Concrete dropping device in prefabricated slab production line

A blanking device and production line technology, applied to supply devices, manufacturing tools, etc., can solve problems such as unfavorable operation, waste of man-hours, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

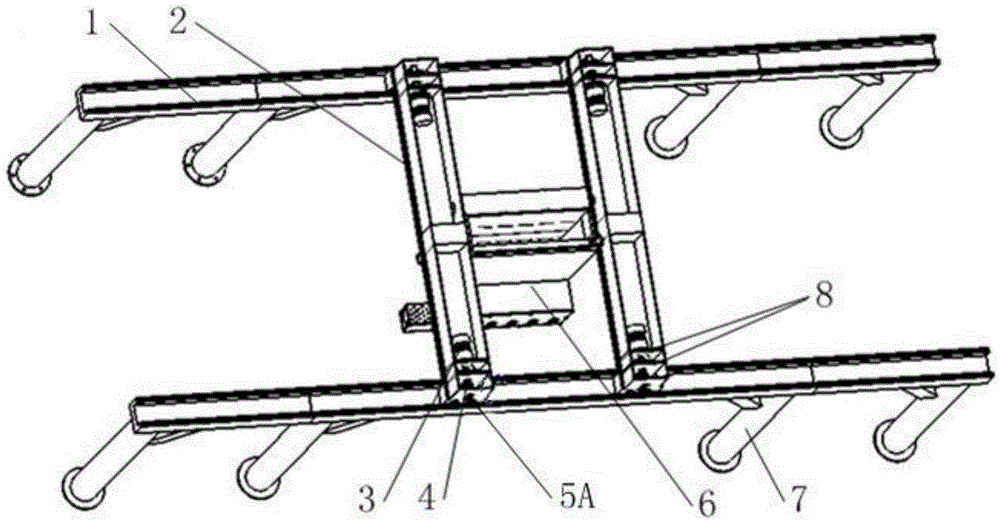

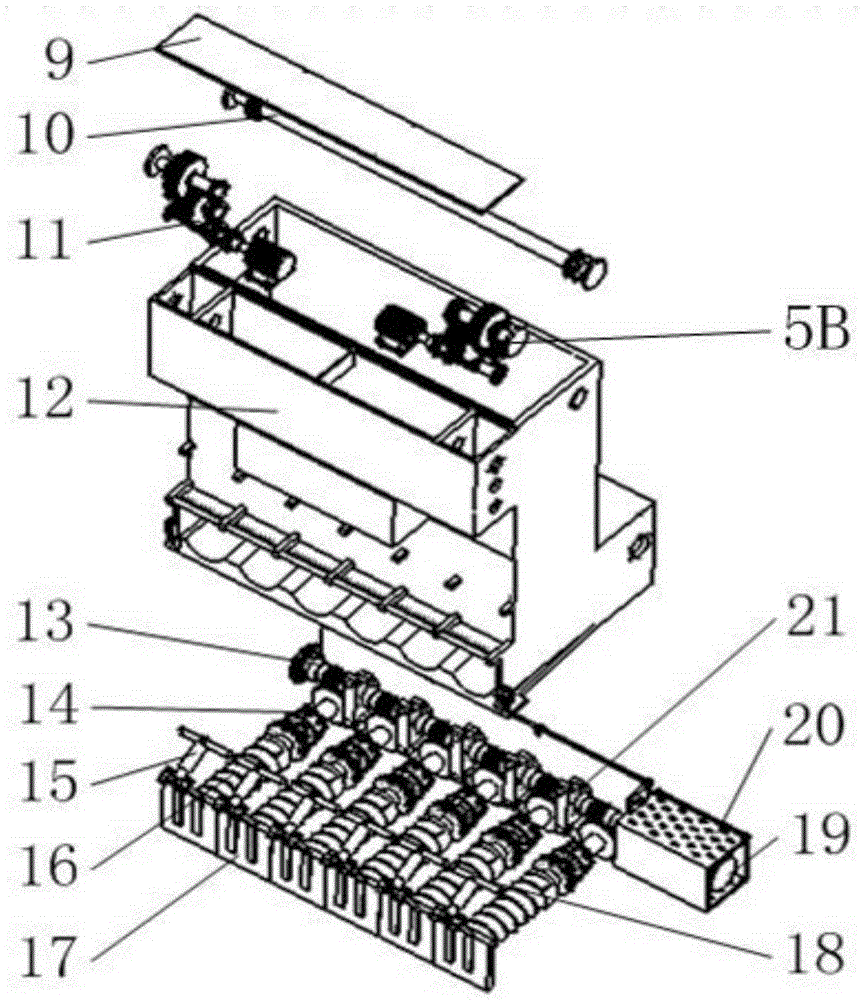

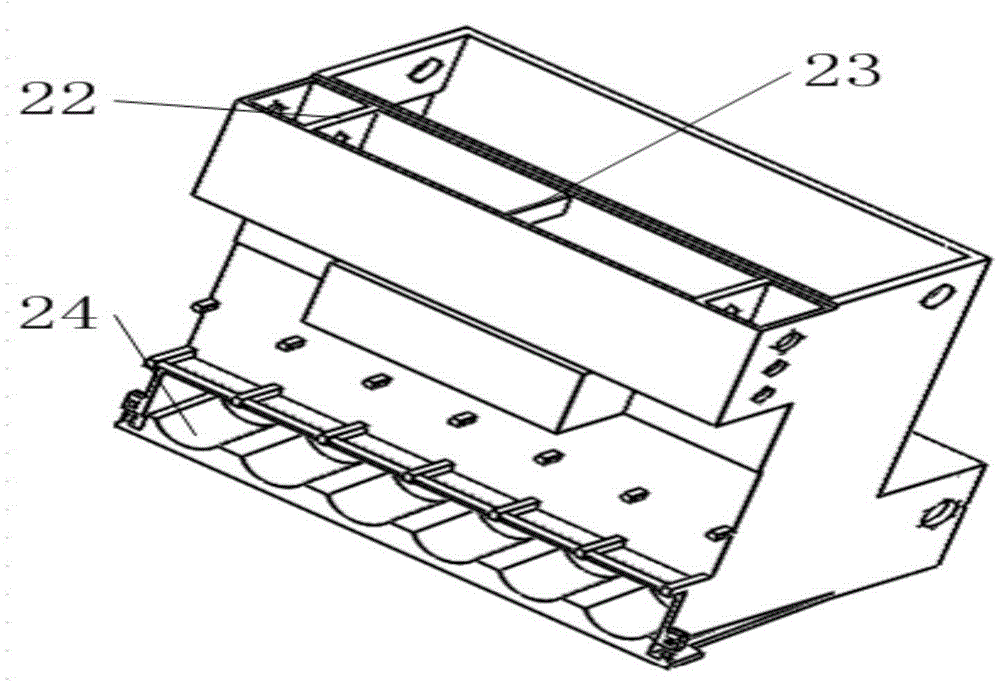

[0013] The concrete blanking device in a prefabricated slab production line provided by the present invention includes a horizontal lifting beam 1, a vertical lifting beam 2, a soft start brake motor 3, a lifting beam secondary reduction gear set 4, and a first traveling wheel 5A , The second walking wheel 5B, the blanking box 6, the column 7 and the transverse rib plate 8. The device adopts a set of horizontal lifting beams as a whole support structure, and a small chute is opened on both sides of the horizontal lifting beam. The blanking box can move left and right along the horizontal lifting beam, and there are small chutes on both sides of the vertical lifting beam, and the blanking box with walking wheels is placed on it, so that the blanking box can move forward and backward, so that The box can move arbitrarily in the four directions of front, back, left, and right to achieve the purpose of controlling the range of blanking. The transmission method adopts worm-worm ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com