High-solid-content NEPE solid propellant slurry, propellant and preparation method

A solid propellant, high solid content technology, applied in offensive equipment, explosive processing equipment, production of compressed gas, etc., can solve the problems of changes in propellant mechanical properties, prolong mixing time, and difficulty in screening additives, and reduce Viscosity and yield value, obvious process improvement, the effect of meeting the casting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention also provides a preparation method of high solid content NEPE solid propellant slurry, comprising the following steps:

[0038] Step 1. Weigh the raw materials, wherein the raw materials include ammonium perchlorate, ammonium nitrate explosive, aluminum powder, adhesive system, curing agent and functional auxiliary agent, and the aluminum powder is ultrafine aluminum powder or ultrafine aluminum Powder and FLTQ1 aluminum powder mixture, the particle size of the ultra-fine aluminum powder d 50 2.5μm-13μm;

[0039] Specifically, the raw materials used in this embodiment are provided by the above-mentioned examples. For specific description, please refer to the above-mentioned examples of raw materials, and details are not repeated here.

[0040] Step 2. Mix part of the binder system with the weighed aluminum powder, ammonium nitrate explosive and functional auxiliary agent to obtain a mixture. The quality of the binder system in th...

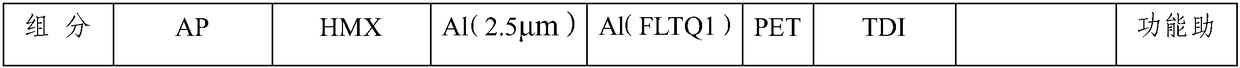

Embodiment 1

[0050] The present embodiment provides a kind of high solid content NEPE propellant slurry and propellant, and the preparation method comprises the following steps:

[0051] Step 1, weigh raw materials according to the formula in Table 1;

[0052] Step 2, mix the weighed PET, NG and TEGDN to obtain a binder system, and combine 10.8 parts by mass of the binder system with the weighed aluminum powder, ammonium nitrate explosive and functional additives at a telecentric pulp linear velocity of 1m / s, mixing temperature of 65 ° C under the condition of mixing for 25 minutes to obtain a mixture,

[0053] Step 3. Add the weighed AP into the obtained mixture, mix for 45 minutes at a telecentric slurry line speed of 1m / s, and a mixing temperature of 60°C, then add a curing agent and the remaining binder system, and The telecentric slurry linear velocity is 1m / s, mixed at a mixing temperature of 45°C for 20 minutes to obtain a propellant slurry;

[0054] Step 4, curing the obtained pr...

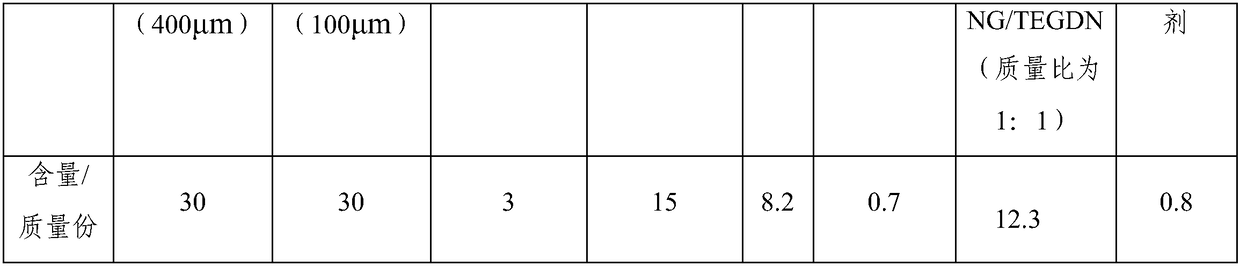

Embodiment 2

[0061] The present embodiment provides a kind of high solid content NEPE propellant slurry and propellant, and the preparation method comprises the following steps:

[0062] Step 1, weigh raw materials according to the formula in Table 2;

[0063] Step 2. Mix the weighed PET, NG and TEGDN to obtain a binder system, and combine 12 parts by mass of the binder system with the weighed aluminum powder, ammonium nitrate explosive and functional additives at a telecentric pulp line speed of 1.2 m / s and mixing temperature of 65°C for 20 minutes to obtain a mixture,

[0064] Step 3. Add the weighed AP into the obtained mixture, mix for 50 minutes at a telecentric pulp line speed of 1.2m / s, and a mixing temperature of 65°C, then add the curing agent and the remaining binder system, and The telecentric slurry linear velocity is 1.2m / s, and the mixing temperature is 50°C and mixed for 20 minutes to obtain the propellant slurry;

[0065] Step 4, curing the obtained propellant slurry at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com