Integrated ceramic resistor relay box

A technology of ceramic resistors and relay boxes, applied in circuits, electrical switches, electrical components, etc., can solve the problems of poor reliability of winding resistors, unsupported resistor bodies, and large heat generation, to ensure sealing and vibration performance, improve Product reliability, the effect of convenient production line production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below through specific embodiments.

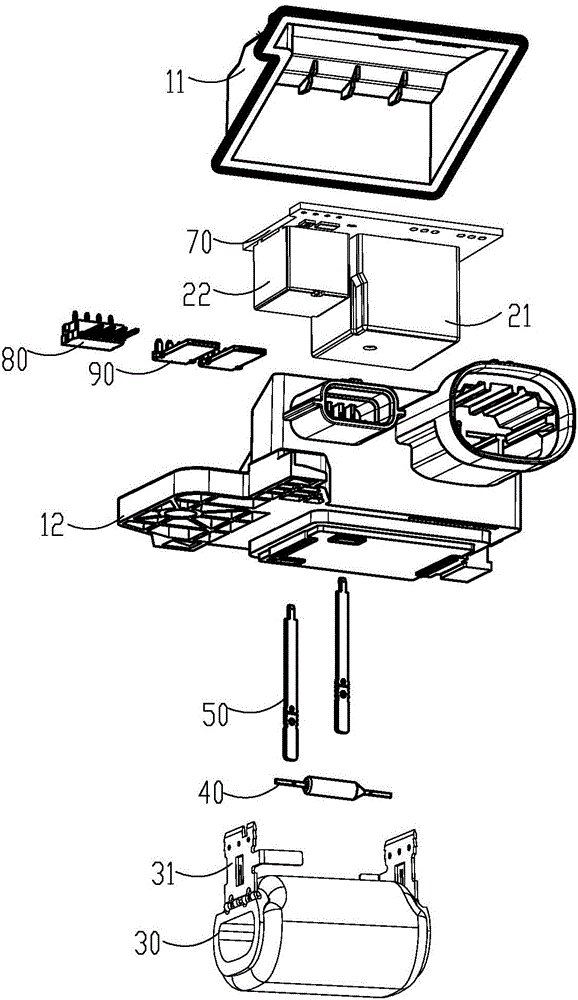

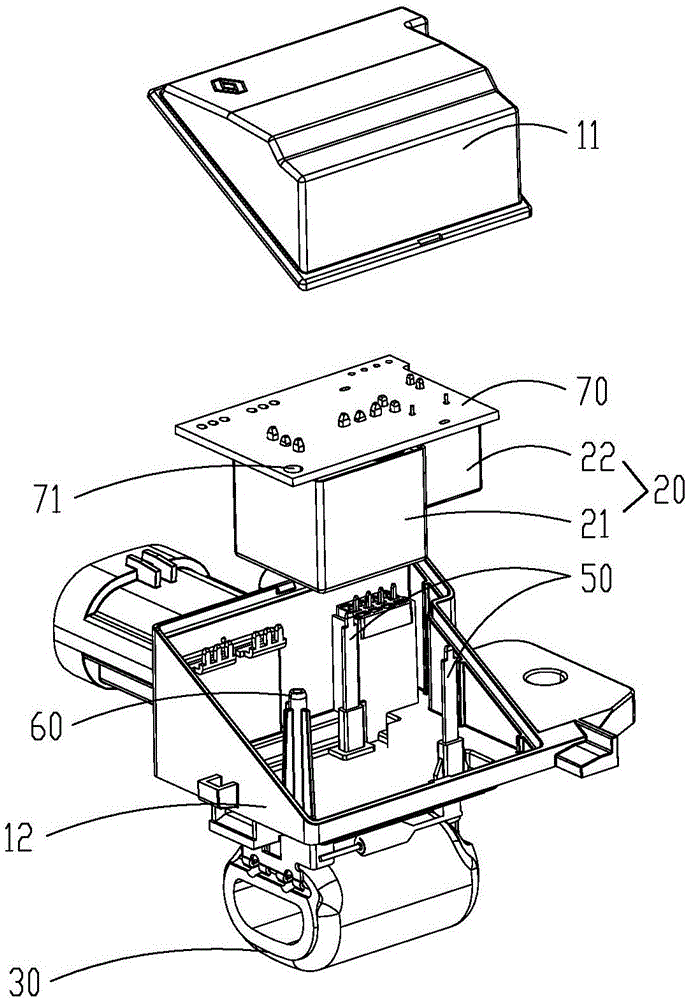

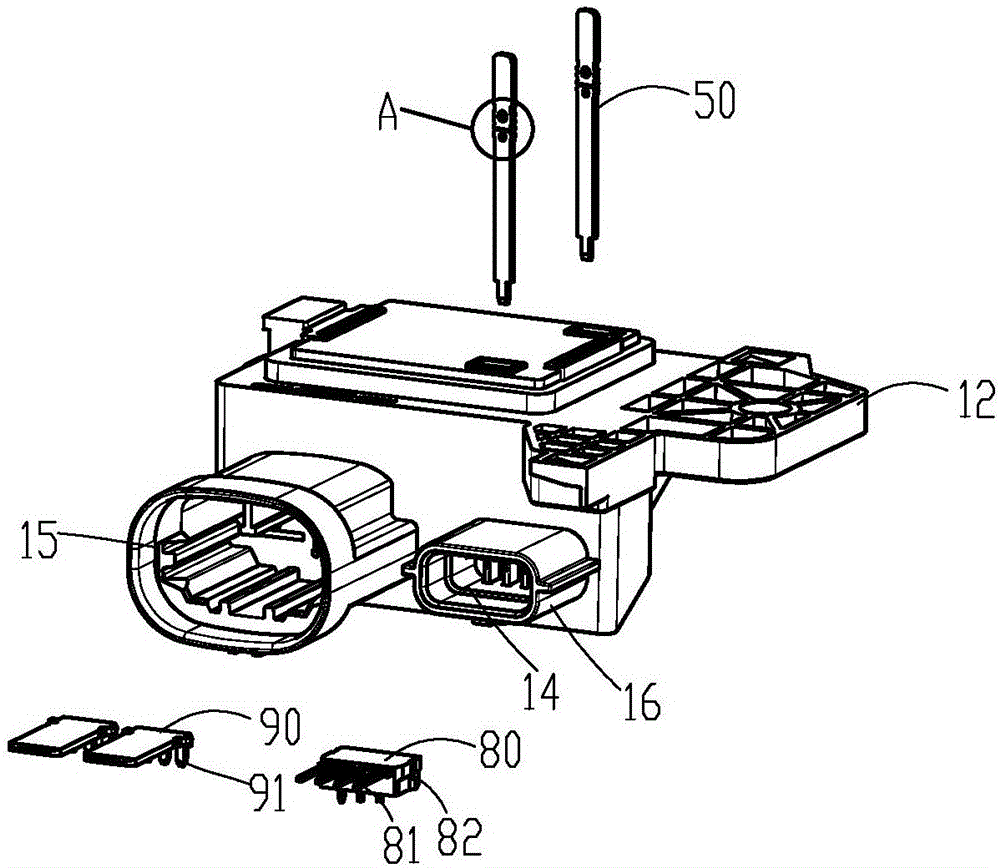

[0045] refer to Figure 1 to Figure 14 , an integrated ceramic resistance relay box, including a housing 10 and an electromagnetic relay group 20 located in the housing 10 , a PCB board 70 , a ceramic resistor 30 , a thermal fuse 40 and two metal conductive connecting pieces 50 . The electromagnetic relay group 20 includes a relay 21 for controlling a high-speed fan and a relay 22 for controlling a low-speed fan. The electromagnetic relay group 20 can also be replaced by a MOS tube or other electronic switching elements, which are welded on the PCB 70 . The housing 10 includes an upper shell 11 and a lower shell 12. The junction of the upper shell 11 and the lower shell 12 forms a dispensing groove 13, which is formed at the joint after the upper shell 11 and the lower shell 12 are assembled. Groove, by dispensing glue in the dispensing groove 13, the waterproofing of the casing 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com