Patents

Literature

145results about How to "Improve shrinkage resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

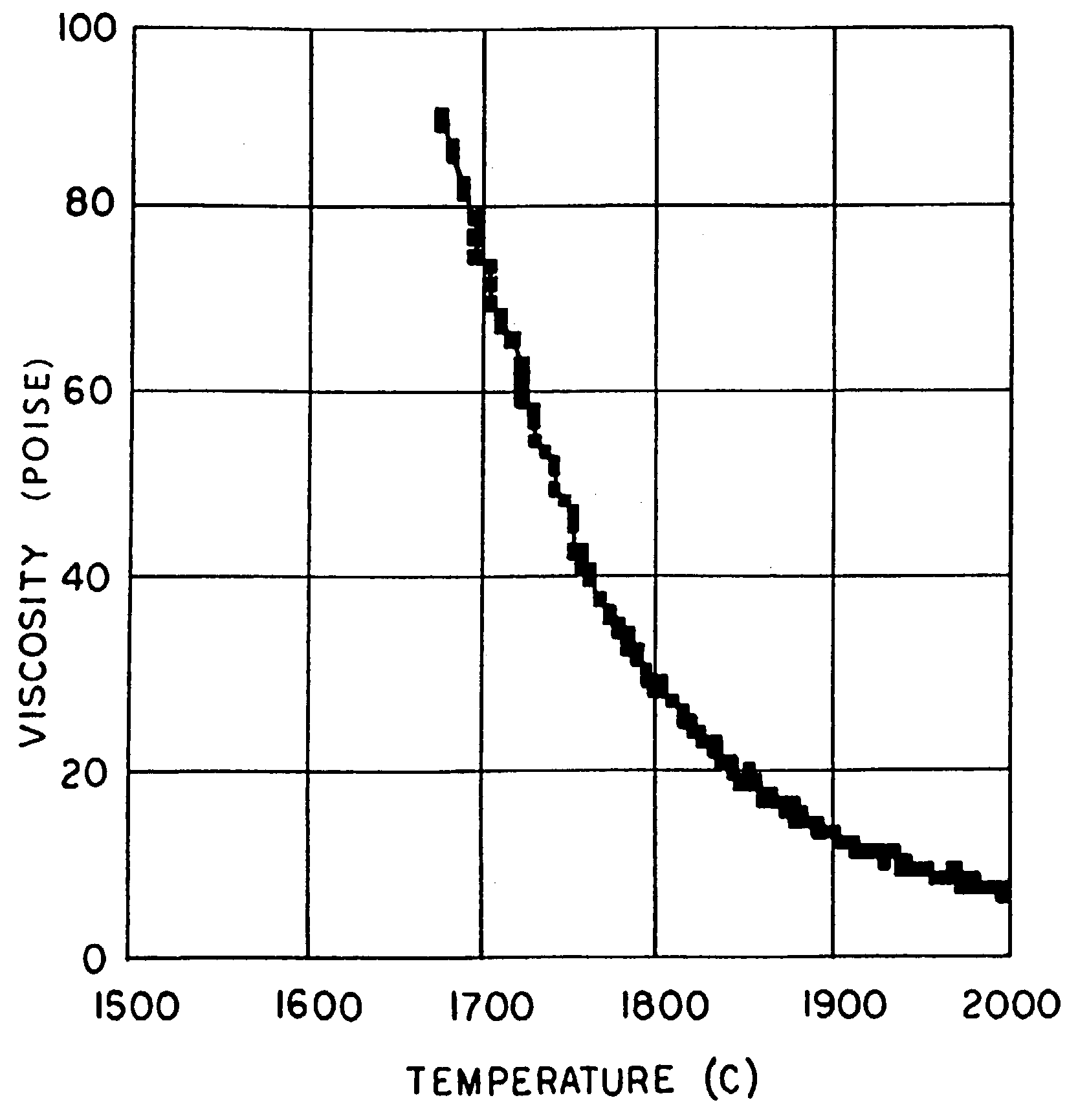

High temperature a resistant vitreous inorganic fiber

InactiveUS6953757B2Easy to manufactureLow shrinkageInorganic fibres/flakesInorganic material artificial filamentsFiberPhysiological fluid

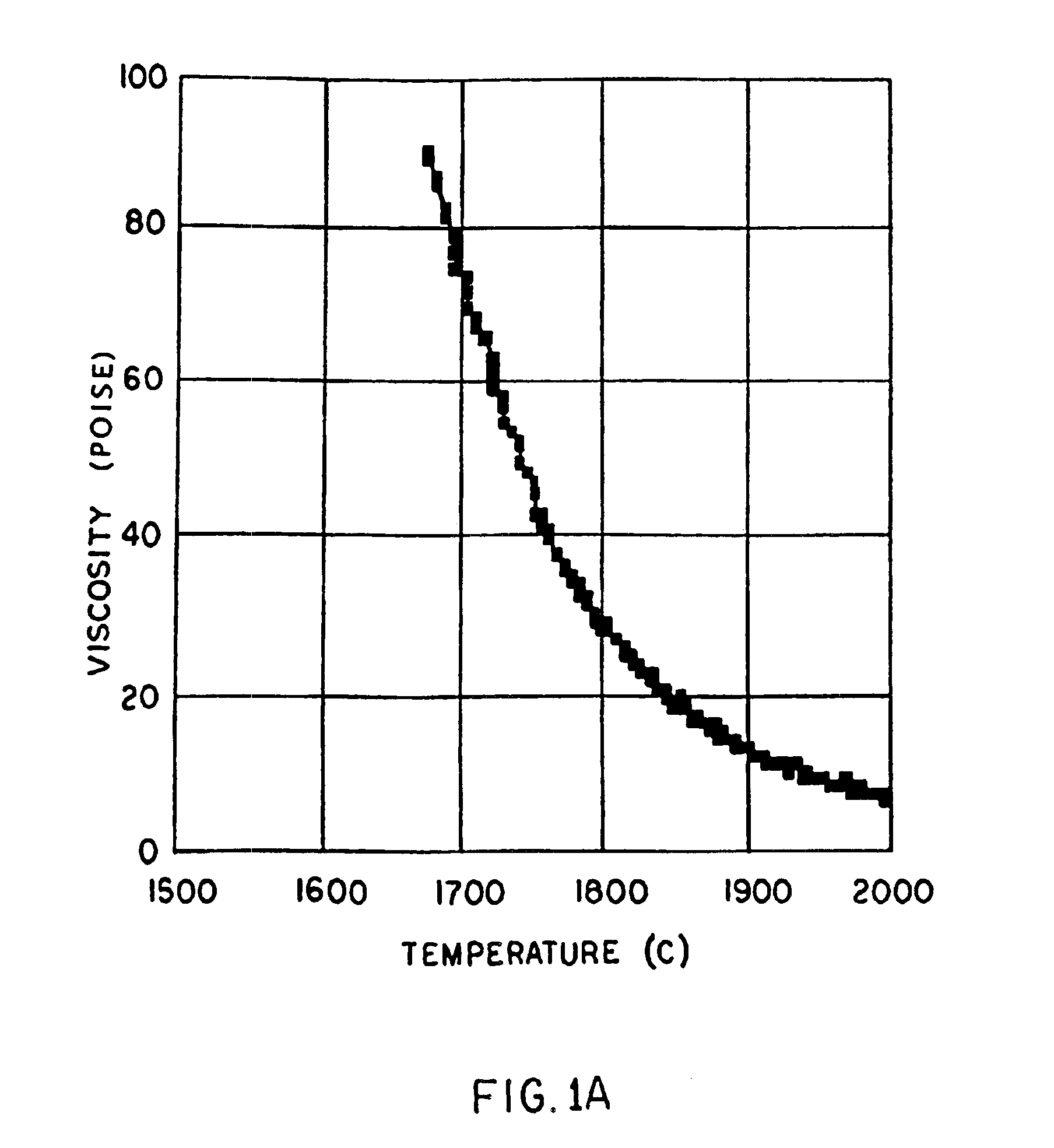

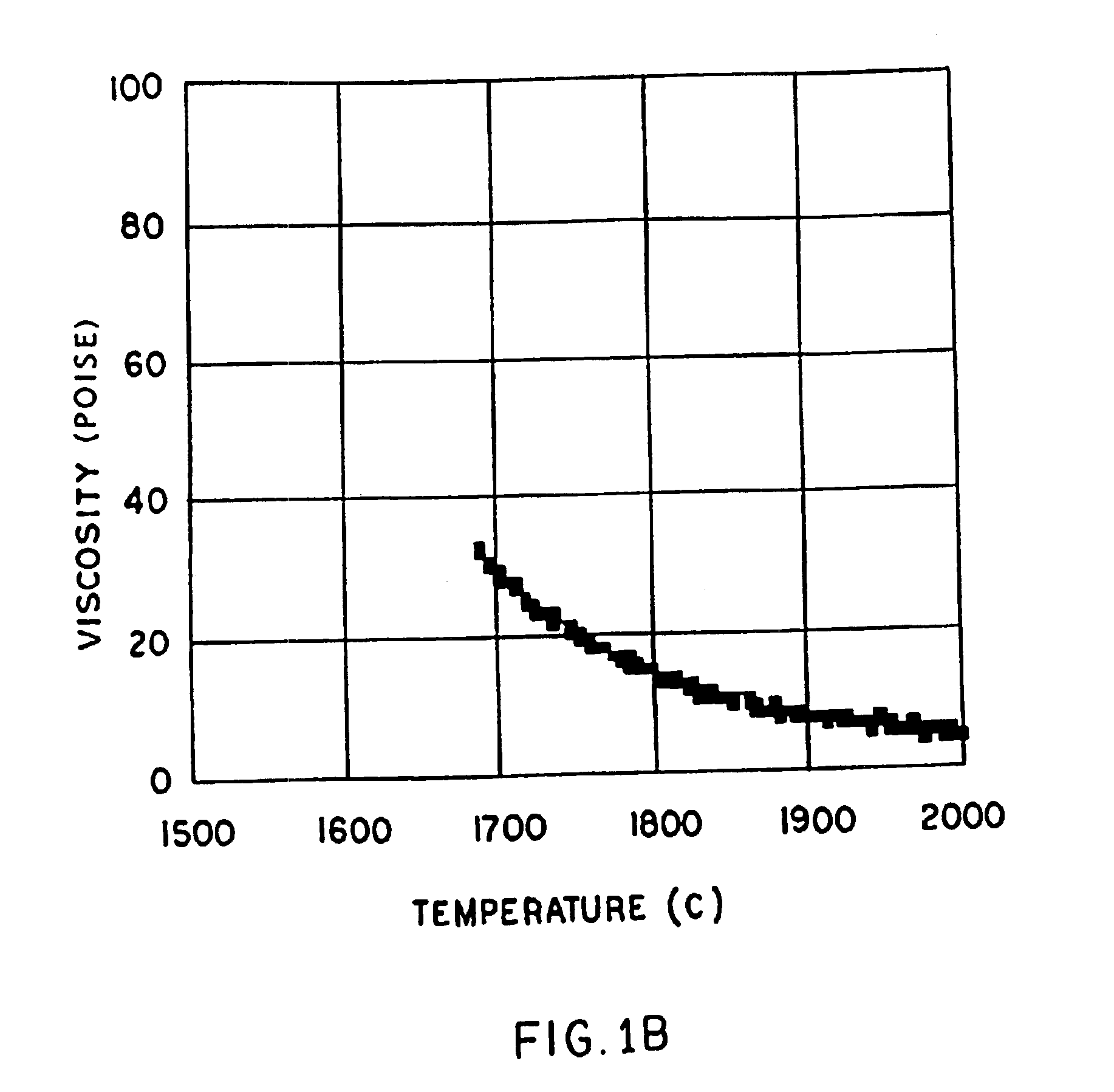

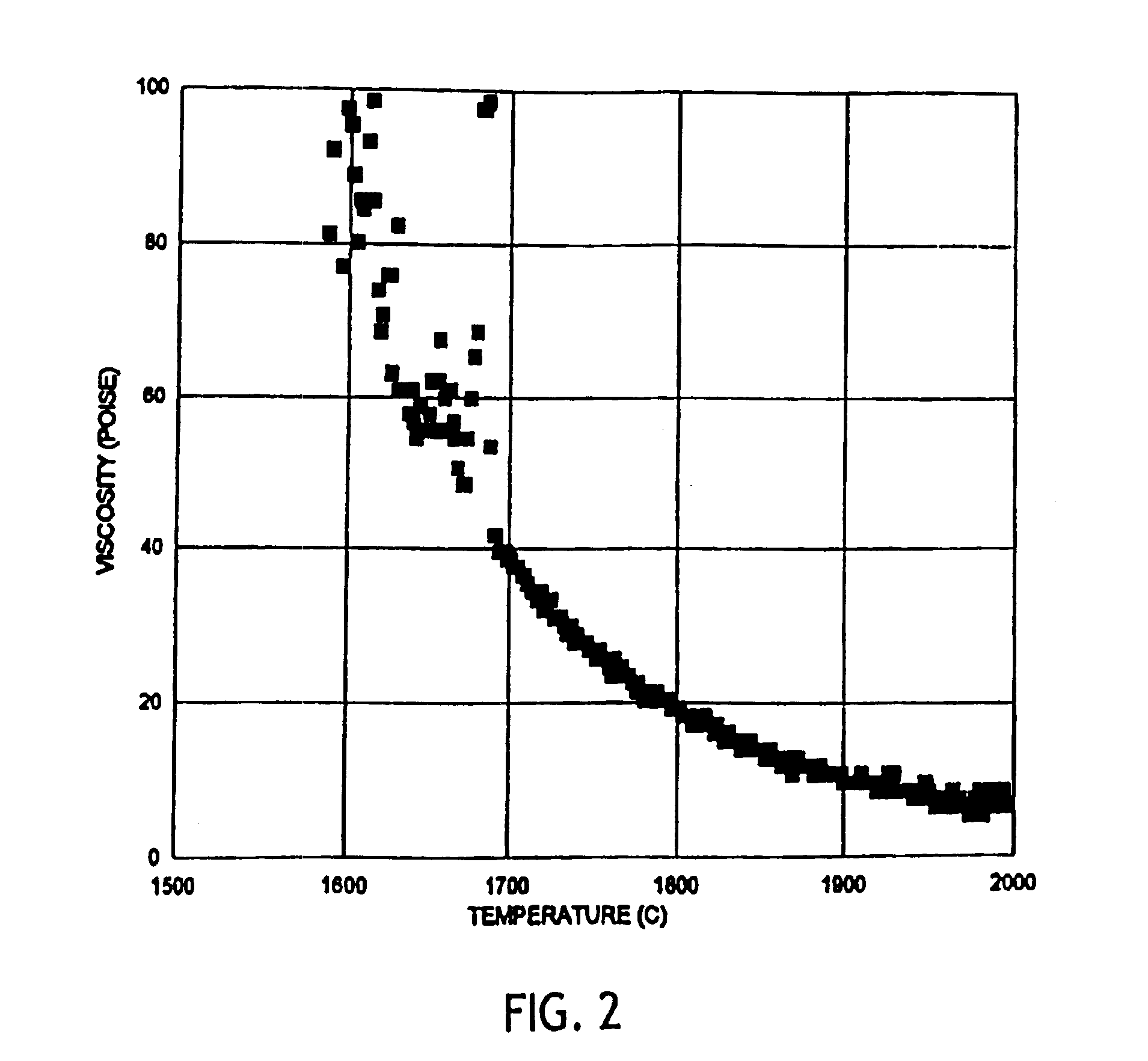

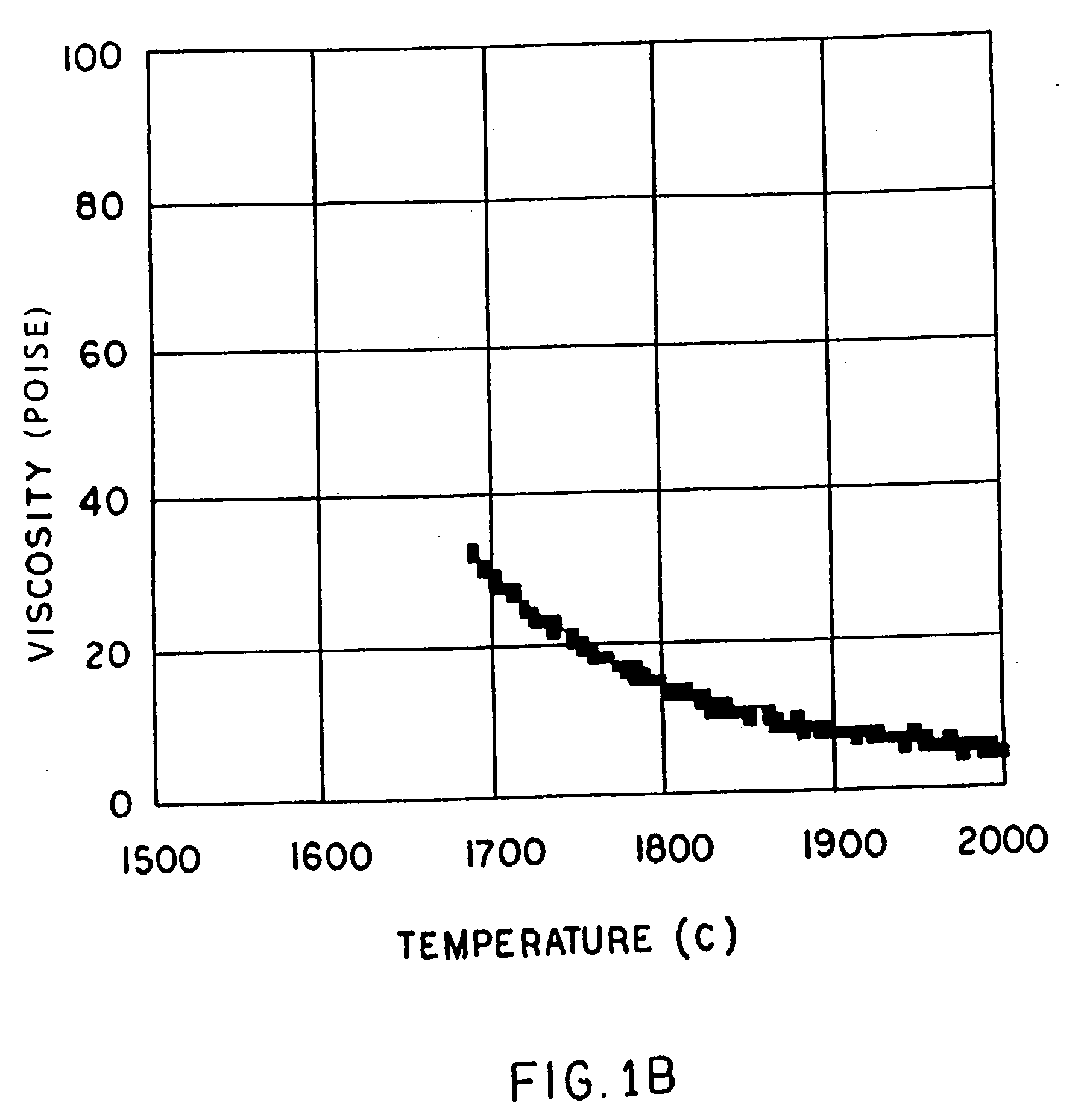

A low shrinkage, high temperature resistant vitreous inorganic fiber having a use temperature up to at least 1330° C., which maintains mechanical integrity after exposure to the use temperature and which is non-durable in physiological fluids, is prepared by the method of forming a melt with ingredients including greater than 71.25 weight percent silica, 0 to about 20 weight percent magnesia, and about 5 to about 28.55 weight percent of calcia, 0 to about 5 weight percent zirconia, and optionally a viscosity modifier in an amount effective to render the product fiberizable; and producing fibers from the melt.

Owner:UNIFRAX I LLC

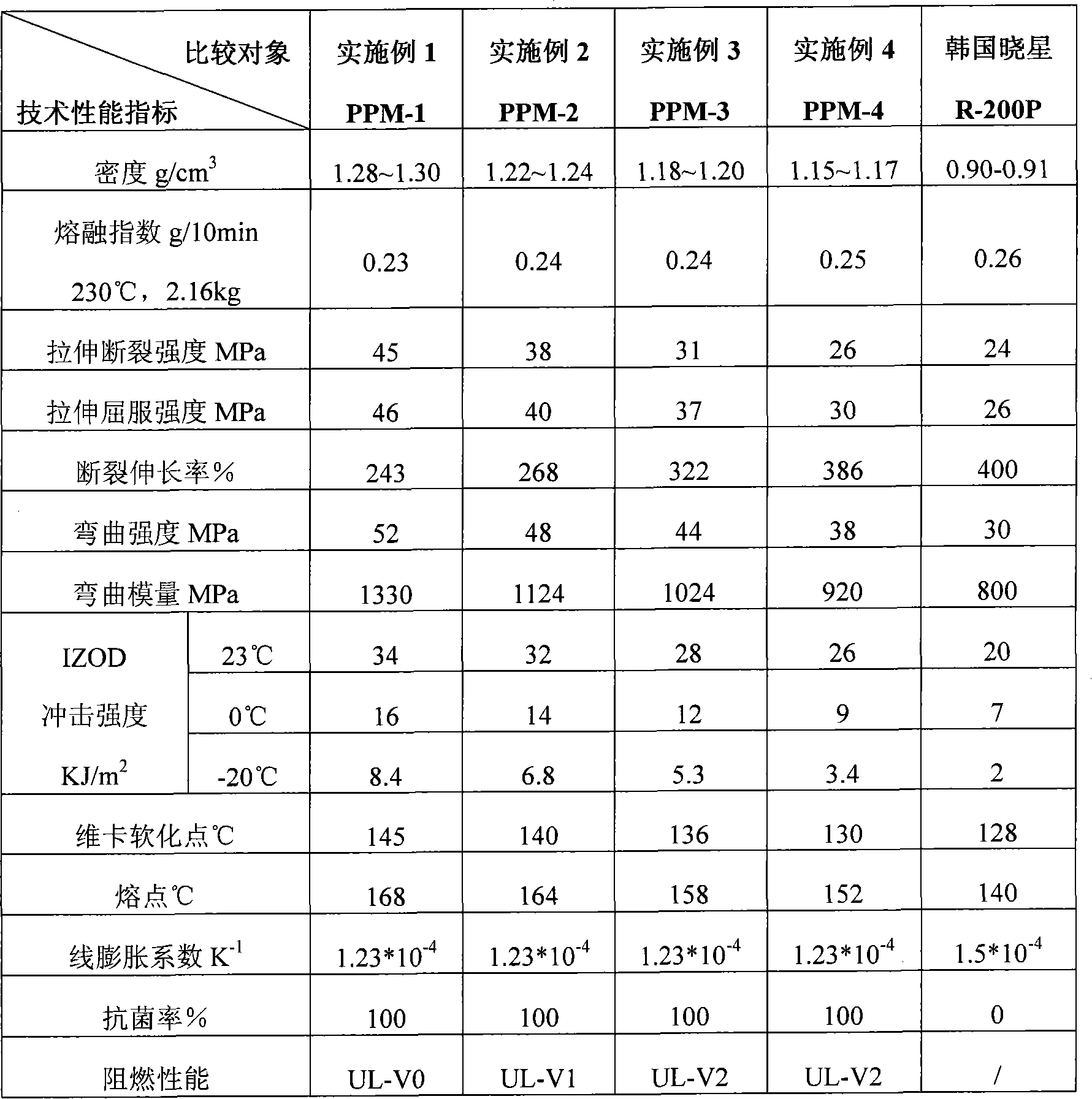

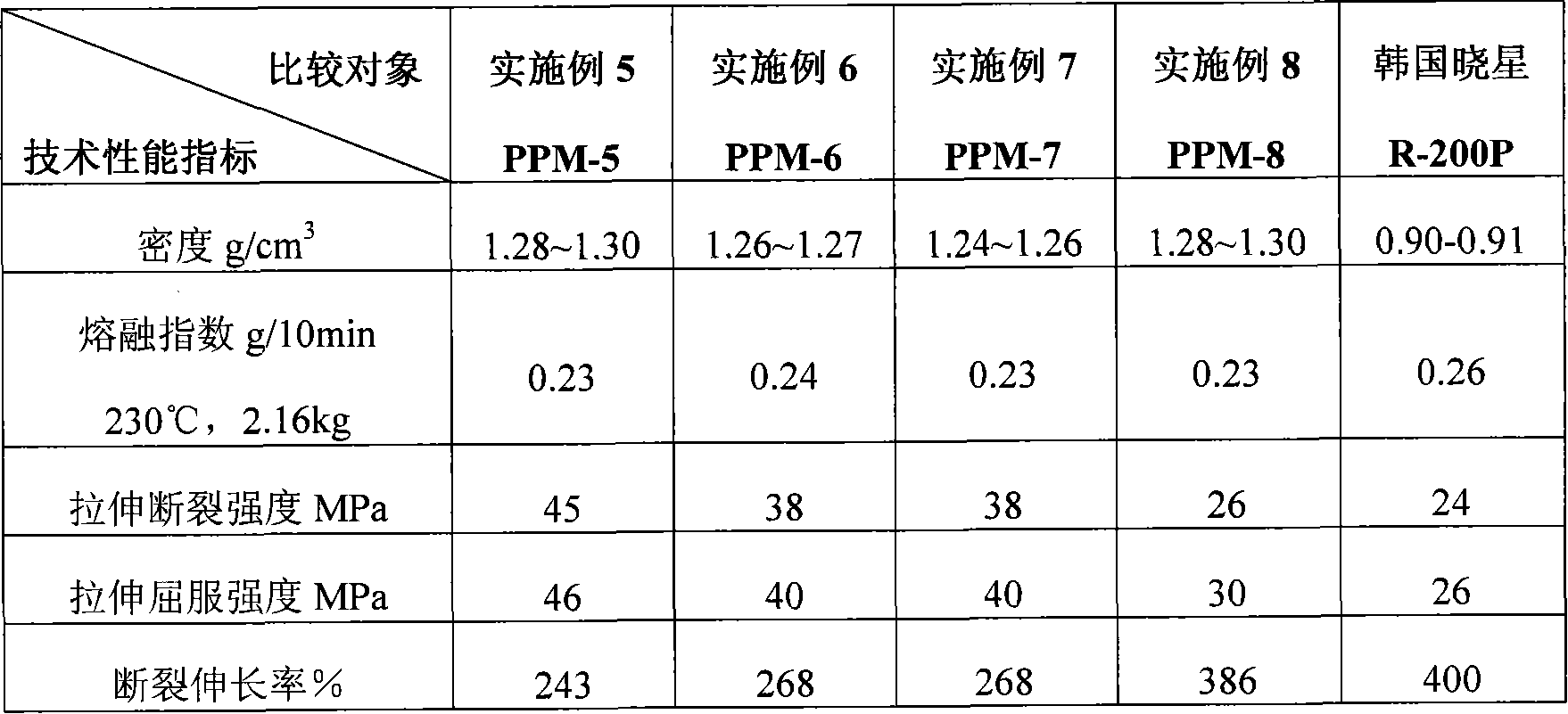

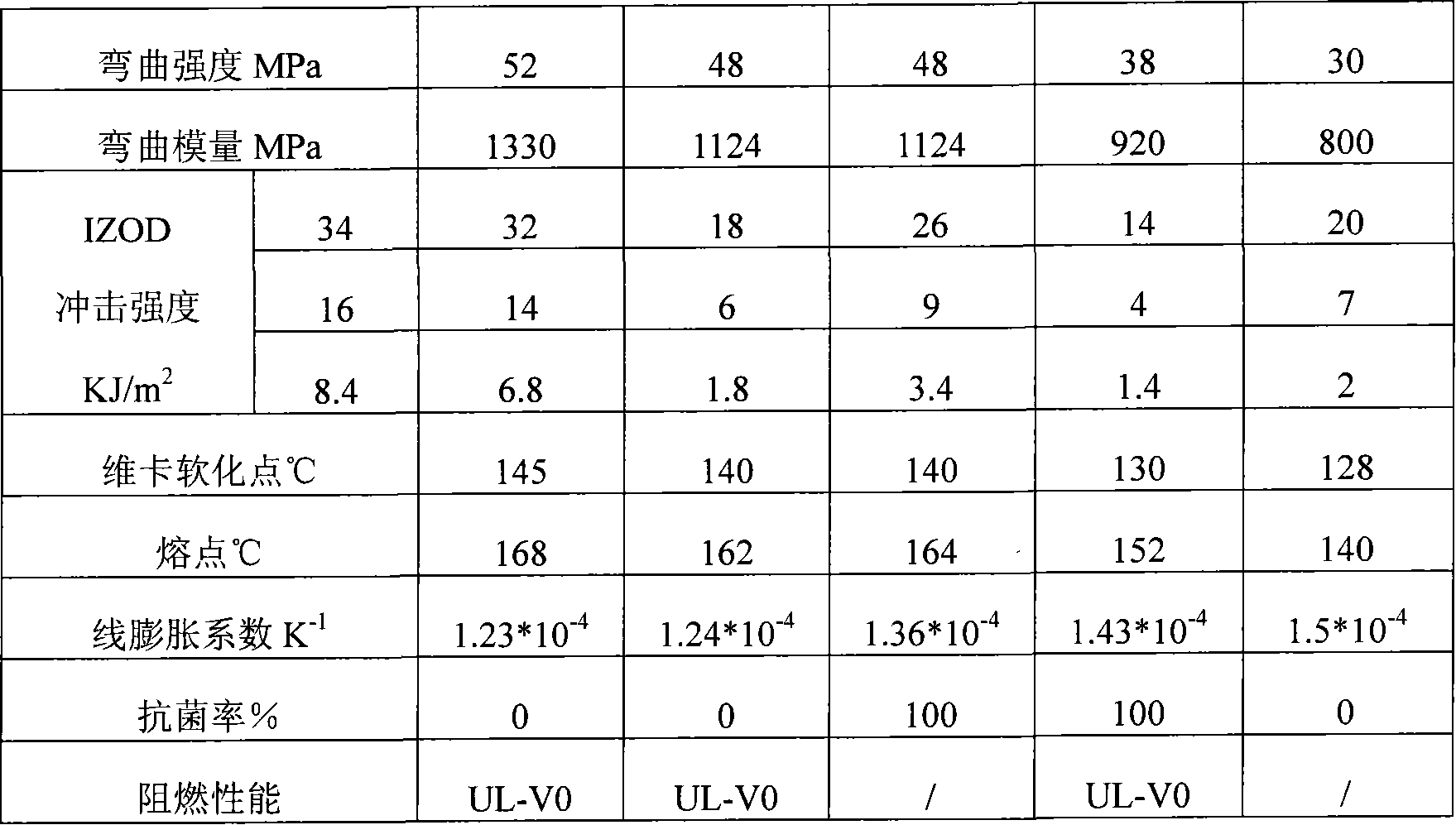

Special-purpose multifunctional modified random polypropylene material for pipe and its preparing process and application

InactiveCN101148530AWith flame retardant and antibacterial functionImprove heat resistanceFood industryHeat stability

The present invention discloses one kind of multifunctional modified atactic polypropylene pipe material and its preparation process. The atactic polypropylene pipe material consists of atactic copolypropylene, environment friendly fire retardant, pre-dispersed master batch of inorganic stuffing, impact modifier, antioxidant, composite antibacterial master batch and dispersant. It is applied in building pipes, pipeline for beverage and food industry, heat supply system and farm irrigation system. It has fire retarding and antibacterial functions, less shrinkage, high low temperature impact resistance, high heat resistance, high mechanical performance and excellent heat stability.

Owner:合诚技术股份有限公司

High temperature resistant vitreous inorganic fiber

InactiveUS20030162019A1Non-durableImprove shrinkage resistanceInorganic fibres/flakesInorganic material artificial filamentsFiberPhysiological fluid

A low shrinkage, high temperature resistant vitreous inorganic fiber having a use temperature up to at least 1330° C., which maintains mechanical integrity after exposure to the use temperature and which is non-durable in physiological fluids, is prepared by the method of forming a melt with ingredients including greater than 71.25 weight percent silica, 0 to about 20 weight percent magnesia, and about 5 to about 28.55 weight percent of calcia, 0 to about 5 weight percent zirconia, and optionally a viscosity modifier in an amount effective to render the product fiberizable; and producing fibers from the melt.

Owner:UNIFRAX I LLC

Block copolymer, composition thereof, and film made thereof

InactiveUS6841261B2Favorable spontaneous shrinkage resistanceLow temperature shrinkabilitySynthetic resin layered productsDomestic articlesDynamic viscoelasticityAromatic hydrocarbon

It is to provide a block copolymer and its copolymer composition which provides a heat shrinkable (multilayer) film with less spontaneous shrinkage while maintaining favorable low temperature shrinkability, and a heat shrinkable (multilayer) film containing the block copolymer. By using a block copolymer comprising a vinyl aromatic hydrocarbon and a conjugated diene characterized in that the relation of the loss tangent value obtained by dynamic viscoelasticity measurement with the temperature satisfies specific conditions, or a composition containing the copolymer composition as an essential component, a heat shrinkable (multilayer) film with less spontaneous shrinkability and less odor while maintaining favorable low temperature shrinkability can be obtained.

Owner:DENKA CO LTD

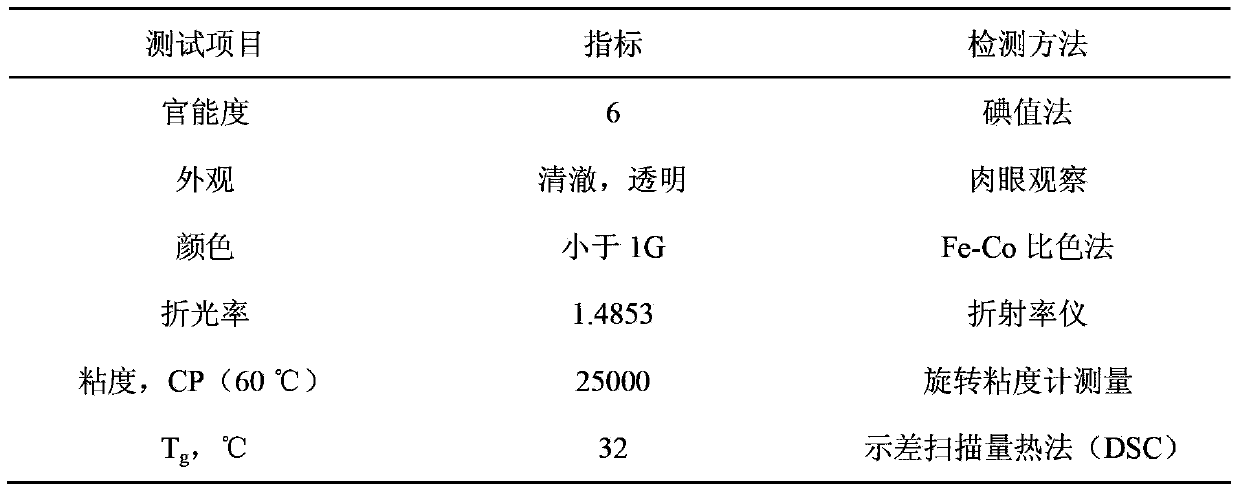

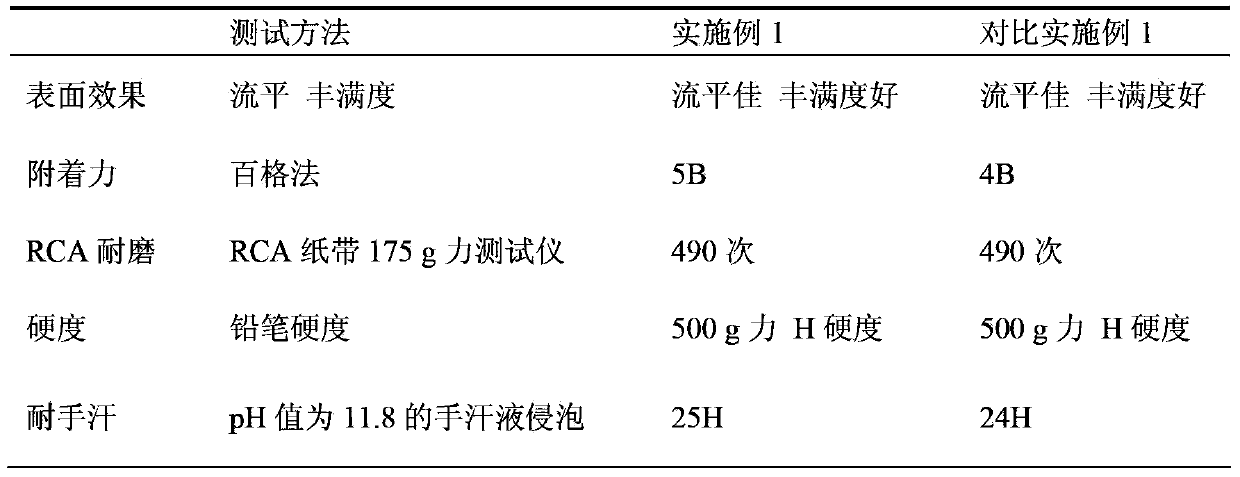

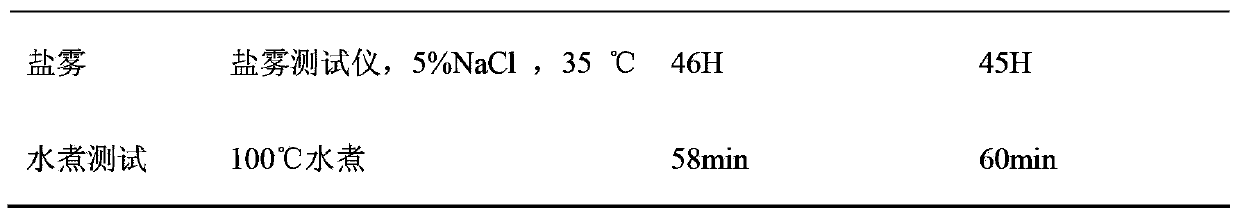

UV curing resin, preparation method thereof and application of UV curing resin in UV curing colored paint

ActiveCN103421156ASolve technical problems that are difficult to cureGuaranteed color uniformityInksPolyurea/polyurethane coatingsPolyolFoaming agent

The invention discloses a UV curing resin, a preparation method thereof and the application of the UV curing resin in a UV curing colored paint. The preparation method comprises the following steps: mixing polyalcohol, polyacid and fatty acid at first, adding a reflow solvent to prepare alkyd resin, then mixing an ester compound and isophorone diisocyanate, adding a polymerization inhibitor and a catalyst, reacting to obtain acrylic acid modified polyurethane, reacting the acrylic acid modified polyurethane and the alkyd resin for 2-3 h at the temperature of 60-100 DEG C to obtain the YV curing resin, and performing reaction of the UV curing resin, an acrylic acid alkyl oxidation polyol ester active diluent, a pigment, thermoplastic acrylic resin, a photoinitiator, an alkyd resin drier, a dispersant, a foam agent and a flattening agent to obtain the UV curing colored paint. The invention solves the problems that as a pigment in a conventional ultraviolet light curing colored paint system shields ultraviolet light, the paint system can not be completely cured, and as the UV curing resin can not well moisten the pigment, and the coating adhesive force is poor.

Owner:SOUTH CHINA UNIV OF TECH

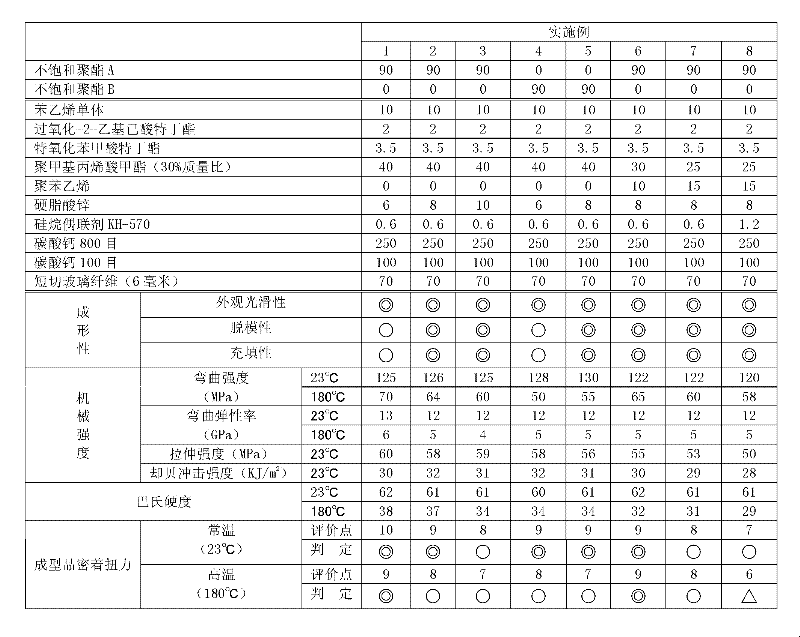

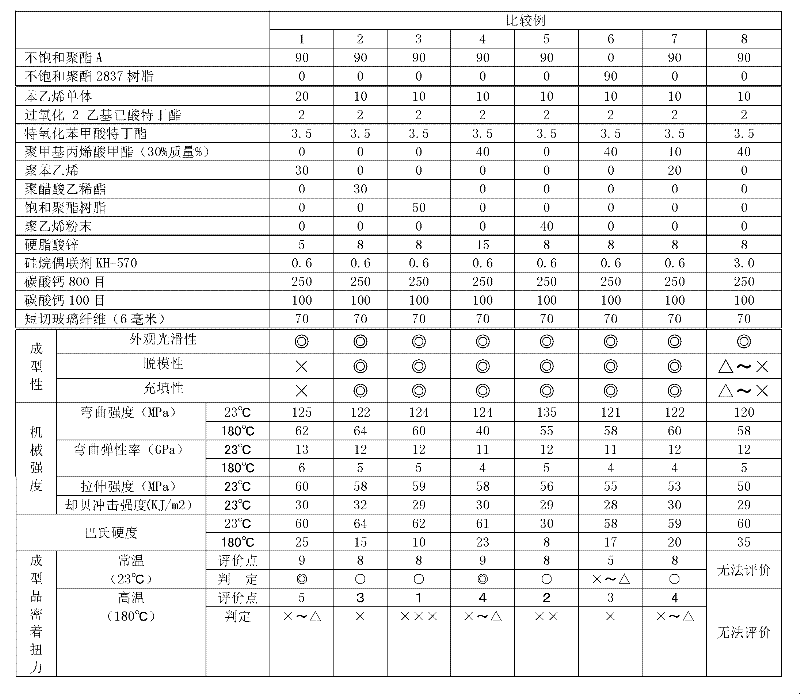

Unsaturated polyester bulk molding compound as well as method and application thereof

The invention relates to the technical field of a bulk molding compound for metal bonding, and specifically relates to an unsaturated polyester bulk molding compound as well as a method and application of the bulk molding compound. The bulk molding compound is prepared from the following raw materials in parts by weight: 8-20 parts of unsaturated polyester, 5-15 parts of low shrink agent, 55-70 parts of inorganic filler, 0.8-1.8 parts of internal demolding agent, 6-20 parts of fiber-reinforced material, 0.3-0.7 parts of curing agent, 0-3 parts of styrene, and 0.05-0.3 part of coupling agent. According to the invention, after the bulk molding compound (BMC) is molded, fast setting is realized and the appearance is excellent; and when used for electric tool and motor loop sealing and other fields, the bulk molding compound has excellent bonding property and torsion to the metal surface at normal temperature and high temperature, excellent resistance to impact, and excellent voltage withstand performance, conforms to the reliability required by product use, and fills up the blank of the field.

Owner:SHANGHAI SHOWA HIGHPOLYMER CO LTD

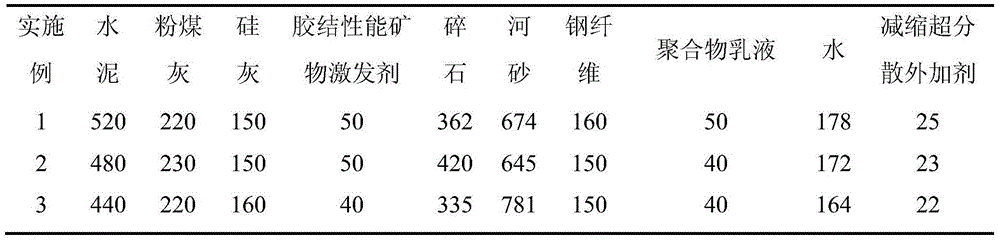

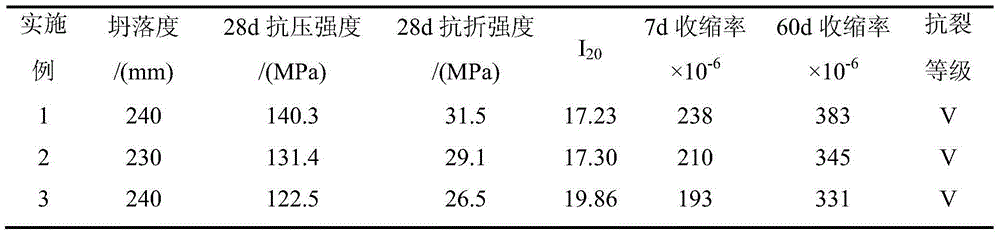

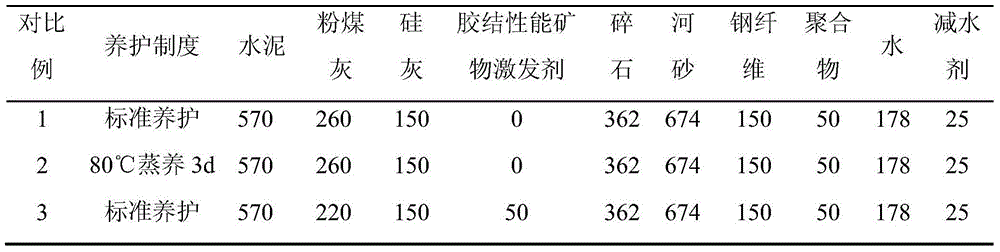

Anti-cracking steam-curing-free ultra-high-strength high-toughness concrete and preparation method thereof

The invention discloses anti-cracking steam-curing-free ultra-high-strength high-toughness concrete. The anti-cracking steam-curing-free ultra-high-strength high-toughness concrete is prepared from cement, fly ash, silica fume, a mineral activator with cementing property, gravel, river sand, steel fibers, a polymer emulsion, water and a shrinkage-reducing super-dispersing admixture, wherein the mineral activator with cementing property comprises waste prefabricated concrete set cement crystal seeds and desulfurized gypsum. By using the mineral activator with cementing property in the concrete, high-temperature steam curing and pressurized steam curing systems adopted in the ordinary ultra-high-performance concrete are eliminated; and the shrinkage-reducing super-dispersing admixture having the functions of super-dispersing cement, reducing shrinkage, decreasing viscosity and the like is adopted to enable the hydration activity of cement to give a full play so that the strength of the concretes has no obvious change after cement usage is decreased by about 10%; and meanwhile, the mineral activator and the admixture can effectively suppress the shrinkage of concrete. The concrete prepared by the preparation method is higher in strength, toughness and shrinkage resistance, low in cost and simple in preparation method and has important practical application value.

Owner:WUHAN UNIV OF TECH

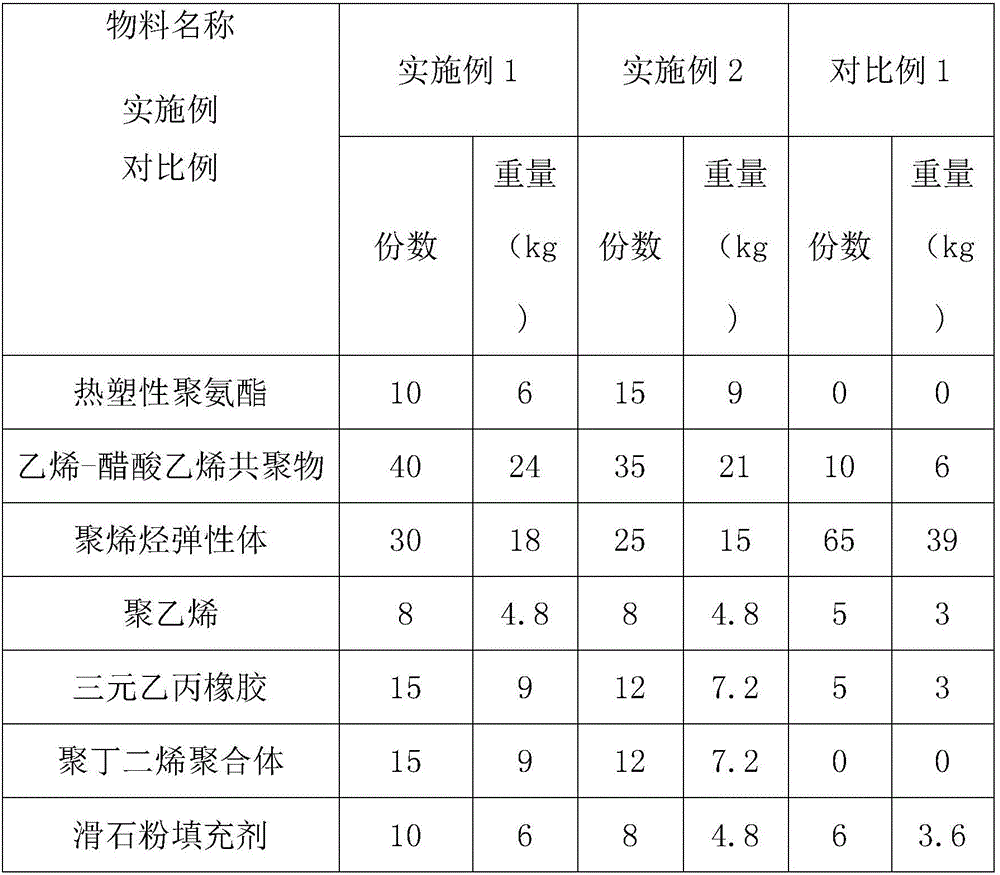

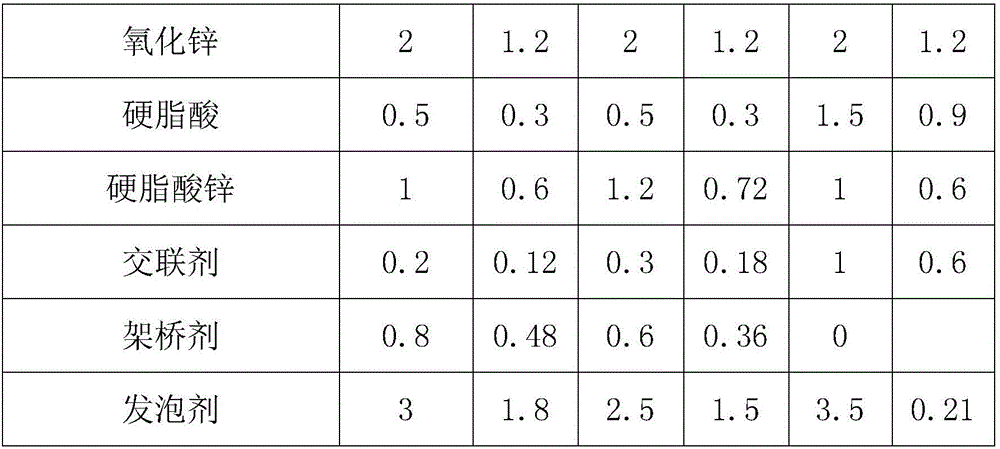

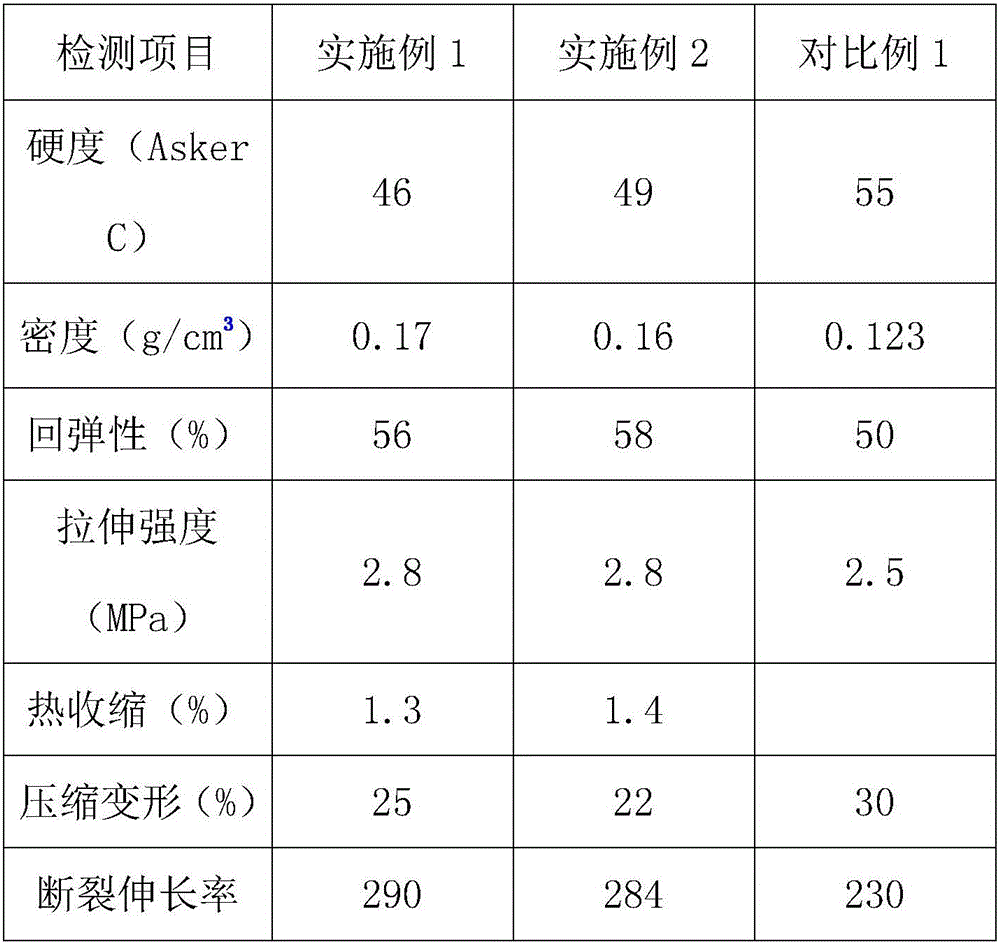

Thermoplastic polyurethane composite foamed material and preparation method thereof

The invention provides a thermoplastic polyurethane composite foamed material and a preparation method thereof. The thermoplastic polyurethane composite foamed material is prepared from 10-25 parts of polyurethane, 35-45 parts of ethylene-vinyl acetate copolymers, 15-30 parts of polyolefin elastomers, 6-10 parts of polyethylene, 6-18 parts of ethylene propylene diene monomers, 6-15 parts of polybutadiene polymers, 3-5 parts of filler, 1.5-2.2 parts of zinc oxide, 0.4-0.6 parts of stearic acid, 0.8-1.4 parts of zinc stearate, 0.1-0.4 parts of a cross-linking agent, 0.7-1.0 part of a bridging agent and 2.5-3.5 parts of a foaming agent. The thermoplastic polyurethane composite foamed material is high in rebound resilience, resistant to compression and good in tear resistance. The preparation method of the thermoplastic polyurethane composite foamed material comprises steps as follows: 1) components except zinc oxide, the cross-linking agent, the bridging agent and the foaming agent are weighed; 2) all the components weighed in the step 1) are mixed; 3) the rest components are weighed; 4) the components weighed in the step 3) are added to a material obtained after mixing in the step 2) for mixing; 5) granulation is performed; 6) foaming is performed.

Owner:ANTA CHINA

Atomic ash special for wood decoration

The invention relates to a polymeric putty, in particular to an atomic ash specialized for carpentry decoration. The invention is specialized for meeting the using requirements of the carpentry furniture production and the interior decoration and fitment industry. The invention consists of two compositions: main ash and an evocating agent; the weight percentage of the main ash and the evocating agent is 100:2; when the invention is used, two compositions are evenly mixed according to mixture ratio. The main ash consists of the following compositions in percentage by weight: 35 to 45 portions of unsaturated polyester resin, 5 to 10 portions of saturated polyester resin, 0.003 to 0.005 portion of anti skinning agent, 8 to 12 portions of styrene, 0.3 to 1.2 portions of accelerant, 0.2 to 0.5 portion of wetting agent, 1 to 2 portions of thixotropic agent, 1 to 3 portions of zinc stearate, 5 to 8 portions of titanium pigment, 5 to 8 portions of permanent white, 20 to 35 portions of talcum powder and 8 to 12 portions of atomic powder. The evocating agent consists of the following compositions in percentage by weight: 45 to 55 portions of cyclohexanone peroxide or methyl ethyl ketone peroxide, 35 to 48 portions of dibutyl phthalate and 4 to 9 portions of SiO2. The atomic ash specialized for carpentry decoration has the following advantages that: the atomic ash has good adhesive force with various carpentry materials, good construction and flexility and shrinkage resistance and rapid drying speed and can fill up large holes or cracks; the putty film is exquisite, smooth and good in air-drying property and can be matched with wood lacquer in the market for use.

Owner:GUANGDONG SANVO CHEM IND TECH

Environment-friendly building outer wall simulated tile coating and preparation method thereof

The invention relates to an environment-friendly building simulated tile coating and a preparation method thereof, and belongs to building materials. The environment-friendly building simulated tile coating is used for the decoration of surfaces of outer walls of buildings, and the defects of high possibility of dropping, large dead height of tiles and high cost in the conventional tile system are overcome. The environment-friendly building simulated tile coating consists of water, titanium dioxide, colorful sand and a dispersing agent, 2 weight percent of cellulose ether aqueous solution, a pure acrylic emulsion, ethanediol, a thickening agent, a film-forming aid, a defoamer, a preservative, a pH regulator and a multifunctional aid in a specific weight ratio. The preparation method comprises the following steps of: mixing liquid materials uniformly, mixing solid materials uniformly, adding the uniformly-mixed solid materials into the uniformly-mixed liquid materials slowly, and stirring uniformly to obtain the environment-friendly building simulated tile coating. The environment-friendly building simulated tile coating has a vivid tile visual effect and is diversified in colors, simple and tasteful, high in contractibility resistance, resistant to aging, long in service life, non-toxic and tasteless, and environmental protection is facilitated; and the environment-friendly building simulated tile coating can be constructed at the temperature of -5 DEG C, and compared with like products, the environment-friendly building simulated tile coating has the advantage that the construction period can be prolonged by one month.

Owner:JILIN KELONG BUILDING ENERGY SAVING TECH

Block copolymer, its composition and film made of it

InactiveUS20050089702A1Increase resistanceImprove shrinkabilitySynthetic resin layered productsDomestic articlesPolymer scienceDynamic viscoelasticity

It is to provide a block copolymer and its copolymer composition which provides a heat shrinkable (multilayer) film with less spontaneous shrinkage while maintaining favorable low temperature shrinkability, and a heat shrinkable (multilayer) film containing the block copolymer. By using a block copolymer comprising a vinyl aromatic hydrocarbon and a conjugated diene characterized in that the relation of the loss tangent value obtained by dynamic viscoelasticity measurement with the temperature satisfies specific conditions, or a composition containing the copolymer composition as an essential component, a heat shrinkable (multilayer) film with less spontaneous shrinkability and less odor while maintaining favorable low temperature shrinkability can be obtained.

Owner:DENKA CO LTD

Plastering gypsum and preparation method thereof

The invention discloses plastering gypsum and a preparation method thereof, and relates to the technical field of gypsum. The plastering gypsum comprises the following raw materials in parts by weight: 55-65 parts of desulfurated gypsum, 40-42 parts of modified rubber powder, 34-36 parts of cement, 24-26 parts of liquid paraffin, 20-22 parts of modified kieselguhr, 18-20 parts of mineral admixture, 14-16 parts of manganese slag, 10-14 parts of an auxiliary agent and 45-65 parts of water. The plastering gypsum is adhered to a base wall well, a coating cannot crack and cannot drop easily, and construction is facilitated.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Waterborne binder for tile

InactiveCN106566441AGood anti-sag effectImprove shrinkage resistanceCellulose adhesivesHydrocarbon polymer adhesivesHydroxypropylmethyl celluloseEmulsion

The invention discloses a waterborne binder for tile. The waterborne binder comprises an acrylic pressure-sensitive adhesive, hydroxypropyl methyl cellulose, polyvinyl alcohol (PVA) powder, water, an antifoaming agent, an antiseptic, a styrene-acrylic emulsion and an antifreezing agent. The above components are subjected to mechanical processing so as to prepare the waterborne binder for tile. The waterborne binder for tile has good thixotropic performance, improved shrinkage and cracking resistance, enhanced surface quality, improved bonding strength, good smoothness in brushing and excellent tile wettability and spreadability; with the binder, the tile is hard to slide and not prone to the phenomena of hollowing, tile falling and the like after bonded onto a wall; and the binder has good bonding performance, high strength, good resistance to water, freezing and thawing and ageing and allows the surface of the bonded tile to be easy to clean due to usage of the antifoaming agent as the component.

Owner:沈屏

Low-cement refractory castable for pumping construction

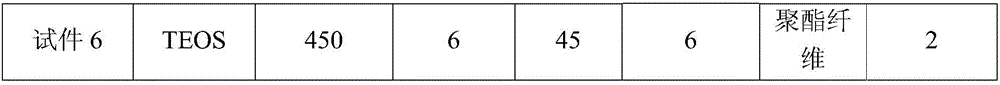

InactiveCN113149675APumping achievedSolve the problem of vertical conveyingFiberMechanical engineering

The invention relates to a low-cement refractory castable for pumping construction, which comprises a dry material and an additive, the dry material comprises the following components in parts by weight: 55-68 parts of refractory aggregate, 12-27 parts of refractory powder, 3-10 parts of superfine powder and 1-9 parts of binding agent, the additive comprises fibers and a composite additive, the weight of the fibers is 0.01-3% of the weight of the dry material, the weight of the composite additive is 0.1-0.5% of the weight of the dry material, and the weight of the water is 5-12% of the weight of the dry material. The invention provides the low-cement refractory castable with the volume density of 2.2-2.8 g / cm3, the castable makes up the defect that the traditional low-cement refractory castable cannot be pumped, realizes the pumping of the low-cement refractory castable, is convenient for on-site pouring construction, solves the difficult problem of vertical conveying of the refractory castable of a high and large furnace body, reduces the workload of workers, and improves the pouring efficiency; and the stirred material reaches the working surface within a short time, so that the working surface can be prevented from being added with water again, and the performance of the refractory lining is effectively ensured.

Owner:HENAN YU & NEW ENERGY SAVING BUILDING MATERIALSCO

Photosensitive resin composition and light blocking layer using the same

ActiveCN102540717AIncreased sensitivityExcellent developabilityPhotosensitive materials for photomechanical apparatusNon-linear opticsSolventBlocking layer

Disclosed is a photosensitive resin composition that includes (A) a cardo-based monomer represented by the following Chemical Formula 1 or 2, (B) a cardo-based resin, (C) a reactive unsaturated compound, (D) a pigment, (E) an initiator, and (F) a solvent, and a light blocking layer using the same. In Chemical Formulae 1 and 2, each substituent is the same in the detailed description.

Owner:CHEIL IND INC

Preparation method of fireproof, heat-resistant and light-weight partition plate

The invention discloses a preparation method of a fireproof, heat-resistant and light-weight partition plate, and relates to the technical field of partition plates. The preparation method comprises the following steps: (1) preparing a fiber enhancer; (2) preparing modified expansible graphite; (3) preparing a flame-retardant covering agent; (4) preparing a matrix; and (5) preparing a finished product. The fireproof, heat-resistant and light-weight partition plate is excellent in fireproofing and heat resisting performance and high in stability, difficult to deform under heat, and safe and convenient to use.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

A coated bismuth oxy halide-based pigment

InactiveCN108699351AReduce warpagePromote migrationCosmetic preparationsToilet preparationsPhosphoric Acid EstersAlkaline earth metal

The present invention is directed to a coated bismuth oxy halide-based pigment having a coating comprising an antioxidant, said antioxidant is being a phenol based, a phosphite or phosphonate based, or a thioether based stabilizer, and the coating comprising an inner coating and an outer coating, wherein the outer coating comprises the antioxidant, and wherein the inner coating comprises a first layer consisting of one or more salts, or one or more oxides, heteropolyacids, organic acids, sulphites, sulfides, sulfates, phosphates, pyrophosphates, polyphosphates, hydrates, carbonates, or a combination thereof, selected from the group of alkali-earth metals, metals, non-metals, transition metals or lanthanides. Further, the present invention is directed to a composition comprising a paint, alacquer, an ink, a cosmetic, a resin, a plastisol or a polymer formulation, and such pigment. In addition, the present invention is directed to a method for manufacturing a coated bismuth oxy halide-based pigment, said method comprising the steps of: - providing a dispersion of a bismuth oxy halide-based pigment, adding a dispersion of an antioxidant, mixing and drying.

Owner:FELLOWES INC

Compound type thickening agent applicable to common wet-mixed mortar

ActiveCN102153311AEasy to useIn line with the policy of sustainable developmentSolid waste managementSlagTriterpenoid saponin

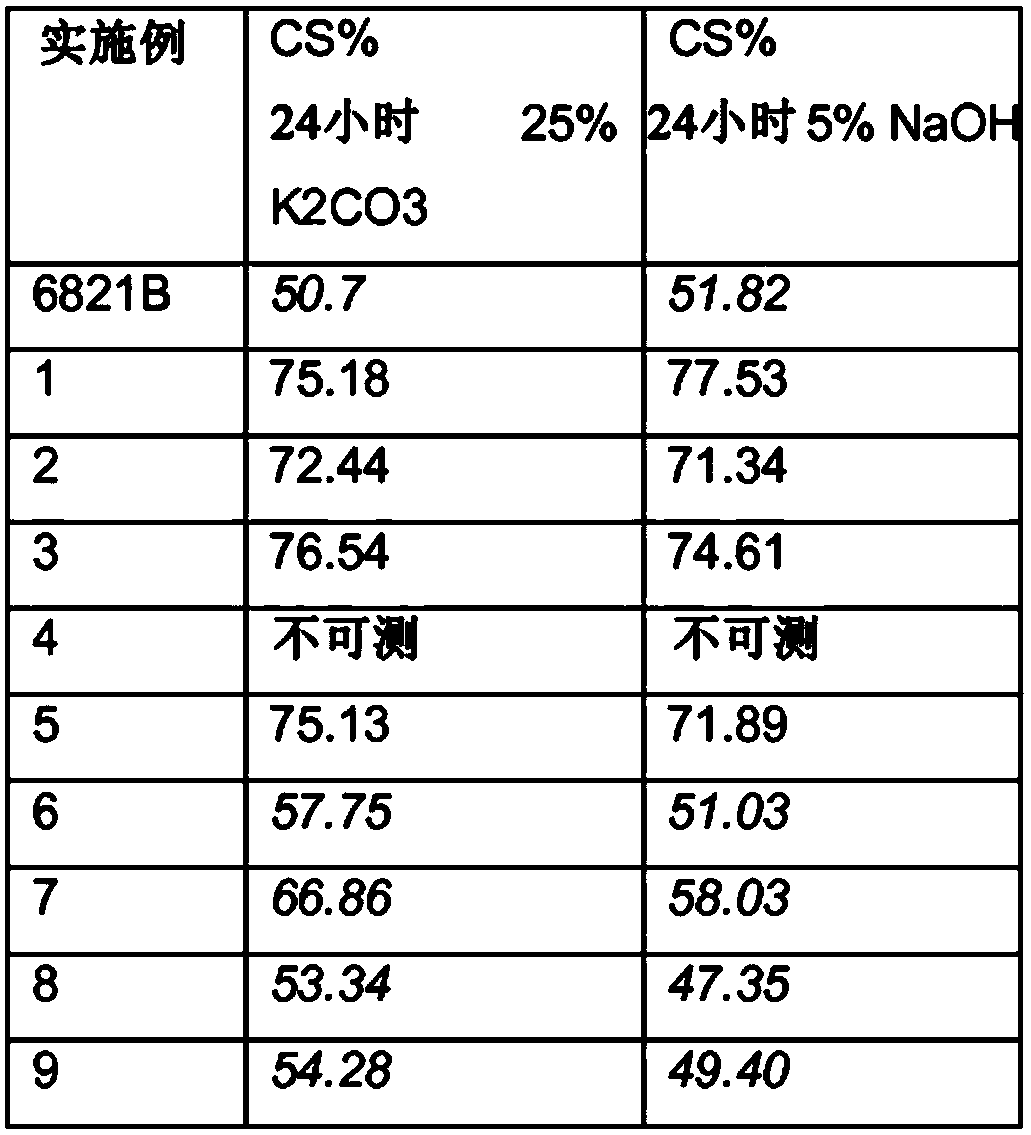

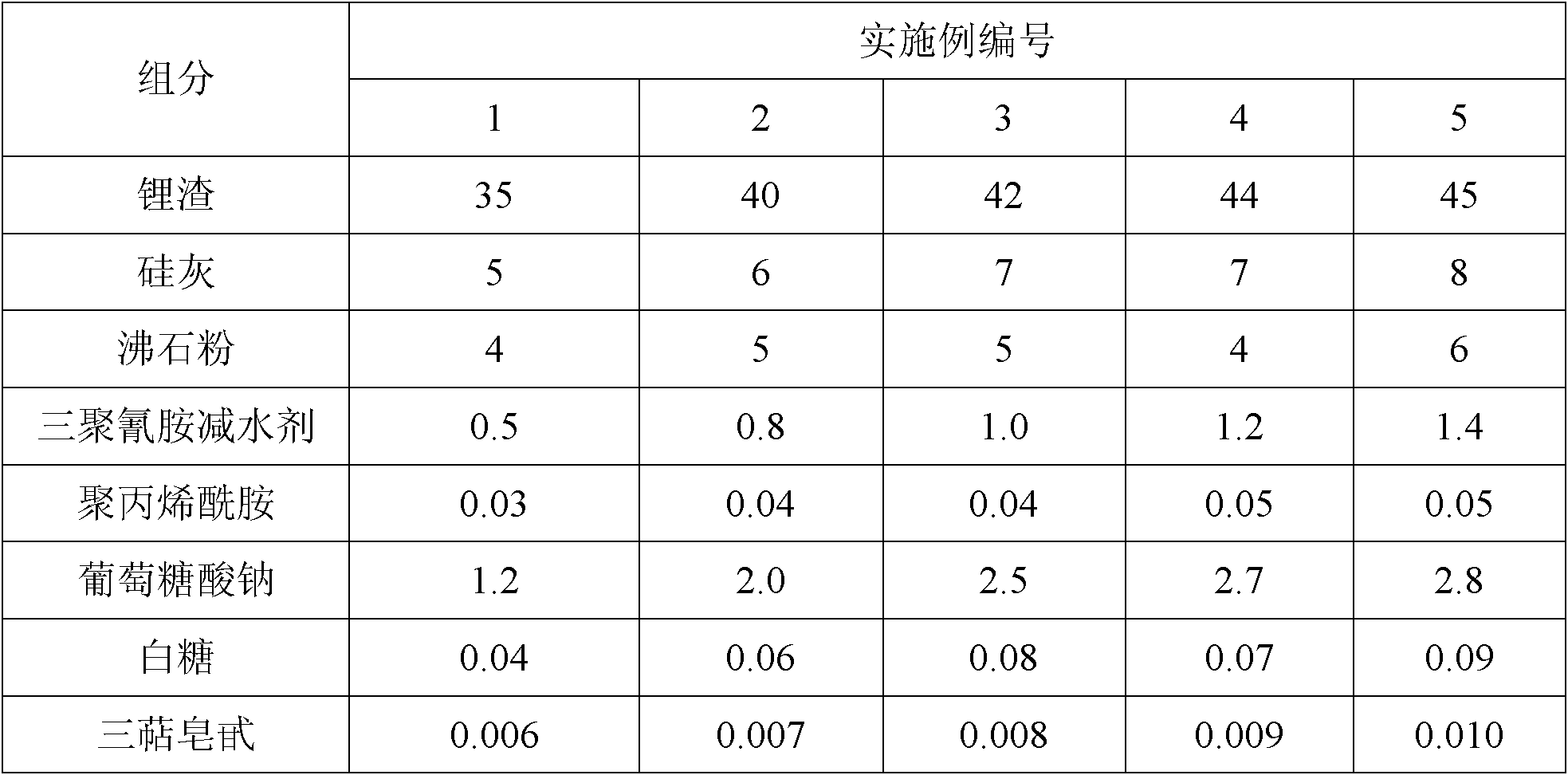

The invention relates to a compound type thickening agent applicable to common wet-mixed mortar. The compound type thickening agent applicable to common wet-mixed mortar is characterized by being prepared by mixing a raw materials including 35-54 parts of lithium slags by weight, 5-8 parts of siliceous dust by weight, 4-6 parts of zeolite powder by weight, 0.5-1.4 parts of melamine water reducer by weight, 0.03-0.05 part of polyacrylamide by weight, 1.20-2.80 parts of sodium gluconate by weight, 0.04-0.09 part of sugar by weight and 0.006-0.010 part of triterpenoid saponins by weight. The raw materials are weighted according to the mass proportioning, added in a mixing machine and fully mixed to be uniform, and then the product of the compound type thickening agent can be obtained. The compound type thickening agent can obviously improve the water-retaining property, the cohesiveness and the softness of the common wet-mixed mortar, and enable the common wet-mixed mortar to obtain not only excellent working properties which can meet construction requirements but also better anti-compression strength, cohesive strength and anti-contraction property; and the compound type thickening agent can be applicable to ground mortar, masonry mortar and plastering mortar in the common wet-mixed mortar.

Owner:中建西部建设西南有限公司 +1

Coarse composite foaming material for sneaker soles as well as preparation method and application of coarse composite foaming material

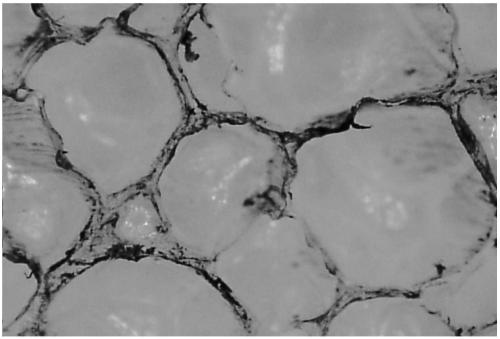

The invention provides a coarse composite foaming material for sneaker soles as well as a preparation method and application of the coarse composite foaming material. The material is prepared by foaming an expandable elastomer composite material, wherein the expandable elastomer composite material is prepared from the following components in parts by mass: 15 to 25 parts of a polyolefin elastomer,20 to 45 parts of an ethylene vinyl acetate copolymer, 15 to 35 parts of an olefin block copolymer, 5 to 10 parts of polyethylene, 2 to 8 parts of calcium carbonate, 0.6 to 1.5 parts of nano active zinc oxide, 0.5 to 0.8 part of a stearic acid, 0.5 to 0.8 part of a cross-linking agent and 3 to 5 parts of a coarse foaming agent. The coarse composite foaming material for the sneaker soles has an open spherical foam structure. The coarse composite foaming material provided by the application has the advantages of excellent rebound performance, compression resistance, lower density, capability ofachieving high light transmission, unique appearance effects and facilitation for producing high-quality sneaker soles.

Owner:ANTA CHINA

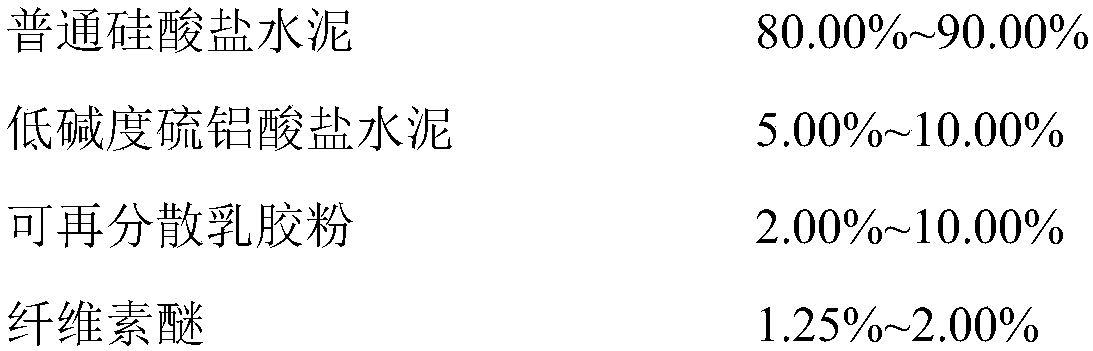

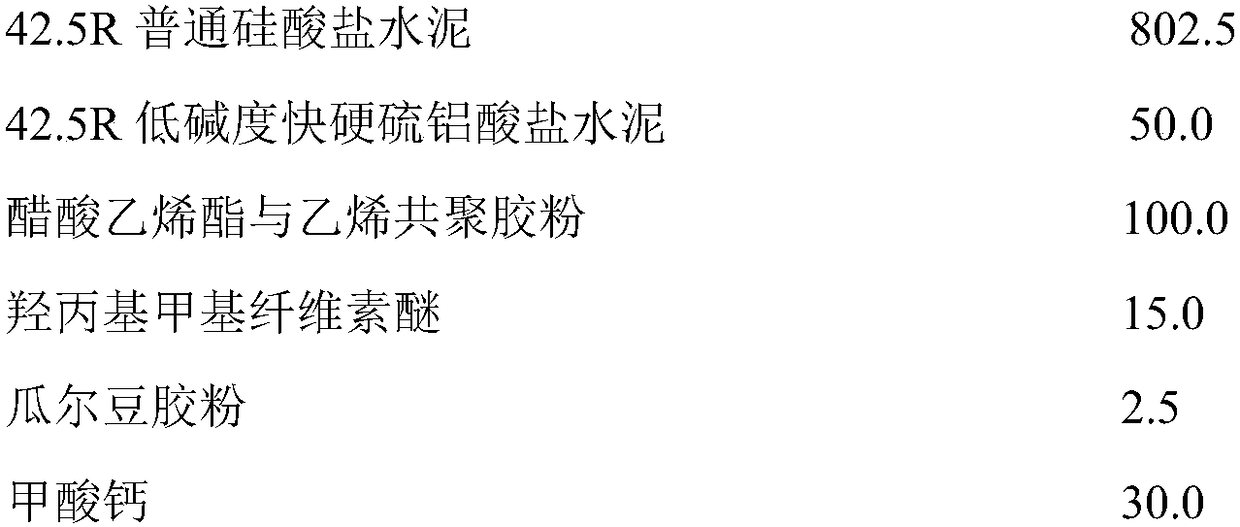

Cement-based tile adhesive and composition for preparing same

The invention discloses a cement-based tile adhesive. The adhesive comprises composition prepared from raw materials in percentage by mass as follows: 80.00%-90.00% of ordinary Portland cement, 5.00%-10.00% of low-alkalinity sulphoaluminate cement, 2.00%-10.00% of redispersible latex powder, 1.25%-2.00% of cellulose ether, 0.25%-0.50% of guar gum powder, 1.00%-6.00% of an early strength agent, sand and water, Wherein the mass ratio of the composition to the sand is 1:4, and water accounts for 10%-15% of the total mass. Compared with the prior art, the cement-based tile adhesive has the advantages that the amount of aggregate (sand) in a formula is increased to 65% or above, the shrinkage of the system is well reduced, so that the tile adhesive can be thick, and the production cost is greatly reduced.

Owner:KESHUN WATERPROOF TECH CO LTD

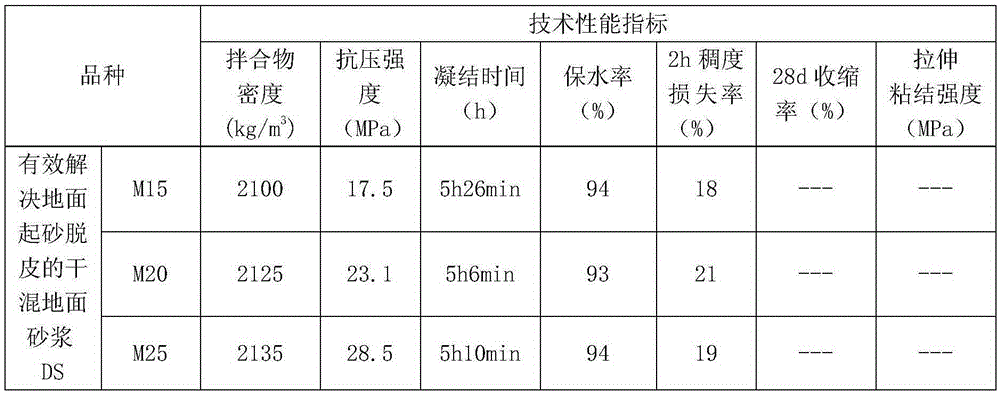

Dry mixed ground mortar for effectively solving dusting and peeling of ground and preparation method for dry mixed ground mortar

The present invention relates to the technical field of premixing mortar, particularly dry mixed ground mortar for effectively solving dusting and peeling of a ground. The mortar comprises the following components in percentage by mass: 40%-60% of limestone rock machine-made sand, 20%-30% of yellow sand, 3%-7% of coal ash, 15%-21% of cement and the balance of an additive, wherein the additive is a modifying agent and a thickening agent; the modifying agent is one of or a mixture of cellulose ether, an air entraining agent or a water reducing agent.

Owner:浙江兆山建材科技有限公司

Formula of gypsum binder

The invention discloses a formula of a gypsum binder. The gypsum binder comprises the following raw materials in parts by weight: 100 parts of desulfurized gypsum, 0-5 parts of polyvinyl alcohol, 0.1-0.7 part of methyl cellulose and 0-0.2 part of sodium citrate. The dry powder is evenly stirred and mixed to obtain the product. The test report indicates that the initial setting time is 30-100 minutes, the final setting time is 45-115 minutes, the folding strength is 2.3-2.9 MPa, the compression strength is 5.5-6.5 MPa, and the bonding (compression shear) strength is 0.40-0.9 MPa. The invention has the advantages of favorable stability, water retention and flow slide property, strong binding performance and favorable affinity, has the function of interfacial activity and greatly enhances the adhesive force between the product and the base material; and the invention has stable pH values, favorable lubricating property, favorable shrink resistance, favorable mildew resistance and the like, and does not need to use gauze at the seam, thereby having the advantages of firm binding and slight expansibility and preventing the phenomenon of cracking.

Owner:河南省翔宇建材科技有限公司

Low-temperature plasma pre-treatment process

InactiveCN104674577AGood hair effectGood moisture absorptionSucessive textile treatmentsDyeing processCamel hairPolymer science

The invention relates to a low-temperature plasma pre-treatment process which is characterized by comprising the following steps: sorting wool; washing wool; drying; carrying out low-temperature plasma treatment; sizing and the like. The invention is the low-temperature plasma pre-treatment process which is clean and uniform to treat and has water-saving and energy-saving effects, and the surface hydrophilic performance of spinnable blanket wool (yak hair, wool, camel hair and the like) is effectively improved, so that the dyeing property of the wool is improved, and the dyeing, coating and bonding performances are improved.

Owner:青海大自然地毯纱有限公司

Highly twisted multi-strand knitting yarn and its production technology

A high-twisted multi-strand knitting yarn is composed of three fibres, and features that its one fibre is acrylic fibre filament and another two are chosen from silk, bamboo fibre and wood pulp fibre. Its production technology includes pre-treating and double-twisting. The fabric made of it features high air permeability, hydroscopicity, and shrinking resistance.

Owner:陈家标

Anti-shrinkage shock-absorbing EVA foamed material

The invention relates to an anti-shrinkage shock-absorbing EVA foamed material. Raw materials in parts by mass are as follows: 40-80 parts of butadiene styrene rubber, 5-10 parts of EVA, 2-5 parts of azodiisobutyronitrile, 0.1-0.5 part of dibenzoyl peroxide, 0.2-0.7 part of titanium dioxide particles, 1-4 parts of dicumyl peroxide, 1-4 parts of talcum powder, 8-12 parts of polyacrylonitrile fibers, 0.8-2.1 part of an initiator and 1.3-1.8 parts of a catalyst. The anti-shrinkage shock-absorbing EVA foamed material provided by the invention is soft in texture and has better shrinkage resistance, fatigue resistance is improved, shock-absorbing performance is also better, and cost is lower.

Owner:青阳县吉祥塑胶有限公司

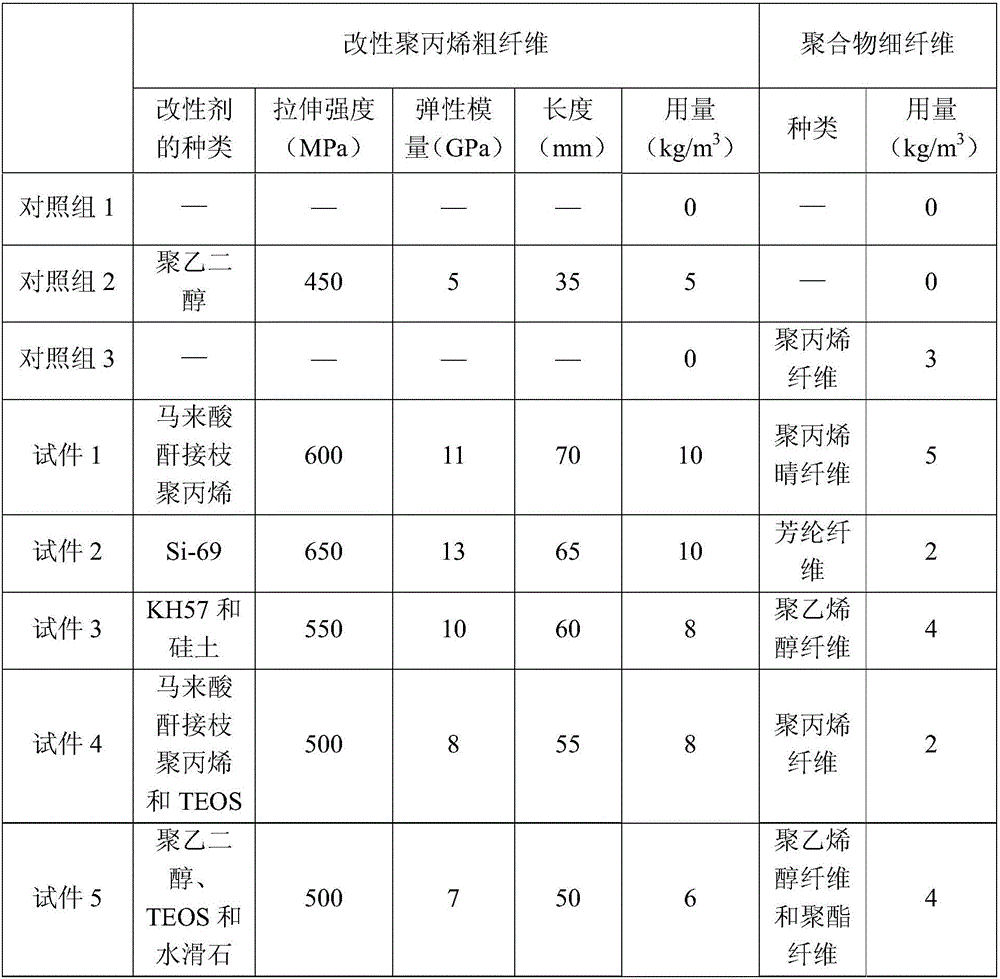

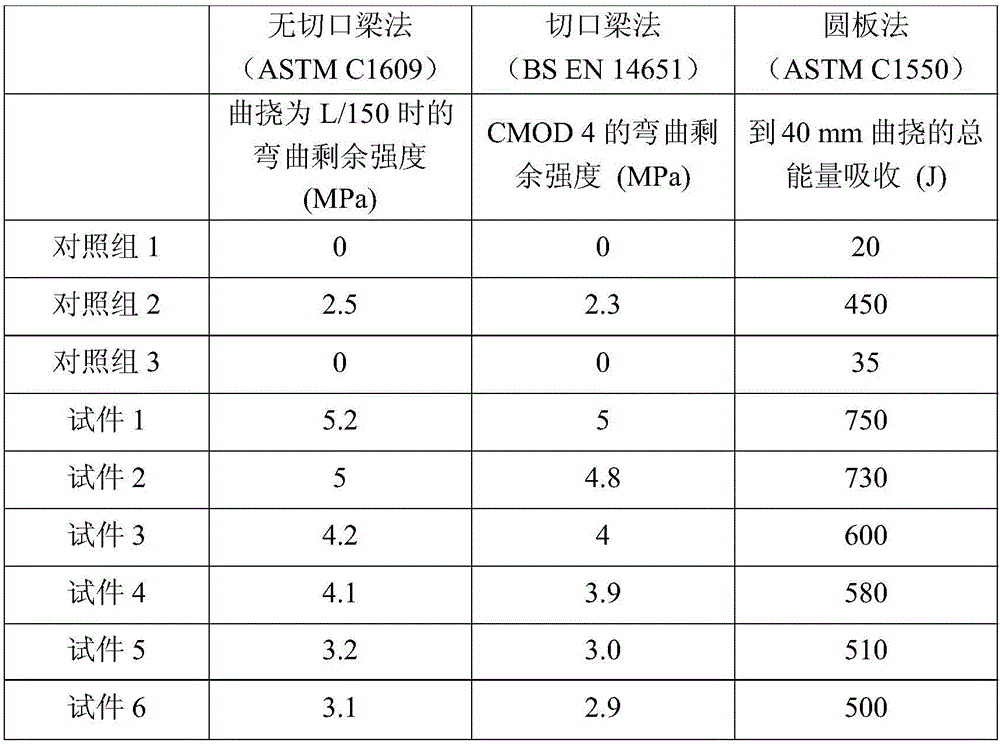

High-performance concrete pavements enhanced by hybrid fibers

The invention discloses high-performance concrete pavements enhanced by hybrid fibers and particularly discloses pavement concrete to which modified polypropylene crude fibers and polymer micro fibers are added.The modified polypropylene crude fibers are prepared in a mode that an organic modifying agent, a silane coupling agent and inorganic modified filler are subjected to melt-spinning and cold-stretching after being modified.The modified polypropylene crude fibers can effectively limit and delay generation and development of macrocrack; the polymer micro fibers can block expansion of original defects and micro cracks of concrete.The modified polypropylene crude fibers and the polymer micro fibers work in a cooperative mode, a hybrid effect can be generated, and crack resistance, stretch resistance, impact resistance, wear resistance, seepage resistance, bending resistance, fatigue resistance, shrinkage resistance, corrosion resistance, freeze thawing resistance and the like of concrete are greatly improved.The concrete can be widely applied to concrete pavements, such as a road pavement, a bridge floor, an airfield pavement, an urban road pavement, a port pavement, a traffic tunnel and an industrial building ground, engineering quality of the concrete pavements is remarkably improved, and the service life is prolonged.

Owner:宁波时科新材料科技有限公司

Wooden furniture surface coating material

The invention relates to the technical field of furniture surface treatment, in particular to a wooden furniture surface coating material. The wooden furniture surface coating material is prepared from a main agent and a curing agent, wherein the main agent is prepared from, by weight, 50-60 parts of saturated polyester resin, 5-10 parts of dimethylglyoxime, 3-5 parts of phosphoric acid triallyl ester, 2-4 parts of white corundum, 1-6 parts of attapulgite, 0.5-1.0 part of copper naphthenate, 0.2-0.4 part of cobalt iso-octoate and 2-6 parts of titanium dioxide, the curing agent is prepared from, by weight, 10-20 parts of methyl ethyl ketone peroxide, 5-8 parts of gas phase SiO2, 15-25 parts of dibutyl terephthalate and 0.1-0.3 part of polyvinylpyrrolidone. According to the wooden furniture surface coating material, no deformation or contraction of a base material will be caused in the base material treatment process, and therefore the decorative coating is not broken.

Owner:桐乡市美意家具有限公司

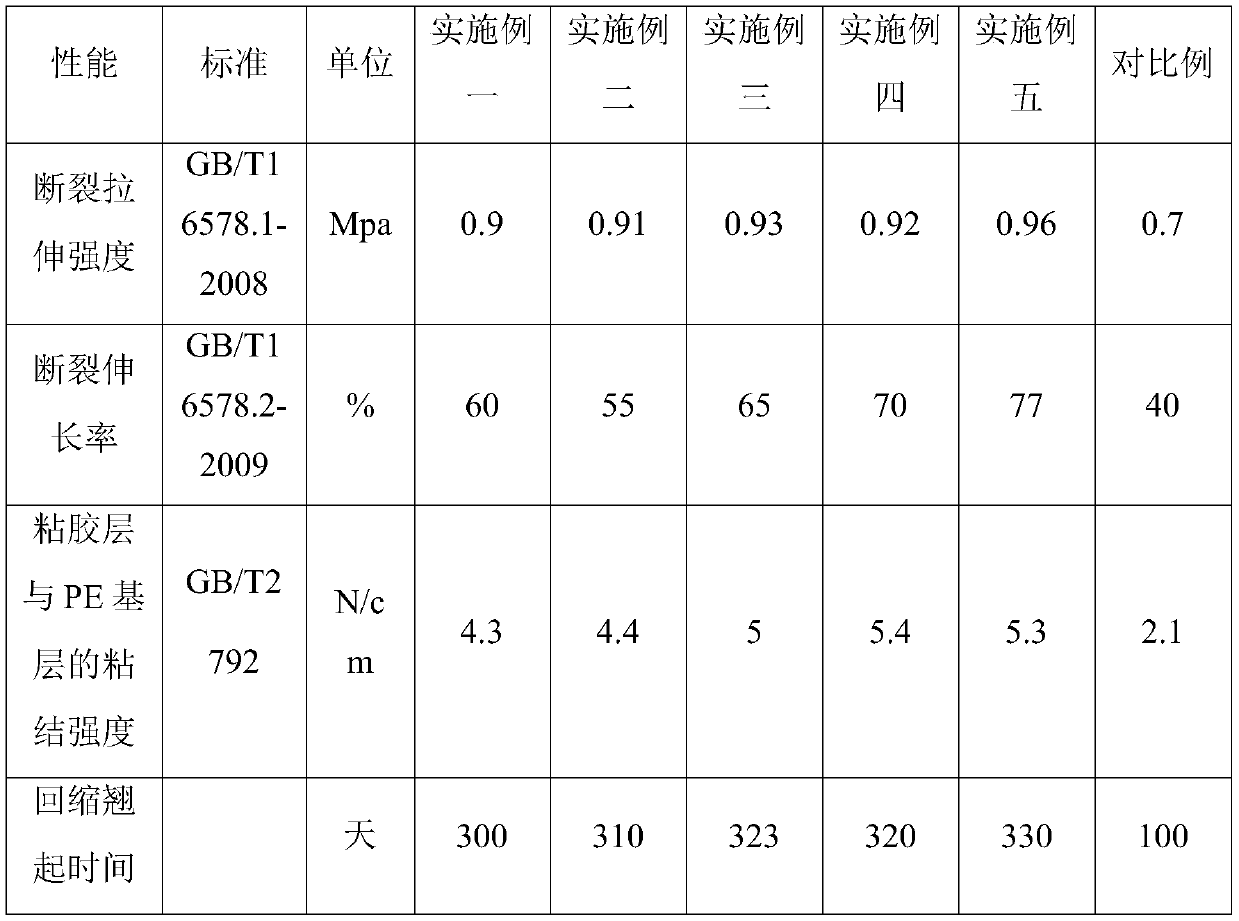

PE protective film

InactiveCN109796897APrevent disengagementInhibition of retraction problemsNon-macromolecular adhesive additivesPressure sensitive film/foil adhesivesLow-density polyethyleneEngineering

The invention discloses a PE protective film and relates to the field of protective films, aiming to solve the problem that the end edge of the existing PE protective film is easy to tilt during use.The technical scheme includes that the PE protective film comprises a PE base layer, a jointing layer, an adhesive layer, an retraction-resistant layer and a protective layer, wherein the jointing layer and the adhesive layer arranged on the inner side of the PE base layer, the retraction-resistant layer and the protective layer are arranged on the outer side of the PE base layer; the PE base layer is prepared from, by weight, 35-65 parts of low-density polyethylene and 12-35 parts of high-density polyethylene; the retraction-resistant layer comprises, by weight, 30-45 parts of thermosetting phenolic resin and 12-45 parts of penetrating agents; the jointing layer comprises, by weight, 12-35 parts of low-density polyethylene and 5-25 parts of cross-linking agents; the adhesive layer is prepared from, by weight, 23-45 parts of silicone pressure sensitive adhesive and 12-35 parts of antiagers; the protective layer comprises, by weight, 20-57 parts of polycarbonate and 7-22 parts of dimethyl siloxane. Retraction in use of the PE protective film can be effectively suppressed, and the adhesive layer of the PE protective film is not easy to fall off, which facilitates application of the PE protective film.

Owner:常州市顺龙弘源科技股份有限公司

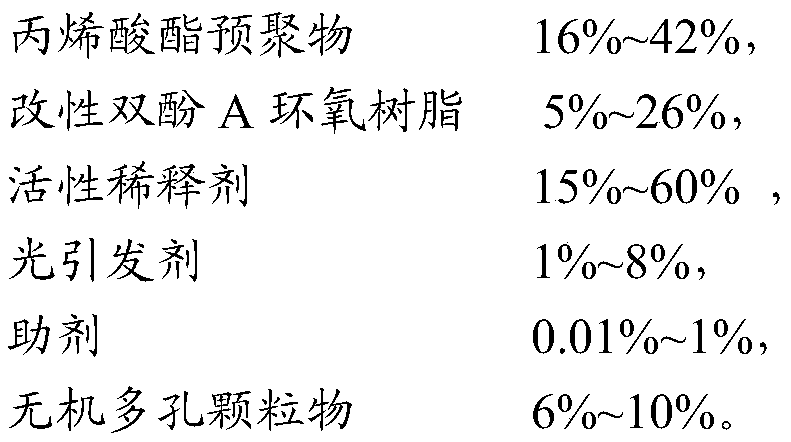

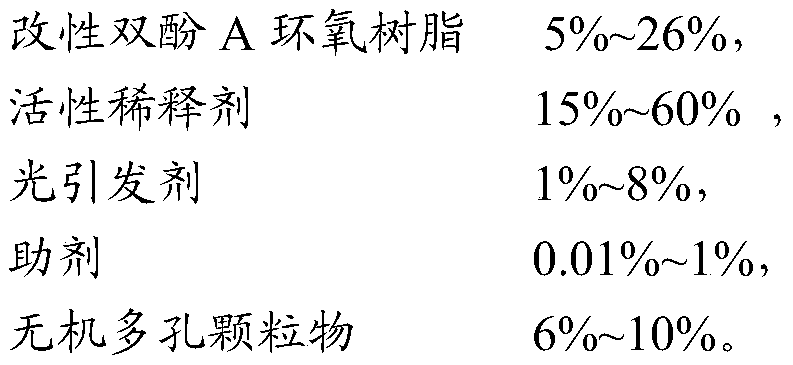

UV glue for package and preparation method thereof

InactiveCN110408350AStrong water vapor adsorption capacityStrong oxygen adsorption functionNon-macromolecular adhesive additivesEster polymer adhesivesParticulatesPolymer science

The invention relates to the field of display technology, in particular to UV glue for package and a preparation method thereof. The UV glue for package is prepared from an acrylic ester prepolymer, modified bisphenol-A epoxy resin, a reactive diluent, a photoinitiator, an addition agent, and inorganic porous particulate matter.

Owner:合肥派森新材料技术有限公司

Inorganic modified high heat-resistant low-shrinkage low-smoke halogen-free flame retardant polyolefin cable material and preparation method thereof

InactiveCN104212055AImprove high temperature resistanceImprove shrinkage resistancePolyolefinPolymer science

The invention relates to a cable material and in particular relates to an inorganic modified high heat-resistant low-shrinkage low-smoke halogen-free flame retardant polyolefin cable material and a preparation method thereof. The formula of the inorganic modified high heat-resistant low-shrinkage low-smoke halogen-free flame retardant polyolefin cable material comprises 100 parts of matrix resin, 120-160 parts of fire retardant, 10-30 parts of inorganic imvite, 1-4 parts of lubricant and 1-3 parts of antioxidant; the preparation method of the cable material comprises the steps of firstly, stirring the raw materials in a high-speed mixer evenly, secondly, banburying in a temperature interval from 110 to 130 DEG C by use of a Banbury mixer, and then feeding by use of a twin-screw feeder, extruding by use of double screws, molding by use of a single screw, hot cutting and pelleting by use of a grinding surface, conveying by use of a cyclone separator, sieving by use of a vibrating sieve and then packaging to obtain the finished inorganic modified high heat-resistant low-shrinkage low-smoke halogen-free flame retardant polyolefin cable material. Compared with a common low-smoke halogen-free flame retardant polyolefin cable material, the thermal aging resistance of the inorganic modified high heat-resistant low-shrinkage low-smoke halogen-free flame retardant polyolefin cable material is improved and the shrinkage performance of the cable material is greatly improved, and therefore, the problem of easy shrinkage of the low-smoke halogen-free polyolefin cable materials at high temperatures is solved.

Owner:HUANGMEI KEPUDA INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com