Patents

Literature

355 results about "Ammonium perchlorate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium perchlorate ("AP") is an inorganic compound with the formula NH₄ClO₄. It is a colorless or white solid that is soluble in water. It is a powerful oxidizer. Combined with a fuel, it can be used as a rocket propellant. Its instability has involved it in a number of accidents, such as the PEPCON disaster.

Fenton and Fenton-like system fortifier and using method thereof

ActiveCN101792205AReduce dosageEasy to useWater treatment parameter controlWater treatment compoundsSulfite saltHydrazine compound

The invention provides a Fenton and Fenton-like system fortifier and a using method thereof, which relate to a water treating fortifier and a using method thereof and overcomes the defects that the pH value of the Fenton and Fenton-like system reaction water body is limited, the adding amount of Fe<2+> is overhigh in the Fenton reaction, and the reaction speed is low in Fenton-like reaction. The fortifier is selected from ascorbic acid, sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine, hydroxyl-ammonium perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, carbohydrazide, ethanolamine, a hydroxylamine solution or N,N,N',N'-tetra substituted phenylenediamines. The using method has the following steps of: adding the Fenton and Fenton-like system fortifier, fortificated chemicals and peroxide into the treated water body; and then, uniformly stirring to react. The fortifier can accelerate the reaction of water treatment and decrease the using amount of the fortificated chemicals.

Owner:HARBIN INST OF TECH

Conductive roller, process cartridge and image forming apparatus

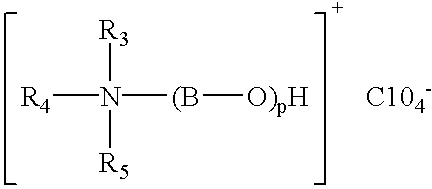

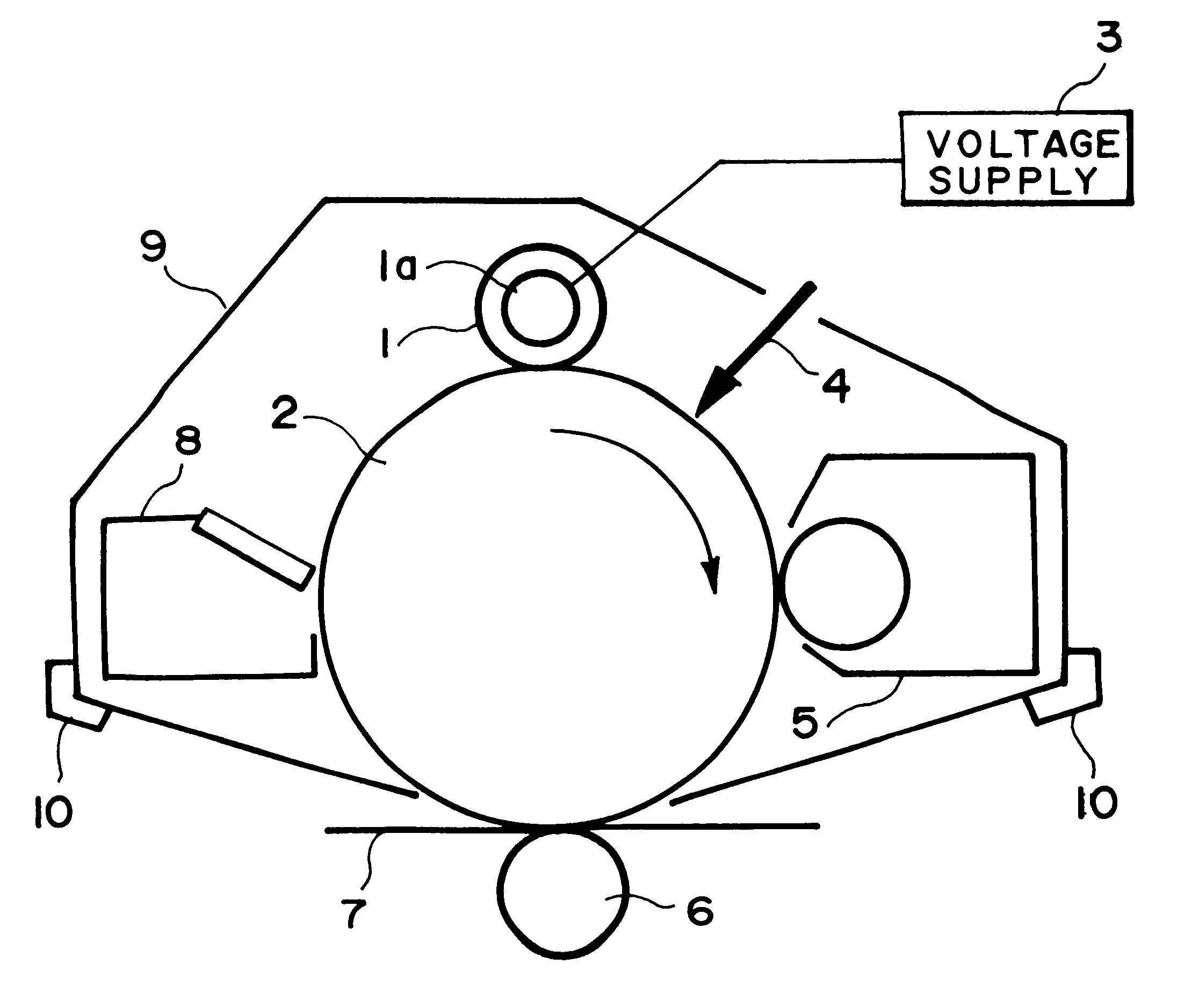

InactiveUS6558781B1Plastic/resin/waxes insulatorsSynthetic resin layered productsPolymer scienceAmmonium compounds

An electroconductive roller is capable of exhibiting stable conductivity regardless of environmental change and is accompanied by small bleed-out of additives. The conductive roller includes an electroconductive support, an electroconductive elastic layer coating the support and a resistance layer coating the elastic layer; wherein the elastic layer comprises at least one species of rubber selected from the group consisting of acrylonitrile-butadiene rubber, epichlorohydrin rubber and chloroprene rubber, an ether oxygen containing alkyl phthalate derivative, a quaternary ammonium perchlorate compound and a fatty oil, and the ether oxygen-containing alkyl phthalate derivative, quaternary ammonium perchlorate compound and fatty oil are contained in a total amount of 0.1-20 wt. parts per 100 wt. parts of the rubber. The conductive roller is suitably used as a contact charging member in an electrophotographic apparatus.

Owner:CANON KK

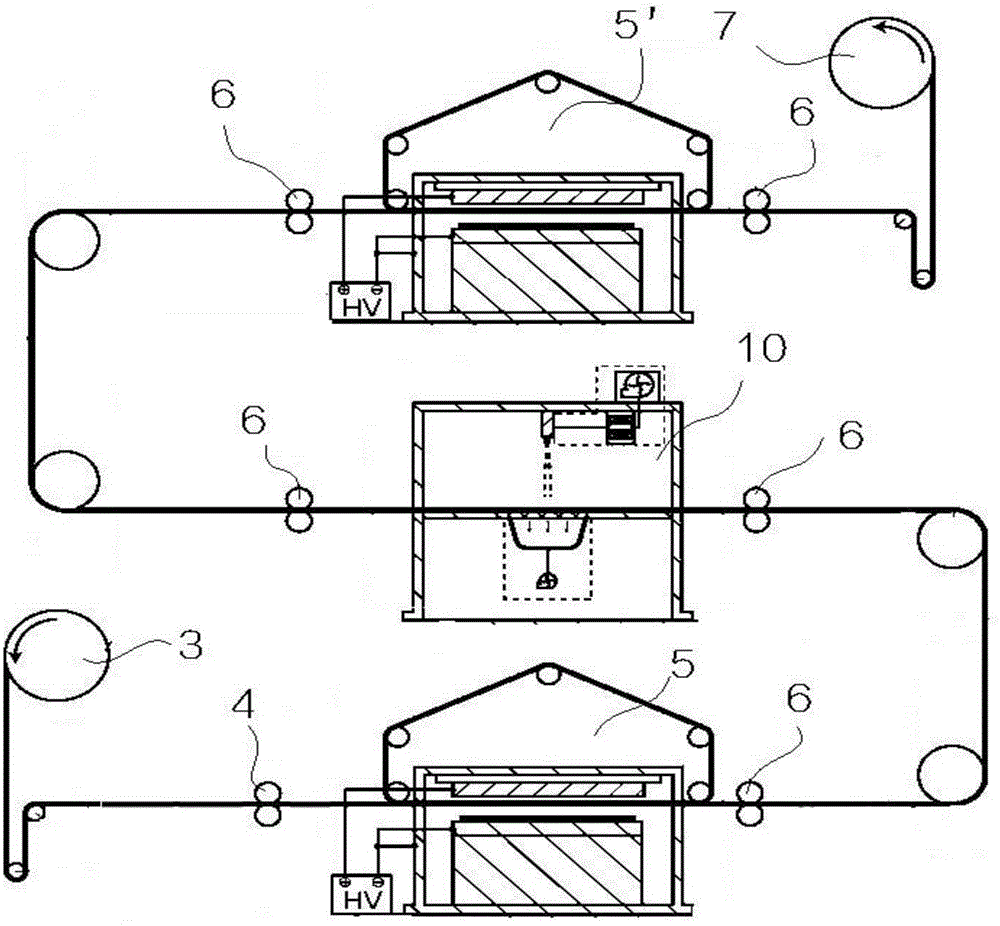

PVDF nano fiber multifunctional air filtering material and preparation method thereof

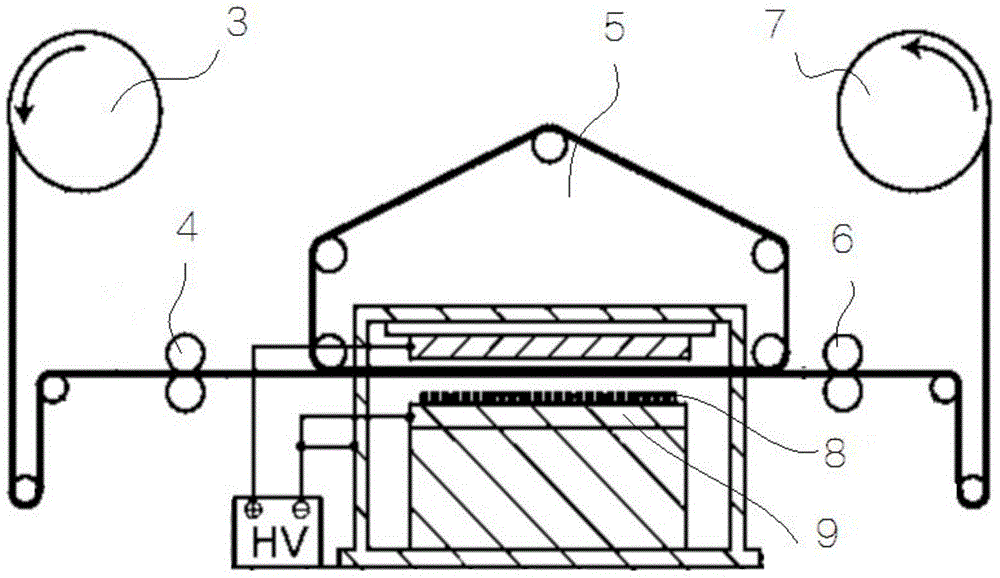

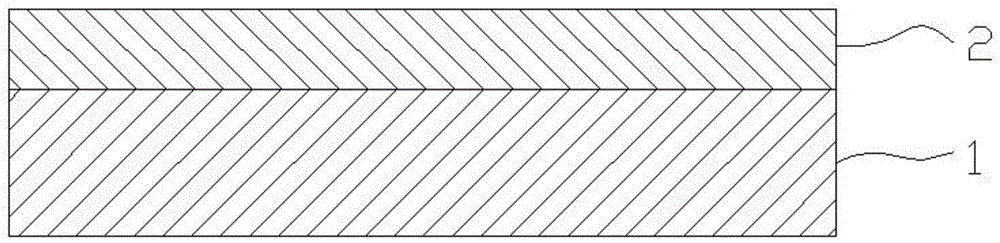

ActiveCN104785018ALower resistanceAntibacterialSynthetic resin layered productsFiltration separationAir filterElectrospinning

The invention discloses a PVDF nano fiber multifunctional air filtering material which comprises a polypropylene micrometer fiber layer and a PVDF nano fiber layer, wherein the PVDF nano fiber is prepared from a spinning solution; the spinning solution comprises the following components in parts by weight: 1 part of PVDF resin and 9-13 parts of a mixed solvent; the mixed solvent comprises an amide solvent and ketone; the preparation method for the material comprises the following steps: 1) adopting the polypropylene micrometer fiber layer as a substrate; 2) stirring and mixing the PVDF resin, the mixed solvent and tetrabutyl ammonium perchlorate, and adding the obtained spinning solution into an electrostatic spinning device; 3) performing bowl hot-pressing on the substrate through a high-temperature calender, and feeding into the electrostatic spinning device for spraying; 4) obtaining a finished product after the spraying is completed. The PVDF nano fiber multifunctional air filtering material can effectively inhibit growth of bacteria, can greatly reduce the content of oily granules and ionic granules, and is long in service life and high in production efficiency.

Owner:SOOCHOW BOYOO NANO TECH CO LTD

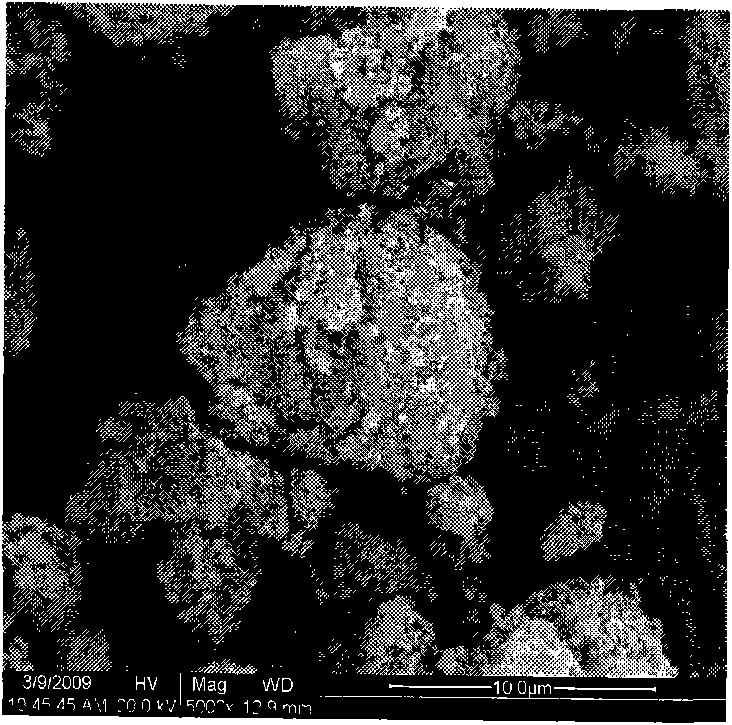

Method for preparing high-quality energetic crystal material fine particles

ActiveCN102320903AReduce crystal defectsReduced Shockwave SensitivityExplosive working-up apparatusShock waveFOX-7

The invention relates to a method for preparing high-quality energetic crystal material fine particles. Various high-quality energetic crystal material fine particle products, such as pentaerythritol tetranitrate (PETN), cyclotrimethylene trinitramine (RDX), cyclotetramethylenetetranitramine (HMX), hexanitrohexaazaisowurtzitane (CL-20), DADNE (FOX-7), ammonium perchlorate (AP), and the like can be prepared by adopting an ultrasound solvating-out crystallization method in the traditional solvating-out crystallization process. The high-quality energetic crystal material fine particle product prepared by the preparation method disclosed by the invention has subglobular particle form, narrow granularity distribution, average particle diameter of 5-50 microns or so, transparent crystals, high particle density, crystal theoretical density of more than 99.9 percent and obviously reduced shock wave sensitivity and is used for pouring or pressing PBX (Plastic-bonded explosives). The method for preparing the high-quality energetic crystal material fine particles has the advantages of simple process flow and mild reaction conditions and is suitable for mass industrialized production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Explosive composition and its use

InactiveUS6984274B2Improve structural strengthLess-expensive productionBelt retractorsPedestrian/occupant safety arrangementNitro compoundPorosity

An explosive composition comprises a porous fuel and an oxidizer. The porous fuel is a solid with a structure size measuring between about 2 nm and 1000 nm and has a porosity that lies between 10% and 98%. The oxidizer is solid or liquid at room temperature and is incorporated into the pores of the porous fuel. The oxidizer is selected, in an amount of at least 50% by weight relative to a total quantity of the oxidizer, from the group consisting of hydrogen peroxide, hydroxyl ammonium nitrate, organic nitro compounds or nitrates, alkali metal nitrates or earth alkali metal nitrates as well as metal nitrites, metal chlorates, metal perchlorates, metal bromates, metal iodates, metal oxides, metal peroxides, ammonium perchlorate, ammonium nitrate and mixtures thereof.

Owner:TRW AIRBAG SYST

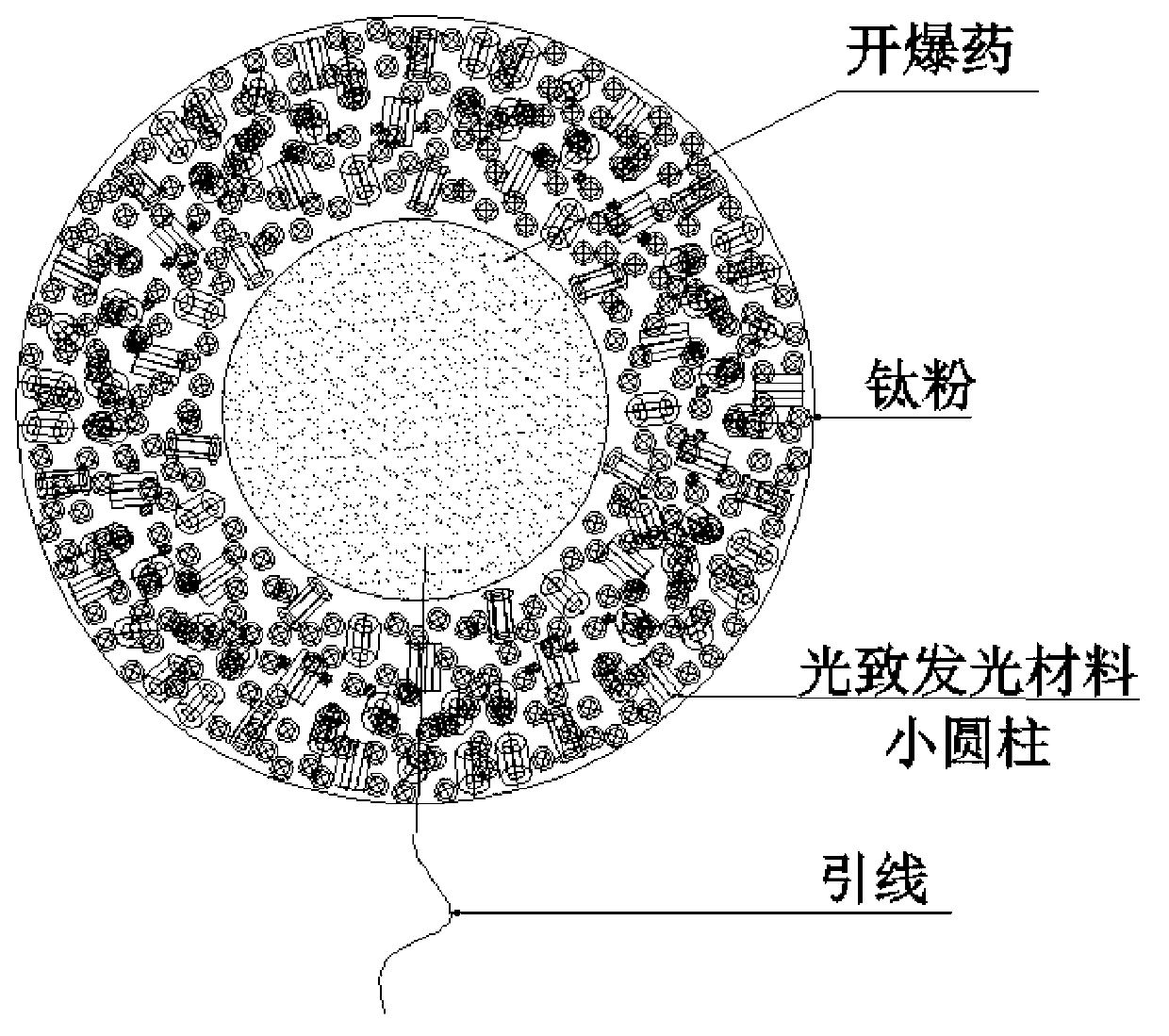

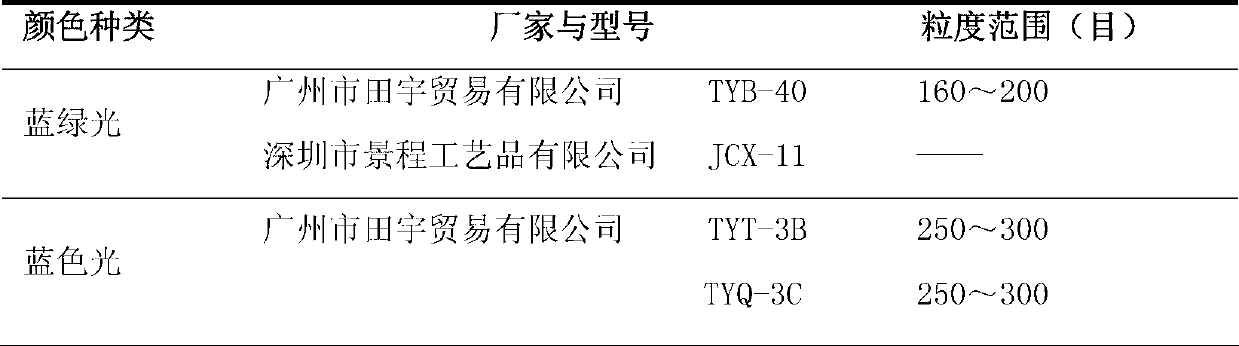

Multicolor cold-firework reagent and manufacturing method of cold fireworks

InactiveCN103121886AEasy to viewExplosive working-up apparatusAmmonium perchlorate explosive compositionsNitrocellulosePhotoluminescence

The invention discloses a multicolor cold-firework reagent and a manufacturing method of cold fireworks. The multicolor cold-firework reagent comprises the following components in percentage by weight: 20-30% of ammonium perchlorate, 20-30% of nitrocellulose, 30-35% of silver titanium powder, 15-20% of photoluminescence material and 5-10% of fluororubber. The manufacturing method of the spraying-decoration cold fireworks comprises the following steps: fuel granulation, reagent mixing, charging and packaging. The manufacturing method of the high-waterfall display shell cold fireworks comprises the following steps: luminescent material granulation, fuel mixing, detonating agent manufacturing and display shell filling. The cold fireworks disclosed by the invention can have multiple bright colors, thereby greatly enhancing the ornamental value of the cold fireworks.

Owner:NANJING UNIV OF SCI & TECH

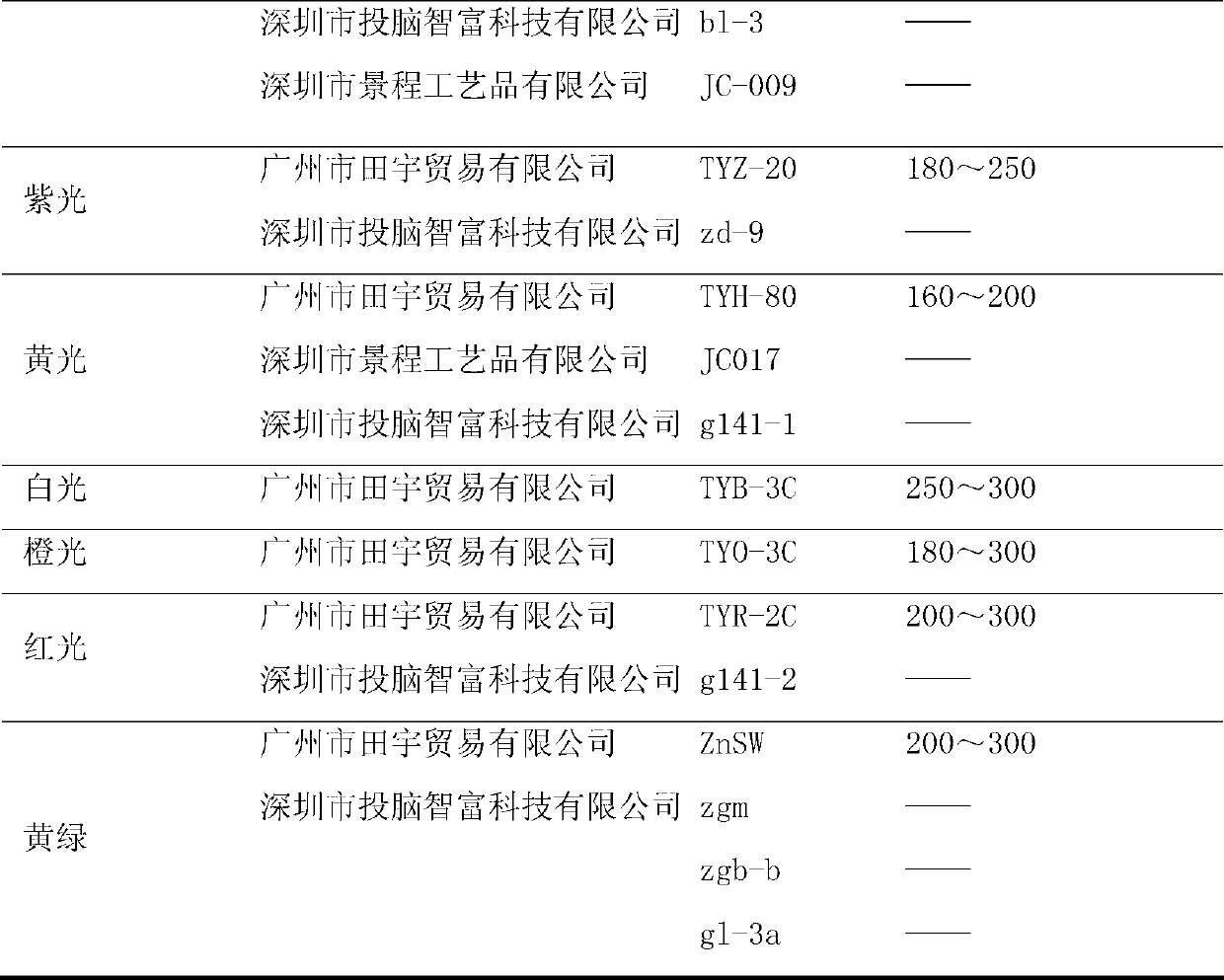

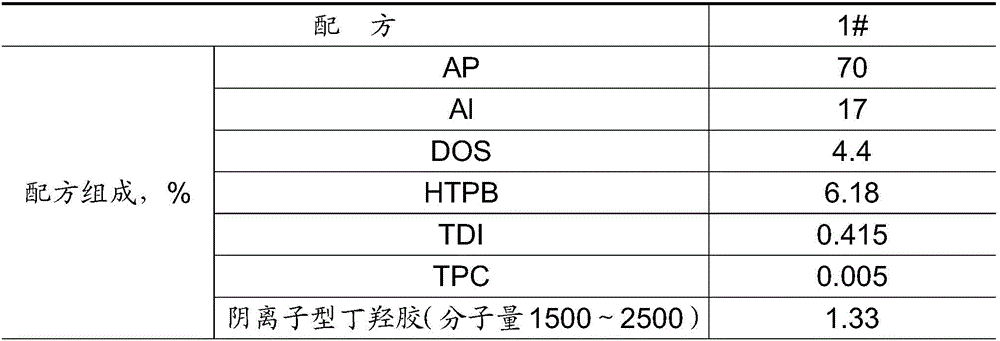

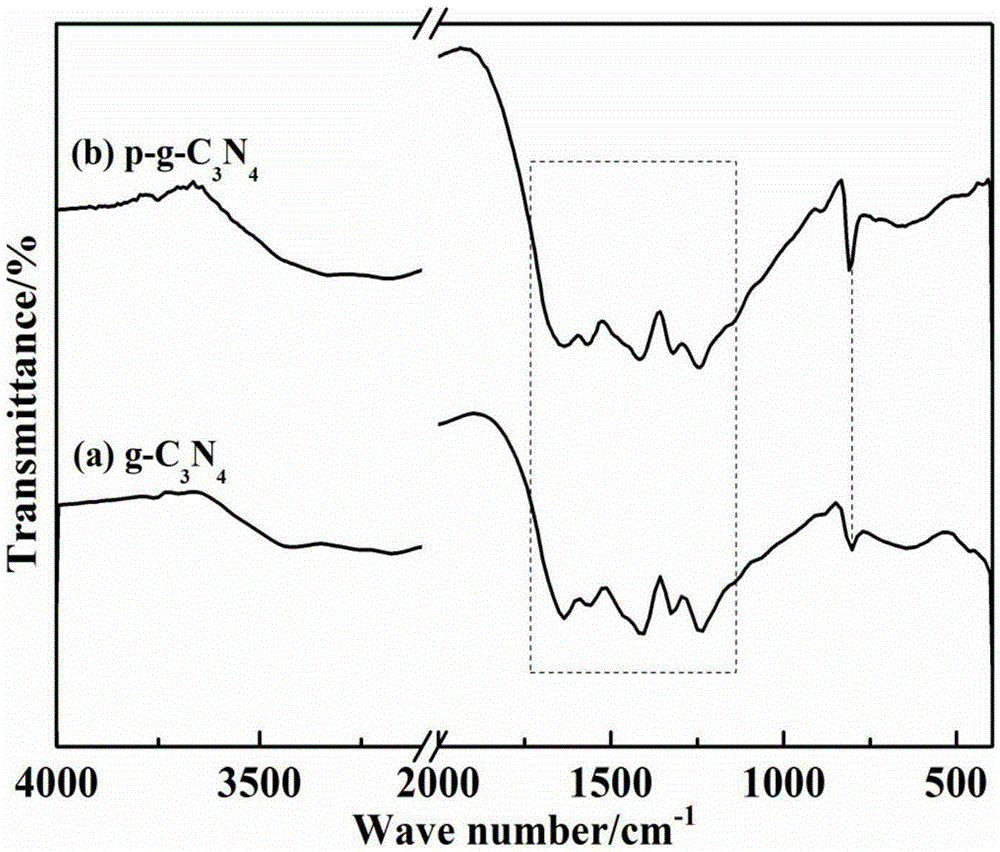

Room-temperature curing propellant

ActiveCN106831279AGood mechanical propertiesReduced activityExplosivesPressure gas generationAnilineMethylene diphenyl diisocyanate

The invention relates to a room-temperature curing propellant. The room-temperature curing propellant is prepared from the following components in percentage by mass: 69 to 77% of AP (ammonium perchlorate), 10 to 18% of Al (aluminum) powder, 1 to 5% of plasticizer DOS, 7 to 10% of adhesive HTPB and curing agent, 0.005 to 0.05% of curing catalyst, and 0.2 to 2.0% of network adjusting agent, wherein the network adjusting agent is an alcohol or amine compound with two degrees of functionality, and is one or combination of N-isopropyl alcohol-N-isopropyl ether-aniline, anionic HTPB (hydroxyl-terminated polybutadiene) or N,N'-dihydroxy(diisopropyl)aniline HPA; the curing agent is one or combination of PAPI (polyaryl polymethylene isocyanate), MDI (methylene diphenyl diisocyanate), XDI (xylylene diisocyanate), or TDI (toluene diisocynate). The room-temperature curing propellant has the advantages that the propellant with effective solid content of more than 85% is mixed and cast at the temperature of 20 to 35 DEG C, and can reach a curing point within 7d after curing; the normal-temperature mechanical strength can reach 0.85MPa or above, and the elongation rate is more than 35%.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Bright green cold firework composition and production method thereof

The invention discloses a bright green cold firework composition and a preparation method thereof. The composition comprises the following ingredients by weight percentage: 25-40% of boron powder, 5-15% of magnalium powder, 6-12% of titanium powder, 8-15% of barium nitrate, 6-10% of 52# chlorinated paraffin, 15-20% of nitrocotton and 15-20% of ammonium perchlorate. The preparation method of the composition comprises the steps of fuel mixing, fuel granulation, fuel grain drying and composition mixing. A cold firework produced by the composition can emit bright green light, the color variety of the cold firework is enriched, and the enjoyment effect of the cold firework is improved.

Owner:NANJING UNIV OF SCI & TECH

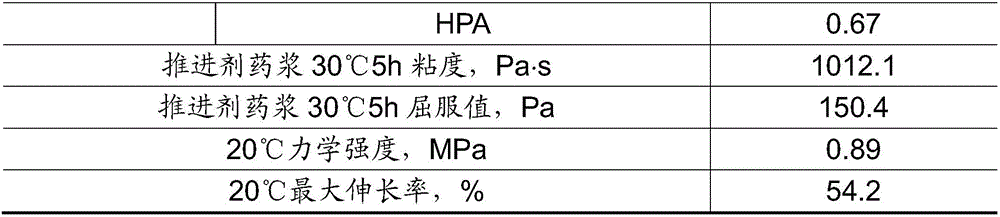

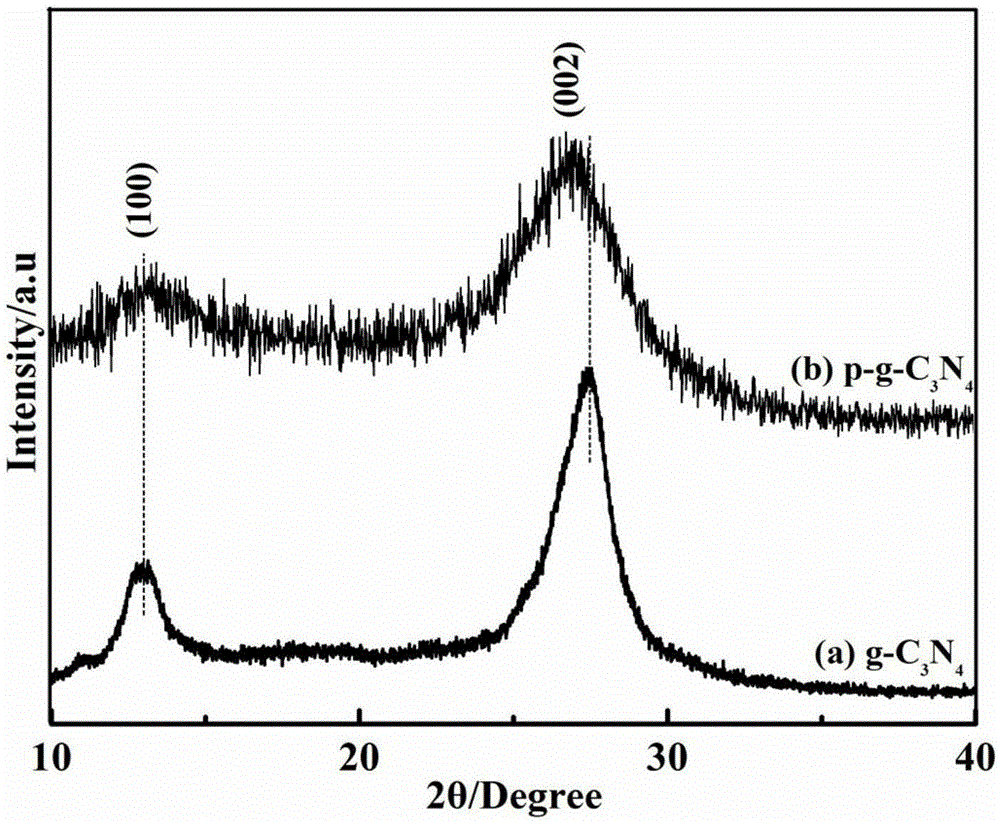

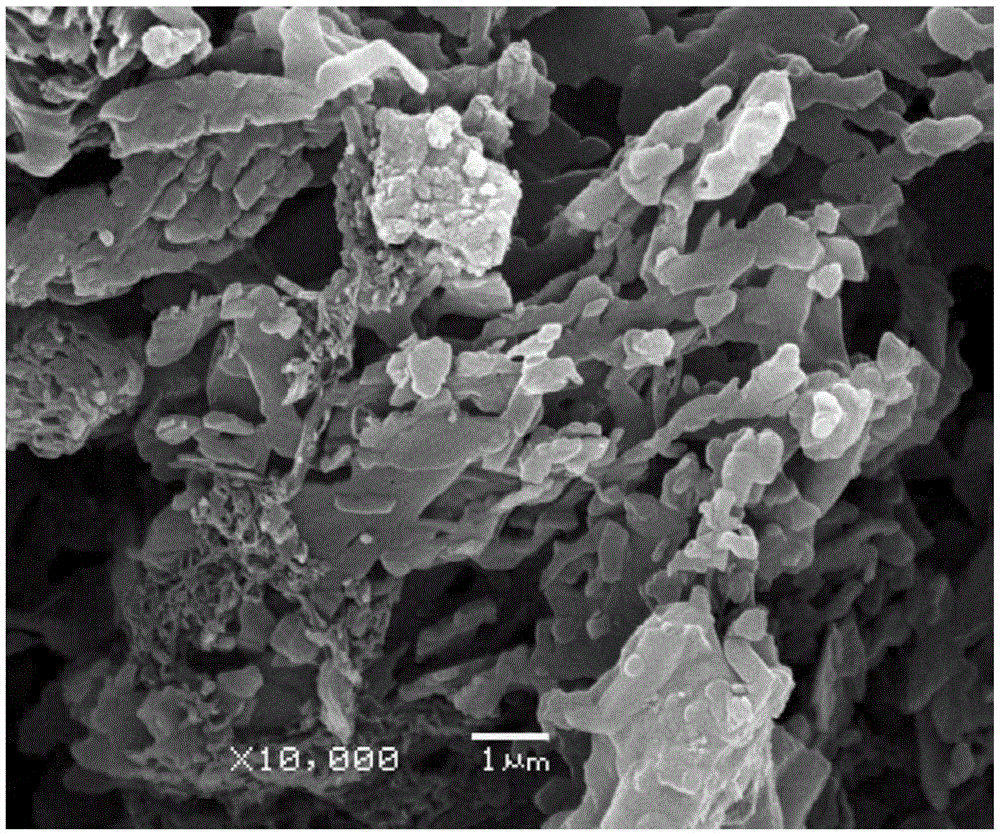

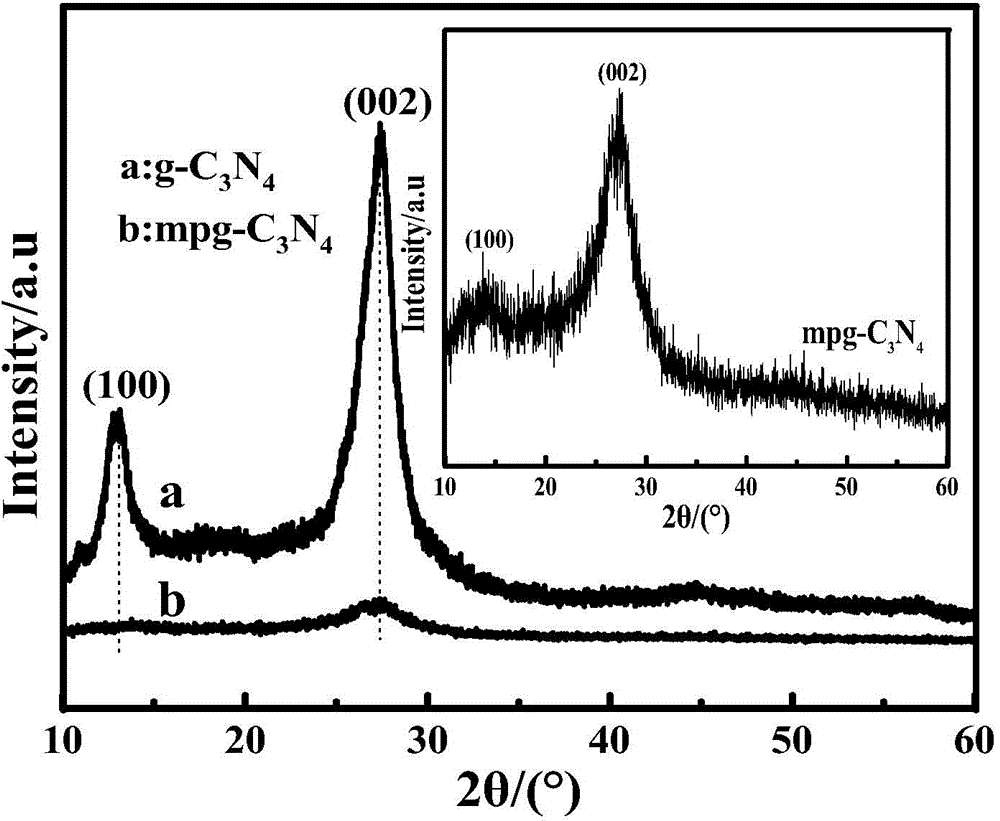

Method for preparing porous graphite-phase carbon nitride material

InactiveCN105271141AAvoid cumbersome synthesisAvoid environmental pollutionNitrogen and non-metal compoundsCarbon nitrideAmmonium perchlorate

The invention discloses a method for preparing a porous graphite-phase carbon nitride material. The method includes the following steps that melamine is placed in hot deionized water to be stirred till the melamine is dissolved; after the mixture is cooled to be at the indoor temperature, a HCl aqueous solution is dripped, and white precipitate is formed by stirring; after the product is dried, porous graphite-phase carbon nitride (p-g-C3N4) is obtained through calcination. The graphite-phase carbon nitride material prepared through the method is of a porous structure, and a good catalytic effect is achieved on thermal decomposition of ammonium perchlorate. According to the preparation method, the raw materials can be obtained easily, the process is simple, and product cost is lowered to a great extent; the method is suitable for industrialized mass production, and wide application prospects are achieved in the field of energetic materials.

Owner:NANJING INST OF TECH

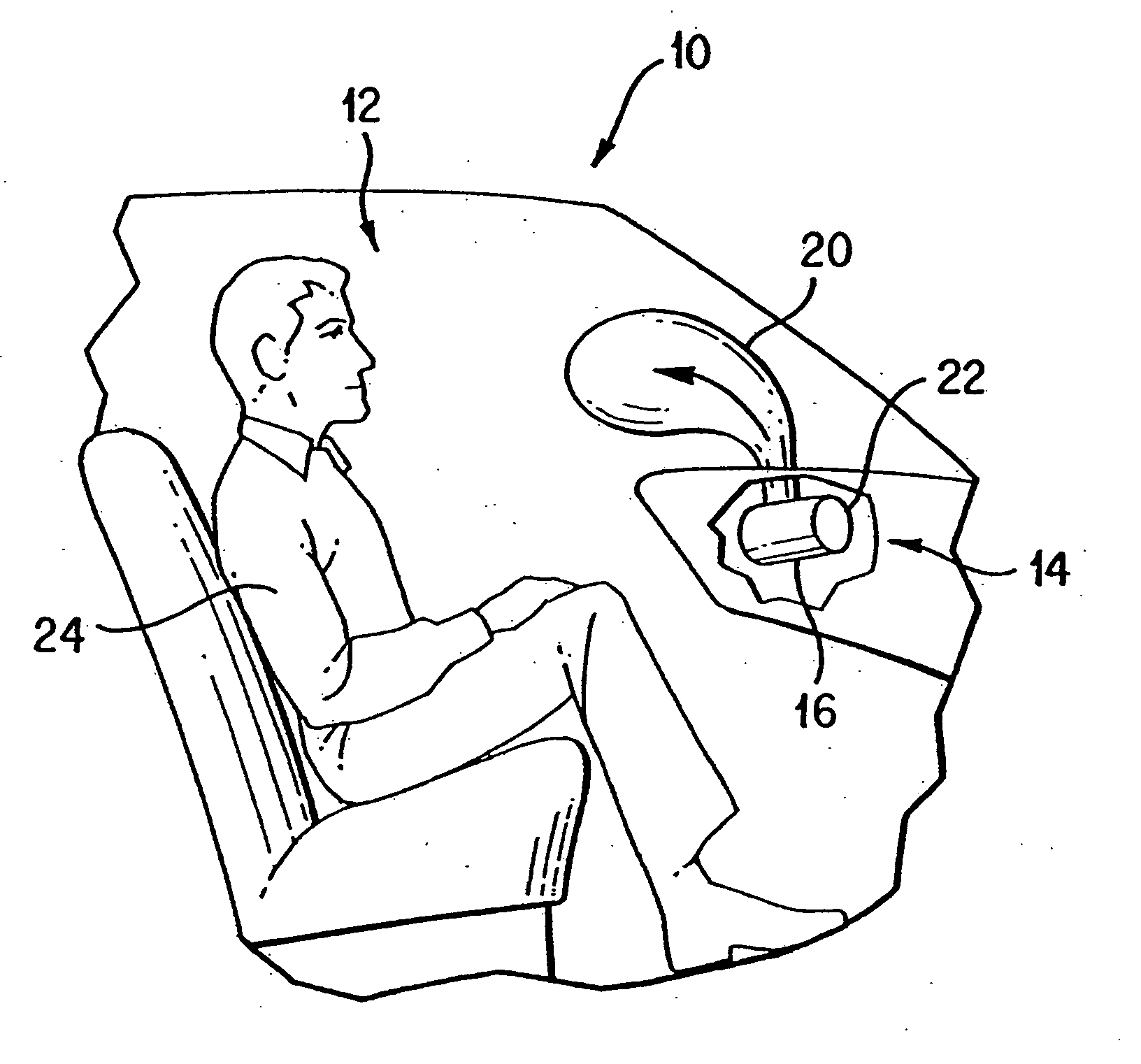

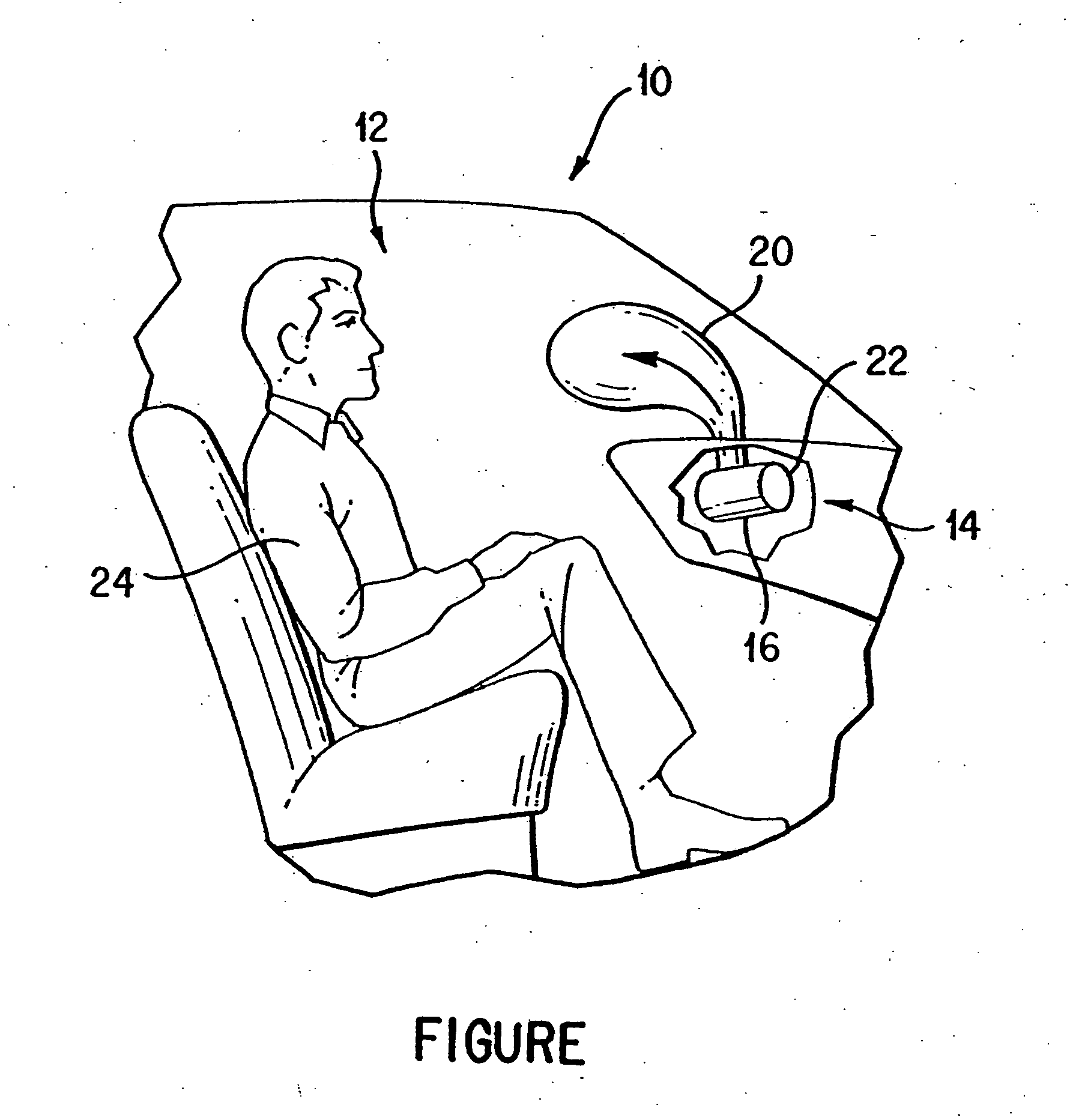

Ammonium perchlorate-containing gas generants

ActiveUS20050067076A1Non-explosive/non-thermic compositionsAmmonium perchlorate explosive compositionsScavengerCopper nitrate

Ammonium perchlorate-containing gas generant compositions which, upon combustion, produce or result in an improved effluent and related methods for generating an inflation gas for use in an inflatable restraint system are provided. Such ammonium perchlorate-containing gas generant compositions include ammonium perchlorate present with a mean particle size in excess of 100 microns. Such ammonium perchlorate-containing gas generant compositions also include or contain a chlorine scavenger present in an amount effective to result in a gaseous effluent that is substantially free of hydrogen chloride when the gas generant is combusted, wherein at least about 98 weight percent of the chlorine scavenger is a copper-containing compound. Suitable copper-containing chlorine scavenger compounds include basic copper nitrate, cupric oxide, copper diammine dinitrate-ammonium nitrate mixture wherein ammonium nitrate is present in the mixture in a range of about 3 to about 90 weight percent, copper diammine bitetrazole, a copper-nitrate complex resulting from reaction of 5-aminotetrazole with basic copper nitrate and combinations thereof.

Owner:AUTOLIV ASP INC

Non-nitrine gas generating agent and production thereof

ActiveCN1644574AReduce dosageReduce generationExplosivesPressure gas generationParaffin waxGas composition

A non-laminated gas producing agent and its production are disclosed. The non-laminated gas producing agent consists of oxygen-enriched carbamidine nitrate 40-60% with granularity 0.5-6mu, basic copper nitrate 10-28% as oxidant with granularity 0.5-6mu, copperon oxide of catalyst with primary oxidant 15-30% with granularity 0.1-6mu, and clay or paraffin wax 0.1-3% as process assistant with granularity 1-20mu. The production is carried out by: breaking the materials, adding into mixer by proportioning, mixing, sieving by screen, adding water 10-30%, agitating, drying, sieving the dried materials by screen with 20-80 mesh to obtain medicine particles, pressing into tablets, and drying the tablets under 100-120deg.C for 1.5-2.5hrs with water content <0.4%. It achieves wide regulating range, high gas output efficiency, and clean gas composition.

Owner:HUBEI HANGPENG CHEM POWER TECH

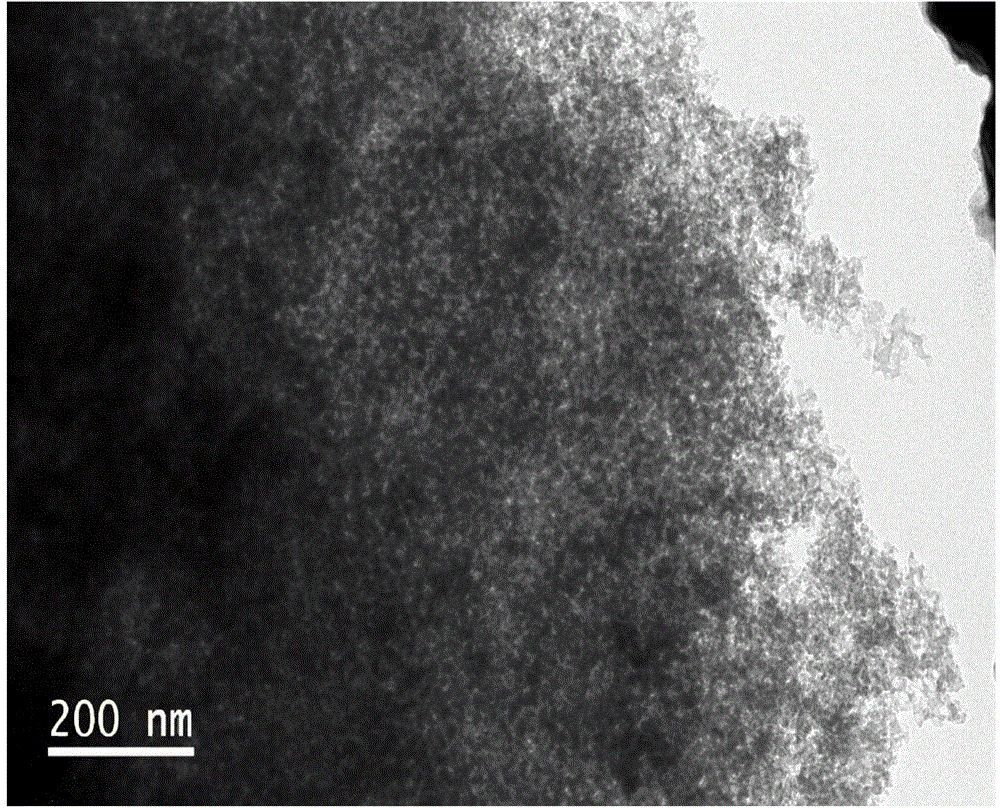

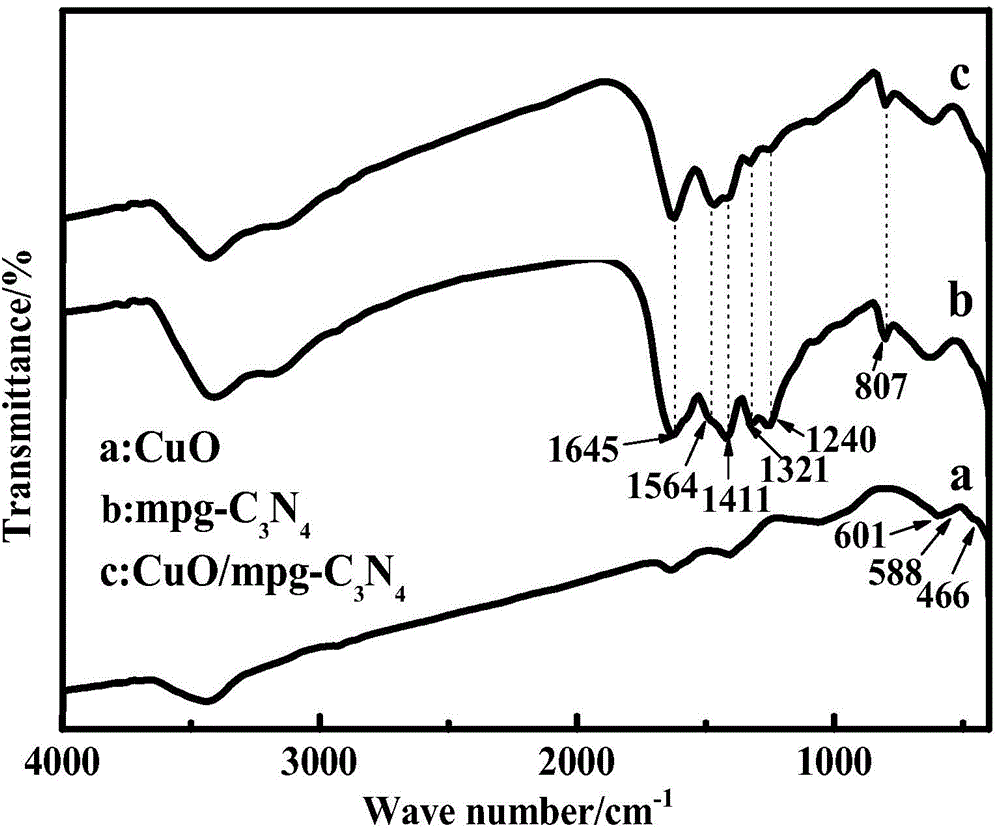

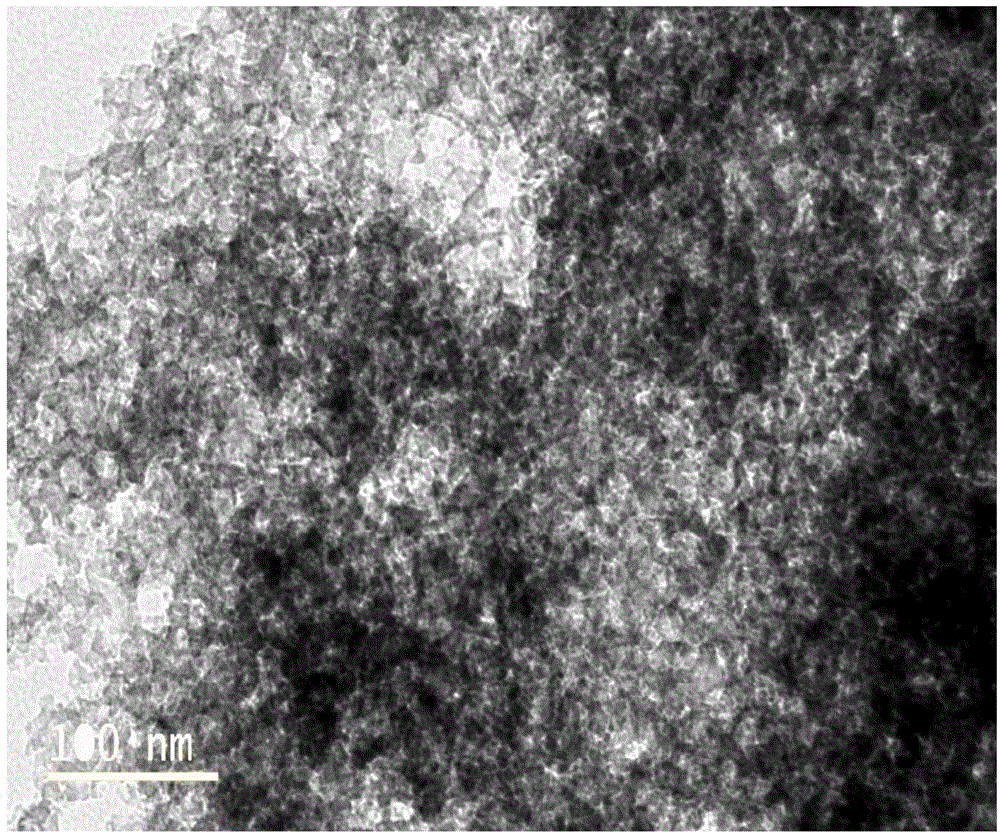

CuO/mpg-C3N4 composite material as well as preparation method and application thereof

InactiveCN104646045AReduce the chance of reunionHigh activityPhysical/chemical process catalystsPressure gas generationTube furnacePhysical chemistry

The invention discloses a CuO / mpg-C3N4 composite material as well as a preparation method and an application thereof. The composite material is compounded by mpg-C3N4 and nano CuO at the mass ratio of (95:5) to (80:20). The preparation method comprises the following preparation steps: ultrasonically dispersing mpg-C3N4 into an ethanol solution; adding C12H25NaO3S, and further ultrasonically dispersing; adding Cu(NO3)2.3H2O, stirring, and continuously dropwise adding a NaOH solution in the stirring process, and then further stirring and reacting for a certain period of time; and filtering, washing and drying the product, and burning in a tube furnace to obtain the CuO / mpg-C3N4 composite material. Two substances of the CuO / mpg-C3N4 composite material prepared by the method have relatively tight contact, and relatively large specific surface area, so as to display relatively good catalysts effect on thermal decomposition of ammonium perchlorate.

Owner:NANJING INST OF TECH

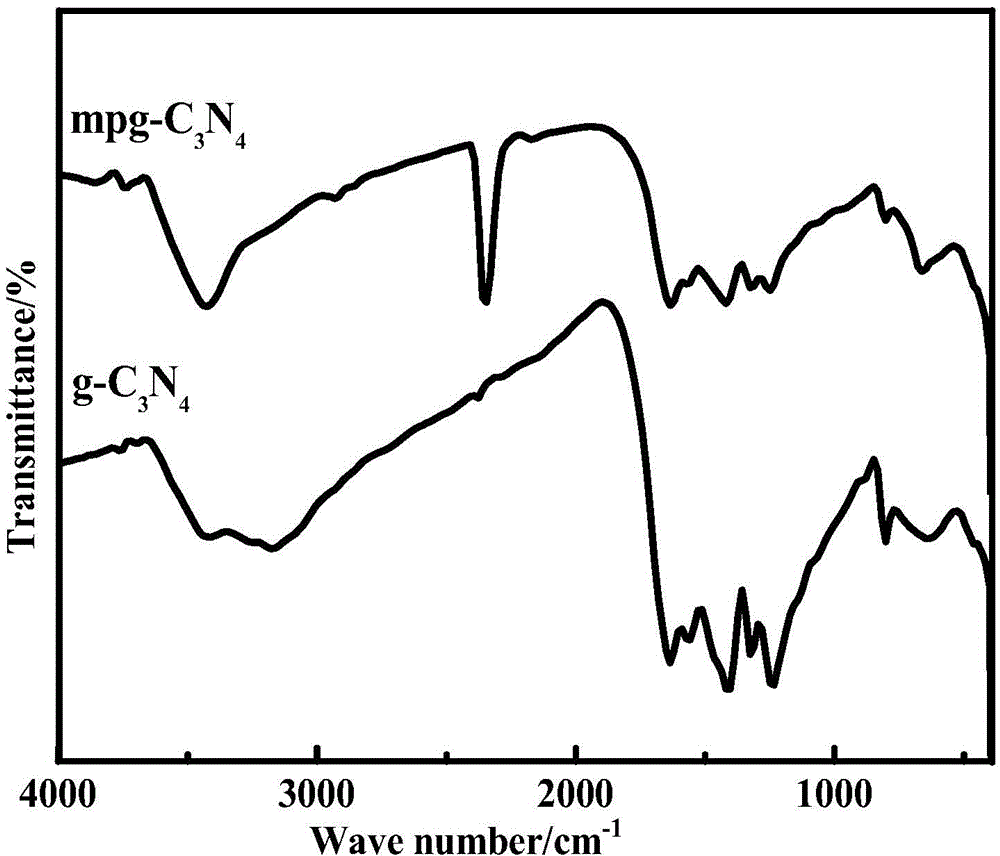

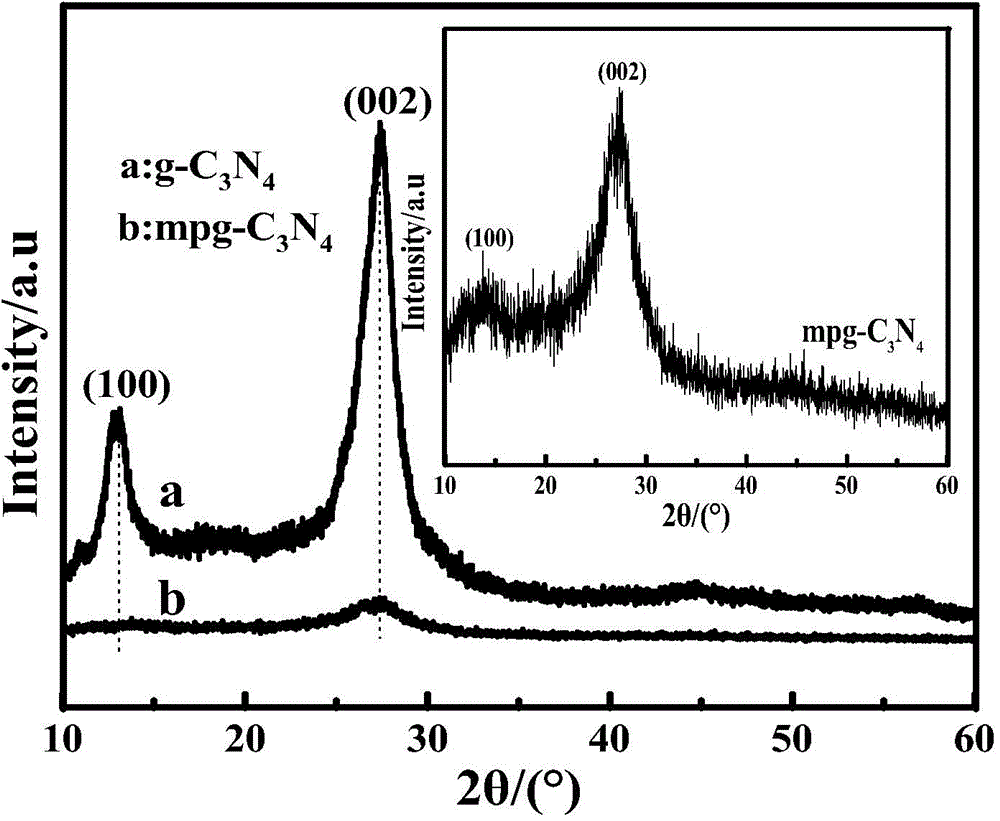

Preparation method of mesoporous graphite-phase carbon nitride material

InactiveCN104692344AMore active pointsHigh activityNitrogen and non-metal compoundsCarbon nitrideAmmonium perchlorate

The invention discloses a preparation method of a mesoporous graphite-phase carbon nitride material. The material is prepared by using a monocyanamide water solution as a raw material and nano colloid SiO2 as a template by a hard template process. The preparation method comprises the following steps: adding nano colloid oxidized SiO2 into a monocyanamide water solution, stirring uniformly, drying and calcining to obtain light yellow powder; putting the powder into an NH4HF2 solution, and stirring to remove the SiO2 template; and washing, and drying to obtain the mesoporous graphite-phase carbon nitride (mpg-C3H4) material. Compared with the common blocky graphite-phase carbon nitride (g-C3H4) material, the mesoporous graphite-phase carbon nitride (mpg-C3H4) material has larger specific area, and thus, has better catalytic effect on thermal decomposition of ammonium perchlorate. The preparation method has the advantages of simple technical operation, wide raw material sources and high preparation efficiency.

Owner:NANJING INST OF TECH

Preparation method of self-cleaning coating and self-cleaning glass

ActiveCN103468109AHas super hydrophilic effectEfficient removalPolyether coatingsWeather resistancePolyethylene glycol

The invention relates to a preparation method of a self-cleaning coating and a self-cleaning glass. The preparation method includes: firstly preparing a SiO2 sol; then mixing the SiO2 sol with polyethylene glycol, ammonium perchlorate and n-butanol evenly to obtain the self-cleaning coating; and spraying the self-cleaning coating on the surface of a clean glass, then carrying out curing treatment, or performing toughening treatment according to a toughened glass process, thus obtaining the self-cleaning curtain wall glass. The self-cleaning film layer formed in the invention is a porous SiO2 structure, is firmly combined with a glass substrate and has excellent weather resistance. The prepared self-cleaning glass surface has a superhydrophilic effect, so that surface dirt can be effectively removed. With good weather resistance, the self-cleaning glass can be used in the curtain wall glass filed.

Owner:佛山中科邦达无机功能材料有限公司

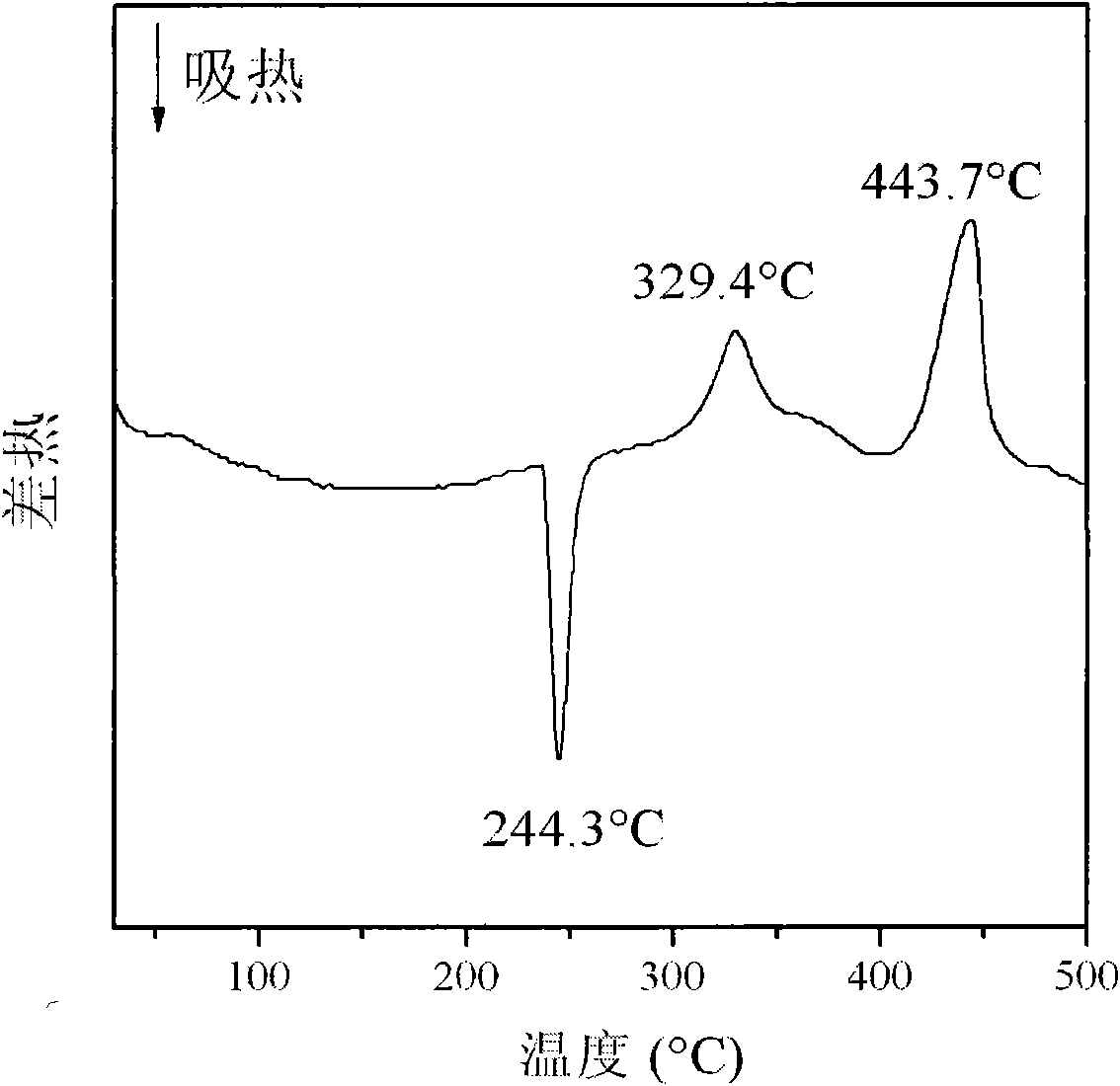

CoAl-metallic oxide/carbon nano tube composite as well as preparation method and application thereof as ammonium porchlorate catalyst

InactiveCN101869837AFirmly assembledGuaranteed smooth assemblyMetal/metal-oxides/metal-hydroxide catalystsAmmonium perchlorate explosive compositionsCross-linkDispersity

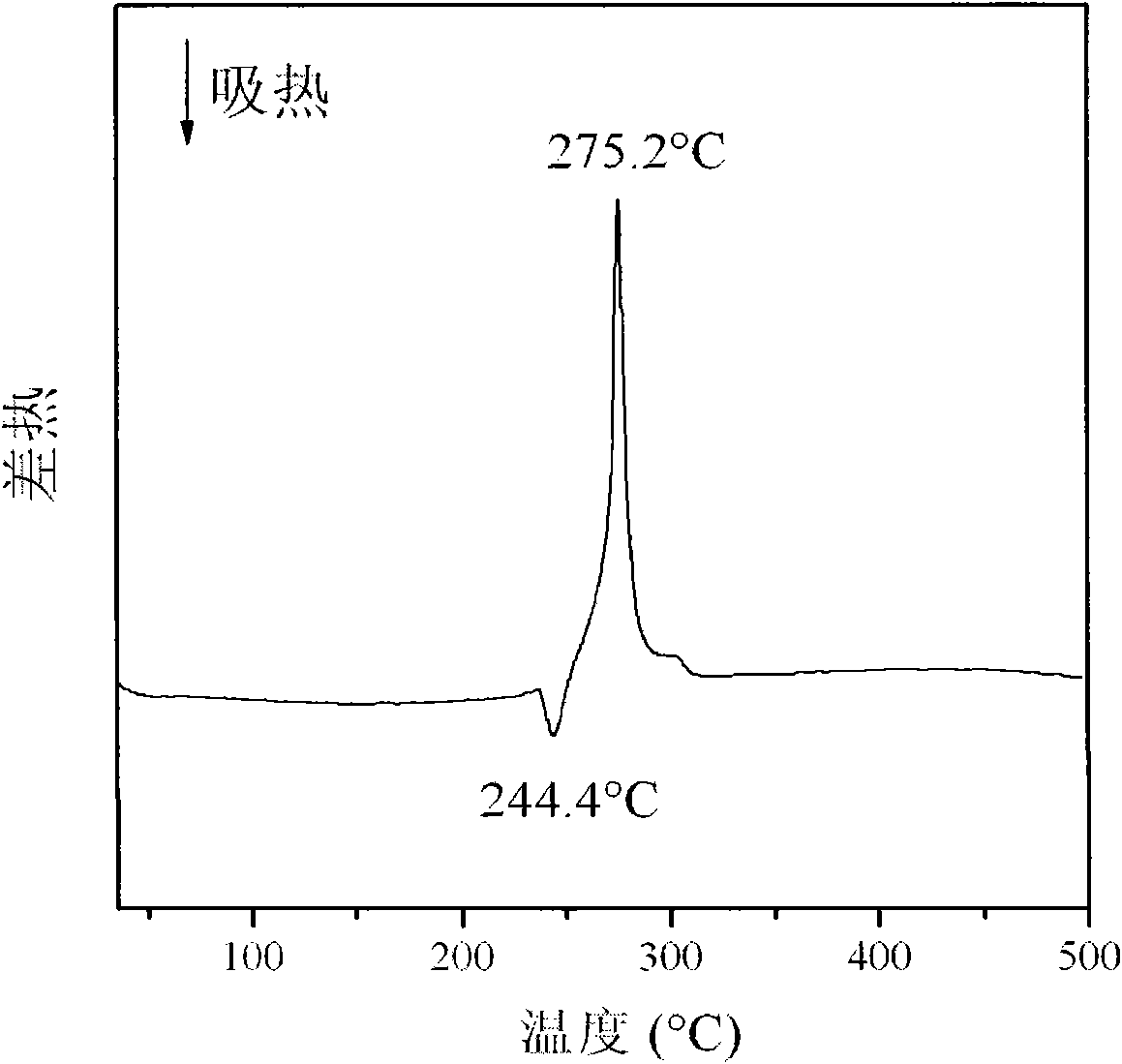

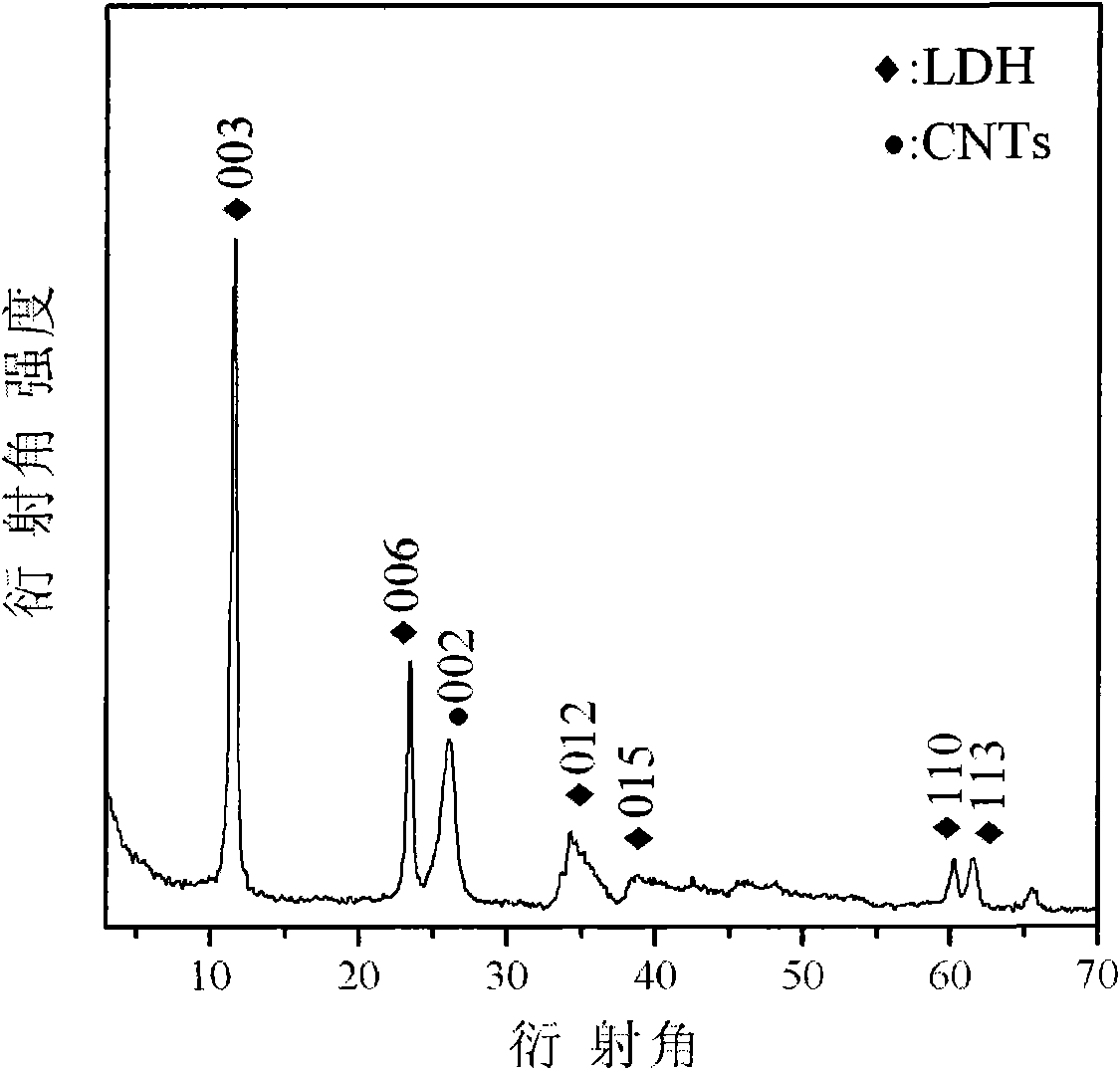

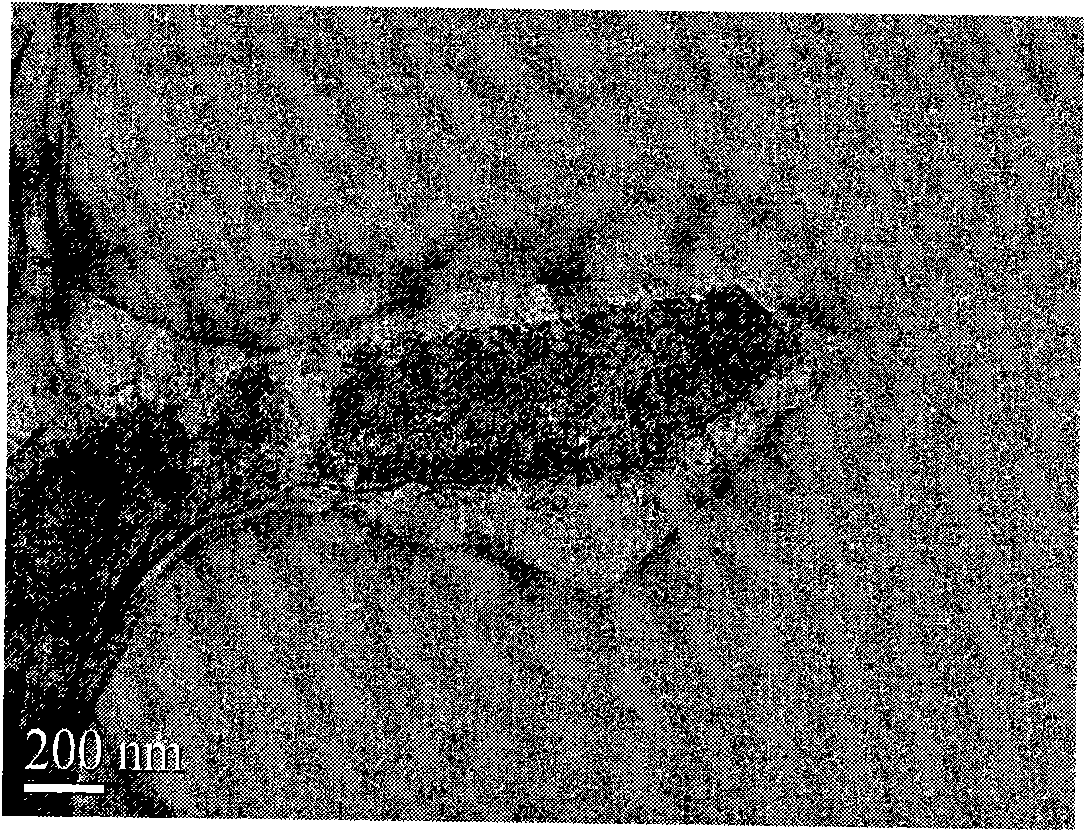

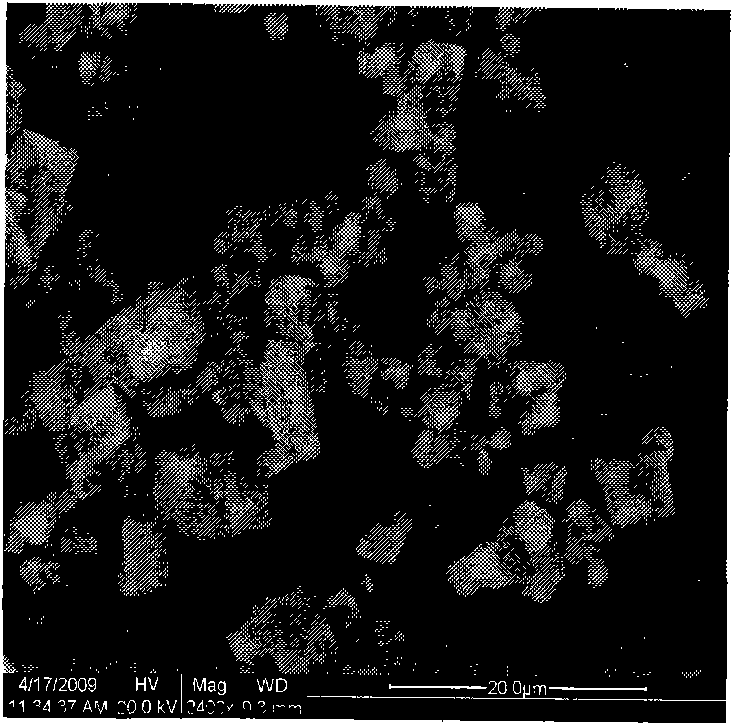

The invention provides a CoAl-metallic oxide / carbon nano tube composite as well as a preparation method and application thereof as an ammonium porchlorate catalyst. The preparation method of the composite comprises the following steps of: preparing a CoAl-layered bimetallic hydroxide / carbon nano tube composite precursor by adopting a coprecipitation method and using L-cysteine as a cross-linking agent; and roasting at 500 DEG C under N2 atmosphere to convert the CoAl-layered bimetallic hydroxide in the composite precursor into CoO and a CoAl2O4 mixedoxide so as to obtain a CoAl-metallic oxide / carbon nano tube composite. The L-cysteine which is used as a cross-linking molecule can enhance the interaction between layered bimetallic hydroxide nano particles and carbon nano tubes in the precursor and improve the dispersity of the layered bimetallic hydroxide nano particles on the surfaces of the carbon nano tubes, thereby further influencing the disperse state of the CoAl-metallic oxide on the surfaces of the carbon nano tubes. The CoAl-metallic oxide / carbon nano tube composite has good thermocatalysis property, and when the composite is used as the ammonium porchlorate catalyst, a low-temperature exothermic peak decomposed by the ammonium porchlorate can be disappeared; the high-temperature exothermic peak temperature is reduced to 271.3-299.1 DEG C, and the decomposition speed is improved to 7.0-13.0mg / min.

Owner:BEIJING UNIV OF CHEM TECH

Gas generating composition

InactiveUS6779464B1Nitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAmmonium perchlorate explosive compositionsNitroguanidinePerchlorate

A gas generating composition is obtained in which an amount of a combustion residue based on a unit amount of a gas generated is reduced.A gas generating composition comprising nitroguanidine, guanidine nitrate or a mixture thereof as a fuel and further an oxidizing agent. The oxidizing agent is a perchloric acid salt, a nitric acid salt or a mixture thereof, and when the oxidizing agent is ammonium perchlorate, a chlorine neutralizer is further incorporated.

Owner:DAICEL CHEM IND LTD

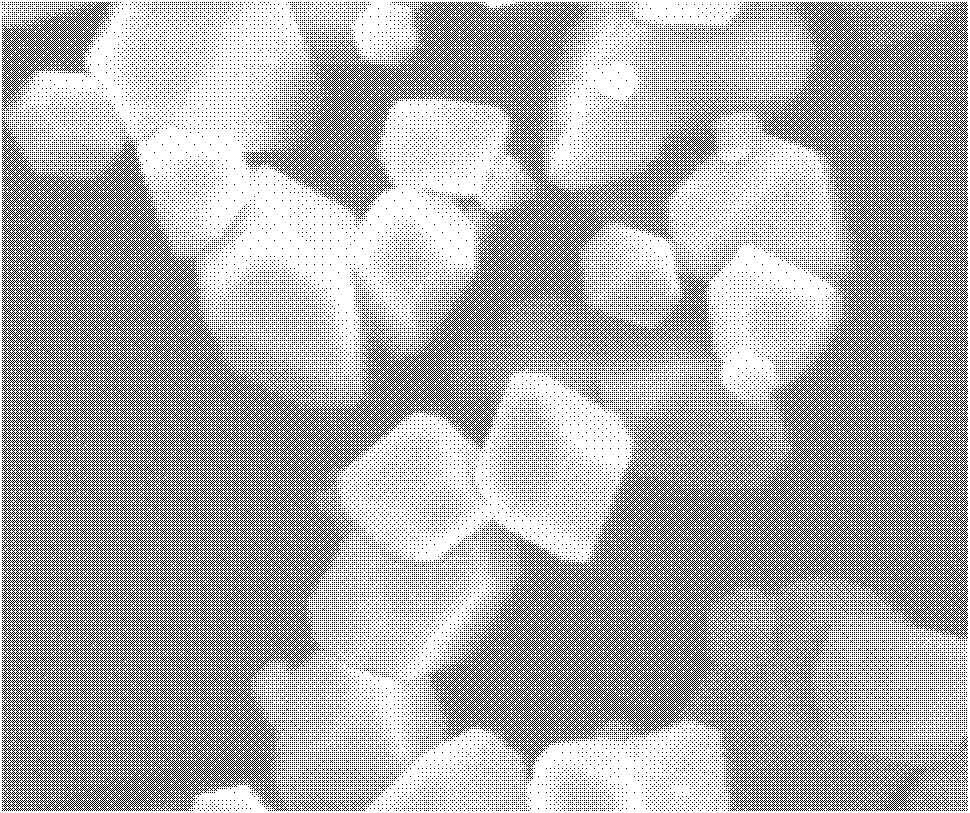

Method for preparing nano catalytic composite materials by utilizing integrating process of ultrasonic-film-anti-solvent method

InactiveCN101863725AEvenly dispersedControllable dispersionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNon solventNano catalyst

The invention relates to a method for preparing nano catalytic composite materials by utilizing an integrating process of an ultrasonic-film-anti-solvent method, comprising the following steps of: (1) the ammonium porchlorate saturated solution preparation process: dissolving ammonium porchlorate into a proper solvent to prepare the ammonium porchlorate saturated solution at certain temperature; (2) the dispersing process of a nano catalyst: uniformly dispersing the nano catalyst into an anti-solvent under ultrasonic action; (3) the preparing process: adding the AP (ammonium porchlorate) saturated solution to a nonsolvent through a film tube under certain pressure, wherein after the anti-solvent carries out desolvation on the solvent, the ammonium porchlorate is separated out and covers on the surfaces of uniformly-dispersed nano particles to form the nano catalytic composite materials; (4) filtering and drying processes: firstly carrying out solid-liquid separation on nano composite particles; and (5) the drying process: drying separated materials at 50-150 DEG C to obtain the nano catalytic composite materials. The nano catalytic composite materials prepared by the method have stable structure, uniform nano catalyst dispersion and controllable particle diameter and appearance.

Owner:NANJING NORMAL UNIVERSITY

Azide-free, gas-generating composition

InactiveUS20050189052A1Burn fasterLow carbon monoxideExplosivesPressure gas generationAlkaline earth metalCopper nitrate

The present invention relates to an azide-free gas-generating composition, in particular for use in safety devices for motor vehicles, comprising a fuel in a proportion of 20 to 60% by weight and consisting of one or more components, and an oxidizer mixture in a proportion of 40 to 80% by weight and consisting of at least three components, each in relation to the total composition. In accordance with the invention, the fuel consists of a guanidine compound in a proportion of at least 95% by weight and a further fuel component in a proportion of 0 to less than 5% by weight, each in relation to the fuel, and the oxidizer mixture consists of one or more transition metal oxides in a proportion of 20 to 80% by weight, basic copper nitrate in a proportion of 0 to 50% by weight, metal chlorate, metal perchlorate, ammonium perchlorate or mixtures thereof in a proportion of 1 to 15% by weight and alkali metal nitrate, alkaline earth metal nitrate or mixtures thereof in a proportion of 1 to 15% by weight, each in relation to the oxidizer mixture.

Owner:TRW AIRBAG SYST

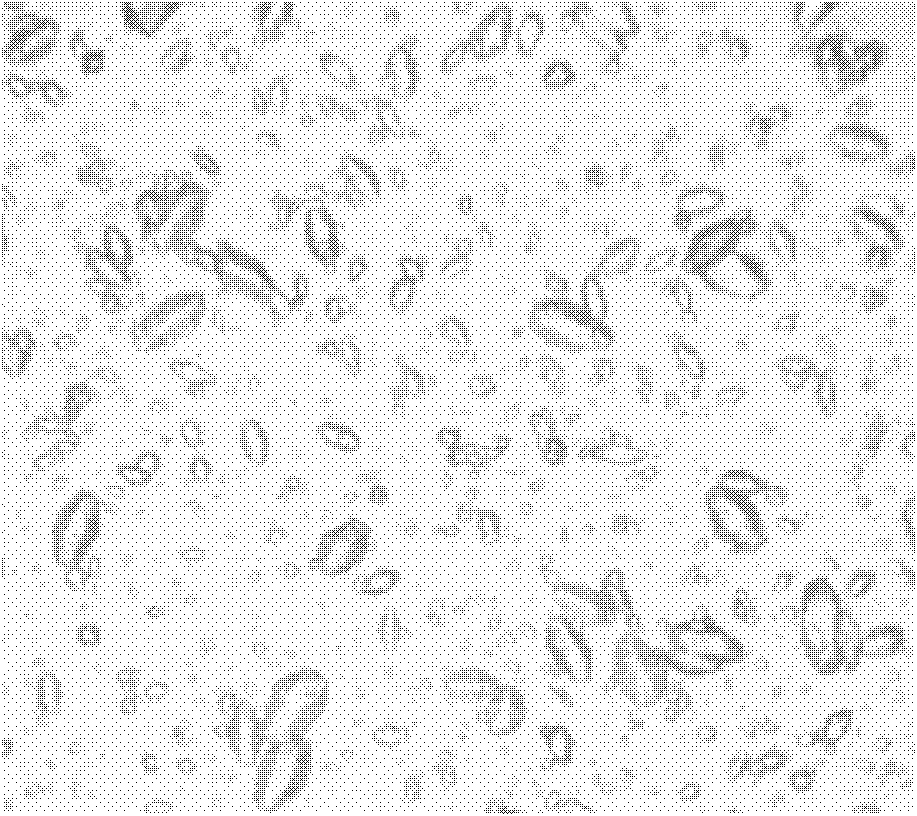

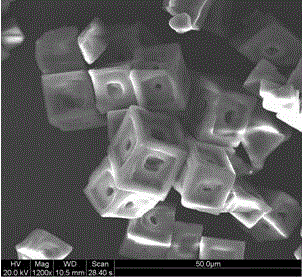

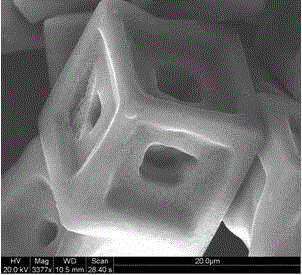

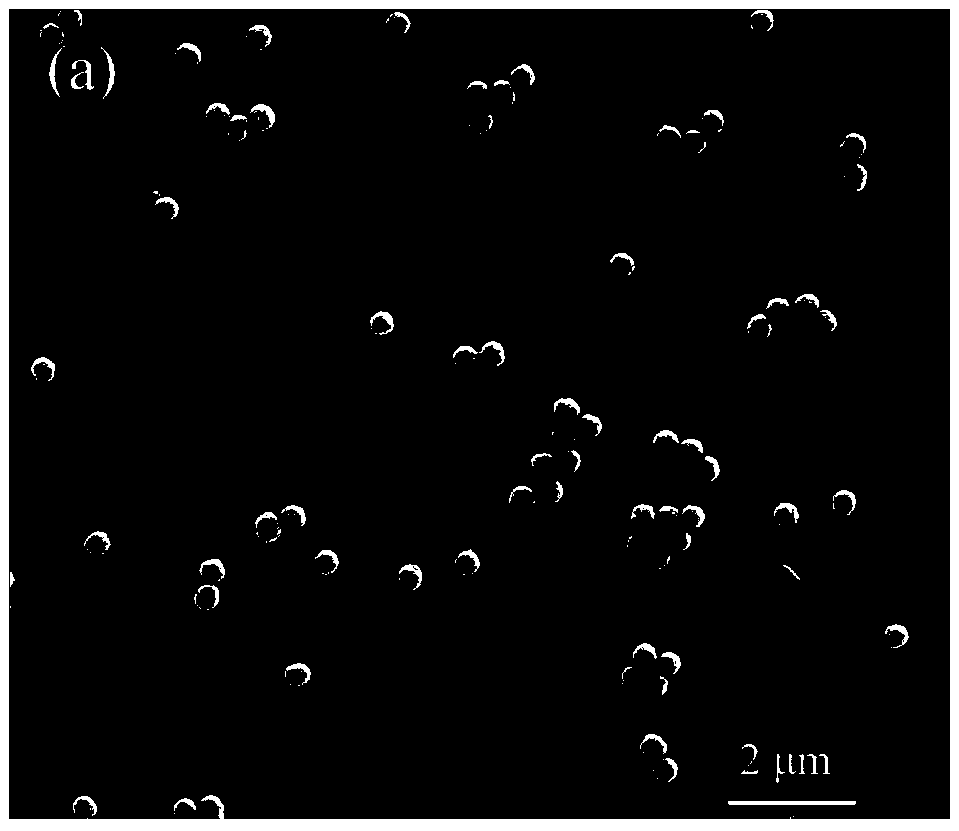

Hollow ultrafine ammonium perchlorate and preparation method thereof

The invention relates to a hollow ultrafine ammonium perchlorate and a preparation method thereof. The ammonium perchlorate is a material with a multilayer cavity structure in the middle part and has the particle size of 1-100mu m. The preparation method adopts a desolvation-recrystallization method, and comprises the following steps of: (1) dissolving the ammonium perchlorate into an N,N-dimethyl formamide / acetone mixed solvent to prepare a saturated solution; (2) under the conditions of certain stirring speed and solvent-anti solvent volume ratio, adding the ammonium perchlorate saturated solution into anti solvent ethyl acetate, and separating out the ammonium perchlorate by crystallization when supersaturation; and (3) after crystallization, filtering, washing and drying the product, thus obtaining the hollow ultrafine ammonium perchlorate. The ammonium perchlorate is an ultrafine powder material and has hollow morphology, thus being good in dispersity and ordered in structure and effectively improving the performance of a solid propellant. The desolvation-recrystallization method is simple, safe and convenient in operation.

Owner:NANJING NORMAL UNIVERSITY +1

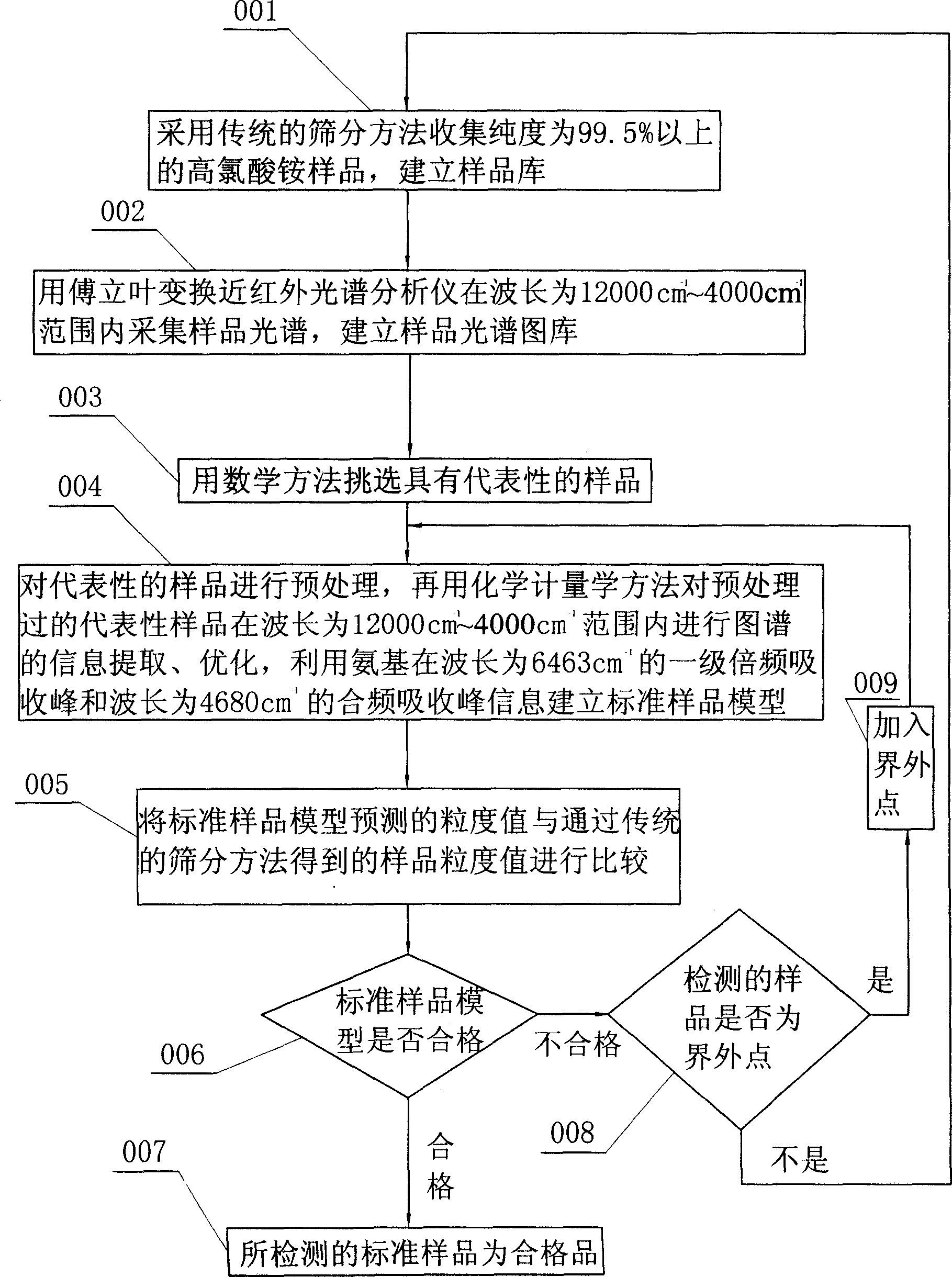

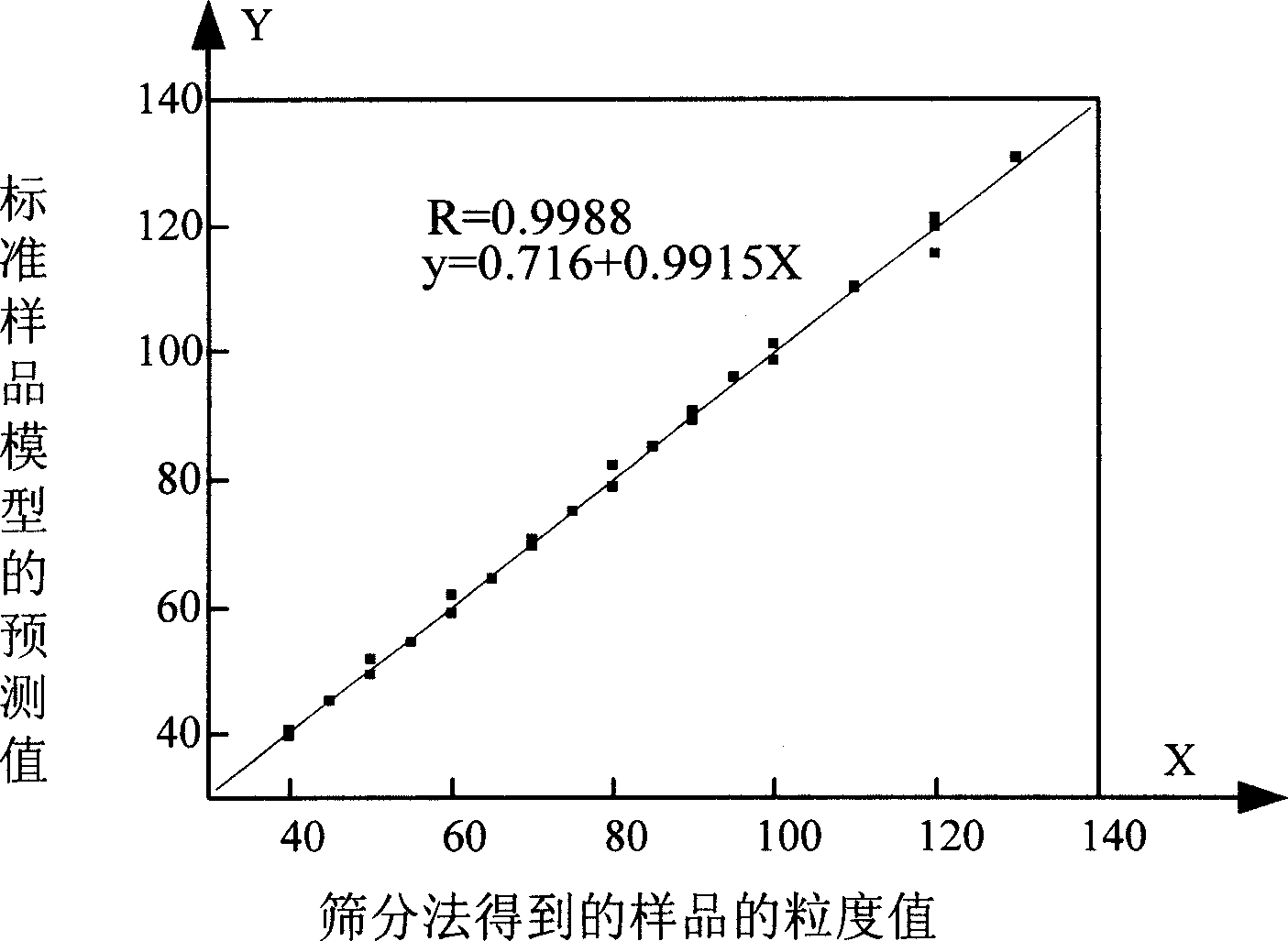

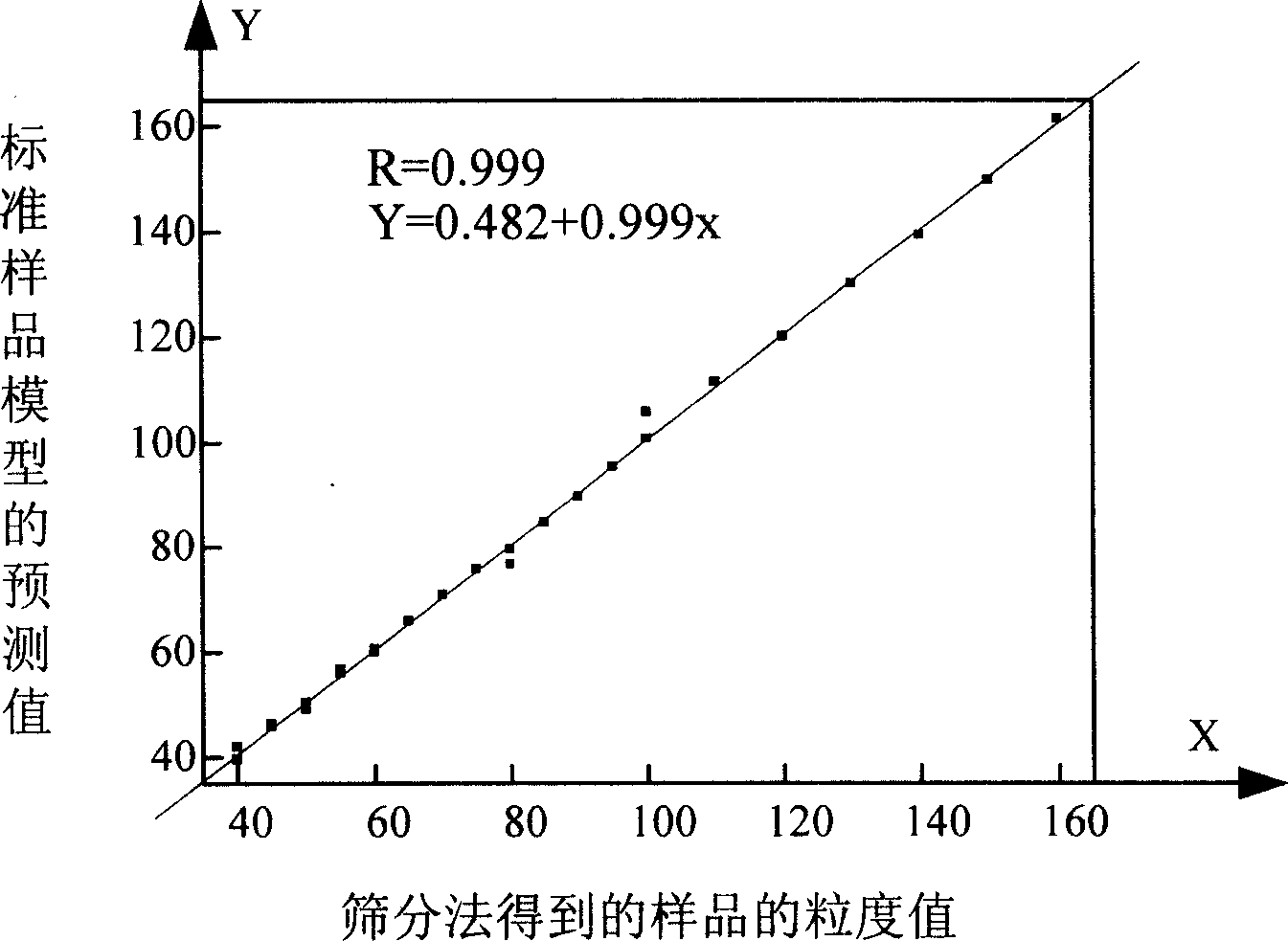

Fast analysis method of ammonium perchlorate particle size in solid propellant

InactiveCN1904584AQuality assuranceAnalysis saves effortParticle size analysisColor/spectral properties measurementsGranularityAmmonium perchlorate

The invention relates to a rapid analysis method for granularity of ammonium perchlorate in solid propellant. It includes the following steps: collecting ammonium perchlorate sample of purity over 99.5% by screen method; gathering sample spectrum and building database; selecting representative sample by math method and taking preprocess, building standard sample model by using the wave length information of amino between first level double frequency absorption peak of 6463cm-1 and combining frequency absorption peak of 4680cm-1; comparing the granularity of pre-testing to that of sample to judge whether it is qualified; if it is not qualified, judging whether it is out-drop point; if it is out-drop point, taking second judgment; if not, returning to the first step. The invention is easy to operate and has rapid analyzing speed.

Owner:HARBIN INST OF TECH

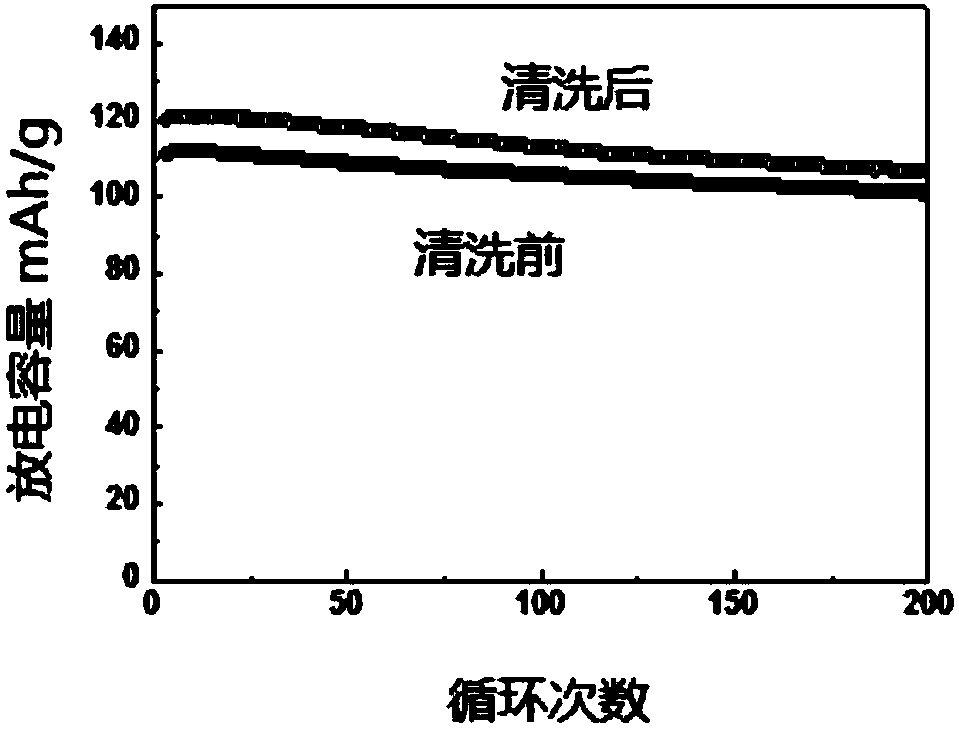

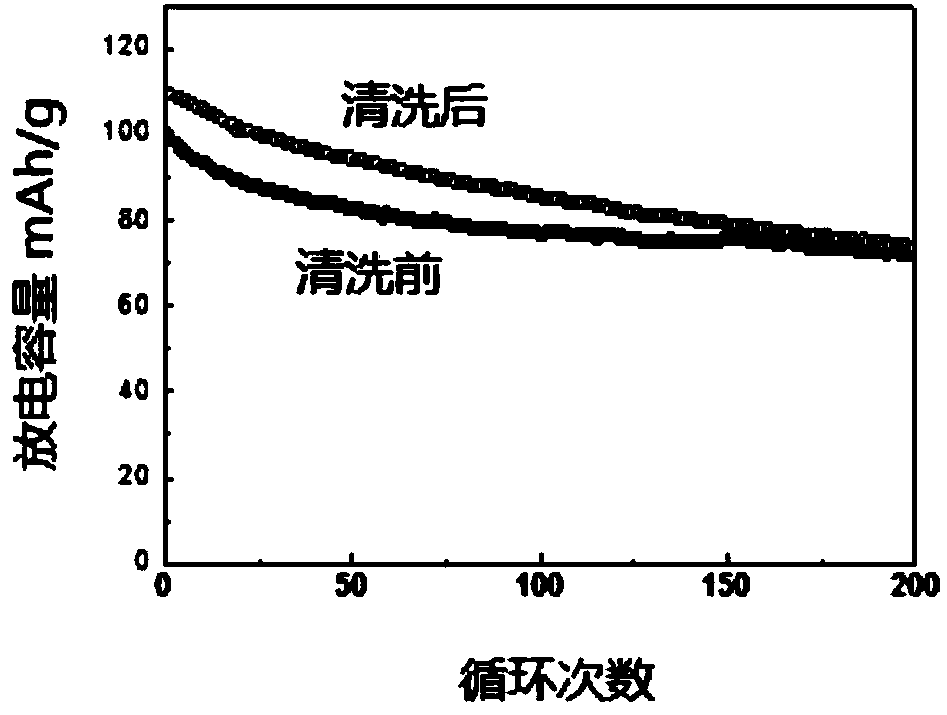

Preparation method of prussian blue type energy storage material

ActiveCN107634220ASimple production processAvoid lossIron cyanidesCell electrodesAmmonium perchlorateSodium-ion battery

The invention provides a preparation method of a prussian blue type energy storage material, and specifically relates to a preparation method of a prussian blue type sodium-ion battery electrode material with high yield. The preparation method comprises the following steps: S1, dissolving divalent transition metal perchlorate and sodium ferrocyanide into water respectively to obtain a divalent transition metal perchlorate solution and a sodium ferrocyanide solution; S2, dissolving sodium perchlorate into water to obtain a sodium perchlorate solution; and S3, mixing the divalent transition metal perchlorate solution and the sodium ferrocyanide solution with the sodium perchlorate solution to obtain a mixed solution, and stirring and standing the mixed solution to obtain a sediment product;and separating and drying the sediment product to obtain the prussian blue type energy storage material. According to the preparation method, a great deal of loss of the prussian blue type material inthe cleaning process is avoided, and high-yield production can be realized. The preparation method is simple and high in yield, and is easy for industrial large-scale production.

Owner:浙江钠创新能源有限公司

Micro-smoke colorful bright bead for firework

The invention discloses a colorful trace fume star used in fireworks. The star consists of an effect agent core, an intermediate agent isolation layer and an ignition agent layer. A layer of intermediate agent is stuck on the effect agent core granules as the intermediate agent isolation layer; and a layer of black powder is stuck on the intermediate agent isolation layer as the ignition agent layer. The effect agent core comprises the following ingredients by weight: 15-30 parts of ammonium perchlorate, 5-15 parts of a colorant, 50-75 parts of single-base and double-base agent and 0-5 parts of magnalium. The intermediate agent comprises the following ingredients by weight: 20-35 parts of potassium perchlorate, 5-15 parts of the colorant, 50-75 parts of the single-base and double-base agent and 0-5 parts of the magnalium. The colorful trace fume star used in fireworks generates fume which is less than 30% of that of the existing agent after burning, and has good moisture resistant performance and long shelf life; and visual observation at the burning field proves that burning rate, lightness and color saturation of the star achieve or exceed the effects of the existing products.

Owner:浏阳市达浒花炮艺术焰火燃放集团有限公司

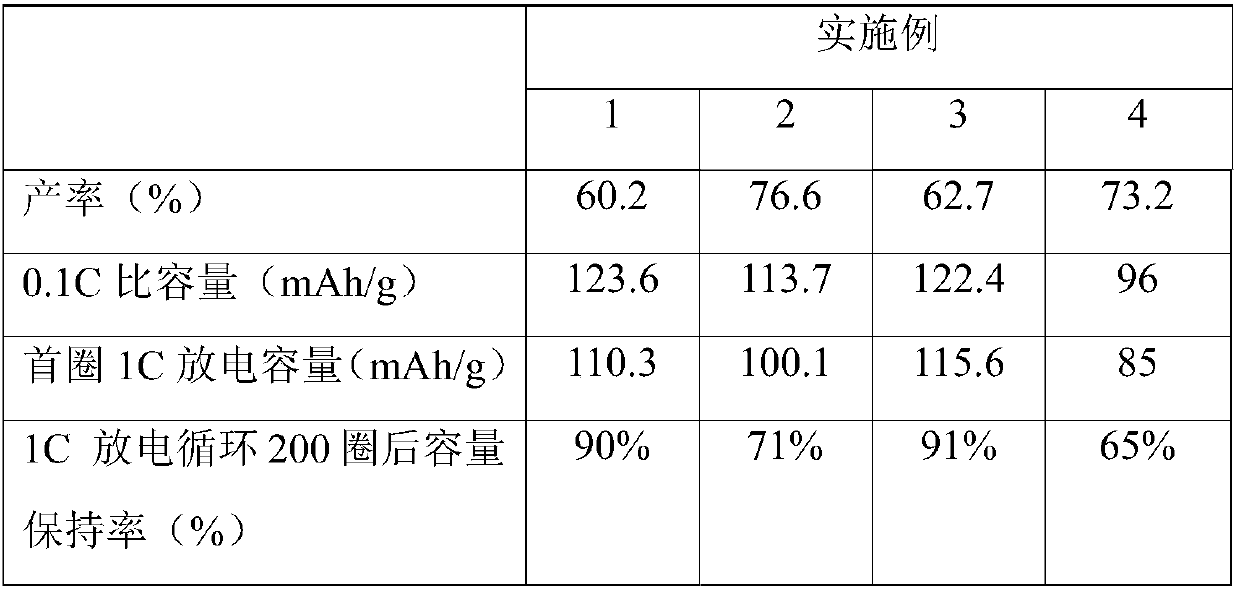

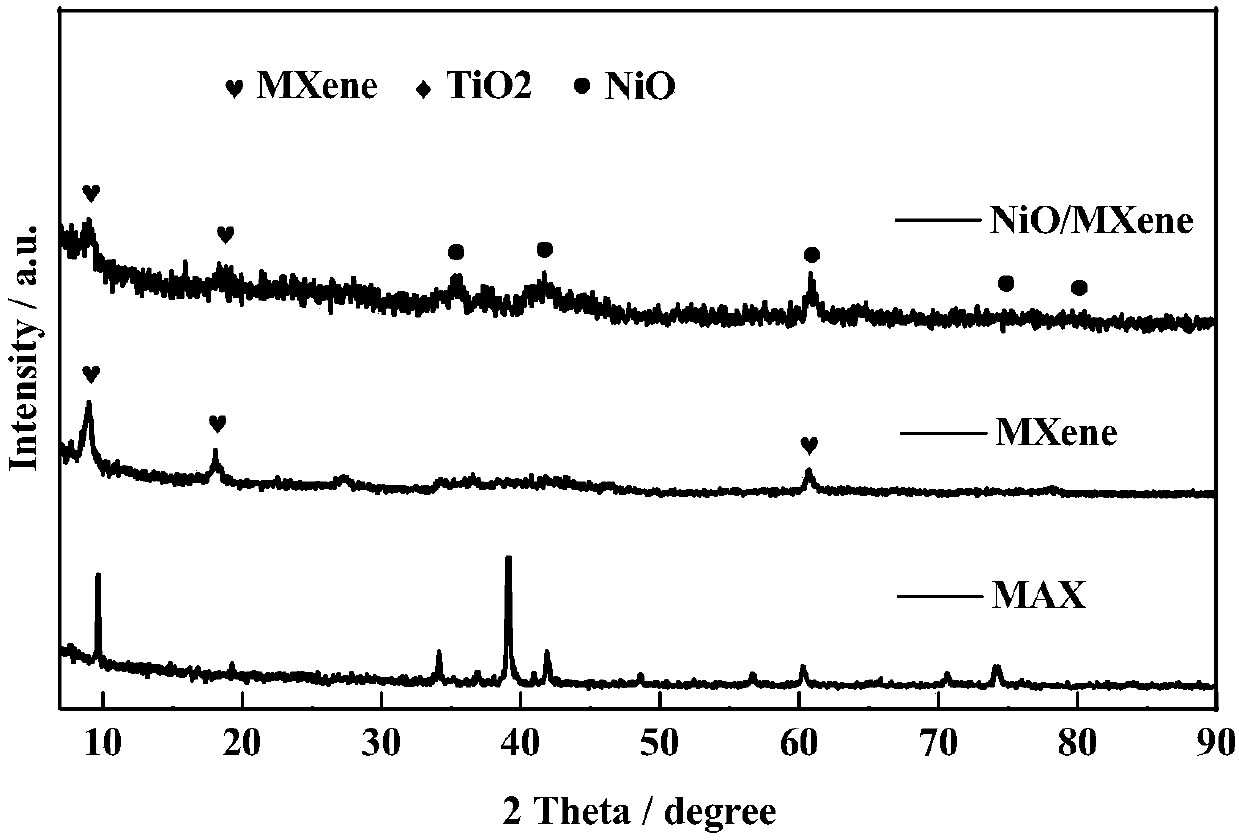

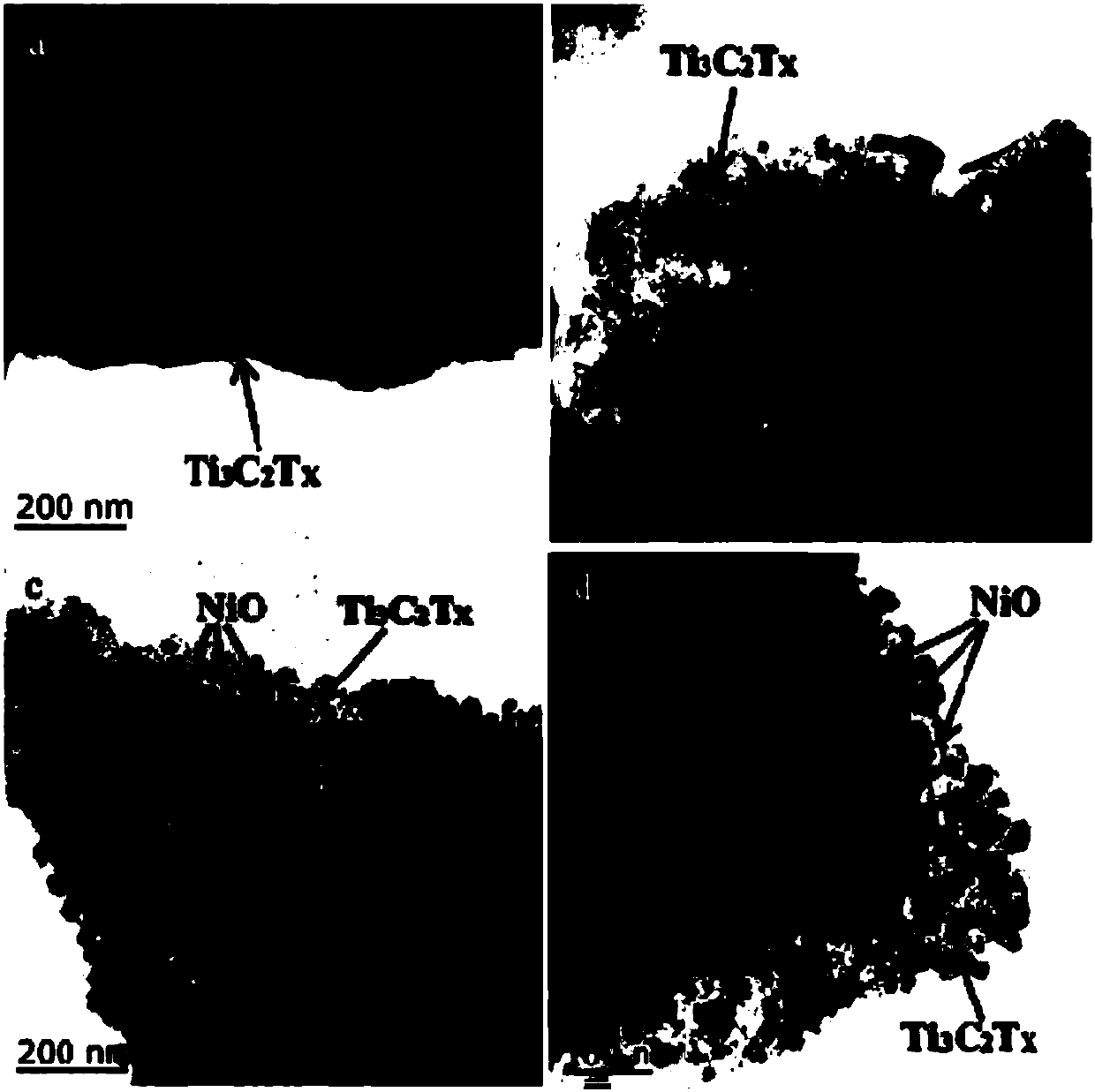

NiO/MXene composite material as well as preparation method and application thereof

ActiveCN107814670AIncrease migration rateEvenly dispersedPhysical/chemical process catalystsExplosive working-up apparatusNickel saltTube furnace

The invention discloses a NiO / MXene composite material as well as a preparation method and application thereof. The composite material takes MXene as a supporting carrier, and NiO particles are uniformly dispersed on the surface of MXene, wherein the mass ratio of NiO to MXene is (2.98-50):50. The preparation method comprises the following =steps: (1) etching a certain amount of MAX material intoa HF acid solution with certain concentration, so as to obtain an MXene material; (2) mixing and stirring a certain amount of nickel salt and the MXene obtained in the step (1) into a beaker while dropwise adding a NaOH solution with certain concentration, stirring for a period of time, then washing, centrifuging, and carrying out vacuum freeze drying; and (3) putting a mixture prepared in the step (2) into a tubular furnace, and calcining in nitrogen atmosphere, so that the target product is obtained. The NiO / MXene composite material is applied to thermal decomposition of ammonium perchlorate(AP) and shows better catalytic effect; meanwhile, preparation technology is simple, and the NiO / MXene composite material has a good application prospect.

Owner:NANJING UNIV OF SCI & TECH

Insensitive propellant composition

InactiveUS20120227875A1Improved SCO propertySuitable for useAmmonium perchlorate explosive compositionsAmmonium perchlorateRocket

The present invention relates to a propellant composition which comprises hydroxy-terminated polyether (HTPE), N-butyl-(2-nitratoethyl)nitramine (BuNENA) and ammonium perchlorate (AP) and is insensitive to impact and thermal reactions and thus suitably used for a solid rocket propulsion unit.

Owner:AGENCY FOR DEFENSE DEV

Gas generating agent for automobile safe gasbag and preparing method thereof

InactiveCN101234943AEasy to mold and releaseImprove adsorption capacityPressure gas generationCarboxymethyl celluloseSesquioxide

The invention discloses an automobile airbag gas generating agent and a preparation method thereof. The invention is characterized in that 30 to 50 percent of guanidine nitrate, 5 to 20 percent of basic cupric nitrate, 10 to 25 percent of strontium nitrate, 3 to 10 percent of ammonium perchlorate, 2 to 6 percent of iron sesquioxide, 2 to 10 percent of sodium carboxymethyl cellulose and 2 to 5 percent of caoline taken in accordance with the weight percentages are mixed thoroughly; after distilled water is added, the mixture is heated and kneaded and cooled for granulation; obtained particles are then dried and sieved to get the gas generating agent. Raw materials for products to be made with the method of the invention are easy to acquire and have low prices. The production process is safe and conducive to safety of automobile occupants and also to environment protection.

Owner:烟台安泰德汽车安全系统有限公司

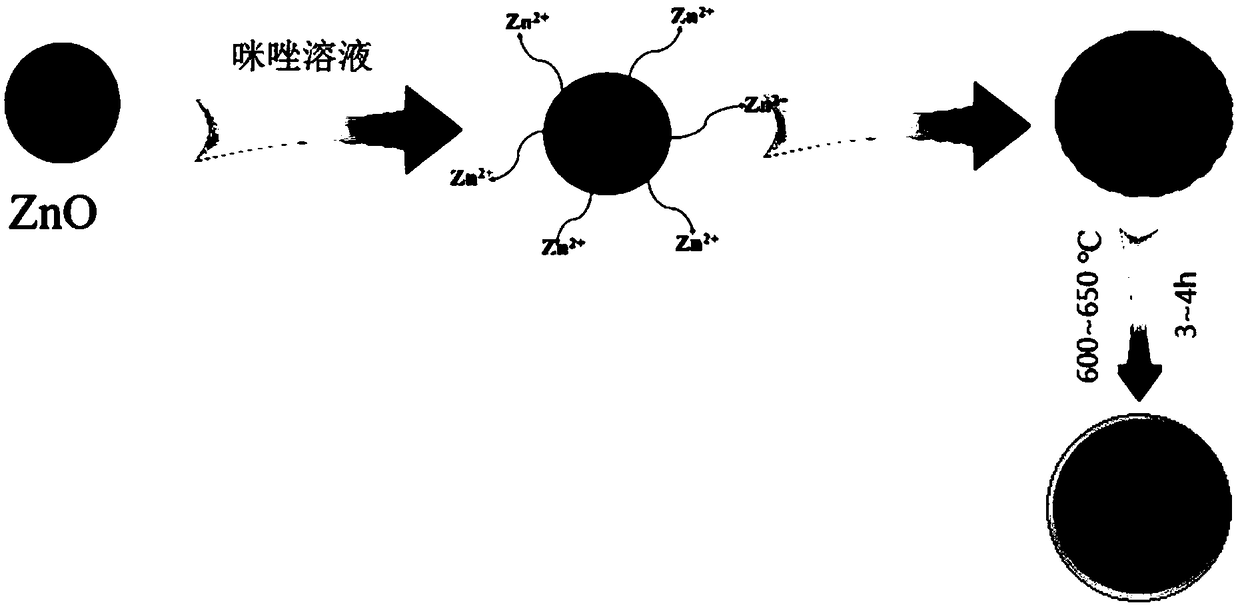

MOFs (Metal-Organic Frameworks)-based carbon-cladded ZnO core-shell structure nano-material and preparation method thereof

ActiveCN108786781AGood dispersionImprove catalytic performanceMetal/metal-oxides/metal-hydroxide catalystsDecompositionZno nanoparticles

The invention provides a MOFs (Metal-Organic Frameworks)-based carbon-cladded ZnO core-shell structure nano-material and a preparation method thereof and relates to a ZnO composite nano-material and apreparation method thereof, aiming at solving the technical problem that the decomposition speed is slow when an existing single ZnO catalyst is used for catalyzing thermal decomposition reaction ammonium perchlorate. The nano-material provided by the invention is a nano-sphere which takes a ZnO spherical nanoparticle as a core and carbon as a shell. The preparation method comprises the followingsteps: 1, dissolving zinc acetate in diethylene glycol and reacting, and taking supernatant; 2, then dissolving the zinc acetate in the diethylene glycol; adding the supernatant and reacting to obtain ZnO nanoparticles; 3, enabling 2-methylimidazole and the ZnO nanoparticles to react to prepare 2-methylimidazole zinc salt cladded ZnO core-shell structure spherical particles; 4, calcining to obtain the carbon-cladded ZnO core-shell structure nano-material. When the material is used for catalyzing thermal decomposition of AP, a decomposition peak is advanced to 293 to 295 DEG C and the apparentdecomposition heat reaches 1,420 to 1,435J / g, so that the material can be applied to the field of catalysis.

Owner:HARBIN INST OF TECH

Micro smoke gun propellant for fireworks

The invention discloses a micro smoke gun propellant for fireworks, which comprises the following components in part by weight: 30-70 parts of nitrocotton, 5-30 parts of moistureproof ammonium perchlorate, 2-10 parts of reducing agent and 5-20 parts of high-nitrogen substance. The safety performance indexes of the micro smoke gun propellant for fireworks completely meet the requirements of the national standard. The micro smoke gun propellant for fireworks not only can meet the propelling requirement of the product, but also produces micro smoke when the gun propellant is combusted. According to the light transmittance detection result, the smoke quantity produced by the gun propellant is only about 30% of that of the traditional equivalent corresponding products.

Owner:浏阳市达浒花炮艺术焰火燃放集团有限公司

Environment protection type micro-fume firecrackers

InactiveCN101275820AIncrease productivityGranulation realizationFirecrackersFirecrackerAdditive ingredient

The invention discloses an environment-friendly minimum smoke firecracker, composed of a high sounder, an igniting wrapped powder on the surface of the high sounder, a lead wire and a casing layer. The high sounder has a lead-free high sounder as a sounder of the firecracker; the igniting wrapped powder has smokeless igniting powder, ingredient and weight proposition of which is as follows: nitrated cellulose 60 to 90 parts; ammonium perchlorate 10 to 40 parts; antiodorant 5 parts; and strong rubber powder 2 parts; the finished product of firecracker is produced by wrapping the lead-free smokeless sounder with smokeless paper and the smokeless lead wire, so as to ensure each step of setting off firecracker is contamination free such as smoke, pungent smell, residue, etc., and implement minimum smoke and even smokeless effect.

Owner:湖南省浏阳金生花炮有限公司

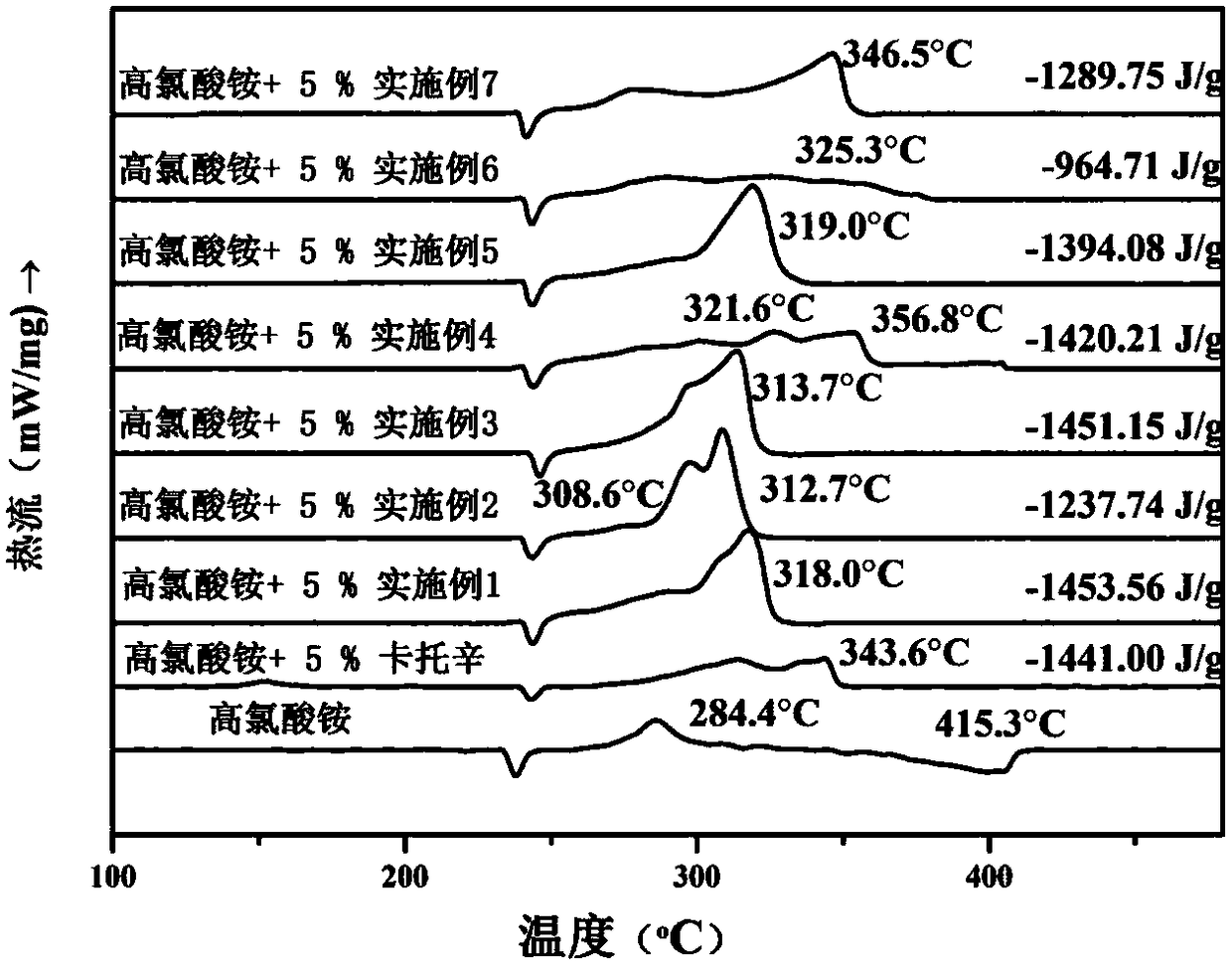

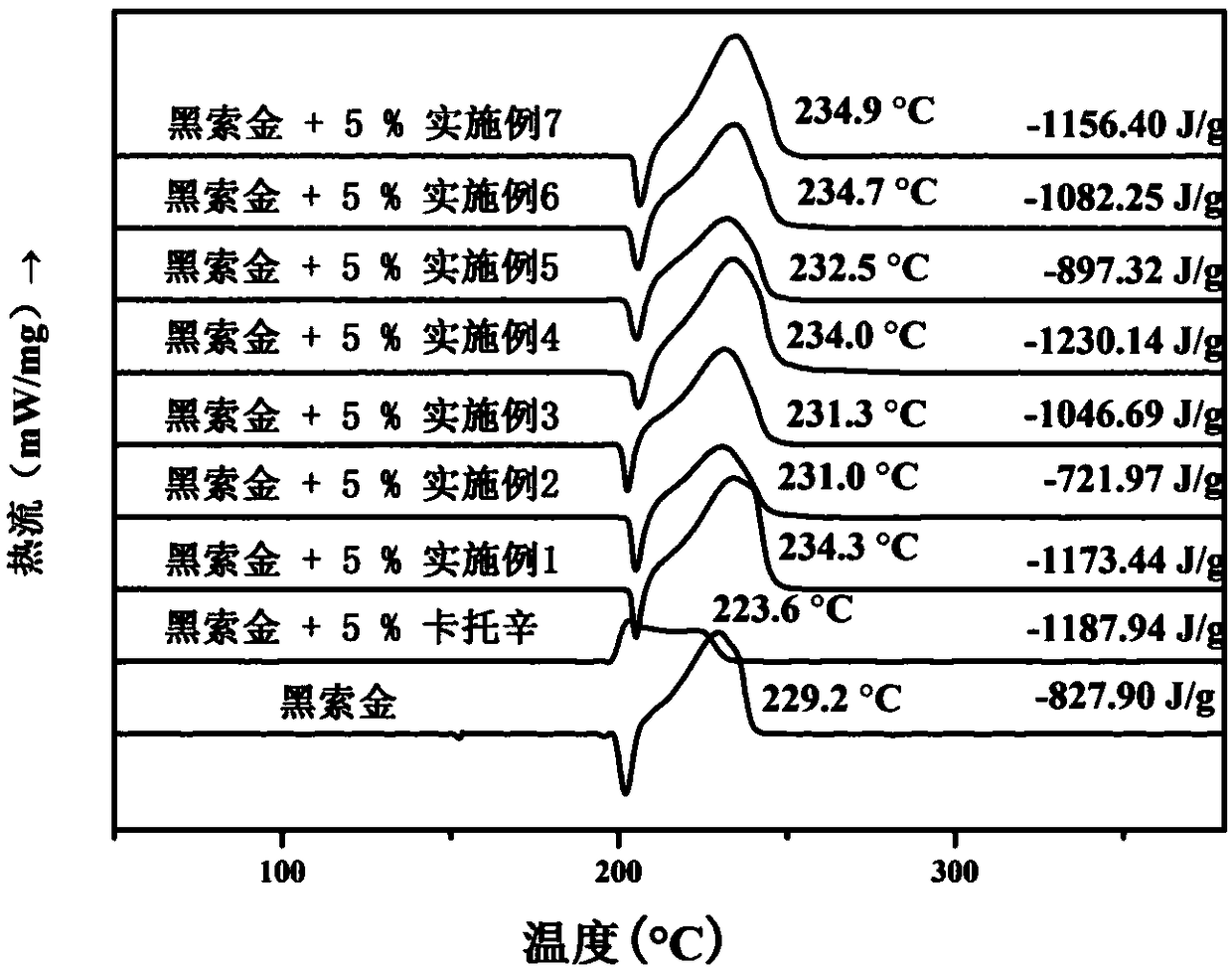

N-ferrocenylmethyl-3-amino-1,2,4-triazole energy-containing transition metal complex and preparation method thereof

ActiveCN108558957AEasy to migrateSolve volatileMagnesium fertilisersMetallocenesBurn rateNitrogen gas

The invention discloses an N-ferrocenylmethyl-3-amino-1,2,4-triazole energy-containing transition metal complex and a preparation method thereof. The structural formula of the complex is as shown in the description, wherein M represents Cu, Zn, Mn, Ni, Co, Cd or Fe, L is 1H, 1'H-(5,5'-bistetrazole)-1,1'-diol dianion, and x is an integer from 0 to 3. The complex disclosed by the invention is simplein preparation method, low in cost and high in yield and has better burning catalysis effect on main components (ammonium perchlorate and hexogen) of a composite solid propellant; the N-ferrocenylmethyl-3-amino-1,2,4-triazole ligand in the complex has high nitrogen content, has higher positive enthalpy of formation and has synergistic catalysis effect with transition metal ions; and by addition of energy-containing compound 1,1'-dihydroxy-5,5'-bistetrazole disodium salt tetrahydrate, the sensitivity of a burning rate catalyst can be reduced, the energy can be supplied for the solid propellant, and the decomposed and released nitrogen gas is friendly to the environment.

Owner:SHAANXI NORMAL UNIV

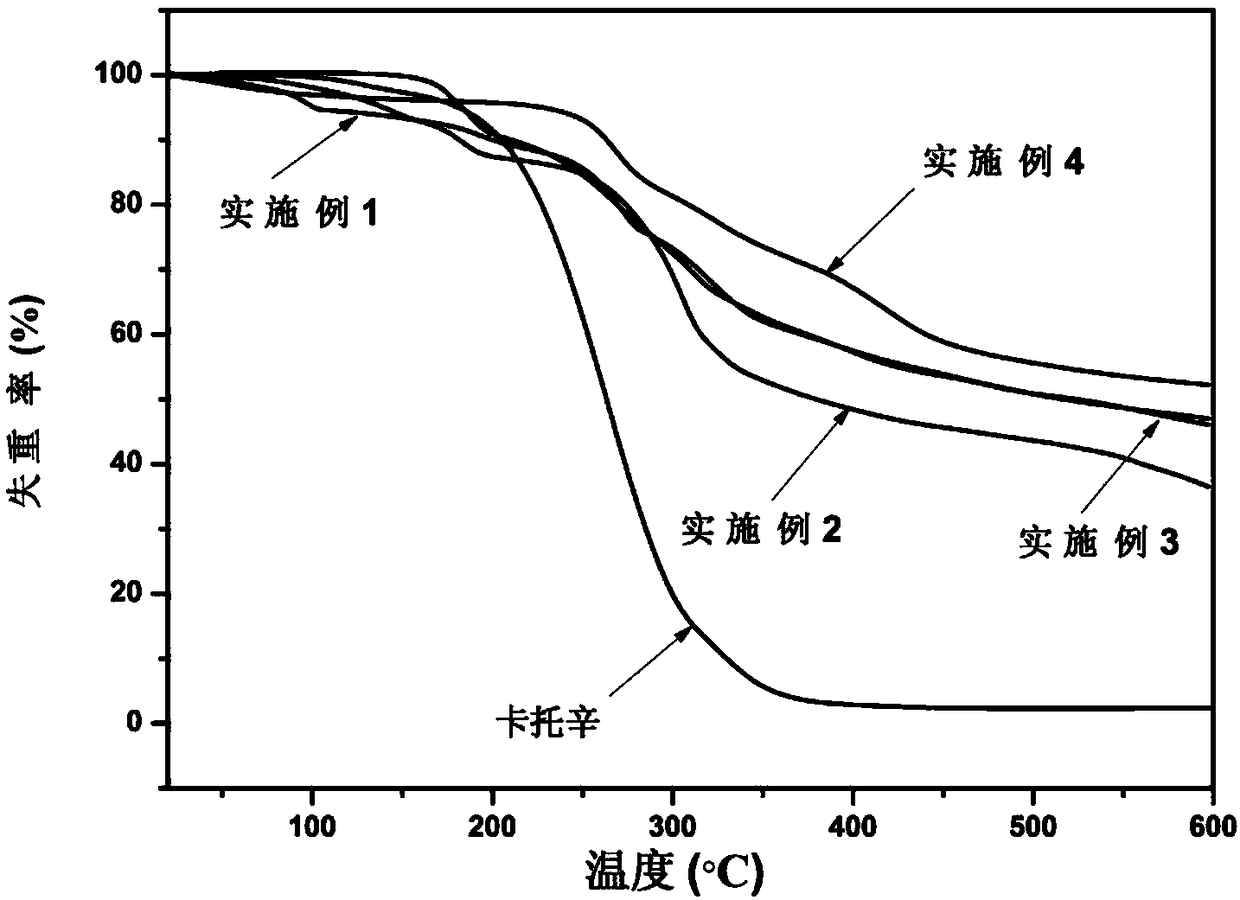

Poly (methyl) acrylic acid ferrocene acyloxy ethyl ester burning-rate accelerator and propellant containing same and preparation method thereof

InactiveCN101659893ASimple structureHigh molecular weightSolid fuelsPressure gas generationDecompositionFerrocene

The invention discloses a poly (methyl) acrylic acid ferrocene acyloxy ethyl ester burning-rate accelerator and a propellant containing the burning-rate accelerator and a preparation method thereof, wherein the molecular weight (Mw) of the poly (methyl) acrylic acid ferrocene acyloxy ethyl ester burning-rate accelerator is 6000 to 16000, and the structural formula is shown as follow, wherein R1 is -H or CH3; and the propellant comprises the following components by the mass percent: 70 to 80 percent of oxidant, 12 to 25 percent of binder, 1 to 3 percent of poly (methyl) acrylic acid ferrocene acyloxy ethyl ester burning-rate accelerator and 4 to 6 percent of curing agent. The invention has the advantages that the burning-rate accelerator has simple structure, high molecular weight and stable performance and can distinctly reduce decomposition temperature of ammonium perchlorate, and the effect is better than that of normal ferrocene burning-rate accelerator; and the poly (methyl) acrylic acid ferrocene acyloxy ethyl ester burning-rate accelerator is not apt to be transferred during storage in the propellant so as to lead the preparation process of the propellant to be safer; and the burning-rate catalysis effect of the propellant adopting the poly (methyl) acrylic acid ferrocene acyloxy ethyl ester burning-rate accelerator is better.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com