Patents

Literature

149 results about "Saturation ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saturation ratio. The ratio of the actual specific humidity to the specific humidity of saturated air at the same temperature.

Method for obtaining oil-water common-layer original oil-containing saturation degree and method for estimating non-test oil-water common-layer original oil-containing saturation degree

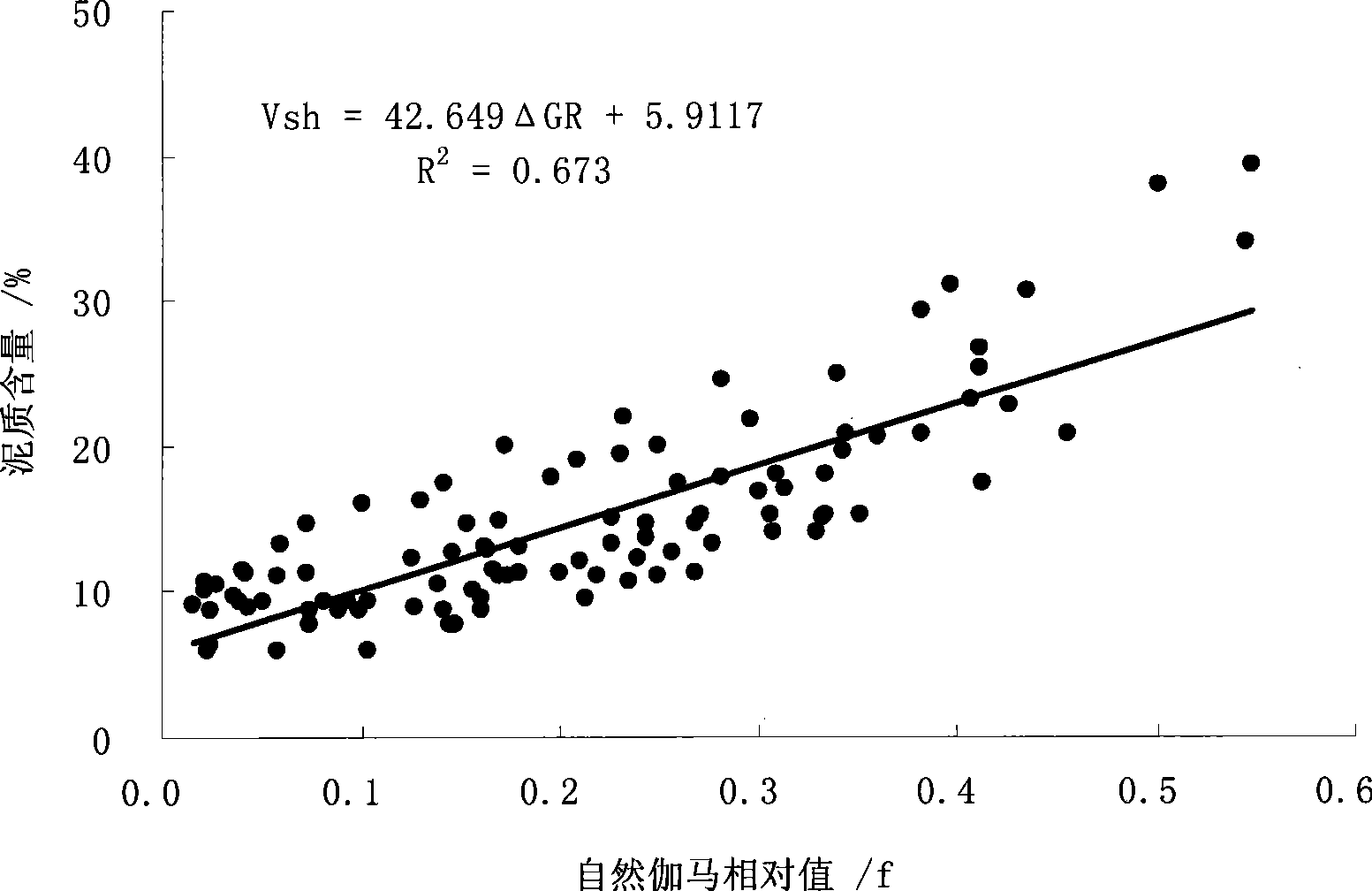

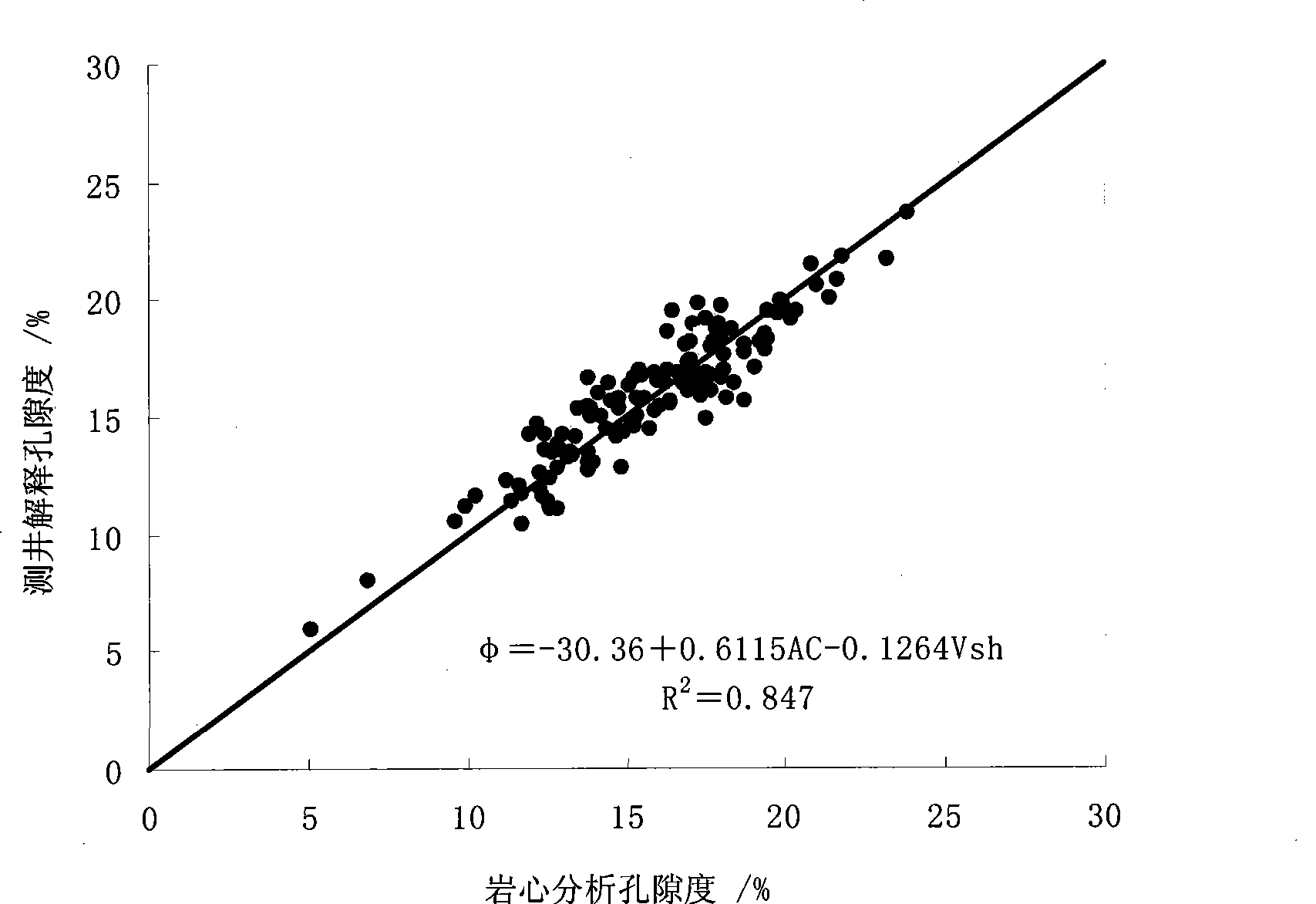

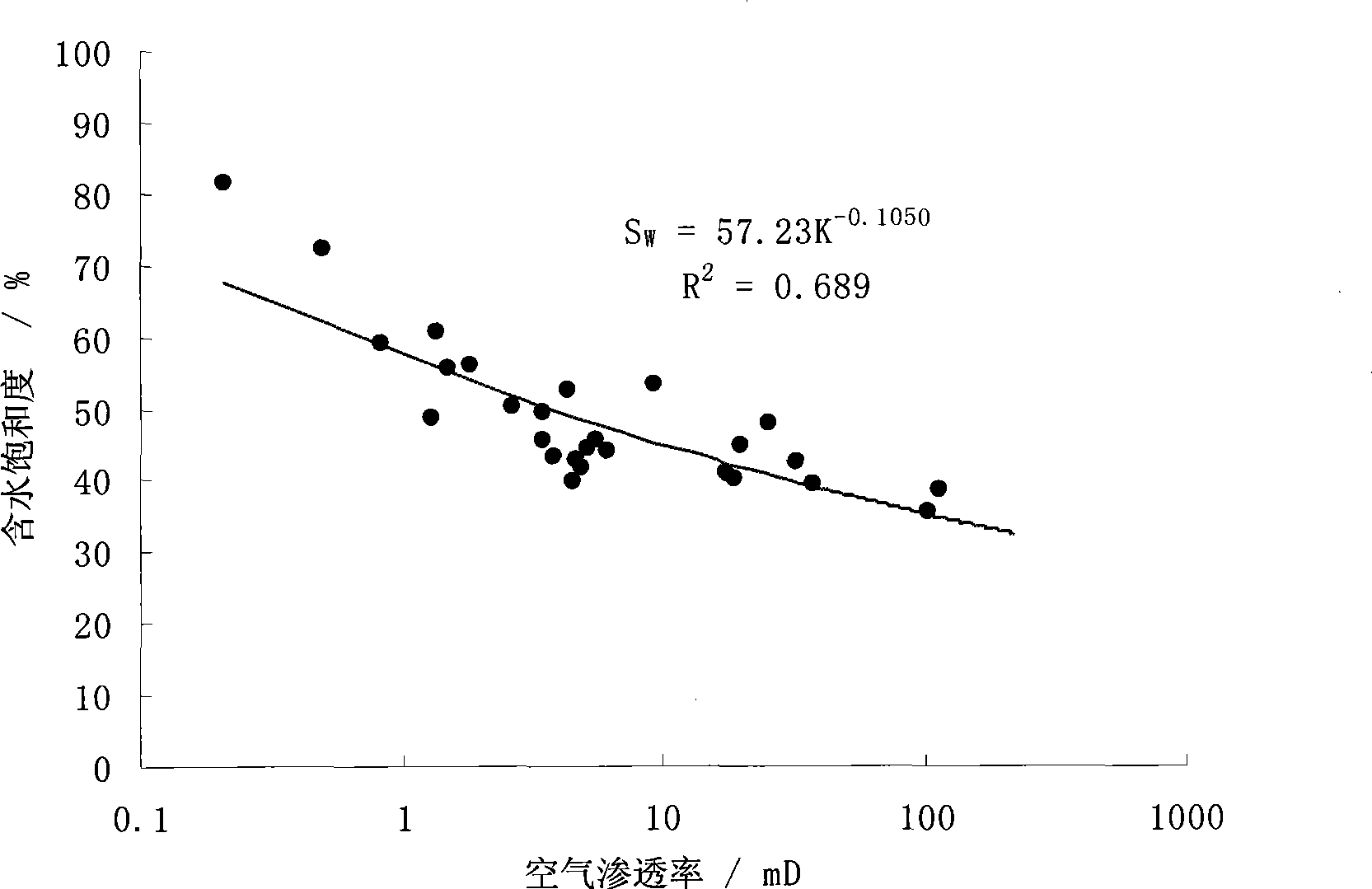

InactiveCN101413388ABorehole/well accessoriesNuclear radiation detectionCalculation errorPoor correlation

The invention relates to a method for acquiring the initial oil saturation of an oil-water layer and a method for estimating the initial oil saturation of the oil-water layer of untested oil, which relate to a method for calculating the initial oil saturation in a reserve parameter log interpretation. The method solves the problem of large calculation error in the prior method for acquiring the initial oil saturation of the oil-water layer. In the method for acquiring the initial oil saturation of the oil-water layer, the initial oil saturation of a tested oil layer of the oil-water layer is calculated by application of an initial oil saturation model of the oil layer first, and corrected according to interpenetration data and oil testing data to obtain the initial oil saturation of the oil-water layer of tested oil. The method is suitable for the oil-water layer with poor correlation between the initial oil saturation and the resistivity and can be used for calculating the petroleum reserve by the volumetric method. The method for estimating the initial oil saturation of the oil-water layer of the untested oil according to the interpenetration data and the oil testing data is to estimate the initial oil saturation of the oil-water layer of the untested oil by applying and researching the average moisture content of the oil-water layer of a working area.

Owner:DAQING OILFIELD CO LTD

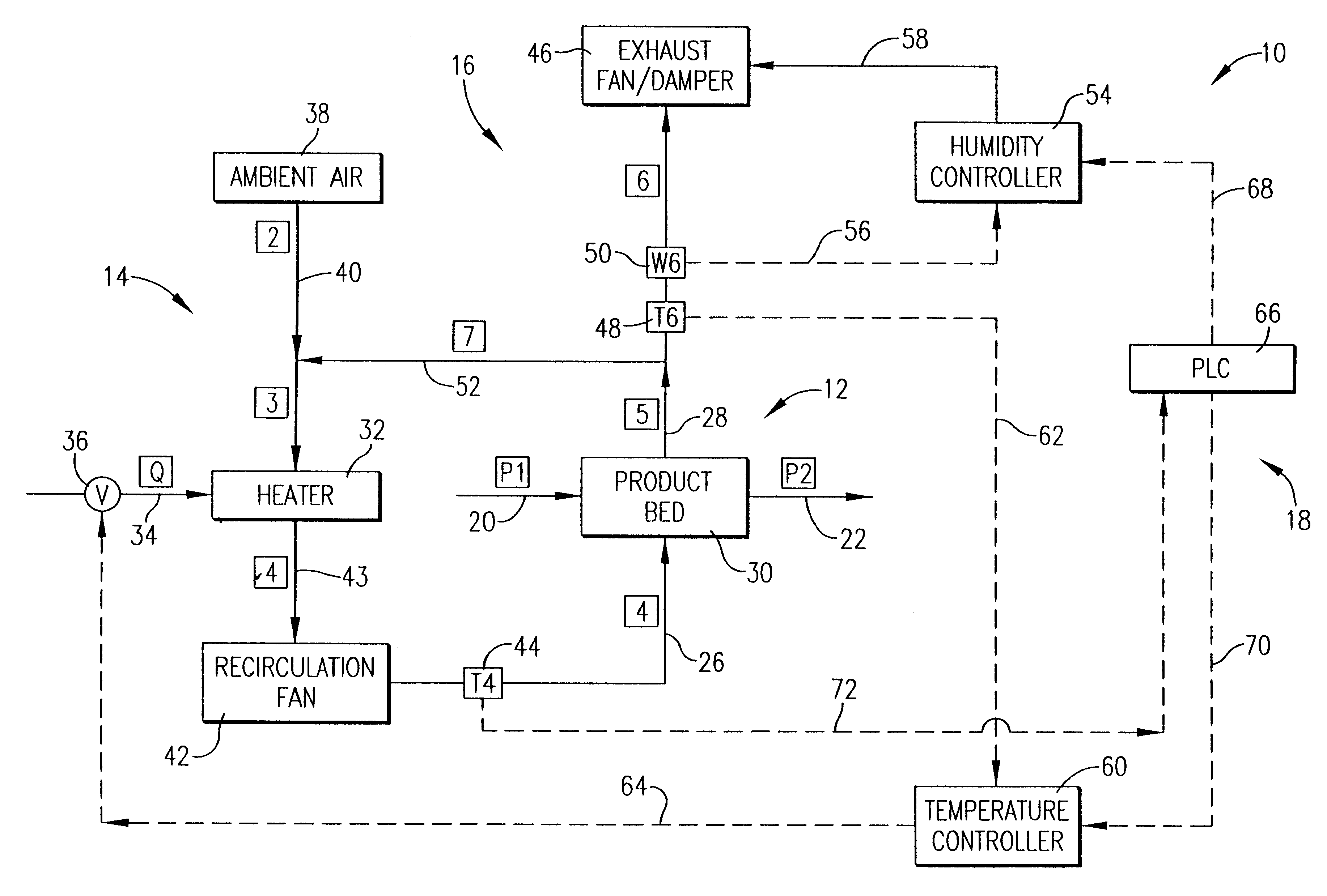

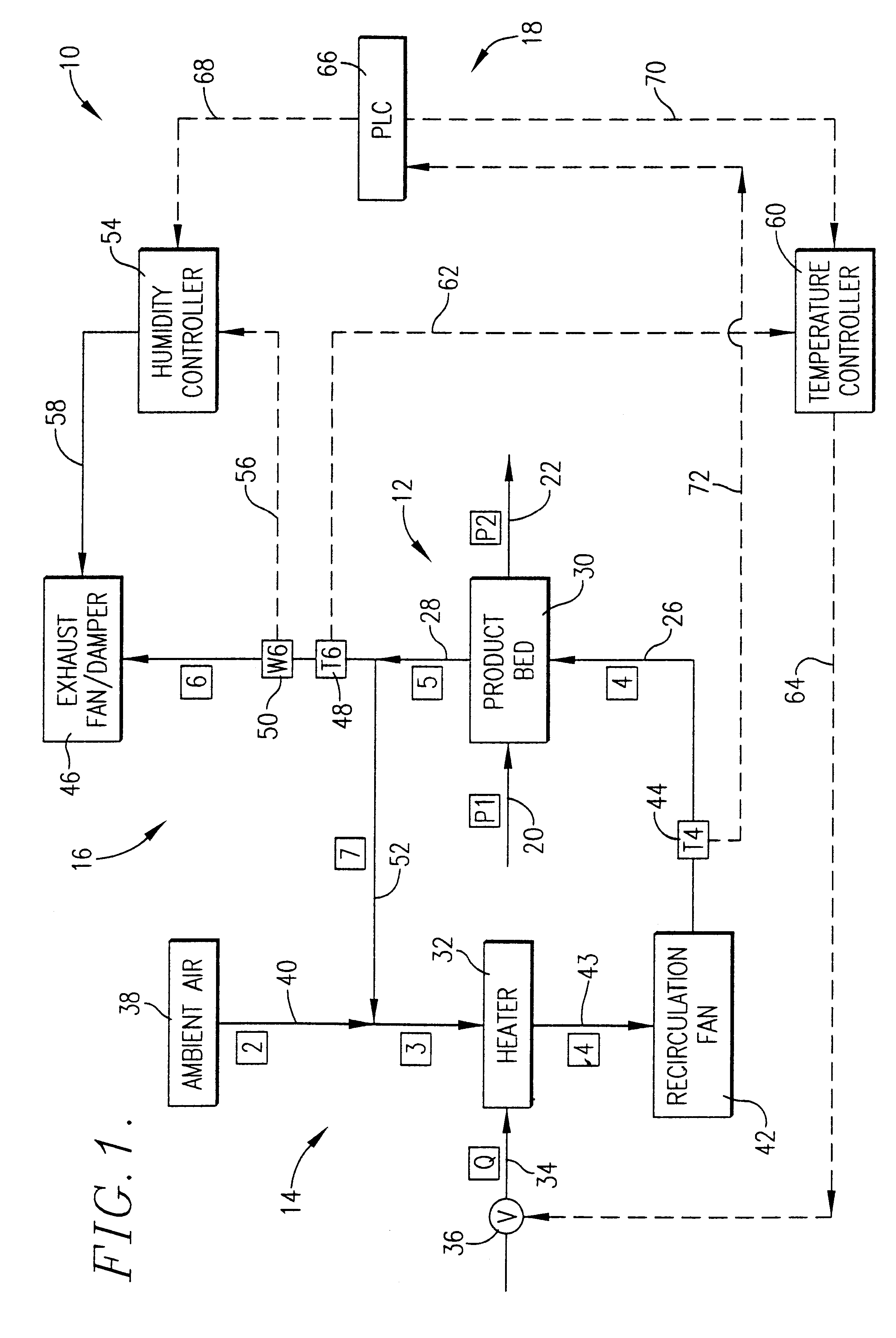

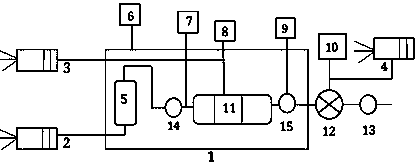

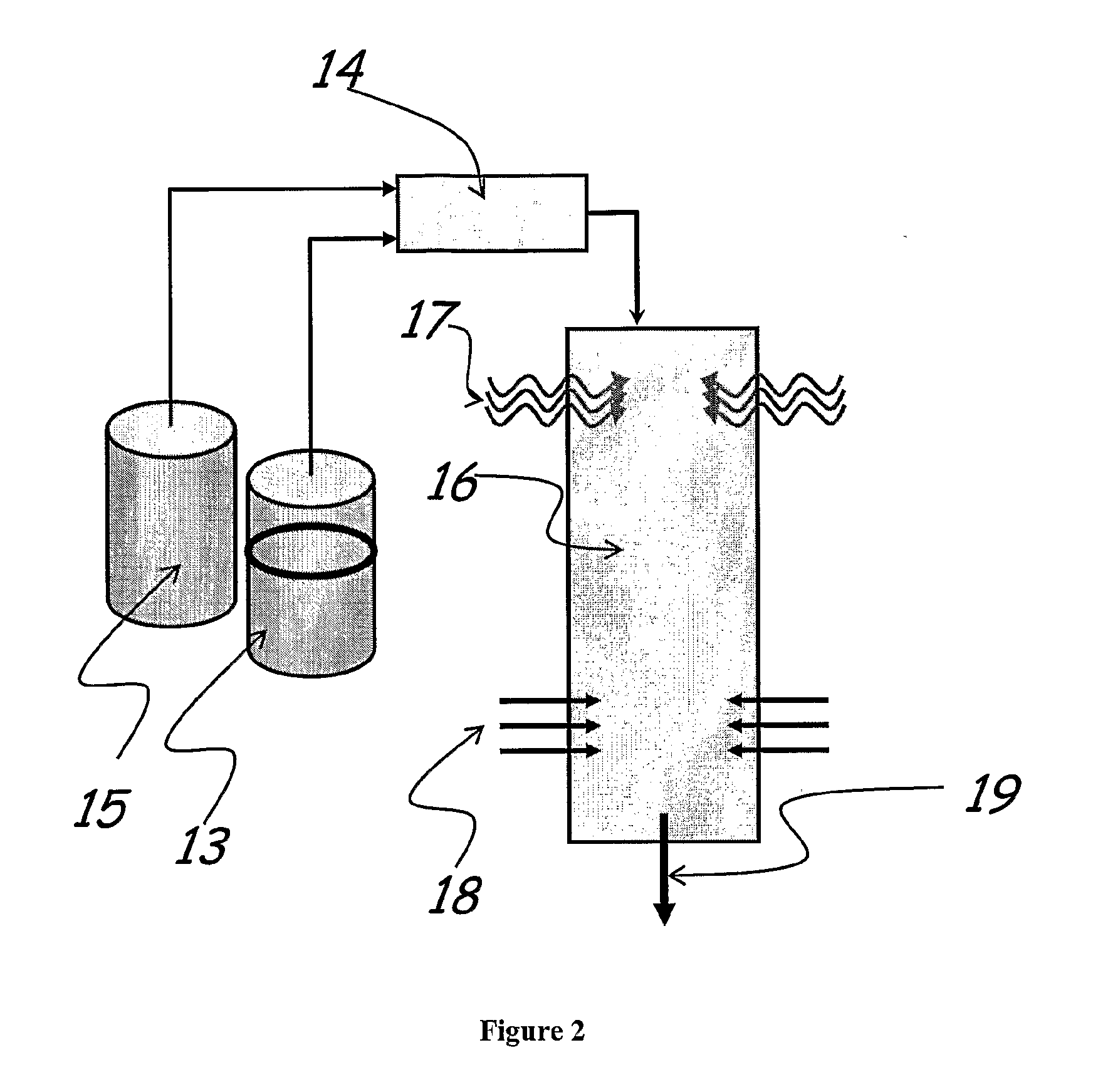

Dryer apparatus and dryer control system

InactiveUS6484417B2Drying solid materials with heatDrying gas arrangementsContinuous measurementAtmospheric air

An improved dryer (10) and drying methods are provided which increase overall dryer efficiency by maintaining substantially constant output air stream adiabatic saturation ratio and temperature values during the course of drying, notwithstanding the occurrence of upset conditions. The dryer (10) includes a dryer body (12), an input air heater assembly (14) including an air heater (32), and a control assembly (18). The dryer body (12) has a drying zone (30), with product inputs and outputs (20, 22) as well as an input (26) for a heated air stream and an output (28) for the cooled, moisture-laden output air stream. The dryer control assembly (18) includes temperature and humidity sensors (48, 50) coupled to controllers (54, 60) and a PLC (66). The controller (54) is coupled with an exhaust fan / damper unit (46) while controller (60) is connected with a fuel valve (36). In operation, the temperature and humidity of the output air stream are continuously measured by the sensors (48, 50), and the controllers (54, 60, 66) are operable to adjust the exhaust fan / damper unit (46) to regulate the relative proportion of output air exhausted to the atmosphere and recycled via conduit (52) for mixing with the input air stream, and also regulate the energy input to the dryer. Maintaining a substantially constant output air stream adiabatic saturation ratio and temperature allows dryer operation at significantly higher efficiencies as compared with prior systems.

Owner:WENGER MANUFACTURING INC

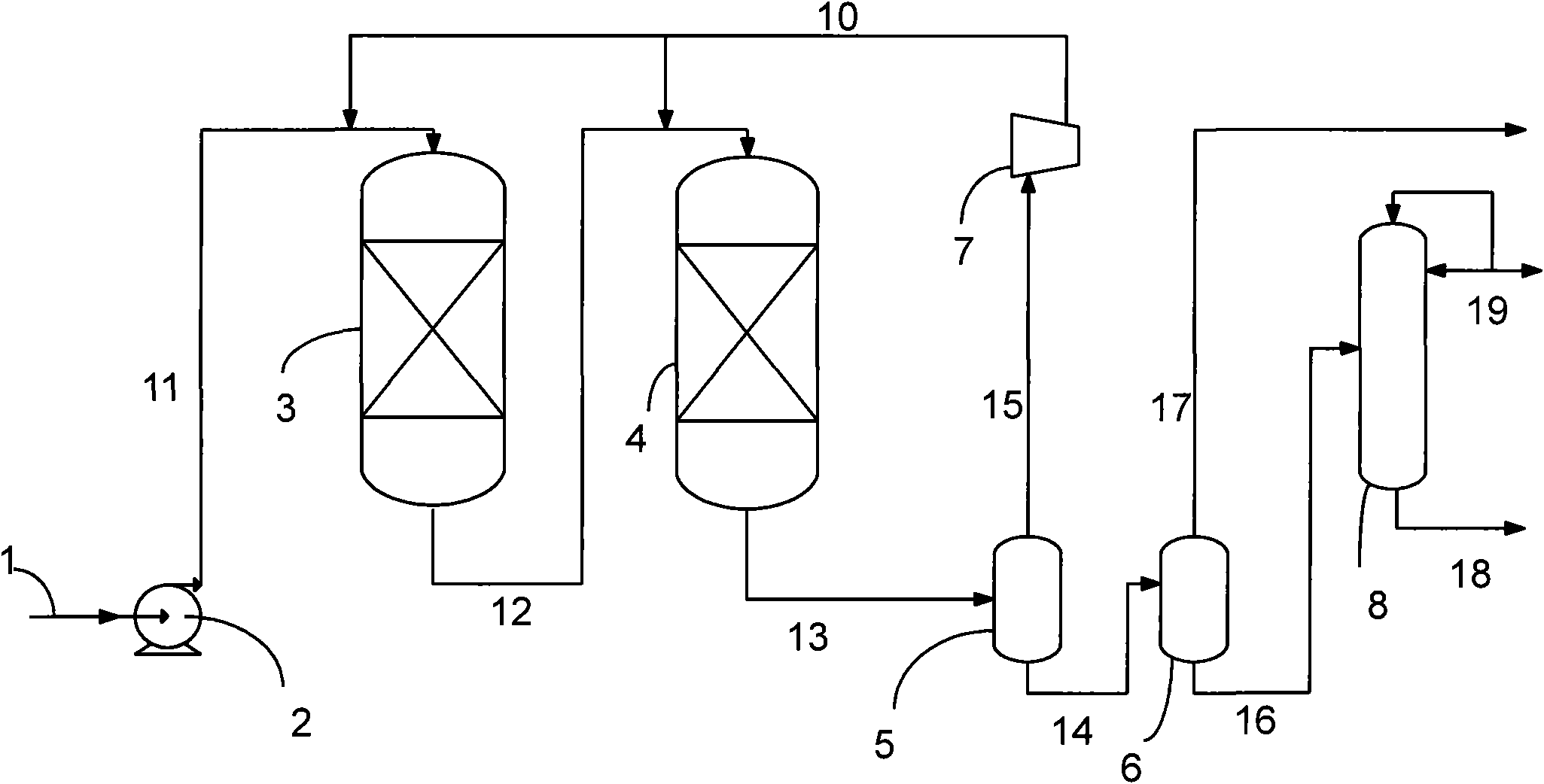

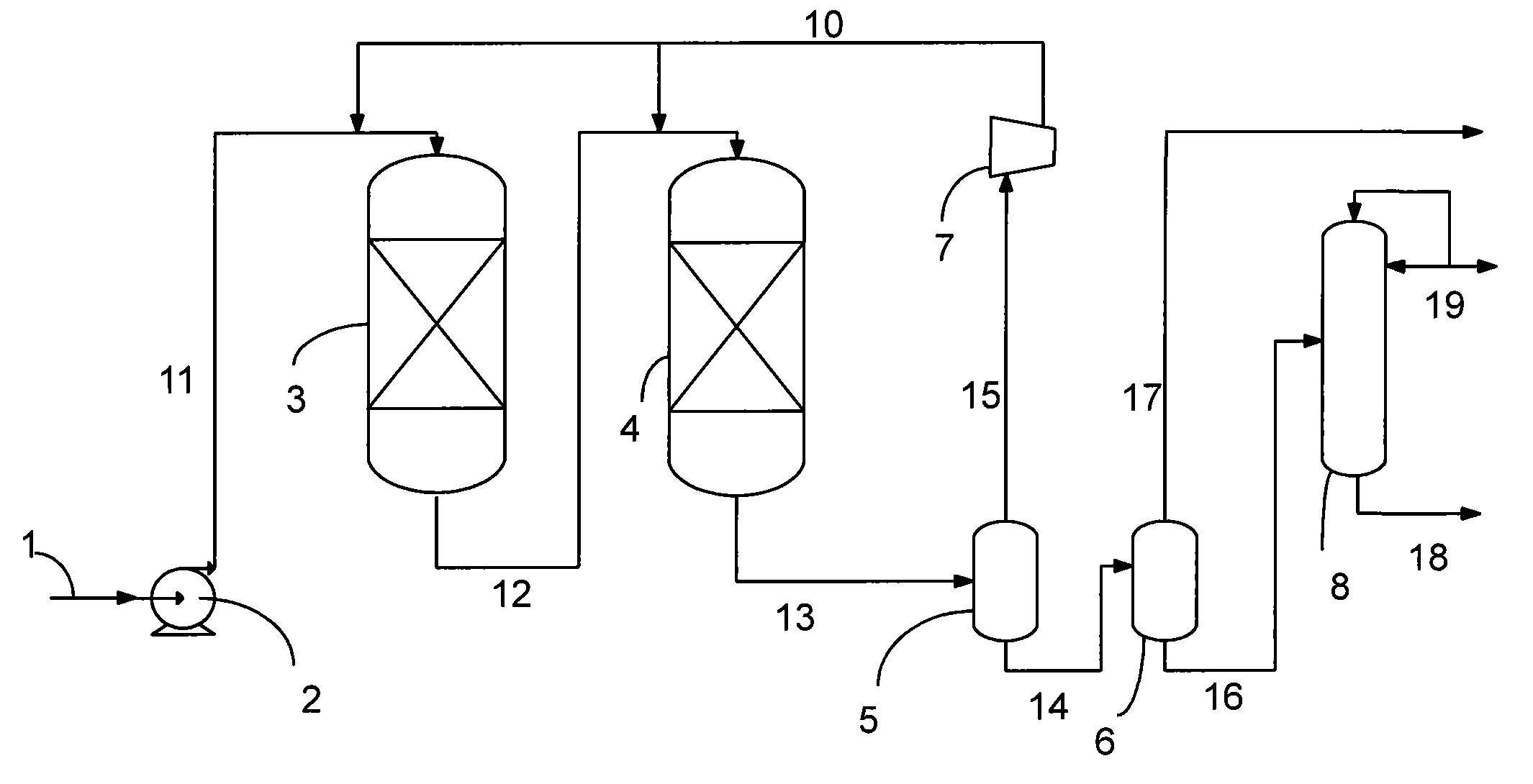

Method for producing high-octane petrol by inferior diesel

ActiveCN101987971ASimple processEasy to operateHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenSulfur

The invention relates to a method for producing high-octane petrol by inferior diesel. A mixture of diesel raw oil and hydrogen gas reacts with a hydrorefining catalyst in a first reaction zone and a hydrocracking catalyst in a second reaction zone in sequence, the saturation depth of arene in the first reaction zone is controlled, i.e. compared with diesel raw oil, the saturation ratio of two-ring and more than two-ring arene in reaction effluent of the first reaction zone is more than 50%, and taking the liquid components of the reaction effluent of the first reaction zone as a reference, the content of single-ring arene is increased to more than 40% by mass. Low-sulfur high-octane petrol can be produced from inferior diesel fractions with high arene content by using the single-pass process flow and a method of properly controlling reaction depth, and meanwhile, a low-sulfur clean diesel blend component can also be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

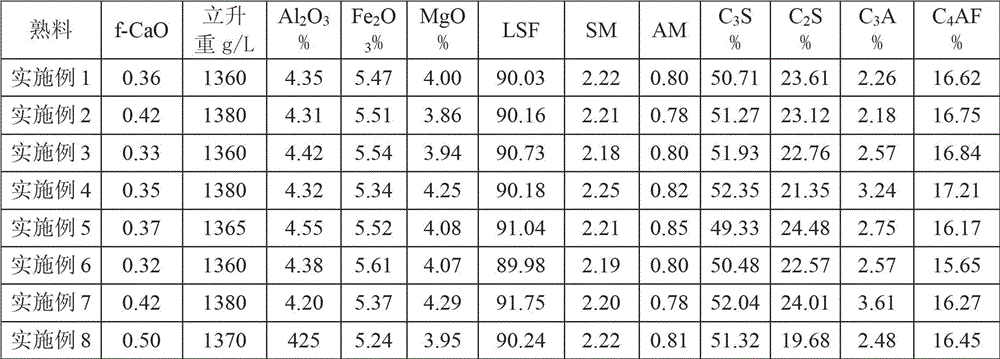

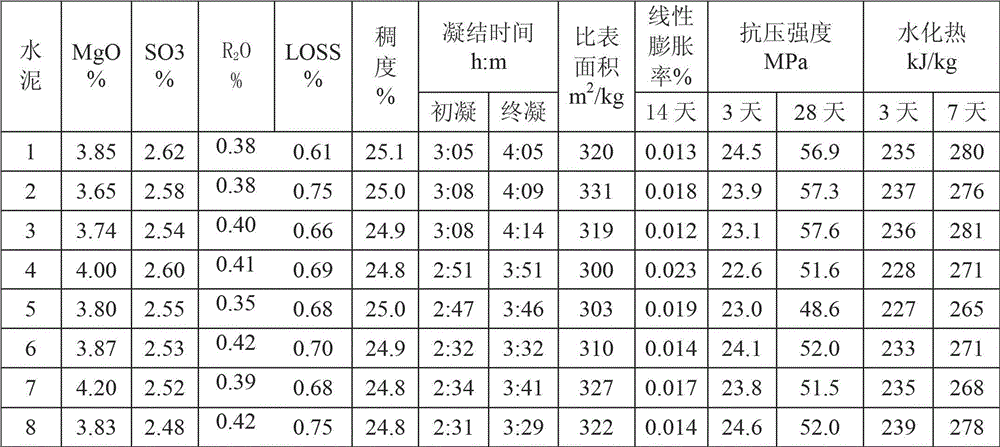

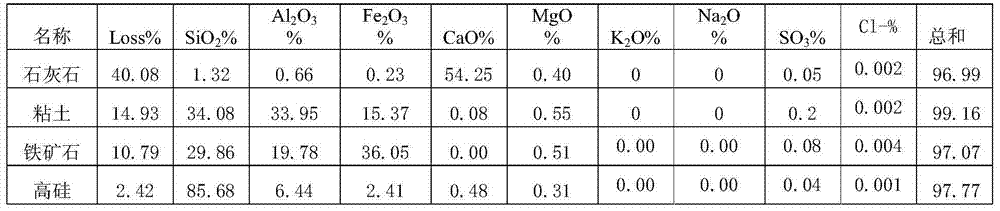

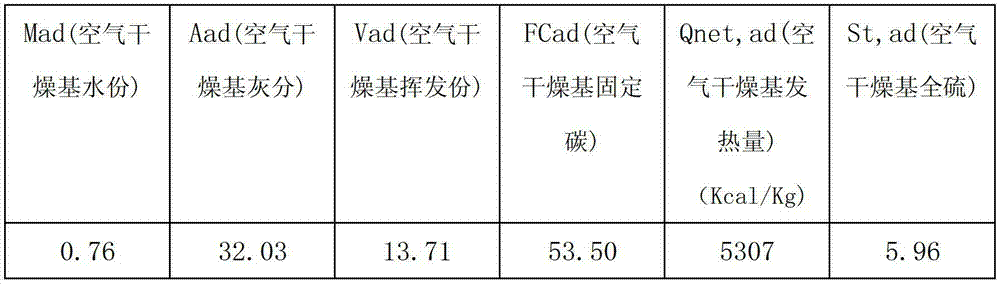

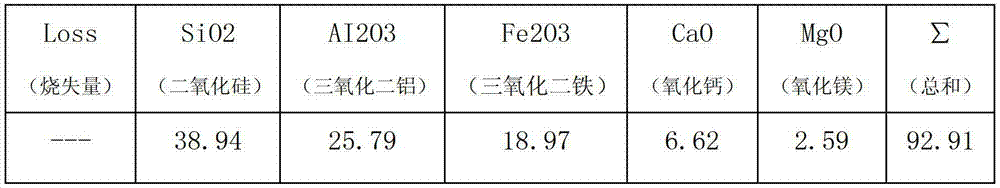

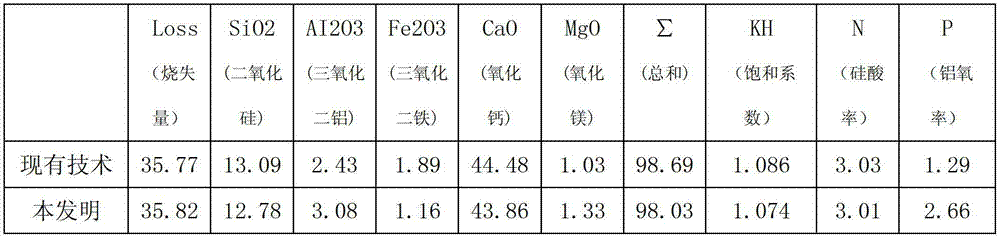

Micro-expansive moderate-heat Portland cement and production method thereof

InactiveCN102976641AHigh strengthHeat of hydration controlClinker productionHigh magnesiumPortland cement

The invention discloses a micro-expansive moderate-heat Portland cement and a production method thereof. The cement contains micro-expansive moderate-heat Portland cement clinker and gypsum in a weight ratio of 92:8-98:2, and also comprises grinding aid which accounts for 0-0.1 wt% of the sum of micro-expansive moderate-heat Portland cement clinker and gypsum. The raw meal of the micro-expansive moderate-heat Portland cement clinker is prepared from the following raw materials in percentage by weight: 65-80% of calcium raw material, 5-20% of silicon correction raw material, 5-15% of iron correction raw material and 3-10% of magnesium correction raw material. The micro-expansive moderate-heat Portland cement clinker is prepared by the following steps: grinding the raw meal, dehydrating the slurry, drying and crushing the filter cake, and firing to obtain the clinker. By adopting the low-aluminum high-iron high-magnesium low-saturation-ratio formula, the invention effectively controls the hydration heat of cement, displays the micro-expansive property, and can compensate the volume shrinkage in the concrete cooling process, thereby reducing or avoiding cracks.

Owner:GUANGXI YUFENG CEMENT

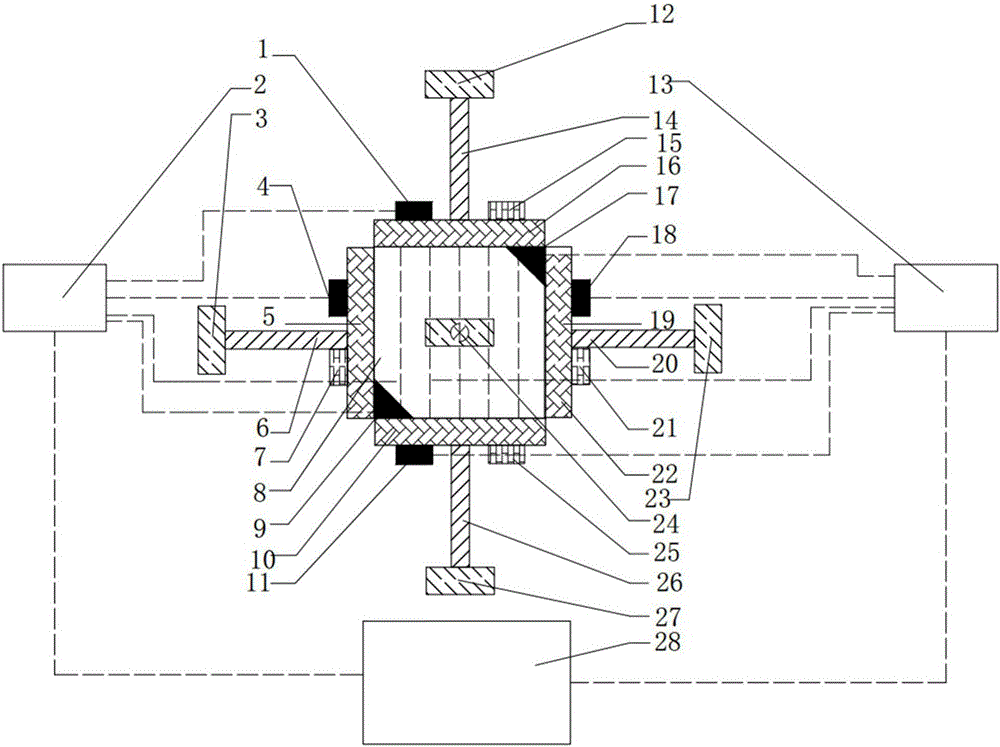

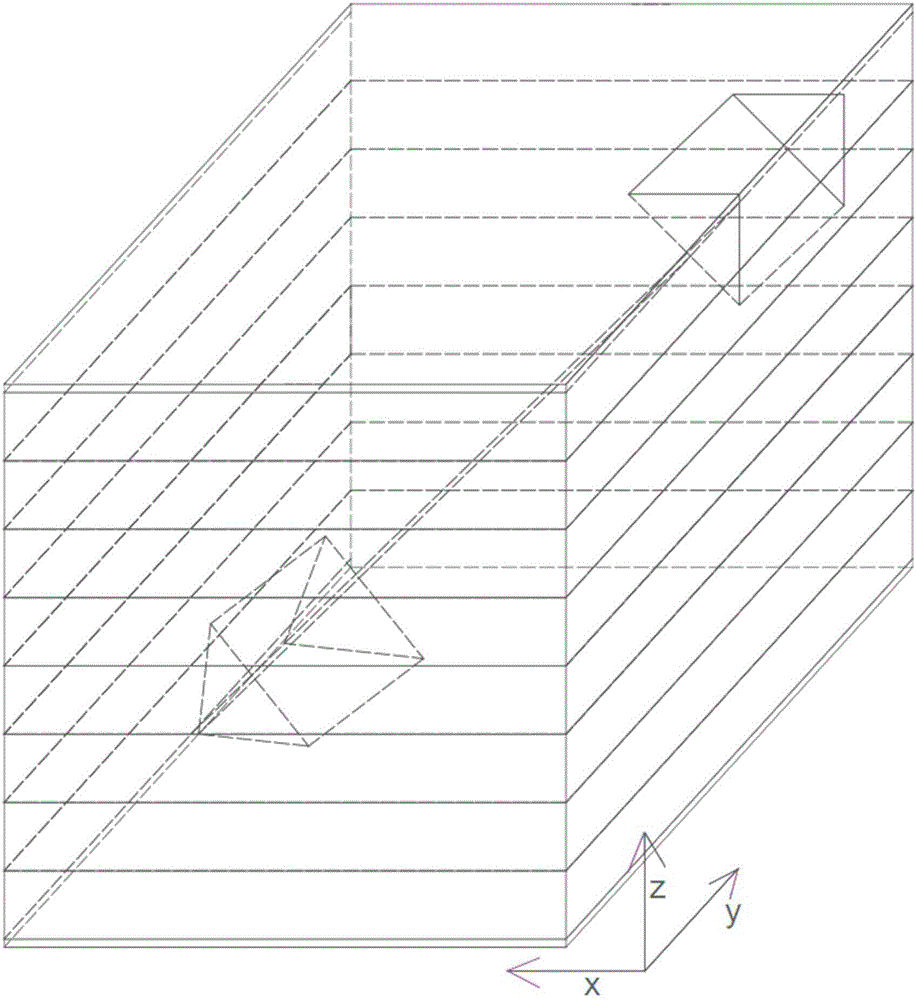

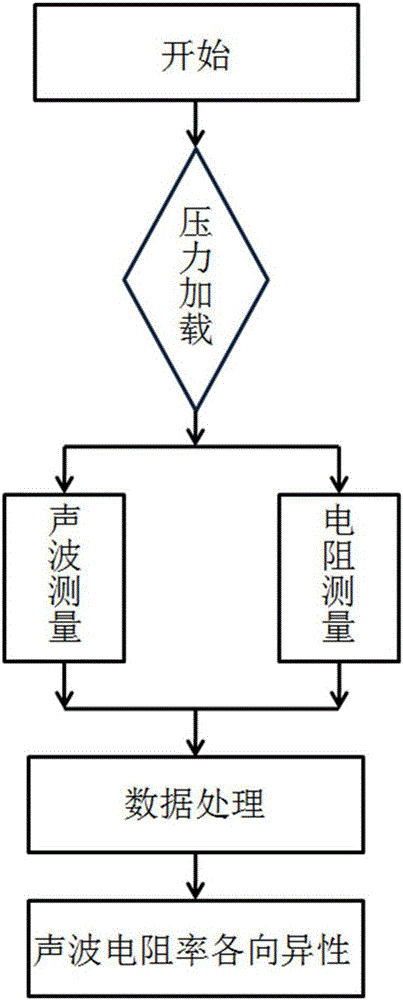

Testing device for anisotropism of shale in true-triaxial condition and testing method of testing device

InactiveCN106053231ATrue stress stateReflect the state of stressResistance/reactance/impedenceMaterial strength using tensile/compressive forcesAcoustic waveStressed state

The invention discloses a testing device for the anisotropism of shale in a true-triaxial condition and a testing method of the testing device, and aims at solving the problems that the conventional testing method for the anisotropism of shale needs at least 3 times of coring, and the anisotropism of the shale at true crustal stress state cannot be really reflected. The testing device comprises a pressurization mechanism, an acoustoelectric testing mechanism and a data processing mechanism, wherein the pressurization mechanism can apply different pressures to X, Y and Z directions, so that the stress state of the shale in a formation condition can be more really simulated. The acoustoelectric testing mechanism can measure the sound wave and the specific resistance of the shale when the mechansim forms 0 degrees, 45 degrees and 90 degrees with shale bedding. The acoustic and electrical anisotropisms of the shale can be obtained through measured sound wave and specific resistance information. The testing device has the advantages that rock samples are easy to obtain, the success ratio is high, the measurement result is real and reliable, and a reference base can be provided for the accurate evaluation of the thickness of a container rock, the accurate evaluation of water saturation and the design of a fracturing operation scheme.

Owner:SOUTHWEST PETROLEUM UNIV

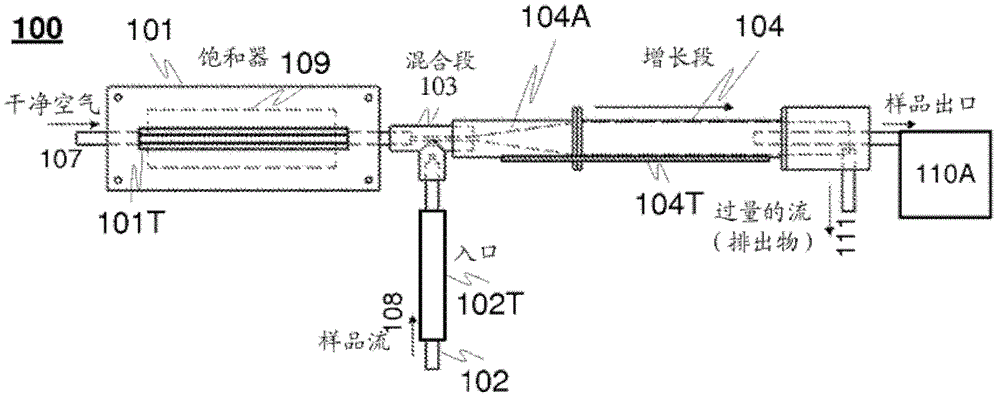

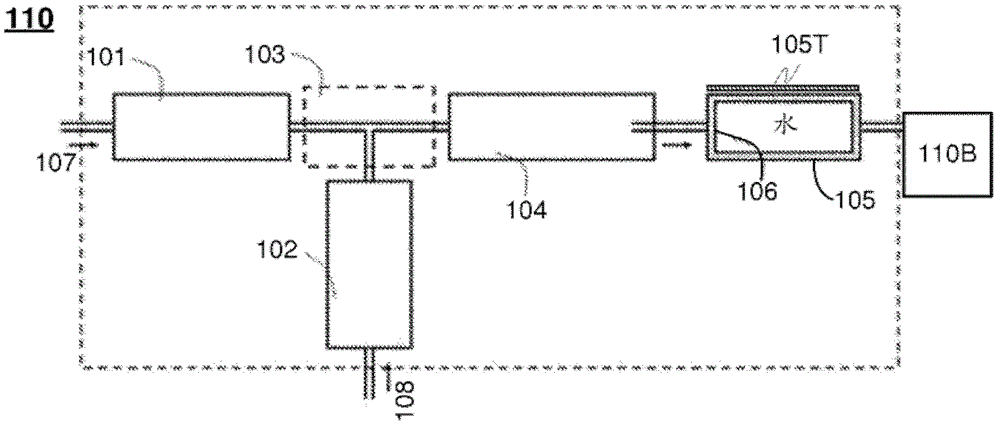

Method and device for detecting aerosol particles

ActiveUS20120131989A1Growth correctionSmall sizeNanoparticle analysisParticle size analysisParticle flowPrill

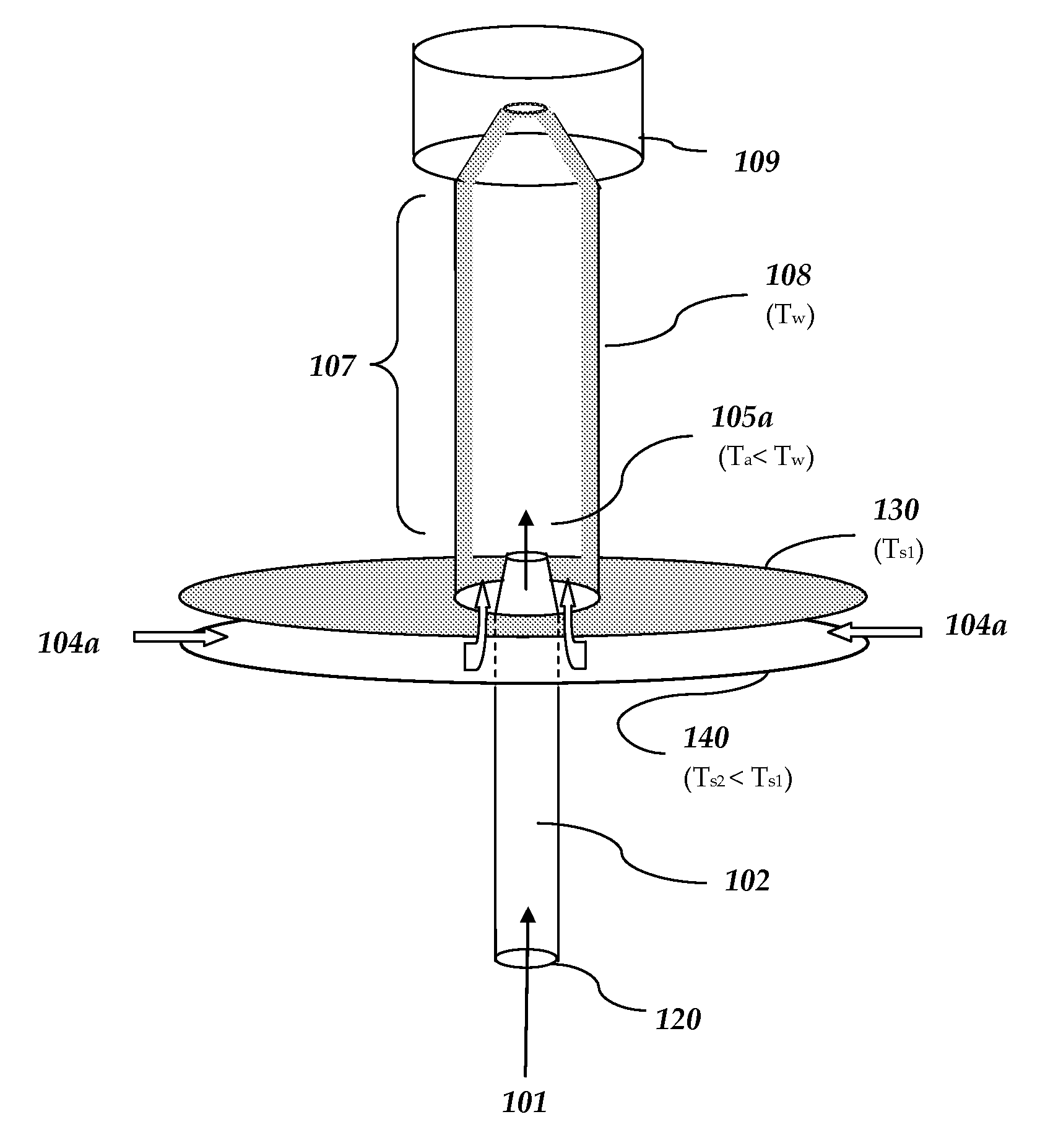

Sizes or size distribution of aerosol particles of an aerosol gas stream is detected. A particle-free carrier flow is saturated in a saturator by a first condensing medium, after which, the carrier flow is mixed in a mixing section turbulently with aerosol particle flow. Advantageously, a plurality of separate mixtures with different saturation ratios are provided and introduced to the first condensing environment in order to condensate the condensing medium onto the aerosol particles. Depending on the saturation ratio, the particles with different lowest original size are activated and grown in a growing section and / or in the condensing environment. After activation and growing, the particles are detected by a detecting means.

Owner:AIRMODUS

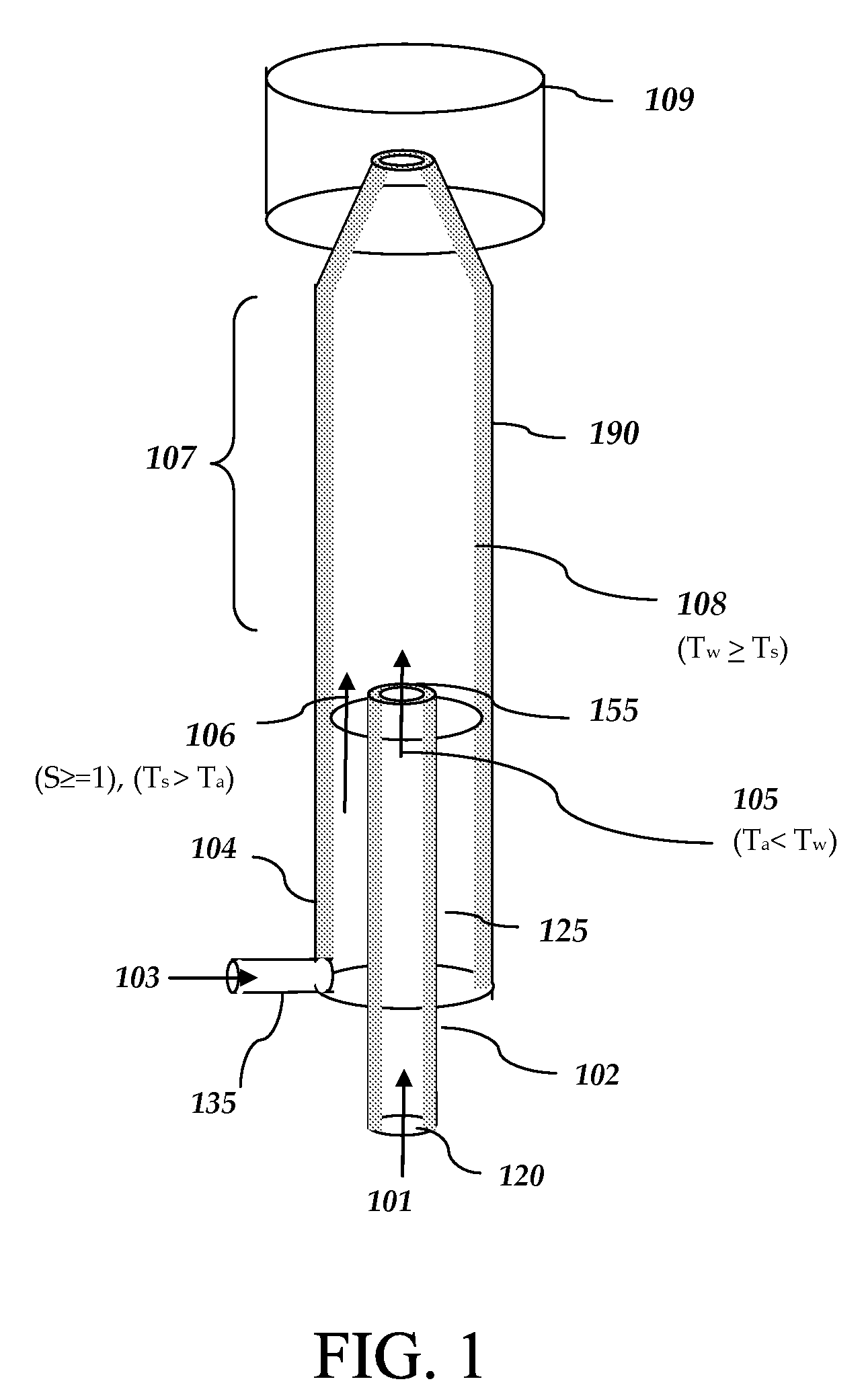

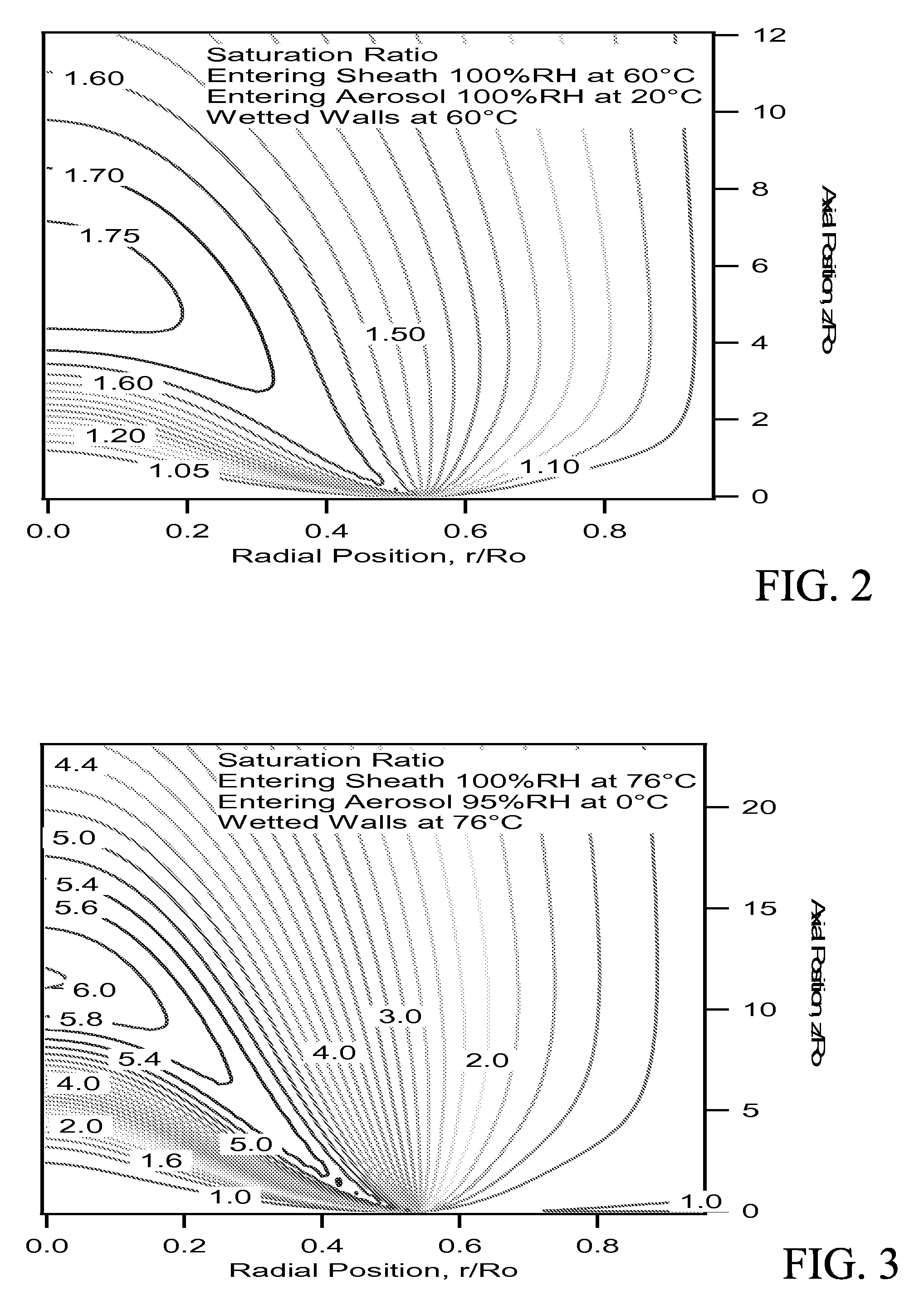

High saturation ratio water condensation device and method

An apparatus and method for producing a region of vapor super-saturation and particle growth in a laminar flow by surrounding the particle flow with a saturated or super-saturated sheath flow from which vapor diffuses into the aerosol flow. This method is applicable when the mass diffusivity of the condensing vapor is greater than the thermal diffusivity of the carrier gas, such as is the case when water vapor diffuses into air.

Owner:AEROSOL DYNAMICS INC

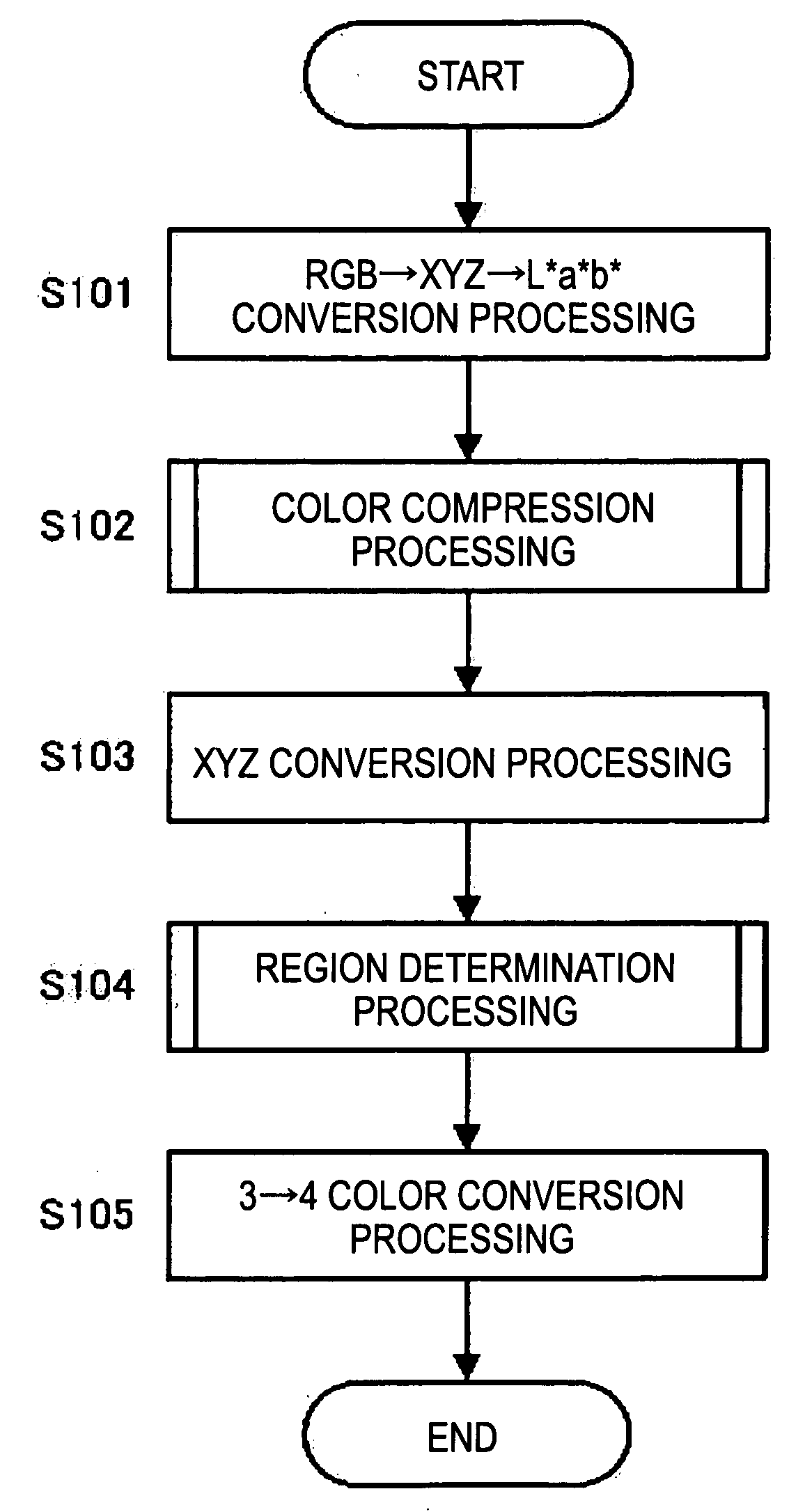

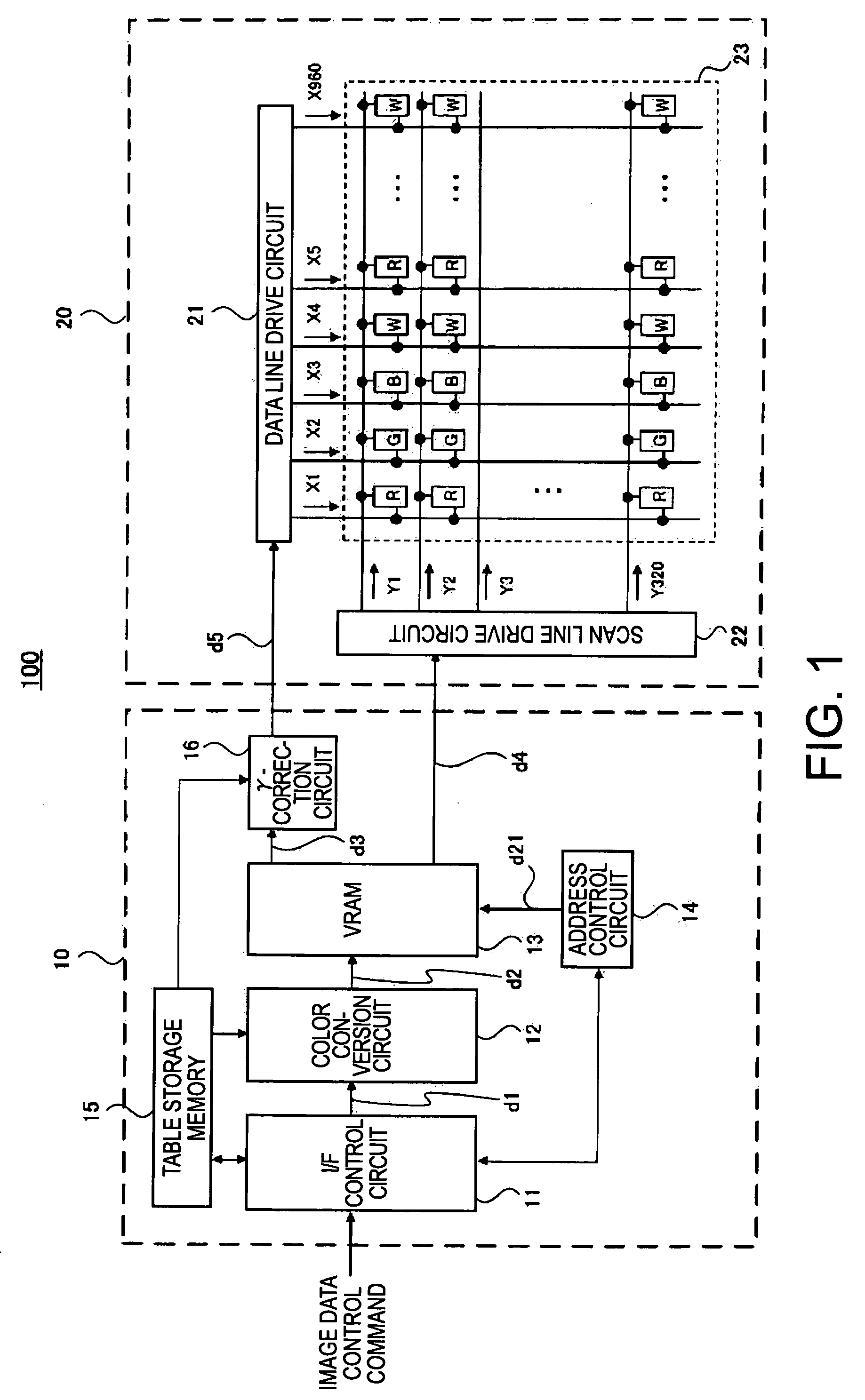

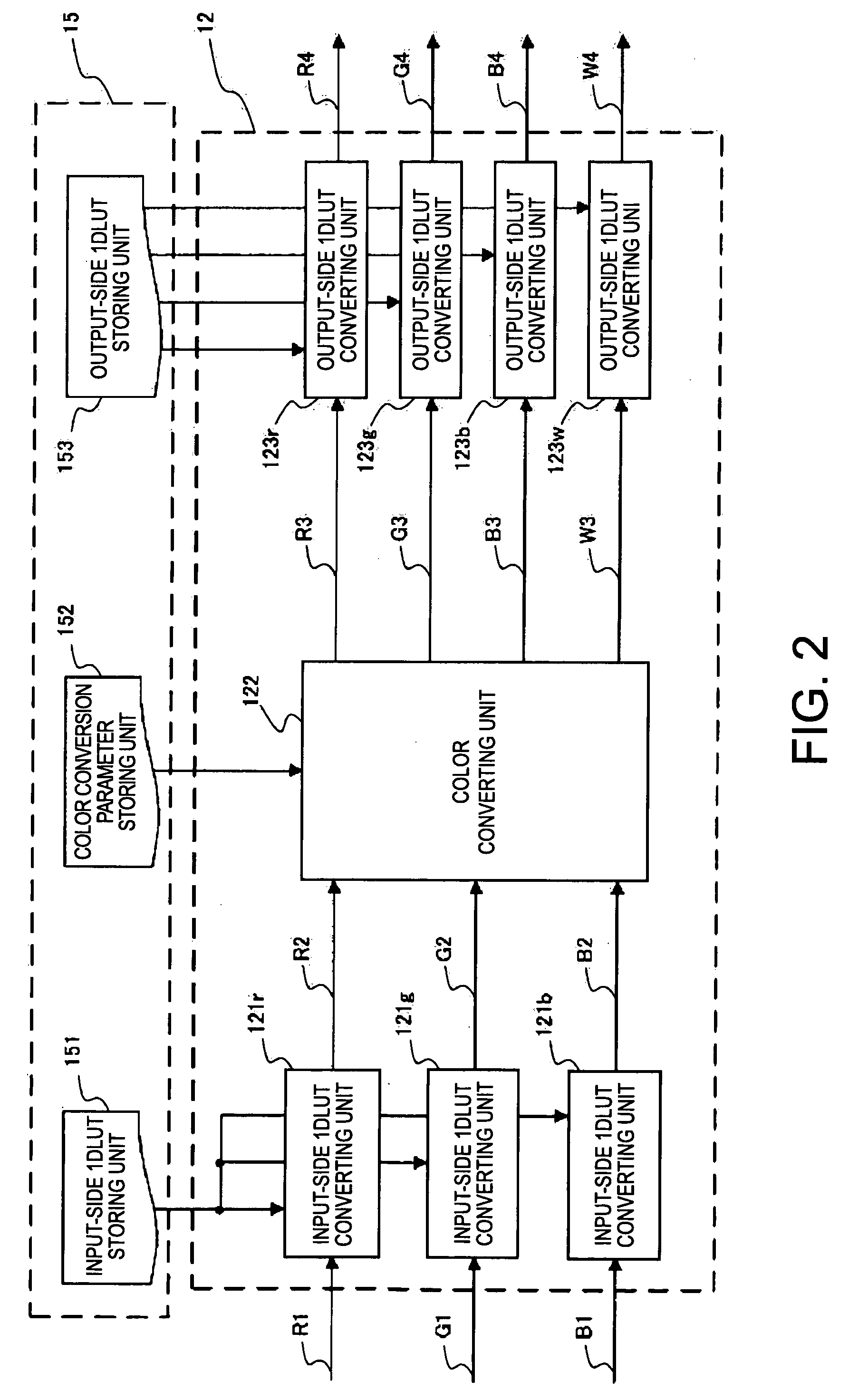

Color conversion device, color conversion method, color conversion program, recording medium recording color conversion program, image processing device, and image display device

ActiveUS20080186328A1Appropriately reproducedInappropriate color compression can be suppressedCharacter and pattern recognitionCathode-ray tube indicatorsColor transformationImaging processing

A color conversion device that color-converts colors of input image data into colors used in a display unit for displaying images using at least white includes: a ratio calculating unit that calculates a lightness ratio and a saturation ratio between a color reproduction range in the standard color space and a color reproduction range in colors used by the display unit in L*a*b* space at least when a color outside of the color reproduction range in colors used by the display unit is calculated; and a color compressing unit that performs color compression on the image data based on the ratios calculated by the ratio calculating unit.

Owner:138 EAST LCD ADVANCEMENTS LTD

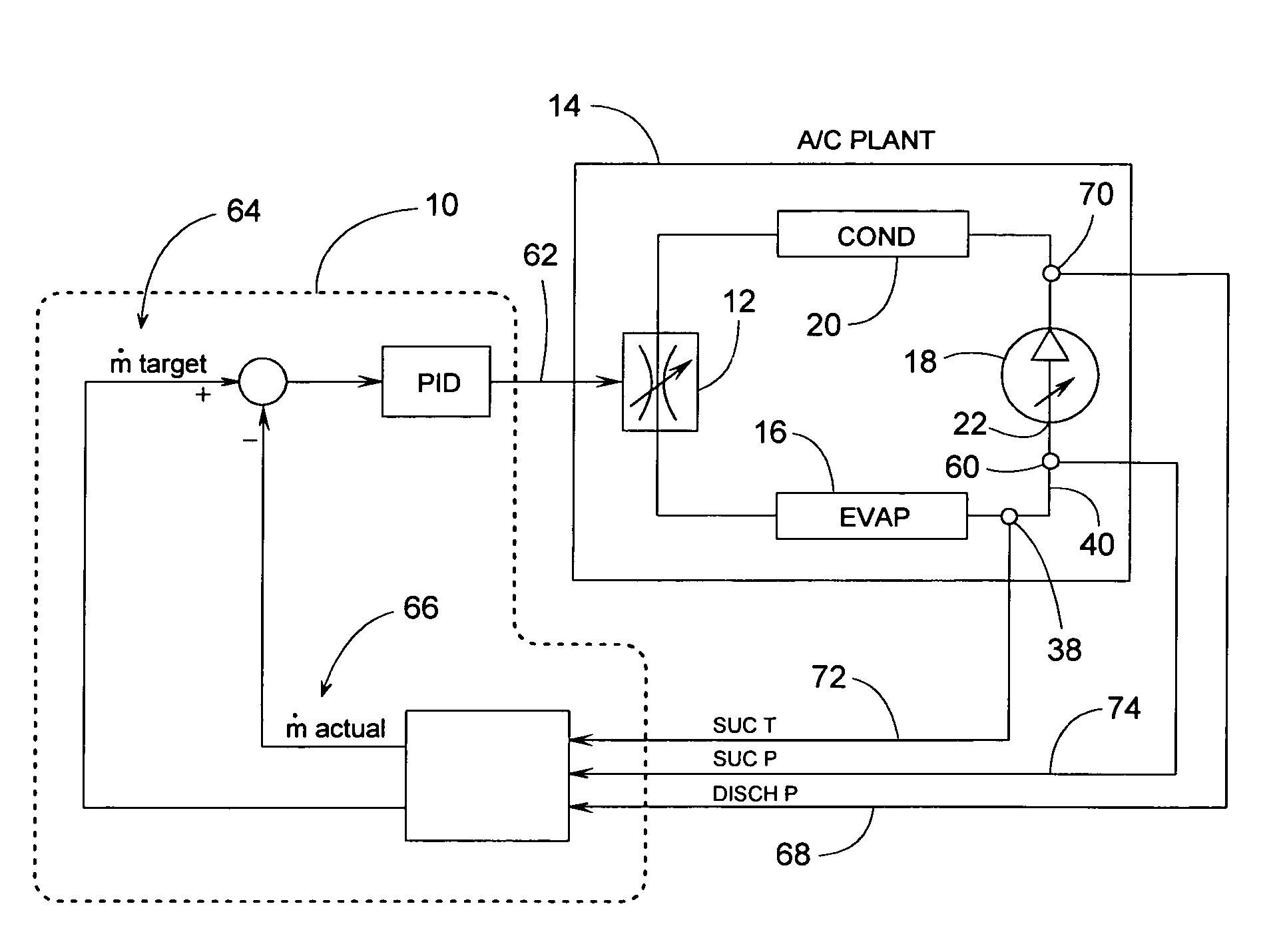

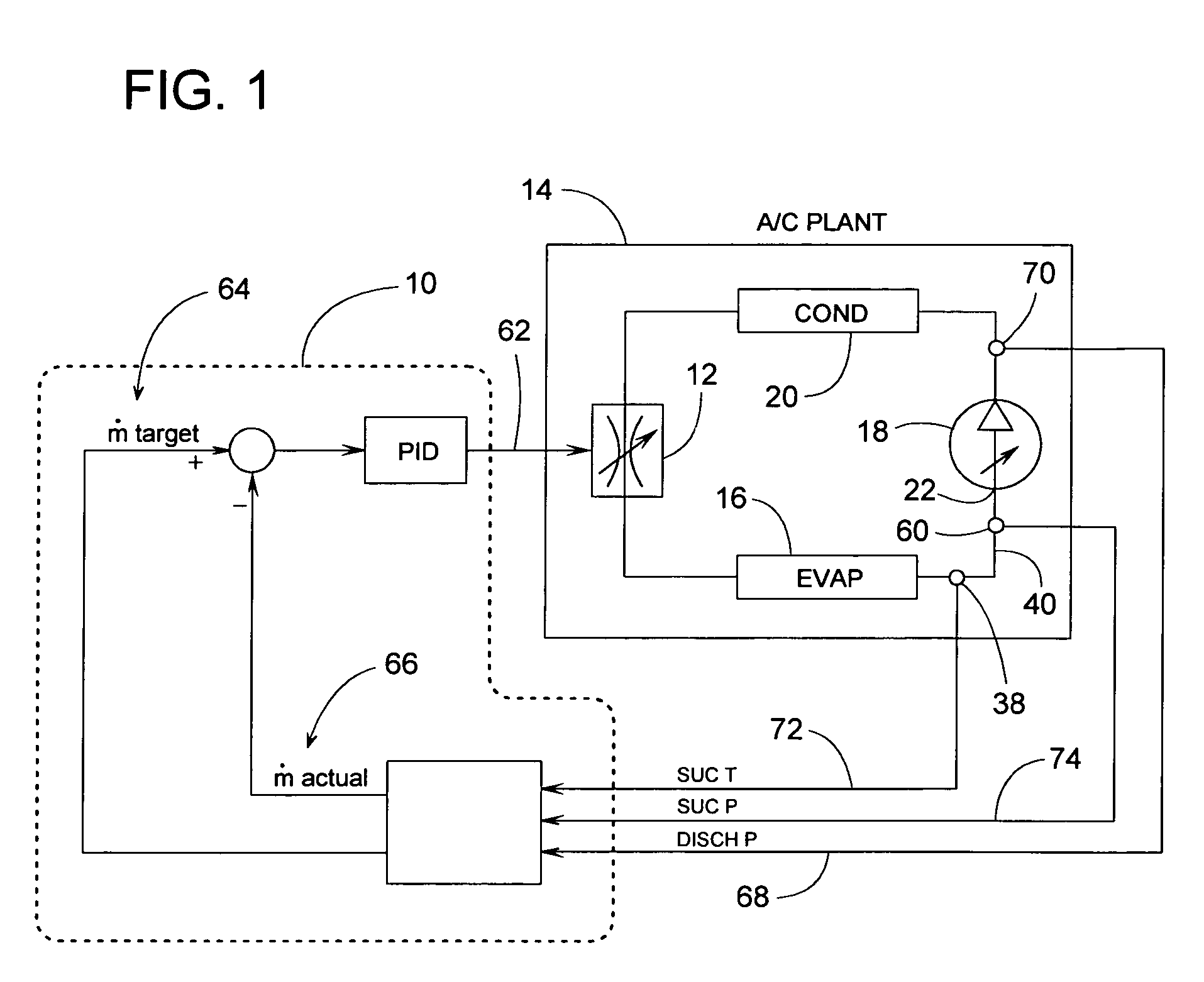

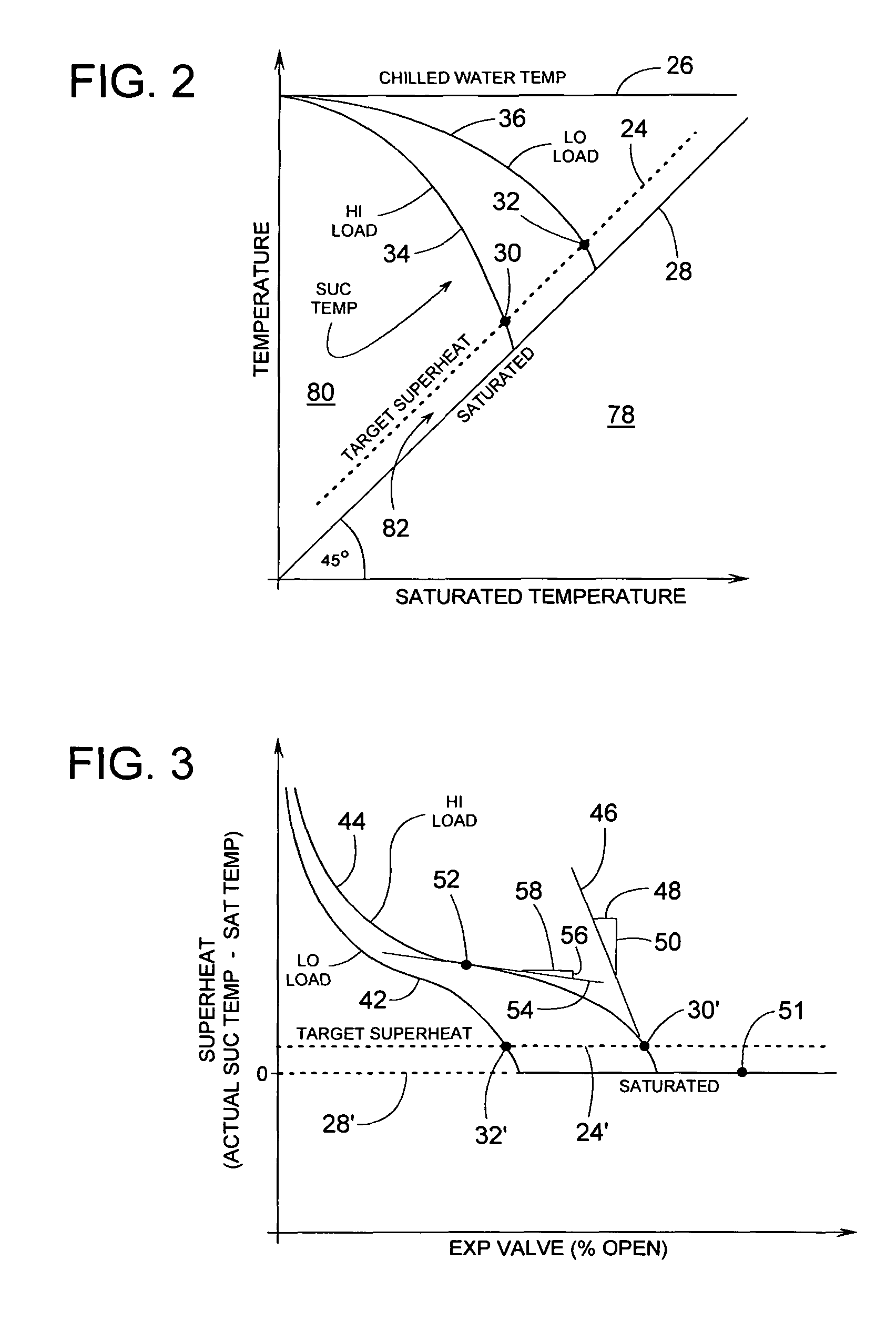

Superheat control by pressure ratio

ActiveUS8096141B2Slow down increaseRapid responseMachines using electric/magnetic effectsFluid circulation arrangementControl theoryElectronic expansion valve

Owner:TRANE INT INC

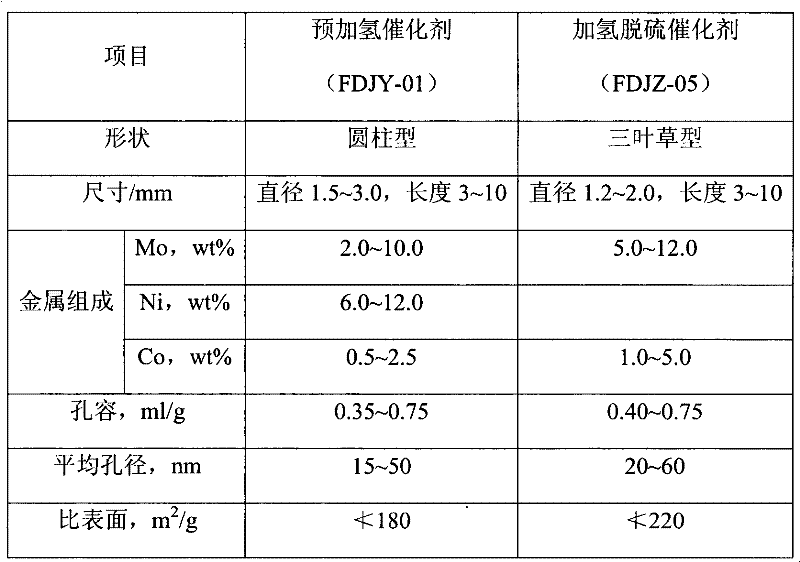

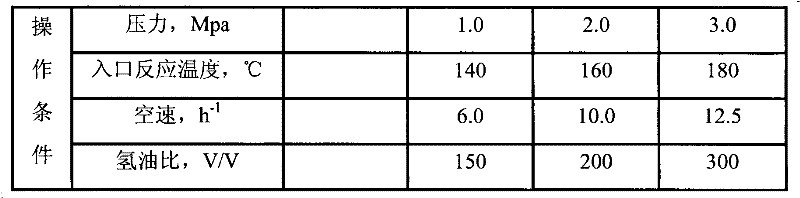

Gasoline selective desulfurization catalyst

InactiveCN101844088AReduce saturation rateHigh activityMolecular sieve catalystsHydrocarbon oils refiningAlkaline earth metalHydrodesulfurization

The invention aims to provide a gasoline selective desulfurization catalyst, and particularly relates to an FCC gasoline selective desulfurization catalyst. The catalyst is prepared by mixing a molecular sieve and a binder, forming the mixture to obtain a carrier and loading active metal ingredient and alkaline metal and / or rare-earth metal to the carrier, wherein the molecular sieve in the carrier is SAPO and / or APO molecular sieve; the binder is aluminum oxide or silicon dioxide; the active ingredient is cobalt-molybdenum composite metal and accounts for 6.5 to 20 weight percent of the catalyst, the alkaline metal and / or the rare-earth metal ingredient account(s) for 0.05 to 8.0 weight percent of the catalyst, and the balance is the carrier; and the relative mass ratio of the molecular sieve to the binder in the carrier is (5-9):(1-5). The catalyst has high hydrodesulfurization activity and selectivity and low olefin saturation ratio when gasoline with low sulfur content is produced by hydrodesulfurization of all fractions of catalytic gasoline, particularly heavy fractions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

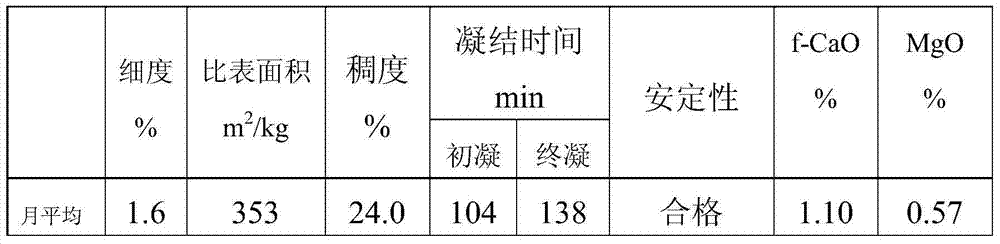

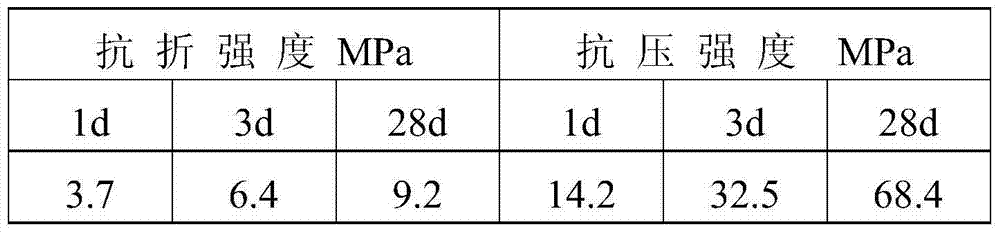

Preparation method of low-heat-consumption low-silicon-rate and high-strength silicate cement clinker

ActiveCN104724959AReduced calcined standard coal consumptionReduce power consumptionClinker productionMaterials scienceHeat consumption

The invention discloses a preparation method of a low-heat-consumption low-silicon-rate and high-strength silicate cement clinker. According to the preparation method, when a cement clinker is calcined on a new dry process line, the silicon rate of the clinker breaks a traditional range of a new dry process kiln and is decreased to be 2.0+ / -0.1, so that the content of flux minerals in the calcining of the clinker is increased, the content of liquid phase quantity is increased, the burnability of a raw material is improved, and the calcining coal consumption of the clinker is reduced; meanwhile, the saturation ratio of the clinker is increased, and aluminum rate is adjusted to be applicable to an operation state of a rotary kiln, so that the content of C3S in the clinker is increased, and the strength of the clinker is guaranteed; by virtue of optimization and improvement of a calcining process, the agglomeration in the kiln caused by high liquid phase quantity is prevented; the energy consumption and the emission load of CO2 are reduced, but the strength of the clinker is not reduced, and other properties of the clinker such as coagulation time, stability and contents of f-CaO and MgO meet the national standard.

Owner:华润水泥技术研发(广西)有限公司

High-temperature high-pressure gas reservoir permeability flow velocity sensitivity test method considering bound water

ActiveCN110793901AOptimization of Gas Permeability FormulaAccurately find the critical velocityPermeability/surface area analysisBound waterInlet pressure

The invention relates to a high-temperature and high-pressure gas reservoir permeability and flow velocity sensitivity test method considering bound water. The method comprises the a step of cleaning,drying and vacuumizing a rock sample and putting the rock sample into formation water for saturation for 24 hours, a step of establishing rock core bound water saturation, a step of displacing humidified gas into a rock core at a constant speed of 0.2 ml / min by a displacement pump, wherein confining pressure is greater than inlet pressure by 500psi in a displacement process, the outlet pressure is greater than return pressure in the displacement process, the humidified gas of 2PV is displaced to obtain gas logging permeability K1 of the rock core after first constant-speed displacement, a step of obtaining a gas logging permeability Ki of the rock core after ith constant-speed displacement by analogy, wherein if the change rate of the rock core permeability is greater than 20% in an nth displacement experiment, a (n-1)th displacement experiment is the moment when the rock core has velocity sensitivity, the seepage velocities of the gas at an inlet end and an outlet end of the rock core are v1 and v2 respectively, and a critical flow velocity v of the rock core is between v1 and v2. The rock permeability can be measured under the conditions of bound water, high temperature and highpressure, the critical flow velocity can be rapidly and accurately solved, and a theoretical basis is provided for the development of high-pressure gas reservoirs.

Owner:SOUTHWEST PETROLEUM UNIV

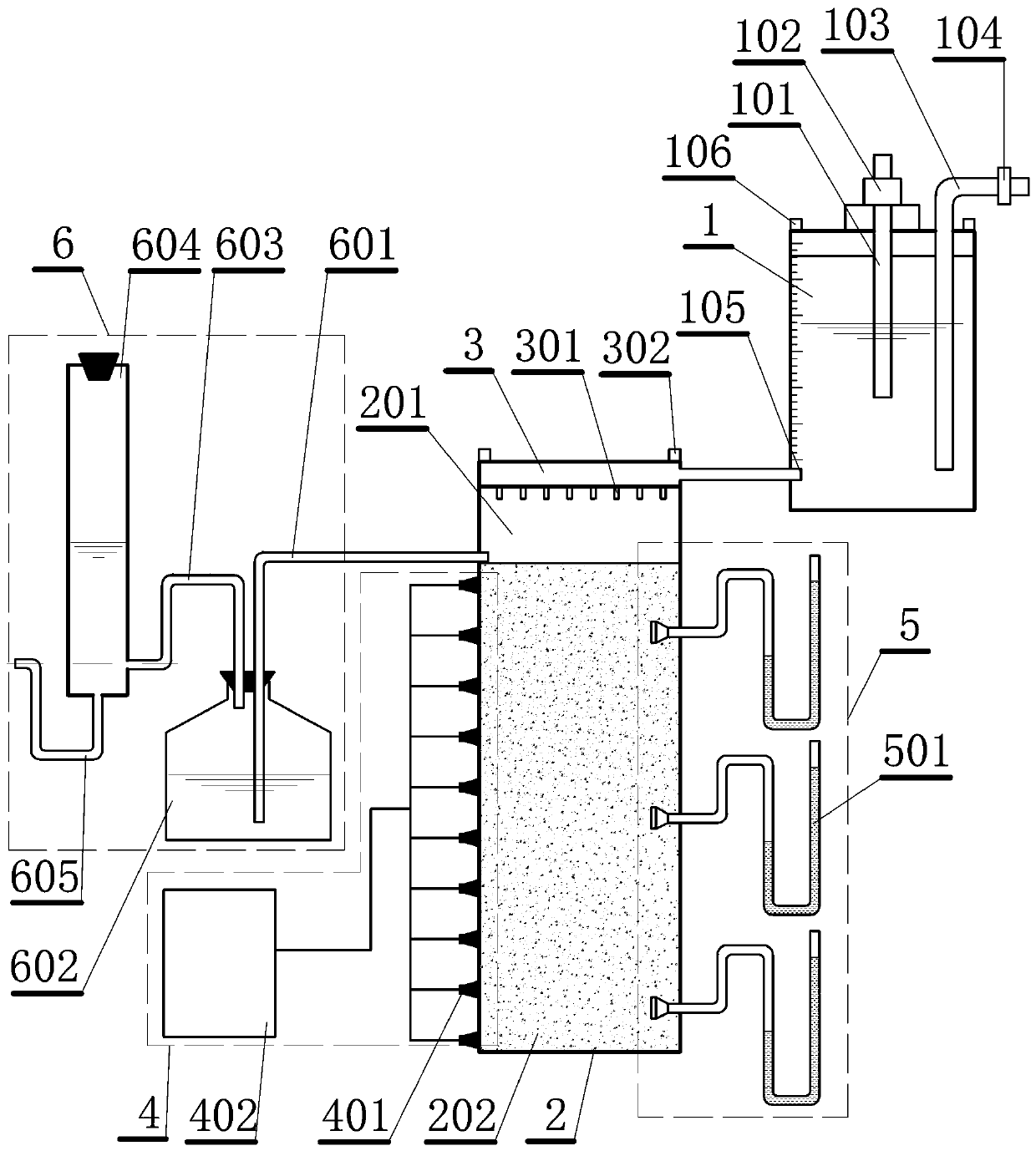

Device for adjusting and controlling dissolved gas saturation in water under different pressure intensities

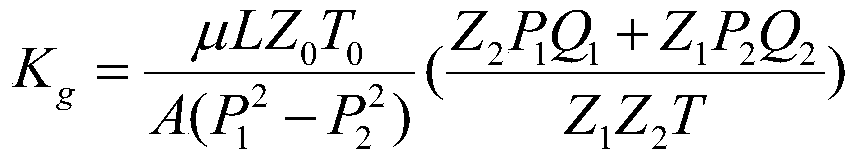

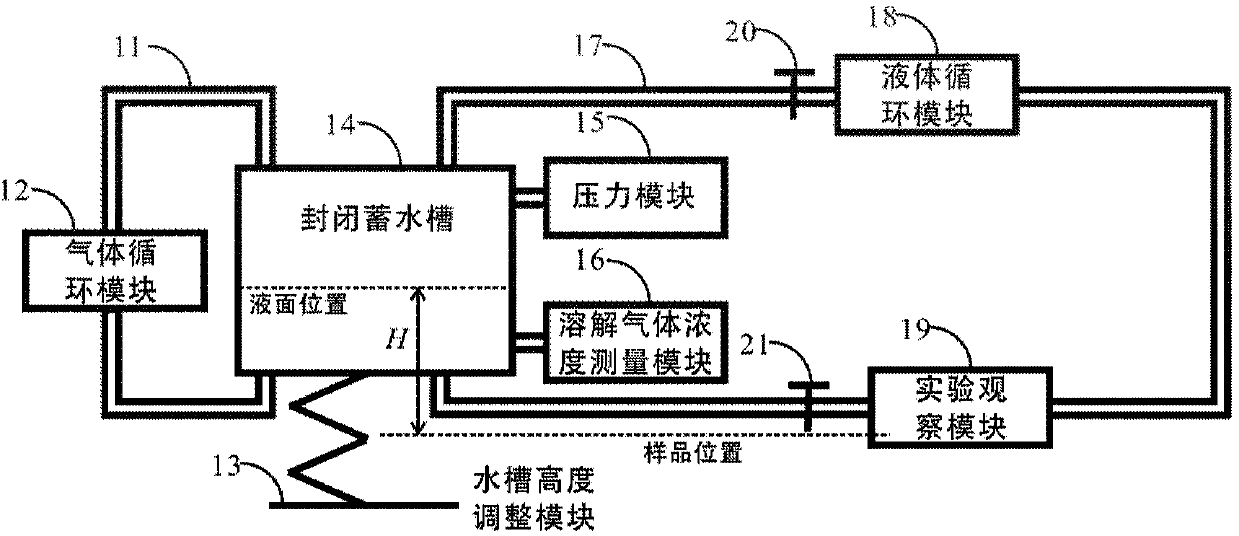

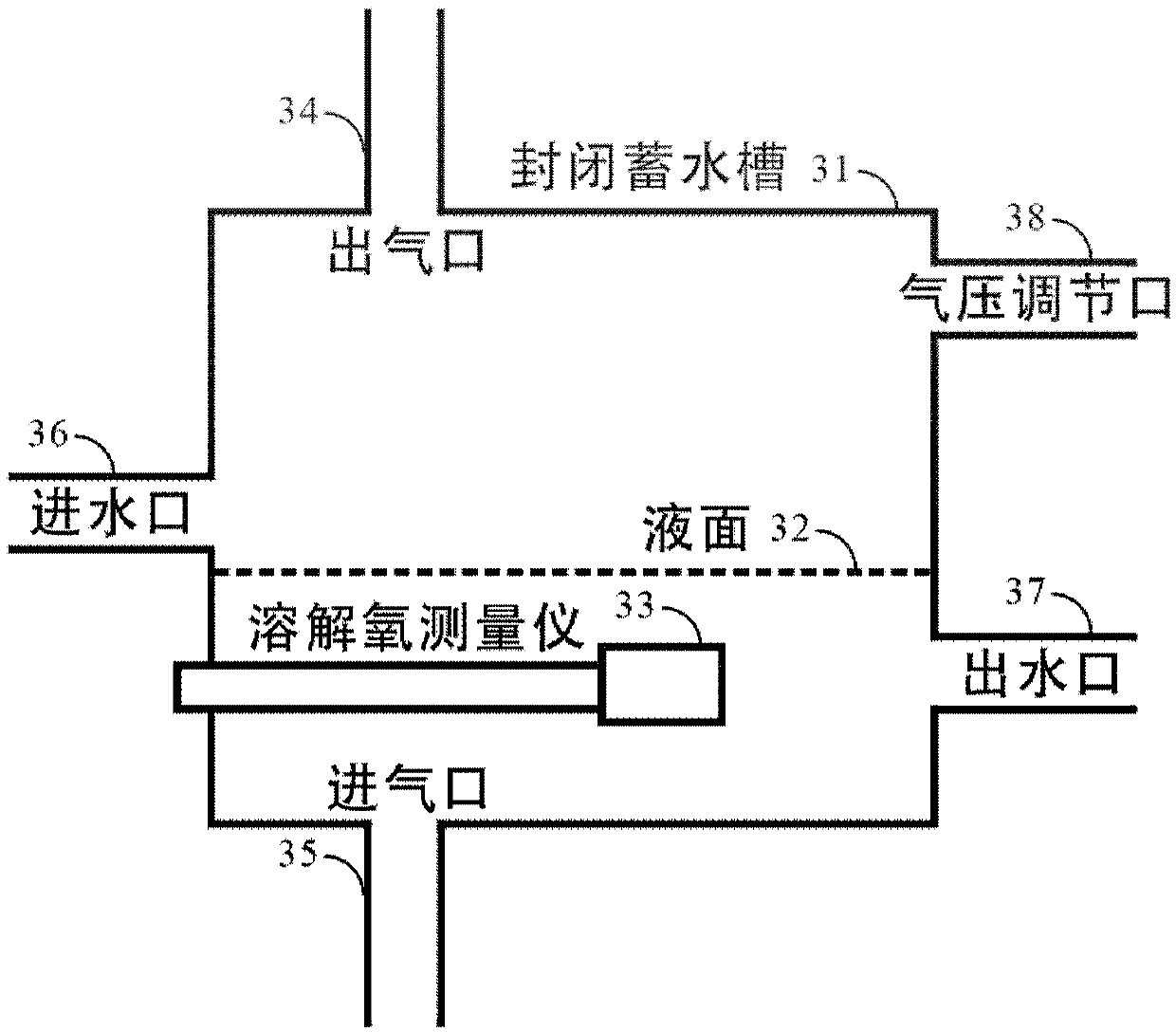

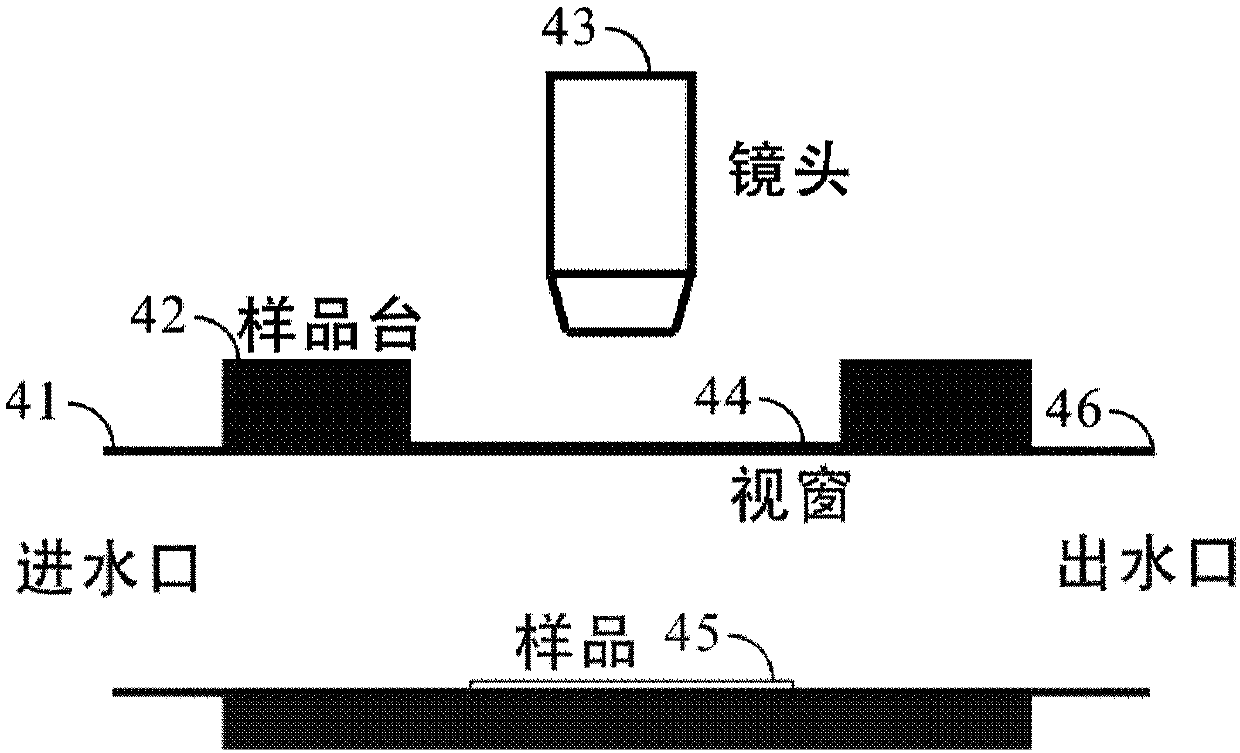

PendingCN107621433ADissolved gas saturation controlCalculate SaturationSurface/boundary effectControl saturationWater storage tank

The invention discloses a device for adjusting and controlling dissolved gas saturation in water under different pressure intensities. The device comprises a closed water storage tank, a liquid circulation module, a test observation module, a pressure module, a dissolved gas concentration measurement module, a gas circulation module and a water tank height adjusting module, the liquid circulationmodule provides circulation liquid for the closed water storage tank, the test observation module comprises a test table for placing samples, the test observation module is connected with the water storage tank and the liquid circulation module, the pressure module is used for measuring and adjusting gas pressure intensity and arranged at the top of the closed water storage tank, the dissolved gasconcentration measurement module is used for measuring the oxygen content in liquid in the closed water storage tank, and the gas circulation module is connected with the top and the bottom of the closed water storage tank through pipelines, so that air of the top of the closed water storage tank is pumped into liquid of the bottom of the water storage tank. According to the device, the dissolvedgas saturation in the water is adjusted and controlled, gas pressure intensity of the upper portion of the water surface is adjusted by the pressure module, relative liquid level and relative heightof the samples are adjusted by the water tank height adjusting module, and the device controls saturation states to keep stable or change.

Owner:PEKING UNIV

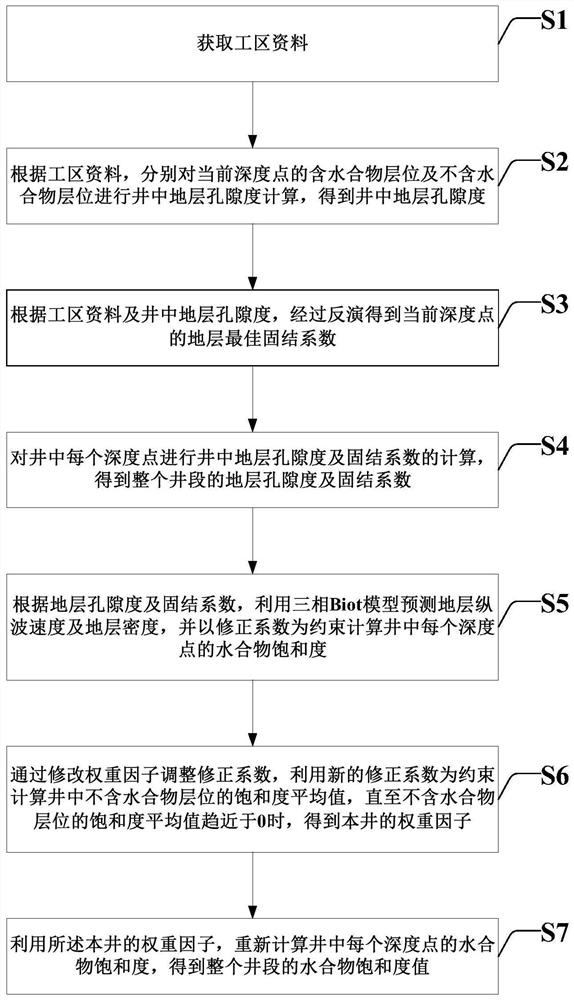

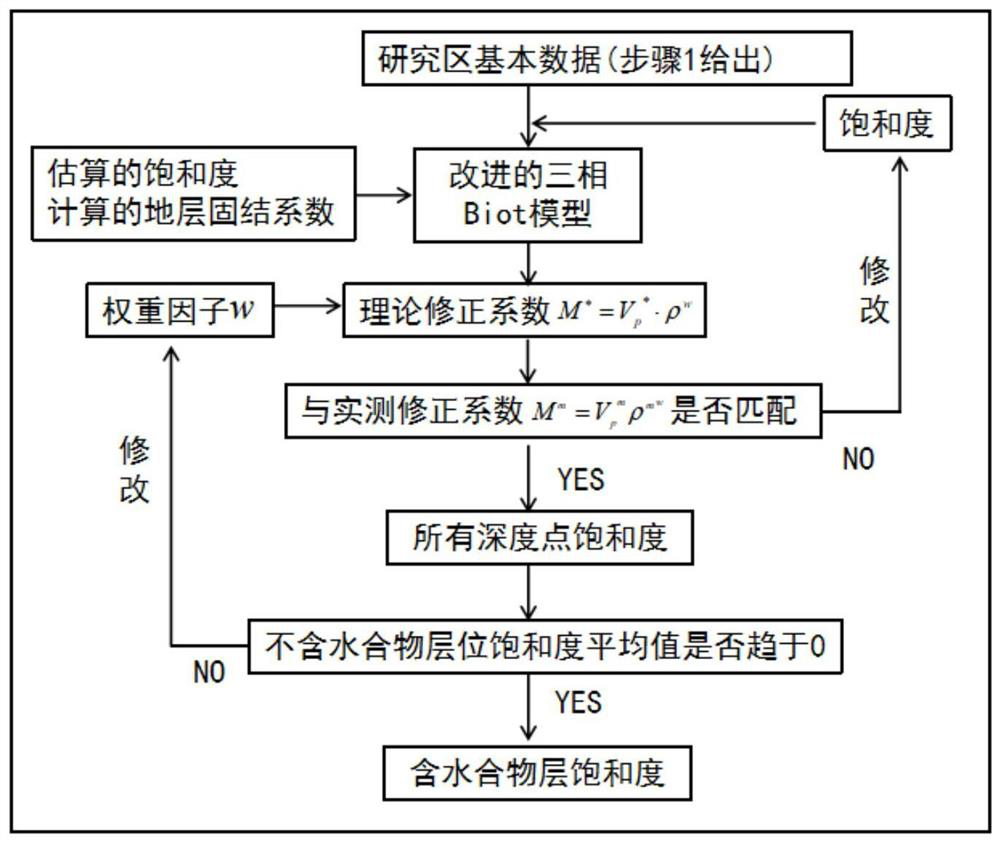

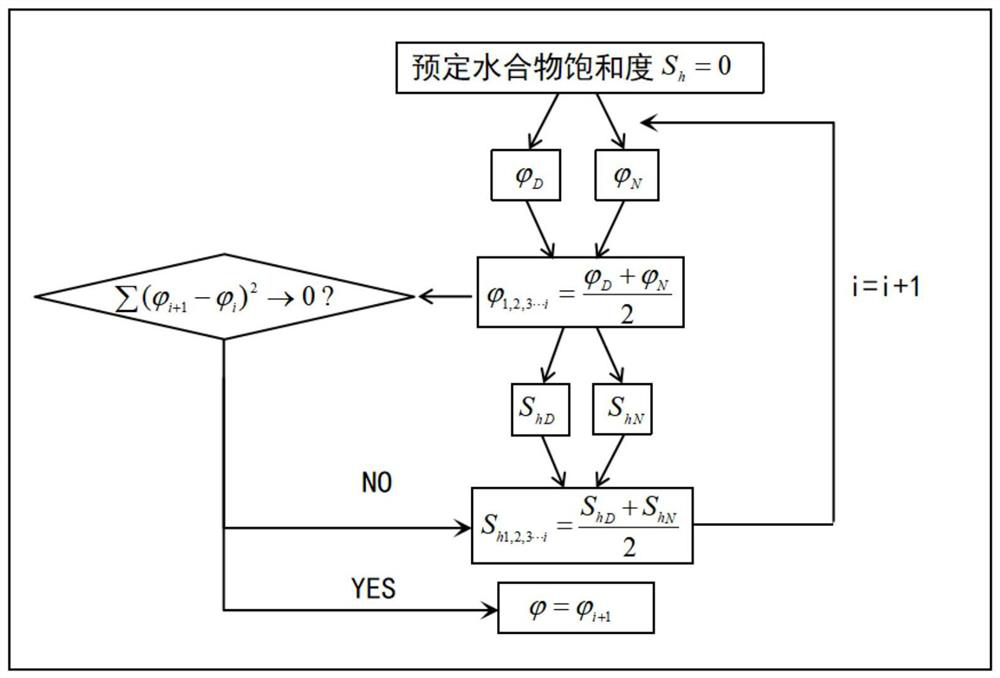

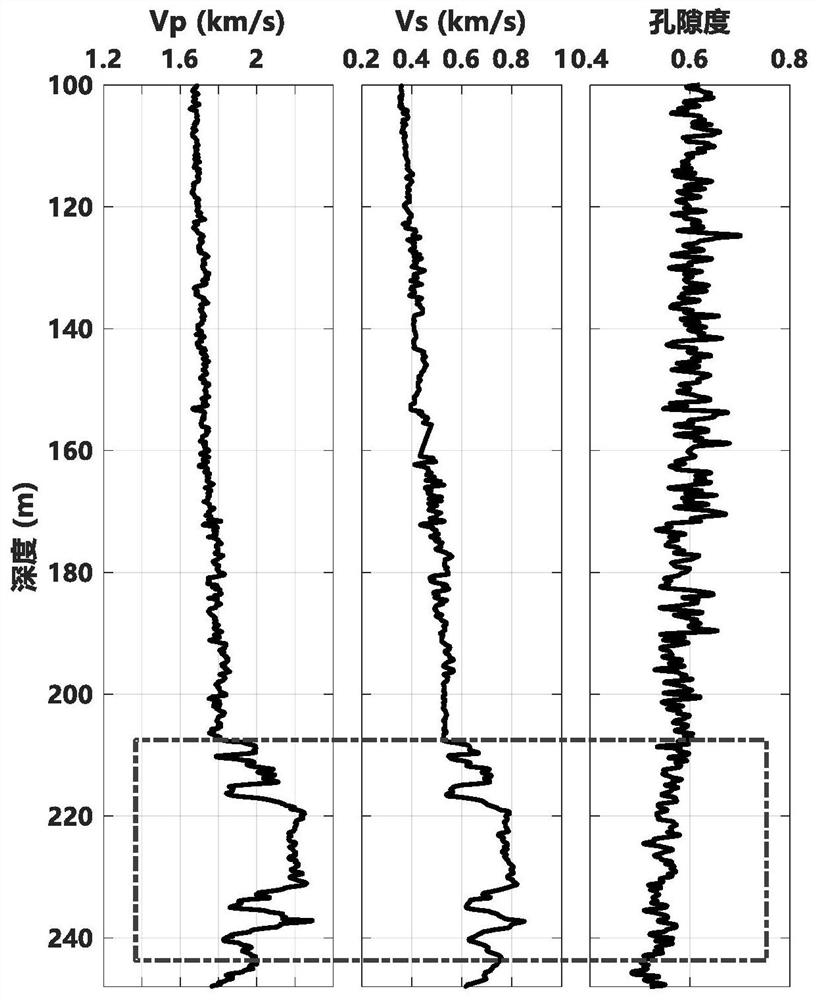

Rock physics calculation method and system for saturation of natural gas hydrate in well

PendingCN112149282AImprove estimation accuracyHigh feasibilityForecastingDesign optimisation/simulationPorosityLongitudinal wave

The invention provides a rock physics calculation method and system for saturation of natural gas hydrate in a well. The method comprises the following steps: obtaining the porosity of a stratum in the well through calculation according to the data of a work area; obtaining the stratum optimal consolidation coefficient of the current depth point through inversion; calculating the stratum porosityand the consolidation coefficient in the well at each depth point in the well to obtain the stratum porosity and the consolidation coefficient of the whole well section; utilizing a three-phase Biot model to predict stratum longitudinal wave speed and stratum density, and calculating hydrate saturation of each depth point in the well by taking a correction coefficient as a constraint; adjusting the correction coefficient by modifying the weight factor, calculating the saturation average value of the hydrate-free horizon in the well by using the new correction coefficient as a constraint, and obtaining the weight factor of the well until the saturation average value of the hydrate-free horizon approaches 0; and recalculating the hydrate saturation of each depth point in the well by utilizing the weight factor of the well to obtain the hydrate saturation value of the whole well section.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

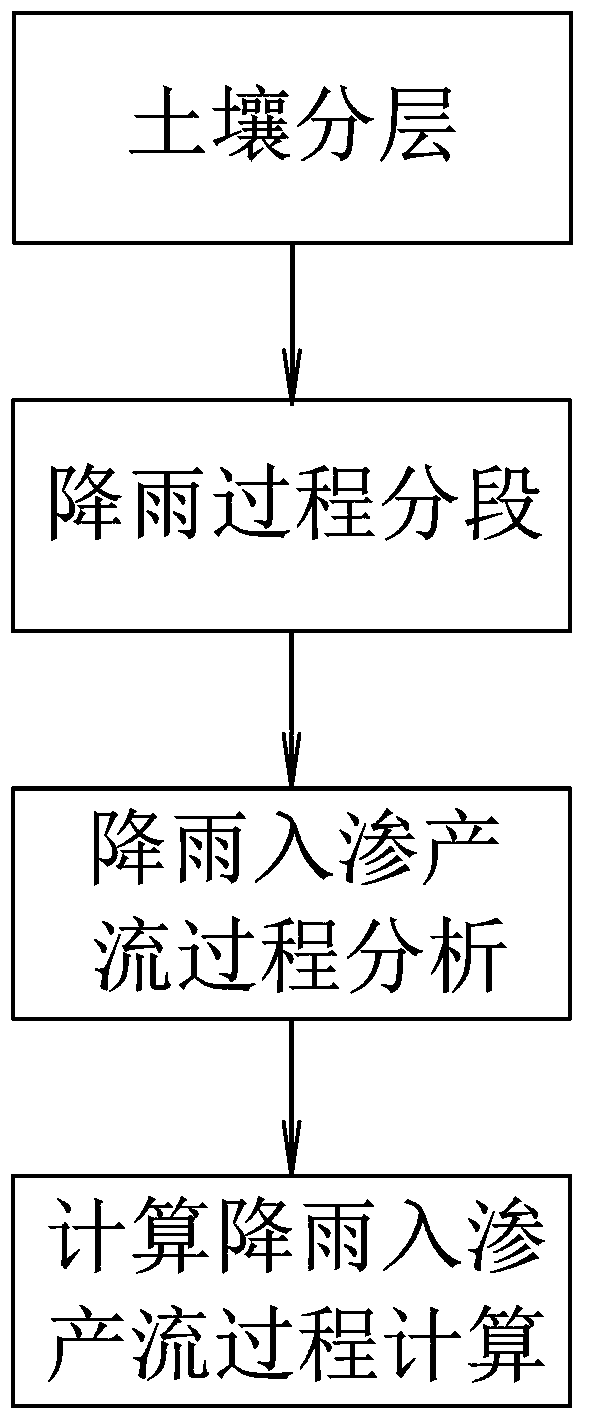

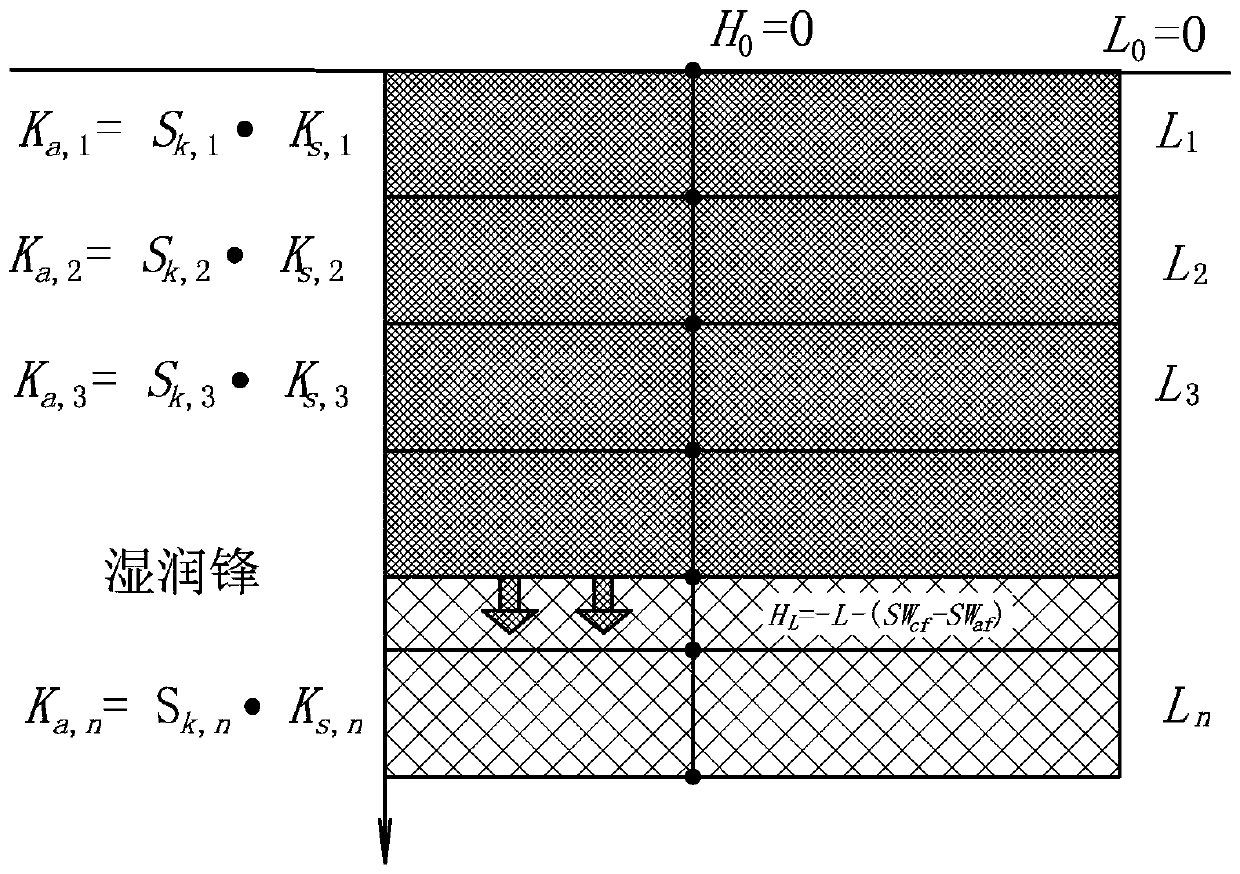

Soil rainfall infiltration measurement system and method considering air resistance effect

ActiveCN107066687AImprove simulation accuracyImprove analog distortion problemDesign optimisation/simulationSpecial data processing applicationsSoil columnEngineering

The invention relates to a soil rainfall infiltration measurement system and method considering an air resistance effect. The system comprises a Markov bottle; the Markov bottle is connected with a rainulator mounted in a soil column tank through a pipeline; the soil column tank is a vertical columnar body; the upper and lower ends of the soil column tank are sealed; a soil column is arranged on the lower side in the tank; a rainfall space is arranged on the upper side of the tank; the rainulator is arranged at the top end of the tank and keeps a certain distance from the soil column; the soil column part of a side surface of the soil column tank is provided with a soil moisture monitoring apparatus and an air pressure measurement apparatus; and the rainfall space part is provided with a moisture collection apparatus. According to the system, a watershed rainfall infiltration runoff process is simulated more really; and a measurement result can provide support for research on a mechanism of influence of air resistance on rainfall infiltration runoff. According to the method, a Green-Ampt model is corrected; a saturation coefficient is introduced, so that the influence of air entrapment on soil moisture content and soil water conductivity coefficient is quantized; and a water inflow value is introduced, so that the influence of an air pressure generated by air confinement on soil water potential is quantized.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Method and device for detecting aerosol particles

ActiveCN102803925AConstant flowGrowth particlesNanoparticle analysisMaterial analysis by optical meansParticle flowChemical physics

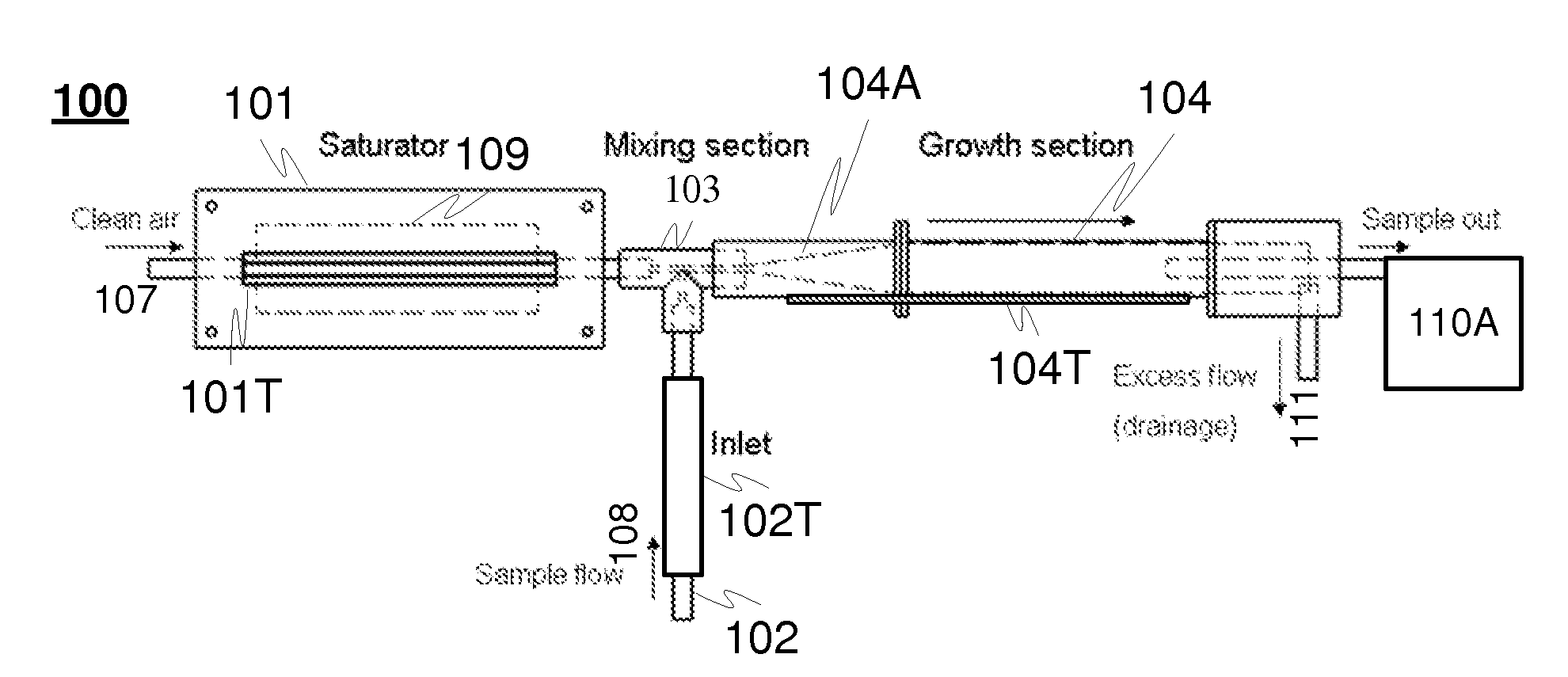

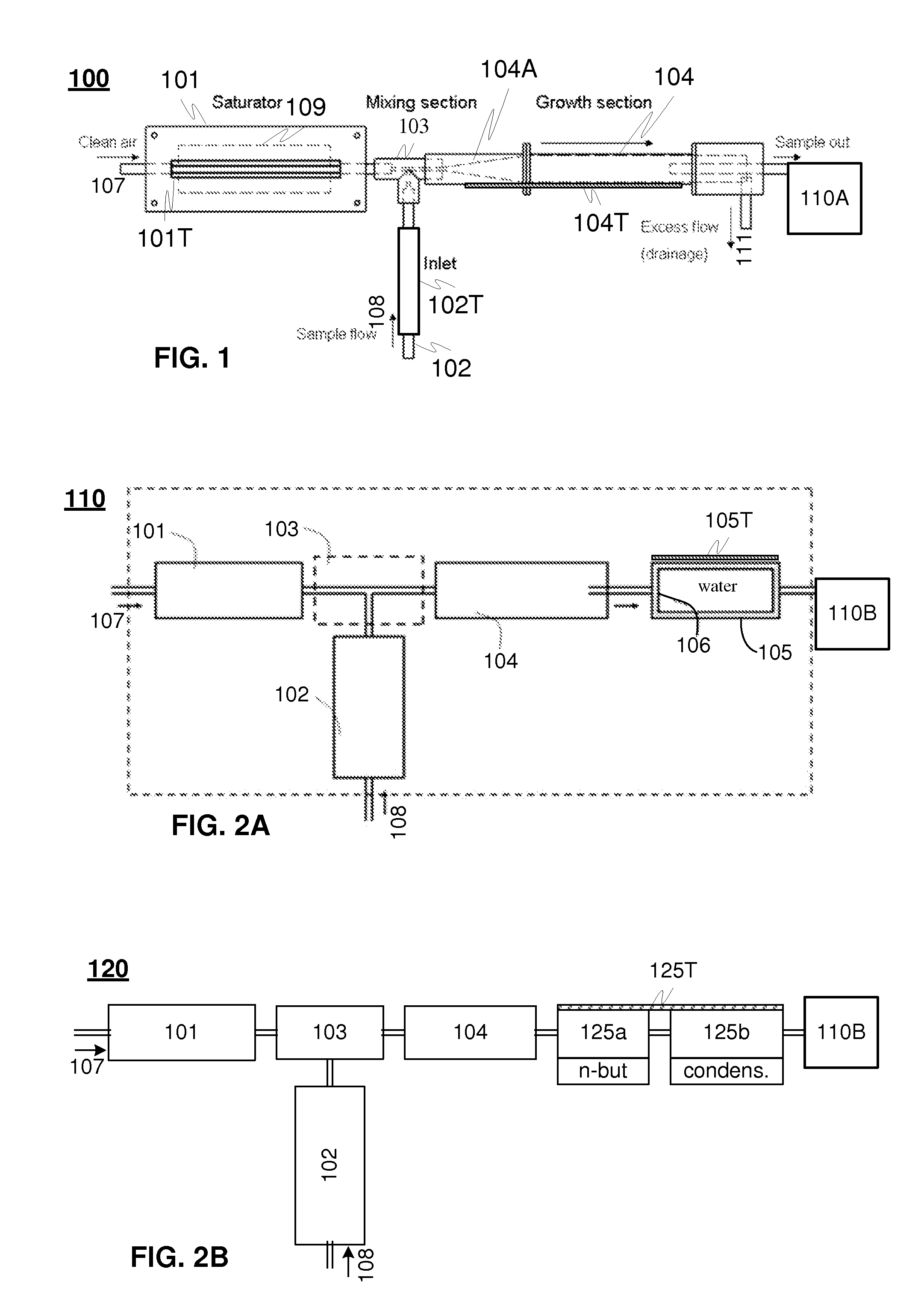

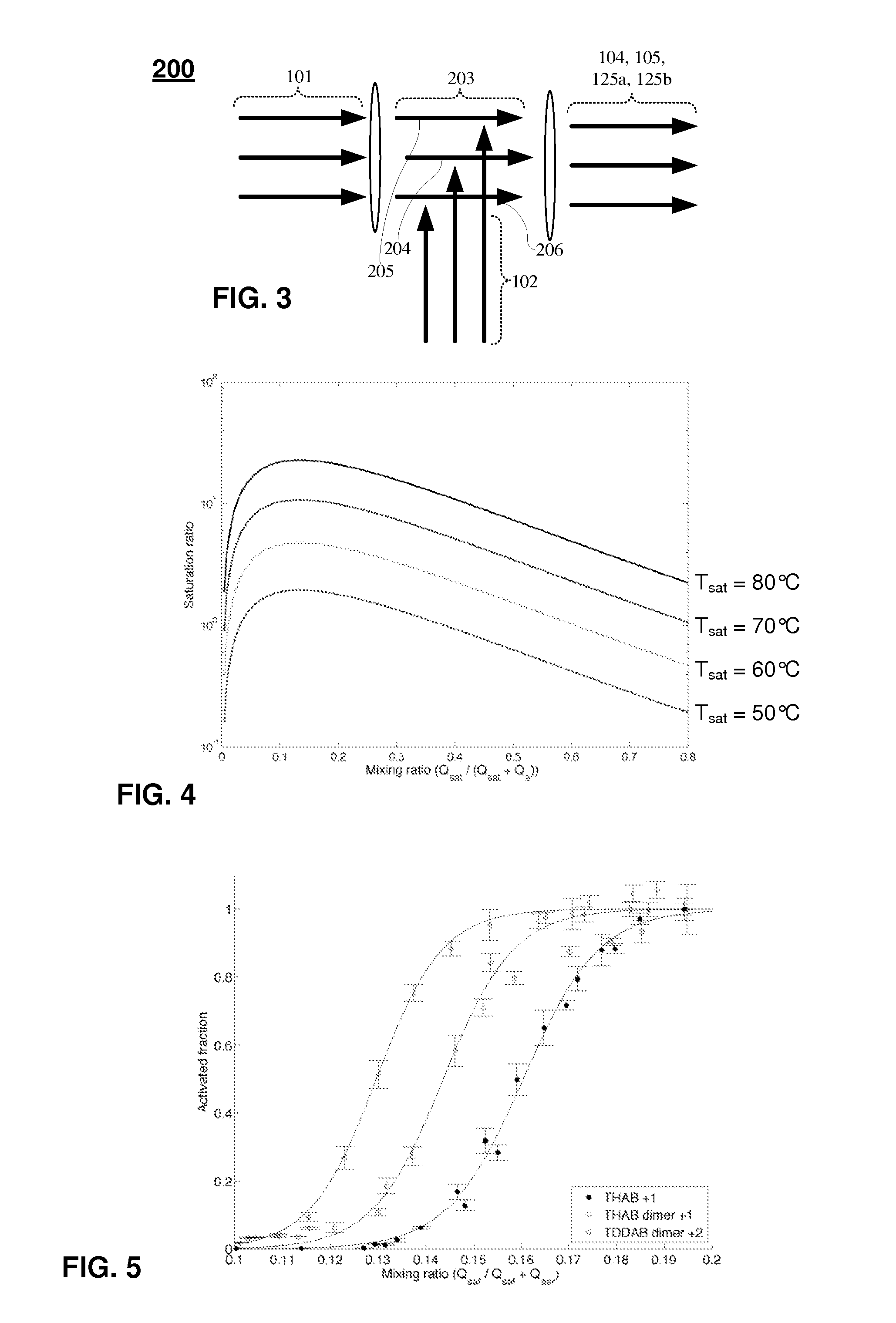

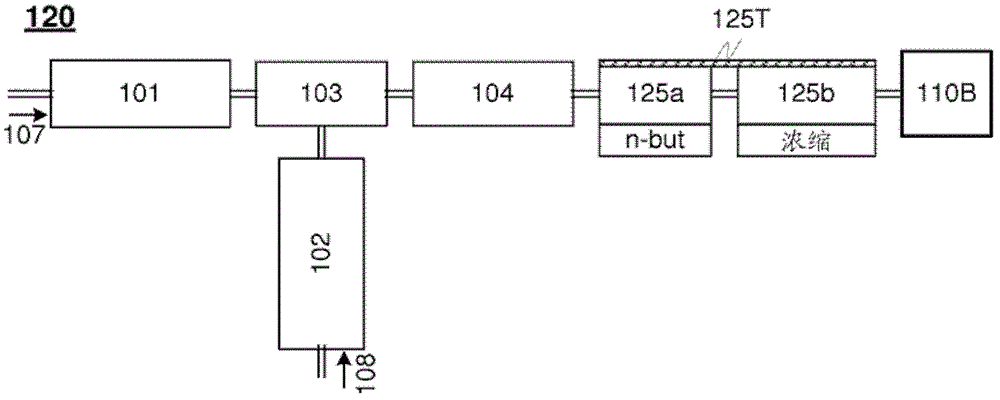

Sizes or size distribution of aerosol particles of an aerosol gas stream is detected. A particle-free carrier flow is saturated in a saturated or (101) by a first condensing medium, where after the carrier flow(107) is mixed in a mixing section (103) turbulently with aerosol particle flow (108). Advantageously plurality of separate mixtures with different saturation ratios are provided and introduced to the first condensing environment (104) in order to condensate the condensing medium onto the aerosol particles. Depending of the saturation ratio the particles with different lowest original size are activated and growth in a growing section (104A) and / or in the condensing environment (104). After activation and growing the particles are detected by a detecting means(110).

Owner:AIRMODUS

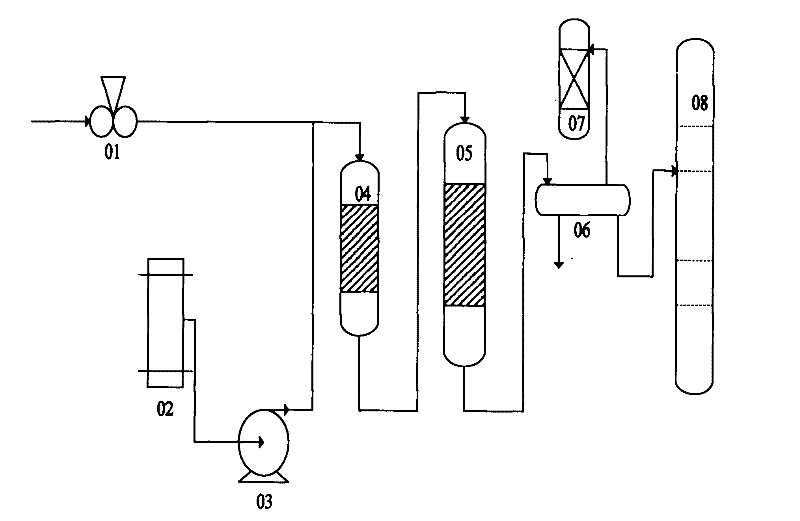

Method for producing ultralow-sulfur cleaning gasoline through full-distilling hydrogen desulfurization of catalytic gasoline

InactiveCN102649914AReduce lossesSimple processTreatment with hydrotreatment processesIsomerizationHydrodesulfurization

The invention relates to a method for producing ultralow-sulfur cleaning gasoline through full-distilling hydrogen desulfurization of catalytic gasoline. The method mainly solves the problems of the prior art that the process flow of hydrogen desulfurization of catalytic gasoline is complex, the reaction condition is rigorous, the saturation ratio of the gasoline olefin after being subjected to hydrogen desulfurization is ultrahigh, the loss of octane value is big, and the like. The method comprises the following steps of: firstly, mixing hydrogen with the full-distilling catalytic gasoline, and then entering into a hydrogenation unit; removing alkadiene in the mixture while causing a part of hydrocarbon to perform isomerization reaction; placing a product obtained by pre-hydrogenating into a selective hydrogenating desulfurization unit; removing majority of sulfides in the product by performing the selective hydrogenating desulfurization reaction while maximally protecting the olefin from being saturated; and finally removing the hydrogen sulfide from the gasoline after being subjected to the selective hydrogenating desulfurization by a hydrogen sulfide removing unit, thereby obtaining a cleaning product of gasoline. According to the technical scheme, the problem is more efficiently solved. The method is suitable for the industrial production of the catalytic gasoline with low-sulfur high-octane value.

Owner:江苏佳誉信实业有限公司

Method for measuring moisture supersaturation degree and device of method

The invention relates to a method for measuring the moisture supersaturation degree and a device of the method. The method specifically includes the steps of measuring temperature and pressure of gas in the supersaturation state to obtain the saturated gas moisture content under the condition of the temperature and the pressure, conducting isobaric heating on the gas in the supersaturation state till the state that RH is smaller than 100% is obtained, measuring temperature and relative humidity of the heated gas, and obtaining the absolute moisture content of the gas on this basis, wherein the ratio of the absolute moisture content of the gas to the gas moisture content, under the temperature and pressure conditions, of the gas which is not heated is the supersaturation degree of the gas. The invention provides the method for indirectly measuring the supersaturation degree and the device of the method, the supersaturation degree of the supersaturated gas containing moisture is measured, and the measurement range of hygrometers is widened to the range that RH is larger than 100%.

Owner:SOUTHEAST UNIV

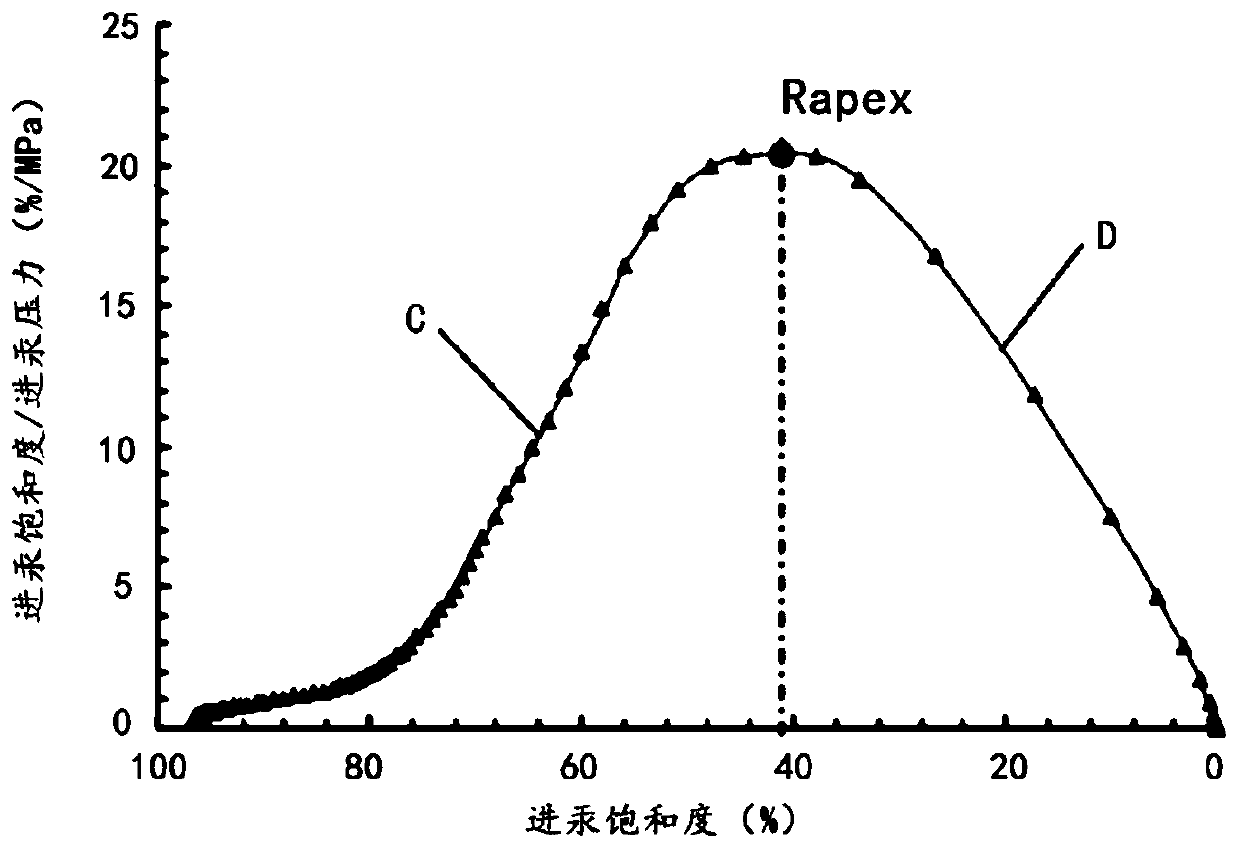

Pore movability classification and evaluation method for tight sand reservoir

ActiveCN110687153AAccurate understandingImprove the success rate of exploration and developmentPreparing sample for investigationParticle size analysisSoil scienceNMR - Nuclear magnetic resonance

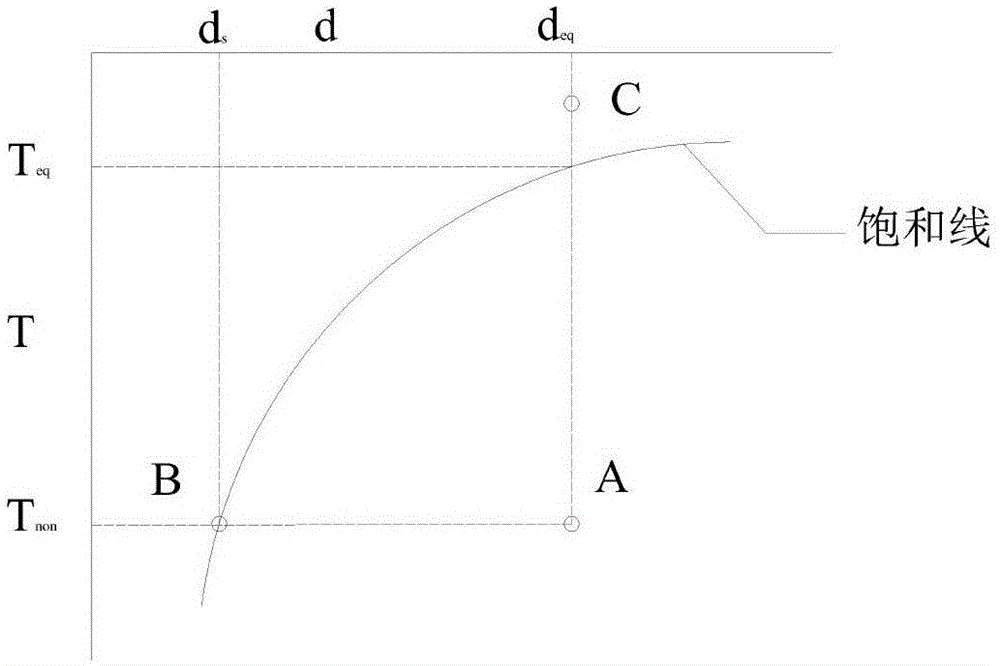

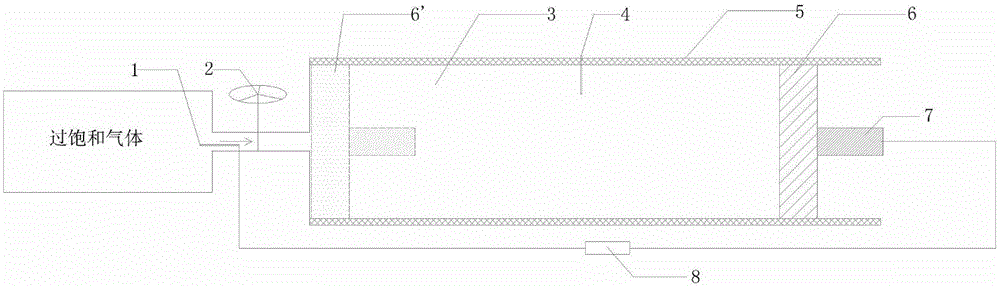

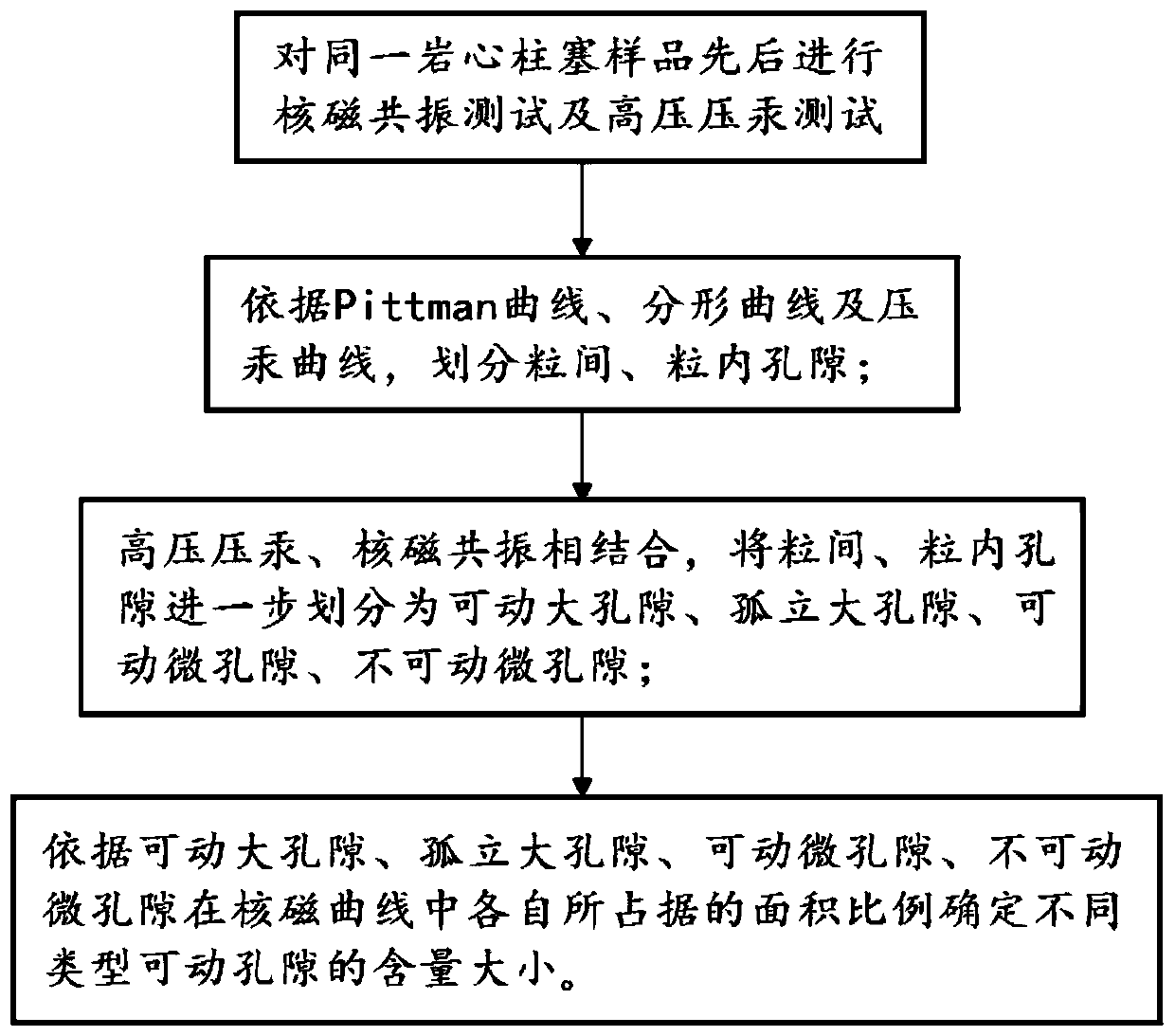

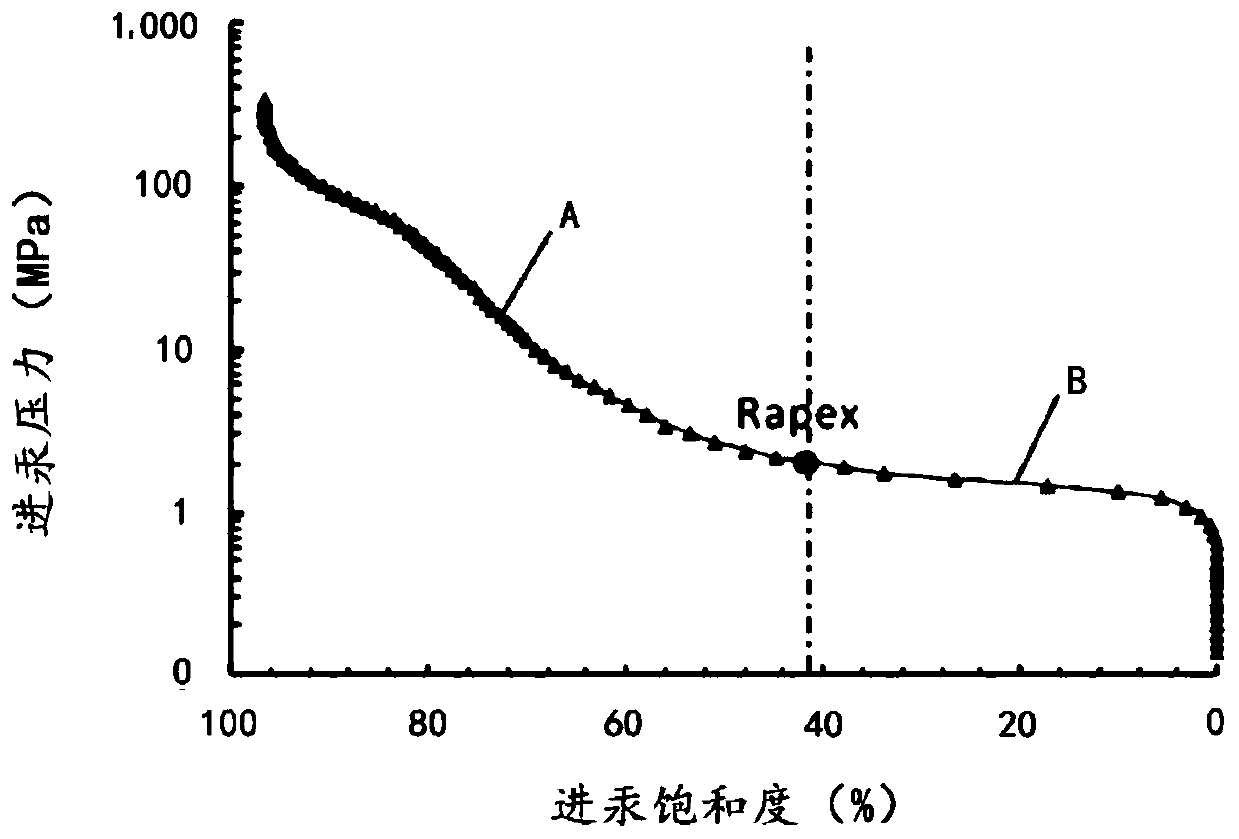

The invention relates to a pore movability classification and evaluation method for a tight sand reservoir. The pore movability classification and evaluation method for the tight sand reservoir comprises the specific steps of: S1, preparing a sample, and carrying out nuclear magnetic resonance and high-pressure mercury injection test on the sample; S2, drawing a mercury injection curve, a Pittmancurve and a fractal curve according to a mercury inlet saturation and a mercury inlet pressure Pc, determining boundaries of intergranular pores and intragranular pores according to a boundary of a platform section and an increasing section of the mercury injection curve, a vertex of the Pittman curve and a turning point of the fractal curve, and dividing into the intergranular pores and the intragranular pores according to the boundaries; S3, according to a relationship between a saturated water nuclear magnetic curve and a bound water nuclear magnetic curve, by combining the boundaries of the intergranular pores and the intragranular pores, dividing the intergranular pores into movable large pores and isolated large pores and dividing the intragranular pores into movable micro pores andunmovable micro pores; and S4, calculating content of different types of pores. According to the invention, evaluation on movability of different types of pores of the tight sand reservoir can be implemented, movability evaluation of the pores of the reservoir further accords with the actual geological condition, and an evaluation result is more accurate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Treatment method for construction residue soil in construction waste

InactiveCN109956686AIncrease the amount of liquid phaseImprove early strengthCement productionChemical compositionCalcination

The invention relates to a treatment method for construction residue soil in construction waste. The method comprises the following steps: performing material separation on the construction waste to obtain the construction residue soil, detecting a chemical component content of the obtained construction residue soil, performing preparation to obtain a cement raw material including limestone, the construction residue soil, an iron raw material and sandstone, enabling a saturation ratio of the cement raw material to be 0.8-1.0, a silicon ratio to be 1.9-2.5 and an aluminum ratio to be 1.3-1.9, and producing cement clinker. The treatment method for the construction residue soil in the construction waste provided by the invention can continuously and effectively utilize the construction residue soil in the construction waste and is almost not limited by generation time and regions of the construction waste of each batch, and after high-temperature calcination is performed to form the cement clinker, harmful substances mixed in the construction residue soil are solidified in the cement clinker and do not cause harm to the environment and humans, and cement products produced by the method are qualified.

Owner:广西华润红水河水泥有限公司 +1

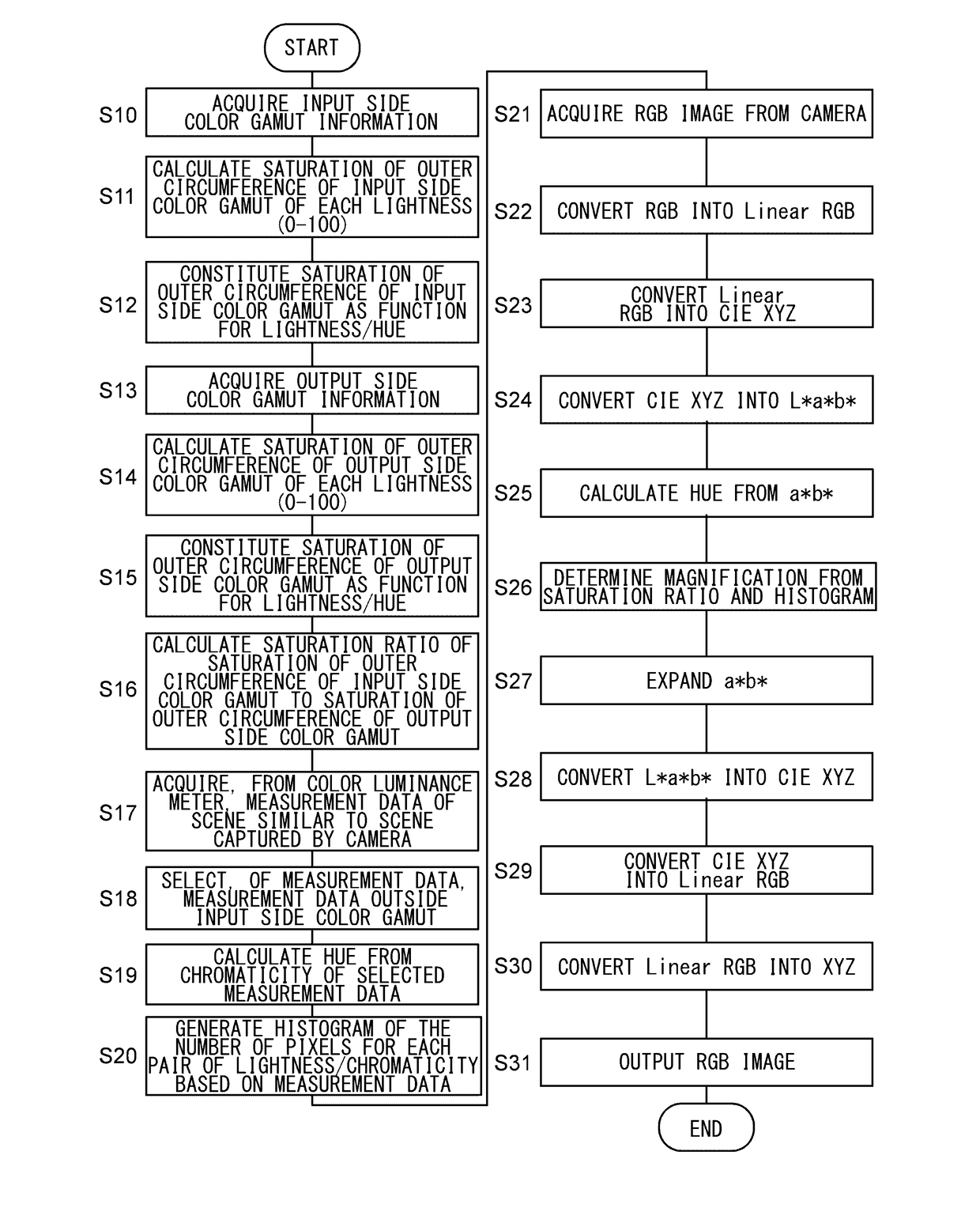

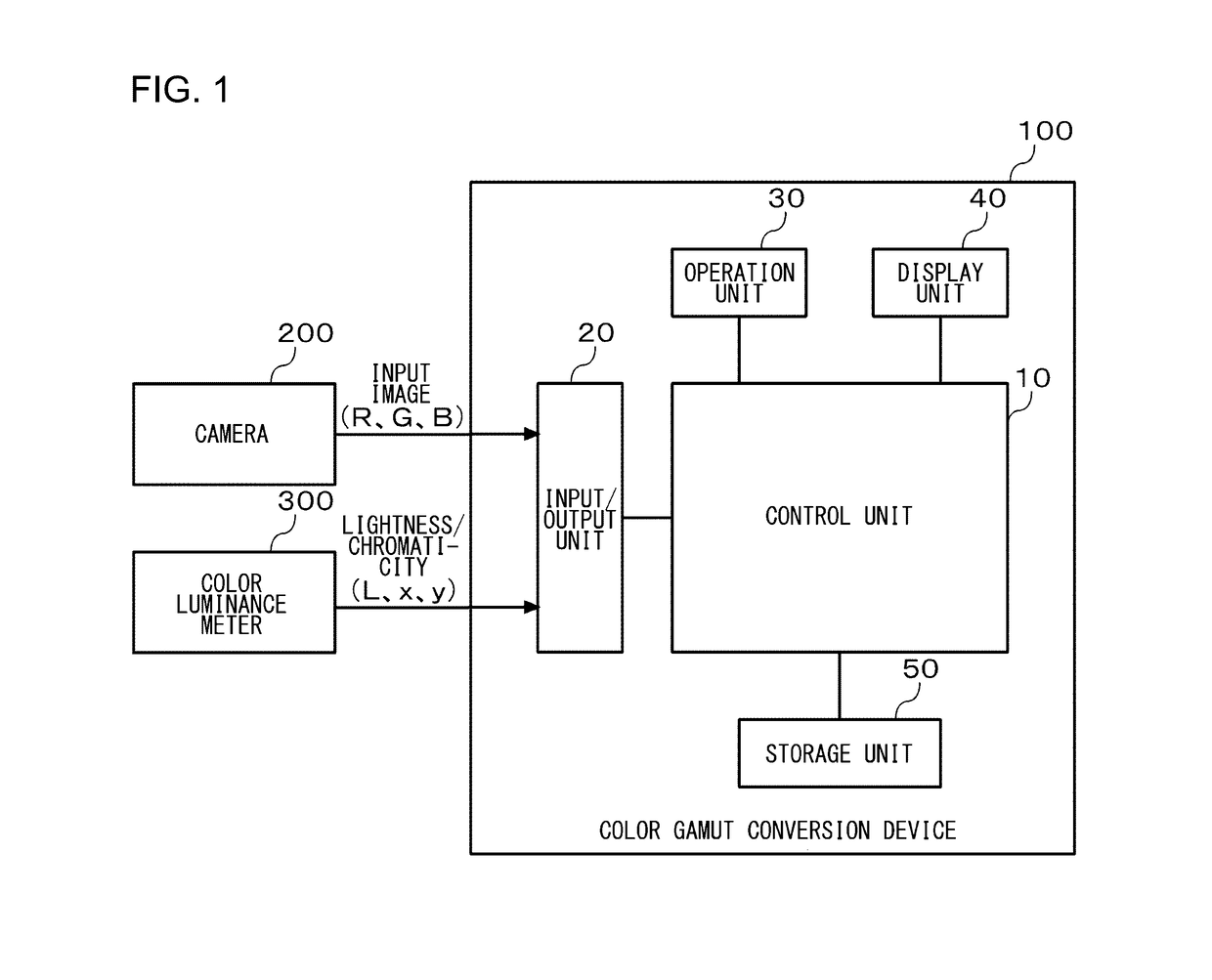

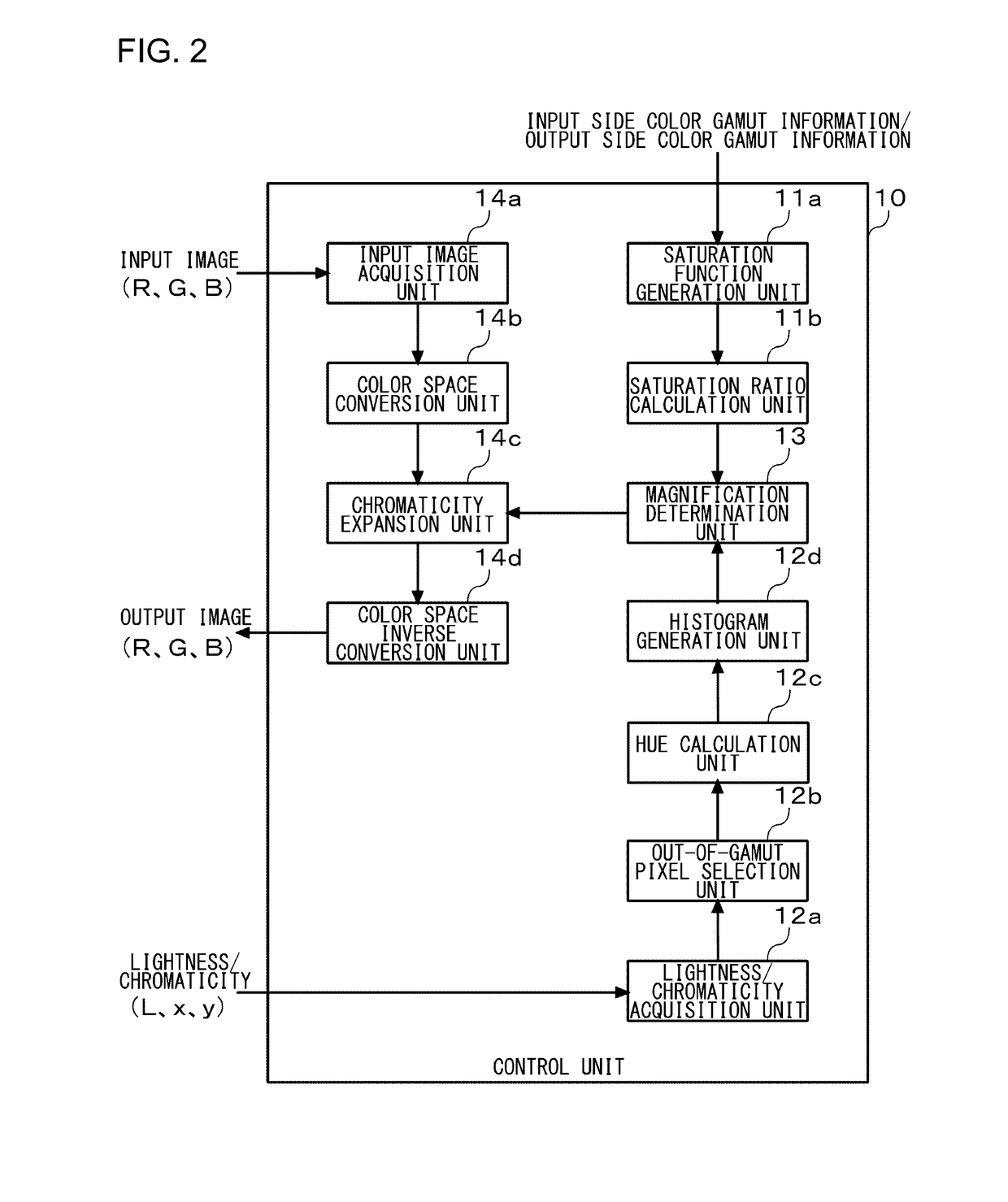

Color gamut conversion device, color gamut conversion method, and color gamut conversion program

A saturation ratio calculation unit calculates a saturation ratio of the saturation of an outer circumference of a color gamut of an input image to the saturation of an outer circumference of a color gamut of an output image. A histogram generation unit generates a histogram in which a plurality of pixels selected as pixels outside the color gamut are counted for each pair of lightness and hue. A magnification determination unit determines, within a range of not less than 1 and not more than the saturation ratio, a magnification by which the chromaticity of the input image to be subjected to the color gamut conversion is to be multiplied for each pair of lightness and hue based on the histogram.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

Method for roasting cement clinker through sulphur coal by dry-process rotary kiln

The invention provides a method for roasting a cement clinker through sulphur coal by a dry-process rotary kiln. The method comprises the following steps of: (1) preparation of raw materials: the material preparation scheme of intermediate saturation ratio, intermediate-low silica modulus and high aluminum-oxygen modulus is adopted, and the materials are that 0.90+ / -0.02 of KH, 2.5+ / -0.1 of N, and 2.0+ / -0.1 of P; and the raw materials comprise 84% of limestone, 4% of high siliceous shale, and 12% of siliceous shale; and (2) roasting of clinker: the sulphur coal is adopted and used as the fire coal and contains 7.0 to 8.0% of sulphur content and 12 to 15% of volatile matter; the air inlet angle of a coal-injection duct of the rotary kiln is set to 34 degrees, the inner air opening is in a full opening state, the outer air opening degree is set to reach 50 to 70%, the throat of a smoke chamber is set to reach 1100mm; when in roasting, the temperature of an outlet of a decomposing furnace is controlled to 860 to 880 DEG C, the temperature of the smoke chamber is controlled to reach 950 to 1050 DEG C, and the rotation speed of the rotary kiln is controlled to more than 3.8 revolutions per minute at the same time; the crust on the smoke chamber is removed twice every eight hours in each shift during roasting, as well as removing the crust on a gooseneck of the decomposing machine every 12 hours. According to the method, the total sulfur in the fire coal for the dry-process rotary kiln is expanded to reach 7.0 to 8.0%, the qualified clinker can be normally roosted, and no influence is brought to the output and the quality.

Owner:CHONGQING XIUSHAN SOUTHWEST CEMENT

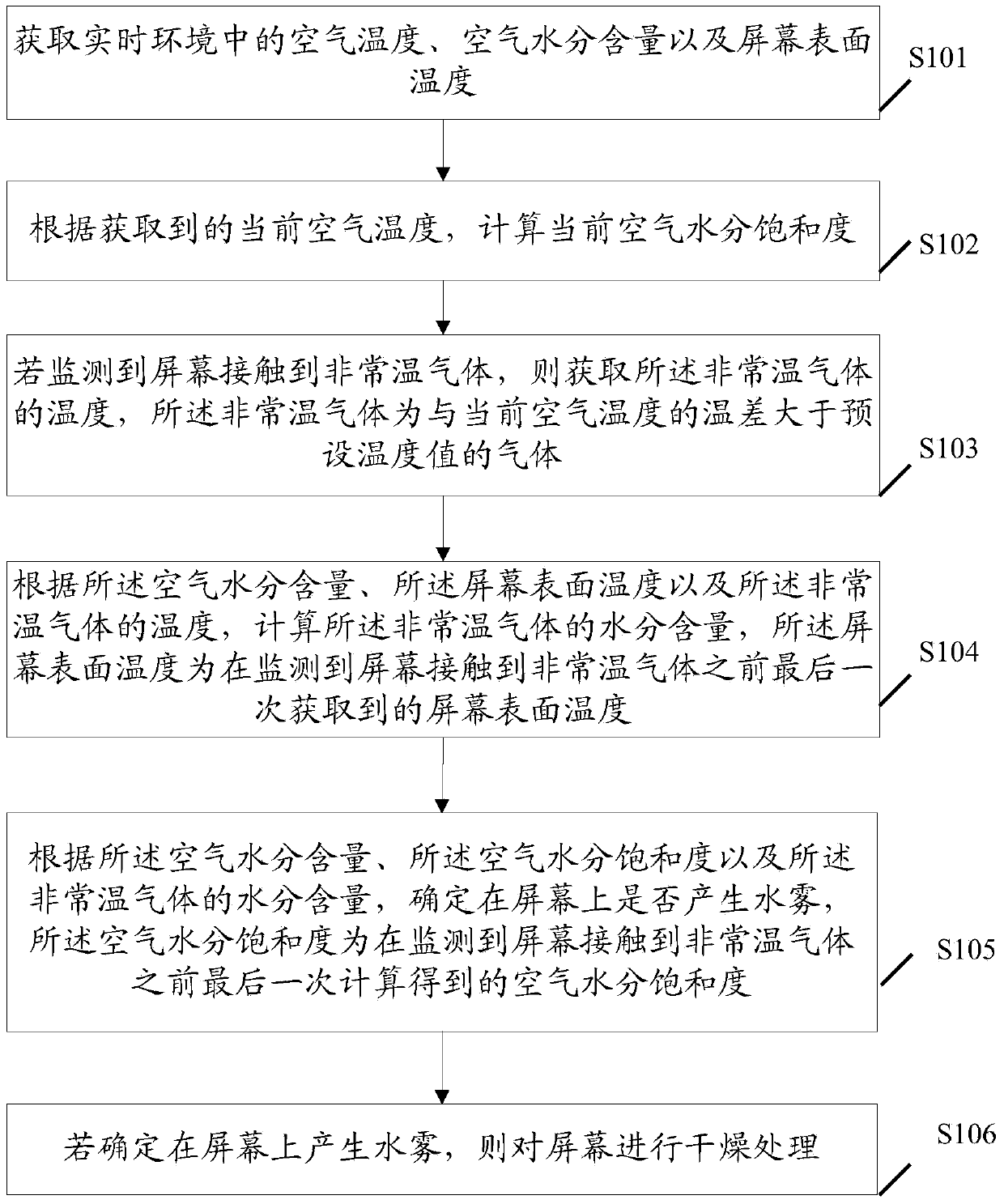

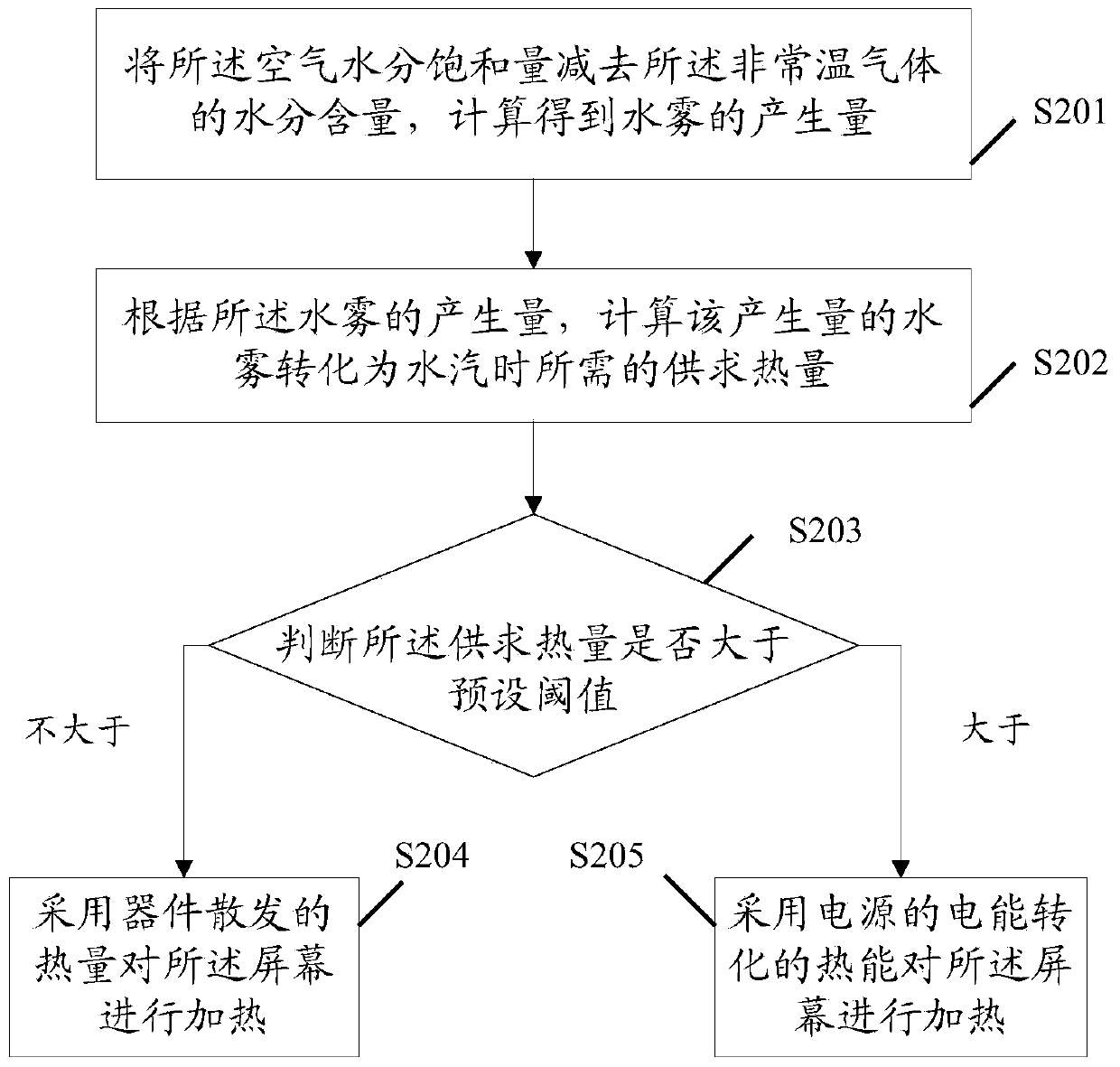

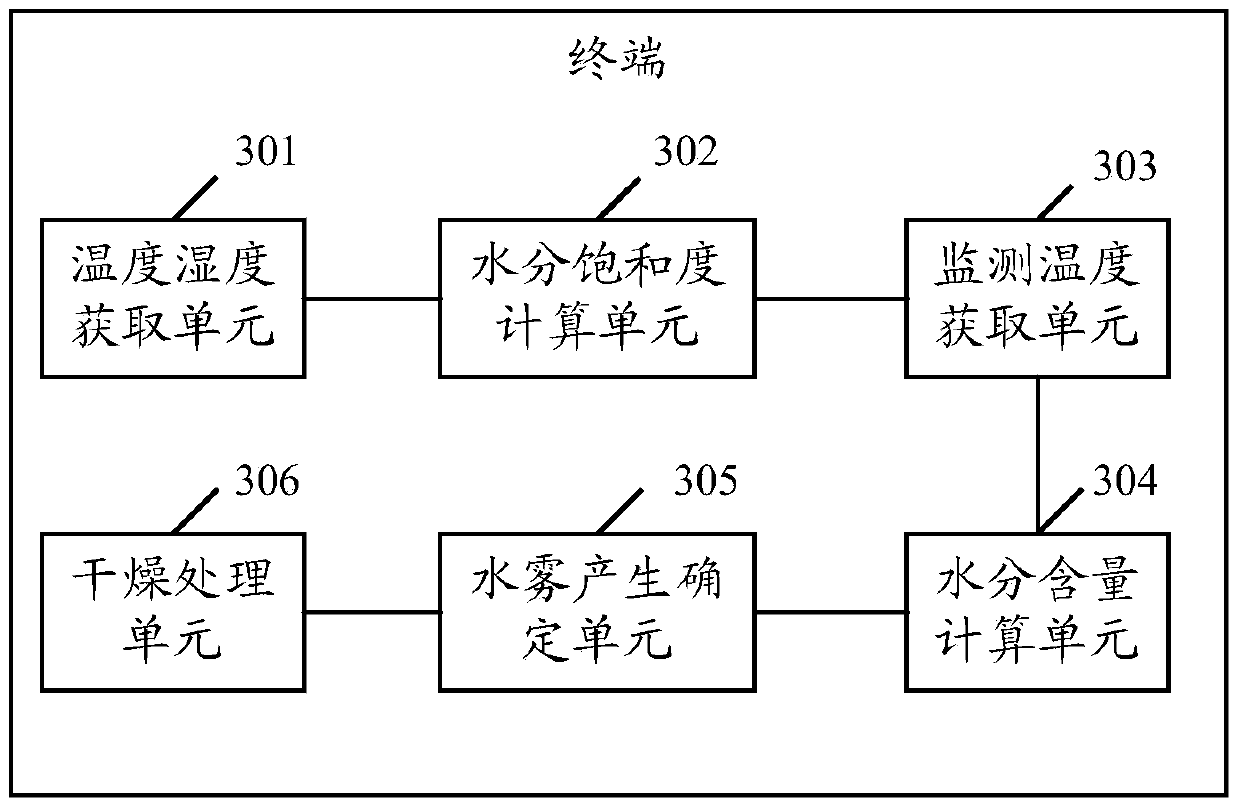

Screen water mist processing method and terminal

InactiveCN103995552AImprove user experienceDrying solid materialsSimultaneous control of multiple variablesEngineeringEnvironmental engineering

The embodiment of the invention discloses a screen water mist processing method. The method comprises the steps of obtaining air temperature, air moisture content and screen surface temperature of a real-time environment; calculating the current air moisture saturability according to the obtained current air temperature; obtaining temperature of abnormal-temperature air if it is detected that a screen makes contact with the abnormal-temperature air; calculating the moisture content according to the air moisture content, the screen surface temperature and temperature of the abnormal-temperature air; judging whether water mist is formed on the screen according to the air moisture content, the air moisture saturability and the moisture content of the abnormal-temperature air; drying the screen if the water mist is formed on the screen. The embodiment of the invention further discloses a terminal. By adopting the method and the terminal, whether the water mist is formed on the screen in the real-time environment can be determined, the water mist is prevented in a drying mode, and user experience is enhanced.

Owner:SHENZHEN GIONEE COMM EQUIP

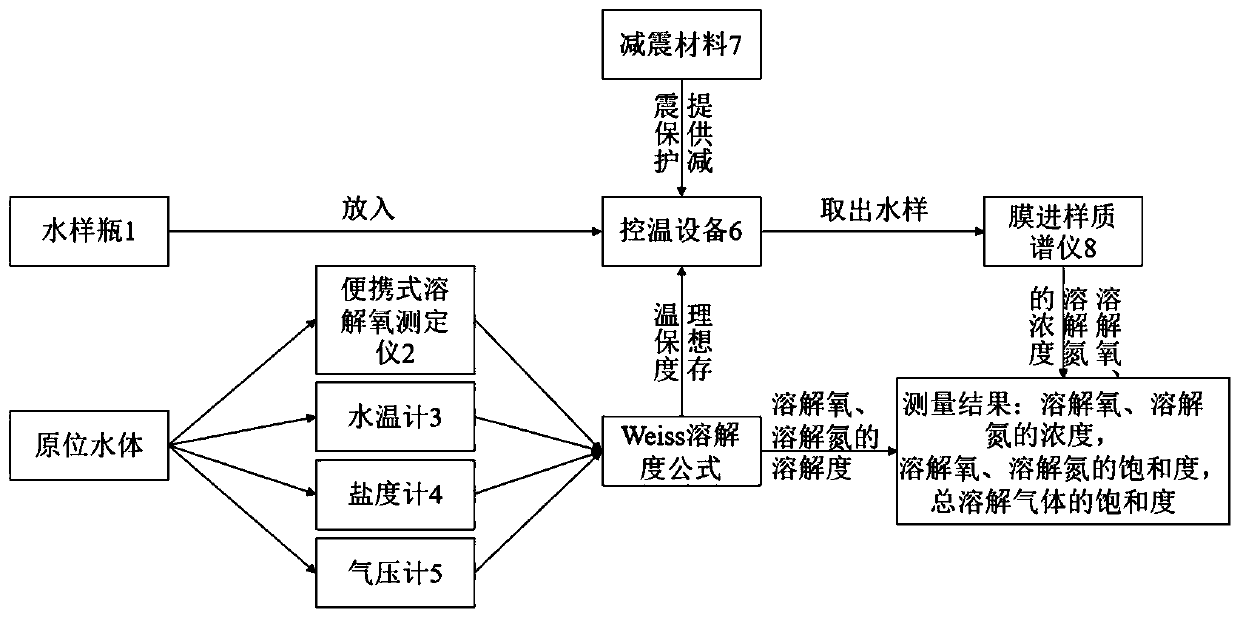

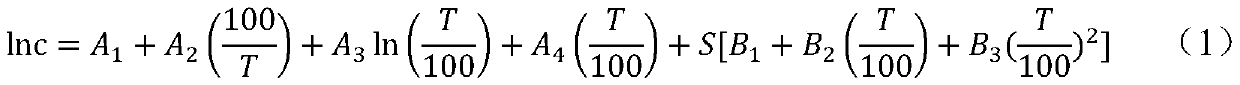

Method for improving measurement accuracy of concentration of dissolved gas in water

ActiveCN111289601AReduce measurement impactReduce the effect of dissolved gas contentWithdrawing sample devicesMaterial analysis by electric/magnetic meansTemperature controlSoil science

The invention discloses a method for improving the measurement accuracy of the concentration of dissolved gas in a water body. After water sample collection, an in-situ water body is measured immediately by using a portable dissolved oxygen tester; the water temperature and salinity of the in-situ water body are measured at the same time; the atmospheric pressure at the same time of sampling is recorded; an ideal storage temperature of the water sample is calculated by adopting a Weiss formula according to the data; a water sample bottle is arranged into temperature control equipment, and thetemperature of the temperature control equipment is adjusted to the ideal storage temperature, so as to carry out long-distance transportation and long-time storage. According to the invention, a problem of low accuracy of directly measuring the concentration of dissolved gas in a water sample by using a membrane sample introduction mass spectrometer when the water sample collected from the fieldenters a laboratory is solved; in the process of storing and transporting a water sample collected in the field to a laboratory for measurement, the content of original dissolved gas in the collectedwater body can be kept as much as possible, the disturbance influence of external factors is reduced, and the accuracy of dissolved gas concentration and saturation measurement is improved.

Owner:SICHUAN UNIV

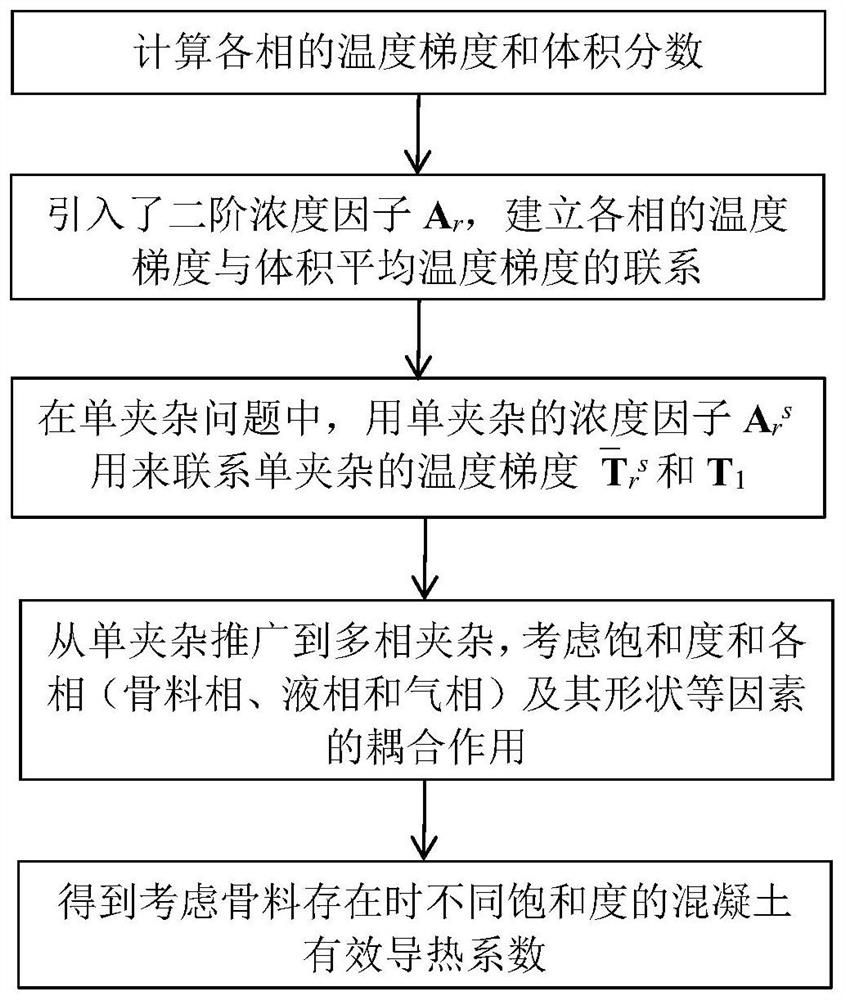

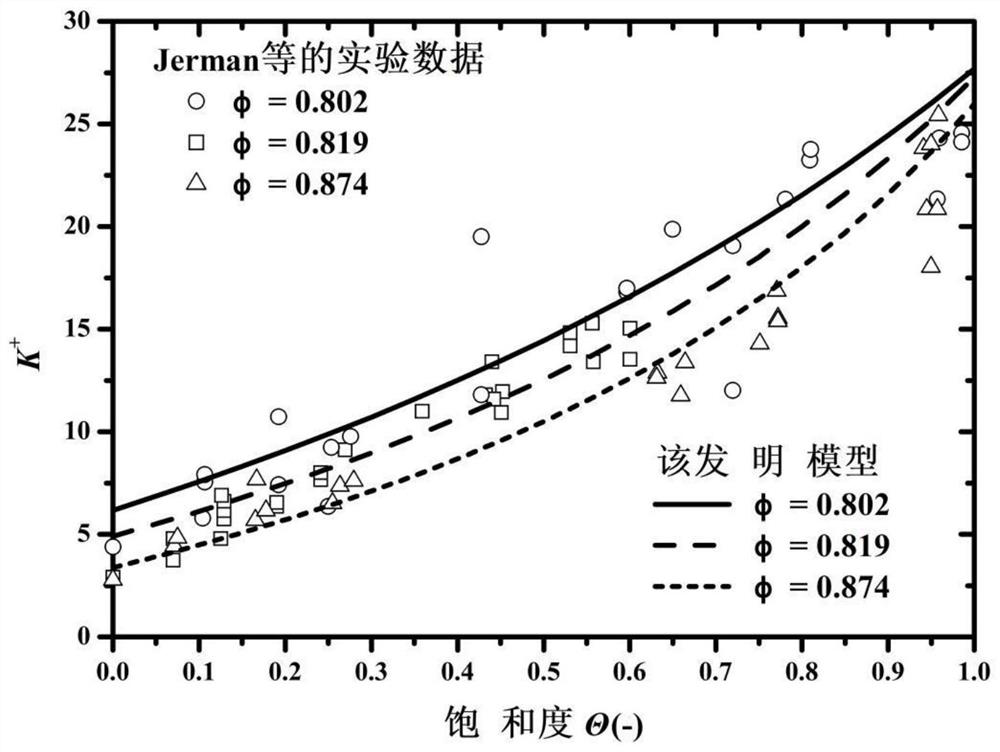

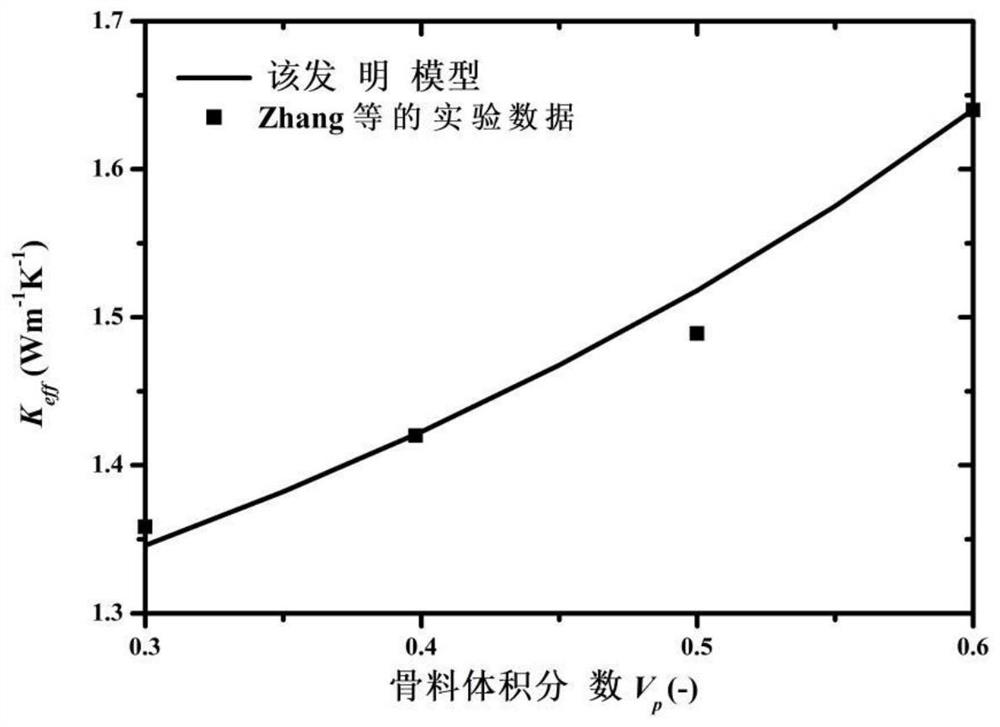

Concrete heat conductivity coefficient calculation method considering aggregate shape

ActiveCN111678945AShorten the timeSave human effortMaterial thermal conductivityMaterial heat developmentThermodynamicsEngineering

The invention discloses a concrete heat conductivity coefficient calculation method considering aggregate shape. comprises the following steps that firstly, the temperature gradient and volume fraction of each phase are calculated; a second-order concentration factor Ar is introduced, and the relation between the temperature gradient of each phase and the volume average temperature gradient is established; secondly, in the single inclusion problem, the concentration factor of single inclusion is used for connecting the temperature gradient of single inclusion with T1; single inclusion is popularized to multi-phase inclusion, and the coupling effect of saturation, phases (aggregate phase, liquid phase and gas phase), shapes of the phases and other factors is considered; and finally, the effective heat conductivity coefficients of the concrete considering different saturations in the presence of the aggregate are obtained. The method provides a theoretical basis for calculation and prediction of the effective heat conductivity coefficient of the concrete, is used for designing a high-performance concrete material and predicting the service cycle life of a concrete structure, has highscientific research and practical application values, can save a large amount of time, manpower and material resources, and is high in matching degree of a prediction result and an experiment.

Owner:HOHAI UNIV

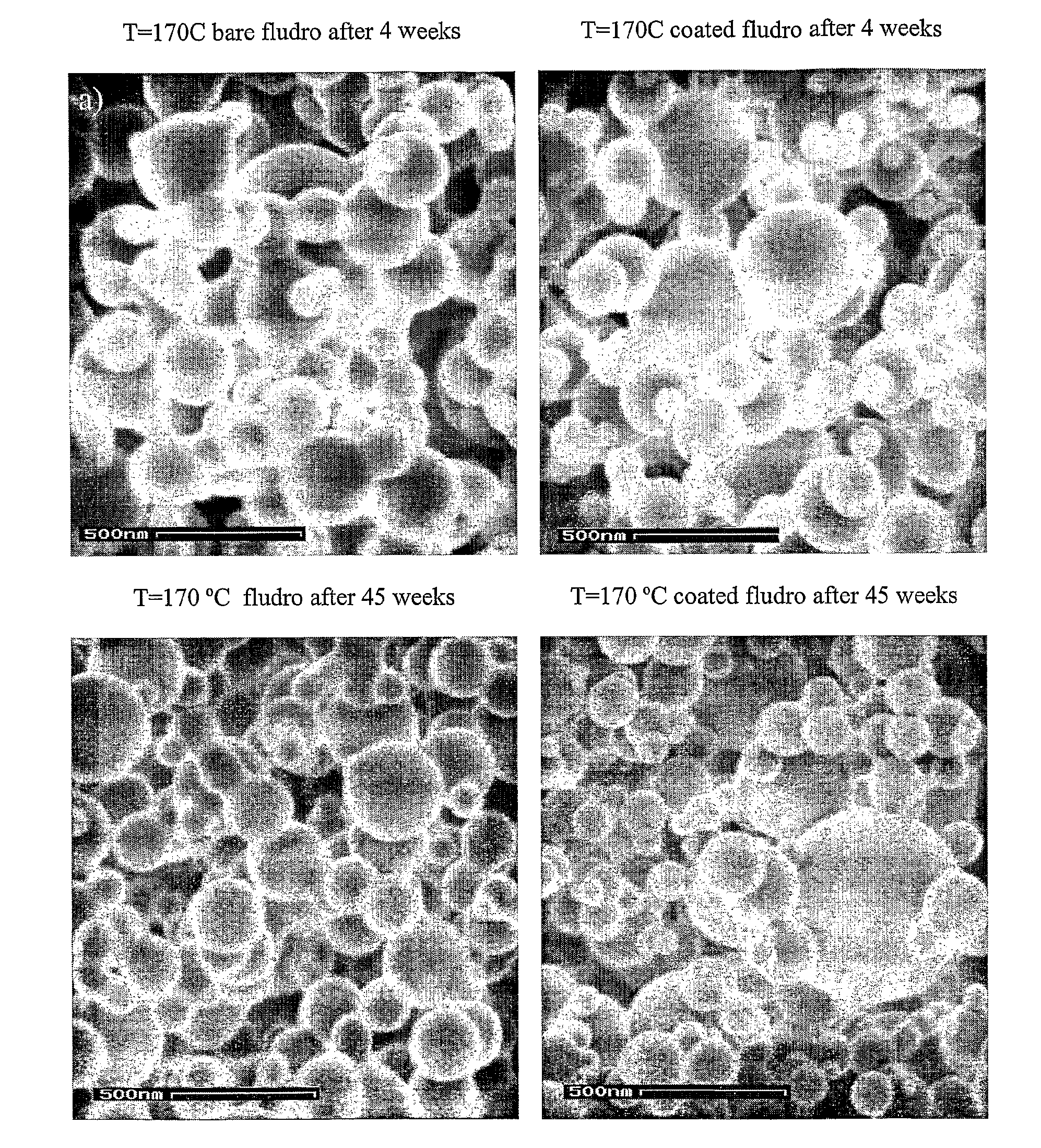

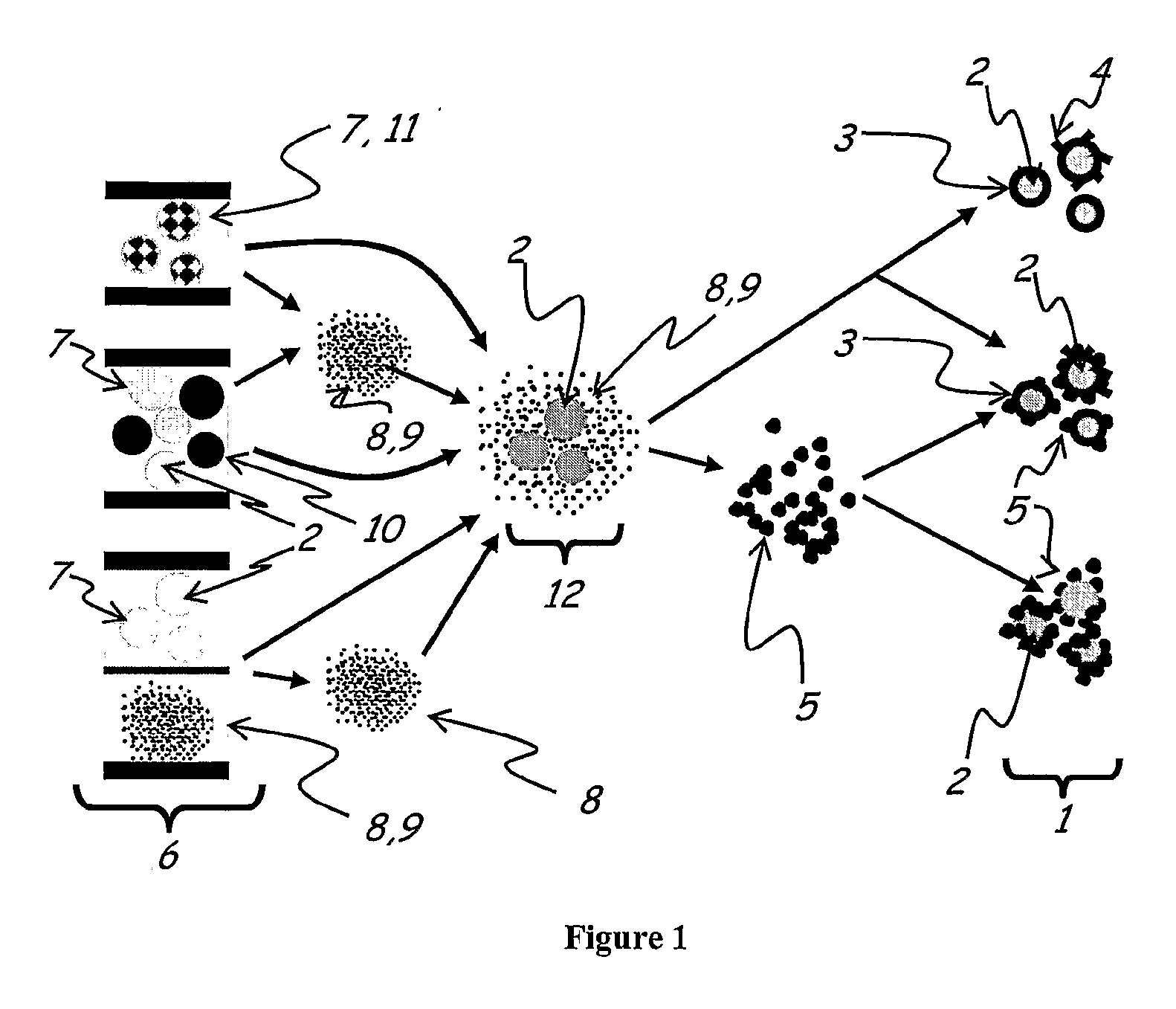

Surface modified aerosol particles, a method and apparatus for production thereof and powders and dispersions containing said particles

A method and apparatus for multicomponent surface modified aerosol particle production suitable for, for instance, therapeutic, cosmetic or diagnostic use in which an aerosol containing an active agent is introduced in an aerosol reactor together with a surface agent or surface agent source and / or precursor and wherein the surface agent and / or surface agent precursor is volatilizable. The surface agent vapor saturation ratio is elevated so to cause it to nucleate from the gas phase. Reactor conditions are maintaining such that the active agent remains in the condensed phase and provides a surface for the surface agent to deposit on the active agent containing aerosol particle thus producing surface modified aerosol particles. The method can be used for batch or continuous production. Particles made according to the method and powders and dispersions containing the particles are also described.

Owner:TEICOS PHARMA

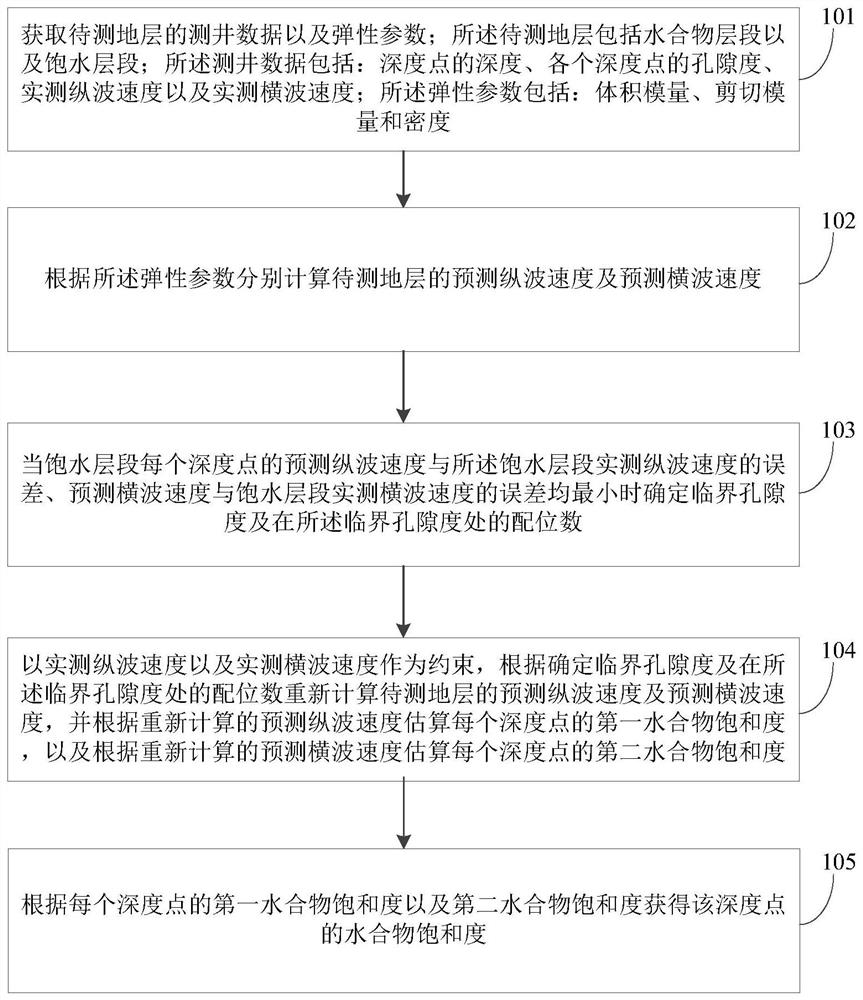

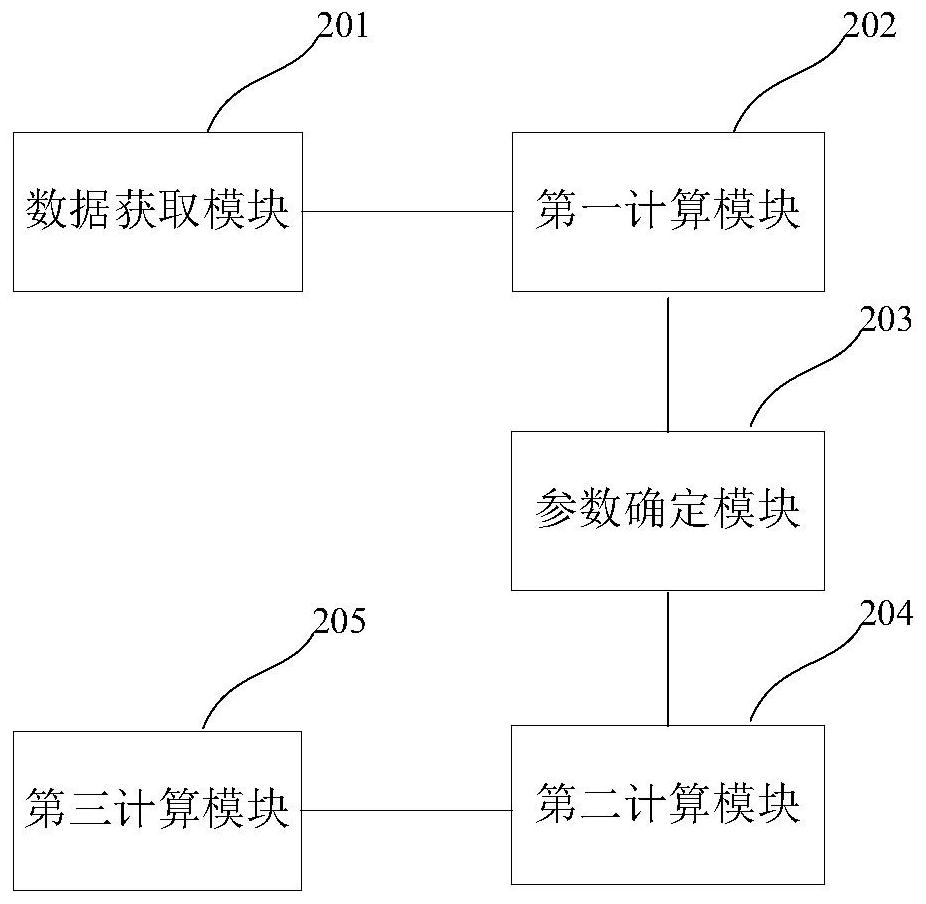

Natural gas hydrate saturation estimation method and system

PendingCN113189674AImprove estimation accuracyActive guidanceGeological measurementsComplex mathematical operationsLongitudinal waveTransverse wave

The invention provides a natural gas hydrate saturation estimation method and system. The method comprises the following steps: acquiring logging data and elastic parameters of a stratum to be measured; respectively calculating a predicted longitudinal wave velocity and a predicted transverse wave velocity of the stratum to be measured; when the error between the predicted longitudinal wave speed of each depth point of the water-saturated layer section and the actually measured longitudinal wave speed of the water-saturated layer section and the error between the predicted transverse wave speed and the actually measured transverse wave speed of the water-saturated layer section are both minimum, determining the critical porosity and the coordination number at the critical porosity; and recalculating the predicted longitudinal wave velocity and the predicted transverse wave velocity of the stratum to be measured, estimating the first hydrate saturation of each depth point according to the recalculated predicted longitudinal wave velocity, estimating the second hydrate saturation of each depth point according to the recalculated predicted transverse wave velocity, and obtaining the hydrate saturation. The method is high in estimation accuracy, and has a positive guiding effect on hydrate reservoir reserve evaluation and subsequent exploration and development.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

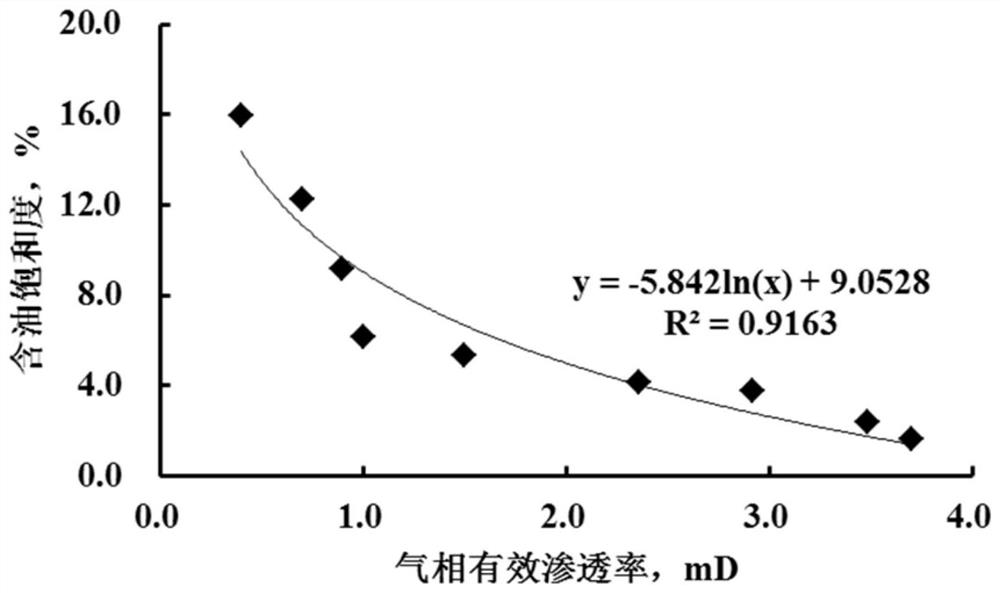

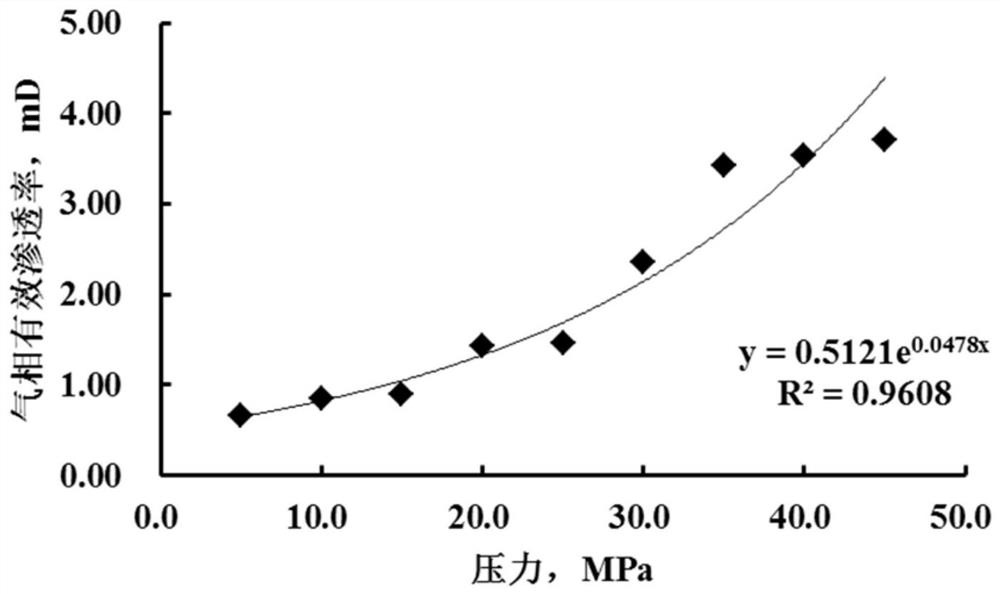

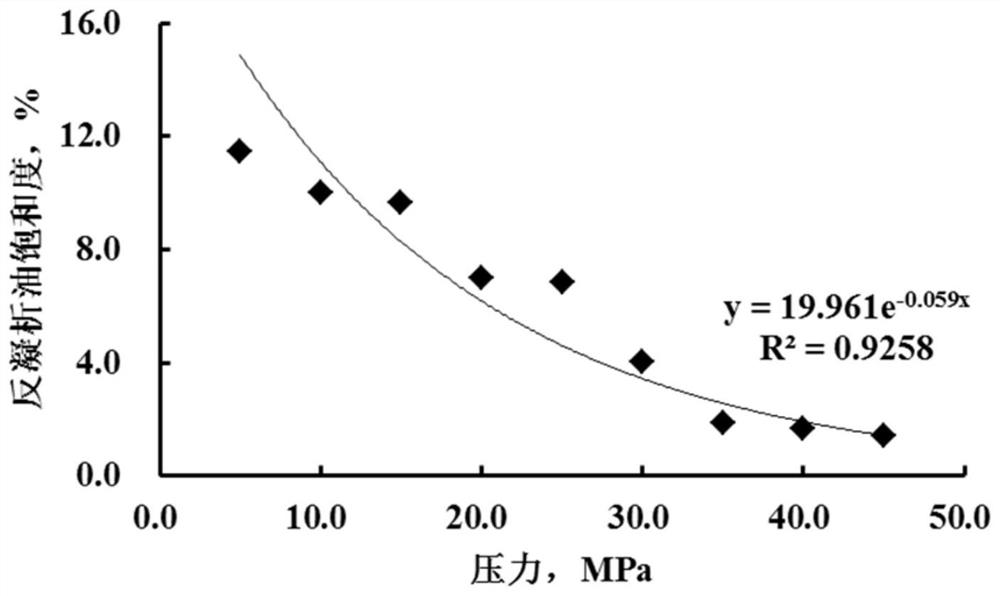

Method for determining reverse condensate oil saturation

PendingCN113189309AThe principle of the method is reliableBe sure to be accurate and objectiveMaterial testing goodsPermeability/surface area analysisRock coreBound water

The invention provides a method for determining reverse condensate oil saturation, which comprises the following steps of: (1) under T0 and P0, injecting a condensate gas sample into the inlet end of a first rock core for establishing bound water saturation until the condensate gas sample of the first rock core is saturated; (2) standing the first rock core, then reducing the pressure at the outlet end of the first rock core, injecting dry gas into the inlet end of the first rock core, and collecting a first outflow sample at the outlet end of the first rock core; (3) obtaining the gas phase permeability of the condensate oil under the average pressure; and (4) according to the corresponding relationship among the gas phase permeability, the gas phase permeability of the condensate oil and the oil saturation, obtaining the reverse condensate oil saturation of the condensate gas sample under the average pressure. The method can be used for determining the reverse condensate oil saturation of the condensate gas reservoir under different pressure conditions in the cyclic gas injection process, and is of great significance to quantitative evaluation of condensate oil loss and the influence of the condensate oil loss on the gas phase flow capacity.

Owner:PETROCHINA CO LTD

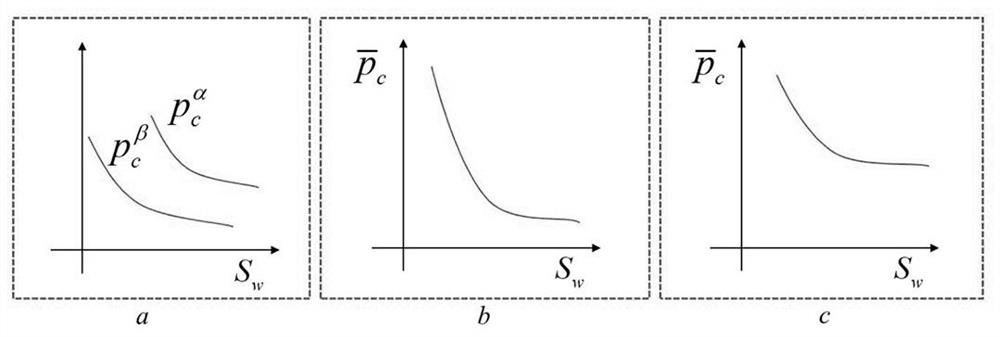

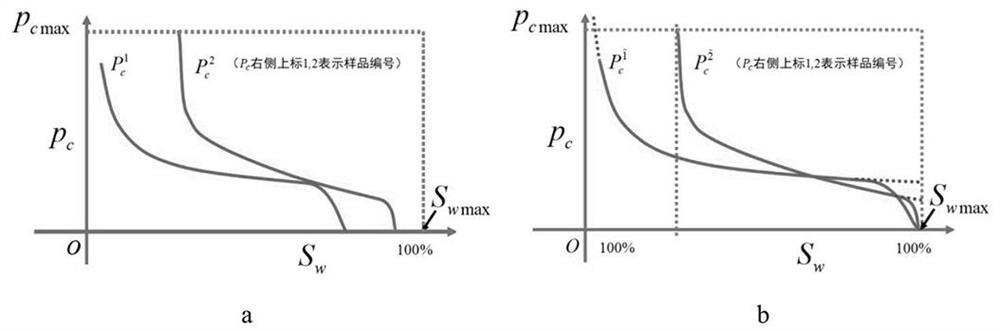

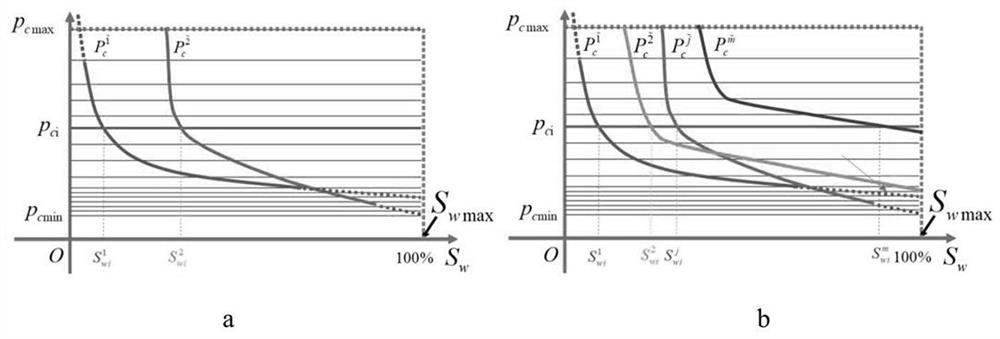

Multi-capillary force curve averaging method based on multi-sample overall virtual measurement

The invention relates to a multi-capillary force curve averaging method based on multi-sample overall virtual measurement, which comprises the following steps of 1, obtaining m rock samples, and obtaining a capillary force-saturation curve, appearance volume and porosity of each sample; 2, checking the capillary force-saturation curve quality of each sample, and pre-treating curve endpoints; 3, calculating the average wet phase saturation corresponding to different capillary force values of a plurality of samples under overall virtual measurement; and 4, marking data points on a graph by taking the wet phase saturation as a horizontal coordinate and the capillary force as a vertical coordinate, and smoothly connecting all the data points to obtain an averaged capillary force curve. The method is reliable in principle, easy and convenient to operate, suitable for various types of samples with different physical properties, wide in application range, accurate and convenient in calculation result and capable of better meeting the actual working condition, and operation is directly conducted on the capillary force curve, and the influence of the reservoir number represented by the sample is considered.

Owner:SOUTHWEST PETROLEUM UNIV

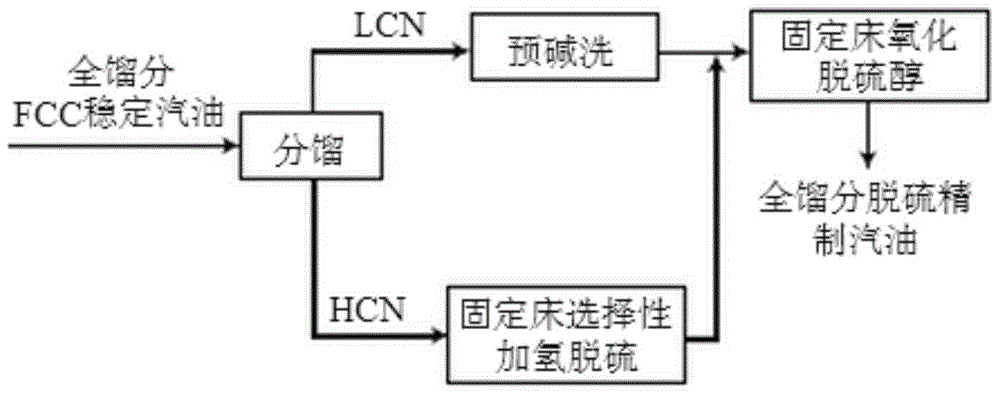

Catalytically cracked gasoline desulphurization method

InactiveCN105670687AReduce saturation rateReduce the depth of hydrodesulfurizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationGasoline

The invention discloses a catalytically cracked gasoline desulphurization method. The method comprises 1, according to raw material properties and product targets, selecting an appropriate cut point and carrying out fraction cutting on whole-fraction catalytically cracked stable gasoline from a catalytically cracking device, 2, removing sulfides of heavy fraction gasoline HCN in a fixed bed hydrodesulfurization reactor, and 3, carrying out caustic pre-washing on the light fraction gasoline LCN through a mercaptan removal unit, blending the light fraction gasoline LCN and the heavy fraction subjected to hydrogenation, and carrying out fixed-bed oxidation mercaptan removal to obtain refined catalytically cracked gasoline. The method greatly reduces a gasoline olefin saturation ratio, greatly reduces catalytically cracked gasoline heavy fraction hydrodesulfurization depth and reduces alkene hydrogenation saturation.

Owner:SHANDONG LIANXING ENERGY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com