High-polymer waterproof coiled material hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive, polymer waterproof technology, applied in the direction of non-polymer adhesive additives, adhesives, adhesive types, etc., to achieve the effect of fewer steps, excellent heat aging resistance, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

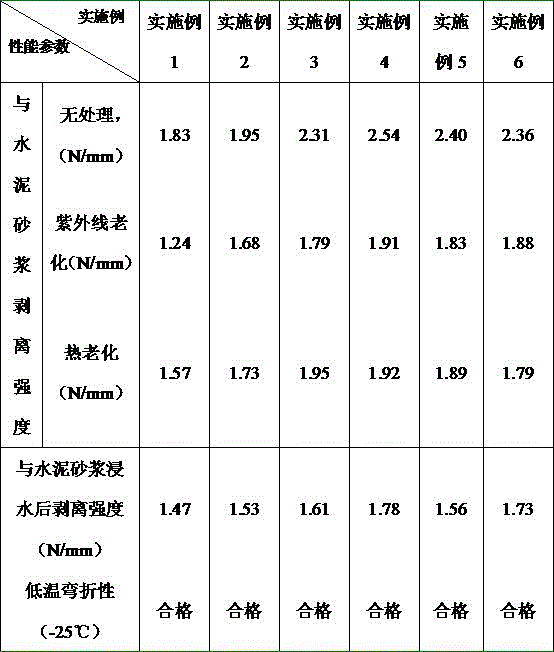

Examples

Embodiment 1

[0027] The invention discloses a polymer waterproof membrane hot-melt pressure-sensitive adhesive. The preparation method of the polymer waterproof membrane hot-melt pressure-sensitive adhesive comprises the following steps:

[0028] The first step is to add 70 parts by mass of plasticizer, 2.5 parts by mass of stabilizer and 0.1 part by mass of additives into the reactor, control the vacuum degree to -0.05 ~ -0.1MPa and stir at a low speed, heat to 130 ° C, add 200 parts by mass Part elastomer composition, continue to heat up to 160 ° C, keep warm and stir at high speed for 40 minutes, until the elastomer is completely melted;

[0029] The second step is to add 70 parts by mass of tackifying resin, control the vacuum degree to -0.05 ~ -0.1 MPa, keep warm and stir at high speed for 40 minutes, wait for it to melt evenly, and discharge the material to obtain a hot-melt pressure-sensitive polymer waterproof membrane.

[0030] In this embodiment, the elastomer composition is a co...

Embodiment 2

[0032] The invention discloses a polymer waterproof membrane hot-melt pressure-sensitive adhesive. The preparation method of the polymer waterproof membrane hot-melt pressure-sensitive adhesive comprises the following steps:

[0033] The first step is to add 45 parts by mass of plasticizer, 0.3 parts by mass of stabilizer and 3 parts by mass of additives into the reactor, control the vacuum degree to -0.05 ~ -0.1MPa and stir at a low speed, heat to 140 ° C, add 120 mass parts Part elastomer composition, continue to heat up to 130 ° C, keep warm and stir at high speed for 80 minutes, until the elastomer is completely melted;

[0034] The second step is to add 40 parts by mass of tackifying resin, control the vacuum degree to -0.05 ~ -0.1MPa, keep warm and stir at high speed for 60 minutes, wait for it to melt evenly, and discharge the material to obtain a hot-melt pressure-sensitive polymer waterproof membrane.

[0035]In this embodiment, the elastomer composition is SIS / SBS, t...

Embodiment 3

[0037] The invention discloses a polymer waterproof membrane hot-melt pressure-sensitive adhesive. The preparation method of the polymer waterproof membrane hot-melt pressure-sensitive adhesive comprises the following steps:

[0038] The first step is to add 20 parts by mass of plasticizer, 5 parts by mass of stabilizer and 1.6 parts by mass of additives into the reactor, control the vacuum degree to -0.05 ~ -0.1MPa and stir at a low speed, heat to 120 ° C, add 30 parts by mass Part elastomer composition, continue to heat up to 140 ° C, keep warm and stir at high speed for 120 minutes, until the elastomer is completely melted;

[0039] The second step is to add 100 parts by mass of tackifying resin, control the vacuum degree to -0.05 ~ -0.1 MPa, keep warm and stir at high speed for 20 minutes, wait for it to melt evenly, and discharge the material to obtain a hot-melt pressure-sensitive polymer waterproof membrane.

[0040] In this embodiment, the elastomer composition is SIS / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com