Hot melt adhesive for PVC-U winding pipe and preparation method and application thereof

A PVC-U, hot-melt adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the difficulty in meeting the bonding requirements of PVC-U winding pipes and the sealing of PVC-U winding pipes Problems such as difficulty in sex and affecting health, achieve superior compatibility, enhanced hardness and rigidity, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

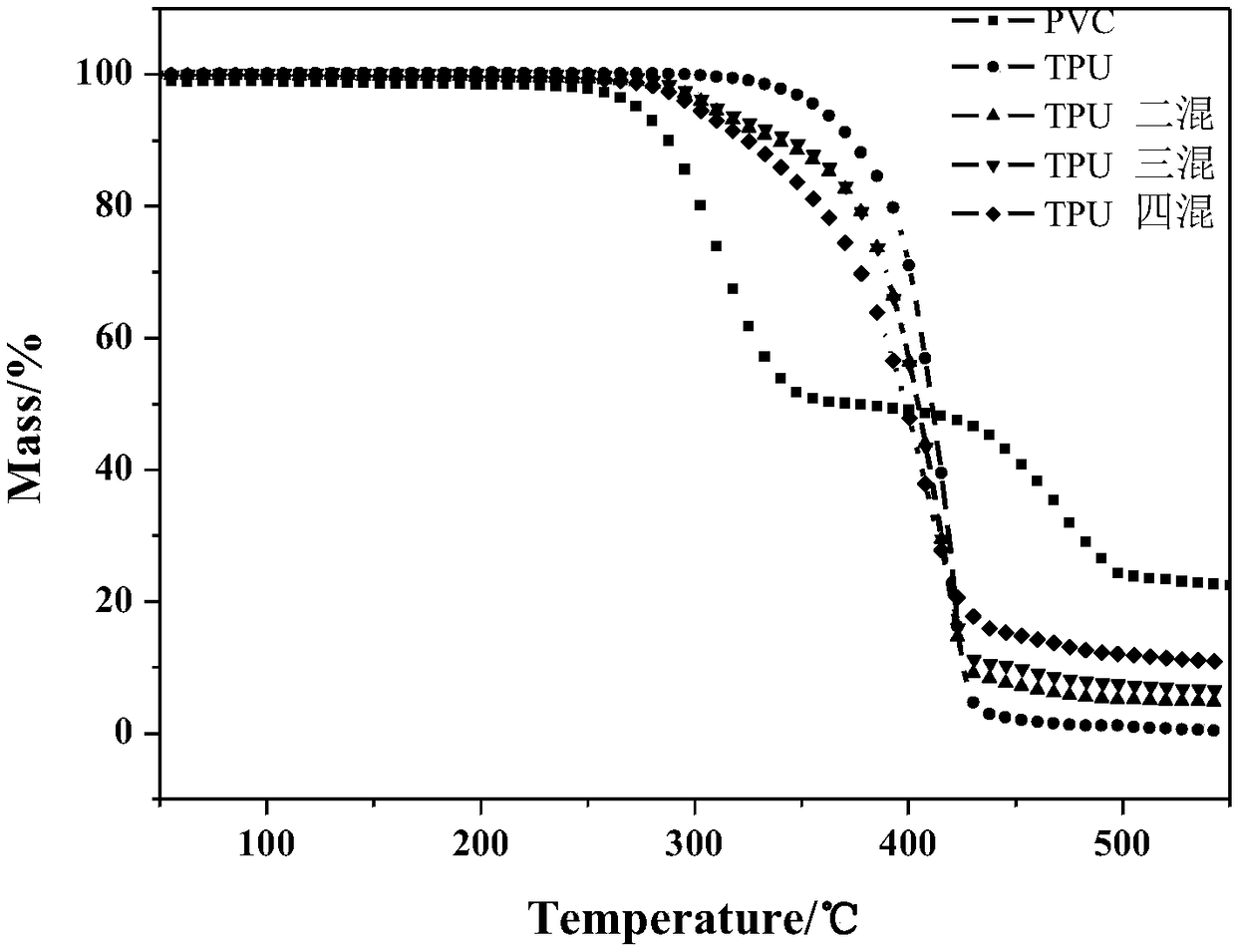

[0067] Embodiment 1: Compatibility and thermogravimetric analysis experiment

[0068] Weigh according to the following weight ratio, TPU / PVC=8:1, TPU / PVC / 138 rosin resin=8:1:0.5, TPU / PVC / 138 rosin resin / NanoCaCO 3 =8:1:0.5:0.5, the respectively weighed mixture is packed in a beaker, and add 0.1% antioxidant 1010, 0.1% antioxidant 168 of total weight, pour in the internal mixer after mixing, Set the number of revolutions to 30rpm, and the temperature to 150°C. After banburying for 5 minutes, stop banburying. Then use a copper shovel to scrape off the banburying product, put it on a polytetrafluoroethylene plate to cool to room temperature (15-25°C), and put it into a sealed bag with a label for later use.

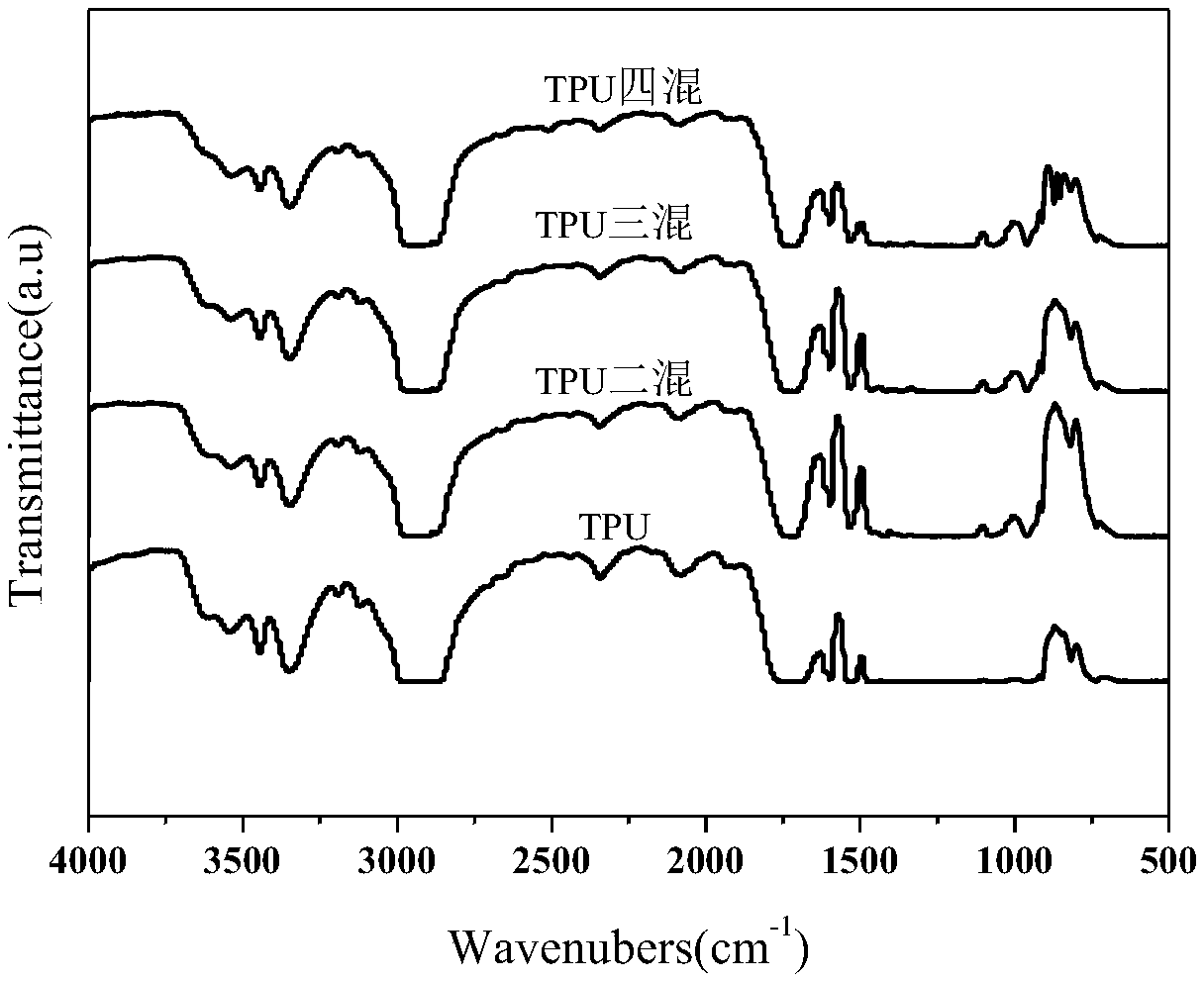

[0069] (1) Fourier transform infrared spectroscopy (FTIR) analysis

[0070] First, the hot melt adhesive sample to be tested is pressed into a light-transmitting film on a hot press, and the hot pressing temperature is the mixing temperature of the hot melt adhesive (150°C...

Embodiment 2-6

[0080] Embodiment 2-6: TPU / PVC Optimum Proportion Experiment

[0081] A preparation method of hot melt adhesive for PVC-U winding pipe, the steps are:

[0082] A. Weigh thermoplastic polyurethane and polyvinyl chloride respectively according to the weight ratio in Table 1, put them into a beaker, add antioxidant 1010 and antioxidant 168, mix well, and pour them into the internal mixer;

[0083] B. Set the rotation speed of the internal mixer to 30rpm / min, the temperature to 150°C, and stop the internal mixing after 5 minutes;

[0084] C. Scrape off the banburying product with a copper shovel, put it on a polytetrafluoroethylene plate to cool to room temperature (15-25°C), and then put it in a sealed bag with a label for later use to obtain hot melt adhesive samples A2-A6 .

[0085] Table 1 Embodiment 2-6 raw material ratio table

[0086]

Example 2

Example 3

Example 4

Example 5

Example 6

Thermoplastic Polyurethane (wt%)

83.2

85.5

...

Embodiment 7-11

[0093] Embodiment 7-11: 138 rosin resin optimal addition experiment

[0094] Weigh thermoplastic polyurethane (TPU), polyvinyl chloride (PVC), 138 rosin resin (rosin) respectively according to the weight ratio in Table 3, put into a beaker, add antioxidant 1010 and antioxidant 168, mix well , into the internal mixer;

[0095] Other steps were the same as in Example 2 to obtain samples A7-A11 of hot melt adhesive for PVC-U winding pipes.

[0096] Table 3 Embodiment 7-11 raw material ratio table

[0097]

Example 7

Example 8

Example 9

Example 10

Example 11

Thermoplastic Polyurethane (wt%)

87.8

86

85.2

84.3

83.4

Polyvinyl chloride (wt%)

11

10.8

10.6

10.5

10.4

138 Rosin resin (wt%)

1

3

4

5

6

Antioxidant 1010(wt%)

0.1

0.1

0.1

0.1

0.1

Antioxidant 168(wt%)

0.1

0.1

0.1

0.1

0.1

[0098] Leave the samples A7, A8, A9, A10, and A11 to cool for mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com