Patents

Literature

35results about How to "Meet pouring requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

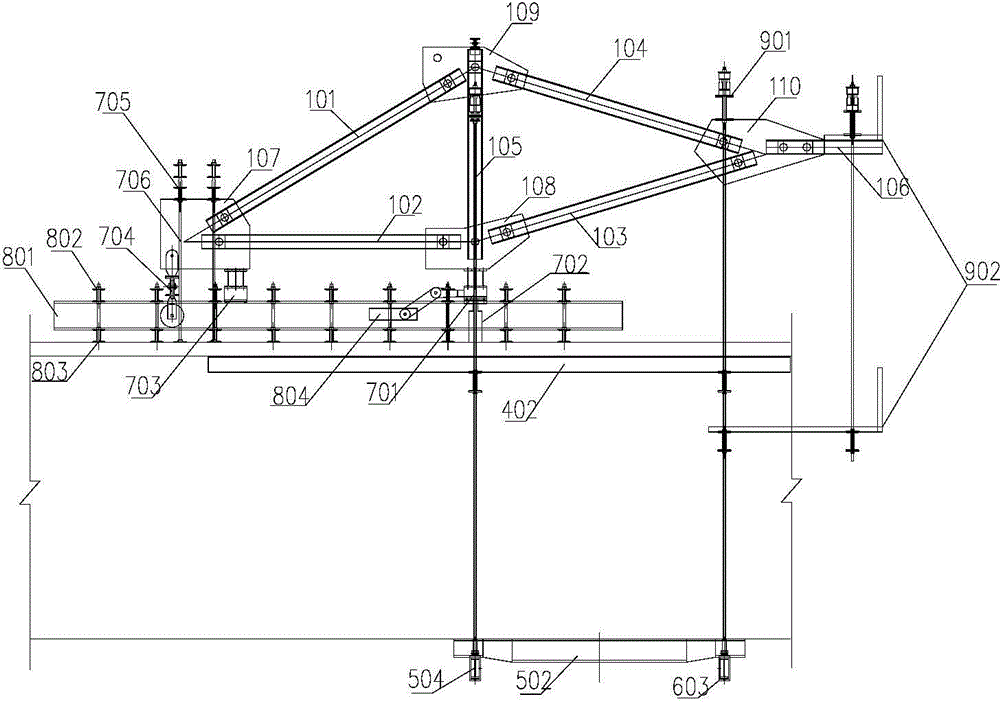

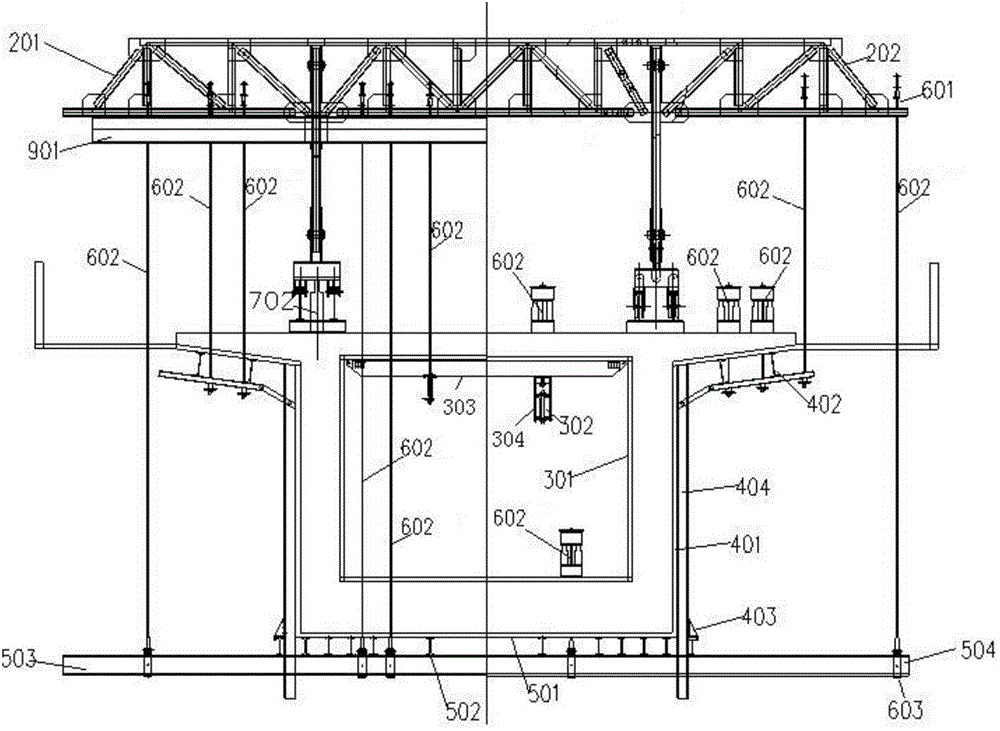

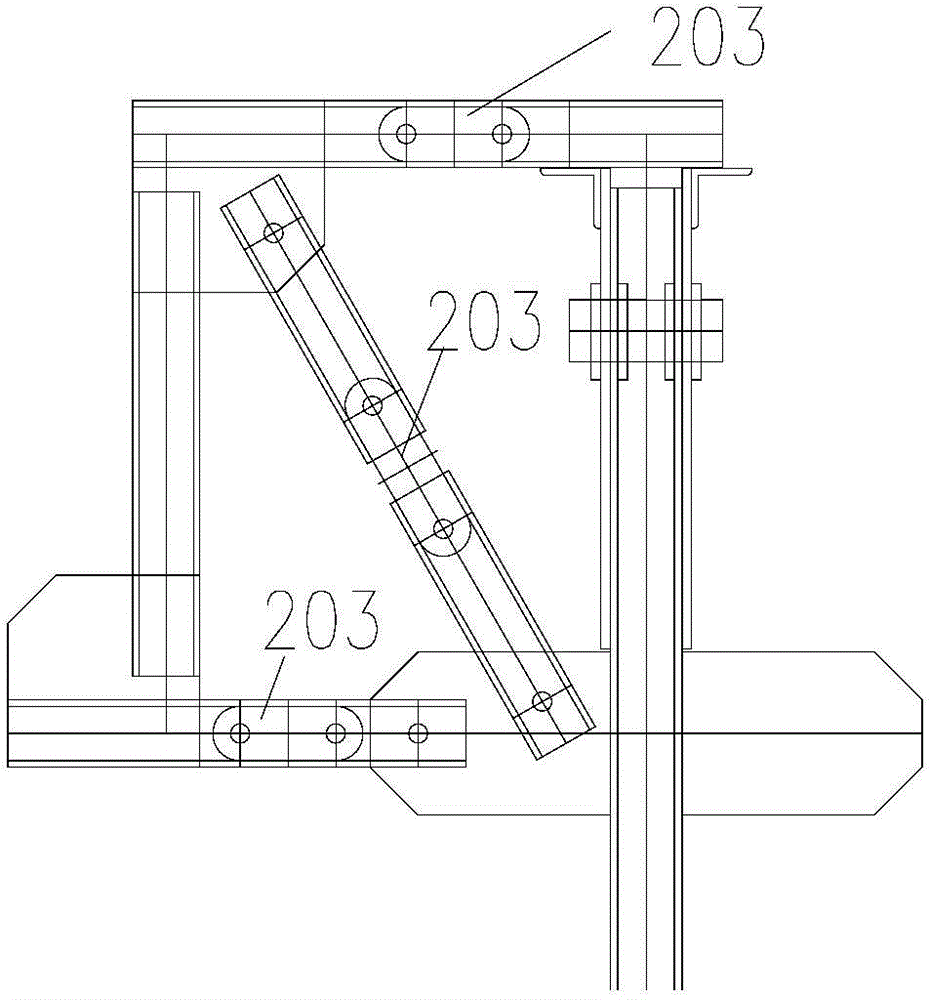

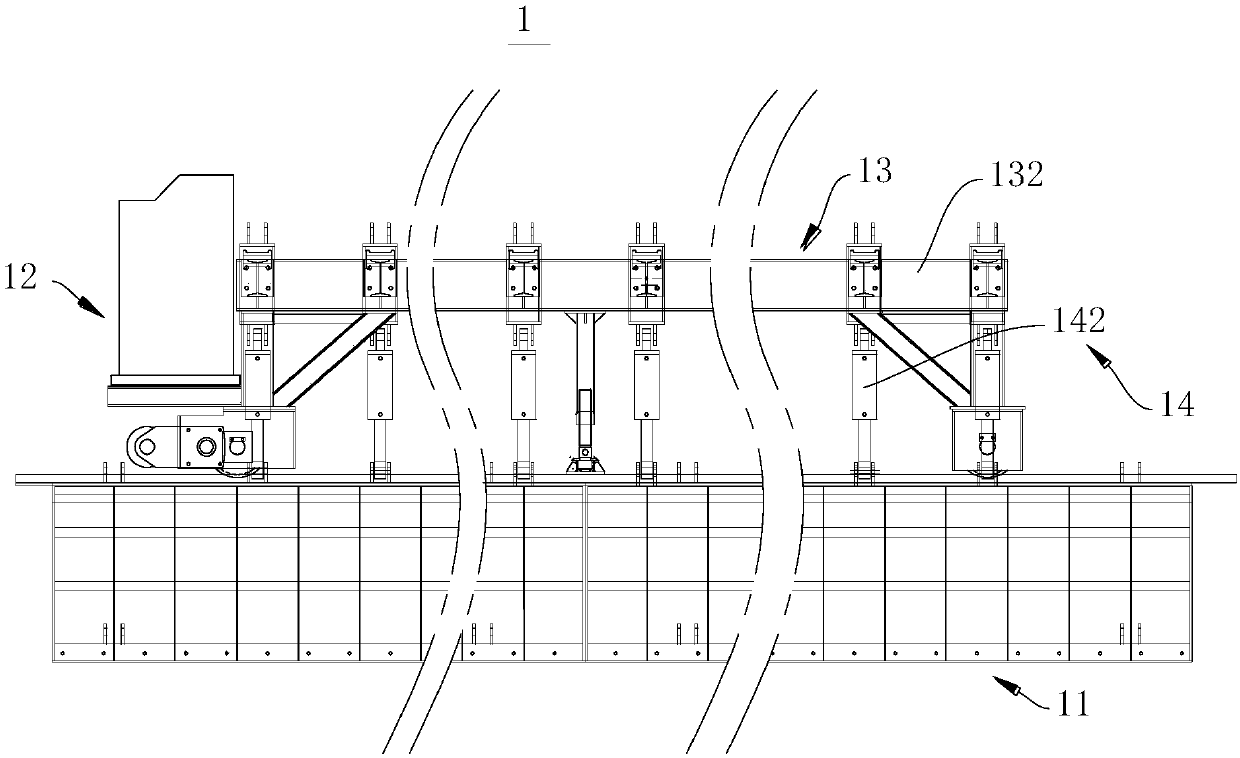

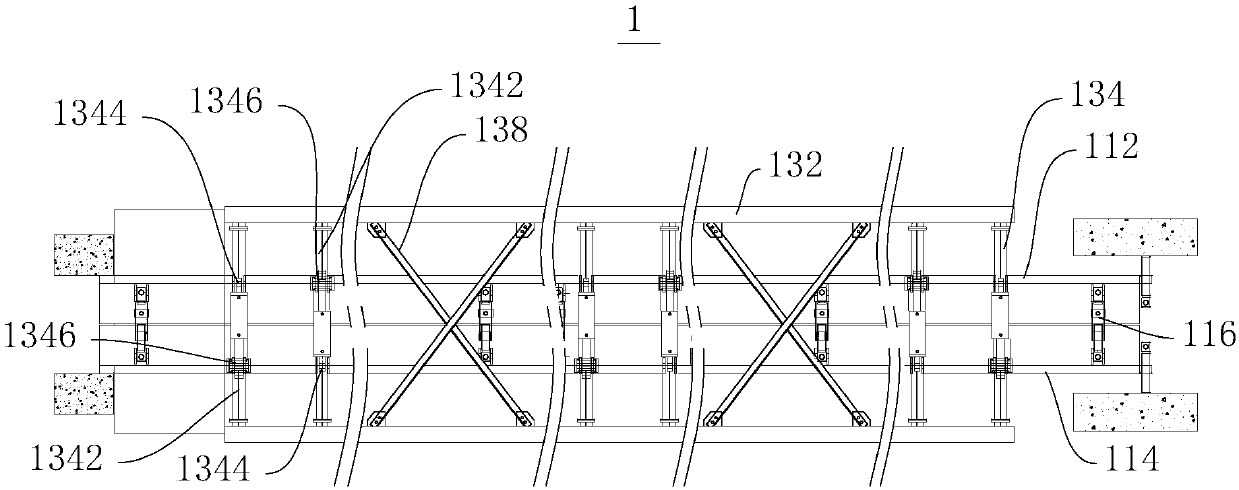

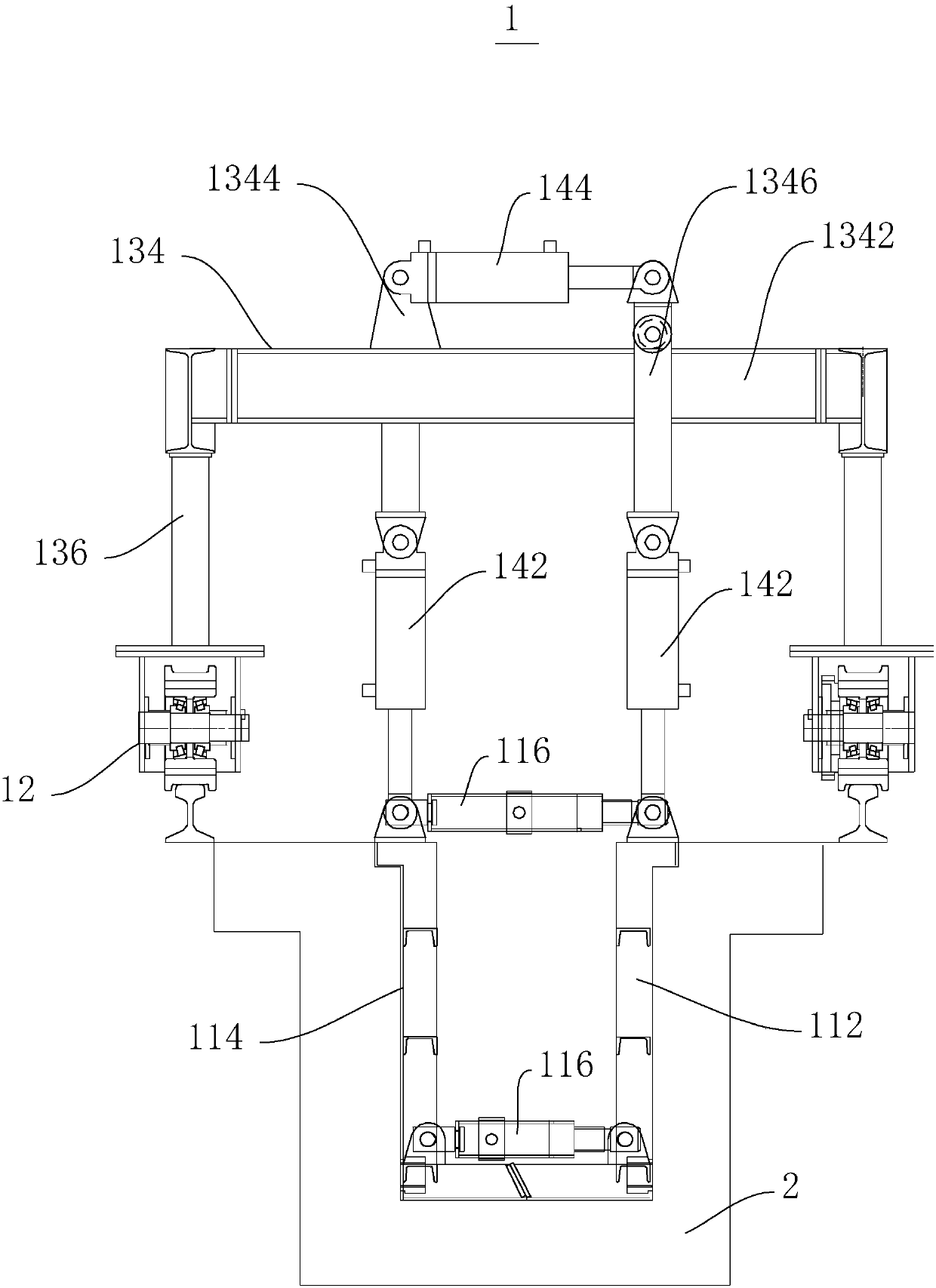

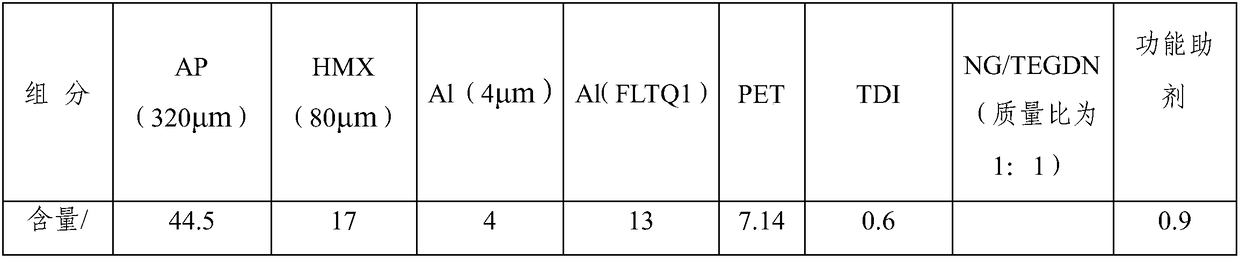

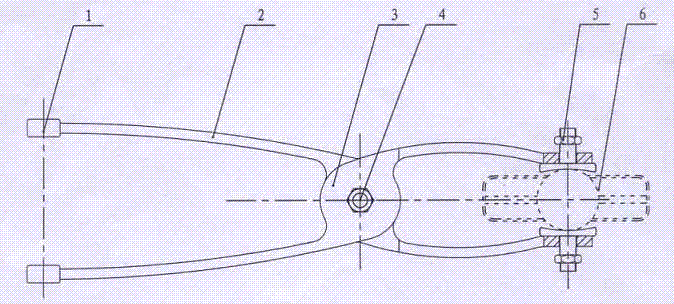

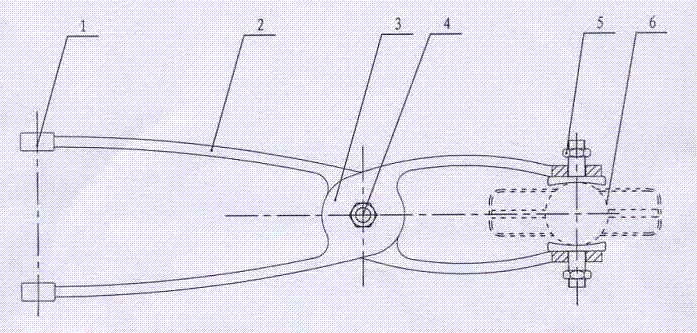

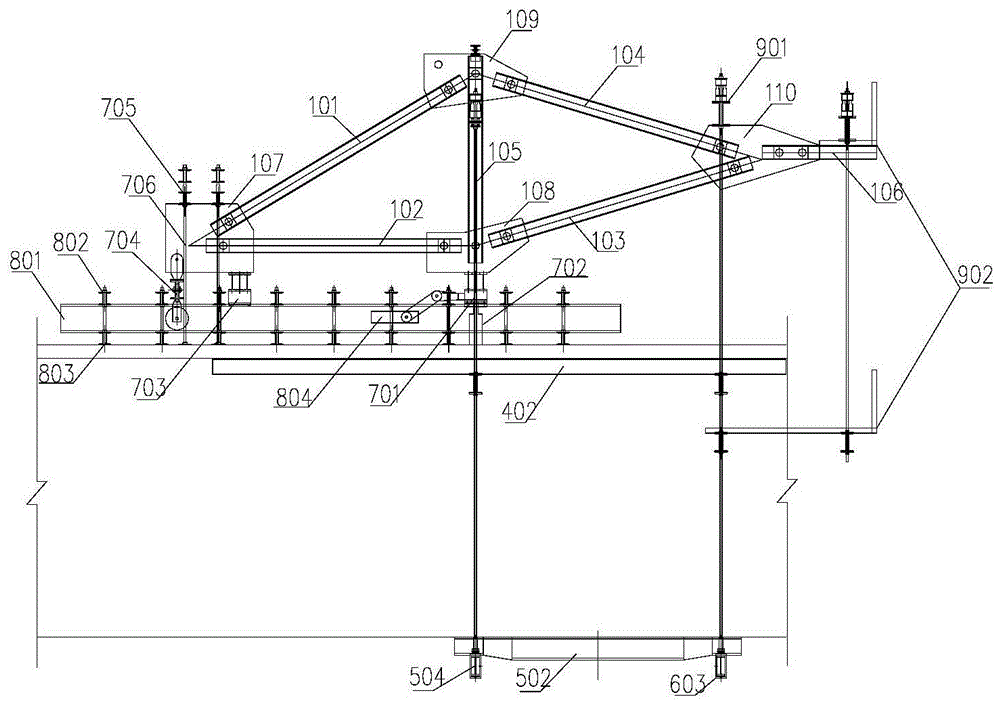

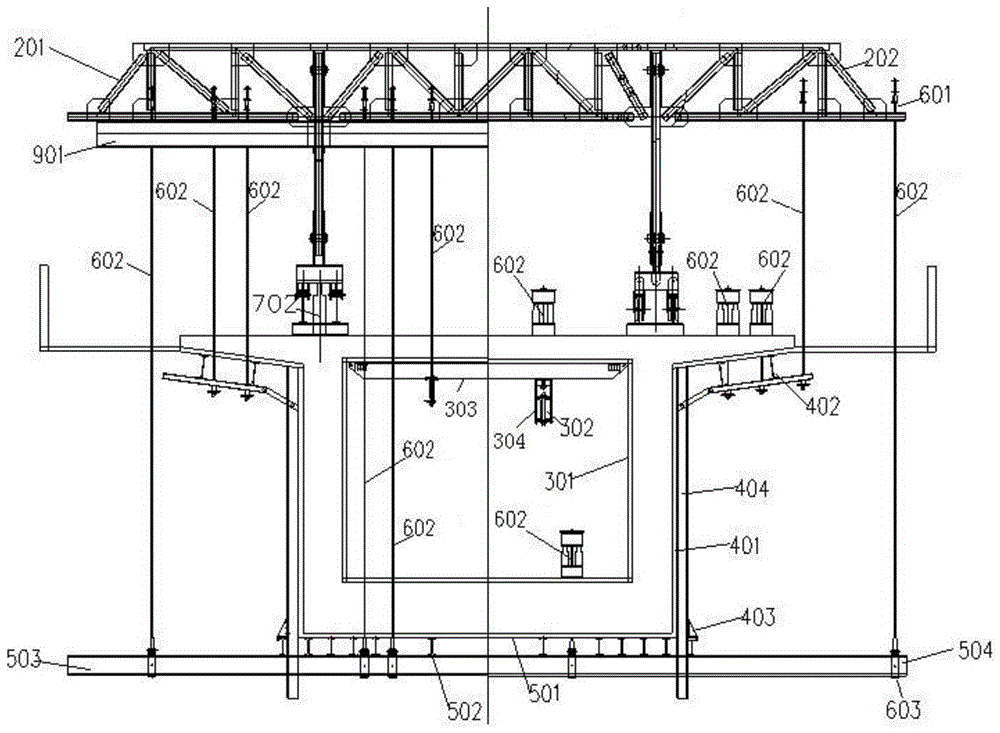

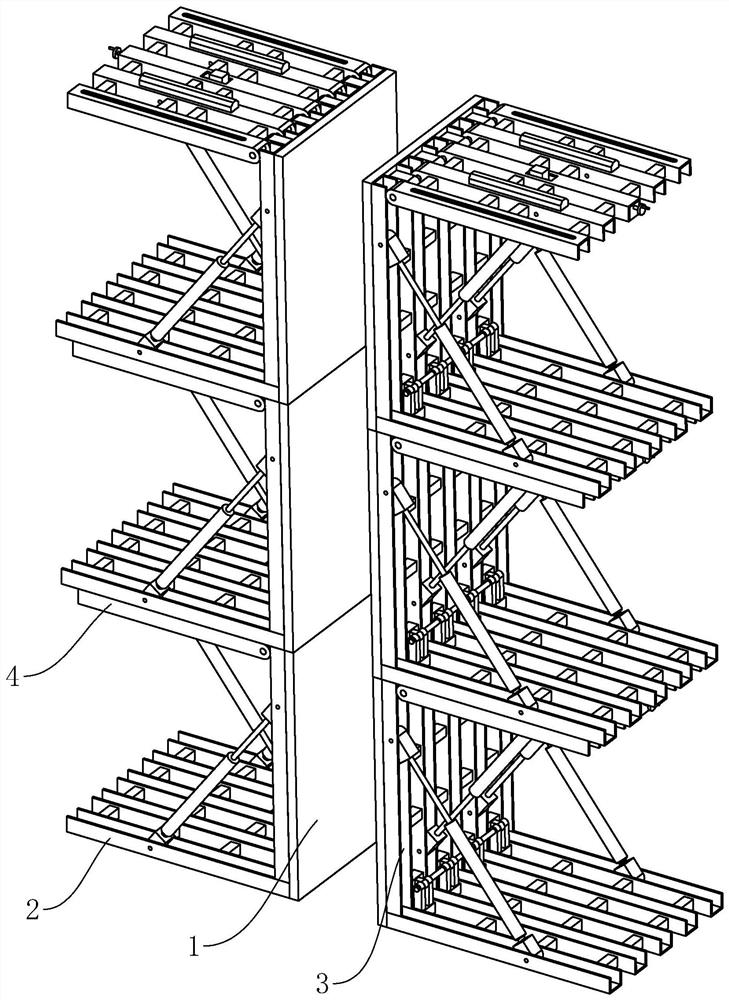

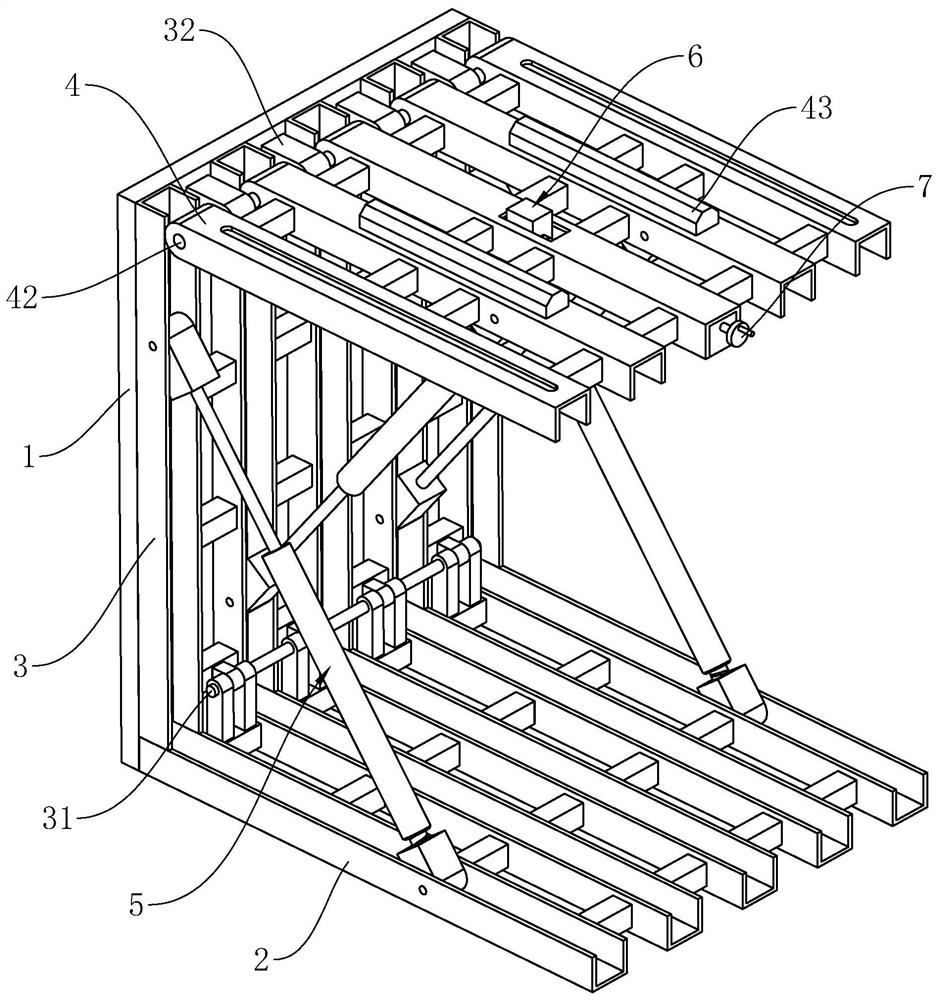

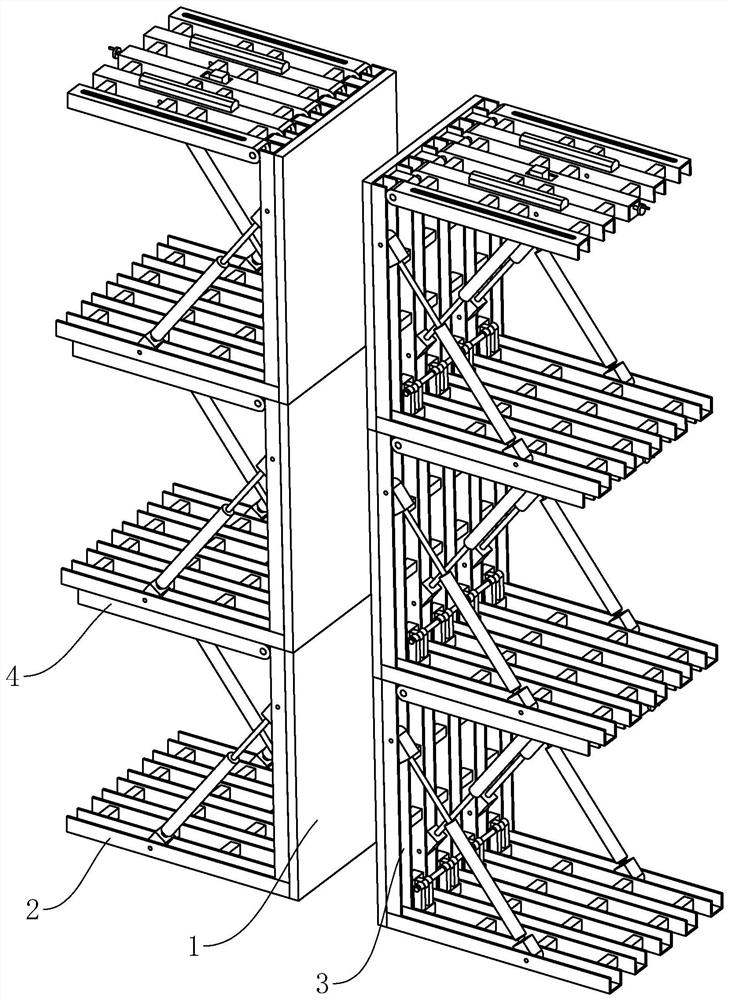

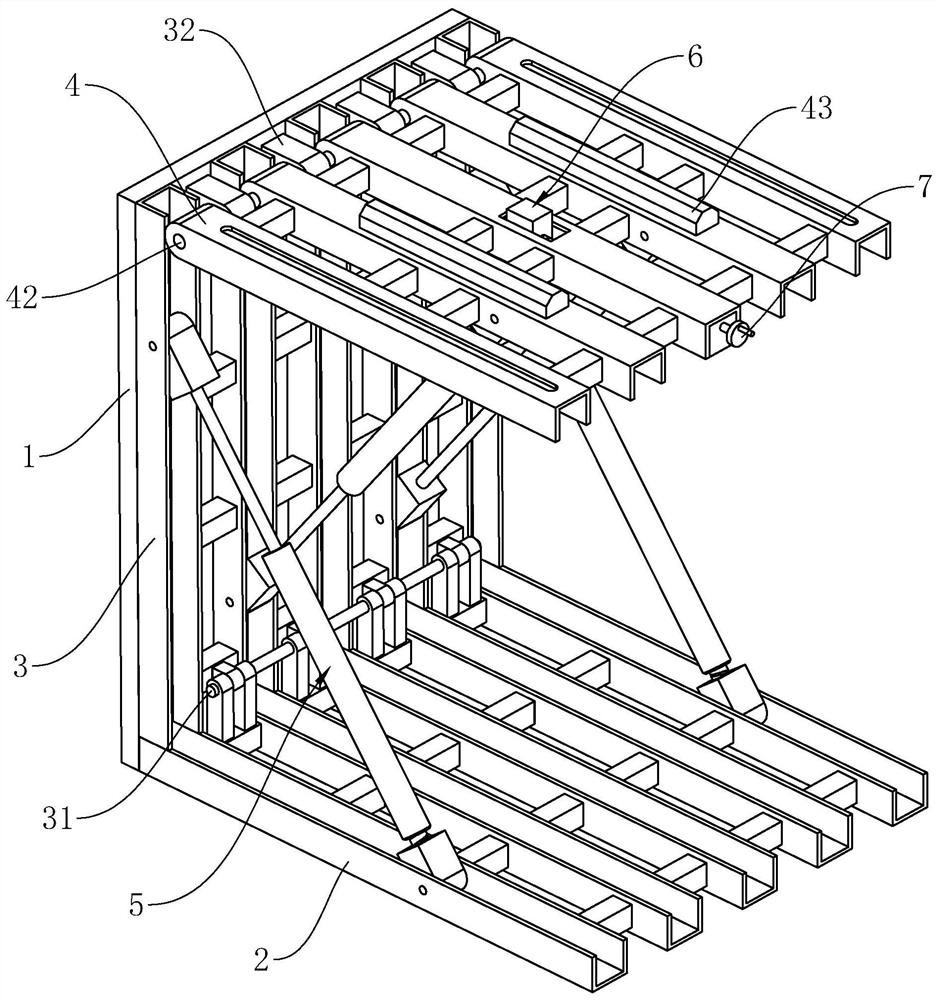

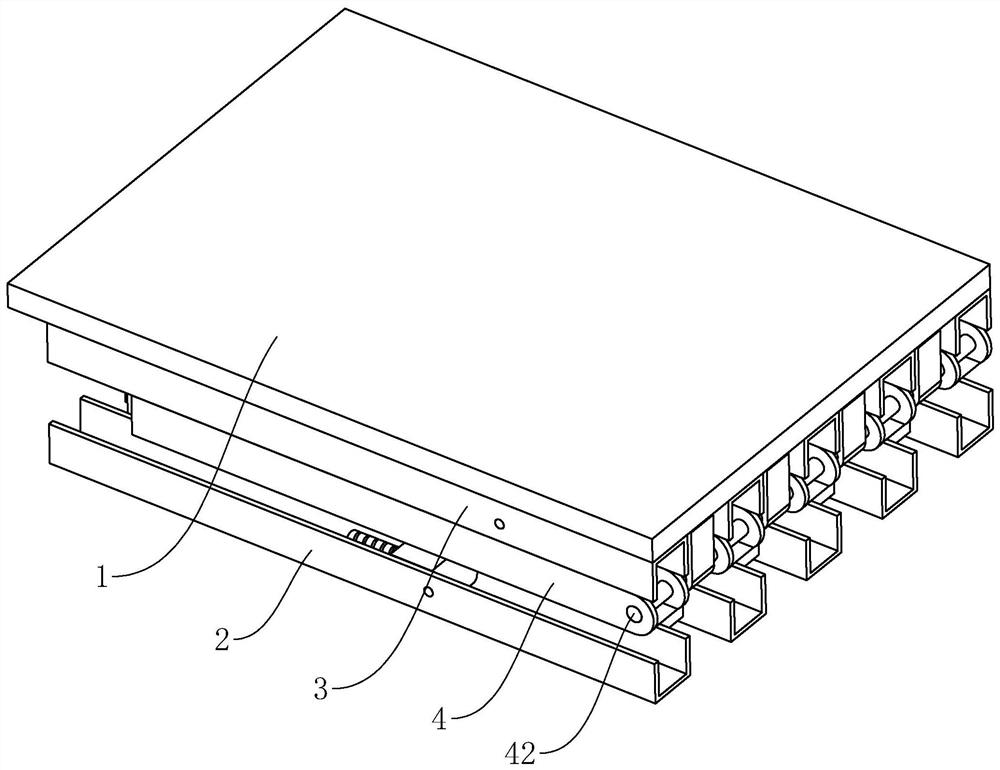

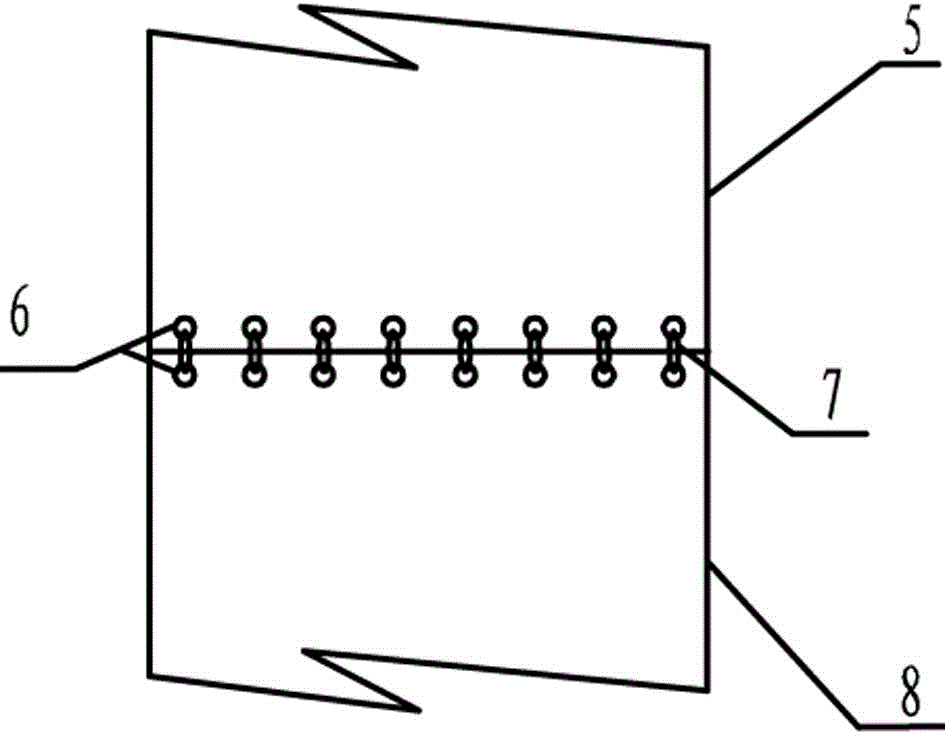

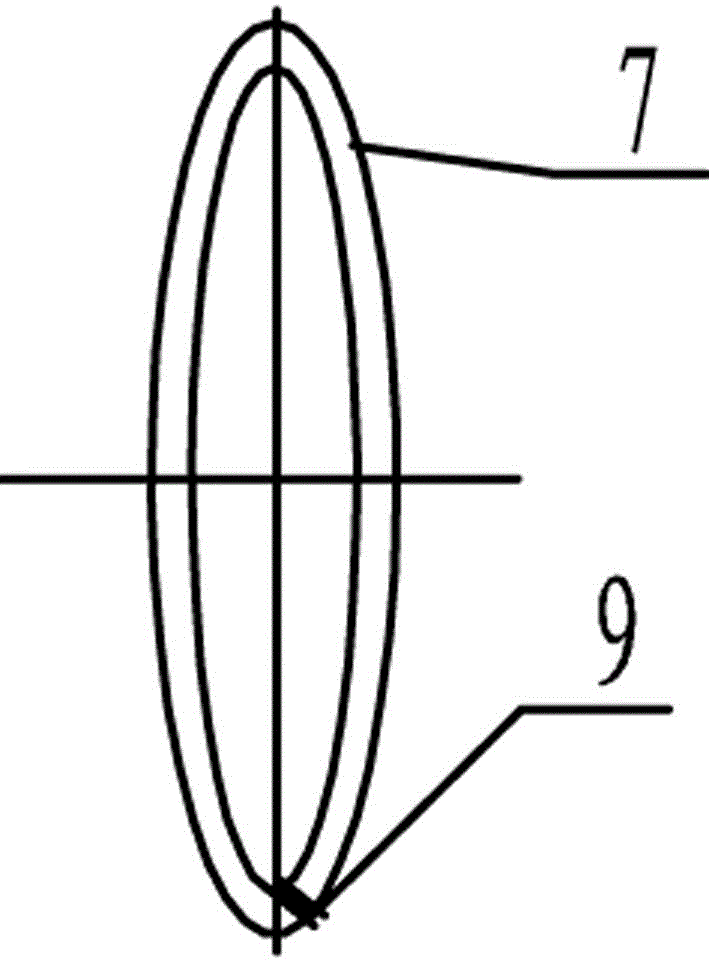

Self-travelling diamond-shaped pin-connected truss-type form traveler structure and form traveler travelling and constructing method

InactiveCN104631343AEven by forceMeet stability requirementsBridge erection/assemblyEconomic benefitsJackscrew

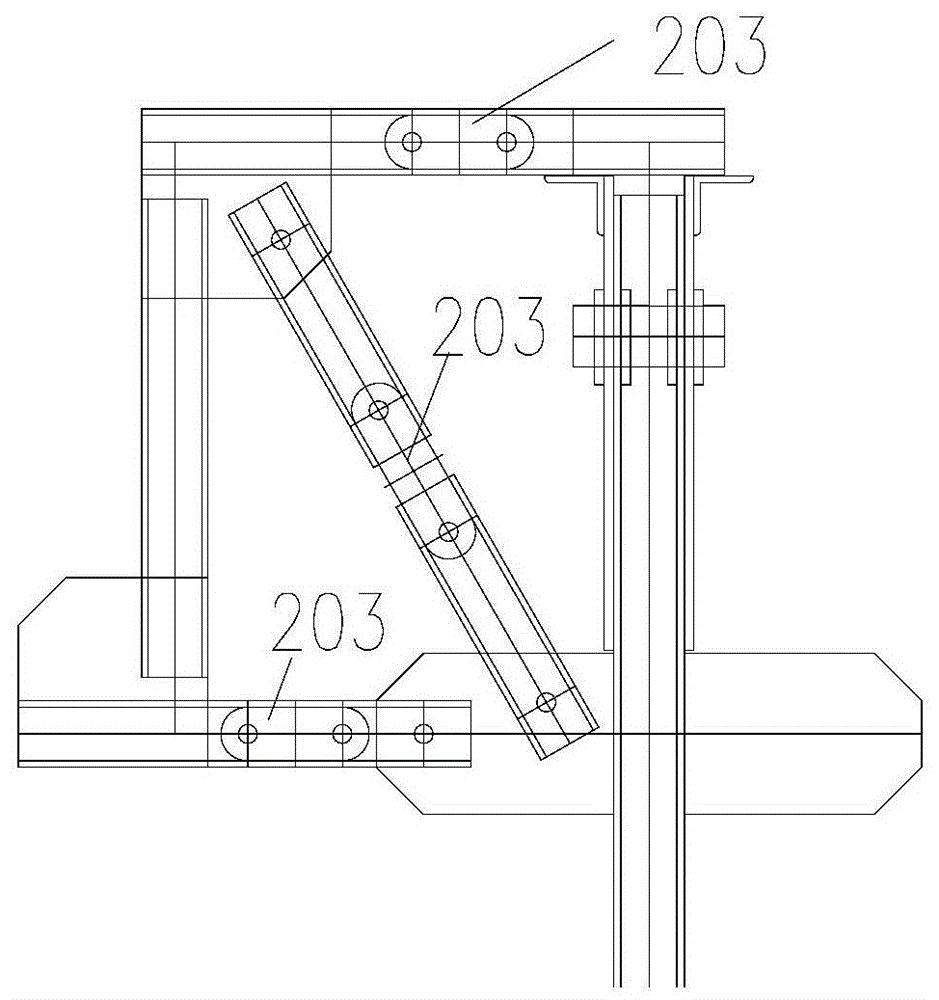

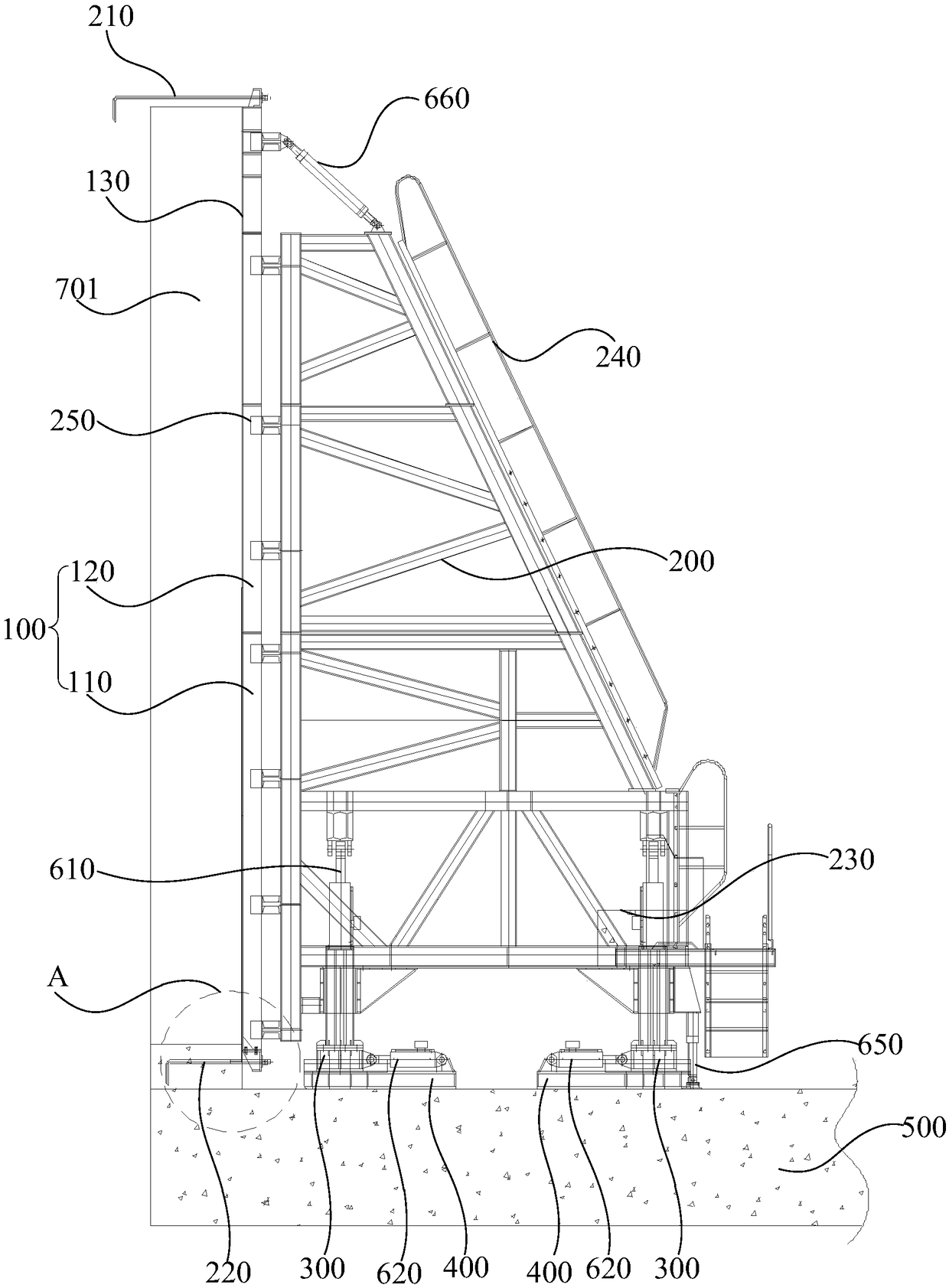

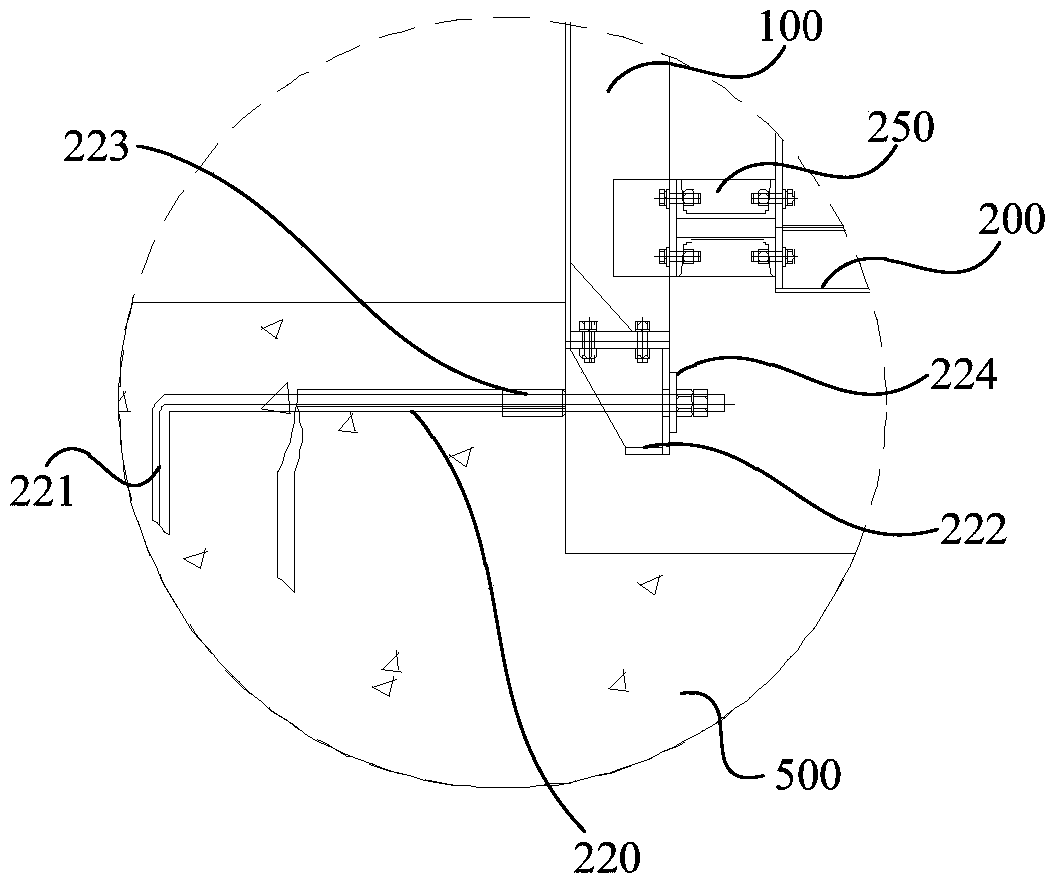

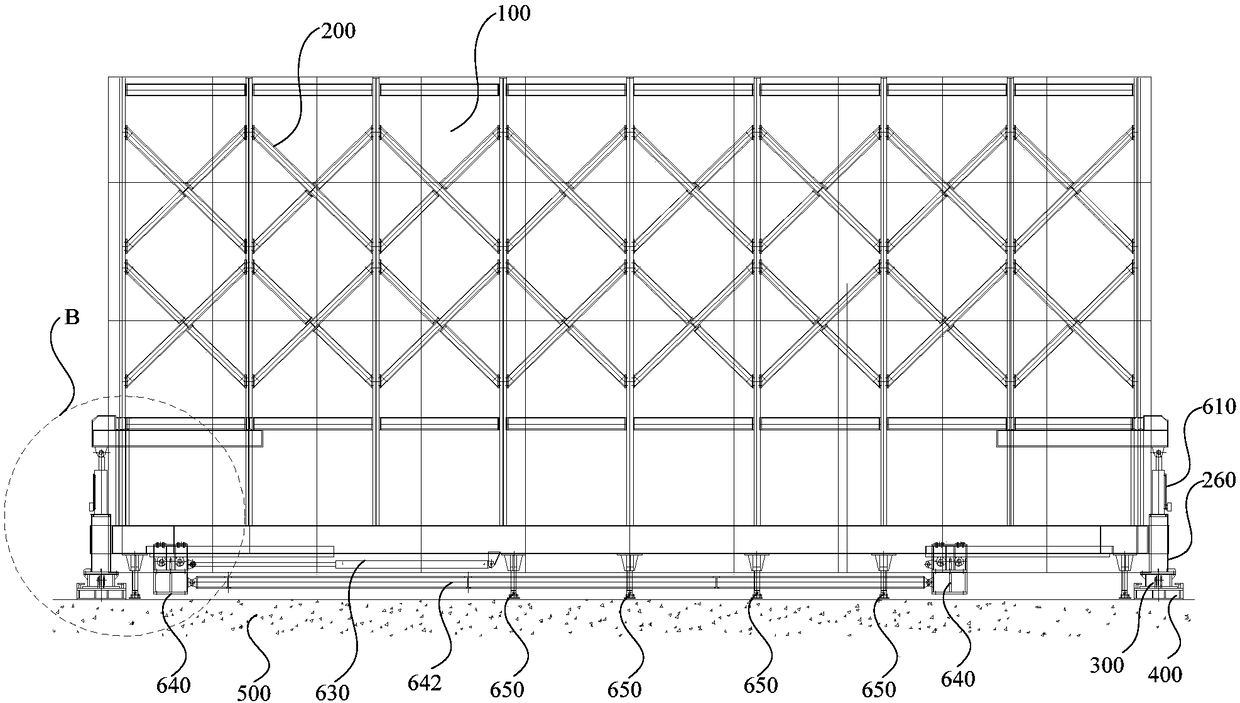

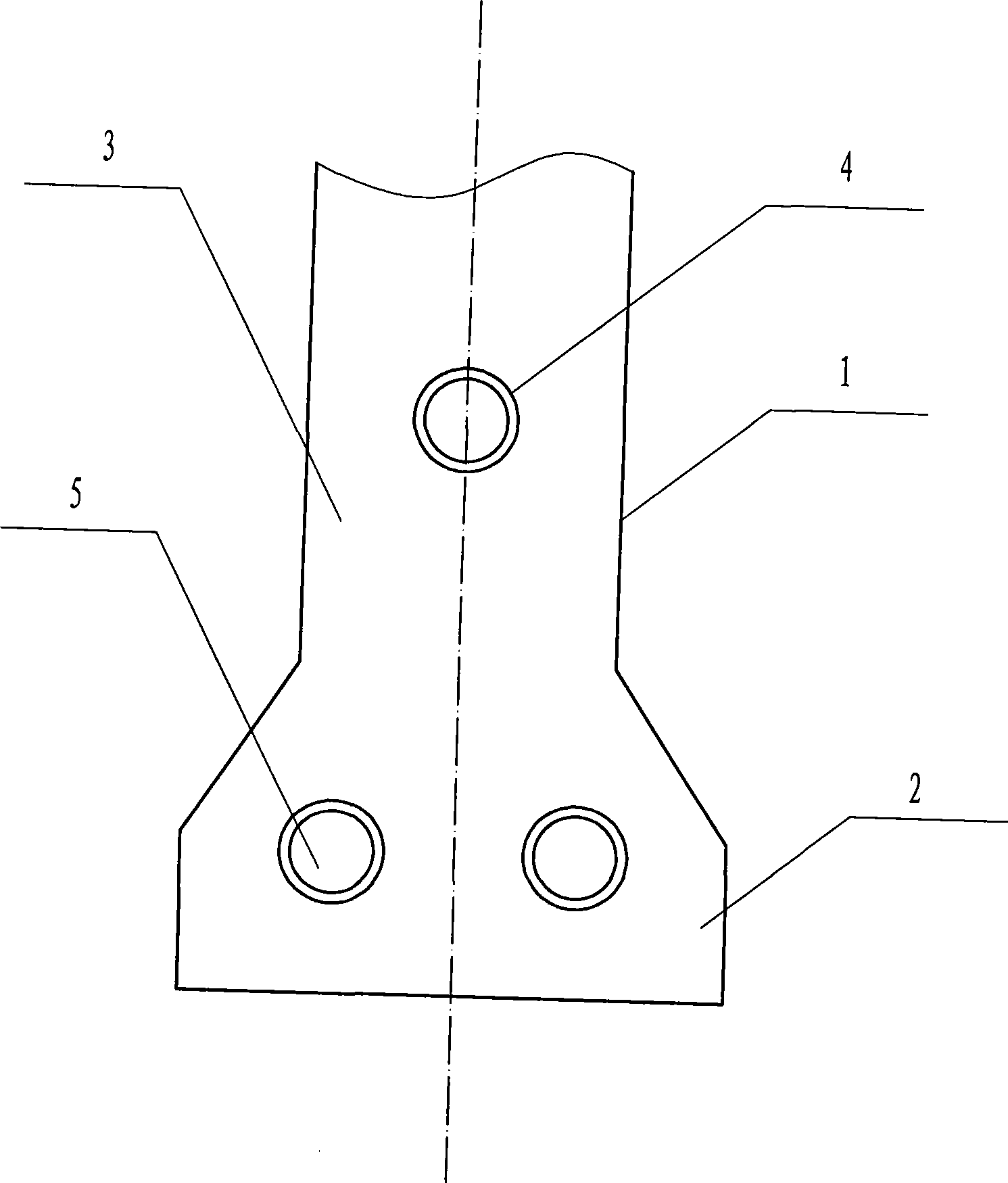

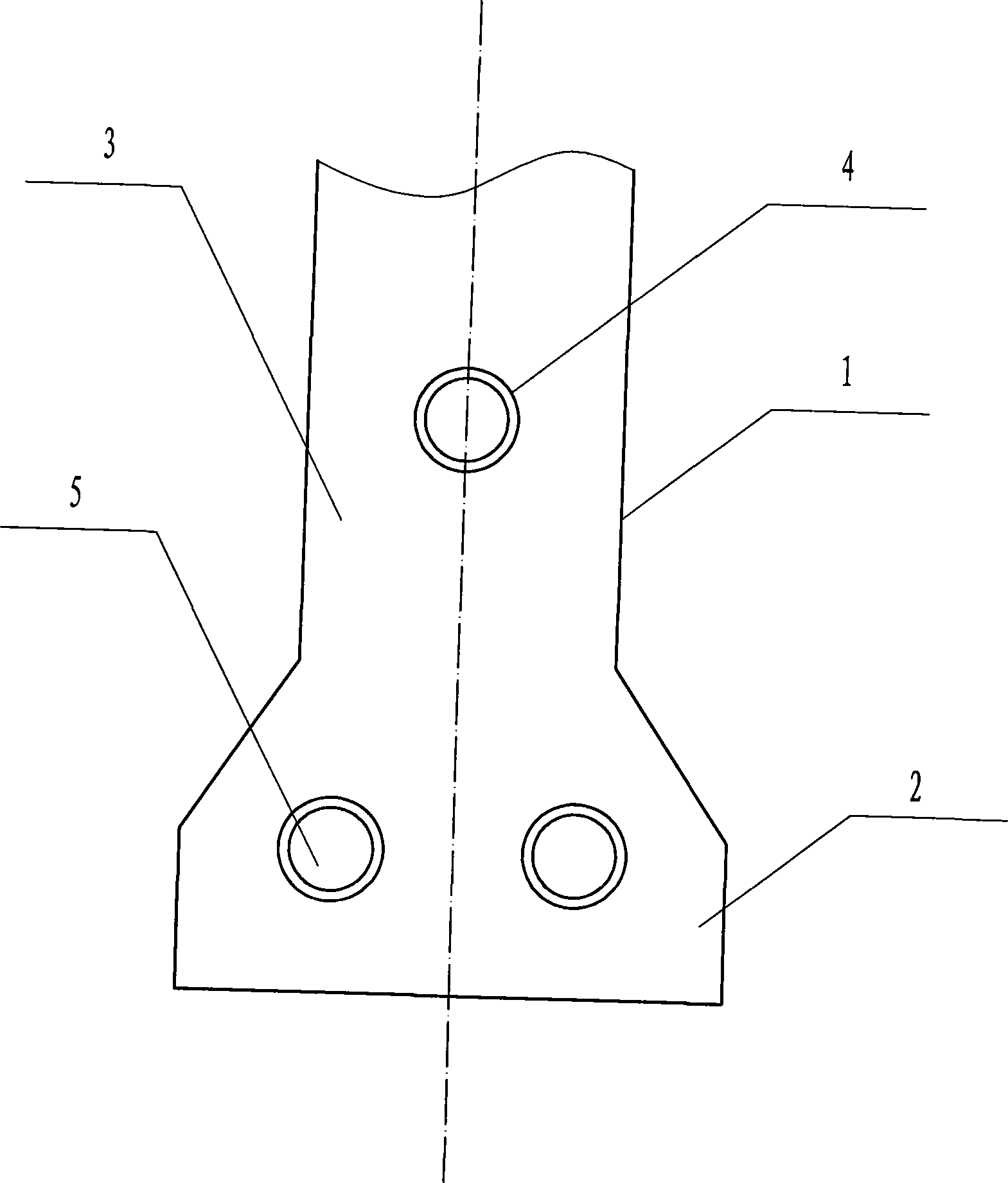

Disclosed are a self-travelling diamond-shaped pin-connected truss-type form traveler structure and a form traveler travelling and constructing method. A form traveler is mainly composed of a main truss system, a horizontal connection system, an internal formwork system, an external formwork system, a bottom formwork platform system, a hanging system, an anchoring system and a travelling system. The main truss system is composed of two main trusses and horizontal bracings, and each single main truss is composed of a lower chord, an upper chord, a diagonal rod and a vertical rod which are connected into a whole via single-hole bolt pins through joint boxes. The two main trusses are connected by the spacing-adjustable horizontal bracings. A rear anchoring system is connected to the rear of the lower chords of the main trusses. The travelling system comprises a section rail located under the main trusses, a left-handed wheel, rollers, a travelling pushing jack and the like. The self-travelling diamond-shaped pin-connected truss-type form traveler structure is quick to install, the spacing between the main trusses and the positions of hanging rods can be adjusted according to the section forms of different box girders on the basis that load bearing is satisfied, the optimal stress state is formed, universality is high, turnover rate of the form traveler is increased greatly, project cost is saved, and economical benefit is obvious.

Owner:HOHAI UNIV

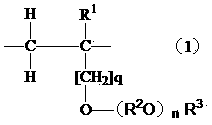

Polycarboxylic acid water reducer for preparing fair-faced concrete

The invention discloses a polycarboxylic acid water reducer for preparing fair-faced concrete. The water reducer is composed of following components in percentage by weight: 5.00% to 60.00% of polycarboxylic acid copolymer, 0.02% to 1.00% of slow-release antifoaming agent, 0.01% to 1.00% of antifoaming agent, 0.01% to 1.00% of air-entrainer, 0.00% to 10.00% of delayed coagulant, and the balance being water. The polycarboxylic acid water reducer for preparing fair-faced concrete has the characteristics of low mixing amount, low air-entraining, low consistency, continuous defoaming ability, and improvement on concrete uniformity, is capable of producing green concrete, which has the advantages of excellent construction performance, low consistency, and good concrete wrapping ability, and also can produce fair-faced concrete, which has a mirror-face effect.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Silicon-based ceramic core preparation method

The invention discloses a silicon-based ceramic core preparation method. The method comprises the following steps: powder configuration and mixing, slurry preparation, compression moulding and sintering, wherein the sintering step comprises the following processes: wax melting, gasification, intensified gasification, cristobalite transitional change, cristobalite change and final sintering. The silicon-based ceramic core prepared by using the preparation method is good in creep resistance, low in high temperature deflection, low in shrinking percentage, high in strength, high in porosity, and easy for core leach.

Owner:兴化市兴东铸钢有限公司

Organic carbon source for pouring and molding silicon carbide aqueous gel and molding technique

The invention relates to selecting a new organic carbon source which is suitable for a gel casting molding process of silicon carbide and can meet the requirements of the dispersion, stability and a subsequent curing process of slurry with high solid content in water-base gel casting as well as provide carbon powder after cracking. The invention adopts dextrin as the organic carbon source and adds dimethyl sulfoxide to improve the stability of the dextrin. According to conventional gel casting process, the SiC slurry with solid content to be 50vol percent can be prepared and the viscosity can be about 300 to 600MPa*s; gel casting bisques with uniform structures and 55 to 60 percent of relative density can be prepared by the slurry according to needs; the bisques are further de-glued and sintered to obtain compact silica carbide ceramic. By adopting the dextrin as the organic carbon source in the invention, the cost is low; the gel casting process can be easily realized and the technological process can be easily controlled. The new carbon source can prepare silicon carbide ceramic materials with high performance and complex shapes with low cost and is suitable for the preparation of block or porous silicon carbide ceramics.

Owner:中科西卡思(苏州)科技发展有限公司

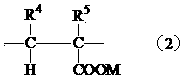

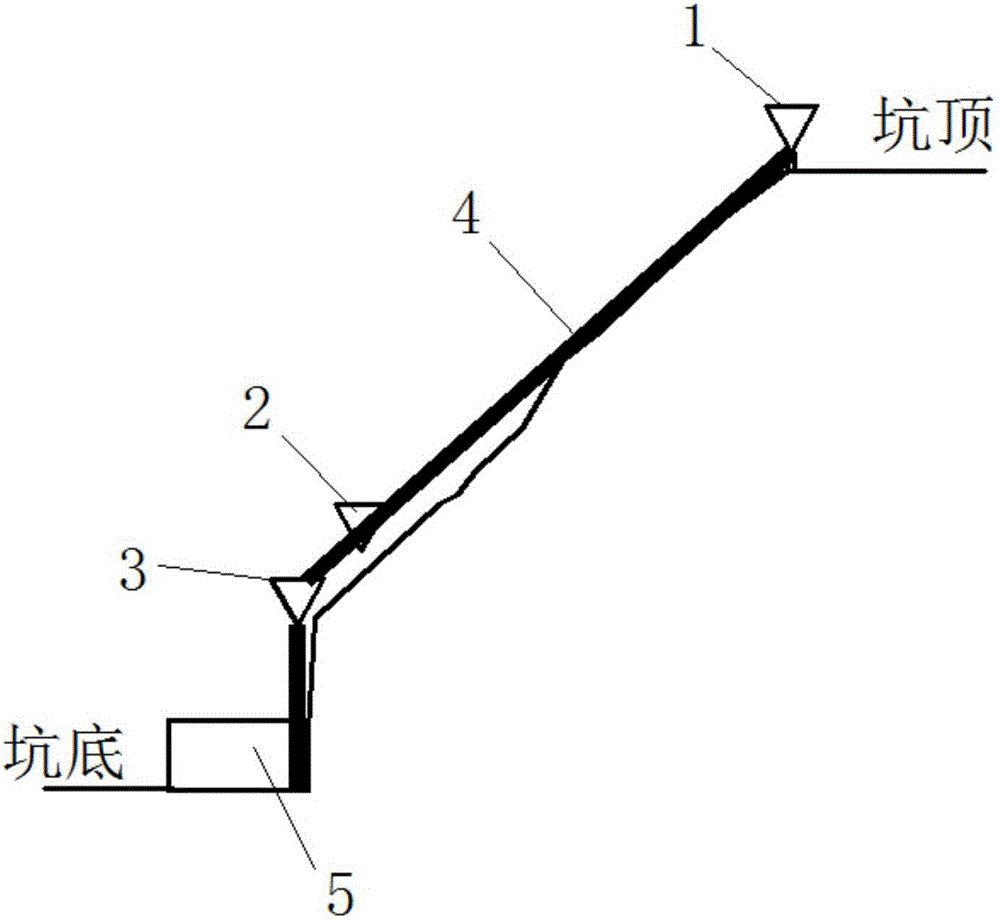

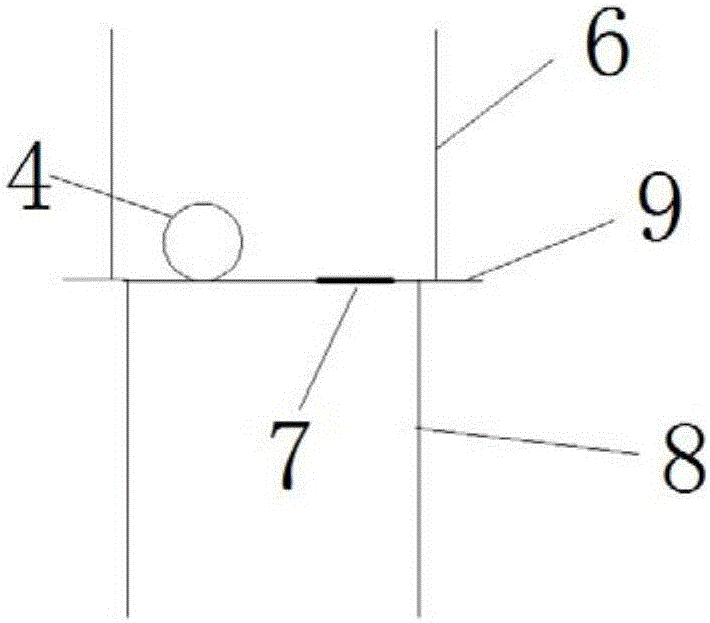

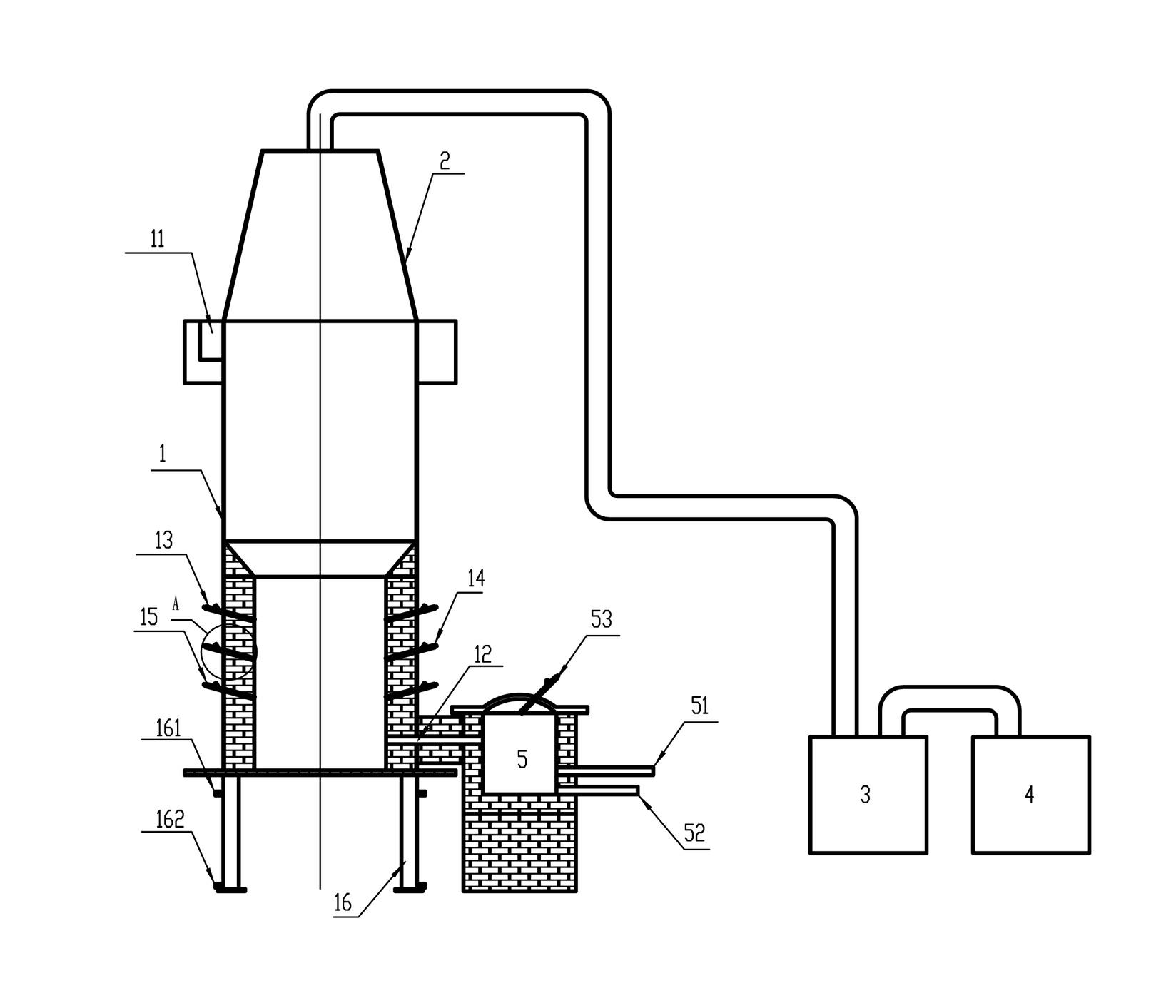

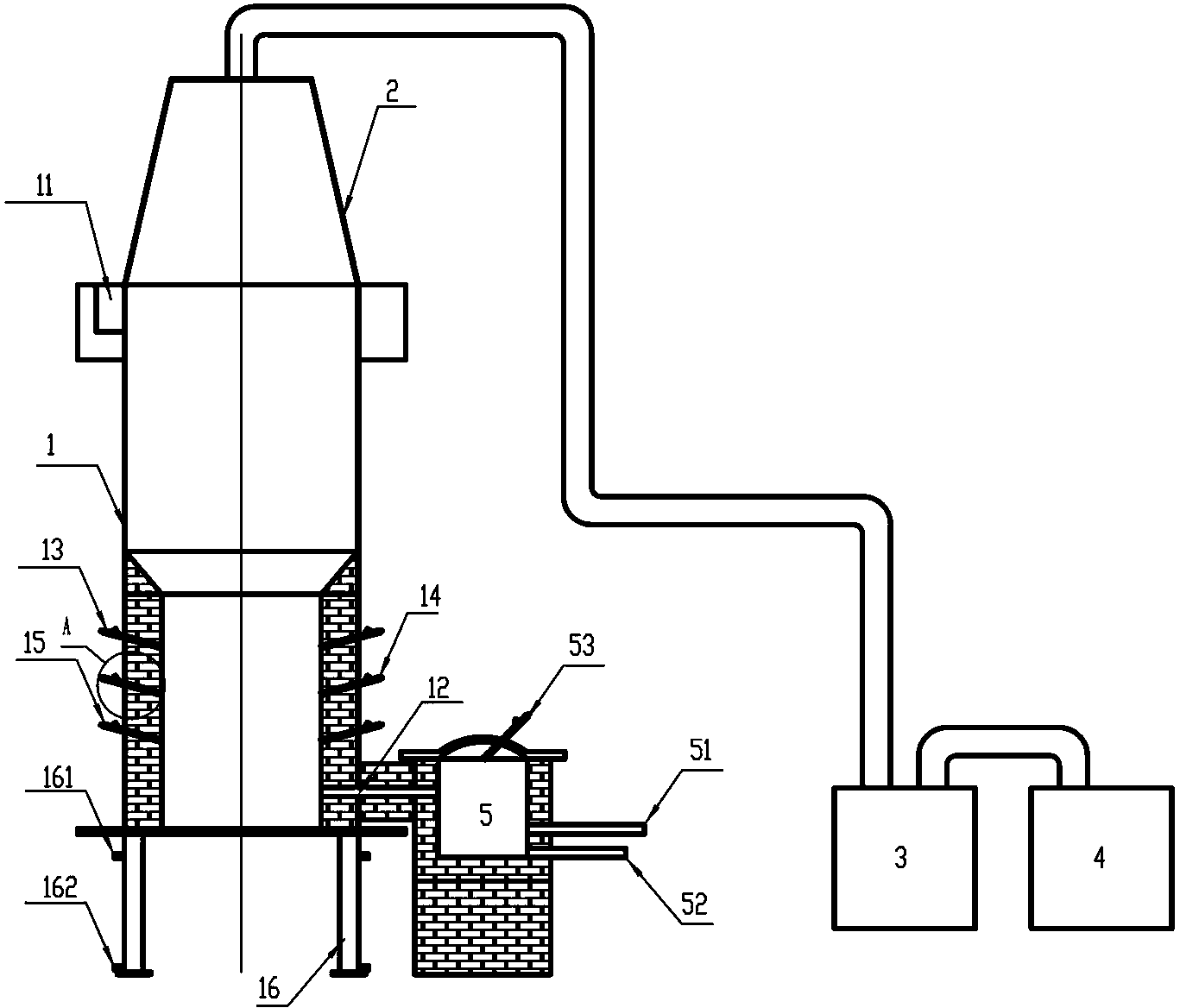

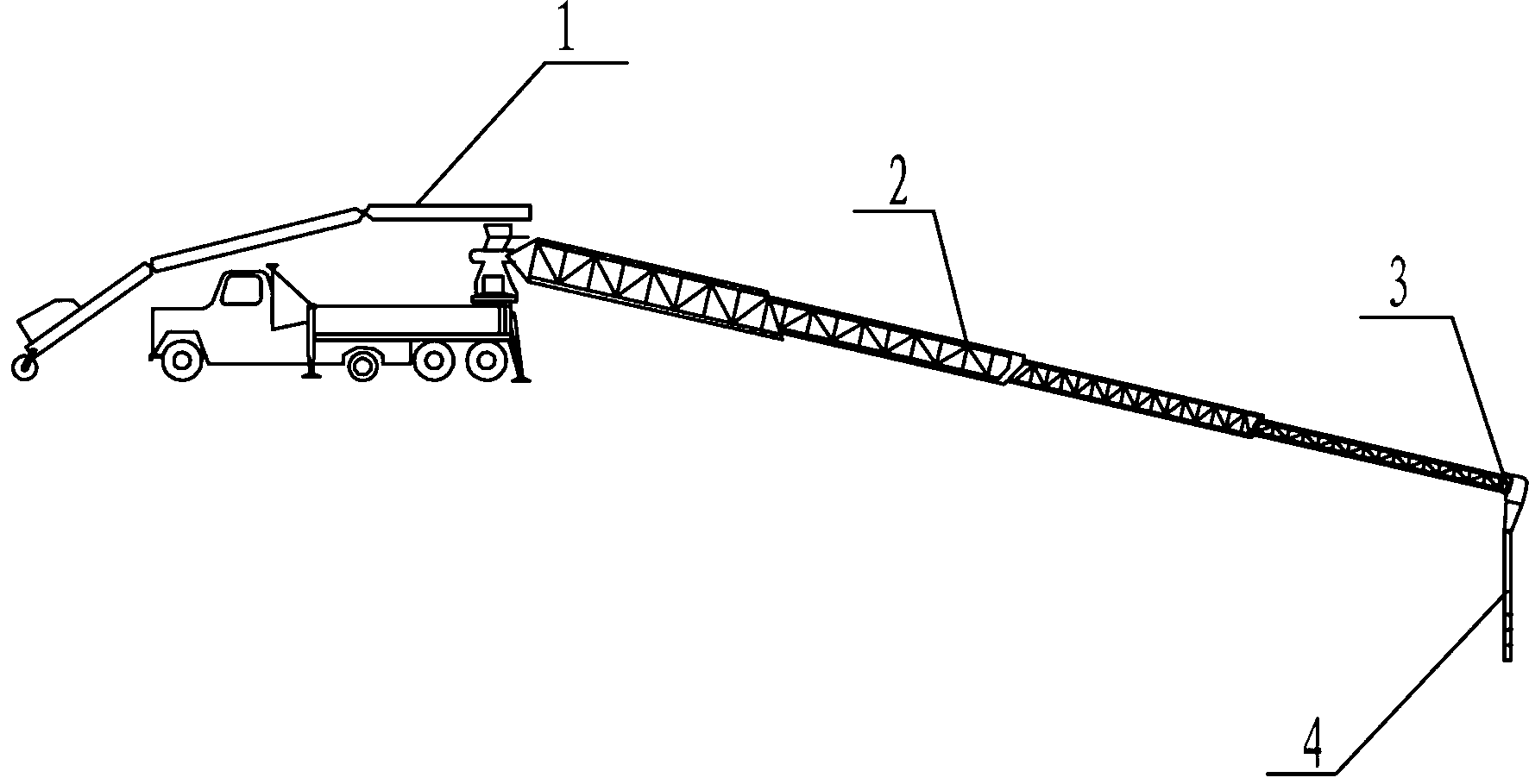

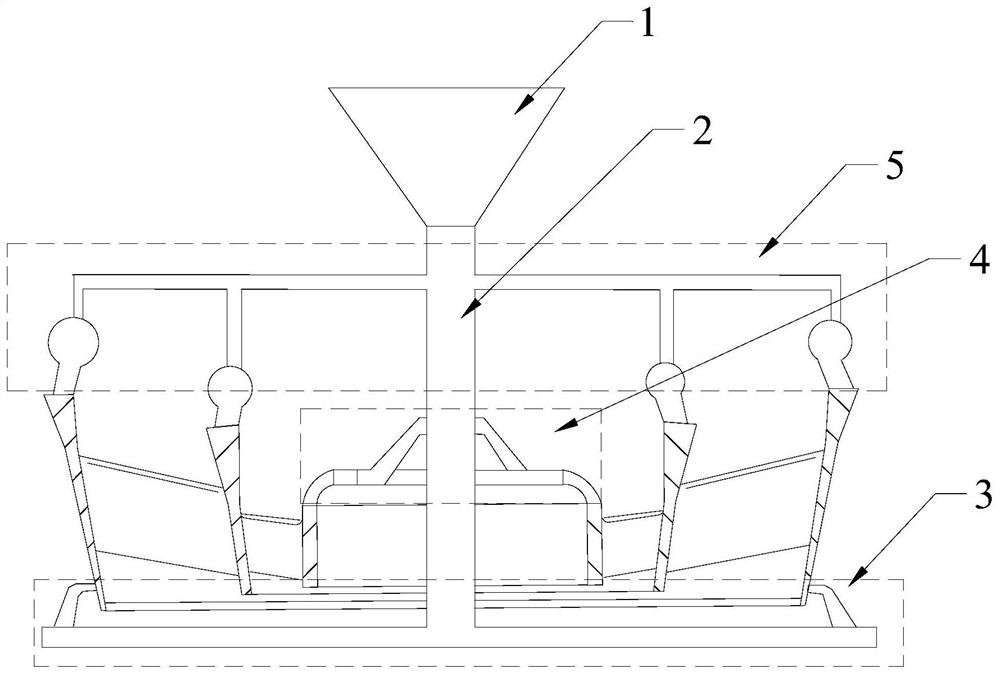

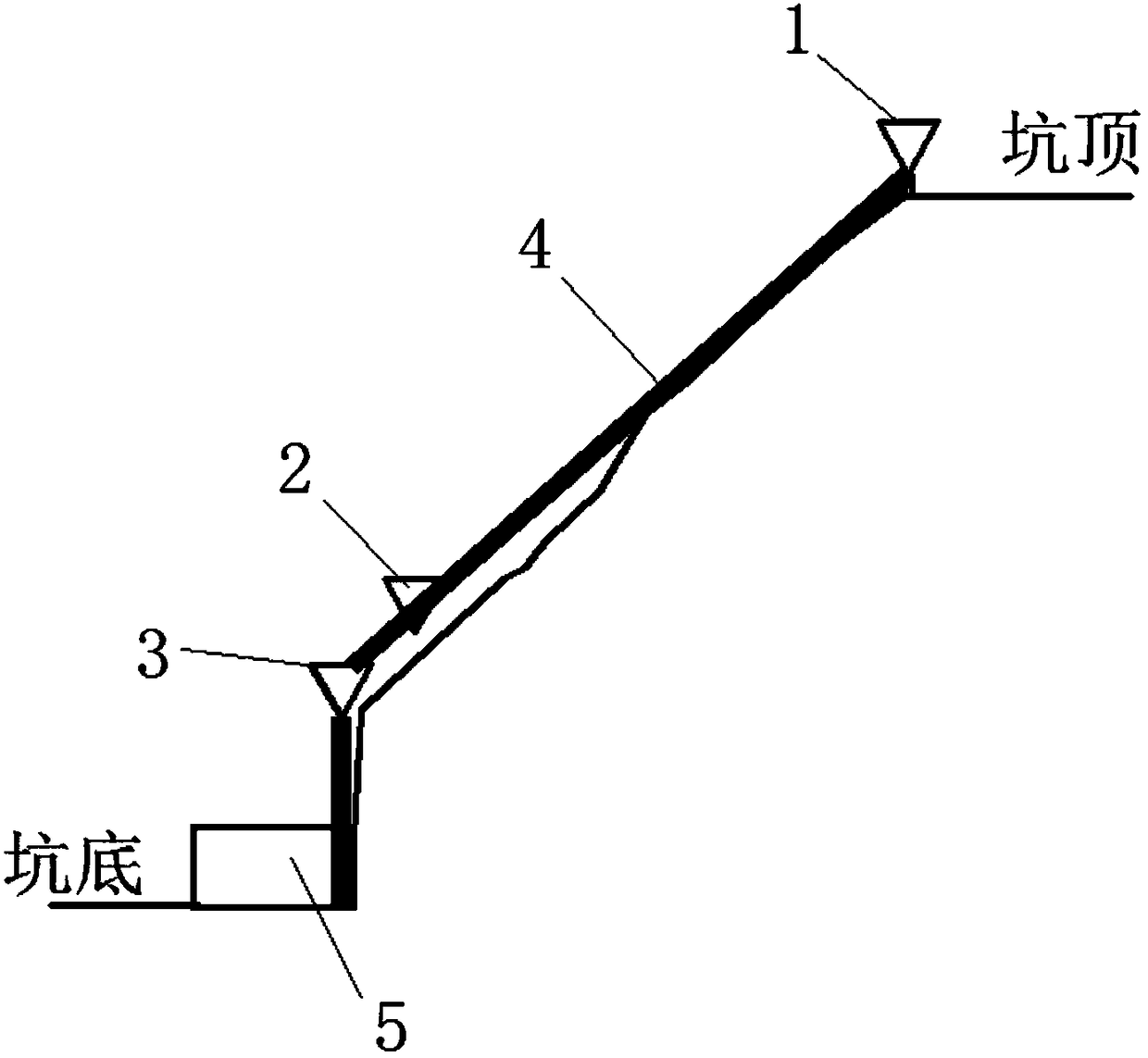

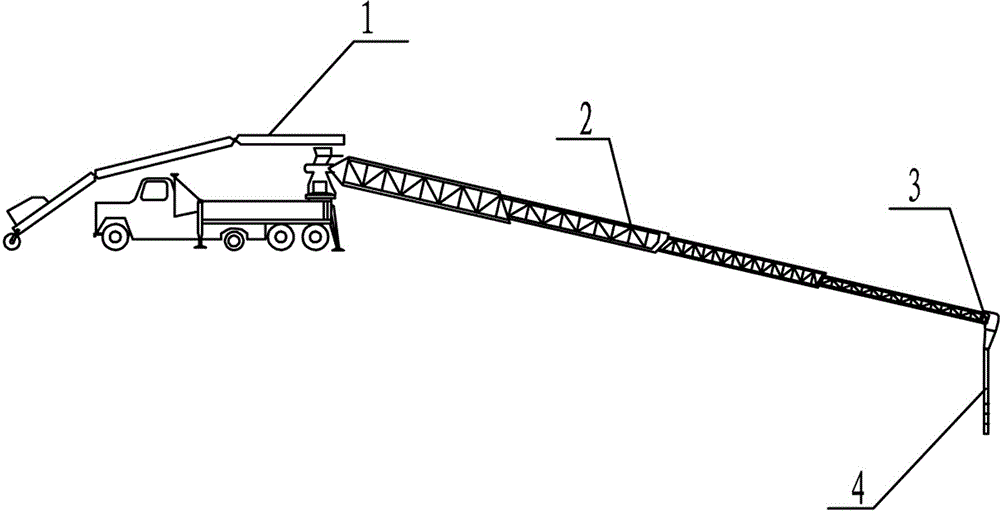

Construction method for large-drop downward concrete transporting

ActiveCN106049501ASimple structureEasy to operateFoundation engineeringWork performanceStructural engineering

The invention discloses a construction method for large-drop downward concrete transporting. The construction method comprises the steps of downward concrete transporting device installing, long articulated chute support reinforcing and moisturizing and buffer device installing, pedestrian overhauling channel arranging and articulated chute downward concrete transporting operation control. The problem that concrete cannot be directly downwards transported from a large-drop steep precipice is solved from pit large-drop steep precipice downward concrete transporting device installing, long articulated chute support reinforcing and moisturizing and buffer device installing, pedestrian overhauling channel arranging, the concrete working performance and other links. The construction method for large-drop downward concrete transporting has the advantages that the transporting pipeline structure is simple; the technological process operation is easy; pipe blocking and pipe exploding are not prone to happening; the concrete transporting efficiency is high; and the equipment cost is low. Meanwhile, the pressure loss problem caused by concrete pumping is avoided. The construction method is suitable for underground engineering, especially concrete transporting and pouring of a subway, a tunnel, an urban underground complex and other pit projects.

Owner:中建五局第三建设有限公司

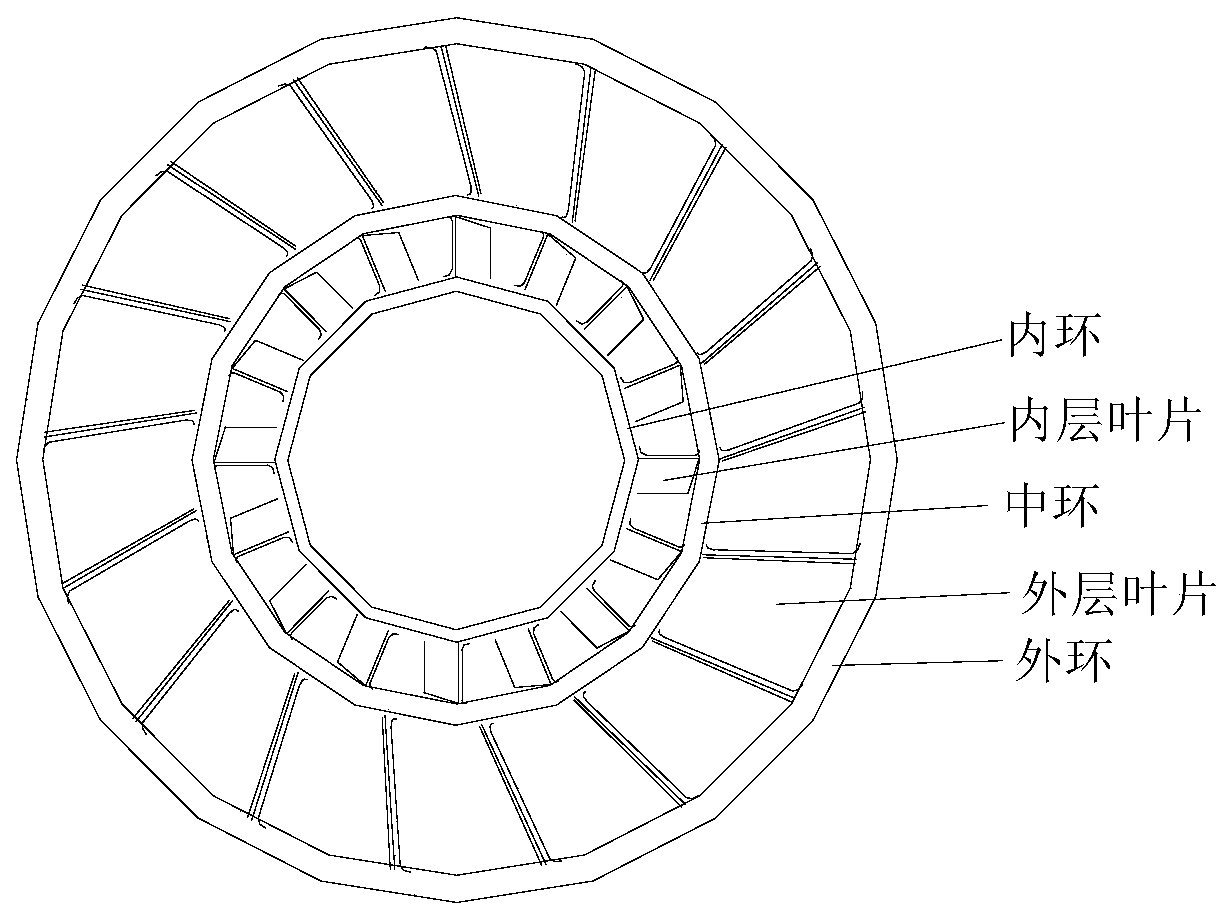

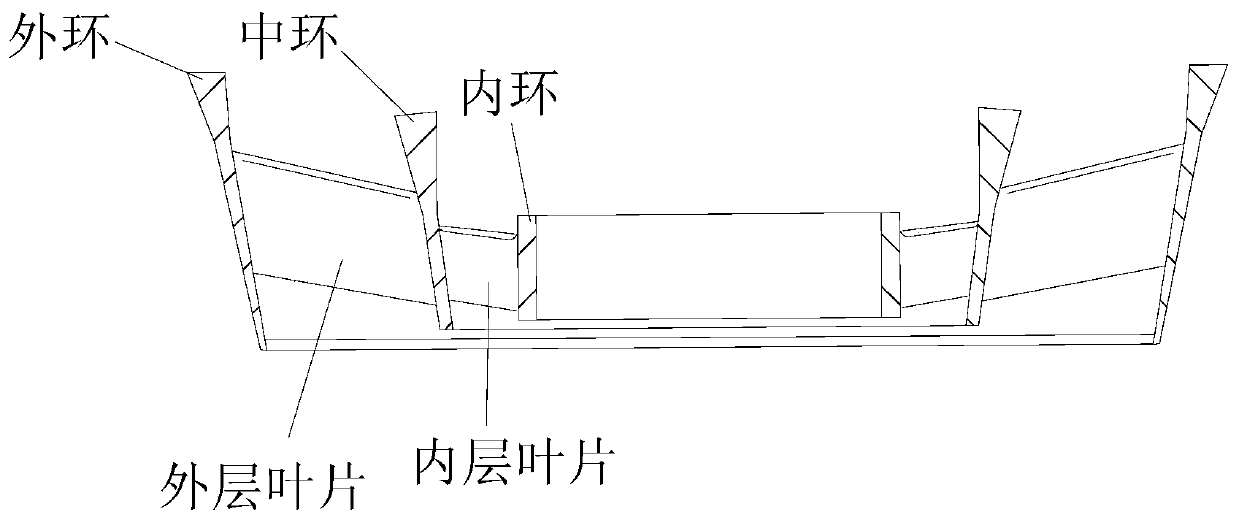

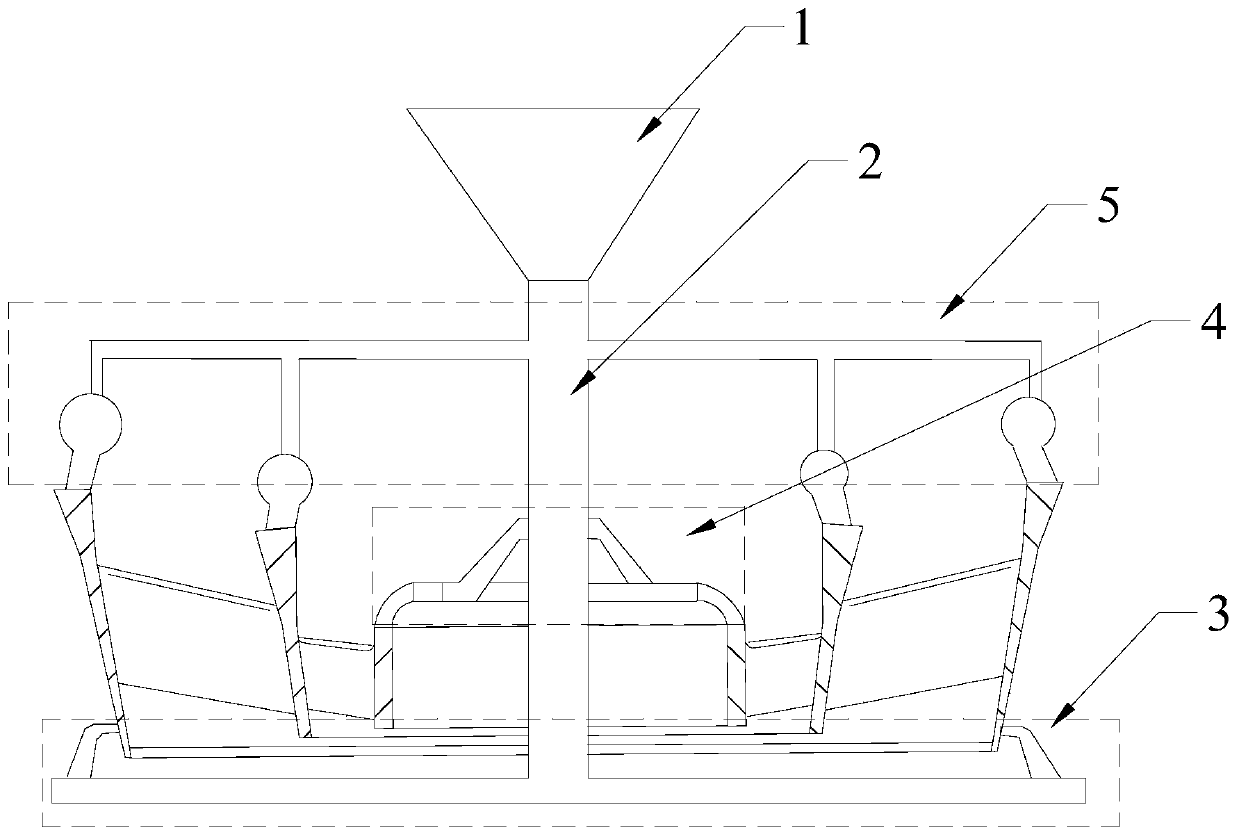

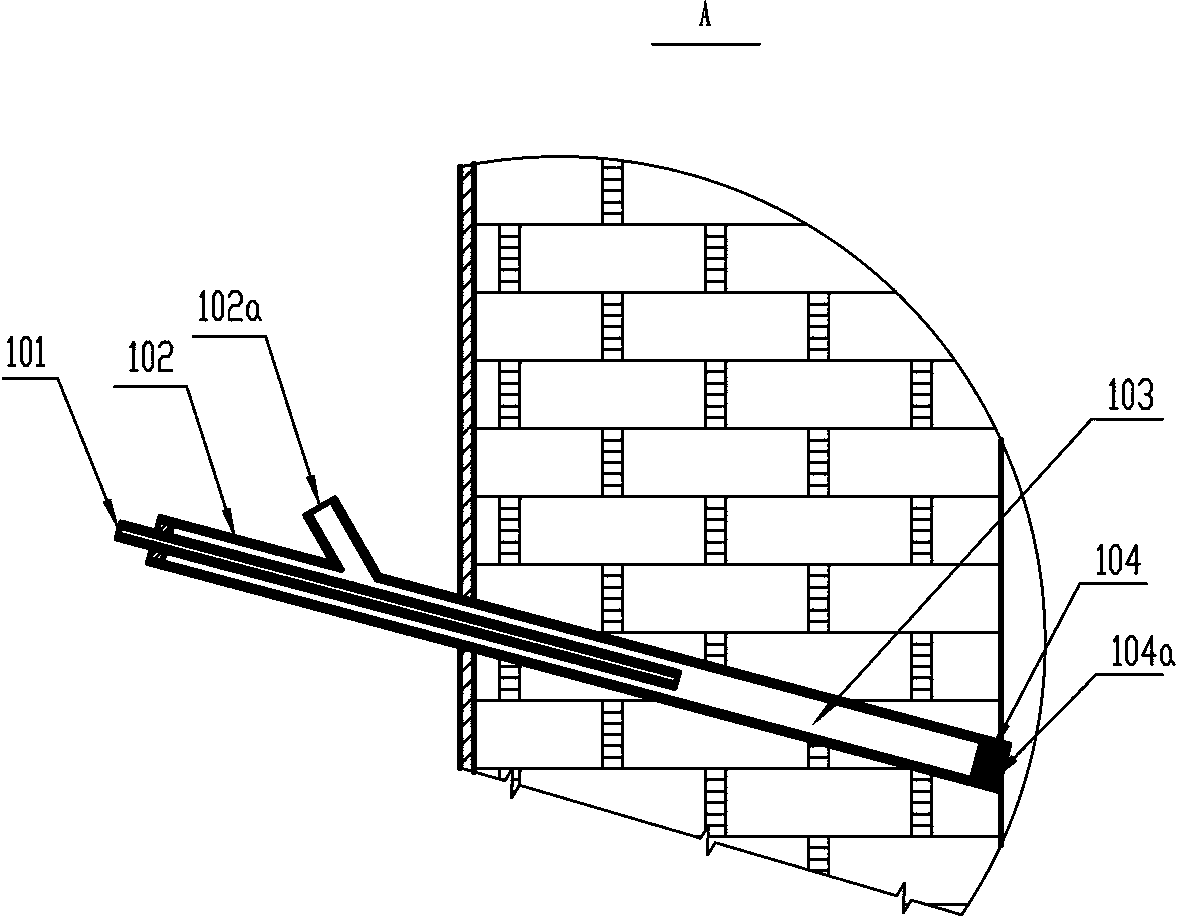

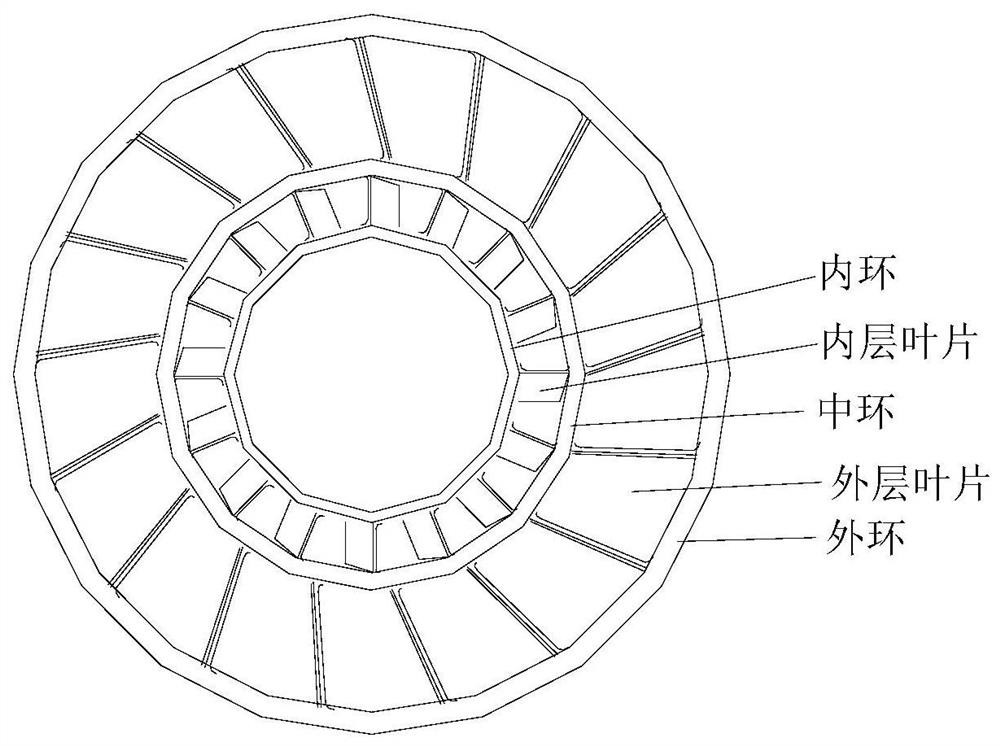

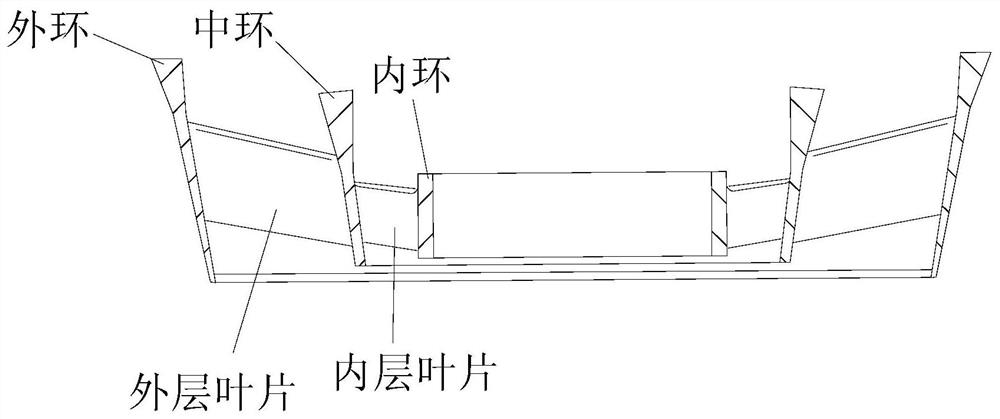

Dynamic balance pouring system of double-layer blade thin-wall guider

ActiveCN111531130AMeet pouring requirementsImprove feeding efficiencyFoundry mouldsFoundry coresMold fillingEngineering

The invention discloses a dynamic balance pouring system of a double-layer blade thin-wall guider. According to the system, a three-dimensional pouring system taking a sprue as a central axis in cooperation with three layers of transverse pouring gates is adopted, firstly, a first flow of molten alloy is guided to the outer ring position through the first layer of transverse pouring gate at the bottom layer so as to fill an outer ring and an outer-layer blade from bottom to top, then a second flow of molten alloy is guided to the inner ring position through the second layer of transverse pouring gate in the middle so as to fill an inner ring and an inner-layer blade, and finally a third flow of molten alloy is guided to the riser position through the third layer of transverse pouring gateat the top layer for filling. According to the system, mold filling is integrally realized from bottom to top and from inside to outside, temperature gradient can be naturally formed to achieve the purpose of sequential solidification, and particularly, the riser is finally filled and solidified, so that the feeding efficiency is favorably improved, the loosening rejection rate is favorably reduced, risks caused by various defects can be effectively balanced and inhibited, and the pouring requirement of the double-layer blade thin-wall guider is well met.

Owner:CHINA HANGFA SOUTH IND CO LTD

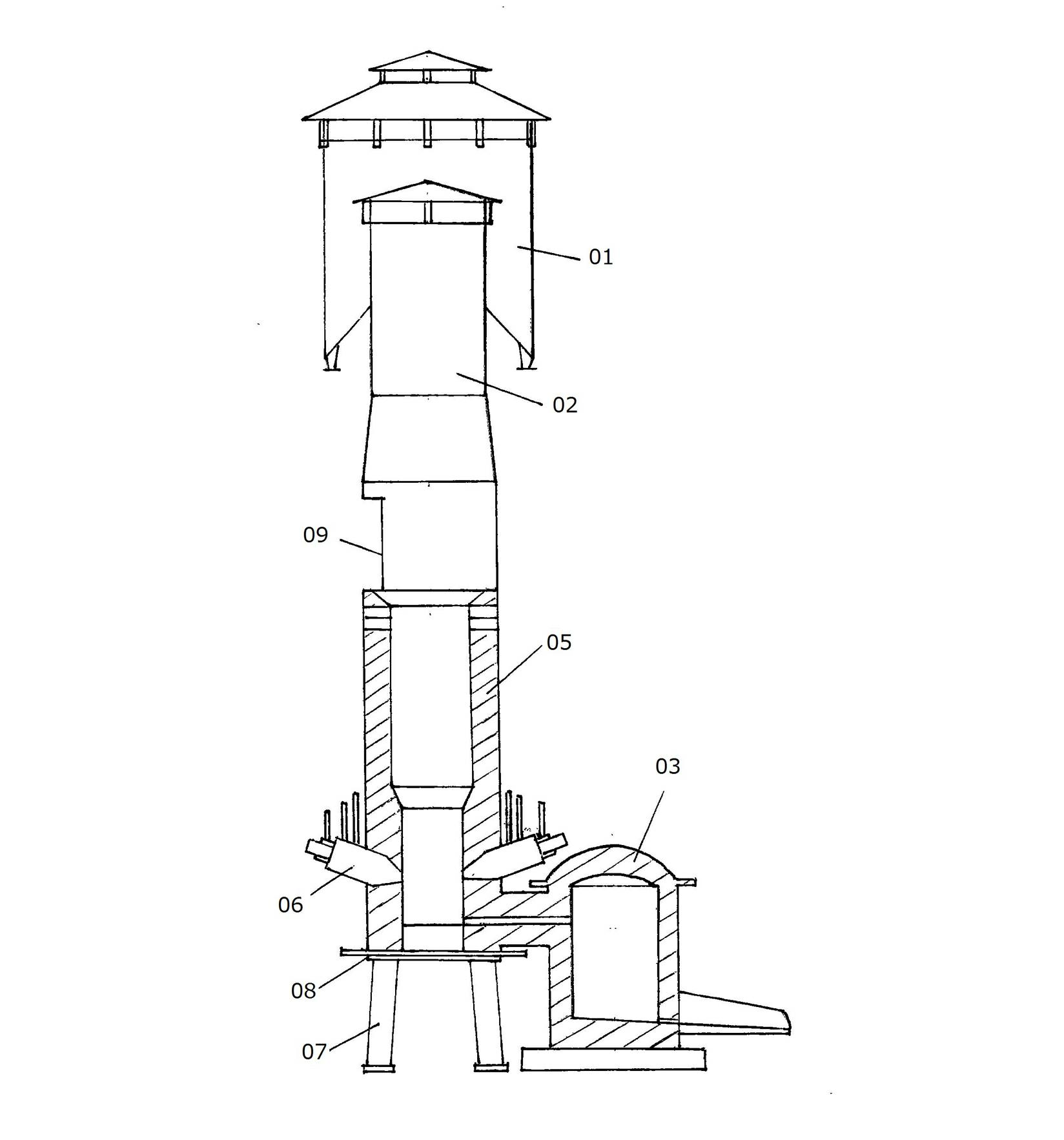

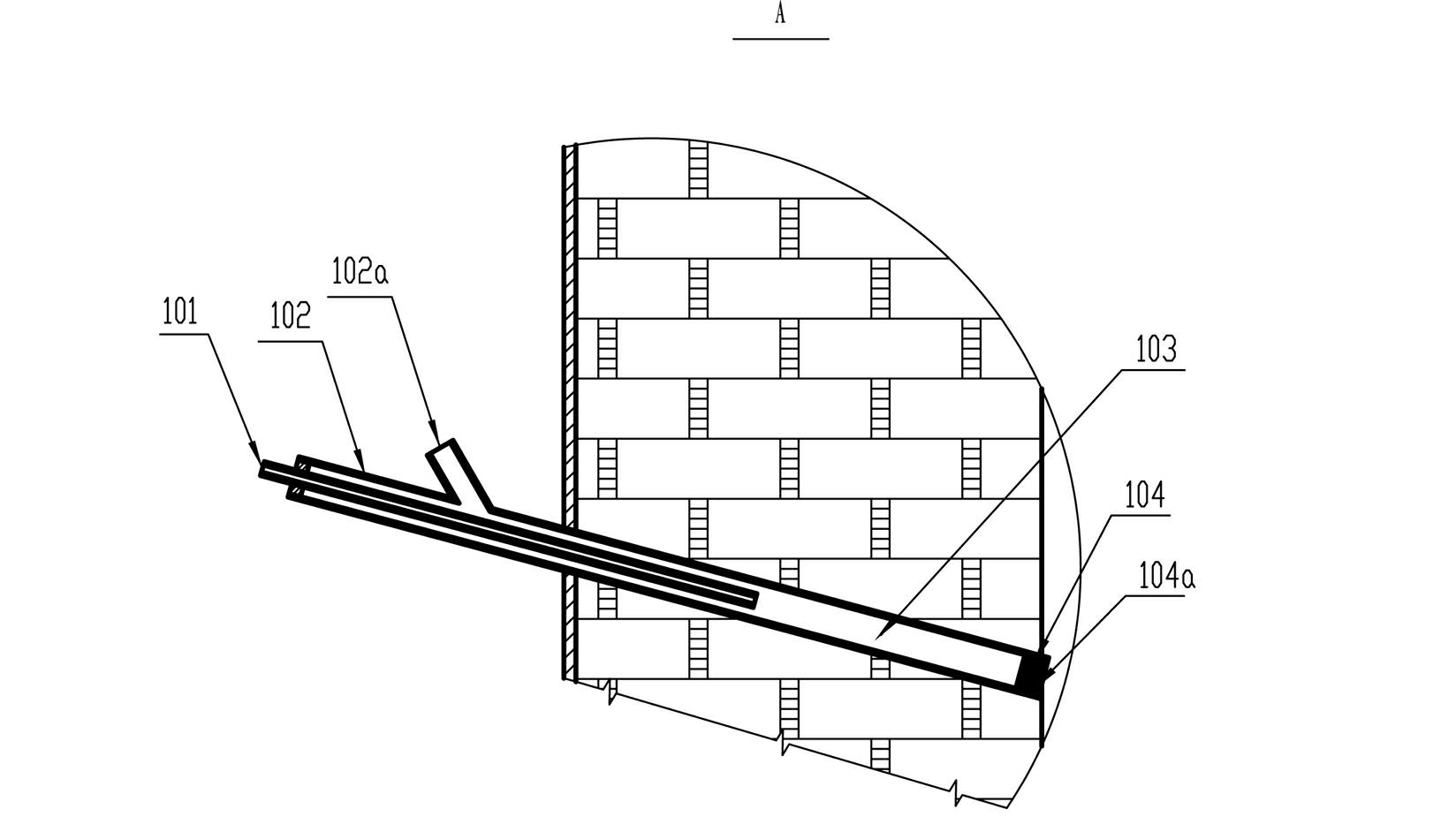

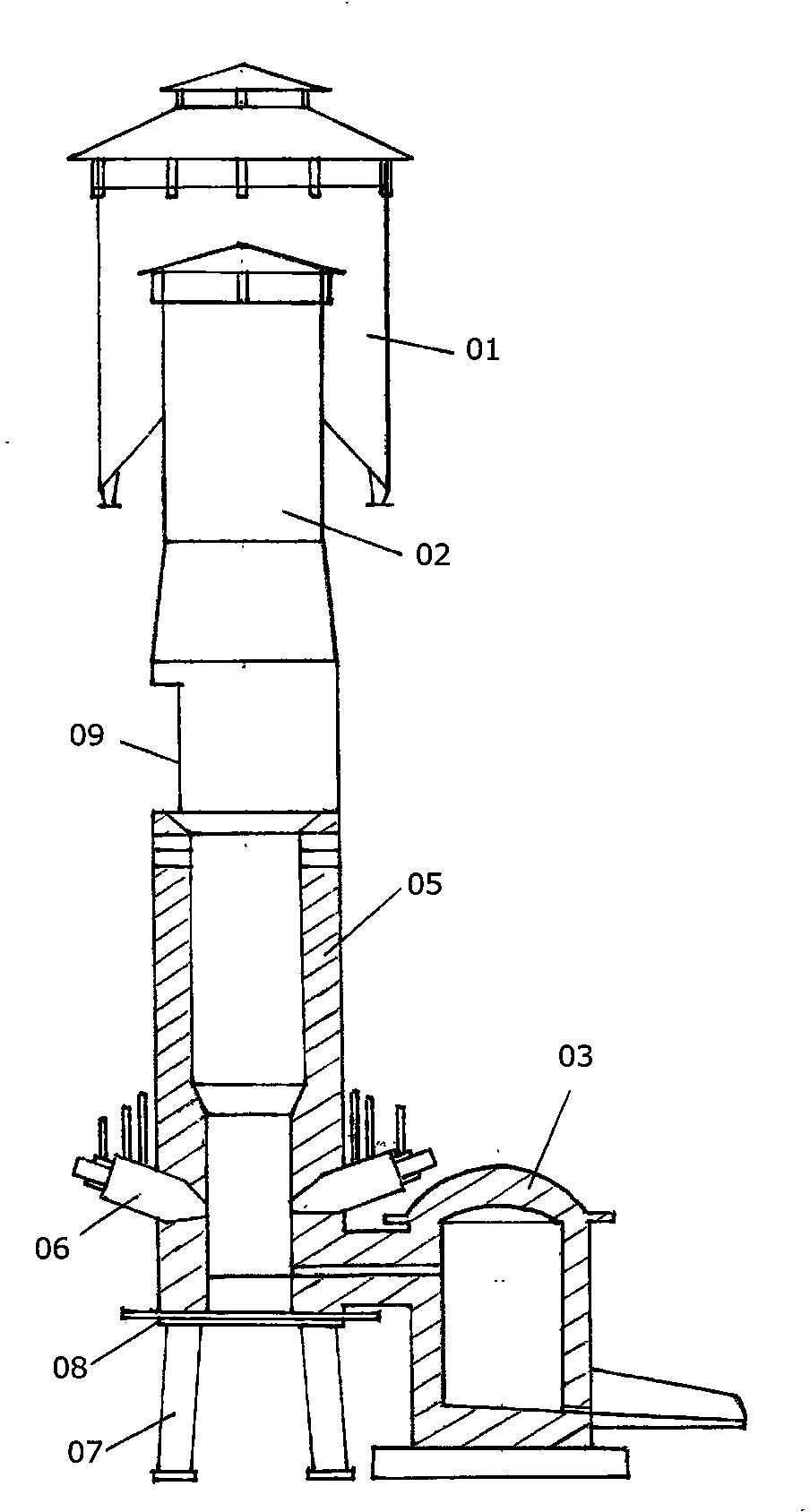

Gas smelting furnace and smelting method using gas

InactiveCN102692123AGood liquidityAvoid temperature dropGaseous fuel burnerVertical furnacesCast ironEngineering

The invention provides a gas smelting furnace and a smelting method using gas. The smelting furnace comprises a furnace body. At least two rows of gas and combustion-supporting gas nozzles which surround the side wall of the furnace body are arranged between a feed inlet and a feed outlet from top to bottom in the furnace body; one row of nozzles are arranged at the set height of the furnace body to smelt materials; in addition, at least one row of nozzles are arranged above and / or below the row of nozzles. The nozzles which are arranged above the row of nozzles perform preheating on the materials before melting and / or the nozzles which are arranged below the row of nozzles perform over-heating heating on the materials after smelting. A plurality of rows of nozzles are arranged at the smelting furnace body to heat the materials in the furnace and different heating temperature can be provided in the furnace body, so that iron and steel pieces can be rapidly smelted in the furnace body, the problem of oxidation is avoided, the flowability of the molten liquid is good and the furnace is beneficial to the pouring of cast steel and cast iron pieces.

Owner:薛良

Manufacturing method of high-collapsibility mold shell

ActiveCN108500209AReduce generationImprove breathabilityFoundry mouldsFoundry coresSurface layerSlurry

The invention relates to a manufacturing method of a high-collapsibility mold shell. The manufacturing method comprises the following steps that surface layer slurry with first specific viscosity is prepared; white corundum sand is scattered, and a surface layer is formed on the surface of a mold set; a transition layer slurry with second specific viscosity is prepared; mullite sand and graphite particles are fully mixed uniformly and manufactured into mixed sand; sequentially, the transition layer slurry coats the surface of the surface layer, and the mixed sand is scattered on the surface ofthe surface layer, so that a transition layer is formed; reinforcing layer slurry with third specific viscosity is prepared; a reinforcing layer is formed on the surface of the transition layer; slurry sealing is carried out on the mold set, and a mold shell is formed; and the mold shell is subjected to dewaxing, roasting and cooling to be manufactured into the high-collapsibility mold shell. According to the manufacturing method of the high-collapsibility mold shell, the mold shell is easy to dry, the manufacturing efficiency is high, remnant of the mold shell is small, strength is low, themold shell is easy to clear, the mold shell has good breathability, and the defects of air hole and pinhole looseness and the like on the surface of a casting can be reduced.

Owner:HEBEI GANGYAN DEKAI TECH CO LTD +1

High-thermal-conductivity composite modified sodium silicate sand for pump valve castings, and preparation method thereof

InactiveCN105414459AExcellent normal temperature wet strengthGood thixotropy and rheologyFoundry mouldsFoundry coresLubricationSodium silicate

The invention discloses high-thermal-conductivity composite modified sodium silicate sand for pump valve castings. A modified sodium silicate binder in the sodium silicate sand is higher in constant-temperature wet strength, thixotropy and rheological property compared with a conventional modified sodium silicate binder, high in reaction binding activity, and green and environment-friendly, and the dosage of sodium silicate is lower; in addition, beryllium oxide in raw materials is capable of effectively improving the thermal conductivity of moulding sand, and preventing sand inclusion of the castings, and bentonite-supported nano-calcium fluoride has lubrication and reinforcement effects in case of being dispersed in sand materials, and capable of forming a non-stick impermeable layer, preventing sand sticking of the castings, and improving the surface quality of the castings; and the composite modified sodium silicate sand is excellent in comprehensive performance, uniform in strength, high in casting quality, and capable of meeting the pouring requirements of the high-accuracy pump valve castings.

Owner:合肥李诺新材料贸易有限公司

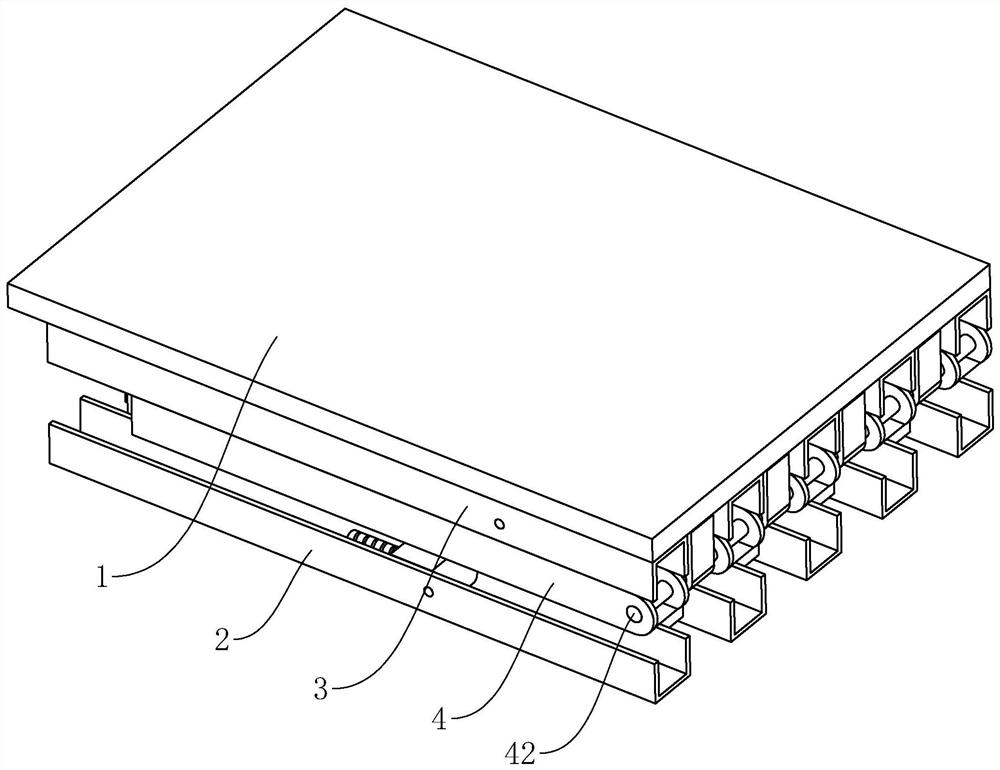

Moving formwork and pouring method for pouring tunnel center ditch

PendingCN109899088AImprove pouring efficiencyStable positionUnderground chambersDrainageEngineeringTunnel construction

The invention relates to the field of tunnel construction equipment, in particular to a movable formwork and a pouring method for pouring a tunnel central ditch. The movable formwork for pouring the tunnel center ditch includes a mold assembly and a walking assembly; the mold assembly includes a first template and a second template, the first template and the second template are disposed oppositely, and the first template and the second template can be close to or away from each other; and the walking assembly is connected to the mold assembly, and the walking assembly can drive the mold assembly to move. The pouring method for pouring the tunnel center ditch includes the following steps that a, the movable formwork is operated until the mold assembly moves into an area to be poured; b, concrete is poured; c, demoulding is performed after the center ditch is formed; and d, the movable formwork is operated until the mold assembly moves to a next area to be poured. The movable formwork and the pouring method for pouring the tunnel center ditch have the advantages of rapid transition, low labor intensity and easy organization.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

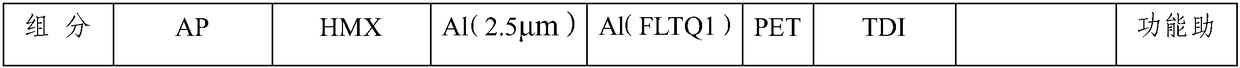

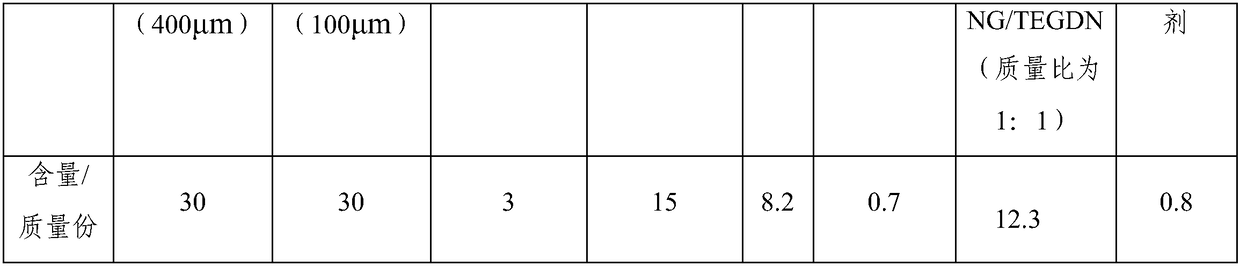

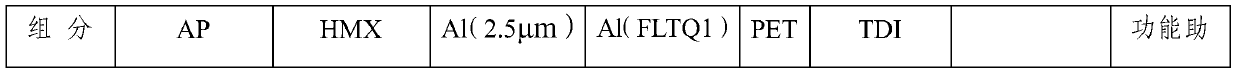

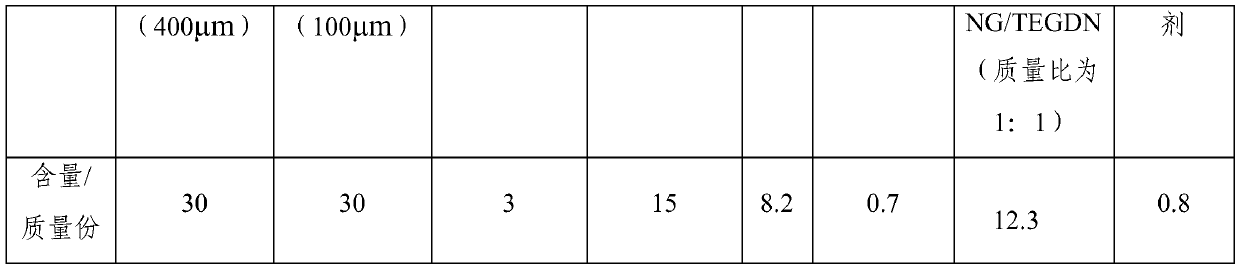

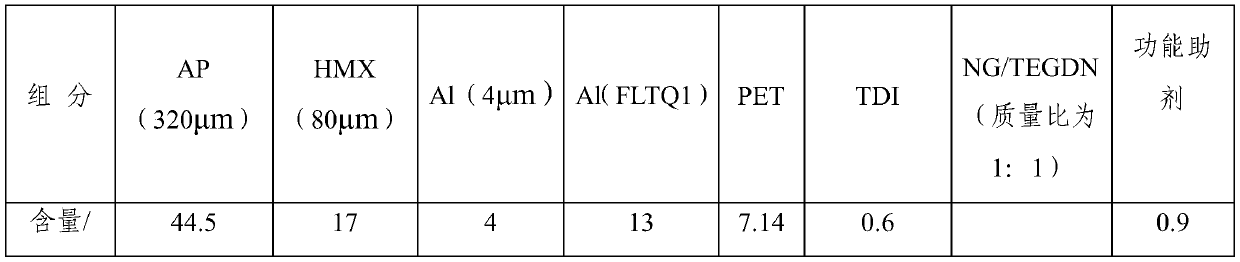

High-solid-content NEPE solid propellant slurry, propellant and preparation method

ActiveCN108530239ASolve the problem of poor technology and difficult pouringDoes not affect propellant energyExplosive working-up apparatusPressure gas generationMicrometerAmmonium perchlorate

The invention provides high-solid-content NEPE solid propellant slurry, propellant and a preparation method, and belongs to the technical field of solid propellant. The preparation method of the slurry comprises the following steps that raw materials are weighed, wherein the raw materials comprise ammonium perchlorate, ammonium nitrate explosives, aluminum powder, an adhesive system, a curing agent and a functional agent, the aluminum powder is superfine aluminum powder or a mixture of the superfine aluminum powder and FLTQ1 aluminum powder, and the particle size d50 of the superfine aluminumpowder ranges from 2.5 micrometers to 13 micrometers; part of the adhesive system and the weighed aluminum powder, ammonium nitrate explosives and functional agent are mixed, a mixture is obtained, and the mass of part of the adhesive system accounts for 9.5% to 12% of the total mass of the raw materials; the weighed ammonium perchlorate and ammonium nitrate explosives are added into the obtainedmixture, mixing is carried out, then the curing agent and the remaining adhesive system are added, mixing is carried out, and the propellant slurry is obtained. According to the high-solid-content NEPE solid propellant slurry, propellant and the preparation method, the process performance of the propellant slurry can be obviously improved on the premise of not influencing the energy, mechanical property and mixing time of the propellant.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

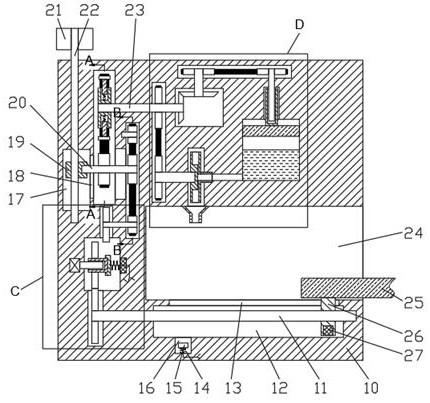

High-temperature formwork turning clamp

InactiveCN102335724AImprove protectionImprove the authenticity rateFoundry mouldsFoundry coresEngineeringGravity center

The invention relates to the field of precision casting and provides a high-temperature formwork turning clamp for the precision casting industry. A high-temperature formwork on a roasting furnace platform is in a situation that a pouring port is downward and a formwork bottom is upward, and when the formwork is taken out of a roasting furnace for being poured, the formwork is turned by a hand with an asbestine glove so as to be in the situation that the pouring port is upward and the formwork bottom is downward, but such an operation wastes time, an operator can be easily burnt and the temperature of the formwork is reduced rapidly. The turning clamp can be used for directly holding and carrying the formwork with the downward pouring port and the upward formwork bottom on the roasting furnace platform, the gravity centre of the formwork can be utilized to drive a jaw to turn so as to turn the pouring port to be upward and the formwork bottom to be downward, and the operation is time-saving, is free from hurting the operator, is safe and reliable and ensures the temperature of the formwork to meet a pouring demand.

Owner:江苏万恒铸业有限公司

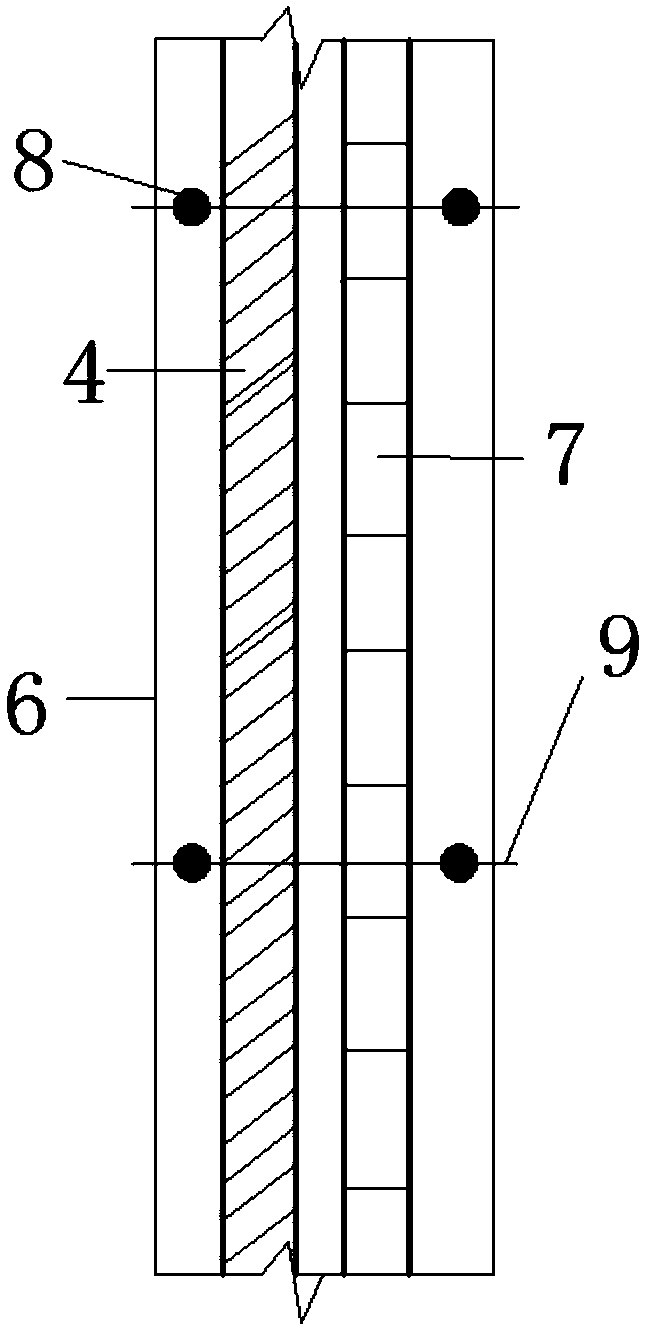

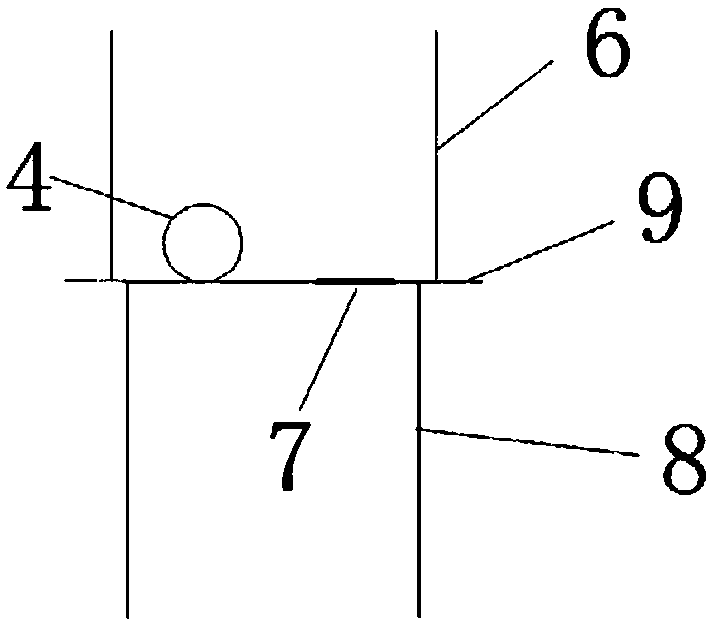

Self-propelled diamond pinned truss hanging basket structure and hanging basket walking and construction method

InactiveCN104631343BEven by forceMeet stability requirementsBridge erection/assemblyArchitectural engineeringEconomic benefits

A self-propelled rhombus-shaped pin-knot truss type hanging basket structure and the walking and construction method of the hanging basket. system and walking system. The main truss system consists of two main trusses and horizontal parallel connections. The single main truss is composed of lower chords, upper chords, oblique rods and columns, and the single-hole pins connect the members into one body through the node box. The two main trusses are connected by horizontal parallel connections with adjustable spacing. The rear anchorage system is connected to the rear of the lower chord of the main truss. The running system includes segmented track located under the main truss, reverse buckle wheels, rollers and traveling jacks and other devices. The invention is quick to install, and on the basis of satisfying the load bearing, the spacing of the main truss and the position of the suspender can be adjusted according to different box girder cross-section forms to form the best stress state, which has strong versatility, greatly increases the turnover rate of the hanging basket, and saves project costs , the economic benefit is obvious.

Owner:HOHAI UNIV

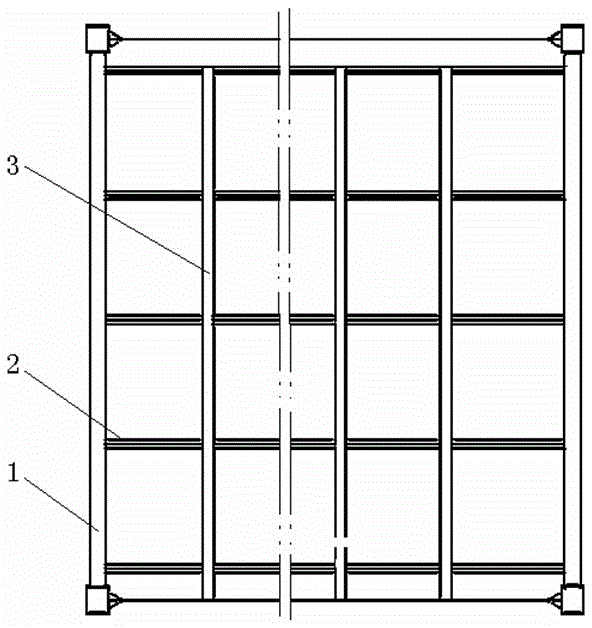

Sunken type tunnel side wall formwork trolley device and construction method thereof

PendingCN109322679AHeight adjustableReduce work intensityUnderground chambersTunnel liningStructural engineeringUltimate tensile strength

The invention relates to a sunken type tunnel side wall formwork trolley device and a construction method thereof. The sunken type tunnel side wall formwork trolley device comprises formworks, brackets, sliding pieces, hydraulic mechanisms and bases, wherein the bases are used for being placed on a foundation. Transverse sliding rails are arranged on the bases, the sliding pieces are slidably arranged in the sliding rails, the hydraulic mechanisms comprise first oil cylinders vertically arranged and second oil cylinders transversely arranged, cylinder bodies of the second oil cylinders are mounted on the bases, piston rods of the second oil cylinders are connected with the sliding pieces, cylinder bodies of the first oil cylinders are mounted on the sliding pieces, piston rods of the firstoil cylinders are connected with the brackets, and the formworks are mounted on one sides of the brackets. When the sunken type tunnel side wall formwork trolley device is used, the second oil cylinders drive the sliding pieces to slide on the bases to realize that the formworks are close to or away from the pouring positions of side walls, automatic mold forming and demoulding are realized withthe help of the hydraulic mechanisms, and thus, the working intensity of workers is reduced.

Owner:GUANGZHOU EXPRESSWAY CO LTD +1

Organic carbon source for pouring and molding silicon carbide aqueous gel and molding technique

The invention relates to selecting a novel organic carbon source which is suitable for a gel casting molding process of silicon carbide and can meet the requirements of the dispersion, stability and a subsequent curing process of slurry with high solid content in water-base gel casting as well as provide carbon powder after cracking. The invention adopts dextrin as the organic carbon source and adds dimethyl sulfoxide to improve the stability of the dextrin. According to conventional gel casting process, the SiC slurry with solid content to be 50vol percent can be prepared and the viscosity can be about 300 to 600MPa*s; gel casting bisques with uniform structures and 55 to 60 percent of relative density can be prepared by the slurry according to needs; the bisques are further de-glued and sintered to obtain compact silica carbide ceramic. By adopting the dextrin as the organic carbon source in the invention, the cost is low; the gel casting process can be easily realized and the technological process can be easily controlled. The novel carbon source can prepare silicon carbide ceramic materials with high performance and complex shapes with low cost and is suitable for the preparation of block or porous silicon carbide ceramics.

Owner:中科西卡思(苏州)科技发展有限公司

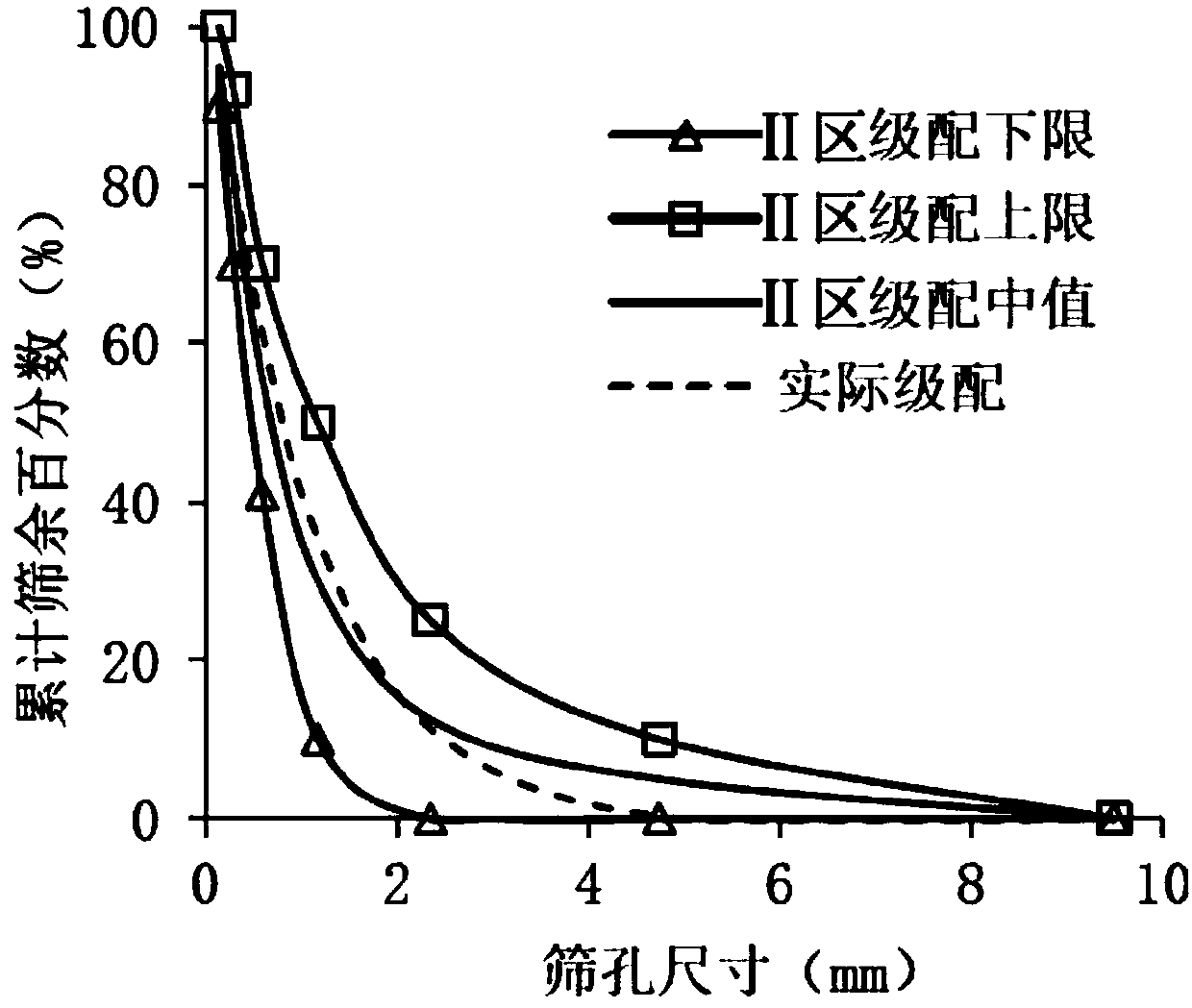

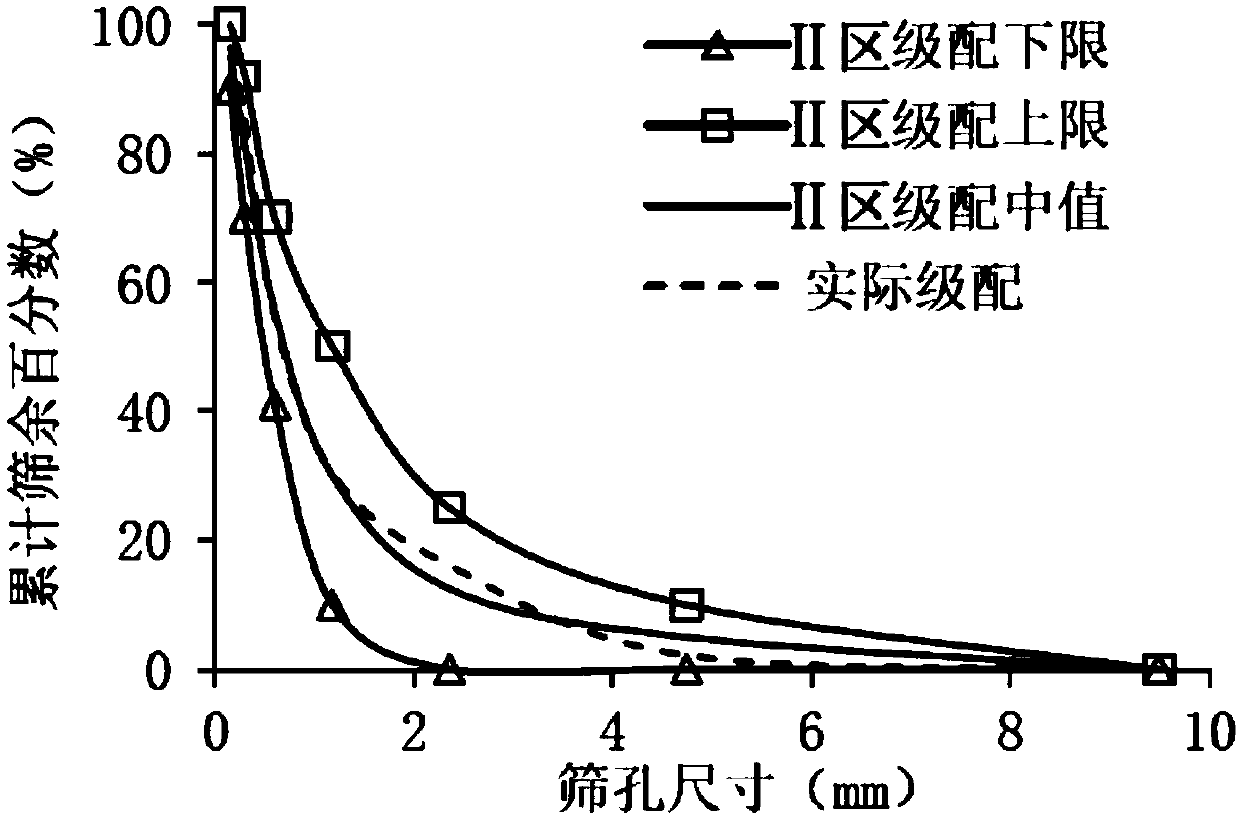

Manufactured sand self-compacting concrete applied to corrugated steel web box girder

The invention belongs to the field of building materials and in particular relates to manufactured sand self-compacting concrete applied to a corrugated steel web box girder. The manufactured sand self-compacting concrete is prepared from the following raw materials in parts by weight: 431 to 437 parts of cement, 78 to 85 parts of fly ash, 637 to 655 parts of manufactured sand, 1097 to 1112 partsof crushed stones with the grain diameter of 5mm to 20mm, 4.7 to 5.1 parts of a water reducing agent and 165 parts of water. The manufactured sand is continuously-graded region II manufactured sand, the fineness modulus is 2.7 to 3.0, the MB value is less than 1.4 and the content of mountain flour is 6 percent to 8 percent. The crushed stones are continuously-graded crushed stones; the mass ratioof the crushed stones with the grain diameter of 5mm to 10mm to the crushed stones with the grain diameter of 10mm to 20mm is 3 to 7. The concrete provided by the invention is prepared by replacing river sand with the manufactured sand which is graded well, and has the advantages of good working performance and good flowability and filling performance; the manufactured sand self-compacting concrete has relatively high mechanical strength and can meet pouring requirements of the corrugated steel web combined box girder, and the cost is relatively low.

Owner:CCCC SECOND HARBOR ENG

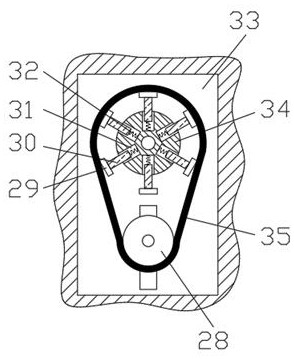

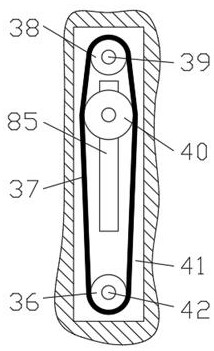

Automatic pouring device with adjustable flow speed for sand casting

InactiveCN112276058AMeet pouring requirementsReduce workloadMolten metal pouring equipmentsMould handling equipmentsGear wheelSand casting

The invention relates to the related field of casting, and discloses an automatic pouring device with an adjustable flow speed for sand casting. The automatic pouring device comprises a main box body,a pouring cavity with a rightward opening is formed in the main box body, a movable nut cavity is formed in the lower side of the pouring cavity, and a movable plate through cavity is formed betweenthe upper end wall of the movable nut cavity and the lower end wall of the pouring cavity in a communicating manner. A lead screw gear cavity is formed in the left side of the movable nut cavity. Molten iron uniformly flows into a pouring opening of a sand mold box under the action of centrifugal force, automatic pouring is achieved, the workload of operators is reduced, the pouring efficiency isimproved, meanwhile, pouring is conducted in a mechanical mode, the safety during pouring can be improved, and the health of the operators is protected; and in addition, the pouring speed can be freely controlled through a molten iron flow speed adjusting mechanism, the requirement for different pouring speeds in different pouring stages is met, meanwhile, the pouring requirements of different sand mold boxes can be met, and the practicability of the device is improved.

Owner:福州经济技术开发区星络网电子科技有限公司

High-pouring-precision composite modified sodium silicate-bonded sand for pump valve casting and preparation method thereof

InactiveCN105414460AExcellent normal temperature wet strengthImprove thixotropyFoundry mouldsFoundry coresThermal expansionThermal stability

The invention discloses high-pouring-precision composite modified sodium silicate-bonded sand for a pump valve casting. Compared with conventional modified sodium silicate binding agents, modified sodium silicate binding agents in the sodium silicate-bonded sand have more excellent normal-temperature wet strength, better thixotropy and rheological property and higher binding speed, and are environmentally friendly, and the use amount of sodium silicate is small. In addition, aluminum titanate added into the sand is low in coefficient of thermal expansion, so that the thermal stability and air permeability of the sand form are improved, and the melt pouring precision is improved; bentonite-loaded nano calcium fluoride is dispersed into the sand to achieve the lubricating and reinforcing effects, a non-stick impermeable layer is formed, and the casting is prevented from carrying and adhering to the sand. The composite modified sodium silicate-bonded sand is excellent in comprehensive performance, compact in structure, rapid in scatter cleaning and high in casting precision and can meet the pouring requirements of the high-precision pump valve casting.

Owner:合肥李诺新材料贸易有限公司

High-compressive-strength composite modified sodium silicate sand for pump valve castings, and preparation method thereof

InactiveCN105414458AExcellent normal temperature wet strengthGood thixotropy and rheologyFoundry mouldsFoundry coresSodium silicateLubrication

The invention discloses high-compressive-strength composite modified sodium silicate sand for pump valve castings. A modified sodium silicate binder in the sodium silicate sand is higher in constant-temperature wet strength, thixotropy and rheological property compared with a conventional modified sodium silicate binder, high in reaction binding activity, green and environment-friendly, and lower in dosage; sand materials in a formula can be mixed to form a high-strength and high-breathability material, the added perfluoropolyether is high in lubricating property and high-temperature stability, and capable of effectively improving stress defects in the material, increasing compressive strength, and enabling the material to be more compact in structure, and bentonite-supported nano-calcium fluoride has lubrication and reinforcement effects in case of being dispersed in the sand materials, and capable of forming a non-stick impermeable layer and preventing sand sticking of the castings; and the composite modified sodium silicate sand is excellent in comprehensive performance, not liable to absorb moisture, high in use efficiency, fast to scatter and clean, and capable of meeting the pouring requirements of the high-accuracy pump valve castings.

Owner:合肥李诺新材料贸易有限公司

Gas smelting furnace and smelting method using gas

InactiveCN102692123BReasonable structureMelting efficiencyGaseous fuel burnerVertical furnacesProduct gasEngineering

The invention provides a gas smelting furnace and a smelting method using gas. The smelting furnace comprises a furnace body. At least two rows of gas and combustion-supporting gas nozzles which surround the side wall of the furnace body are arranged between a feed inlet and a feed outlet from top to bottom in the furnace body; one row of nozzles are arranged at the set height of the furnace body to smelt materials; in addition, at least one row of nozzles are arranged above and / or below the row of nozzles. The nozzles which are arranged above the row of nozzles perform preheating on the materials before melting and / or the nozzles which are arranged below the row of nozzles perform over-heating heating on the materials after smelting. A plurality of rows of nozzles are arranged at the smelting furnace body to heat the materials in the furnace and different heating temperature can be provided in the furnace body, so that iron and steel pieces can be rapidly smelted in the furnace body, the problem of oxidation is avoided, the flowability of the molten liquid is good and the furnace is beneficial to the pouring of cast steel and cast iron pieces.

Owner:薛良

A kind of concrete engineering construction technology

ActiveCN112554554BMeet pouring requirementsReduce workloadAuxillary members of forms/shuttering/falseworksArchitectural engineeringRebar

This application relates to a concrete engineering construction process. The construction steps are: binding steel cages, concrete preparation; building formwork in order from bottom to top, the bottom formwork is fixed on the ground, and the rest of the formwork is sequentially fixed on the formwork below it Then connect the top of the uppermost formwork with the top of the opposite formwork with a screw; brush the release agent on the surface of the built formwork, and then pour concrete into the space surrounded by the formwork, and use vibration during the pouring process The rods vibrate the concrete continuously; after the concrete is solidified, the formwork is removed in order from top to bottom, and the excess bolts left at the top are cut off. The application has the effect of reducing the screw rods that need to be removed after the concrete is solidified, and speeding up the construction efficiency.

Owner:浙江河海建设有限公司

Method for casting prestressed concrete T beam without shutter vibrator

Owner:CHINA METALLURGICAL CONSTR ENG GRP

A kind of high collapsible ceramic core and preparation method thereof

ActiveCN105499480BMixed shape is goodImprove sinterabilityFoundry mouldsFoundry coresPlasticizerParaffin oils

The invention discloses a high-collapsibility ceramic mould core which comprises quartz glass, a mineralizer, a binder and a plasticizer, wherein a, the quartz glass is powder which is a stem material; the grain size of the quartz glass powder is 150-400 meshes, and the powder is a mixture of the quartz glass powder with different grain sizes; b, the mineralizer is boric acid; c, the binder is silica sol or ethyl silicate; and d, the plasticizer is a mixture of paraffin and polyethylene. A preparation method for the ceramic mould core comprises the following steps: 1) mixing and stirring the quartz glass powder, the mineralizer and the binder according to the proportion of the formula until the state of the mixture is sand cluster; 2) drying the mixed materials; 3) ball-milling the mixed materials after drying the mixed materials; 4) preparing ball-milled powder and the plasticizer in proportion to prepare slurry; and 5) pressing the slurry into mould core blank; and feeding the mould core blank into a roasting furnace to carry out roasting. The ceramic mould core mixed blank is good in molding and is high in strength, and has good sintering characteristics; and after being poured, the mould core has good collapsibility.

Owner:兴化市兴东铸钢有限公司

A kind of high solid content nepe solid propellant slurry, propellant and preparation method

ActiveCN108530239BGood workmanshipShort mixing timeExplosive working-up apparatusPressure gas generationExplosive AgentsAmmonium perchlorate

The invention provides high-solid-content NEPE solid propellant slurry, propellant and a preparation method, and belongs to the technical field of solid propellant. The preparation method of the slurry comprises the following steps that raw materials are weighed, wherein the raw materials comprise ammonium perchlorate, ammonium nitrate explosives, aluminum powder, an adhesive system, a curing agent and a functional agent, the aluminum powder is superfine aluminum powder or a mixture of the superfine aluminum powder and FLTQ1 aluminum powder, and the particle size d50 of the superfine aluminumpowder ranges from 2.5 micrometers to 13 micrometers; part of the adhesive system and the weighed aluminum powder, ammonium nitrate explosives and functional agent are mixed, a mixture is obtained, and the mass of part of the adhesive system accounts for 9.5% to 12% of the total mass of the raw materials; the weighed ammonium perchlorate and ammonium nitrate explosives are added into the obtainedmixture, mixing is carried out, then the curing agent and the remaining adhesive system are added, mixing is carried out, and the propellant slurry is obtained. According to the high-solid-content NEPE solid propellant slurry, propellant and the preparation method, the process performance of the propellant slurry can be obviously improved on the premise of not influencing the energy, mechanical property and mixing time of the propellant.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

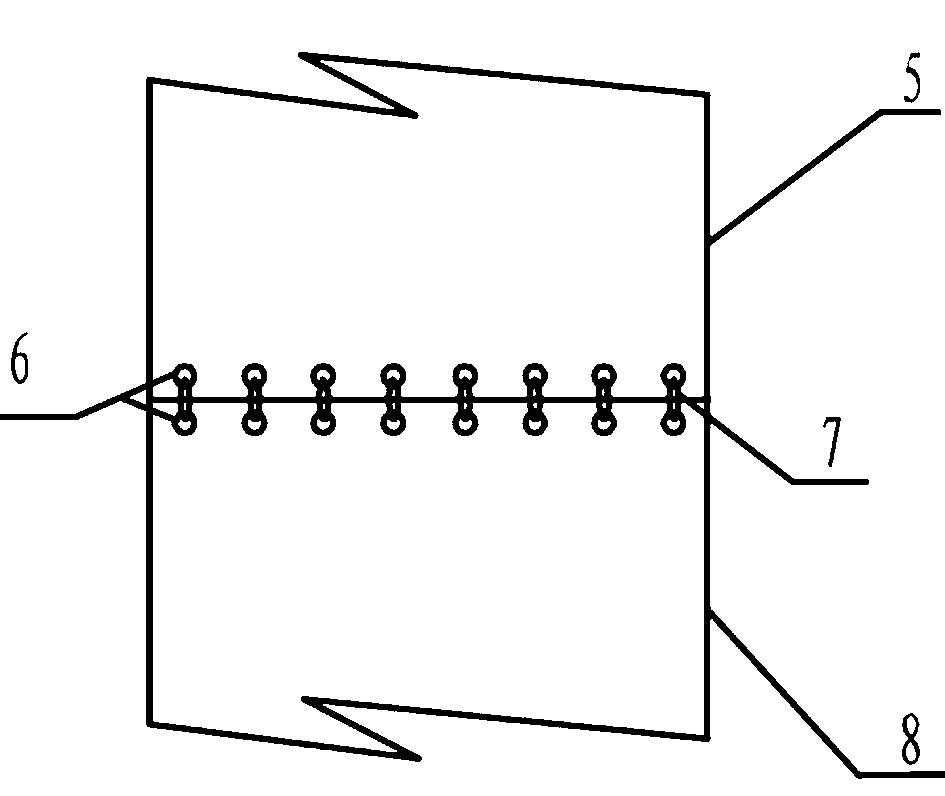

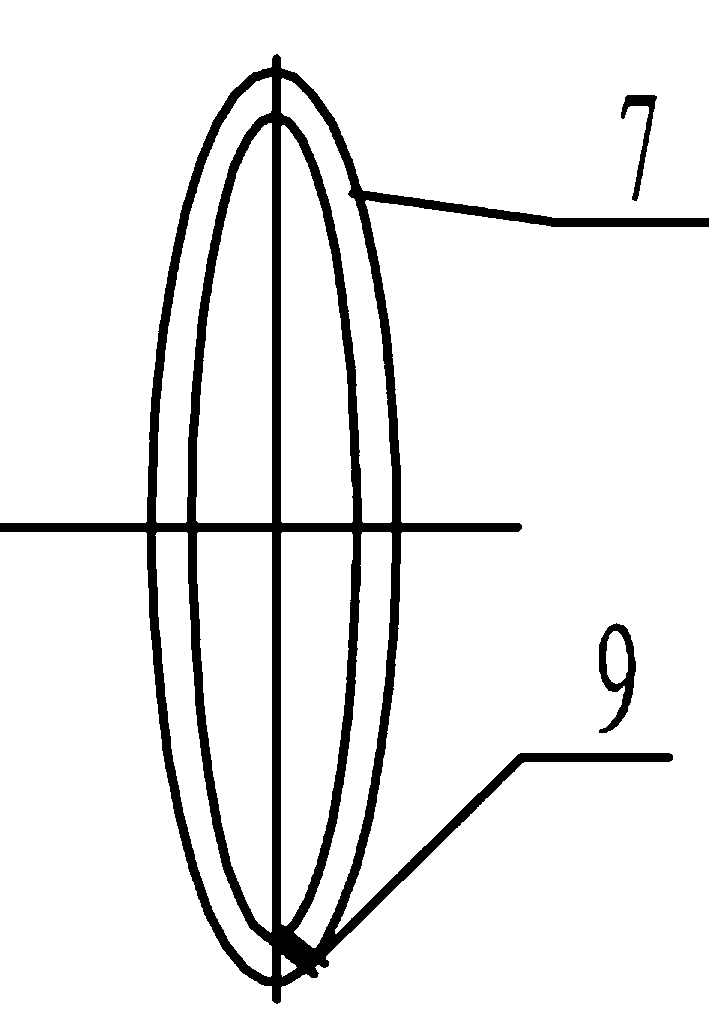

Ring joint and fixed pull force cracking leather cylinder for material distribution belt machine

The invention relates to a ring joint and fixed pull force cracking leather cylinder for a material distribution belt machine. The leather cylinder comprises an upper joint leather cylinder and a lower joint leather cylinder, wherein leather cylinder end opening pull rings are arranged on the upper joint leather cylinder and the lower joint leather cylinder; and one fixed pull force cracking ring is arranged between every two leather cylinder end opening pull rings; and an invisible crack is formed on each fixed pull force cracking ring. According to the ring joint and fixed pull force cracking leather cylinder for the material distribution belt machine, the length of the leather cylinder can be customized according to actual production, and the pouring requirements of various altitude difference bins are met by combining the leather cylinders of several length models. The elliptical fixed pull force cracking rings penetrate between the upper joint leather cylinder and the lower joint leather cylinder and are used for connecting the upper joint leather cylinder and the lower joint leather cylinder; and when the overloading of the leather cylinders caused by material blockage occurs, the fixed pull force cracking rings are released due to the overloading, and the lower joint leather cylinder drops down naturally, so that the tipover of protective equipment due to the overloading is avoided. The fixed pull force cracking rings can also be independently applied to other occasions where fixed pull force cracking is required.

Owner:CHINA THREE GORGES CORPORATION

Dynamic balanced gating system for thin-wall guider with double-layer blades

ActiveCN111531130BMeet pouring requirementsImprove feeding efficiencyFoundry mouldsFoundry coresEngineeringMaterials science

The invention discloses a dynamic balanced pouring system of a double-layer blade thin-walled guider. By adopting a three-dimensional pouring system with a sprue as the central axis and a three-layer runner, first passing through the first runner of the bottom layer Drain the first molten alloy liquid to the outer ring to fill the outer ring and the outer blades from bottom to top, and then drain the second molten alloy liquid to the inner ring through the second runner in the middle to fill the inner ring. Filling with the inner blade, and finally draining the third alloy liquid to the riser for filling through the third runner on the top layer, realizing the overall filling from bottom to top, from inside to outside , which is conducive to the natural formation of a temperature gradient to achieve the purpose of sequential solidification, especially the final filling and solidification of the riser, which is conducive to improving the feeding efficiency and reducing the loose and scrap rate, and can effectively balance and suppress the risks of various defects, which is very good It meets the pouring requirements of the thin-walled guide for double-layer blades.

Owner:CHINA HANGFA SOUTH IND CO LTD

Construction method of conveying concrete downwards with large drop

ActiveCN106049501BEasy maintenanceMeet pouring requirementsFoundation engineeringWork performanceStructural engineering

The invention discloses a construction method for large-drop downward concrete transporting. The construction method comprises the steps of downward concrete transporting device installing, long articulated chute support reinforcing and moisturizing and buffer device installing, pedestrian overhauling channel arranging and articulated chute downward concrete transporting operation control. The problem that concrete cannot be directly downwards transported from a large-drop steep precipice is solved from pit large-drop steep precipice downward concrete transporting device installing, long articulated chute support reinforcing and moisturizing and buffer device installing, pedestrian overhauling channel arranging, the concrete working performance and other links. The construction method for large-drop downward concrete transporting has the advantages that the transporting pipeline structure is simple; the technological process operation is easy; pipe blocking and pipe exploding are not prone to happening; the concrete transporting efficiency is high; and the equipment cost is low. Meanwhile, the pressure loss problem caused by concrete pumping is avoided. The construction method is suitable for underground engineering, especially concrete transporting and pouring of a subway, a tunnel, an urban underground complex and other pit projects.

Owner:中建五局第三建设有限公司

Concrete engineering construction process

ActiveCN112554554AMeet pouring requirementsReduce workloadAuxillary members of forms/shuttering/falseworksArchitectural engineeringRebar

The invention relates to a concrete engineering construction process. The concrete engineering construction process comprises the following construction steps: binding a reinforcement cage and preparing concrete; building formworks according to a sequence from bottom to top, fixing the lowest formwork on the ground, sequentially fixing the rest formworks on the formworks below, and connecting thetop end of the uppermost formwork with the top end of the opposite formwork by using a screw rod; coating the surfaces of the built formworks with a release agent, then pouring concrete a space defined by the formworks, and using a vibrating rod for continuously vibrating the concrete in the pouring process; and after concrete solidification, sequentially dismantling the formworks from top to bottom, and cutting off the redundant parts, left at the topmost end, of bolts. The construction process has the effects that the screw rod needing to be cut off after concrete solidification is reduced,and the construction efficiency is improved.

Owner:浙江河海建设有限公司

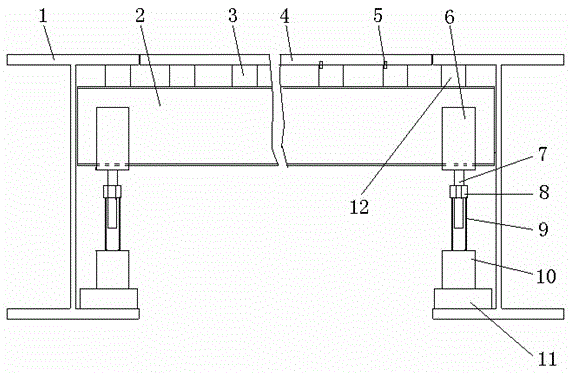

Concrete formwork support device for floor pouring

ActiveCN103967273BEasy to adjustFulfill pouring requirementsAuxillary members of forms/shuttering/falseworksFloor slabKeel

Owner:云南昆钢钢结构股份有限公司

Ring joint and fixed pull force cracking leather cylinder for material distribution belt machine

The invention relates to a ring joint and fixed pull force cracking leather cylinder for a material distribution belt machine. The leather cylinder comprises an upper joint leather cylinder and a lower joint leather cylinder, wherein leather cylinder end opening pull rings are arranged on the upper joint leather cylinder and the lower joint leather cylinder; and one fixed pull force cracking ring is arranged between every two leather cylinder end opening pull rings; and an invisible crack is formed on each fixed pull force cracking ring. According to the ring joint and fixed pull force cracking leather cylinder for the material distribution belt machine, the length of the leather cylinder can be customized according to actual production, and the pouring requirements of various altitude difference bins are met by combining the leather cylinders of several length models. The elliptical fixed pull force cracking rings penetrate between the upper joint leather cylinder and the lower joint leather cylinder and are used for connecting the upper joint leather cylinder and the lower joint leather cylinder; and when the overloading of the leather cylinders caused by material blockage occurs, the fixed pull force cracking rings are released due to the overloading, and the lower joint leather cylinder drops down naturally, so that the tipover of protective equipment due to the overloading is avoided. The fixed pull force cracking rings can also be independently applied to other occasions where fixed pull force cracking is required.

Owner:CHINA THREE GORGES CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com