Patents

Literature

1543results about "Rosin adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

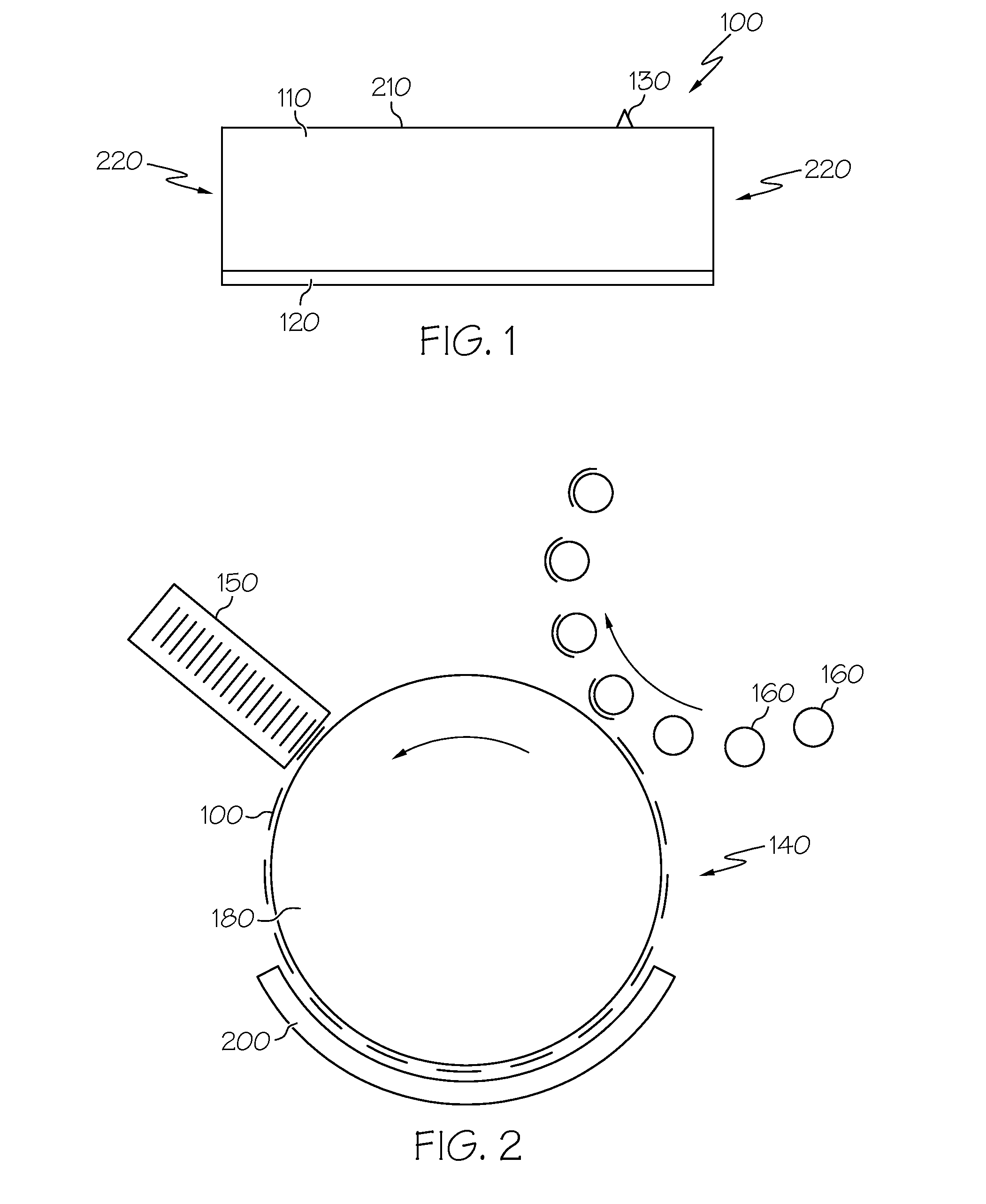

Spin-on adhesive for temporary wafer coating and mounting to support wafer thinning and backside processing

InactiveUS6869894B2Semiconductor/solid-state device testing/measurementSynthetic resin layered productsAdhesiveFluorescence

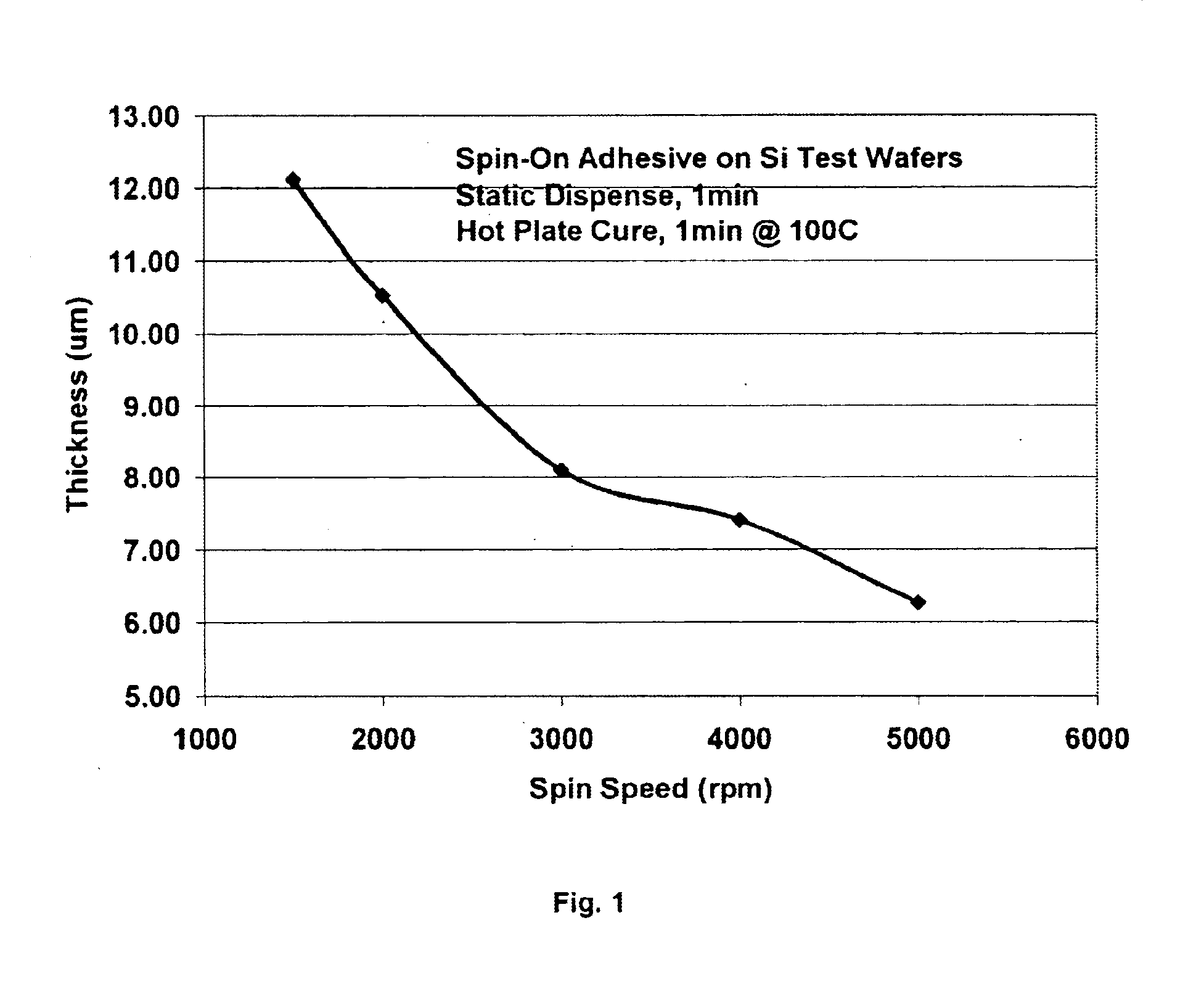

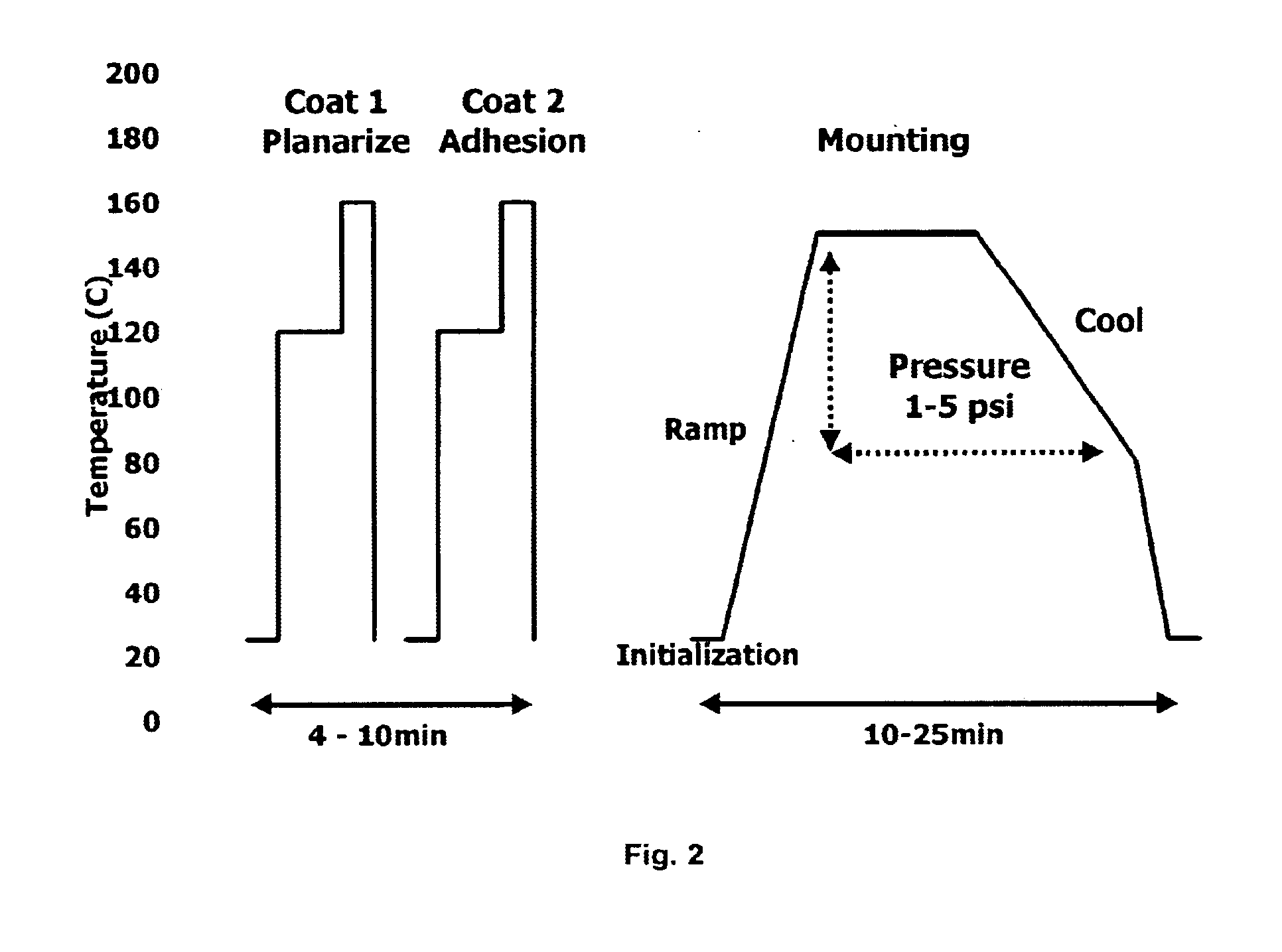

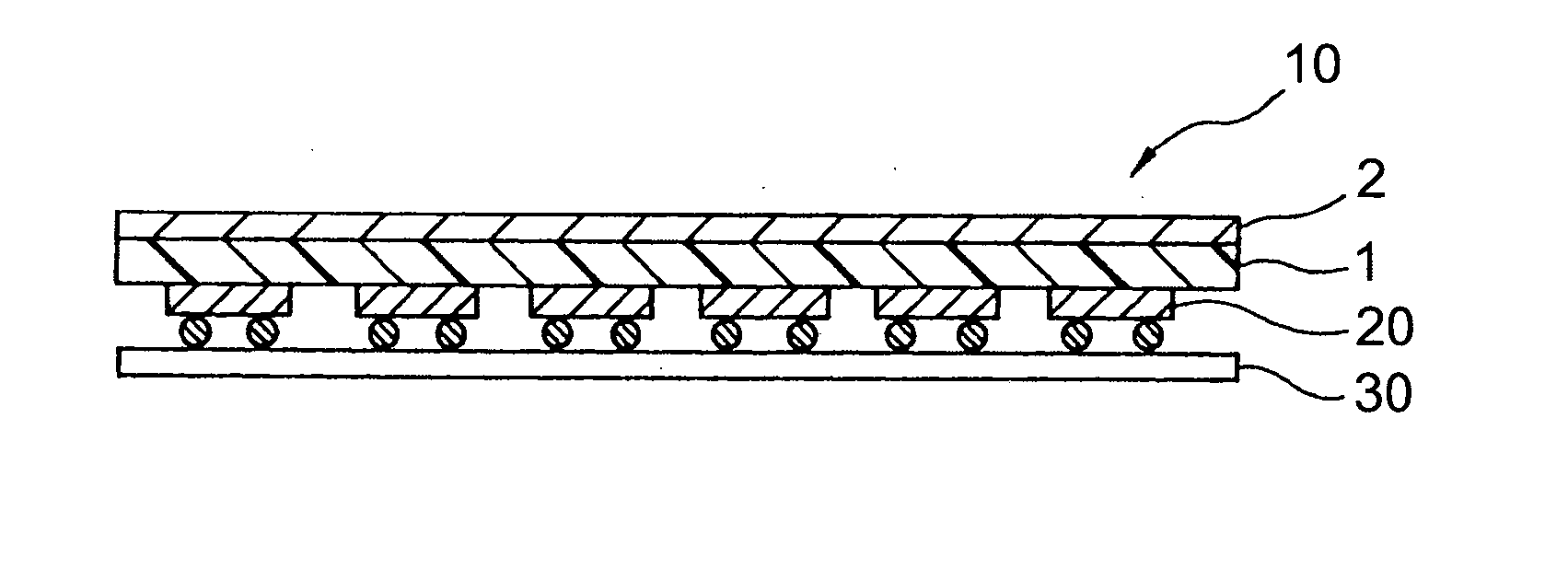

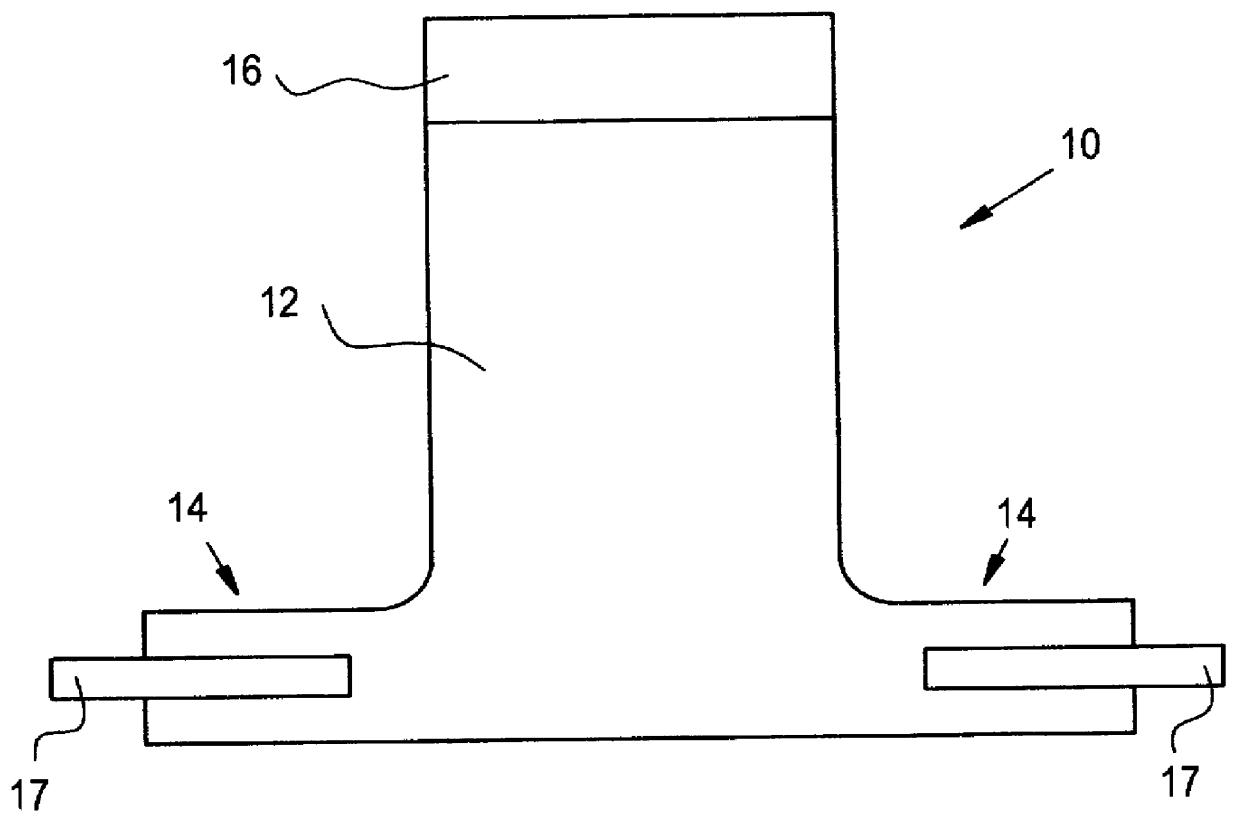

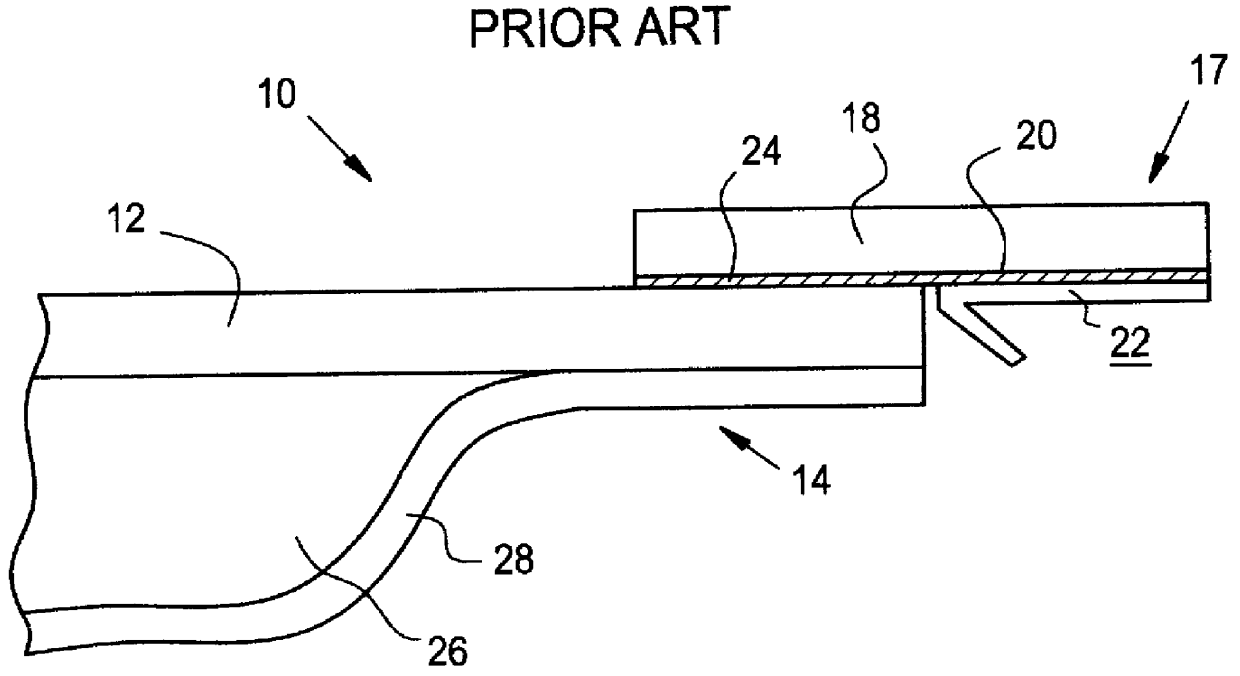

A liquid form adhesive system is provided for spin-coating on wafers and mounting to rigid carrier substrates to support thinning and backside processing. The liquid adhesive comprises about 30-35% of a rosin, between 5-10% of a thermoplastic urethane, a nonionic surfactant present between 1-3%, and a trace of an ultraviolet fluorescing dye. The entire system is dissolved in 50-65%, by weight, of a dual solvent mixture composed of dimethylacetamide and propylene glycol monomethyl ether. When the mixture is made to a specific viscosity, filtered, applied by a spin-coating method to the wafer frontside surface, and cured, the result is a uniform and smooth surface of defined thickness. When the coated wafer is mounted to a rigid substrate, it may be mechanically thinned to thicknesses down to and beyond 25 um, depending upon the wafer composition, diameter, and process. Once thinned, the adhesive is safe for backside processing and is dissolved away at completion to provide a thinned wafer that is clean and ready for final dicing or chipping operations.

Owner:GENERAL CHEM CORP +1

Film adhesive for sealing, film laminate for sealing and sealing method

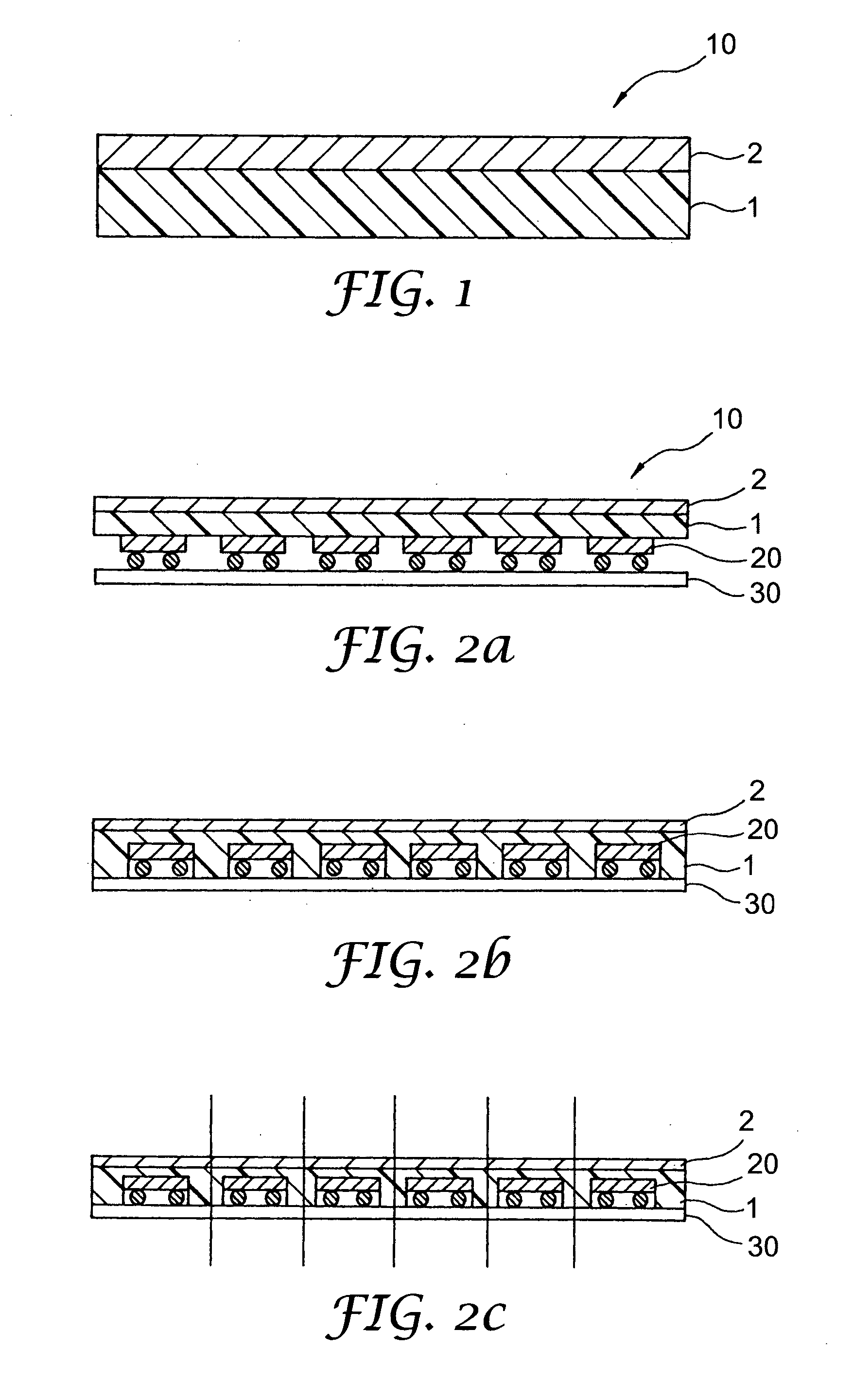

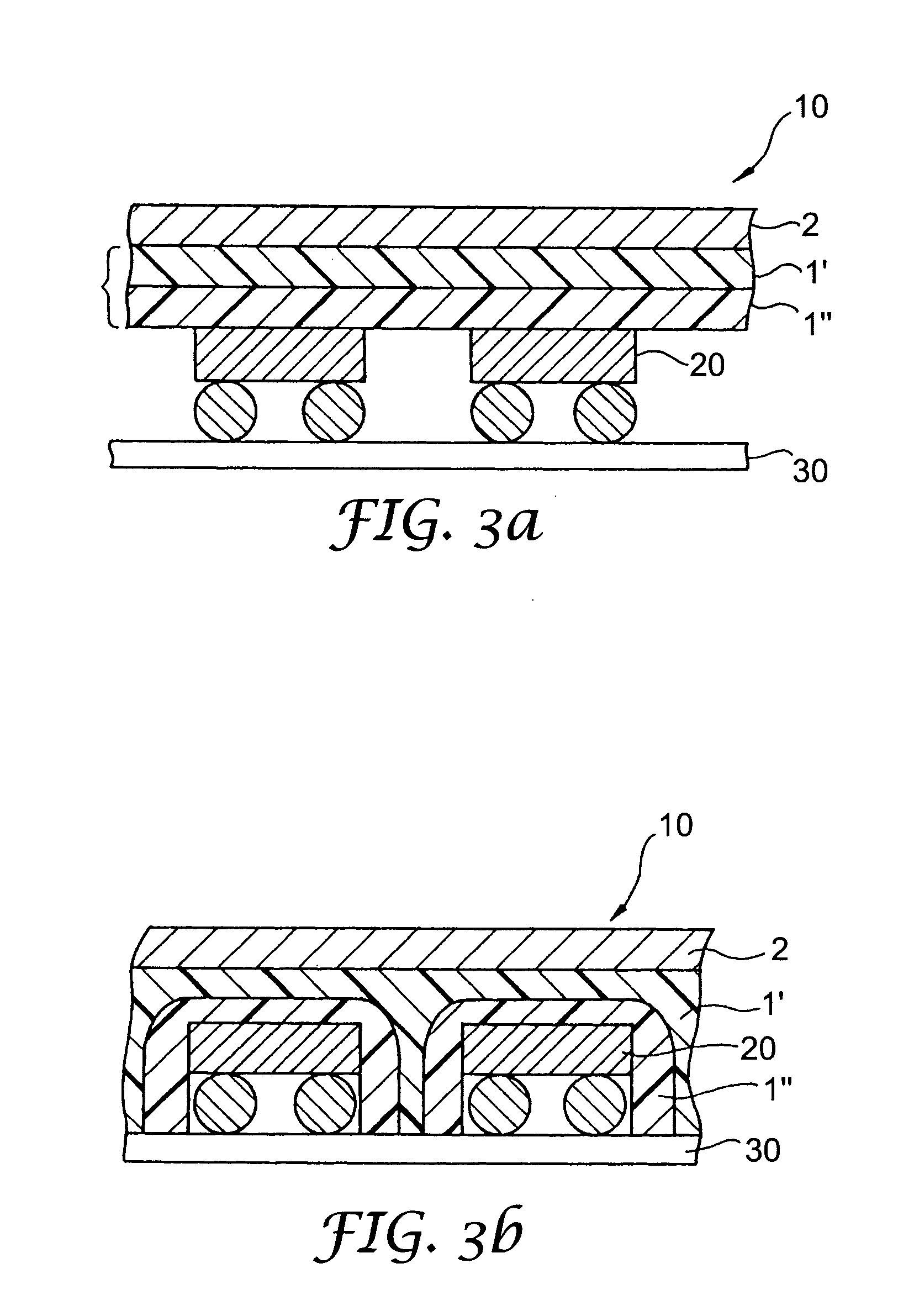

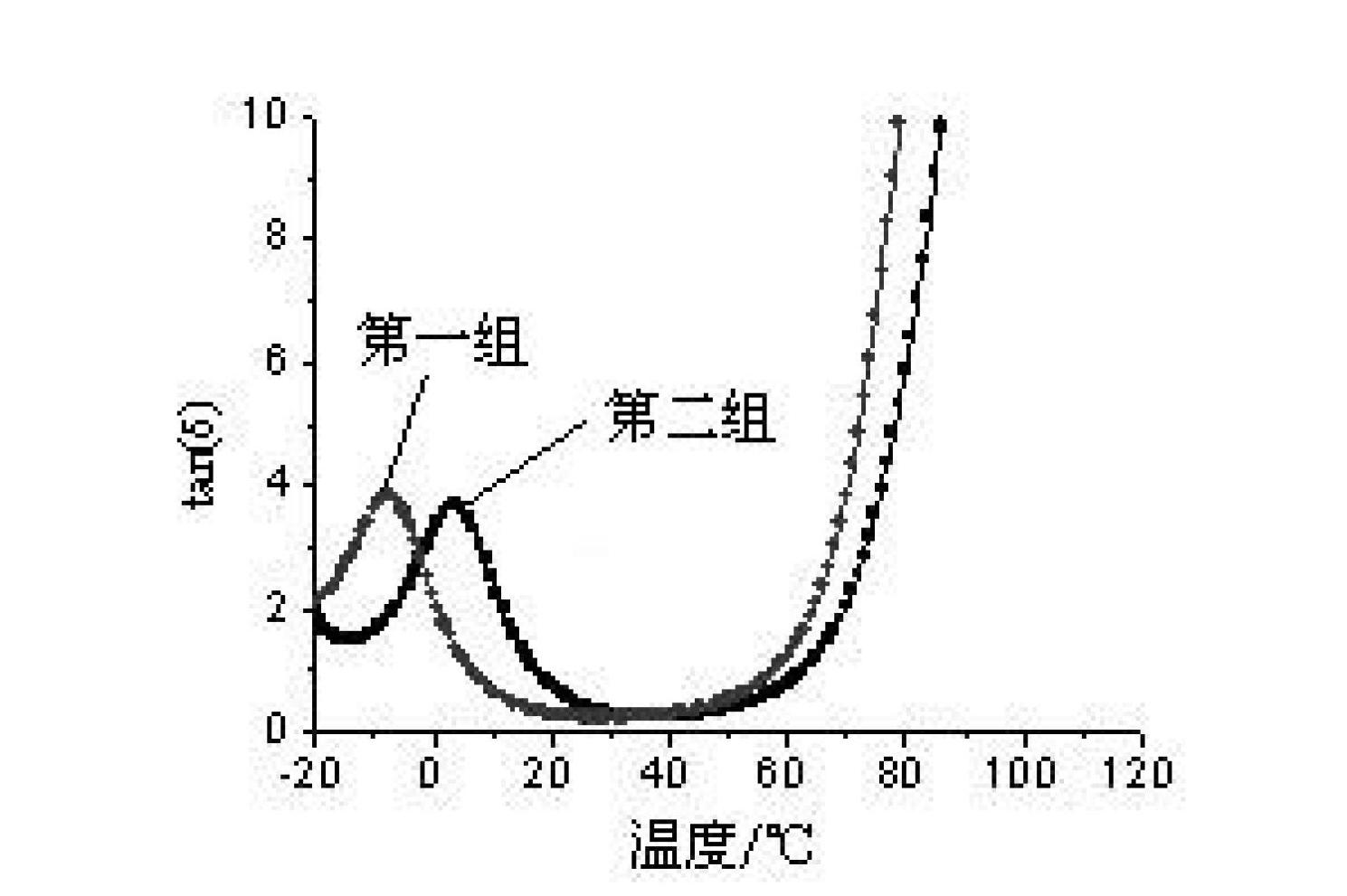

InactiveUS20040213973A1Poor compatibilityReduce adhesionImpedence networksSemiconductor/solid-state device detailsDynamic viscoelasticityAdhesive

A film adhesive for sealing a plurality of chip-type devices on a substrate at one time, including an adhesive layer of an adhesive composition which exhibits a minimum value of a storage modulus of elasticity before curing from 1x10<3 >to 5x10<5 >Pa measured by using a dynamic visco-elasticity measuring apparatus while elevating the temperature from 80° C. to 150° C. at an elevating temperature rate of 2.4° C. / min and at a shearing rate of 6.28 rad / sec and a storage modulus of elasticity after curing from 5x10<5 >to 5x10<7 >Pa measured by using a dynamic visco-elasticity measuring apparatus at a sample temperature of 150° C. in a tensile mode at a measuring frequency of 6.28 rad / sec.

Owner:3M INNOVATIVE PROPERTIES CO

Thin plastic film

A covering for a portion of a body or an object, as well as improved, thin plastic films for use in such coverings, are disclosed. The covering comprises a thin plastic film and a pressure sensitive adhesive contacting at least a portion of, and forming a joint with, the thin plastic film. The plastic film comprises from about 85 to about 95 weight percent plastic, and from about 5 to about 15 weight percent tackifier. Such joints may be found in diapers, adult incontinent briefs, bandages, and other body coverings, as well as packagings for a variety of objects. Such joints exhibit unexpectedly high shear adhesion as compared to conventional joints.

Owner:TREDEGAR FILM PROD CORP

Polyolefin Based Hot Melt Containing a Solid Plasticizer

A hot melt adhesive that is composed of a metallocene catalyzed polyethylene polymer, a hydrogenated styrenic block copolymer, a tackifying resin, and a solid plasticizer. The preferred polyethylene polymer is an ethylene-octene copolymer, and the preferred styrenic block copolymer is a styrene-ethylene-butylene-styrene having less than 30% styrene content. The preferred solid plasticizer is either glycerol tribenzoate or 1,4-cyclohexane dimethanol dibenzoate.

Owner:BOSTIK INC

Thermal- and chemical-resistant acid protection coating material and spin-on thermoplastic adhesive

New compositions for use as protective coatings and / or adhesives are provided. The compositions comprise a hydrocarbon resin (e.g., terpene rosin) and a rubber (e.g., EPDM) dispersed or dissolved in a solvent system. The solvent system is preferably a single-solvent system, and the compositions are preferably free of surfactants, dyes, and chromophores. The compositions can be cured or dried to form layers or films that are chemically and thermally resistant, but that can be readily dissolved and removed at the appropriate stage in the fabrication process.

Owner:BREWER SCI

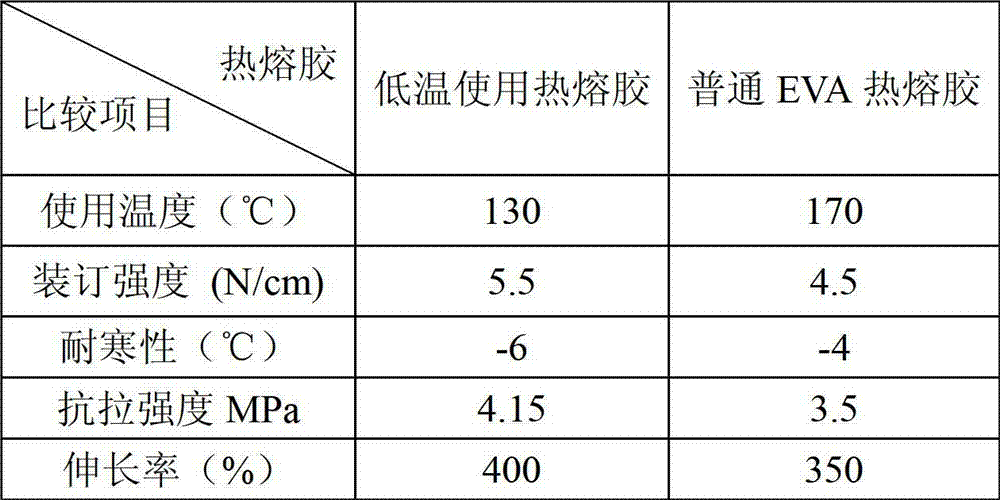

Book thermoplastic binding hot melt glue used at low temperature and preparation method thereof

InactiveCN102925080AImprove performanceNot easy to carbonizeMineral oil hydrocarbon copolymer adhesivesRosin adhesivesThermoplasticPolymer science

The invention relates to hot melt glue and a preparation method thereof, and belongs to the technical field of preparation of hot melt glue. The preparation method comprises the following steps of: starting stirring and opening a heat-conduction oil heating valve; sequentially filling ethylene-vinyl acetate (EVA) resin, a filler, a wax diluents and an antioxygen according to the proportion into a reaction kettle for heating; totally melting each component; adding tackified resin to heat until the tackified resin is totally melted; vacuumizing a reaction system until the reaction system has no bubbles; adding a filter screen and discharging at a discharging port of the reaction kettle; and cooling and forming the materials to obtain a product. The book thermoplastic binding hot melt glue can be used at about 130 DEG C, and is suitable for linkage line production; compared with the traditional book thermoplastic binding hot melt glue, the using temperature is reduced by 30 DEG C to 50 DEG C, so that the production energy consumption (electric energy, heat energy and the like) is reduced, the maintenance cost of equipment is reduced, and the production efficiency is improved; and the glue performance in a glue groove is stable, energy-saving production is facilitated, and the hot melt glue is environment-friendly.

Owner:WUXI WANLI ADHESION MATERIALS

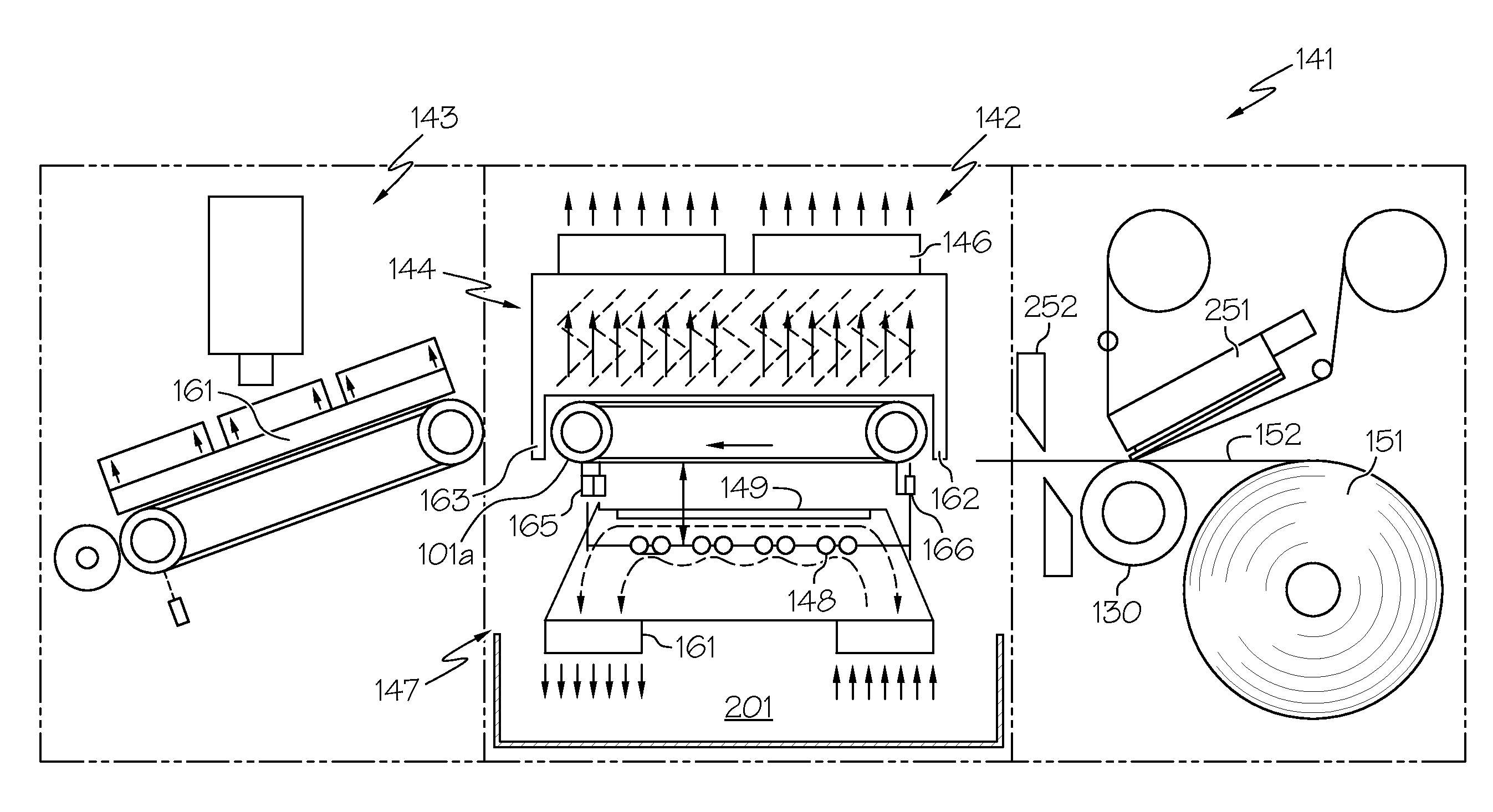

Linerless labels and activatable adhesives, systems, machines and methods therefor

InactiveUS20130133532A1Improve securityEasy to operateStampsRecord information storagePlasticizerAdhesive

A system is disclosed for printing, activating and applying a flow of linerless activatable labels to a flow of items to be labeled. An activatable adhesive is formulated to readily absorb energy from a given radiation source, an activatable adhesive linerless label incorporates such the activatable adhesive. Related methods and uses are described. The activatable adhesive includes a plasticizer, a tackifier, and an adhesive base polymer that includes butyl acrylate, styrene, methyl methacrylate, methacrylic acid, and acrylic acid.

Owner:AVERY DENNISON CORP

Universal adhesive and preparation technology thereof

InactiveCN102604588AExtended shelf lifeAvoid serious wasteMineral oil hydrocarbon copolymer adhesivesChemical industryHydrocarbon solventsProduction line

The invention relates o a universal adhesive and a preparation technology thereof. The universal adhesive is prepared by using the following raw materials in parts by weight: rubber, a tackifying resin, a hydrocarbon solvent, an ester solvent and a propellant; the preparation technology comprises the following steps of: firstly adding the barreled hydrocarbon solvent and the ester solvent to the stirred vessel through the compressed air of an air compressor, then successively adding the rubber, the tackifying resin and the other additives one by one to prepare a stock solution; and respectively charging the stock solution to iron tanks on an aerosol filling production line, sealing and then filling the propellant to obtain the product. When in use, the universal adhesive provided by the invention is rapid to operate and convenient to use; in addition, environment-friendly solvents such as methyl acetate and ethyl acetate are mainly adopted in the universal adhesive so that the universal adhesive is safer in use and environment-friendly; finally, the aerosol packaging form of the universal adhesive is firstly put forward; the universal adhesive has good packaging leak tightness and is long in the quality guarantee period; the rest of universal adhesive can be stored for long term after the universal adhesive is used, thereby the serious wasting of the universal adhesive is avoided; and the universal adhesive is in line with and abides by the standard requirements of energy saving, emission reduction and environmental protection.

Owner:FUJIAN NANAN DAYANG AEROSOL MFG

Polyurethane hot-melt adhesive for bonding and preparation method thereof

ActiveCN102585753AExcellent peelabilityEasy to apply glueNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to a polyurethane hot-melt adhesive for bonding and a preparation method thereof, belonging to the technical field of preparation of automobile hot-melt adhesives. The preparation method comprises the following steps of: firstly, feeding high-crystalline polyester glycol, polyester polyol and tackifying resin into a reactor, heating, dehydrating at vacuum while stirring, andthen cooling; secondly, preheating diisocyanate, adding the preheated diisocyanate to the reactor to uniformly stir and carrying out prepolymerization reaction; after the prepolymerization is finished, sequentially adding weighed catalyst, antioxidant, coupling agent, viscosity stabilizer and grey paste under nitrogen circulation, and stirring till being mixed uniformly; discharging in the nitrogen protection condition, sealing and packaging so as to obtain the product, that is, the polyurethane hot-melt adhesive for bonding automobile lights. The hot-melt adhesive prepared by adopting the preparation method disclosed by the invention can be used for bonding a plurality of base materials such as PP (Polypropylene), PBT (polybutylece terephthalate), ABS (Acrylonitrile Butadiene Styrene), PMMA (polymethyl methacrylate), PC (Poly Carbonate) and inorganic glass.

Owner:WUXI WANLI ADHESION MATERIALS

Hot-pressed veneer adhesive and preparation method thereof

ActiveCN102585736ALow costShort curing timeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveCarvacryl acetate

The invention discloses a hot-pressed veneer adhesive and a preparation method thereof. The hot-pressed veneer adhesive mainly comprises the following components: deionized water, polyvinyl alcohol, an emulsifier, an initiator, methacrylic acid, N-methylol acrylamide, vinyl acetate, a plasticizer, a buffering agent, cassava starch, borax, a dispersing agent, aqueous rosin, a defoaming agent and a corrosion inhibitor. When the hot-pressed veneer adhesive is prepared, the preparation method comprises the following steps of: firstly synthesizing a self-crosslinked polyvinyl acetate copolymerization modified emulsion, then adding 20-35% of raw cassava starch, a crosslinking agent, waterborne tackifying resin and other auxiliaries for mixing and finally preparing the hot-pressed veneer adhesive with excellent performances. Compared with a traditional urea resin veneer adhesive, the adhesive prepared by the invention has the advantages of convenience in use, low curing temperature, short curing time and no harm to an environment and a human body.

Owner:顶立新材料科技股份有限公司

Resin composition, laminate using the same, and molded body using the laminate

InactiveUS8114522B2Improve adhesionSynthetic resin layered productsDomestic containersPolyolefinPetroleum resin

Disclosed is a resin composition forming an adhesive layer between a polylactic acid resin substrate layer and a polyolefin resin substrate layer. The resin composition includes a modified polyolefin resin (A) and a terpene resin (B), and the mass ratio (A) / (B) between the both resins (A) and (B) is 20 / 80 to 99 / 1. Alternatively, the resin composition may be a resin composition including 10 to 90% by mass of a polylactic acid resin (C), 5 to 89% by mass of the modified polyolefin resin (A) and 1 to 80% by mass of a hydrogenated petroleum resin (D), with the total amount of these resins constrained to be 100% by mass.

Owner:UNITIKA LTD

Acrylate solvent-based pressure sensitive adhersive and product thereof

InactiveCN102226067AMeet performance needsSimple structureFilm/foil adhesivesEster polymer adhesivesCross-linkSolvent based

The invention discloses an acrylate solvent-based pressure sensitive adhersive. The acrylate solvent-based pressure sensitive adhersive comprises, by weight, 100 parts of a tackifying resin modified acrylate prepolymer, 0.5-3 parts of a catalyst and 0.1-2 parts of a cross linking agent. The invention further discloses adhesive products prepared from the acrylate solvent-based pressure sensitive adhersive. The acrylate solvent-based pressure sensitive adhersive is characterized by: adopting the tackifying resin modified acrylate prepolymer as a main component, adding proper catalyst and proper cross linking agent according to different use requirements before being coated to adjust performance of the adhersive so as to satisfy performance requirements of a plurality of products, optimize product structures, raise production efficiency and facilitate product development and product transformation.

Owner:永一胶粘(中山)有限公司

Multifunctional glue spray formula and process

ActiveCN102295912AMonocarboxylic acid ester polymer adhesivesMineral oil hydrocarbon copolymer adhesivesPolymer scienceButadiene-styrene rubber

The invention relates to the technical field of chemical detergents, in particular to a multifunctional spray glue formula and process. The spray glue formula comprises the following components in percentage by weight: 1-12 percent of rubber, 1.0-15 percent of synthetic resin, 10-40 percent of tackifying resin, 10-60 percent of hydrocarbon solvent, 30-75 percent of propellent, 10-40 percent of chlorine solvent, 3-30 percent of cosolvent, 2-8 percent of plasticizer and 0.05-1 percent of essence. The spray glue is prepared by the following steps of: adding the hydrocarbon solvent, the chlorine solvent and a part of cosolvent such as acetone and the like into a stirring kettle according to formula metering, opening and stirring; adding rubber such as SBS (Styrene-Butadiene-Styrene) thermoplastic elastomer and the like and synthetic resin such as acrylate resin and the like in a stirring state and stirring until the rubber and the synthetic resin are fully dissolved; adding the tackifyingresin such as rosin and the like and stirring until the rosin is fully dissolved; adding remaining cosolvent such as the acetone and the like and the plasticizer and stirring until glue liquid is fully dispersed; and filtering and canning, sealing, and inflating a can. The spray glue formula has the advantages of no toxin, no pollution, super-strong viscosity and adaptation to gluing of various materials, and is white and non-yellowing.

Owner:DONGGUAN DAYANG CHEM

Low-temperature hot-melt pressure-sensitive adhesive for disposable hygienic product and preparation method thereof

ActiveCN106047287AReduce maintenance costsLow viscosity valueMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesWaxDecomposition

The invention discloses a low-temperature hot-melt pressure-sensitive adhesive for a disposable hygienic product. The low-temperature hot-melt pressure-sensitive adhesive is prepared from 10-30wt% of styrenic thermoplastic elastomer, 40-60wt% of tackifying resin, 15-35wt% of naphthenic oil, 0.1-1.0wt% of antioxidant, and selectively 0.1-5wt% of wax. The low-temperature hot-melt pressure-sensitive adhesive has appropriate melt viscosity, good initial bonding performance, persistent bonding performance, operative weldability, heat resistance and the like within the using temperature range from 120 DEG C to 130 DEG C, carbonization is effectively reduced, the equipment failure rate is lowered, the production efficiency is improved, ageing and decomposition of the tackifying resin and the other constituents are reduced, and the environment pollution is reduced. The invention further discloses a preparation method for the hot-melt pressure-sensitive adhesive.

Owner:GUANGDONG RURGA NEW MATERIAL TECH

Hot-extrudable pressure-sensitive hot-melt adhesives and their use in multilayer films

InactiveUS20040077759A1Simple manual pressureNon-macromolecular adhesive additivesFilm/foil adhesivesEngineeringHot melt

The present invention relates to hot-coextrudable hot-melt pressure-sensitive adhesives particularly suitable for the production of multilayer films intended for what are called "repositionable" packages that are opened and reclosed easily. The films used in these packages comprise at least three layers, namely an outer layer intended to be complexed thereafter, a sealing and separable layer, defining all or part of the internal surface of the package, and between them a hot-melt adhesive layer that joins them together. In this type of package, the adhesive plays an essential role insofar as, once the package has been opened by the end user, the quality of the reclosure and of the reopening will depend on the performance of the adhesive, which is of course a pressure-sensitive adhesive, that is to say an adhesive that adheres simply by manual pressure.

Owner:BOSTIK SA

High-temperature-resistant paper-plastic laminating adhesive and preparation method thereof

InactiveCN102433087AImprove high temperature resistanceNon-macromolecular adhesive additivesWax adhesivesCross-linkPolymer science

The invention discloses a preparation method of a high-temperature-resistant paper-plastic laminating adhesive. To calculate by mass percent, the high-temperature-resistant paper-plastic laminating adhesive consists of the following components by mass percent: 60-90 of composite emulsion, 1-15 of vinyl acetate ethylene (VAE) emulsion, 1-15 of tackifying resin, 1-10 of inorganic powder filler, 1-10 of cross-linking agent, 0.2-0.5 of antifoaming agent and 0.2-0.5 of thickening agent. Firstly the composite emulsion of ethylene vinyl acetate (EVA) resin and mixed wax is prepared, then the emulsion is built up with the VAE emulsion, the antifoaming agent, the inorganic powder filler, the tackifying resin, the cross-linking agent and the thickening agent, and finally the high-temperature-resistant paper-plastic laminating adhesive is prepared. The product has the advantages of high-temperature resistance, high initial adhesive force, high peeling strength and high water resistance. After paper and plastic are separated, the bonding surface is dry, paper scraps are not stuck and an adhesive film has a transfer printing effect.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing polystyrene-polyisoprene-polystyrene ternary segmented copolymer hot melt pressure-sensitive adhesive

InactiveCN101709201ALow costReduce manufacturing costMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPolystyreneHot melt

The invention discloses a method for preparing polystyrene-polyisoprene-polystyrene ternary segmented copolymer hot melt pressure-sensitive adhesive, which comprises the following steps: orderly weighing polystyrene-polyisoprene-polystyrene ternary segmented copolymer, composite tackifier resin, softening agent and antioxidant in a mass ratio, and stirring the mixture at the rotating speed of 300 to 600 rpm / min; heating, stirring and melting the mixture till forming transparent glue solution at the temperature of between 150 and 180 DEG C after uniformly mixing; and then placing the transparent glue solution on a coating machine preheated at the temperature of between 80 and 120 DEG C, and adhering a piece of isolation paper after coating to obtain the polystyrene-polyisoprene-polystyrene ternary segmented copolymer hot melt pressure-sensitive adhesive. The method has the advantages of available raw materials, low cost, simplicity and feasibility, environmental protection, excellent comprehensive performance, and suitability for scale industrial production, and provides a new path for the preparation of the hot melt pressure-sensitive adhesive.

Owner:SHANGHAI INST OF TECH

Acrylic pressure sensitive adhesive composition and pressure sensitive adhesive tape

InactiveUS20050209380A1Improve adhesionExcellent pressure-sensitive adhesionInksAcid polymer adhesivesPolymer scienceMeth-

Provided is an acrylic pressure sensitive adhesive composition excellent in pressure sensitive adhesive characteristics and removability and a pressure sensitive adhesive tape using the acrylic pressure sensitive adhesive composition. An acrylic pressure sensitive adhesive composition containing an acrylic polymer obtained by at least copolymerizing a (meth)acrylic acid alkyl ester with an alkyl group having 2 to 14 carbon atoms and a carboxyl group containing unsaturated monomer copolymerizable with the (meth)acrylic acid alkyl ester, and tackifier resins, wherein the tackifier resins are respective resins each containing a natural product as a raw material, include at least 4 kinds of the resins-different in a molecular structure from one another and a content of each of the tackifier resins is in the range of 5 parts by weight or more and 20 parts by weight or less relative to 100 parts by weight of the acrylic polymer.

Owner:NITTO DENKO CORP

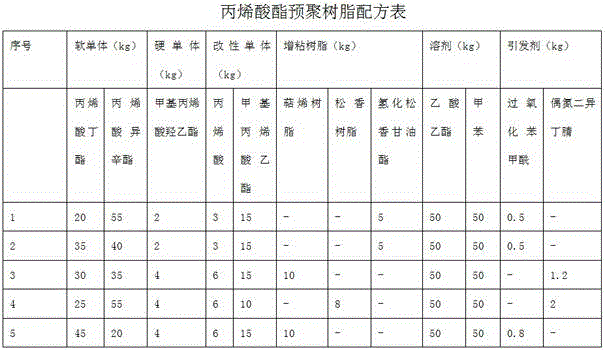

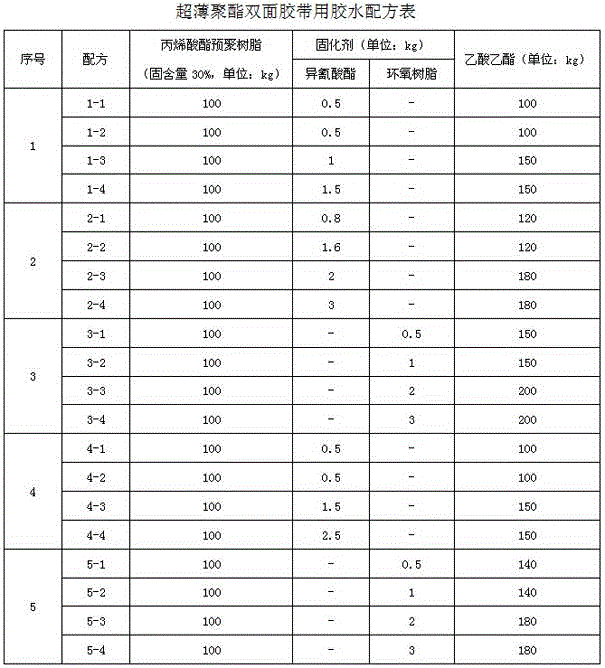

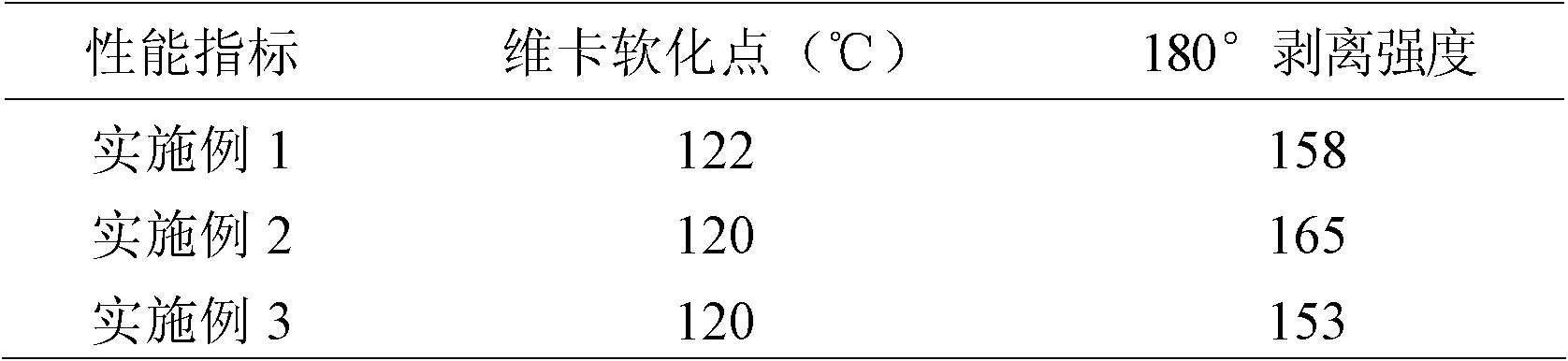

Ultra-thin polyester double-sided adhesive tape, glue thereof, and preparation method thereof

ActiveCN104152077AHigh bonding strengthImprove cohesionFilm/foil adhesivesEster polymer adhesivesPolyesterAdhesive

The invention discloses an ultra-thin polyester double-sided adhesive tape comprising a polyester thin film layer and two glue layers formed by glue coated on front and back sides of the polyester thin film. The thickness of the polyester thin film is 0.001-0.0012mm. The thickness of the glue layer is 0.002mm. Therefore, the thickness of the double-sided adhesive tape is only 0.005mm, such that electronic product development trends of thin and light can be satisfied. The total thickness of adhesive is 0.004mm, such that the tape has ultra-low thermal resistance, and heat generated by electrical components can be conducted in time. Therefore, electrical component damage caused by long-term working under high temperature is avoided. Also, the invention discloses a formula for the glue used in the ultra-thin polyester double-sided adhesive tape. The glue comprises the raw materials of, by weight, 100 parts of acrylate prepolymer resin, 0.5-3 parts of a curing agent, and 100-200 parts of ethyl acetate. With the glue, a single side thickness is 0.002mm, and high adhesive performance can be provided.

Owner:四川羽玺新材料股份有限公司

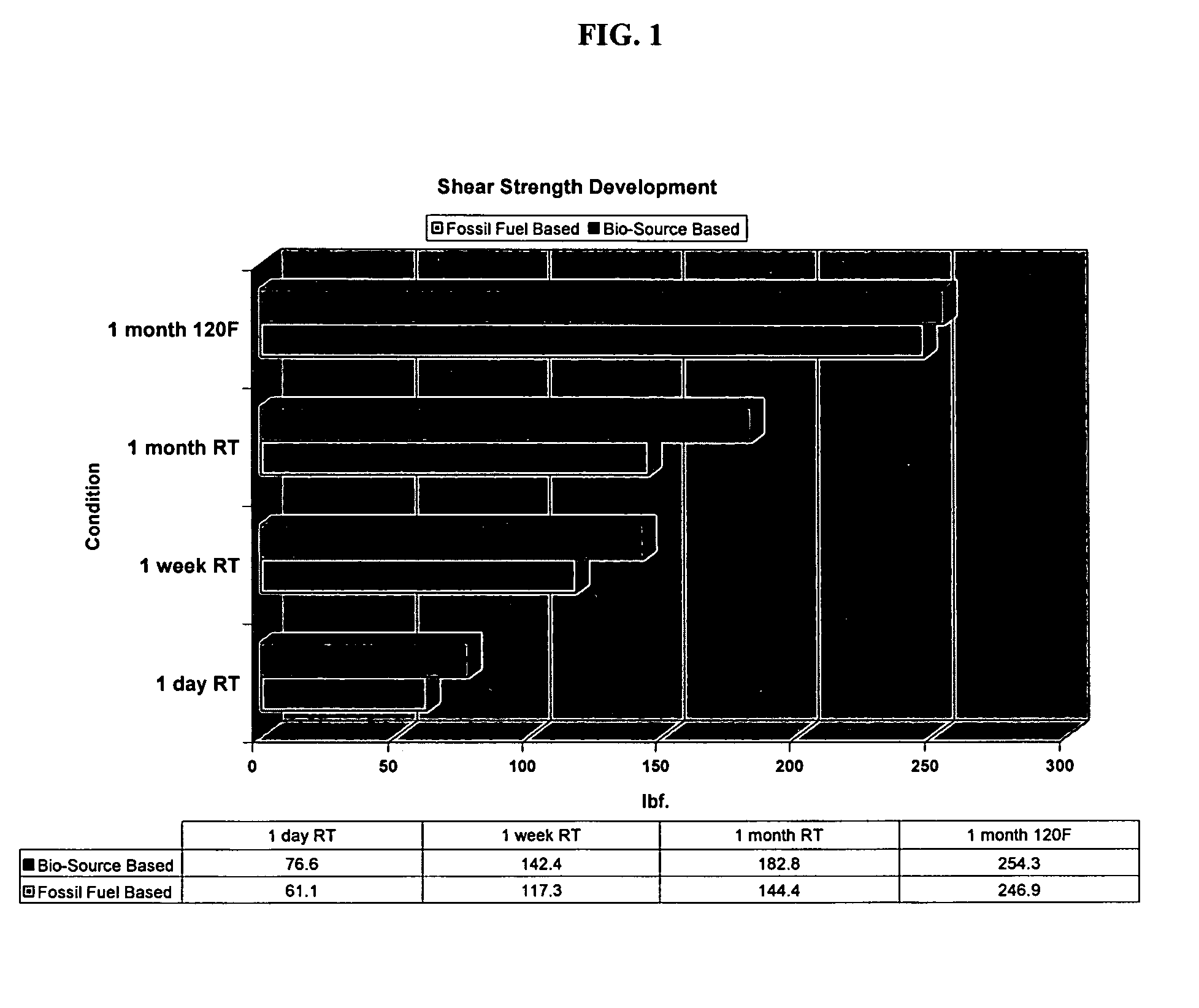

Low VOC bio-source adhesive

ActiveUS20080064852A1High strengthLow and substantially no VOC emissionDrying oil adhesivesProtein adhesivesAdhesiveFatty acid

A one component adhesive composition is provided, which can be formulated from substantially or totally bio-based, renewable raw materials. Such adhesives can be formulated to have high strength and / or low or substantially no VOC emissions. This can be achieved by utilizing polymers that are derived or extracted from renewable plant materials such as soybeans, corn, sunflowers, wheat, etc. Adhesive compositions in accordance with the invention can include oils. The composition preferably contains bio-based oils only, but need not be completely free of fossil fuel or synthetic based oils. It should also include drying oils and / or similarly acting polymers, co-polymers, and fatty acids. Plasticizers, such as hydrogen oxide, derived from renewable sources are utilized to impart performance properties to the formulated adhesive. Metal napthanates can be used to catalyze the drying and / or curing speed when the adhesive composition is applied to a substrate.

Owner:W F TAYLOR

Adhesive resin used for steel band reinforced polyethylene spiral corrugated pipe and preparation method thereof

ActiveCN102086357AResidue reductionSmall smellMineral oil hydrocarbon copolymer adhesivesRigid pipesMasterbatchChemical reaction

The invention discloses adhesive resin used for a steel band reinforced polyethylene spiral corrugated pipe and a preparation method and applications thereof. The adhesive resin comprises the following raw materials in parts by weight: 20-30 parts of modified grafted polyolefin masterbatch, 55-60 parts of polyethylene, 10-15 parts of tackifying resin, 5 parts of lubricant and 0.3-0.5 part of antioxidant. The preparation method comprises the following steps: mixing the raw materials evenly, performing extrusion reaction, blending and granulating to prepare the finished product. The adhesive resin of the invention has less odor, stable product performance and higher heat resistance and mechanical strength; and the requirements of processing technology of the steel band reinforced polyethylene spiral corrugated pipe can be fully satisfied, and the defects of the products adopting the existing technologies such as high penetrating odor, low heat resistance and mechanical strength and unstable chemical reaction can be overcome.

Owner:合诚技术股份有限公司

Rosin esters for non-woven applications, methods of making and using and products therefrom

InactiveUS20110213120A1Good viscosity stabilityLow color requirementNatural resin chemical modificationNon-woven fabricsNonwoven fabricRosin

Owner:ARIZONA CHEM CO

High speed cigarette mouth building hot melt adhesive and preparation method thereof

InactiveCN101538450AEasy to dryMeet the requirements of high-speed cigarette operationMineral oil hydrocarbon copolymer adhesivesRosin adhesivesAntioxidantSolvent

The invention belongs to the technical field of novel cigarette materials, in particular relates to a high speed cigarette mouth building hot melt adhesive and a preparation method thereof. The cigarette mouth building hot melt adhesive is prepared from ethylene-vinyl acetate copolymer, tackifying resin, nanometer silicon dioxide and antioxidant, and includes the following components according to percentage by weight: 25 to 35 percentages of ethylene-vinyl acetate copolymer, 35 to 45 percentages of tackifying resin, 20 to 40 percentages of viscosity modifier, 5 to 10 percentages of nanometer silicon dioxide and 0.1 to 0.5 percentage of antioxidant, wherein the components are heated and melted by a reaction kettle and are sequentially added and uniformly stirred. The cigarette adhesive prepared by the method has strong quick-drying performance, the ring and ball softening point nearly ranges from 95 to 105 DEG C, the softening range is from 5 to 8 DEG C, the operation of adhesion can be accomplished in 5 seconds, and the cigarette adhesive has the characteristics of no solvent, no absorption of moisture, corrosion resistance, aging resistance, and the like; the flowability and the wetting quality of the adhesive can be controlled by changing the parameters of wax, the method is suitable for the preparation of different cigarettes, and the adhesive and the method have good value of market popularization and application.

Owner:SHANGHAI JENTAI NANO SCI & TECH CO LTD

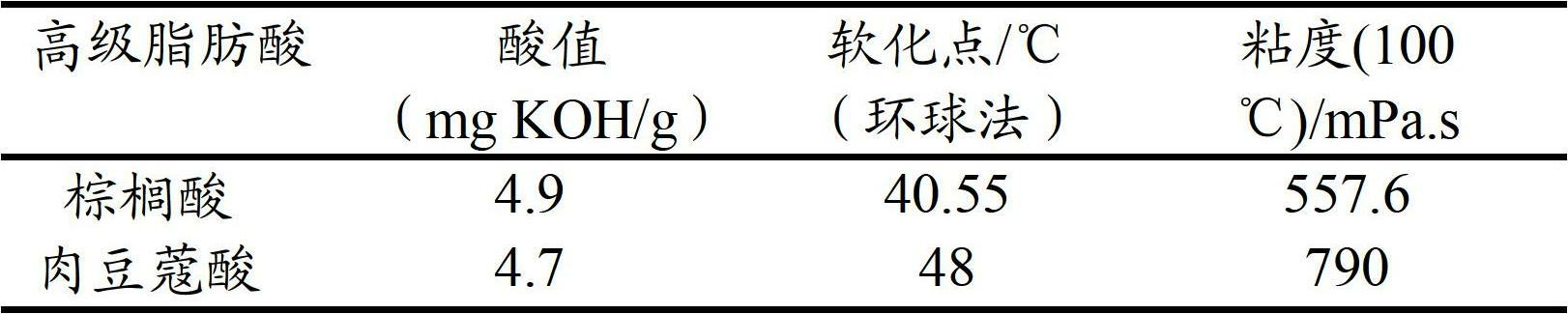

Low-temperature resistant rosin thickening resin, preparation method and usage thereof

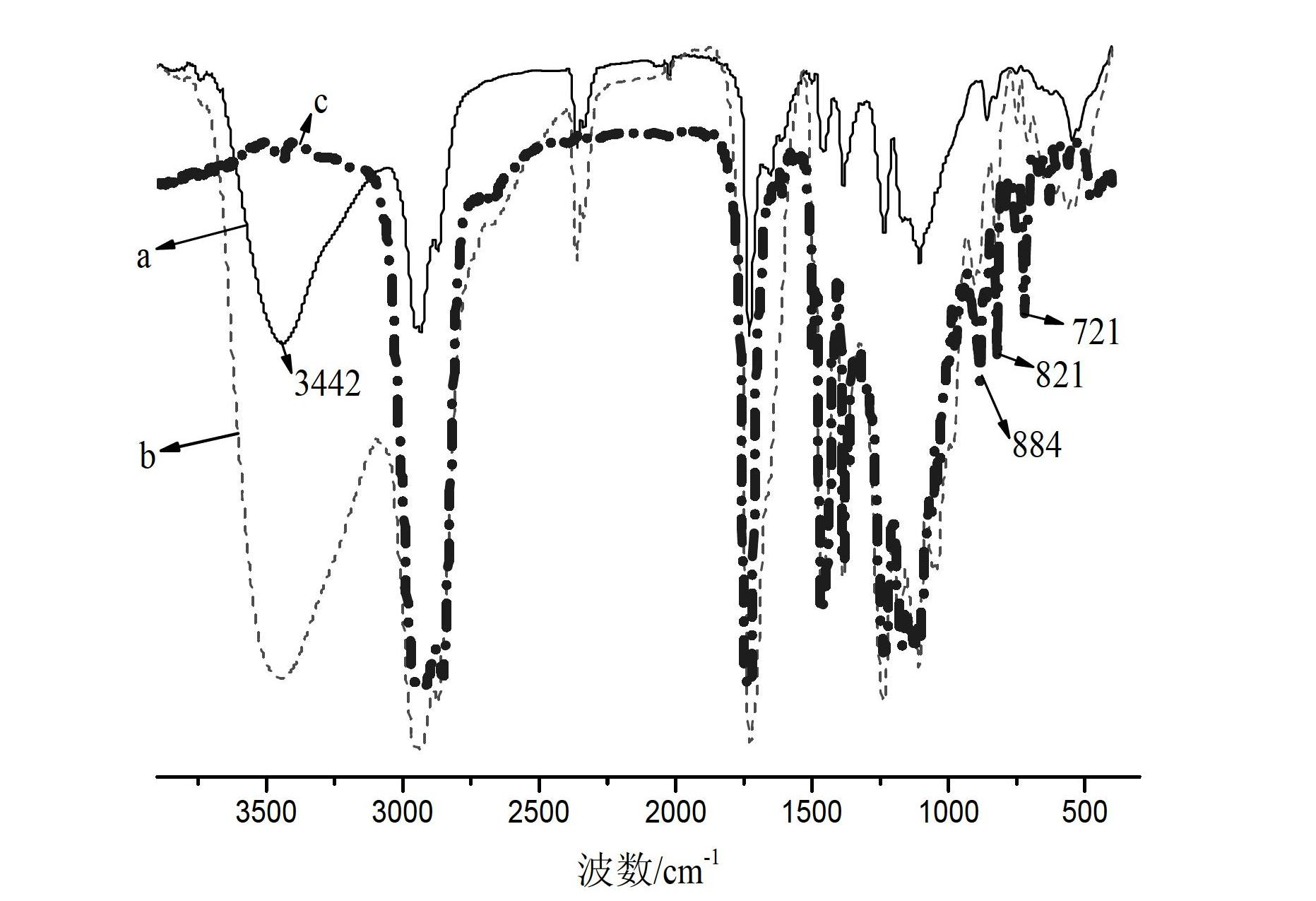

ActiveCN102676062ALow softening pointLow viscosityNatural resin chemical modificationRosin adhesivesPolyolHot melt

The invention discloses a preparation method of low-temperature resistant rosin thickening resin, which comprises the following steps of: under the protection of inert gas, melting rosin, and reaction the melted rosin with polyalcohol for 4-24h at the temperature of 200-290 DEG C under the action of catalyst; discharging to obtain polyalcohol modified abietate; and then, under the protection of inert gas, reacting the obtained polyalcohol modified abietate with higher fatty acid at the temperature of 200-290 DEG C for 4-24h, and discharging to obtain the rosin thickening resin; or under the protection of inert gas, melting the rosin, and then adding catalyst, the polyalcohol and the higher fatty acid into the melted rosin, carrying out reaction for 4-24h at the temperature of 200-290 DEG C, and discharging to obtain the rosin thickening resin. The rosin thickening resin prepared by the method is low in softening point and viscosity and higher in cold resistance. Meanwhile, the invention also discloses the low-temperature resistant rosin thickening resin prepared by the method disclosed by the invention, and the usage of the low-temperature resistant rosin thickening resin in preparation of a hot melt pressure sensitive adhesive.

Owner:普洱科茂林化有限公司

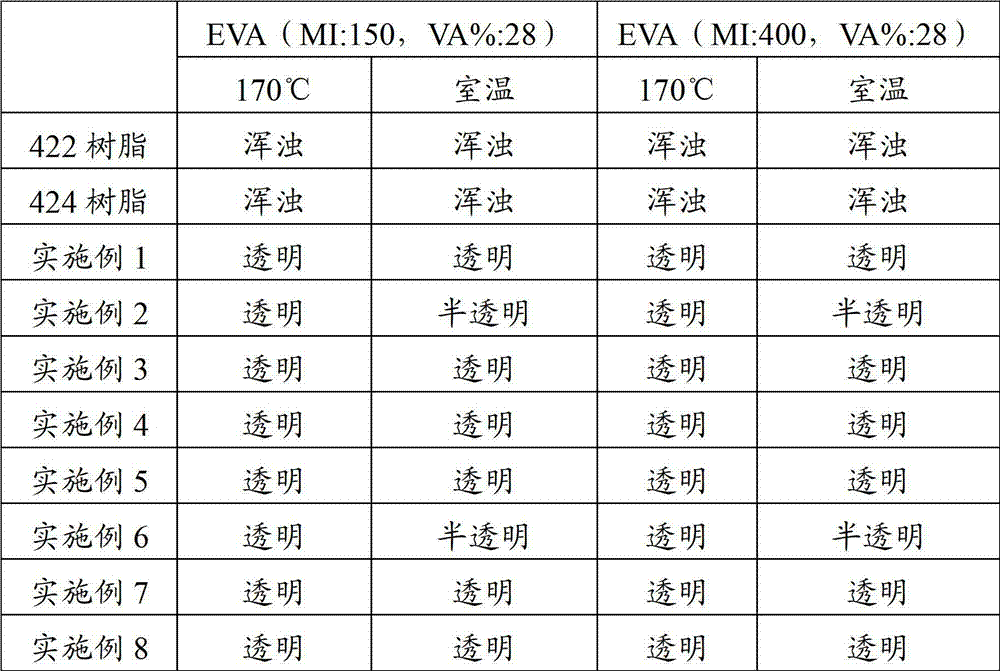

Rosin viscosified resin as well as preparation method and application thereof

ActiveCN102965024AImprove molecular structureHigh softening pointNatural resin chemical modificationRosin adhesivesElastomerDistillation

The invention discloses a preparation method of rosin viscosified resin, and the preparation method comprises the following steps of: (1) adding rosin into a distillation flask, vacuumizing, heating and distilling at the temperature of 240-280 DEG C, so that part of rosin is distilled; and (2) adding the rest rosin in the distillation flask into a reaction flask, adding a catalyst and polyalcohol into the reaction flask under the inert gas protection condition, and reacting for 4-24 hours at the temperature of 240-290 DEG C, so that the rosin viscosified resin is obtained, wherein the rosin contains pinus latteri acid. According to the preparation method disclosed by the invention, the pinus latteri acid contained in the rosin component is utilized, and the pinus latteri acid is rosin binary acid, so that the molecular structure of the resin is increased and the aim of increasing the softening point of the rosin viscosified resin is achieved. Meanwhile, the invention also provides rosin viscosified resin prepared by adopting the preparation method disclosed by the invention, and the rosin viscosified resin has higher softening point and good compatibility with EVA (ethylene vinyl acetate) elastomer and can be better used for preparing hot melt glue.

Owner:普洱科茂林化有限公司

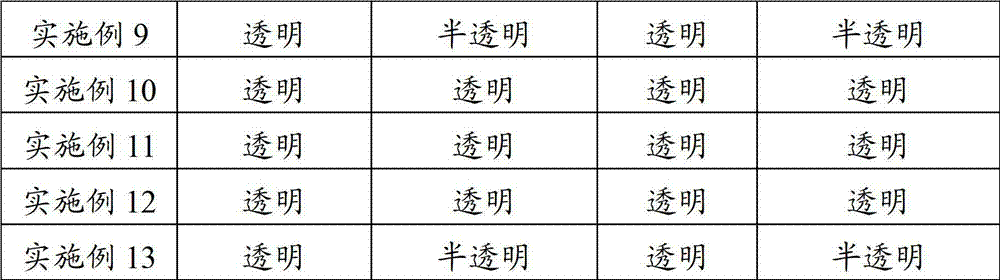

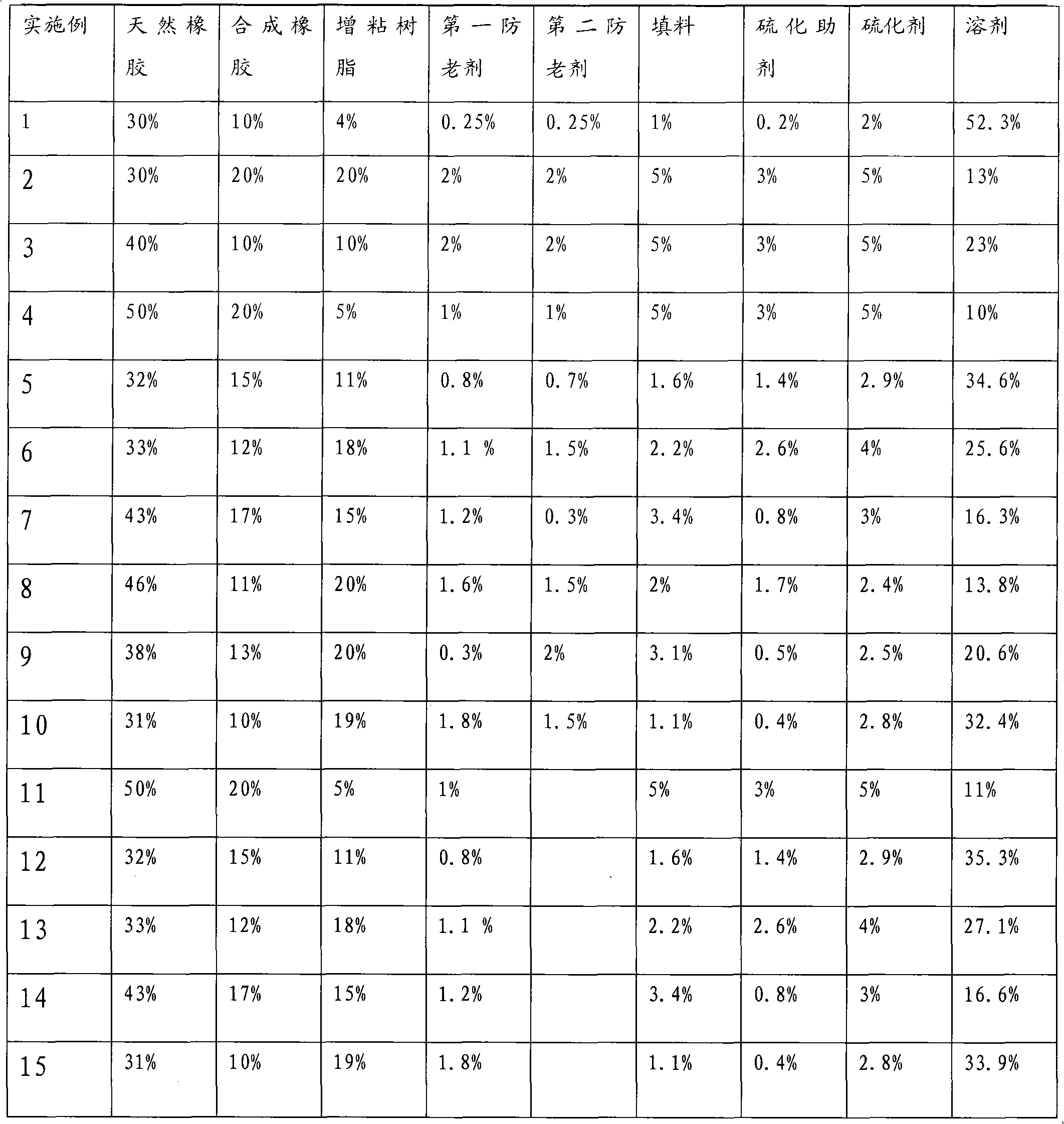

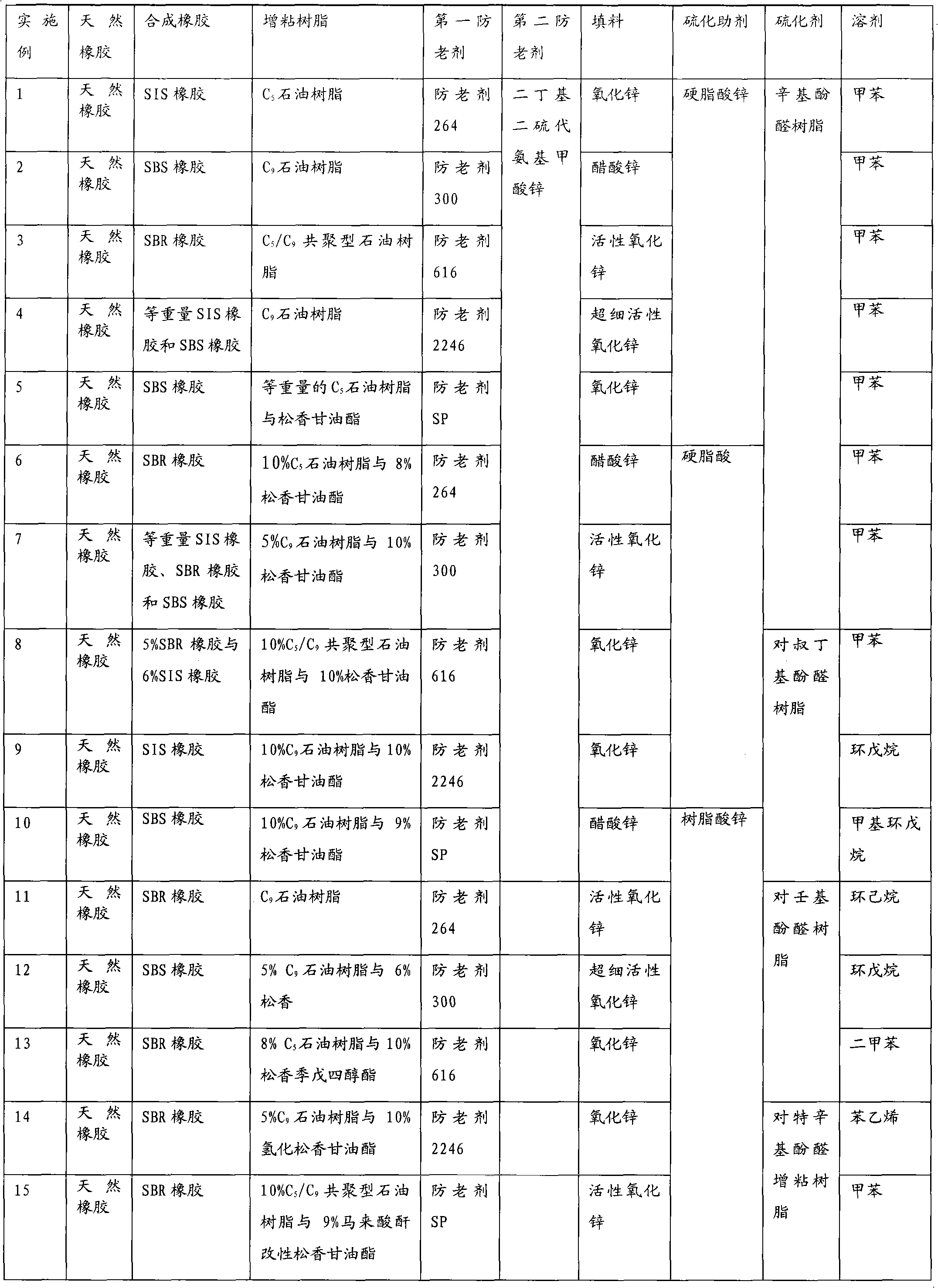

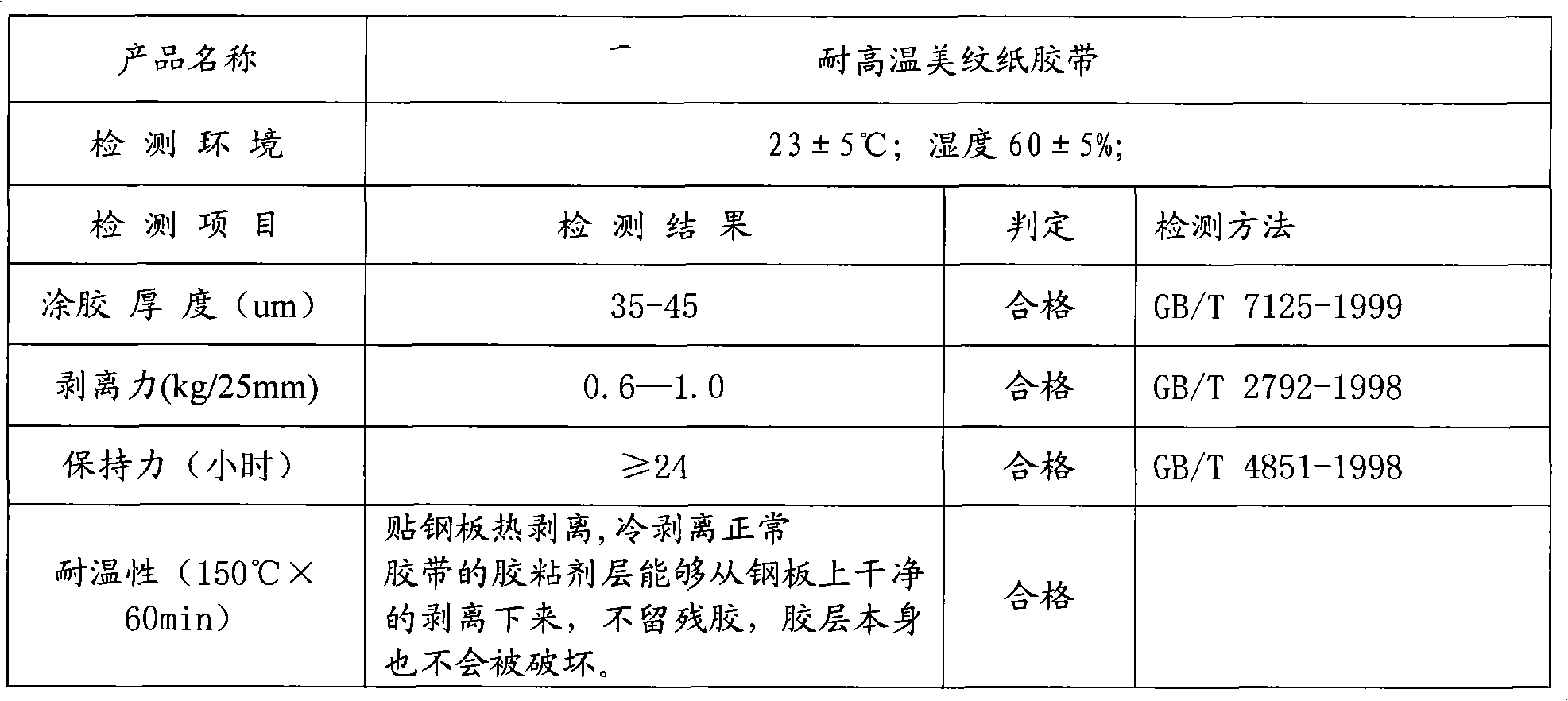

Adhesive for high-temperature-resistant masking tape and high-temperature-resistant masking tape

ActiveCN102120922AThermal peeling is normalCold peeling index is normalMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesVulcanizationMasking tape

The invention discloses an adhesive for a high-temperature-resistant masking tape. The adhesive for the high-temperature-resistant masking tape is characterized by comprising the following components in percentage by weight: 30 to 50 percent of natural rubber, 10 to 20 percent of synthetic rubber, 4 to 20 percent of viscous resin, 0.5 to 4 percent of anti-aging agent, 1 to 5 percent of filler, 0.2 to 3 percent of vulcanization auxiliary agent, 2 to 5 percent of vulcanizing agent and the balance of solvent. The adhesive for the high-temperature-resistant masking tape has high temperature resistance and normal hot stripping and cold stripping indexes after being used continuously at the temperature of 150 DEG C for 60 minutes. The adhesive is applied to adhesion at the temperature of 150 DEG C without degumming and cracking and is particularly applied to high-temperature environments such as automobile baking varnish, an electronic circuit board and the like.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Polyester elastomer hot melt adhesives and preparation method thereof for bonding polar polymers and metallic materials

InactiveCN103059792AModerate polarityGood compatibilityFilm/foil adhesivesEster polymer adhesivesElastomerPolyester

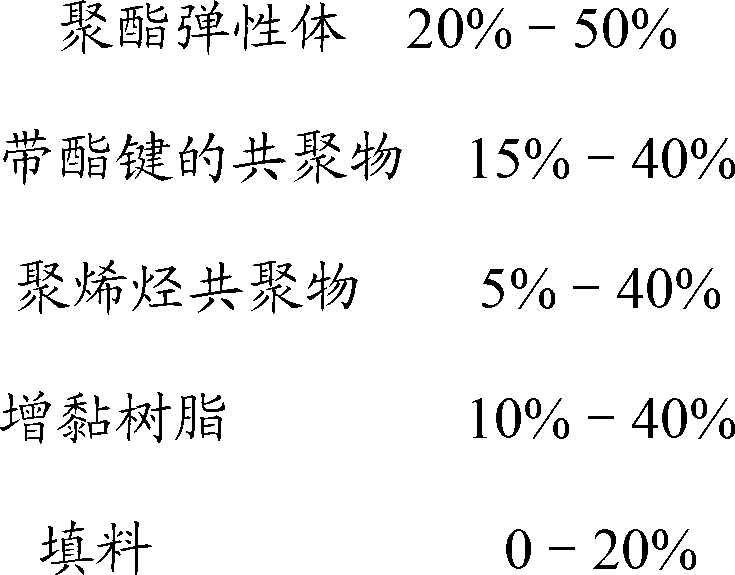

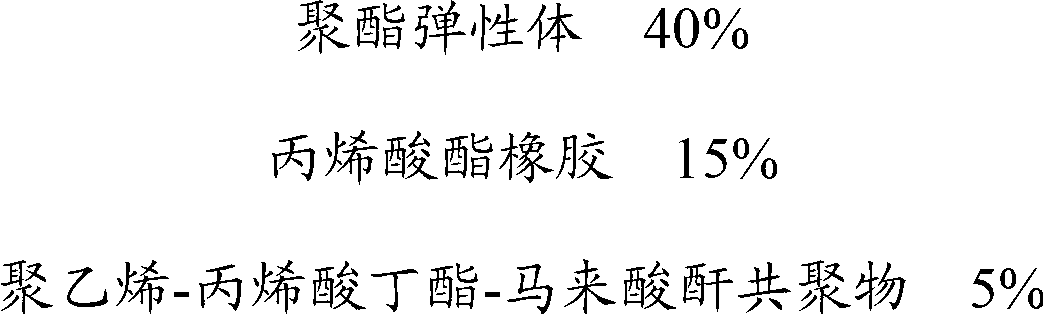

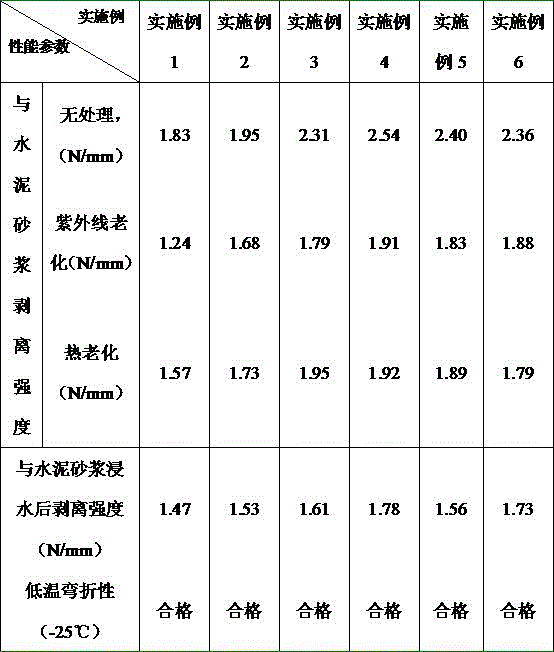

The invention discloses polyester elastomer hot melt adhesives for bonding a polar polymer and metallic materials. The polyester elastomer hot melt adhesives for bonding the polar polymer and the metallic materials comprise, by weight, polyester elastomer 20%-50%, copolymers with ester bond 15%-40%, polyolefin copolymers 5%-40%, tackifying resin 10%-40%, filler 0%-20%, and functional additives 0%-3%. Due to the fact that the polyester elastomer hot melt adhesives are thermoplastic adhesives, bonding process is simple, bonding speed is fast, the thermotolerance of the polyester elastomer hot melt adhesives can be adjusted by selecting polyester elastomer of different melting points, and bonding strength is strong. In addition, the polyester elastomer hot melt adhesive for bonding the polar polymer and the metallic materials has the advantages of being strong in bonding strength, waterproof, moist-heat resistant, high and low temperature resistant, ageing resistant and durable and stable in bonding.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +2

High-polymer waterproof coiled material hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN105694776AImprove heat aging resistanceAccelerated agingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerButadiene-styrene rubber

The invention discloses a high-polymer waterproof coiled material hot-melt pressure-sensitive adhesive and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises the following components in parts by mass: 30-200 parts of elastomer composition, 40-100 parts of tackifying resin, 20-70 parts of plasticizer, 0.3-5 parts of stabilizer and 0.1-3 parts of additive. The elastomer composition is selected from SIS (styrene-isoprene-styrene) / SEPS (styrene-ethylene / propylene-styrene), SIS / SBS (styrene-butadiene-styrene), and / or SBS / SEBS (styrene-ethylene-butadiene-styrene). The mass ratio of the two components in the elastic composition is 1-20; the styrene in the SIS in the elastic composition accounts for 15-30 wt%, the styrene in the SEPS accounts for 10-30 wt%, the styrene in the SBS accounts for 20-50 wt%, and the styrene in the SEBS accounts for 10-40 wt%. The hot-melt pressure-sensitive adhesive has the characteristics of excellent ultraviolet aging resistance, favorable thermal aging resistance, high peel strength, simple technique and low cost.

Owner:HUIZHOU NENGHUI CHEM CO LTD

Pressure-sensitive adhesive tape and pressure-sensitive adhesive composition

InactiveUS20060182958A1Mineral oil hydrocarbon copolymer adhesivesOperating means/releasing devices for valvesRosinAcrylic polymer

A pressure-sensitive adhesive tape is characterized by containing at least (A) an acrylic polymer, (B) a petroleum resin, and (C) a rosin-based resin, wherein the component (B) and the component (C) are contained in proportions of from 1 to 50 parts by weight and from 1 to 50 parts by weight, respectively based on 100 parts by weight of the component (A). In addition, it is preferable that the total sum of the component (B) and the component (C) is not more than 60 parts by weight based on 100 parts by weight of the component (A). As the rosin-based resin (C), a rosin ester-based resin is preferable.

Owner:NITTO DENKO CORP

Aqueous emulsion type nm adhesive for paper or plastics and its preparing process

InactiveCN1342735AImprove low temperature resistanceNo degumming phenomenonEster polymer adhesivesRosin adhesivesAdhesivePolyvinyl chloride

An emulsion-type paper-plastic adhesive is prepared from emulsion base material (40-70 wt.%), viscosity increaser (25-50) and nm inorganic powder (5-15). The emulsion base material contains butyl acrylate (25-60 wt. portions), vinyl acetate (20-50), acrylic acid (0-10), hydroxypropyl acrylate (5-15), PVA (2-8) ammonium persulfate (0.8-3.2), emulsifier OP-10 (0.3-3), sodium laurylsulfate (0.3-3) and water (80-207). Its advantages include no poison, excellent resistance to low temp., high temp and water, good adhesion, and fast drying.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com