Small concrete compaction and curing slowing device used for experiment and its implementation method

A curing device and concrete technology, applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problems of inability to take into account centrifugal compaction and slow curing functions, single vibration function, etc., to prevent concrete splashing, reduce losses, reduce Effects of noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further facilitate those of ordinary skill in the art to better understand the essence of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

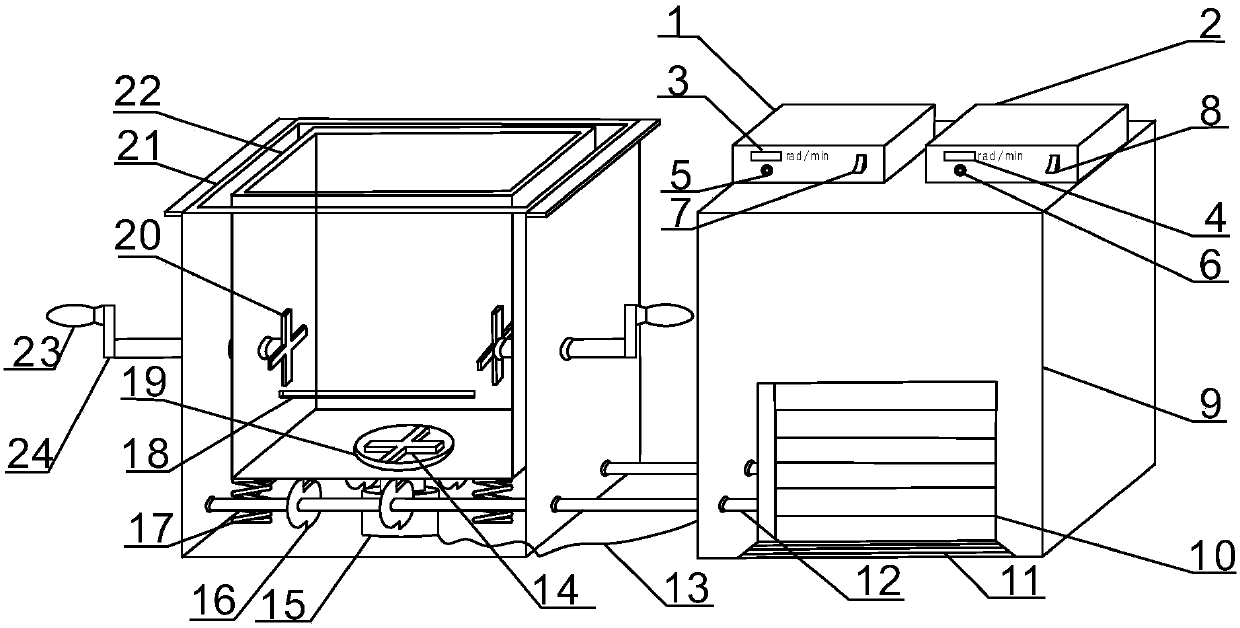

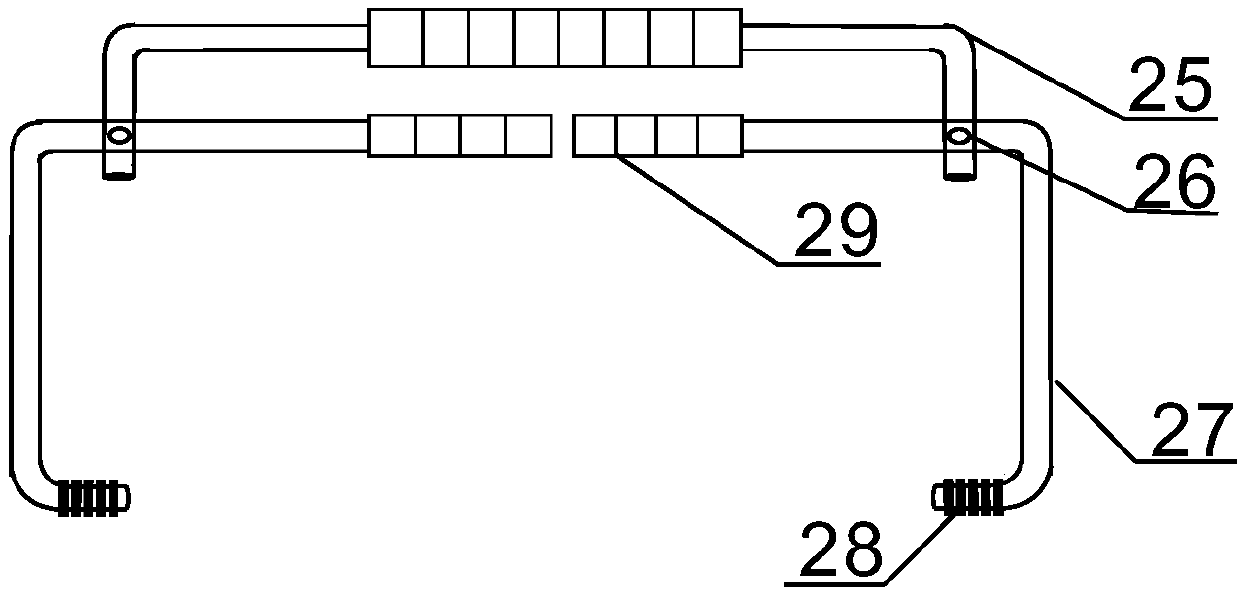

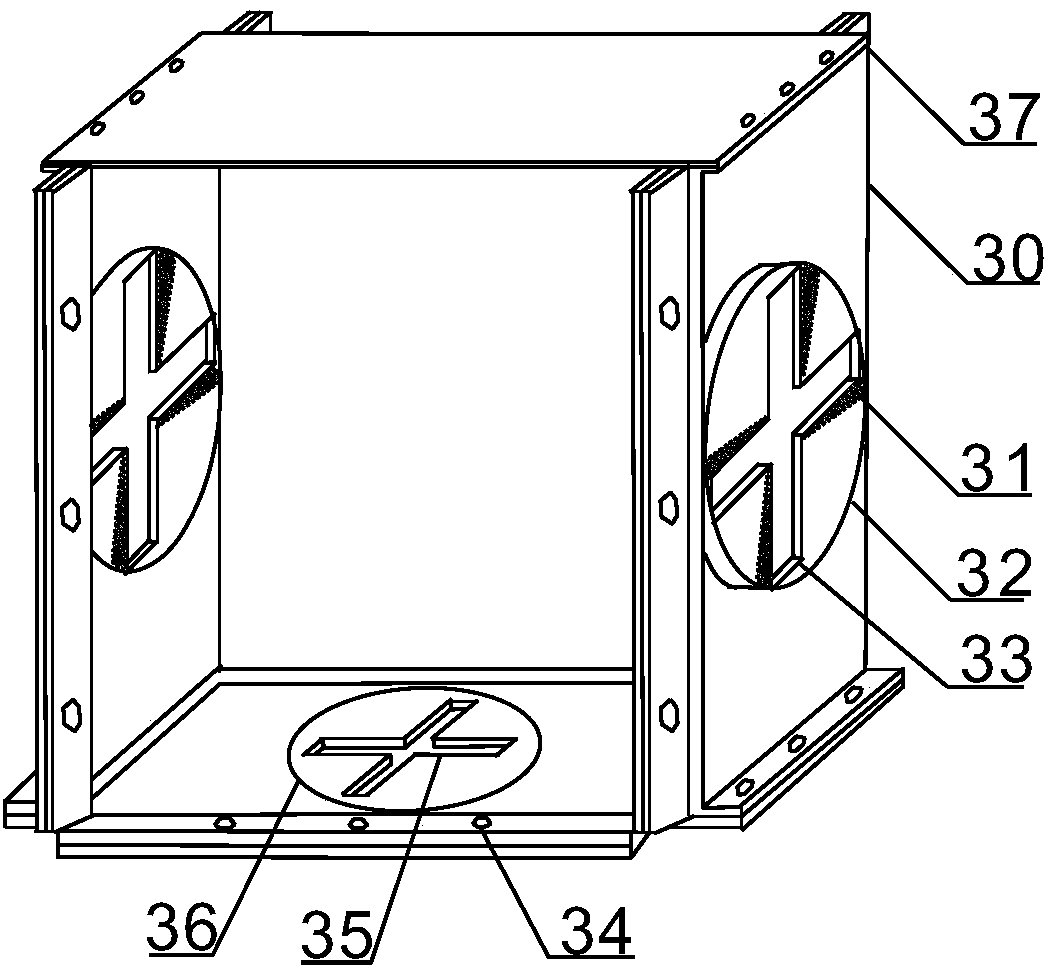

[0032] The invention relates to a small concrete vibration and slow curing device for testing, which includes a vibration mechanism, a centrifugal mechanism, a slow curing mechanism, a material loading and unloading mechanism and a clamping mechanism. The vibration mechanism is located at the outermost layer of the device, and the centrifugal mechanism is located at The middle layer of the device, the slow curing mechanism is located in the second inner layer of the device, and the material handling mechanism is located in the innermost layer of the device, and it is characterized in that: after the material handling mechanism is loaded, the box of the material handling mechanism is fixed Cover, the box cover of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com