Patents

Literature

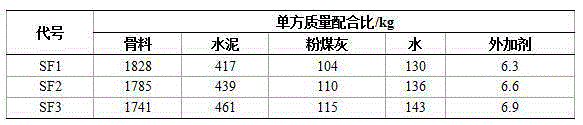

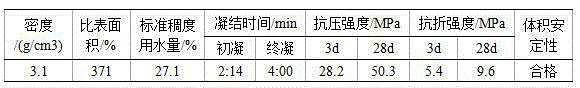

949 results about "High performance concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-resistant high performance concrete composition

InactiveUS6881256B2Improve fire resistanceSolid waste managementCeramicwareFiberCompressive strength

The invention concerns the use of organic fibers having a melting point lower than 300° C., an average length l more than 1 mm and a diameter Ø not more than 200 μm, in ultra high performance concrete for improving the concrete fire resistance, the amount of organic fibers being such that their volume ranges between 0.1 and 3% of the concrete volume after setting and the concrete having a compressive strength at 28 days of at least 120 Mpa, a bending strength of at least 20 Mpa, and a spread value in non-hardened state of at least 150 mm, the values being for a concrete preserved at 20° C., the concrete consisting of a particularly hardened cement matrix wherein metal fibres are dispersed.

Owner:BOUYGUES TRAVAUX PUBLICS SA +1

Nano-material composite concrete with super high performance

InactiveCN102199021AImprove mechanical propertiesIncreased durabilitySolid waste managementCarbon nanotubeAmmonium bromide

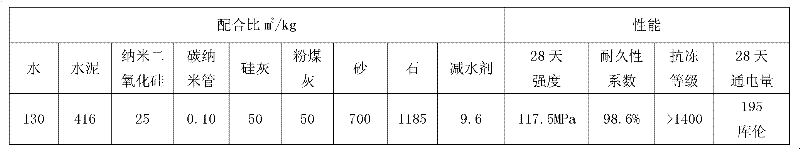

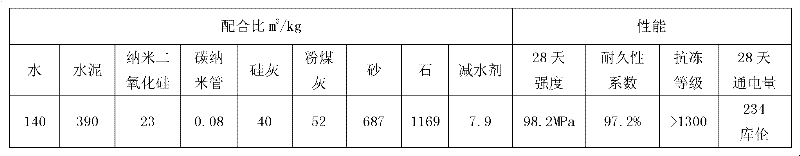

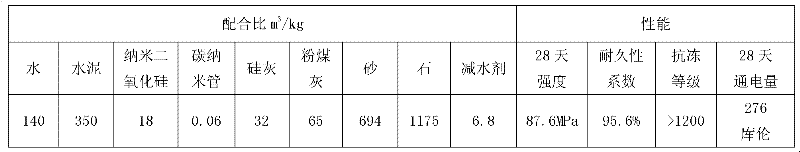

The invention relates to a preparation technology for concrete with super high performance, and belongs to the field of concrete technology in civil engineering. The invention is characterized in that: 1 m<3> of concrete contains 380 to 420 kg of cement, 680 to 740 kg of fine aggregate, 1120 to 1190 kg of coarse aggregate, 130 to 160 kg of water, 50 to 75 kg of fly ash, 25 to 64 kg of silica fume, 6.1 to 10.4 kg of a high performance water reducer, 0.05 to 0.25 kg of multi-walled carbon nanotubes and 15 to 25 kg of nanometer silica. The preparation technology is to carry out mechanical stirring for 180 to 240 seconds. The carbon nanotubes are added in the form of dispersion liquid, and a dispersant is cetyl trimethyl ammonium bromide (C16TAB), wherein the dispersion liquid is prepared according to the following portion MWNRs : C16TAB : water = 0.48 g : 4.1 g : 40 ml. The invention enables the super high performance concrete to have an enhanced mechanical property and lasting quality, a drastically increased service life, and capacity of being used in projects where requirements for the performance of concrete are high, for example, large-scale cross-sea bridges, super high buildings, and the like. The invention has a high utility value.

Owner:DALIAN UNIV OF TECH

Design method for mixing proportion of self-compacting concrete mixture

ActiveCN105224727AQuick lockPrevent disengagementSpecial data processing applicationsParticulatesVoid ratio

The present invention belongs to the technical field of concrete construction and particularly relates to a design method for a mixing proportion of a self-compacting concrete mixture. The method comprises the steps of: determining a performance design target; determining mixing strength and a water-binder ratio; determining densest gradation (or a sand rate) of aggregates and void ratios of different packing states; determining the usage amount of binding materials and mixing water; determining the usage amount of the aggregates; determining the usage amount of additives; determining the actual adding amount of the mixing water; and the like. According to the method provided by the present invention, aimed at blindness of material selection during self-compacting concrete mixing proportion design in the prior art, based on a fundamental theory of particulate dense packing and a composition rule of reaching a densest packing state of solid particulate materials with different particulate diameters, a mixing proportion of different materials is determined by an actually measured densest packing state, and relationships are established between the material mixing proportions corresponding to different densest packing states and expected self-compacting performance grades of the mixture, so that the design method used for the mixing proportion of the self-compacting high-performance concrete mixture and based on a use performance as a target is constructed.

Owner:ZHENGZHOU UNIV

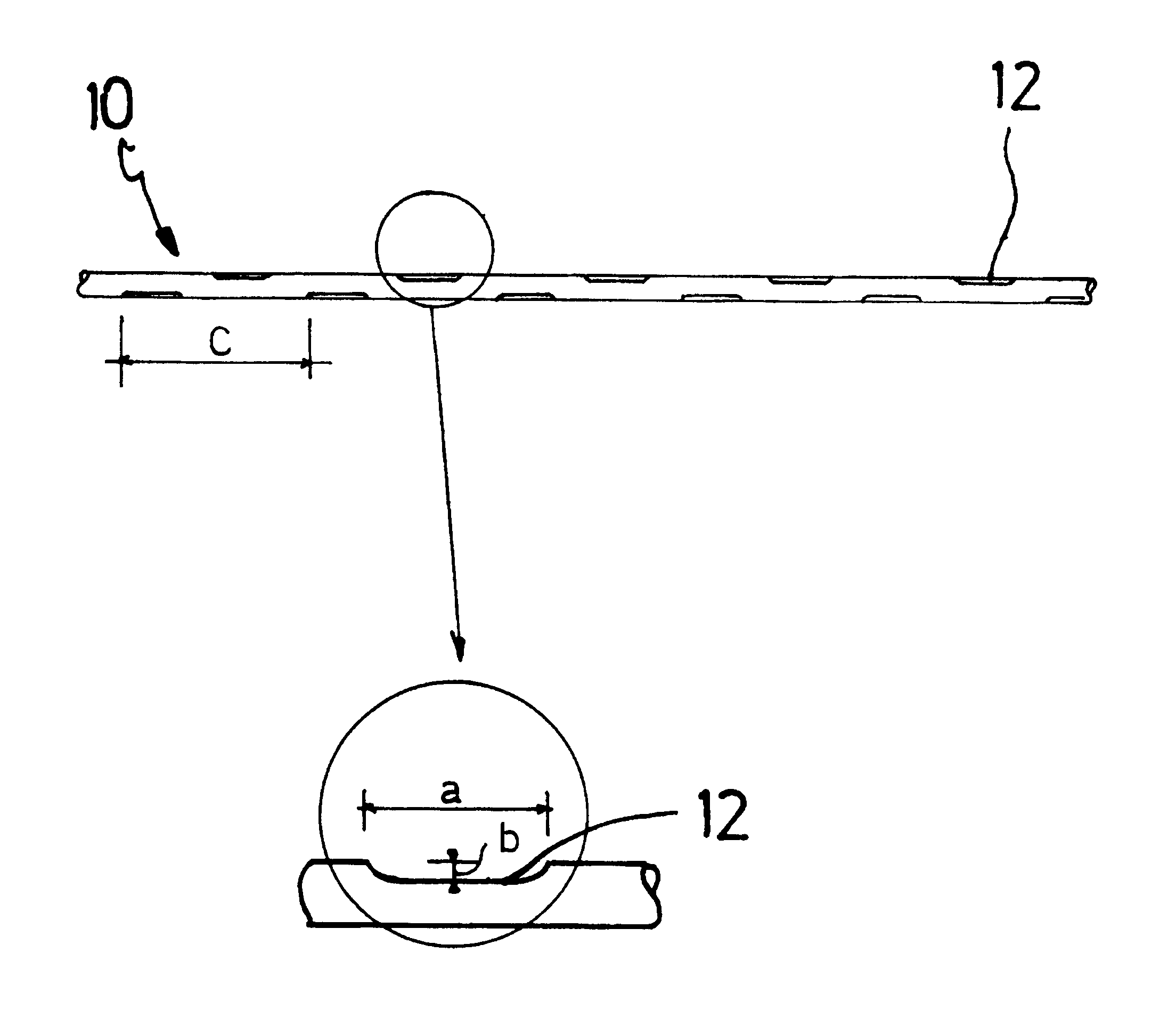

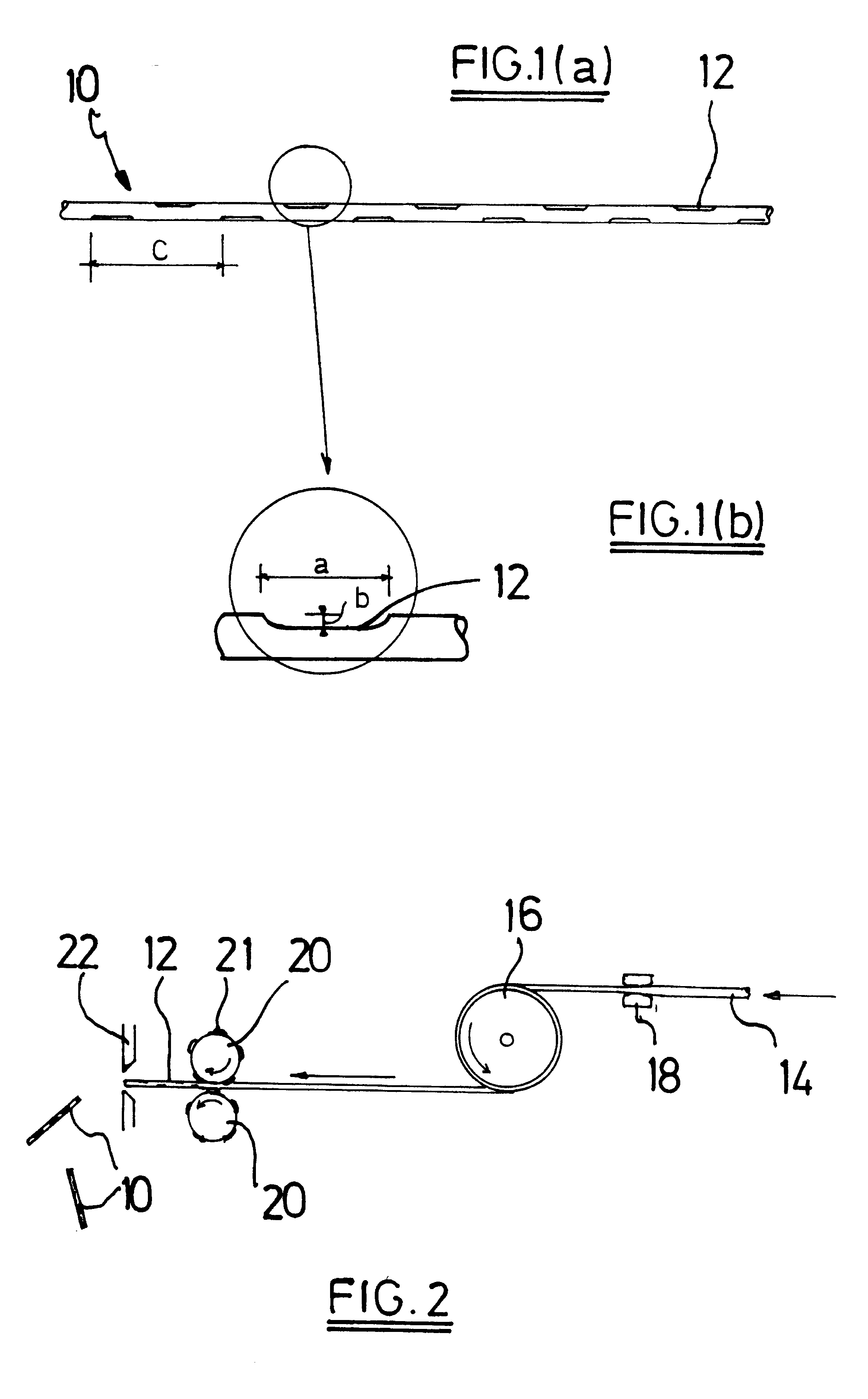

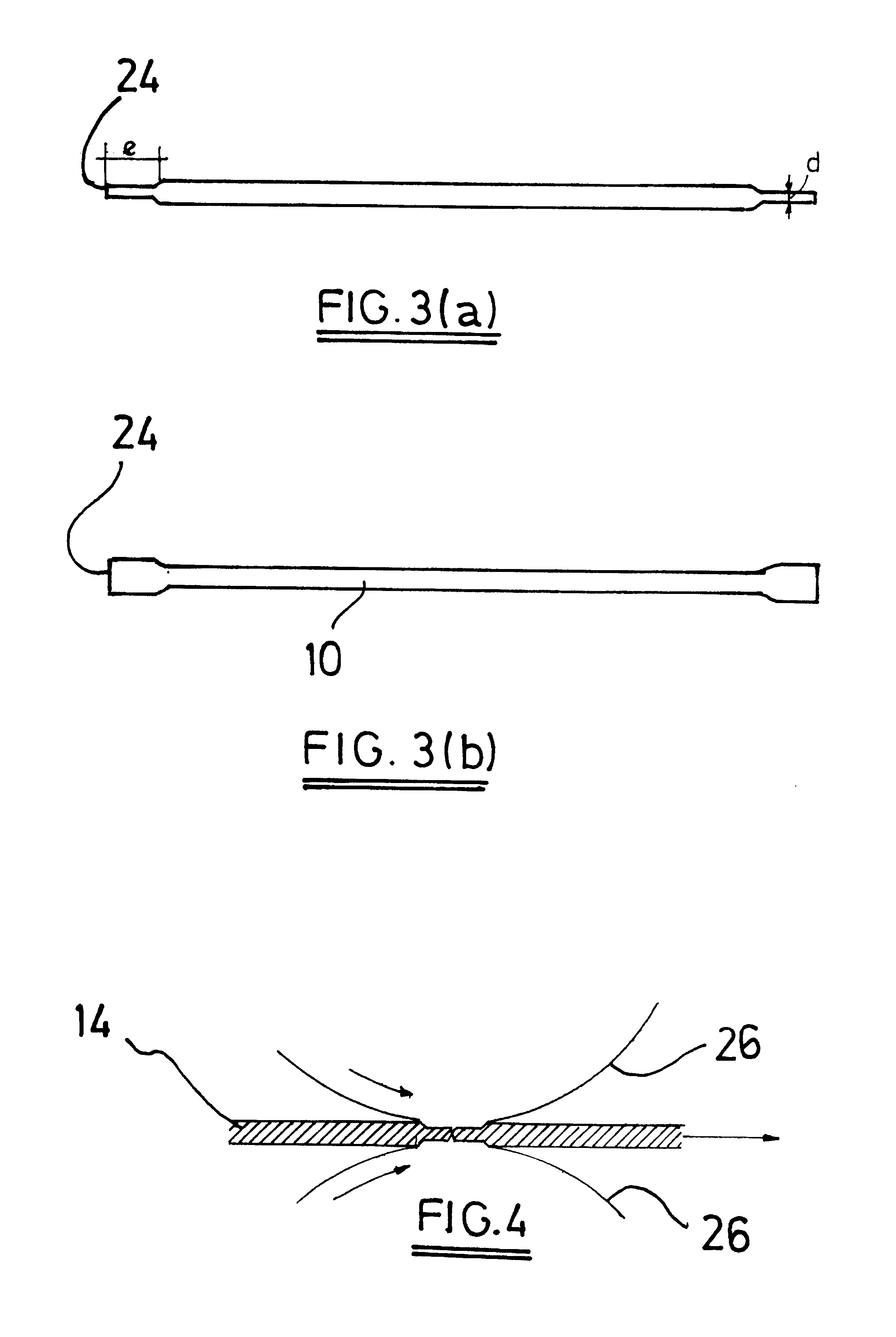

Steel fiber for reinforcement of high-performance concrete

InactiveUS6235108B1Reduce decreaseIncrease anchorageBuilding reinforcementsYarnMetallurgySteel fibre

A steel fiber (10) for reinforcement of high-performance concrete or mortar has a length ranging from 3 mm to 30 mm, a thickness ranging from 0.08 mm to 0.30 mm, and a tensile strength greater than 2000 MPa. The steel fiber is provided with anchorages (12,24) the dimension of which in a direction perpendicular to the longitudinal axis of the steel fiber is maximum 50% of the thickness. These anchorages provide an effective staying in the high-performance concrete without influencing the mixability of the steel fibers in a negative way.

Owner:NV BEKAERT SA

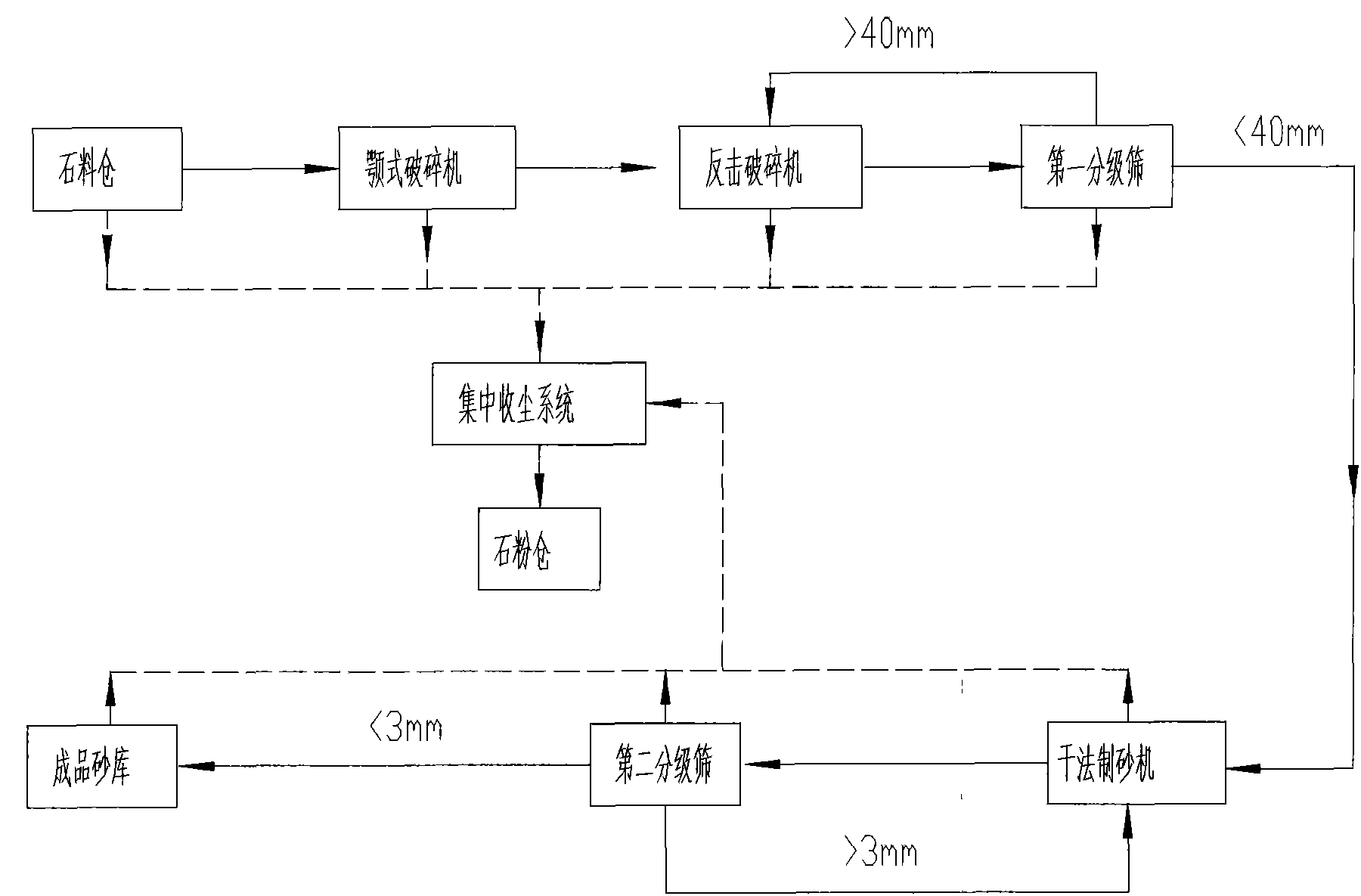

Drying-method sand making device and process

A drying-method sand making device and a process relate to the field of sand making technology. The device includes: a jaw crusher, an impact crusher, a first grading screen, a drying-method sand making machine, a second grading screen and a concentrated dust collecting system. The production process comprises the steps: a stone material in a stone material bin is evenly fed into the jaw crusher through a feeder for a first rough crushing, the crushed material is transported to the impact crusher for a second fine crushing, the crushed material goes into the first grading screen for grading, sandstones with the size of less than 40 mm are fed to the drying-method sand making machine through a conveyor for crushing and sand making, and broken stones with the size of more than 40 mm are returned to the impact crusher; the sandstones going into the drying-method sand making machine are transported to the second grading screen for grading after being crushed by the drying-method sand making machine, sand with the size of less than 3 mm is directly fed into a finished product sand bin, and a stone material with the size of more than 3 mm is afresh returned to the drying-method sand making machine for crushing. The produced machine-made sand has good particle shape and high finished product rate, and can meet the technical index of high-performance concrete on the machine-made sand.

Owner:王燕

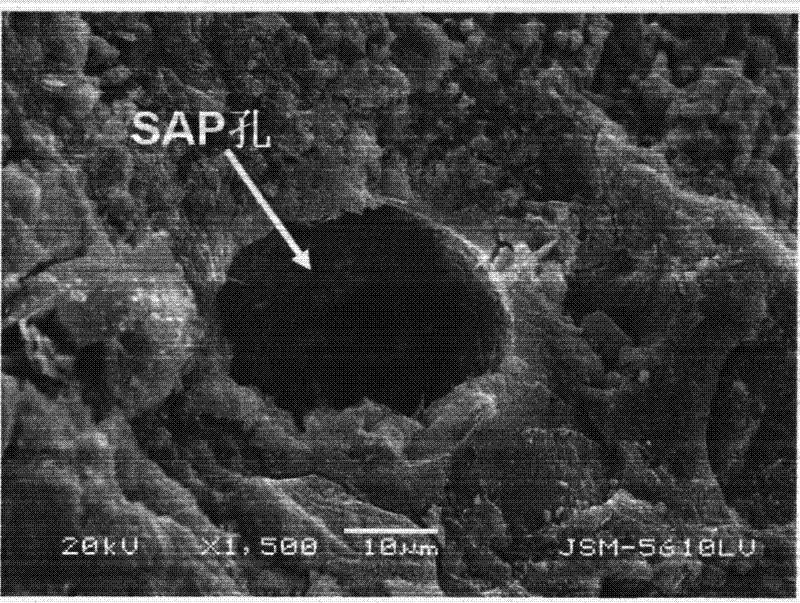

Preparation method for water-preserving and salt-tolerant alkaline concrete internal curing agent

The present invention discloses a preparation method for a water-preserving and salt-tolerant alkaline concrete internal curing agent. According to the method, plant starch, inorganic powder with a layered structure, an anionic monomer, a non-ionic monomer and water are adopted as main raw materials; under effects of an initiator, a cross-linking agent and a certain temperature, treatments of dissolving, reacting, filtering, washing, drying and crushing are performed to obtain the internal curing agent. The internal curing agent of the present invention has the following advantages that: the internal curing agent of the present invention provides the stronger deionized water absorbency than the existing internal curing agent, wherein the deionized water absorbency is increased by 200-500 times; the saline solution absorbency and the alkaline solution absorbency are 35-55% of the deionized water absorbency; the water-preserving rate of the internal curing agent of the present invention is 55-65% after the internal curing agent absorbs the alkaline solution; with adopting the low mixing amount of 0.05-0.5% of the internal curing agent, the strength of the silica fume-doped C60-C100 high-performance concretes is not reduced while the 7-day autogenous shrinkage rates of the concretes are reduced by 65-85%; the internal curing agent of the present invention is applicable for the high strength and early strength concrete pavement, steel pipe concrete under the closed environment, self-compacting concrete and other engineering fields, wherein the fields adopt the design with a low water-cement ratio and a high cementing material content, and adopt a large amount of high activity mineral admixtures.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

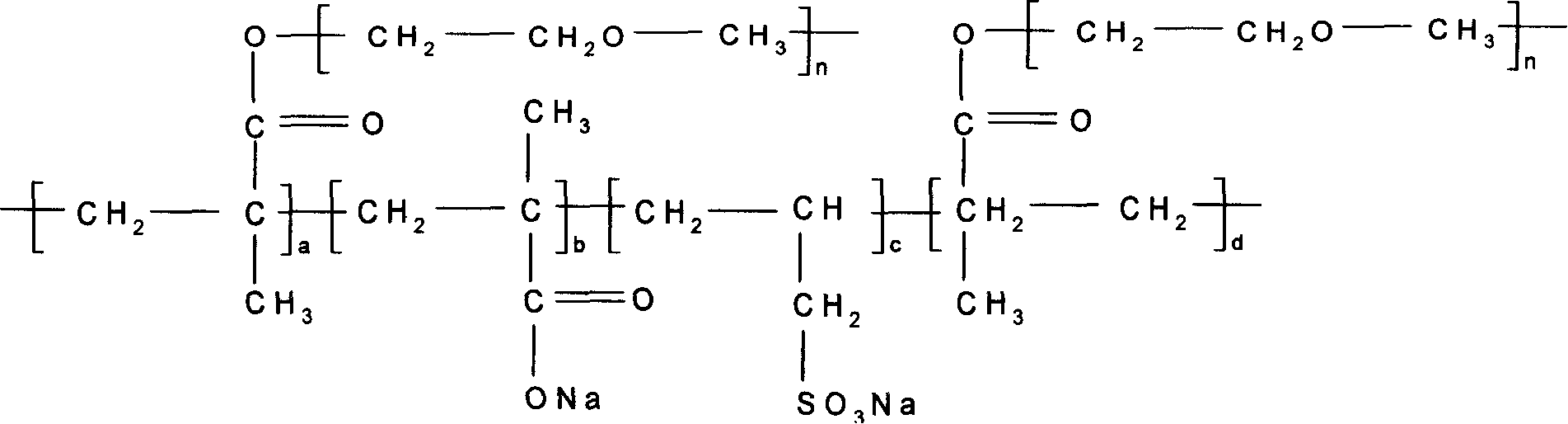

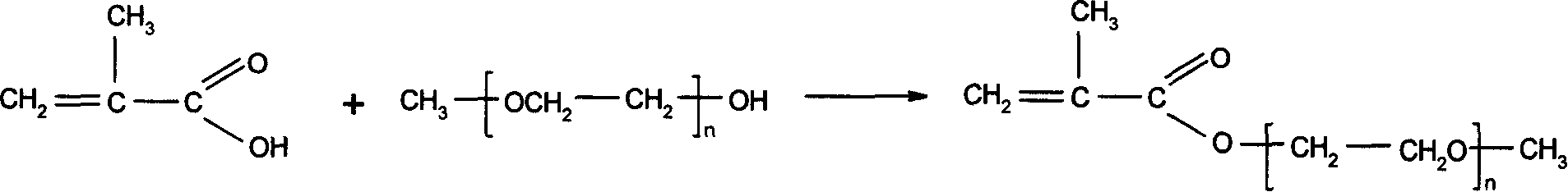

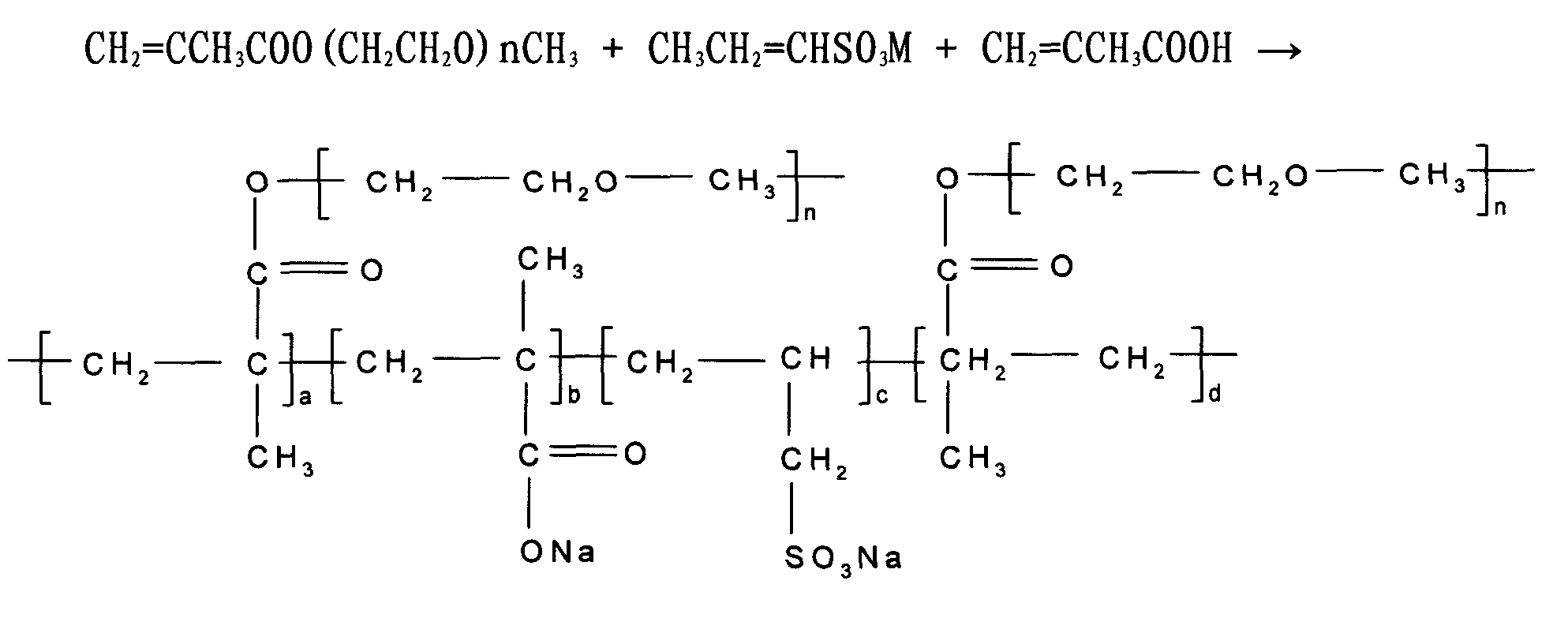

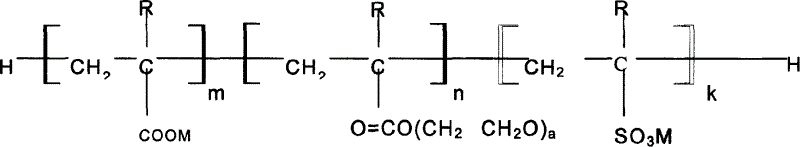

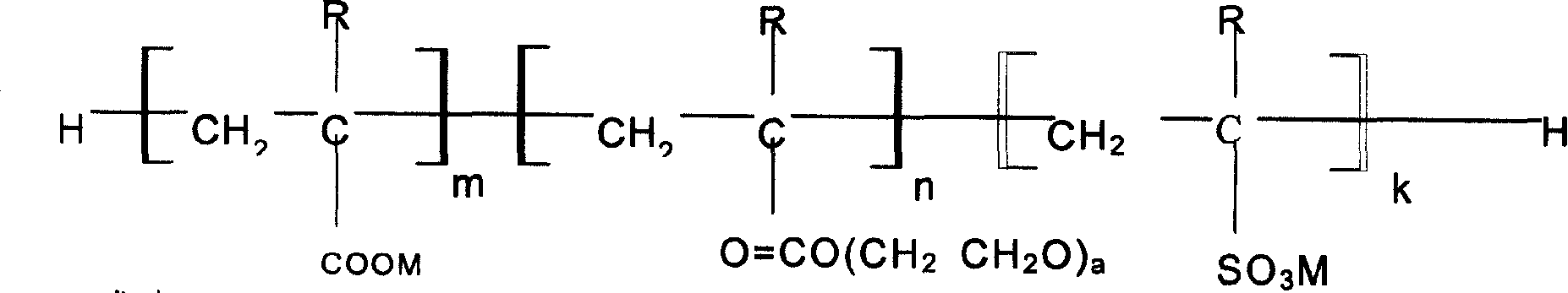

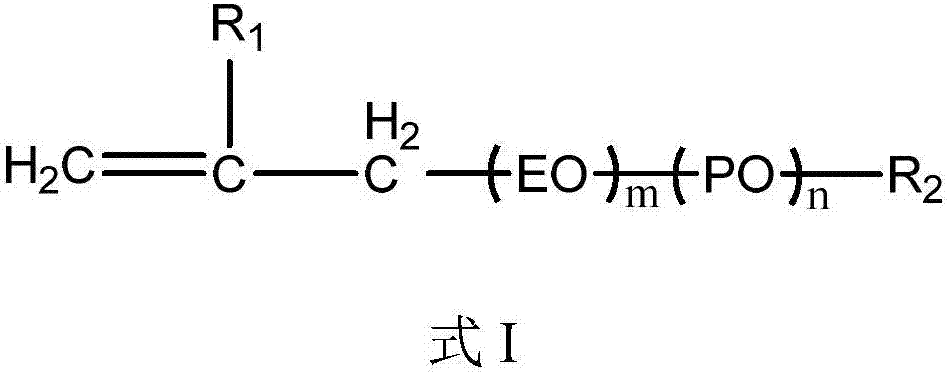

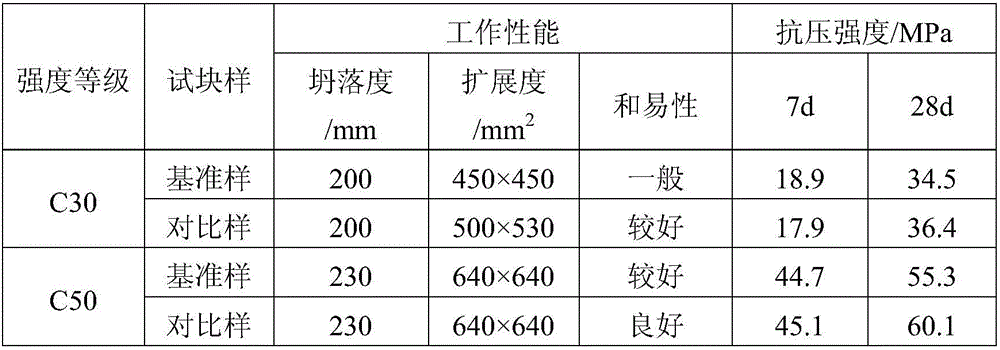

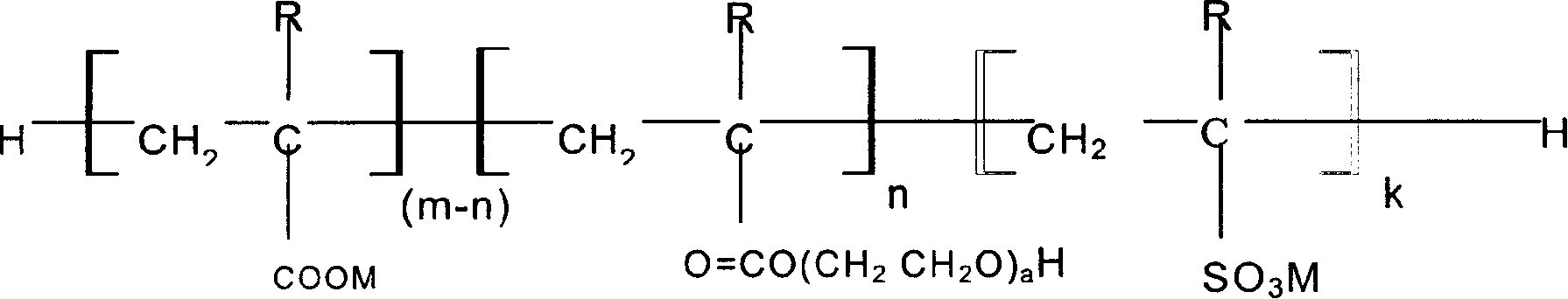

Polycarboxylic acids series concrete high efficiency water reducing agent and synthesizing process

InactiveCN101244907AHigh compressive strengthImprove appearance qualityNuclear powerSuperplasticizer

The invention relates to a water reducing agent with high efficiency used in polycarboxylate concrete and a synthetic method thereof, which is characterized in that: plyethylene glycol methylacrylic acid single armor esterification (MPEGMA) macromonomer synthesized by (methyl) acrylic and polyethylene glycol monomethyl ether added with catalyst and other (methyl) acrylic or (methyl) allyl sodium monomer are grafted and copolymerizated to synthesize into binary or polybasic copolymer comprising carboxyl, sulfonic group and polyoxyethylene chain side under the effect of initiator and chain transfer agent. The products synthetically prepared by the invention has the advantages of high water reducing ratio, low chlorine and low alkali; the cement mixture is high in fluidity and good in mixability, and can restrain slump loss effectively, when 0.7 to 1.2 percent by weight of cement material is added. The water reducing agent with high efficiency used in polycarboxylate concrete is simple in technology, easy in control of reaction condition and reasonable in cost, does not pollute environment, and can be used as the important component of high performance concrete, marine concrete, nuclear power station concrete and anticorrosion concrete and is widely used in the field of industry, civil building, water conservancy, road traffic and nuclear power engineering.

Owner:SHANGHAI SHENLI BUILDING MATERIAL

High-magnesium low-heat portland cement clinker aggregate and preparation method thereof

InactiveCN101041560AImprove crack resistanceLow heat of hydrationClinker productionHigh magnesiumPortland cement

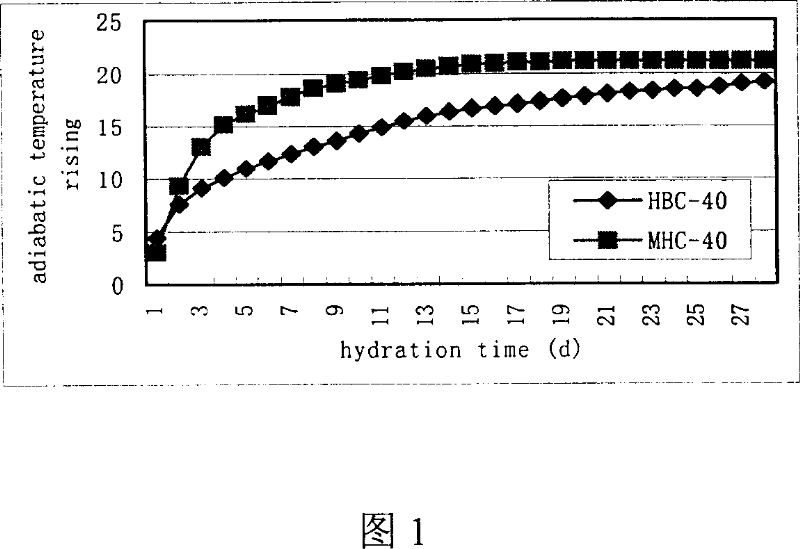

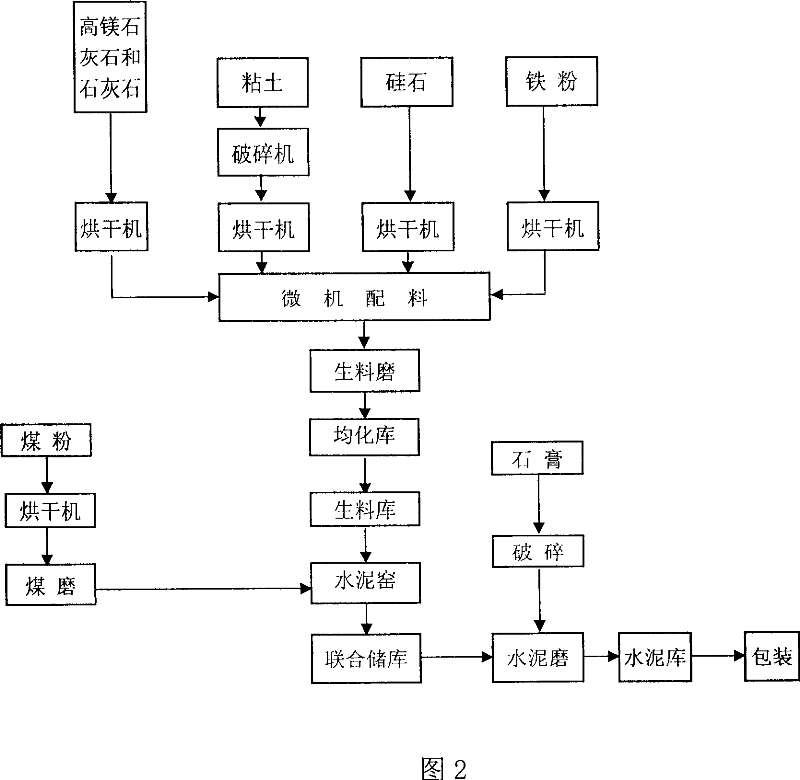

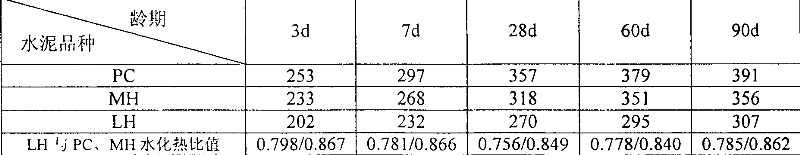

The invention discloses a high-magnesium lower thermal silicate cement clinker, making mineralogical composition at (mass percent): 40 -65% C2S, 15-40% C3S, 1-8% C3A, 10-25% C4AF and content of MgO at 2.0-6.0%. The invention also discloses a preparing method of high-magnesium lower thermal silicate cement clinker, including indispensable steps of producing cement clinker with raw materials and controlling content of MgO of cement clinker at 2.0-6.0%.

Owner:CHINA BUILDING MATERIALS ACAD

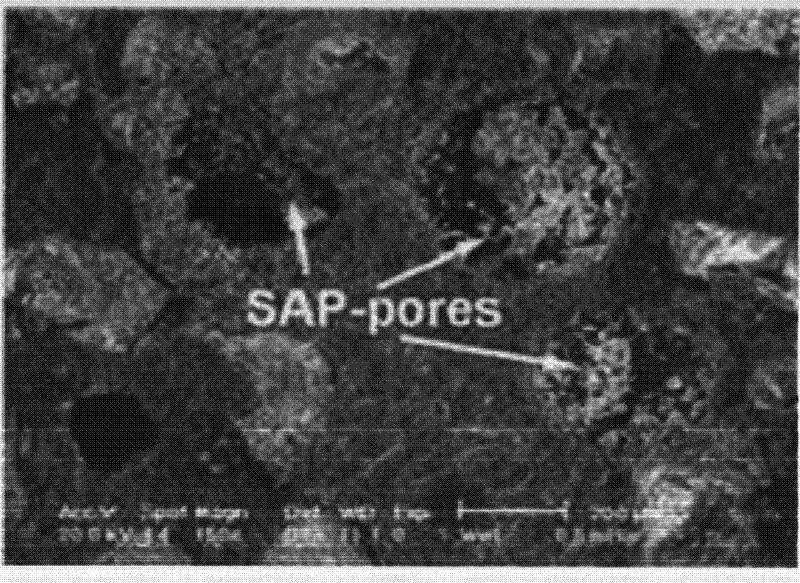

Ultra-high performance concrete with micro-expansion and compensation shrinkage and preparation method thereof

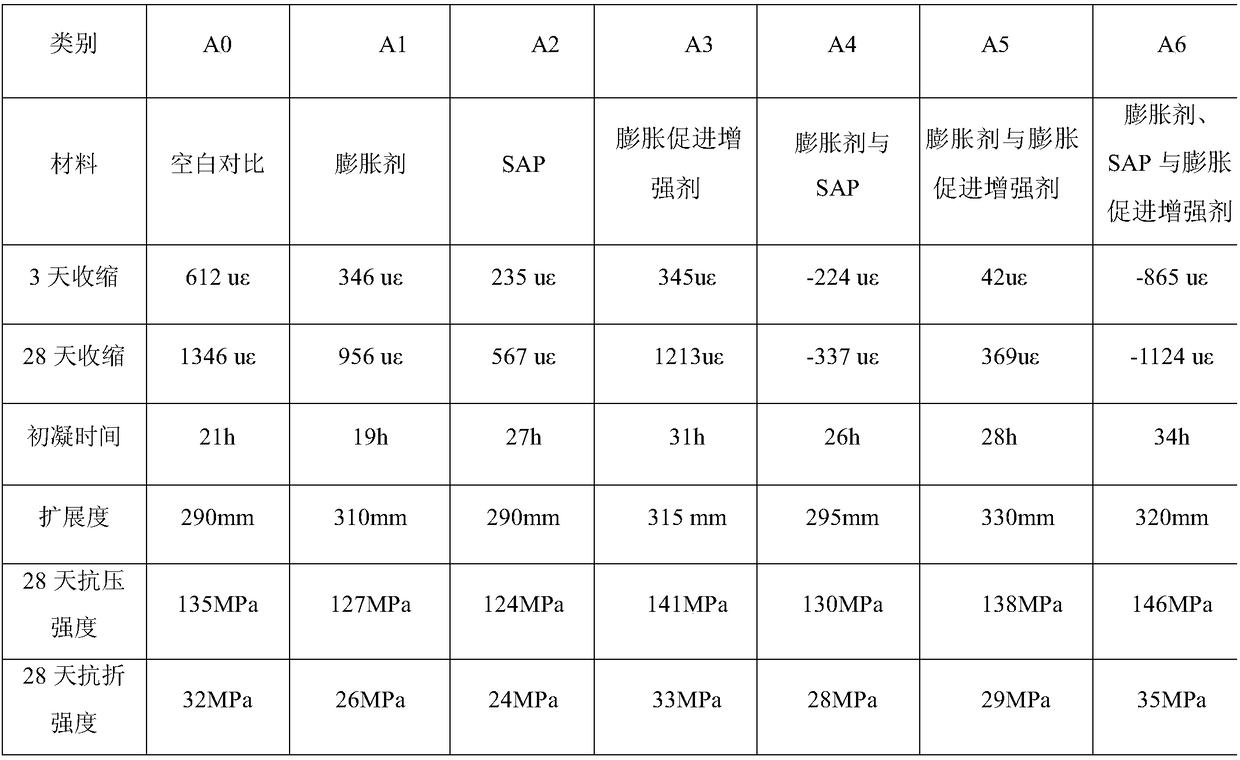

The invention belongs to the field of building materials, and especially relates to ultra-high performance concrete with micro-expansion and compensation shrinkage and a preparation method thereof. Raw materials include, by weight, the following components: 1 part of cement, 0.05-0.2 part of fly ash, 0.2-0.5 part of silica fume, 0.1-0.25 part of mineral powder, 0.05-0.2 part of quartz powder, 0.9-1.2 parts of quartz sand, 0.04-0.2 part of an expanding agent, 0.01-0.03 part of a water reducing agent, and 0.01-0.03 part of an expansion promotion reinforcing agent. A mixing amount of super absorbent resin is 0.4%-0.8% of a cementing material; a volume mixing amount of steel fiber is 1%-3% of a total volume of the concrete; the water-to-binder ratio is 0.16-0.22; and the compressive strength is 100-160 MPa. The ultra-high performance concrete with the micro-expansion and the compensation shrinkage has the characteristics of micro-expansion, high strength, high toughness, excellent workingperformance, and the like, and solves the problem that the expanding agent is difficult to produce effective expansion in the ultra-high performance concrete with a low water-to-binder ratio, and so,the risk of early shrinkage cracking of the ultra-high performance concrete is reduced, and the ultra-high performance concrete can maintain the micro-expansion for a long time.

Owner:HUNAN UNIV

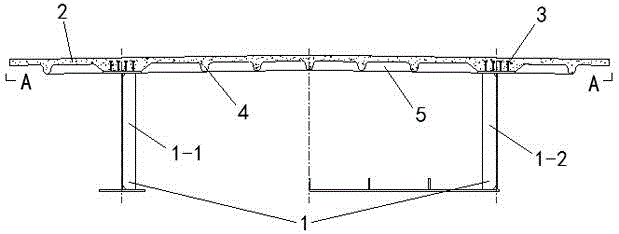

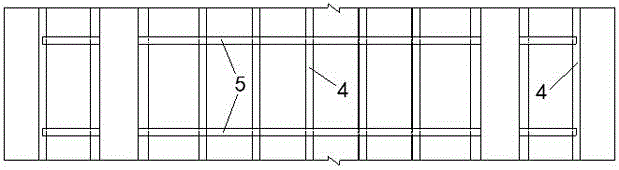

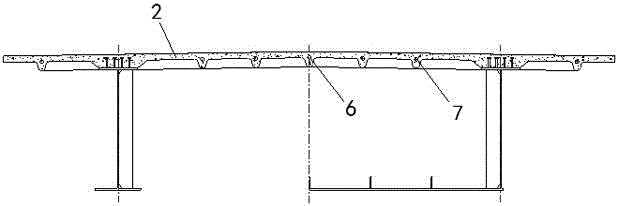

Steel-super high performance concrete composite beam based on ribbed plate type bridge deck and construction method

InactiveCN104831617AReasonable forceHigh strengthBridge structural detailsBridge erection/assemblyCrack resistanceBridge deck

The invention discloses a steel-super high performance concrete composite beam based on a ribbed plate type bridge deck and a construction method. The construction method includes the following steps that step1, steel beams are machined, manufactured and installed; step2, shearing force connecting parts are welded; step3, the super high performance concrete bridge deck is constructed; step4, a guardrail or an anti-collision wall is constructed; step5, bridge deck pavement is constructed, wherein the super high performance concrete bridge deck and the steel beams are fixed through the shearing force connecting parts, the cross section or / and the longitudinal section of the super high performance concrete bridge deck is / are of a ribbed plate structure, and pre-stressed reinforcements can be arranged on a longitudinal rib region or / and a transverse rib region. The composite beam is reasonable in stress, high in strength and capable of substantially reducing the structure dead weight, effectively avoiding defects at a hogging moment region of a composite continuous beam and bringing tensile strength, compressive strength and high durability of super high performance concrete into full play; the composite beam has the advantages of being small in building height, high in rigidity, small in dead weight, good in durability, crack resistance and fatigue resistance and the like, and has great practical value and good economic benefits.

Owner:FUZHOU UNIV

Method for preparing high-class concrete admixture with composite powder of steel slag and mineral slag

The invention discloses a method for preparing a high-class concrete admixture with composite powder of steel slag and mineral slag and belongs to the fields of solid waste resource utilization and building materials. A novel crushing machine with a high-efficiency deironing function, a vertical mill with a high-efficiency circulation deironing function or a rolling mill with the high-efficiency circulation deironing function, and a tubular mill with the high-efficiency circulation deironing function are connected in three stages in series, so that the powder mill equipment can take the synergistic and real-time circulation deironing and low-energy-consumption low-cost superfine milling in the granulated blast-furnace slag and steel slag powder milling process are achieved. In the product, steel slag micro powder accounts for 20-50%, the mineral slag micro powder accounts for 35-65%, the flue gas desulfurization gypsum micro powder accounts for 5-15%, and the specific surface area of the product is 630-750m<2> / kg. Due to the synergetic stimulation effect of the granulated blast-furnace slag micro powder, the steel slag micro powder and the flue gas desulfurization gypsum, the ratio of the admixture in a concrete gel material can be up to 60-100%, and ordinary-strength and high-property concrete, high-strength and high-property concrete and super-high strength and high-property concrete with C40-C100 can be prepared. By adopting the method, the production of high-property concrete is greatly improved, the energy is saved, the emission is reduced, and the cost is lowered.

Owner:河北科晖环境资源有限公司

Premixed and pumped heavy concrete

InactiveCN101676239AGuaranteed homogeneityGuaranteed uniformitySolid waste managementApparent densityParticle accelerator

The invention relates to a premixed and pumped heavy concrete which comprises 80-93 parts by weight of heavy aggregate, 6-15 parts by weight of cement materials, 2-5 parts by weight of water, less than 0.4 part by weight of concrete additive and less than 0.01 part by weight of function regulator. The apparent density of the concrete is more than 3500kg / m<3>, the mixture has no phenomena of lamination and segregation, and the concrete has good cohesion and plasticity protection, thereby being applicable to long-distance pumping. The concrete selects a high-performance concrete admixture and can avoid the occurrence of cracks of the large-volume concrete caused by hydration heat of cement. The concrete is applicable to an anti-radiation heavy concrete engineering with the thickness of morethan 1500mm. The concrete can be widely used in shielding places of nuclear reactors, medical particle accelerators, customs inspection, scientific research laboratories and other applications of therelated nuclear industry and the radioactive isotope technology.

Owner:HUNAN NO 6 ENG CO LTD

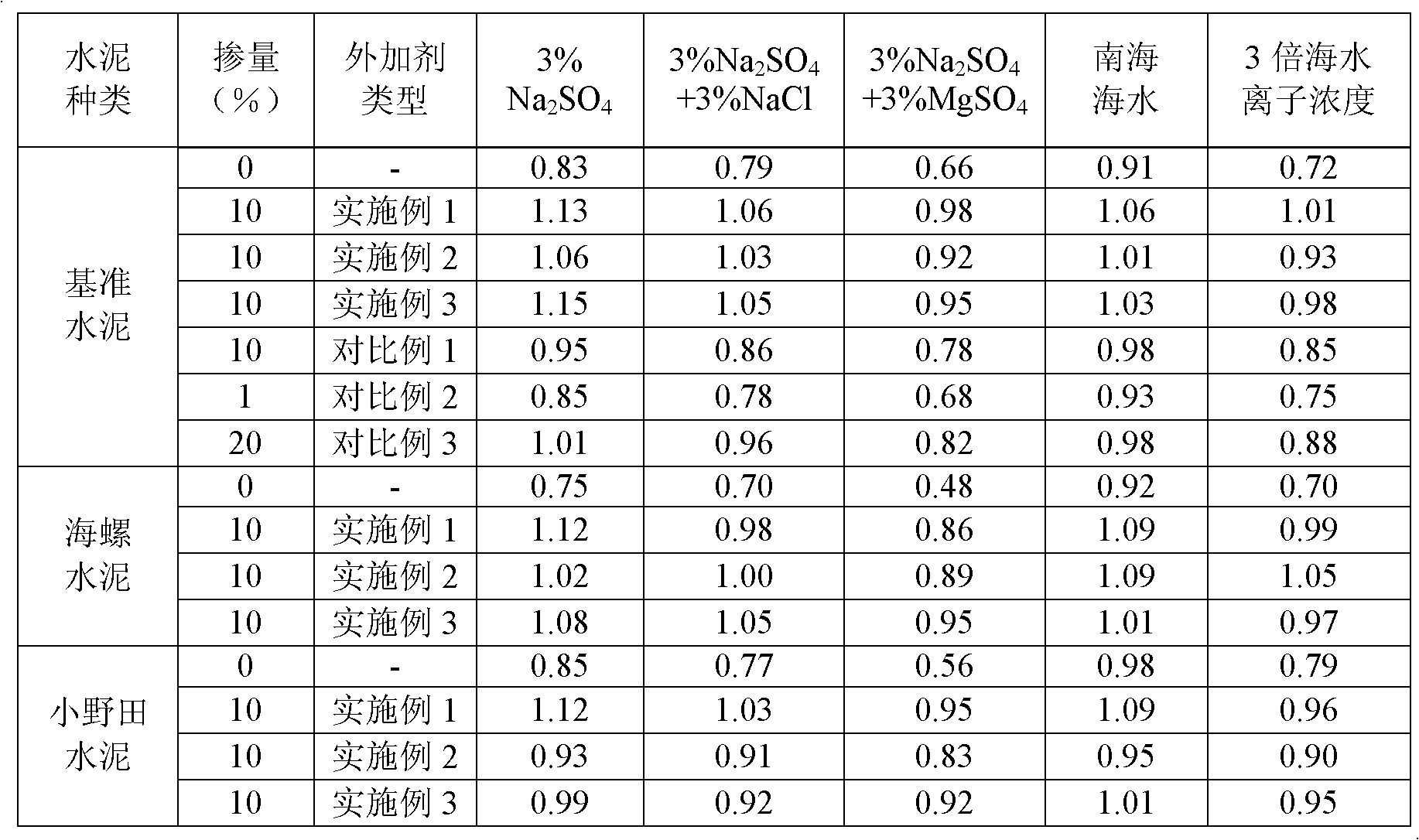

Seawater corrosion resisting mineral additive for concrete, and preparation method thereof

The invention discloses a seawater corrosion resisting mineral additive for concrete, and a preparation method thereof. The seawater corrosion resisting mineral additive for concrete comprises components of, by weight: 15 to 40% of calcium sulphoaluminate mineral, 10 to 40% of anhydrite, 10 to 30% of calcined diatomite, 10 to 30% of natural volcanic ash, 5 to 25% of quartz powder, and 2 to 8% of an auxiliary agent. The seawater corrosion resisting mineral additive provided by the invention has good corrosion resisting capacities against corrosion media such as Na2SO4, NaCl, and MgSO4. The corrosion resisting coefficient is higher than 0.9. Therefore, the mineral additive can be used for preparing high-strength high-performance seawater corrosion resisting concrete, or underwater concrete placed in corrosion media. The mineral additive can also be used in water conservancy and hydropower projects for improving the corrosion medium resisting performances of buildings, wherein in the corrosion media comprise sulfate, chloridion, and the like. With the mineral additive, cracks of buildings can be reduced or eliminated, and the service lives of the buildings can be prolonged.

Owner:深圳市德宜新材料科技有限公司

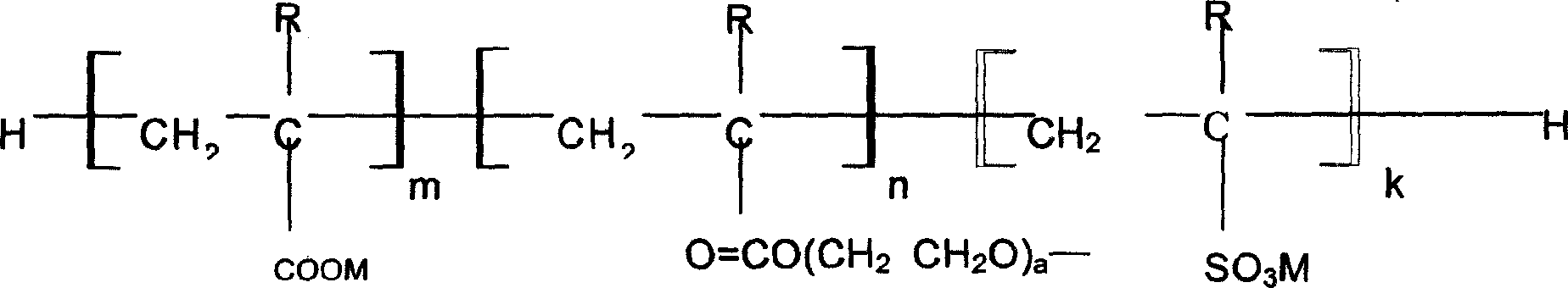

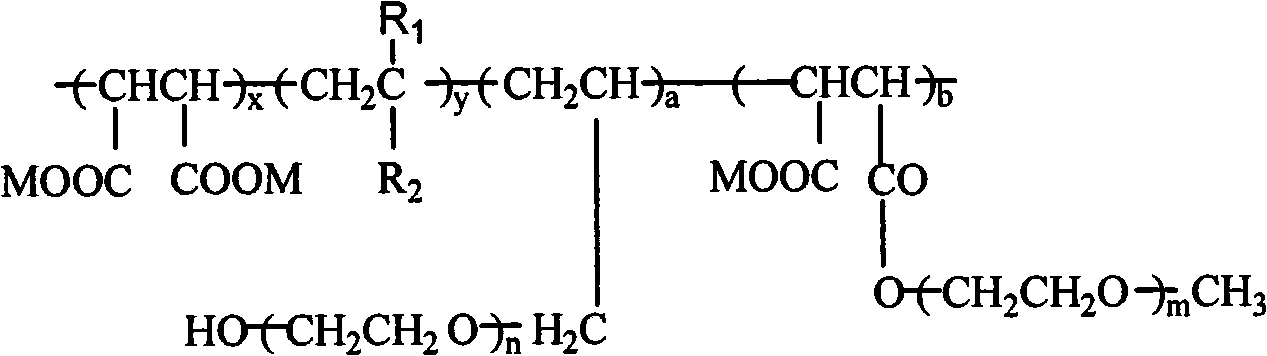

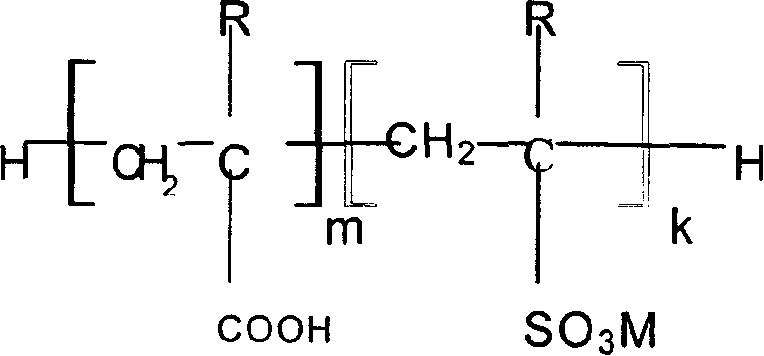

Concrete water reducing agent of polycarboxylic acid and its prepn process

The concrete water reducing agent of polycarboxylic acid is prepared through esterification between polyglycol and acrylic acid in the presence of catalyst to obtain esterified product PEA, and the copolymerization of the esterified product PEA with methyl propenyl sodium sulfonate and other sulfonate and acrylic acid. The concrete water reducing agent contains carboxy radical, sulfo radical and polyoxyethylene side chain. The concrete water reducing agent has low alkali content and high water reducing rate, and may be added into concrete in the amount of 0.6-1.2 wt% of gelatinous material to result in concrete with easy operation, high flowability, excellent placeability, no loss of slump and raised early strength. The concrete water reducing agent may be used as the important component of high performance concrete.

Owner:WUHAN UNIV OF TECH

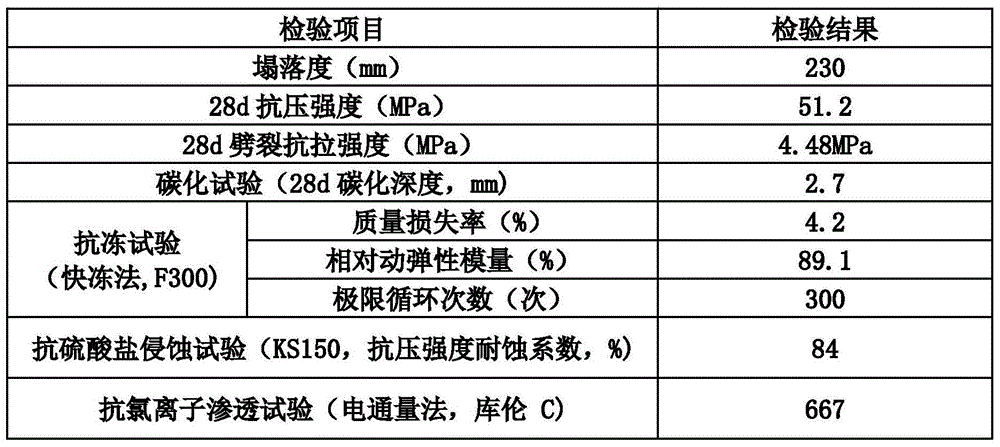

A kind of marine self-compacting high-performance concrete and its preparation method

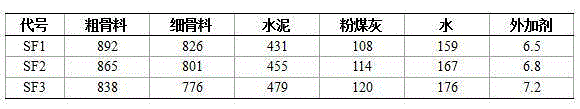

The invention provides marine engineering self-compacting high-performance concrete, which comprises the following raw material components in part by weight: 450 to 540 parts of gel material, 1,640 to 1,725 parts of aggregate, 7 to 8 part of polycarboxylic acid water reducer and 160 to 175 parts of water, wherein the gel material, based on the total weight of the gel material, consists of 30 to 45 percent of type-II 52.5 portland cement, 20 to 40 percent of fly ash and 30 to 50 percent of slag powder. The self-compacting high-performance concrete doped with fly ash and slag has high flowability, fallibility, high passing capacity and high segregation-resistance stability. In addition, the marine engineering self-compacting high-performance concrete also has long-lasting chlorine salt corrosion resistance, high freezing resistance and high thermal performance.

Owner:CCCC THIRD HARBOR ENG +2

Composite gelate material and method of producing the same

InactiveCN101549977AImprove early strengthImprove internal crystal structureSolid waste managementCement productionSlagPortland cement

The present invention disclose a composite gelate material and method of producing the same, including portland cement, fly ash, steel scoria powder, granulated blast furnace slag, admixture of pozzuolana, silicon gray, sulphates excitant, alkaline excitant, additive etc, through technics of mix grinding, agitating to get the needed powder; possessing advantages of high high-early strength, perfect workability, perfect antifreezing and impervious ability, high dose of waste, no environment polluting etc, simultaneity being able to improve concrete stability with a low cost and simple technics, which can be used as cementing materials of high-performance concrete.

Owner:CHANGSHA YUANPENG CHEM TECH

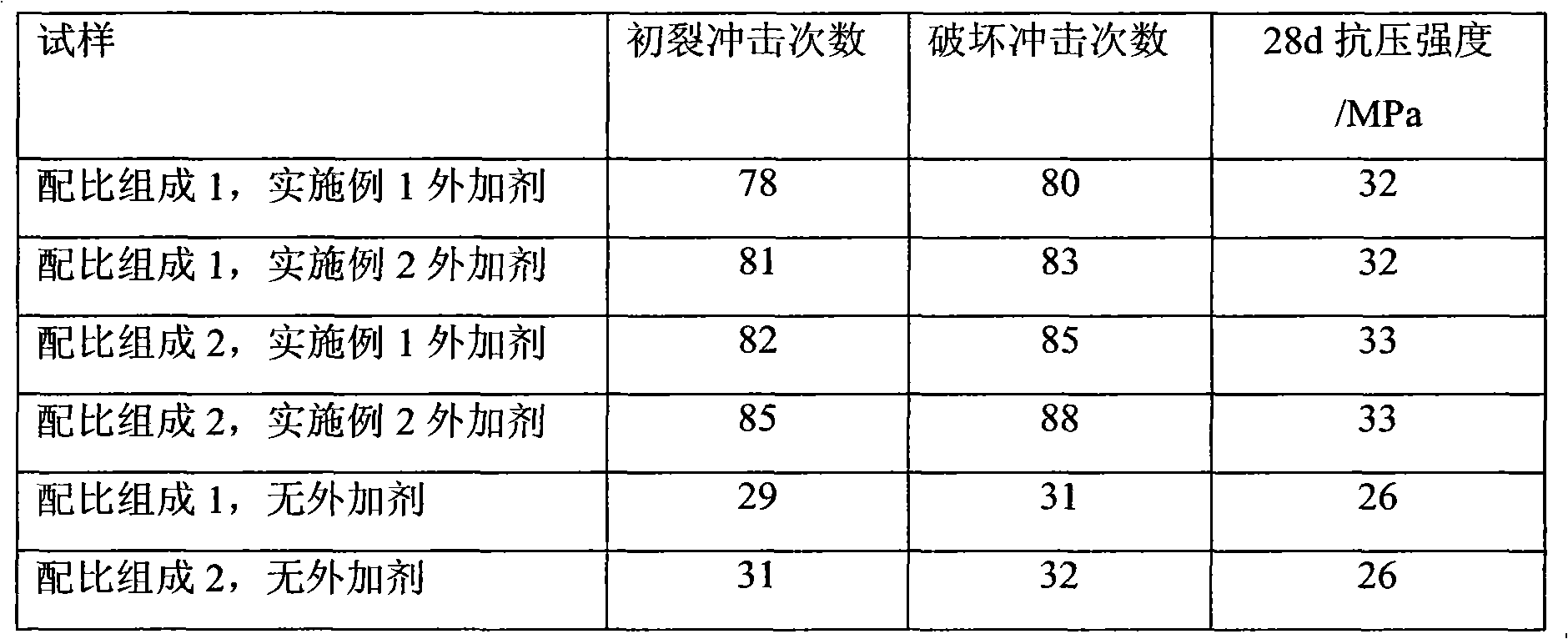

Concrete complex additive

The invention provides a concrete complex additive which comprises the following components by weight percent: 17.5-58.0% of efficient water reducing agent, 0.5-5.5% of organosilicon waterproofing agent, 0.2-2.5% of organosilicon reinforcing agent, 3.5-25% of polyacrylamide, 1.2-2.8% of triethanolamine, 3.2-6.3% of sodium nitrite, 0.3-1.2% of glycol, 0.6-1.3% of glycerol, 2.8-5.5% of sodium gluconate and the balance of water. The impact resistance, crocking resistance, impermeability and waterproofness of the concrete material can be obviously improved by using the complex additive provided by the application in the preparation process of the concrete, thus the concrete complex additives is especially suitable for the requirement on high-performance concrete for construction of airfield runways or highway bridges.

Owner:JIANGSU FENGTAI TOOLS

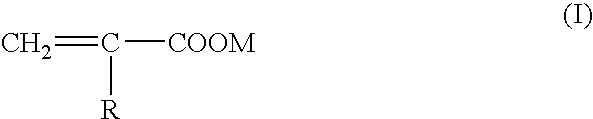

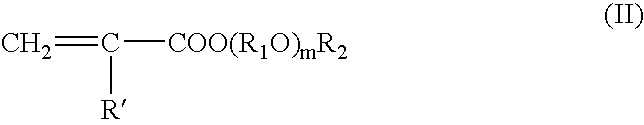

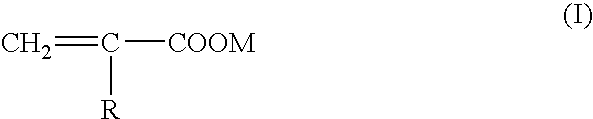

Cement dispersant and concrete composition contain the dispersant

[Object] To provide a cement dispersant and a concrete composition containing the cement dispersant, the cement dispersant having a superior effect of decreasing a high concrete paste viscosity while a water reducing effect, a slump flow retention, and rapid strength development are being satisfied in a region having a low water / binder ratio. [Solving Means] The cement dispersant for ultrahigh performance concrete is provided which is a water-soluble amphoteric copolymer obtained by copolymerizing (A) an alkylene oxide adduct of a polyamide polyamine having an unsaturated group, (B) (meta)acrylic acid or a salt thereof, (C) an ester of a short-chain alkylene glycol and (meth)acrylic acid, and (D) an ester of a long-chain alkylene glycol and (meth)acrylic acid at ratios A:B:C:D of 5 to 25:5 to 30:5 to 40:20 to 80 (percent by weight), in which the total is 100% percent by weight. In addition, the concrete composition containing the above cement dispersant is provided.

Owner:TOHO CHEM IND +1

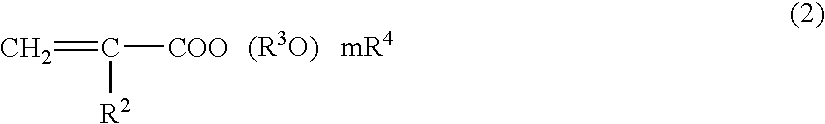

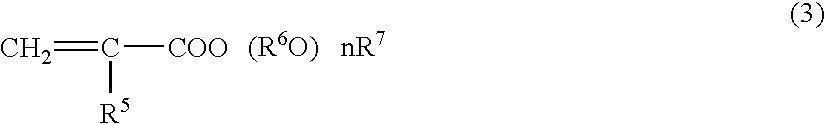

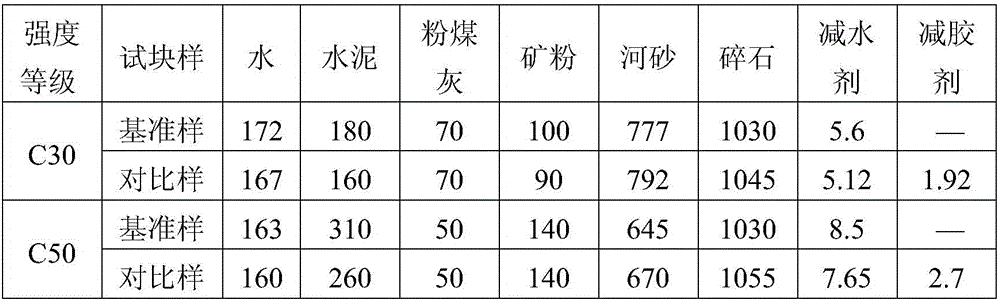

Polycarboxylic retarding high-performance water reducing agent for preparing concrete of middle and low strength grade

InactiveCN101580354AReduce shrinkage ratioGood retarding effectSuperplasticizerUltimate tensile strength

The invention discloses a polycarboxylic retarding high-performance water reducing agent used for preparing concrete of middle and low strength grade. According to the weight percentage of the effective solid content, the water reducing agent comprises 9-15% of low air-entrained mother liquor, 0.5-3.0% of retarder, 0.01-0.03% of foam stabilizer, 0.03-0.10% of air-entraining agent, 0.02-0.08% of thickener, 0.05-0.20% of activator and the balance of water. The preparation method comprises the following steps of: weighing all compositions by the weight percentage of each effective solid content, putting and slowly mixing the compositions in a reaction kettle for 10-30min, thus obtaining the concrete. By adjusting the proportion of all compositions, the polycarboxylic retarding high-performance water reducing agent can meet the usage requirements of the concrete of middle and low strength grade (C15-C40), has the advantages of wide doping range, high water reducing ratio, good retarding effect, low chlorine and alkali content, low concrete shrinkage ratio, greenness, environmental protection and the like, and can prepare the green and economic high-performance concrete.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

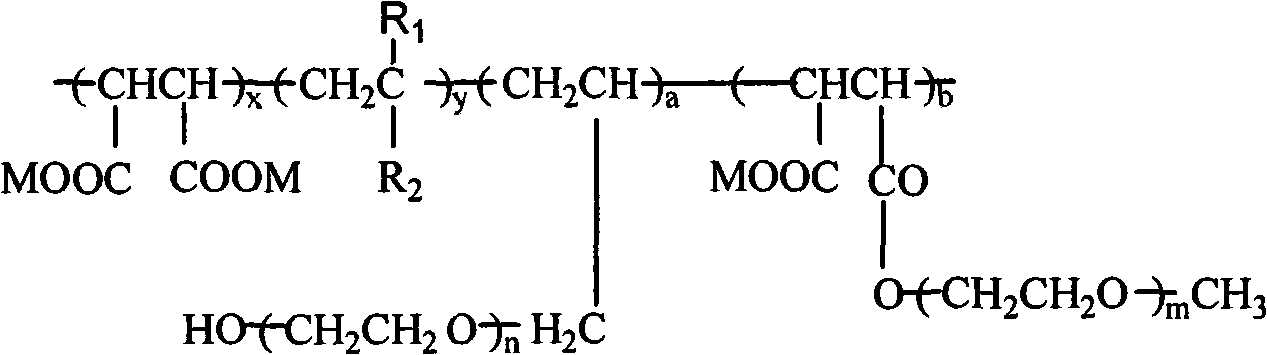

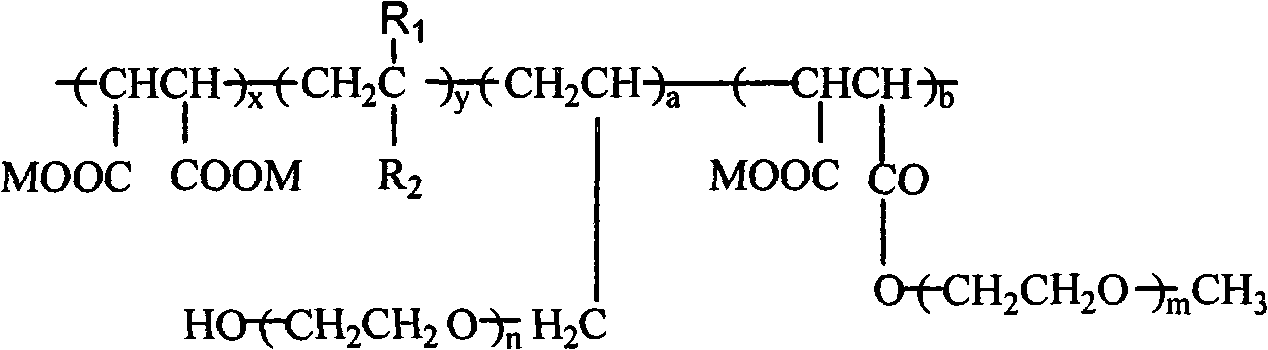

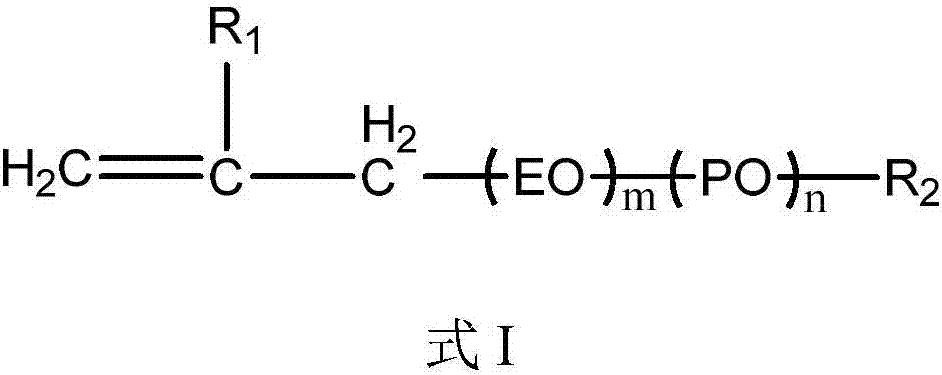

Method for preparing viscosity-reducing polycarboxylate superplasticizer

The invention provides a method for preparing viscosity-reducing polycarboxylate superplasticizer. The viscosity-reducing polycarboxylate superplasticizer is prepared through a bulk polymerization reaction, and the method comprises the following steps of: (1) mixing polyoxyethylene polyoxypropylene ether and polyoxyethylene ether, controlling the temperature at 40-60 DEG C, stirring the mixture evenly, and then adding an initiator and a mixture of unsaturated carboxylic acids, hydroxyalkyl unsaturated carboxylate and a chain transfer agent; and (2) performing aging for 1-1.5 hours after the step (1) is completed, and reducing the temperature to obtain the viscosity-reducing polycarboxylate superplasticizer. Since the bulk polymerization reaction is carried out at a low temperature, the method has strong operability, mild conditions and low energy consumption; the viscosity-reducing polycarboxylate superplasticizer prepared by using the method is at a liquid state at room temperature, has effective concentration of 100% and stable storage performance, and is suitable for long-distance transportation and use; meanwhile, the viscosity of a concrete mixture can be reduced effectively through the superplasticizer so that stirring, transportation and pumping of concrete can be facilitated, and the superplasticizer is suitable for the promotion and application of high-rise engineeringand high-performance concrete.

Owner:JIAHUA CHEM MAOMING

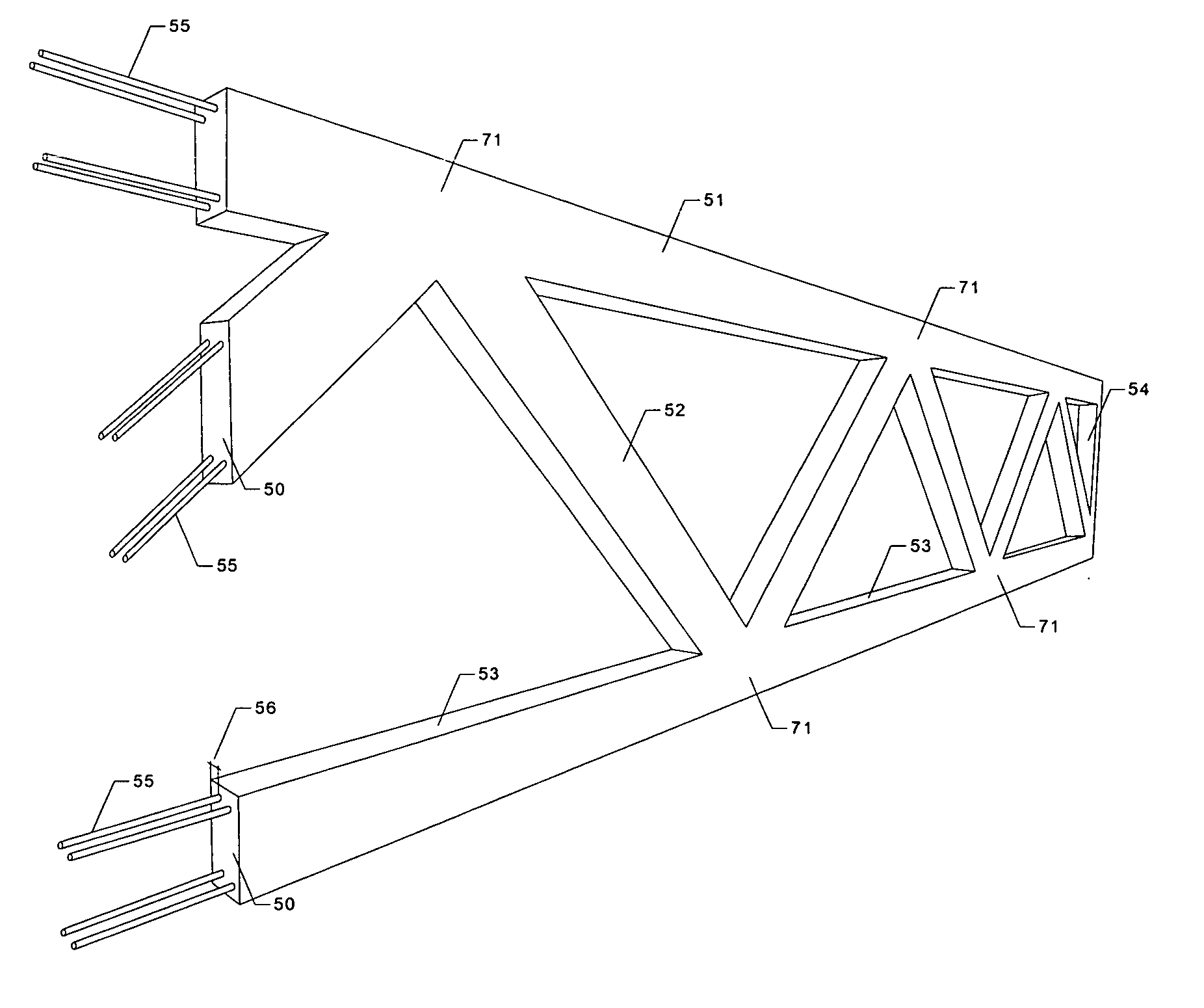

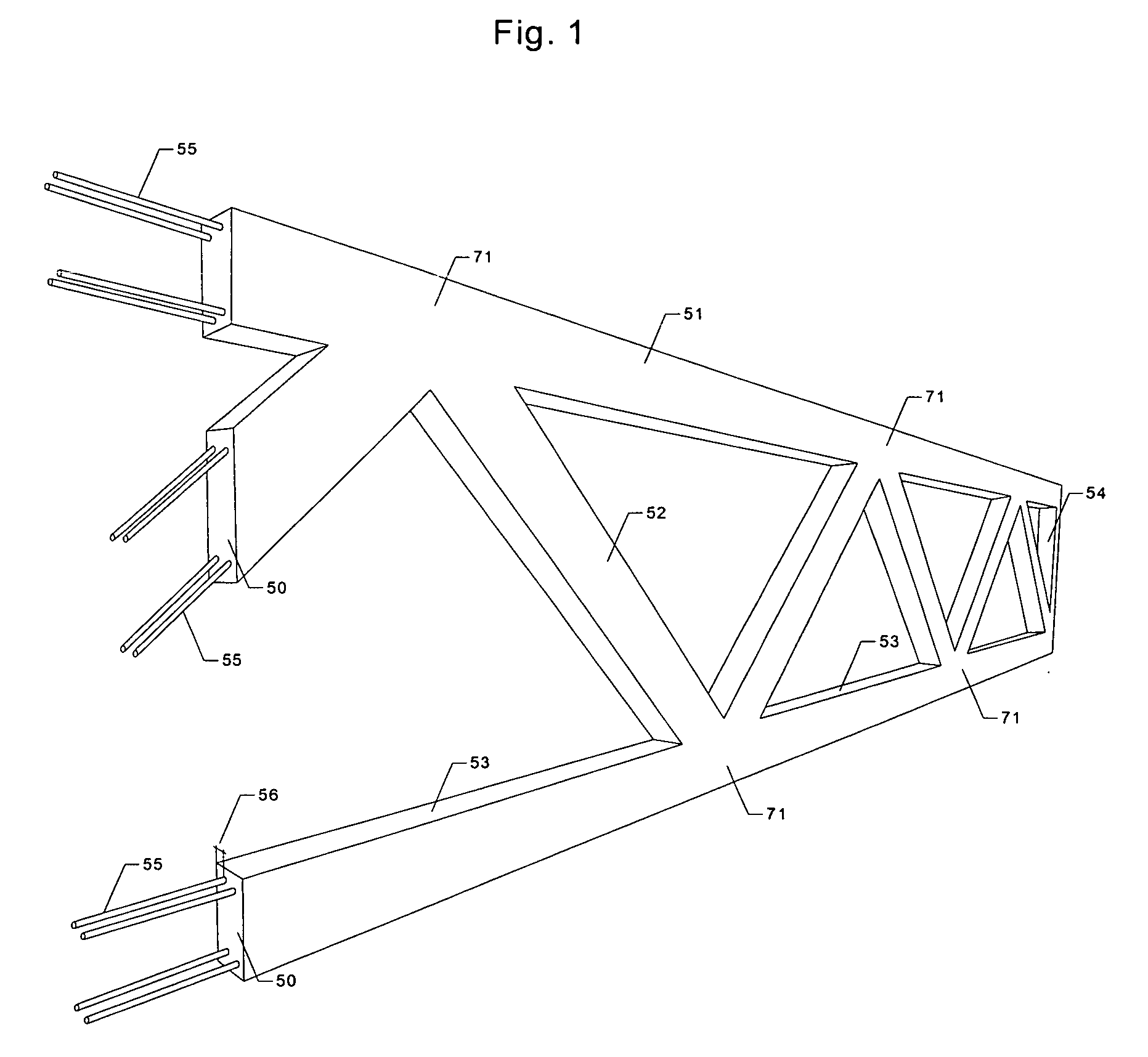

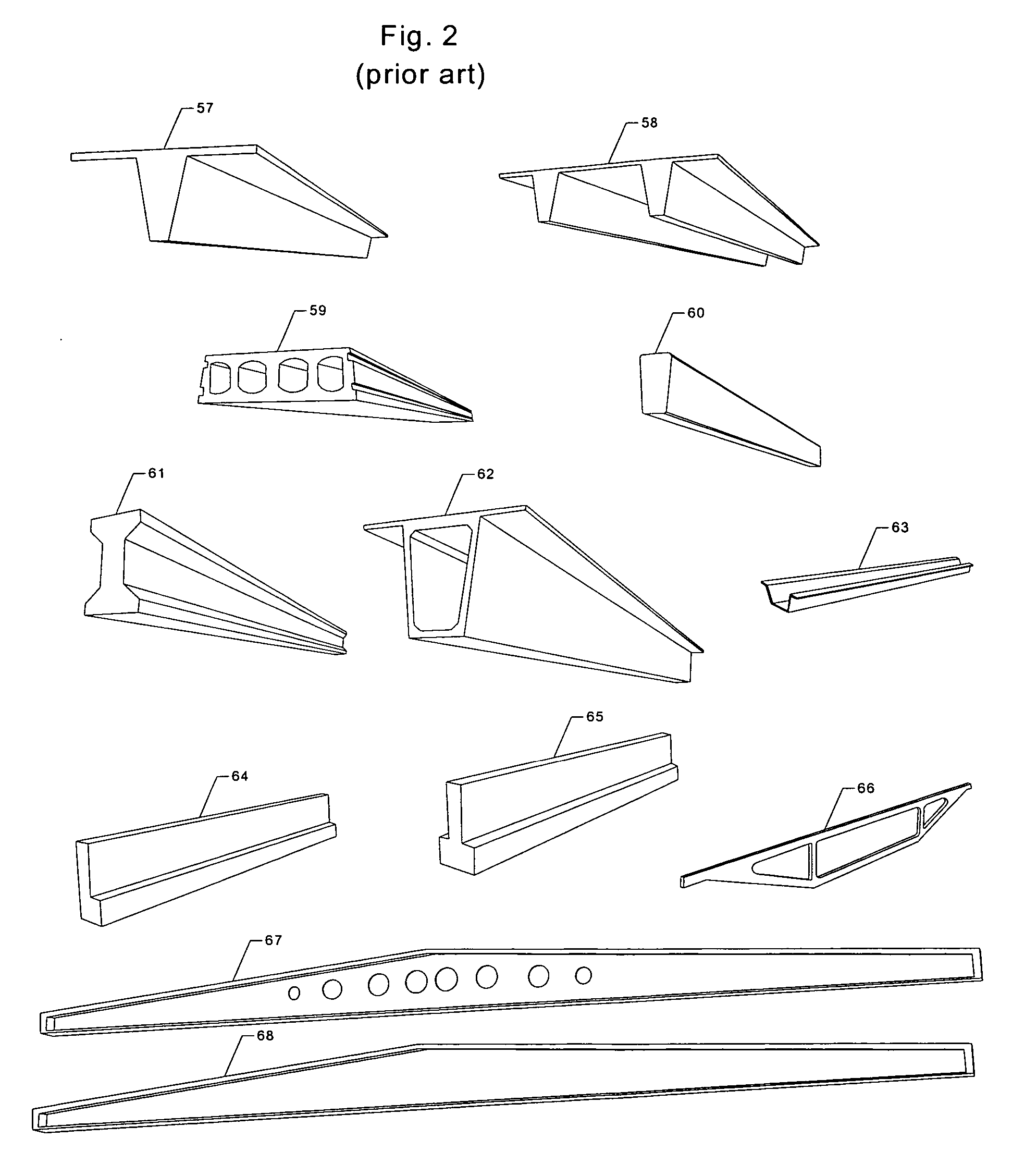

Concrete truss

A concrete structural framework comprised of a combination of reinforced steel, including pre-stressed and post-tensioned, with high performance concrete (HPC), for use in construction and other industries. This framework provides a highly fire resistant structure that is also resistant to the forces of nature and maintains a high level of structural integrity. The members of this concrete truss are joined or otherwise secured together by monolithic means, welded with badges, rivets, screws, or the like, in a triangular weblike configuration which provides the ultimate support against forces of compression and tension.

Owner:MENTADO DURAN JAVIER

Cement dispersant and concrete composition containing the dispersant

A cement dispersant (especially a dispersant for concretes with ultrahigh performance) comprising as a main component a water-soluble amphoteric copolymer obtained by copolymerizing (A) a polyamide-polyamine of an alkylene oxide adduct thereof with (B) (meth)acrylic acid or an alkali metal, ammonium, or alkanolamine salt thereof and (C) a polyalkylene glycol ester of (meth)acrylic acid in an A / B / C ratio of (10-40) / (10-40) / (50-80) (wt. %); and a concrete composition (especially an ultral high-performance concrete) containing the dispersant. The dispersant satisfies all of a water-reducing effect, slump flow retention, strength development, etc.

Owner:TOHO CHEM IND

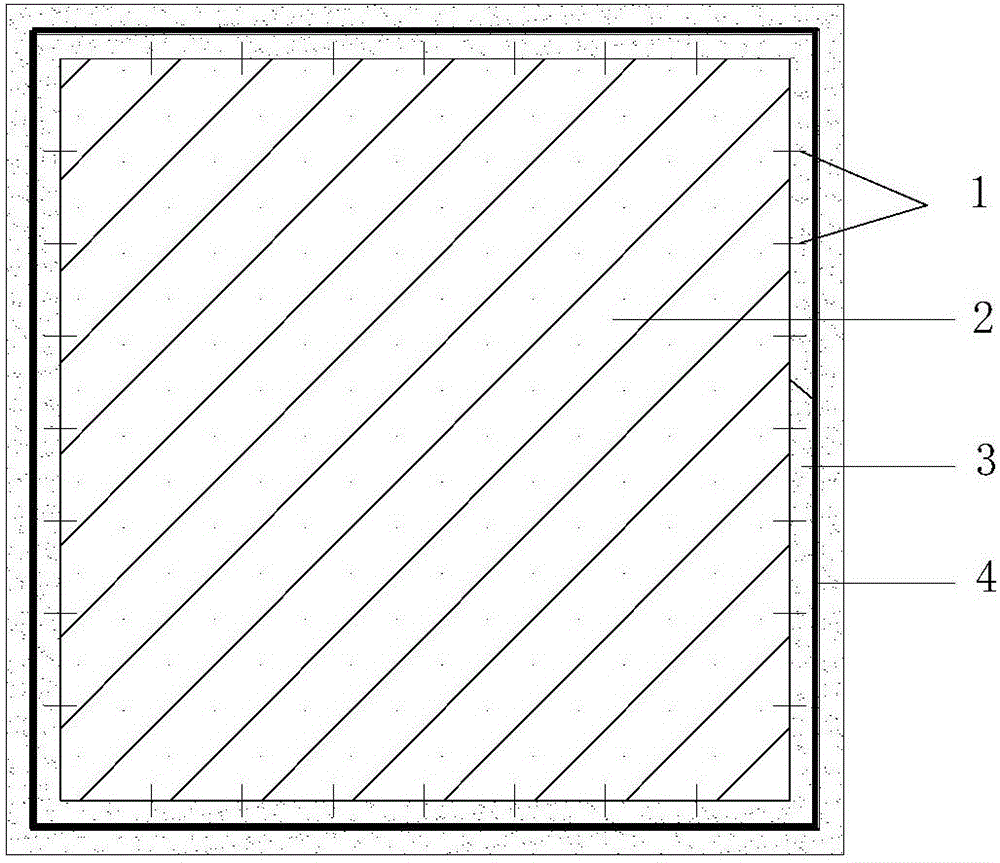

Preparation method for TRC formwork reinforced concrete column

ActiveCN106760207AAvoid erosionEven by forceStrutsForms/shuttering/falseworksReinforced concrete columnResist

A preparation method for a TRC formwork reinforced concrete column comprises the following steps that a fiber woven mesh with high tensile resist strength and good decay resistance is adopted, and the fiber woven mesh is dipped into glue or strengthened through a steel wire mesh liner; an inner mould is mounted, shear resistant hooks are mounted in drill holes of the inner mould in an inserting mode, and the fiber woven mesh is fixed to the outer side of the inner mould; an outer mould is built on the outer side of the fiber woven mesh, prepared high-performance concrete is slowly poured into space formed by the inner mould, the fiber woven mesh and the outer mould, and manufacturing of a TRC formwork is finished; and after a TRC formwork layer reaches the set strength, formwork disassembling is carried out, the concrete is poured into the TRC formwork, and preparing of the TRC formwork reinforced concrete column is finished. Compared with the prior art, time and labor are saved, the cost is reduced, and the construction efficiency is improved; the bearing capacity and ductility of the reinforced concrete column are improved, and the durability of components in severe environments such as a cold environment and an alkalinity environment is improved; and strengthening of a building is more efficient, simpler, cheaper and more environmentally friendly.

Owner:CHINA UNIV OF MINING & TECH

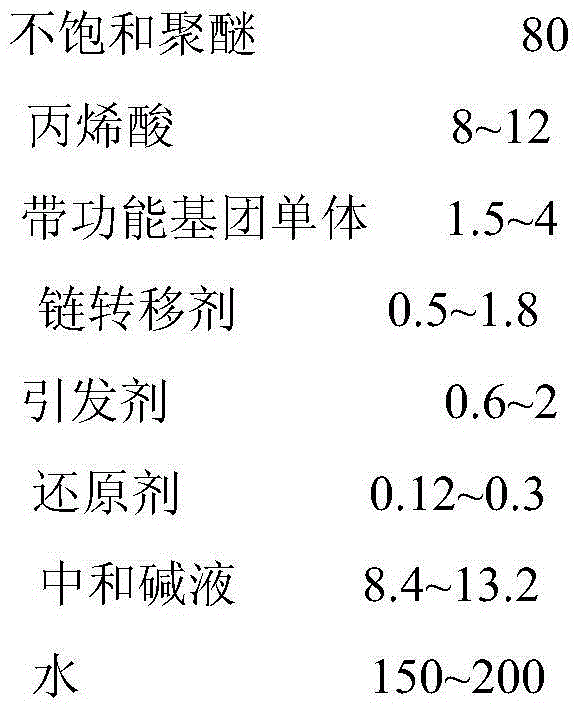

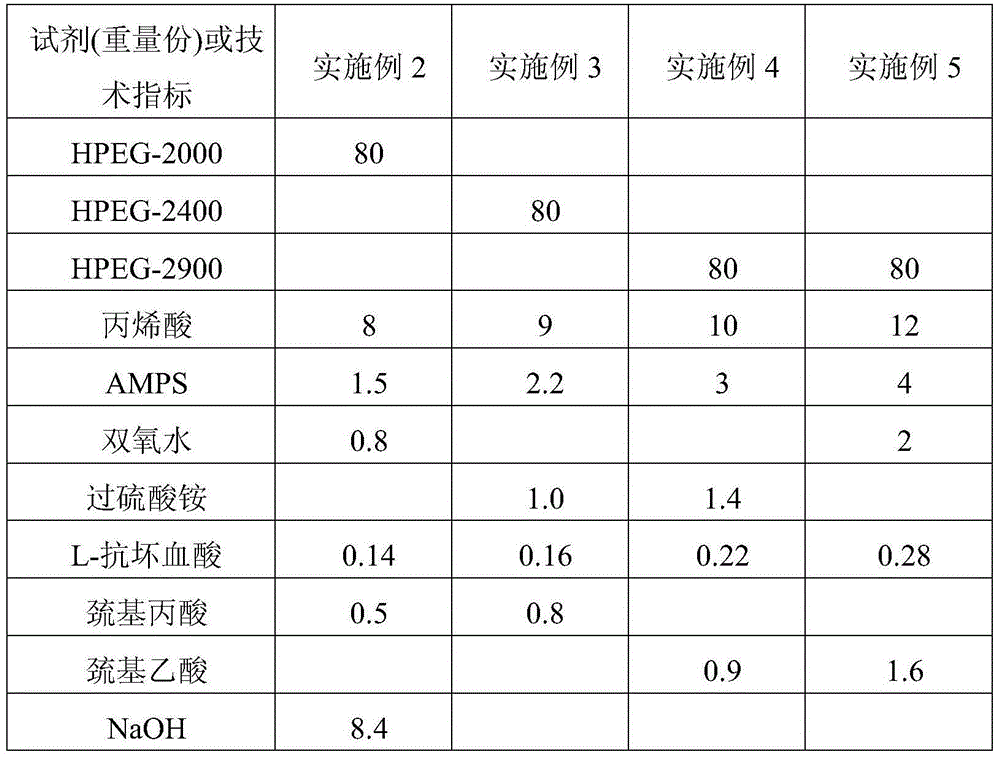

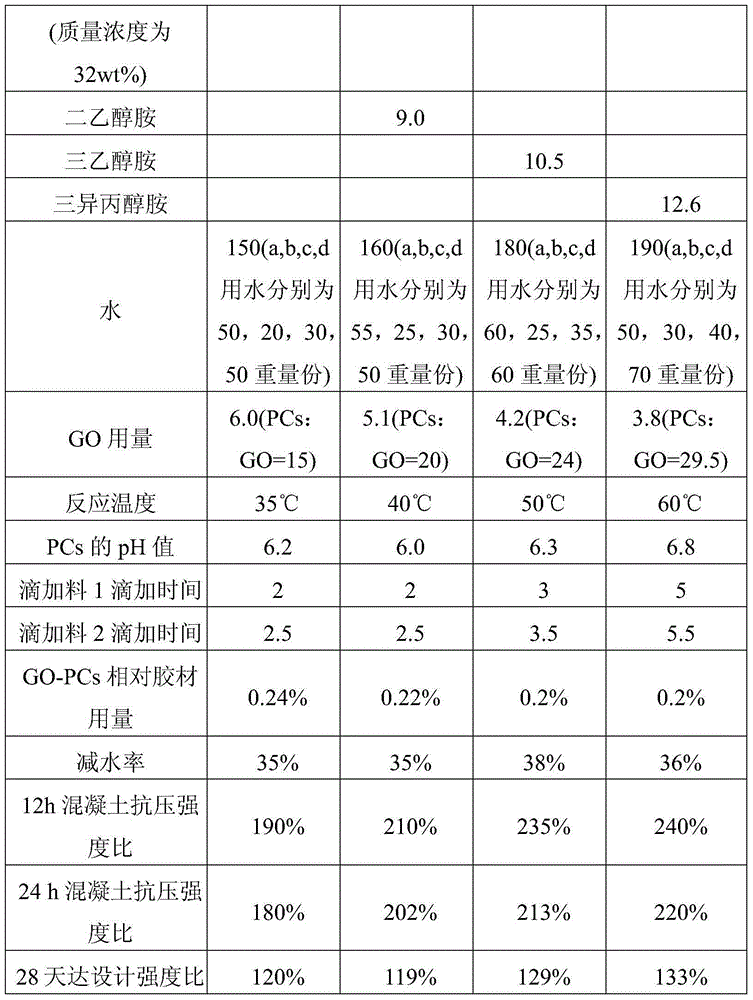

Multifunctional enhancement-type concrete admixture and preparation method thereof

The invention relates to a multifunctional enhancement-type concrete admixture and a preparation method thereof. The concrete admixture is composed of an early-strength polycarboxylic acid water reducing agent (PCs) and nano graphene oxide (GO). The mass ratio of the solid to the GO in the early-strength water reducing agent (PCs) is (10-30):1. The early-strength polycarboxylic acid water reducing agent (PCs) is composed of the following components in parts by weight: 80 parts of unsaturated polyether, 8-12 parts of acrylic acid, 1.5-4 parts of monomer with functional groups, 0.5-1.8 parts of chain-transfer agent, 0.6-2 parts of initiator, 0.12-0.3 part of reducer, 8.4-13.2 parts of neutralizing alkali liquor and 150-200 parts of water. The admixture has an obvious enhancement action on concrete, implements high-strength long-service-life green concrete, and has important meanings in the field of application of high-strength high-performance concrete.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

High-performance multifunctional cement reducing agent for concrete and preparation method for same

InactiveCN105906230ANo pollution in the processIntensity level unchangedCarbonizationUltimate tensile strength

The invention belongs to the field of concrete additives and provides a high-performance multifunctional cement reducing agent for concrete, which is characterized by including the following raw materials, by mass: 10-20% of modified polyether, 5-20% of mixed alcohol amine, 3-10% of mixed alcohol, 1-5% of unsaturated acid, 0.1-1% of modified siloxane, 0.1-0.3% of an initiator and the balanced being water. The cement reducing agent is toxic-free, is harmless, is free of environment pollution, is green and environment-friendly, is free of chlorine ion and alkali, can maintain strength grade of concrete to be not changed and can reduce the use amount of a cementing material in the concrete by 10-15 mass%. When the cement reducing agent is employed in ordinary concrete, the concrete is increased in strength by 10-20%. The cement reducing agent can improve peaceability, cohesiveness, homogeneity and anti-separation water bleeding, can improve pumpability of the concrete and can improve freezing resistance, carbonization resistance and the like durability properties of the concrete.

Owner:武汉金磊珂建材科技有限公司 +1

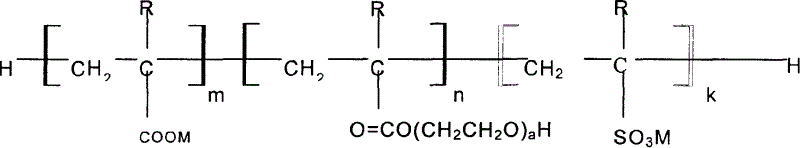

Water reducing agent of poly carboxylic acid series concrete and its preparation process

A poly-carboxylic acid-series water reducing agent for high-performance concrete is prepared through reaction between sodium methylacrylsulfonate and acrylic acid under the action of trigger to obtain a high-molecular polymer, and esterifying reaction on polyethanediol. Its advantages are low content of alkali, high water reducing effect, and high effect to improve performance of concrete.

Owner:WUHAN UNIV OF TECH

High-performance concrete

Disclosed high-performance concrete comprises the following compositions in parts by weight: 100-140 parts of cement, 500-700 parts of broken stone, 100-180 parts of river sand, 30-60 parts of fly ash, 20-50 parts of mineral slag, 50-90 parts of silica fume, 10-30 parts of limestone powder, 20-50 parts of basalt fiber, 30-80 parts of straw powder, 2-6 parts of a water reducer, 20-80 parts of nanometer silicon dioxide, 5-15 parts of nanometer calcium carbonate, 5-30 parts of multiwalled carbon nanotube, 1-3 parts of sodium dodecyl sulfate, 3-6 parts of zine stearate, 2-5 parts of boric acid, 3-7 parts of sodium citrate, and 80-100 parts of water. The high-performance concrete is high in strength, good in impermeability and good in endurance.

Owner:WUWEI HENGJI COMML CONCRETE

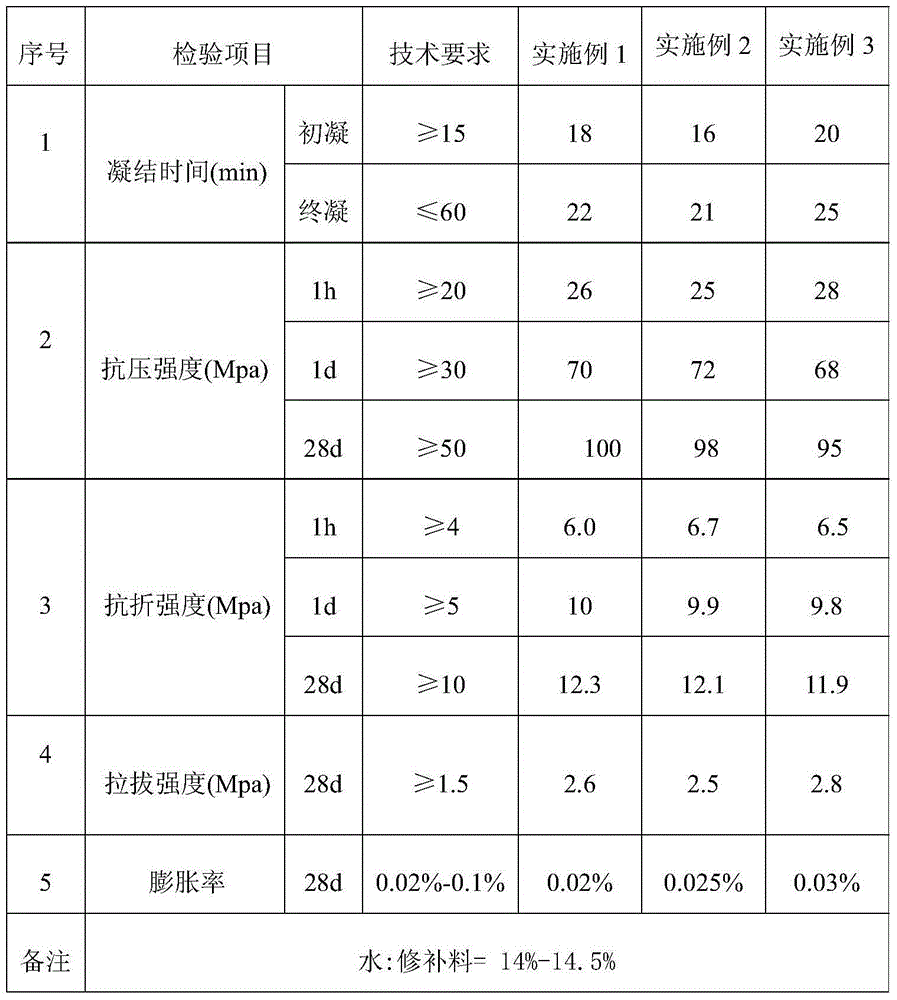

Pavement/bridge deck concrete fast mending material and application thereof

The invention relates to a pavement / bridge deck concrete fast mending material and application thereof. The mending material comprises the following raw materials by weight: 20 to 30 parts of sulphoaluminate cement, 8 to 10 parts of ordinary Portland cement 52.5, 5 to 10 parts of polymer powder, 0.5 to 1.5 parts of aluminium sulphate, 1 to 2 parts of water glass, 0.1 to 1 part of organic silicon, 1 to 2 parts of gypsum, 2 to 3 parts of slag, 0.1 to 0.5 part of silica micropowder, 0.5 to 1 part of an HPCA high-performance concrete expansive material, 3 to 5 parts of fly ash, 20 to 30 parts of washed-out and dried sand, 25 to 30 parts of corundum, 3 to 5 parts of composite fiber, 1 to 3 parts of a polycarboxylate superplasticizer, 0.1 to 0.5 part of boric acid, 0.1 to 0.3 part of sodium gluconate, and 0.2 to 1 part of lithium carbonate. The mending material is high in early strength, and has the advantages that traffic can be opened fast only 1 to 2 hours after mending is completed, so as to reduce traffic jams, and effectively reduce the generation of traffic accidents.

Owner:HENAN HUINENG ROAD & BRIDGE TECH CO LTD

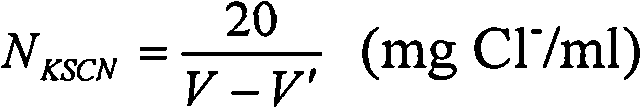

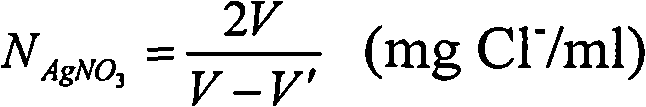

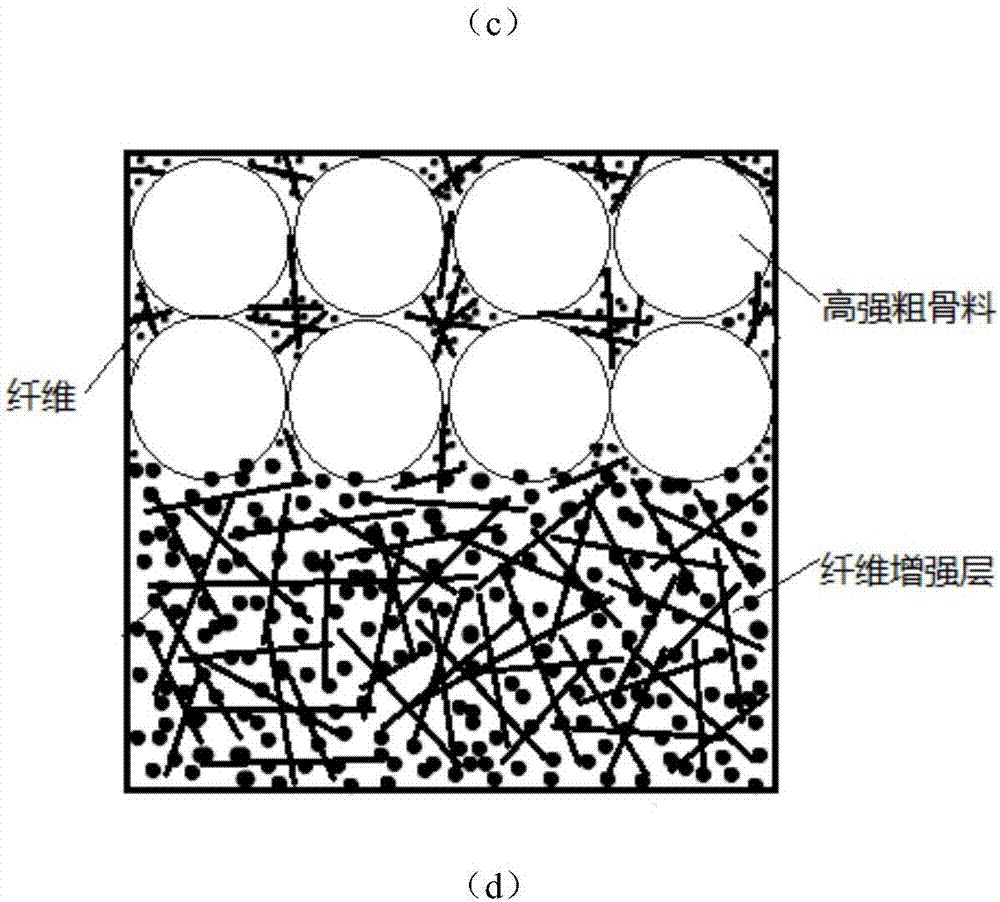

Method for measuring chloride ion content in high-performance concrete

ActiveCN101614718AHigh measurement accuracySimple and fast operationChemical analysis using titrationPreparing sample for investigationIon contentChloride

The invention relates to a method for measuring chloride ion content in high-performance concrete, comprising the steps: (1) free chloride ions and total chloride ions in the high-performance concrete can be extracted by a normal temperature soaking and oscillating method; (2) an improved Volhard chemical titration method is utilized to respectively measure the chloride ion content in the filtrate of the free chloride ions and the total chloride ions obtained in the step (1). The method has the advantages of simple operation, complete extraction, stable result and convenient operation, so as to meet the content measuring requirements of the solution with low concentration chloride ion, and be widely applied to the durability analysis and service life study of the high-performance concrete structure in the chloride environments such as oceans, deicing salt, etc.

Owner:GUANGXI UNIV

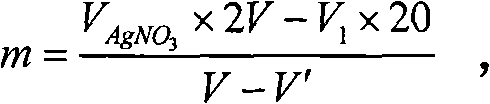

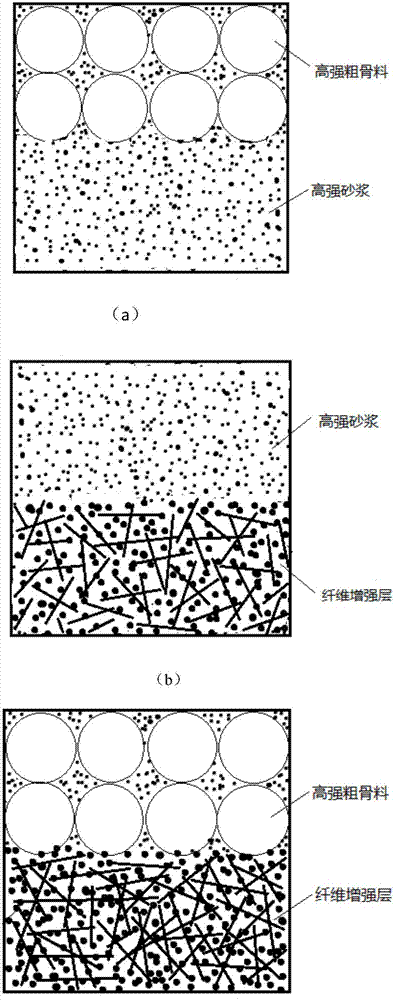

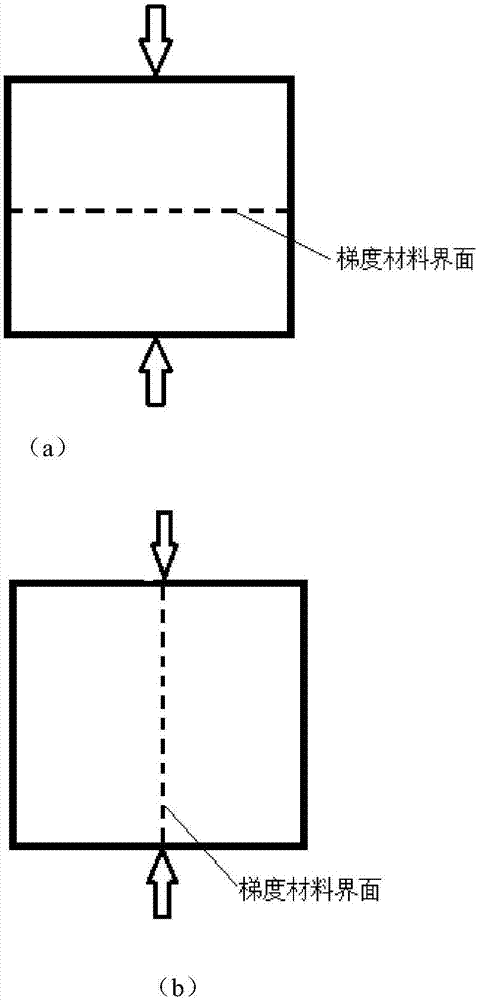

Functional gradient cement-based composite material enhanced by nano material and preparation method thereof

ActiveCN107098657AWide variety of sourcesConducive to ecological sustainable developmentCement pasteUltimate tensile strength

The invention discloses a functional gradient cement-based composite material enhanced by a nano material and a preparation method thereof. The composite material is composed of two or more of high-strength mortar, high-strength crude aggregate concrete, the fiber-enhanced super-high performance concrete, and the fiber-enhanced crude aggregate concrete according to isopyknic ratio. The nano material is doped into the composite material, an aperture and a gap of a gelling system can be filled with the material taken as a micro aggregate, the hydration rate at an early stage of cement paste is increased; at the same time, the gradient design is employed, by aiming at out-phase in the composite material and an interface in a functional zone, the performance of the cement-based composite material is effectively improved, and the functional gradient cement-based composite material is prepared, and the performances of intensity, toughness, impact resistance, penetration resistance, and blast resistance are greatly increased.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com