Premixed and pumped heavy concrete

A technology of concrete and concrete admixture, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as cracking of large-volume concrete, to avoid cracking, improve compactness, strength and durability, The effect of ensuring homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Selected materials: thick and fine aggregates are all of the same type of barite ore, processed through washing, crushing and screening, and the apparent density of the ore is 4360kg / m 3 , mud content <1%, coarse aggregate size 5-20mm, crushing index 28%, fineness modulus of fine aggregate is 2.58.

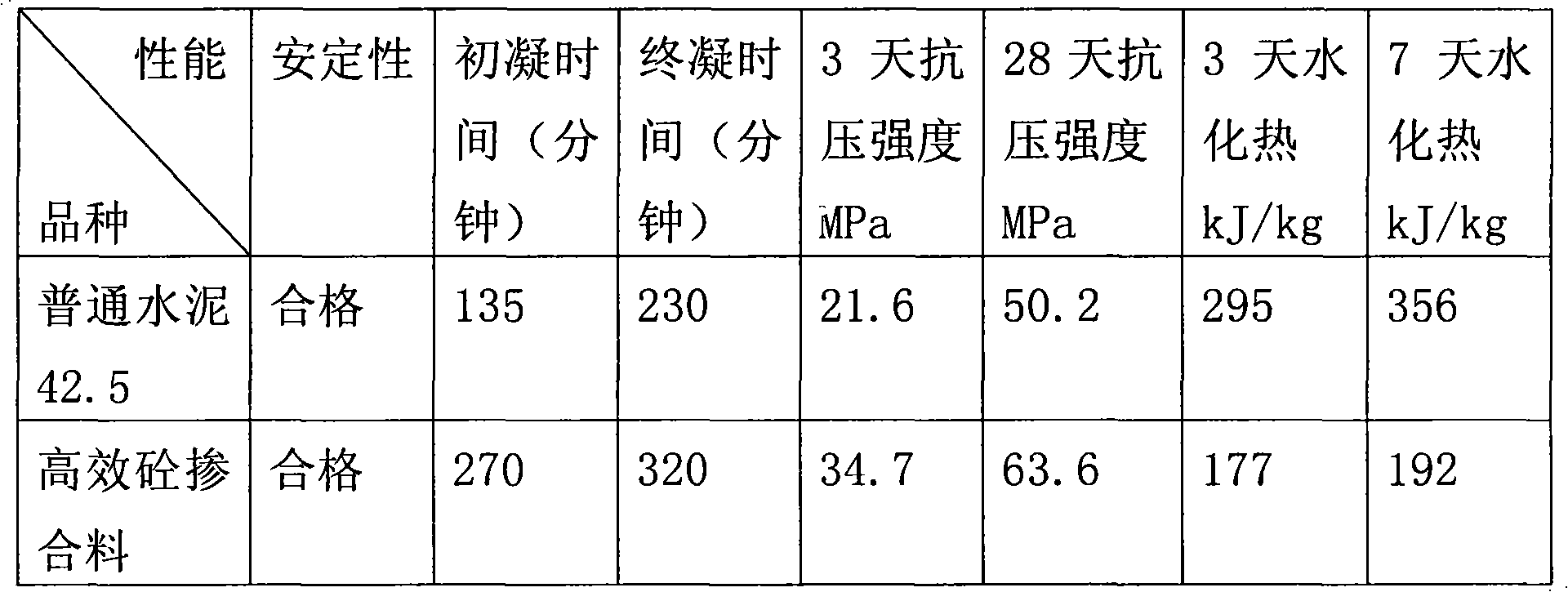

[0026] Cement materials use high-efficiency concrete admixtures produced by Xiangtan Changqing Building Materials Co., Ltd.

[0027] The functional modulators are selected from hydroxypropyl methylcellulose and high-viscosity starch sodium.

[0028] Concrete admixtures are selected from polycarboxylate water reducers, polyol derivatives, hydroxycarboxylates and sulfates.

[0029] Heavy concrete mix ratio:

[0030] Material

[0031] Concrete performance:

[0032] performance

[0033] The heavy concrete mixture has good cohesiveness, plastic retention, no stratification and segregation phenomenon, is stable and does not block the pump during pumping, a...

Embodiment 2

[0035] Thick and fine aggregates, variety and quality are the same as the above example.

[0036] Cement materials use ordinary cement 42.5 and S105 slag powder.

[0037] Carboxymethyl cellulose and polyvinyl alcohol are selected as functional regulators.

[0038] Concrete admixtures are selected from naphthalene-based water reducers, polyol derivatives, sodium polyphosphate and sulfates.

[0039] Heavy concrete mix ratio:

[0040] Material

[0041] Concrete performance:

[0042] performance

[0043] The heavy concrete mixture has good cohesiveness, plastic retention, no stratification and segregation phenomenon, is stable and does not block the pump during pumping, and is easy to vibrate for construction. The amount of mixing and transportation per production is 40% less than usual. The concrete is suitable for large-volume radiation-proof heavy concrete projects with a thickness less than 1500mm.

Embodiment 3

[0045] Use scrap iron and barite as coarse aggregate, and iron sand and barite sand as fine aggregate. Scrap iron and iron sand need to be degreased and cleaned. The size of scrap iron is 5-35mm, and the iron sand is less than 5mm. Stone coarse and fine aggregates meet the aforementioned technical requirements.

[0046] The cement materials are high-efficiency concrete admixtures produced by Xiangtan Changqing Building Materials Co., Ltd.

[0047]The functional modifier is selected from hydroxyethyl cellulose.

[0048] Concrete admixtures are selected from naphthalene-based water reducers, polyol derivatives, sodium polyphosphate and sulfates.

[0049] Heavy concrete mix ratio:

[0050] Material

[0051] Concrete performance:

[0052] performance

[0053] The heavy concrete mixture has good cohesiveness, plastic retention, no stratification and segregation phenomenon, is stable and does not block the pump during pumping, and is easy to vibrate for const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com