Anti-cracking steam-curing-free ultra-high-strength high-toughness concrete and preparation method thereof

An ultra-high-strength and high-toughness technology, applied in the field of building materials, can solve the problems of ineffective activation of activity, difficulty in obtaining raw materials, and high energy consumption, and achieve the effect of effective reuse, saving maintenance costs, and saving resources and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0029] Crack-resistant, non-steamed, ultra-high-strength and high-toughness concrete, made of cement, fly ash, silica fume, cementation performance enhancer, river sand, gravel, steel fiber, polymer emulsion, water, and shrinkage-reducing hyperdispersive admixture as raw materials The preparation method includes the following steps: weighing each raw material according to the proportion, pouring cement, fly ash, silica fume, cementing performance mineral activator, gravel, river sand and steel fiber into a concrete mixer for dry mixing for more than 2 minutes, Then add water, shrinkage-reducing super-dispersion admixture, and polymer emulsion, and continue to stir for more than 5 minutes; vibrate the mixture, and cover the surface with an impermeable film to prevent water loss after molding, and remove the mold after 1 day for standard maintenance, and you can get The ultra-high-strength and high-toughness concrete.

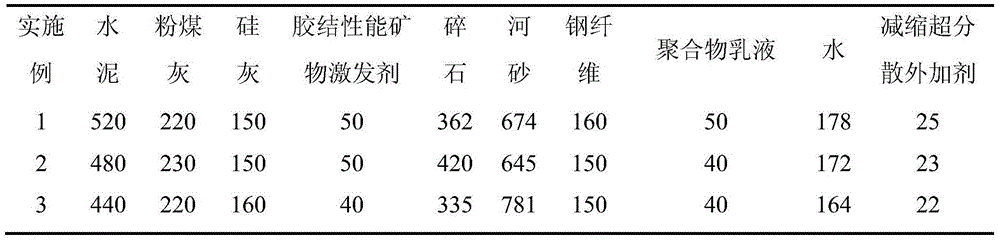

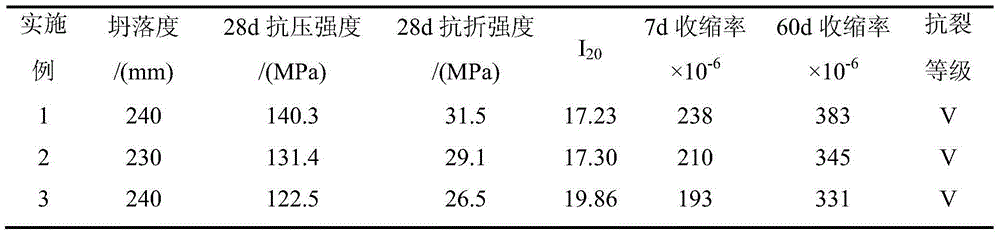

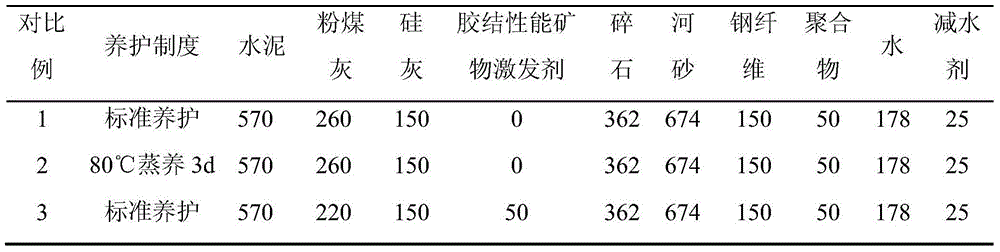

[0030] See Table 1 for the raw material ratio of the ultra-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com