Patents

Literature

148results about How to "Difficult to shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

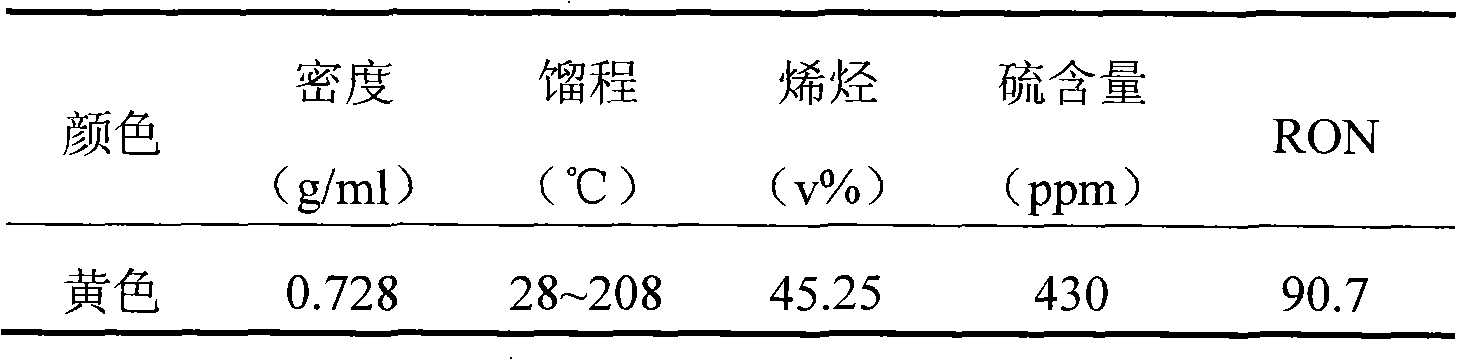

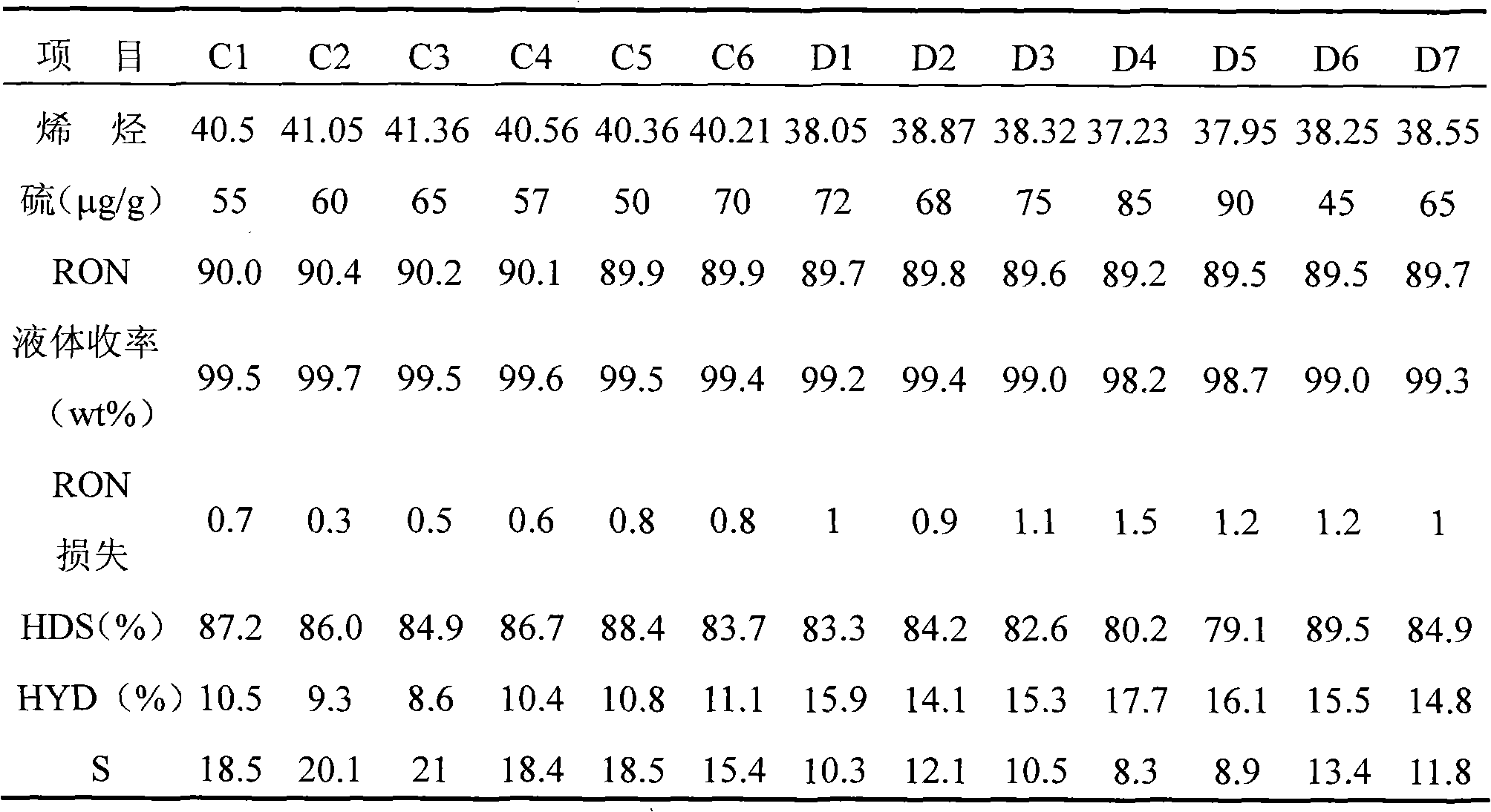

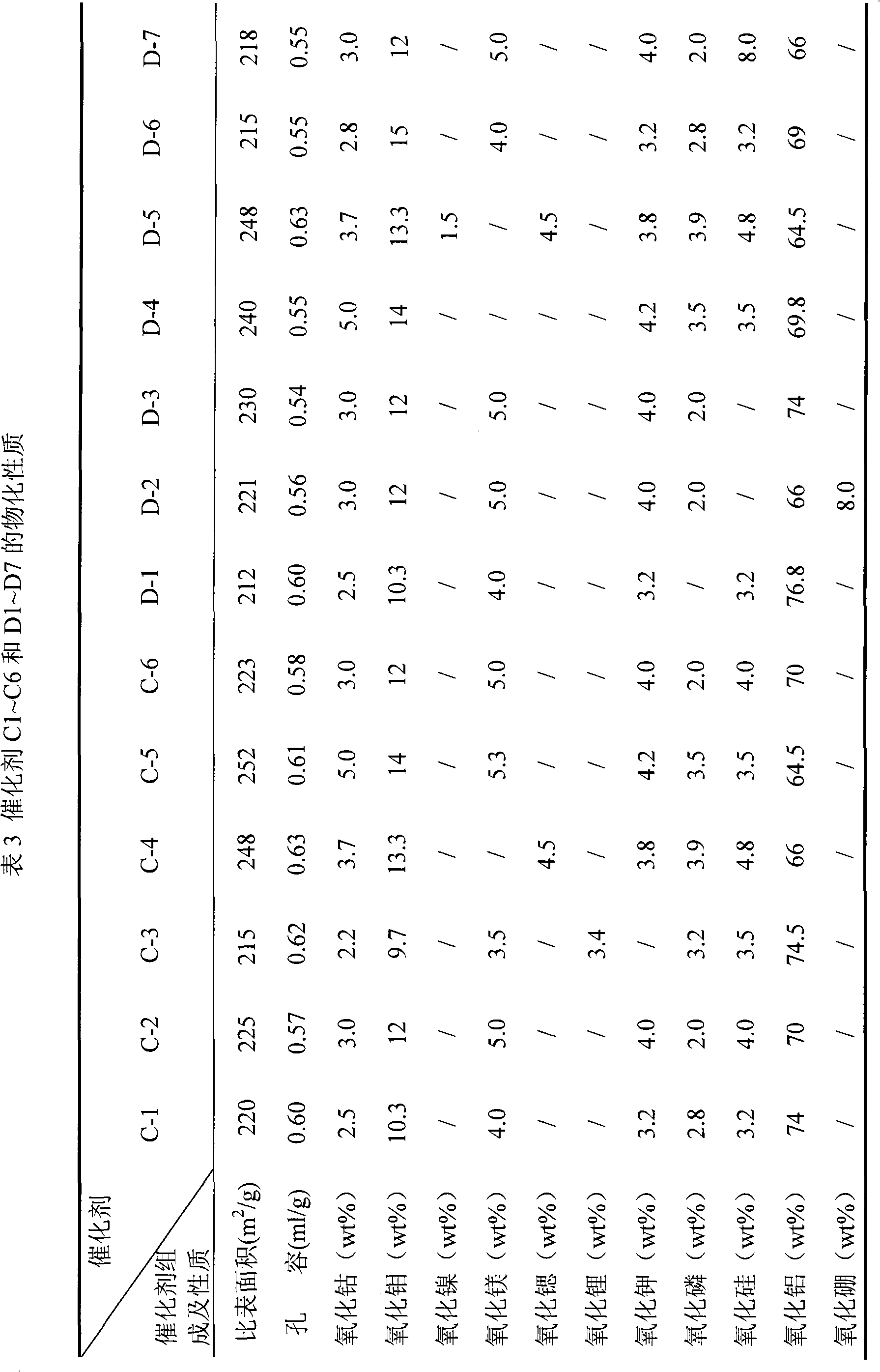

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

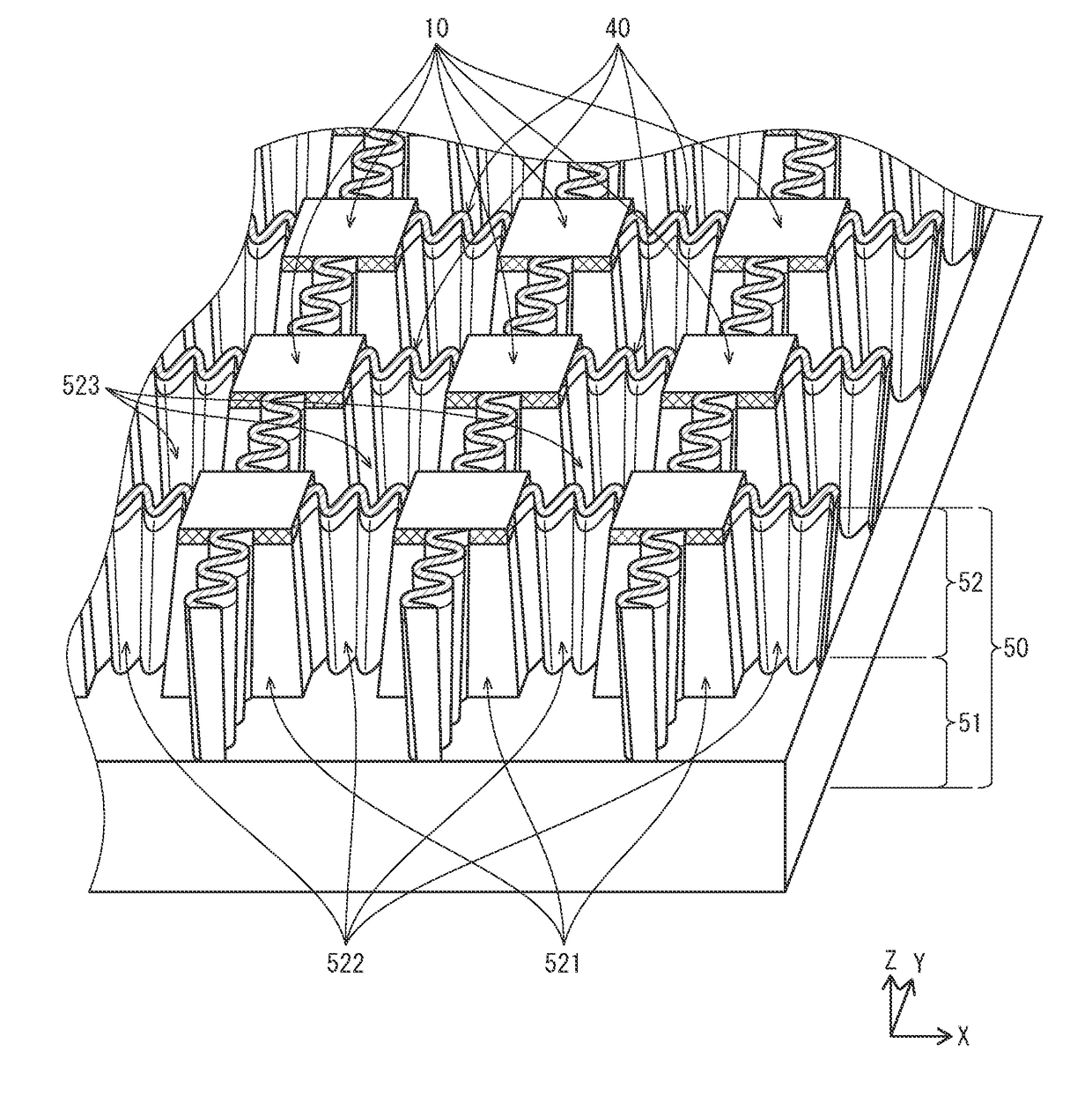

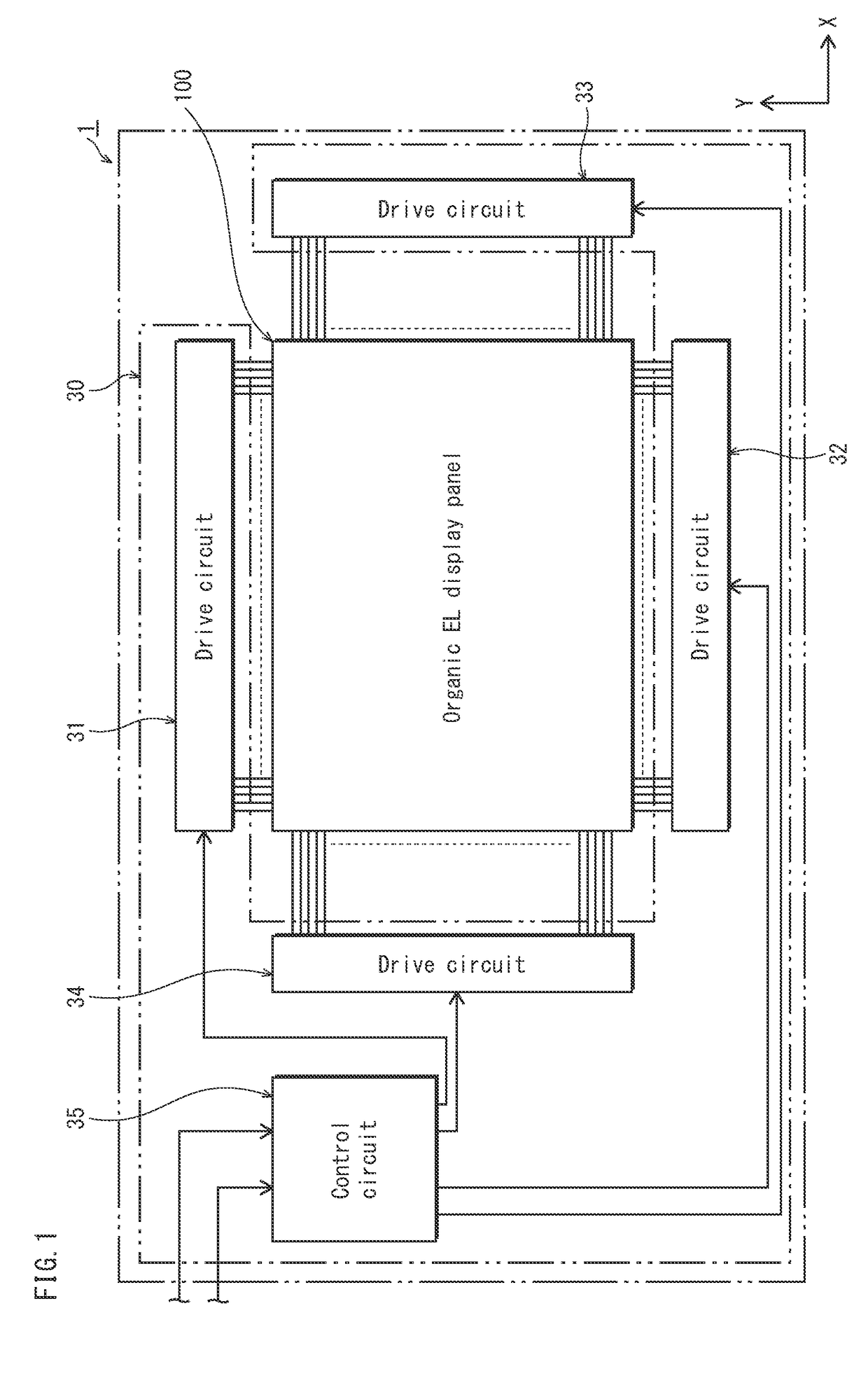

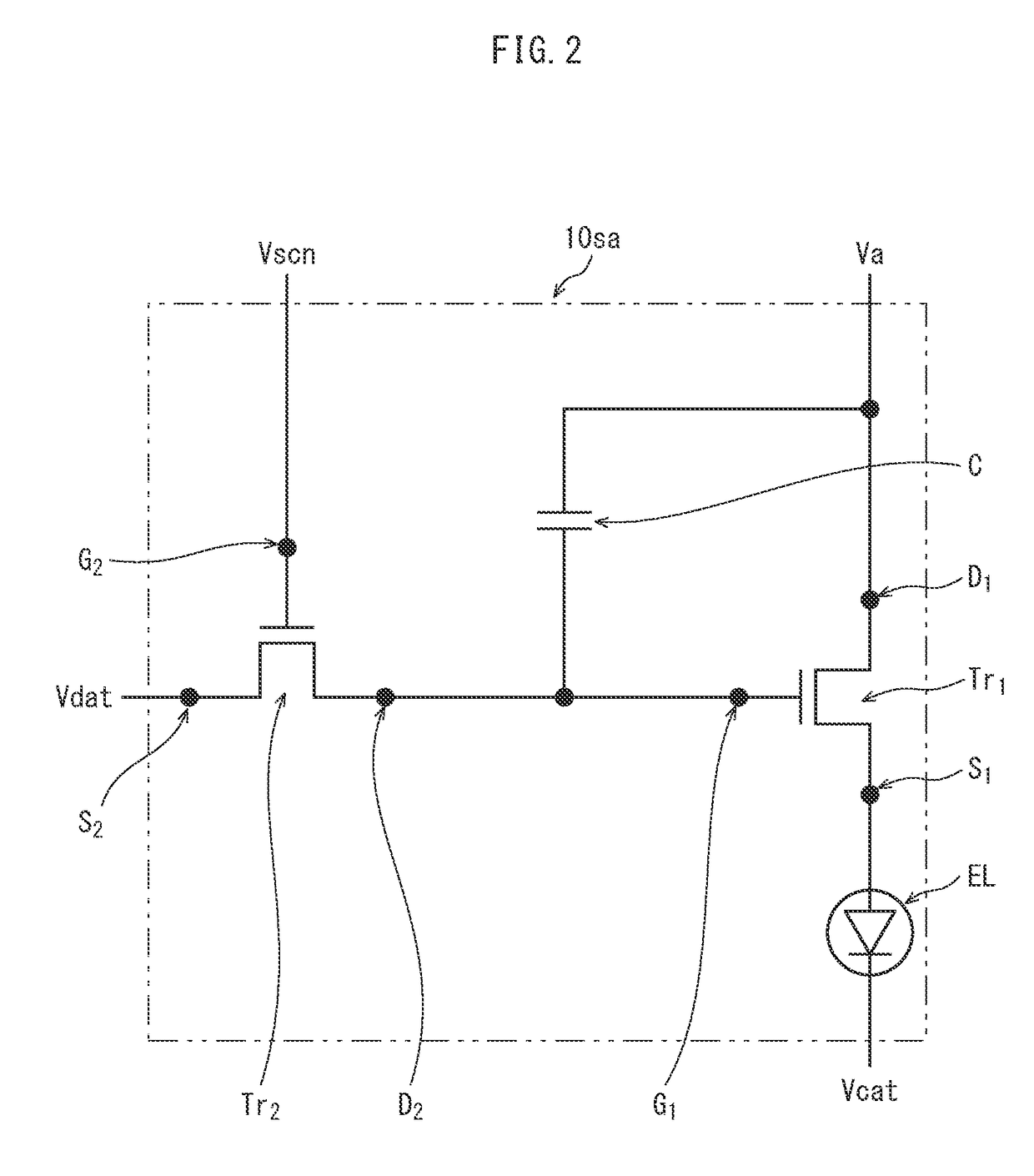

Organic el display panel, organic el display device, and method of manufacturing organic el display panel and organic el display device

ActiveUS20170294610A1Difficult to shapeIncrease demandFinal product manufactureSolid-state devicesElectrical connectionDisplay device

In an organic electroluminescence (EL) display panel including: a substrate that is flexible and is made of a resin material; a plurality of light-emitting elements that are disposed on the substrate and are spaced away from one another; and a plurality of wire units that are disposed on the substrate and establish electrical connection between the plurality of light-emitting elements, a first region of the substrate that is below the light-emitting elements has greater stiffness than a second region of the substrate that is a remainder of the substrate.

Owner:JOLED INC

Deep smoke purifying material, and preparation method and use method thereof

InactiveCN104275150ALarge specific surface areaImprove adsorption capacityGas treatmentOther chemical processesPhysical chemistryEmission standard

The invention discloses a deep smoke purifying material, and a preparation method and a use method thereof. The deep smoke purifying material comprises the following components in percentage by weight: 0-20 wt% of metal oxide, 1-40 wt% of alkaline or an alkali compound and 50-80 wt% of a carrier. The deep smoke purifying material is prepared by using a dipping method. According to the use method of the deep smoke purifying material, the deep smoke purifying material is used in a form of a stationary bed, and is suitable for being used in occasions with the smoke concentration of less than 2 percent, the pressure of 0.1-1MPa, the temperature of 0-200 DEG C, and the space velocity of 100-20000h<-1>; when an adsorbing material adsorbs smoke until saturation and the purifying efficiency is reduced, no stop is required for replacing the deep smoke purifying material, the deep smoke purifying material can be cleaned by directly using a solution of the alkaline or alkali compound, and the purifying efficiency can be recovered to reach an original level after the deep smoke purifying material is cleaned. The use method is low in operation cost, is capable of deeply purifying smoke, and is capable of meeting the emission standard of sulfur dioxide of 50mg / m<3>.

Owner:GUANGZHOU BOXENERGY TECH

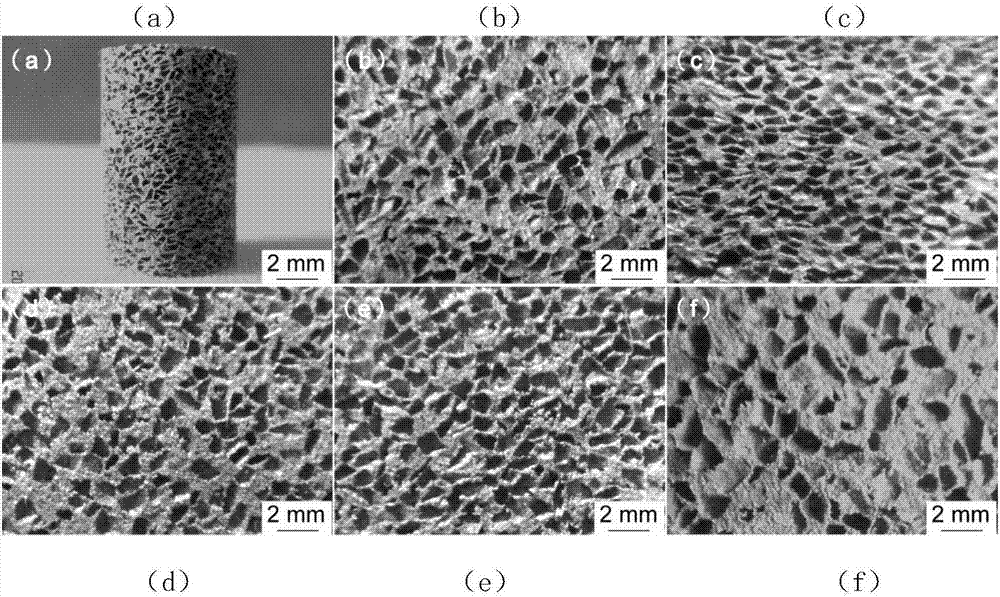

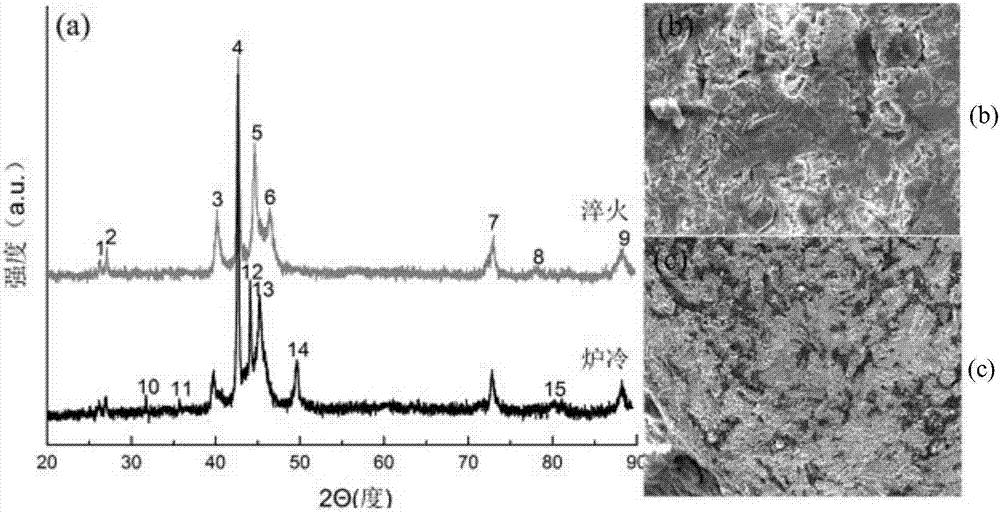

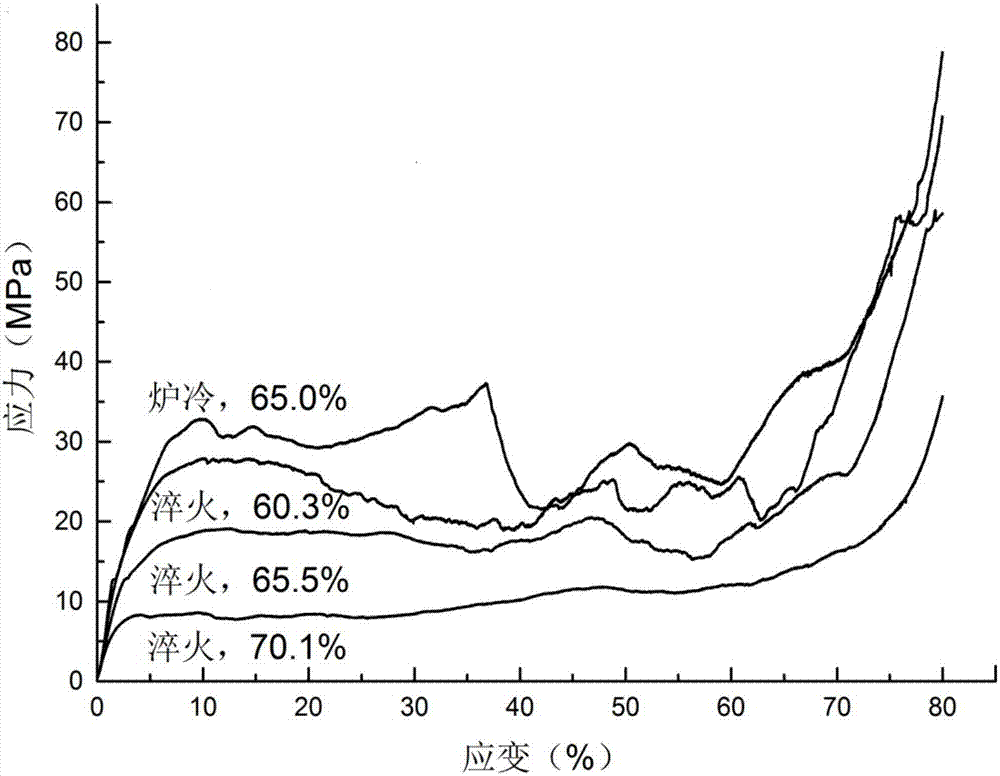

Preparation method of porous copper-based shape memory alloy

The invention discloses a preparation method of a porous copper-based shape memory alloy and relates to manufacturing of the porous shape memory alloy. Cu-Al-Mn prealloying powder prepared by compounding of original metal pure Cu powder, pure Al powder and pure Mn powder serves as a base material; the base material is uniformly mixed with absolute ethyl alcohol and then uniformly mixed with decrystallization water NaCl particles, and pressing is conducted to obtain a green body; and the green body is subjected to sinter molding, then placed in boiling water of 100 DEG C to thoroughly removing the residual NaCl particles in holes in a boiling mode and finally placed in a dryer of 60 DEG C to be subjected to heat preservation for 20-30 minutes, and the porous copper-based shape memory alloy with a through hole structure, the average porosity being 50-80% and the average pore diameter being 0.2-1.5 mm is prepared. The defects that in the prior art, the preparation cost of a product is high, and production safety is low are overcome.

Owner:HEBEI UNIV OF TECH

Konjac glucomannan contained filament fiber material and preparation method thereof

InactiveCN102505183ALow priceSimple moldingWet spinning methodsConjugated artificial filamentsFiberPolymer science

The invention discloses a konjac glucomannan contained filament fiber material and a preparation method thereof, which belong to the technical field of environment-friendly polymer fiber materials. The konjac glucomannan contained filament fiber material comprises, by mass percent, 0.1-75% of starch, 5-80% of konjac fine powder, 1-25% of water, 1-10% of lactic acid, and 0.1-5% of coagulator made up of ethanol, glycerol and ammonia water. The main materials, such as the natural starch, the konjac fine powder and the like, are from rich food-grade natural polymers, and the konjac glucomannan contained filament fiber material is harmless to human bodies and capable of degrading under natural conditions. Process parameters of microwave pretreatment-wet spinning can be adjusted to achieve regulation of degradation rate of the fiber material, and environment friendliness is achieved. The fiber can be widely applied to uses, such as food packaging, gas filtration, biochemical dialysis, disposable garments, breathable fabrics, beauty masks, slow release of perfumes or deodorization using perfumes, antiseptic wipes, baby diapers, feminine napkins, wound bandages, surgical dressings, slow release of drugs, tissue engineering scaffolds and the like.

Owner:KUNMING UNIV OF SCI & TECH

Composition and method for producing an ultra-lightweight ceramic proppant

InactiveUS20120118574A1Low viscosityEconomical pumping rateFluid removalFlushingMetallurgyHydraulic fracturing

An ultra-lightweight, high strength ceramic proppant made from mixture of naturally occurring clays, preferably porcelain clay, kaolin and / or flint-clay, earthenware clay or other naturally occurring clays having an alumina content between about 5.5% and about 35%. The proppant has an apparent specific gravity from about 2.10 to about 2.55 g / cc, and a bulk density of from about 1.30 to about 1.50 g / cc. This ultra-lightweight proppant is useful in hydraulic fracturing of oil and gas wells, and has greater conductivity than sand at pressures up to 8,000 psi as measured by Stim-Lab after 50 hours and 275° F. on Ohio Sandstone, in the presence of deoxygenated aqueous 2% solution of KCI.

Owner:PROP SUPPLY & SERVICE

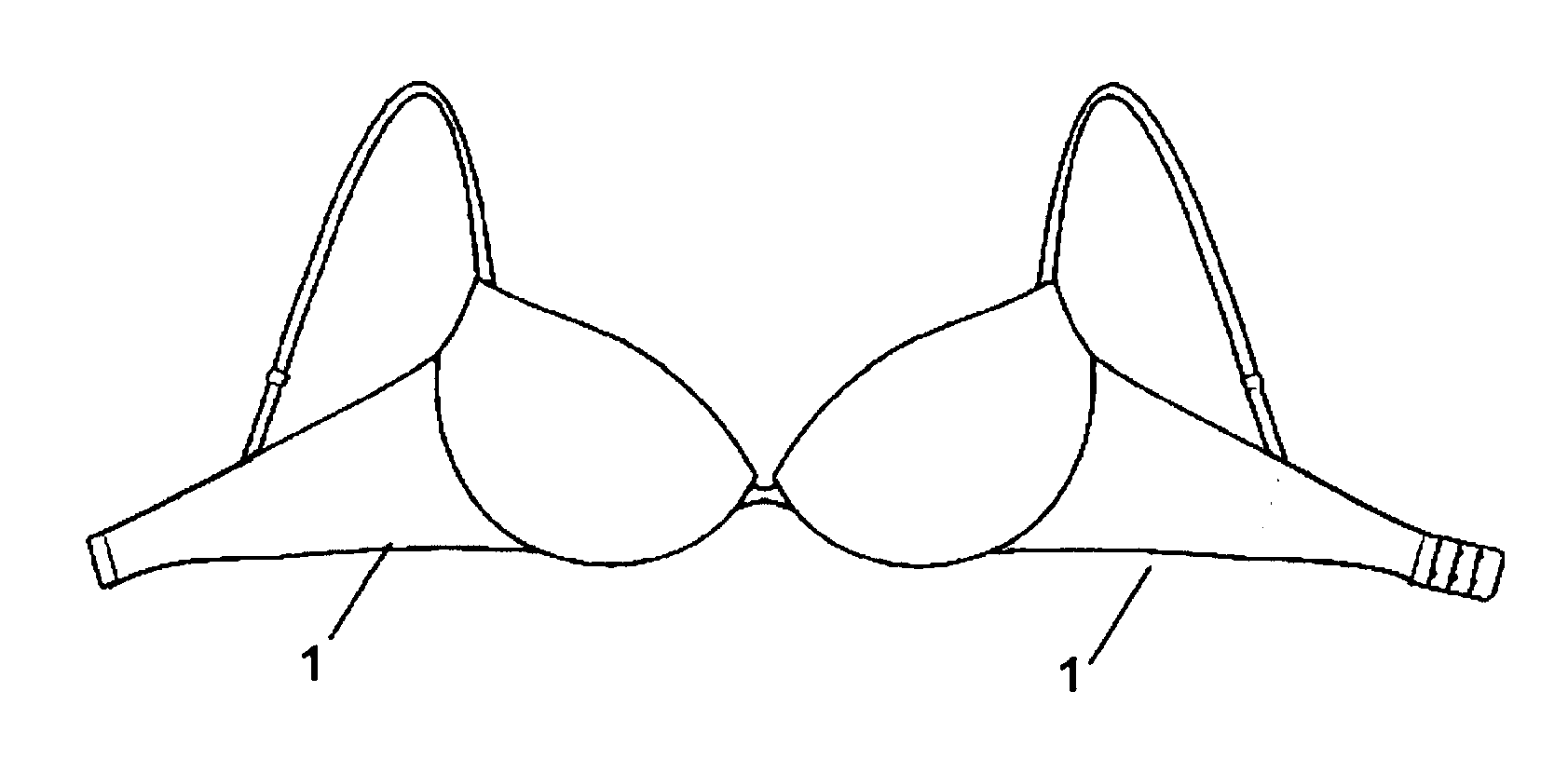

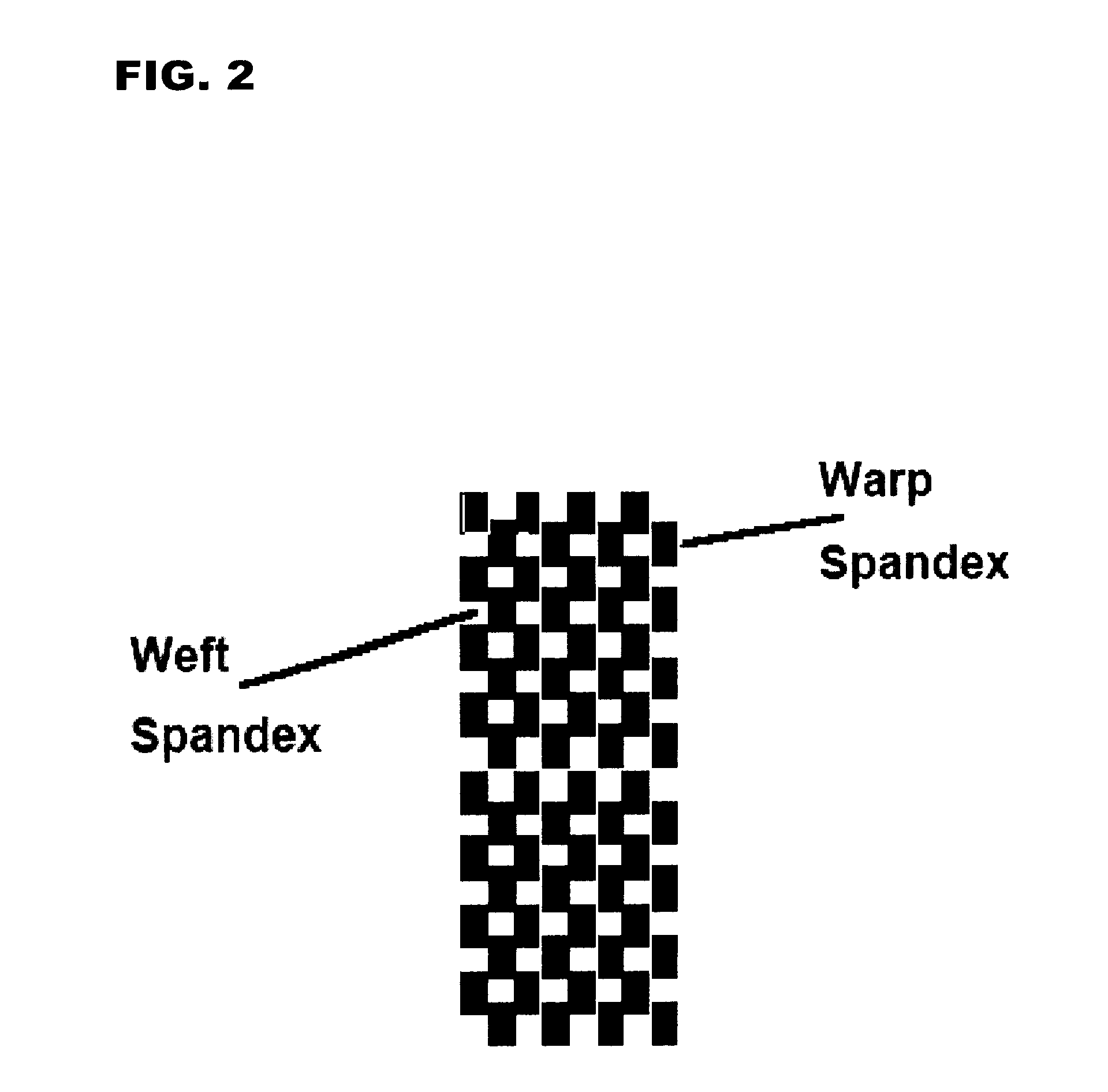

Novel Fabric Made of All Elastomeric Fiber and Its Applications

The present invention relates to a knitted fabric which adopts a novel weaving principle of changing knitting material structure to realize functions and effects which can not be achieved by ordinary fabric. The knitted fabric comprises the main component of novel woven 100 percent spandex fabric made of 100 percent spandex filament. Presently, elastic rubber pieces, rubber bands, etc., are applied to the underwear at the market for enhancing the elasticity and supporting effect. The common features is that they all have a poor elastic resilience, unstable structure, and prone to distortion and raveling. The present novel knitted fabric changes the principle of crocheting of the ordinary material of the traditional knitted fabric, adopting 100 percent spandex filament as the main material to change the elastic resilience, force, and structure stability of the traditional knitted fabric. The mutual double pulling effect of the knitted fabric in the spandex filament after crocheting is to remedy the defaults of the fabric of which the structure is deformed and the elastic resilience and the force are weakened after the fabric is elongated. Compared with the original fabric, the elastic recovery and the elastic force of the fabric are greatly increased and improved.The weaving process and the features of the novel 100 percent spandex fabric are as follows:(1) Warp yarn and weft yarn which are made of 100% spandex filament material are mutually crocheted.(2) The back weft of the spandex filament is required to pass through a filament packaging frame and a weft yarn accelerating conveyer device is provided.(3) Curling is required to be avoided. The specification of the spandex filament of which the warp yarn used required to be considered, so is the specification and constituents of the back weft made of the spandex filament.The preset novel 100% spandex fabric can completely replace the elastic woven band and rubber piece in the prior underwear to play a role of enhancing the elasticity and strength. It can also completely replace the prior common elastic woven band and rubber piece, providing good hand feel, flatness, smoothness, close fit, sound elastic resilience, comfort wear, etc. It can be widely applied to garment industry, particularly to the underwear, such as brassiere, swimwear, briefs, etc.A strap having a memory function, comprising yarns of substantially 100% spandex. The rubber band and ordinary strap applicable in the present market provide a poor elastic resilience, which would easily deform. The said strap having a memory function weaved with warp yarn made of 100% spandex and weft yarn made of 100% spandex, whose structure could be not only plain weave, but also twill or tracery. The fabric has the “memory” function by which it returns to substantially its original shape after being stretched many times it original size. It can provide excellent hand feel, good flatness, smoothness, close fit, sound elasticity, and comfortable wear when used to replace the existing ordinary elastic rubber bands. It can be widely applied in the garment industry, especially in the field of underwear such as brassiere, swimwear, briefs, lingerie, etc.The present patent for utility model discloses a laminable elastic fabric whose main components are 100% spandex elastic woven band and warp knitted shell fabric or weft knitted cloth, and the elastic fabric is formed through laminating processing. The laminated fabric currently used on the market does not have good elastic resilience and is thus easily deformed and is relatively thick. The new laminated elastic fabric of the present patent is relatively light and thin, and the elastic woven band is formed by interweaving 100% spandex warp threads and 100% spandex weft threads, and the elastic fabric is formed by laminating it to the inner side of the shell fabric. The fabric has a recovery of nearly 100% after many times of use. The fabric laminated with said woven band has the characteristics of excellent hand feel, good levelness, softness and smoothness, close fit, good elasticity, comfortable wear, etc. Meanwhile, the processing is simple, and mechanical automation and mass production can be realized, which complies with the efficiency of market economy.

Owner:BEST PACIFIC TEXTILE

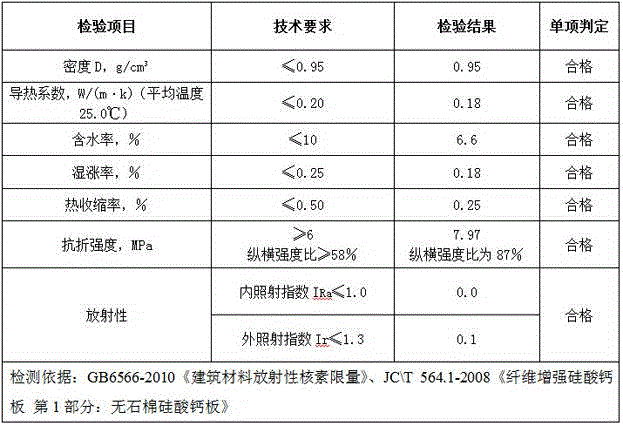

Low-density ash silicon plate produced with industrial wastes as raw materials and production process of ash silicon plate

The invention relates to a low-density ash silicon plate produced with industrial wastes, such as coal ash and acetylene sludge, as main raw materials and a production process of the ash silicon plate, in particular to a low-density ash silicon plate produced with industrial wastes as raw materials, and belongs to the technical field of building materials. The low-density ash silicon plate comprises 60-65% of coal ash, 10-15% of cement, 10-15% of acetylene sludge, 5-8% of porcelain clay, 0.5% of iron oxide and 8-10% of wood fiber. The production process comprises the following steps: extraction and preparation of the wood fiber, preparation of plate blank slurry, manufacturing of a plate blank, pressurization and demoulding of the plate blank, steam curing of the treated plate blank, and obtaining of the finished plate. The low-density ash silicon plate provided by the invention is high in performance, relatively low in cost, convenient for construction, relatively high in toughness, and high in moisture resistance; the fire-resistant level is A1; the utilization ratios of the coal ash and calcium carbide sludge reach 65% and 15%, so that the industrial wastes are utilized sufficiently, and environmental pollution is relieved; the protection process is relatively easy to operate; the problem that the construction of a cement plate, a calcium silicate plate and other similar products are difficult is solved.

Owner:JIANGXI YUANYANG WEILI IND CO LTD

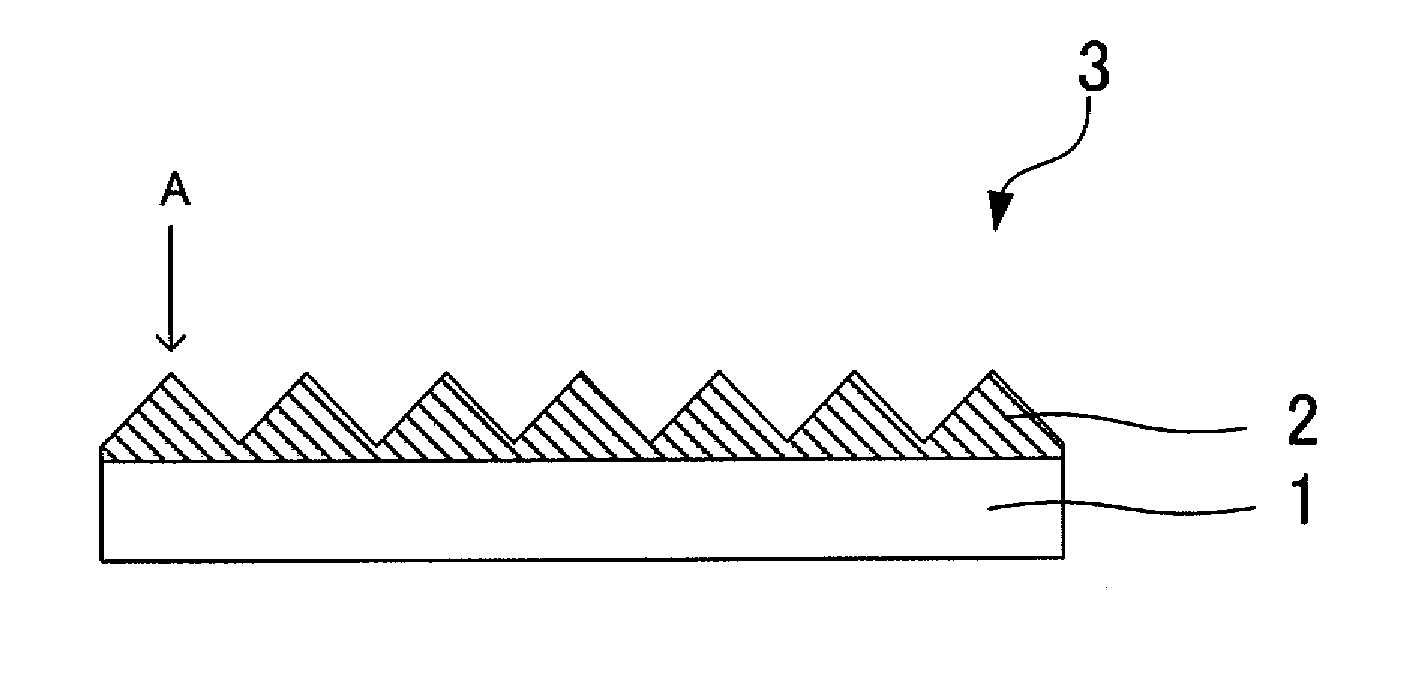

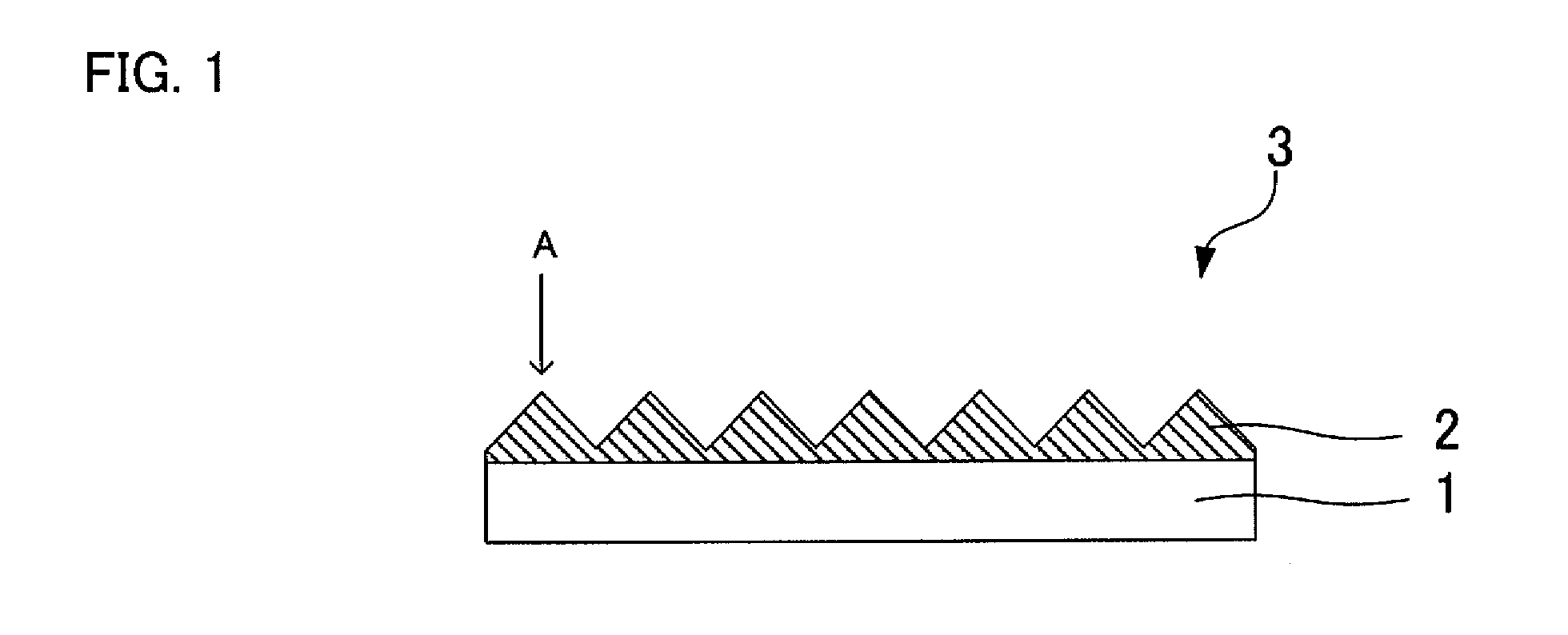

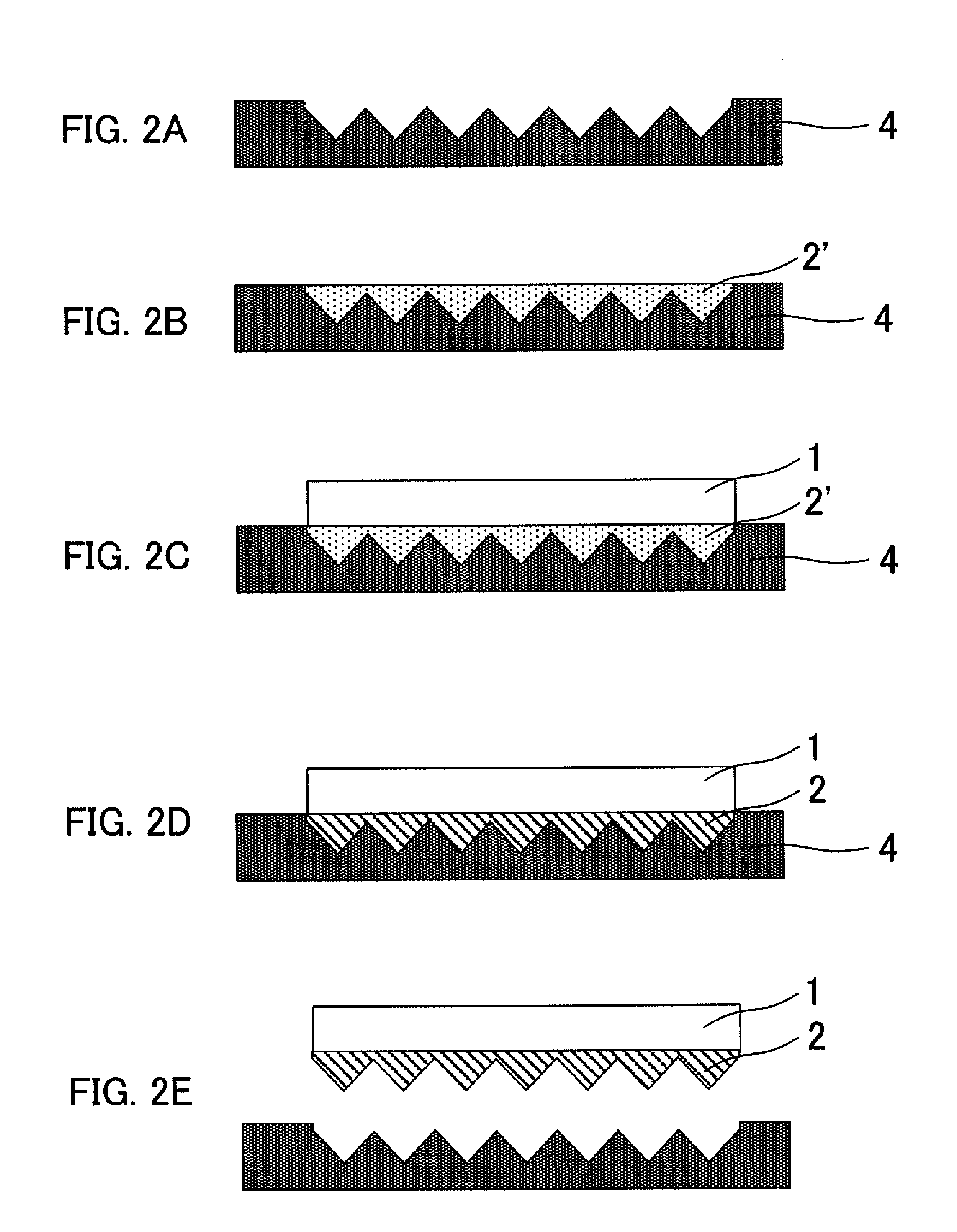

Sheet-like optical member, resin composition for optical sheet, optical sheet and method for producing the same

ActiveUS20100103529A1Not easy to damageImprove productivityPrismsMechanical apparatusUltrasound attenuationEngineering

A sheet-like optical member being difficult to damage a shape of a lens part. The sheet-like optical member includes: a substrate; and a lens part, which is formed on the substrate, is made of an active energy ray-curable resin, and has a plurality of unit prisms. The maximum logarithmic attenuation rate ΔE of the lens part measured by a rigid body pendulum method is 0.4 or less.

Owner:DAI NIPPON PRINTING CO LTD

Manufacturing Method of Decorative Molded Article and Decorative Molded Article

ActiveUS20150202807A1Excellent surface appearanceEffective preventionSynthetic resin layered productsWood working apparatusPolymer scienceCarbon fibers

In a manufacturing method of a decorative molded article, in which a surface of a fiber-reinforced resin shaped product including carbon fibers in which some carbon fibers are contained in a form of carbon fiber bundle and a thermoplastic resin, is decorated in the mold, a decorative molded article having excellent surface smoothness and an excellent appearance is provided by controlling a pressure in the mold during cooling.

Owner:TEIJIN LTD

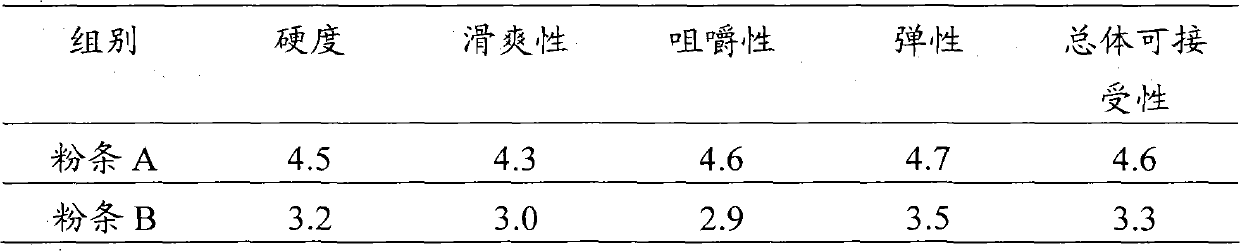

Potato whole flour and staple food prepared by employing same

InactiveCN104886504AReasonable retention of nutrientsKeep the quality reasonablyFood preparationPotato starchHardness

The invention belongs to the technical field of food processing. In order to solve the problems that the existing potato whole flour is relatively high in processing cost and relatively complex in processing step while the existing potato whole flour which is used for manufacturing staple food products is hard to mold, is great in hardness and is not resistant to cooking, the potato whole flour is low in content, the cost for manufacturing a potato food made of flour is high and the like, the invention provides potato whole flour and staple food prepared by employing the potato whole flour. The preparation method of the potato whole flour comprises the following steps: choosing raw materials; cleaning and peeling the raw materials; selecting the raw materials; cutting the raw materials into slices; blanching the raw materials; cooling and drying the raw materials; and pulverizing the raw materials. The potato whole flour is mixed with oat flour to prepare steam buns; the potato whole flour is mixed with wheat flour and potato starch to prepare noodles; the potato whole flour is mixed with wheat flour to prepare cakes; the potato whole flour is mixed with potato starch to prepare dough and dumpling wrappers; and the potato whole flour is mixed with oat flour and potato starch to prepare Helaomian (a kind of noodles). The staple food preparation process is time-saving, simple and convenient and the prepared food is suitable for the public to eat, the popularization is facilitated, and the potato flour is industrially produced and is stable in quality; the staple food is easy to mold, is tenacious, is complete in nutrition and is good in taste.

Owner:SHANXI SHUYAN FOOD

Preparation method of completely environment-friendly leather base cloth

The invention relates to a preparation method of completely environment-friendly leather base cloth. The preparation method includes the following steps that firstly, polyester fibers are dispersed into water, and polyester fiber turbid liquid is prepared; and a dispersing agent is added in, uniform stirring is performed, and a polyester solution is obtained; secondly, the polyester solution is used for preparing two layers of polyester paper through a paper making method by means of two upper and lower paper machines, the two layers of upper and lower polyester paper are made to be compositedwith base cloth through a composting roller, the base cloth is made to be in the middle, the polyester paper is made to be on the two sides of the base cloth, and the leather cloth is obtained; and thirdly, the leather cloth is subjected to high pressure spunlace treatment and pressing dewatering, and then enters a drying cylinder to be dried, winding and final slitting are performed, and the completely environment-friendly leather base cloth is obtained. The leather base cloth prepared through the preparation method is simple in step, forming is easy, drying is easy, productivity is high, and the leather base cloth can be used for replacing animal leather, is attractive, economical, practical and wide in purpose, and can be used for automobile trim, cloth materials and the like.

Owner:山东昌诺新材料科技有限公司

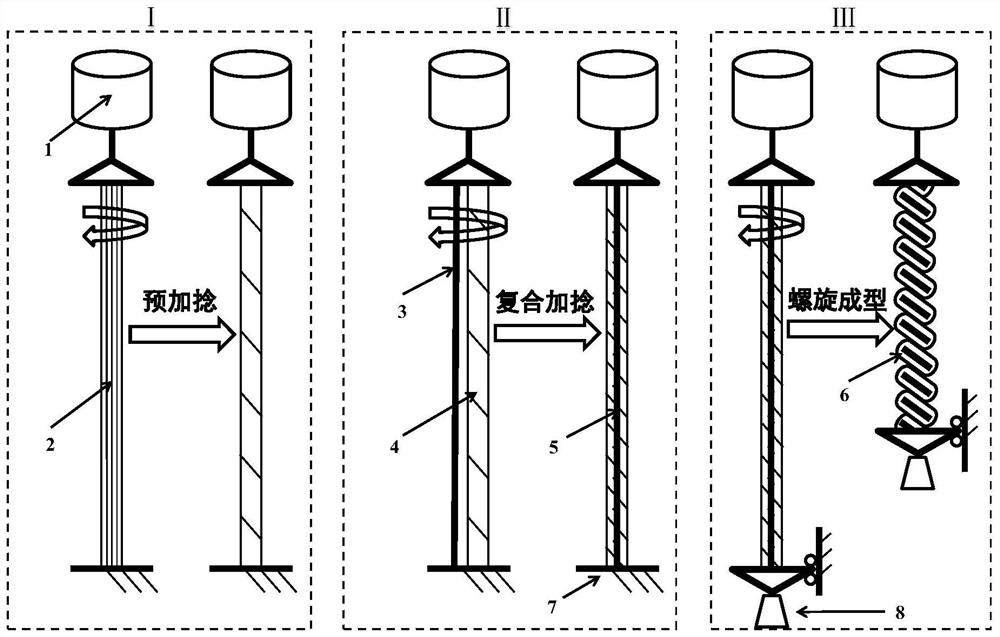

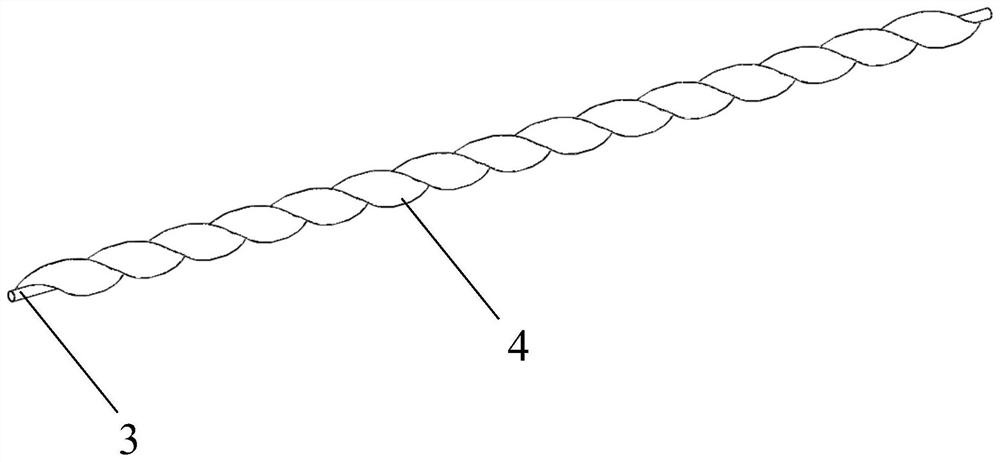

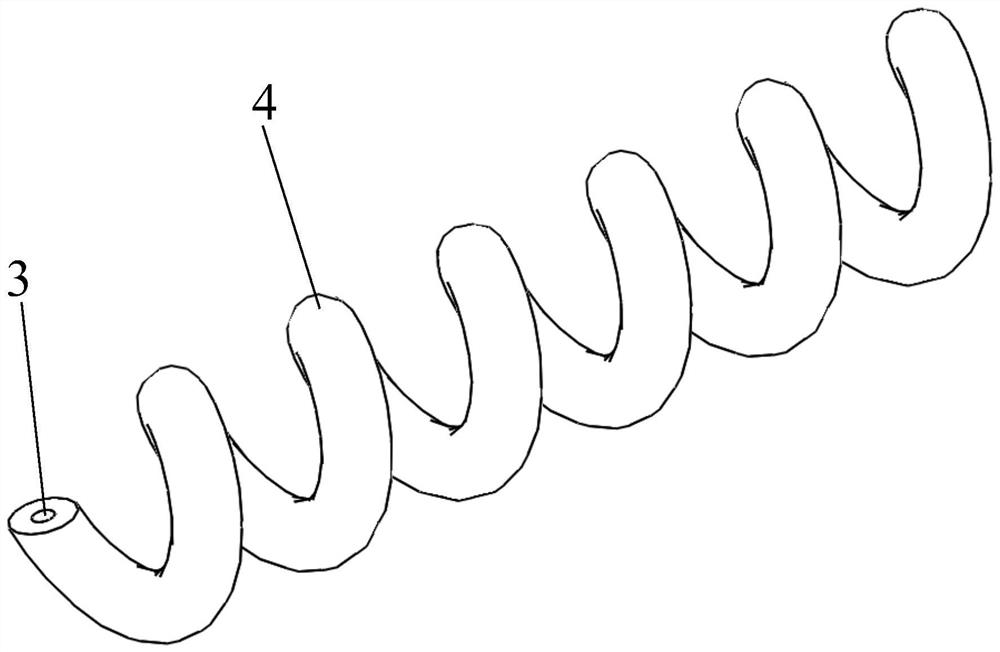

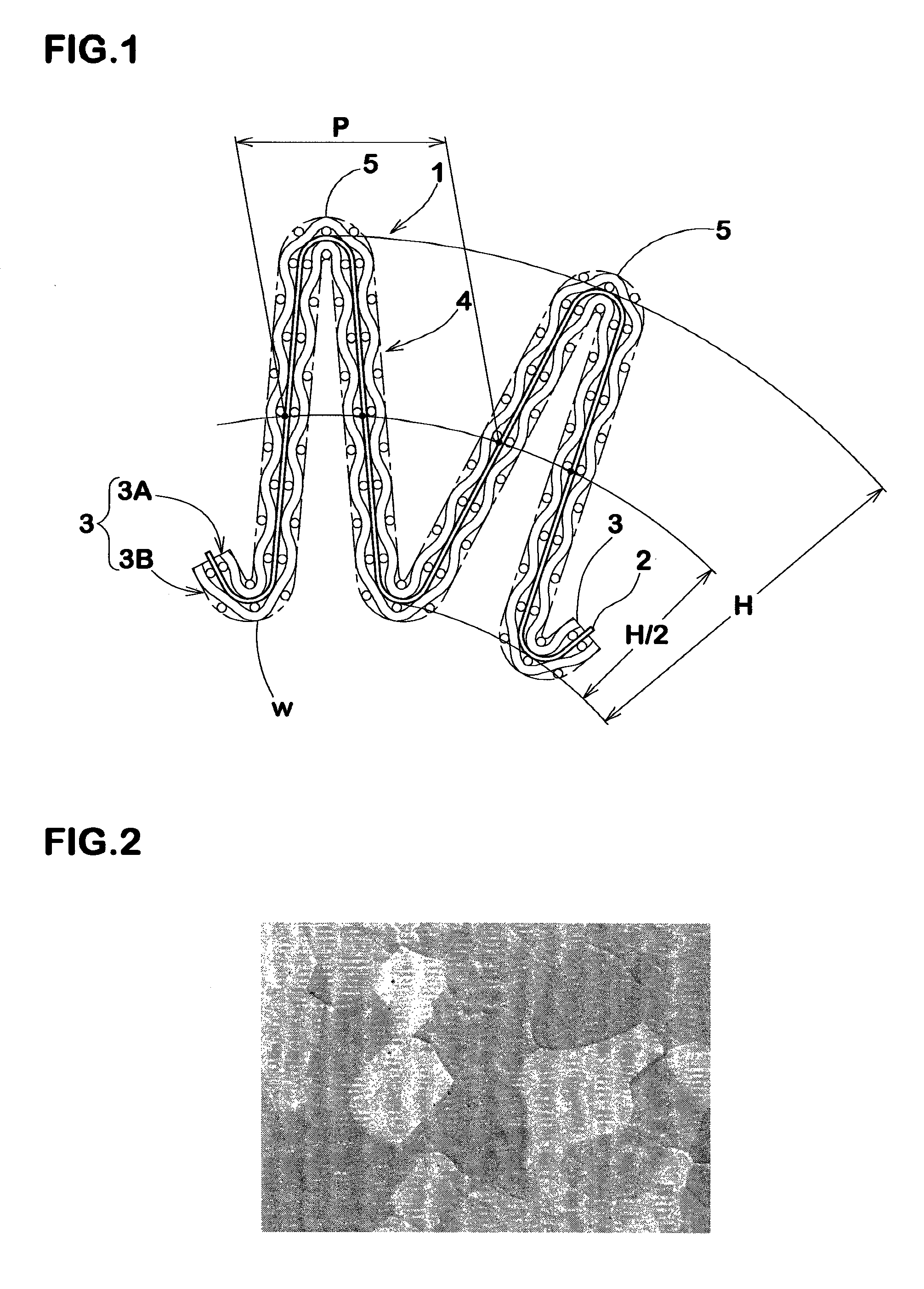

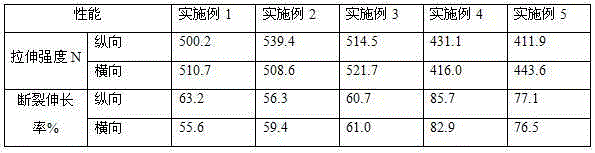

Electrically-driven metal wire framework-spandex fiber twisted composite artificial muscle and preparation method thereof

ActiveCN112936250ASmall unscrewing torqueLow unscrewing torqueProgramme-controlled manipulatorFiber bundleArtificial muscle

The invention discloses an electrically-driven metal wire framework-spandex fiber twisted composite artificial muscle and a preparation method thereof. The preparation method comprises the following steps that in the pretreatment stage, spandex fibre bundles are sequentially subjected to pre-stretching and pre-twisting treatment; in the compounding stage, the pre-treated spandex fiber bundles are rotated and twisted to enable the spandex fiber bundles to be spirally wound onto the surface of a metal wire, and the fiber bundles are twisted to a limit number of turns under the condition of keeping the length of the metal wire-spandex fiber composite structure unchanged; in the spiral forming stage, the fixed end of the metal wire-spandex fiber composite structure twisted to the limit number of turns into a movable end, certain loads are further added, and twisting continues to be conducted to obtain the twisted composite artificial muscle of a spiral spring structure; and in the annealing training stage, the loads of the movable end of the twisted composite artificial muscle of the spiral spring structure are reduced, intermittent currents are loaded on the metal wire, the processes of Joule heat generation heating and heat dissipation are repeatedly conducted till residual stresses are eliminated, and the highest temperature of Joule heat generation heating is lower than 130 DEG C.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

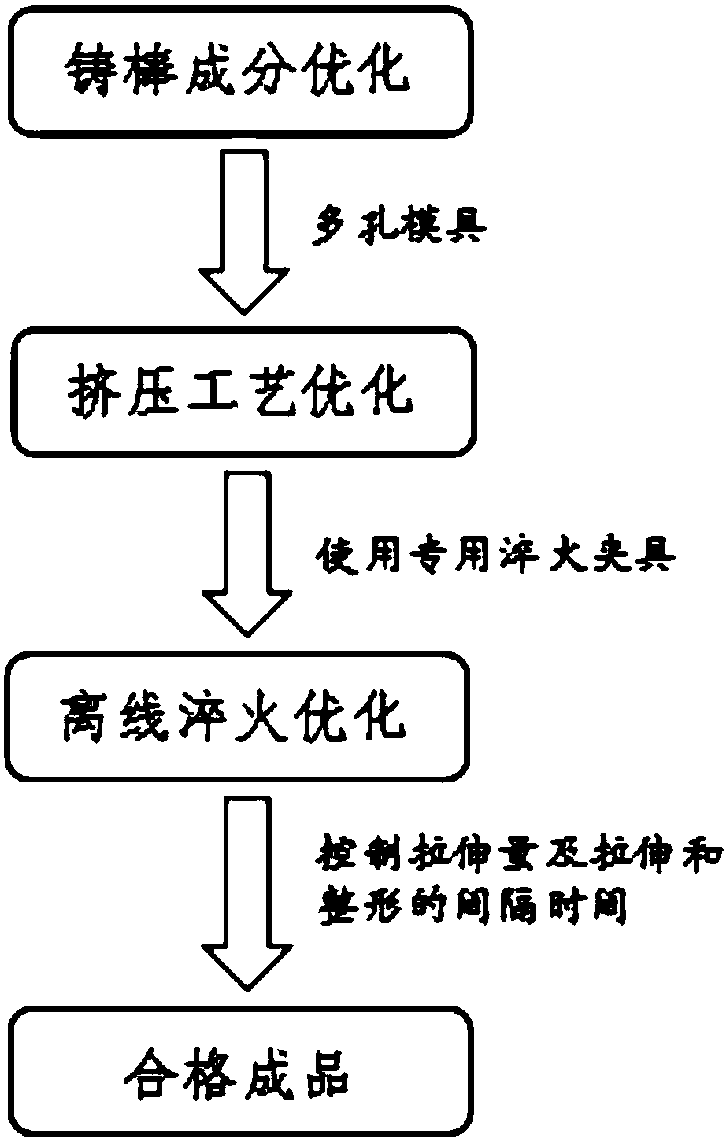

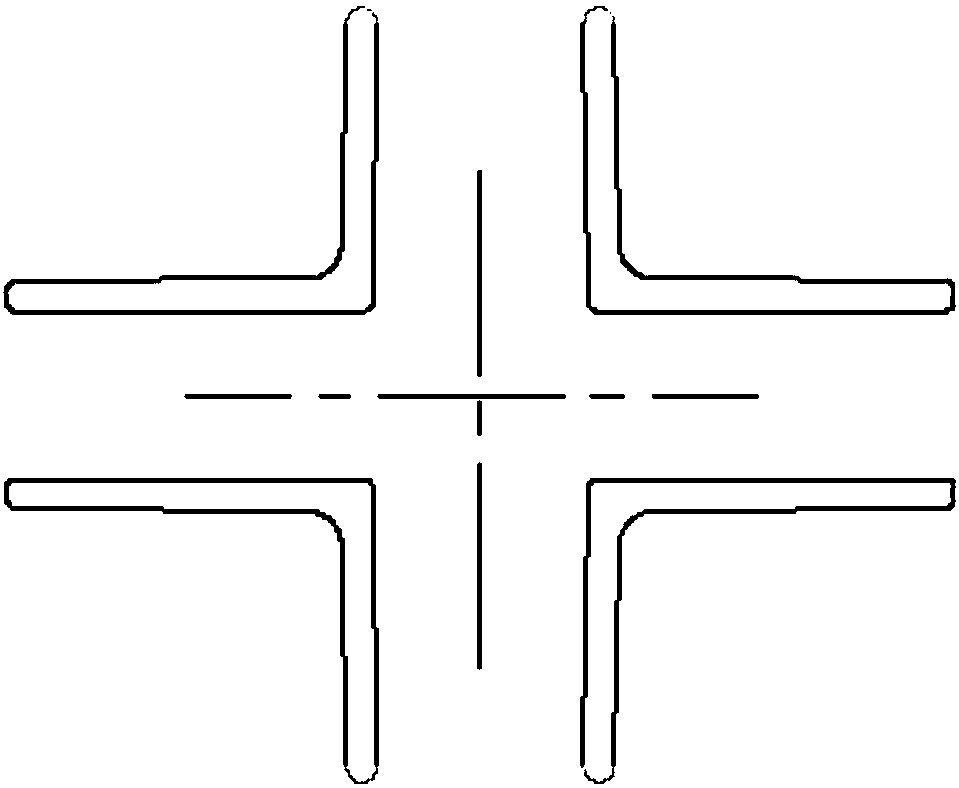

Production process of 2024 high-strength aluminum alloy special thin-walled section steel

The invention belongs to the technical field of aluminum alloys, and relates to a production process of a 2024 high-strength aluminum alloy special thin-walled section steel. flat mold form with fourextrusion holes and no flow guide pit in design aspect of a mold, an extrusion ratio of the whole section steel is reduced to 40, a 6.6MN non-standard extrusion machine is selected in the aspect of extrusion machining, the extrusion ratio is 40.2, the section steel is stretched within 1 hour after extrusion, and an off-line quenching degree is 455 DEG C * 30 minutes, the section steel is stretchedwithin 1 hour after the off-line is carried out, and the stretching amount is controlled at the upper limit of 2.5%-to 3%. The shaping and extrusion production interval time is controlled within 3 hours, a shaping rate is improved, a novel quenching clamp is designed for the section steel, so that the deformation of the section steel is reduced to the minimum while the section steel is fully quenched, the 2024 aluminum alloy section steel is subject to a serious of machining process of mold adjusting, production equipment structure is changed, extrusion, the off-line quenching, quenching clamp manufacturing, shaping and the like, all detection indexes meet the standard requirement of GJB2507A in detection aspects of mechanical property, low-magnification, high-magnification and dimensional tolerance.

Owner:CHINA ZHONGWANG

Composition and method for producing an ultra-lightweight ceramic proppant

InactiveUS8727003B2Difficult to shapeReduce plasticityFluid removalExplosive working-up apparatusMetallurgyHigh intensity

An ultra-lightweight, high strength ceramic proppant made from mixture of naturally occurring clays, preferably porcelain clay, kaolin and / or flint-clay, earthenware clay or other naturally occurring clays having an alumina content between about 5.5% and about 35%. The proppant has an apparent specific gravity from about 2.10 to about 2.55 g / cc, and a bulk density of from about 1.30 to about 1.50 g / cc. This ultra-lightweight proppant is useful in hydraulic fracturing of oil and gas wells, and has greater conductivity than sand at pressures up to 8,000 psi as measured by Stim-Lab after 50 hours and 275° F. on Ohio Sandstone, in the presence of deoxygenated aqueous 2% solution of KCI.

Owner:PROP SUPPLY & SERVICE

Aluminum-based composite radiating material for high strength LED

The invention relates to a lamp radiating material and particularly relates to an aluminum-based composite radiating material for a high strength LED and a production method of the material. The radiating material is prepared from the following raw materials in parts by weight: 78-82 parts of aluminum, 5-7 parts of aluminum nitride, 1-2 parts of nanocarbon, 8-10 parts of nicochrome, 7-9 parts of nano ceramic powder, 12-15 parts of metakaolin, 1-2 parts of graphene, 5-8 parts of sodium aluminate, 2-4 parts of zinc sulfate, 3-5 parts of mulberry wood, 2-3 parts of folium mori powder and 4-5 parts of auxiliaries. The radiating material provided by the invention integrates the advantages of substances such as the nano ceramic powder, metakaolin, graphene, mulberry wood and the like; metakaolin is soaked by using a sodium aluminate solution, so that the radiating material is high in strength, hard to disintegrate at a high temperature and easy to form; the mulberry wood and folium mori powder which is soaked by the sodium aluminate solution and carbonized at the high temperature is strong in heat absorption. The radiating material prepared by the invention is smooth and compact in surface, has a high heat conductivity coefficient and a quick radiating capacity, and is good in insulating property, high in strength, strong in impact resistance, aging-resistant and long in service life.

Owner:RUIHUA HEFEI ELECTRONICS TECH

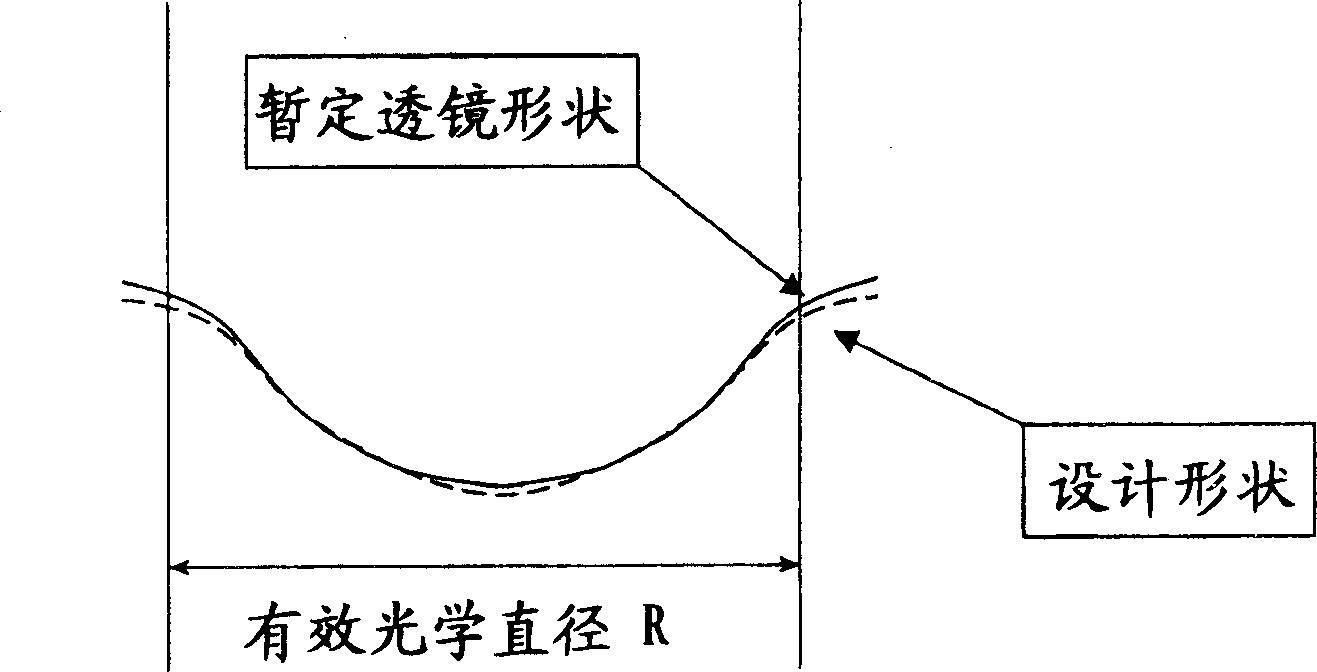

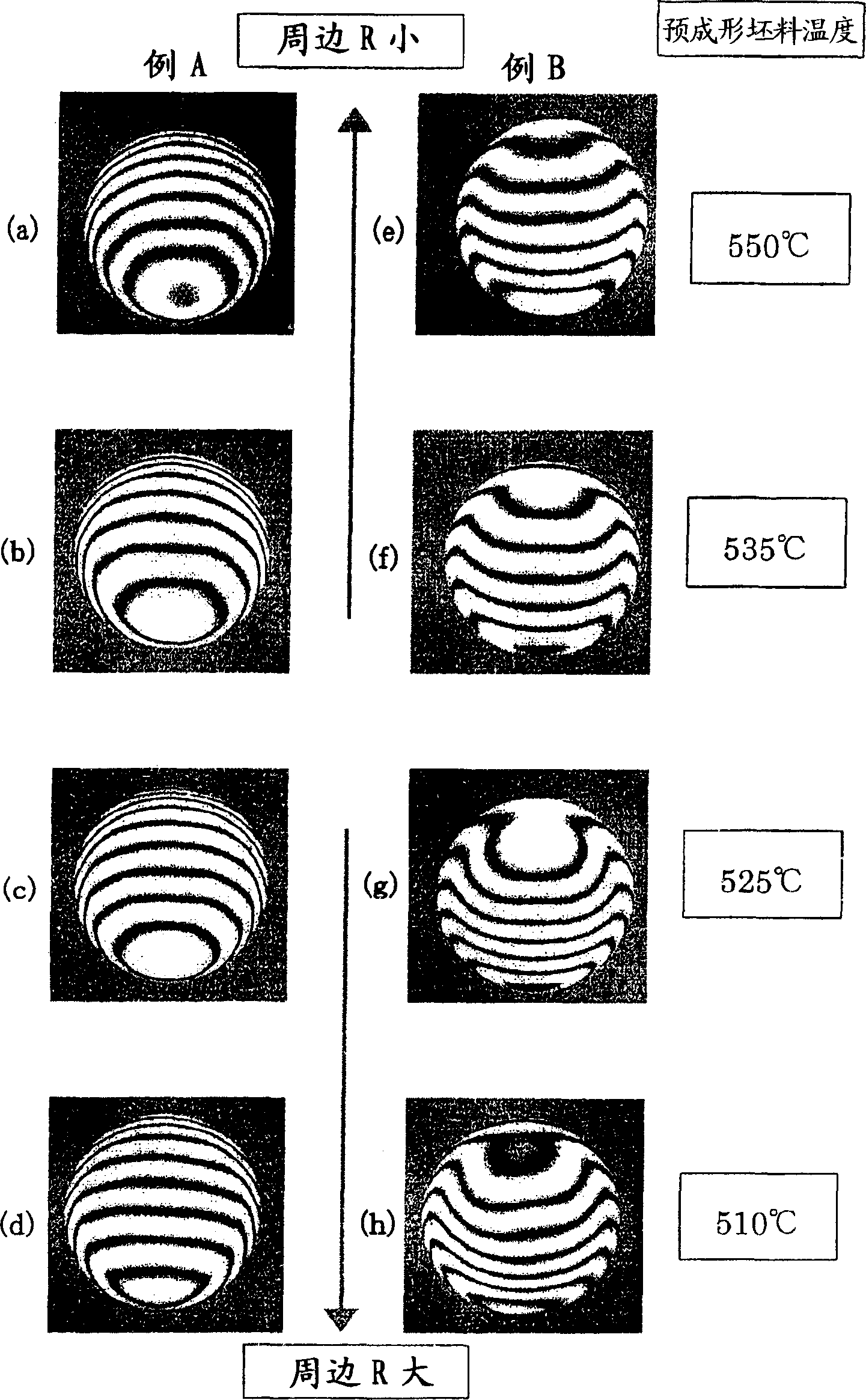

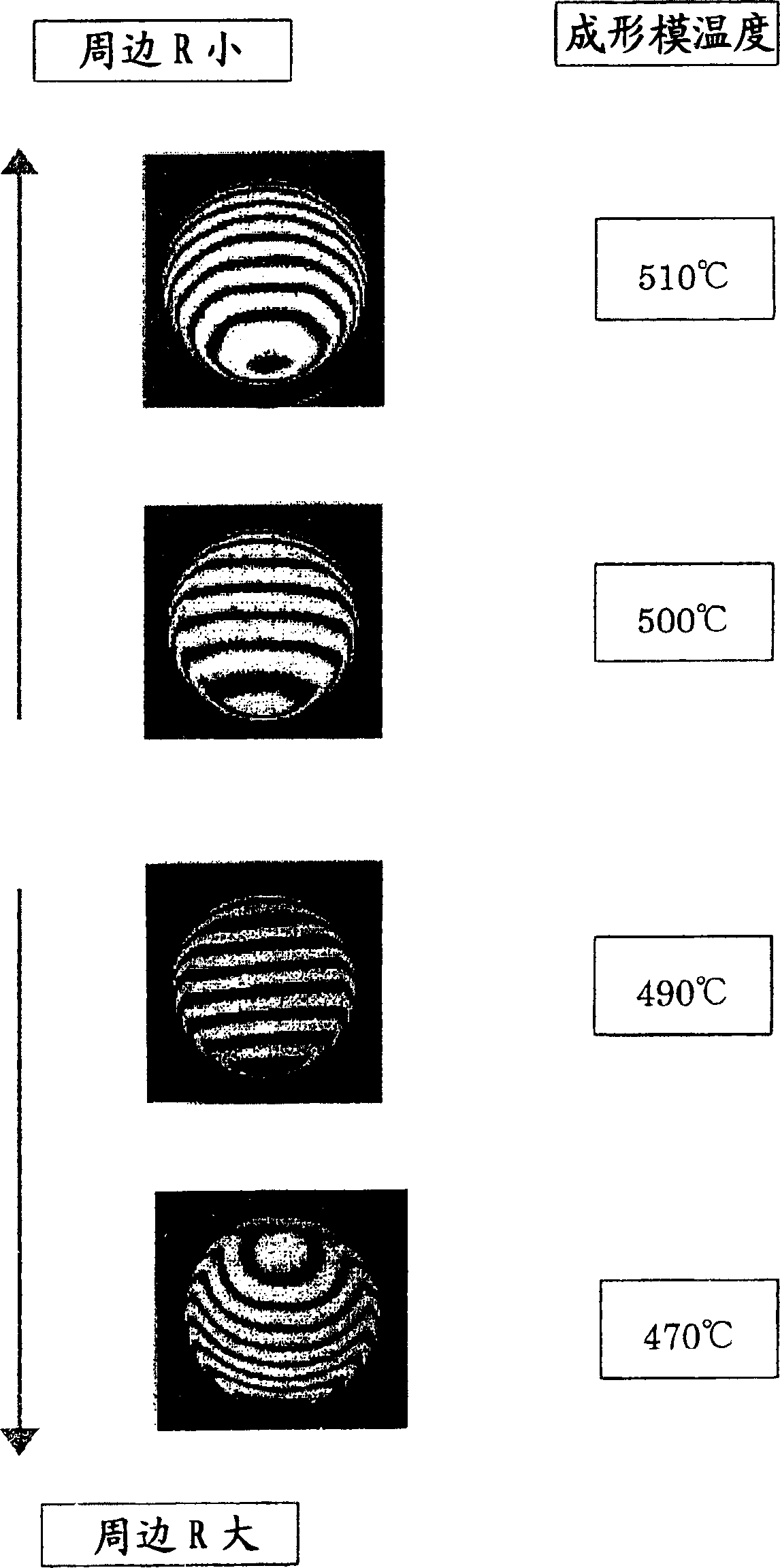

Method for manufacturing lens

InactiveCN1550458AImprove surface accuracyOptimum pressure processing conditionsGlass pressing apparatusGlass press-moulding apparatusEngineeringMechanical engineering

Method of manufacturing a concave meniscus lens with good surface precision. The method of manufacturing a concave meniscus lens method comprises press molding a glass material in a heat-softened state with a pressing mold. The heated glass material is fed between the molding surfaces of the preheated upper and lower pressing molds and press molded, and the upper and lower pressing molds are cooled to obtain a temporary lens; and when an irregularity is produced on one of the surfaces of the temporary lens, the temperature of the glass material, the preheating temperature of the upper and / or lower molds, or the cooling rate of the upper and / or lower molds is corrected to obtain a corrected lens. When the press molding of the temporary lens is conducted by the first and second pressure applications and an irregularity is produced on one of the surfaces of the temporary lens, the load of the second pressure application is corrected to obtain a corrected lens. The correction is repeated until the irregularity of the corrected lens obtained falls within the permitted range.

Owner:HOYA CORP

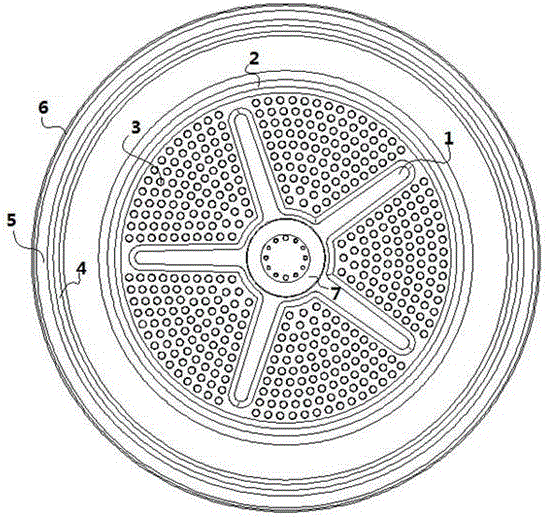

Inner-barrel back cover for dry washers and manufacturing method of inner-barrel back cover

InactiveCN106702670AMeet the needs of useNo loss of lightOther washing machinesTextiles and paperPunchingMachining

The invention discloses an inner-barrel back cover for dry washers and a manufacturing method of the inner-barrel back cover and belongs to the technical field of inner-barrel back cover machining. The inner-barrel back cover is manufactured by steps of material cutting, blanking, stretching, punching, flanging, riveting, packaging and the like. Quality of the product is strictly controlled, so that machining qualification rate of the inner-barrel back covers is high, and surface quality is good.

Owner:WUHU XIECHENG METAL PROD

Method for preparing bitter herb tea

The invention belongs to the field of tea processing, in particular relating to a method for preparing bitter herb tea, which is characterized by comprising the following steps: a, picking and pre-processing; b, de-enzyming; c, rolling and modeling; d, parching; and e, selecting. The invention solves the problems of ordinary mouthfeel and stronger bitter taste of the bitter herb tea manufactured by the existing method and a great amount of tea mince in the production process. The bitter herb tea obtained in the invention is characterized by having good mouthfeel, favorable color and less nutrition loss, has light bitterness, and is mellow and fragrant. The method realizes large scale industrialized production of the bitter herb tea.

Owner:陈进实

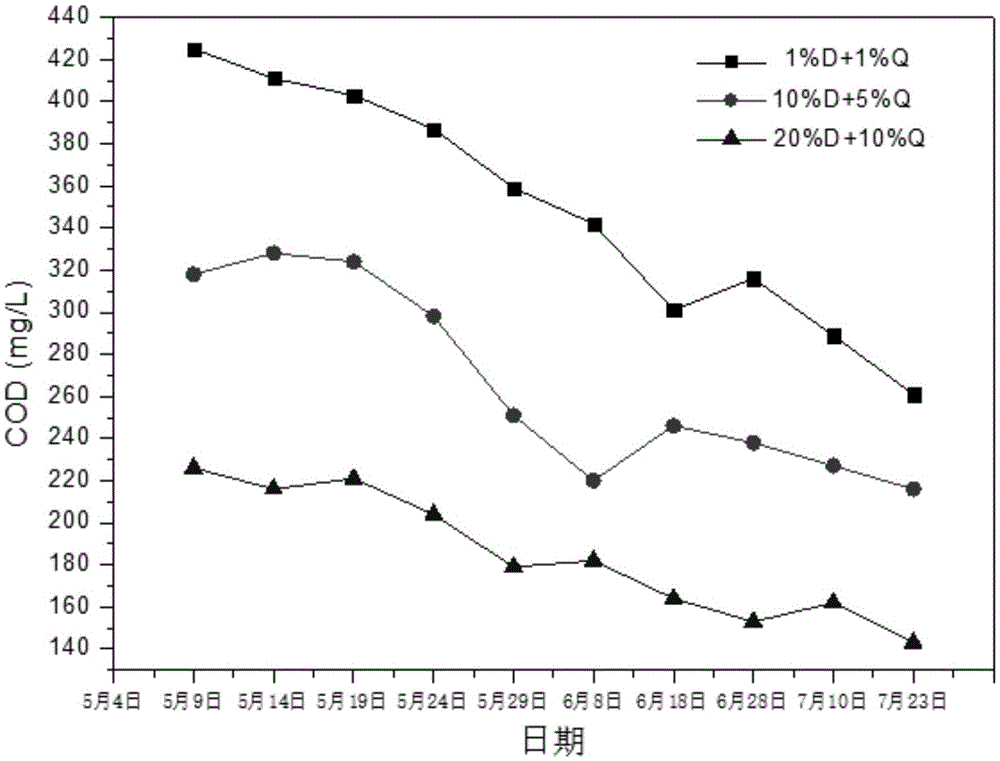

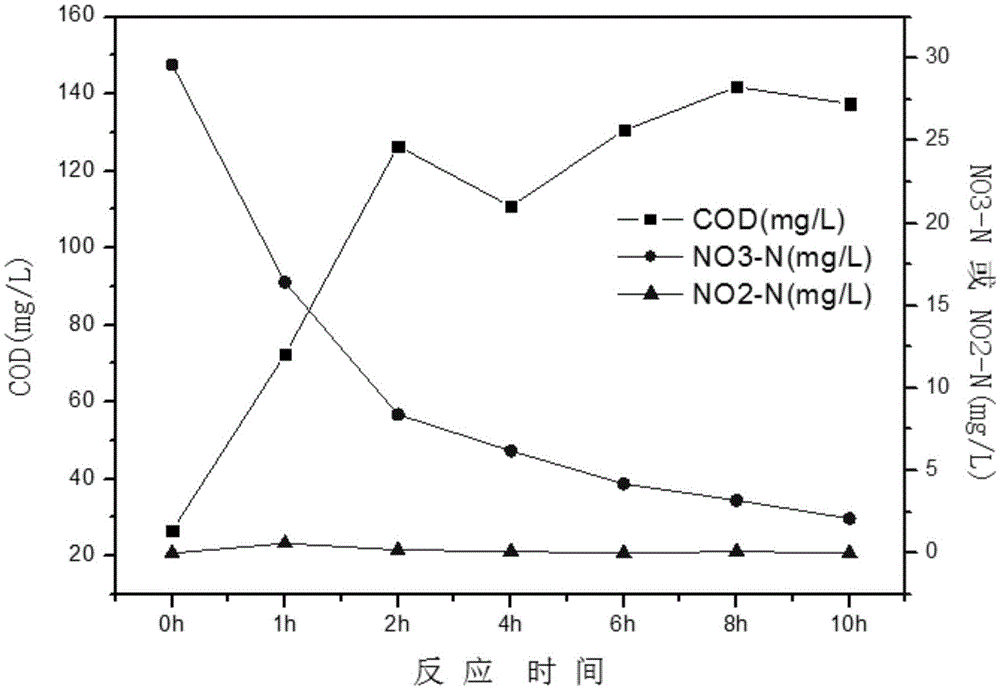

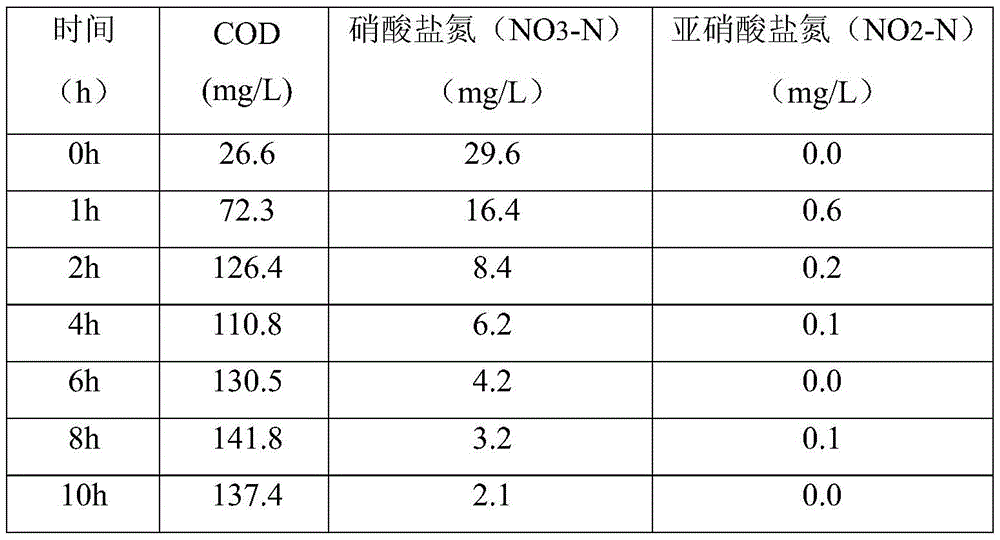

Bio-degradable sustained-release carbon material and preparation method thereof

InactiveCN105600926ALow priceEasy accessWater treatment compoundsTreatment with anaerobic digestion processesSolid carbonPollution

The invention discloses a solid carbon source having durable and stable sustained-release performance and a preparation method thereof. The method comprises the following steps: preparing an aqueous turbid liquid from a certain mass of starch-type powder and agar powder; heating, boiling, modeling and cooling to prepare a gel-shape solid sustained-release carbon material. The carbon material is a high-strength gel carbon source, has excellent strength, elasticity, transparency, permeability and reversibility, can be used for adjusting the carbon release amount at different levels, and has relatively high application effect and value. The sustained-release carbon material is simple in process, is prepared from low-price and easily-available raw materials, does not need to be added with other auxiliary materials, is low in cost, does not have secondary pollution, and is suitable for long-term application in water treatment. According to the carbon material, microorganisms have strong adaptability to the carbon source in the denitrification process, hardly have delay, and have good biodegradability. The method also can be used for sustainably releasing pesticide, fertilizer and the like.

Owner:卓勒(上海)环境工程有限公司

Boiler molded coal and preparation thereof

The invention discloses a boiler type coal and a method for preparing the same. The boiler type coal comprises the following compositions in portion by weight: 60 to 90 portions of Datong coal powder, 5 to 15 portions of caking agent (counted by dry matter), 1 to 20 portions of clinker, 1 to 10 portions of sulfur-fixing agent and 0.05 to 1.5 portion of combustion-supporting agent. The caking agent is formed by treating a starch material in inorganic dilute alkali solution at a temperature of between 50 and 85 DEG C. The preparation method comprises the following steps: the raw materials of the powdery coal, the caking agent, the clinker, the sulfur-fixing agent and the combustion-supporting agent are evenly mixed, molded and dried. The boiler type coal can be well molded, has good mechanical strength and waterproof performance and is suitable for a large-medium-scale boiler of over 20 tons / hour.

Owner:天津环宇净能环保科技有限公司

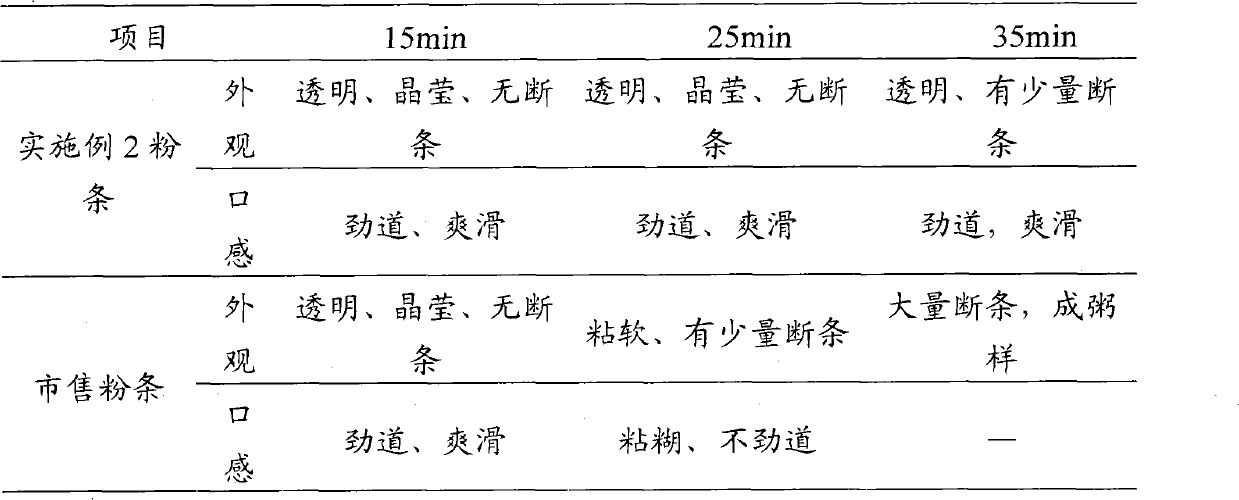

Production method of starch noodles

The invention provides a production method of starch noodles, comprising the following steps of: mixing 20-40 parts by weight of mung bean starch and 60-80 parts by weight of potato starch to make dough after being gelatinized; sequentially carrying out steaming, forming, noodle leaking and soaking processing on the dough to obtain soft starch noodles; freezing the soft starch noodles, and drying to obtain the starch noodles. The potato starch has less viscosity and difficult forming, the mung bean starch with better hardness is added to the potato starch so as to enhance the forming property of the starch and enable the starch to be subjected to the traditional noodle leaking process to obtain the starch noodles which have better taste and difficult overmaturation and breakage. The production method does not need the dry process for a long time, freezes and dries the soft starch noodles obtained after the noodle leaking and the soaking and can eliminate the water contained in the soft starch noodles within shorter time, thereby shortening the production period of the starch noodles and enhancing the production efficiency of the starch noodles.

Owner:吕福玲

Inorganic particle modified magnetic composite material and preparation method thereof

InactiveCN105778089AImprove magnetic propertiesImprove surface strengthDispersityPolyethylene glycol

The invention discloses an inorganic particle modified magnetic composite material. The composite material is composed of, by weight, 3-4 parts of aluminum isopropoxide, 100-130 parts of ferric chloride hexahydrate, 60-69 parts of ferrous chloride tetrahydrate, 0.1-0.2 part of silane coupling agent kh560, 0.3-0.5 part of tea saponin, 40-54 parts of ammonium persulfate, 40-57 parts of pyrrole, 0.4-0.6 part of ethyl cellulose, 3-6 parts of tetraethoxysilane, 1-2 parts of polymaleic anhydride, 0.04-0.1 part of palm wax, 0.06-0.1 part of polysorbate, 0.4-1 part of polyacrylamide, 2-3 parts of polyethylene glycol, 0.1-0.16 part of dipotassium glycyrrhizinate, 0.7-1 part of calcium acetylacetonate, 50-60 parts of alcohol solution of 70-75% and 60-70 parts of anhydrous alcohol. By adding the composite material high in dispersity into polypyrrole, compactness of polypyrrole can be improved to certain extent, so that electroconductivity and environmental stability of the composite material are improved. The inorganic particle modified magnetic composite material has both electrical performance and magnetic performance and has important application value in the field of stealth technology and electromagnetic shielding.

Owner:赵守彬

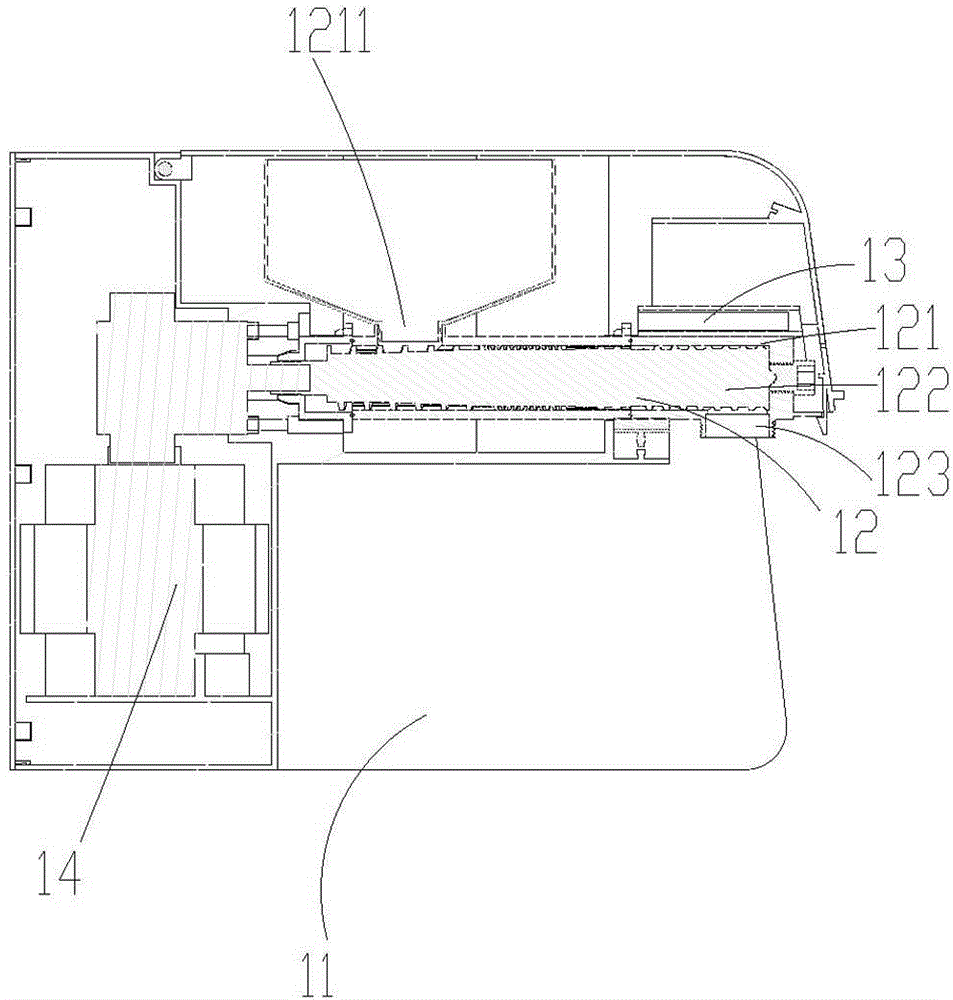

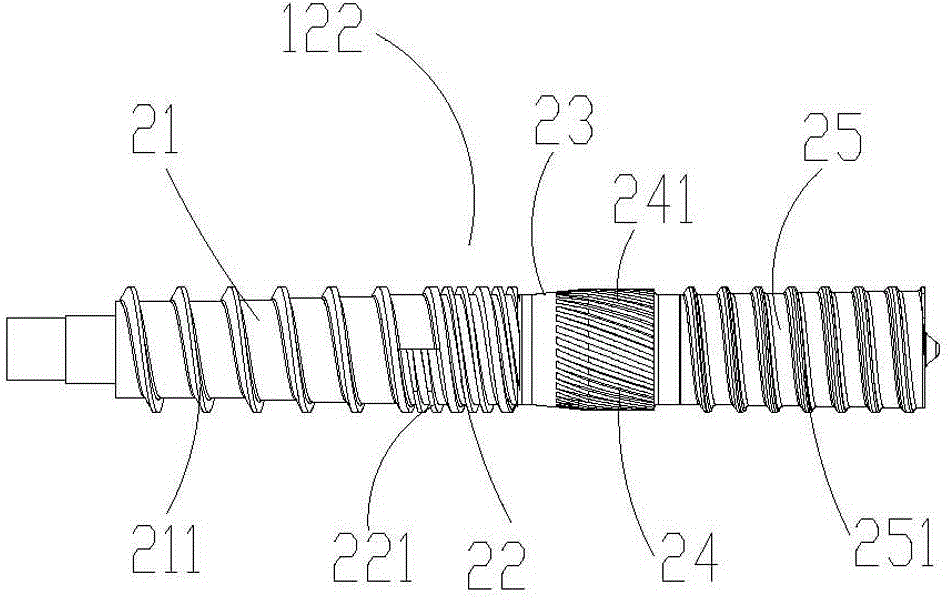

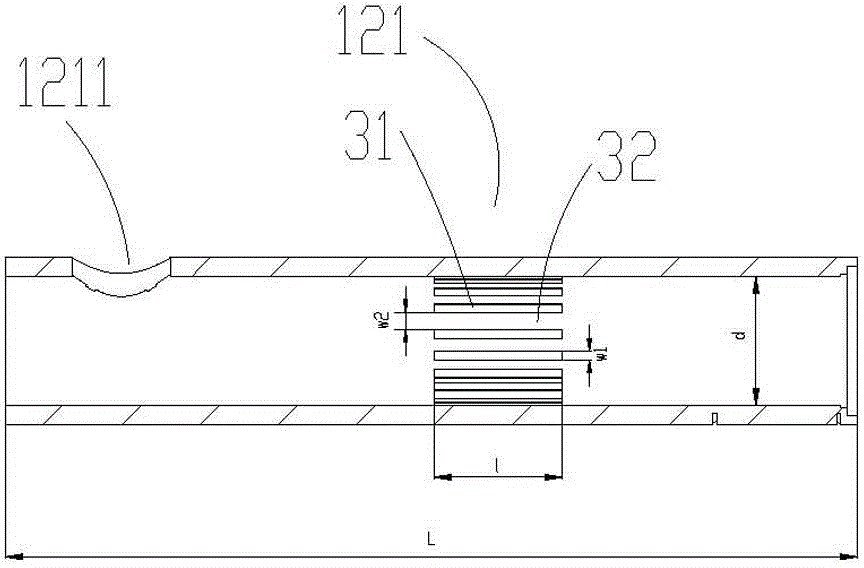

Household rice noodle machine

ActiveCN104642865APoor feedingImprove water absorptionFood shapingFood preparationEngineeringRice flour

The invention relates to a household rice noodle machine which comprises a base, a crushing, extruding and forming system, a heating device and a driving system, wherein the crushing, extruding and forming system comprises an extruding and grinding cavity, a screw rod and a forming die head; the heating device is used for heating the extruding and grinding cavity; a feed inlet is formed in one end of the extruding and grinding cavity while the forming die head is formed at the other end of the extruding and grinding cavity; the screw rod is located in the extruding and grinding cavity, and is sequentially provided with a material propelling section, a coarse crushing section, a fine crushing and grinding section and an extruding section along the direction from the feed inlet to the forming die head; the screw rod is integrally formed; grinding helical teeth are uniformly distributed in the circumferential direction of the fine crushing and grinding section; grinding straight teeth corresponding to the grinding helical teeth are formed in the extruding and grinding cavity; the grinding straight teeth are uniformly distributed on the inner surface of the extruding and grinding cavity; a grinding slot is formed between every two adjacent grinding straight teeth; and a grinding gap h1 is formed between each grinding straight tooth and the grinding helical tooth. The household rice noodle machine provided by the invention is provided with the screw rod and the extruding and grinding cavity which is matched with the screw rod, and rice noodles which are relatively good in taste and appearance are prepared.

Owner:JOYOUNG CO LTD

Method for manufacturing carbon nanotube electrocatalytic electrode for organic waste water treatment

InactiveCN1763253ASpecial hollow structureImprove electrocatalytic activityWater/sewage treatmentElectrodesEpoxyCarbon nanotube

The present invention relates to the making process of carbon nanotube electrically catalytic electrode for treating organic waste water, and belongs to the field of electrode material production in electrically catalytic oxidation technology. After carbon nanotube with high catalytic activity and great specific surface area and binder PTFE in certain ratio are mixed, the mixture is cold pressed to form and wire is led out from one end of the epoxy resin cured electrode. The carbon nanotube electrically catalytic electrode has high conducting performance and low power consumption, and may be modified to obtain high electrically catalytic activity. The carbon nanotube electrically catalytic electrode is suitable for use in treating organic waste water and has high degradation rate on organic matter in waste water.

Owner:SHANGHAI UNIV

High toughness ceramic material for cutting tools and preparation method thereof

The invention relates to a high toughness ceramic material for cutting tools. The high toughness ceramic material is prepared from the following raw materials by weight part: 2-3 of glycerol, 5-6 of diethylene glycol, 20-25 of silicon nitride, 3-5 of Y2O3, 18-22 of spodumene, 7-9 of eucryptite, 3-5 of lithium carbonate, 0.5-0.7 of rhodium oxide, 34-37 of ZrO2, 1-2 of zinc phosphate, 50-58 of mullite, a proper amount of deionized water, a proper amount of ethanol, 1.7-2 of polyethylene glycol, and 3-4 of a wear-resistant additive. The ceramic provided by the invention is added with rhodium oxide, so that the ceramic has increased toughness, is easy to shape and is not easy to break. By adding zinc phosphate and mullite, the wear resistance of the ceramic is increased, the ceramic can be suitable for making cutting tools, and the cost is low. By using the wear-resistant additive involved in the invention, surface smoothness, wear resistance and heat resistance of the ceramic can be increased.

Owner:HEFEI DONGLU MACHINERY MFG

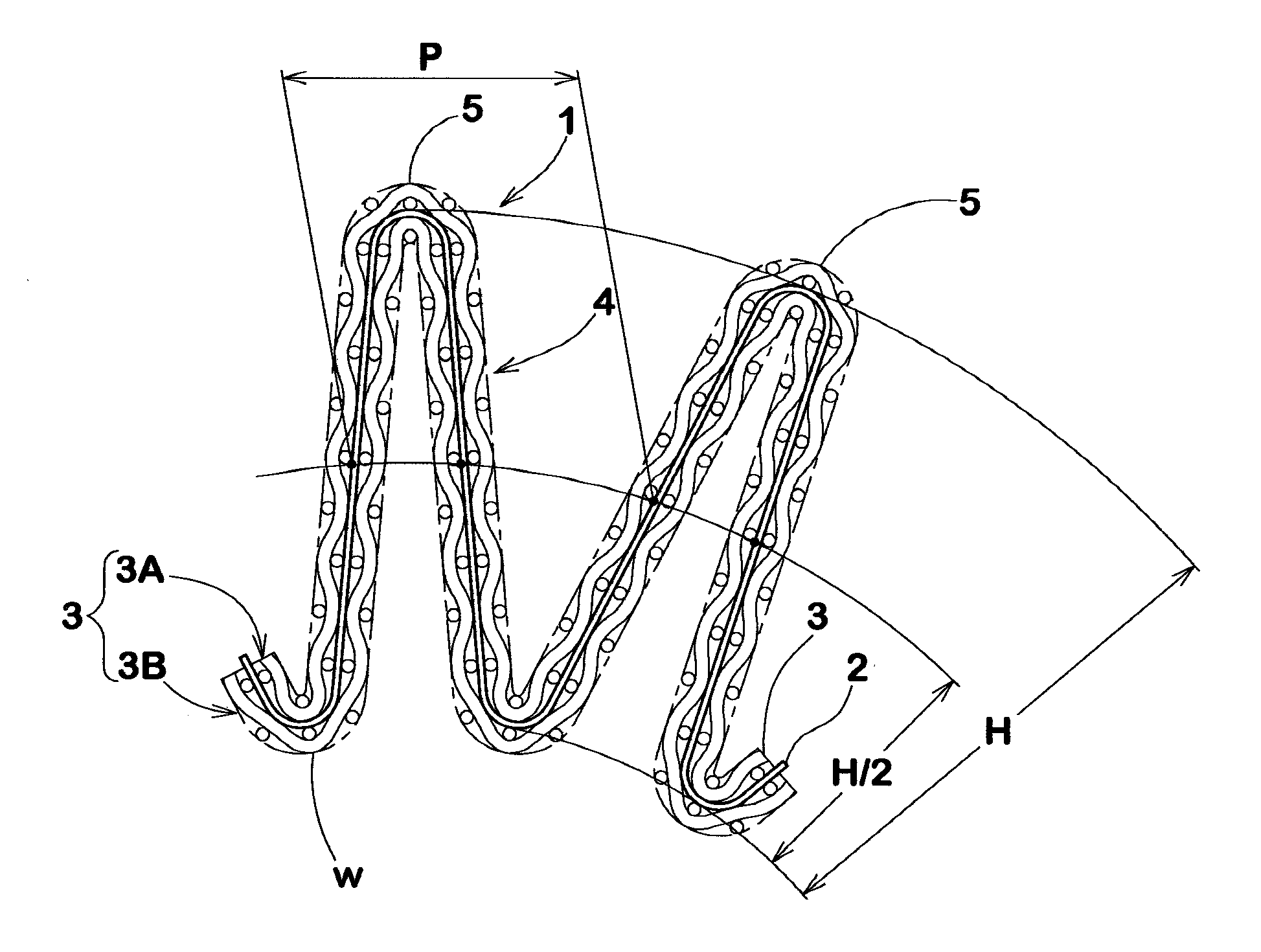

Composite membrane material for hydrogen separation and element for hydrogen separation using the same

ActiveUS8226751B2Effectively utilize it for hydrogen separationDifficult to shapeSemi-permeable membranesMembranesHydrogenMetal

A composite membrane material characterized by comprising a hydrogen-permeable membrane which is selectively permeable to hydrogen and is formed by rolling to a thickness of 30 μm or less which is difficult for the membrane by itself to retain its shape, and a shape-retention mesh which is disposed on at least one side of the hydrogen-permeable membrane and is composed of a wire of a high-melting metal which does not cause thermal diffusion into the hydrogen-permeable membrane, wherein the hydrogen-permeable membrane and the shape-retention mesh are superposed and subjected to a pleat processing in a non-bonded state so that they are separable and the hydrogen-permeable membrane has a surface area increased at least 3 times per unit area. This material is used to constitute a hydrogen separation element.

Owner:NIPPON SEISEN CO LTD

Manufacturing method of non-woven needle-punched jacquard pad

The invention discloses a manufacturing method of a non-woven needle-punched jacquard pad. The manufacturing method comprises following steps of opening a net, mixing, laying the net, needling, secondary needling, rolling, raising and needling the texture. The manufacturing method of the non-woven needle-punched jacquard pad has following beneficial effects: forming processes such as two-sided needling and secondary needling are utilized so that a fiber net is wound densely more; the needle-punched jacquard pad is not easily deformed and has high strength; the roller forming step is taken on a roller press and a water-spraying humidifying process goes on prior to rolling depression so that the fiber net is more easily deformed; a Jacquard technique is controlled at the same time; and the manufactured non-woven needle-punched jacquard pad is high in deformation resistance and better in flatness.

Owner:FUJIAN CHANGGENG NEW MATERIALS CO LTD

Composition and method for producing an ultra-lightweight ceramic proppant

ActiveUS20140216741A1Difficult to shapeReduce plasticityFluid removalCeramic shaping apparatusMetallurgyHydraulic fracturing

An ultra-lightweight, high strength ceramic proppant made from mixture of naturally occurring clays, preferably porcelain clay, kaolin and / or flint-clay, earthenware clay or other naturally occurring clays having an alumina content between about 5.5% and about 35%. The proppant has an apparent specific gravity from about 2.10 to about 2.55 g / cc, and a bulk density of from about 1.30 to about 1.50 g / cc. This ultra-lightweight proppant is useful in hydraulic fracturing of oil and gas wells, and has greater conductivity than sand at pressures up to 8,000 psi as measured by Stim-Lab after 50 hours and 275° F. on Ohio Sandstone, in the presence of deoxygenated aqueous 2% solution of KCI.

Owner:PROP SUPPLY & SERVICE

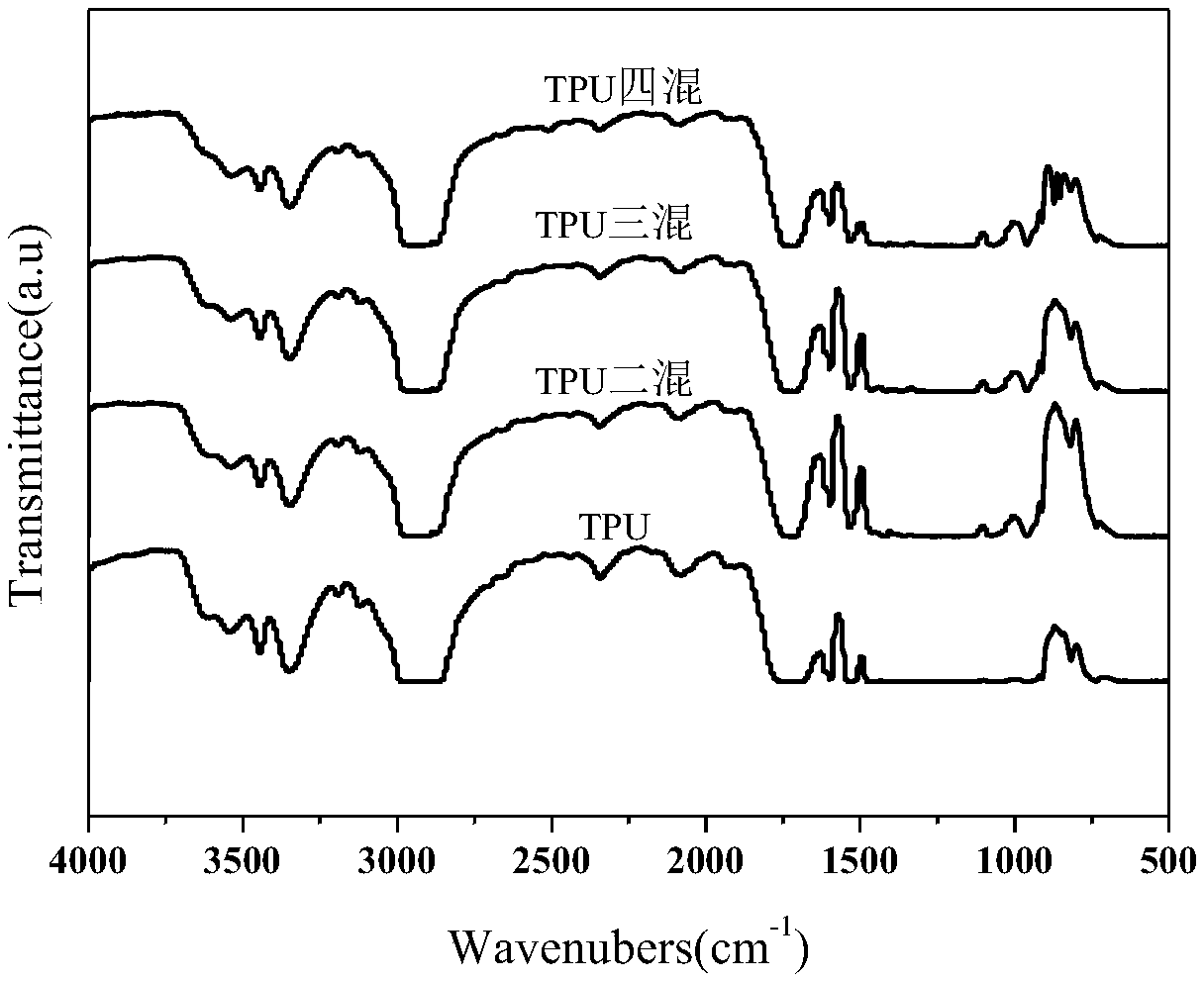

Hot melt adhesive for PVC-U winding pipe and preparation method and application thereof

InactiveCN108641661AImprove liquidityImprove high temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyvinyl chlorideThermoplastic polyurethane

The invention discloses hot melt adhesive for PVC-U winding pipe and a preparation method and application thereof. The hot melt adhesive is composed of thermoplastic polyurethane, polyvinyl chloride,138 rosin resin, nano CaCO3 and an antioxygen according to certain proportions. The preparation method comprises the steps that A, the thermoplastic polyurethane, the polyvinyl chloride, the 138 rosinresin and the nano calcium carbonate are respectively weighed and placed in a beaker, the antioxygen is added, and the mixture is mixed uniformly and poured in an internal mixer; B, the revolution ofthe internal mixer is set as 25-30 rpm / min, a certain temperature is controlled, and after the controlled certain banburying time, banburying stops; C, the banburying product is scraped by using a copper shovel, put on a polytetrafluoroethylene board for cooling, and put in a sealing bag with a label for standby application, and the hot melt adhesive for the PVC-U winding pipe is obtained. The invention further relates to application of the hot melt adhesive in sealing adhesion of the PVC-U winding pipe. The formula is reasonable, the method is simple, and the glue has good adhesive performance and good affinity with PVC board materials, is waterproof, has good corrosion resistance performance and good sealing performance, can replace traditional PVC glue, and has a good adhesive effect especially on PVC-U winding pipes with large diameters.

Owner:HUAZHONG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com