Patents

Literature

70results about How to "Realize automatic pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

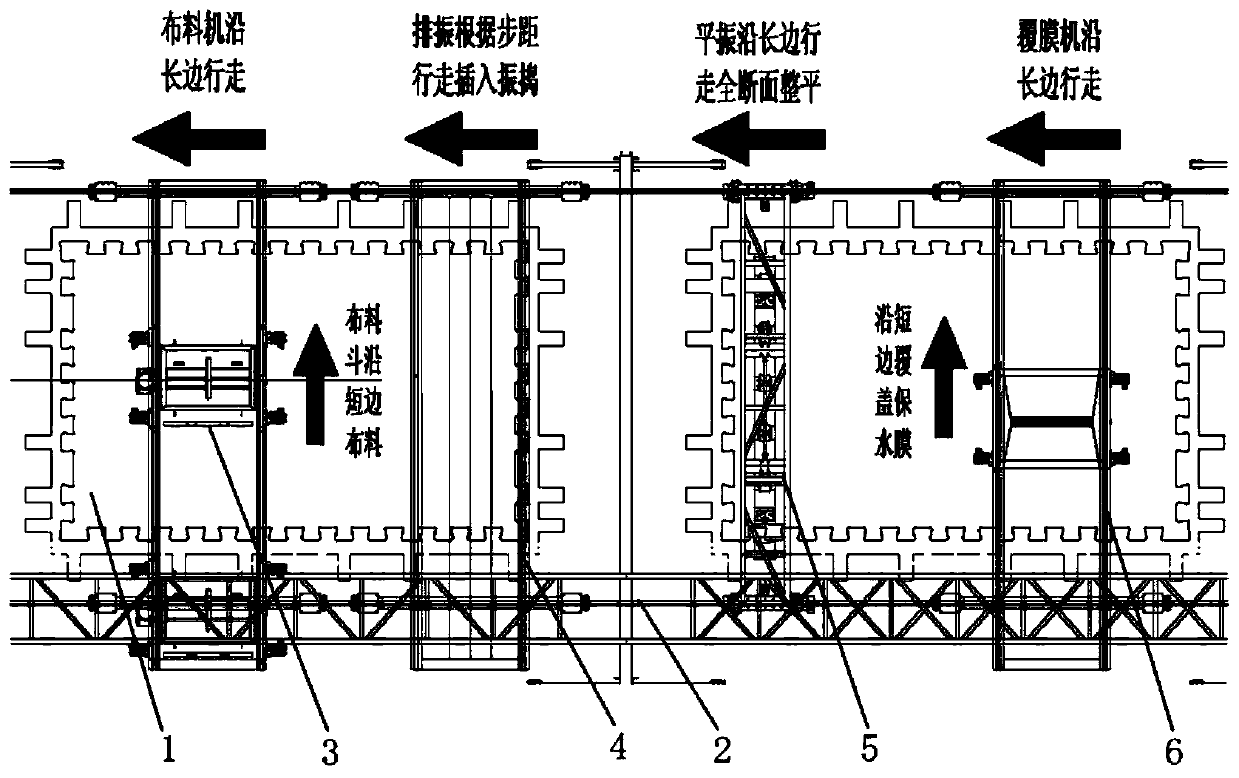

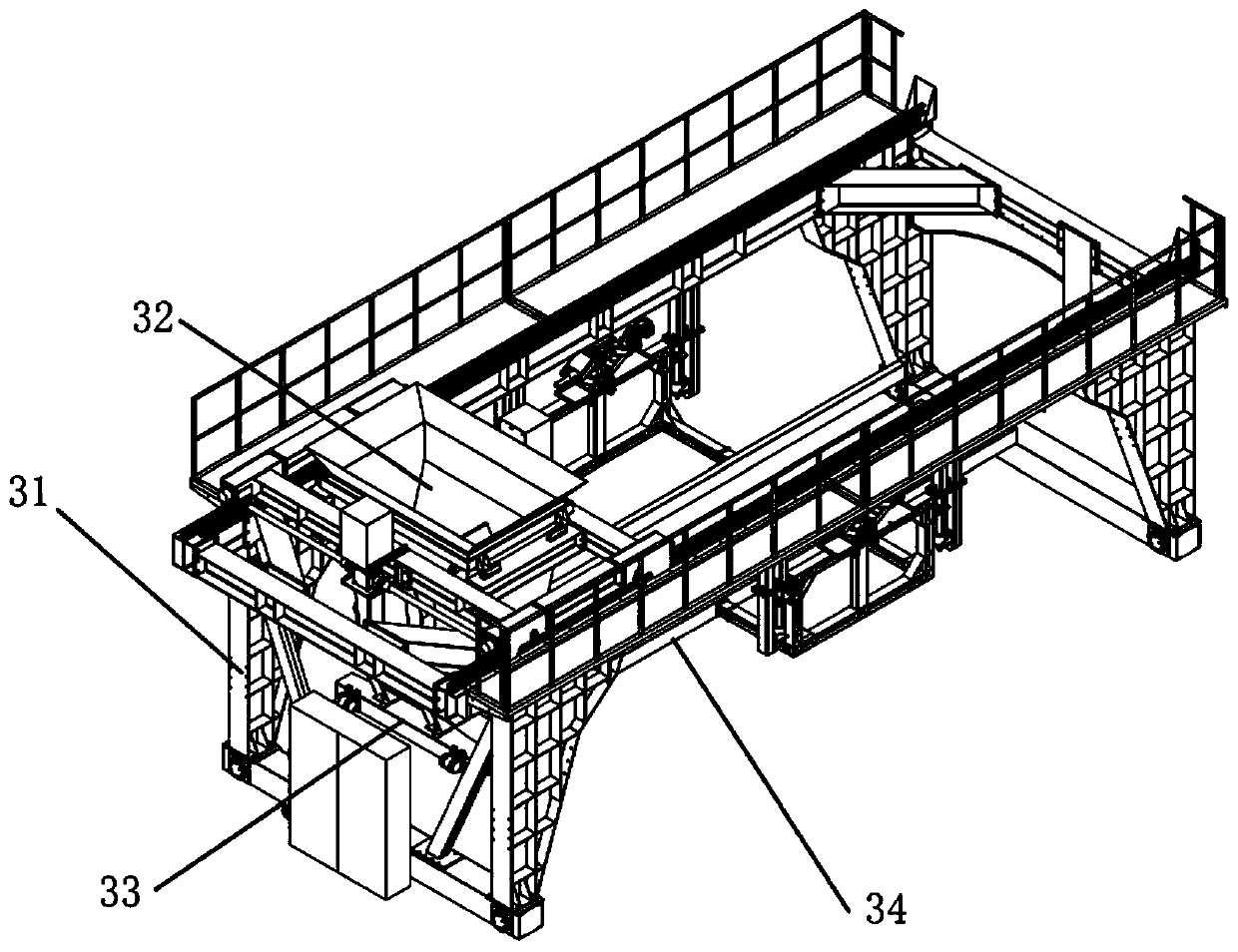

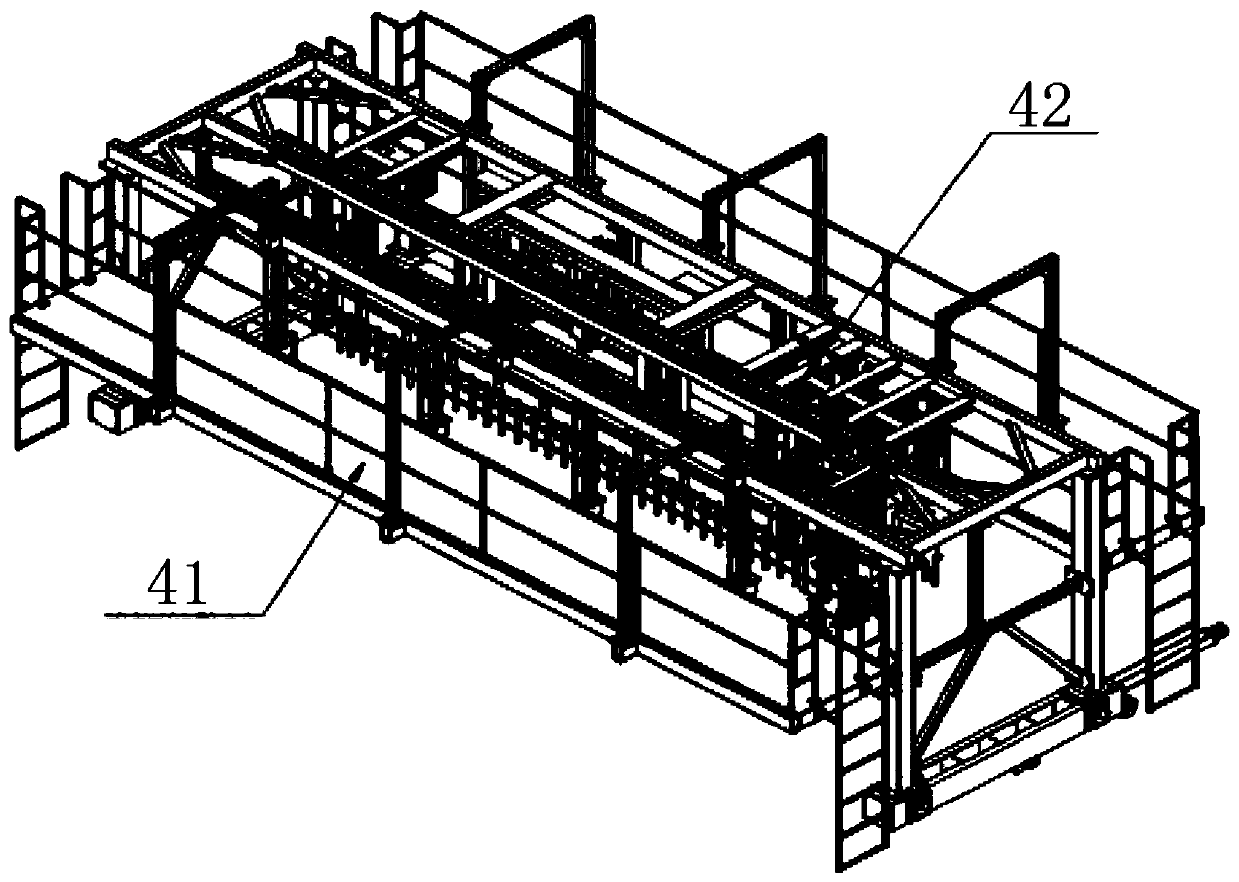

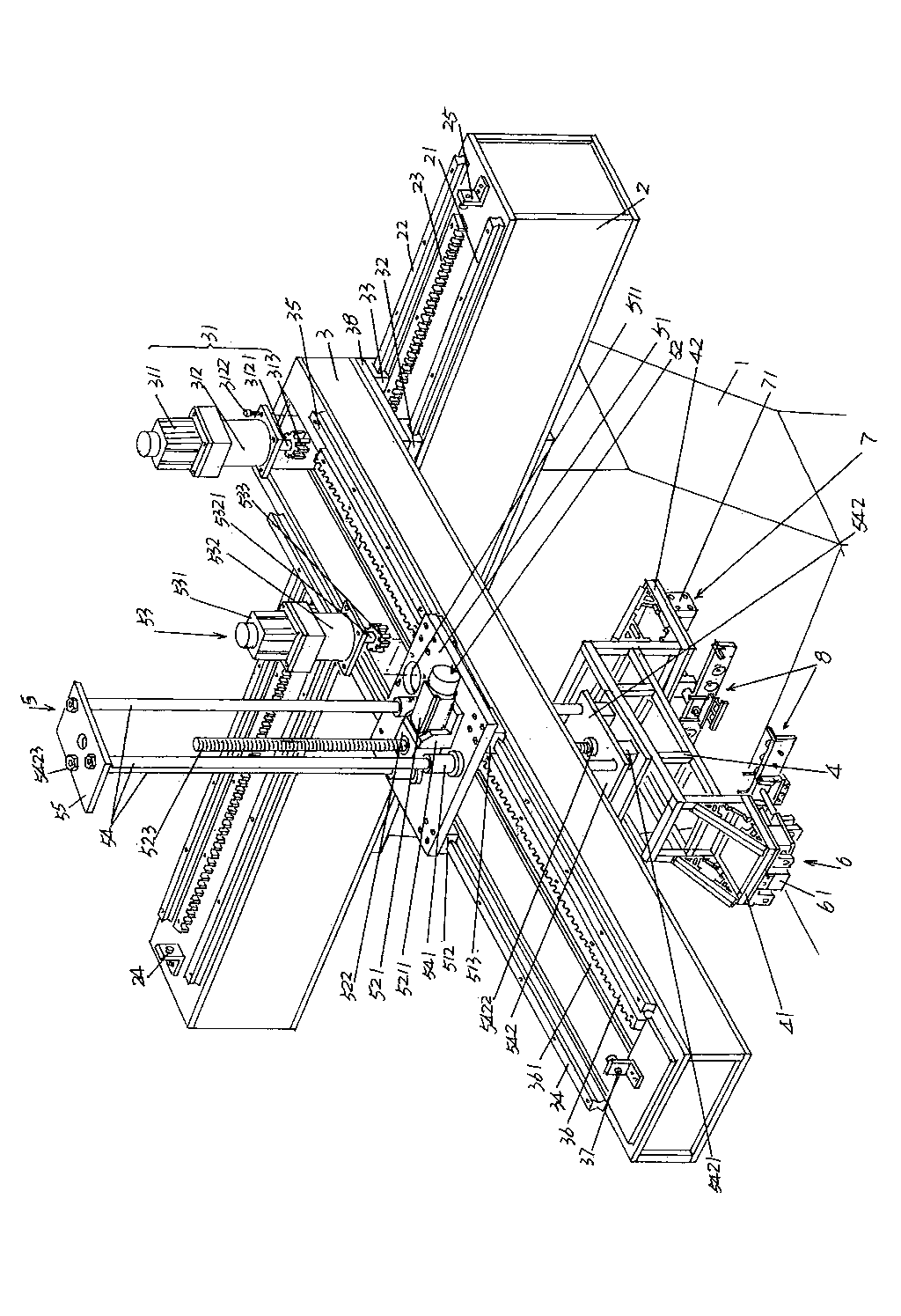

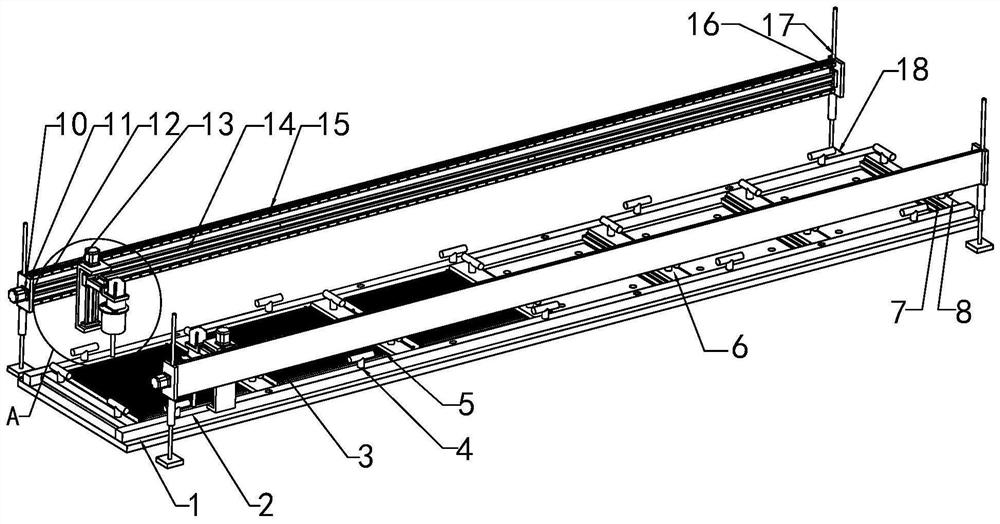

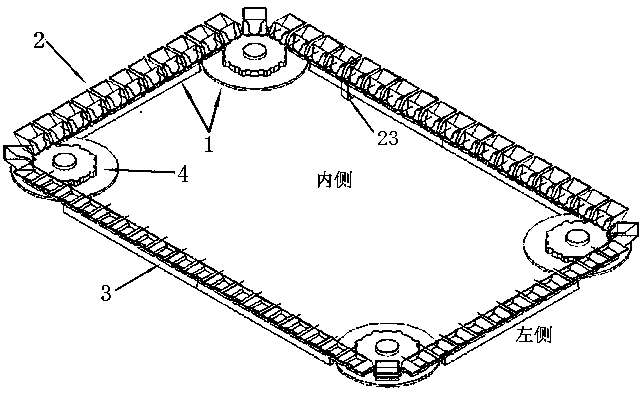

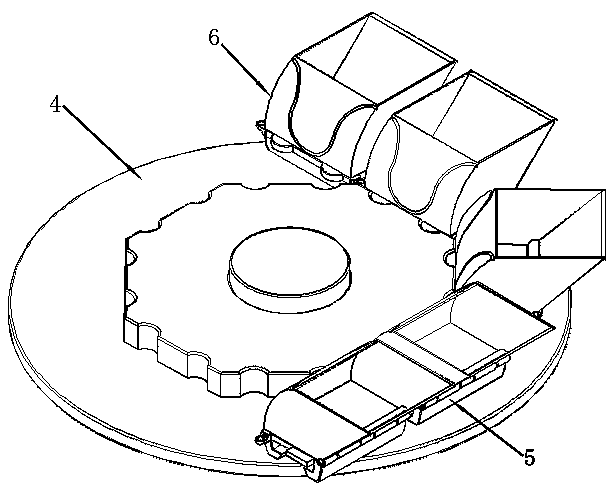

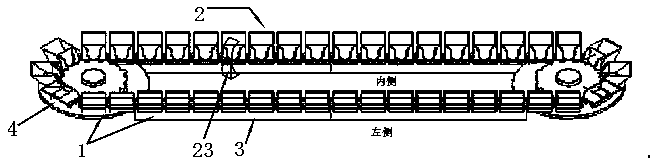

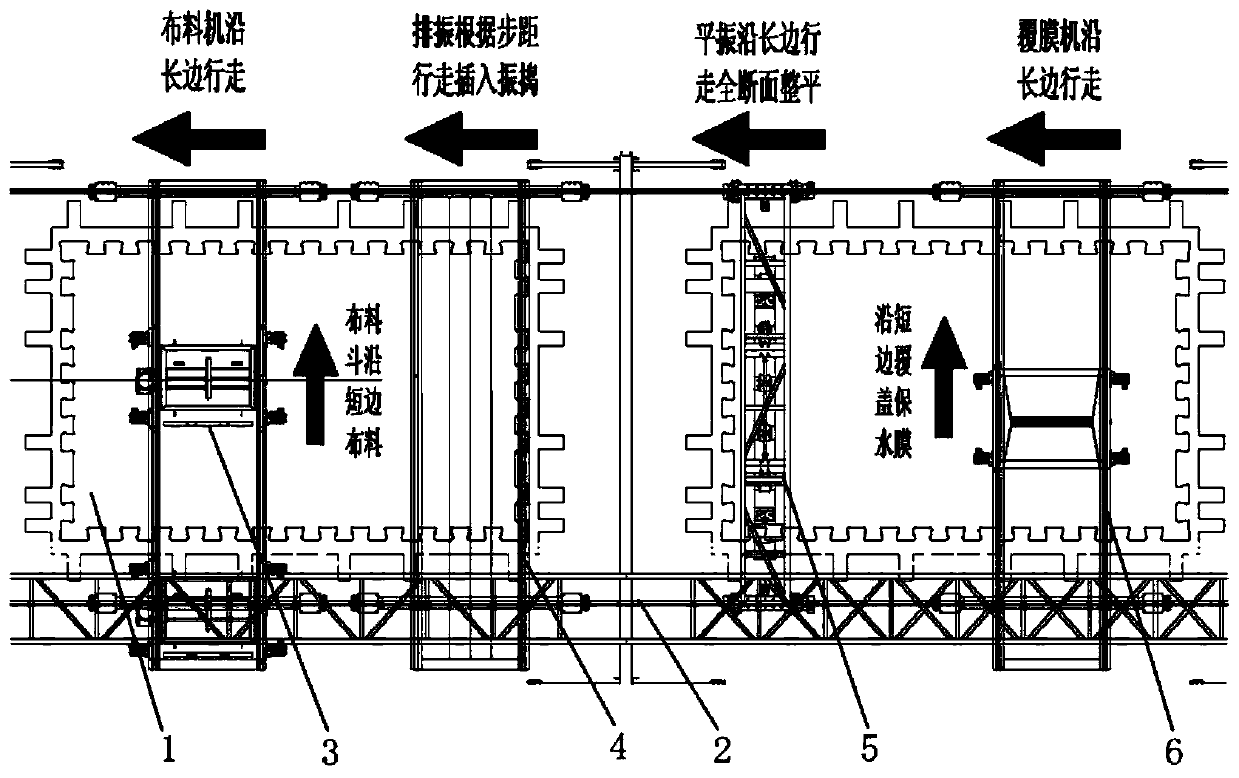

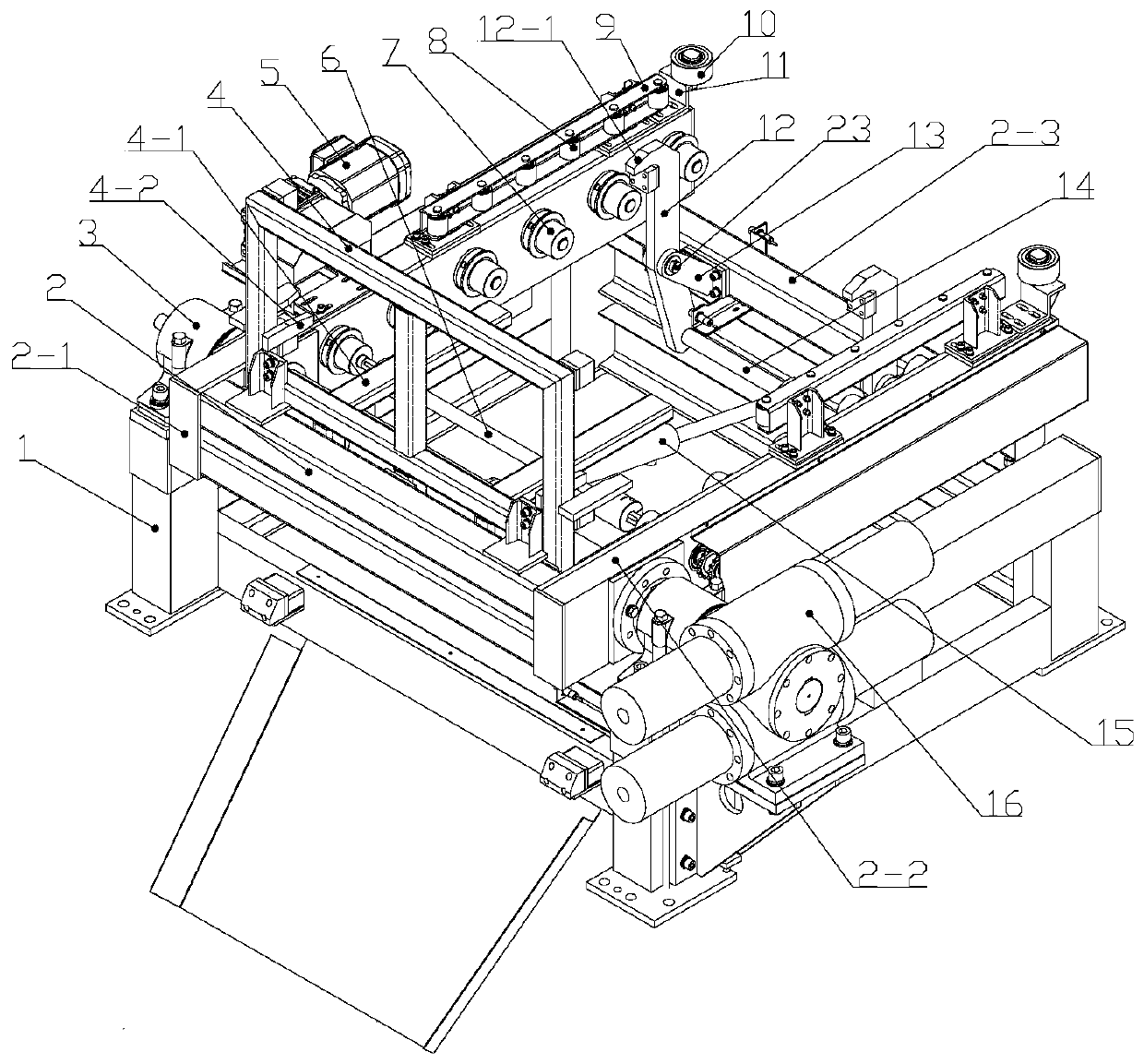

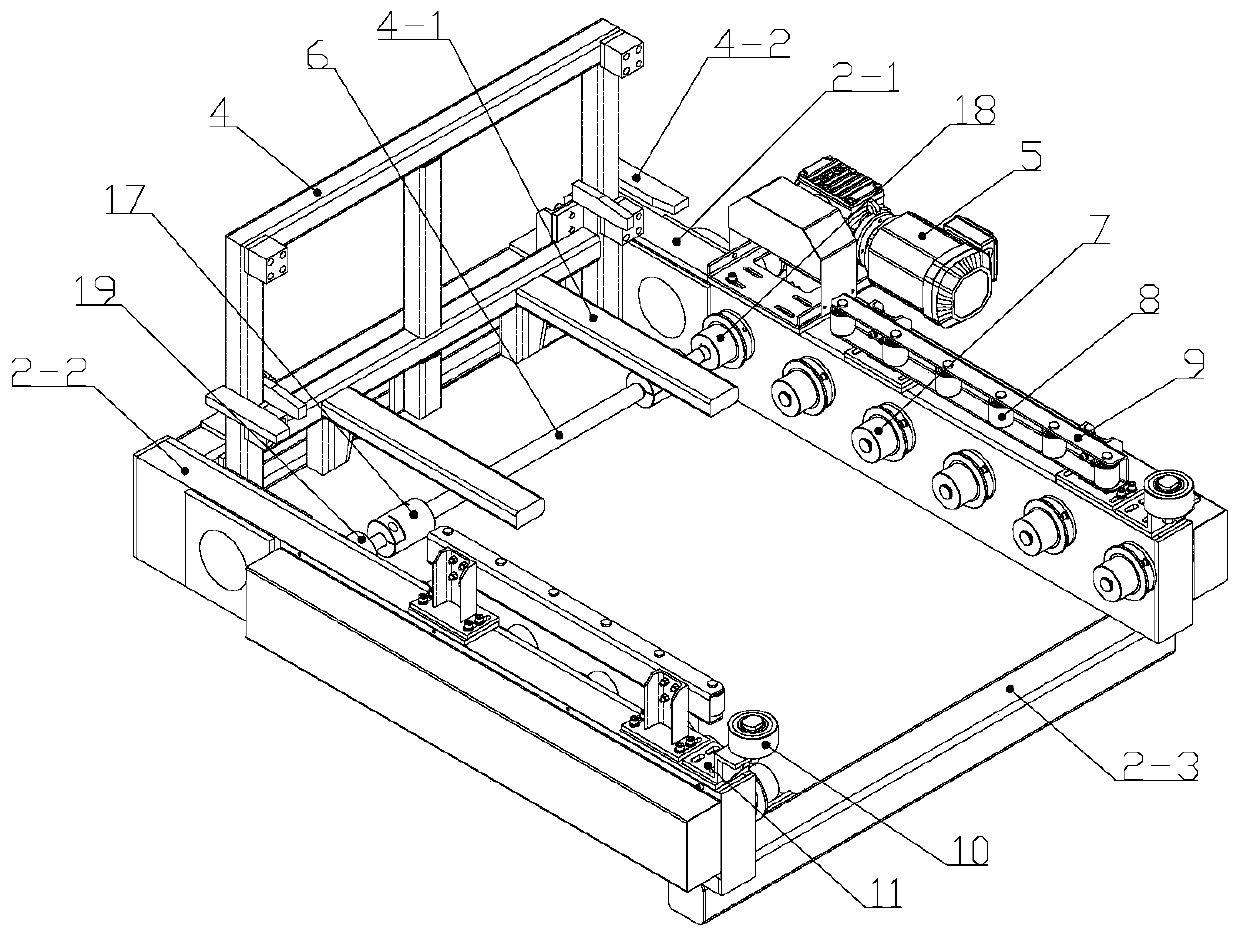

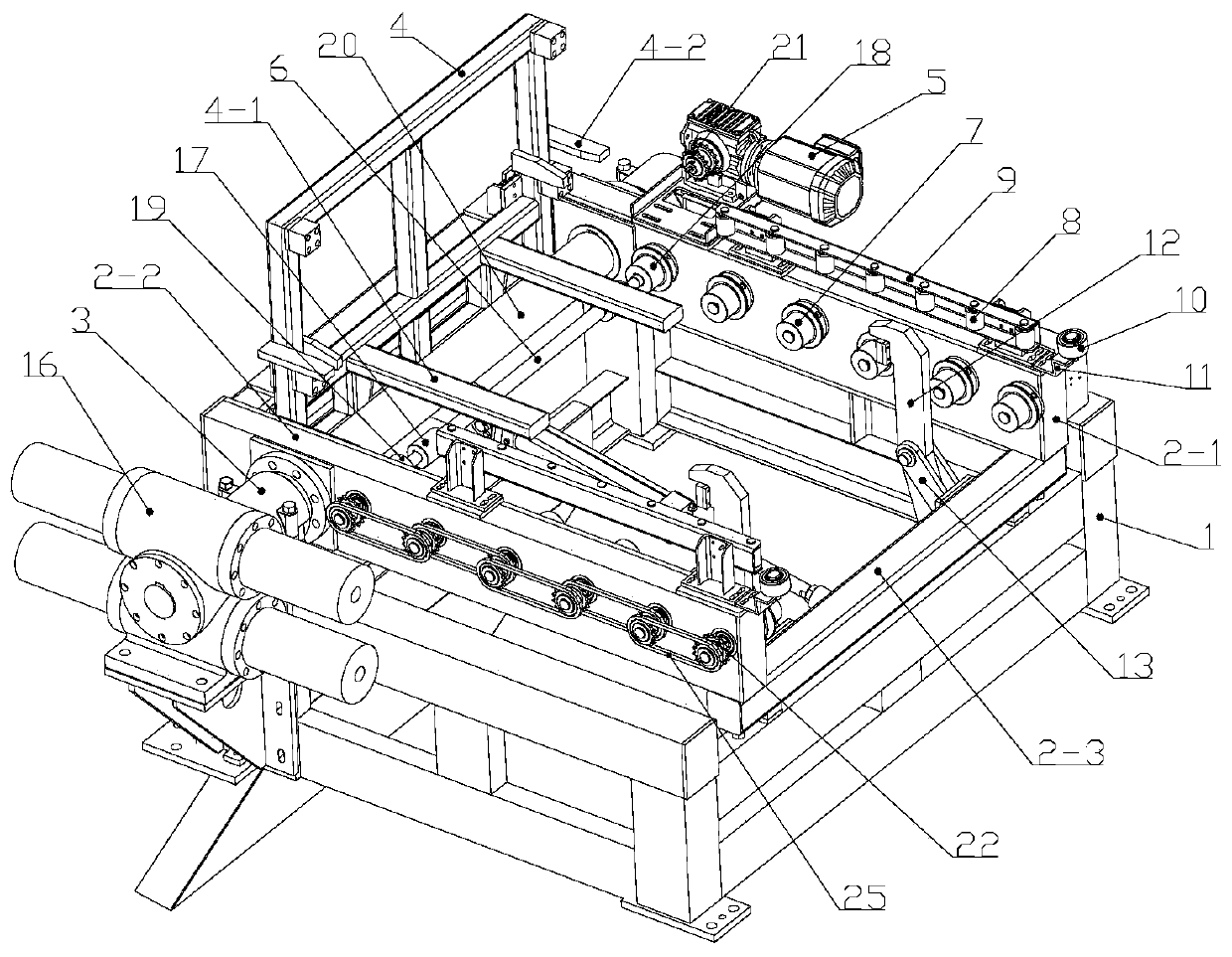

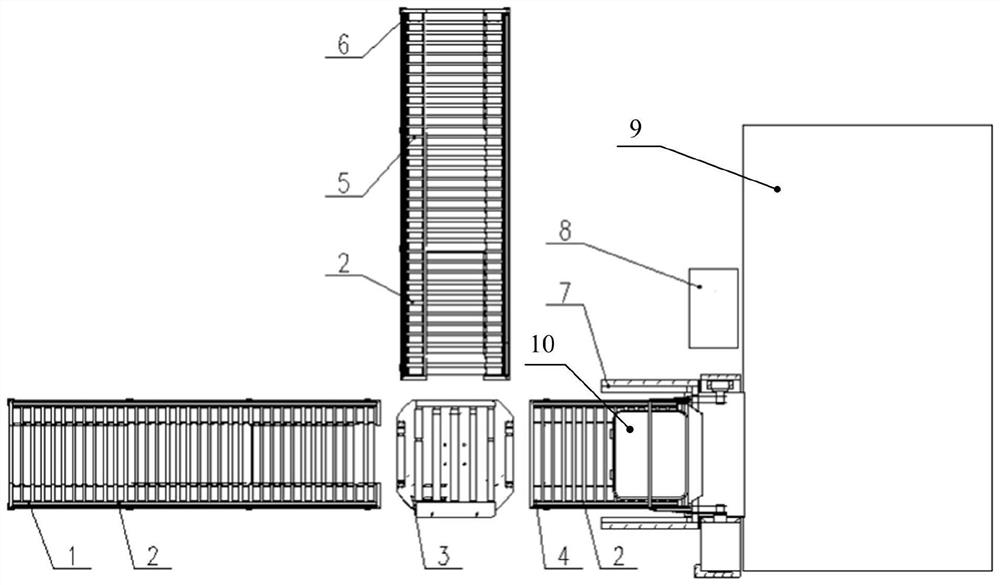

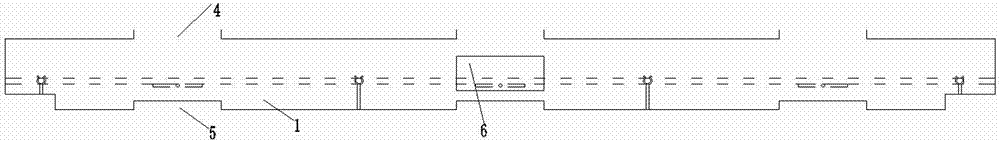

Automatic material distributing and vibrating system for concrete bridge deck slab and control method thereof

InactiveCN110777657AReduce construction waiting timeOvercoming problems that cannot be implemented quicklyBridge erection/assemblyProgramme control in sequence/logic controllersControl systemBridge deck

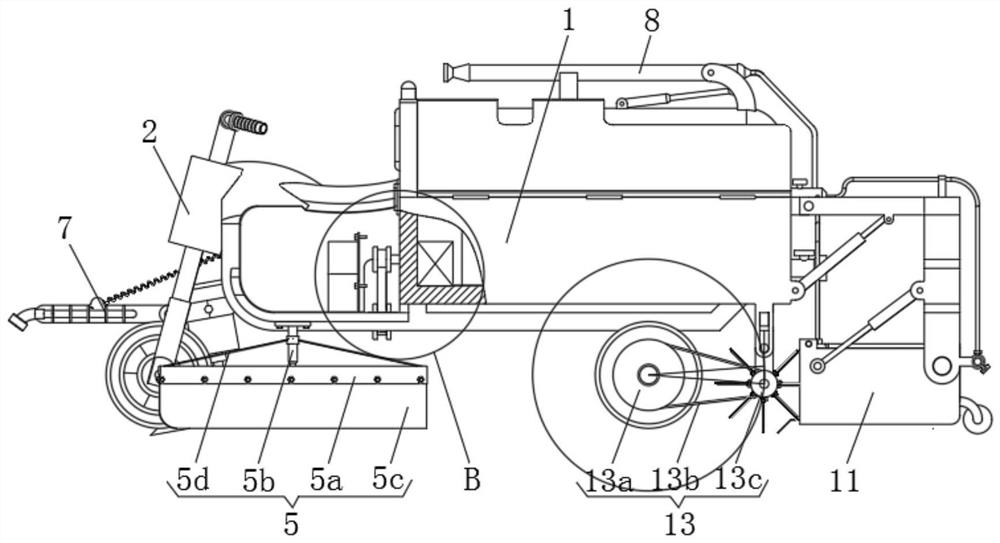

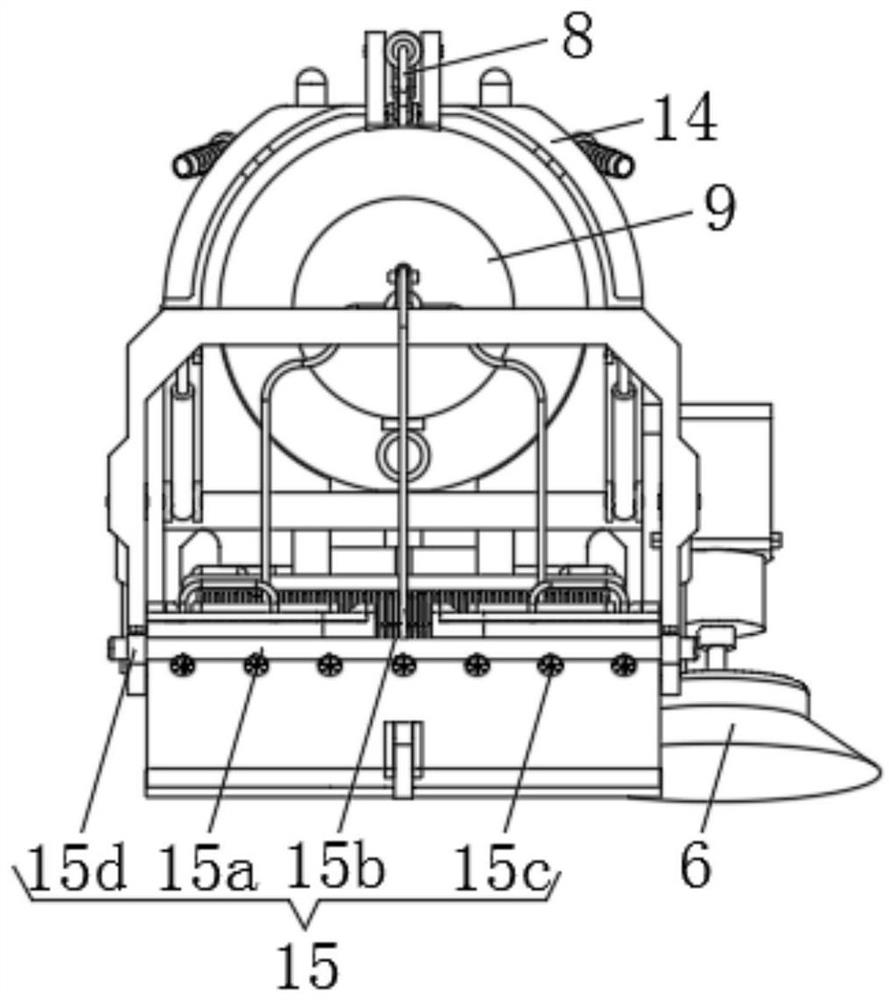

The invention discloses an automatic material distributing and vibrating system for a concrete bridge deck slab and a control method thereof. The automatic material distributing and vibrating system comprises a track, a material distributing machine, an array type vibrating machine, a flat plate vibrating and leveling machine, a rolling film laminating machine and a control system, wherein the material distributing machine comprises a walking frame moving along the track and a material distributing hopper mounted below the walking frame; the material distributing hopper moves along a frame cross beam; the frame cross beam is parallel to the short edge of a mold; the array type vibrating machine comprises a first walking cart moving along the track and an array device mounted below a crossbeam of the first walking cart; a plurality of rows of vibrating rods are arranged below the array device in the advancing direction of the array device; the first row of vibrating rods are special dovetail joint vibrating rods arranged at intervals according to the designed dovetail joint positions; and the other rows of vibrating rods are arranged in a full-section mode and correspond to steel bar meshes. The requirement of coarse aggregate reactive powder concrete for distribution uniformity can be met, and the influence of environment changes on the bridge deck slab is reduced.

Owner:CCCC SHEC FOURTH ENG

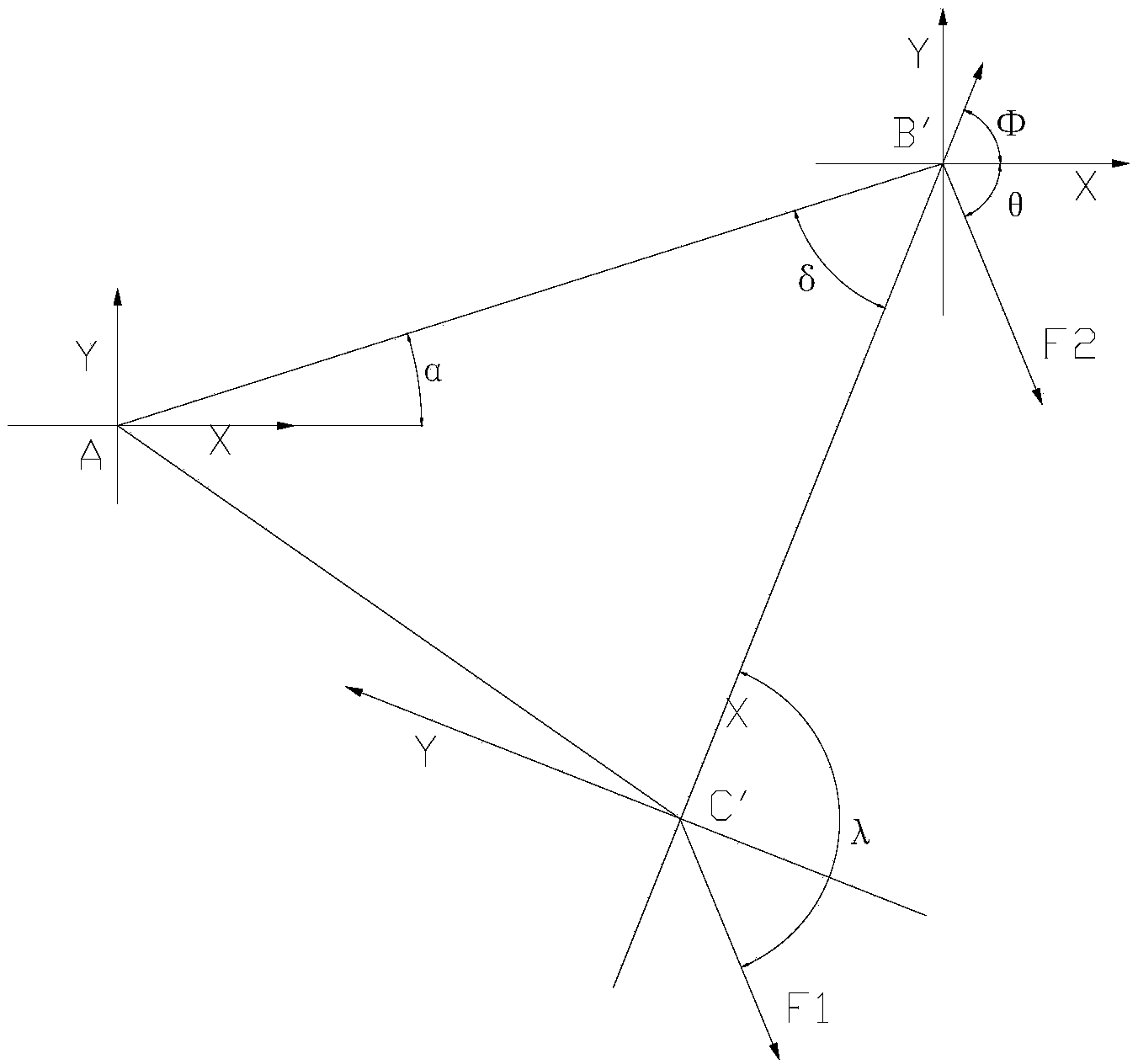

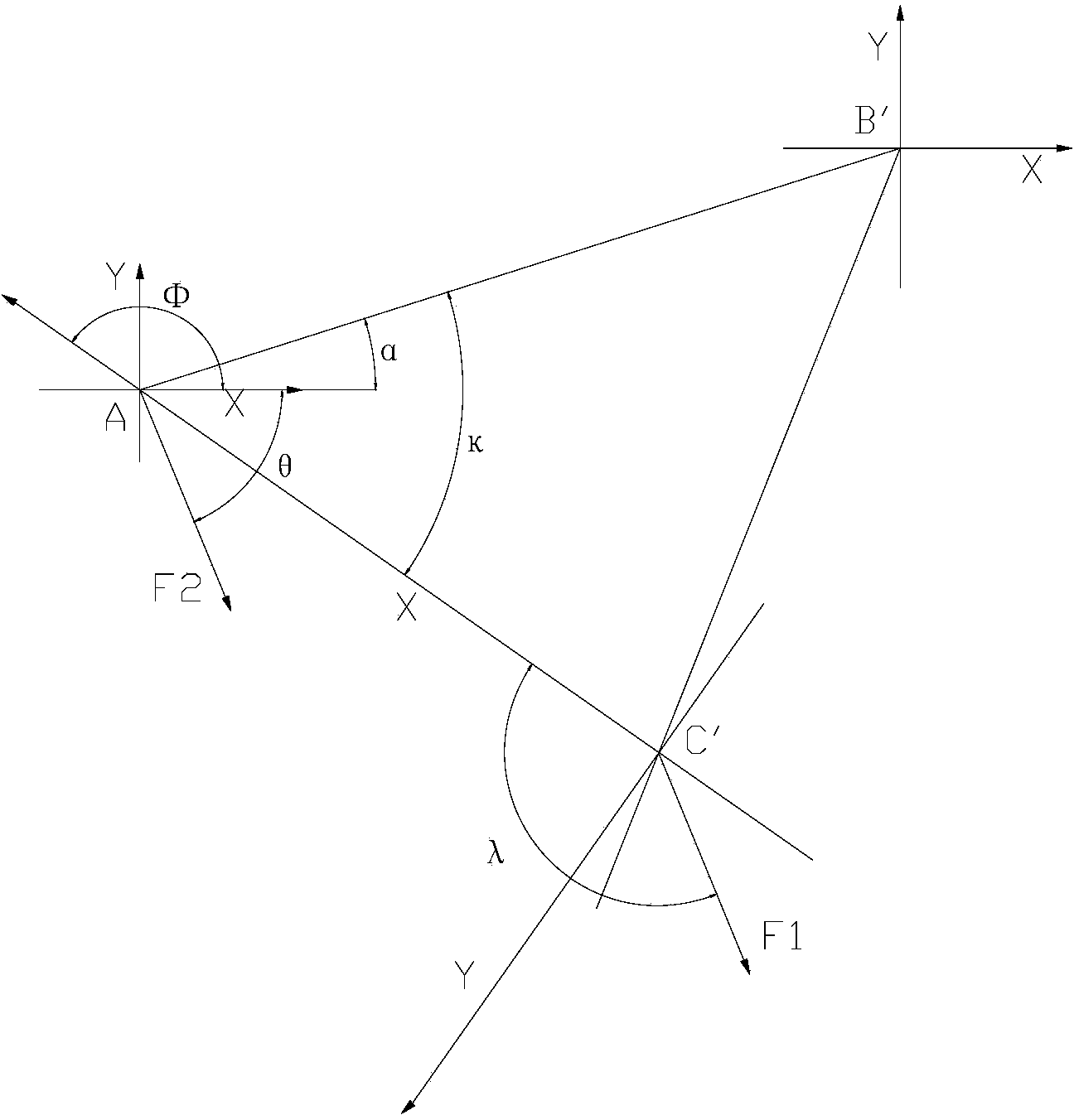

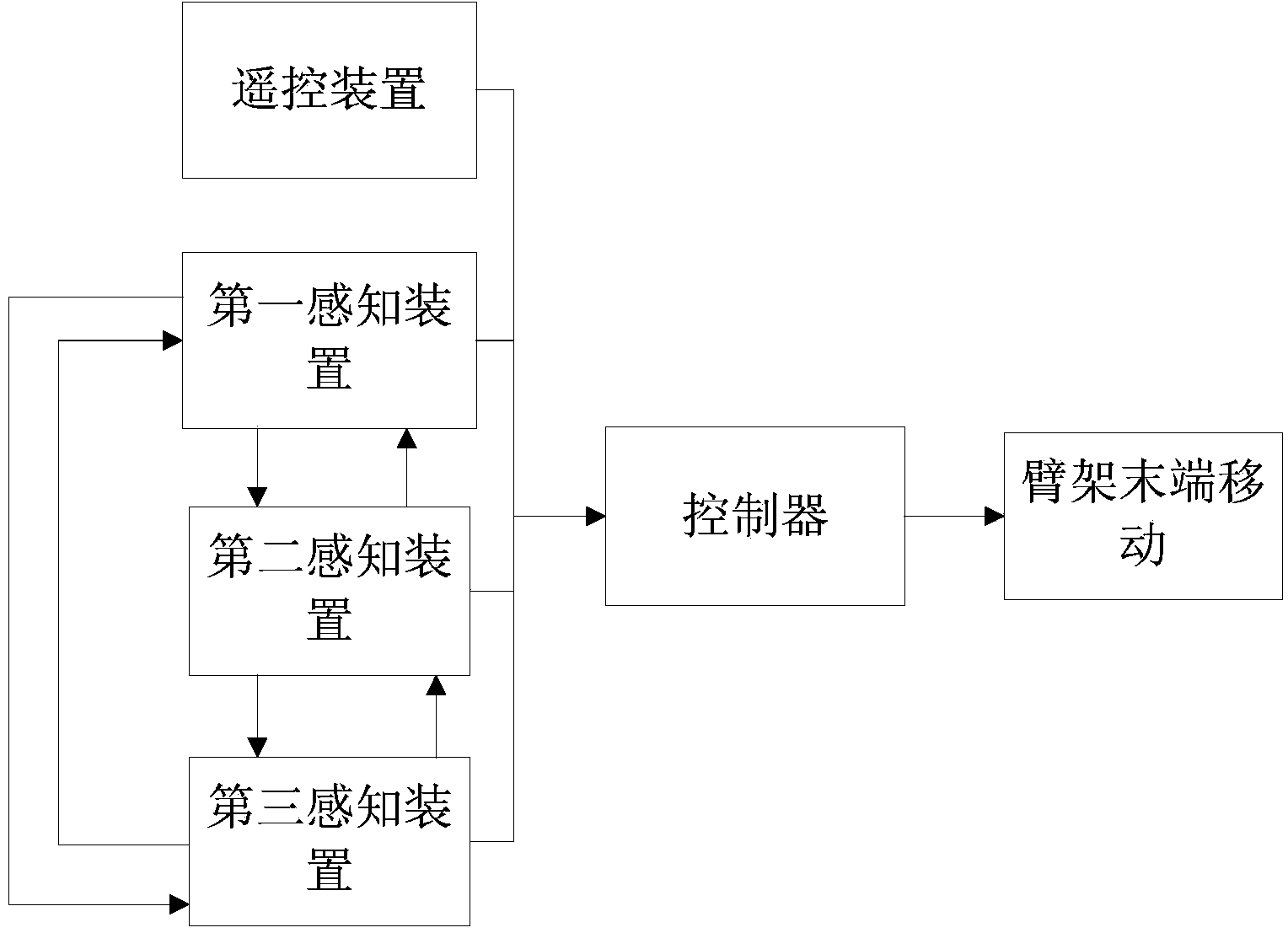

Placing boom control method, placing boom control device, concrete pump truck and material distributing machine

ActiveCN103590606AEasy to controlReduce the difficulty of operationBuilding material handlingLoad-engaging elementsRemote controlCentre of rotation

The invention discloses a placing boom control method. The placing boom control method comprises the steps that a two-dimensional absolute coordinate system is established on the horizontal plane; a two-dimensional dynamic coordinate system is established on the horizontal plane, wherein the connection line between the original point of the two-dimensional absolute coordinate system and the original point of the two-dimensional dynamic coordinate system is an axis of the two-dimensional dynamic coordinate system, the original point of the two-dimensional absolute coordinate system is located on the rotating central point of a placing boom or the tail end point of the placing boom, and the original point of the two-dimensional dynamic coordinate system is located on a remote control device; the angles formed between the swinging direction of an operating hand shank of the remote control device and the coordinate axes of the two-dimensional dynamic coordinate system are obtained; the angle that the two-dimensional dynamic coordinate system rotates relative to the two-dimensional absolute coordinate system is obtained; through coordinate system conversion computation, the angles formed between the swinging direction of the operating hand shank of the remote control device and the coordinate axes of the two-dimensional absolute coordinate system are obtained to control the tail end of the placing loom to move. The invention further discloses a placing boom control device and a concrete pump truck. According to the placing boom control method, the placing boom control device, the concrete pump truck and a material distributing machine, the degree of intellectualization is high, operation difficulty of an operator is reduced, and moving accuracy and flexibility performance of the tail end of the placing loom are improved.

Owner:SANY AUTOMOBILE MFG CO LTD

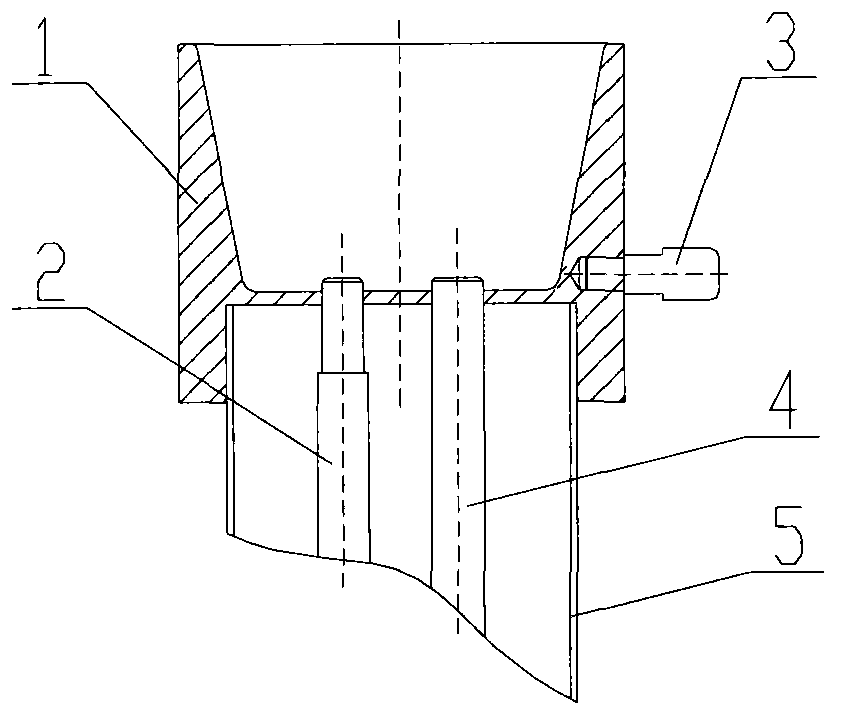

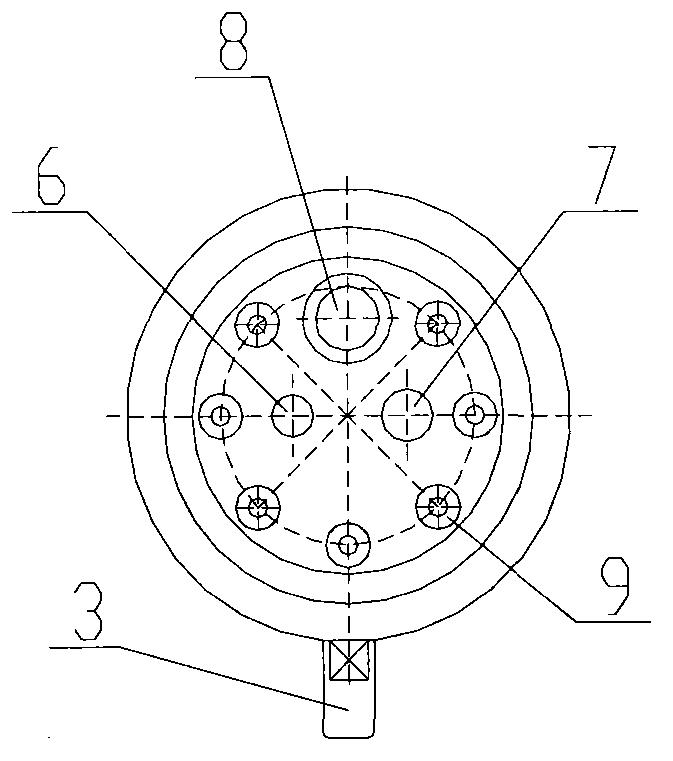

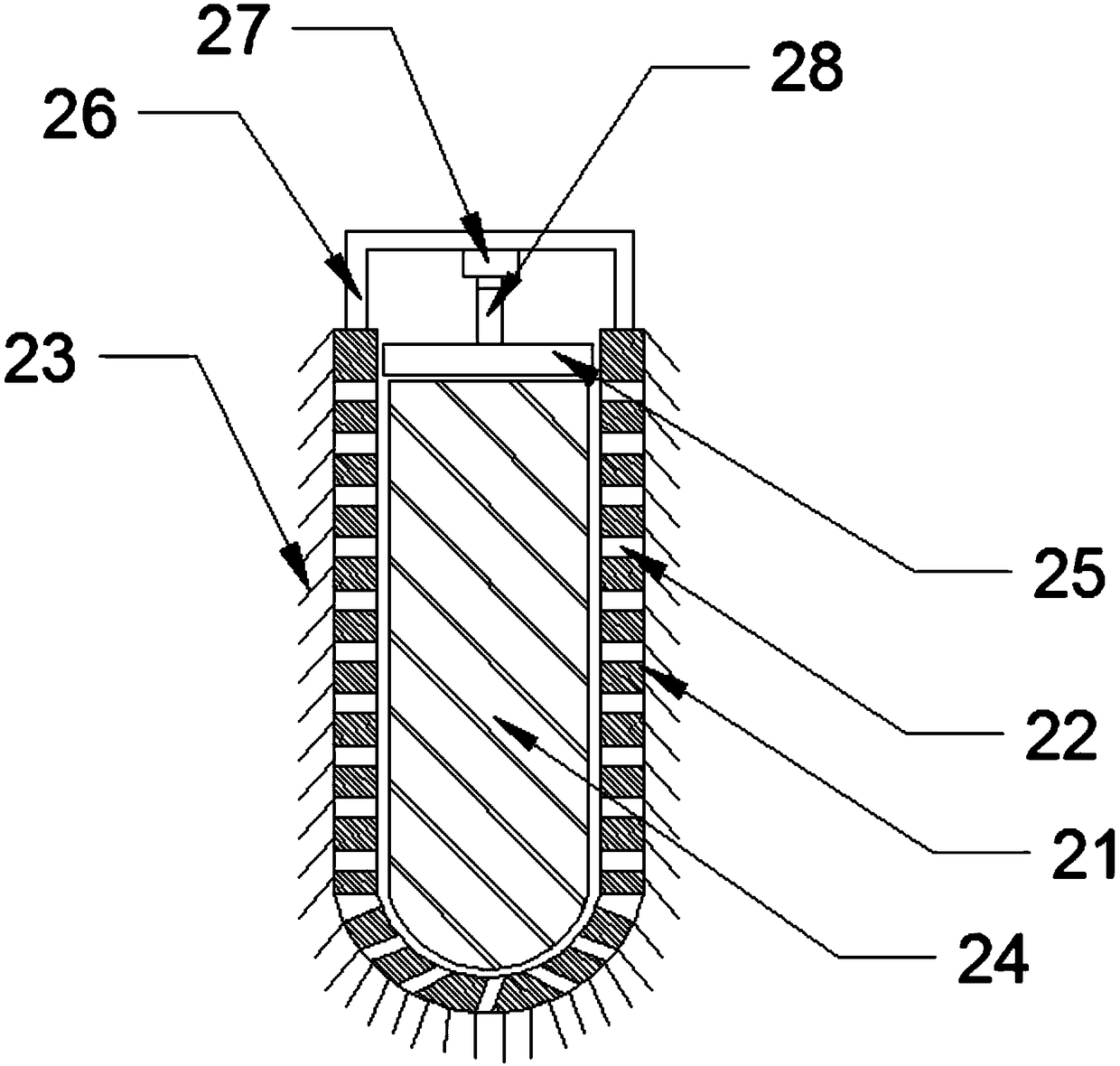

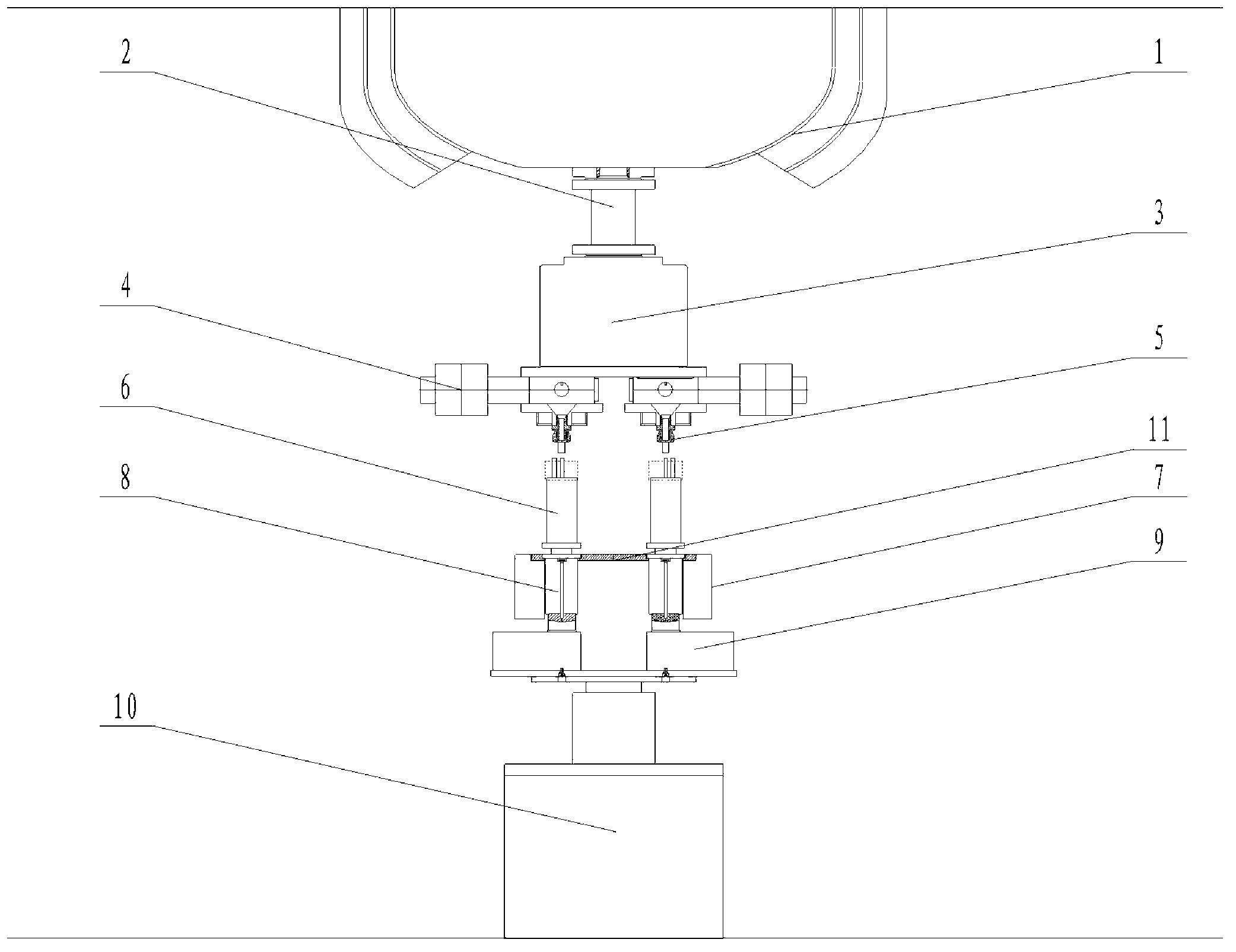

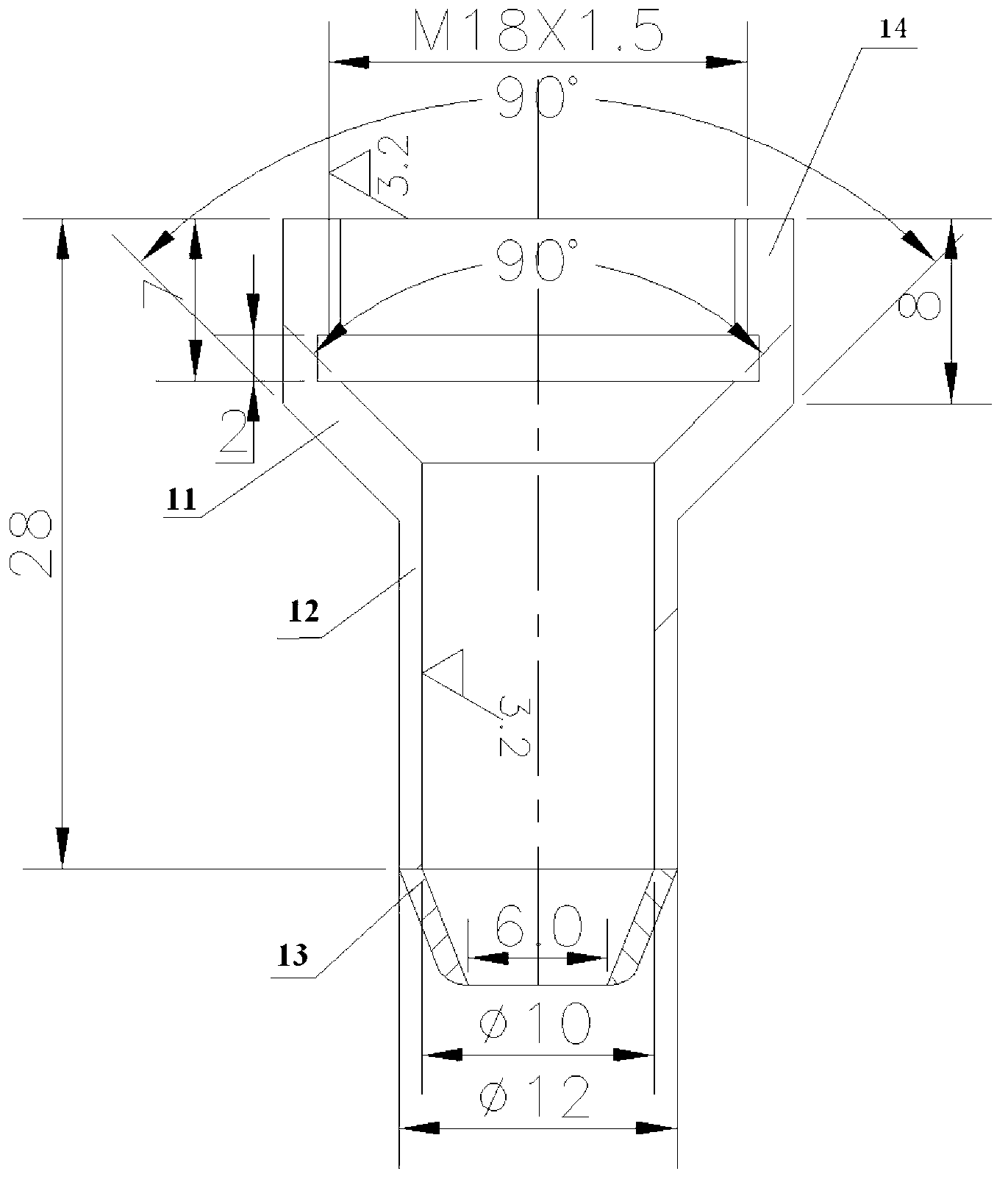

Explosive filling riser of primer

The invention belongs to the technical field of primer production of civil explosive industry, and particularly relates to an explosive filling riser of a primer. The riser comprises a riser body, a push rod, a first core rod, a second core rod and a primer shell, wherein the first core rod and the second core rod are vertically placed in the primer shell side by side; the first core rod and the second core rod are arranged opposite to the center of the primer shell; the upper end of the primer shell is provided with an opening; the first core rod and the second core rod protrude out of the upper end of the primer shell for 5-8 mm; the bottom end of the riser body is provided with a first core rod positioning hole, a second core rod positioning hole, a pouring hole and an exhaust hole respectively; the riser body is placed on the primer shell and is assembled with the first core rod and the second core rod; and the push rod is arranged on the riser body at a position which is 20 mm away from the bottom end. The product provided by the invention has a simple structure and is safe and reliable. Field personnel and the labor intensity of workers are reduced, and the production efficiency and the intrinsic safety of production are improved.

Owner:CHINA WUZHOU ENG GRP +1

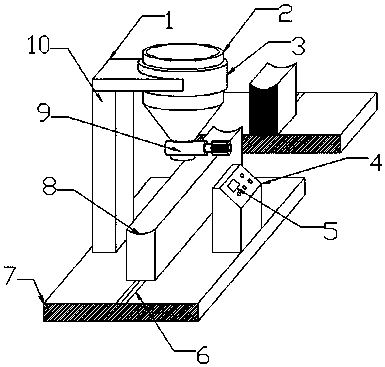

Forming die for toys

The invention relates to the field of dies for toys, particularly to a forming die for toys. The forming die is mainly used for making the toys with planar bottoms, and comprises a die lifting rack, and a fixed plate is installed above the die lifting rack, and used for installing a storage tank; the front end of the fixed plate is provided with a flowmeter and a solenoid valve, and the storage tank is installed above the fixed plate; a discharge port is formed at the part below the fixed plate, and a die fixture is installed in the middle of the die lifting rack, and used for installing and externally connecting the die; the die fixture is connected to the die lifting rack through a sliding sleeve used for moving the die fixture easily, and the sliding sleeve is installed on the die lifting rack. According to the forming die for the toys, provided by the invention, the problems that the toy casting molding is slow, the toys are uneasy to carry, the models are less, the operation is inconvenient, and different kinds of flat toys can not be manufactured simultaneously in the prior art are solved.

Owner:汕头市裕晟塑胶实业有限公司

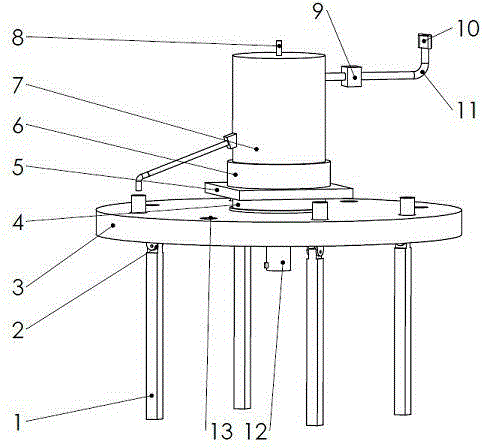

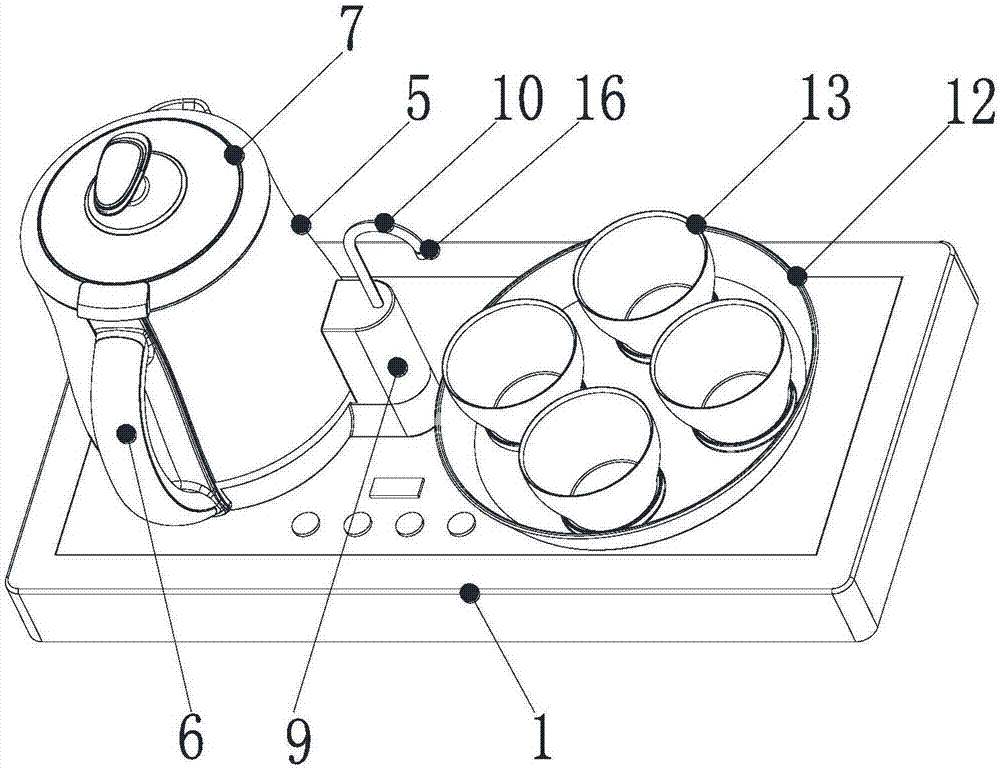

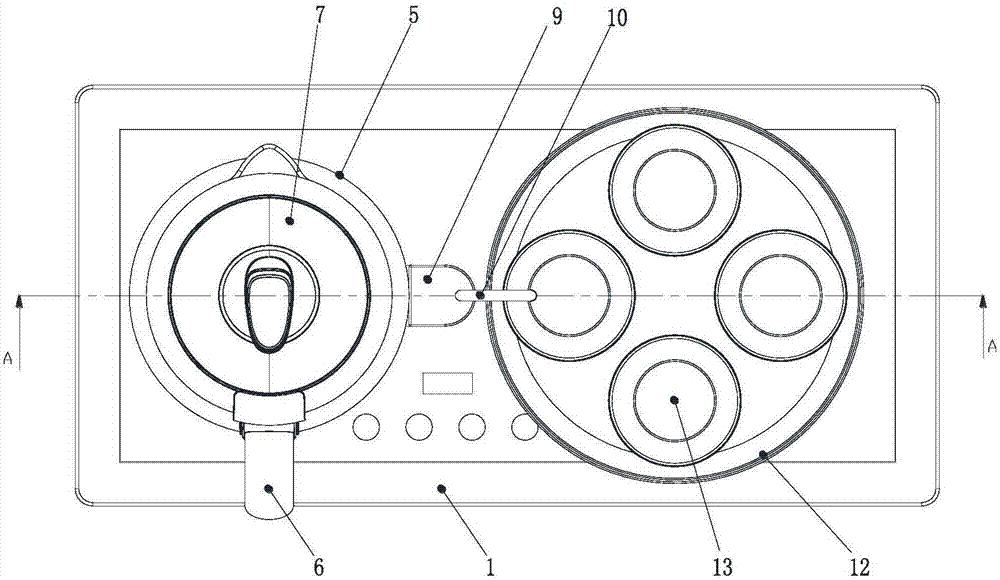

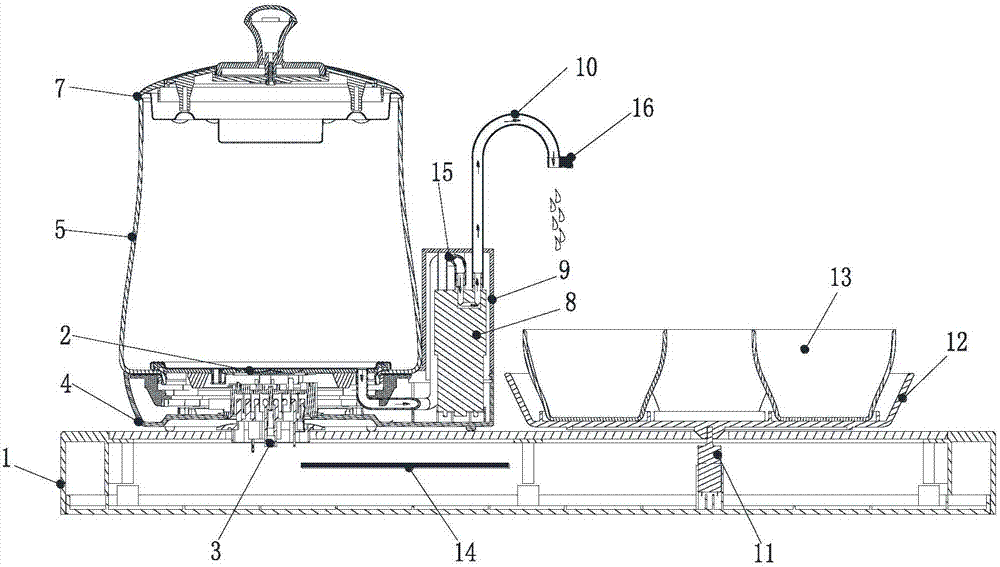

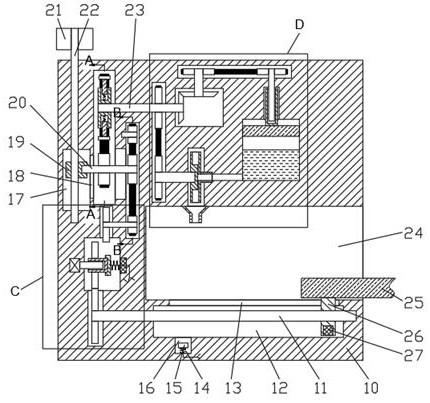

Automatic water pouring device

InactiveCN104687933ARealize automatic pouringRealize automatic water additionDomestic vesselsOptical axisEngineering

The invention provides an automatic water pouring device. The automatic water pouring device comprises four table legs, hinge joints, a tabletop, a rotary table, an electromagnetic heater, a protection device, an intelligent kettle, an air outlet, a filter, a telescopic bent pipe, a quick joint, a servo motor and eight positioning grooves. The automatic water pouring device is characterized in that the hinge joints are fixed to the bottom of the tabletop through screws, each table leg is connected with the corresponding hinge joint through an unthreaded shaft, the tabletop is supported by the four table legs, and the rotary table is mounted in the middle of the tabletop; the protection device is mounted on the electromagnetic heater which is mounted on the rotary table, the intelligent kettle is mounted in the protection device, and the air outlet is formed in the center of the upper portion of the intelligent kettle; the filter is connected with the intelligent kettle through a common water pipe, the telescopic bent pipe and the quick joint are in threaded connection with the common water pipe, the servo motor is fixed to the bottom of the tabletop and connected with the rotary table, and pressure sensors are arranged in the eight positioning grooves uniformly distributed in the tabletop. The automatic water pouring device has the advantages that automatic water pouring can be realized when water in cups is too little, automatic water adding can be realized when water in the intelligent kettle is too little, and automatic heating can be realized when water temperature is too low, so that a host is free of constantly pouring water for guests and heating water in the kettle when people get together for chatting.

Owner:UNIV OF JINAN

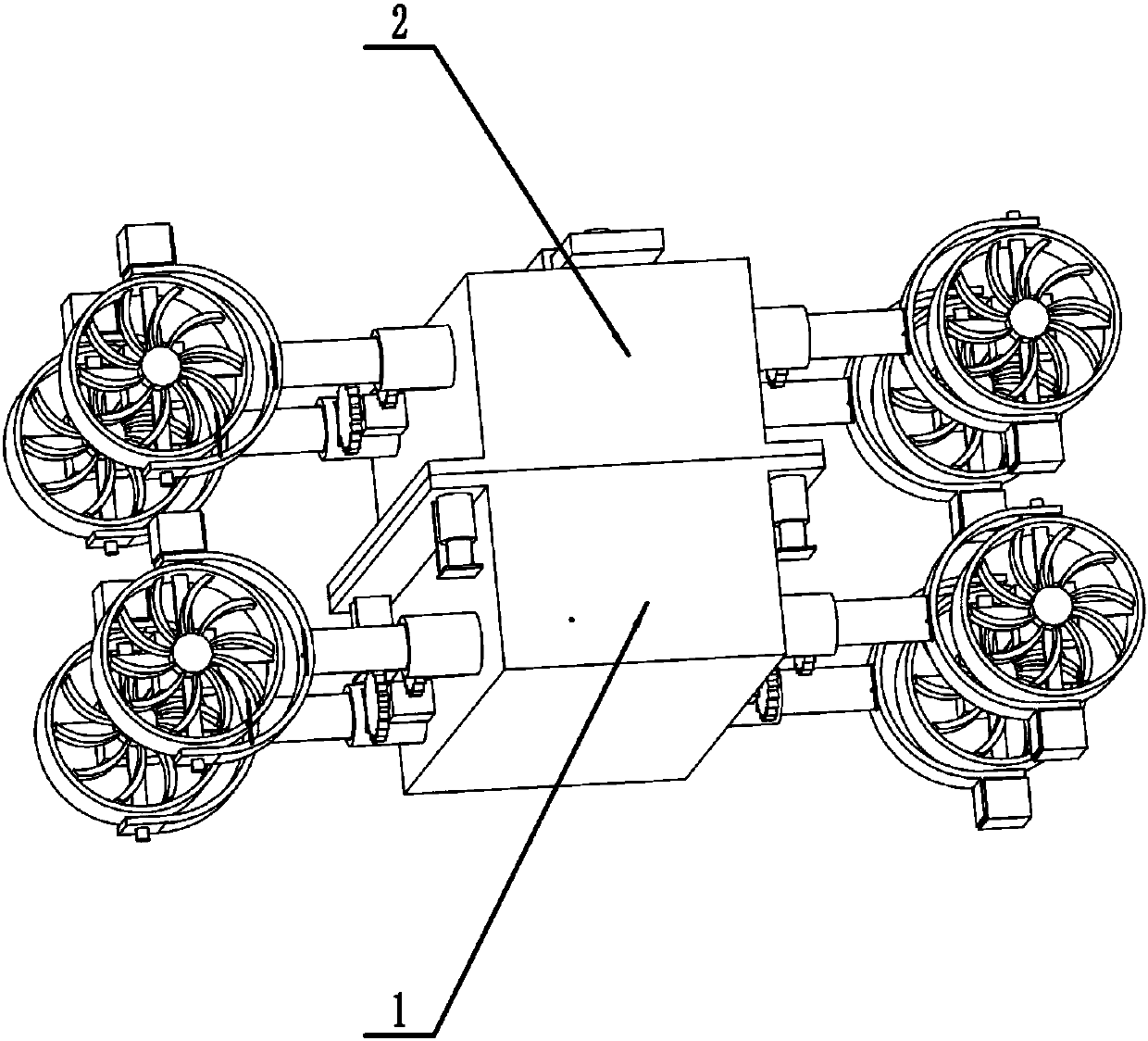

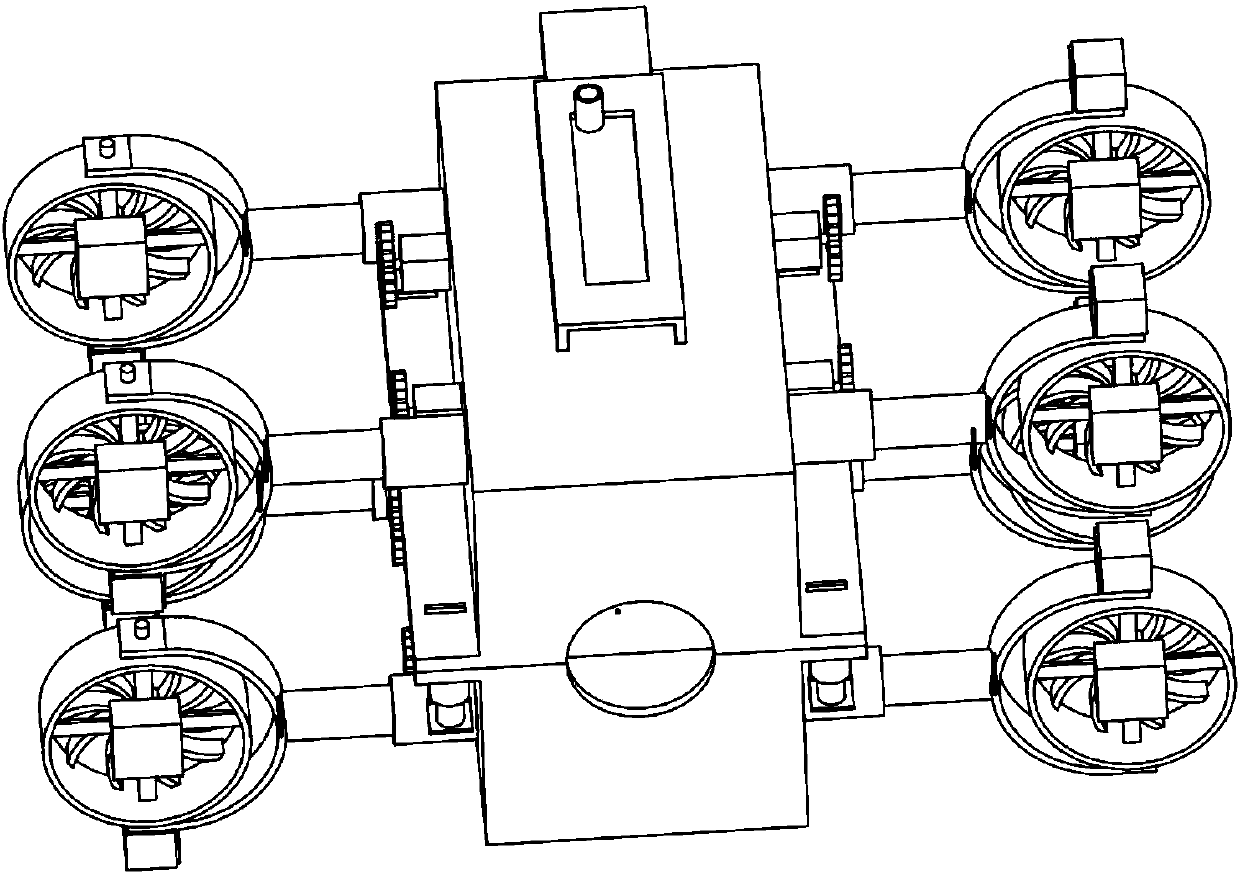

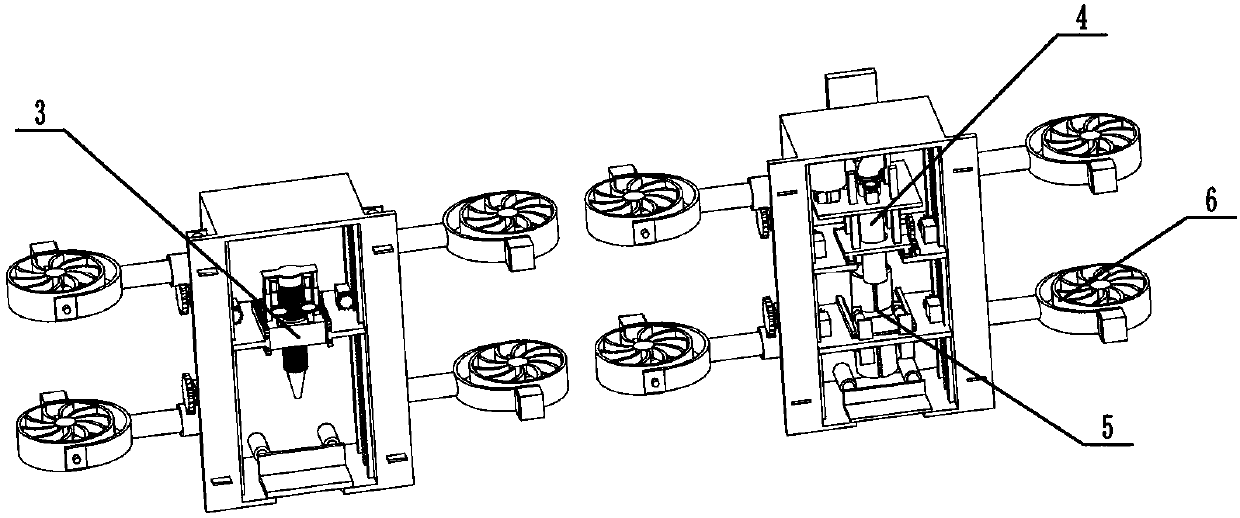

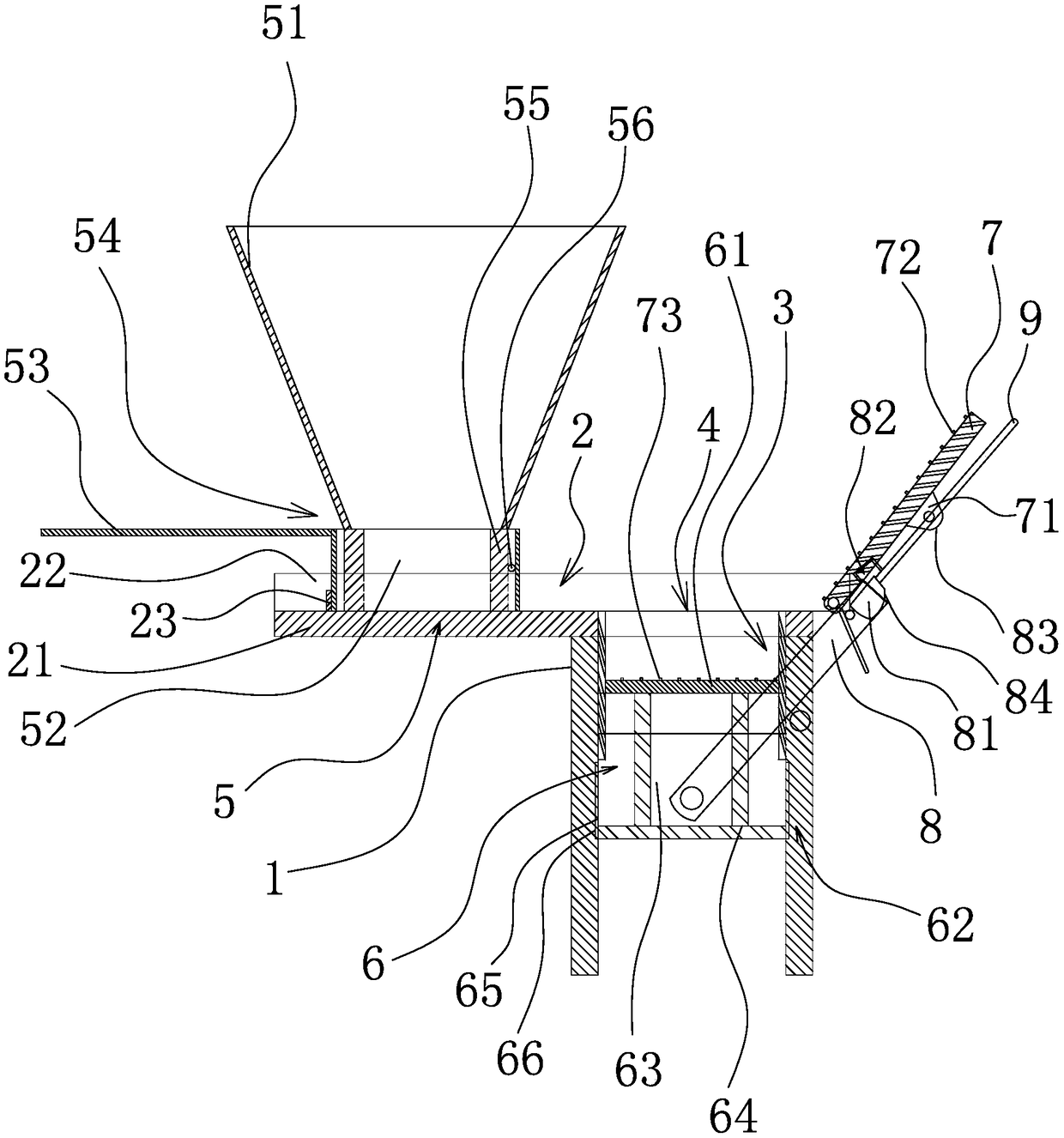

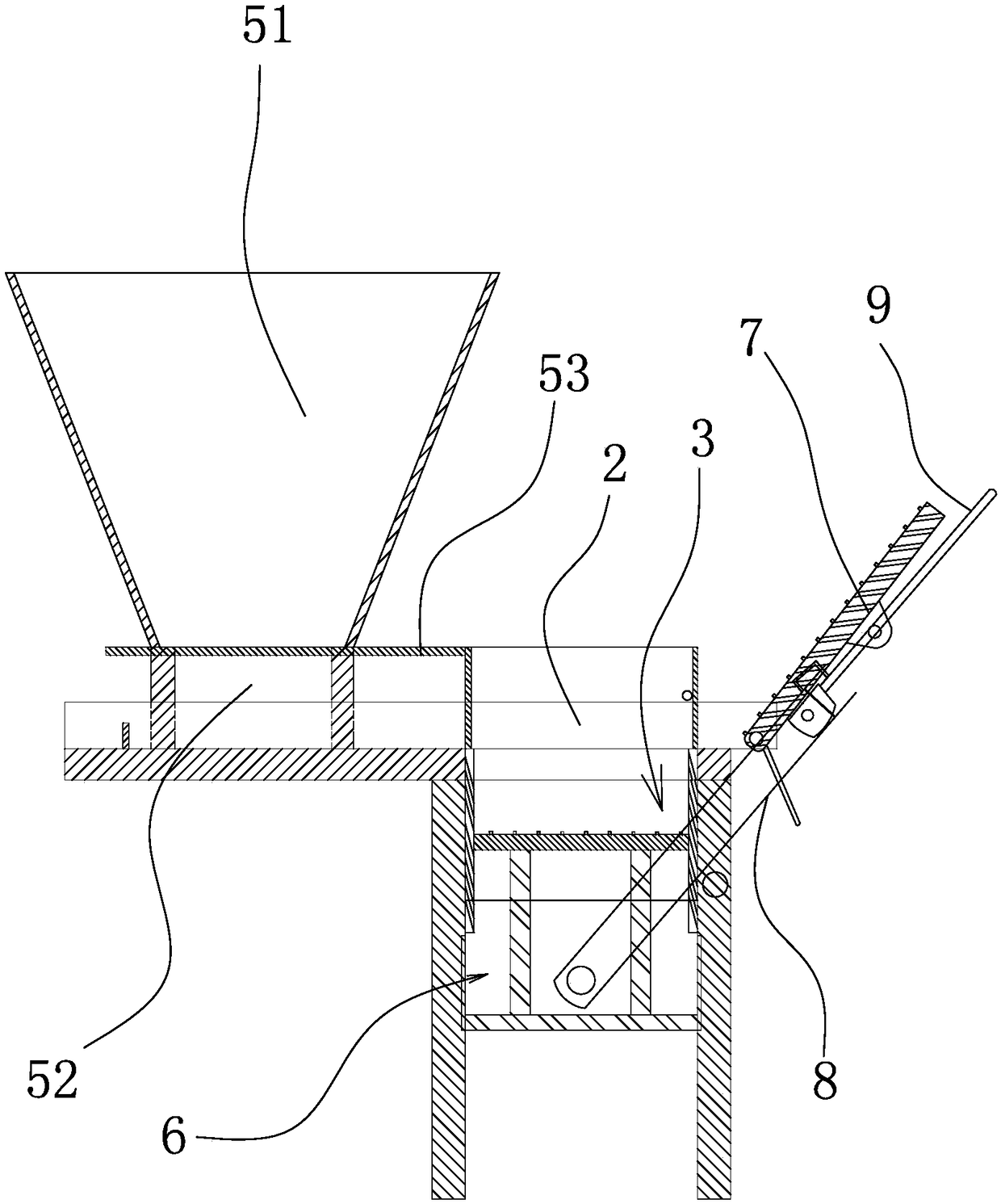

Underwater pier pouring machine

ActiveCN107675629ARealize automatic pouringImprove pouring efficiencyFoundation engineeringBridge erection/assemblyMotor driveEngineering

The invention discloses a pier pouring machine which comprises a first shell portion, a second shell portion, a borehole portion, a pouring portion, a supporting tube portion, and eight turbine portions. The pier pouring machine is characterized in that four second L-shaped plates of the first shell portion are respectively slidably installed in the four first rectangular grooves of the second shell portion. A ninth step motor drives an eighth gear to rotate and the rotation of the eighth gear further drives a ninth gear to rotate and a first connecting tube to rotate 90 degrees so that the first connecting tube and the second connecting pipe are connected and discharged through a third connecting tube. Then the ninth step motor drives the eighth gear to rotate and the rotation of the eighth gear further drives the ninth gear to rotate and the first connecting tube to rotate 90 degrees so that the first connecting tube is connected with the connecting tube on the side surface of a stirring barrel. An eighth step motor drives a stirring wheel to stir the cement and pour the cement into a prepared hole. The underwater pier pouring machine achieves automated suction of the water fromthe hole and automated pouring of the cement into the hole, realizes automated pouring of the bridge pier and the improvement of the pouring efficiency and quality of the pier.

Owner:四川域高建筑工程有限公司

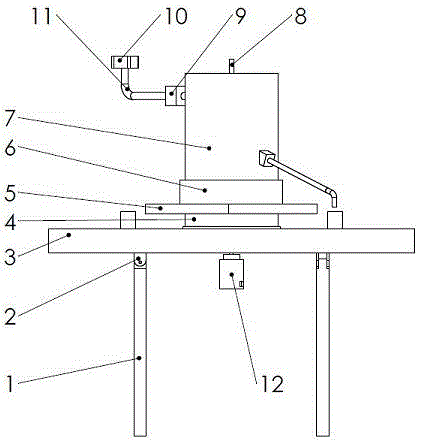

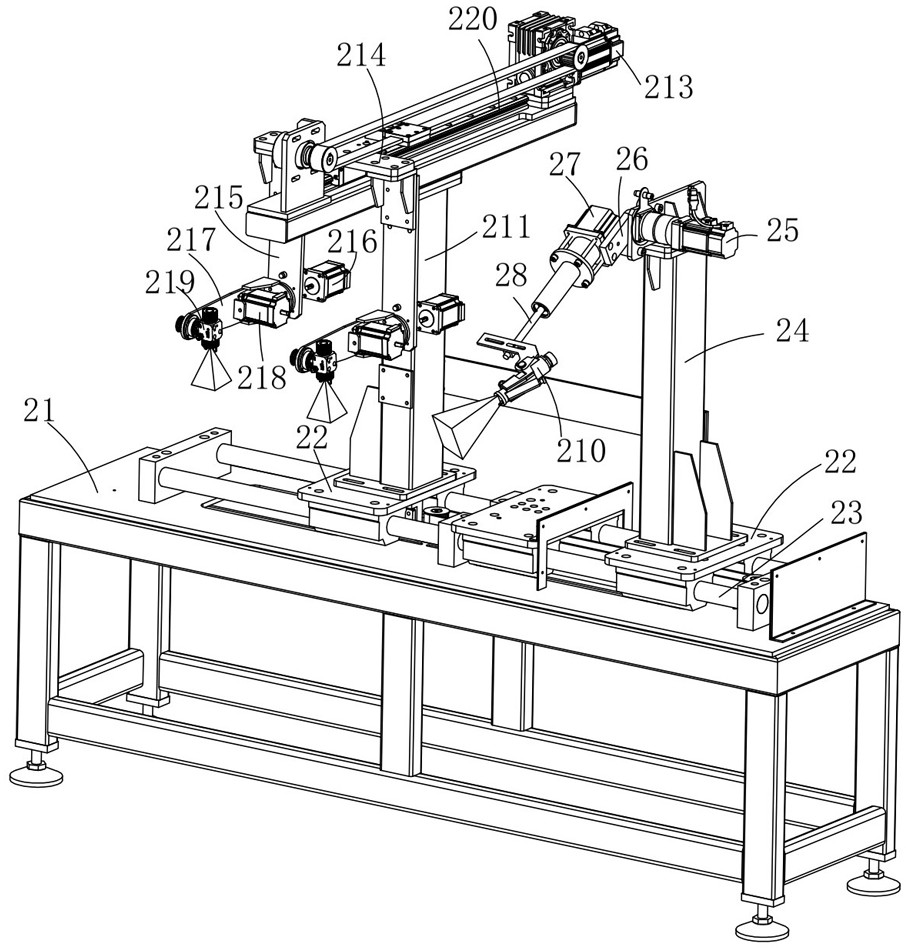

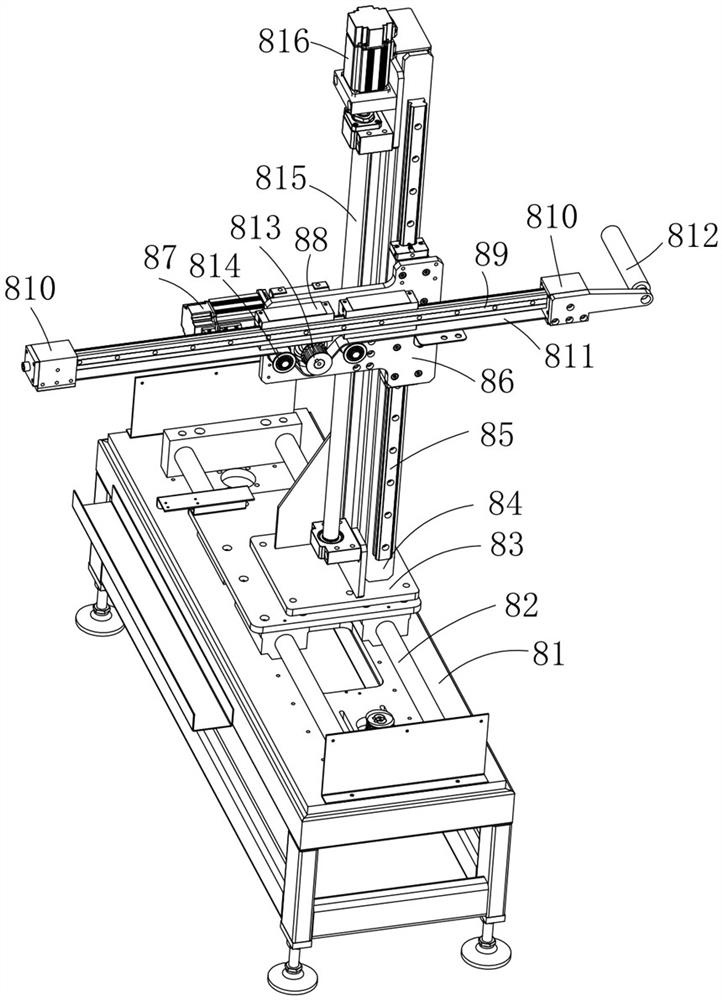

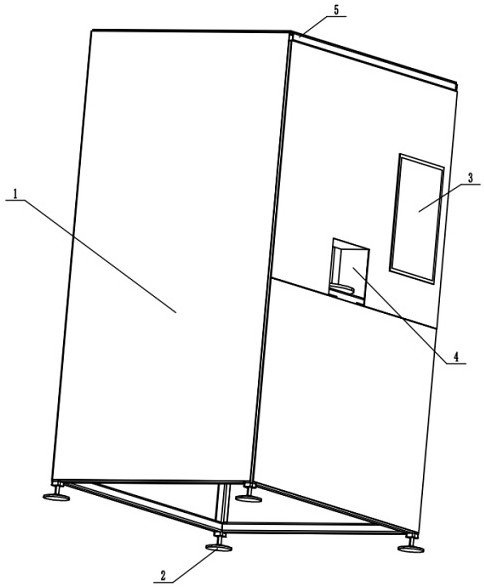

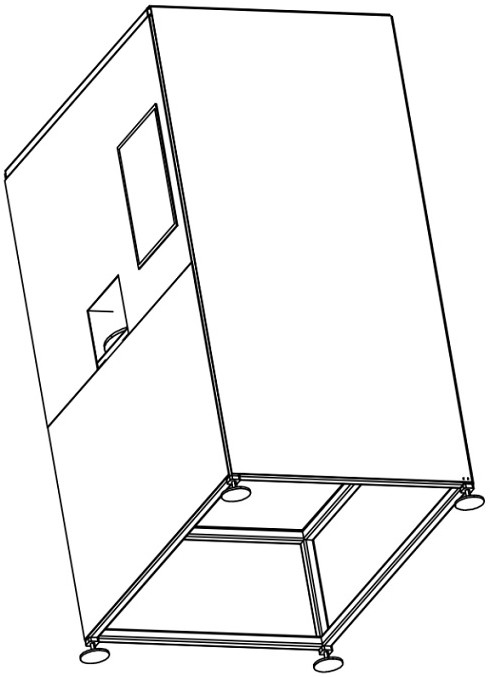

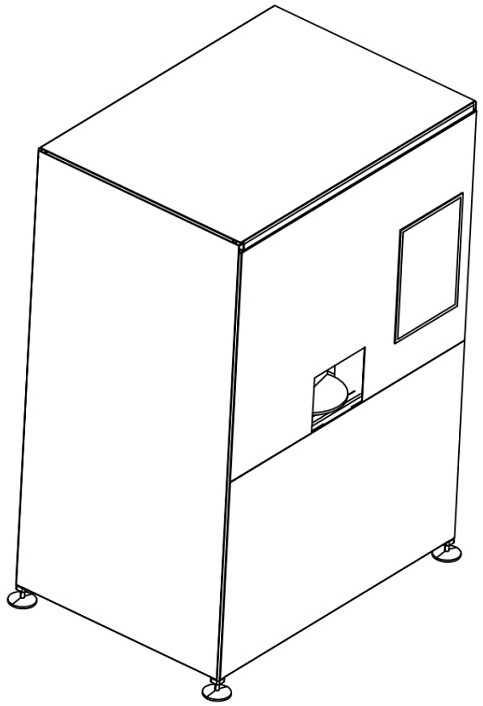

Automatic delivery device for electronic kiln

ActiveCN102706165AAvoid pan nestingEasy extractionCharge manipulationEngineeringMechanical engineering

The invention belongs to the technical field of electronic kiln auxiliary facilities, and discloses an automatic delivery device for an electronic kiln, which includes a machine frame equipped at the electronic kiln in a use state, a vertical guide beam arranged at the top of the machine frame, a horizontal guide beam being in sliding fit with the vertical guide frame, a mechanical hand rack lifting mechanism arranged on the horizontal guide beam, a mechanical hand rack positioned below the horizontal guide beam and connected with the mechanical hand rack lifting mechanism, a charging tray clamping mechanism arranged on one side of the mechanical hand rack, a charging tray overturning mechanism arranged on the other side of the mechanical hand rack, and a pair of charging tray support and protection mechanisms arranged on the charging tray clamping mechanism and the charging tray overturning mechanism respectively. The automatic delivery device for the electronic kiln has the advantages that uninterrupted material delivery is realized, a charging tray can be drawn or released conveniently, is prevented from falling off, and is definitely positioned between the charging tray clamping mechanism and the charging tray overturning mechanism, and automatic material discharge can be realized.

Owner:佛山市盛光窑炉有限公司

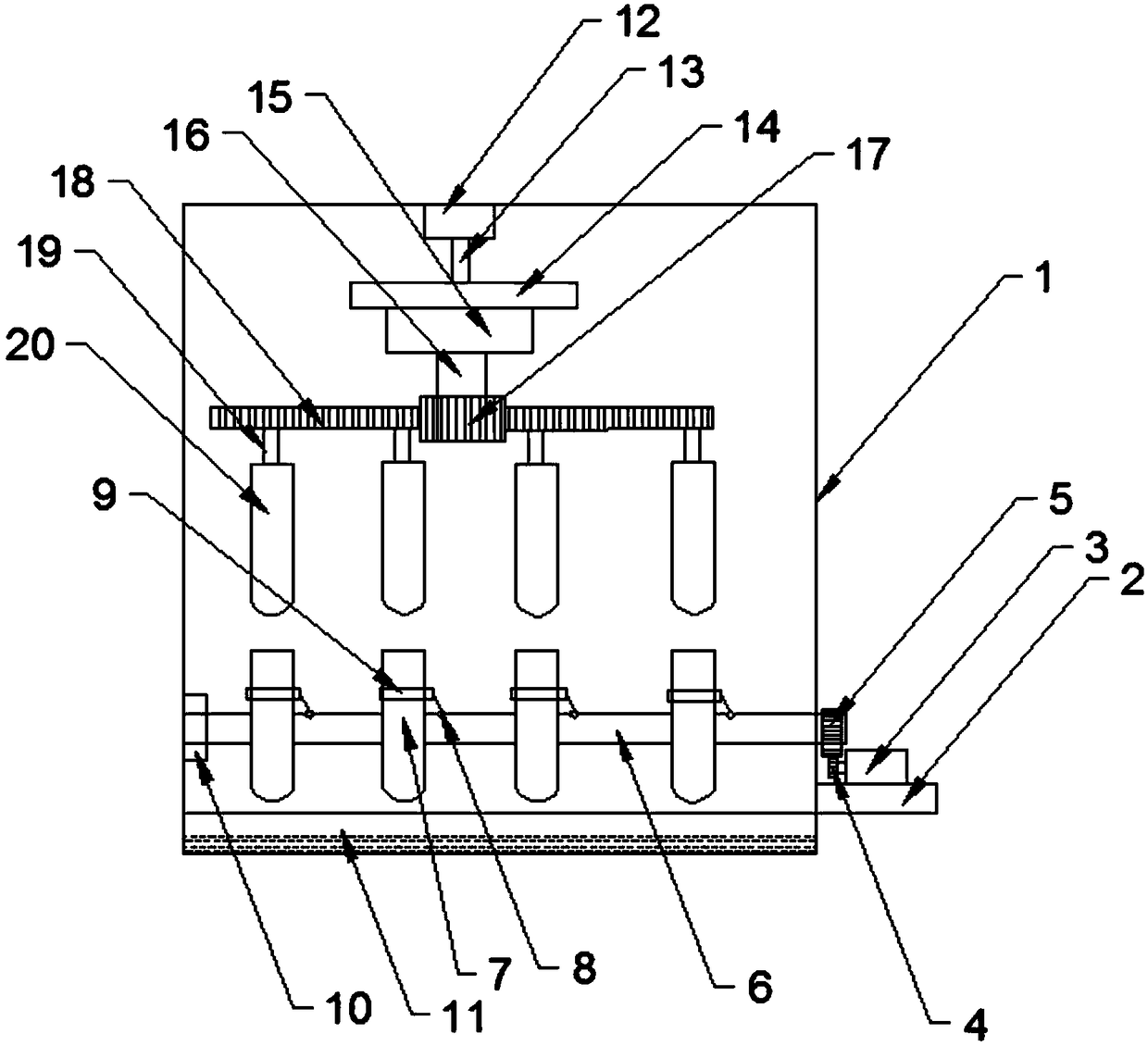

Environment-friendly medical glass test tube cleaning equipment

InactiveCN108160636AAvoid pollutionRealize automatic cleaningBrush bodiesHollow article cleaningEngineeringSewage

The invention relates to environment-friendly medical glass test tube cleaning equipment which comprises a shell. A sewage pool is arranged on the bottom of the shell. A cleaning assembly is arrangedabove the sewage pool. A cleaning brush assembly is arranged above the cleaning assembly. The cleaning assembly comprises a cleaning rod. The cleaning rod is connected with a driven gear of a first rotating motor. Multiple storing holes are uniformly formed in the cleaning rod. The cleaning brush assembly comprises a first air pressure cylinder. The first air pressure cylinder is connected with asecond rotating motor through a telescoping rod. The second rotating motor is connected with a cleaning brush through a gear and a rotating rod. The cleaning brush comprises a cylindrical part and a hemispherical part. The cleaning brush comprises a cleaning shell. Water absorbing sponge is arranged in the cleaning shell. A water outlet is formed in the cleaning shell. A pressing plate is connected to the top of the cleaning shell through a support and a second air pressure cylinder. A second rotating rod is fixedly connected with the support on the top of the cleaning brush. According to thecleaning equipment, the cleaning brush and cleaning liquid are integrated, the cleaning efficiency is high, and cleaning is thorough.

Owner:河南省康源生物工程技术有限公司

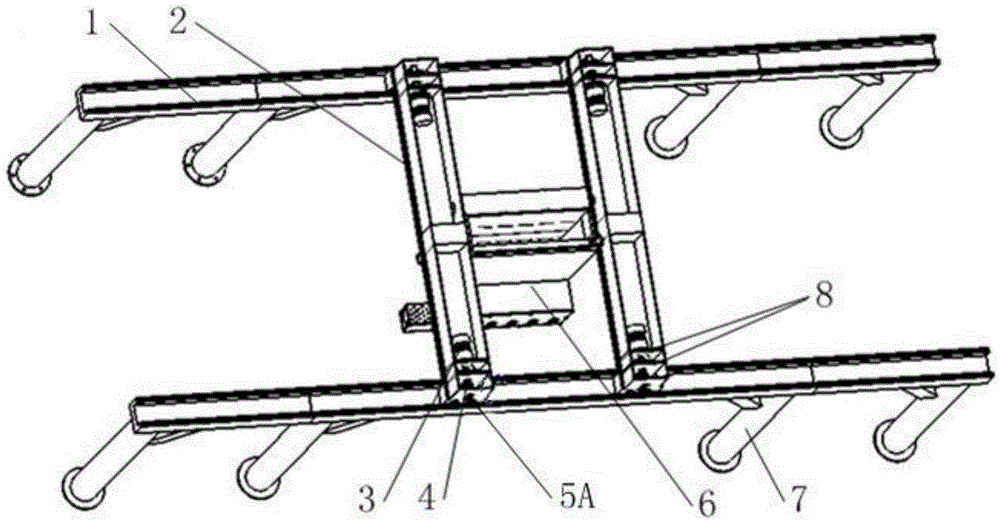

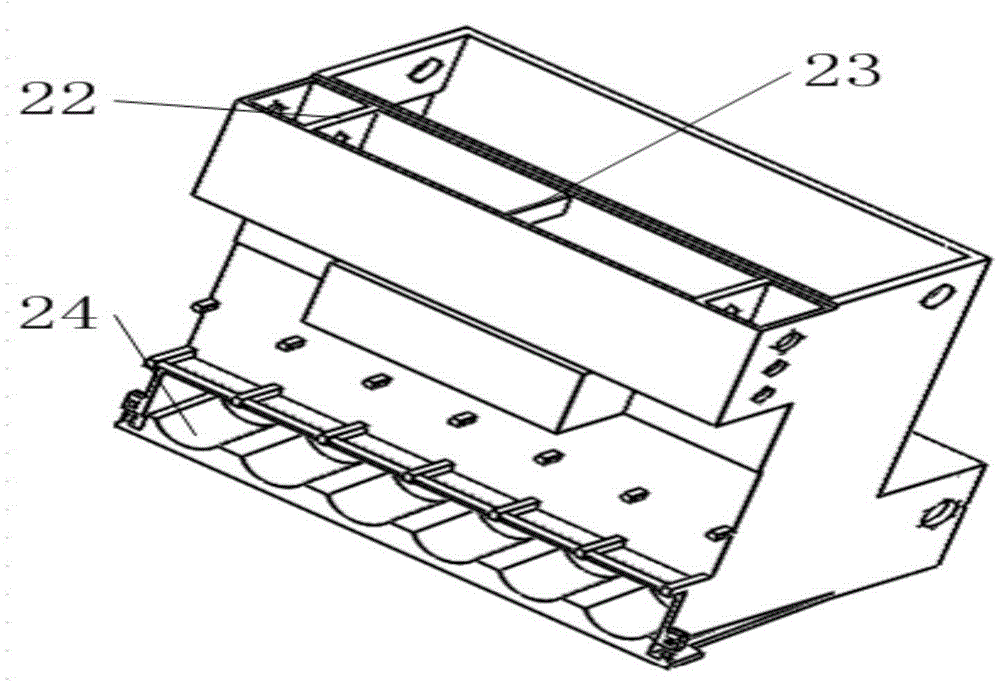

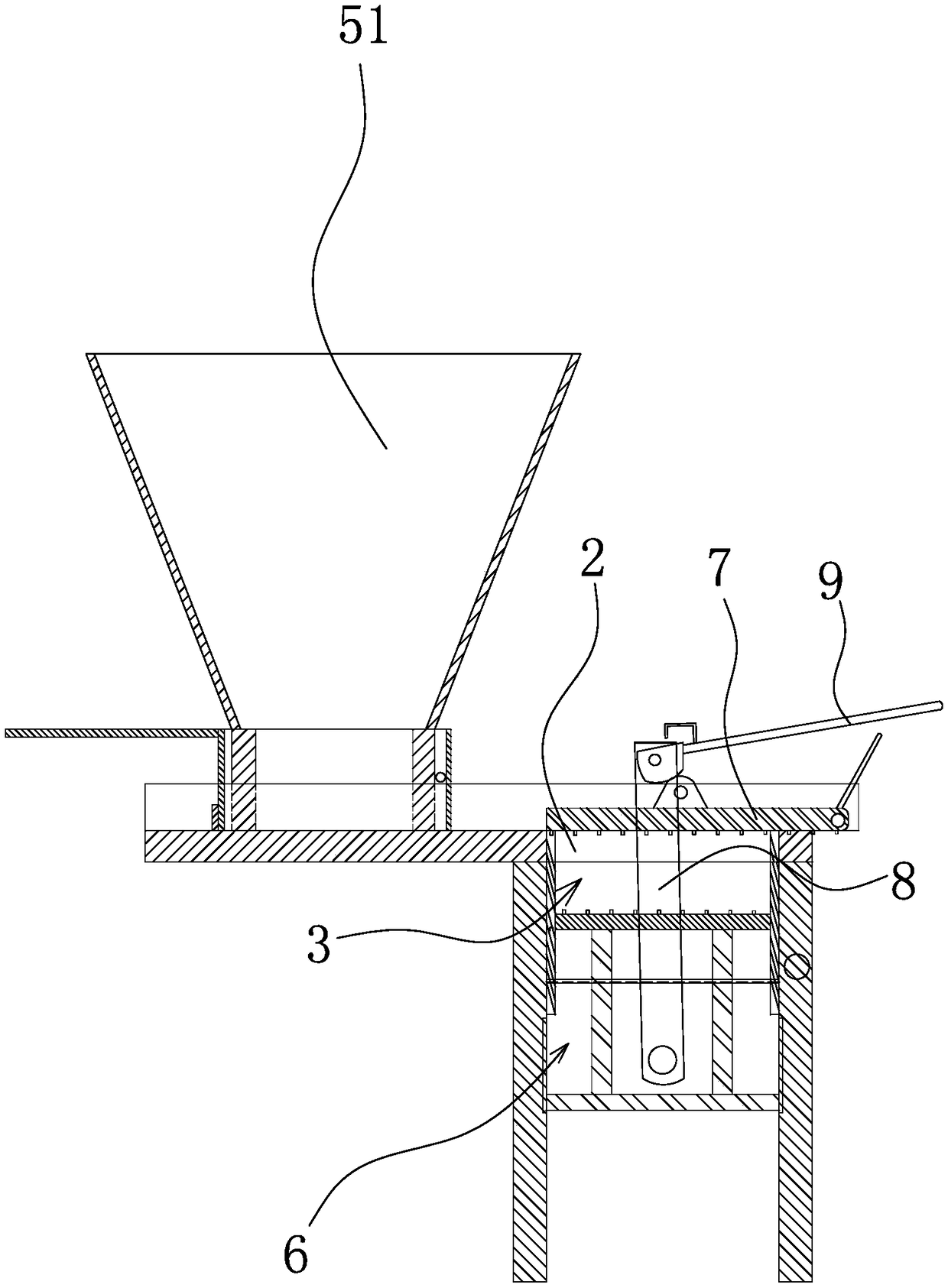

Concrete dropping device in prefabricated slab production line

The invention discloses a concrete dropping device in a prefabricated slab production line and belongs to the technical field of concrete production. The device comprises transverse lifting beams, longitudinal lifting beams, a soft starting brake motor, a lifting beam double reduction gear set, traveling wheels, a dropping box, stand columns, transverse rib slabs, a double reduction gear set, a box body and a long worm. The transverse lifting beams and the longitudinal lifting beams are of supporting movement structures. The longitudinal lifting beams are placed on the transverse lifting beams. The dropping box is placed on the longitudinal lifting beams. The traveling wheels are installed at the two sides of the longitudinal lifting beams and the dropping box. The motor drives the worm and worm gears. Spiral shafts stir and deliver concrete, and a dropping port is formed in the lower side of the dropping box. By means of the concrete dropping device, automatic concrete pouring in the prefabricated slab production can be achieved, the pouring range can be controlled by moving the transverse lifting beams and the longitudinal lifting beams according to production requirements, the dropping amount is controlled by adjusting a valve, and accordingly prefabricated slabs of with different specifications are produced.

Owner:HUANGSHAN ZHONGYOU CHAIN MFG CO LTD OF ANHUI

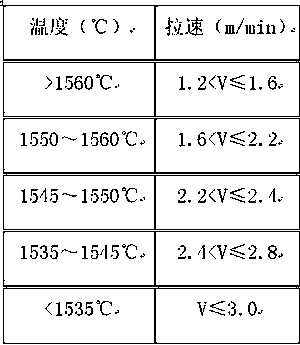

Sizing nozzle casting method utilized by tundish of small square billet continuous casting machine in steelmaking enterprise

ActiveCN108326251AReduce the situation of tipping outContinuous casting pouring stabilitySteelmakingAutomatic control

The invention discloses a sizing nozzle casting method utilized by a tundish of a small square billet continuous casting machine in a steelmaking enterprise. The method is characterized in that (1), the temperature of sizing starting-up molten steel is 1605 DEG C to 1630 DEG C, the temperature under a normal casting state is 1575 DEG C to 1595 DEG C, and the temperature of the tundish is larger than 1570 DEG C when casting is started and is less than or equal to 1550 DEG C under a normal casting state; (2), sizing casting and pulling speed is controlled, the starting pulling speed is 1.2 m / min, and the temperature pulling speed is 1.2 to 3 m / min; (3), the liquid level of the tundish is controlled, and the depth of the molten steel in the tundish is controlled at 450 to 750 mm; and (4), key points of the sizing are characterized in that a, continuous baking is carried out on the tundish for more than 60 minutes according to the order of soft fire, middle fire and large fire, b, dummy ingot feeding and plugging and cooling strip placing are carried out, and c, starting operation is carried out, the emergence time is longer than 13 seconds, and the method of pulling speed automatic control is adopted. According to the method, casting of molten steel flow injected into a crystallizer is controlled through the inner diameter of the sizing nozzle, a stopper rod and a stopper rod control mechanism are not needed, the control of the flow of the sizing nozzle is relatively stable, the improvement of the quality of the continuous casting blank is facilitated, automatic casting is realized, and the labor intensity of workers is reduced.

Owner:XINJIANG BAYI IRON & STEEL

Method for improving automatic casting of continuous casting ladle

InactiveCN109402319ARealize automatic pouringQuality improvementMelt-holding vesselsManufacturing convertersAutomatic controlMolten steel

The invention discloses a method for improving automatic casting of a continuous casting ladle. According to the method, the temperature of a ladle lining of the casting ladle before smelting steel tapping of a converter is controlled to be 850-900 DEG C, the steel tapping temperature is controlled to be 80-100 DEG C above a steel grade liquidus, and the argon flow after steel tapping is controlled to be 120-160 L / min; and the time from steel tapping of the converter to continuous casting in the continuous casting process is controlled to be less than or equal to 180 min, automatic casting ofthe continuous casting ladle is realized, the quality of molten steel is improved, the labor intensity is reduced, the quality of finished steel products is enhanced, and the continuous casting rate of the continuous casting ladle reaches over 98%. The method for improving automatic casting of the continuous casting ladle is simple and convenient to operate and stable in effect, provides a technical support for automatic control of continuous casting, and has broad application prospects.

Owner:HANDAN IRON & STEEL GROUP +1

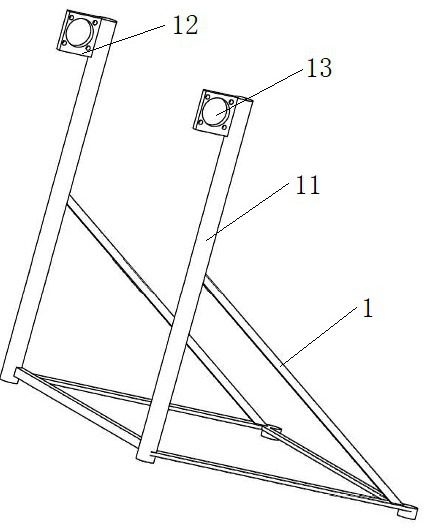

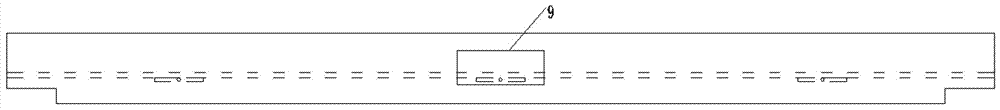

Novel electric pole feeder

InactiveCN107813420AReduce jitterPouring labor-saving and efficientFeeding arrangmentsArchitectural engineeringTime-Consuming

The invention discloses a new electric pole feeder, which comprises a base and an outer bucket, a track is arranged in the middle of the top of the base, a mold fixing platform is arranged on the track, a control box is arranged on one side of the track, and a control box is embedded in the control box. Weight transmitter, the weight transmitter is electrically connected to the external power supply, the other side of the track is fixed with a second fixed plate, the top of the second fixed plate is equipped with a first fixed plate, the first fixed plate and the second fixed plate There is a weight sensor between them; by setting the mold fixing table to be movable and the outer bucket device to be fixed, the pouring is more labor-saving and efficient, and the automatic pouring can be realized through the set discharge valve, avoiding the time-consuming and laborious manual pouring ; By setting the return spring, the vibration caused by the external bucket when the vibrator is working can be effectively weakened, the vibration of the vibrator can be avoided from affecting the equipment, and the service life of the equipment can be protected.

Owner:SUZHOU JUHUIBANG NEW MATERIAL TECH CO LTD

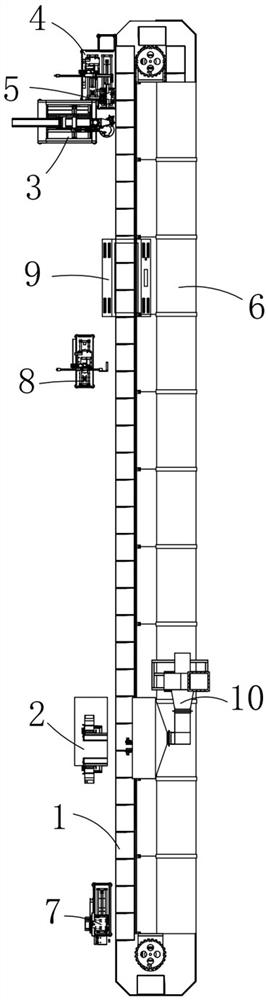

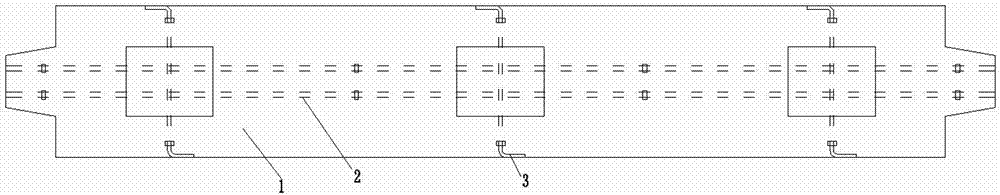

Full-automatic intelligent polyurethane pouring assembly line

PendingCN111941709ARealize automatic pouringImprove productivityDomestic articlesStructural engineeringAssembly line

The invention relates to a full-automatic intelligent polyurethane pouring assembly line capable of achieving forming of double-layer shoe soles. The full-automatic intelligent polyurethane pouring assembly line comprises a ring-shaped conveying device, a mold base placed on the ring-shaped conveying device and used for placing molds, and a shoe mold locking device. The assembly line is characterized in that the ring-shaped conveying device is provided with a station section and a drying section, a mold release agent spraying device, a longitudinal mold opening device, a polyurethane pouring device, a longitudinal mold closing device, a transverse mold closing device and a transverse mold opening device are installed beside the station section of the ring-shaped conveying device, and the drying section of the ring-shaped conveying device is located in a drying channel. According to full-automatic intelligent polyurethane pouring assembly line, by means of structure innovating and upgrading, automatic pouring is achieved, automatic transverse mold opening and closing, automatic longitudinal mold opening and closing and automatic mold releasing agent spraying are achieved, labor is replaced to the maximum degree, the product productivity is improved greatly, and the product production cost is reduced.

Owner:RUIAN ZHONGDA PU MACHINERY

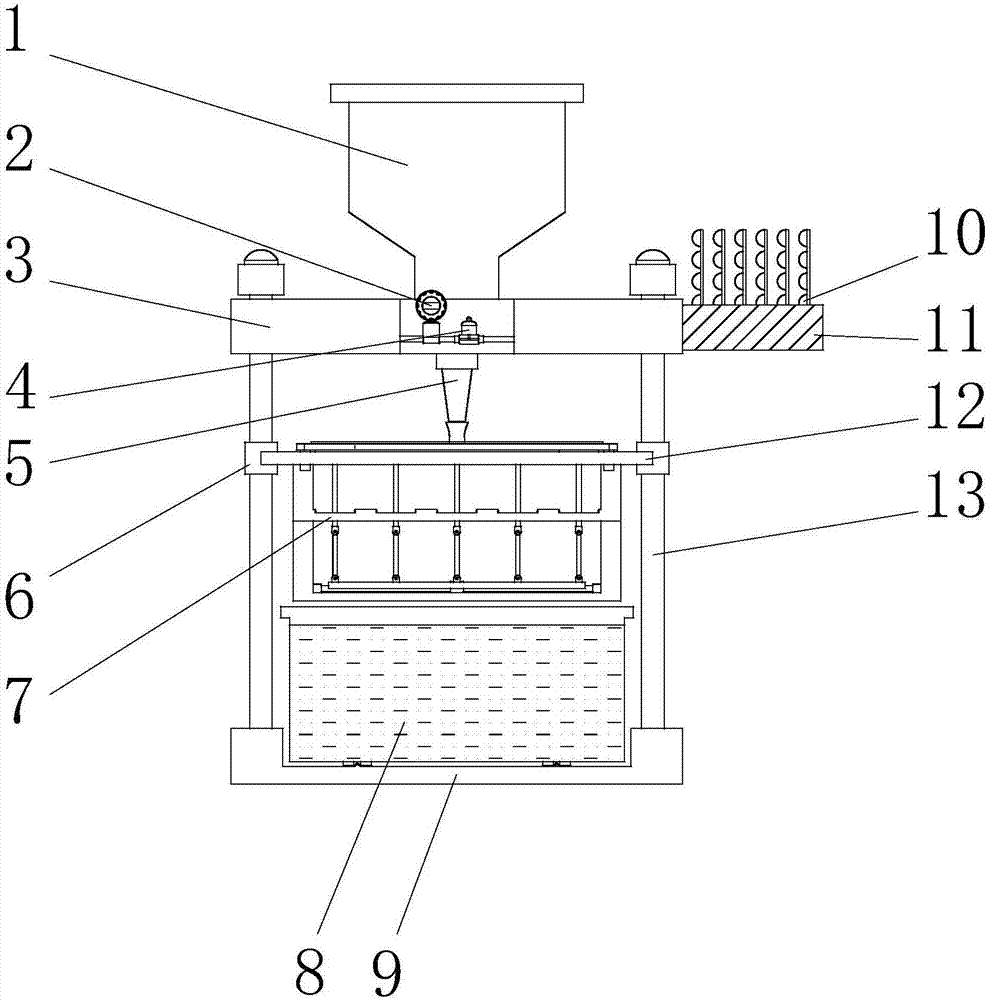

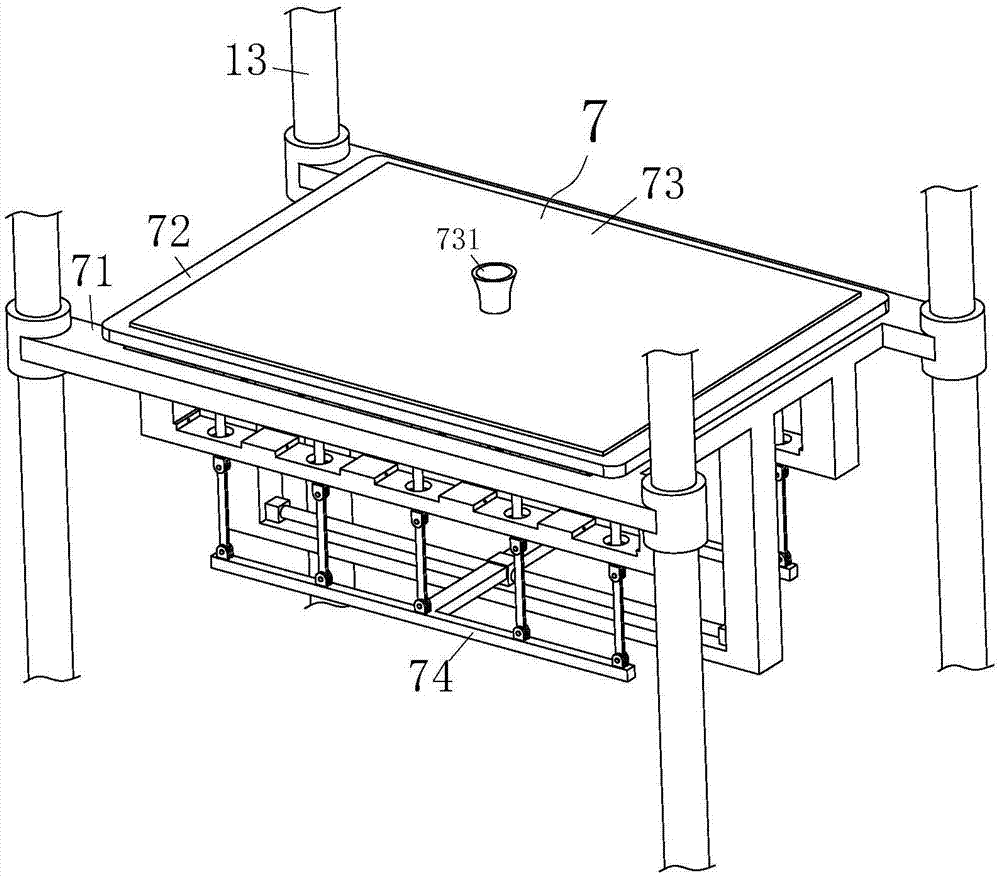

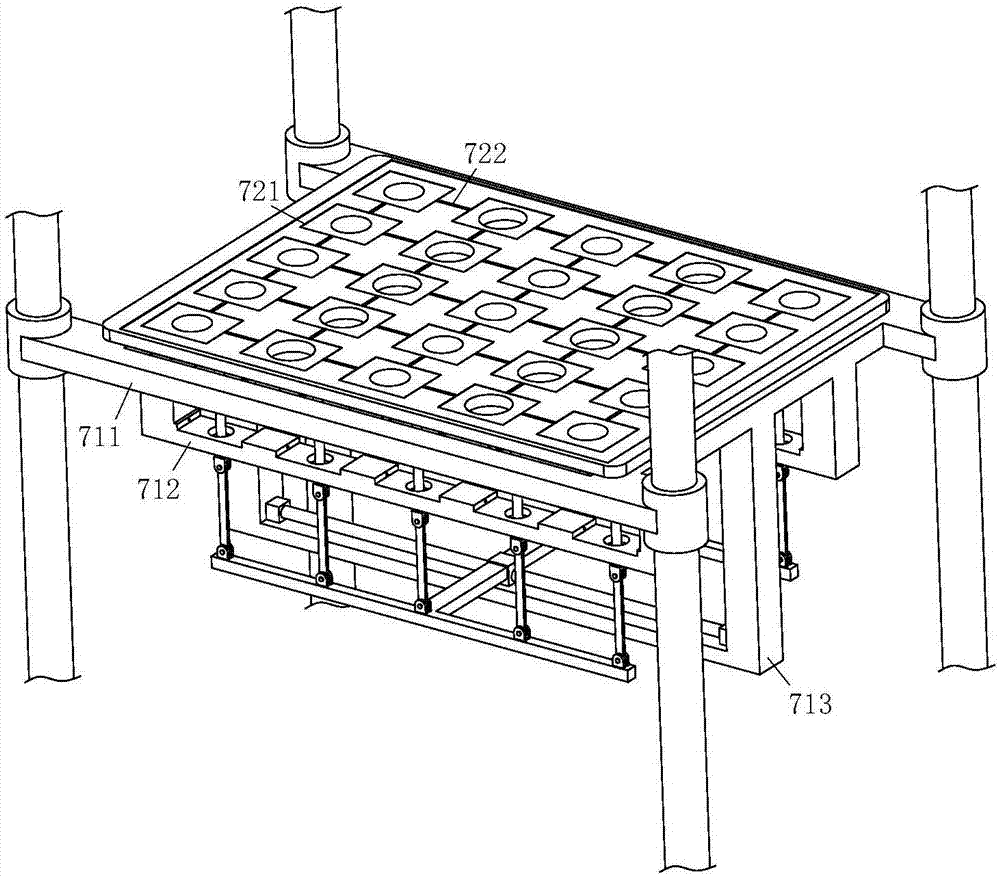

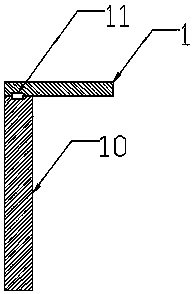

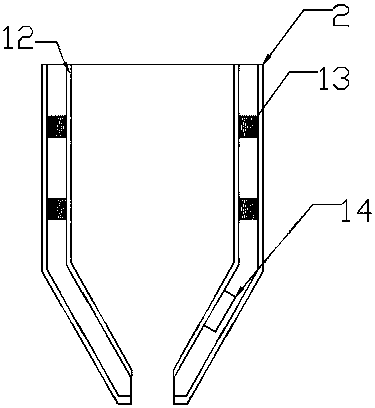

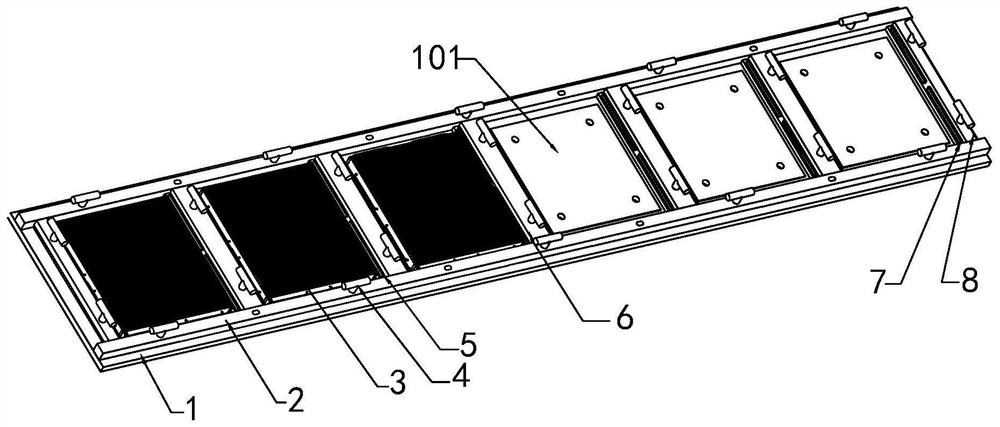

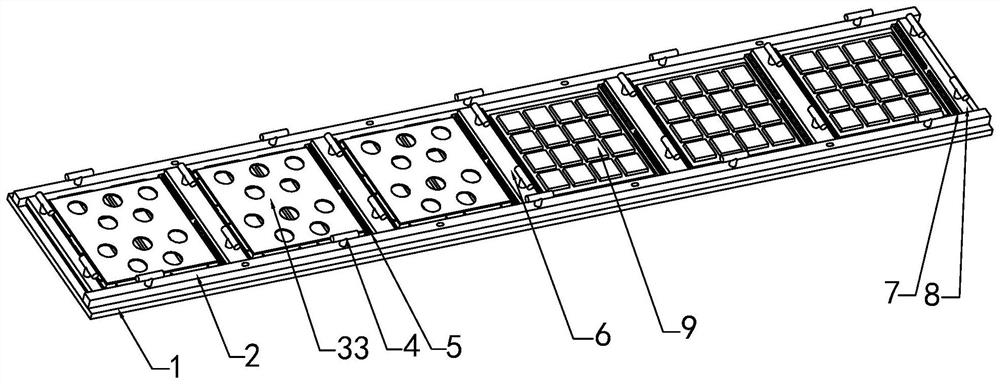

One-mold multi-cavity multipurpose screen plate casting mold system

The invention relates to a one-mold multi-cavity multipurpose screen plate casting mold system, and belongs to the technical field of screen plate casting molds. A mold framework is placed in a mold body; an adhesive stirring mechanism is arranged above the mold framework; the mold body comprises a motherboard (1) and a positioning frame; the motherboard (1) is arranged on a bottom plate on the bottom part of the positioning frame; the positioning frame is arranged on the upper end face of the motherboard (1); multiple installation grooves for placing the mold framework is formed on the motherboard (1) through the positioning frame; a clamping device is arranged in each installation groove; and a pressing and positioning mechanism is arranged on the periphery of each installation groove. The one-mold multi-cavity multipurpose screen plate casting mold system provided by the invention is simple in overall structure, convenient to maintain, low in mold cost, and convenient to assemble and disassemble. A one-mold multi-cavity casting process can be realized, so that the production efficiency is greatly improved.

Owner:陕西博选科技有限公司

Horizontal circulation type magnetic levitation conveyor belt

PendingCN109051822AAvoid wear and tearExtend the life cycleNon-mechanical conveyorsSteering wheelEngineering

The invention discloses a horizontal circulation type magnetic levitation conveyor belt. A track is composed of horizontally arranged straight section guide rails and steering guide wheels for connecting the guide rails end to end. The conveyor belt is arranged on the track and composed of moving bases and box bodies arranged on the moving bases. The bottom of each moving base is provided with a secondary power component. Primary power components are mounted at first grooves of the guide rails. First hook grooves and second hook grooves of the moving bases are provided with first electromagnets. Second grooves of the guide rails are provided with second electromagnets. After power is applied, the moving bases are suspended on the guide rails through attraction cooperation of the first electromagnets at the first hook grooves and the second hook grooves and the second electromagnets at the second grooves, through fitting connection of moving base bosses and guide wheel grooves, the moving bases are steered along with the steering guide wheels, the primary power components push the moving bases to start for transmission, and materials are continuously conveyed forwards through mutualextrusion of adjacent moving bases. Magnetic levitation transmission is adopted, and the conveyor belt is energy-saving, environmentally friendly, stable in arrangement and convenient to maintain.

Owner:NANJING FORESTRY UNIV

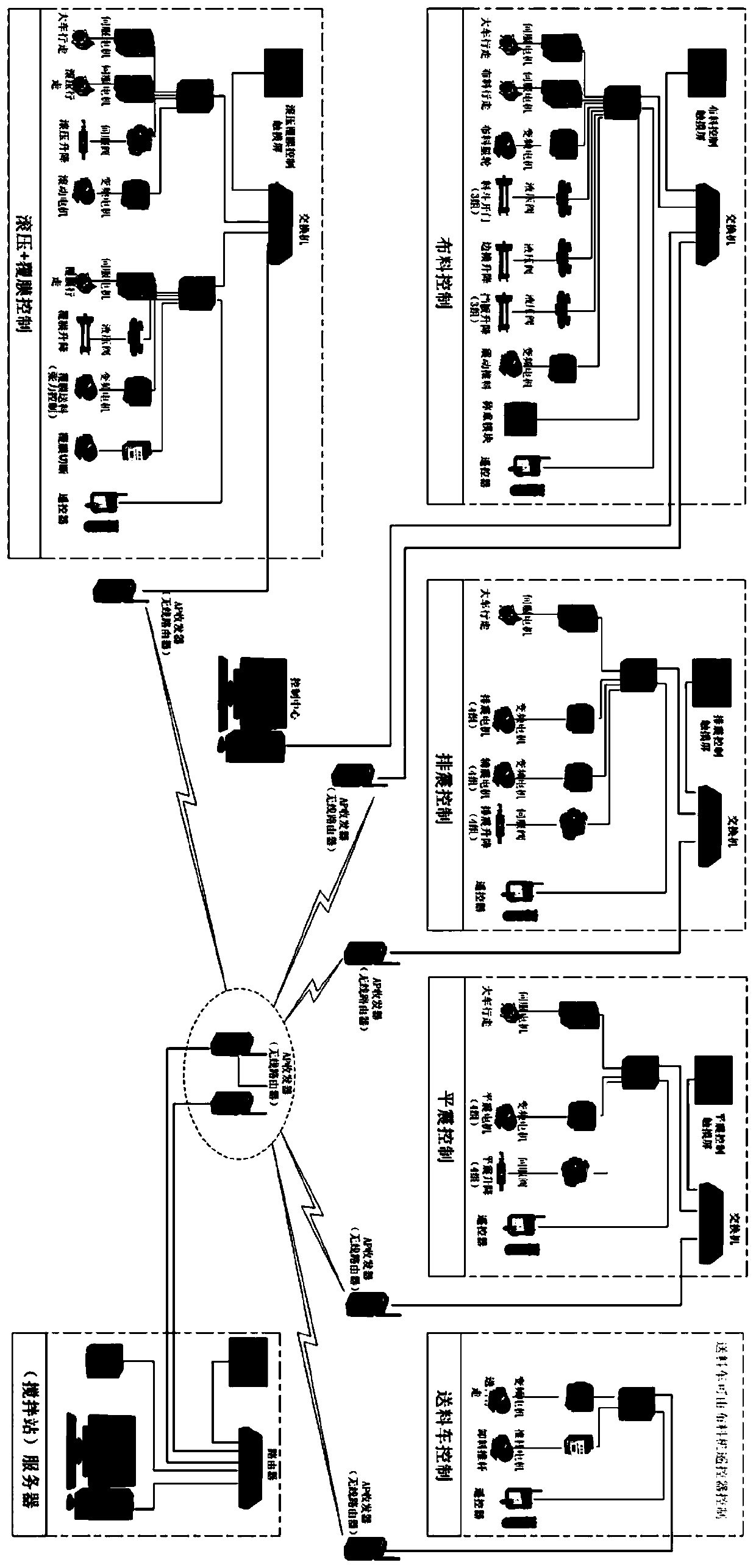

Control system and method of concrete bridge deck slab prefabricated slab production line

ActiveCN110757612AAvoid shortageAvoid problems with spacingFeeding arrangmentsAuxillary shaping apparatusBLENDER/MIXERProduction line

The invention discloses a control system and method of a concrete bridge deck slab prefabricated slab production line. The control system comprises a control center, a material distribution vibratingsystem, a concrete conveying system and a blender communication system. The material distribution vibrating system comprises a material distribution machine control subsystem, an insertion type vibrating control subsystem, a flat slab vibrating control subsystem and a rolling and film covering control subsystem. The material distribution vibrating system adopts event triggering. The concrete conveying system controls a mixture conveyer to convey concrete between the material distribution vibrating system and a blender. The blender communication system controls the blender to produce a corresponding amount of concrete according to feedback information of the material distribution vibrating system and sends a signal to the concrete conveying system after production. The control system and method of the concrete bridge deck slab prefabricated slab production line overcomes the technical problems that since the performance interval is long during pouring in the prior art, the pouring effect is influenced by environment change in the pouring interval process, and then the pouring effect is instable.

Owner:CCCC SHEC FOURTH ENG

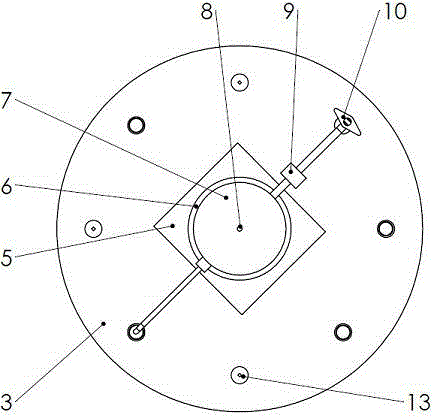

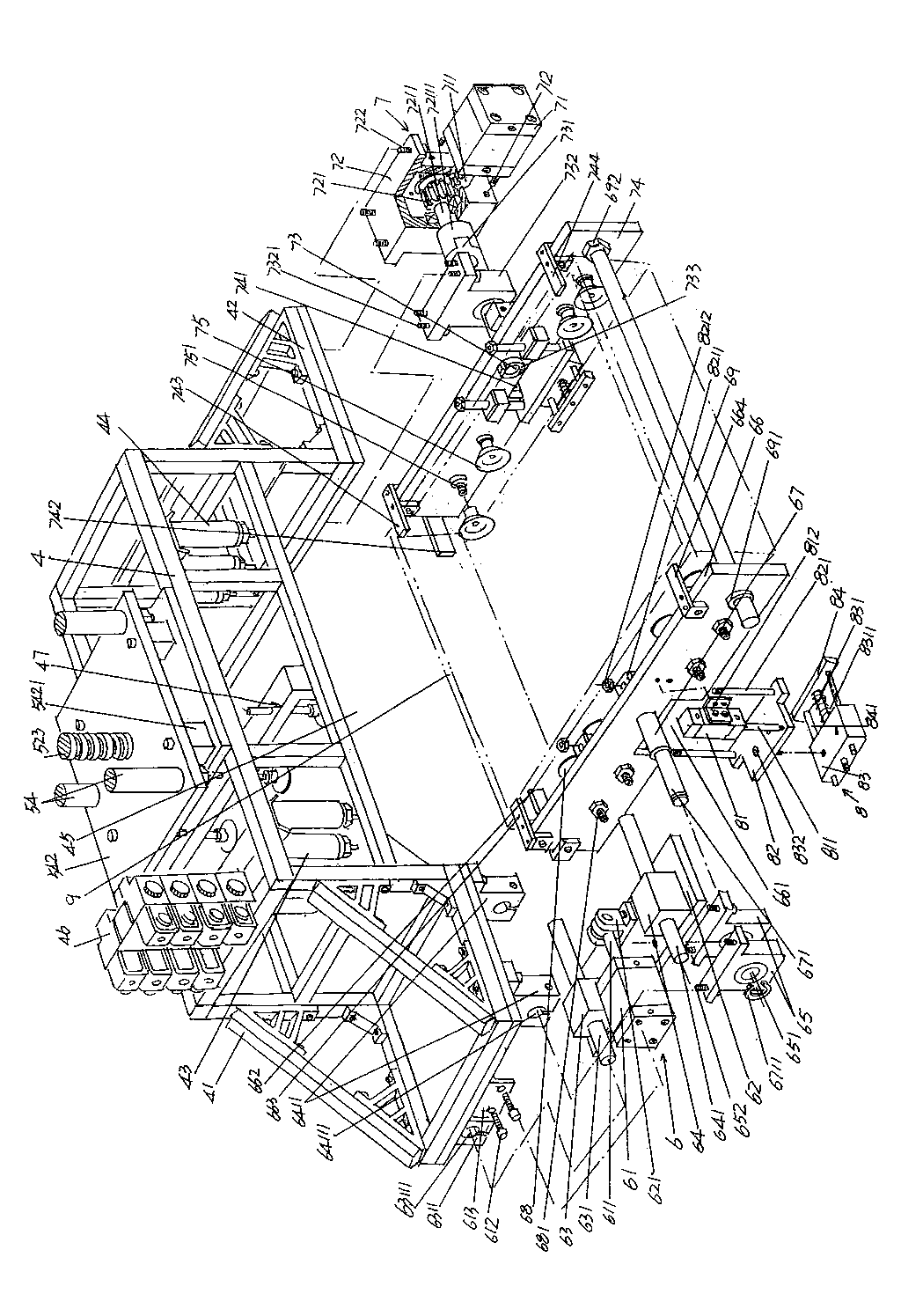

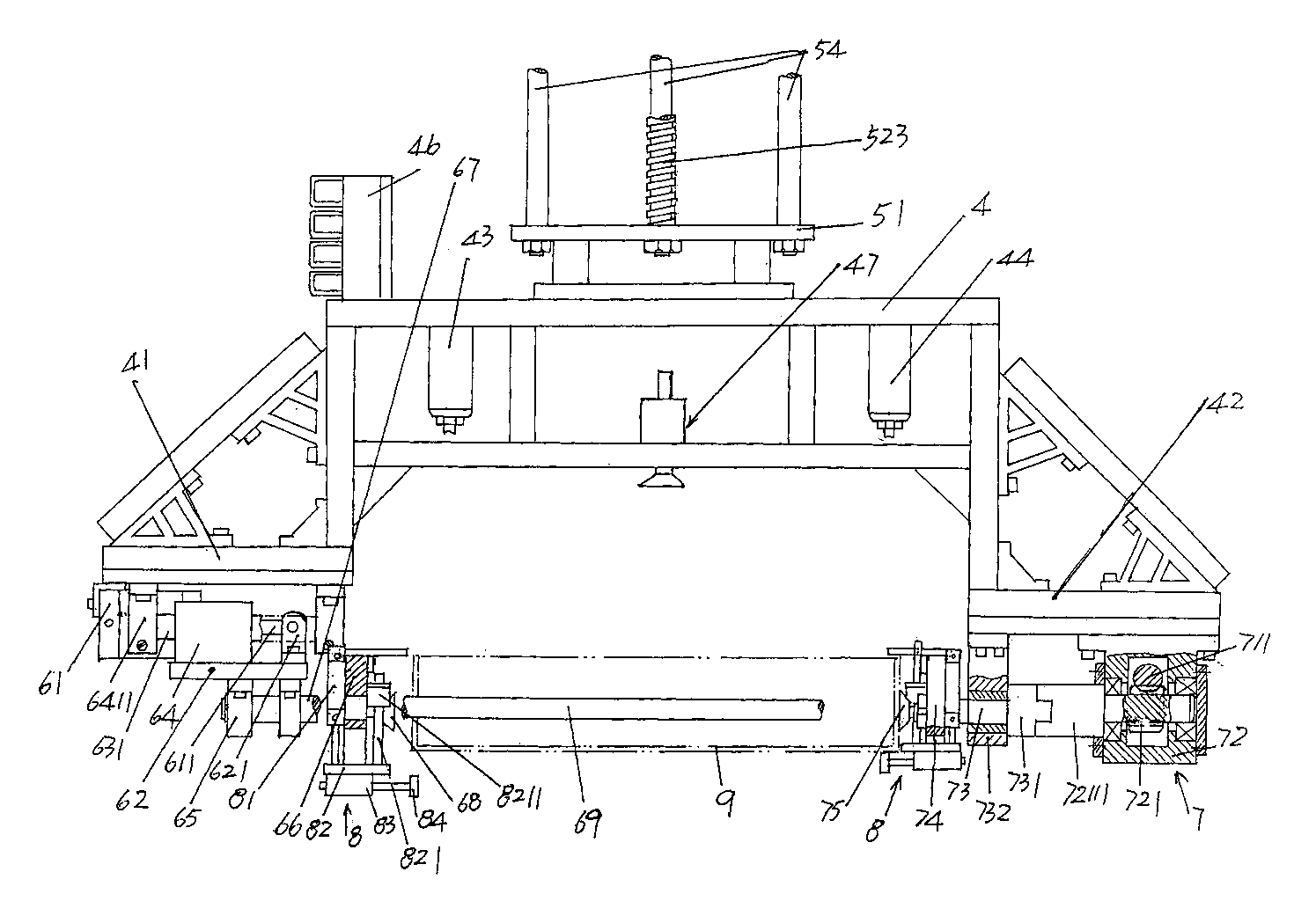

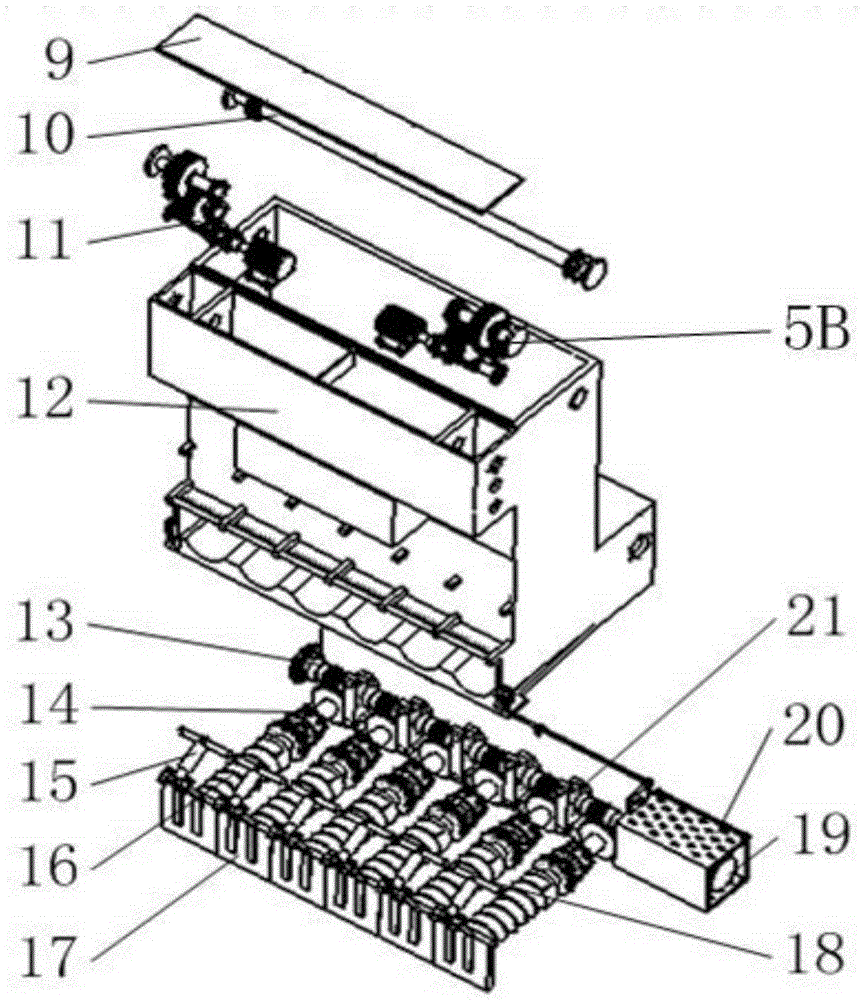

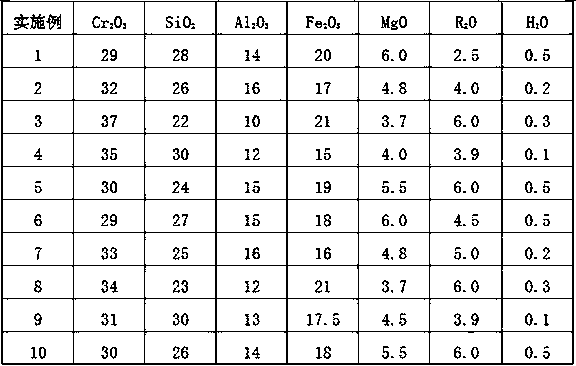

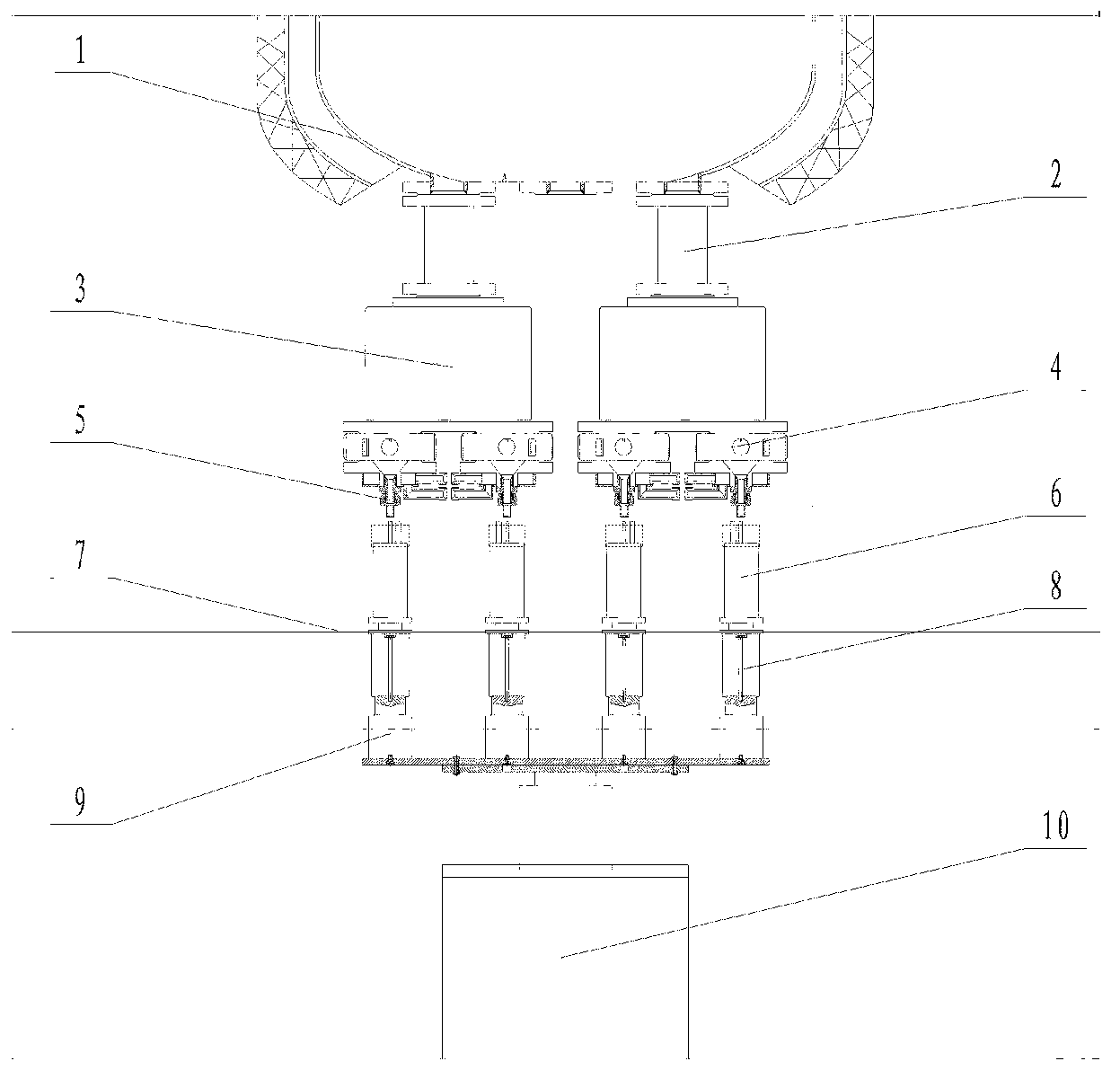

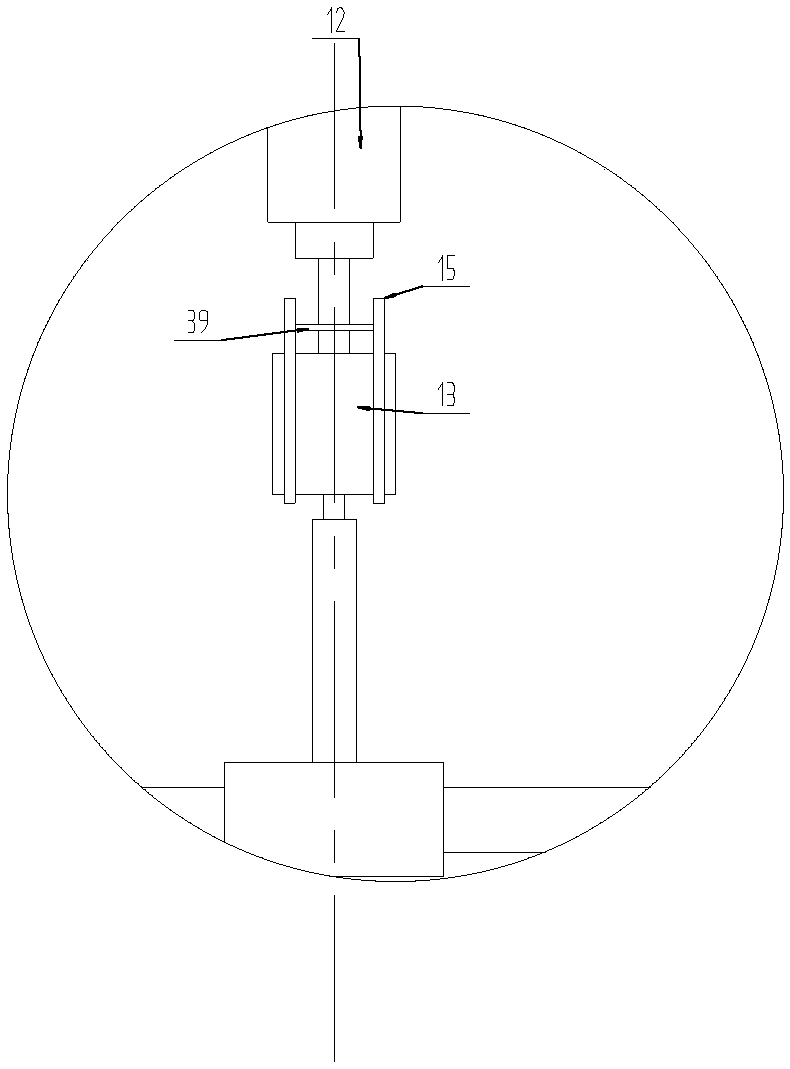

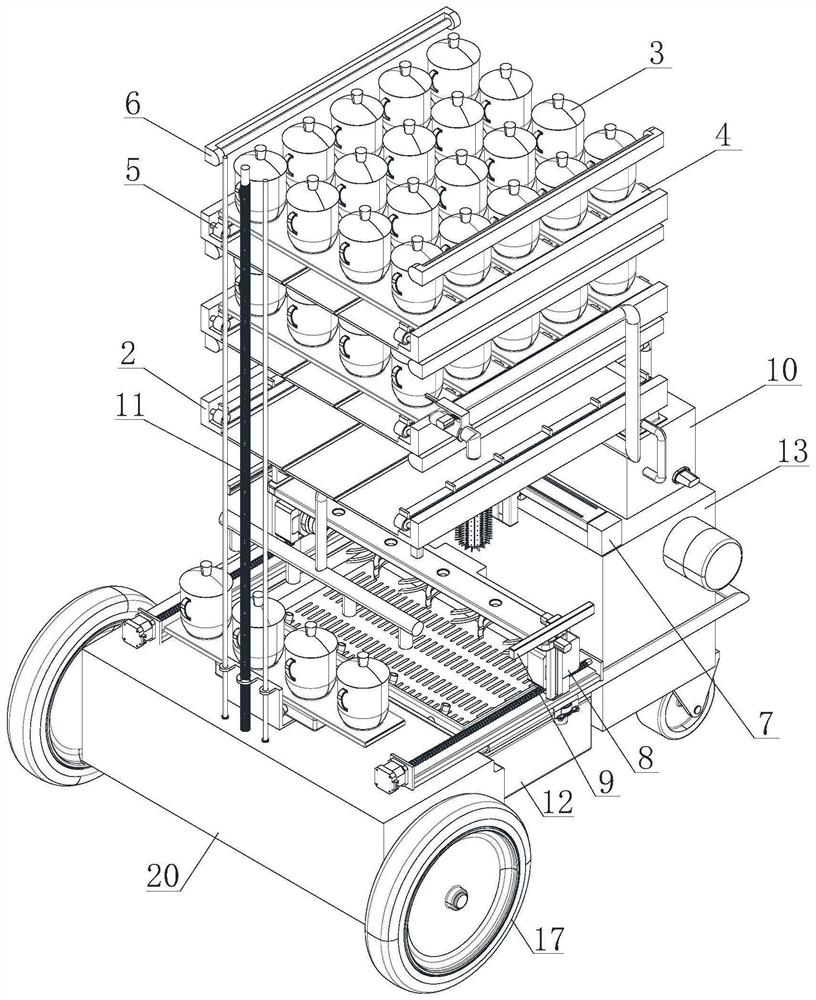

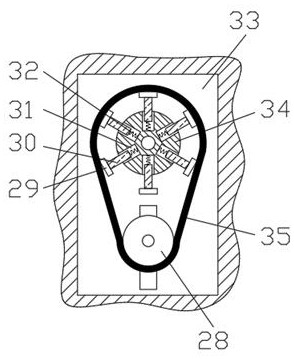

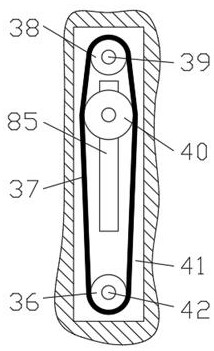

Automatic and intelligent primer gating system and working method thereof

ActiveCN103196338AReduce the number of peopleRealize the purpose of automatic pouringBlastingProgrammable logic controllerSafety coefficient

The invention relates to an automatic and intelligent primer gating system which comprises a control module and a gating module, wherein the control module monitors the working state of the gating module in real time via a sensor and controls the gating module to work according to regulation on the monitored working state so as to realize closed-loop control work. The automatic and intelligent primer gating system adopts PLC (programmable logic controller) control, thereby realizing the purpose of automatic gating and greatly improving the production efficiency while reducing the labor intensity; operators are reduced, and the safety in production is improved; and the gating system is safe and reliable in design, and is matched with a safety interlocking control monitoring system, thereby increasing the safety coefficient of production. The medicine injection structure adopted by the gating system is reasonable, is unlikely to cause remaining medicines, and is smooth in blanking, thereby reducing the manual maintenance cost of the system.

Owner:SHANDONG TIANBAO CHEM

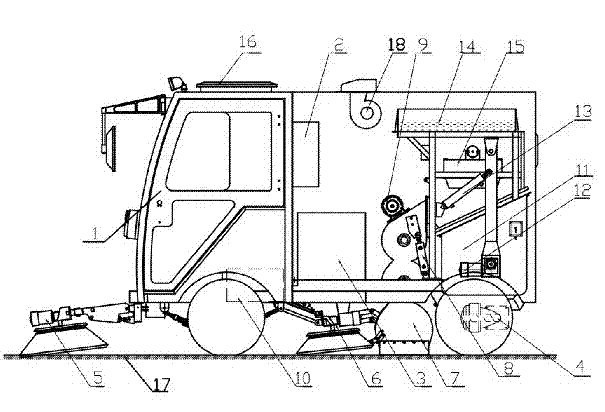

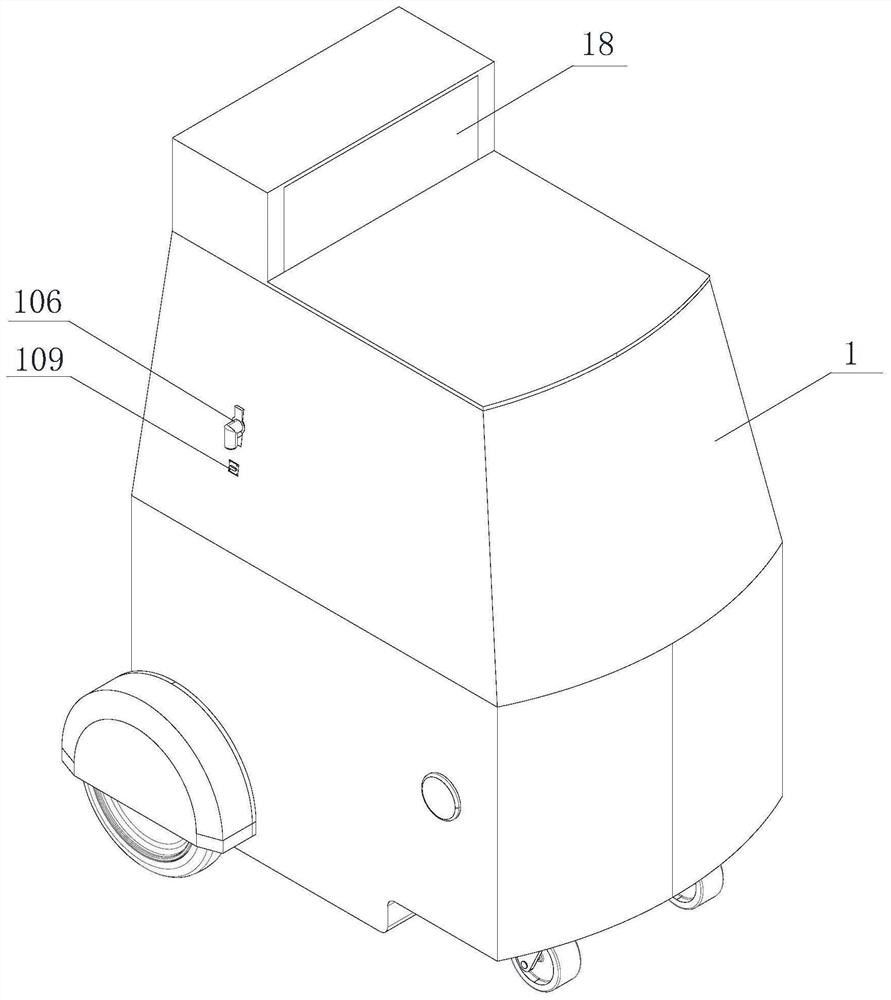

Electric cleaning vehicle

The invention discloses an electric cleaning vehicle in the field of environmental sanitation equipment for cleaning roads. The electric cleaning vehicle comprises a vehicle body, front side brush devices and rear side brush devices, wherein the rear ends of the rear side brush devices are closely connected with a three-rolling-brush cleaning device; the three-rolling-brush cleaning device is in a three-stage same-direction rotational structure; the bottom end of the three-rolling-brush cleaning device is connected with a main brush; and a high material level device is connected onto the top layer of the three-rolling-brush cleaning device. When a purely electric device is adopted for the driving and the cleaning operation of the whole vehicle, the energy consumption is low, the energy is saved and the environment is protected; meanwhile, the three-rolling-brush cleaning device and the high material level device are additionally installed on the cleaning vehicle, the high efficiency work of the cleaning vehicle can be kept during the use process; moreover, the energy consumption is low; the power utilization rate is high; the working intensity is decreased for workers; and furthermore, the electric cleaning vehicle can be easily jointed with a standard garbage barrel end to end, so that the transfer is facilitated.

Owner:苏州市京达环卫设备有限公司

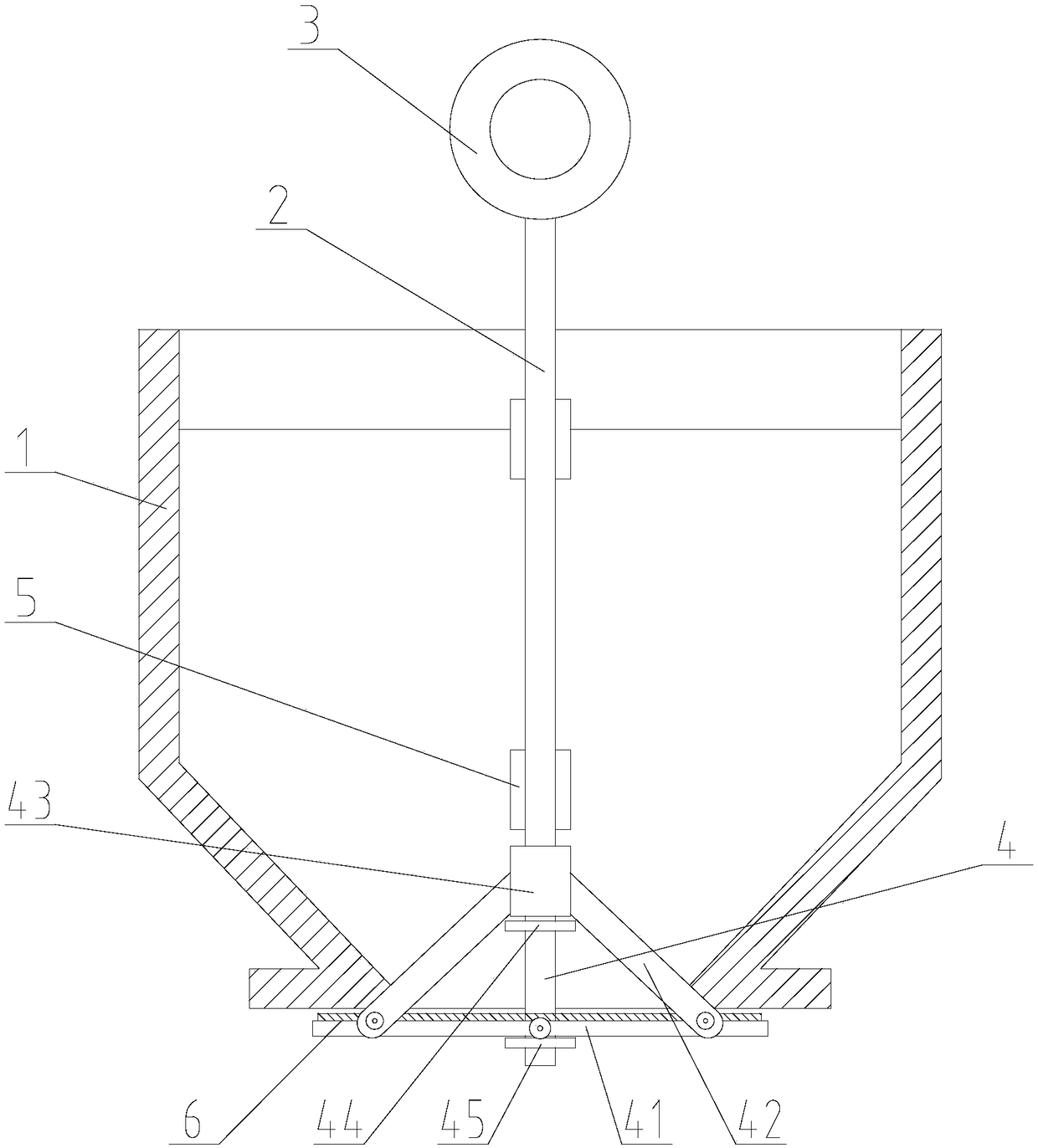

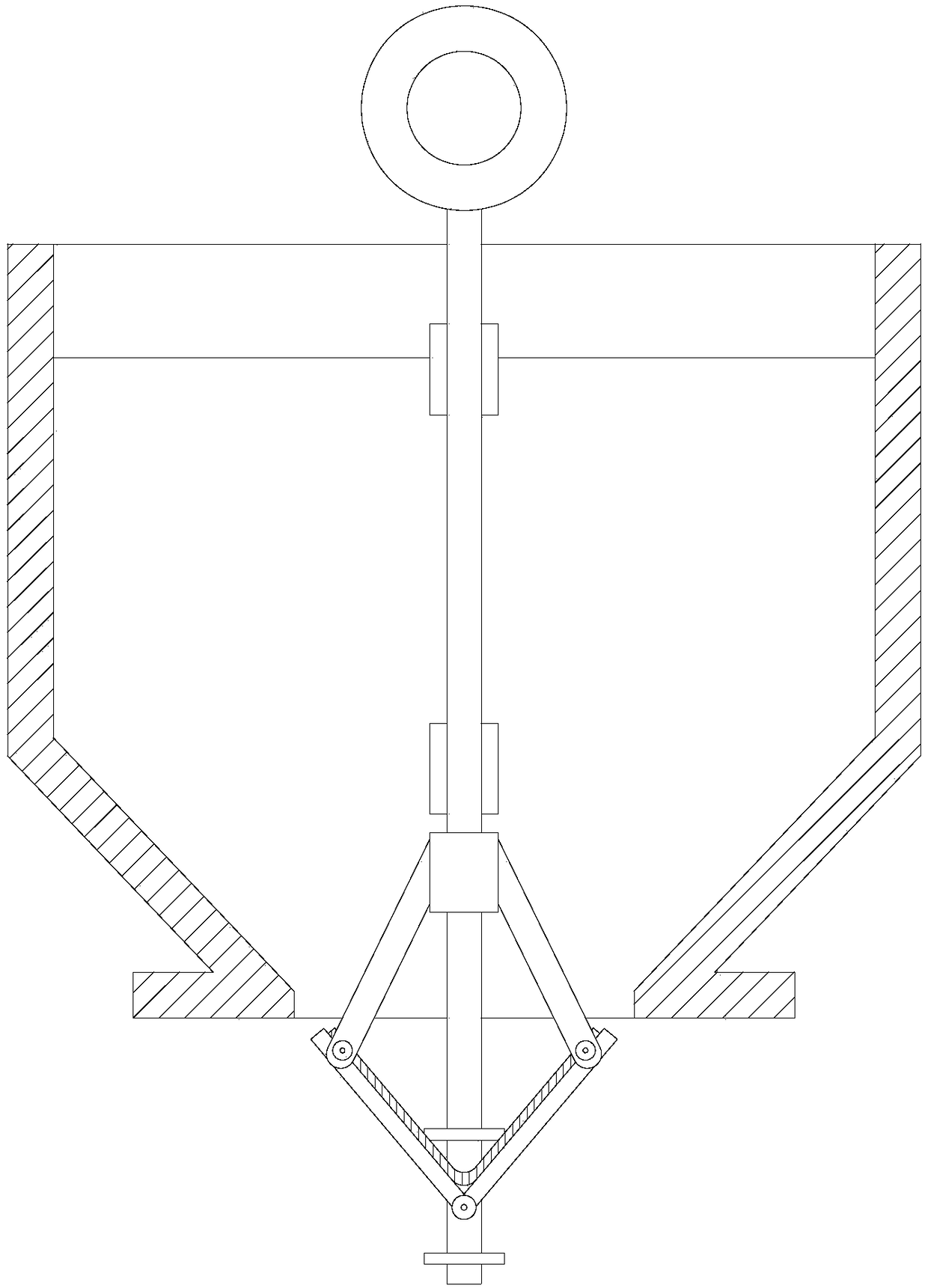

Powder transferring device

InactiveCN108285016ARealize automatic pouringNo manual operation requiredLarge containersEngineeringMechanical engineering

The invention discloses a powder transferring device. The device comprises a storage bin and a movable pull rod, a discharging opening is formed in the bottom of the storage bin, the end of the movable pull rod is provided with a sealing conical plate, and the sealing conical plate can seal and block the discharging opening by pulling the movable pull rod. The storage bin is hoisted by an overheadcrane, the sealing conical plate of the movable pull rod seals the discharging opening of the storage bin during transportation, when material pouring is carried out, the storage bin is descended, the sealing conical plate automatically exposes the discharging opening to enable the powder to be poured out, automatic pouring of the powder in the storage bin is realized, manual operation is not needed, the conveying and pouring efficiency is high, and the labor cost is saved.

Owner:PANZHIHUA BOTE BUILDING MATERIALS

Multifunctional pavement cleaning vehicle

The invention discloses a multifunctional road surface cleaning vehicle which comprises a vehicle body, a spraying and dust falling assembly, a blocking component, a sweeping device, a collecting hopper component, a rolling brush device and a water tank supercharging device. The vehicle body is composed of a vehicle hopper and a vehicle head, wherein rear wheels and a transmission shaft are arranged on the lower side of the vehicle hopper, the rear wheels are driven by the transmission shaft to rotate, and front wheels are installed on the lower side of the vehicle head. The sweeping device isarranged on the right side of the vehicle head in the advancing direction and used for sweeping garbage on the right ground of the vehicle head towards the left side of the vehicle head. The stoppingpart is arranged on the left side of the vehicle head; the stop part and the cleaning device are arranged on the left and right sides of the headstock respectively; the rolling brush device is used for enabling garbage outside the left-right range of the rolling brush device to get close to the middle position of the rolling brush device, so that the rolling brush device sweeps the garbage into the collecting hopper component better and more conveniently, the good cleaning effect on various sundries on the road surface where a vehicle body walks can be achieved, and no-missing sweeping of theroad surface is achieved.

Owner:李从军

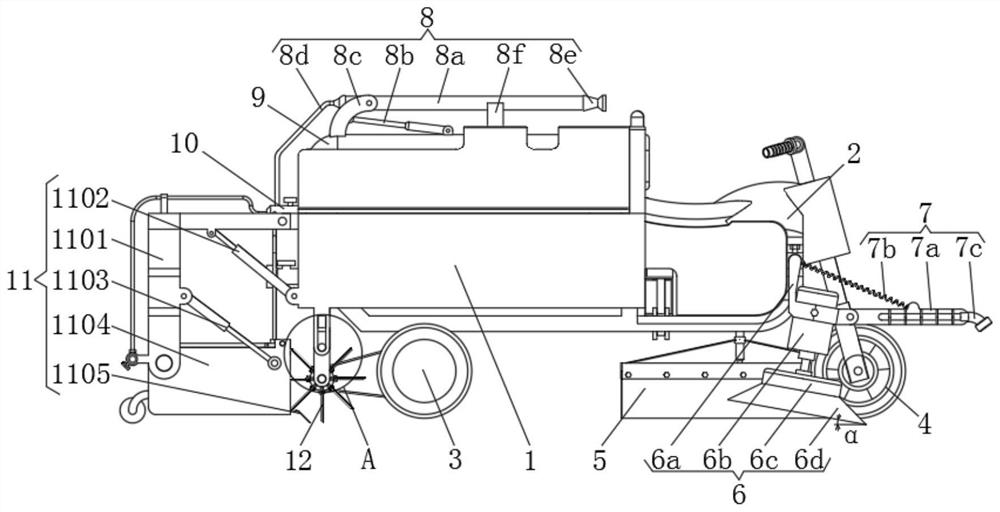

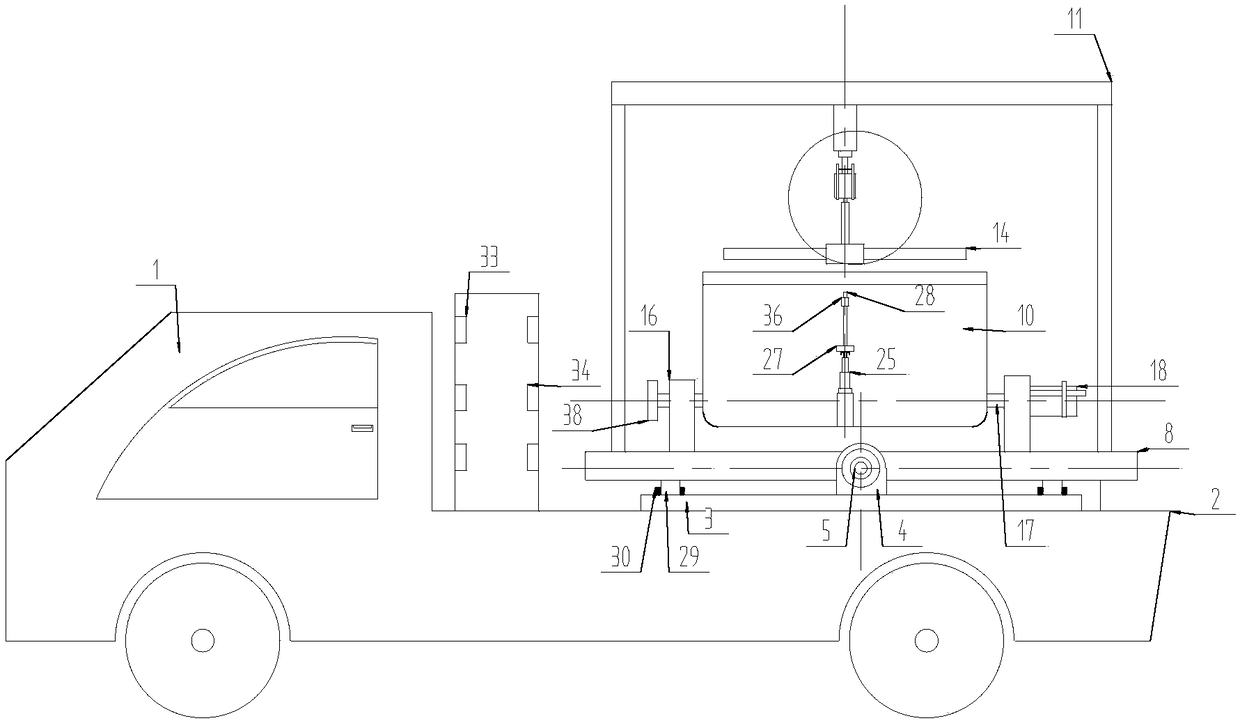

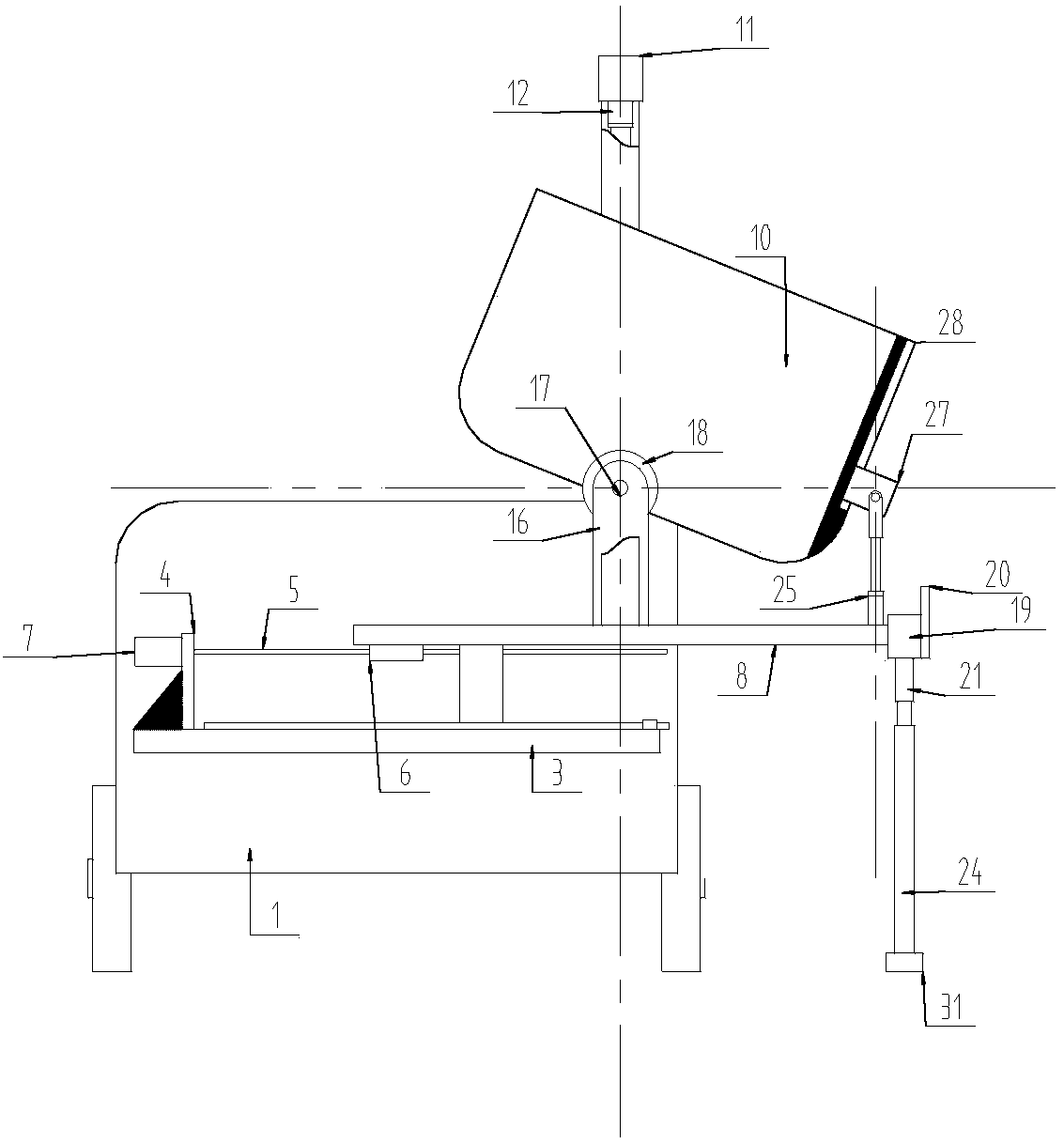

Mobile automatic stirring equipment based on vehicle body and used for building construction

ActiveCN108079836ARealize automatic pouringImprove limitationsRotary stirring mixersMixer accessoriesEngineeringCushion

The invention discloses mobile automatic stirring equipment based on a vehicle body and used for building construction. The stirring equipment comprises the vehicle body, wherein a carriage is arranged on the vehicle body, a cushion plate is arranged at the bottom of the carriage, and a moving unit is arranged on the cushion plate and comprises a shaft bracket, a lead screw, a lead screw pair, a driving part, a mounting plate and an auxiliary part; the shaft bracket is fixed on the cushion plate, the lead screw is inserted into the shaft bracket and sleeved with the lead screw pair, the driving part is fixed on the outer wall of the shaft bracket, a driving end of the driving part is connected with the end surface of the lead screw, the bottom of the mounting plate is fixed on the lead screw pair, and two ends of the mounting plate are assembled at the auxiliary part. The mobile stirring equipment has the benefits as follows: the stirring structure can move through multi-level driving,so that operation limitation is eliminated; meanwhile, a stirring barrel can be correspondingly rotated through a rotating structure after stirring is completed, and accordingly, a material is automatically poured out.

Owner:天长市水电建筑安装工程公司

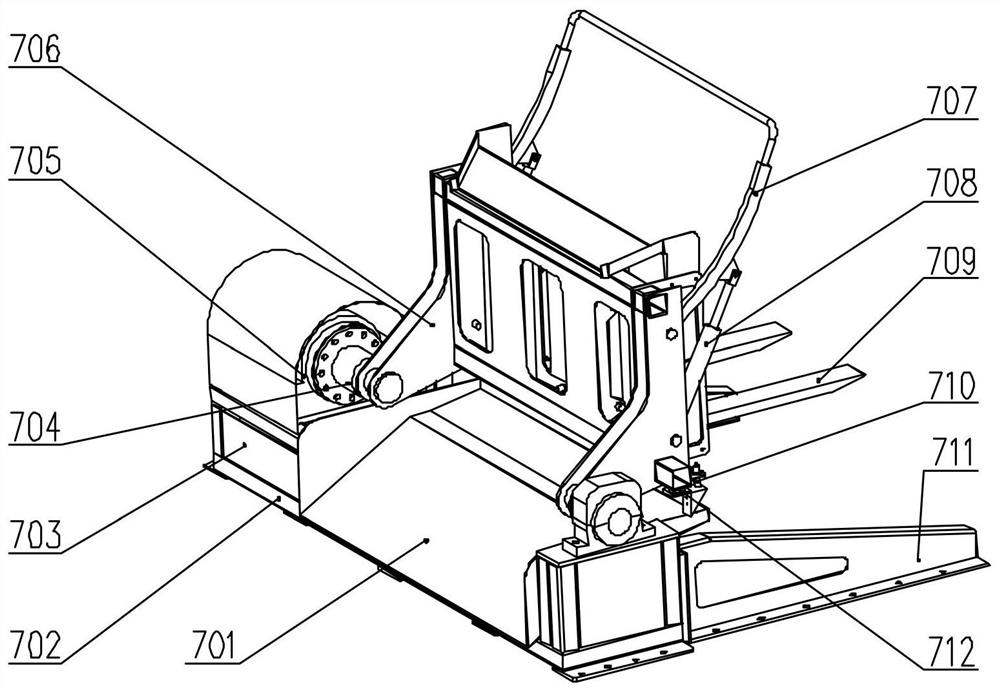

Hazardous waste special container automatic clamping turnover machine

PendingCN110015571ARealize automatic pouringAchieve recyclingBottle emptyingLoading/unloadingHydraulic cylinderDrive shaft

The invention provides a hazardous waste special container automatic clamping turnover machine. The hazardous waste special container automatic clamping turnover machine comprises a base frame. A rotary shaft is supported by two rotary shaft supporting bases on the base frame. One end of the rotary shaft is connected with an output shaft of a swing hydraulic cylinder. The rear ends of left and right longitudinal beams of a turnover frame at the upper end of the base frame are circumferentially fixed to the rotary shaft. The left longitudinal beam and the right longitudinal beam of the turnoverframe are each provided with a row of driving rolling wheels. The driving rolling wheels are supported onto the corresponding longitudinal beams through rolling wheel shafts. A double-row toothed chain wheel is mounted on each rolling wheel shaft. The adjacent double-row toothed chain wheels are connected through a chain. An output shaft of a driving motor of the turnover frame is connected withthe rolling wheel shaft of the first driving rolling wheel through a speed reduction mechanism. The rolling wheel shafts of the first driving rolling wheel and the second driving rolling wheel are connected through a transmission shaft. The lower end of a container locating rack at the rear end of the turnover frame is provided with forks. Hinge supports on a front cross beam of the turnover frameare hinged to the middle portions of clamping rotary arms. The upper portion of each clamping rotary arm is provided with a claw hook. Piston cylinders are hinged to hinged seats located on the rearside of the turnover frame. Piston rods of the piston cylinders are hinged to force arms located on the lower portions of the clamping rotary arms through second pin shafts.

Owner:CHONGQING LIYANG ENVIRONMENTAL PROTECTION TECH DEV

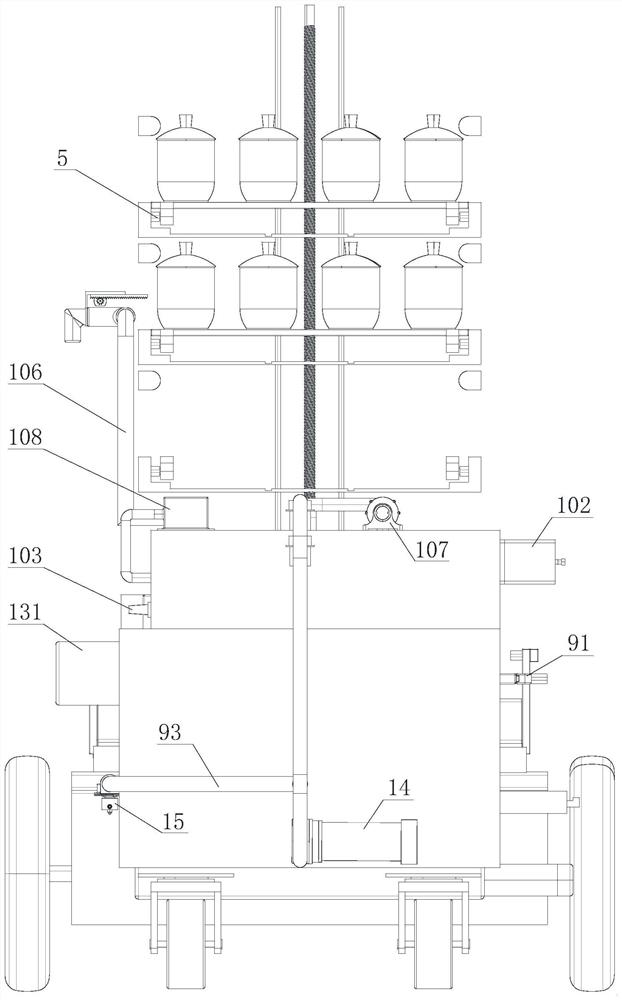

Multifunctional cleaning and tea making all-in-one machine for conference

ActiveCN112998520AKeep clean and hygienicReduced risk of rollover and crushingClimate change adaptationBeverage vesselsUv disinfectionProcess engineering

The invention discloses a multifunctional cleaning and tea-making all-in-one machine for a conference. The machine comprises a shell; a cup storage area and a cleaning and tea making area are arranged in the shell, a cup taking opening is formed in the top of the shell, a driving wheel is arranged at the bottom, and a water adding pipe extending out of the shell is arranged on the side. An inertia device is arranged on the driving wheel; the cup storage area is used for storing teacups and is provided with an ultraviolet disinfection lamp; the cleaning and tea making area is arranged below the cup storage area, is used for making tea and cleaning tea cups, and comprises a clear water tank, a tea cup cleaning device, a tea cup clamping device, a cup cover cleaning device, a tea making device, a lifting platform device for transporting the tea cups and a waste recovery device. The cleaning and tea making all-in-one machine can store a plurality of teacups, and automatic cleaning and disinfection of the teacups are achieved; the automatic tea making function can be achieved, and the risk that workers are scalded in the tea making process is avoided; by sensing the teacup, water is automatically discharged, so that it is convenient to refill the teacup in a meeting process.

Owner:TAIZHOU UNIV

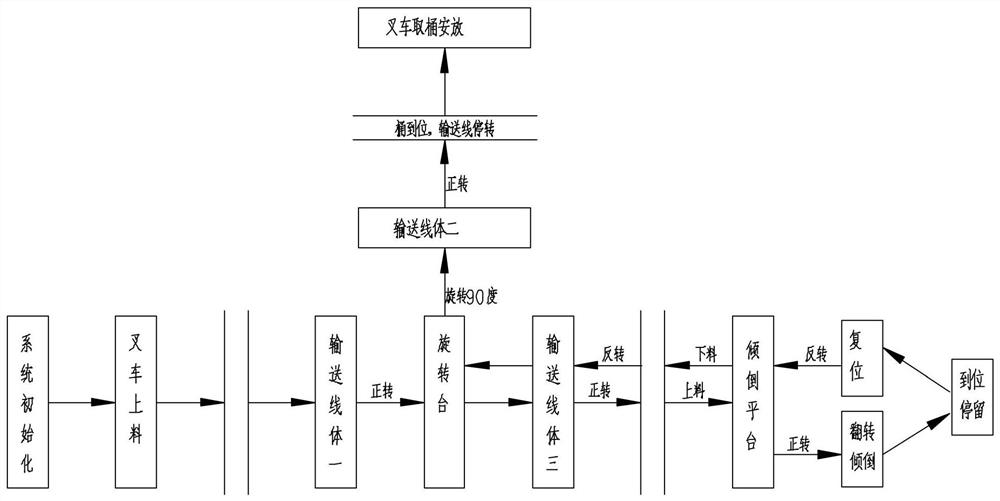

Automatic turning over and dumping system for ton barrels

PendingCN112173749ASolved the problem of not being able to automatically carry to the storage areaWith automatic pouringBottle emptyingLoading/unloadingMechanical engineeringDelivery system

The invention discloses an automatic turning over and dumping system for ton barrels. The automatic turning over and dumping system comprises a feeding conveying system, a material pouring system anda discharging conveying system, wherein the feeding conveying system can convey the ton barrels to a material pouring and feeding position of the material pouring system, and the discharging conveyingsystem can convey the ton barrels reset to the material pouring and discharging position of the material pouring system to the barrel discharging position. According to the solution, on the basis ofthe feeding conveying system, the material pouring system and the discharging conveying system, the solution has a long-distance feeding and discharging function, automatic pouring is achieved, and the effects that personnel are far away from a material pit operation area and automatic pouring operation can be achieved are achieved, the problems that the occupational health of the personnel does not guaranteed, the personnel operation risk is high, turning over and material pouring are difficult, and the working intensity is high are solved, meanwhile the operation efficiency and safety are greatly improved, and in addition, based on the discharging conveying system, the problem that the empty charging barrels cannot be automatically carried to a storage area can be further solved.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

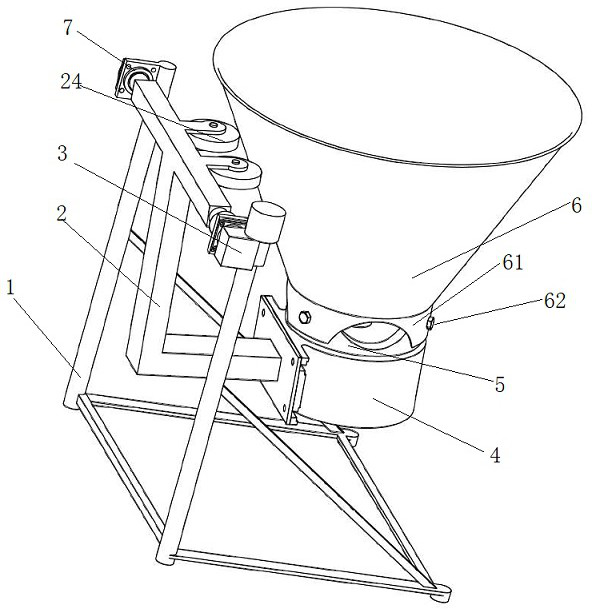

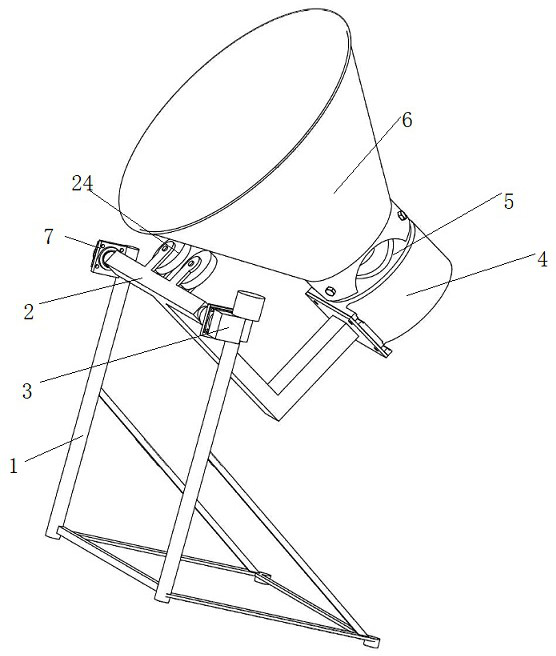

Overturning type discharging hopper capable of imitating manual material pouring

PendingCN113023384ARealize automatic pouringAvoid the risk of manual contactBottle emptyingLoading/unloadingControl engineeringElectric machinery

Owner:南通剑烽机械有限公司

Automatic ice cream and fruit juice vending machine

ActiveCN112820028ARealize automatic pouringRealize the function of automatically pouring ice creamFrozen sweetsApparatus for dispensing fluids/granular materialsFruit juiceIce Creams

The invention discloses an automatic ice cream and fruit juice vending machine, which comprises a frame mechanism, an ice cream storage mechanism, a fruit juice storage mechanism, a rotary conveying mechanism, a clamping and carrying mechanism, a cover sealing mechanism and a control mechanism, wherein the ice cream storage mechanism and the juice storage mechanism are fixedly installed on a baffle on the rear end face of the inner side of the box body, the ice cream storage mechanism is used for storing and pouring ice cream, and the juice storage mechanism is used for storing and pouring juice; the rotary conveying mechanism is fixedly mounted on the inner side of the box body; the clamping and carrying mechanism is fixedly mounted in the box body; and the cover sealing mechanism is fixedly installed on the side end face of the box body. A rotating shaft in an extrusion screw is driven by a servo motor, so that ice cream in an ice cream raw material barrel is extruded into an ice cream cup, and the function of automatically pouring the ice cream is realized; and a suction pump sucks juice in a juice barrel, and then the juice is poured into a juice cup through a discharging pipe, so that the function of automatically pouring the juice is achieved.

Owner:盐城更酷智能科技有限公司 +1

Electric kettle capable of automatically pouring water

InactiveCN107468058ARealize automatic pouringRealize automatic water collectionWater-boiling vesselsControl engineeringControl circuit

The invention provides an electric kettle capable of automatically pouring water. The electric kettle comprises a heating base, a heating device, a control circuit board, a temperature controller, a kettle base, a kettle body, a handle and a kettle cover. The control circuit board is connected with the temperature controller and the heating device. The electric kettle capable of automatically pouring the water further comprises a water pump, a water pump shell, a faucet, a motor, a rotary plate and a water glass, the water pump is arranged in the water pump shell, the water inlet end of the water pump is communicated with the kettle body through a water pipe, the water outlet end of the water pump is connected with the faucet which is fixed to the water pump shell, the motor is fixedly arranged in the heating base, the water glass is placed in the rotary plate, the output shaft of the motor is connected with the rotary plate and drives the rotary plate, and the control circuit board is connected with the water pump and the motor and controls the water pump and the motor. The electric kettle has the advantages that after heating is completed, the functions that the water is automatically poured and the water glass automatically receives the water can be automatically achieved by means of the electric kettle, and the electric kettle is convenient to operate and high in intelligence degree.

Owner:东莞市圣志达科技有限公司

Automatic pouring device with adjustable flow speed for sand casting

InactiveCN112276058AMeet pouring requirementsReduce workloadMolten metal pouring equipmentsMould handling equipmentsGear wheelSand casting

The invention relates to the related field of casting, and discloses an automatic pouring device with an adjustable flow speed for sand casting. The automatic pouring device comprises a main box body,a pouring cavity with a rightward opening is formed in the main box body, a movable nut cavity is formed in the lower side of the pouring cavity, and a movable plate through cavity is formed betweenthe upper end wall of the movable nut cavity and the lower end wall of the pouring cavity in a communicating manner. A lead screw gear cavity is formed in the left side of the movable nut cavity. Molten iron uniformly flows into a pouring opening of a sand mold box under the action of centrifugal force, automatic pouring is achieved, the workload of operators is reduced, the pouring efficiency isimproved, meanwhile, pouring is conducted in a mechanical mode, the safety during pouring can be improved, and the health of the operators is protected; and in addition, the pouring speed can be freely controlled through a molten iron flow speed adjusting mechanism, the requirement for different pouring speeds in different pouring stages is met, meanwhile, the pouring requirements of different sand mold boxes can be met, and the practicability of the device is improved.

Owner:福州经济技术开发区星络网电子科技有限公司

Brick tea manual-press molding device

InactiveCN109221464AImprove pressing qualityRealize automatic pouringPre-extraction tea treatmentMechanical engineeringBrick

The invention relates to a brick tea manual-press molding device, which solves the problems of high cost, poor pressing effect and the like of an existing device. The device comprises a rack, whereina feeding channel is arranged on the rack; a molding cylinder is additionally arranged on the rack; a feed opening is formed in the upper end of the molding cylinder; a lifting rack body is arranged in the molding cylinder and is provided with a jacking bottom plate; a jacking top plate is arranged in the feeding channel; a molding cavity is formed by the jacking top plate, the jacking bottom plate and the molding cylinder; a jacking seat is arranged outside the jacking top plate; a U-shaped rack is arranged on the lifting rack, and a jacking block is arranged inside the middle of the U-shapedrack; and a driving rod is connected on the jacking block. The brick tea manual-press molding device has the advantages of being simple in operation and control, high in brick tea pressing quality, low in cost and the like, and is suitable for production by conventional small tea farmers.

Owner:沈佰安

Composite plastic counter-weight shell

The invention relates to a composite plastic counter-weight shell. The composite plastic counter-weight shell is prepared from, by weight percentage, 45-70 parts of polyvinyl chloride resin, 5-15 parts of reinforced fiber, 5-15 parts of plasticizer, 20-80 parts of barium sulfate powder, 40-80 parts of calcium carbonate powder, 0.5-1.5 parts of stabilizer, 0.5-1.5 parts of stearic acid, 0.5-1.5 parts of polyethylene wax, 1.5-3 parts of modifier, 0.5-1.5 parts of flame retardant and 0.5-1.5 part of pigment. The reinforced fiber, the calcium carbonate powder and the like are utilized to replace traditional counter-weight block iron materials for the shell, the counter-weight shell is formed through one-time extrusion without iron shell and steel bar welding operation, emissions of pollution gas are decreased, the labor and manufacturing cost for manufacturing counter-weight blocks can be remarkably reduced, and a shell painting process is omitted.

Owner:XUANCHENG VALIN PRECISION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com