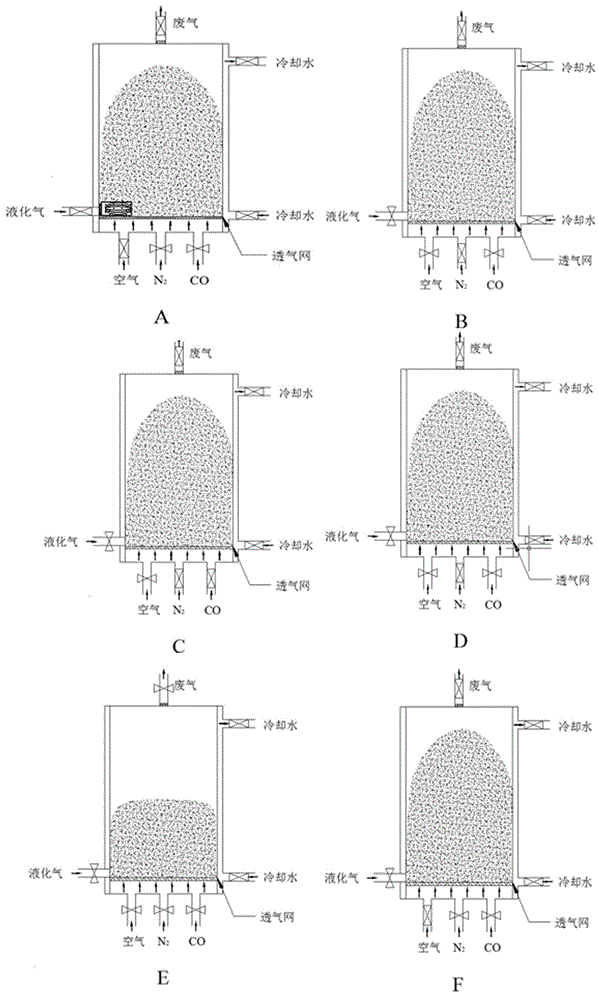

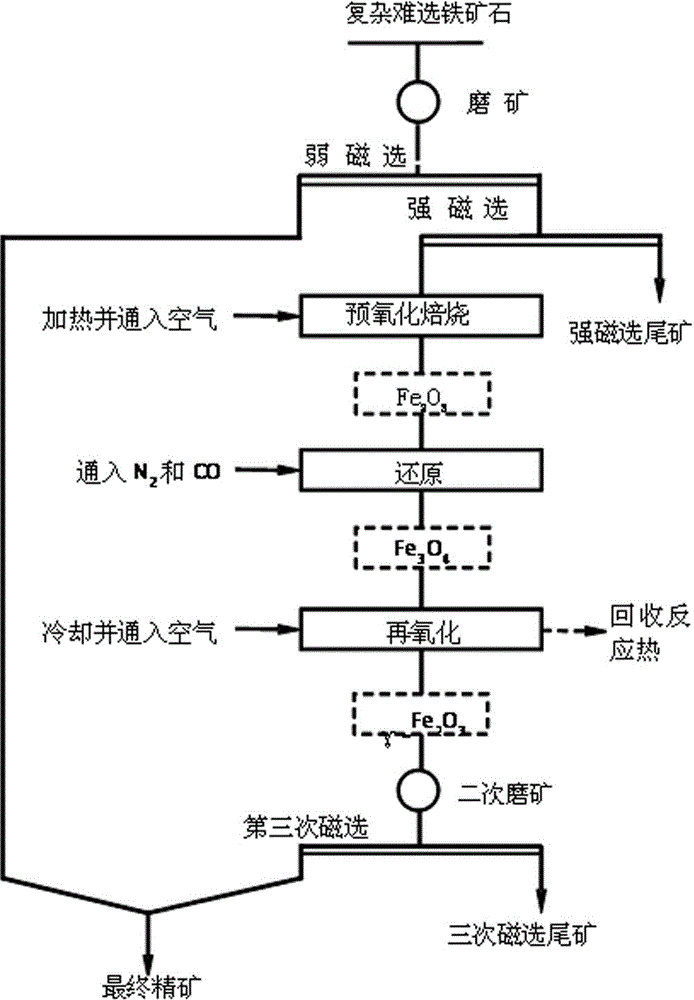

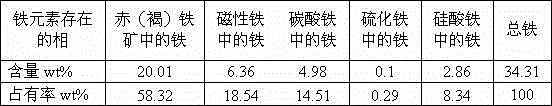

Preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores

The invention discloses a preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores, and belongs to the technical field of mineral processing. The method comprises the following steps: 1, levigating the complex refractory iron ores, carrying out weak magnetic separation, and carrying out strong magnetic separation on mine tailings; 2, putting concentrate obtained after strong magnetic separation in a suspension roasting furnace, and heating to 450-800DEG C in a suspension state in order to carry out pre-oxidation roasting; 3, introducing nitrogen to displace air, and introducing a reducing gas to carry out reduction in a suspension loose state; 4, introducing air when the temperature decreases to 250-400DEG C in order to oxidize, taking out the obtained material when the temperature decreases to below 100DEG C, and carrying out ore milling; and 5, carrying out third segment magnetic separation, and mixing concentrate obtained after three segment magnetic separation with concrete obtained after the weak magnetic separation to obtain finial concentrate. The method has the advantages of simple process, improvement of the recovery rate of the complex refractory iron ores, strong adaptability, safe and reliable process, uniform and stable product quality, energy saving and consumption reduction.

Owner:上海逢石科技有限公司

Dephosphorus iron extraction production method of oolitic high phosphorus red iron ore

The present invention relates to a production method for dephosphorization and extracting iron from oolitic high-phosphorus haematite. Said method includes the following steps: uniformly mixing (by wt%) 60%-90% of oolitic high-phosphorus haematite powder, 8%-20% of coke powder or coal powder and 0-20% of lime hydrate, briquetting or balling, drying, making reduction at 1100 deg.C-1450 deg.C in high-temperature furnace, reduction time is 10-30 min, cooling reduced product, grinding and making magnetic separation, finally making the metal iron granules be separated from phosphorus-rich ganque or slag.

Owner:WUHAN UNIV OF SCI & TECH

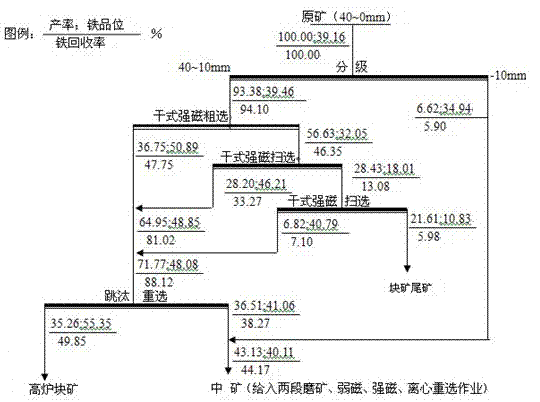

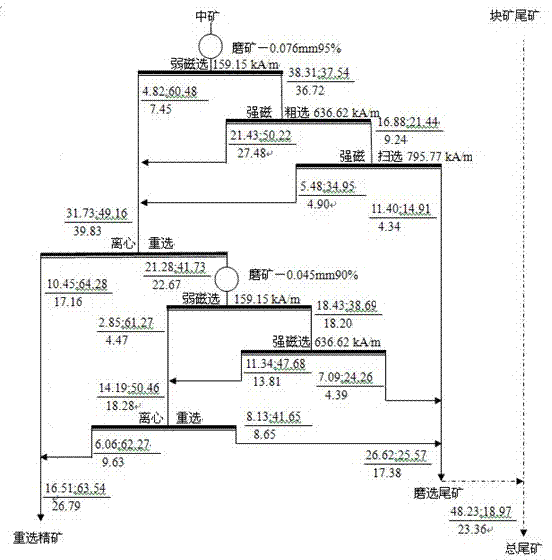

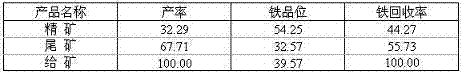

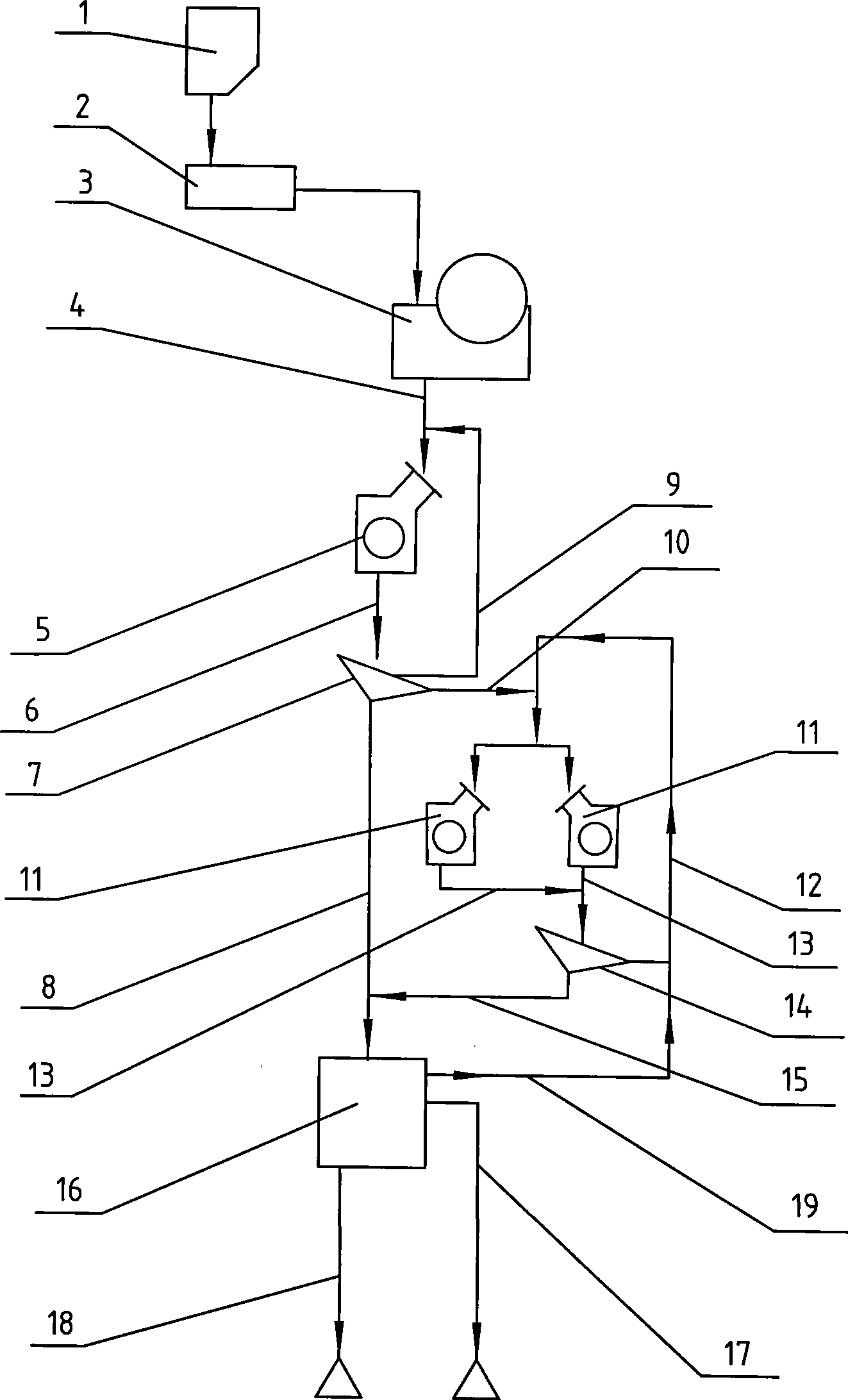

Magnetic-gravity combined ore dressing technology for hematite

InactiveCN102773161AHigh recovery rateThe amount of ball grinding is reducedMagnetic separationIronstoneCrushed stone

The invention discloses a magnetic-gravity combined ore dressing technology for hematite, comprising the following steps of: carrying out dry magnetic separation and jigging gravity separation to obtain blast furnace lump ore, throwing the tailings of the lump ore, carrying out first-stage ore grinding, weak magnetic separation, strong magnetic separation and centrifugal gravity separation on middlings, and carrying out second-stage ore grinding, weak magnetic separation, strong magnetic separation and centrifugal gravity separation. According to the technology, part of qualified blast furnace lump ore (the iron grade is large than 54%) can be obtained in advance, the massive tailings (the iron grade is less than 12%) can be thrown out, the quantity of the ball-milled ore (the middlings) can be greatly reduced, and the grinding and separation energy consumption can be greatly reduced. The massive tailings which are thrown out can replace the macadam and the stone to be taken as the building material, so that the comprehensive utilization of the bulk quantity of the tailings resource can be realized, and the technology is prominent in emission reduction effect; and the whole ore dressing technology is the magnetic-gravity combined ore dressing technological process, so that the flotation reagents can not be consumed, the technology is very friendly to the work environment and the neighboring environment, the environment can be protected, the pollution of the beneficiation reagent to the environment caused by the flotation work can be avoided, and the technology is particularly suitable for the ore dressing of the medium and high-grade (the iron grade is more than or equal to 38%) hematite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Dry dressing method for separating iron from iron ore

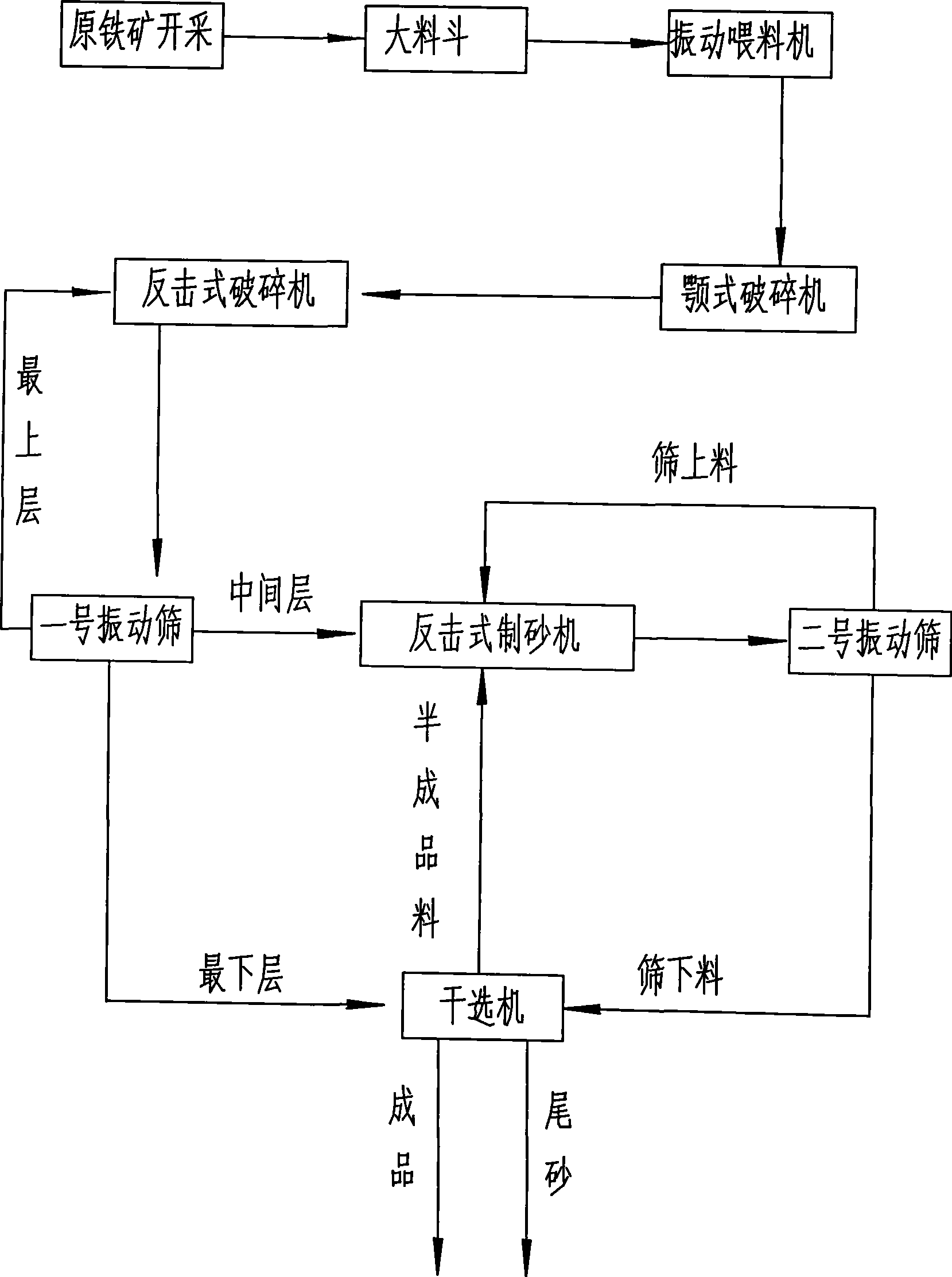

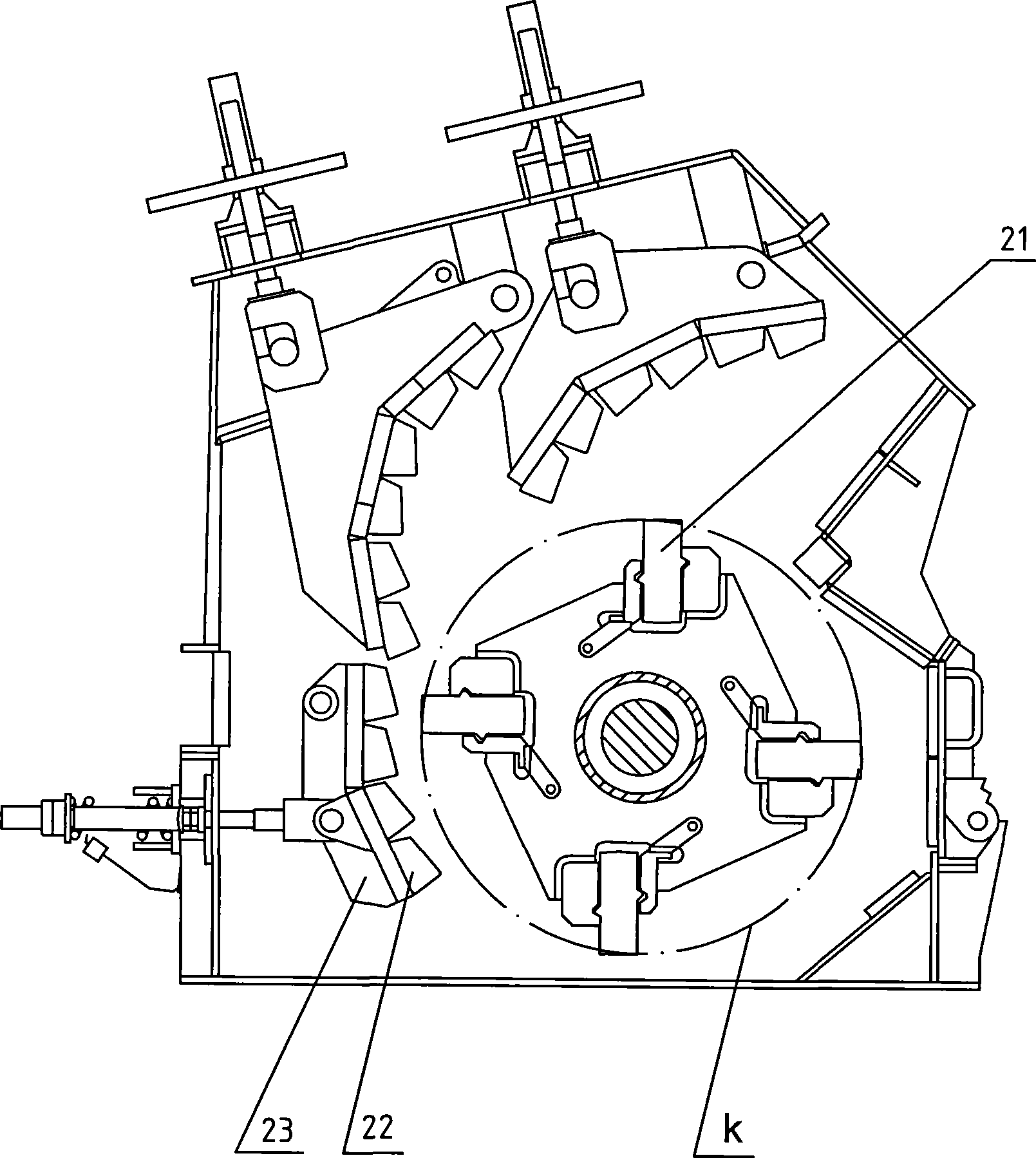

InactiveCN101385992AIncrease profitSimple processMagnetic separationGrain treatmentsIronstoneCrusher

The invention relates to a dry separation method used for separating iron from iron ore, belonging to an ore dressing process. At present, no iron ore dry separation method with strong production capability, uniform selected grain size and high grade exist. The invention provides a dry separation method which separates iron from iron ore; firstly, original iron ore is crushed sequentially by a jaw crusher, an impact crusher and an impact sand making machine, screened and dry-separated by a dry separation machine; the method is characterized in that after the iron ore is crushed by the impact crusher and the grain size of the iron ore is less than 50mm; after the iron ore is crushed by the impact sand making machine, the grain size of the iron ore is less than 10mm; after the iron ore is screened and enters the dry separation machine, the grain size of the iron ore is less than 4mm; after the iron ore is dry-separated by the dry separation machine, the iron concentrates with the iron content more than 55% is gained. The method has simple process, the grade of the iron concentrate which is selected finally is high, and the iron content of the iron concentrate is more than 55%.

Owner:海盐机械厂

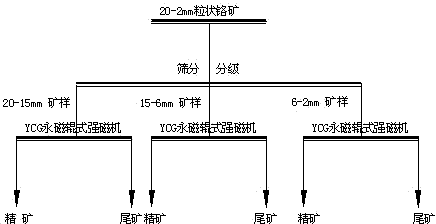

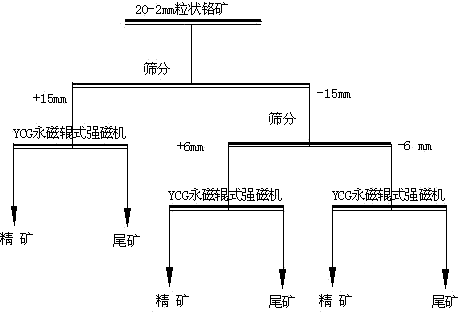

Novel beneficiation technology of high-grade ferrochrome ore

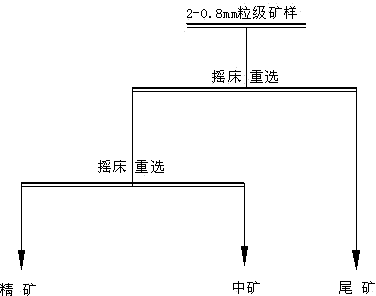

The invention discloses a novel beneficiation technology of high-grade ferrochrome ore. The novel beneficiation technology includes the following technological processes that ferrochrome ore is broken and is screened and classified into the ore of +20 mm fraction and the ore of -20 mm fraction. The ore of the +20 mm fraction receives manual back picking or hotching, large waste ore is thrown, and block concentrate is obtained. The narrow grade of the -20 mm fraction is screened and classified into four fractions, namely the 20-15 mm fraction, the 15-6 mm fraction, the 6-2 mm fraction and the 2-0 mm fraction. For the 20-15 mm fraction, the 15-6 mm fraction and the 6-2 mm fraction, a permanent magnet roller type intensity magnetic separator is used for performing dry intense magnetic separation. The 2-0 mm fraction is further screened and classified into the 2-0.8 mm fraction and the 0.8-0 mm fraction. For the 2-0.8 fraction, a shaker is selected again to obtain shaker gravity concentrate, and for the 0.8-0 mm fraction, a spiral chute and the shaker are used and a united procedure is selected again to obtain the thin-particle gravity concentrate. The novel beneficiation technology can be used for obtaining the concentrate and removing tailings in advance and has the advantage of being lower in energy consumption compared with other technologies. The technology can be used for grading chrome ore and can also be used for grading other weak magnetic iron minerals such as manganese ore, goethite, siderite and limonite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

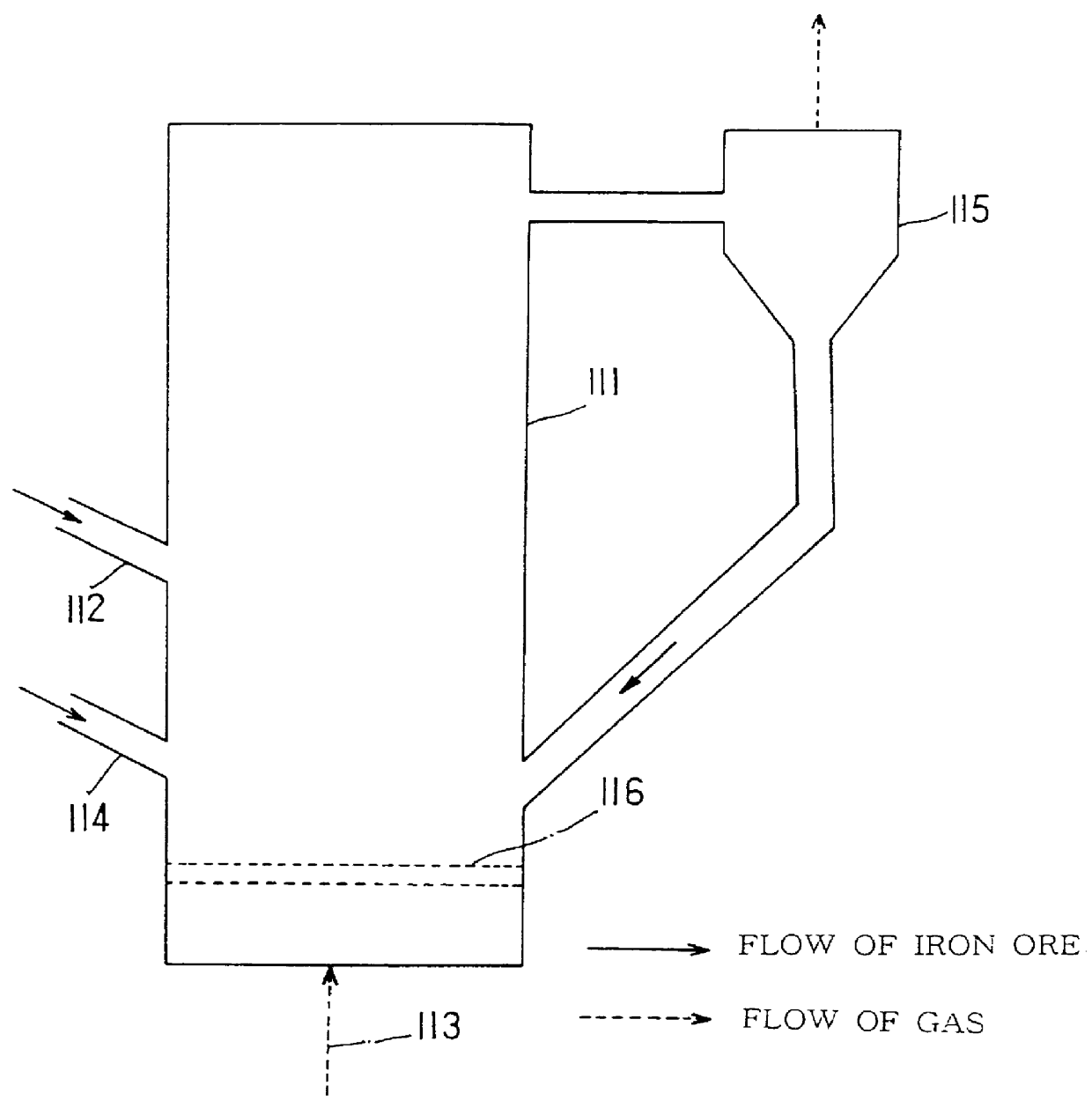

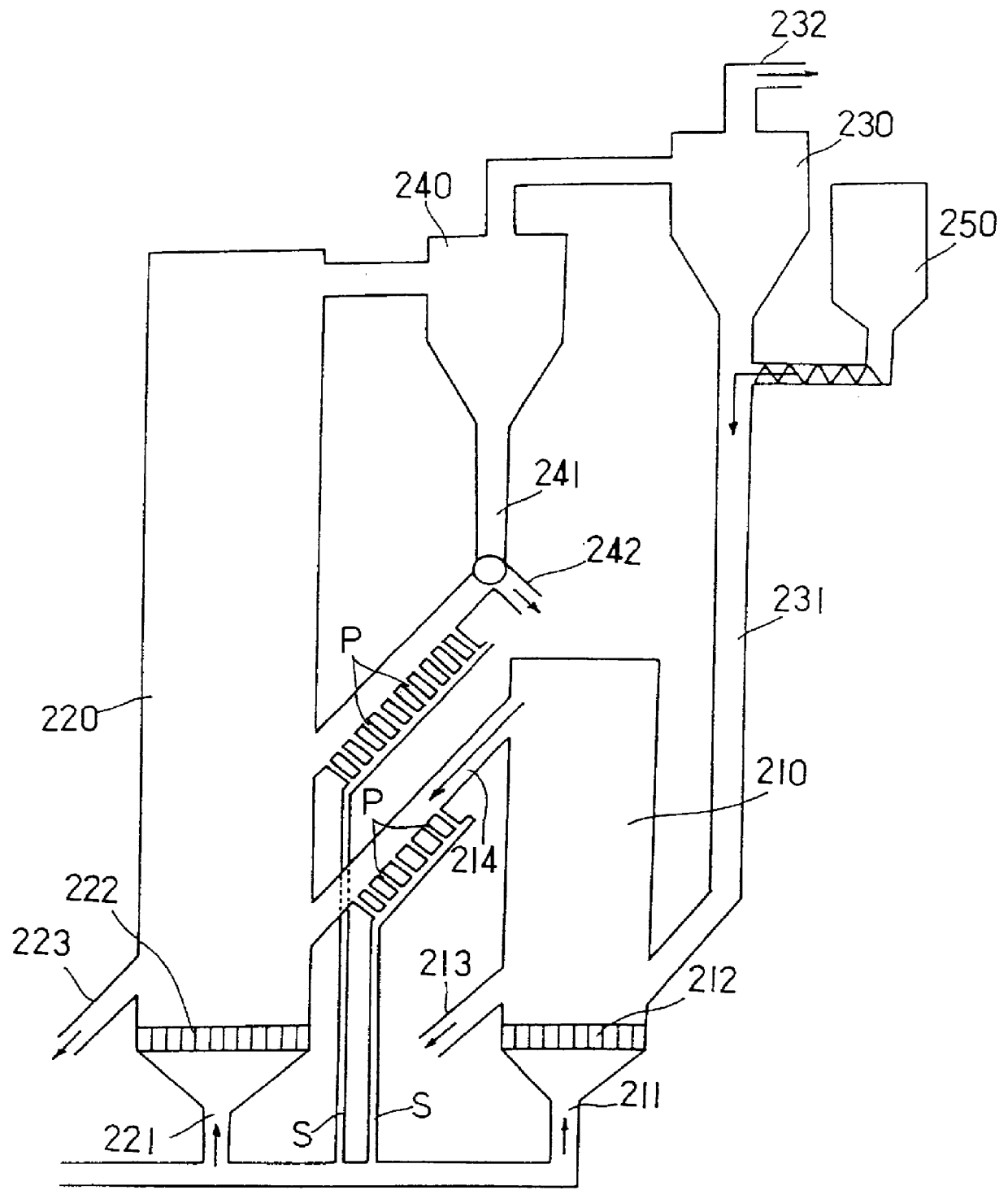

3-Stage fluidized bed reducing apparatus for reducing fine iron ore

InactiveUS6110413AReduce probabilityReduce consumption rateBlast furnace detailsExhaust gas handlingIronstoneExhaust gas

PCT No. PCT / KR97 / 00275 Sec. 371 Date Aug. 20, 1998 Sec. 102(e) Date Aug. 20, 1998 PCT Filed Dec. 19, 1997 PCT Pub. No. WO98 / 28449 PCT Pub. Date Jul. 2, 1998A 3-stage fluidized bed type iron ore reducing apparatus having X shaped circulating tubes is disclosed for forming a gas pore fluidizing layer of a fine iron ore, and for drying / pre-heating it to reduce it, so that the gas utilization rate and the reducing rate can be improved, as well as decreasing the gas consumption rate. The present invention relates to a 3-stage fluidized bed type iron ore reducing apparatus having X shaped circulating tubes comprising: a shaft type single type first fluidized bed furnace where a raw fine iron ore is dried and pre-heated in a bubbling fluidization state; a first cyclone for collecting fine iron ore particles from a exhaust gas of said first fluidized bed type furnace; a shaft type single type second fluidizing bed furnace where the dried and pre-heated fine iron ore is pre-reduced in a bubbling fluidization state; a second cyclone for separating the fine iron ore particles from a exhaust gas from said second fluidizing bed type furnace so as to re-circulate them; a twin type third fluidized bed furnace consisting of a first reaction furnace and a second reaction furnace, for separating the pre-reduced iron ore from said second fluidized bed type furnace into coarse particles and medium / fine particles so that the coarse particles and medium / fine particles ore finally reduced in separate reactors in bubbling fluidization states; and a third cyclone for separating fine iron ore particles from the exhaust gas of said second reaction furnace of said third fluidized bed type furnace so as to re-circulate them to said first reaction furnace.

Owner:POHANG IRON & STEEL CO LTD +2

Water-resistant magnesium phosphate cement and application thereof

InactiveCN104591570AReduce penetrationIncreased durabilityBuilding constructionsOrganic fertilisersIronstoneMagnesium phosphate

The invention provides water-resistant magnesium phosphate cement. The water-resistant magnesium phosphate cement comprises the following components: dead burned magnesia, phosphate and mineral waste residues, wherein the molar ratio of magnesium element in the dead burned magnesia to phosphorus element in the phosphate is (4-5):1; the content of the mineral waste residues by mass is 10-30% of the total mass of the magnesium phosphate cement; the mineral waste residues are residues of iron ores obtained after mineral separation and smelting; the water-resistant magnesium phosphate cement provided by the invention not only can improve the early strength but also can maintain the strength for a long time, the permeability is reduced and the water resistance is improved, thereby providing favorable conditions for the improvement of the endurance of the magnesium phosphate cement.

Owner:ZHEJIANG UNIV OF TECH

Automatic recognition and classification of ore and mineral images

InactiveCN109284780AImprove work efficiencyReduce subjectivityCharacter and pattern recognitionNeural architecturesIronstoneVisual technology

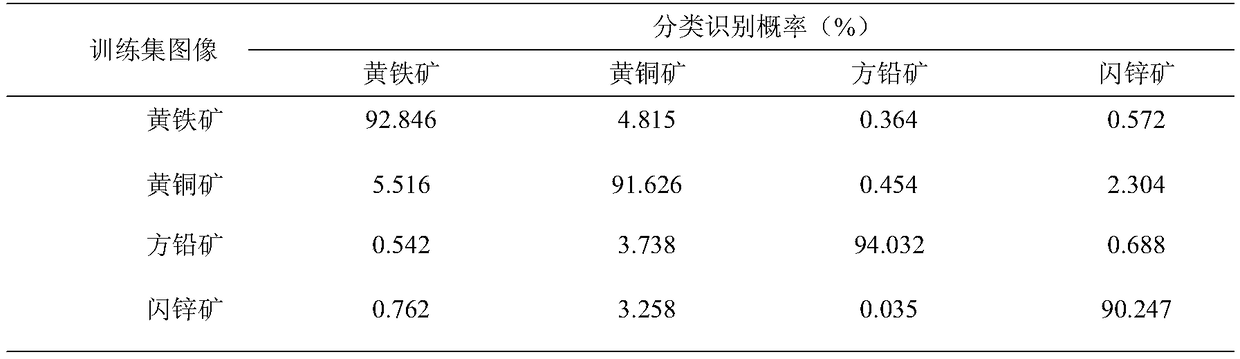

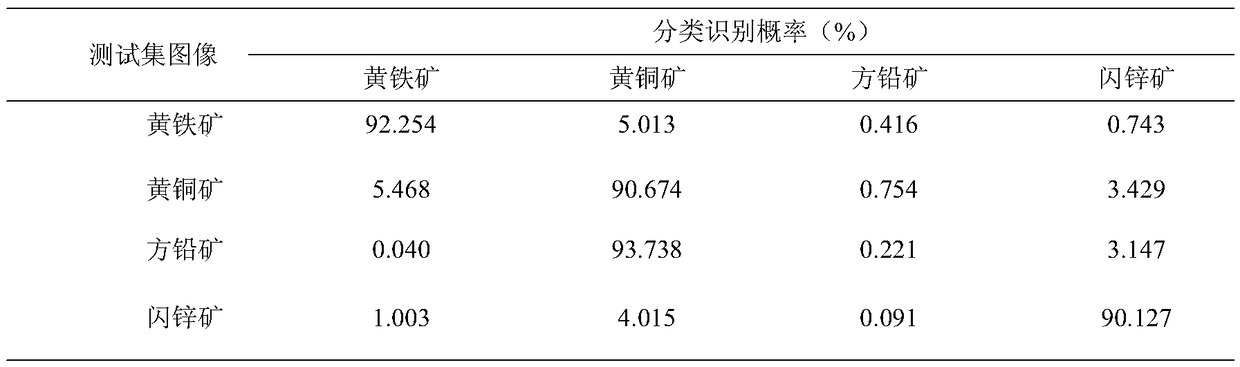

An automatic recognition and classification of ore and mineral images are disclosed in the invention. the invention utilizes the computer vision technology and the depth convolution neural network theory, Based on the big data platform Tensorflow, the convolution artificial neural network model is established, and the image data input model is trained according to the microscopic photographs of yellow iron ore from Jiapigou Gold Mine in Jilin Province, so as to realize the automatic recognition and classification of different ore minerals in the microscopic photographs of yellow iron ore. Theinvention can assist geologists to identify and classify the microscopic photographs of ore minerals and improve the working efficiency of geologists.

Owner:SUN YAT SEN UNIV

Method for reducing phosphorus by chloridization separation-weak of high phosphor iron ore

InactiveCN101457288AReduce phosphorus contentGood beneficiation indexMagnetic separationWet separationIronstoneIron increased

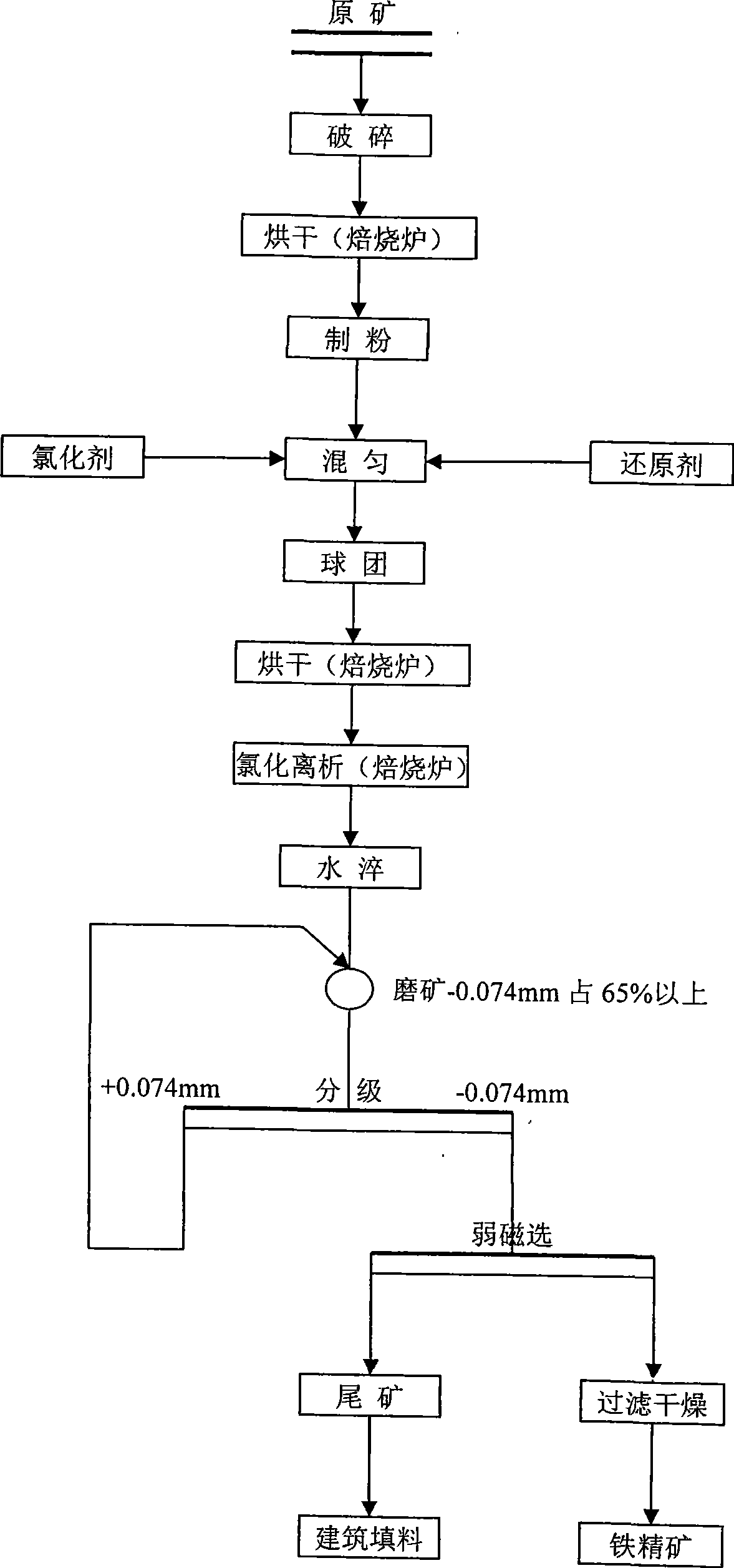

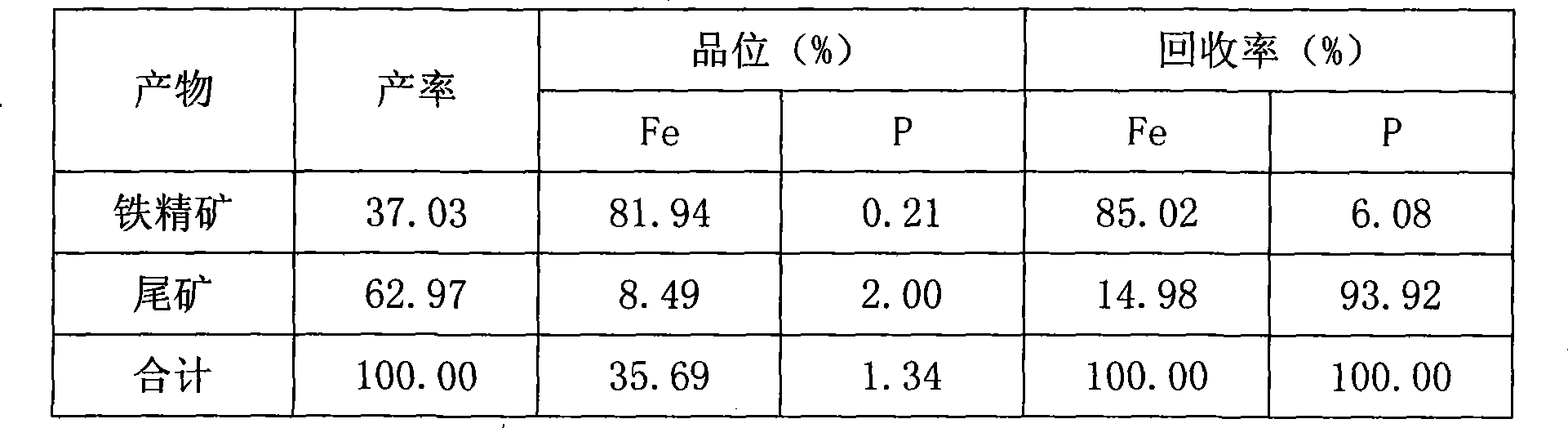

The invention relates to a chloridizing segregation-low-intensity magnetic separation method for reducing phosphorus of a high phosphorus iron ore. A chloridizing segregation-low intensity magnetic separation process is adopted to realize iron increase and phosphorous reduction in the method. A chlorinating agent and a reducing agent coke are added to the high phosphorus iron ore and mixed evenly, then chloridizing segregation roasting is carried out in a roasting furnace; the roasted product is water quenched and ball milled, and then separated by a low-intensity magnetic field magnetic separator, thus being capable of obtaining an iron ore concentrate with the iron grade more than 80%, the iron recovery rate more than 85% and the phosphorous content less than 0.20%. The iron ore concentrate powder can be taken as a raw material for smelting pig iron after being pelletized. Additionally, with regard to high phosphorus iron ores which contain sulfur or contain sulfur and arsenic at the same time, such as hematite, hematite-limonite ore, oolitic hematite-limonite ore, hematite, siderite and the like, the product iron ore concentrate with the sulfur content less than 0.20% and the arsenic content less than 0.04% can also be obtained.

Owner:昆明晶石矿冶有限公司

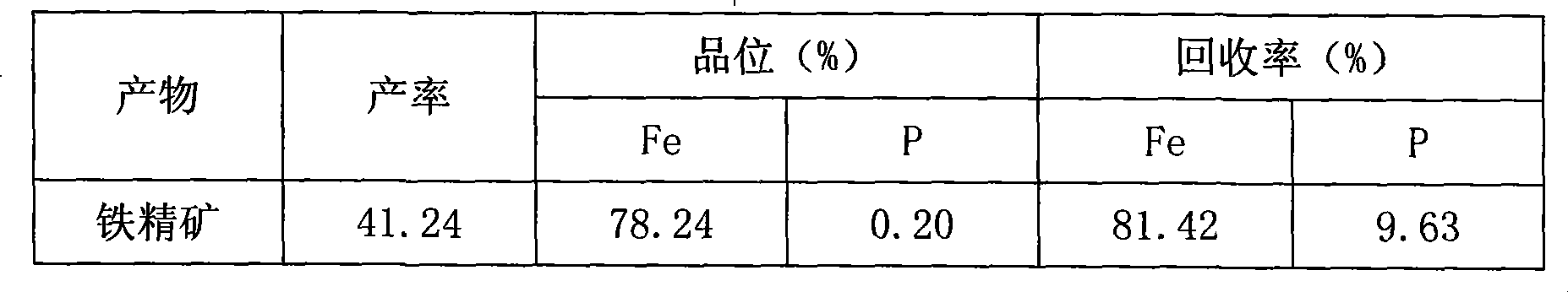

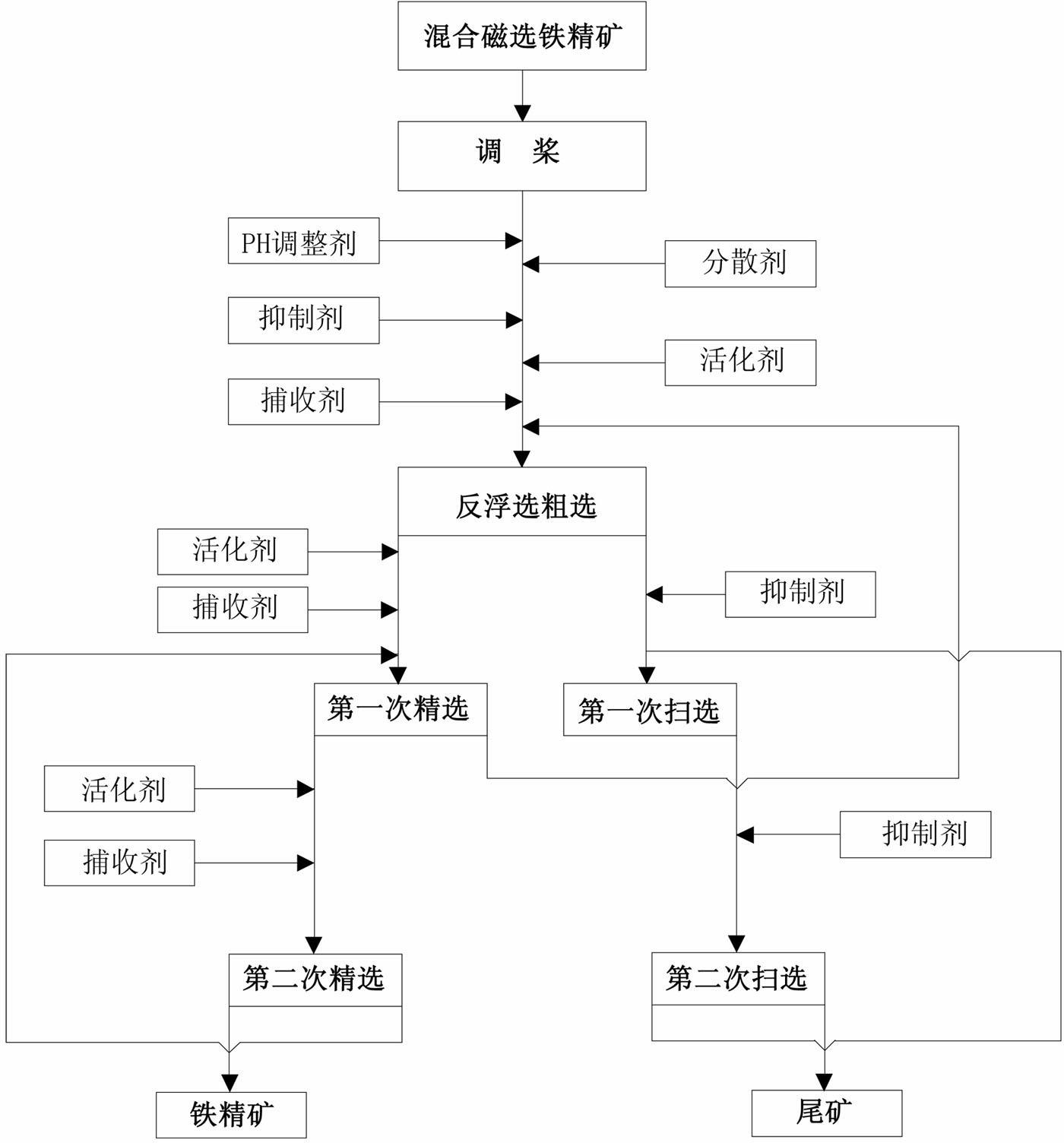

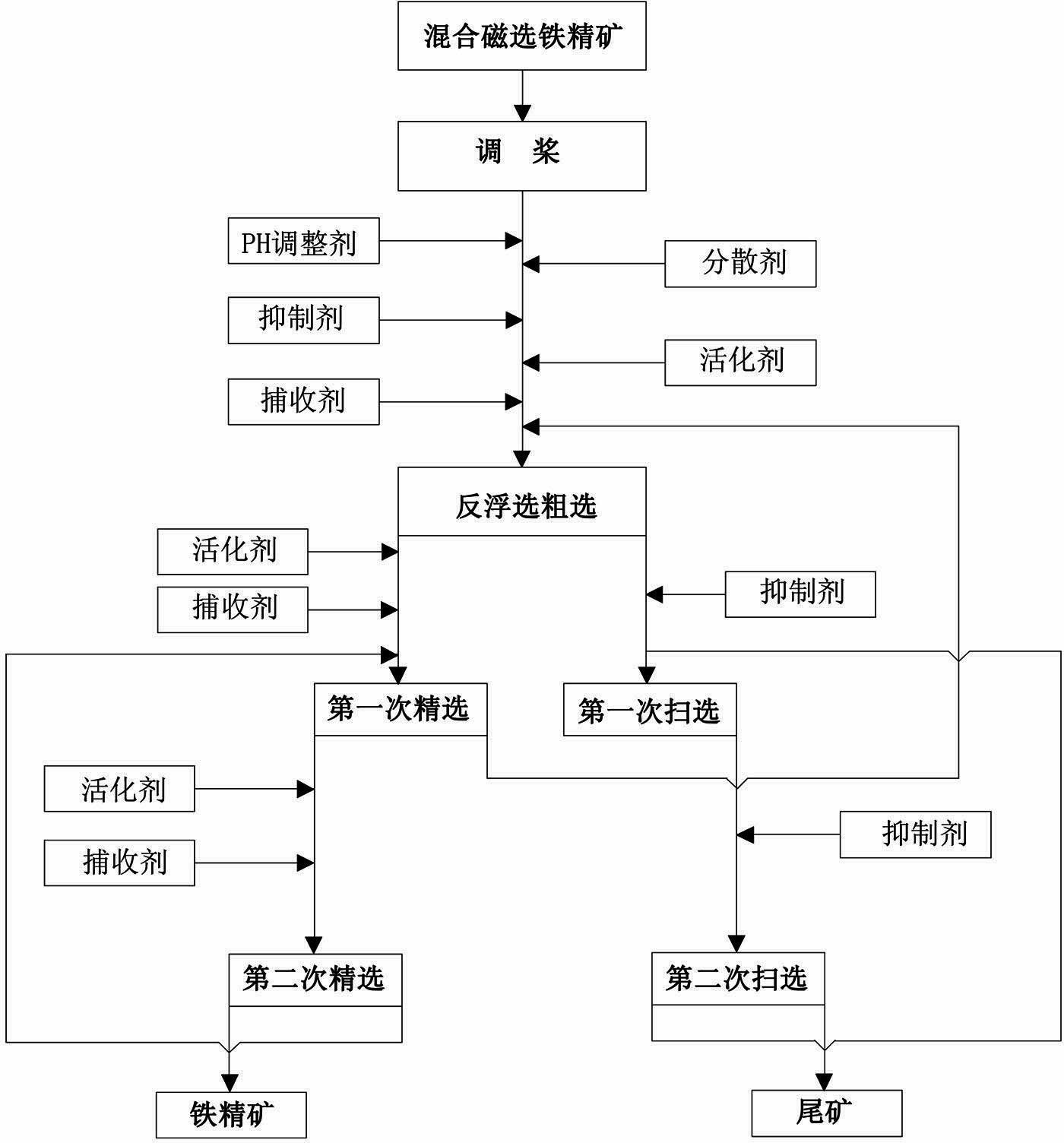

Dispersed flotation separation method for carbonate-containing iron ore

InactiveCN102688806AEliminate or reduce cap phenomenonEliminate or reduce the effects of flotationFlotationIronstoneMining engineering

The invention relates to a dispersed flotation separation method for carbonate-containing iron ore. The reverse flotation is directly carried out on carbonate-containing mixed magnetic separation iron ore concentrate, i.e. the rough concentration, the scavenging and the selection separation. Particularly, a roughing separation method comprises the following steps of: adjusting the mixed magnetic separation iron ore concentrate into ore pulp with the weight concentration of 20-40%, adding 200-1000g / t of dispersing agent-salinized water glass, adding 1200-2400g / t of inhibitor-starch, adding 400-1000g / t of activating agent-lime, and adding 600-1400g / t of collecting agent-KS-III. As the dispersing agent is added, the covering phenomenon among minerals can be eliminated or weakened, so that the ore pulp is under the stable dispersing status, the influence of the iron carbonate to the flotation can be weakened or reduced, and the iron ore concentrate of which the Fe grade is larger than 66% and the recovery rate is 65%-75% can be finally obtained. The method is simple in technological process and lower in cost.

Owner:ANSTEEL GRP MINING CO LTD

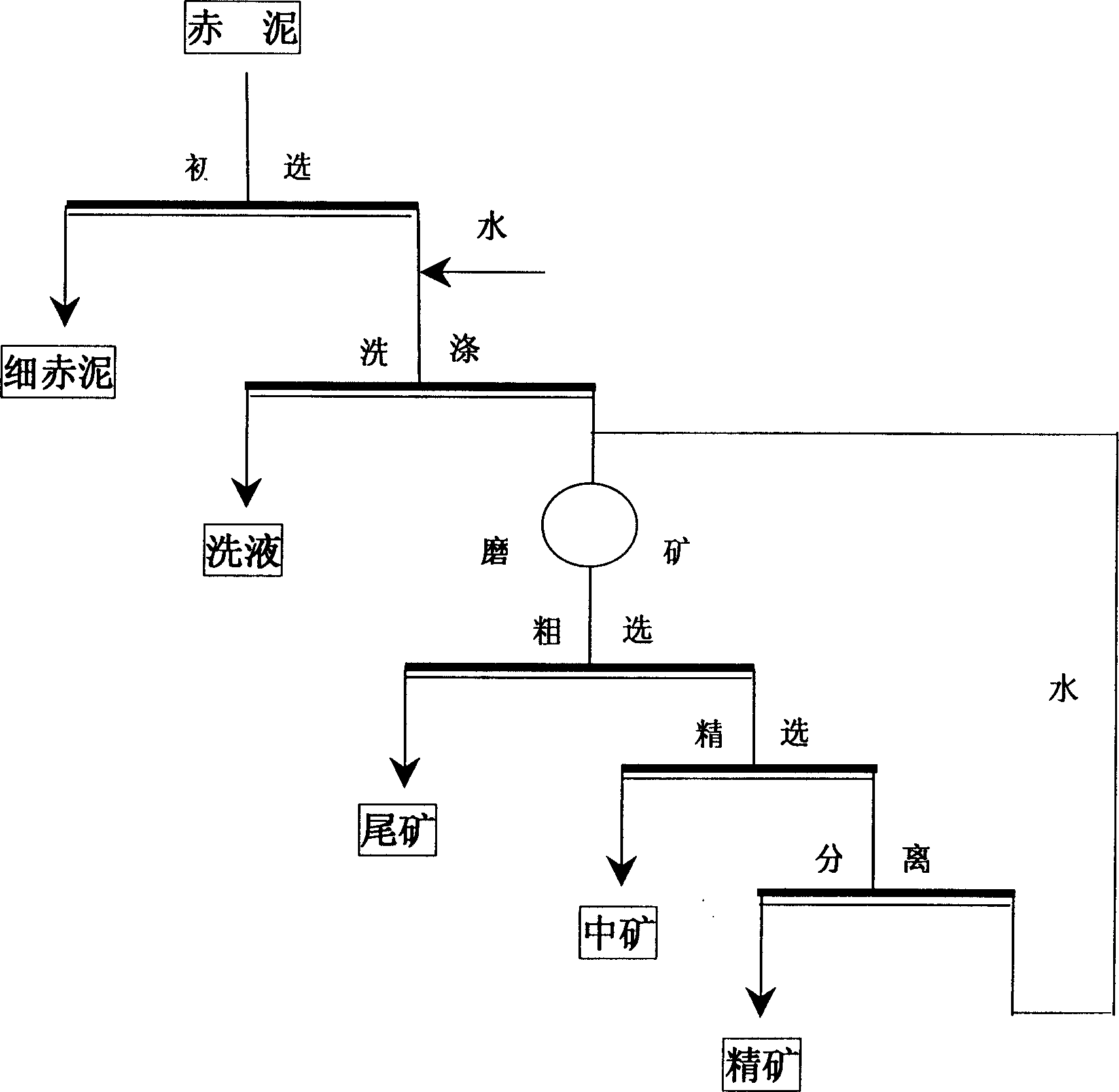

Method for selecting iron ore from red mud

ActiveCN1569341ATo achieve the purpose of comprehensive utilizationHigh yieldMagnetic separationWet separationIronstoneRed mud

The invention is a method for selecting iron ore from red mud. It preprocesses the red mud to eliminate the tiny red mud and acquires the red mud sand, carries on grinding and classification to the red mud sand then eliminates the tail ore through raw selection and acquires the concentrate after choiceness. The picking process uses high background field density and small pulse frequency, the choiceness uses lower background field density and larger pulse frequency. The flow is simple, and the reclaim rate of iron is high, the reclaim rate of iron can reach to 90%. The invention has excellent economical efficiency and social efficiency.

Owner:SHANDONG QIANSHUN MINING & METALLURGY SCI +1

Low-grade magnetite pre-selection and waste abandoning mineral separation process

ActiveCN104874459APromote development and utilizationImprove the grinding gradeGrain treatmentsIronstoneMagnetite

The invention discloses a low-grade magnetite pre-selection and waste abandoning mineral separation process. The process comprises the following steps: carrying out coarse crushing, carrying out medium crushing, carrying out first-section sieving, carrying out first-section pre-selection and waste abandoning, carrying out fine crushing, carrying out ultrafine crushing, carrying out second-section sieving, and carrying out second-section pre-selection and waste abandoning. After raw ores are subjected to the coarse crushing and the medium crushing, three products are sieved by the first-section sieving; oversize products obtained after the first-section sieving is finely crushed through ore concentrate which is obtained by the first-section pre-selection and waste abandoning to form a fine crushing closed cycle; sized products obtained after the first-section sieving and the oversize products obtained after the second-section sieving are finely crushed and then are returned back to the second-section sieving to form an ultrafine crushing closed cycle; undersize products obtained after the first-section sieving and undersize products obtained after the second-section sieving are subjected to the second-section pre-selection and waste abandoning, and tailings in the first-section pre-selection and tailings in the second-section pre-selection are final tailings; and ore concentrate in the second-section pre-selection is a final product. According to the low-grade magnetite pre-selection and waste abandoning mineral separation process, a plurality of waste stones can be abandoned and the amount of ore entering a mill is reduced; the mill-entering grade of iron ores is improved, and the energy consumption and the consumption of steel balls can be reduced; and the development and the utilization of low-grade magnetite ores are facilitated, and the utilization rate of resources is expanded.

Owner:CHINA NERIN ENG

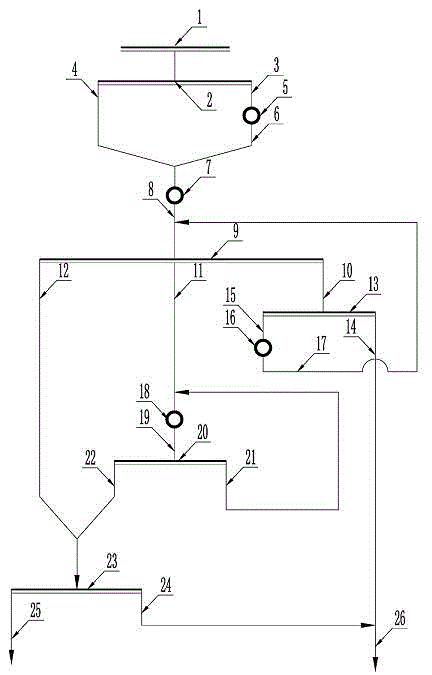

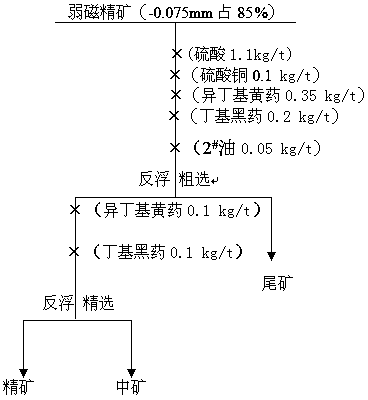

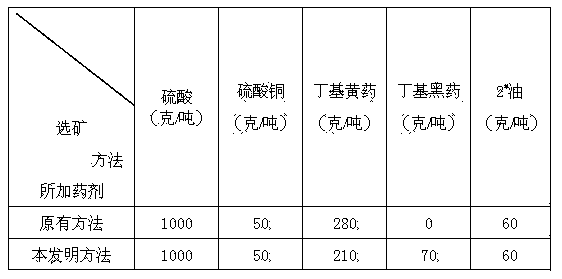

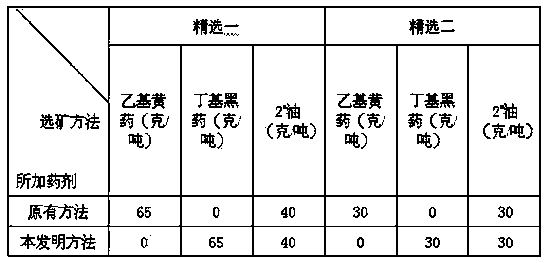

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

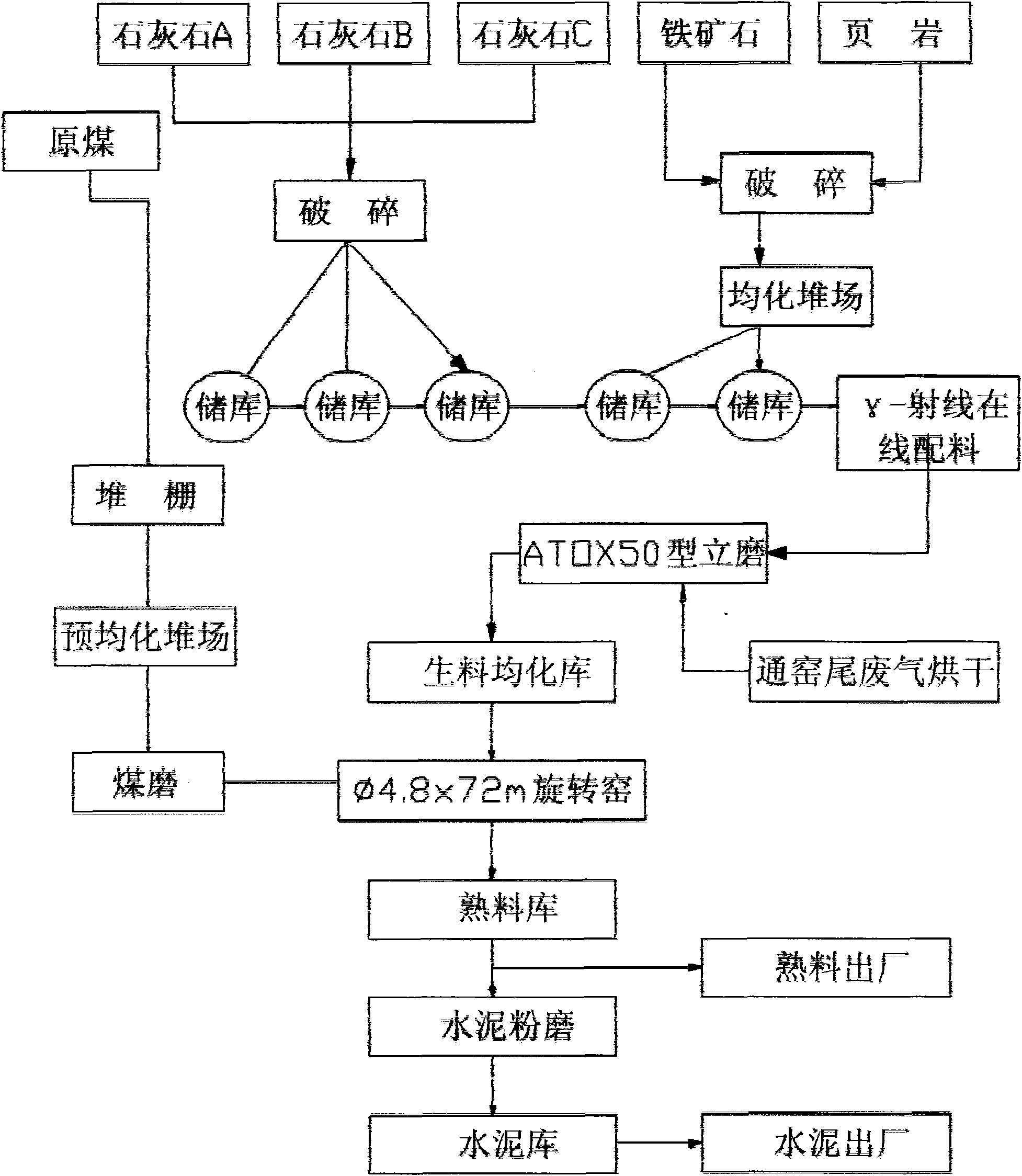

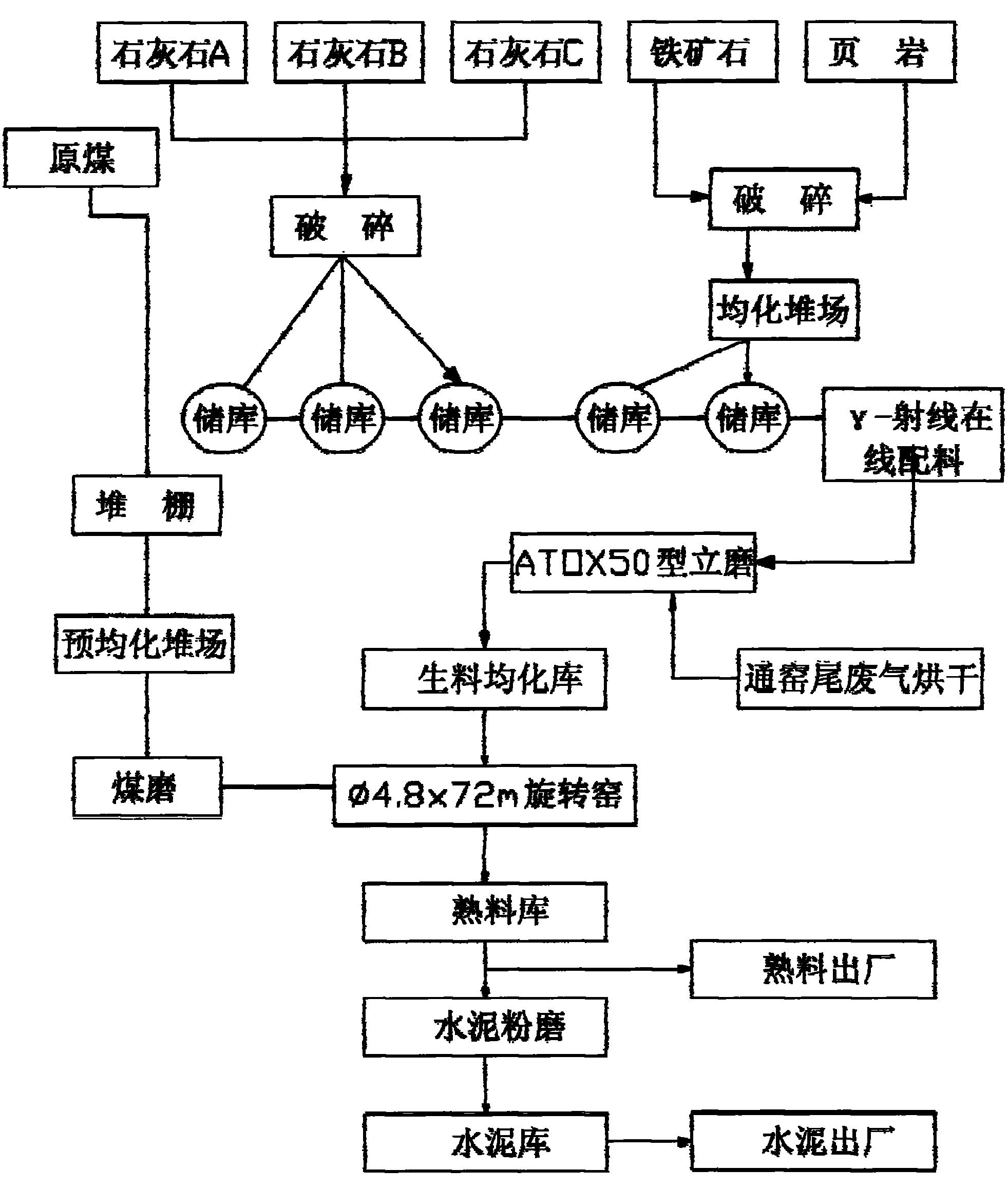

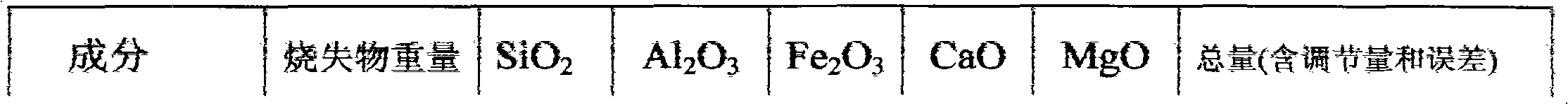

Method for producing cement by utilizing high-silicon low-calcium limestone

InactiveCN101781096AIt has the characteristics of "low calcium and high free silicon"Rich reservesIronstoneMining engineering

The invention relates to a method for producing cement by utilizing high-silicon low-calcium limestone. The cement comprises the following raw materials in percentage by weight: 48 to 50 percent of low-grade high-silicon limestone with CaO content between 42 and 45 percent and f-SiO2 content between 10 and 18 percent, 31 to 33 percent of high-magnesium limestone, 16 to 18 percent of matched limestone, 3 to 6 percent of shale and 2 to 4 percent of ironstone. The method is technology which utilizes low lime saturation ratio and ore of high silicon rate and high alumina rate and has an attribute of low silica modulus; online detection is performed on the mixture ratio of the raw materials by using a gamma ray instrument and a formula is adjusted by using one minute as a cycle; and a plate hammer counterpunch type crusher is used for crushing, a roller-type vertical grinding mill is used for grinding and waste gas at the tail of a kiln is used for drying the raw materials. The method has the advantages of capability of developing and utilizing low-grade limestone resource, accurate material burdening, timely regulation of the mixture ratio, and capability of reducing homogenization facilities and storage yard; and high quartziferous rock ore can be used in vertical milling and has high grindability. The method is suitable for utilizing high-dissociative silicon low-calcium limestone.

Owner:SINOMA TIANSHAN YUNFU CEMENT

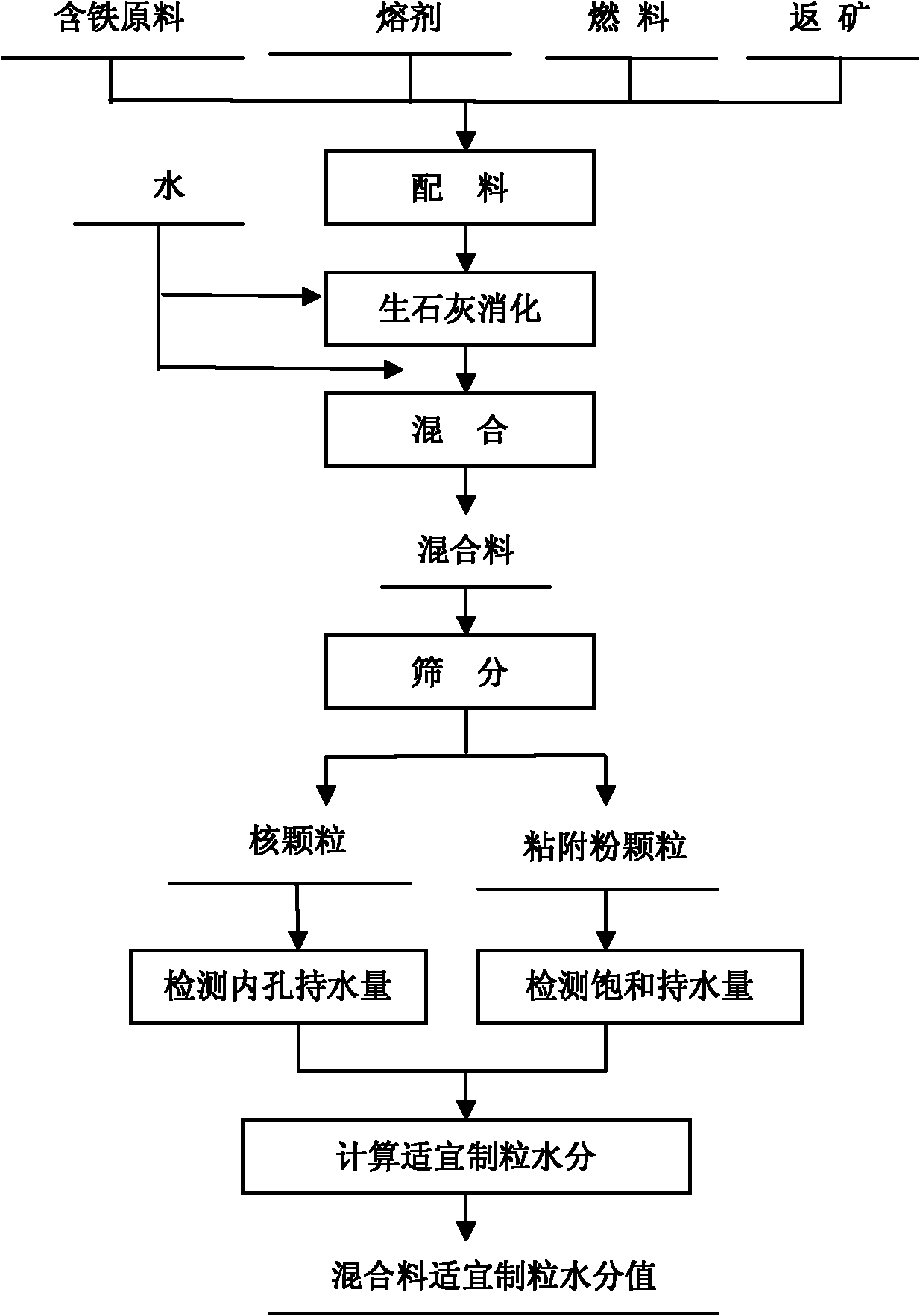

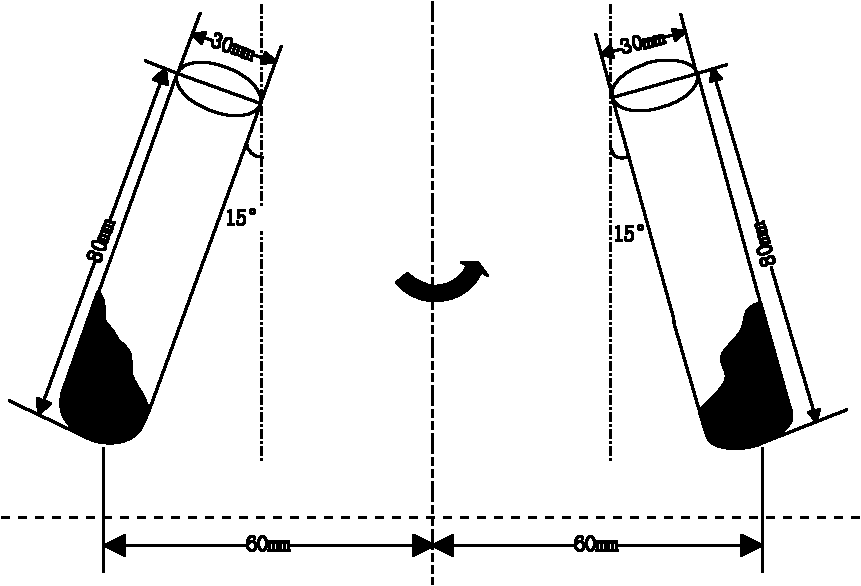

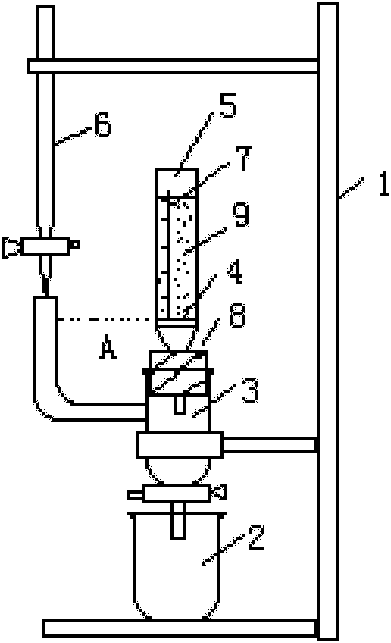

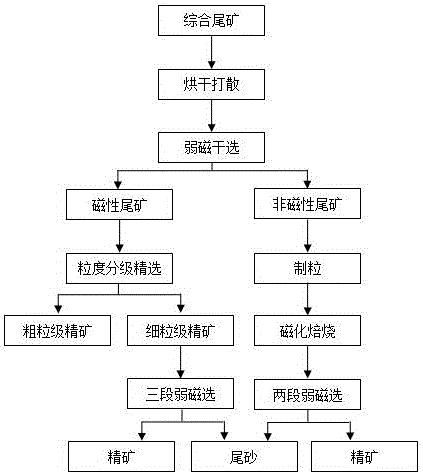

Method for quickly testing appropriate granulation moisture content of iron ore sinter mixture

InactiveCN101974680AShort detection cycleSmall amount of sampleParticle size analysisIronstoneCentrifugation

The invention discloses a method for quickly testing the appropriate granulation moisture content of an iron ore sinter mixture. The appropriate granulation moisture content refers to the moisture content required by the granulated mixture for obtaining optimal breathability. The moisture includes the moisture of the raw materials and the added water during mixing and granulation. The method comprises the following steps: 1) preparing a slurry mixture of which the humidity is 10 to 20 percent from iron ore, solvent, coke powder and sinter return ore; 2) rinsing and sieving the mixture by using saturated lime water as a medium, obtaining adhesive powder and shell grains and testing the content Xa of the adhesive powder; 3) testing the inner hole water-holding capacity of the shell grains by centrifugation; 4) testing the saturated water-holding capacity of the adhesive poser by using saturated water absorption process; and 5) calculating the appropriate moisture content required for the granulation of the mixture according to a formula. The method has the characteristics of simple operation and high accuracy. Based on an absolute error range from -0.3 to +0.3, the accuracy of the prediction of the appropriate moisture content reaches 93.3 percent according to the results of the tests of the moisture content of mixtures prepared by 30 material mixing schemes.

Owner:CENT SOUTH UNIV

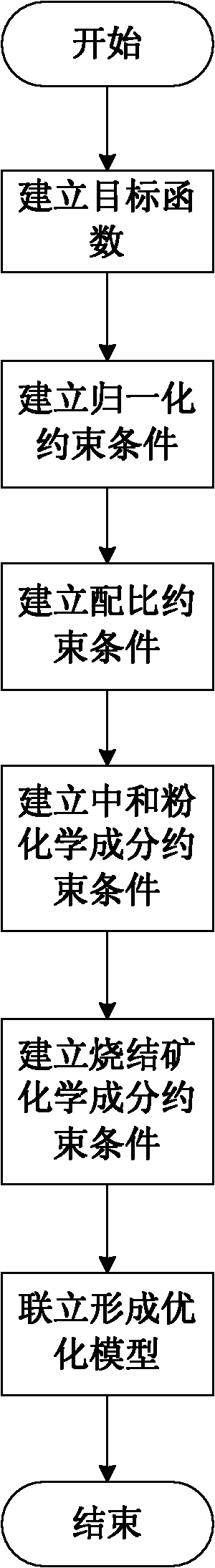

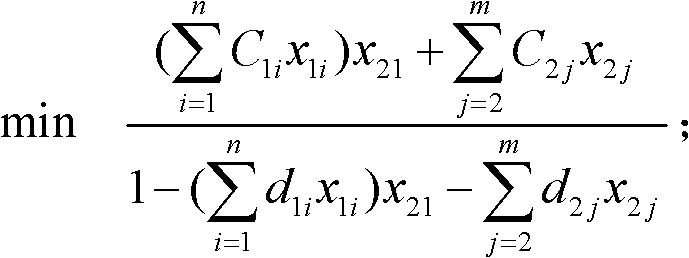

Comprehensive optimization method for steel sintering secondary burdening

The invention discloses a comprehensive optimization method for steel sintering secondary burdening. In the invention, steel sintering pre-burdening and a sintering burdening model are integrated; a comprehensive optimization model of the steel sintering secondary burdening is built through chemical composition information, burning loss rate and proportioning constraint interval of iron ore, fusing agents, fuel and sintering recycled object as well as constraint conditions of chemical composition indexes such as iron grades of neutralization powder and agglomerates, calcium oxide content, silica content, magnesium oxide content, aluminum oxide content, sulfur content and the like; and therefore, the secondary burdening process comprising working procedures of pre-burdening and sintering burdening is accurately described, the problem of local optimization but not global optimization because of respectively solving a pre-burdening optimization model and a sintering burdening optimization model is avoided; and the global comprehensive optimization of the steel sintering secondary burdening is realized.

Owner:CENT SOUTH UNIV

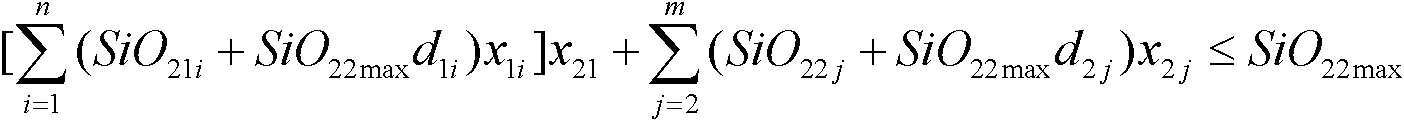

Process for extracting iron from comprehensive tailings of refractory iron ores

ActiveCN106000638AReduce processingImprove disposal efficiencyRotary drum furnacesMagnetic separationIronstoneMagnetic separator

A process for extracting iron from comprehensive tailings of refractory iron ores comprises the following main steps: after drying and scattering the comprehensive tailings of the refractory iron ores, magnetically separating the comprehensive tailings of the refractory iron ores by using a dry type low-intensity magnetic separation machine to obtain magnetic tailings and non-magnetic tailings; and carrying out size grading on the magnetic tailings to remove the magnetic tailings with low coarse fraction grade and high SiO2 content; carrying out three-stage low-intensity magnetic separation and desilicification to increase iron grade so as to obtain qualified iron ore concentrates; granulating and drying the non-magnetic tailings at first, and then mixing the non-magnetic tailings with a pulverized coal reducing agent; loading in a rotary kiln in a mixed manner and magnetically roasting, wherein roasting temperature is 700-850 DEG C and high-temperature roasting time is 30-50 min; after roasting is finished, cooling to the temperature below 100 DEG C by using an indirect water-cooling mode; and then carrying one-stage grinding and two-stage magnetic separation to obtain qualified iron core concentrates finally. Compared with the traditional tailings treatment method, the process is purposeful, the comprehensive tailings are classified according to different properties of the comprehensive tailings, the tailings treatment efficiency can be improved, so that useful resources are extracted to a maximum extent, and the tailings of the refractory iron ores are utilized comprehensively.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Method for sintering vanadium/titanium magnetite concentrate and siderite

The invention discloses a method for sintering a vanadium / titanium magnetite concentrate and siderite, which comprises the steps as follows: crude fuel materials are prepared, and comprises siderite, iron ore, a flux and fuel materials; crude ore of the siderite is processed, the content of one kind of siderite with a particle grade greater than 8 mm is less than 10 wt% of the total siderite, and the content of another kind of siderite with a particle grade less than 1 mm is less than 20 wt% of the total siderite, so that the siderite is obtained, and the iron ore comprises the vanadium / titanium magnetite concentrate and other kind of iron ore; the crude fuel materials are mixed, on the basis of the total weight of the crude fuel materials, the weight percent of the siderite is 1wt%-10wt%, the weight percentage of the vanadium / titanium magnetite concentrate is 50wt%-60wt%, in addition, the weight percentage of the iron ore is 10wt% to 30wt%; mixing, material distribution, ignition and sintering are performed. According to the method for sintering the vanadium / titanium magnetite concentrate and the siderite, low-quality siderite and low-quality vanadium / titanium magnetite concentrate are used and sintered, as a result, the resource shortage can be remitted, the raw material cost is lowered, and the level of main technical indexes is kept.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

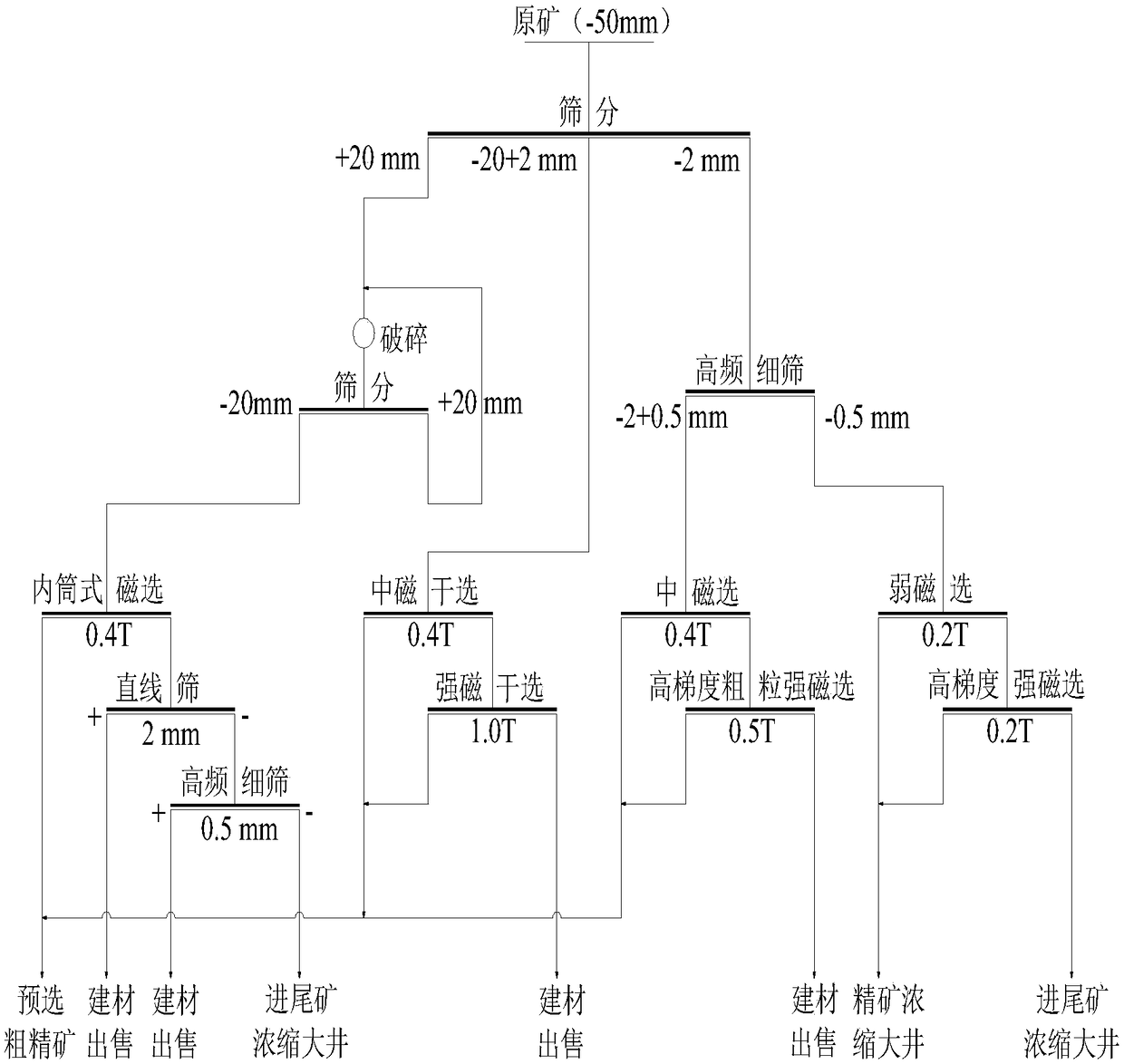

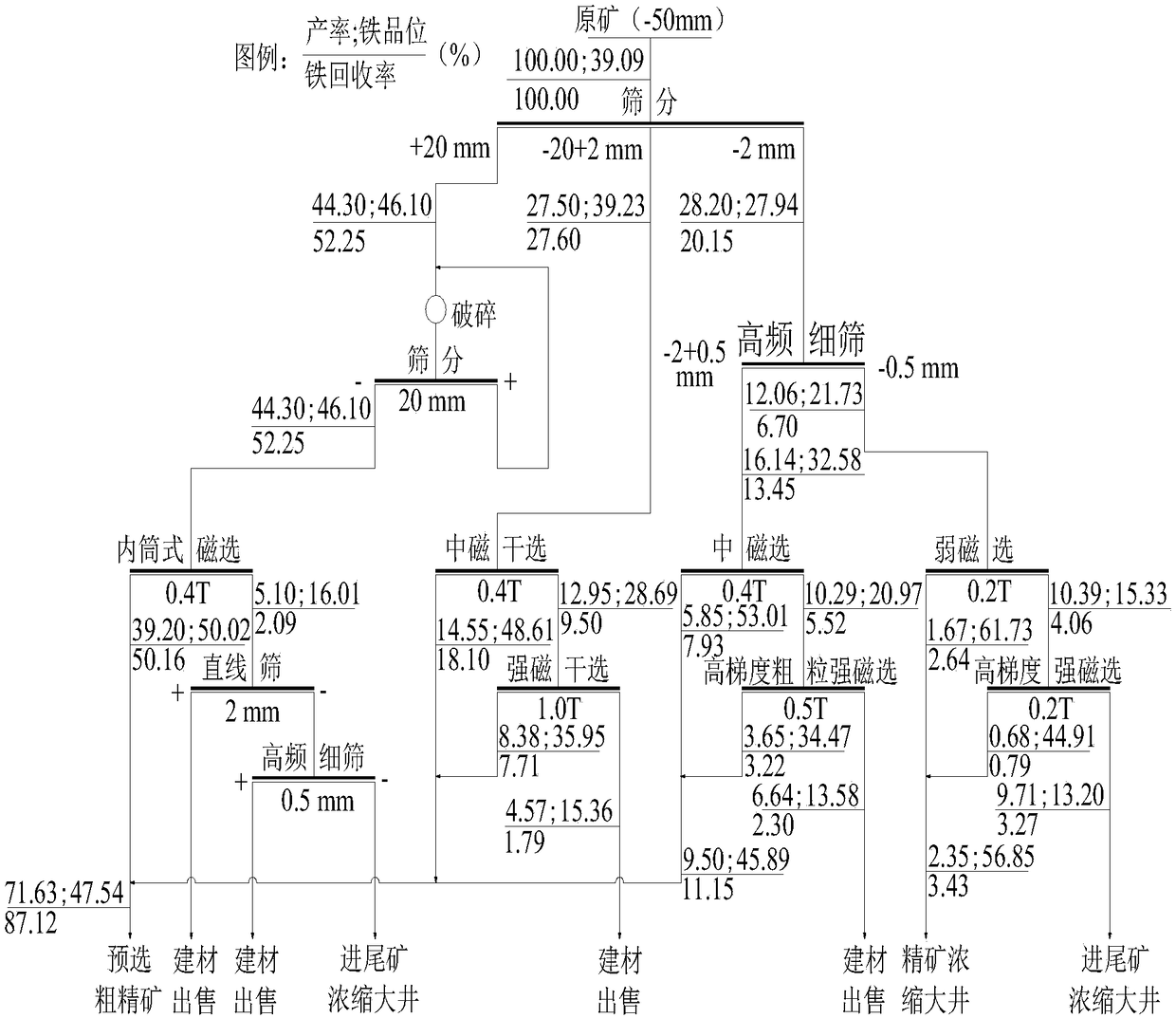

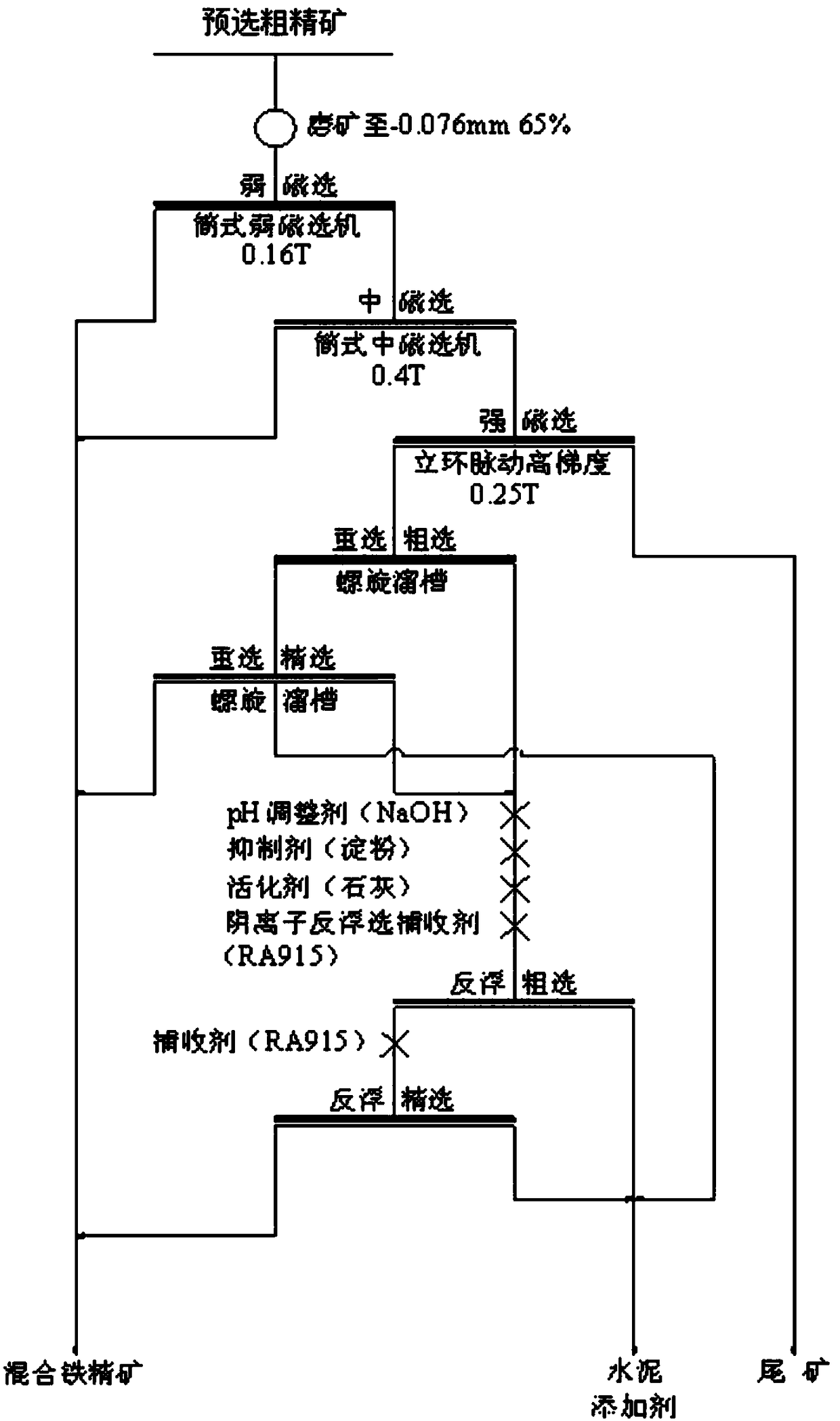

Novel grading prescreening precise separation method for mixed iron ore including magnetic iron ore, hematite and siderite

The invention discloses a novel grading prescreening precise separation method for mixed iron ore including magnetic iron ore, hematite and siderite. Intermediate smashed products with the particle size being -50 mm are subjected to grading prescreening at first, prescreened rough concentrate, prescreened fine-particle iron ore concentrate and building material products with different particle grades are obtained; the prescreened rough concentrate is subjected to ore grinding and grading closed loop operation after being precisely smashed, low intensity magnetic separation concentration (C1),intermediate intensity magnetic separation concentration (C2), gravity concentrate (3) and reverse flotation iron ore concentrate (C4) are obtained, and a cement additive product is obtained. The novel grading prescreening precise separation method has the advantages that the adaptability is high, the energy saving effect is good, economic benefits are large, the separation precision and the resource comprehensive utilization rate are high, and the discharging amount of tailings is small, the method is especially suitable for screening of the mixed iron ore including the magnetic iron ore, thehematite and the siderite, wherein the TFe grade is 35.0%-42.0%, the hematite / limonite difficult to screen accounts for 19-25% of the total amount of the mixed iron ore, and the siderite accounts for17-23% of the total amount of the mixed iron ore.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com