Patents

Literature

59results about How to "Reduce saturation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

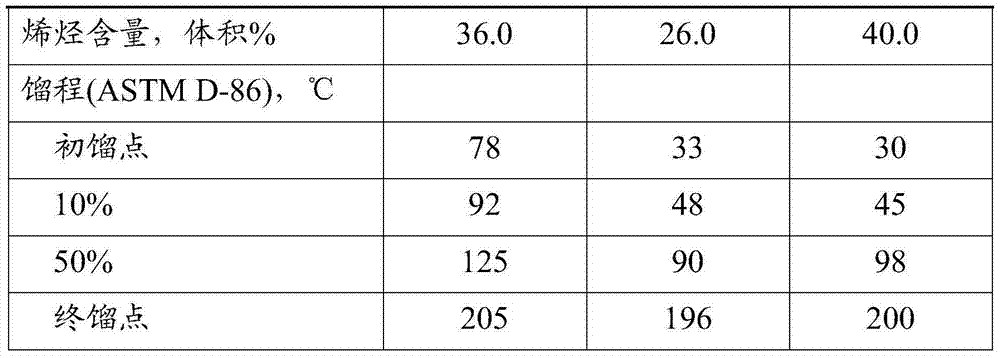

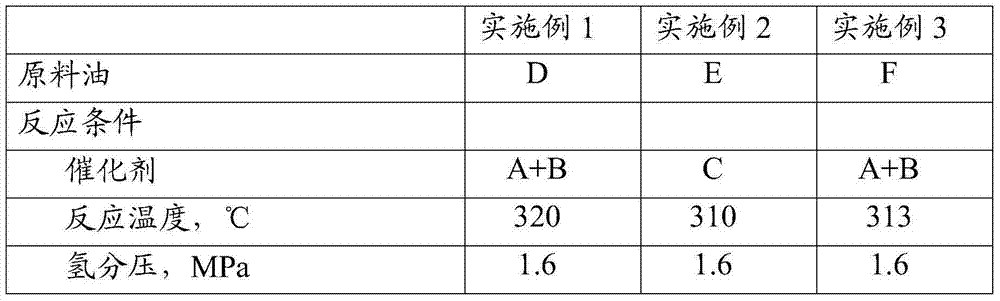

Process for hydrogenating modifying faulty gasoline

ActiveCN1597865ASimple processEasy to operateTreatment with hydrotreatment processesOrganic sulfide compoundIsomerization

The invention provides a process method for making hydrodesulfation and alkene reduction on the bad gasoline, like all-fractional FCC gasoline, etc. Under the conditions of hydrogen gas existence and temperature gradually rising, to contact with three catalysts forms three reaction regions. The first reaction region has lower temperature and uses hydrofining catalyst and mainly eliminates di-alkene in the gasoline; the second reaction region has higher temperature and uses selective hydrodesulfation catalyst and mainly eliminates organic sulfide and some alkenes; the third reaction region has the highest temperature, uses gasoline modifying catalyst and makes the modifying reactions including aromatization, isomerization and benzene alkylation, increasing octane number of gasoline and improving product quality. It has the advantages of simple flow, being easy to operate, fully using reaction heat, prolonging the operating cycle of catalyst, high liquid yield, low hydrogen consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

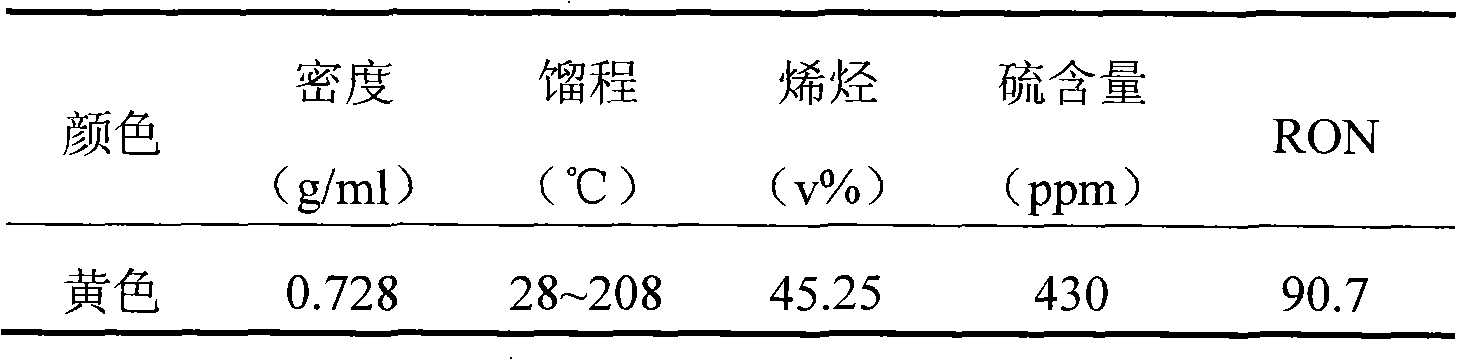

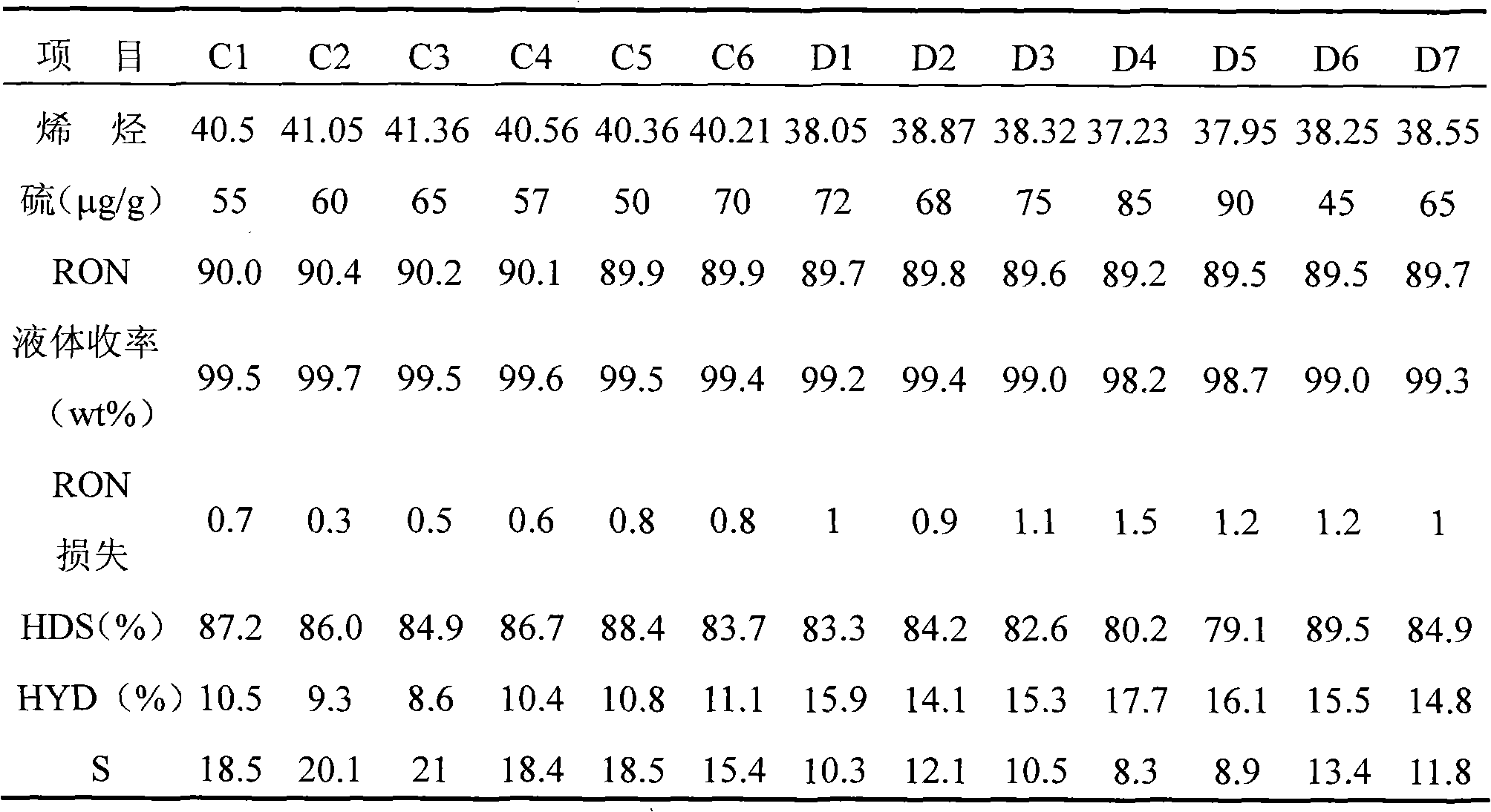

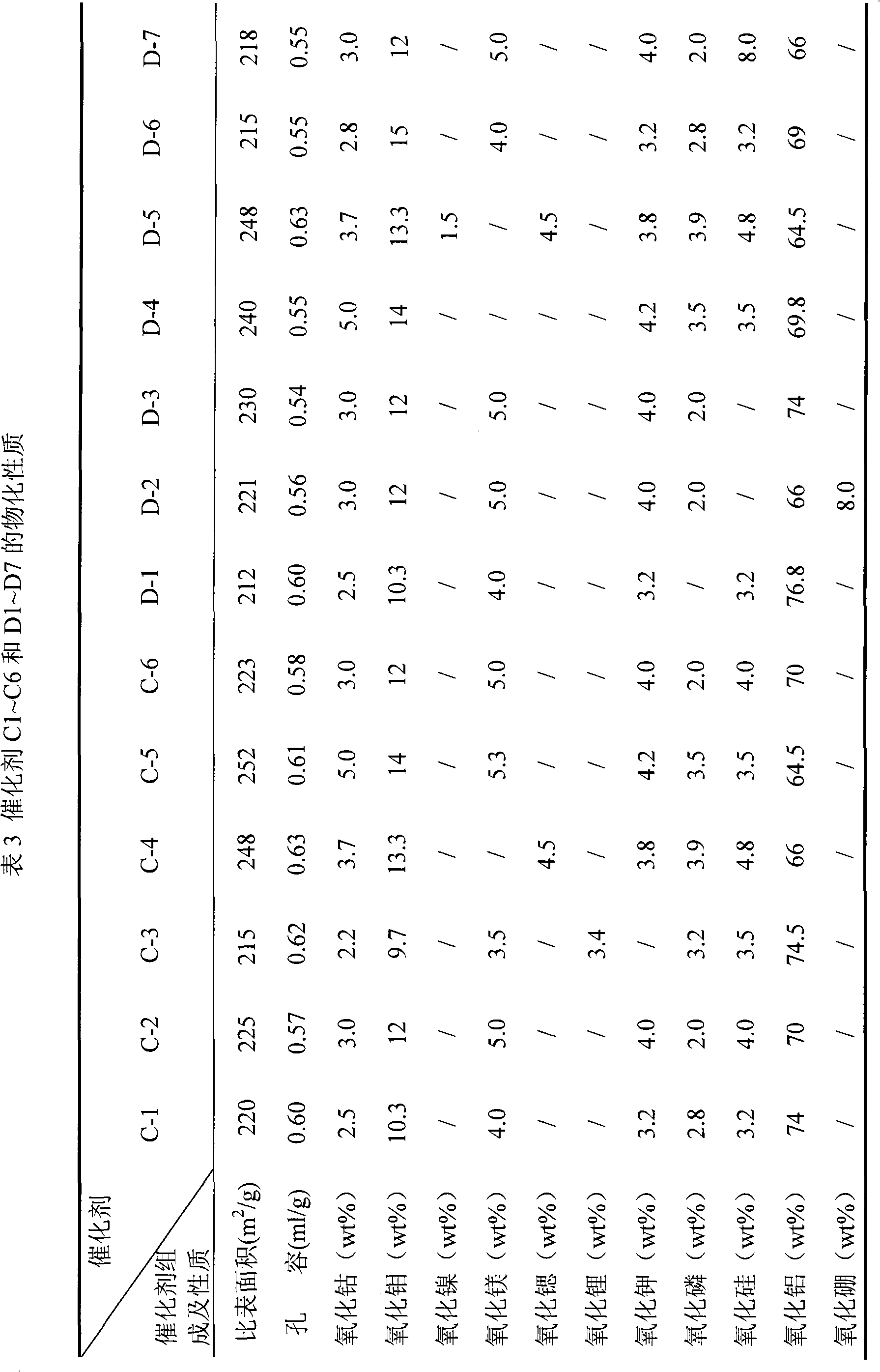

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

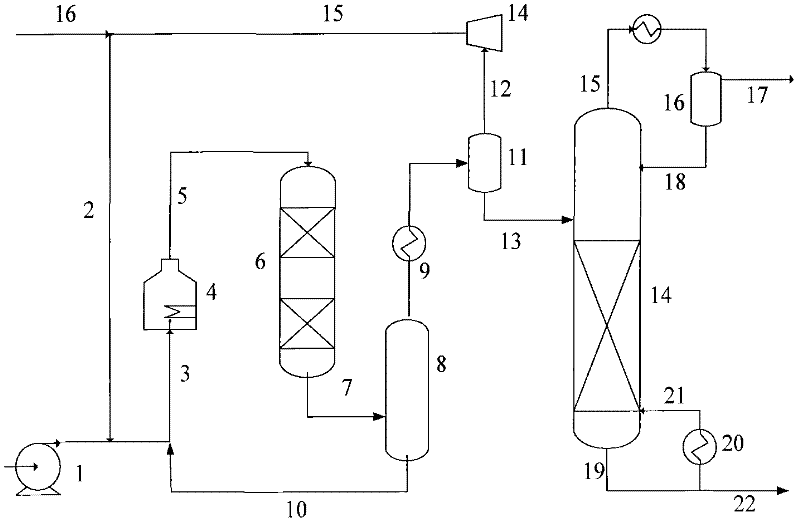

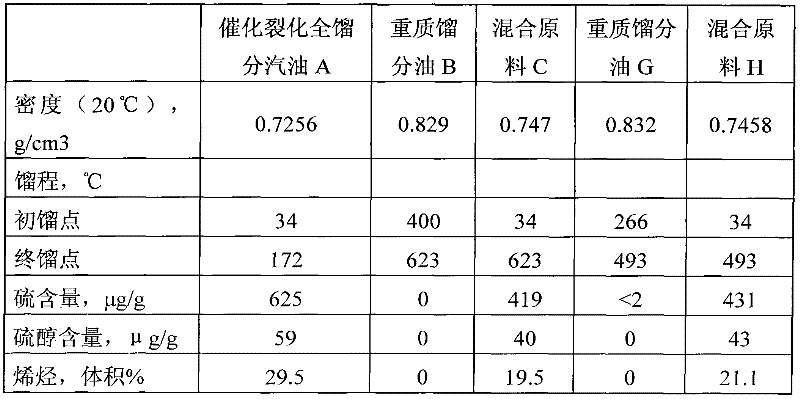

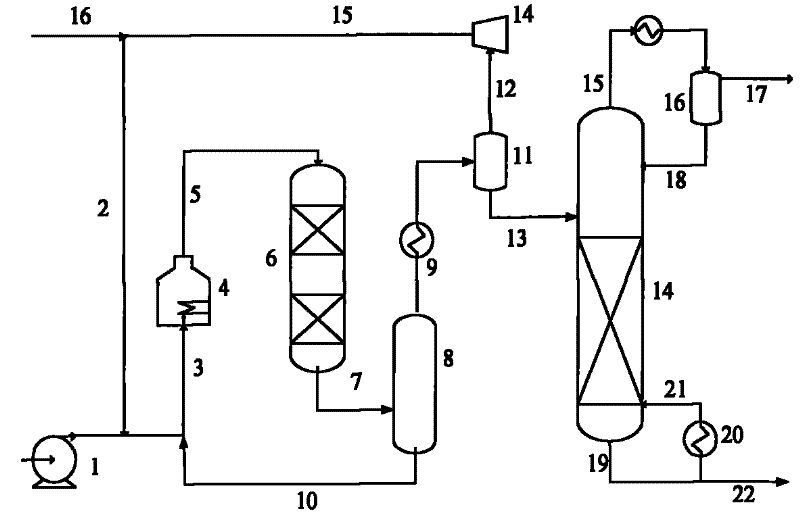

Depth hydrogenation treatment method of faulty gasoline

ActiveCN1718687AReduce saturation rateLow desulfurization activityTreatment with hydrotreatment processesOrganic sulfide compoundHydrodesulfurization

A process for deeply hydrorefining poor-quality gasoline includes such steps as removing biolefine from FCC full-fraction gasoline at lower temp, and modifying (arylisomerizing) and hydrodesulfurizing at higher temp. The hydrodesulfarizing catalyst is the hydrorefining catalyst containing copper oxide and / or zinc oxide.

Owner:CHINA PETROLEUM & CHEM CORP +2

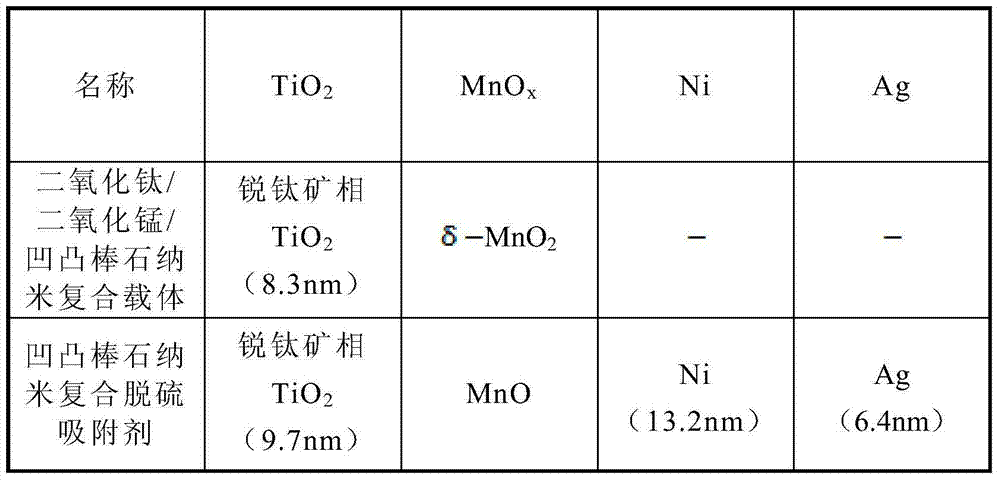

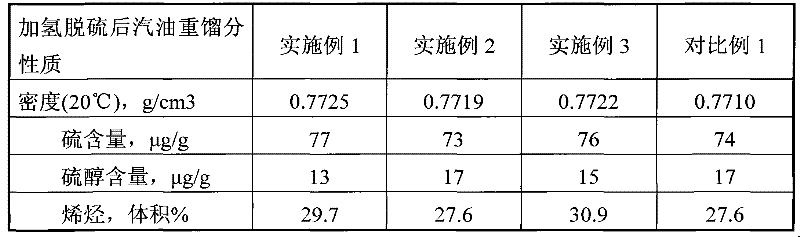

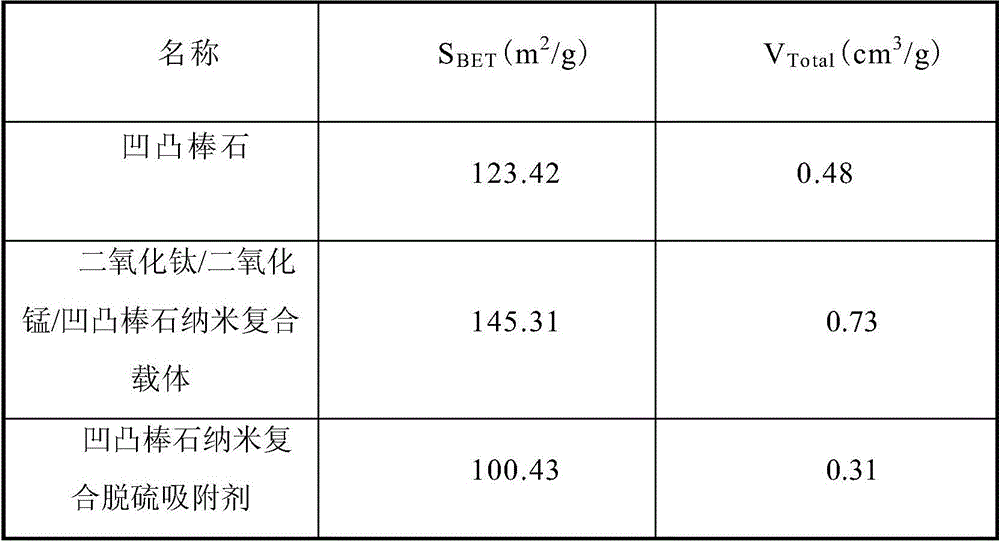

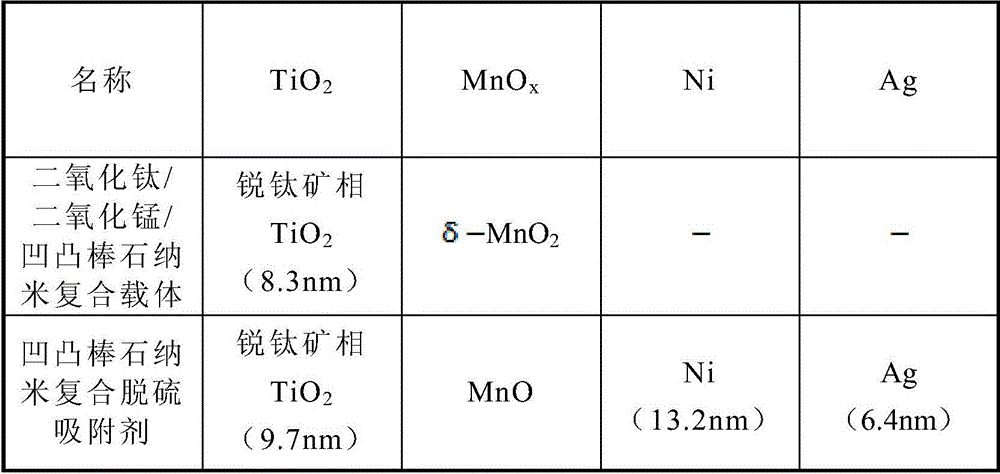

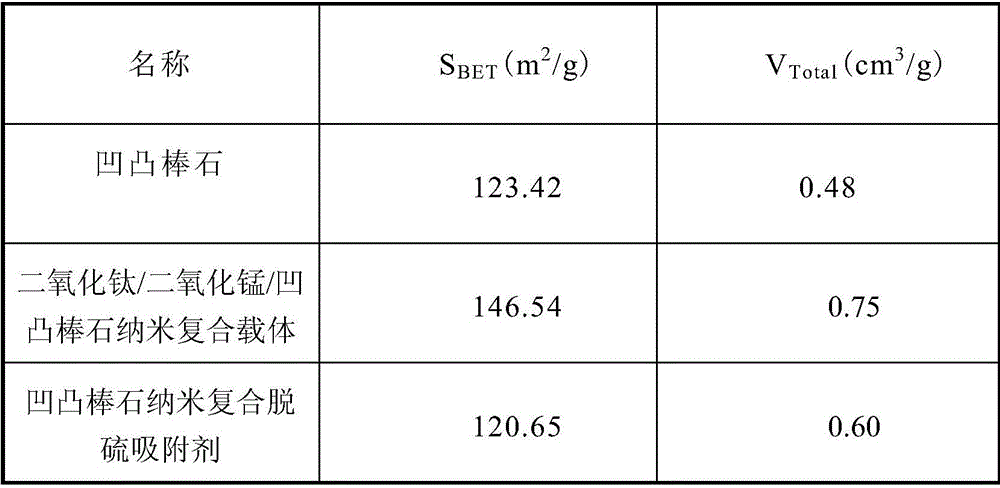

Preparation method of attapulgite-based nano compound desulfurizer

ActiveCN104741071AHigh surface areaHigh pore volumeOther chemical processesHydrocarbon oils refiningSulfurHydrogen atmosphere

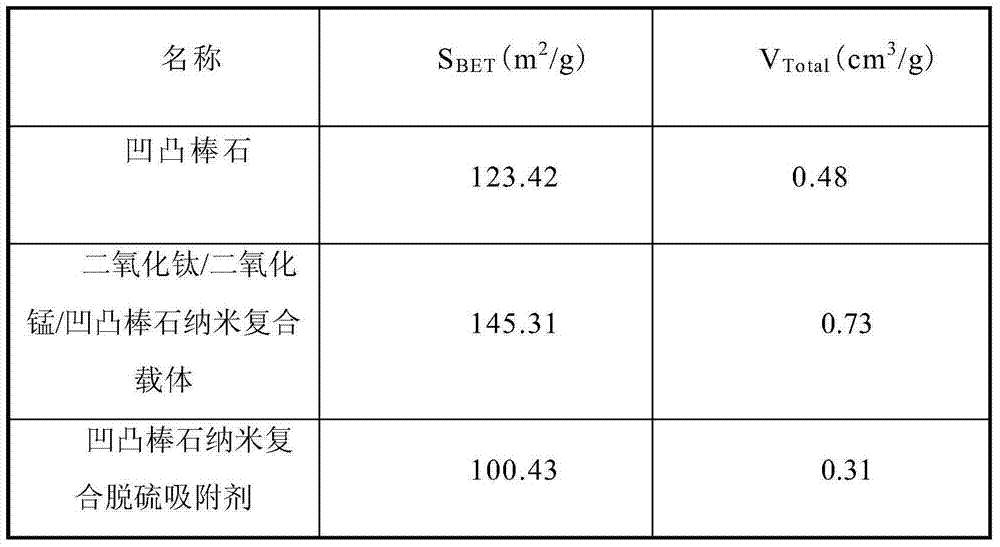

The invention belongs to the field of deep desulfurization of gasoline, relates to a deep adsorption desulfurization technology, and in particular relates to a preparation method of an attapulgite-based nano compound desulfurizer, which is high in selectivity and large in sulfur capacity and has a deep desulfurization effect. The Ni-Ag / TiO2 / MnO / attapulgite compound desulfurizer is prepared by loading nano-grade manganese dioxide and titanium dioxide on the surface of attapulgite to prepare a titanium dioxide / manganese dioxide / attapulgite nano composite carrier, then loading nano nickel oxide and nano silver so as to obtain the precursor of an attapulgite-based nano compound gasoline desulfurizer, and finally, respectively reducing the nickel oxide and the manganese dioxide in the precursor into nano nickel and nano-manganese oxide in a hydrogen atmosphere.

Owner:CHANGZHOU UNIV

Gasoline selective desulfurization catalyst

InactiveCN101844088AReduce saturation rateHigh activityMolecular sieve catalystsHydrocarbon oils refiningAlkaline earth metalHydrodesulfurization

The invention aims to provide a gasoline selective desulfurization catalyst, and particularly relates to an FCC gasoline selective desulfurization catalyst. The catalyst is prepared by mixing a molecular sieve and a binder, forming the mixture to obtain a carrier and loading active metal ingredient and alkaline metal and / or rare-earth metal to the carrier, wherein the molecular sieve in the carrier is SAPO and / or APO molecular sieve; the binder is aluminum oxide or silicon dioxide; the active ingredient is cobalt-molybdenum composite metal and accounts for 6.5 to 20 weight percent of the catalyst, the alkaline metal and / or the rare-earth metal ingredient account(s) for 0.05 to 8.0 weight percent of the catalyst, and the balance is the carrier; and the relative mass ratio of the molecular sieve to the binder in the carrier is (5-9):(1-5). The catalyst has high hydrodesulfurization activity and selectivity and low olefin saturation ratio when gasoline with low sulfur content is produced by hydrodesulfurization of all fractions of catalytic gasoline, particularly heavy fractions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

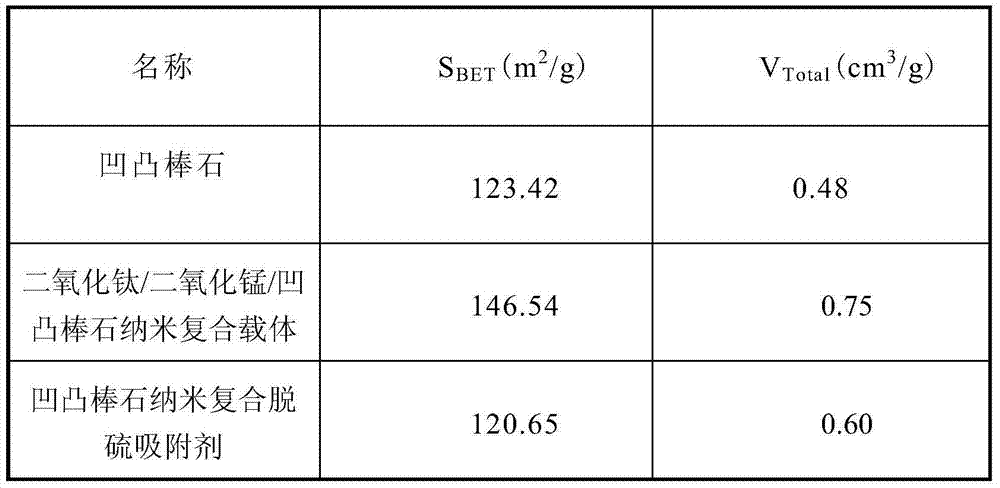

Gasoline hydro-desulfurization method

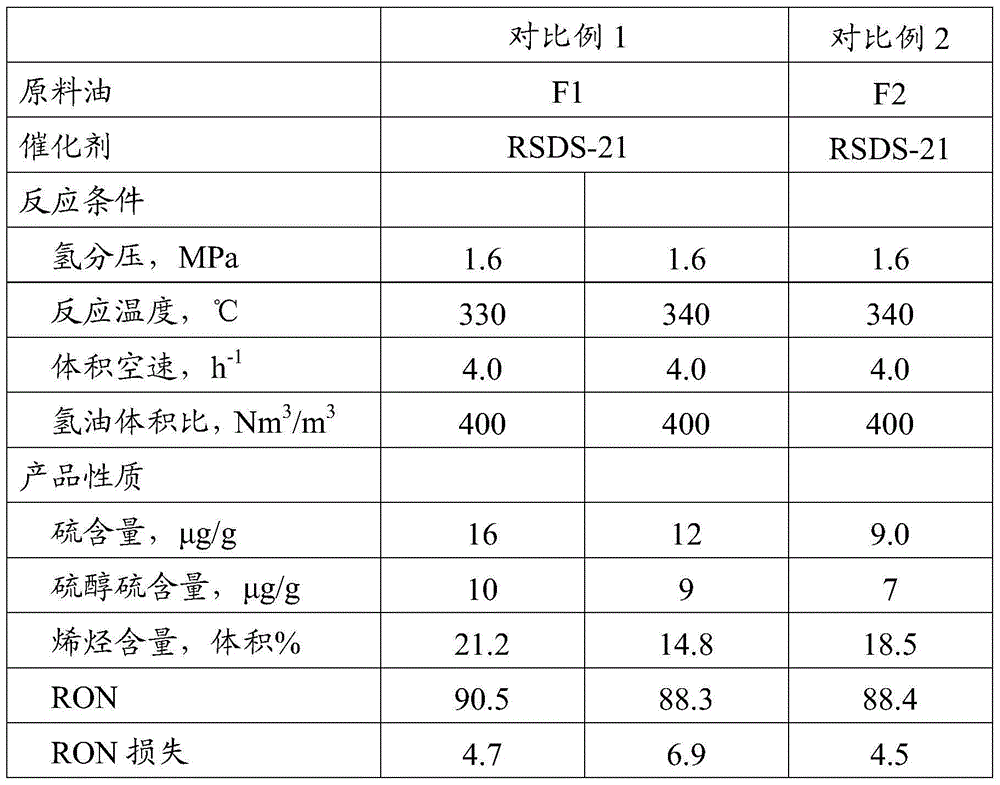

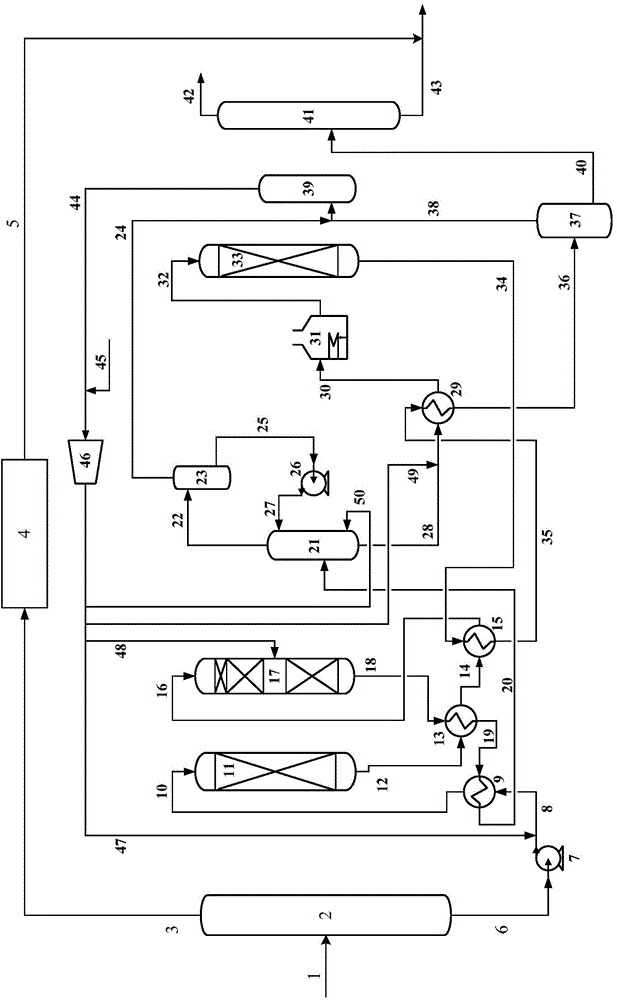

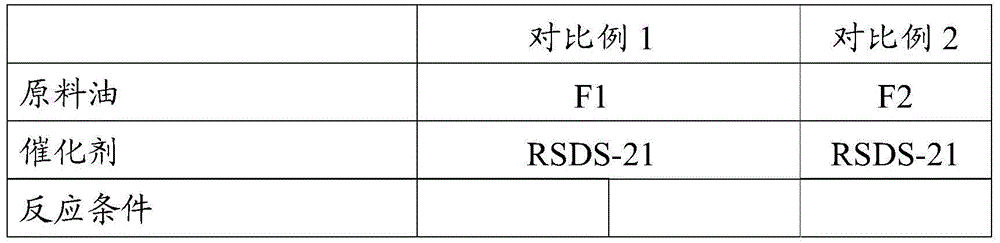

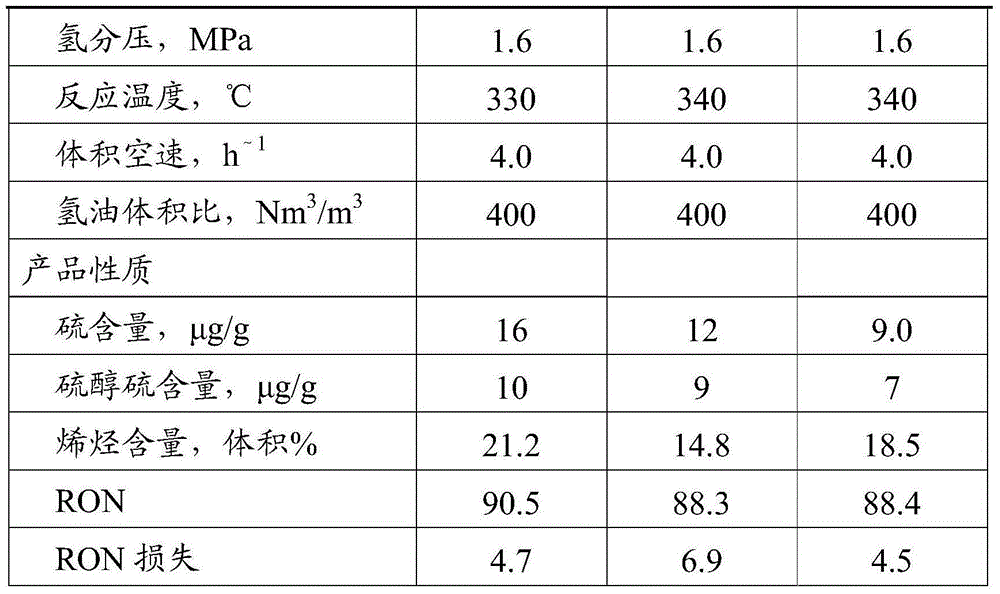

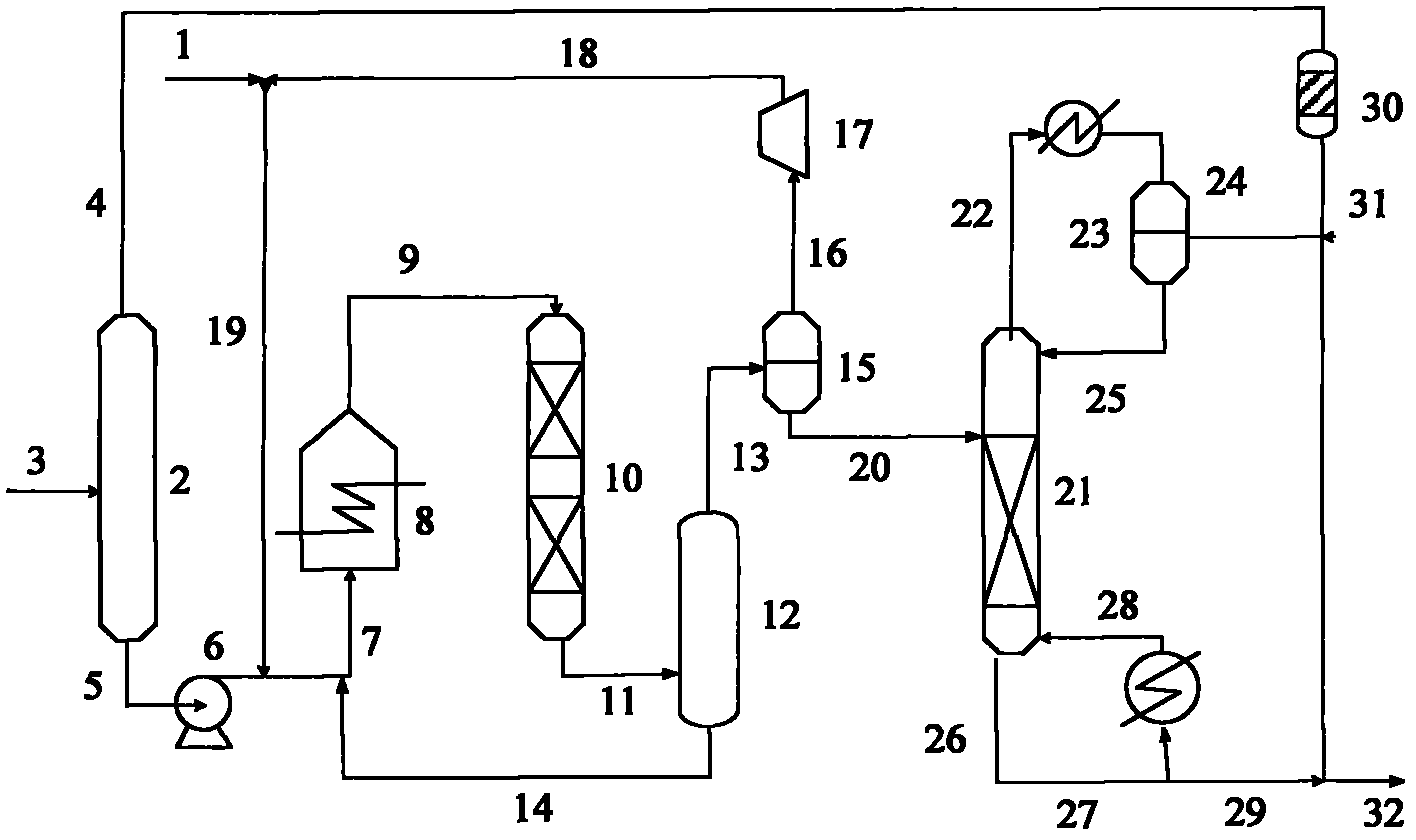

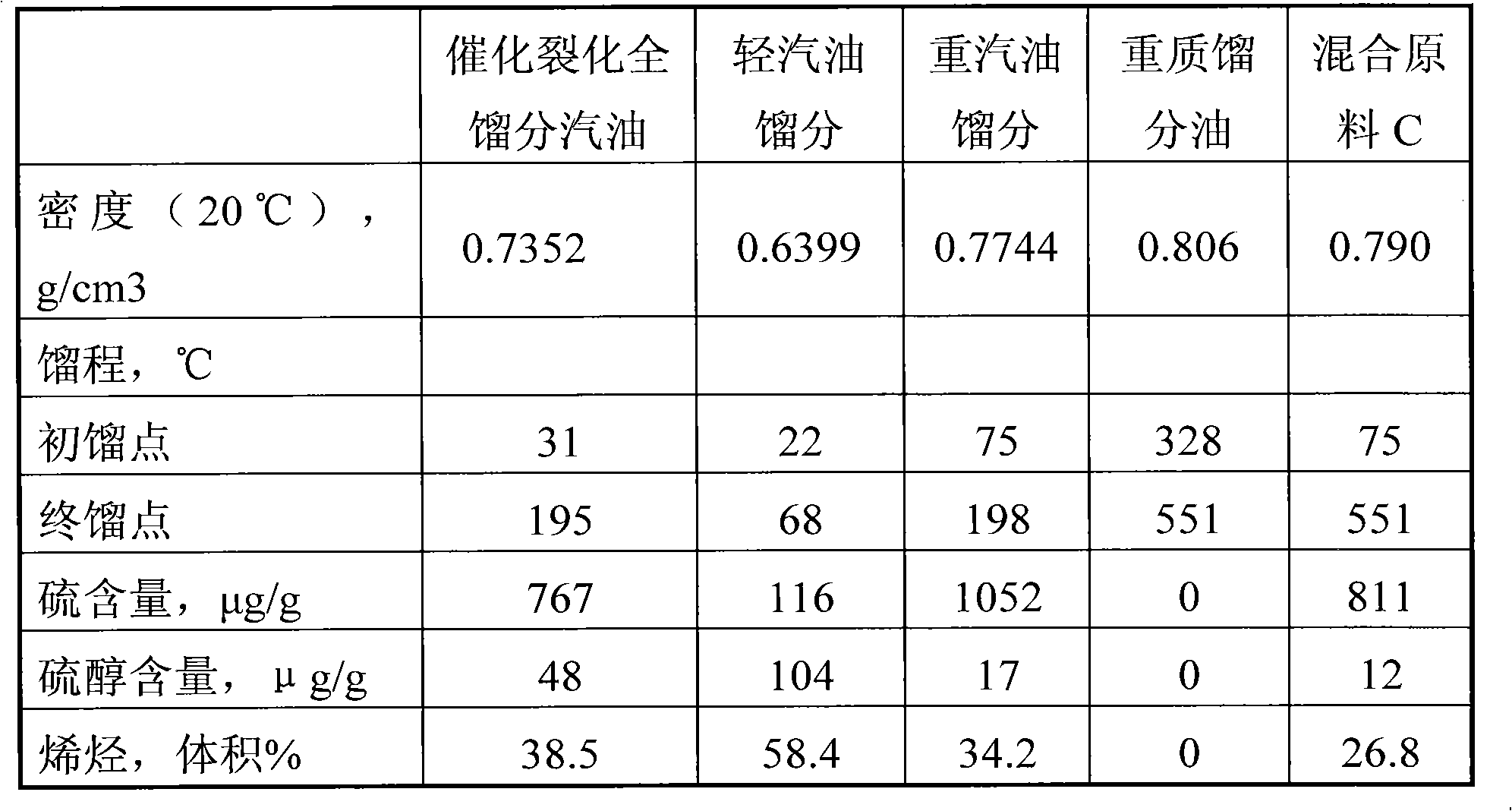

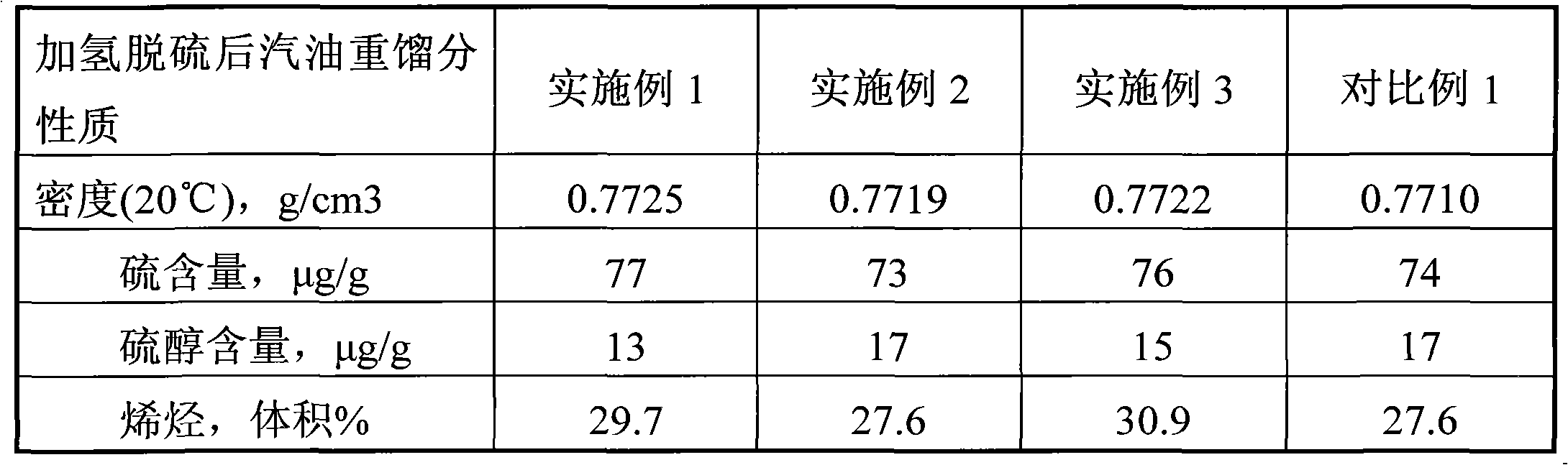

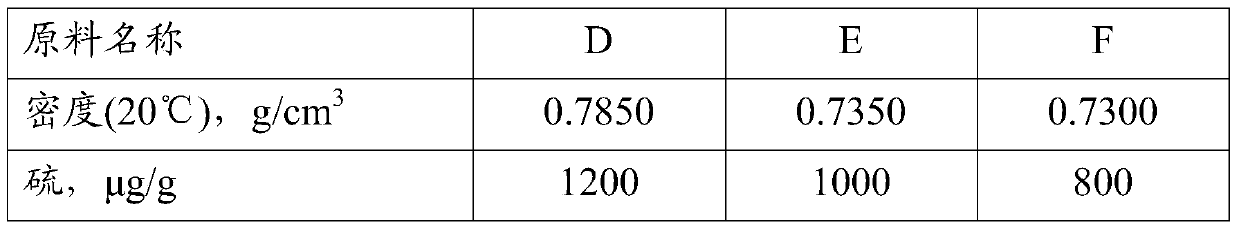

ActiveCN103074104AReduce saturation rateAvoid lostTreatment with hydrotreatment processesHydrodesulfurizationHydrogenation reaction

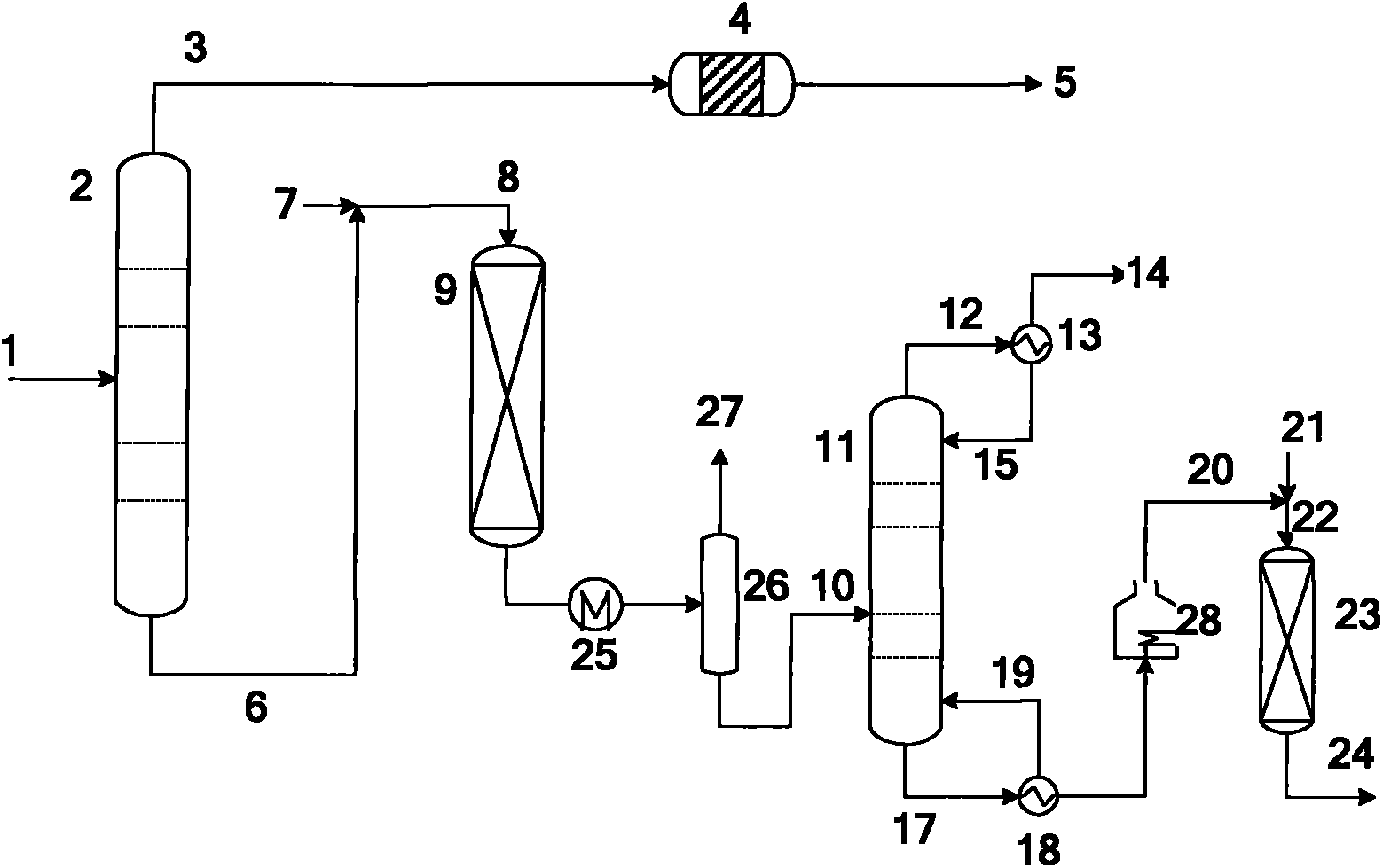

The invention relates to a gasoline hydro-desulfurization method comprising the steps that: (1) a gasoline raw material is fractionated into a light gasoline fraction and a heavy gasoline fraction; mercaptan in the light gasoline fraction is removed; (2) in a first-stage hydrogenation reactor, the heavy gasoline fraction contacts a selective hydro-desulfurization catalyst, and is subjected to a reaction with hydrogen, such that sulfide in the fraction is removed; (3) the hydro-desulfurized heavy gasoline fraction obtained in the step (2) is introduced into an intermediate fractionation tower; H2S-containing hydrogen-rich gas is recovered from the tower top; C6-C7-rich heavy gasoline light components are recovered from the tower top; heavy gasoline heavy components higher than C7 are led out from the bottom of the intermediate fractionation tower; and (4) in a second-stage hydrogenation reactor, the heavy gasoline heavy components from the bottom of the intermediate fractionation tower contact a hydrogenation catalyst, and is subjected to a reaction with H2, such that deep desulfurization is carried out; after desulfurization, the heavy gasoline heavy components are mixed with the mercaptan-removed light gasoline fraction in the step (1) and the C6-C7-rich heavy gasoline light components, such that a desulfurized gasoline product is obtained. With the method provided by the invention, a gasoline product with a sulfur content lower than 20mug / g or even 10mug / g can be obtained. Also, an octane number loss is small. An RON loss is less than 2.0.

Owner:CHINA PETROLEUM & CHEM CORP +1

fcc gasoline selective hydrotreating method

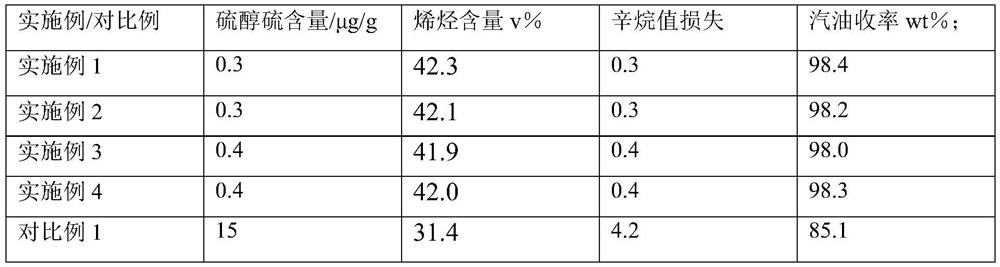

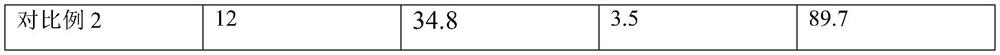

ActiveCN109266387BHigh sweetening activityHigh activityHeterogenous catalyst chemical elementsRefining by selective hydrogenationPtru catalystFixed bed

The invention relates to a selective hydrogenation treatment method for FCC gasoline. A fixed bed reactor is adopted, and a catalyst comprises a silicon oxide-aluminum oxide carrier and metallic active ingredients nickel, molybdenum, zinc and lithium which are loaded on the carrier; the reaction process conditions are as follows: the reaction temperature is 100-230 DEG C, the reaction pressure is1.1-5.5 MPa, the volumetric air speed is 1.2-5.0 h<-1>, and the volume ratio of hydrogen to oil is (7-28) to 1. The method is used for selective hydrogenation of the FCC gasoline to remove mercaptan sulfur and alkadiene.

Owner:林雅娟

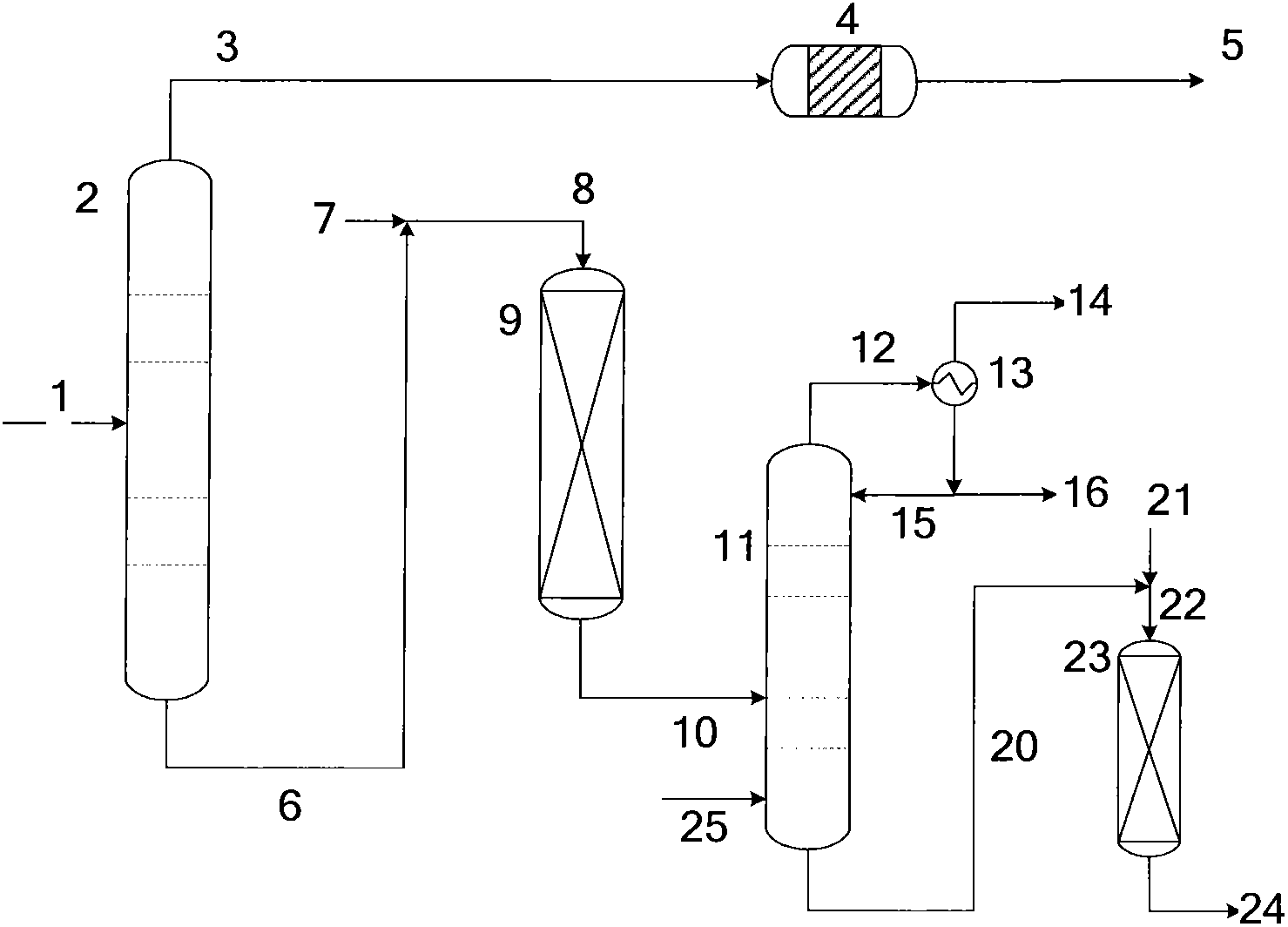

Hydrogenation method for producing ultralow-sulfur gasoline

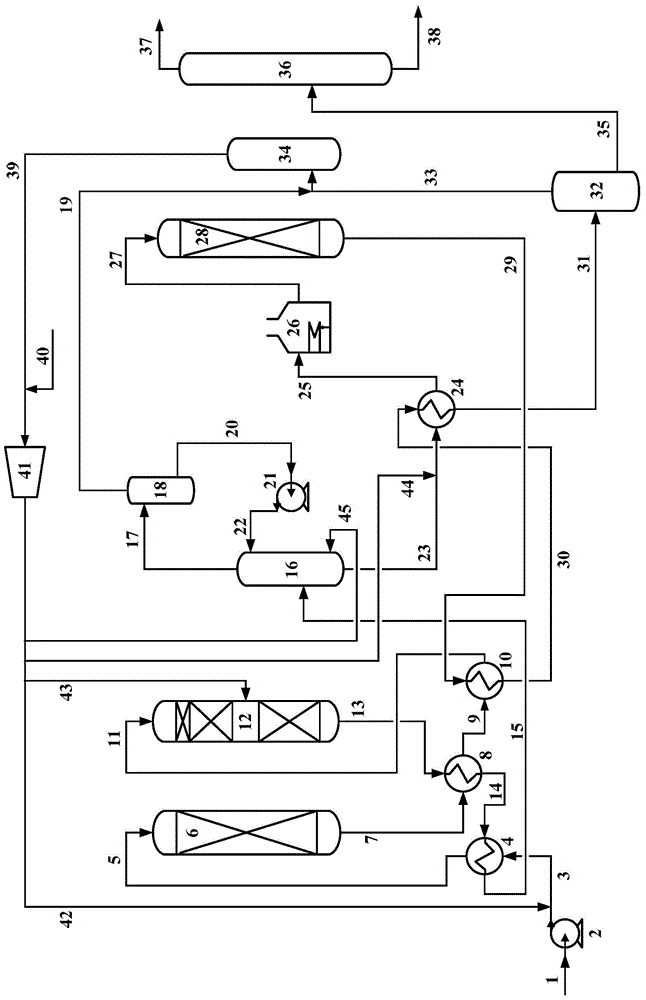

ActiveCN106147844AReduce lossesReduce sulfur contentTreatment with hydrotreatment processesHydrogenGasoline

Provided is a hydrogenation method for producing ultralow-sulfur gasoline. After full-range gasoline and / or a heavy gasoline fraction and hydrogen are mixed, the mixture enters a first hydrogenation reactor to be in contact with a selective hydrogenation diene removal catalyst I for reacting, and effluent of the first hydrogenation reactor enters a second hydrogenation reactor and is in contact with a selective hydrogenation desulfurization catalyst II regulated and controlled selectively for reacting; effluent of the second hydrogenation reactor enters a third hydrogenation reactor after hydrogen sulfide is removed through a flash column and is in contact with a selective hydrogenation desulfurization catalyst III regulated and controlled selectively for reacting, and reaction effluent of the third hydrogenation reactor is separated to obtain an ultralow-sulfur hydrogenation gasoline fraction. High-sulfur high-olefin catalytically cracked gasoline can be treated, the sulphur content of the product is smaller than 10 micrograms / gram, the octane value loss is small, and the gasoline yield reaches 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving selectivity of catalyst

ActiveCN104549556ADecreased Hydrogen SaturationReduced activityCatalyst regeneration/reactivationCatalyst activation/preparationHydrogenation reactionAtmosphere

The invention relates to a method for improving selectivity of a catalyst. A catalyst selectivity regulation and control process is increased between a desulfurization process and a normal production process, and the catalyst selectivity regulation and control process is that activity catalytic raw materials are in contact with the catalyst for 24-96h in an atmosphere of activity catalytic gas under activity catalytic reaction conditions, wherein the activity catalytic gas comprises hydrogen gas and hydrogen sulfide, and based on the whole activity catalytic gas, the volume fraction of the hydrogen gas is not less than 70%, and the volume fraction of hydrogen sulfide is 0.2%-5%; and the normal production process is that gasoline raw material is in contact with the catalyst in the atmosphere which is rich in the hydrogen gas under normal reaction conditions to be in hydrogenation reaction. By adopting the method provided by the invention, the selectivity of the catalyst can be improved. Compared with the prior art, under the situation that the sulfur content in a gasoline product is the same, the olefin saturation rate is lower and the loss in octane number of a product is smaller.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving desulfurization selectivity of catalyst

ActiveCN104560133AReduced activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSaturation rateRaw material

The invention relates to a method for improving desulfurization selectivity of a catalyst. A catalyst selectivity regulation and control process is increased between a desulfurization process and a normal production process, and the catalyst selectivity regulation and control process is that activity catalytic raw materials are in contact with the catalyst for 24-96h in an atmosphere of activity catalytic gas under activity catalytic reaction conditions. By adopting the method provided by the invention, the selectivity of the catalyst can be improved. Compared with the prior art, under the situation that the sulfur content in a gasoline product is the same, the olefin saturation rate is lower and the loss in octane number of a product is smaller.

Owner:CHINA PETROLEUM & CHEM CORP +1

Depth hydrogenation treatment method of faulty gasoline

ActiveCN1294240CReduce saturation rateLow selectivityTreatment with hydrotreatment processesOrganic sulfide compoundHydrodesulfurization

A process for deeply hydrorefining poor-quality gasoline includes such steps as removing biolefine from FCC full-fraction gasoline at lower temp, and modifying (arylisomerizing) and hydrodesulfurizing at higher temp. The hydrodesulfarizing catalyst is the hydrorefining catalyst containing copper oxide and / or zinc oxide.

Owner:CHINA PETROLEUM & CHEM CORP +2

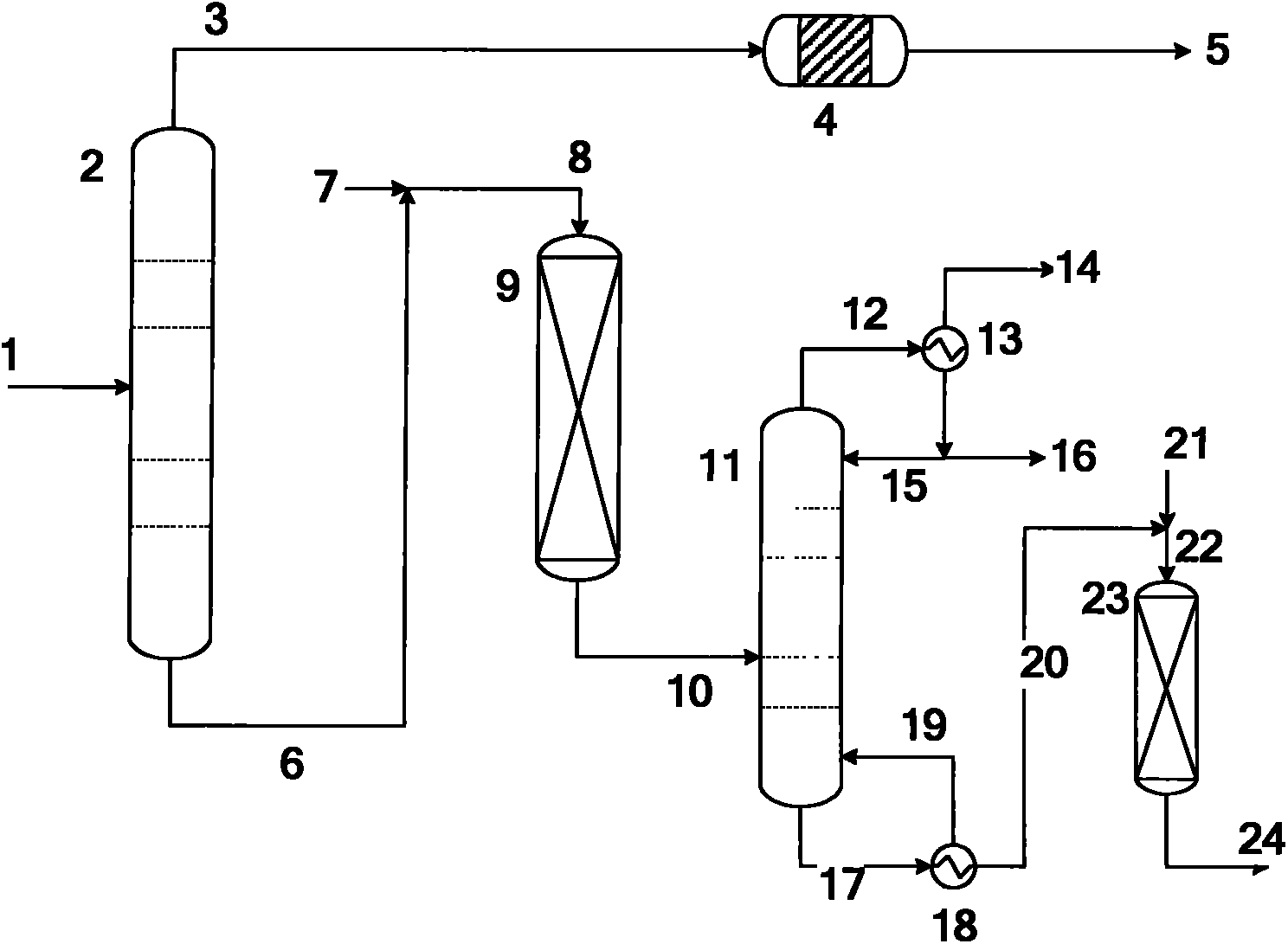

Method for producing ultralow-sulfur gasoline

ActiveCN106147838AReduce lossesReduce sulfur contentTreatment with hydrotreatment processesHydrogenGasoline

The invention discloses a method for producing ultralow-sulfur gasoline. Gasoline raw materials are fractionated into a light gasoline fraction and a heavy gasoline fraction, the light gasoline fraction enters an alkali extraction unit, and a refined light gasoline fraction is obtained. After the heavy gasoline fraction is mixed with hydrogen, the mixture sequentially enters a first hydrogenation reactor and a second hydrogenation reactor and is in contact with a selective hydrogenation diene removal catalyst I and a selective hydrogenation desulfurization catalyst II for reacting, effluent of the second hydrogenation reactor enters a third hydrogenation reactor after hydrogen sulfide is removed through a flash column, the product is in contact with a selective hydrogenation desulfurization catalyst III for reacting, and reaction effluent of the third hydrogenation reactor is separated to obtain a hydrogenation heavy gasoline fraction. The refined light gasoline fraction and the hydrogenation heavy gasoline fraction are mixed to obtain an ultralow-sulfur gasoline product. According to the method, high-sulfur high-olefin catalytically cracked gasoline can be treated, the sulfur content of the product is smaller than 10 micrograms / gram, the octane value loss is small, and the gasoline yield reaches 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing low-sulfur gasoline

ActiveCN102533330AReduce sulfur contentReduce saturation rateTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention discloses a method for producing low-sulfur gasoline. The method comprises the following steps of: (1) in the presence of hydrogen and a catalyst A, performing primary desulfurization reaction on raw gasoline, and separating to obtain hydrogenated and desulfurized gasoline distillate oil; and (2) in the presence of inert gas and a catalyst B, performing secondary desulfurization reaction on the hydrogenated and desulfurized gasoline distillate oil, and separating to obtain the low-sulfur gasoline. Compared with the prior art, the method has the advantages that: the gasoline produced by the method has low sulfur content and low olefin saturation rate, and the method has high desulfurization selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

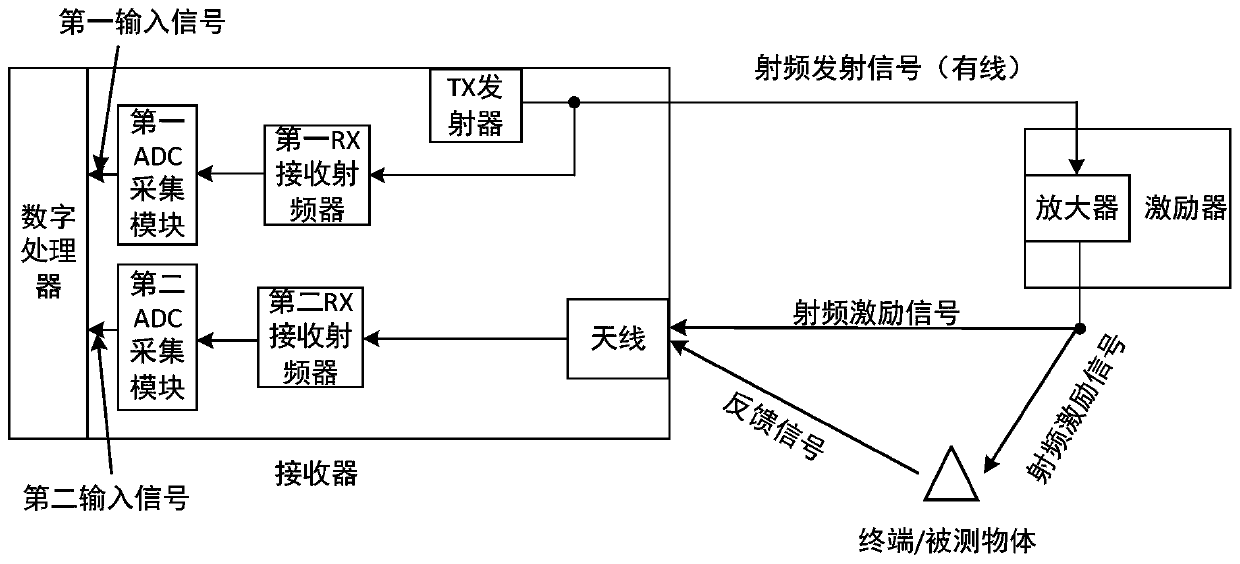

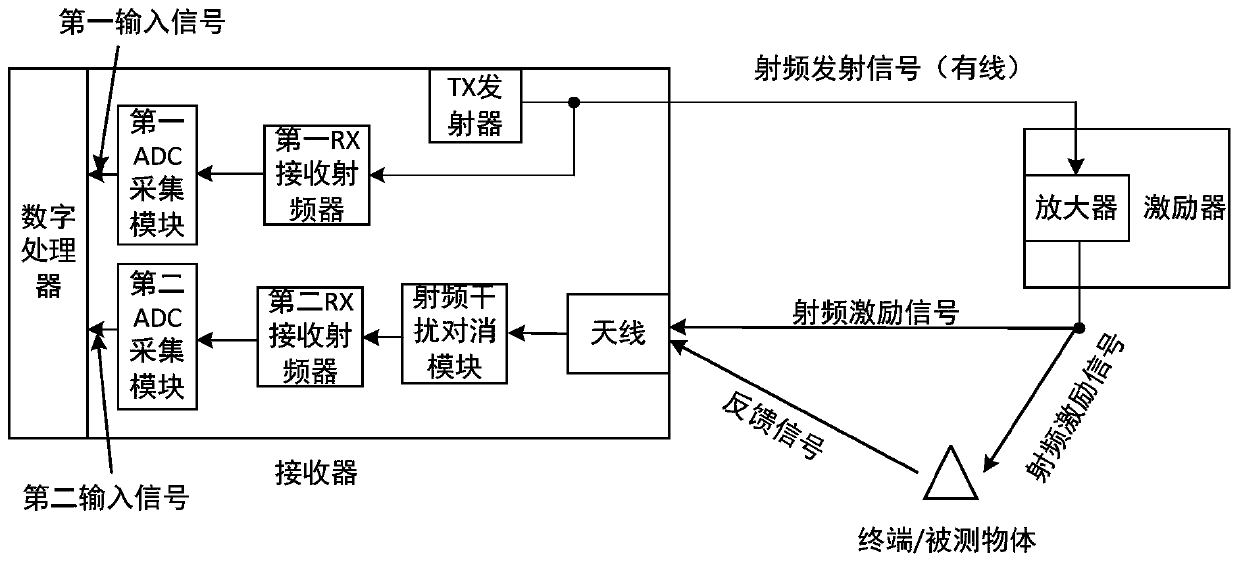

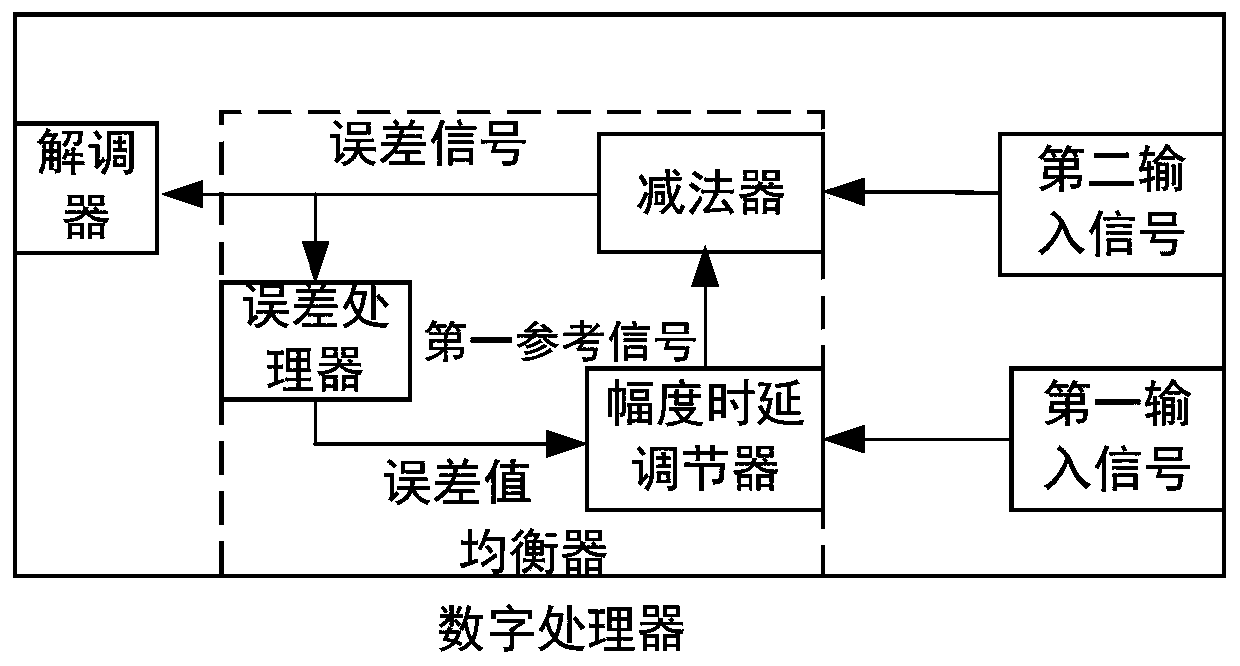

System and method for increasing transceiving separation backscatter communication excitation distance

ActiveCN111092633AReduce or eliminate distractionsImprove the excitation distanceRadio transmissionCommunications systemPhase noise

The invention discloses a system and a method for increasing a transceiving separation backscatter communication excitation distance. In the system and the method, the exciter utilizes a repeater architecture to enable an excitation signal transmitted by the exciter and a carrier signal transmitted by the receiver to have high correlation, so that errors such as corresponding phase noise, frequency spectrum and the like are reserved in the excitation signal received by the receiver. The receiver is divided into two paths to receive a carrier signal transmitted by the receiver, an excitation signal transmitted by the exciter and an attached terminal feedback signal; then, the receiver takes a carrier signal transmitted by the receiver as a reference signal in digital processing; and interference of errors of phase noise, frequency spectrum, spatial multipath and the like of excitation signals transmitted by the exciter on feedback signals of the terminal is reduced or eliminated by means of iterative equalization and the like, so that the excitation distance of the transceiving separation backscatter communication system on the terminal is increased, and an error threshold value canbe flexibly adjusted as required.

Owner:CHENGDU UNIV

Method for removing thiol in FCC gasoline through hydrogenation

ActiveCN109370637AHigh sweetening activityGood choiceMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentFixed bedReaction temperature

The invention relates to a method for removing thiol in FCC gasoline through hydrogenation. A fixed bed reactor is adopted; a catalyst contains a silica-alumina supporter and metal active components including nickel, molybdenum, zinc and strontium supported on the supporter and particularly contains the following components in percentage by weight: 2wt%-15wt% of nickel oxide, 2wt%-18wt% of molybdenum oxide, 0.1wt%-5wt% of zinc oxide, 0.1wt%-2.0wt% of strontium oxide and 65wt%-85wt% of the silica-alumina supporter; and the reaction process conditions are as follows: the reaction temperature is110-240 DEG C, the reaction pressure is 1.1MPa-5.5MPa, the volume velocity is 1.2h<-1>-5.5h<-1>, and the hydrogen-oil volume rate is (7-25) to 1. The catalyst has high thiol removal activity and diolefin hydrogenation selectivity and strong adaptability to different raw materials.

Owner:博兴兴业精细化工产业发展有限公司

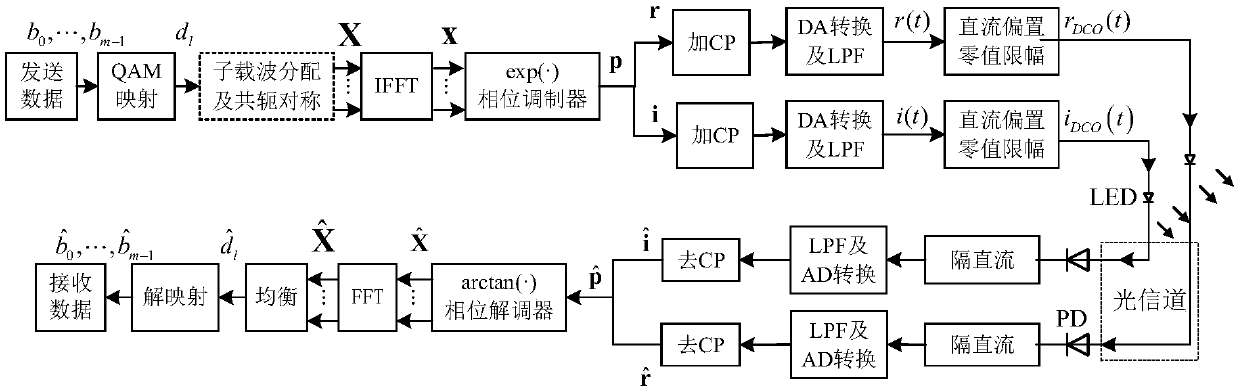

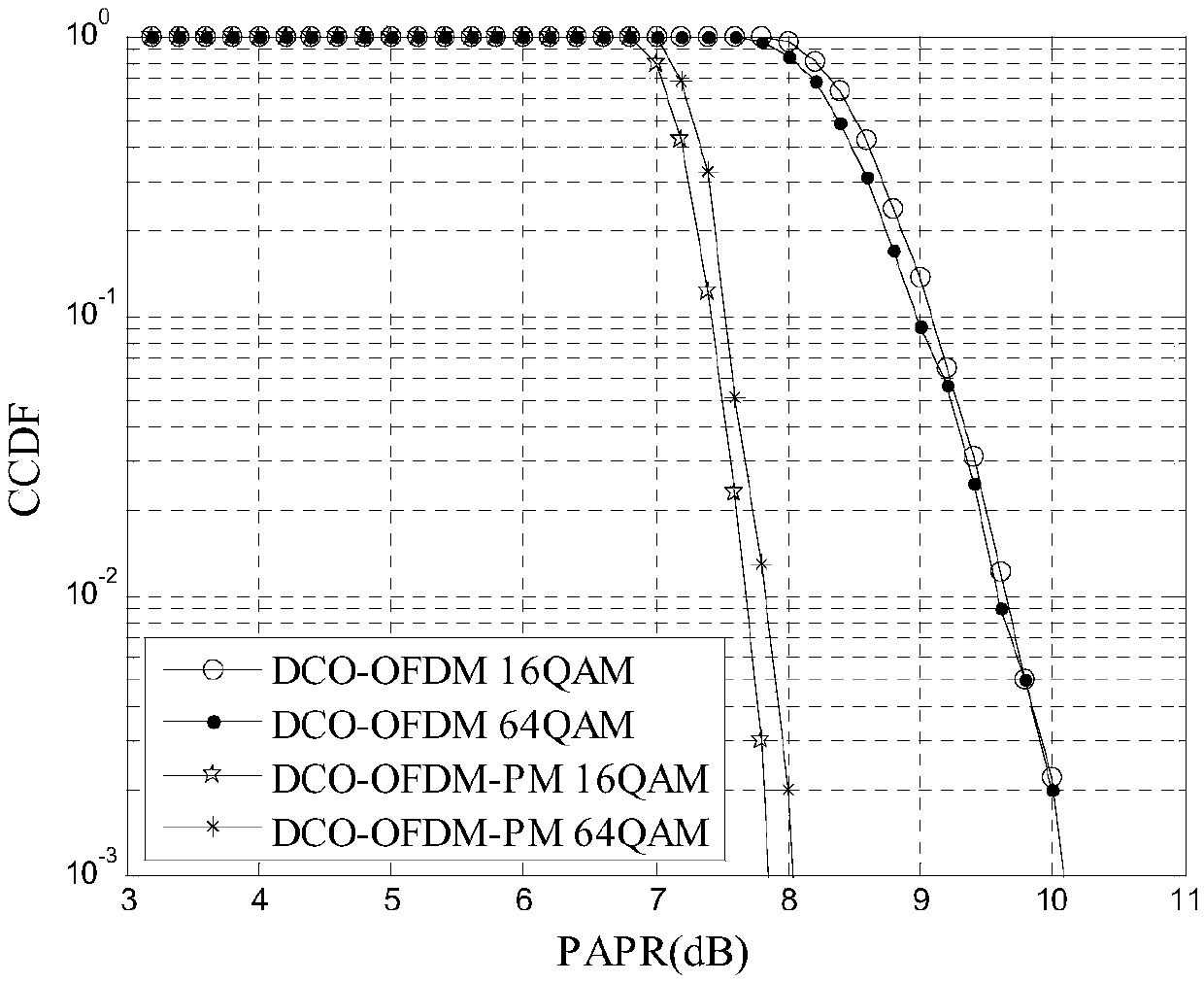

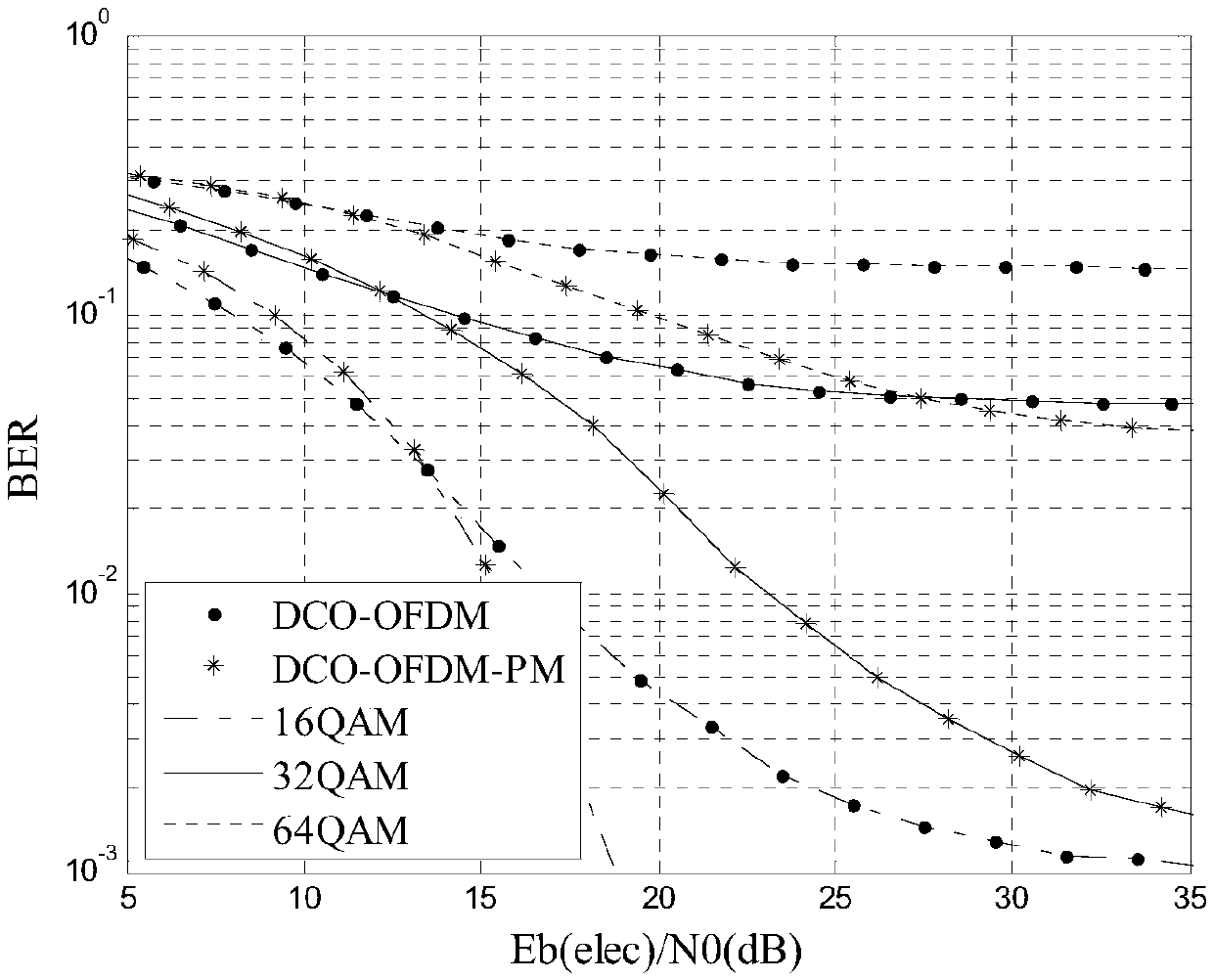

DCO-OFDM modulation-demodulation method and device added with phase modulation

ActiveCN108809433AImprove BER performancePrevent clipping effectClose-range type systemsMulti-frequency code systemsLow-pass filterCyclic prefix

The invention discloses a DCO-OFDM modulation-demodulation method and device added with phase modulation, and a method and system including modulation and demodulation. The DCO-OFDM modulation-demodulation method comprises the following steps: at a sending end, producing time domain data x by performing IFFT processing, and obtaining a sequence by processing the time domain data x by adopting a phase modulator; respectively adding cyclic prefix on each of a real number part r and a virtual number part I of the sequence p, and producing time domain analog signals r(t) and i(t) through a digital-to-analog converter DAC and a low-pass filter; adding DC bias on the r(t) and i(t), enabling the amplitude limiting as zero if the obtained signal still has negative value, thereby producing rDCO(t)and iDCO(t); inputting the signals rDCO(t) and iDCO(t) into two optical modulator LEDs, converting electric signals into optical signals, and enabling the optical signals to achieve a receiver throughan optical channel; at a receiving end, performing DC blocking processing on two optical signals after the PD; sampling two analog signals through the low-pass filter and an ADC, and removing the cyclic prefixes to obtain the sequences as shown in description, wherein the formula as shown in description is used as the real part, and the formula as shown in description is used as a virtual part, thereby obtaining the sequence as shown in description; and obtaining the time domain data as shown in description through one phase demodulator, wherein the processing on the time domain data as showin description is similar to the traditional DCO-OFDM scheme. The DCO-OFDM modulation-demodulation method disclosed by the invention is lower in signal-to-noise ratio and higher in BER performance.

Owner:上海瀚芯实业发展合伙企业(有限合伙)

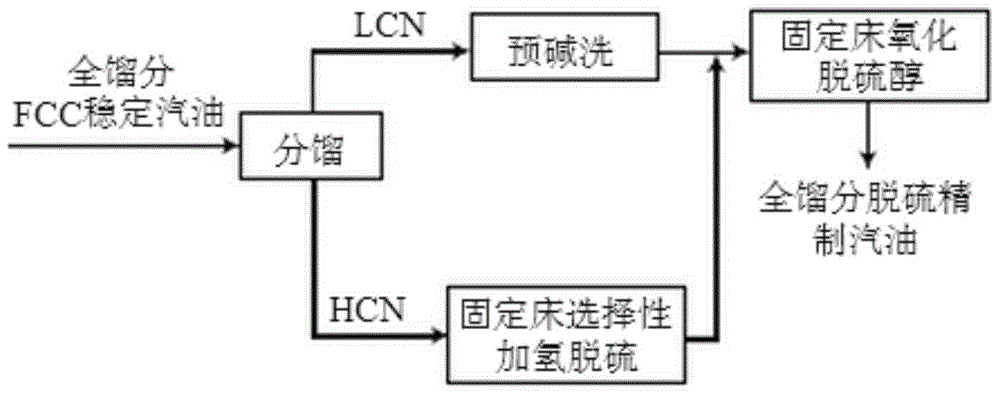

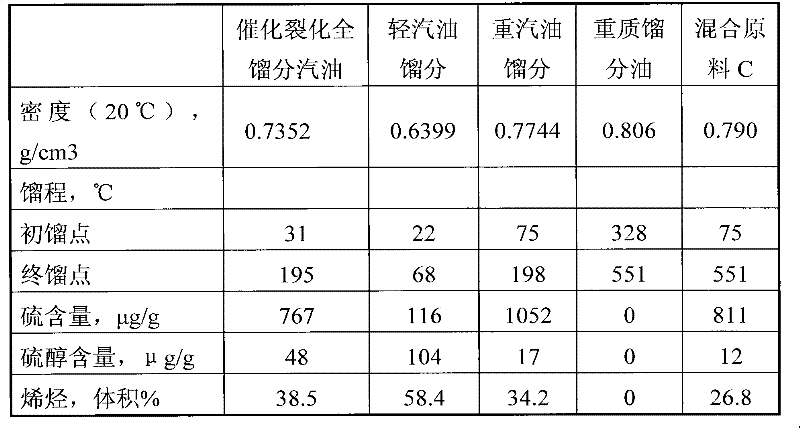

Catalytically cracked gasoline desulphurization method

InactiveCN105670687AReduce saturation rateReduce the depth of hydrodesulfurizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationGasoline

The invention discloses a catalytically cracked gasoline desulphurization method. The method comprises 1, according to raw material properties and product targets, selecting an appropriate cut point and carrying out fraction cutting on whole-fraction catalytically cracked stable gasoline from a catalytically cracking device, 2, removing sulfides of heavy fraction gasoline HCN in a fixed bed hydrodesulfurization reactor, and 3, carrying out caustic pre-washing on the light fraction gasoline LCN through a mercaptan removal unit, blending the light fraction gasoline LCN and the heavy fraction subjected to hydrogenation, and carrying out fixed-bed oxidation mercaptan removal to obtain refined catalytically cracked gasoline. The method greatly reduces a gasoline olefin saturation ratio, greatly reduces catalytically cracked gasoline heavy fraction hydrodesulfurization depth and reduces alkene hydrogenation saturation.

Owner:SHANDONG LIANXING ENERGY GRP CO LTD

Method for producing low-sulfur gasoline

ActiveCN102533325AReduce sulfur contentReduce saturation rateTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention discloses a method for producing low-sulfur gasoline. The method comprises the following steps of: (1) cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction, wherein the cutting point of the light gasoline fraction and the heavy gasoline fraction is 50-100DEG C; (2) performing alkali washing on the light gasoline fraction for desulfurization to obtain the desulfurized light gasoline fraction; (3) in the presence of hydrogen and a catalyst A, performing primary desulfurization reaction on the heavy gasoline fraction, and separating to obtain the hydrogenated and desulfurized heavy gasoline fraction; (4) in the presence of inert gas and a catalyst B, preforming secondary desulfurization reaction on the hydrogenated and desulfurized heavy gasoline fraction, and separating to obtain low-sulfur heavy oil fraction; and (5) mixing the light gasoline fraction obtained in the step (2) and the heavy gasoline fraction obtained in the step (4) to obtain a gasoline product. Compared with the prior art, the method has the advantages that: the gasoline produced by the method has low sulfur content and low olefin saturation rate and the method has high desulfurization selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of attapulgite-based nanocomposite desulfurizer

ActiveCN104741071BHigh surface areaHigh pore volumeOther chemical processesHydrocarbon oils refiningHydrogen atmosphereSulfur

The invention belongs to the field of deep desulfurization of gasoline, relates to a deep adsorption desulfurization technology, and in particular relates to a preparation method of an attapulgite-based nano compound desulfurizer, which is high in selectivity and large in sulfur capacity and has a deep desulfurization effect. The Ni-Ag / TiO2 / MnO / attapulgite compound desulfurizer is prepared by loading nano-grade manganese dioxide and titanium dioxide on the surface of attapulgite to prepare a titanium dioxide / manganese dioxide / attapulgite nano composite carrier, then loading nano nickel oxide and nano silver so as to obtain the precursor of an attapulgite-based nano compound gasoline desulfurizer, and finally, respectively reducing the nickel oxide and the manganese dioxide in the precursor into nano nickel and nano-manganese oxide in a hydrogen atmosphere.

Owner:CHANGZHOU UNIV

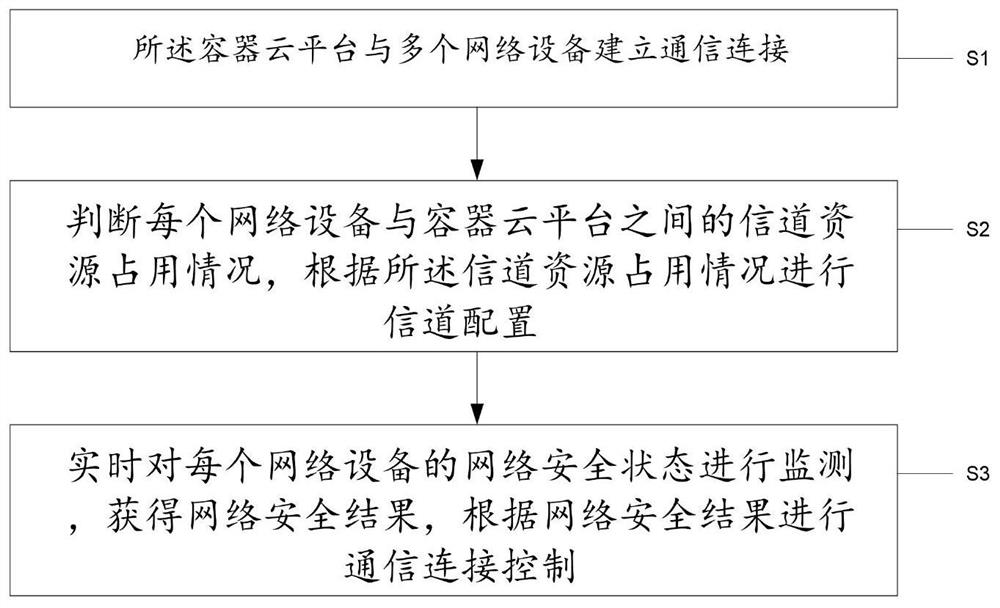

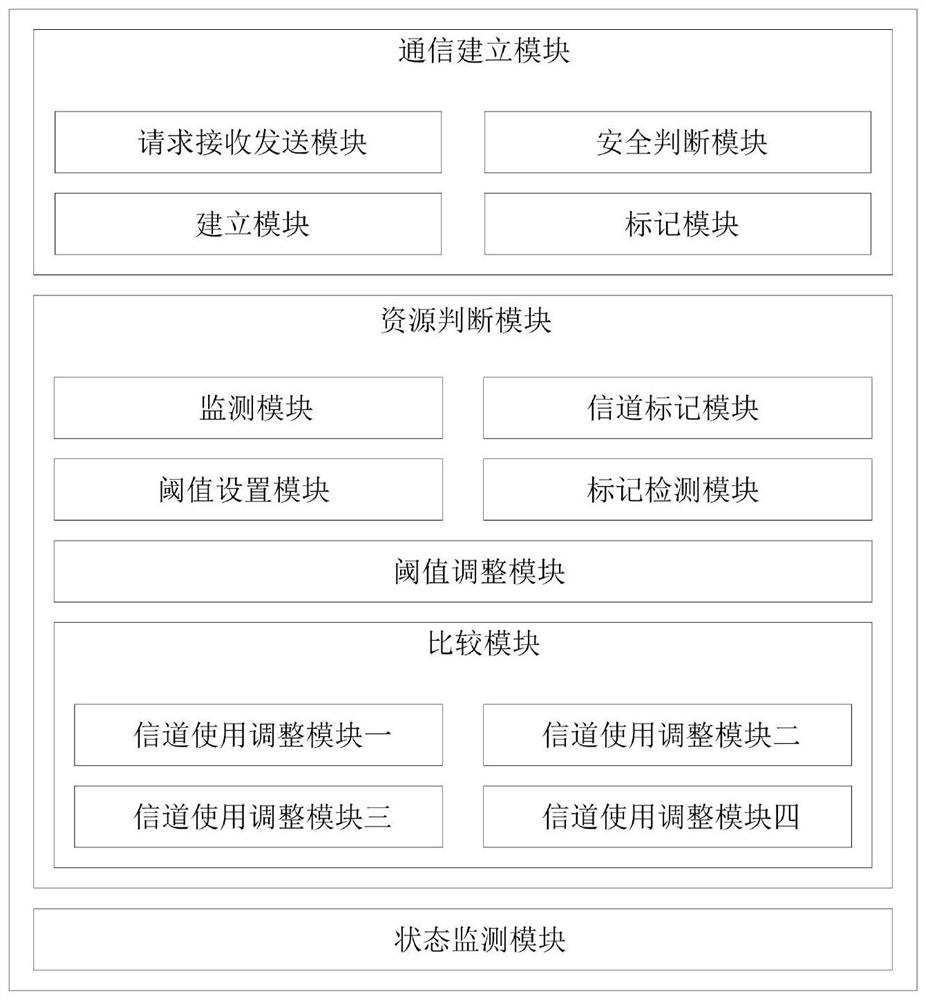

Network management method and system based on container cloud platform

ActiveCN112054862AReduce saturation rateAvoid congestionTransmission monitoringData switching networksEngineeringNetwork management

The invention provides a network management method and system based on a container cloud platform. The method comprises the steps of establishing communication connection with a plurality of network devices by the container cloud platform; judging a channel resource occupation condition between each network device and the container cloud platform, and performing channel configuration according tothe channel resource occupation condition; and monitoring the network security state of each network device in real time to obtain a network security result, and performing communication connection control according to the network security result. The system comprises modules corresponding to the steps of the scheme.

Owner:深圳市中盛瑞达科技有限公司

Alumina support, preparation method therefor, catalyst, preparation method therefor and method for lowering content of dialkene in hydrocarbon oil

ActiveCN110496611ARapid Diffusion-Adsorption-Reaction-DesorptionLarge hole volumeCatalyst carriersAluminium compoundsHydrogenation reactionGasoline

The invention discloses an alumina support and a preparation method therefor. The alumina support has a pore volume of 0.7mL / g to 1.2mL / g, an average pore size of 100 angstroms to 130 angstroms and aprobable pore size of 60 angstroms to 90 angstroms. The invention further discloses an alumina support employing selective hydrogenation catalyst, a preparation method therefor and a method for lowering content of dialkene in hydrocarbon oil by employing the catalyst. The alumina support disclosed by the invention is large in pore volume and centralized in pore size distribution; and when the hydrogenation catalyst prepared by taking the alumina support as a support serves as a catalyst of a selective hydrogenation reaction or lowering the content of the dialkene in the hydrocarbon oil, the content of the dialkene in the hydrocarbon oil can be effectively lowered, and a relatively low mono-alkene saturation rate is obtained. A product obtained by taking catalytic-cracked gasoline treated by adopting the selective hydrogenation catalyst disclosed by the invention as a feed of an S-Zorb device has the advantages that a dry point is basically unchanged compared with that of a catalytic cracking gasoline raw material, a coking trend of the S-Zorb device is inhibited, and the carbon deposit of the catalyst is obviously reduced.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD +2

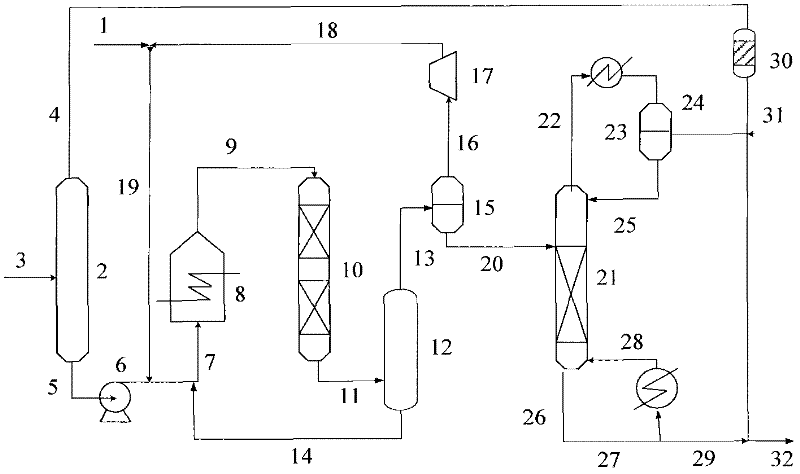

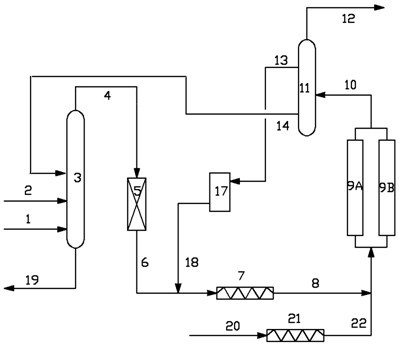

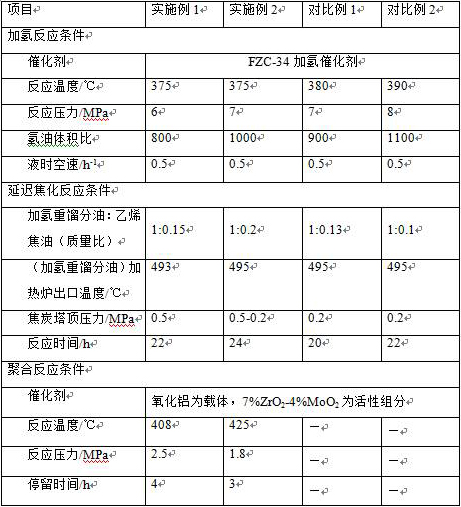

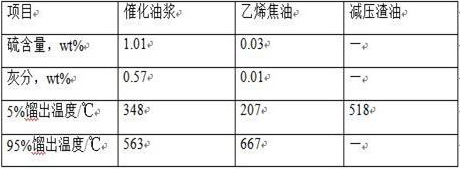

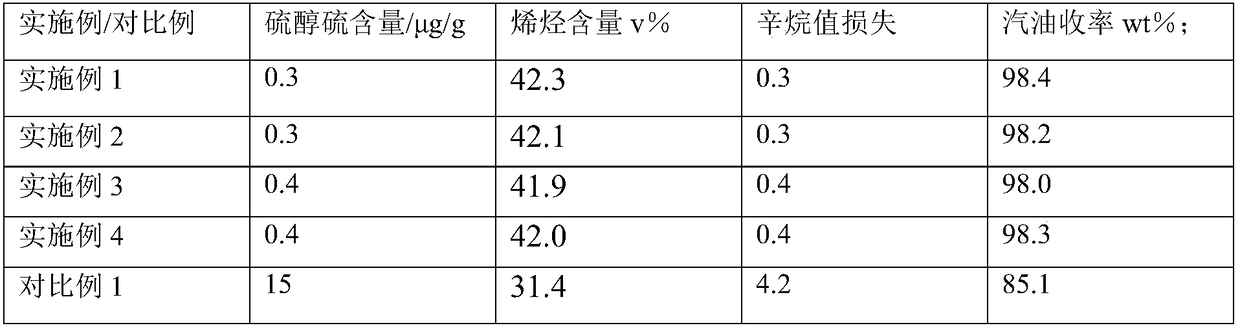

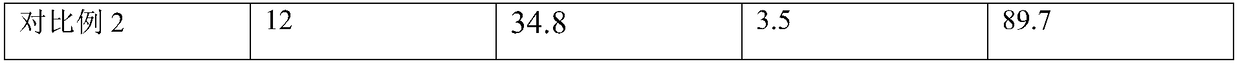

Method and system for preparing petroleum coke from catalytic oil slurry and ethylene tar

The invention discloses a method and system for preparing petroleum coke from catalytic oil slurry and ethylene tar. The method includes the following contents: the catalytic oil slurry is desolidified to obtain extraction oil and tail oil, and the extraction oil is subjected to hydrogenation treatment , the reaction product is separated and the hydrogenated heavy distillate oil and ethylene tar are respectively heated and then sent to the delayed coking unit for reaction. When the reaction time reaches 1% to 50% of the entire reaction cycle, the ethylene tar feed is stopped and the coking reaction product Gas, light oil and heavy oil are obtained after separation; the light oil is polymerized, mixed with hydrogenated heavy distillate oil, heated and then sent to the delayed coking unit for reaction, and the heavy oil is recycled back to be mixed with catalytic oil slurry for desolidification treatment. The method can produce low-sulfur petroleum coke in a maximum amount by organically combining the two raw materials, and the production device can run stably for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective hydrogenation treatment method for FCC gasoline

ActiveCN109266387AHigh sweetening activityHigh activityHeterogenous catalyst chemical elementsRefining by selective hydrogenationFixed bedReaction temperature

The invention relates to a selective hydrogenation treatment method for FCC gasoline. A fixed bed reactor is adopted, and a catalyst comprises a silicon oxide-aluminum oxide carrier and metallic active ingredients nickel, molybdenum, zinc and lithium which are loaded on the carrier; the reaction process conditions are as follows: the reaction temperature is 100-230 DEG C, the reaction pressure is1.1-5.5 MPa, the volumetric air speed is 1.2-5.0 h<-1>, and the volume ratio of hydrogen to oil is (7-28) to 1. The method is used for selective hydrogenation of the FCC gasoline to remove mercaptan sulfur and alkadiene.

Owner:林雅娟

Method for producing low-sulfur gasoline

ActiveCN102533325BReduce sulfur contentReduce saturation rateTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention discloses a method for producing low-sulfur gasoline. The method comprises the following steps of: (1) cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction, wherein the cutting point of the light gasoline fraction and the heavy gasoline fraction is 50-100DEG C; (2) performing alkali washing on the light gasoline fraction for desulfurization to obtain the desulfurized light gasoline fraction; (3) in the presence of hydrogen and a catalyst A, performing primary desulfurization reaction on the heavy gasoline fraction, and separating to obtain the hydrogenated and desulfurized heavy gasoline fraction; (4) in the presence of inert gas and a catalyst B, preforming secondary desulfurization reaction on the hydrogenated and desulfurized heavy gasoline fraction, and separating to obtain low-sulfur heavy oil fraction; and (5) mixing the light gasoline fraction obtained in the step (2) and the heavy gasoline fraction obtained in the step (4) to obtain a gasoline product. Compared with the prior art, the method has the advantages that: the gasoline produced by the method has low sulfur content and low olefin saturation rate and the method has high desulfurization selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for improving selectivity of selective hydrodesulfurization catalyst

ActiveCN107043638BHigh selectivityReduce saturation rateHydrocarbon oils refiningHydrocarbon oils treatmentHydrodesulfurizationSulfidation

A method of improving selectivity of a selective hydrodesulfurization catalyst is provided. A catalyst selectivity regulating step is provided additionally between a sulfidation step and a normal production step. The catalyst selectivity regulating step is a step in which a regulating raw material and the selective hydrodesulfurization catalyst are brought into contact for 24-70 h in a regulating gas atmosphere under regulating reaction conditions. By the method, selectivity of the selective hydrodesulfurization catalyst can be improved. Compared with the prior art, in a situation that the sulfur contents of gasoline products are same, the olefin saturation factor of a product prepared by the method is lower and the octane number loss of a product prepared by the method is lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

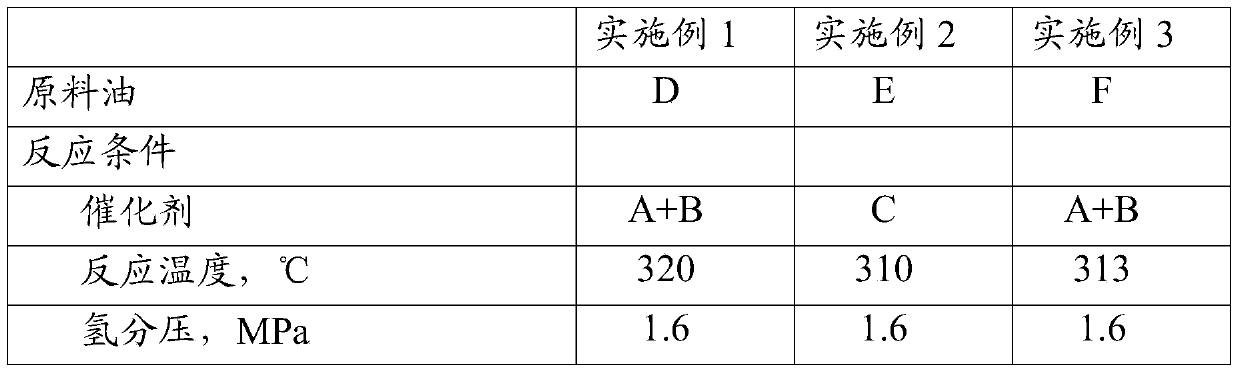

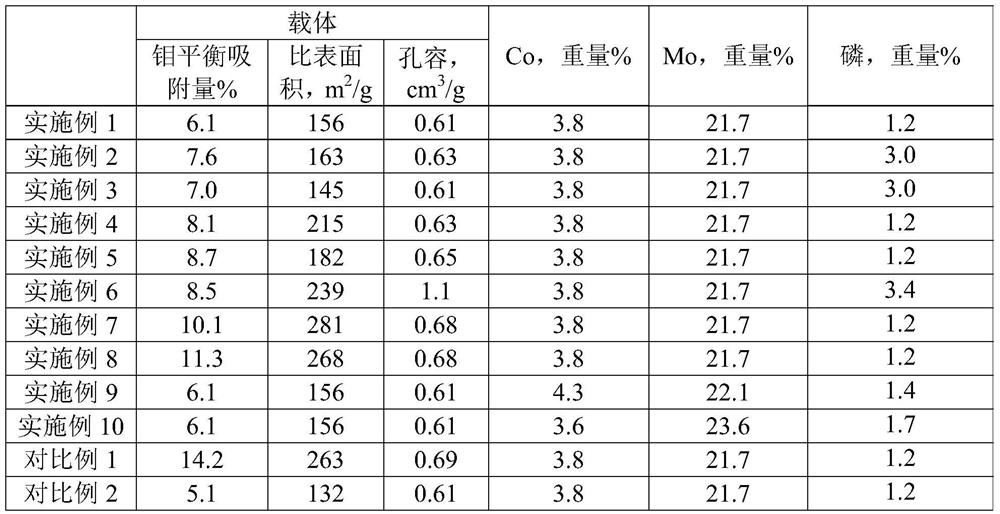

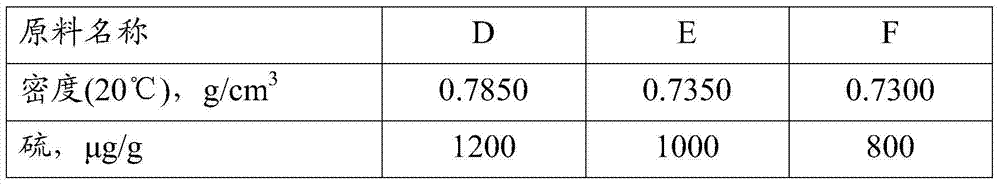

Gasoline selective hydrodesulfurization catalyst, preparation method and application thereof, and gasoline selective hydrodesulfurization method

ActiveCN112742431AHigh activityHigh selectivityPhysical/chemical process catalystsRefining to eliminate hetero atomsPtru catalystHydrodesulfurization

The invention relates to the field of catalysts, and particularly discloses a gasoline selective hydrodesulfurization catalyst, a preparation method and application thereof, and a gasoline selective hydrodesulfurization method. The catalyst comprises a carrier as well as an active component A, an active component B and a phosphorus element which are loaded on the carrier, the active component A is selected from at least one of VIII group metal elements, and the active component B is selected from at least one of VIB group metal elements; and the molybdenum equilibrium adsorption capacity of the carrier is 6-12% in terms of MoO3, the specific surface area is 100-400 m < 2 > / g, and the pore volume is 0.5-1.5 cm < 3 > / g. When the hydrodesulfurization catalyst provided by the invention is used for a gasoline selective hydrodesulfurization reaction, the sulfur content in gasoline can be remarkably reduced, and the hydrodesulfurization catalyst has a relatively high hydrodesulfurization rate and a relatively low olefin hydrogenation saturation rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method of improving selectivity of a selective hydrodesulfurization catalyst

ActiveCN107043638AHigh selectivityReduce saturation rateHydrocarbon oils refiningHydrocarbon oils treatmentHydrodesulfurizationSulfidation

A method of improving selectivity of a selective hydrodesulfurization catalyst is provided. A catalyst selectivity regulating step is provided additionally between a sulfidation step and a normal production step. The catalyst selectivity regulating step is a step in which a regulating raw material and the selective hydrodesulfurization catalyst are brought into contact for 24-70 h in a regulating gas atmosphere under regulating reaction conditions. By the method, selectivity of the selective hydrodesulfurization catalyst can be improved. Compared with the prior art, in a situation that the sulfur contents of gasoline products are same, the olefin saturation factor of a product prepared by the method is lower and the octane number loss of a product prepared by the method is lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of catalyst for gasoline desulfurization and preparation method thereof

InactiveCN109364966BHigh sweetening activityGood choicePhysical/chemical process catalystsRefining by selective hydrogenationPtru catalystGasoline

The invention relates to a catalyst for sweetening gasoline. The catalyst includes a silicon oxide-alumina carrier and metal active components nickel, molybdenum and iron and phosphorus as an auxiliary agent loaded on the carrier. The content of nickel oxide is based on the weight of the catalyst. The content of molybdenum oxide is 2-18wt%, the content of iron oxide is 0.1-5.5wt%, the content of auxiliary phosphorus oxide is 0.01%-2.2wt%; the content of silica-alumina carrier is 65 -85 wt%. The catalyst has the characteristics of high sweetening activity, high selectivity for diolefin hydrogenation, and low octane loss.

Owner:内蒙古致兴能源高科技有限公司

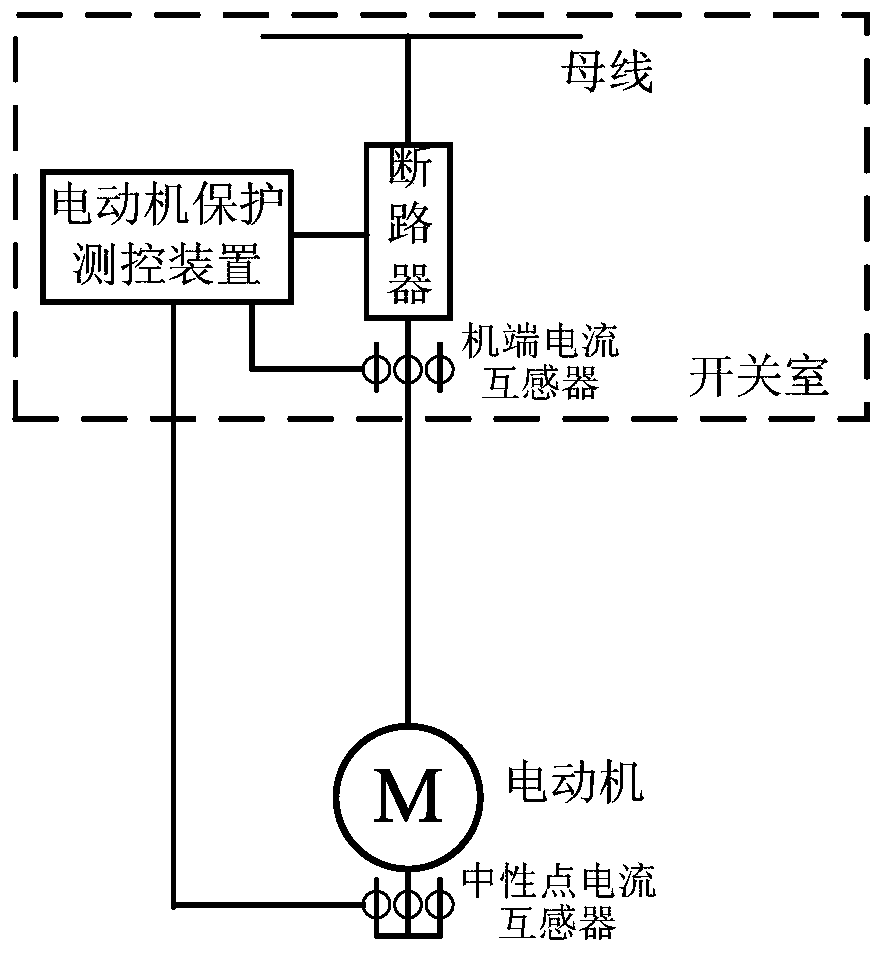

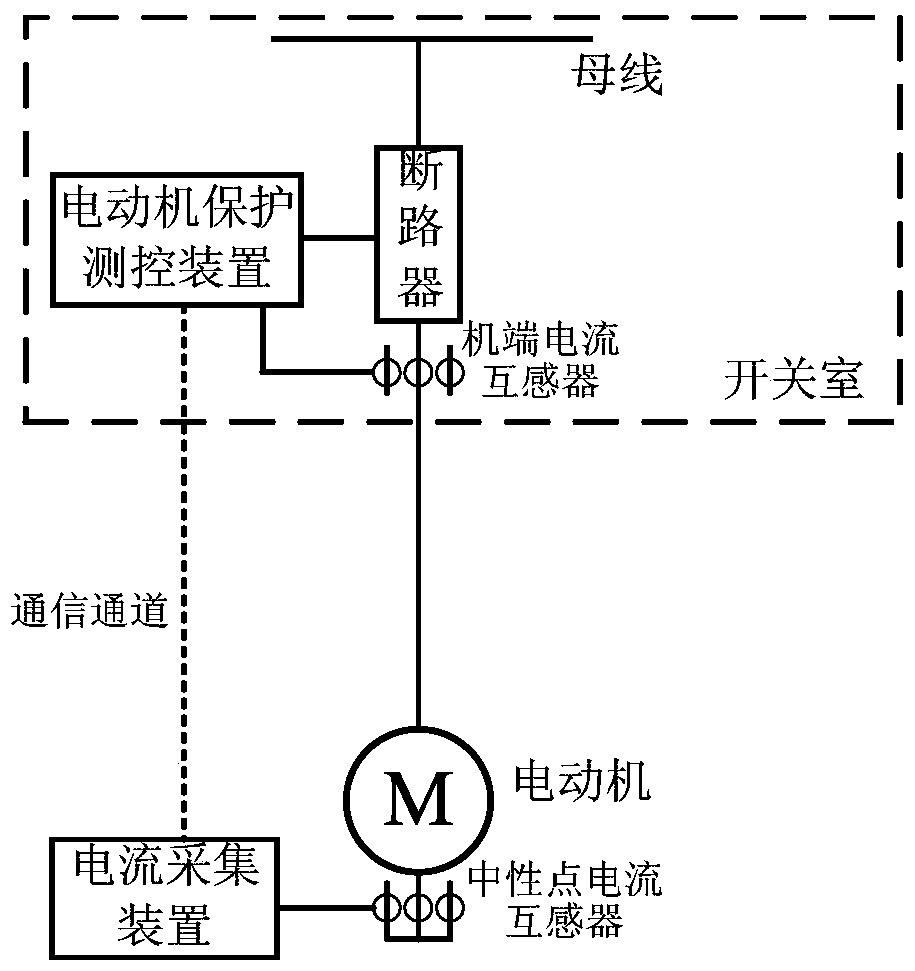

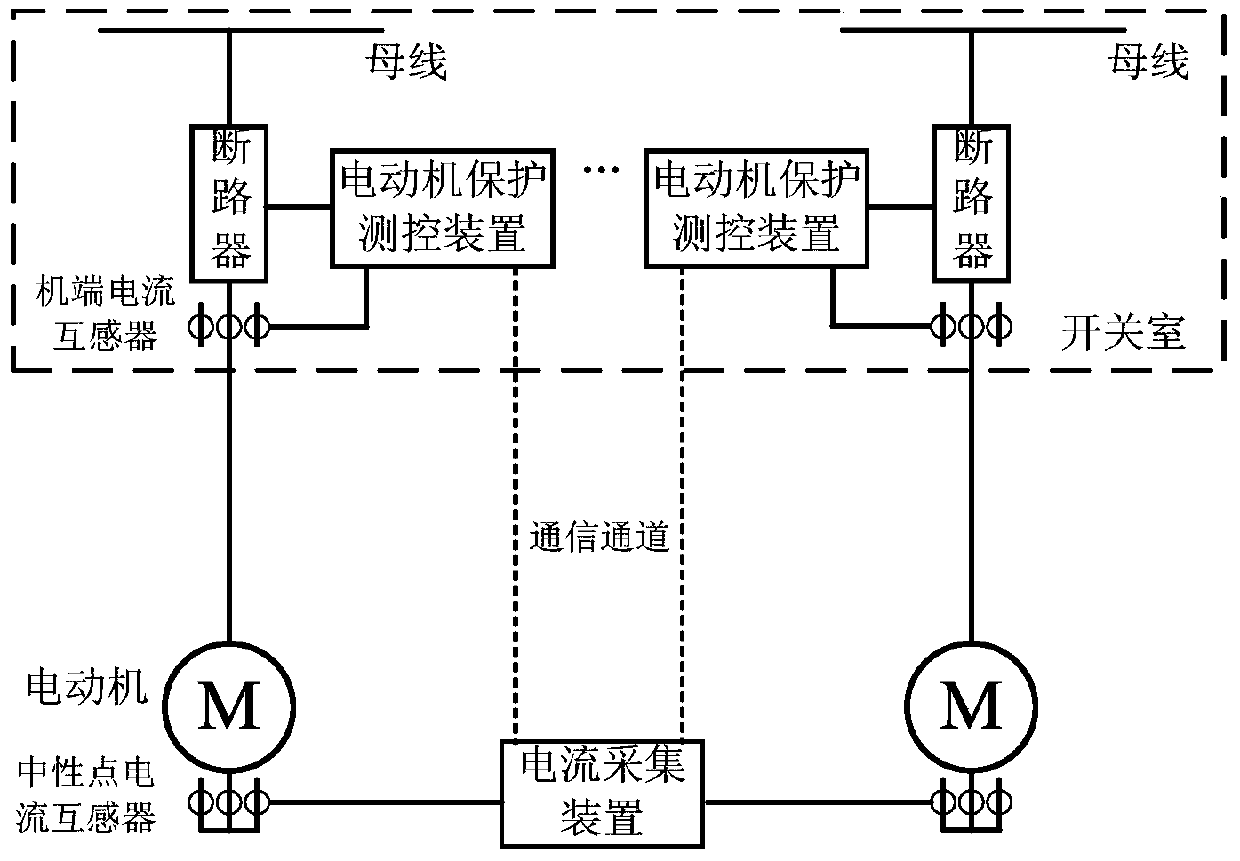

A motor differential protection system and method

ActiveCN104538933BReduce loadEliminate phenomenonEmergency protective circuit arrangementsAfter treatmentCurrent point

The invention discloses a motor differential protection system and method, including a motor protection device and a neutral point current acquisition device corresponding to one or more motors; The neutral point current is converted into a digital signal, and each group of current signals is transmitted to the corresponding motor protection device through communication. The motor protection device collects the end-side current of each motor, and combines the signal transmitted by the neutral point current collection device for synchronization. After processing, the differential protection function is completed. This system and method can solve the problem of CT saturation caused by too long neutral-point current acquisition cables, improve differential protection performance and anti-misoperation ability for external faults, enhance signal reliability, simplify on-site wiring, and save investment.

Owner:NR ELECTRIC CO LTD +1

Catalyst for gasoline de-mercaptaning and preparation method thereof

ActiveCN109364966AHigh sweetening activityGood choicePhysical/chemical process catalystsRefining by selective hydrogenationActive componentGasoline

The invention relates to a catalyst for gasoline de-mercaptaning. The catalyst contains a silica-alumina carrier, metal active components nickel, molybdenum and iron loaded on the carrier and an additive phosphorus, and is prepared from the components in percentage by weight: 2-15 percent of nickel oxide, 2-18 percent of molybdenum oxide, 0.1-5.5 percent of ferric oxide, 0.01-2.2 percent of additive phosphorus oxide and 65-85 percent of silica-alumina carrier. The catalyst has the characteristics of high de-mercaptaning activity, high diolefin hydrogenation selectivity and low octane number loss.

Owner:内蒙古致兴能源高科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com