Catalytically cracked gasoline desulphurization method

A technology for catalytically cracking gasoline and gasoline, which is applied in the petroleum industry, processing hydrocarbon oil, and hydrocarbon oil processing products, etc. The effect of saturation, reduced depth, reduced saturation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

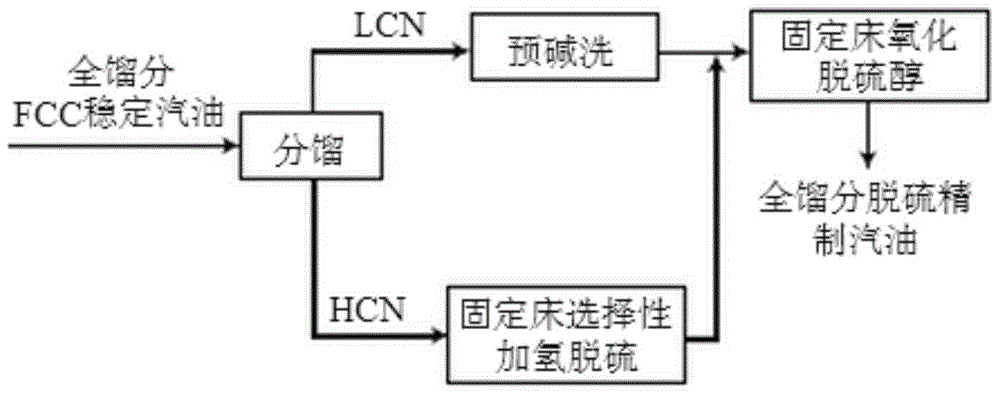

[0013] refer to figure 1 , the present embodiment adopts the following technical solutions: catalytic cracking gasoline desulfurization method, which includes the following steps: 1. Selecting a suitable cutting point according to the raw material properties and product objectives carries out fraction cutting from the full fraction catalytic cracking stable gasoline of the catalytic cracking unit; 2. 1. Heavy distillate gasoline HCN removes sulfide in a fixed bed hydrodesulfurization reactor; 3. Light distillate gasoline LCN is blended with hydrogenated heavy fraction after pre-alkali washing in the demercaptan unit, and then oxidatively desulfurized by fixed bed Alcohol process to obtain refined catalytic cracked gasoline.

[0014] It is worth n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com