Nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material and preparation thereof

A polyolefin cable material, nano-modification technology, applied in the direction of insulating cables, cables, circuits, etc., to achieve high toughness, improved shrinkage performance, and good powder holding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

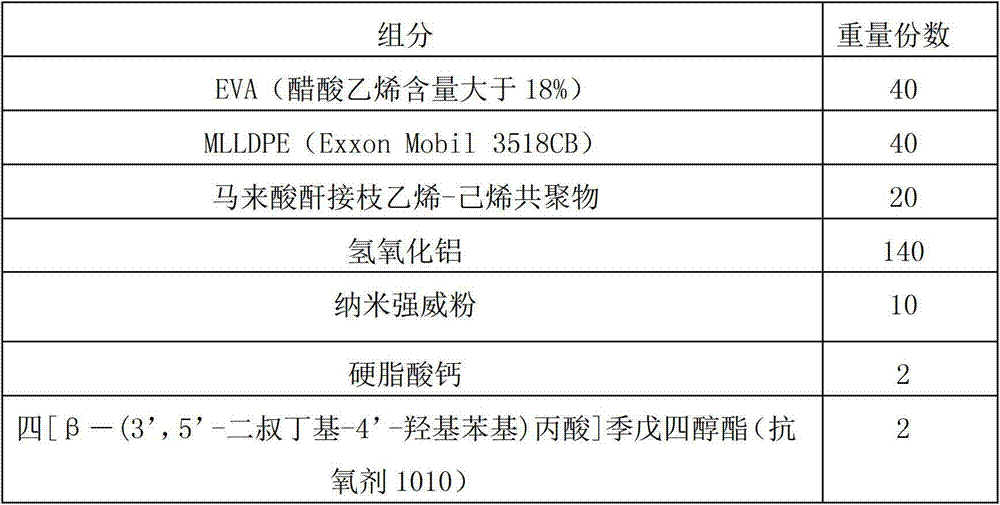

[0020] This example is a nano-modified low-shrinkage, low-smoke, halogen-free flame-retardant polyolefin cable material:

[0021] (1) Raw material formula:

[0022] As shown in the following table:

[0023]

[0024] (2) Preparation process:

[0025] Firstly, base resin, aluminum hydroxide, nano-strength powder, calcium stearate, and antioxidant are thoroughly mixed in a high-speed mixer according to the formula, and then they are internally mixed with an internal mixer at a processing temperature range of 120°C. It is extruded by a twin-screw extruder, then pelletized by a grinding machine, conveyed and cooled by a cyclone separator, and sieved by a vibrating screen to finally make a nano-modified low-shrinkage, low-smoke, halogen-free, flame-retardant polyolefin cable compound.

[0026] (3) Material properties:

[0027] The nano-modified low-shrinkage, low-smoke, halogen-free flame-retardant polyolefin cable material prepared according to the above formula and process h...

Embodiment 2

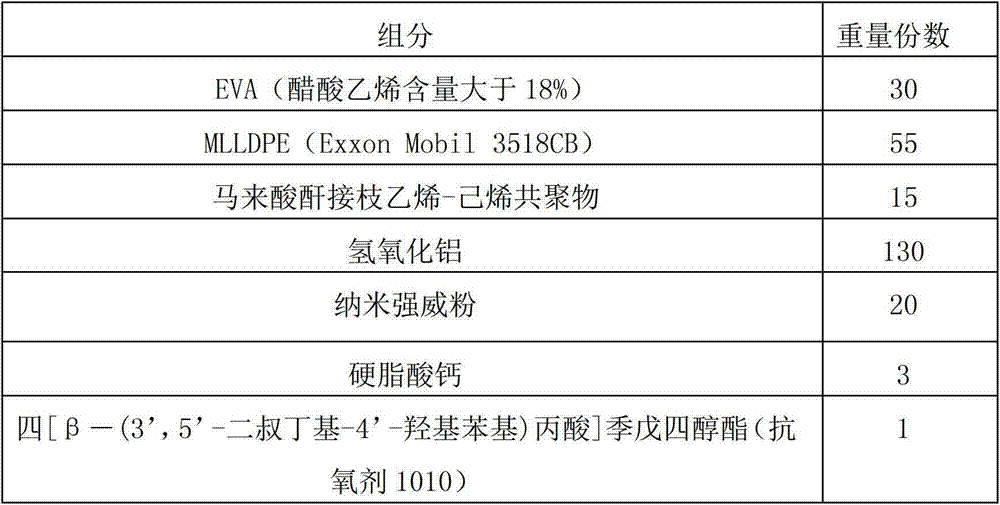

[0029] This example is a nano-modified low-shrinkage, low-smoke, halogen-free flame-retardant polyolefin cable material:

[0030] (1) Raw material formula:

[0031] As shown in the following table:

[0032]

[0033] (2) Preparation process:

[0034] First, the matrix resin, aluminum hydroxide, nano-strength powder, calcium stearate, and antioxidant are fully mixed in a high-speed mixer according to the formula, and then they are internally mixed with an internal mixer at a processing temperature range of 130°C. Extruded by a screw extruder, then pelletized by a grinding machine, conveyed and cooled by a cyclone separator, screened by a vibrating screen, and finally made into a nano-modified low-shrinkage, low-smoke, halogen-free, flame-retardant polyolefin cable compound.

[0035] (3) Material properties:

[0036] The nano-modified low-shrinkage, low-smoke, halogen-free flame-retardant polyolefin cable material prepared according to the above formula and process has the ...

Embodiment 3

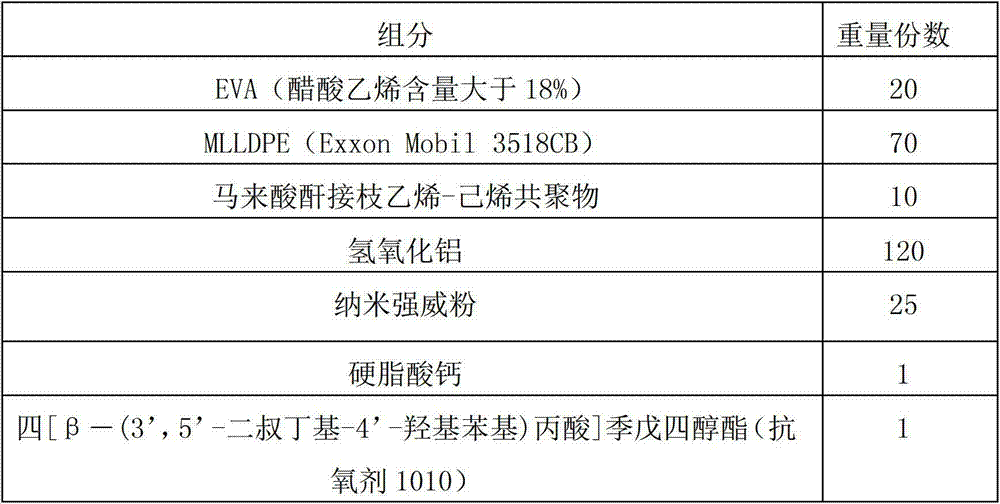

[0038] This example is a nano-modified low-shrinkage, low-smoke, halogen-free flame-retardant polyolefin cable material:

[0039] (1) Raw material formula:

[0040] As shown in the following table:

[0041]

[0042] (2) Preparation process:

[0043]Firstly, the matrix resin, aluminum hydroxide, nano-strength powder, calcium stearate, and antioxidant are thoroughly mixed in a high-speed mixer according to the formula, and then they are internally mixed with a banbury mixer at a processing temperature range of 150°C. It is extruded by a twin-screw extruder, then pelletized by a grinding machine, conveyed and cooled by a cyclone separator, and sieved by a vibrating screen to finally make a nano-modified low-shrinkage, low-smoke, halogen-free, flame-retardant polyolefin cable compound.

[0044] (3) Material properties:

[0045] The nano-modified low-shrinkage, low-smoke, halogen-free flame-retardant polyolefin cable material prepared according to the above formula and proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com