Patents

Literature

81results about How to "Guaranteed vibration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

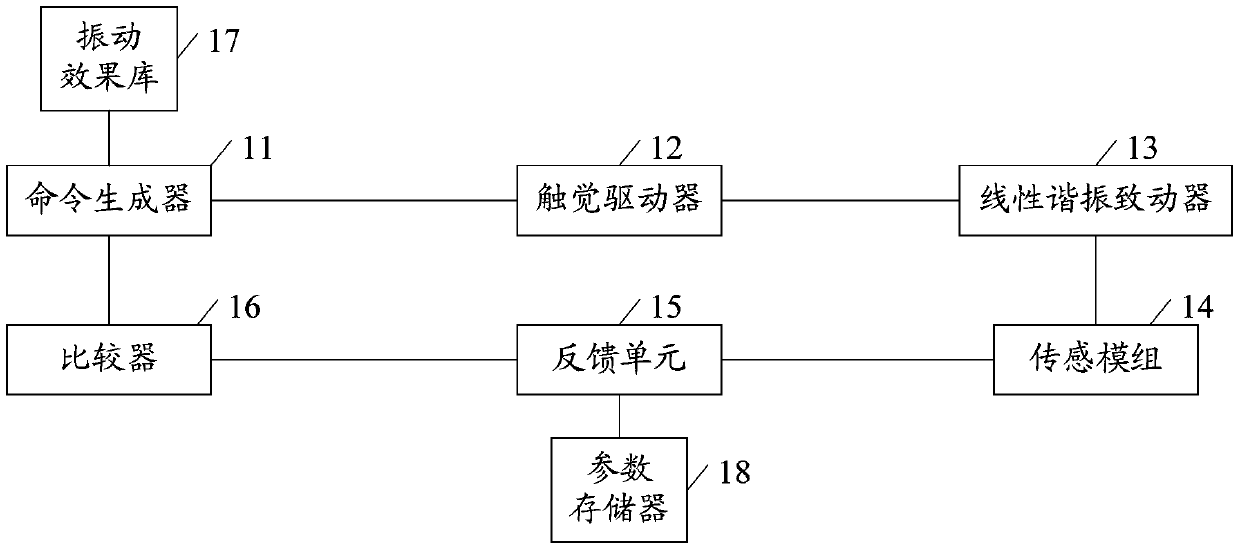

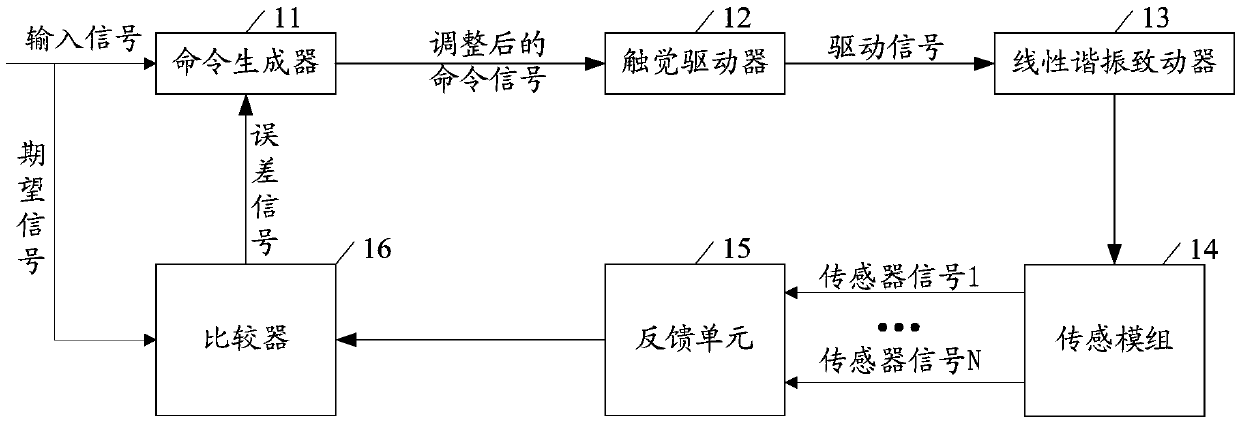

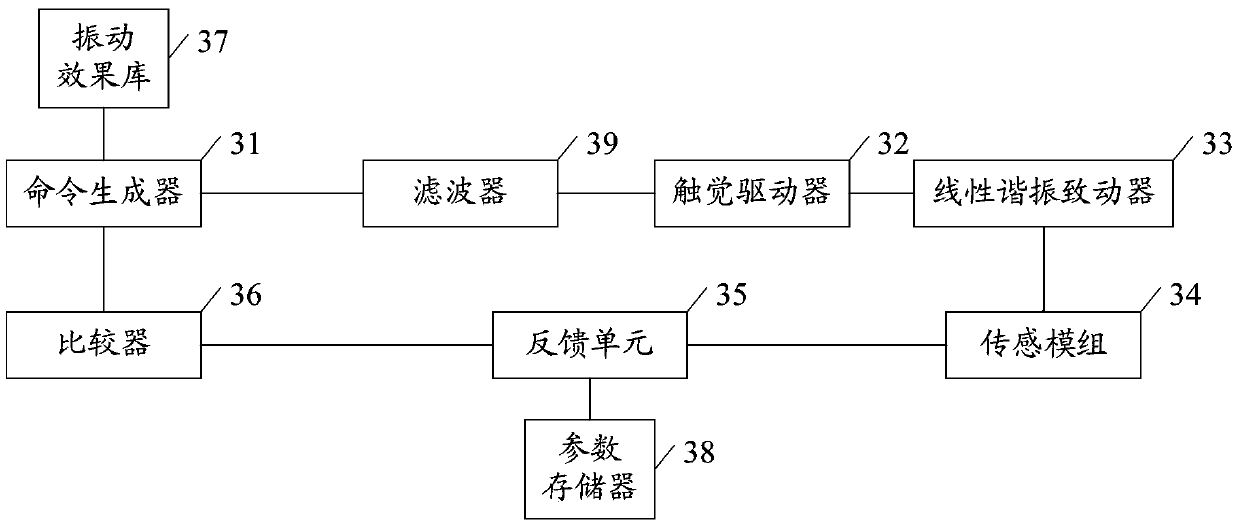

Tactile vibration control system and method for intelligent terminal

ActiveCN105511514ARemnants of smearing resolvedReal-time adjustment of vibration statusAC motor controlMechanical oscillations controlLoop controlVibration control

The invention discloses a tactile vibration control system and method for an intelligent terminal. The system comprises a command generator, a touch driver, a linear resonance actuator, a sensing module, a feedback unit and a comparator, the state of the actuator is monitored or sensed through the sensing module which includes a plurality of sensors, and multiple paths of sensor signals are generated when the actuator vibrates; the feedback unit sends sensing signals output by the plurality of sensors and representing related physical quantities of a vibration mode as feedback signals to the comparator; and the comparator generates an error signal according to the feedback signals and a desired signal in an input signal and sends the error signal to the command generator, so that the command generator adjusts a generated original command signal according to the error signal, thereby completing closed-loop control of the linear resonance actuator. The tactile vibration control system provided by the invention can estimate the state of the actuator robustly and apply control, avoids the residual phenomenon of trailing when the linear resonance actuator vibrates, and achieves the technical effect of adjusting the vibration state of the actuator in real time.

Owner:GOERTEK INC

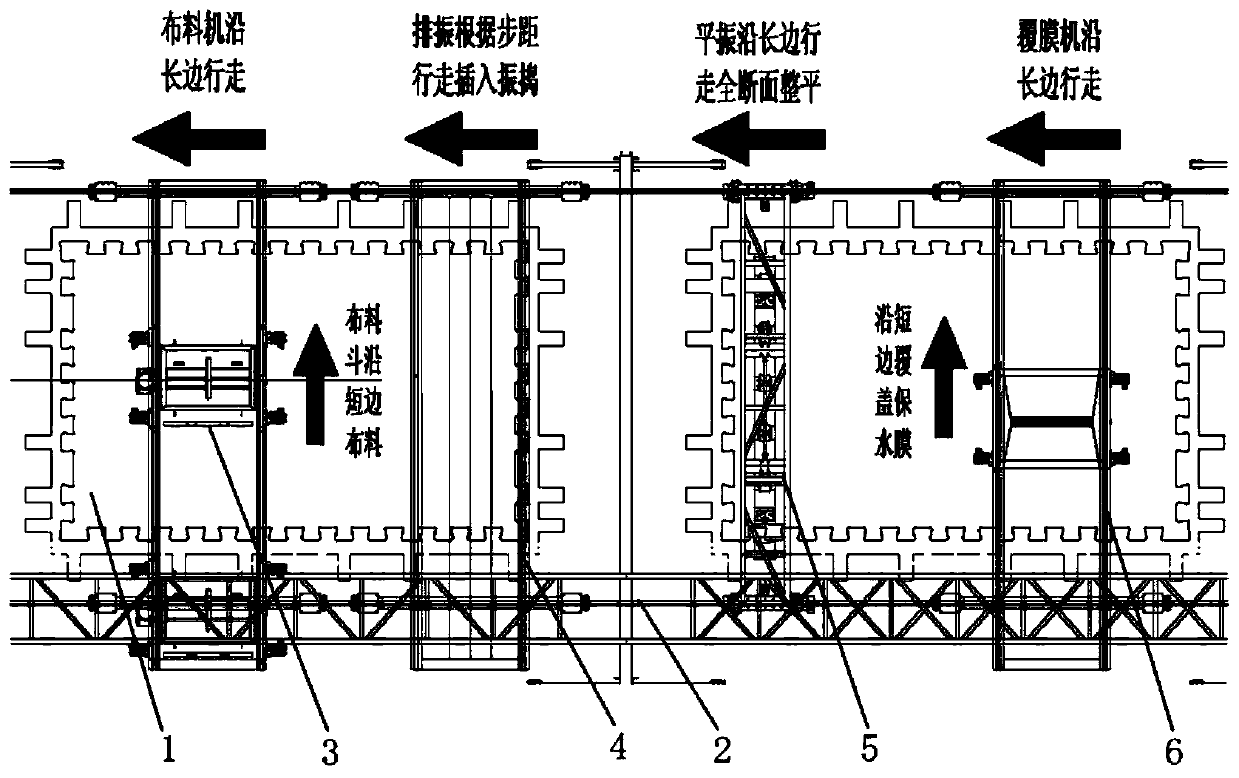

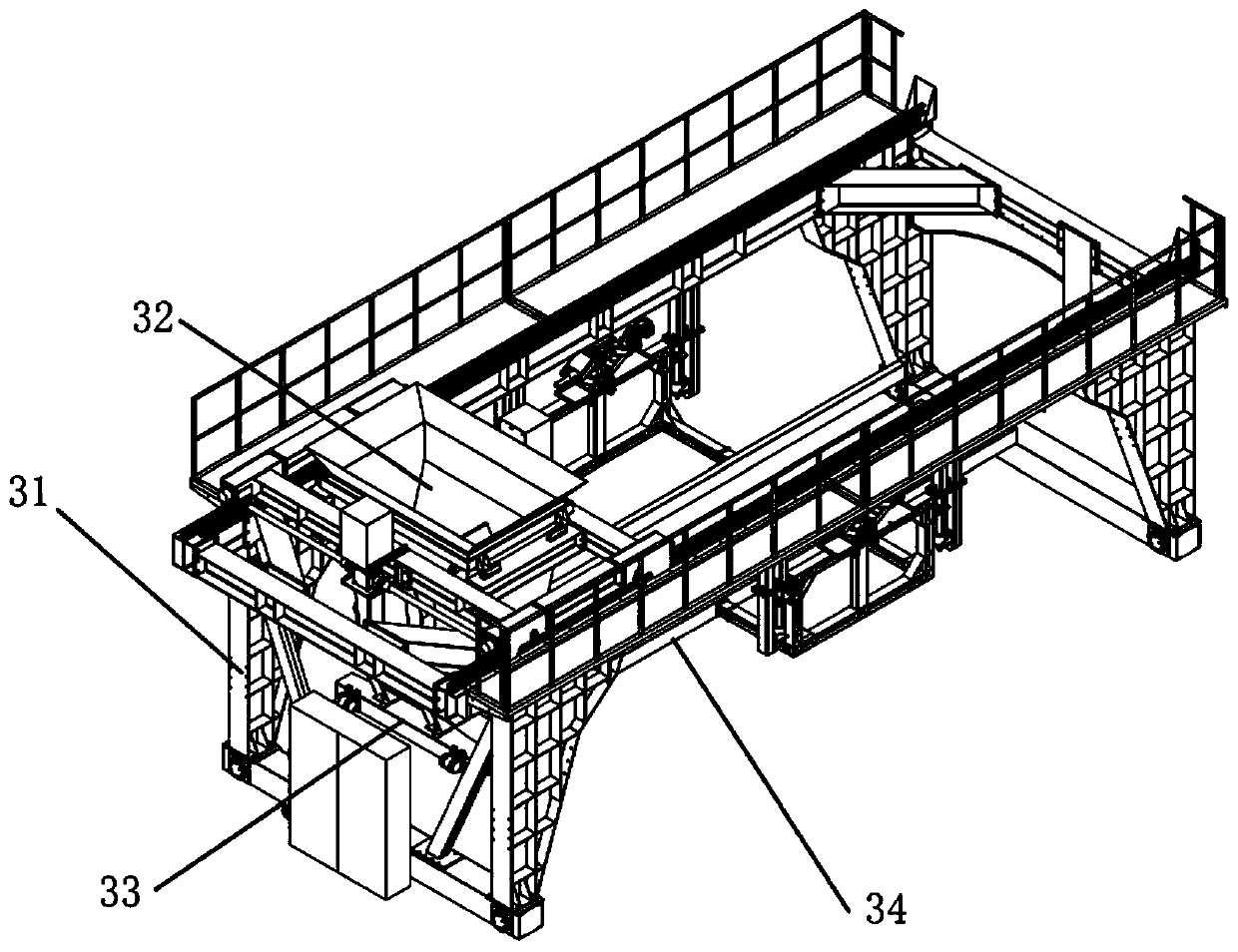

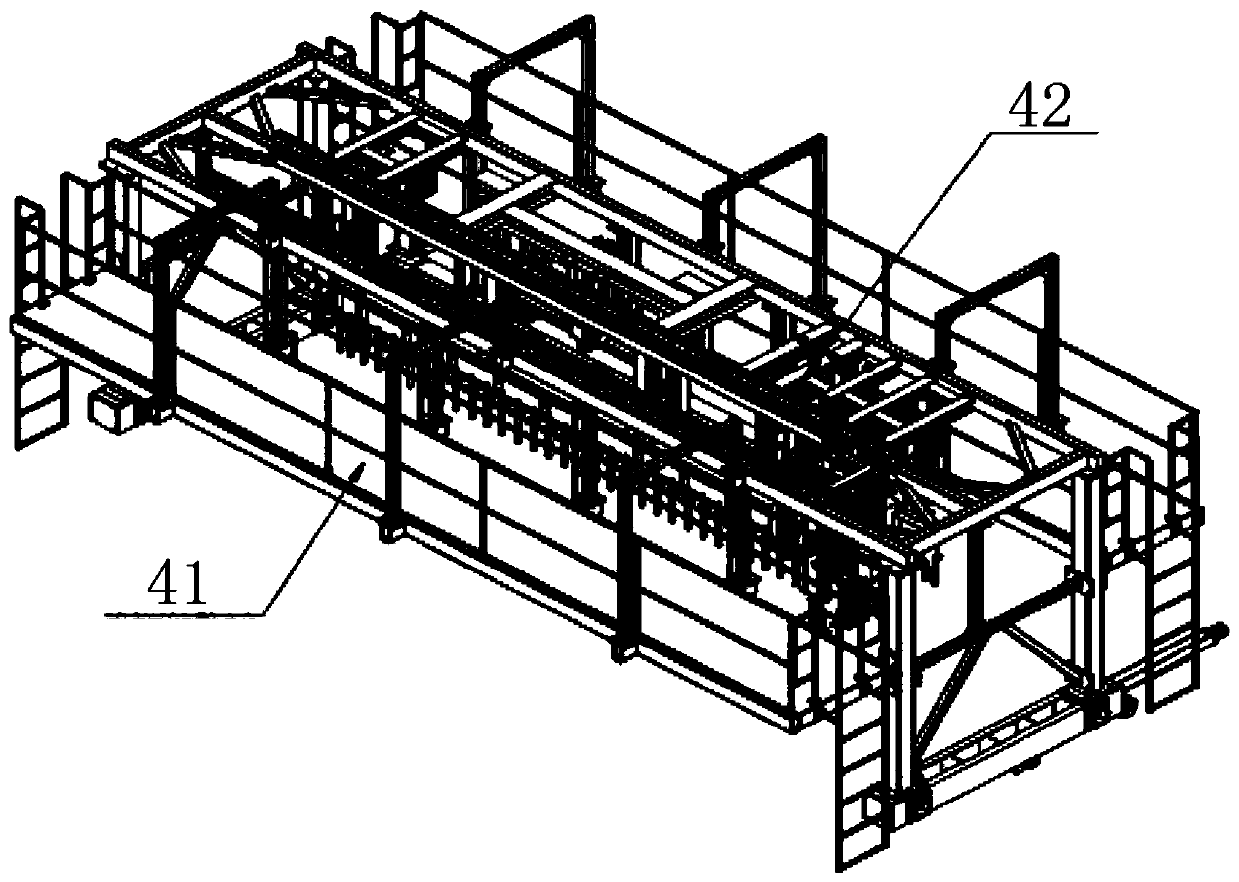

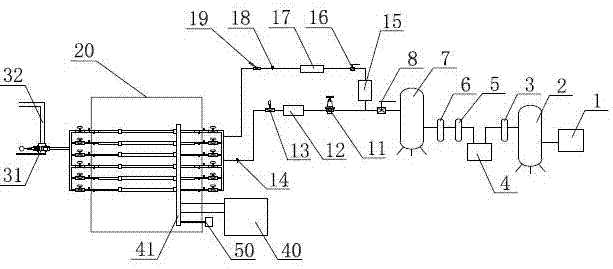

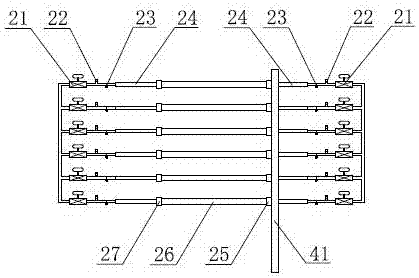

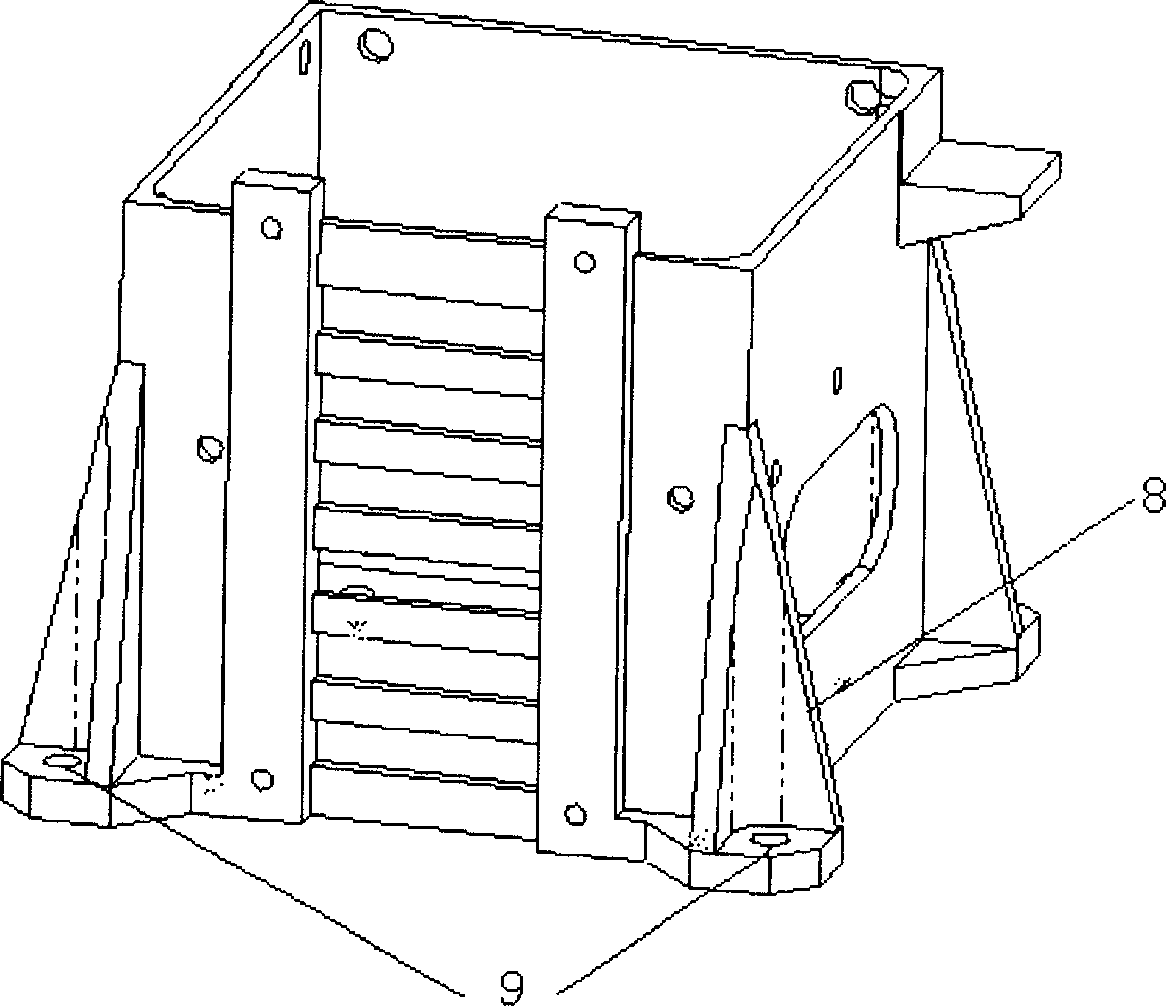

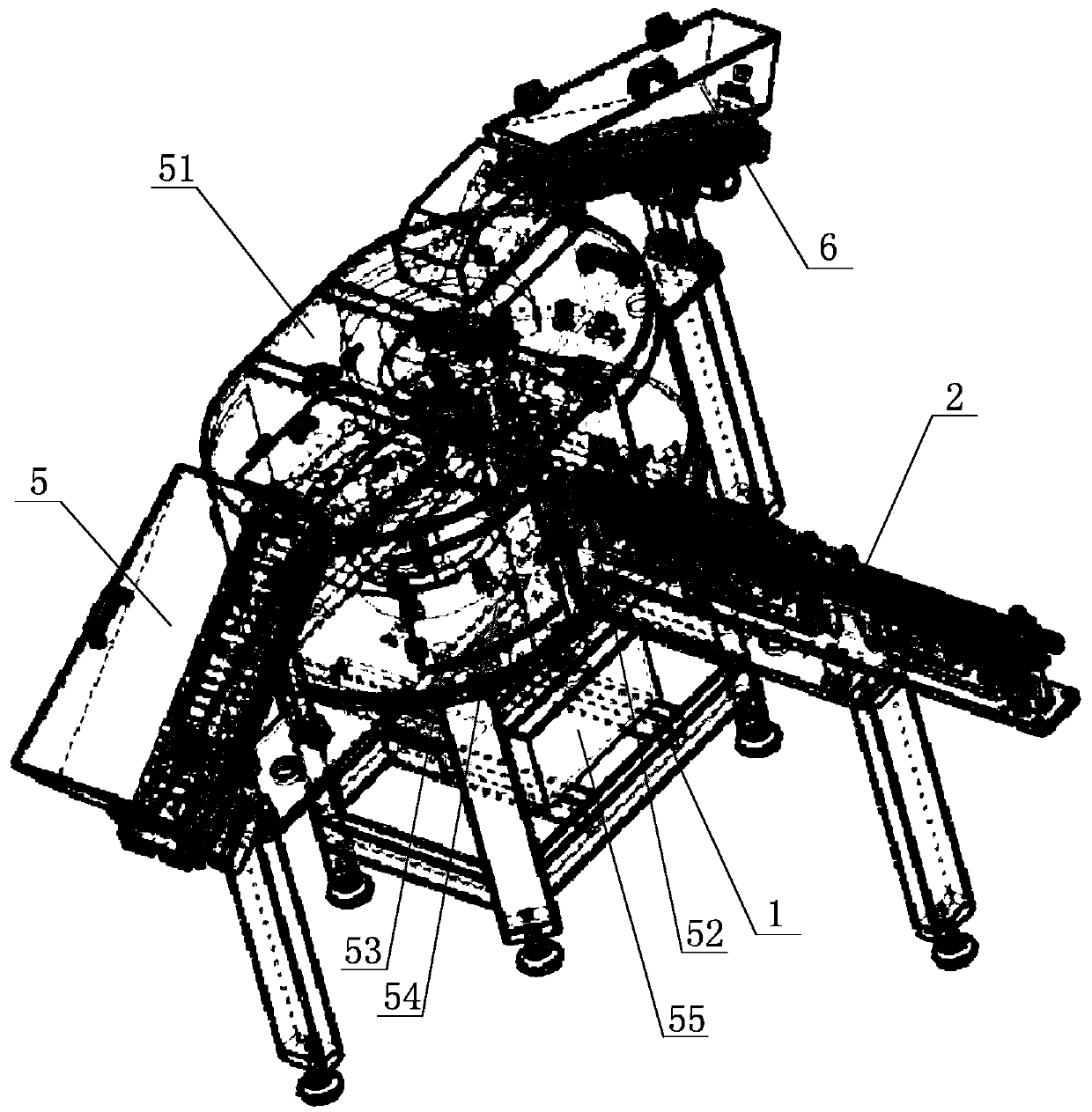

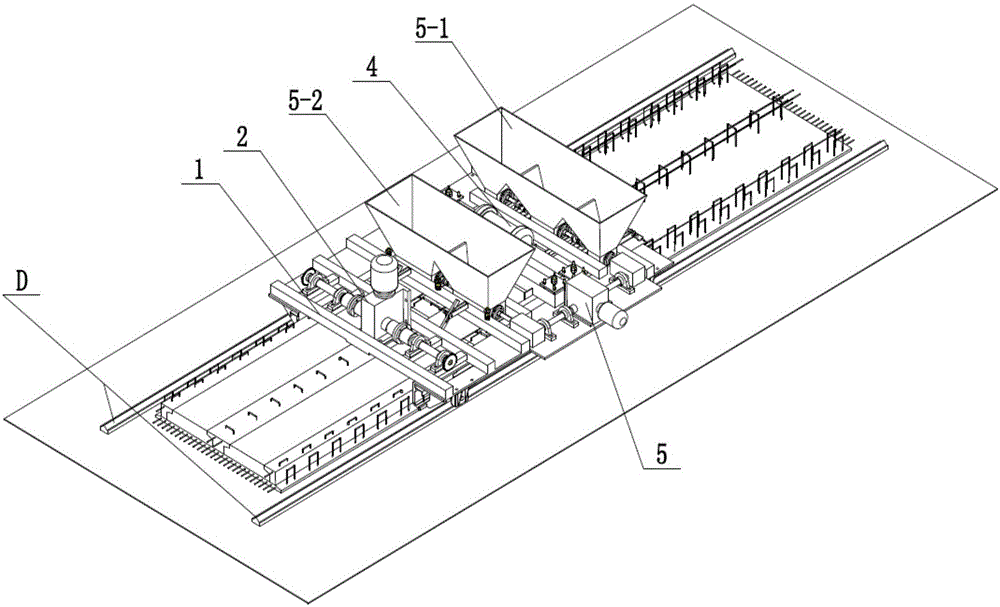

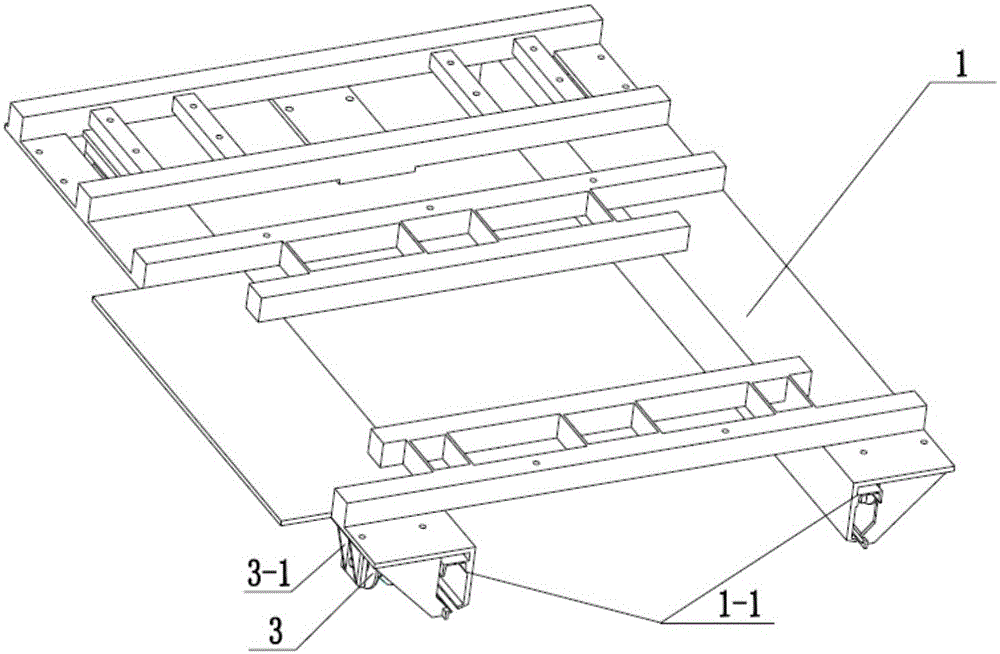

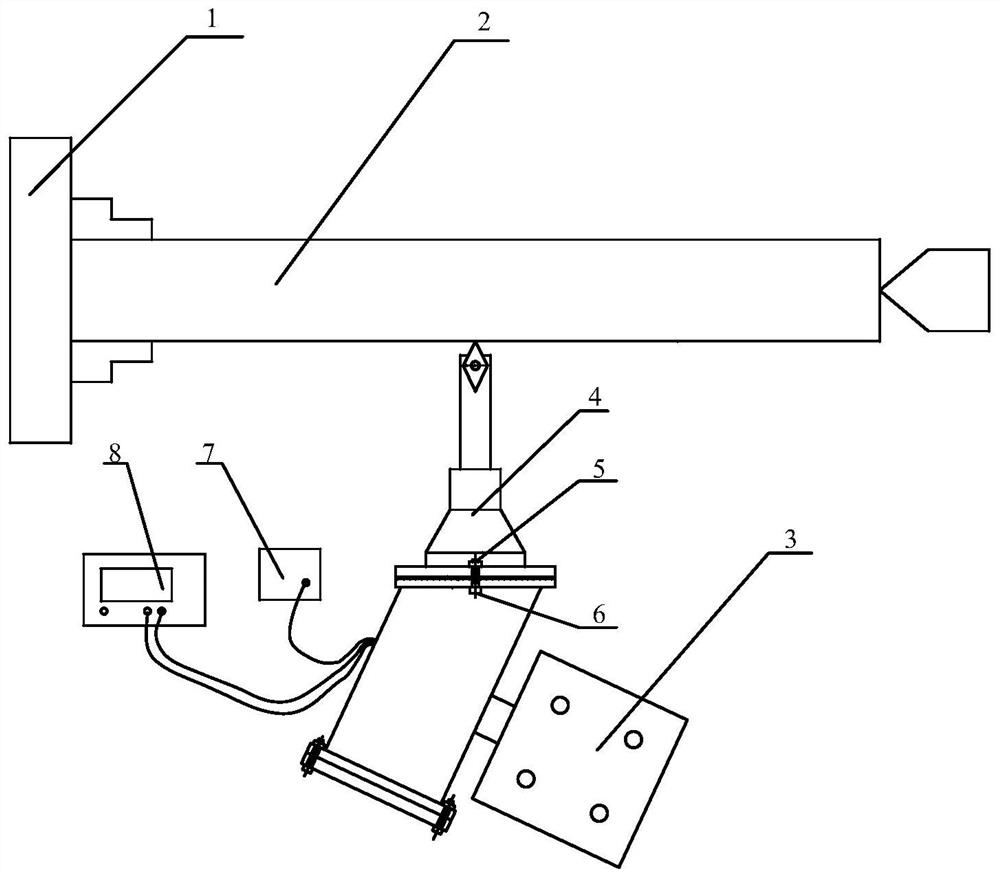

Automatic material distributing and vibrating system for concrete bridge deck slab and control method thereof

InactiveCN110777657AReduce construction waiting timeOvercoming problems that cannot be implemented quicklyBridge erection/assemblyProgramme control in sequence/logic controllersControl systemBridge deck

The invention discloses an automatic material distributing and vibrating system for a concrete bridge deck slab and a control method thereof. The automatic material distributing and vibrating system comprises a track, a material distributing machine, an array type vibrating machine, a flat plate vibrating and leveling machine, a rolling film laminating machine and a control system, wherein the material distributing machine comprises a walking frame moving along the track and a material distributing hopper mounted below the walking frame; the material distributing hopper moves along a frame cross beam; the frame cross beam is parallel to the short edge of a mold; the array type vibrating machine comprises a first walking cart moving along the track and an array device mounted below a crossbeam of the first walking cart; a plurality of rows of vibrating rods are arranged below the array device in the advancing direction of the array device; the first row of vibrating rods are special dovetail joint vibrating rods arranged at intervals according to the designed dovetail joint positions; and the other rows of vibrating rods are arranged in a full-section mode and correspond to steel bar meshes. The requirement of coarse aggregate reactive powder concrete for distribution uniformity can be met, and the influence of environment changes on the bridge deck slab is reduced.

Owner:CCCC SHEC FOURTH ENG

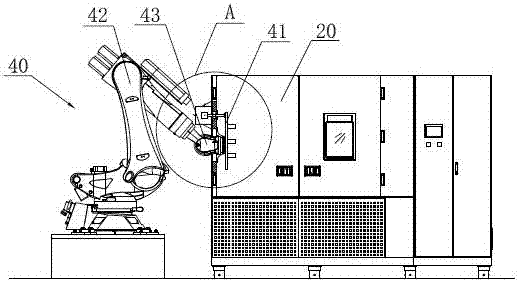

Pipeline reliability testing device

PendingCN107478403ASimple test structureSimple structureMaterial thermal analysisVibration testingTemperature controlEngineering

The present invention provides a pipeline reliability testing device which comprises a drying module, a temperature control module, a testing module and a pulse pressure generator installed in order. The gas outlet end of the drying module is divided into two paths which are respectively connected with the heating gas path and the cooling gas path of the temperature control module, the testing module is at least one testing gas paths which are installed in parallel, the hand of the robot of a vibration device stretches into a test box, a testboard is installed at the end portion of the handle, and the handle drives the testboard and pipeline samples to realize three-axial vibration. The vibration device is simple in structure so as to simulate different temperatures, pulse pressures and vibration conditions of an engine in a working process and test the reliability of a turbocharging tube with no need for configuration of a special engine, the test structure is simple, and the cost is saved. The vibration detection device is connected with the testboard, the amplitudes and frequencies of the three-axial directions of the vibration block are the completely same as these of the handle, and displacement sensors of three directions are employed to accurately detect the amplitudes and the frequencies of three-axial direction vibration so as to ensure that the real vibration effect accords with the test requirements.

Owner:无锡帕捷科技有限公司

Method of designing vibration exciter for constructive machinery

ActiveCN1623749AAmplitude stableSimple amplitudeMechanical vibrations separationCement mixing apparatusTelecommunicationsEngineering

A vibration exciter for the building mechineries, such as vibration stirrer and vibration compactor, is composed of an eccentric shaft, bearings, casing connected via bearing to said eccentric shaft, balancing weights symmetrically connected to said eccentric shaft, and power source for driving said eccentric shaft. Its advantages are simple structure, high vibration effect and long service life.

Owner:德通智能科技股份有限公司

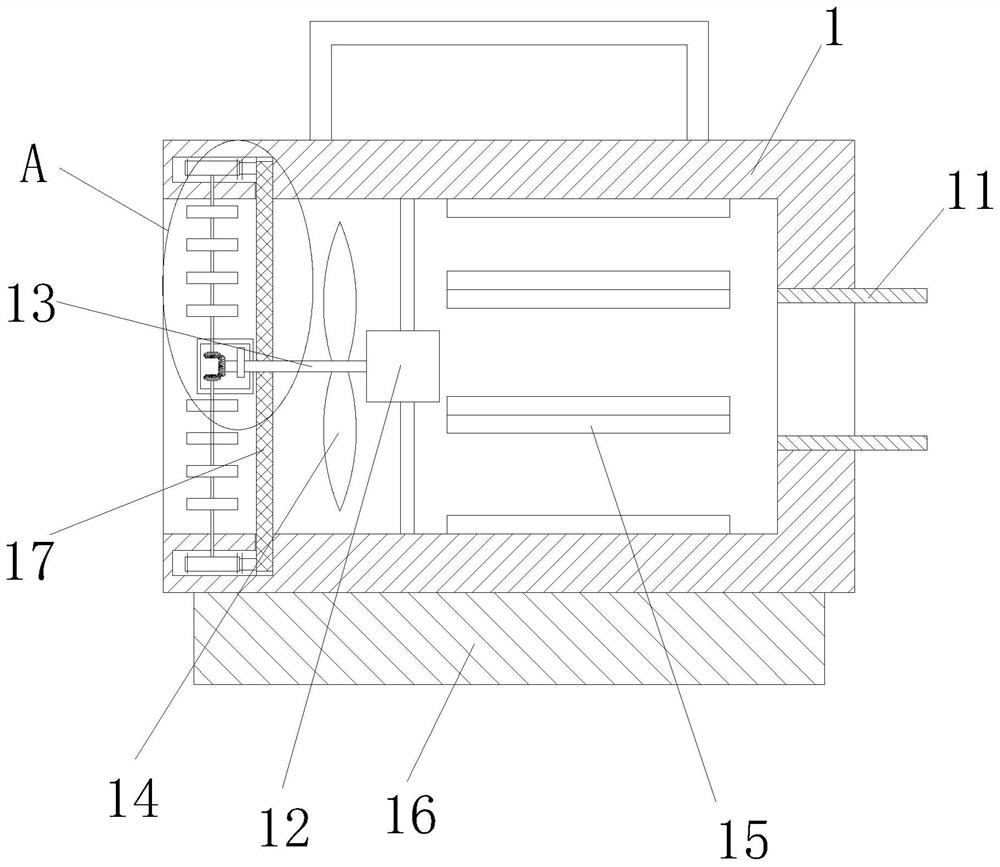

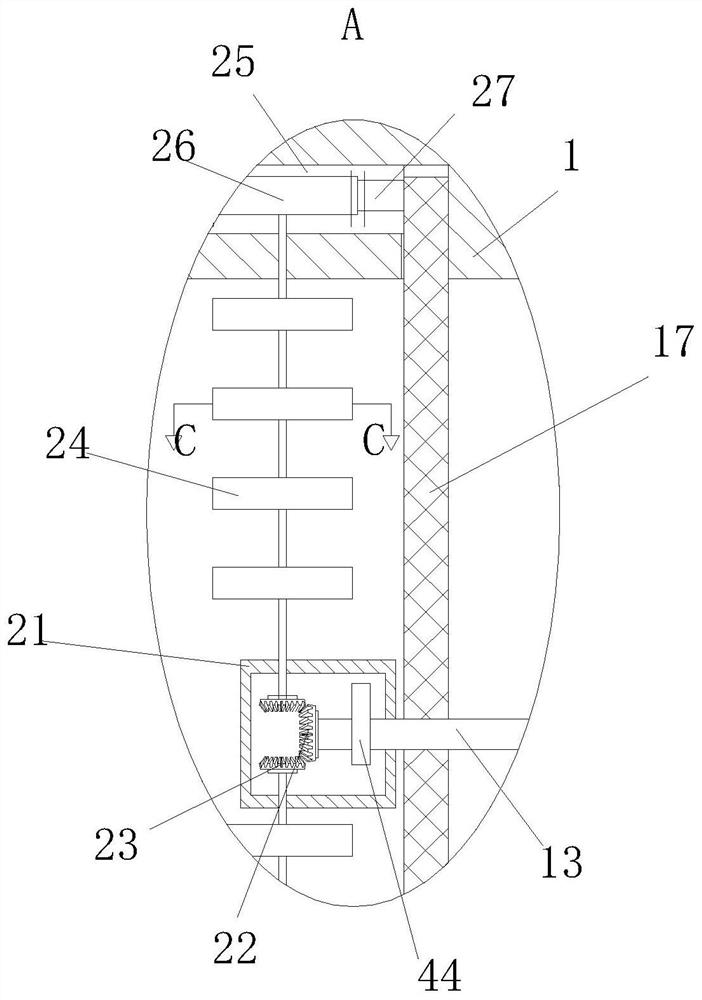

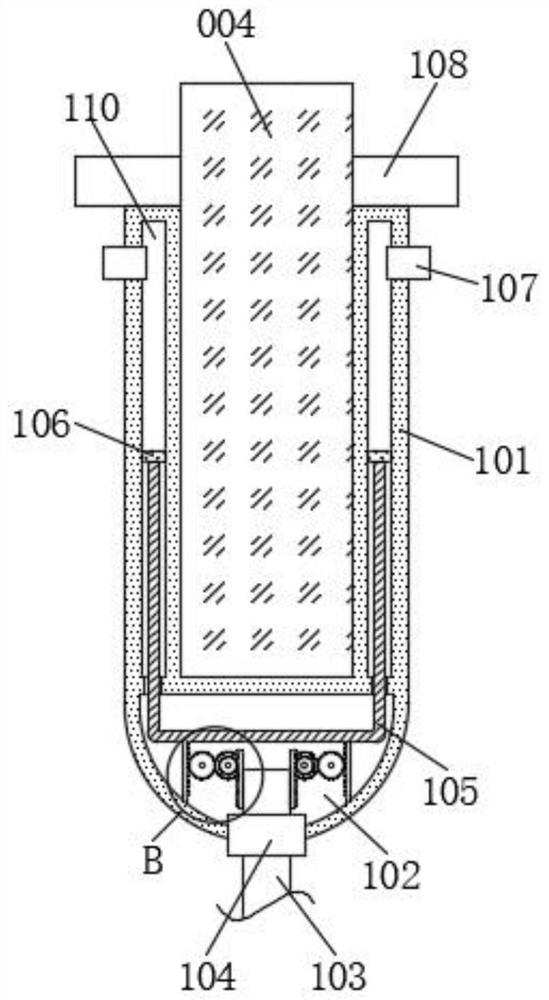

Small concrete compaction and curing slowing device used for experiment and its implementation method

PendingCN107639718AReduce noise pollutionReduce lossCeramic shaping plantsEngineeringExperimental methods

The invention relates to a small concrete compaction and curing slowing device used for an experiment. The device includes a vibration mechanism, a centrifugal mechanism, a curing slowing mechanism, amaterial loading and unloading mechanism and a clamping mechanism; the vibration mechanism is located on the outermost layer of the device, the centrifugal mechanism is located on the middle layer ofthe device, the curing slowing mechanism is located on the secondary inner layer of the device, and the material loading and unloading mechanism is located on the innermost layer of the device. The invention further discloses a concrete compaction and curing slowing method by means of the concrete compaction and curing slowing device. According to the small concrete compaction and curing slowingdevice used for experiment and its implementation method, solid compaction and curing slowing functions are both achieved, there is a big difference between the existing experimental method and corresponding instruments and the small concrete compaction and curing slowing device and its implementation method, the characteristics such as low noise, low loss, low splashing, disassembly, matching, uniform sample discharge and compaction in the compaction process of concrete are taken into consideration, and the device is very high in feasibility and practicability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

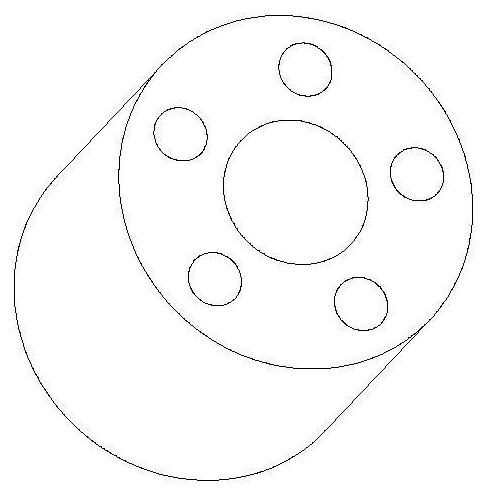

Eccentric vibration device of road roller and arranging structure thereof

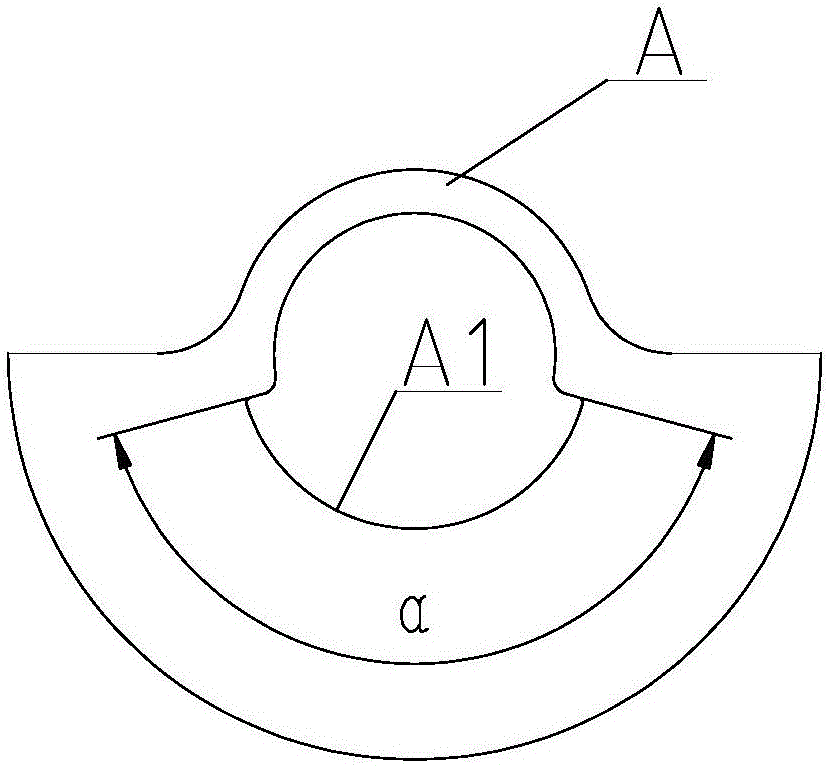

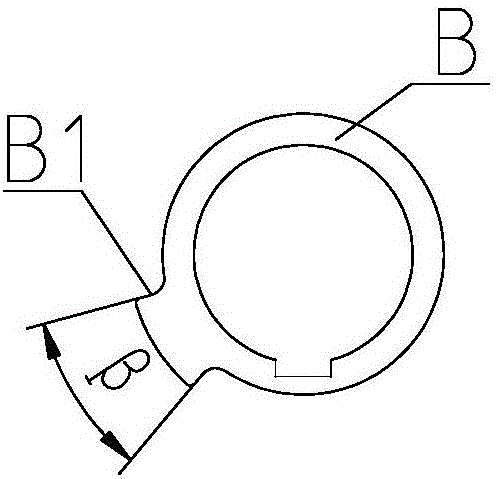

PendingCN106638238AReduce manufacturing difficultyReduce installation difficultyRoads maintainenceEngineeringStructural engineering

The invention relates to an eccentric vibration device of a road roller and an arranging structure thereof. The device comprises a vibration shaft and a movable eccentric block group, wherein the movable eccentric block group is arranged on the vibration shaft; the movable eccentric block group comprises movable eccentric blocks, limiting rings and fixing keys; the limiting rings are fixed to the vibration shaft through the fixing keys, limiting grooves being matched with limiting convex blocks on the limiting rings are formed in the movable eccentric blocks, and the central angles of the limiting grooves are equal to or larger than those of the limiting convex blocks; and when the central angles of the limiting grooves are larger than those of the limiting convex blocks, the limiting grooves are matched with the limiting convex blocks, so that when the vibration shaft positively rotates or negatively rotates, the movable eccentric blocks provided with two vibration limitation positions correspondingly. According to the eccentric vibration device of the road roller and the arranging structure thereof, structures of the movable eccentric blocks are greatly simplified, and manufacturing and installing difficulties of the eccentric blocks are lowered; and meanwhile, the movable eccentric blocks are integrally formed, thus the movable eccentric blocks are not prone to being damaged during using, and during working, stability and reliability are highly maintained.

Owner:合肥永安绿地工程机械有限公司

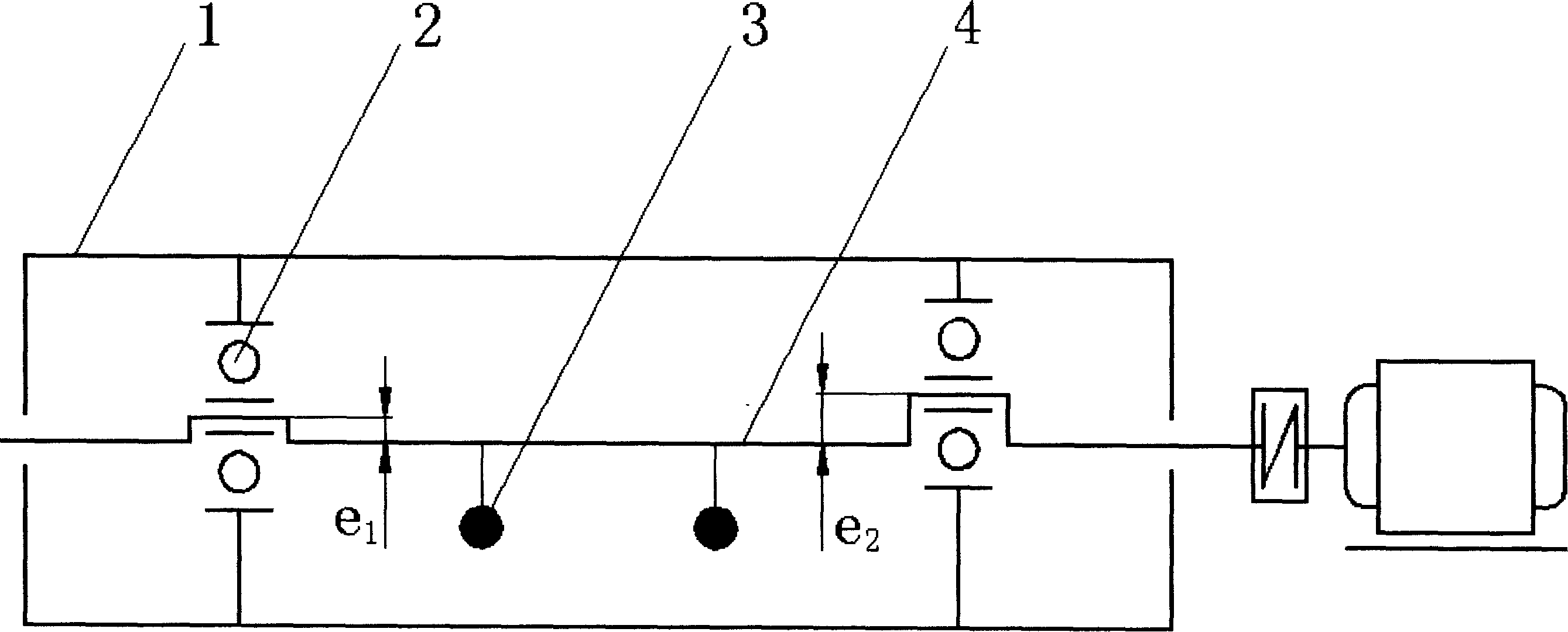

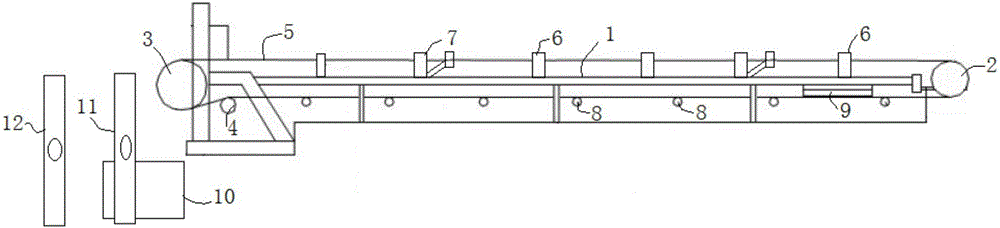

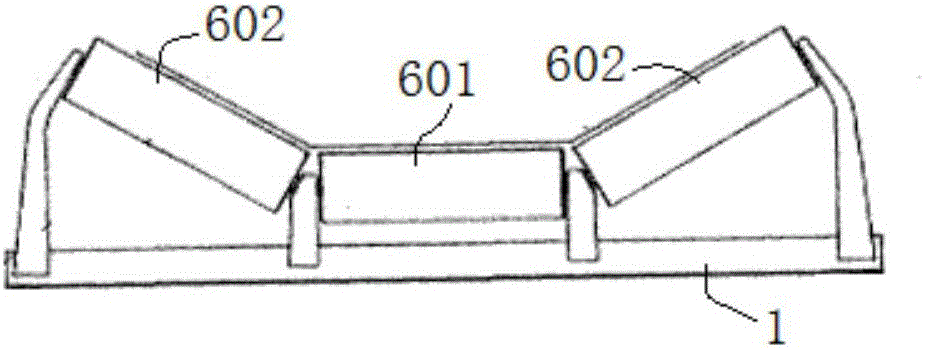

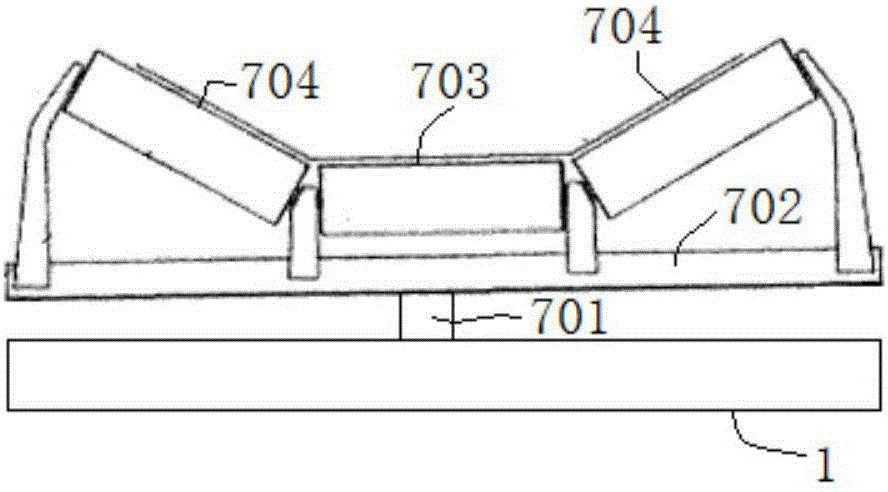

Belt conveying system for transportation of bulk materials

The invention discloses a belt conveying system for transportation of bulk materials, and belongs to the field of conveyers. The belt conveying system comprises a rack, and a driving head wheel and a driving tail wheel are arranged at the two ends of the rack respectively; a conveyer belt coats the driving head wheel and the driving tail wheel and conveys the materials around the driving head wheel and the driving tail wheel; the upper layer conveyer belt is supported by top carrier rollers; the lower layer conveyer belt is supported by bottom carrier rollers; the top carrier rollers comprise fixed carrier rollers and movable carrier rollers; a sweeper is arranged above the lower layer conveyer belt; the materials conveyed by the conveyer belt are collected by a material mover; and a primary material arranging device and a secondary material arranging device are sequentially arranged in the transportation direction of the material mover. According to the belt conveying system, flying dust can be decreased, the production environment is improved, material transportation efficiency is improved, and efficient and stable operation of the conveyers is guaranteed.

Owner:ANHUI TAIFU HEAVY IND MFG CO LTD

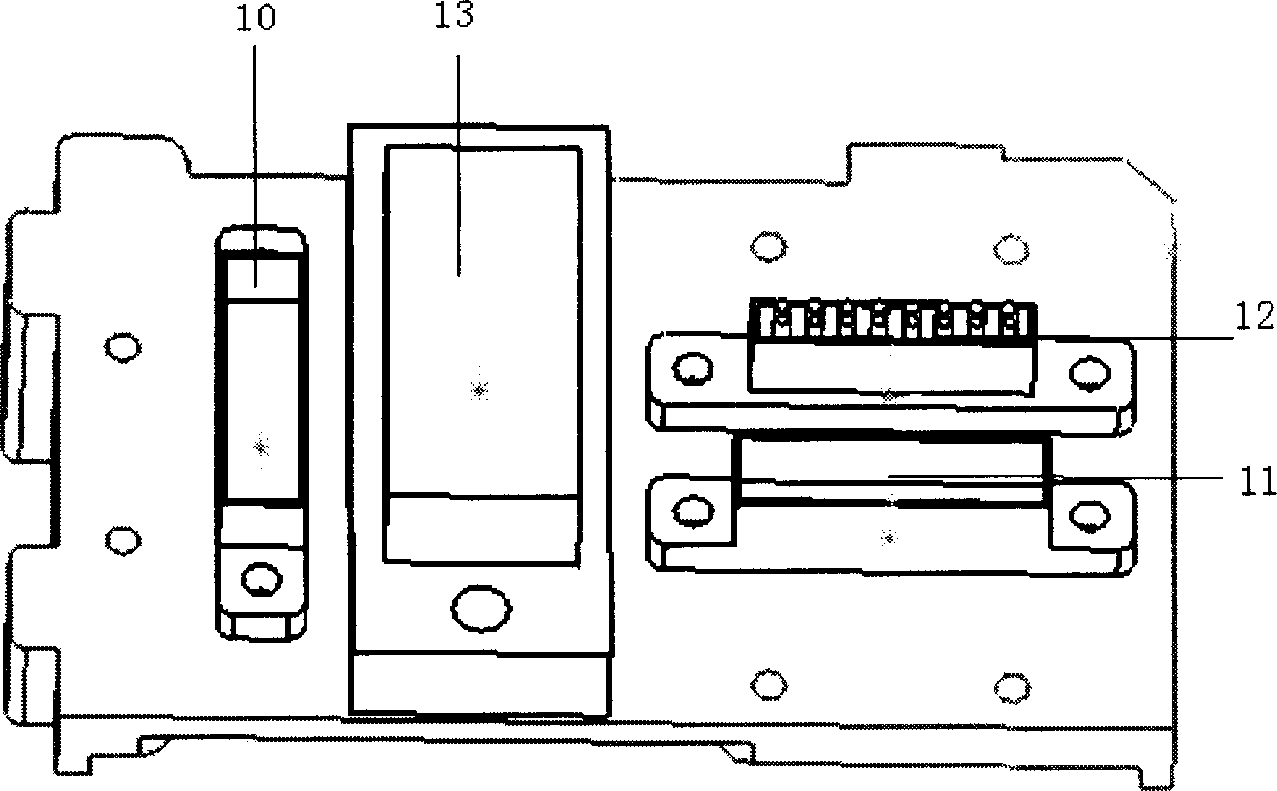

Light assembling structure for optical fiber gyro-space application

InactiveCN1888821AReduce volumeIncrease heat conduction areaSagnac effect gyrometersAttitude controlHeat resistance

Optical fiber peg-top space applied light combination structure has a perpendicular configuration reality and its side faces are vertical with the underside. The outside of two side faces and the inside of underside are the fixing plane to three peg-tops. The rest side faces use to fix the electrical source box and cube mirror. The three peg-tops are perpendicular setting, and the peg-top of x axis and y axis is fixed on the outside of the reality side faces, the peg-top of z axis is fixed on the inside of the reality underside. Their fixing surfaces contact completely to increase the heat exchange area of the peg-top to reduce the heat resistance effectively. The three joining pieces connecting with peg-tops fix on one joining piece plane and put the three joining piece planes into one to connect with the jack of the reality connecting with system. The three peg-tops can debug alone and this is fit for fixing and maintenance the optical fiber peg-top. It is suitable for the gesture controlling of the space aerocraft with small volume, light weight, little heat resistance, high reliability security, well diathermancy.

Owner:BEIHANG UNIV

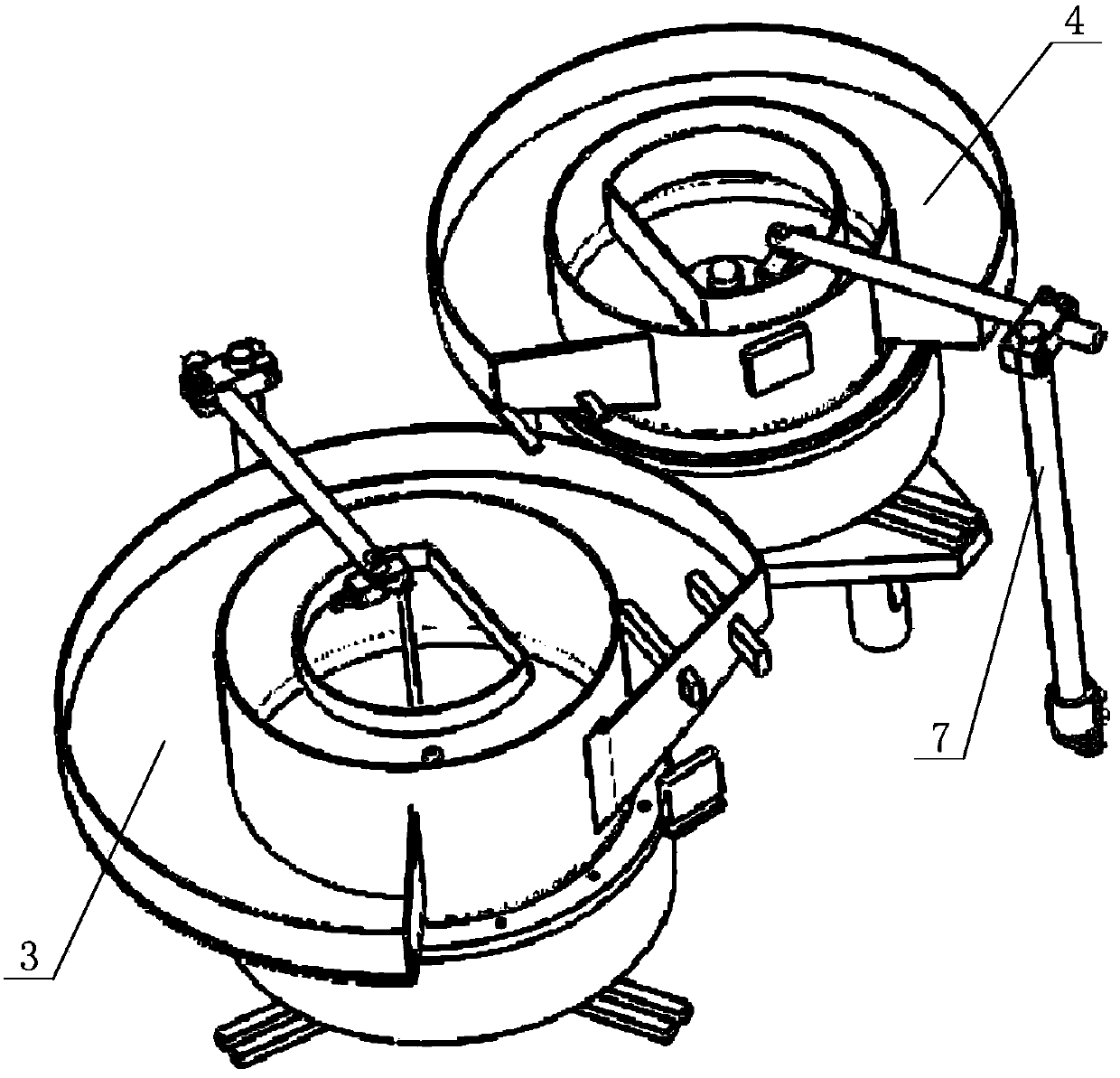

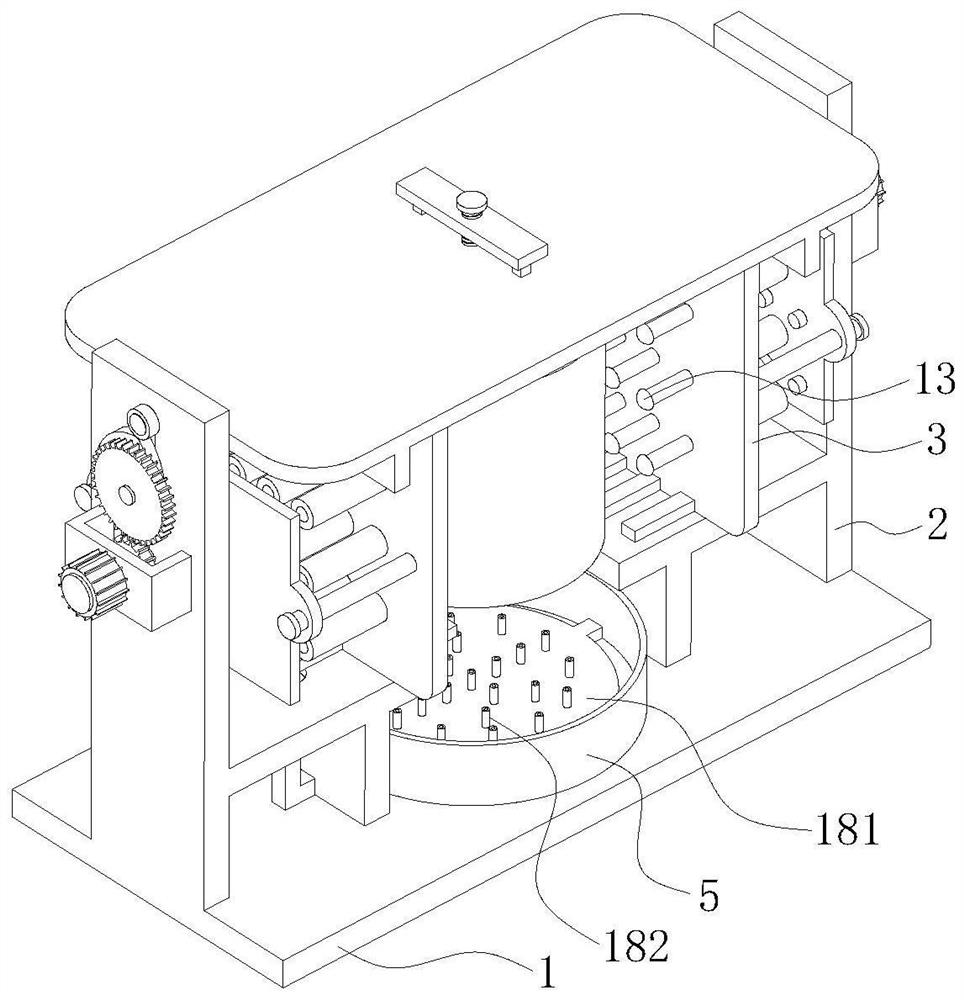

Vibration screening machine

ActiveCN108421704AImprove screening effectAct as a movement guideSievingScreeningRocker armEngineering

The invention discloses a vibration screening machine. Screening components comprises a round frame, a colliding spring, a baffle and a screening disc component, and the colliding spring, the baffle and the screening disc component are located in the round frame. One end of the colliding spring is fixed to the inner wall of the round frame in the radial direction of the round frame, and the baffleis arranged perpendicular to the bottom face in the round frame and can freely slide on the bottom face. A supporting plate is fixed to the upper end of a swing arm, and gear teeth of a gear are arranged on the arc edge of a lower end sector part. A colliding structure comprises an L-shaped rocker arm and a T-shaped movable rod, and a smooth cylinder is arranged at one end of the rocker arm. Thecylinder is detachably fixed into a strip-shaped groove in the rocker arm. The movable rod comprises a vertical rod section and a horizontal rod section. The vertical rod section is perpendicular to the middle of the horizontal rod section, and the vertical rod section is horizontally arranged and located in a pair of fixed guide blocks. A guide column on a rotary disc stretches into a strip-shaped penetrating hole. Sliding columns are arranged at the two ends of a gear rack, and the two sliding columns are located on shaft sleeves at the two ends of a base. The vibration screening machine isstable in structure, high in screening efficiency, good in effect and beneficial to use and popularization.

Owner:长兴县悦林废旧物资回收有限公司

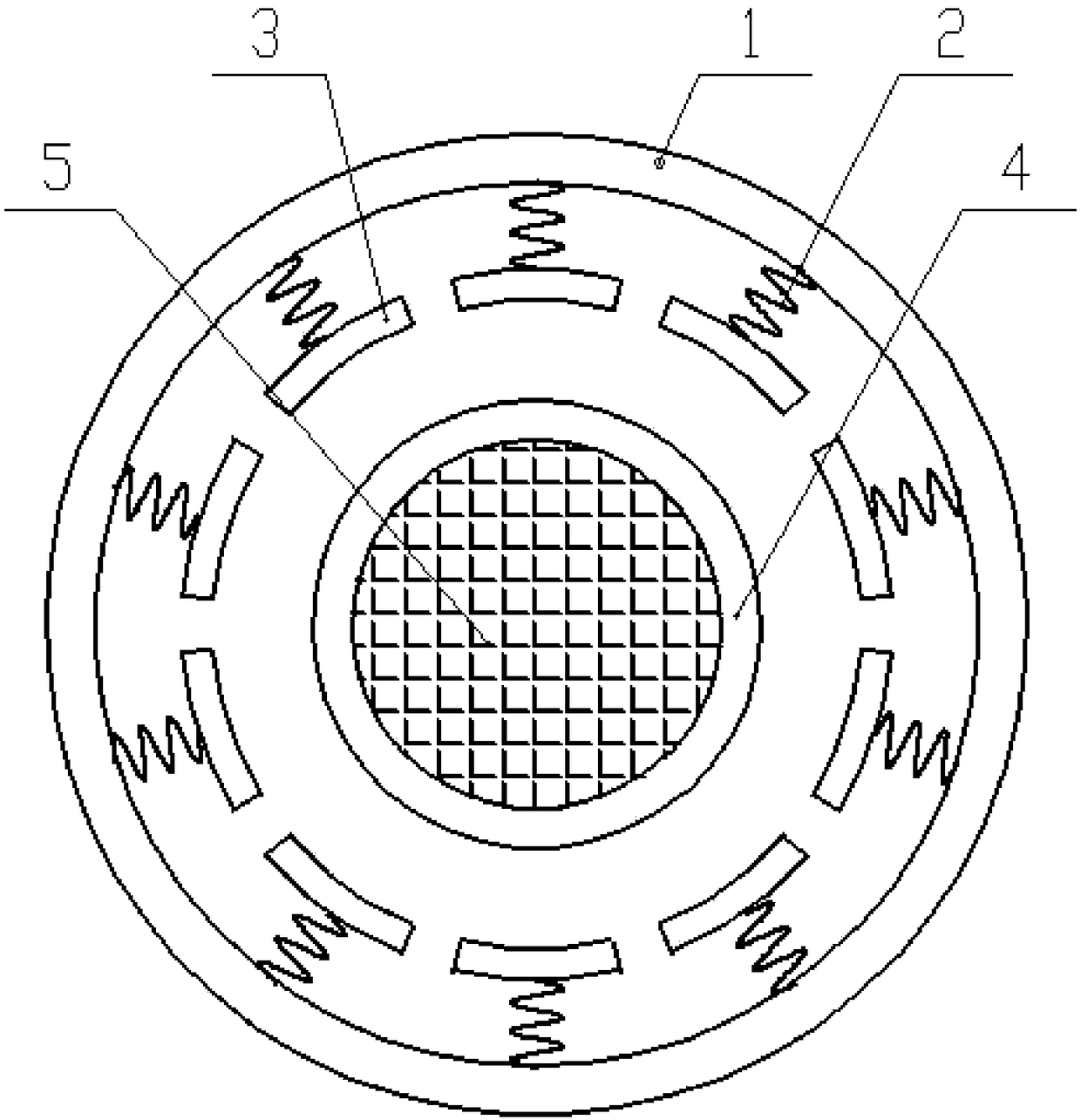

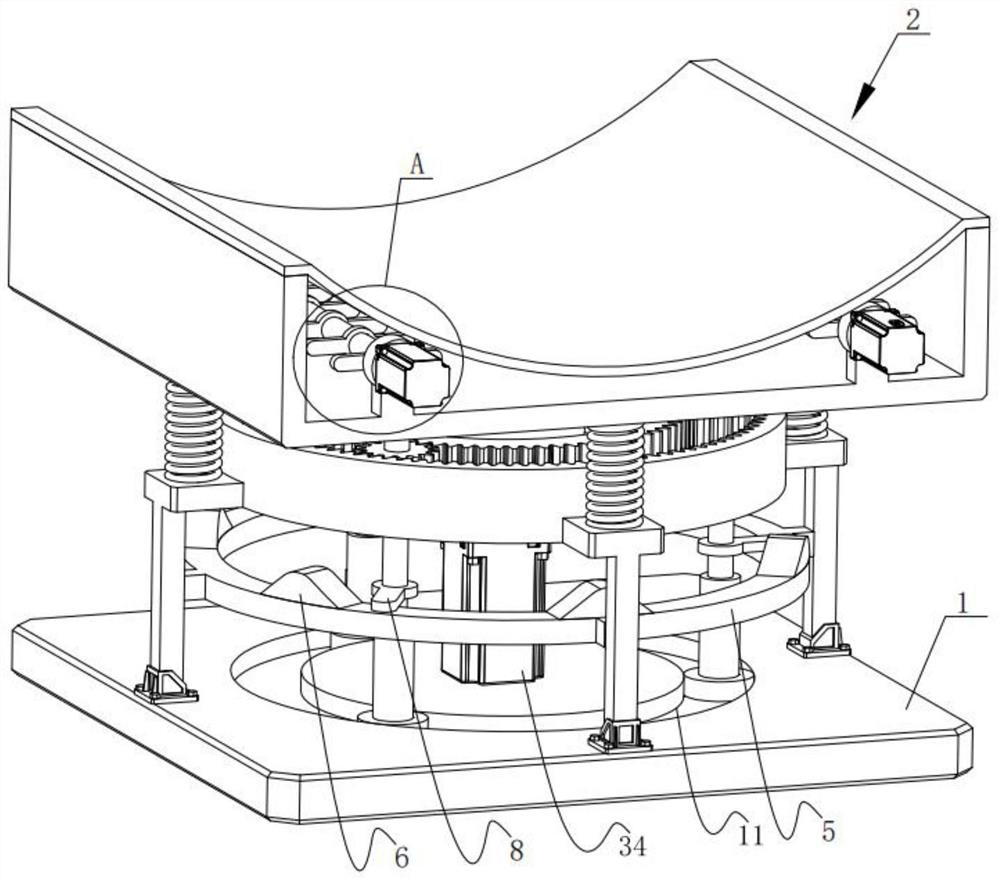

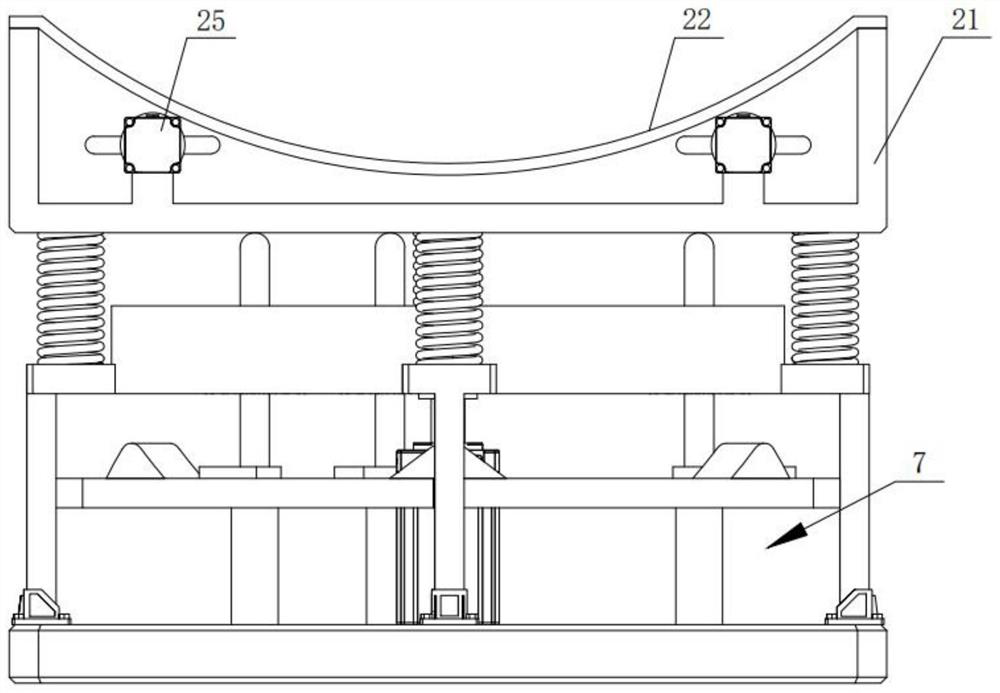

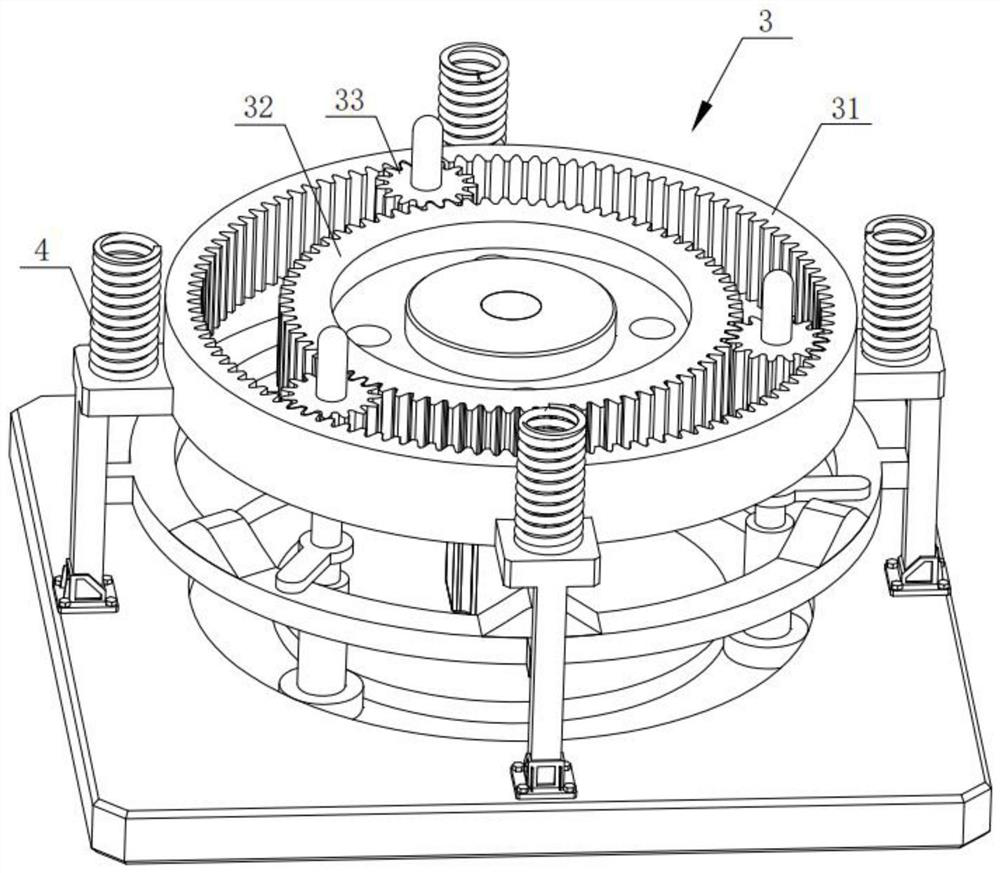

Flour processing vibrating screen

ActiveCN112474303AChange the direction of the shakeGuaranteed vibration effectSievingScreeningGear wheelEngineering

The invention provides a flour processing vibrating screen. The flour processing vibrating screen comprises a rack, a screening assembly, a planetary gear set, springs I, a circular ring, protruding parts, telescopic rod assemblies and baffles, wherein a supporting frame in the screening assembly is arranged on the planetary gear set through the springs I, a filter cloth type screen is arranged onthe supporting frame, the circular ring is located below the planetary gear set, the protruding parts are arranged on the upper end face of the circular ring, the telescopic rod assemblies movably installed in the planetary gear set in the axis direction of a revolution component, and the telescopic ends of the telescopic rod assemblies make contact with the bottom of the supporting frame. Through revolution of planet wheels in the planet gear set along the circle center of a sun wheel, when the baffles make contact with the protruding parts, the telescopic ends in the telescopic rod assemblies can be driven to ascend, then the supporting frame can be pushed to ascend, when the baffles break away from the protruding parts, the supporting frame descends, then cyclic rotation can drive thescreening assembly to shake, and the position of the telescopic ends relative to the supporting frame is changed constantly, so that the shaking direction is correspondingly changed, and the vibrationeffect is guaranteed.

Owner:安徽德鑫源食品有限公司

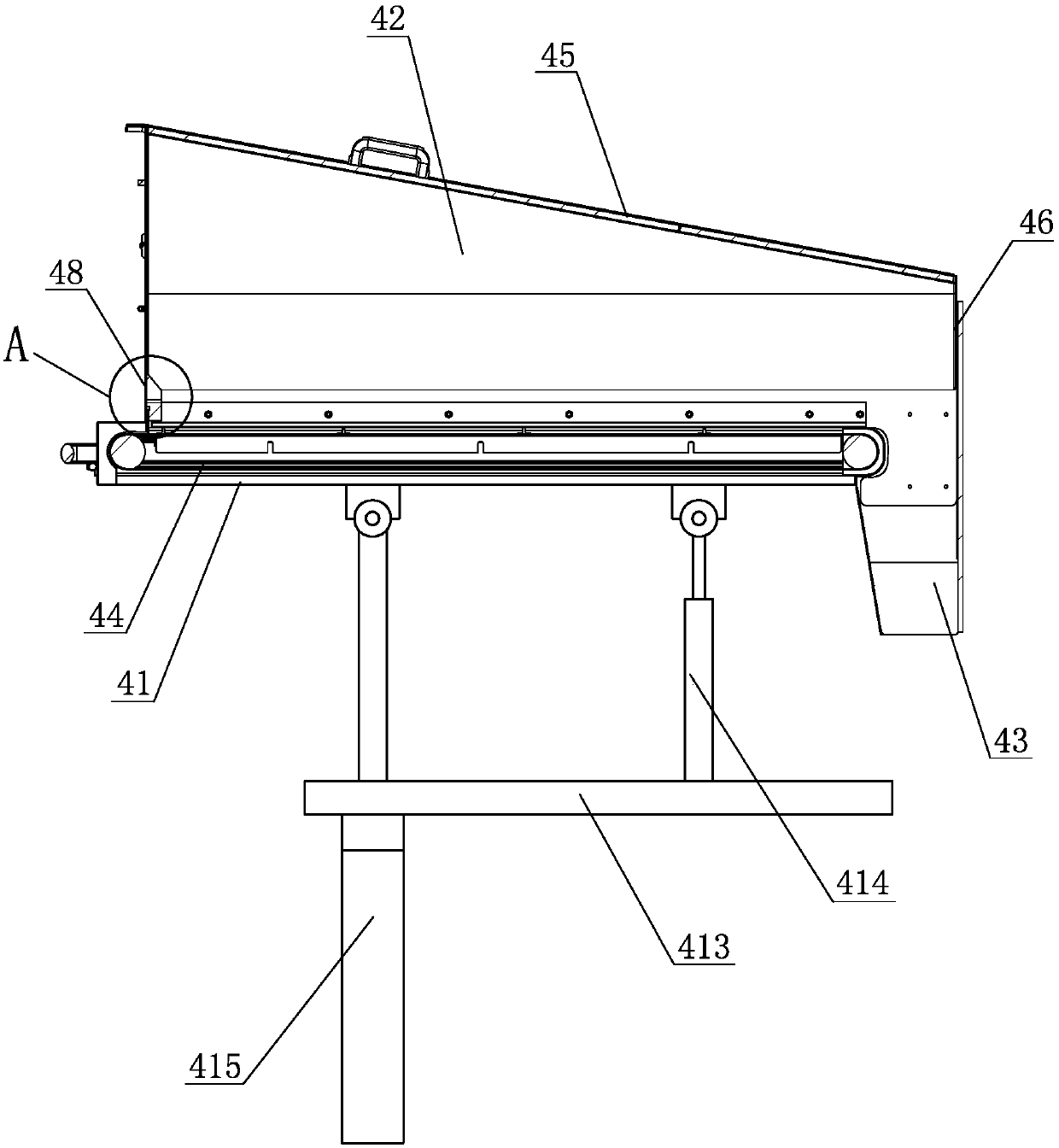

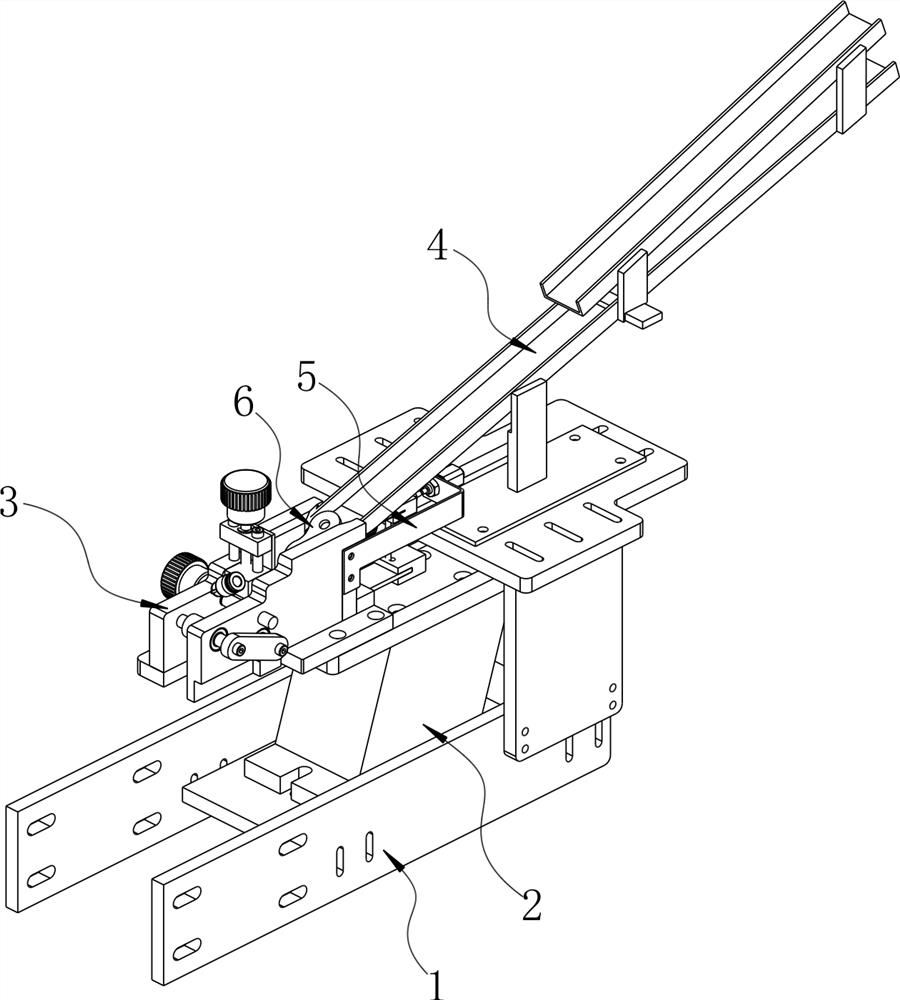

Automatic feeding equipment

PendingCN107720179AReduce occupancyImprove feeding efficiencyCleaningLoading/unloadingMechanical engineeringElectrical and Electronics engineering

Owner:SUZHOU ITS IND TRANSFER SYST CO LTD

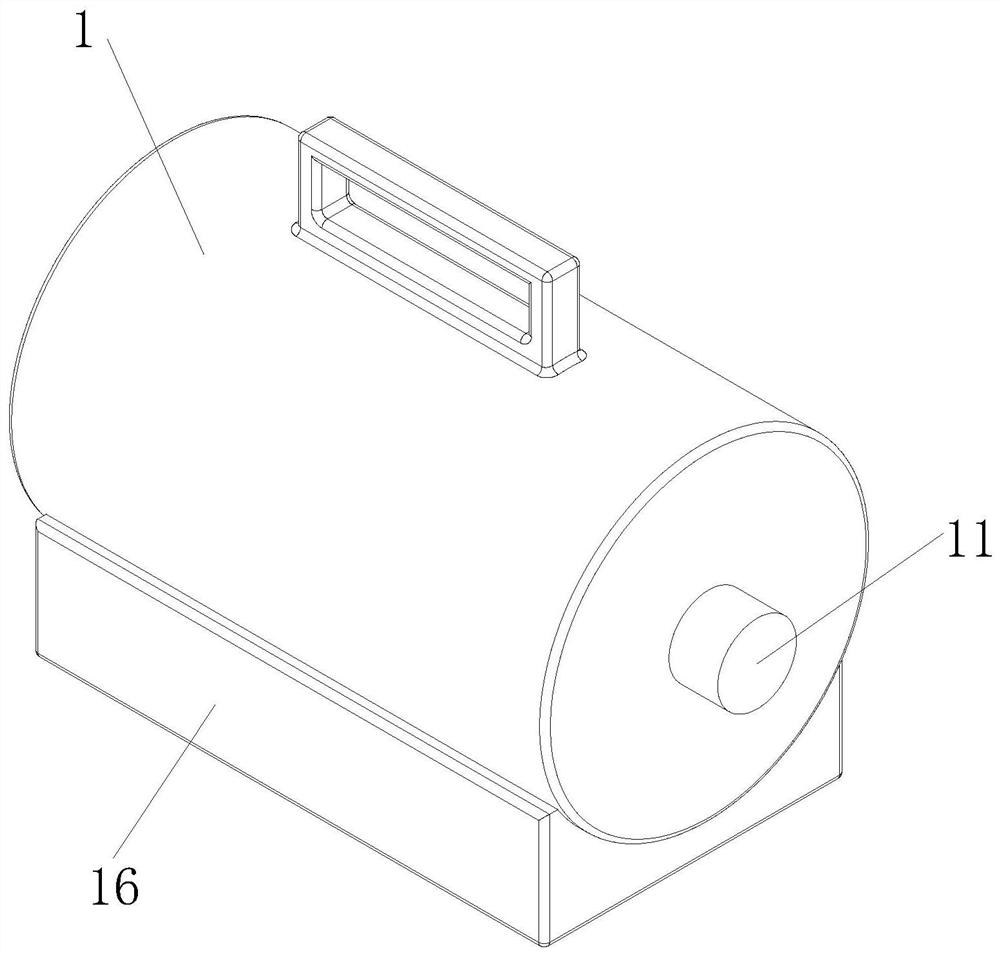

Plasma wind dust removal and disinfection device

ActiveCN113294867AQuality assuranceImprove working environmentMechanical apparatusLighting and heating apparatusUv disinfectionDust control

The invention belongs to the technical field of air purification, and particularly relates to a plasma wind dust removal and disinfection device. The device comprises a box body. The side wall of one side of the box body is in an opening state, and an air outlet is formed in the other side of the box body. A motor is fixedly connected to the inner wall of the box body through a fixing column, and a first rotating shaft is fixedly connected to the output end, facing the opening of the box body, of the motor. A group of fan blades are fixedly connected to the first rotating shaft. The inner wall of the box body is fixedly connected with a group of plasma metal plates. The plasma metal plates are positioned between the motor and the air outlet. An annular groove is formed in the inner wall of the opening of the box body, and a filter screen is rotatably connected into the annular groove. The plasma wind dust removal and disinfection device solves the problems that an ozone disinfection method or an ultraviolet disinfection method is generally adopted for indoor air disinfection, a traditional method is low in disinfection speed and high in energy consumption, and secondary pollution exists.

Owner:安徽中科大禹科技有限公司

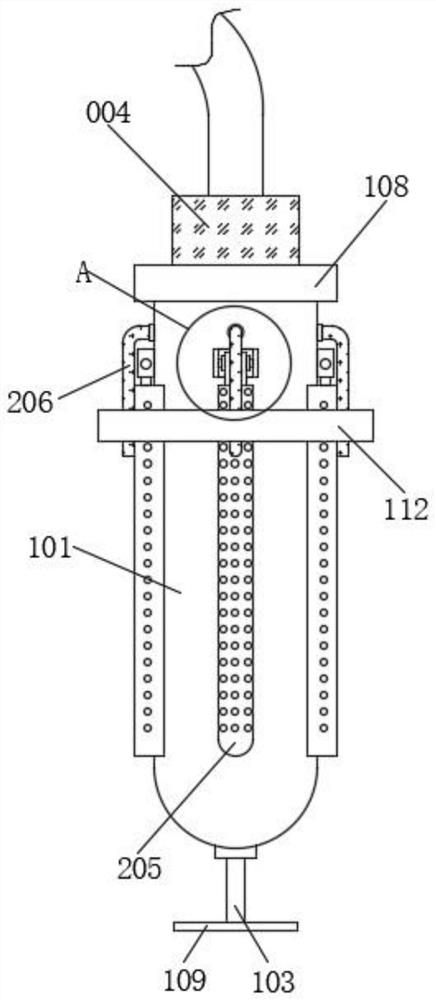

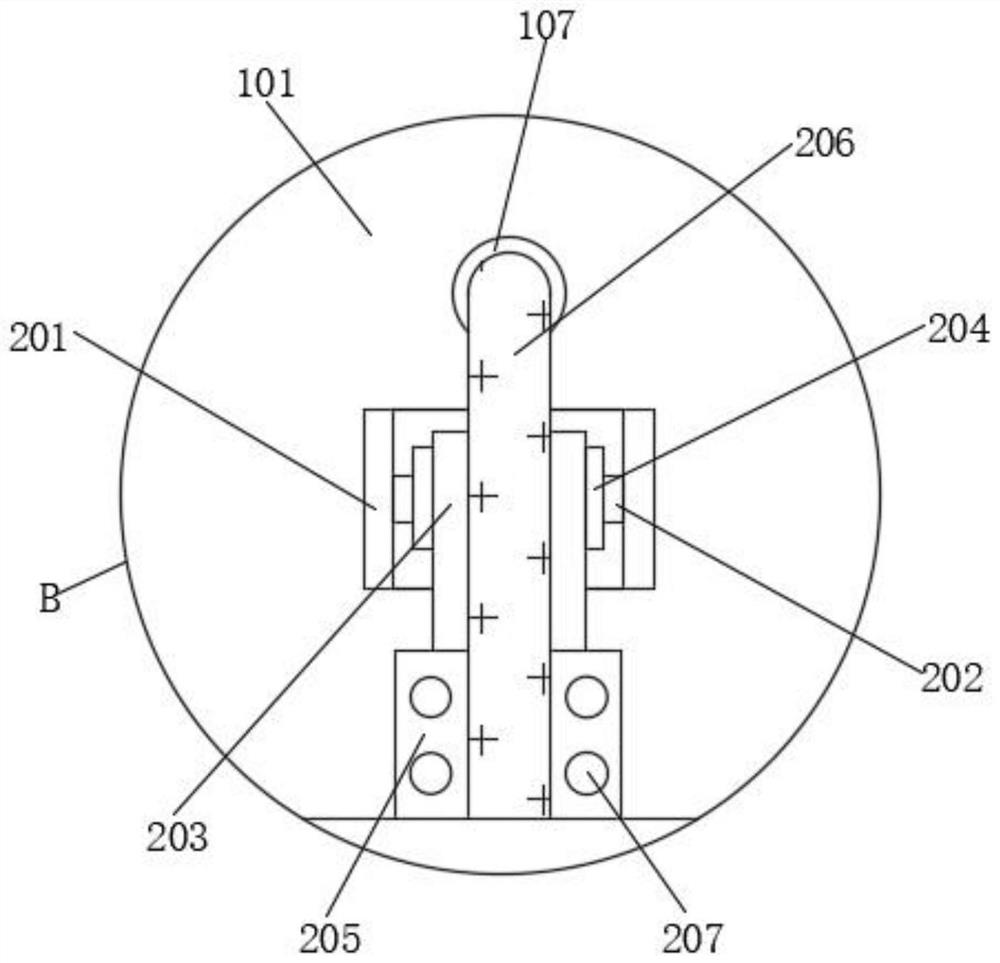

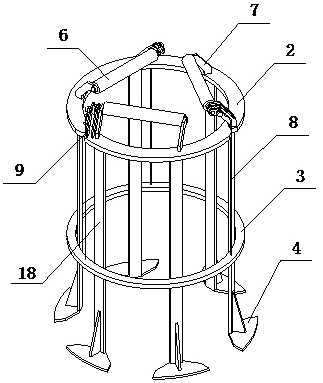

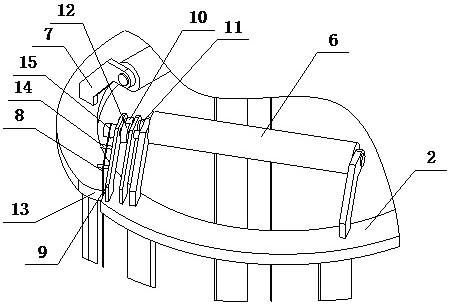

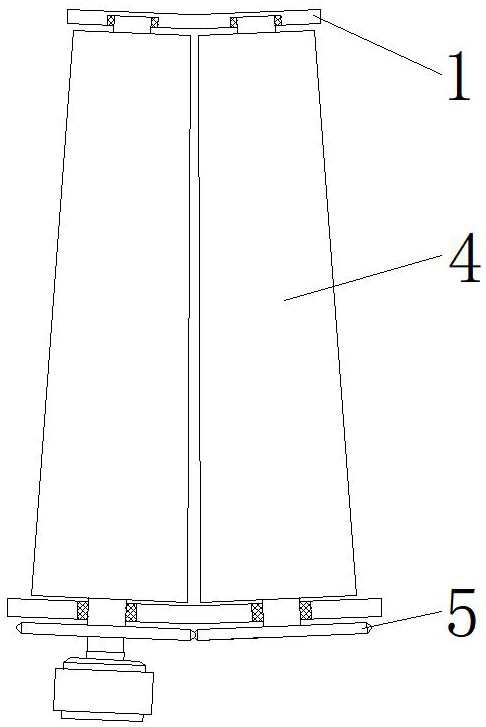

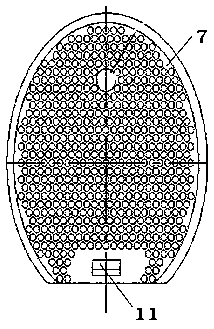

Self-unfolding and self-gathering vibrating type vibrating rod for concrete construction

InactiveCN112412048AIncreased vibration rangeReduce space areaEngine sealsFoundation engineeringStructural engineeringMechanical engineering

The invention discloses a self-unfolding and self-gathering vibrating type vibrating rod for concrete construction, belongs to the technical field of concrete construction, and can realize that underthe linkage of a variable-speed linkage assembly, a driving rod moves up and down relative to a connecting sleeve to drive an annular piston to move up and down, and the annular piston moves upwards to extrude air into a strip-shaped balloon. When the vibrating rod is inserted into concrete, the strip-shaped balloon tends to be horizontally stretched, so that the self-unfolding vibration plate isdriven to be unfolded outwards, when the vibrating rod is inserted into the concrete, the self-unfolding vibration plate can be automatically unfolded, the vibration range of the vibrating rod is effectively enlarged, the vibrating efficiency is improved, and when the vibrating rod is pulled out after vibrating is completed, the self-unfolding vibrating plate can be automatically folded, the spacearea formed when the vibrating rod is drawn out is reduced, then the proper construction amount is guaranteed, the vibrating efficiency and the construction quality can be considered, and on the premise that the construction quality is guaranteed, the vibrating efficiency is effectively improved, and the practicability is remarkably improved.

Owner:张光强

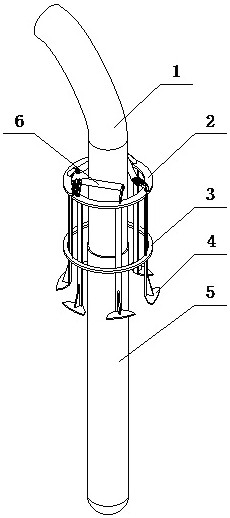

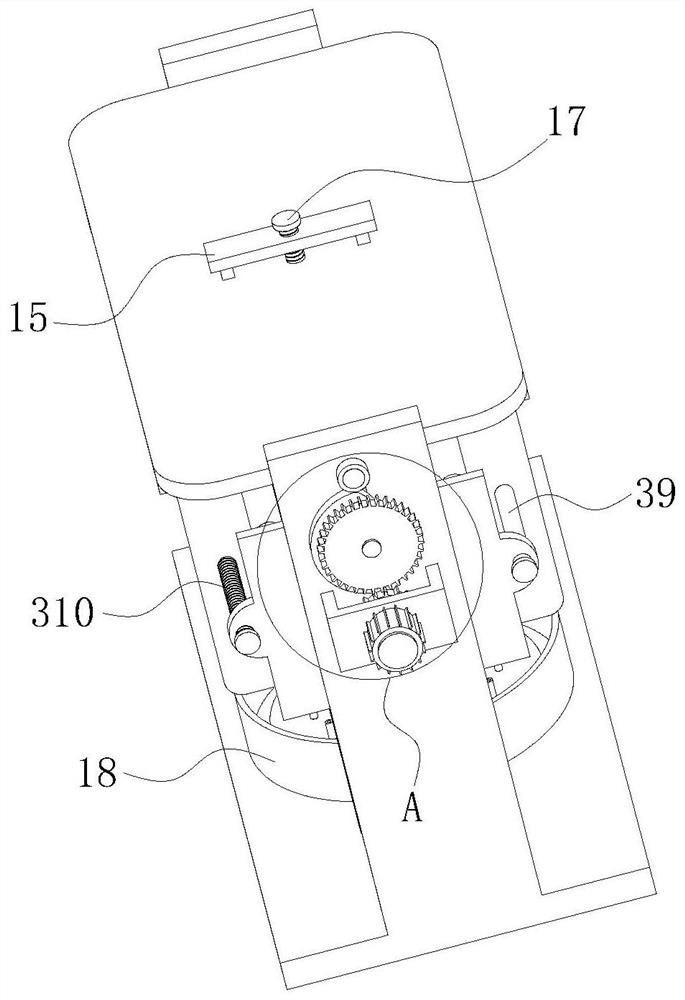

Concrete vibrating rod inserting and pulling speed regulating device for building construction

InactiveCN112160603AReduce the difficulty of operationAvoid skewBuilding material handlingRatchetArchitectural engineering

The invention relates to a concrete vibrating rod inserting and pulling speed regulating device for building construction, and discloses a speed regulating device. The speed regulating device regulates the inserting and pulling speed of a vibrating rod through a ratchet wheel and pawl structure, can form angle guide when the vibrating rod is inserted, and is characterized in that a supporting plate is of an annular plate-shaped structure, one ends of multiple connecting plates are connected with the bottom of the supporting plate at equal angles, the other ends of the connecting plates extenddownwards, bottom supporting feet are arranged at the other ends of the connecting plates, reinforcing ribs are arranged between the bottom supporting feet and the connecting plates, a balance weightring is located below the supporting plate and close to the other ends of the connecting plates, and at least three fixing frames are arranged on the supporting plate at equal angles; and the fixing frames are composed of two fixing plates, one ends of the fixing plates are fixedly connected with the top of the supporting plate, the other ends of the fixing plates extend obliquely upwards close tothe center line of the supporting plate, guide rollers are arranged on the fixing frames through roller shafts, a plurality of anti-skid strips are arranged on the guide rollers, and ratchet wheels are arranged at the positions, close to a supporting frame, of the roller shafts.

Owner:徐州易尚饰家装饰工程有限责任公司

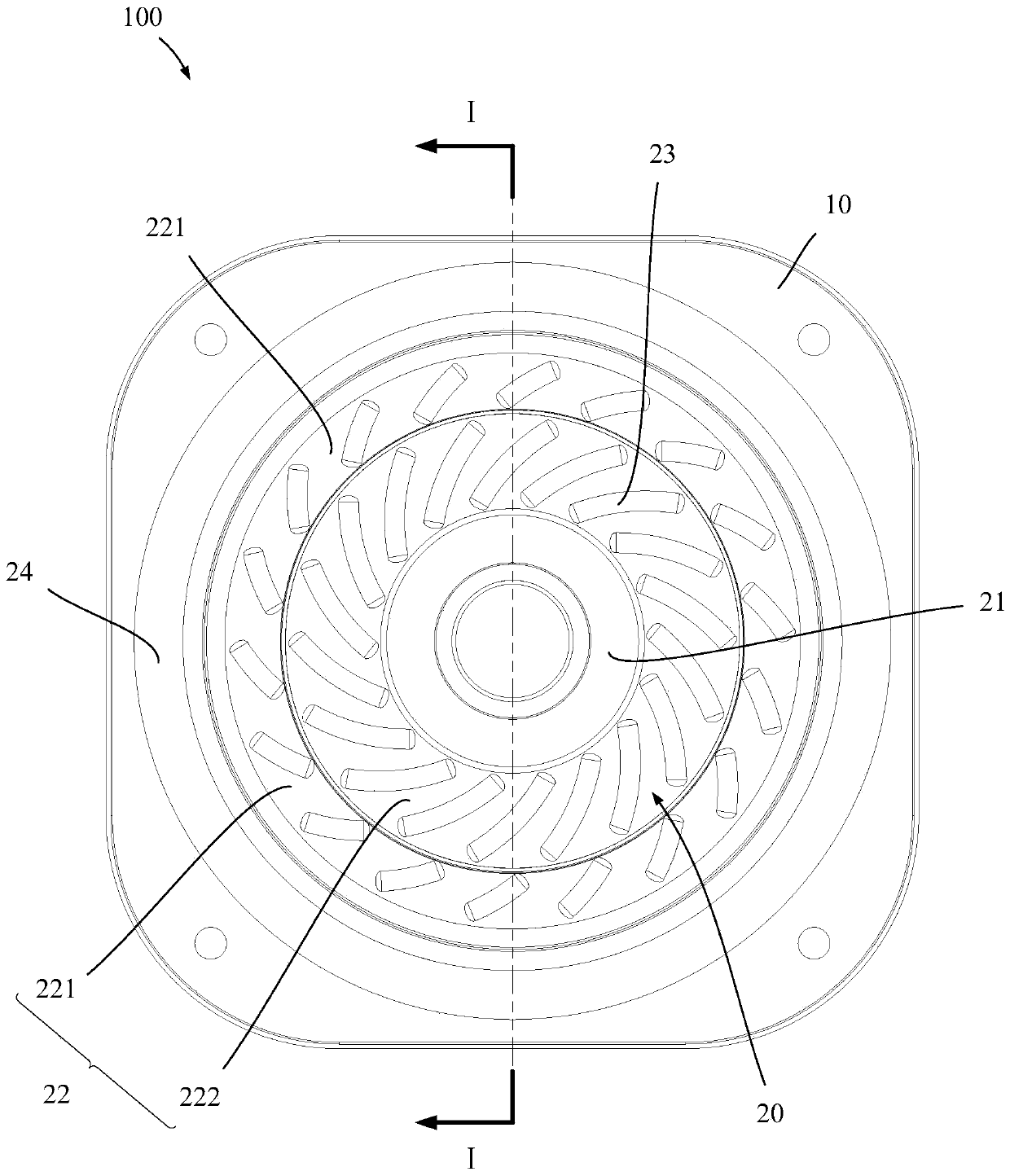

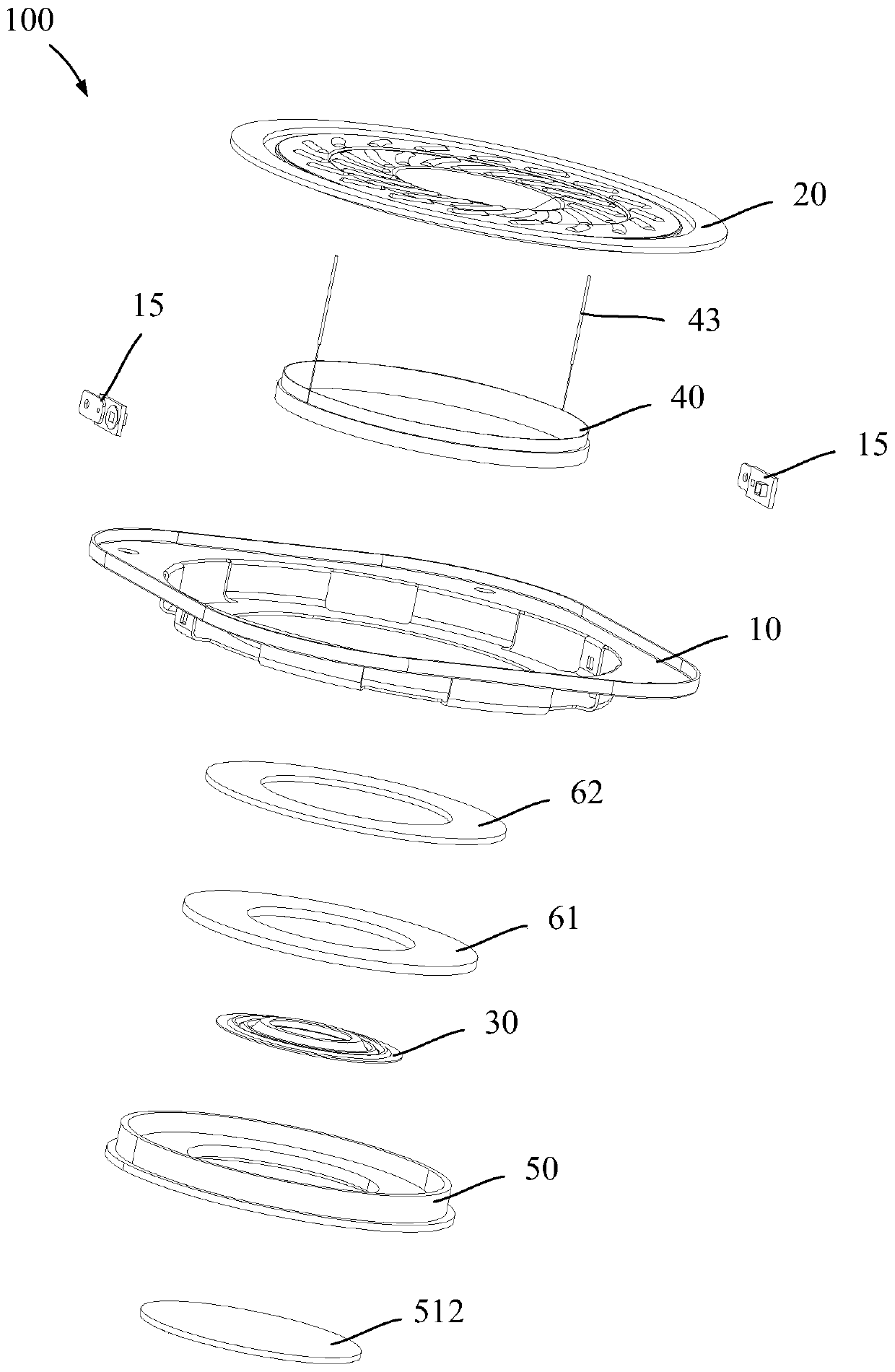

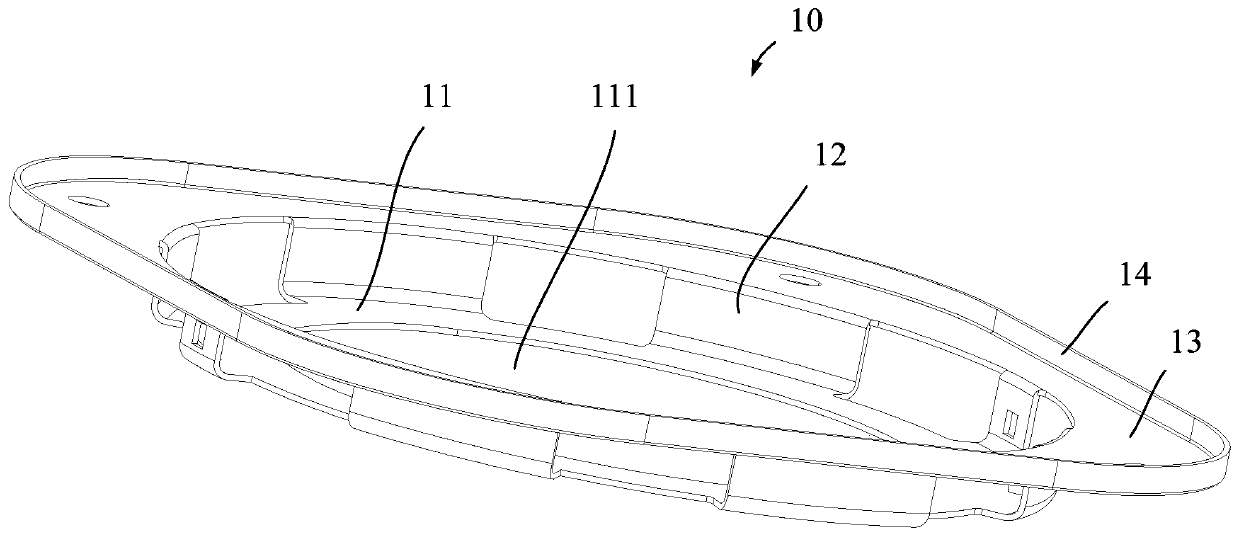

Loudspeaker and audio device

ActiveCN110366080AGuaranteed vibration effectEnhanced interactionElectrical transducersLoudspeakersEngineeringMaximum amplitude

Owner:GOERTEK INC

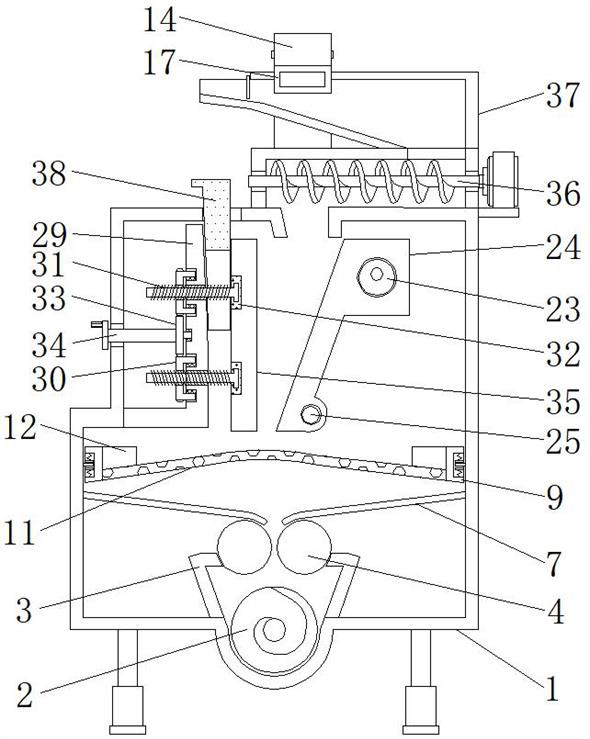

Knocking device for fiber bar stocks

The invention provides a knocking device for fiber bar stocks. The knocking device comprises a motor, a transmission gear, a cam, a driven wheel, a rocker and a knocking hammer. The motor is driven through the transmission gear, the cam is movably connected with a side plate of an arranging box through a bearing, and mutually matched with the driven wheel. The driven wheel is arranged in the middle of the rocker which is hinged to the side plate of the arranging box, and the lower end of the rocker is provided with the knocking hammer. According to the arrangement, when an arranging roller stirs and arranges the bar-shaped fibers, the arranging box is knocked continuously by the knocking device added on the knocking device for the fiber bar stocks so as to vibrate the bar-shaped fibers inside the arranging box; under the comprehensive action of vibrating and stirring arrangement, compactness of the bar-shaped fibers can be achieved, gaps among the bar-shaped fibers can be reduced as far as possible, so that the bar-shaped fibers can be arranged compactly and neatly, requirements of subsequent packing are met, and packing efficiency of the bar-shaped fibers can be effectively improved.

Owner:HENAN HAITIAN AUTOMATION SYST

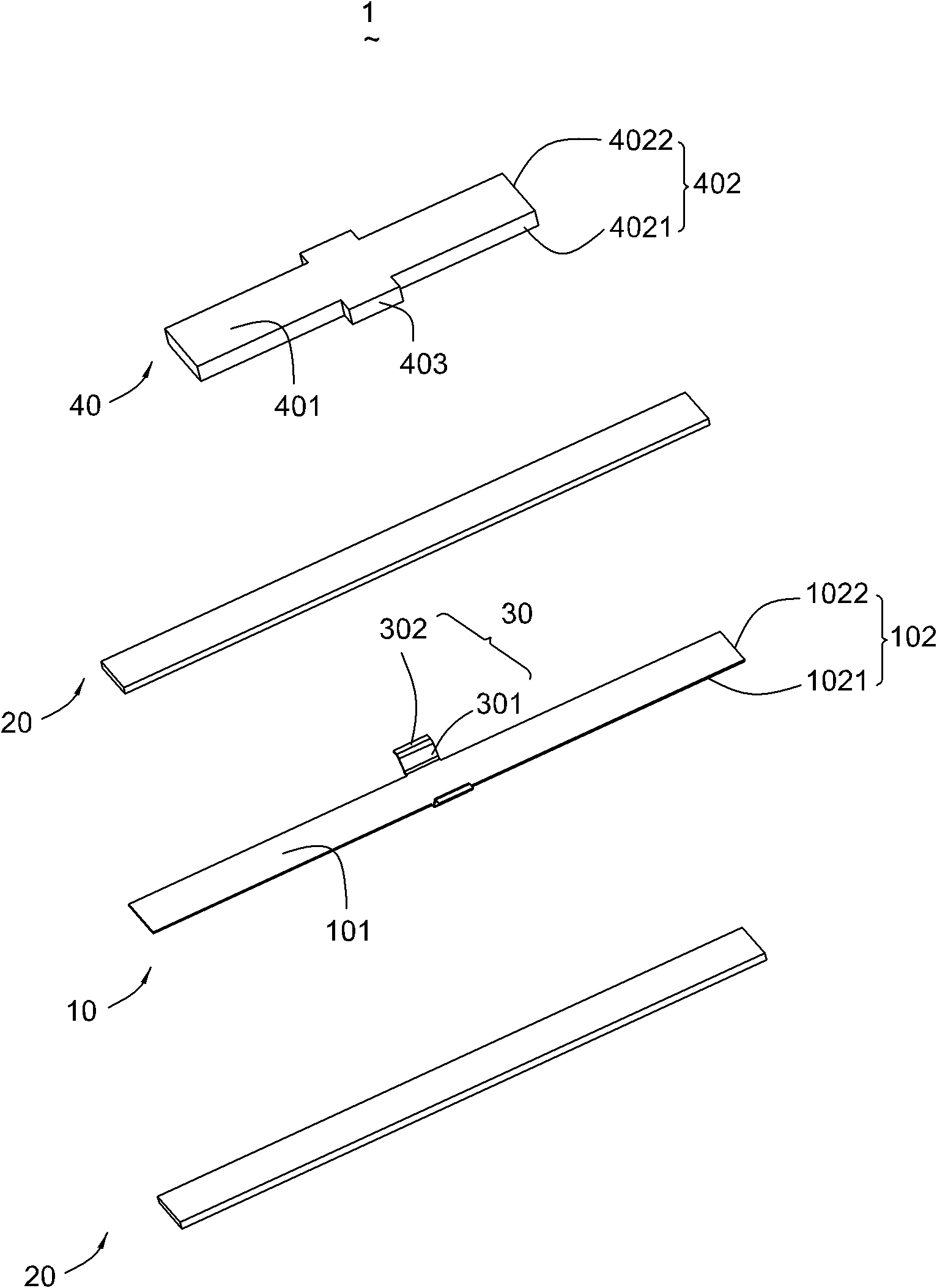

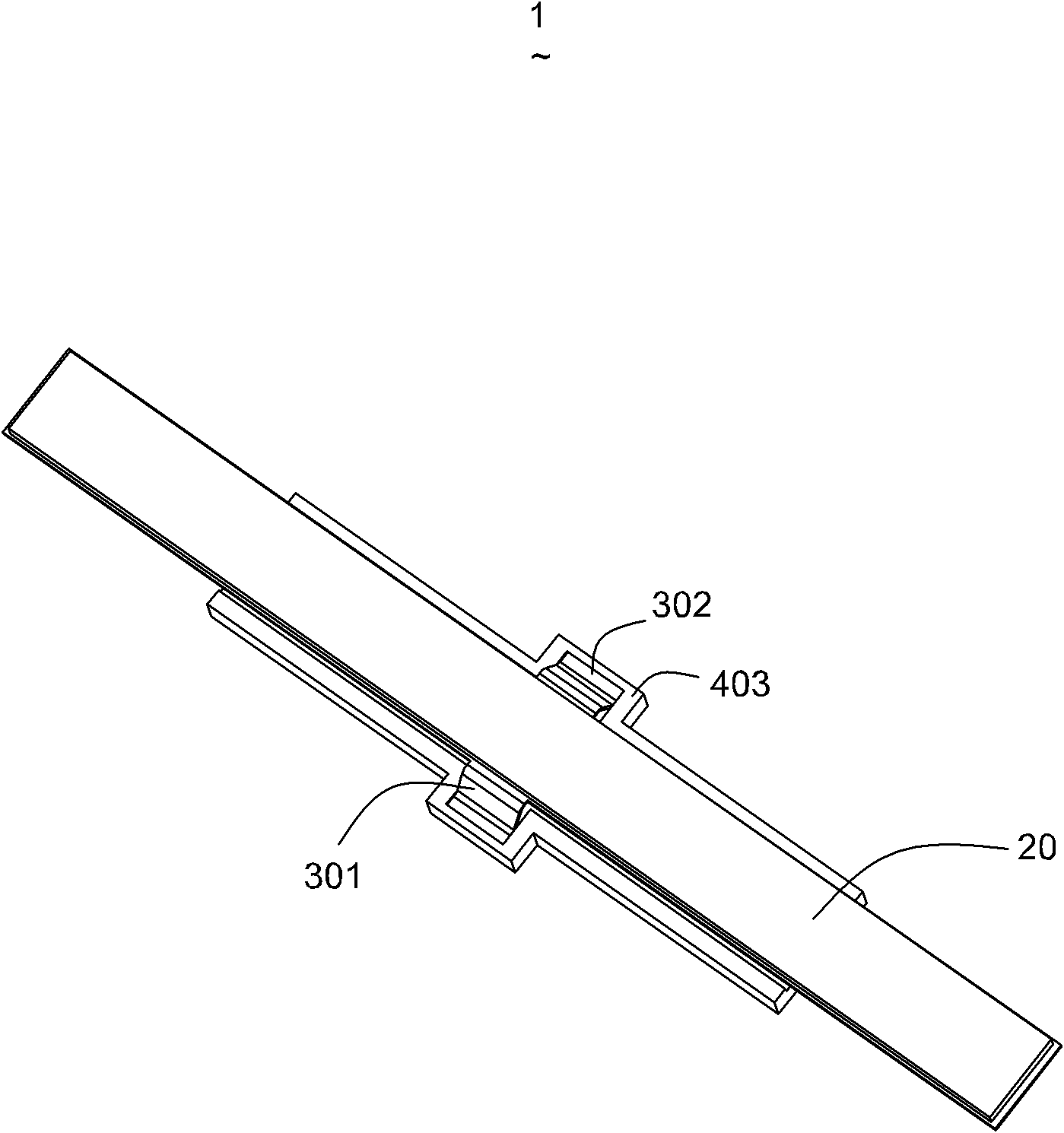

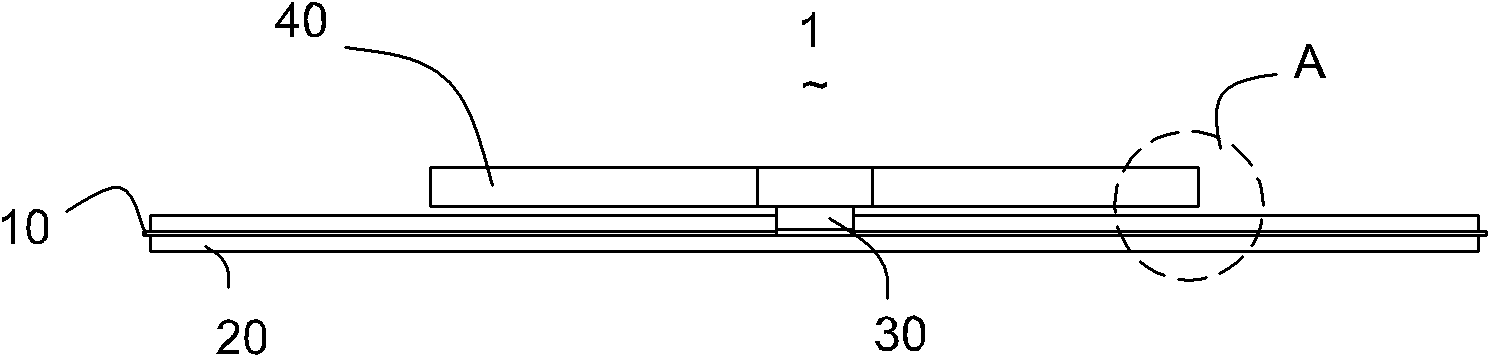

Piezoelectric vibrator

InactiveCN102045038AGuaranteed vibration stabilityGuaranteed vibration effectImpedence networksPiezoelectric actuatorsPiezoelectric generator

The invention discloses a piezoelectric vibrator. The piezoelectric vibrator comprises a substrate, piezoelectric sheets, a self-extending supporting sheet and a mass block, wherein the piezoelectric sheets are placed on the two sides of the substrate; and the mass block is placed on the supporting sheet and has a certain distance with the piezoelectric sheets. The piezoelectric vibrator has high stability.

Owner:AAC TECH PTE LTD

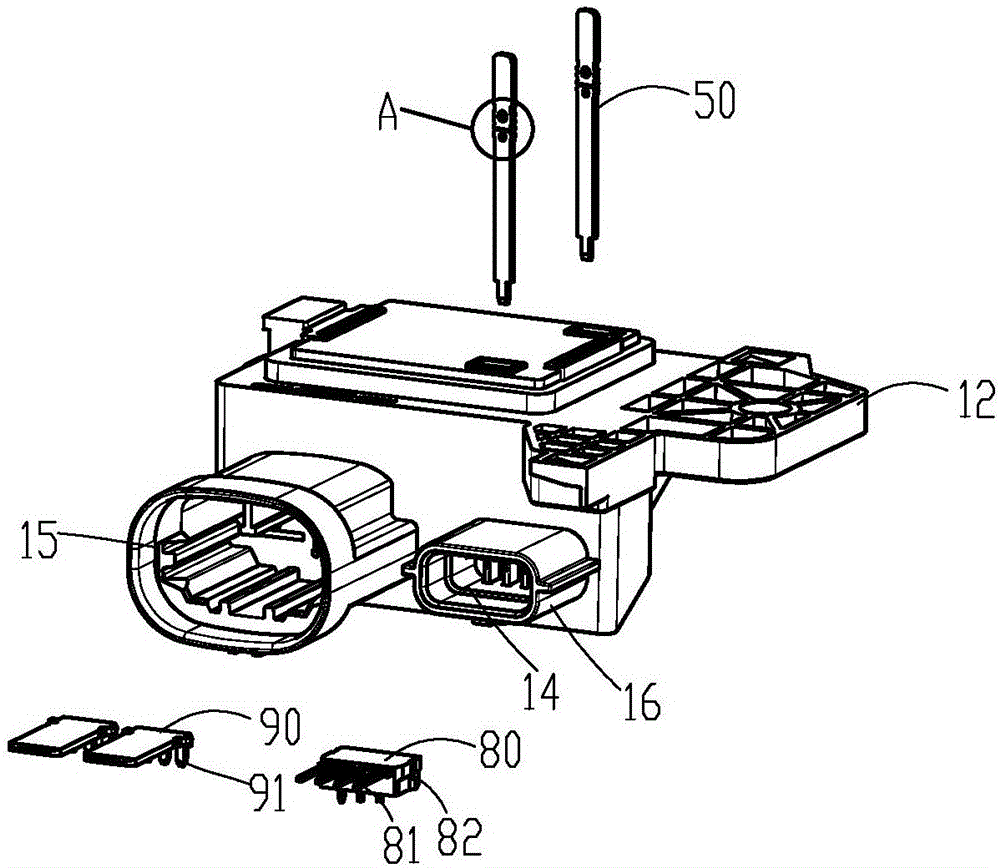

Integrated ceramic resistor relay box

ActiveCN106558465AGuaranteed sealing and vibration performanceConvenient production lineElectric switchesEmergency protective devicesThermal cutoffInjection moulding

An integrated ceramic resistor relay box comprises housing and an electromagnetic relay set located in the housing, a PCB, a ceramic resistor, a thermal fuse and two metal conductive connection sheets. The electromagnetic relay is welded on the PCB, the ceramic resistor is fixed on the housing, one ends of the metal conductive connection sheets are respectively electrically connected with one end of the ceramic resistor and one end of the thermal fuse, the other ends of the metal conductive connection sheets are connected with the PCB, and the integration injection moulding assembling is employed between the two metal conductive connection sheets and the housing; and the other end of the thermal fuse is electrically connected with the other end of the ceramic resistor. The integrated ceramic resistor relay box employs the integration design of employing the ceramic resistor to integrate the electronic devices such as the electromagnetic relay set and the thermal fuse to miniaturize the products and improve the product reliability; and a simple and reliable installation structure is employed between each part to improve the production efficiency.

Owner:XIAMEN HONGFA AUTOMOTIVE ELECTRONICS

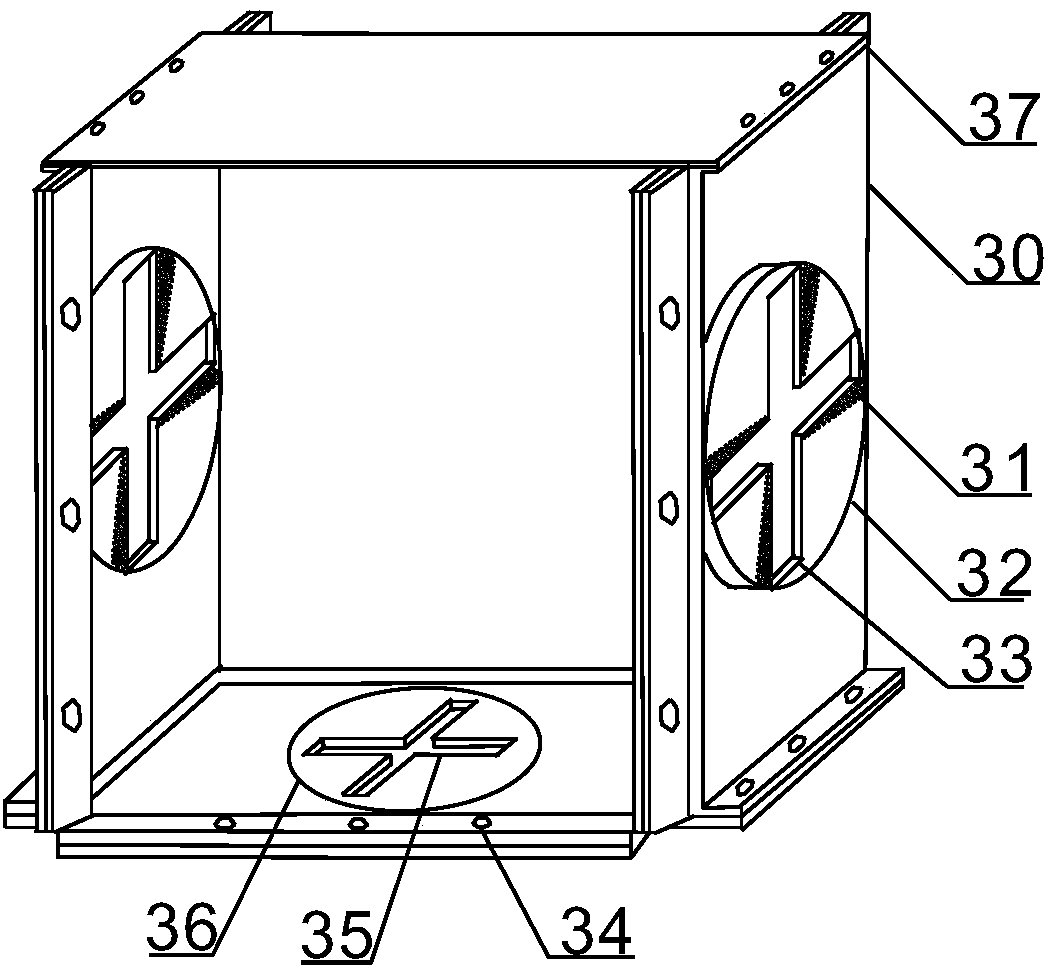

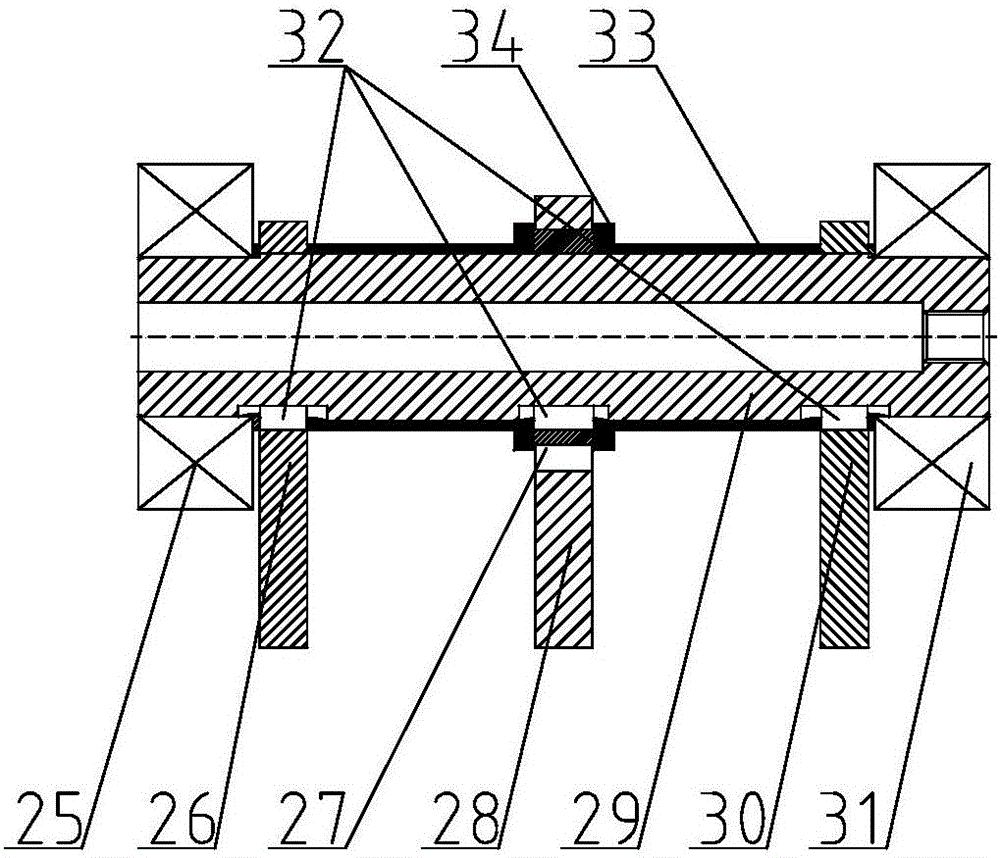

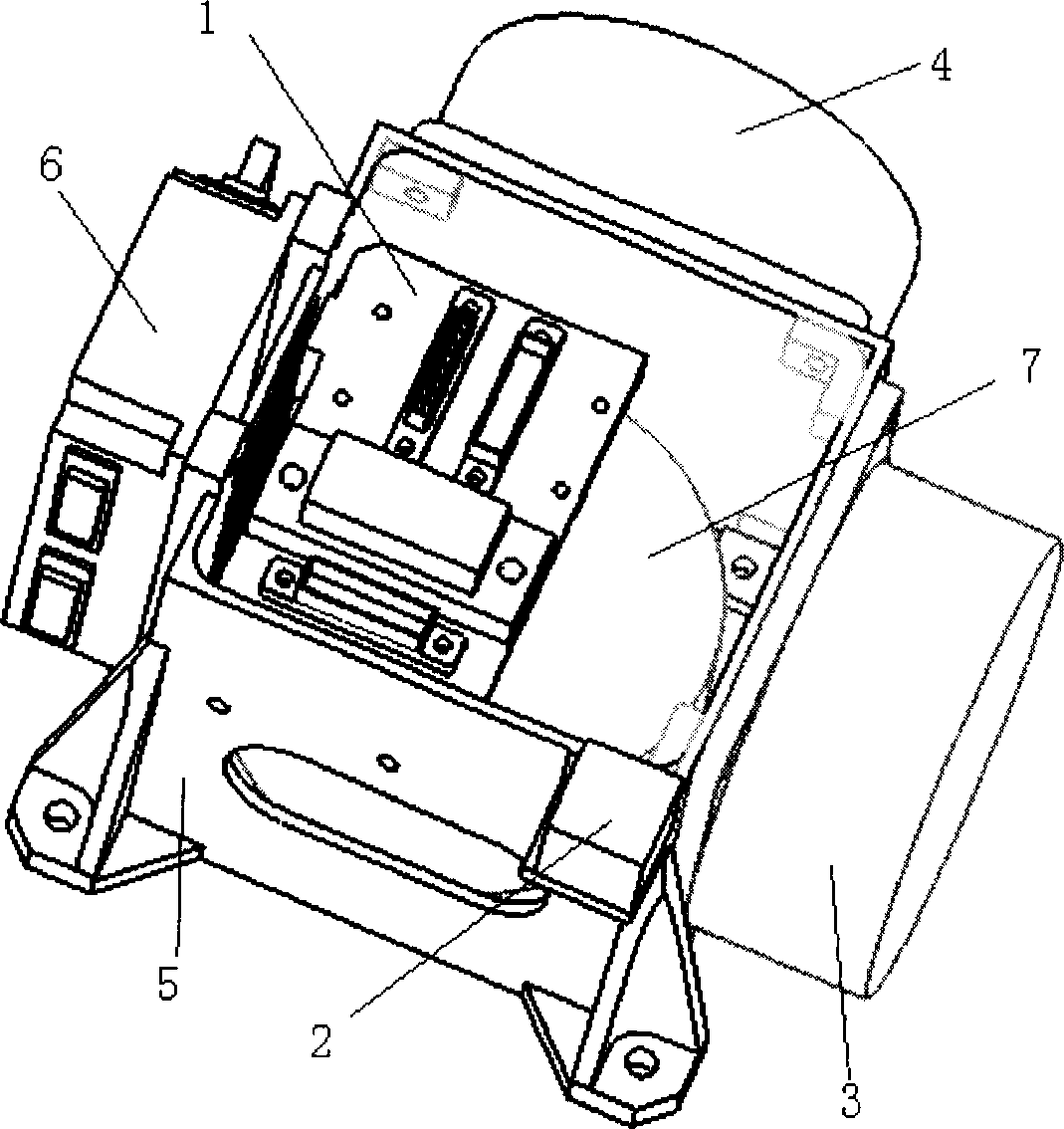

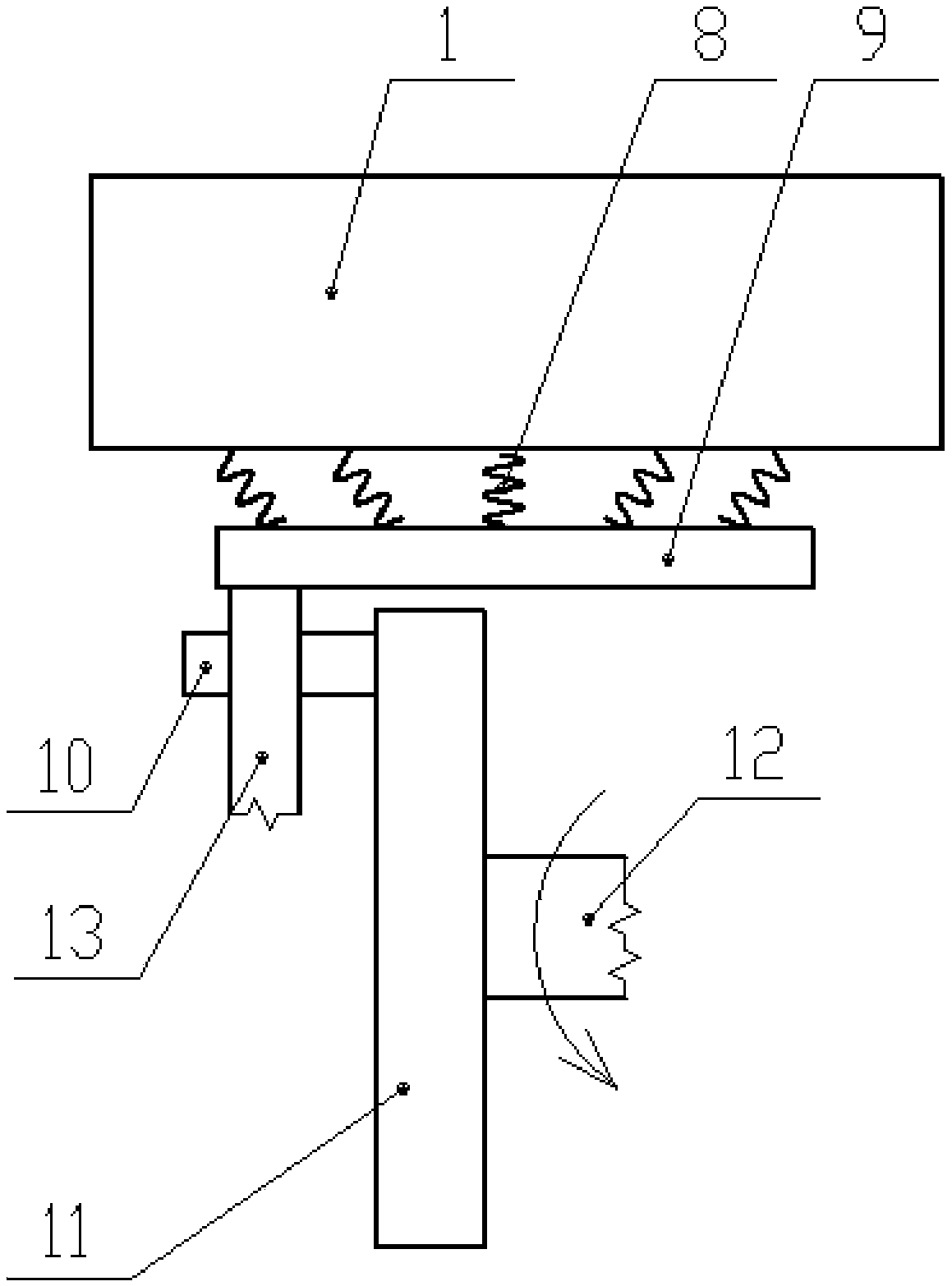

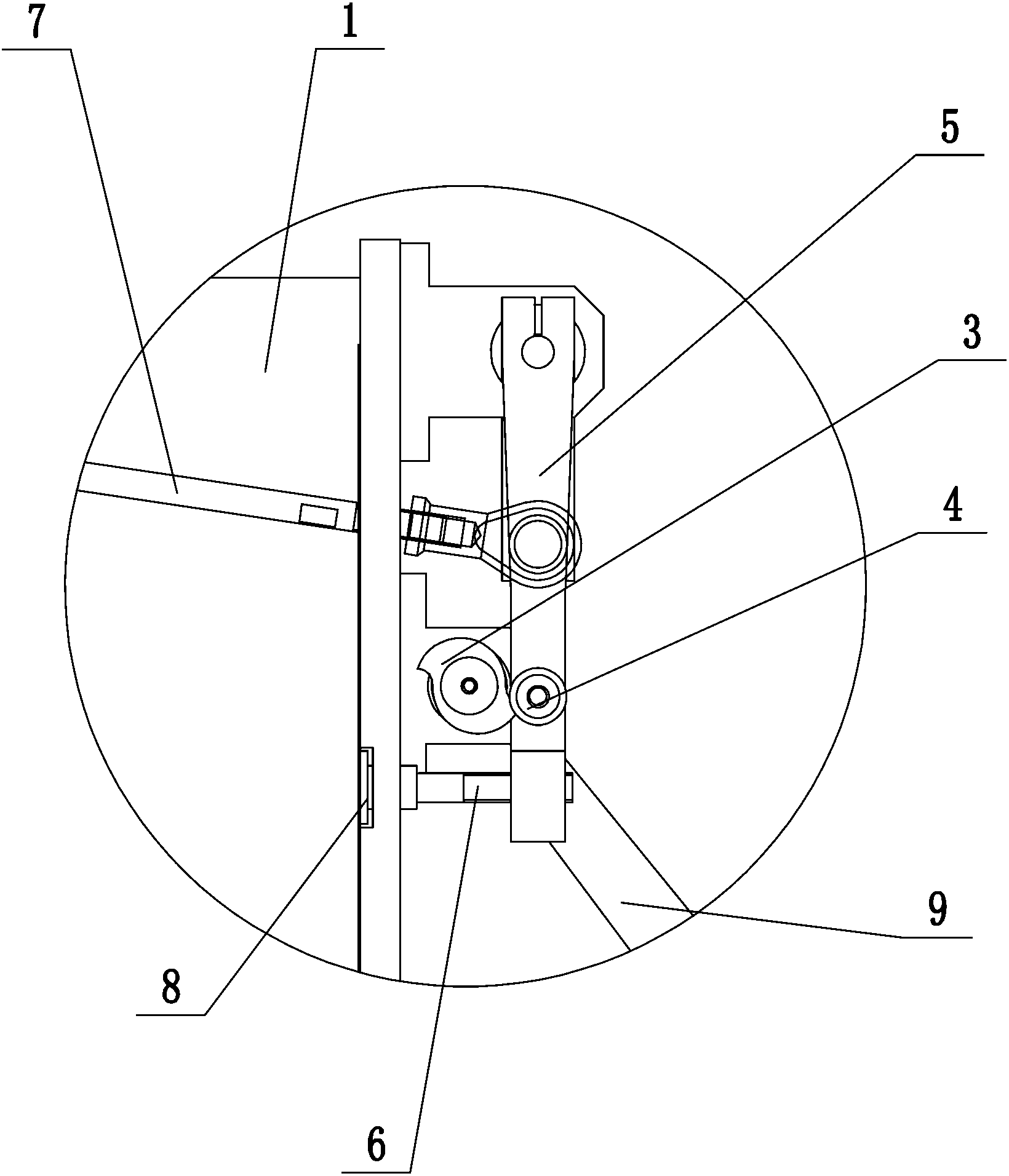

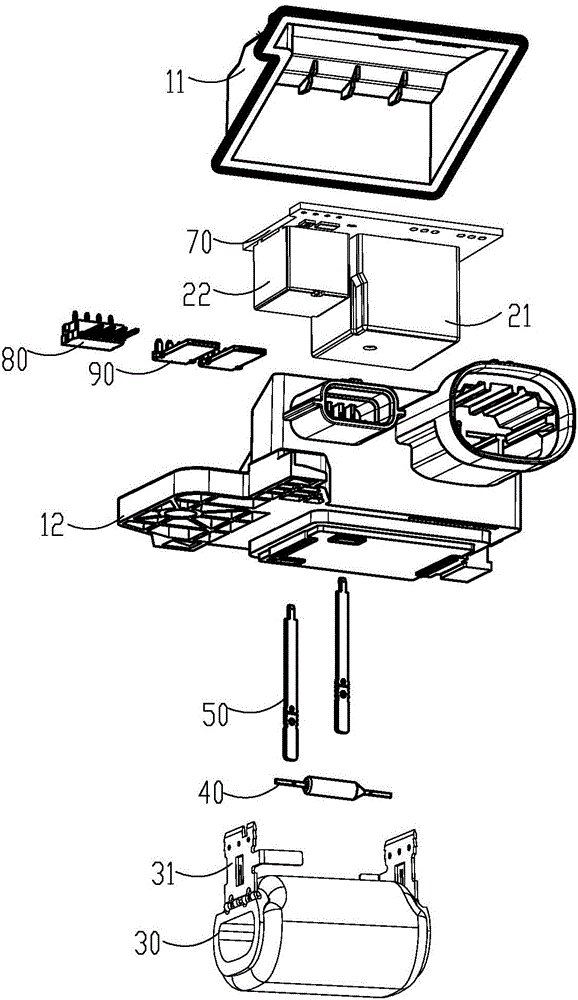

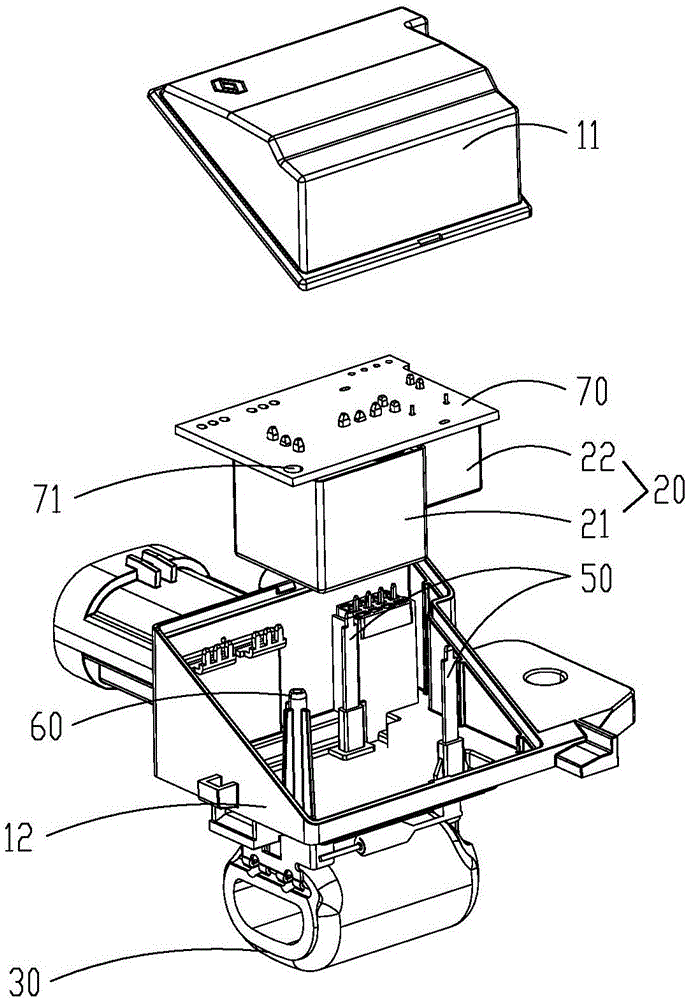

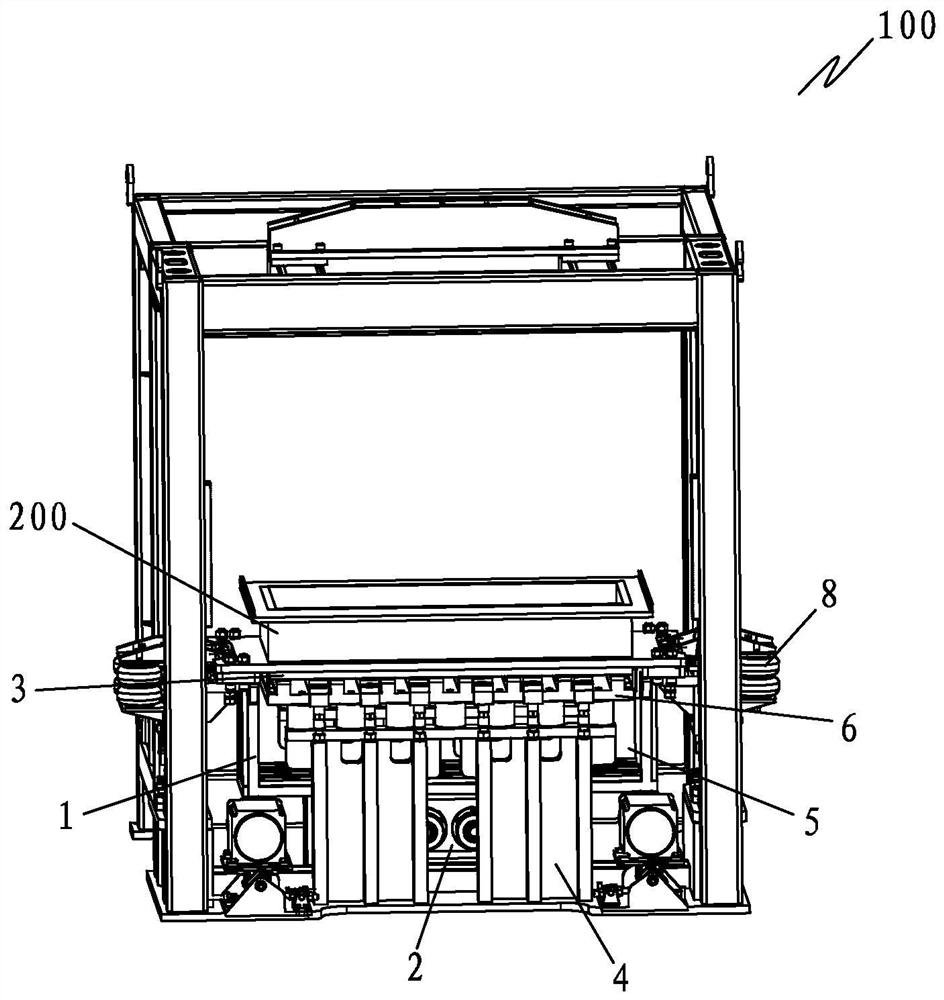

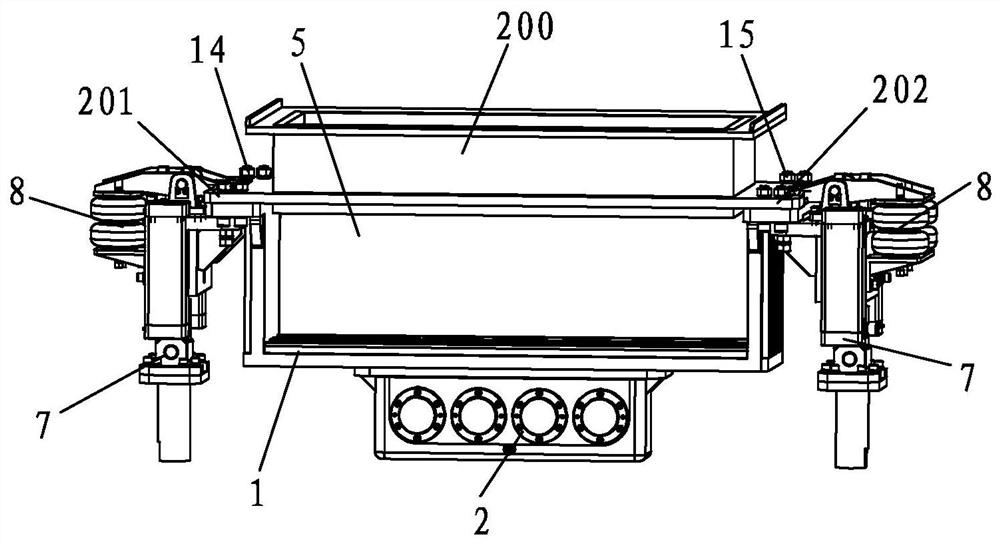

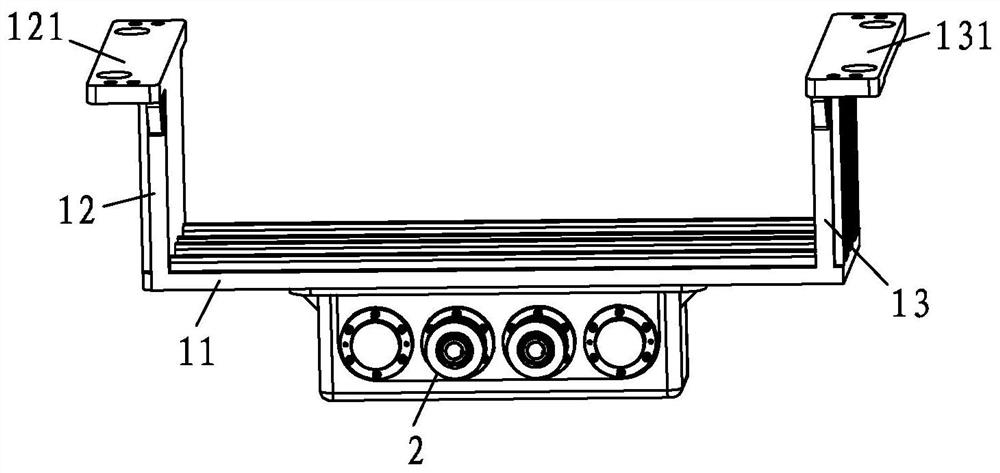

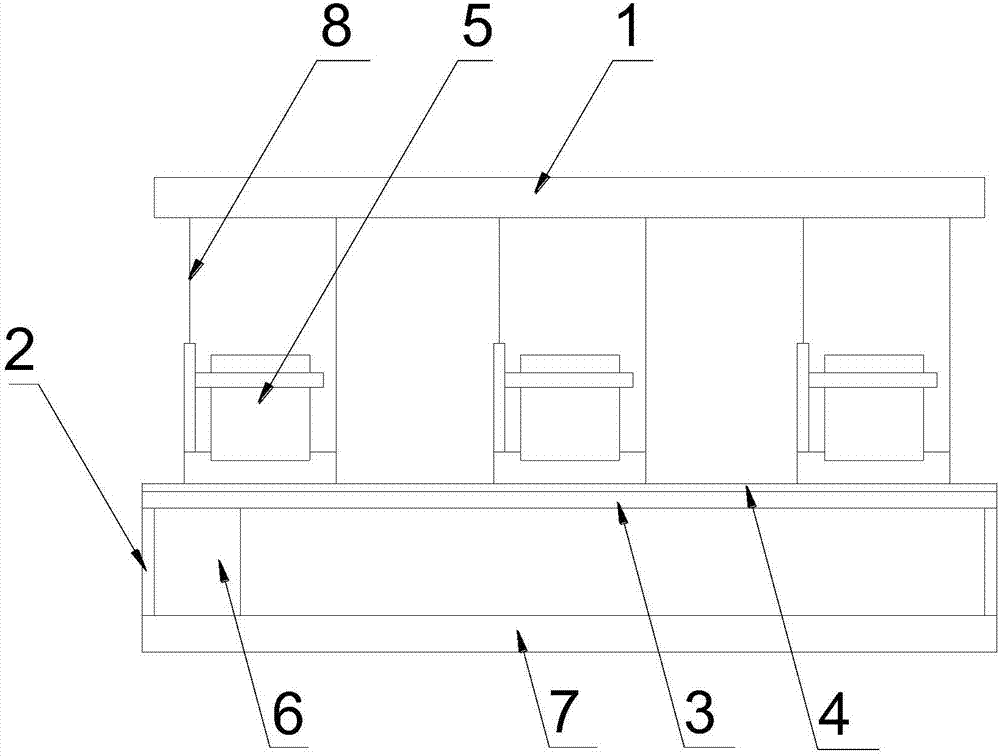

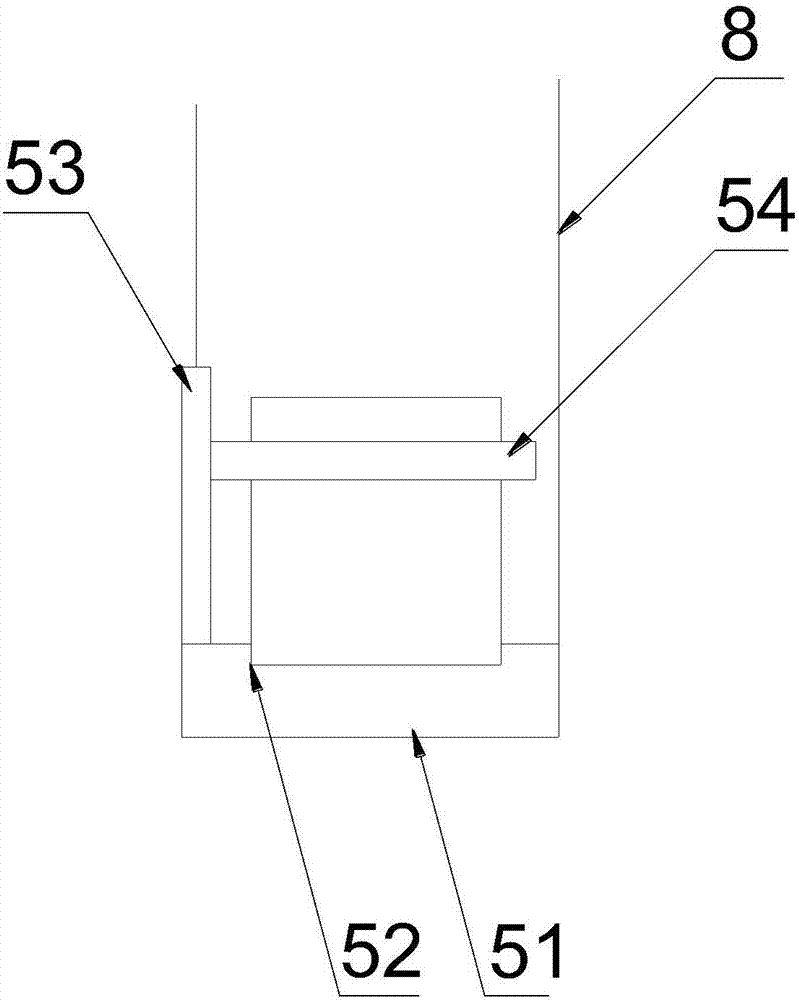

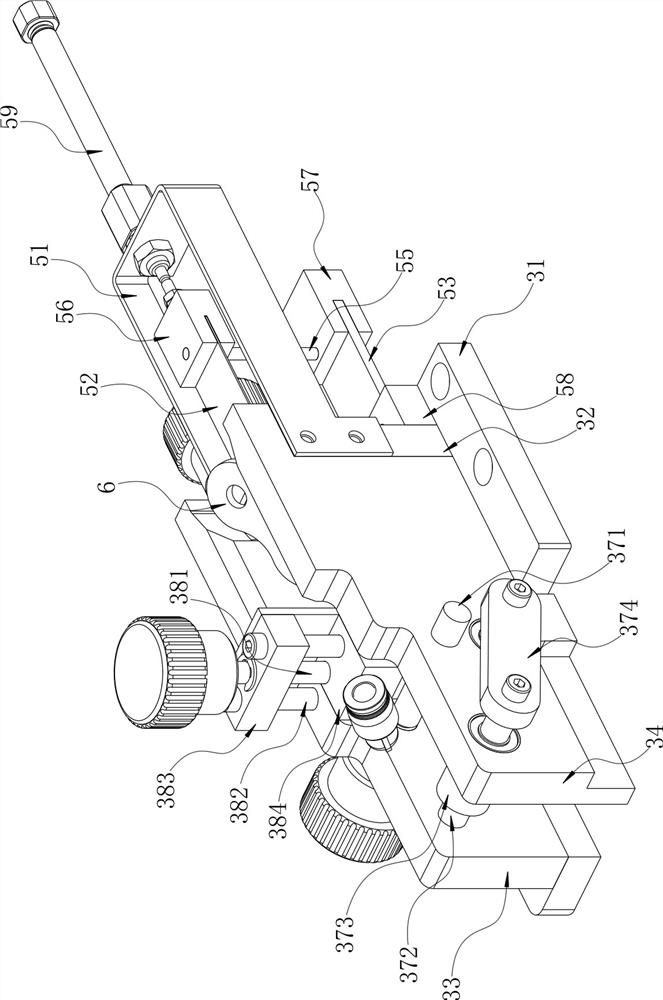

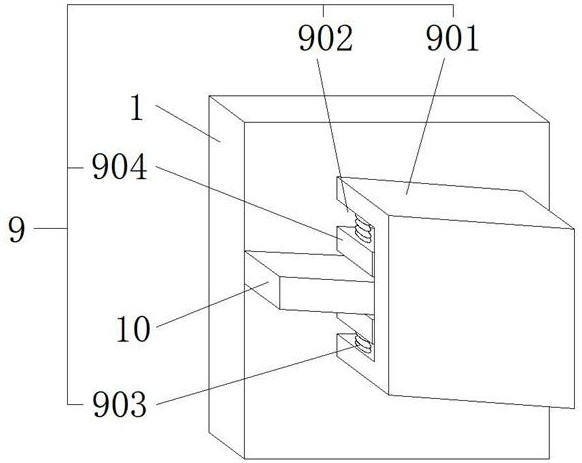

A vibration forming device and forming machine for forming low-noise concrete bricks

ActiveCN112223486BAids in rapid prototypingReduce vibration and working noiseSolid waste managementCeramic shaping apparatusLow noiseBrick

The invention provides a low-noise concrete brick forming vibration forming device and a forming machine. The vibration forming device comprises a connecting piece connected to a concrete brick formwork frame for directly transmitting vibration force to the concrete brick formwork frame, and a connecting piece fixed on the connecting piece. A vibrating mechanism used to provide a vibration source on the part. The advantages of the present invention are as follows: the vibration mechanism providing the vibration source is arranged on the connecting piece, and the connecting piece is directly connected with the concrete brick formwork frame. During operation, the vibration force of the vibration mechanism is directly transmitted to the concrete brick formwork frame through the connecting piece, which greatly improves the efficiency of the present invention. Reduce the energy loss in the vibration transmission process, so that the vibration mechanism does not need to work at a higher frequency; at the same time, it avoids the separation of the traditional concrete brick formwork frame and the vibration mechanism, resulting in the high-frequency collision of the two when the concrete brick is formed. ; Can reduce the vibration noise of the vibration forming device; can improve the vibration efficiency, reduce the vibration time, help the rapid forming of concrete bricks, and achieve high-efficiency and high-yield production.

Owner:FUJIAN QUNFENG MACHINERY

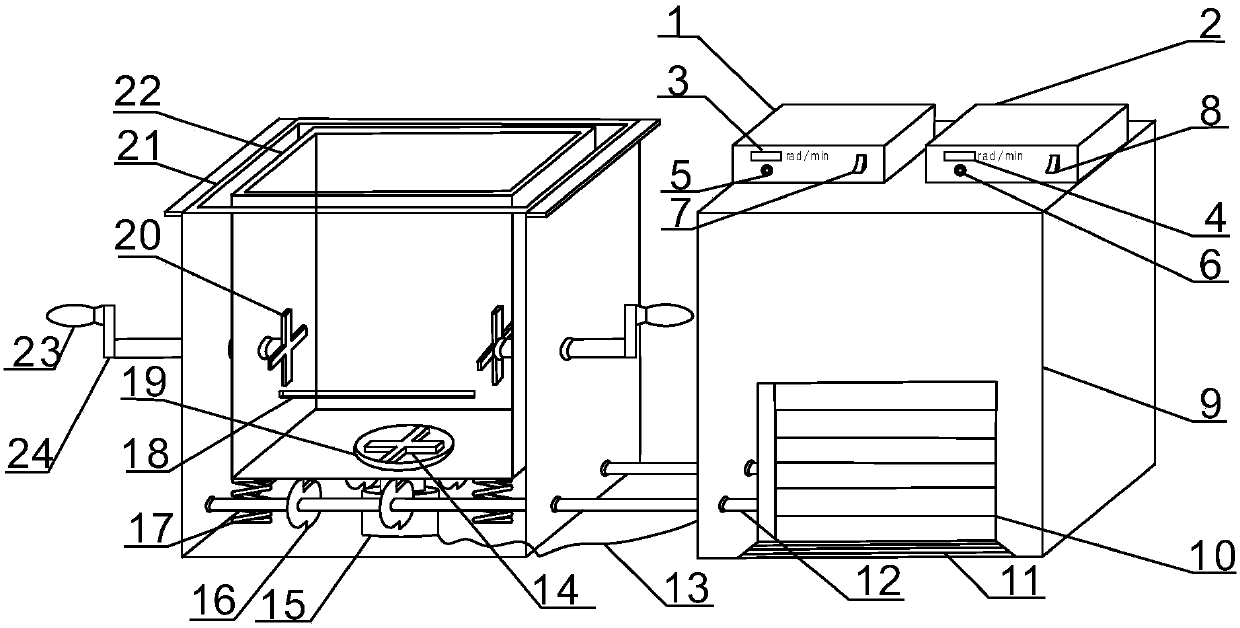

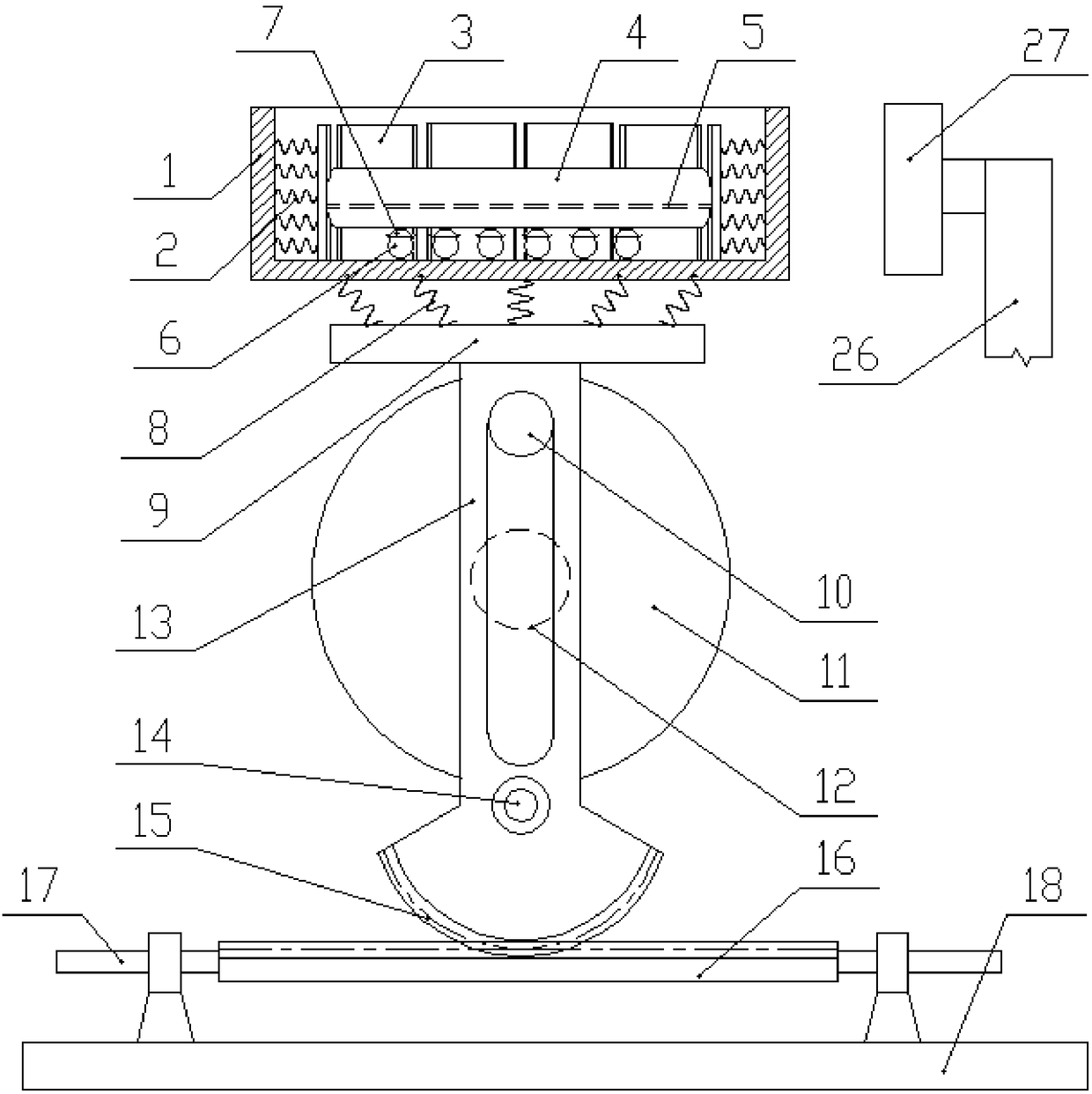

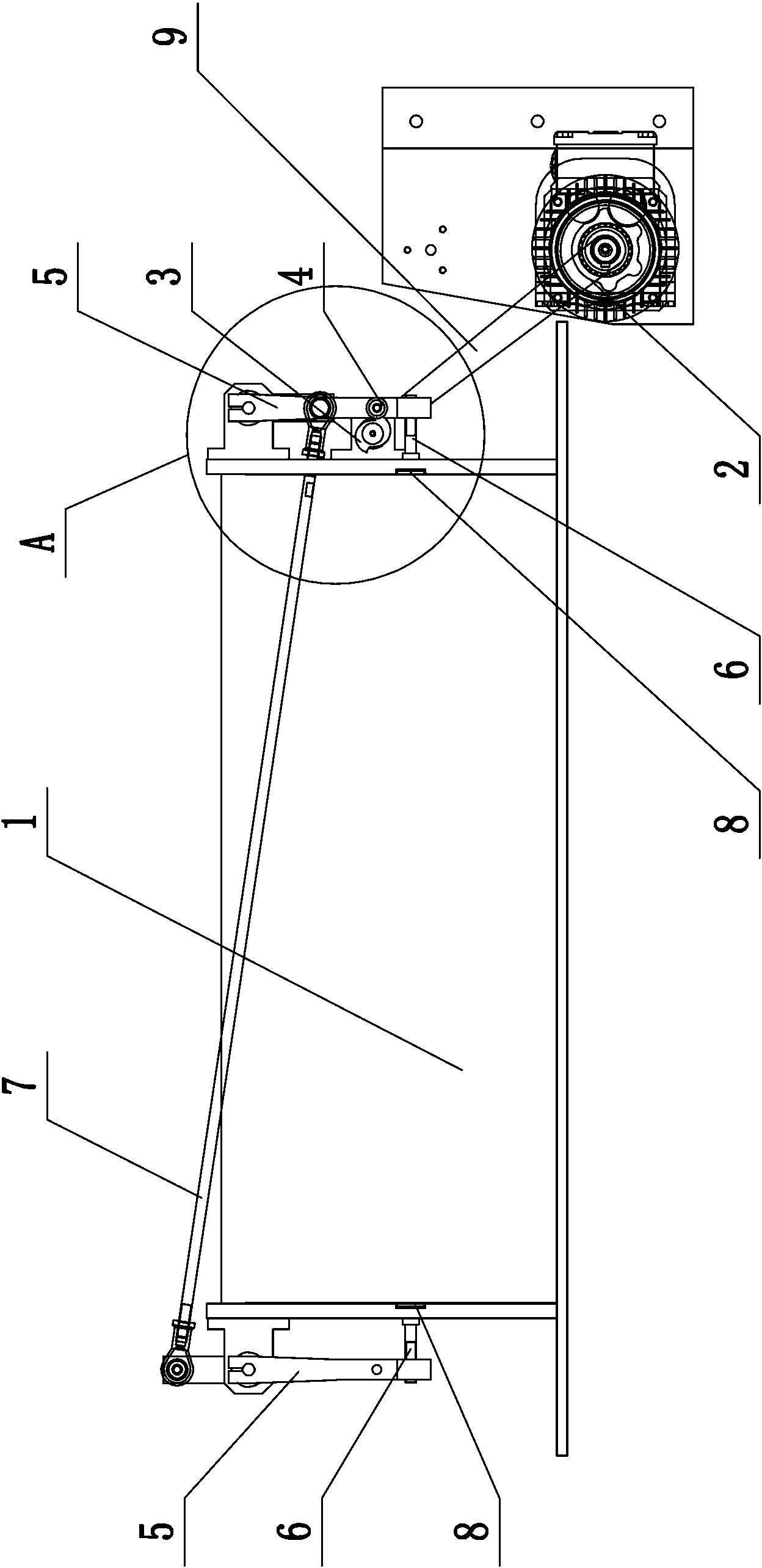

Vibration anti-curing experiment equipment

InactiveCN107983234AImprove the vibration effectGuaranteed vibration effectShaking/oscillating/vibrating mixersTransportation and packagingControl mannerArchitectural engineering

The invention discloses vibration anti-curing experiment equipment which comprises a top plate, a bracket, a vibration plate, a linking component, a vibration motor and a base, wherein the linking component comprises a bottom plate, a holding groove, a fixing rack and a fastening clamp; the top plate is positioned above the vibration plate; the vibration plate is fixedly connected with the base through the bracket; an elastic pad is arranged on the vibration plate; the linking component is placed on the elastic pad; in the linking component, the holding groove is formed in the center of the bottom plate; the fixing rack is arranged on the edge of the bottom plate; the fastening clamp is connected with the middle of the fixing rack; on the edge of the bottom plate, the top of the fixing rack is connected with the bottom end of a steel wire rope; the top end of the steel wire rope is fixed on the lower side of the top plate; the steel wire rope is at a tightened state, so that the bottomplate contacts the vibration plate but the pressure is zero; the vibration motor is arranged below the vibration plate; the vibration motor is fixed on the base; the vibration motor is connected withthe vibration plate in a control manner. By adopting the equipment, reagent bottles are vibrated irregularly, so that reagents are not cured, and the equipment is safe to use.

Owner:安徽依诺格实验室设备有限公司

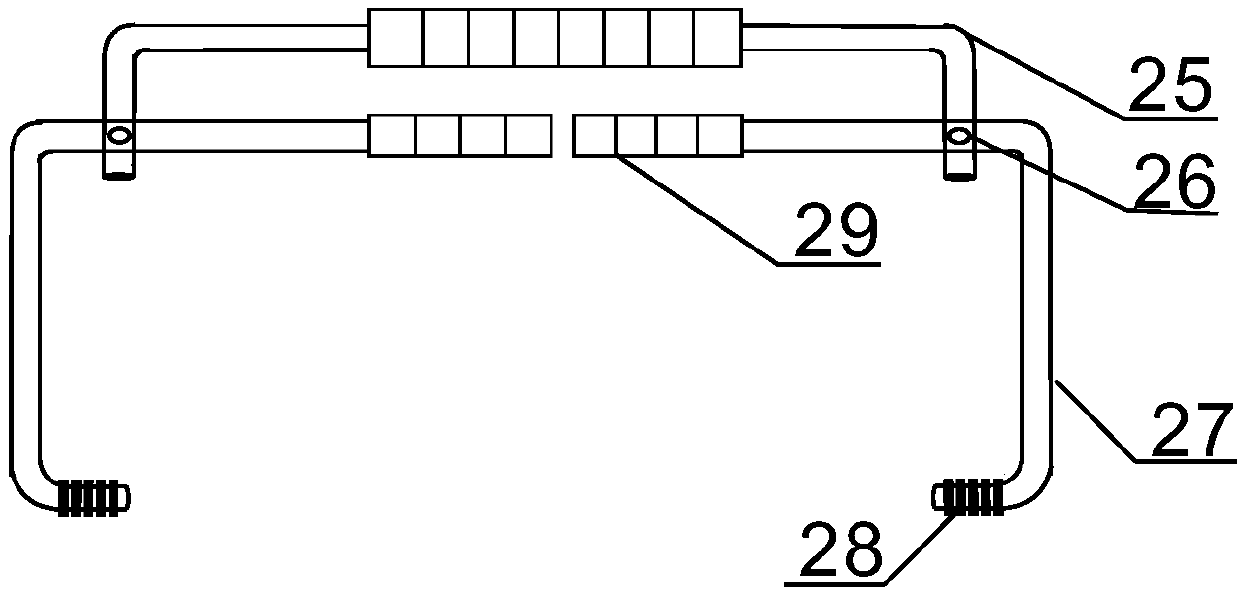

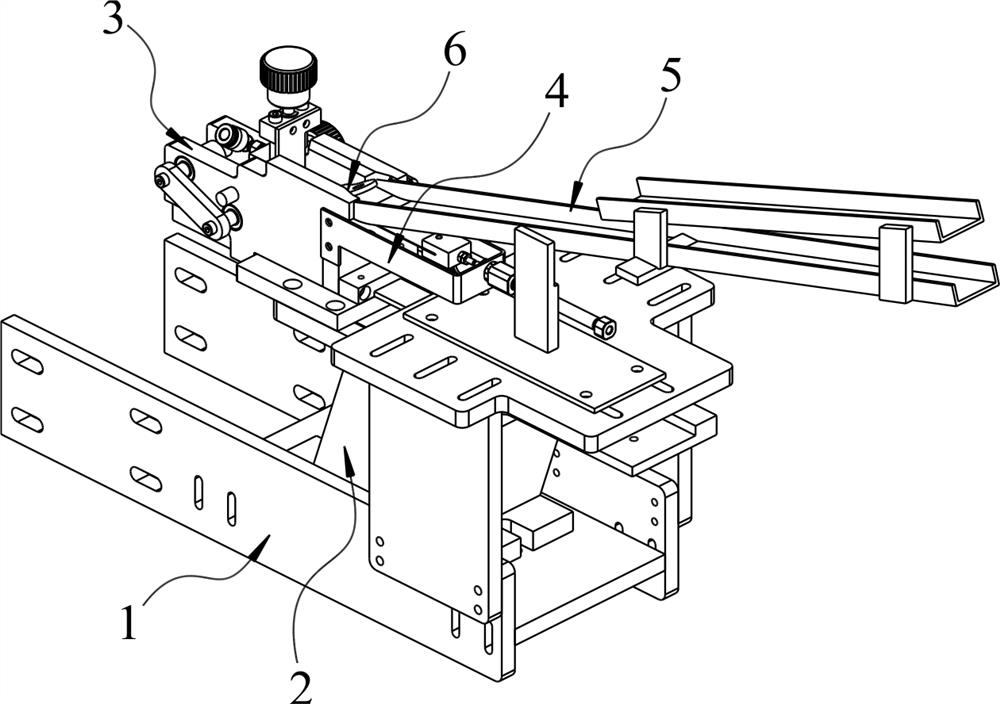

Feeding device for chain piece inspection system

ActiveCN113697508ARealize automatic orientationAvoid getting stuckStacking articlesDe-stacking articlesLinear vibrationMechanical engineering

The invention discloses a feeding device for a chain piece inspection system. The feeding device comprises a support, a linear vibration feeder, a temporary storage material box, a slideway and a material pushing device, wherein the support is used as a supporting base frame and fixedly connected to the chain piece inspection system; the linear vibration feeder is mounted on the support and used for providing a power source, so that chain pieces can be fed into the chain piece inspection system from the temporary storage material box; the temporary storage material box is mounted at the top of the linear vibration feeder; the temporary storage material box is used for temporarily storing the chain pieces and adjusting directions and angles of the chain pieces; the slideway is fixed on the support; the slideway is used for receiving the chain pieces and feeding the chain pieces into the temporary storage material box in a sliding manner; the material pushing device is mounted on the temporary storage material box; and the material pushing device is used for driving the chain pieces to be stacked in the temporary storage material box layer by layer and assisting the linear vibration feeder to push the chain pieces into the chain piece inspection system at the same time. According to the feeding device for the chain piece inspection system, before the inspection of the chain pieces, automatic alignment of the chain pieces is achieved under the action of the temporary storage material box. In addition, the chain pieces are pushed out through the cooperation of the linear vibrator and the material pushing device, so that the directions and angles of the fed chain pieces meet the inspection requirements.

Owner:YANGZHOU POLYTECHNIC INST

Ceramic production recycling device capable of ensuring sufficient crushing

The invention discloses a ceramic production recycling device capable of ensuring sufficient crushing. The ceramic production recycling device comprises a crushing box, an output packing auger, a miniature vibration motor and a material conveying packing auger, wherein the output packing auger is arranged on the middle part of the bottom end of the crushing box; a material drawing plate is fixedlyarranged on the outer surface of a conveyer belt; a recycling pipe is welded to the top end of a shell; the miniature vibration motor is arranged on the front end of a bearing mechanism; a regulationrod penetrates through the middle part of a regulation ring; a rubber block wraps the right end of the regulation rod; a fluted disc is rotatably arranged on the middle part of a fixing plate; a rotary rod is welded to the left side surface of the fluted disc; and the material conveying packing auger is arranged on the upper end of the crushing box. According to the ceramic production recycling device capable of ensuring sufficient crushing, a sufficient crushing effect can be effectively realized through circular crushing; the crushing effect is ensured; recycling and reusing of raw materials are facilitated; and besides, a dust flying phenomenon can be effectively avoided, so that harm caused to workers by flying dust is avoided.

Owner:佛山市金舵陶瓷有限公司

Automobile compressor cylinder body casting molding system

The invention belongs to the technical field of automobile manufacturing, and particularly relates to an automobile compressor cylinder body casting molding system. The automobile compressor cylinderbody casting molding system involves a horizontal bottom plate, wherein two parallel vertical plates are symmetrically and fixedly arranged on the bottom plate, and a clamping mechanism is arranged between the two vertical plates; and bearing plates are horizontally and fixedly arranged on the opposite side faces of the two vertical plates, and a material receiving box is fixedly arranged at the position, located between the two bearing plates, of the upper surface of the bottom plate. According to the automobile compressor cylinder body casting molding system, vibration force transmitted to acylinder body is balanced, so that damage to the cylinder body is avoided while the vibration effect is guaranteed; and according to the automobile compressor cylinder body casting molding system, molding sand and clay mixtures blocked at the bottom of a through groove structure of the cylinder body are dispersed, so that the removal effect is improved.

Owner:丁建丽

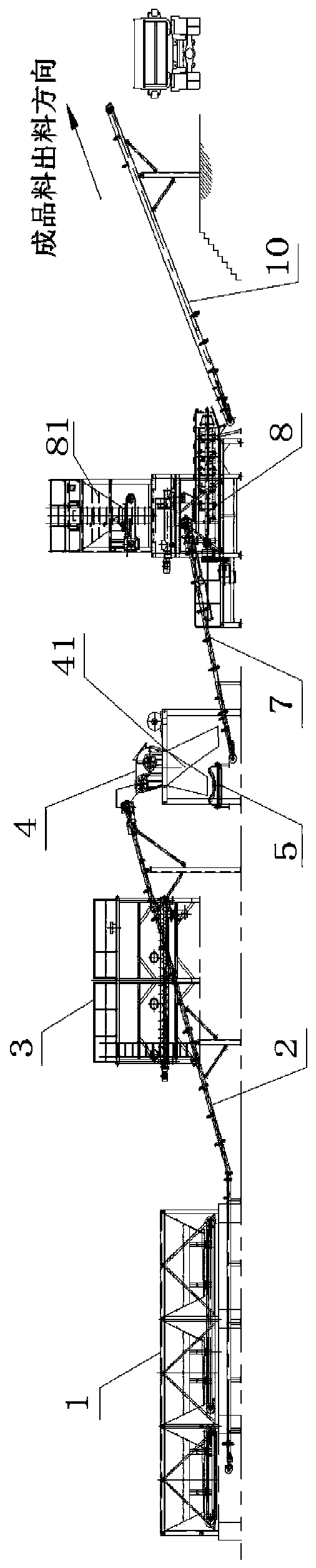

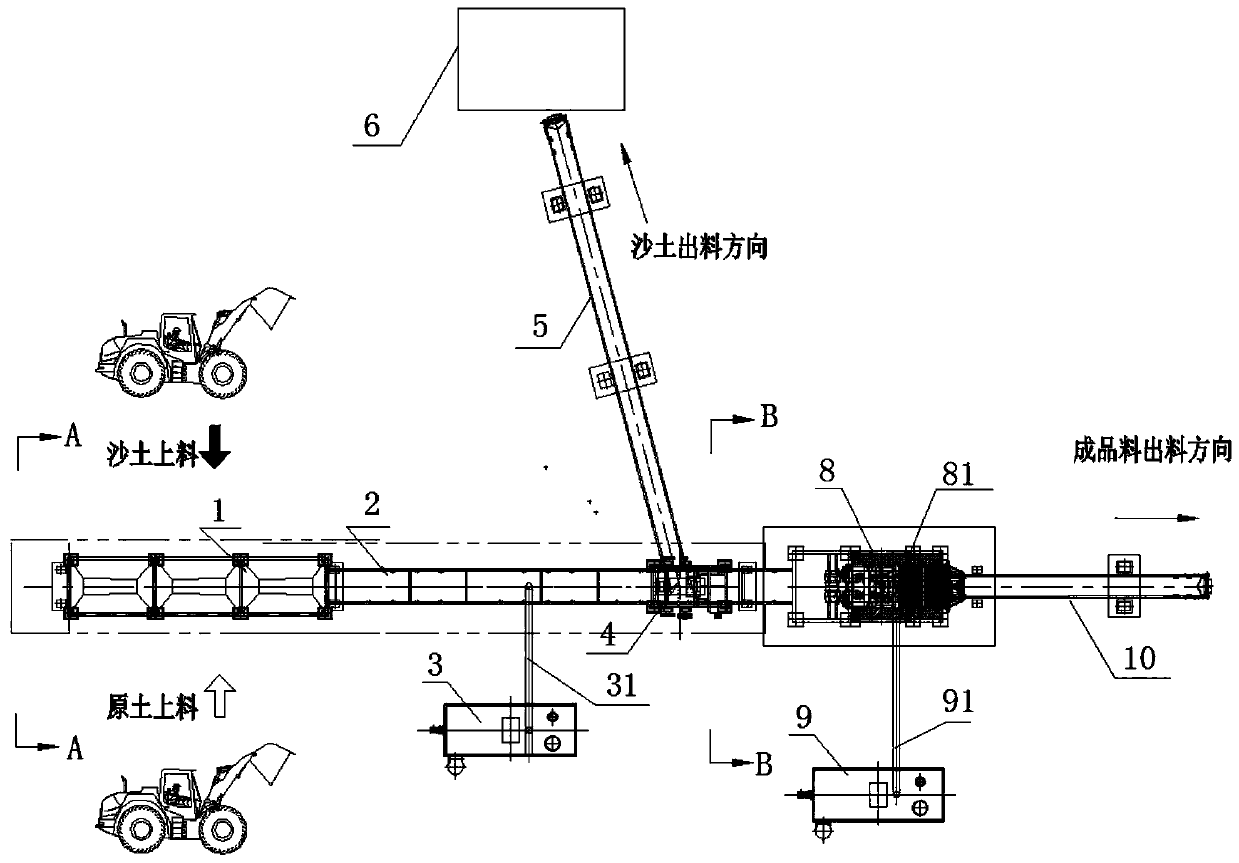

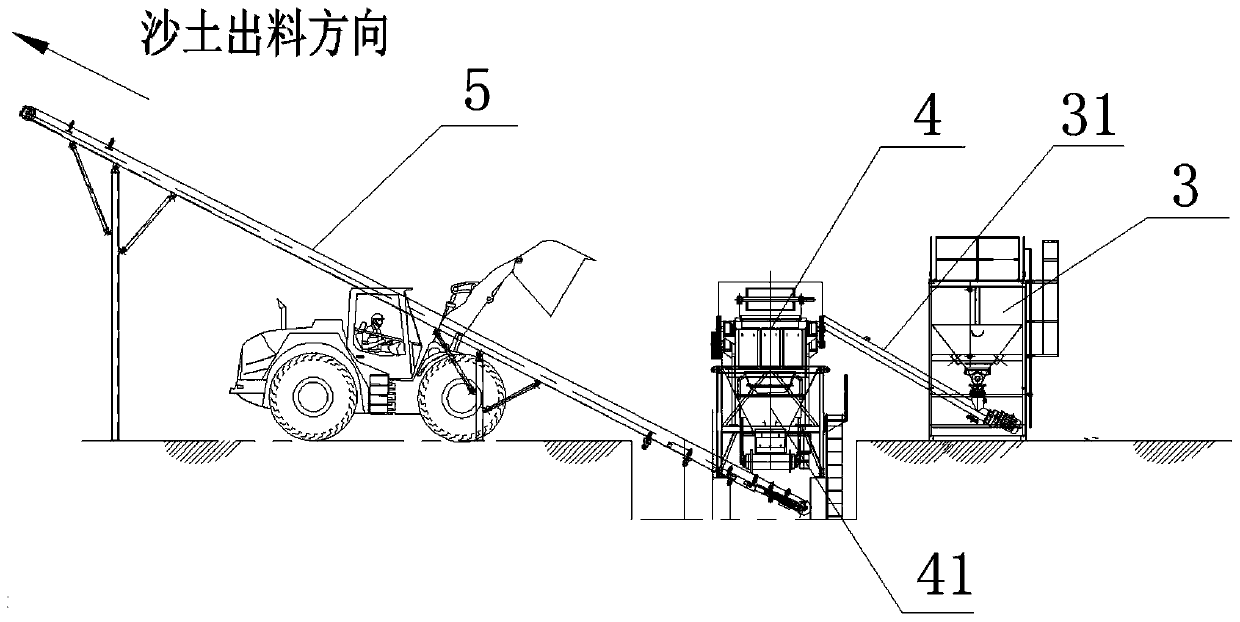

Solidified soil plant mixing treatment method and equipment thereof

The invention relates to a solidified soil mixing method and equipment in highway construction and particularly relates to a solidified soil plant-mixing treatment method and equipment thereof. The method is characterized in that: raw soil is stored in a feeding hopper, after the raw soil is discharged in the feeding hopper, the raw soil is conveyed to a crusher through a first conveying belt, meanwhile, a lime powder bin conveys lime powder to the first conveying belt through a first spiral conveyor, the raw soil is covered with the lime powder, and the lime powder and the raw soil are conveyed into the crusher together; after the crusher performs preliminary crushing treatment and mixing on the mixture of the original soil and the lime powder, the crusher discharges the mixed sandy soilof the original soil and the lime powder to a second conveying belt through a distributor; and the second conveying belt conveys the mixed sandy soil to a soil covering field for soil covering treatment for 48 hours or longer, thus sanding original soil; and when the transport cart transports the sandy soil into the feeding hopper for discharging, the sandy soil is more uniform and smooth, and thesandy soil is easier to crush during crushing treatment.

Owner:镇江路机重工科技有限公司

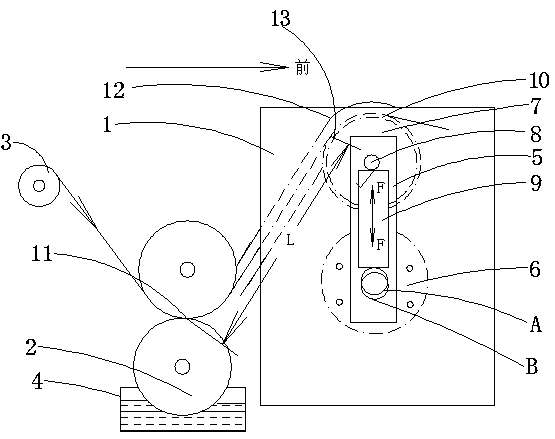

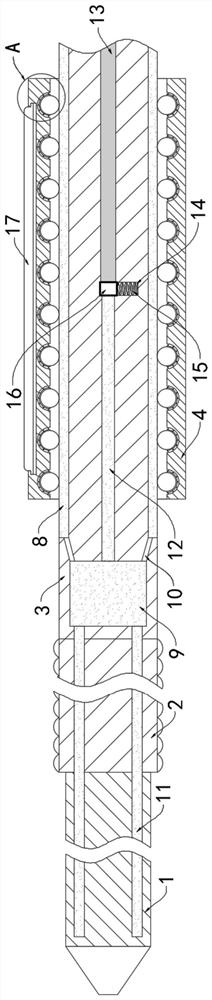

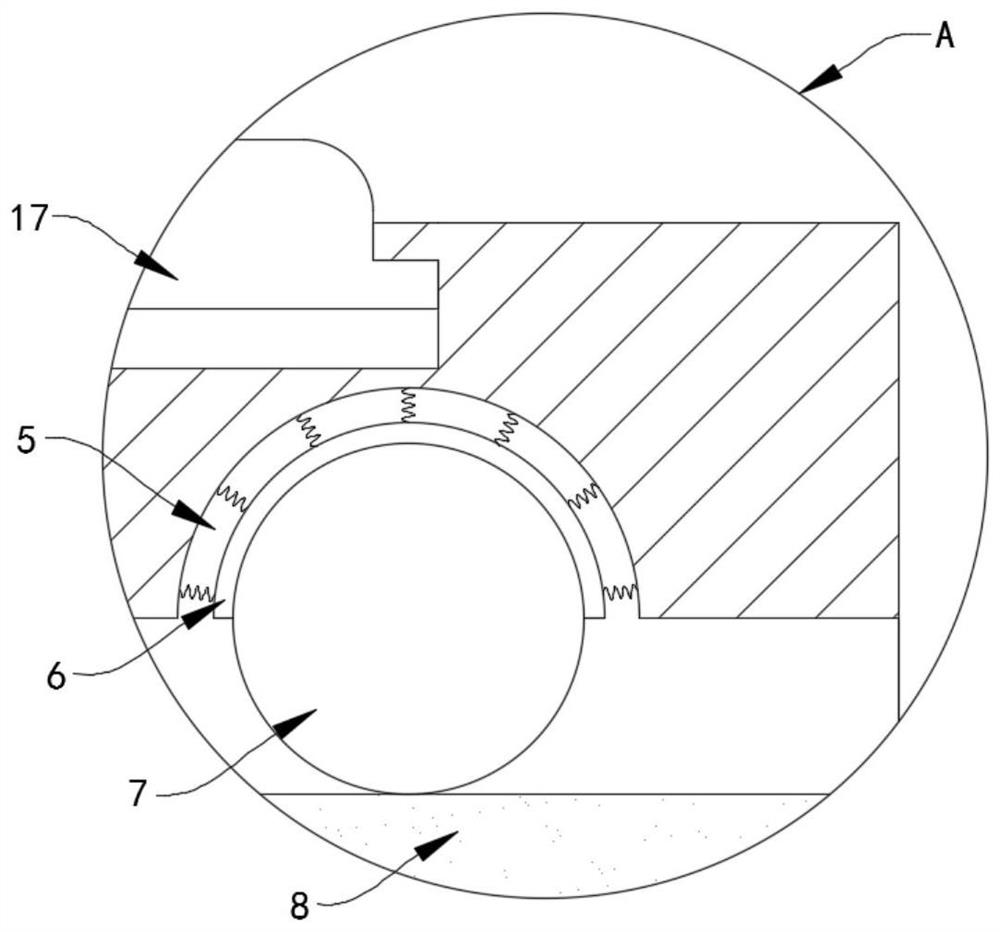

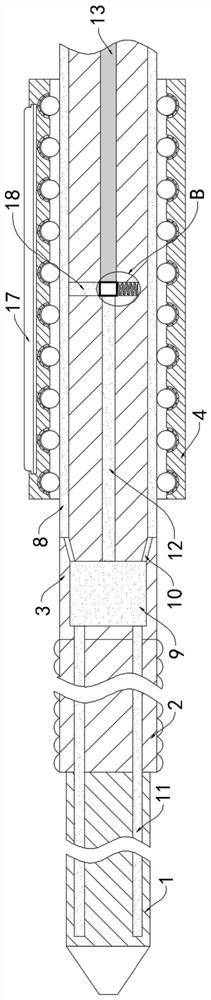

Photosensitive material plate coating machine with vibration device

PendingCN108672203AImprove product qualitySuitable for coatingLiquid surface applicatorsCoatingsEngineeringLiquid tank

The invention relates to equipment in the technical field of photosensitive material production, in particular to a photosensitive material plate coating machine with a vibration device. The photosensitive material plate coating machine comprises a rack. The rack is provided with a coating roll and a conveying roll. A chemical liquid tank for containing photosensitive chemical liquid is located below the coating roll. A photosensitive material plate or a substrate is transferred and conveyed on the rack from back to front. The photosensitive material plate is wound around the conveying roll along a photosensitive material plate path. The two sides of the rack in front of the coating roll are provided with square grooves. Vibrators are mounted below the grooves. The photosensitive materialplate coating machine further comprises a vibration roll. The axis of the vibration roll is perpendicular to the advancing direction of the photosensitive material plate path. The upper face of the vibration roll makes contact with the photosensitive material plate path. The vibration roll is provided with a vibration roll shaft. The vibration roll shaft is mounted above the vibrators. The vibrators vibrate to drive the vibration roll shaft to vibrate up and down. The photosensitive material plate coating machine with the vibration device has the advantages that the generated photosensitive material photosensitive chemical liquid is more uniform, and the product quality is better.

Owner:CHANGGE HUIDA PHOTOSENSITIVE MATERIAL

Comfortable handheld vibrator convenient to operate

ActiveCN112096087AEasy to operateEasy to useBuilding material handlingStructural engineeringElectrorheological fluid

The invention belongs to the field of engineering construction, and particularly relates to a comfortable handheld vibrator convenient to operate. The comfortable handheld vibrator comprises a vibrating rod, a flexible rod and a handheld rod, wherein the flexible rod is fixedly connected between the vibrating rod and the handheld rod; a sliding barrel coaxially sleeves the handheld rod; a plurality of grooves which are uniformly distributed are formed in the inner side wall of the sliding barrel; a hemispherical cover is fixedly connected in each groove through a plurality of outer springs; arolling ball is mounted in each hemispherical cover in a rolling manner; an annular bag is fixedly embedded in the outer side wall of the handheld rod; the rolling balls are in contact with the outersurface of the annular bag; and a liquid storage cavity is formed in the handheld rod. By arrangement of a centralizing mechanism, when a conductive column is connected with electrorheological fluid in a horizontal cavity, the electrorheological fluid in a plurality of communicating tubes can be changed into a solid state, the vibrating rod, the flexible rod and the handheld rod can form a whole,the position of the vibrating rod can be controlled easily through the handheld rod, the vibrating rod can be placed at a position to be machined easily, and the comfortable handheld vibrator is convenient to use.

Owner:新昌县籍服机械有限公司

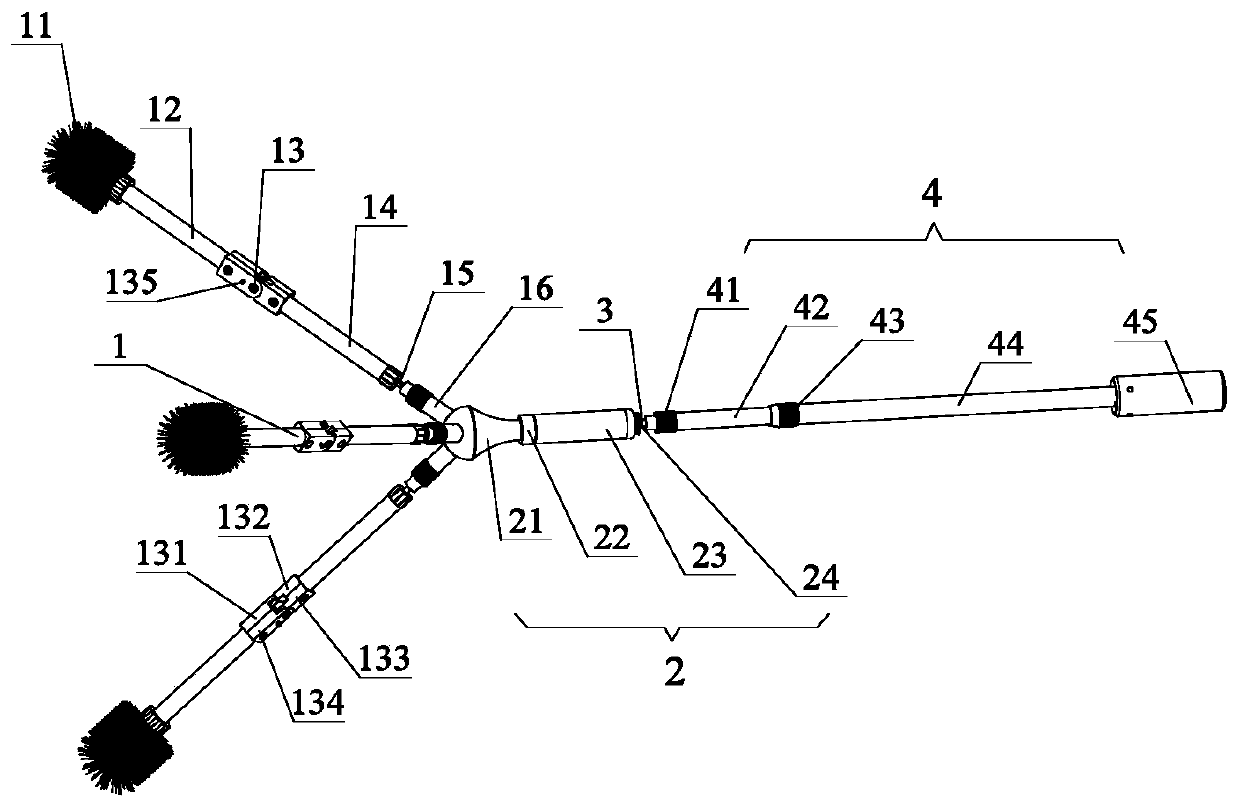

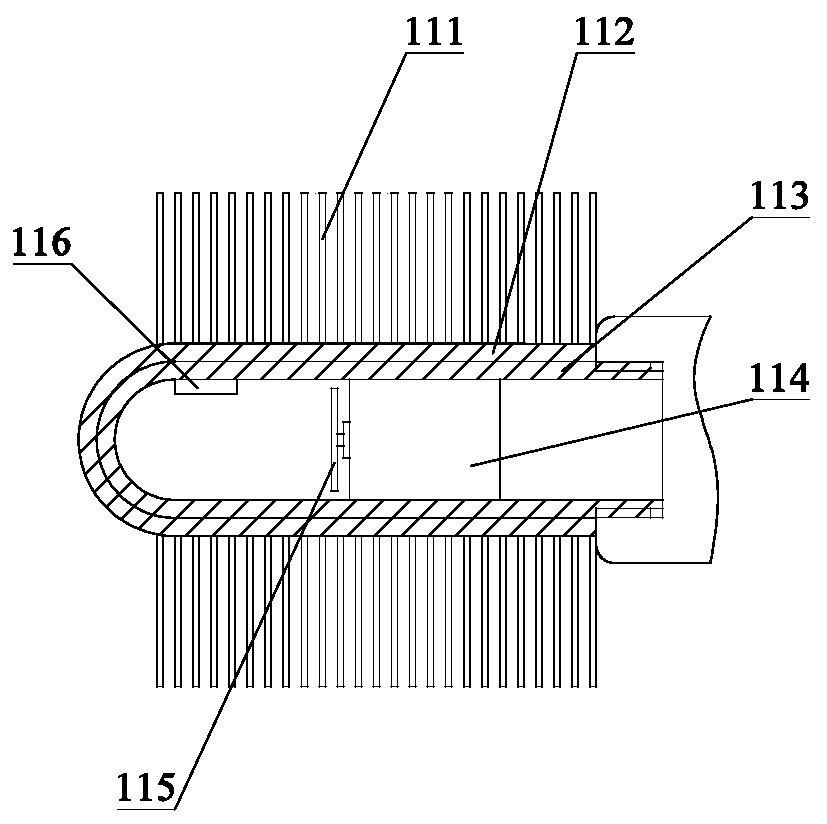

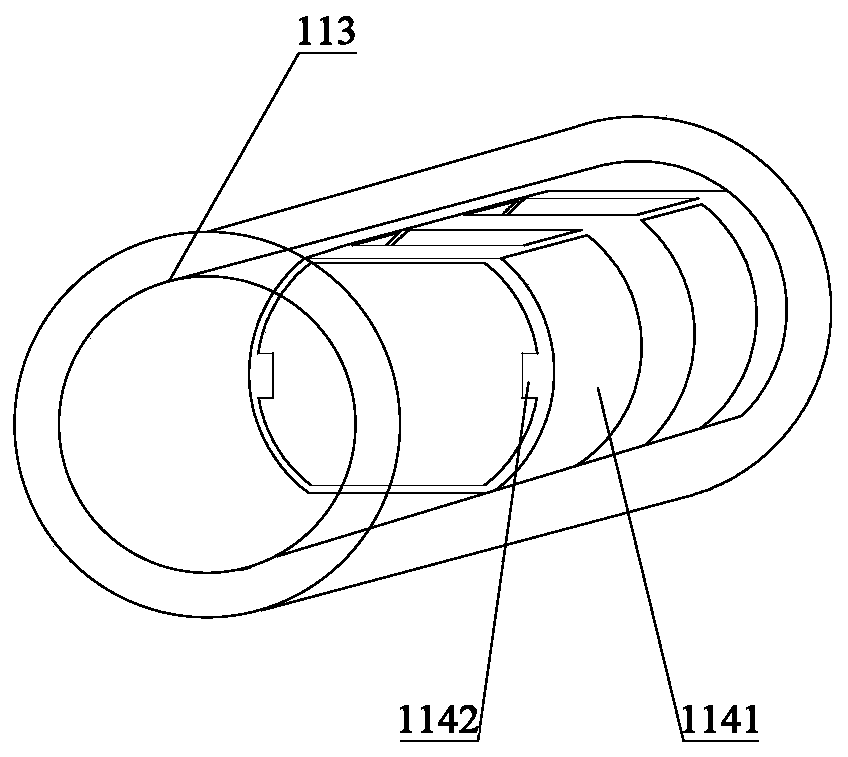

Multi-brush-head cleaning brush with composite working mode

PendingCN110393366ASolve the technical problem of vibration attenuationGuaranteed vibration effectBrush bodiesEngineeringMechanical engineering

The invention discloses a multi-brush-head cleaning brush with a composite working mode. The cleaning brush comprises a rotating mechanism, a universal rotating shaft II and a control handle with a power supply; the tail end of the rotating mechanism is connected with the steering end of the universal shaft II; the fixed end of the universal shaft II is connected with the head end of the control handle; the cleaning brush further comprises a plurality of vibration cleaning mechanisms; each vibration cleaning mechanism comprises a vibration brush head, a connecting rod I, a lockable hinge, a connecting rod II, a universal rotating shaft I and a connecting rod III; the vibration brush heads are detachably connected with the head ends of the connecting rods I in a sealing mode; the tail endsof the connecting rods I are fixedly connected with the head ends of the lockable hinges; the tail ends of the lockable hinges are fixedly connected with the head ends of the connecting rods II; the tail ends of the connecting rods II are detachably connected with the steering ends of the universal rotating shafts I; the fixed ends of the universal rotating shafts I are connected with the head ends of the connecting rods III; and the tail ends of the connecting rods III are detachably connected with the head end of the rotating mechanism. The cleaning brush has the advantages of being adjustable in multi-stage angle, high in cleaning force, low in cost and energy consumption and suitable for multiple scenes.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

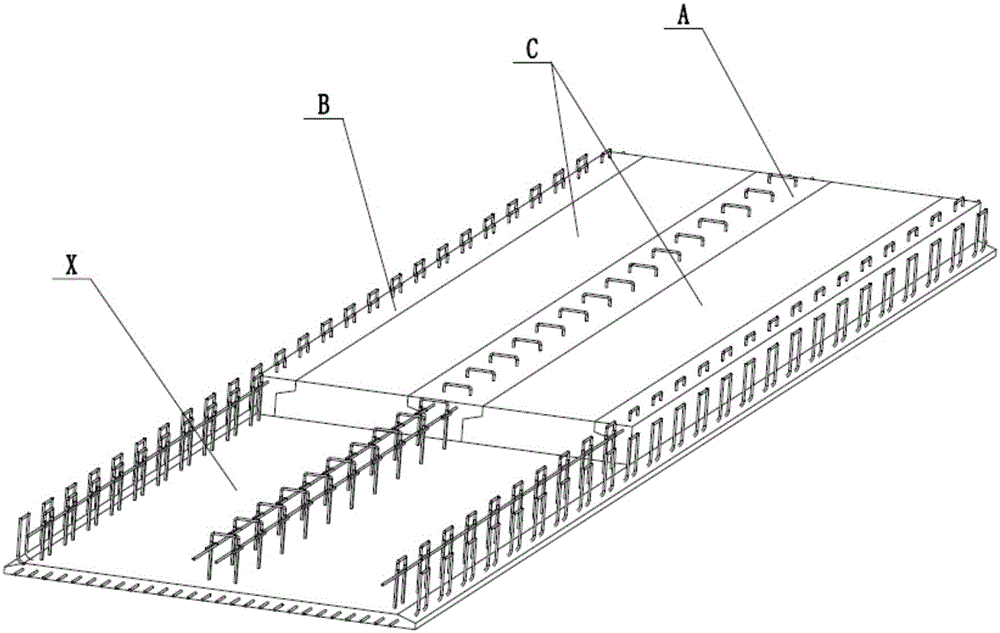

A light-duty steel-concrete prefabricated floor pouring molding machine with shaped lightweight filler

InactiveCN103707407BGuaranteed vibration effectImprove efficiencyCeramic shaping plantsFeeding arrangmentsMetallurgyMolding machine

The invention relates to a pouring molding machine for a light steel mixed prefabricated base plate with molding light fillers, and belongs to the field of building material machinery equipment. A steel mixed light molding plate middle steel mixed main rib molding area, a steel mixed longitudinal edge molding area and a light filler molding area correspondingly formed between the steel mixed light molding plate middle steel mixed main rib molding area and the steel mixed longitudinal edge molding area are respectively formed by concrete vibration molding separation plates of a vibration molding mechanism of the pouring molding machine. A discharging port of a concrete material hopper and a discharging port of a light filler material hopper of a material system correspond to the steel mixed main rib molding area, the steel mixed longitudinal edge molding area and the light filler molding area respectively, the discharging ports are controlled by a flow controller and respectively feed the concrete materials and the light filler materials into the corresponding steel mixed longitudinal edge molding area, the corresponding steel mixed main rib molding area and the corresponding light filler molding area, the light steel mixed prefabricated base plate with the molding light fillers is accordingly molded through vibration of the vibration molding mechanism, one-time simultaneous feeding molding on the two different materials is completed, and mechanical high-efficiency production on the light composite floor prefabricated base plate is achieved.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

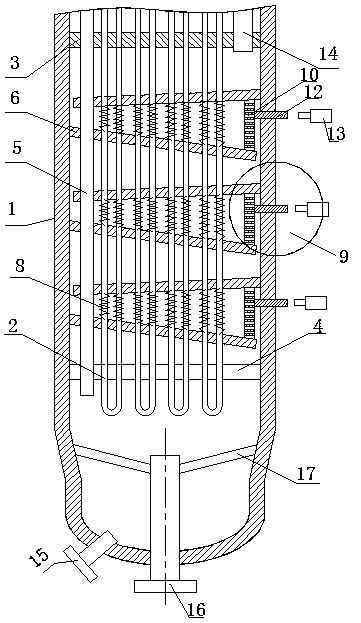

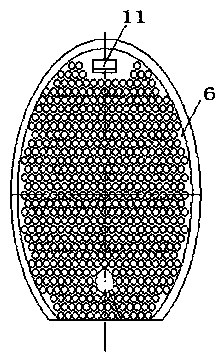

Silicone fluidized bed reactor with vibrating baffle plates

ActiveCN109529733AAvoid accumulationSave time and costChemical/physical processesNuclear engineeringFluidized bed

The invention discloses a silicone fluidized bed reactor with vibrating baffle plates. The silicone fluidized bed reactor comprises a cylindrical shell, a heat exchange tube in the cylindrical shell and a silicon powder feeding tube, at least one baffle device is arranged in the cylindrical shell, the baffle device comprises a baffle plate a and a baffle plate b, the oblique directions of the baffle plate a and the baffle plate b are opposite to each other, an area formed by the two baffle plates has one large end and one small end, and an elastic member is arranged between the baffle plate aand the baffle plate b. The structure of the reactor allows most of generated silicone gas to flow in the fluidized bed reactor in a zigzag direction. Compared with conventional reactors achieving I-shaped flow, the reactor in the invention has the advantages of long reaction time, sufficiency in the reaction of a chloromethane gas and silicon powder, significant reduction of the required height,rapid reduction of the content of the silicon powder under the layer barrier of the baffle plates, ensuring of the purity of the product silicone gas, and avoiding of deposition of the silicon powderthrough driving the baffle plates to vibrate by a driving device.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

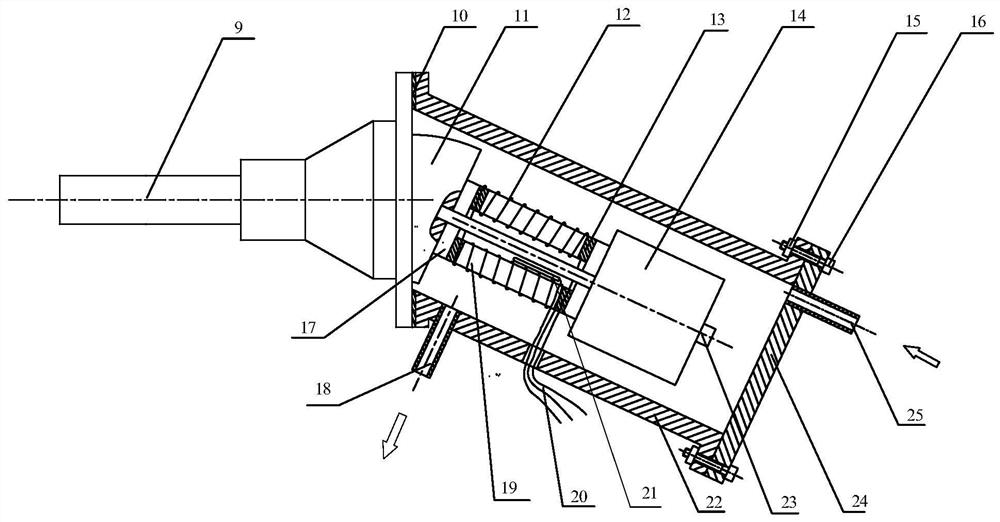

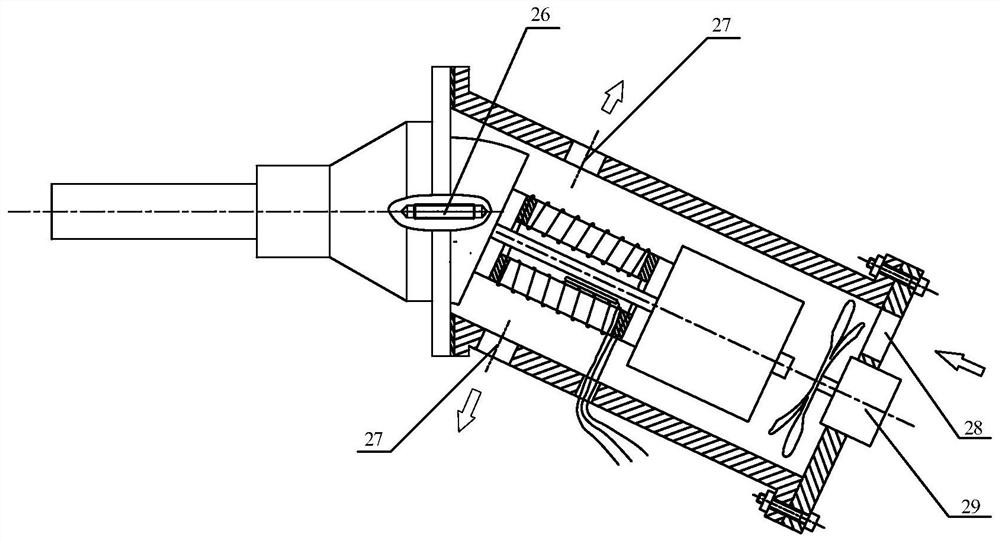

Giant magnetostrictive elliptical vibration turning device and turning method

ActiveCN111702189AReduce wearIncrease output powerAuxillary equipmentTurning machinesVibration amplitudeHigh energy

The invention belongs to the technical field of ultrasonic processing, and relates to a giant magnetostrictive elliptical vibration turning device and a turning method. The device comprises an amplitude transformer bar, a wedge block, a giant magnetostrictive transducer and an ultrasonic power supply, wherein the giant magnetostrictive transducer comprises a housing, a vibration system and a cooling system; the housing is fixed on a tool holder; one end of the housing is fixed to the amplitude transformer bar; the other end of the housing is provided with an end cover; the vibration system isplaced in the housing, and the amplitude transformer bar is connected to the vibration system through the wedge block; the ultrasonic power supply is placed outside the housing and connected to the vibration system; the cooling system is placed on the housing, and during turning, the single-direction vibration generated by the vibration system is converted into two-direction elliptical compound vibration through the wedge block, and the cooling system reduces the internal temperature of the giant magnetostrictive transducer. The giant magnetostrictive elliptical vibration turning device has the advantages of high output power, high energy conversion efficiency and good cooling effect, realizes elliptical vibration output with large amplitude, and improves processing accuracy.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com