Method for preparing nano catalytic composite materials by utilizing integrating process of ultrasonic-film-anti-solvent method

A technology of nano-catalysis and composite materials, which is applied in the field of preparation of nano-catalysis composite materials in the integrated process of ultrasonic-membrane-anti-solvent method, which can solve the problem of uniform dispersion of nano-materials, difficulty in obtaining particle size and shape of nano-catalytic composites The problem of dispersion of materials and nanomaterials cannot be solved, so as to achieve the effect of simple process, low production cost and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

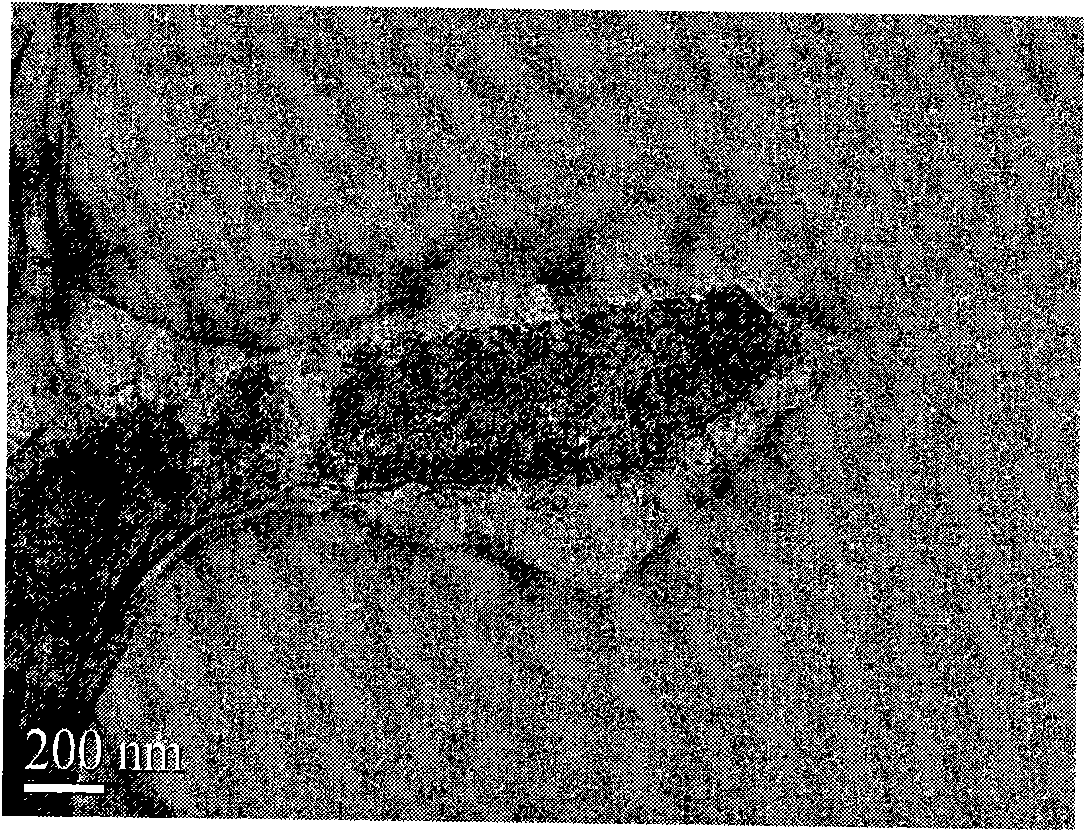

[0029] Embodiment 1, nanometer Fe 2 o 3 Preparation of / AP Catalytic Composite

[0030] First, under the action of ultrasonic waves (ultrasonic power is 1000w, ultrasonic frequency is 10 6 Hz, ultrasonic time is 15min), a certain amount of nano-Fe 2 o 3 (30nm) dispersed in 200mL ethyl acetate. Then, under the action of 0.3MPa nitrogen, press 20mL of AP saturated acetone solution into the crystallization tank, then AP will be converted into nano-Fe 2 o 3 As the nucleus, grow on its surface and finally form nano-Fe 2 o 3 / AP Composite Particles. The prepared nanocomposite material was filtered, washed, and then vacuum-dried at 60° C. for 3 h.

Embodiment 2

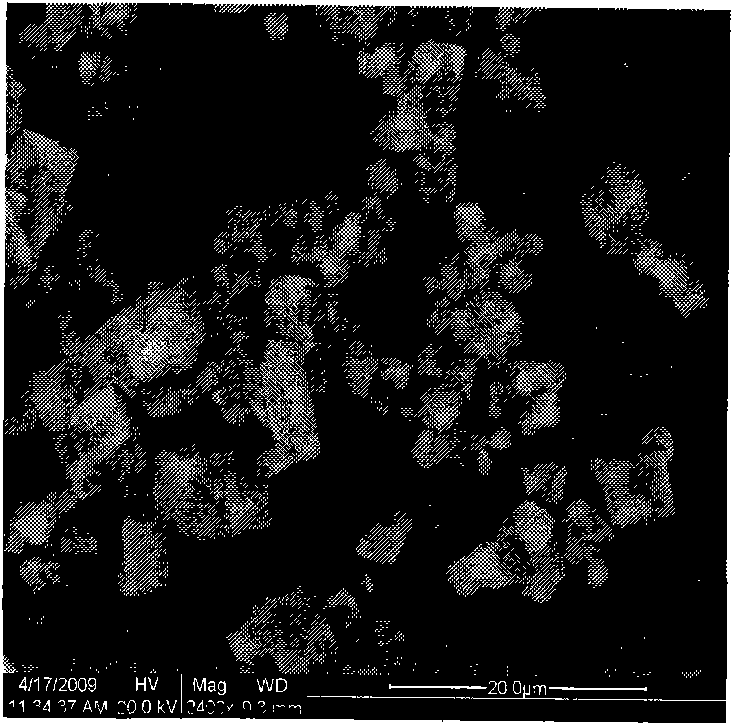

[0031] Embodiment 2, the preparation of nanometer CuO / AP catalytic composite material

[0032] First, under the action of ultrasound (ultrasonic power is 1200w, ultrasonic frequency is 10 7 Hz, ultrasonic time is 20min), a certain amount of nano-CuO was dispersed in 300mL ethyl acetate. Then, under the action of 0.4MPa nitrogen, press 10mL of AP saturated DMF solution into the crystallization tank, then AP will use nano-CuO as the nucleus, grow on its surface and finally form nano-CuO / AP composite particles. The prepared nanocomposite material was filtered, washed, and then vacuum-dried at 60° C. for 3 h.

Embodiment 3

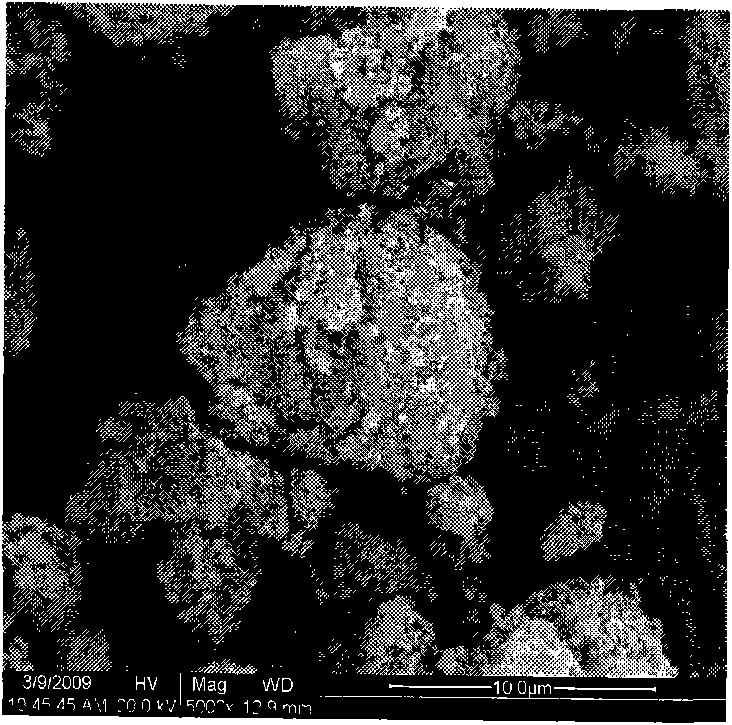

[0033] Embodiment 3 is basically the same as Embodiment 1, but has the following changes:

[0034] The nano catalyst is Co 2 o 3 ; The particle size of the nano-catalyst is 10nm.

[0035] The solvent of the ammonium perchlorate is water; the non-solvent of the ammonium perchlorate is ethanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com