Patents

Literature

31results about How to "Control supersaturation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

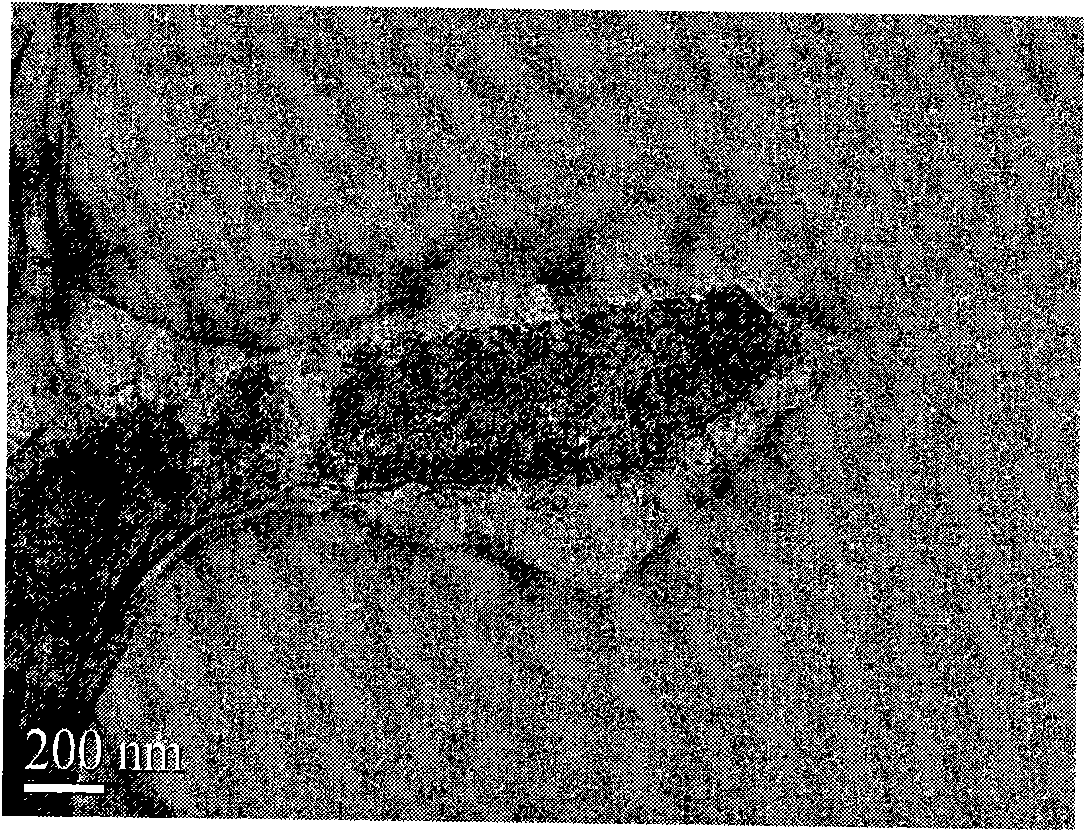

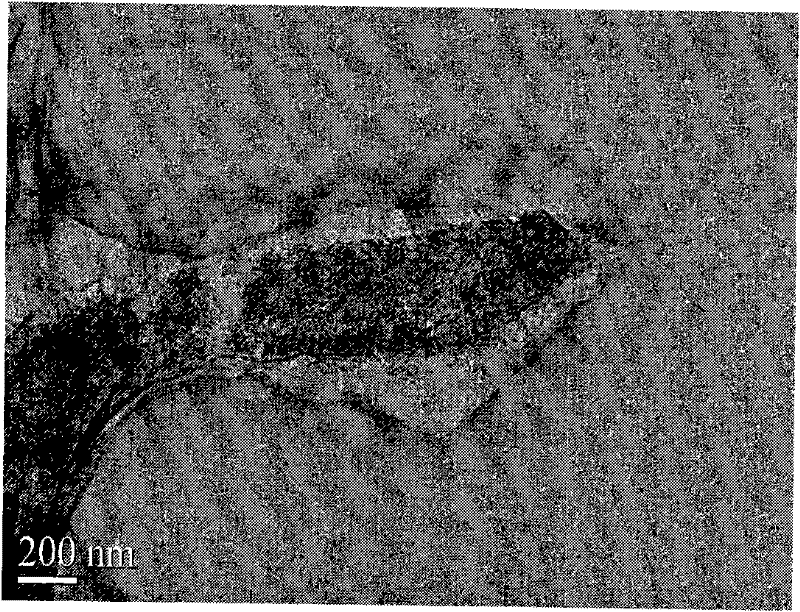

Method for preparing nano catalytic composite materials by utilizing integrating process of ultrasonic-film-anti-solvent method

InactiveCN101863725AEvenly dispersedControllable dispersionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNon solventNano catalyst

The invention relates to a method for preparing nano catalytic composite materials by utilizing an integrating process of an ultrasonic-film-anti-solvent method, comprising the following steps of: (1) the ammonium porchlorate saturated solution preparation process: dissolving ammonium porchlorate into a proper solvent to prepare the ammonium porchlorate saturated solution at certain temperature; (2) the dispersing process of a nano catalyst: uniformly dispersing the nano catalyst into an anti-solvent under ultrasonic action; (3) the preparing process: adding the AP (ammonium porchlorate) saturated solution to a nonsolvent through a film tube under certain pressure, wherein after the anti-solvent carries out desolvation on the solvent, the ammonium porchlorate is separated out and covers on the surfaces of uniformly-dispersed nano particles to form the nano catalytic composite materials; (4) filtering and drying processes: firstly carrying out solid-liquid separation on nano composite particles; and (5) the drying process: drying separated materials at 50-150 DEG C to obtain the nano catalytic composite materials. The nano catalytic composite materials prepared by the method have stable structure, uniform nano catalyst dispersion and controllable particle diameter and appearance.

Owner:NANJING NORMAL UNIVERSITY

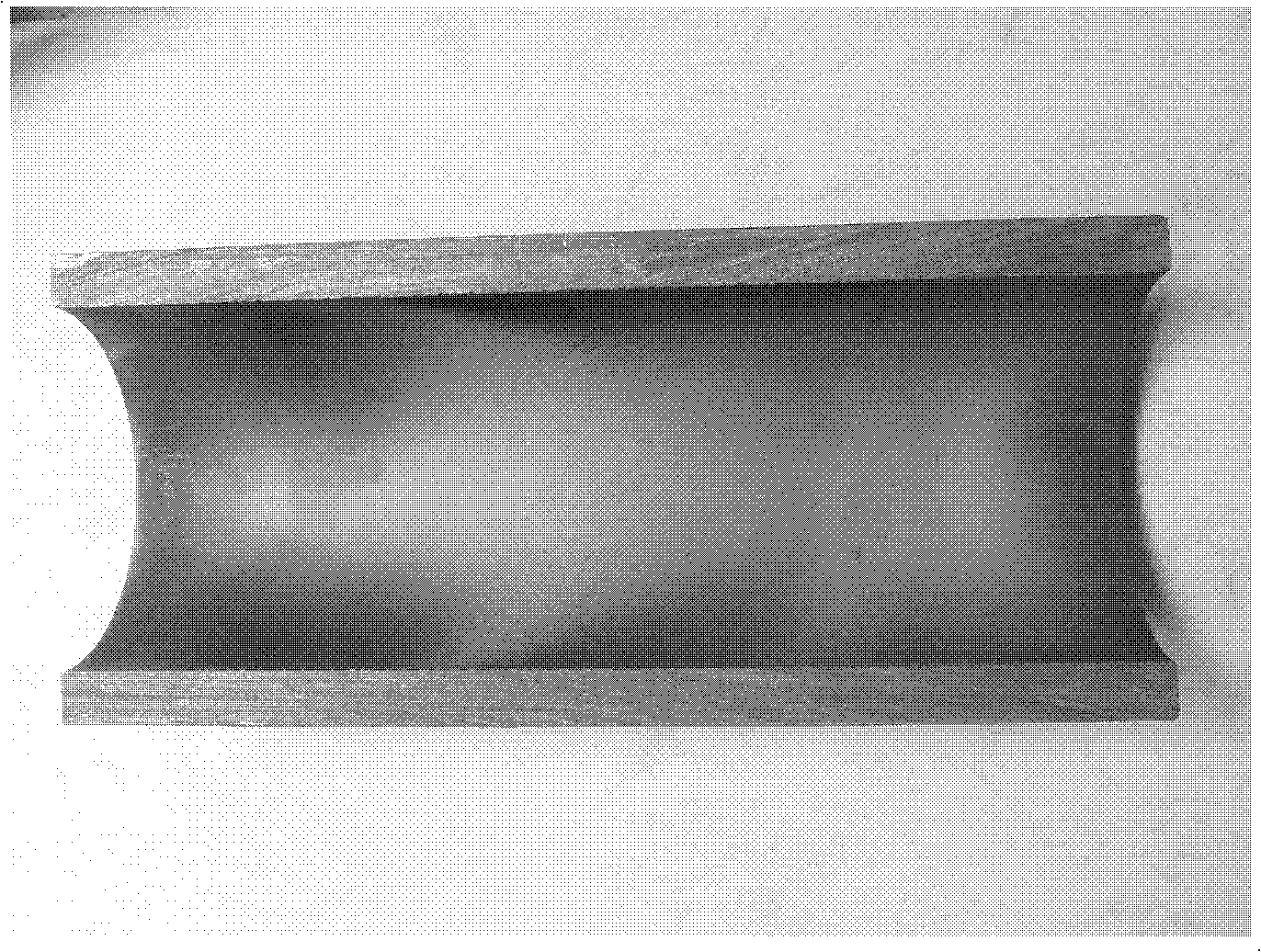

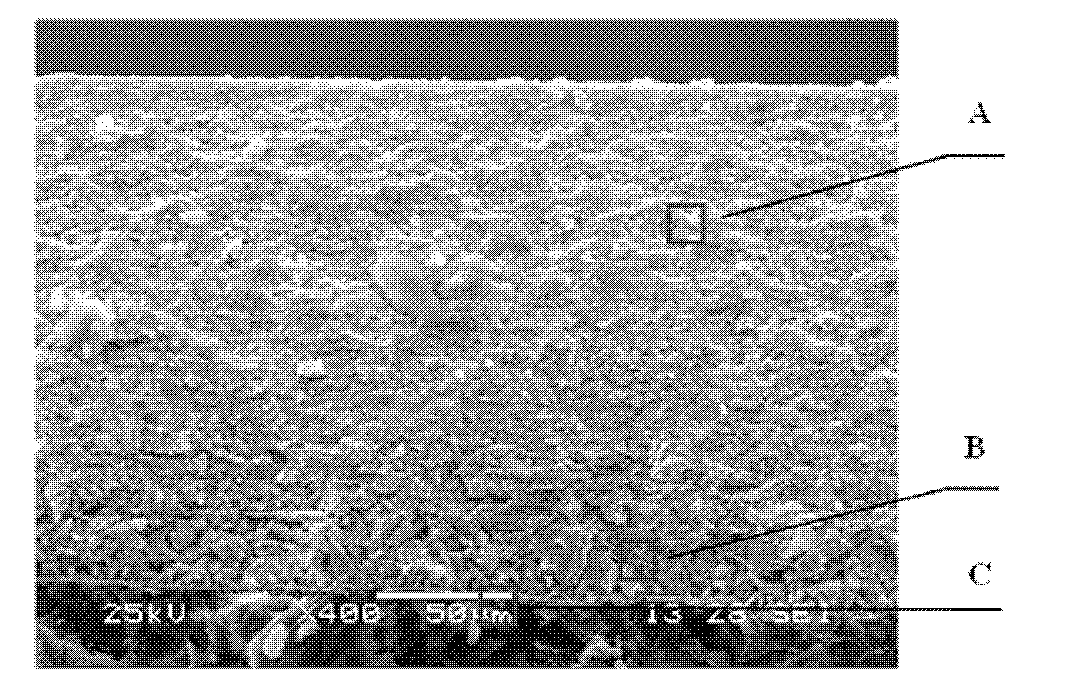

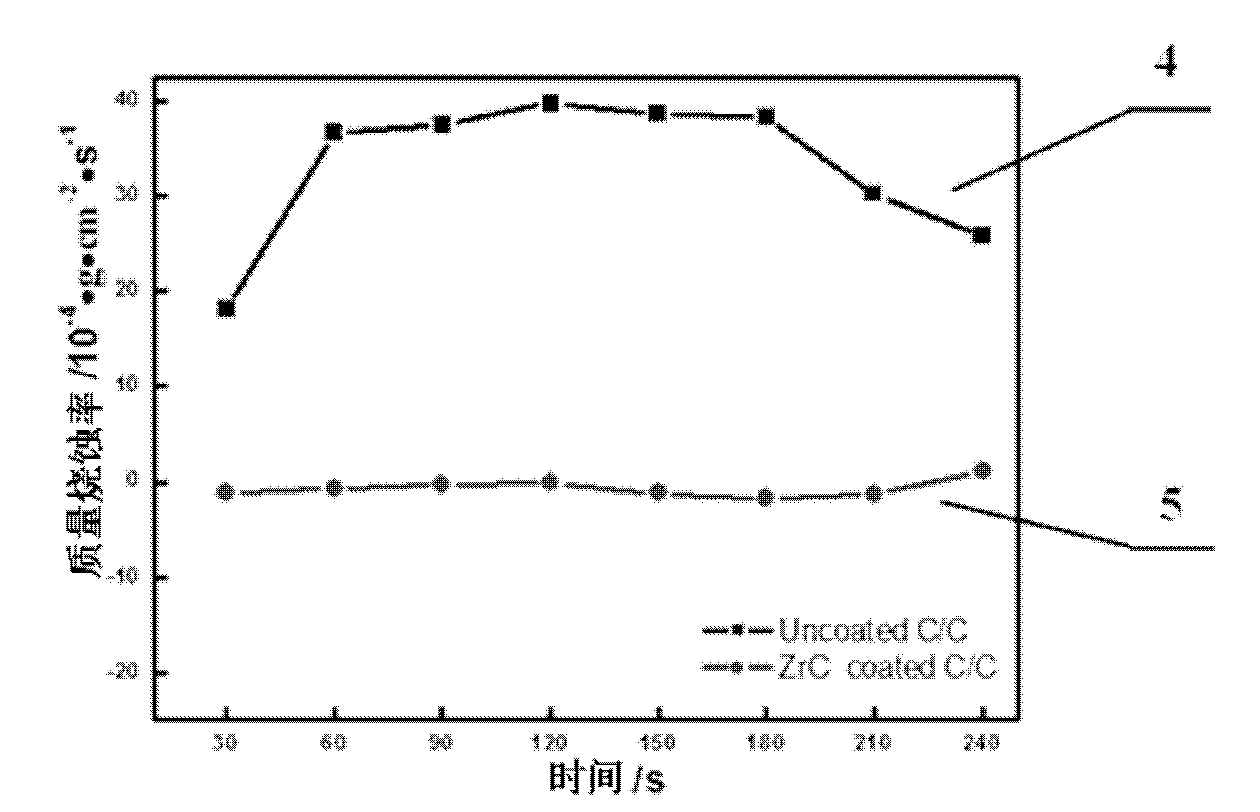

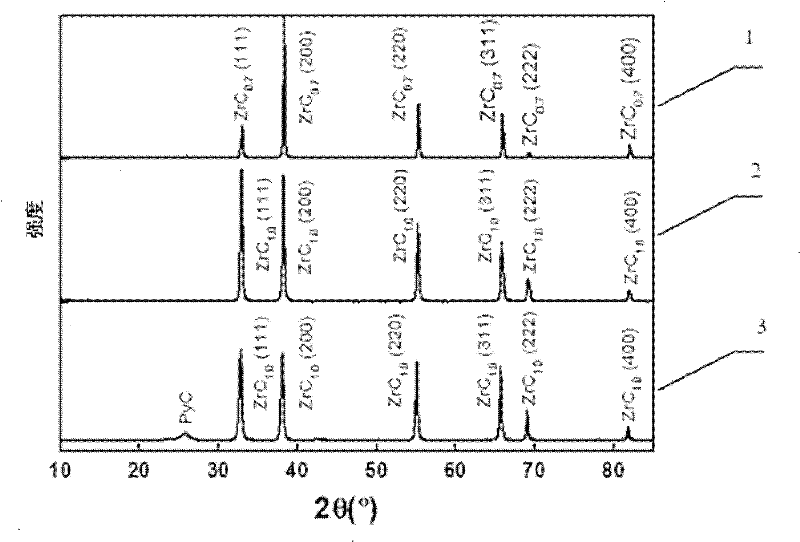

Surface erosion-resistant composite coating of carbon/carbon composite, preparation method and application thereof

InactiveCN101791883AControl supersaturationActive connectionLayered productsChemical vapor deposition coatingCarbon compositesGas phase

The invention relates to a surface erosion-resistant composite coating of a carbon / carbon composite, which sequentially consists of ZrC0.7 / ZrC1.0 / ZrC1.0+C form outside to inside. The preparation method of the surface erosion-resistant composite coating comprises the following three steps: the preparation of a basal layer ZrC1.0+C, the preparation of a middle layer ZrC1.0 and the preparation of an outer-coating layer ZrC0.7; and is characterized in that in a chemical vapor deposition furnace at normal pressure, zirconium tetrachloride is used as the zirconium source, Ar gas is used as the carrier gas, C3H6, acetylene and methane are respectively used as the carbon source gasses, Ar is used as the diluent, H2 is used as the reducing gas, and the surface erosion-resistant composite coating is obtained by deposition at the temperature of 1100-1300 DEG C. The invention has the advantages of simple process method, convenient operation, single heat, stepwise deposition preparation of the composite coating with gradient-changed carbon contents, firm combination between the coating and the basal body, no penetration crack and interlayer crack, and good coating erosion resistance and thermal shock resistance, can realize the industrialized production, and is applicable to the preparation of the erosion-resistant composite coating of the carbon / carbon composite by the chemical gas-phase permeation or the liquid-phase impregnation process.

Owner:CENT SOUTH UNIV

Method for preparing REBa2Cu3Ox (REBCO) high-temperature superconducting block material

InactiveCN102584250AControl supersaturationControl growth rateSpontaneous nucleationHigh temperature superconducting

The invention relates to a method for preparing a REBa2Cu3Ox (REBCO) high-temperature superconducting block material, in particular to a melt texture growth (MTG) method for the REBCO high-temperature superconducting block material. The MTG method for the REBCO high-temperature superconducting block material comprises the following steps of: a) mixing raw materials; b) grinding and calcining to obtain a superconducting material rough blank; c) tabletting; d) firing; and e) cooling to obtain the REBCO high-temperature superconducting block material, namely e1) cooling to buffer temperature, and preserving heat, e2) cooling to growth temperature, and preserving heat, and e3) quenching. By the method, the technical problem that the REBCO high-temperature superconducting block material fails to grow because spontaneous nucleation is generated when temperature is reduced from the maximum temperature to the growth temperature in the conventional MTG method is solved.

Owner:SHANGHAI JIAO TONG UNIV

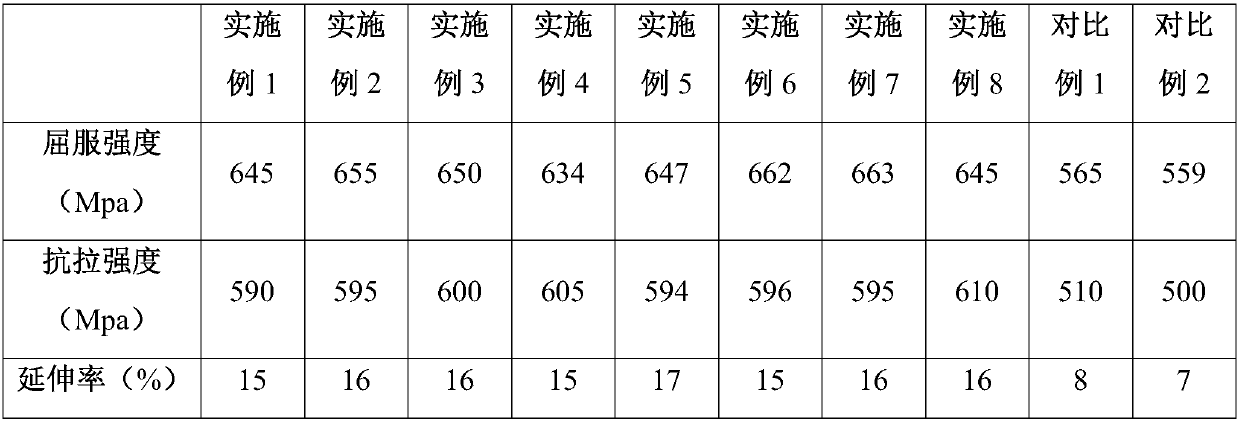

Aluminum alloy profile for aviation and production technology thereof

InactiveCN107675044AImprove mechanical propertiesOmit the steps of manual validationAviationRare-earth element

The invention belongs to the field of aluminum alloy profile production, and relates to an aluminum alloy profile for aviation and a production technology thereof. The aluminum alloy profile includes,by mass, no more than 0.25% of Si, no more than 0.4% of Fe, no more than 0.25% of Mn, 5-20% of Zn, no more than 15% of Mg, no more than 8% of Cu, no more than 1% of Zr, no more than 1% of Ti, 0.01-1.0% of Sr and the balance Al. By adding a proper amount of rare earth element Sc into a composition of 7xxx series aluminum alloy, the prepared aluminum alloy profile can be fine and uniform in grain and have good thermal processing formability, and a recrystallization phenomenon does not exist in the process of hot extrusion and solid solution aging heat treatment, so that grain refining, segregation reduction and more uniform texture of the prepared aluminum alloy profile are achieved.

Owner:CHINA ZHONGWANG

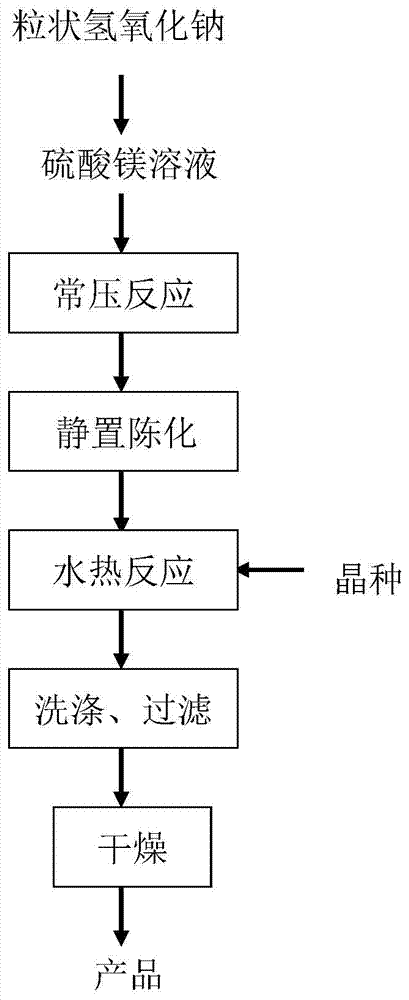

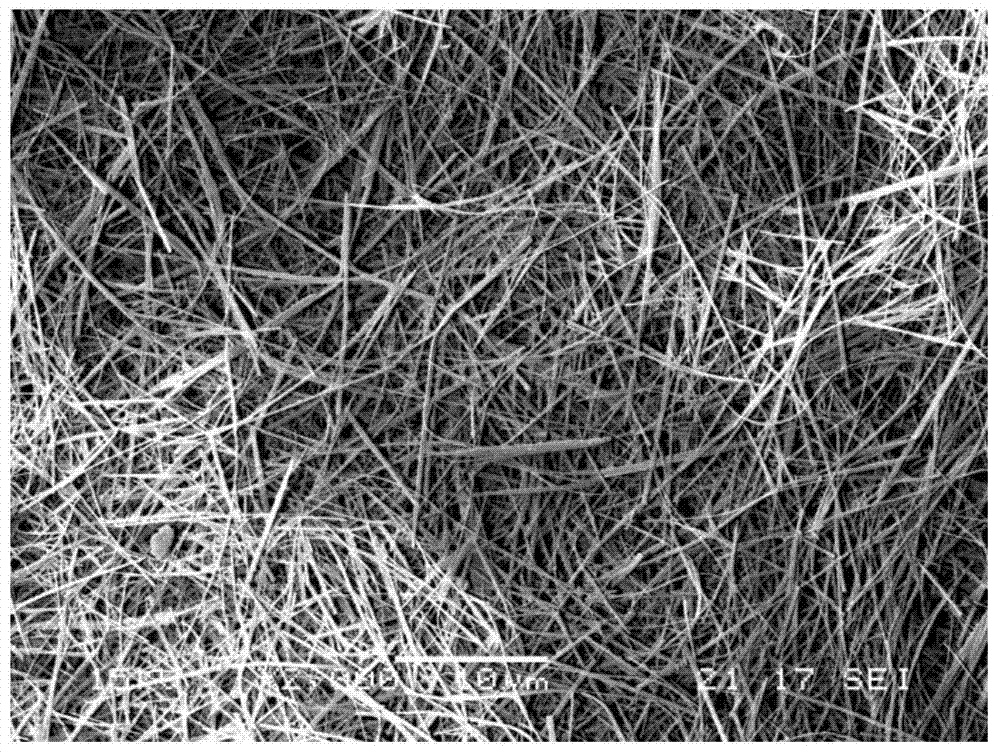

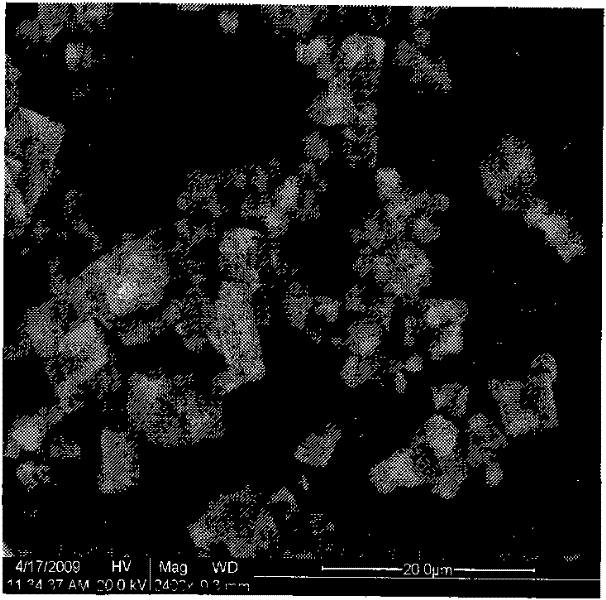

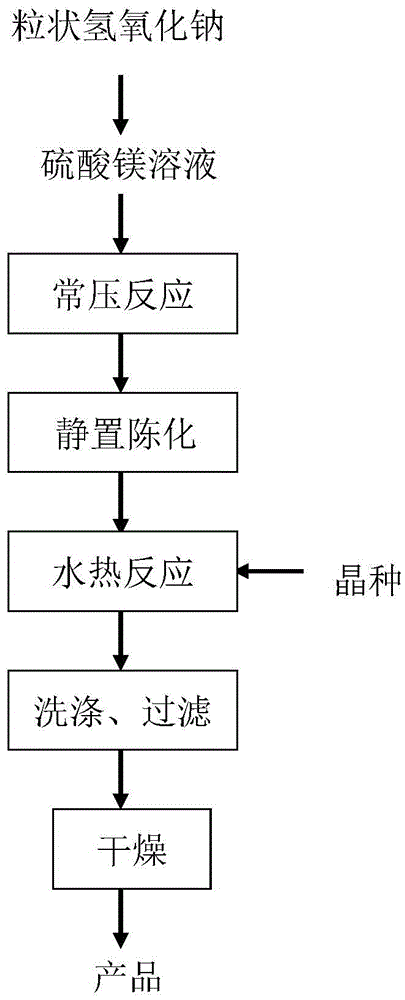

Preparation method of fibrous alkali magnesium sulfate whisker

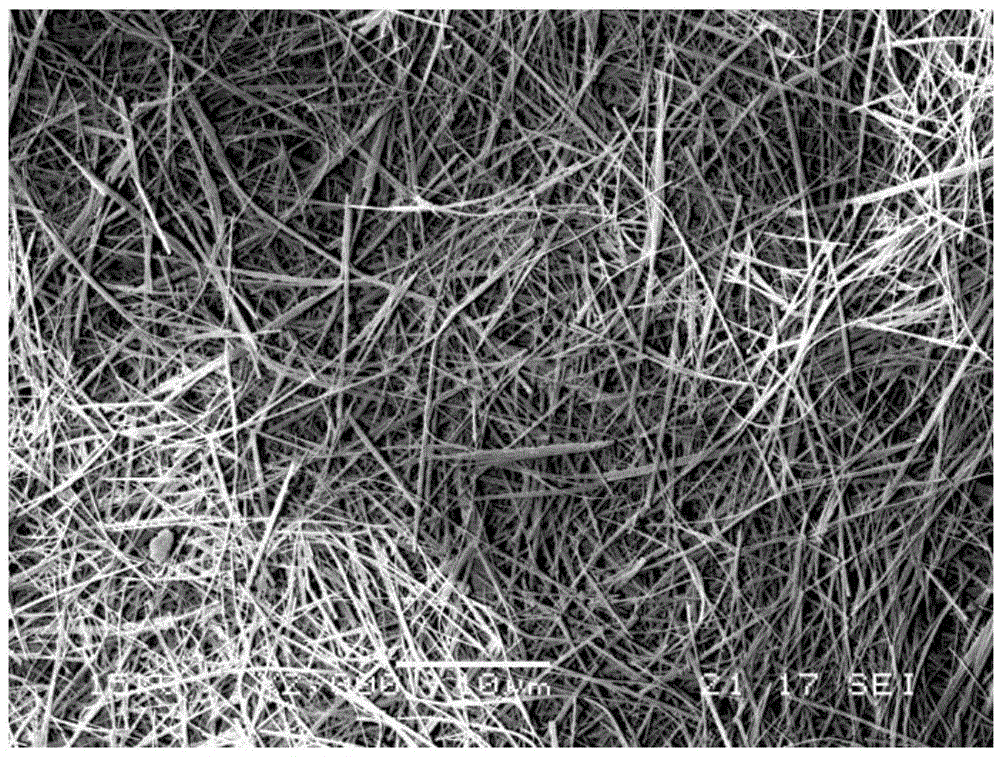

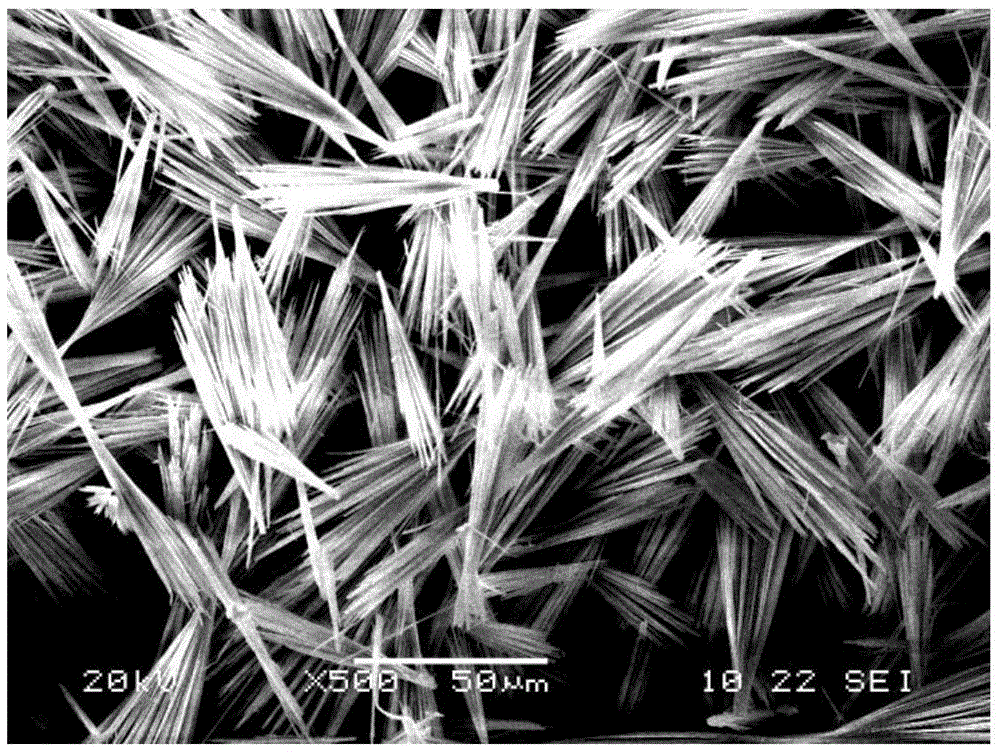

ActiveCN103789819AIncrease profitLow costPolycrystalline material growthFrom normal temperature solutionsMagnesium Sulfate whiskersWhiskers

The invention relates to the preparation field of chemical industrial materials, and particularly relates to a preparation method of a fibrous alkali magnesium sulfate whisker. The preparation method of the fibrous alkali magnesium sulfate whisker comprises the following steps: (1) preparing a magnesium sulfate solution by using MgSO4.7H2O, stirring and adding NaOH granular caustic soda, aging for 2-24 hours at the temperature of 25 to 100 DEG C to obtain a slurry; (2) transferring the slurry obtained in the step (1) into a hydrothermal reactor, wherein the filling degree is 50-80 percent, adding 0.5-5 percent of seed crystal according to the mass of the NaOH granular caustic soda, uniformly stirring, and reacting the slurry for 2-12 hours at the temperature of 130-180 DEG C; (3) cooling after finishing the reaction of the step (2), filtering, washing and drying a obtained white turbid liquid to obtain the fibrous alkali magnesium sulfate whisker. According to the preparation method, the seed crystal is added into the reaction slurry, alkali magnesium sulfate is easily subjected to nucleus formation growth, and the preparation concentration of the reaction slurry can be relatively high; the whisker nucleation time is reduced, and the whisker growth time also can be shortened.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

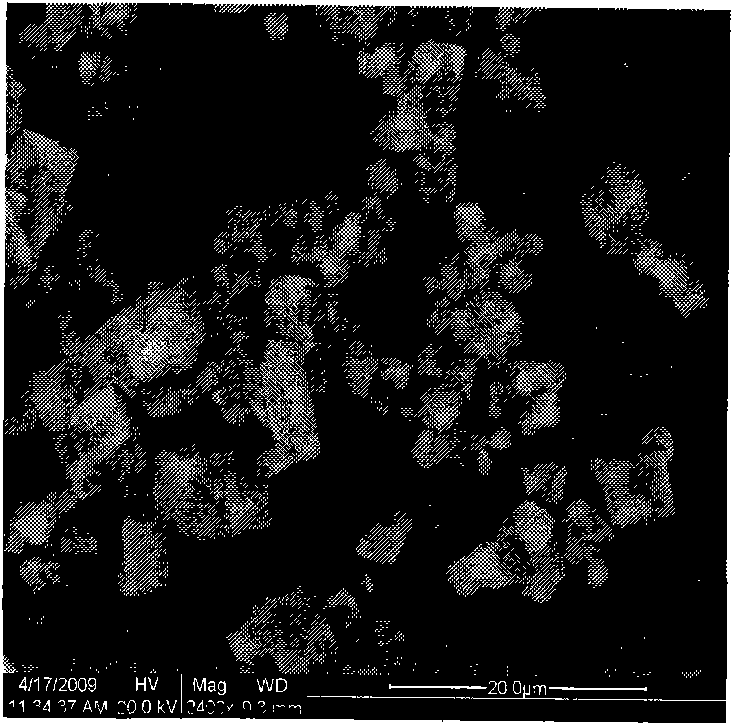

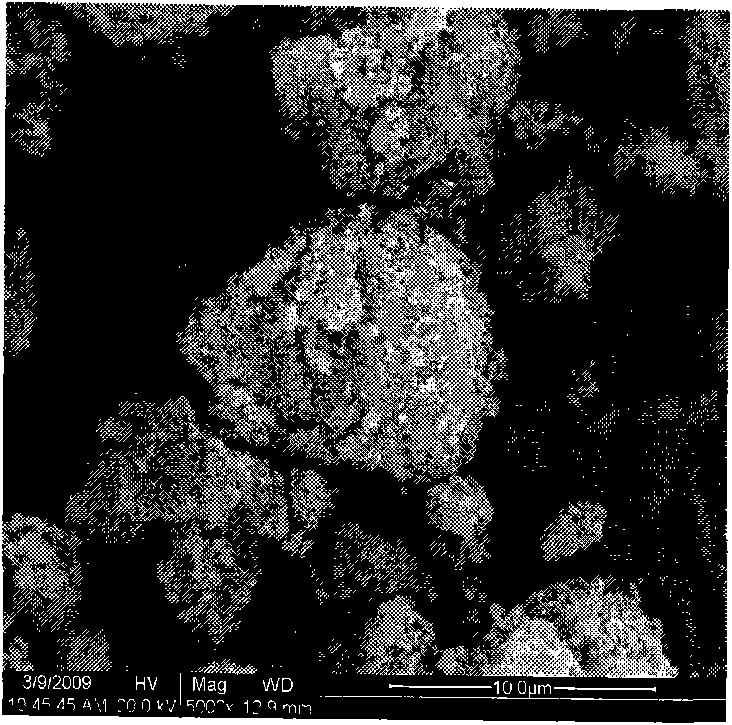

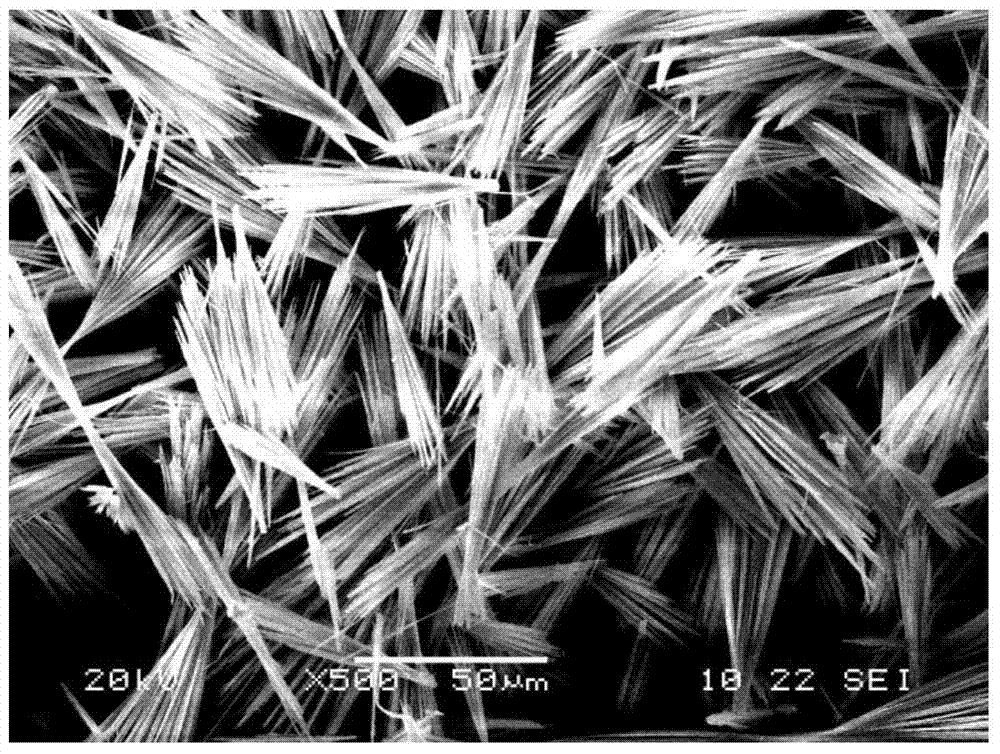

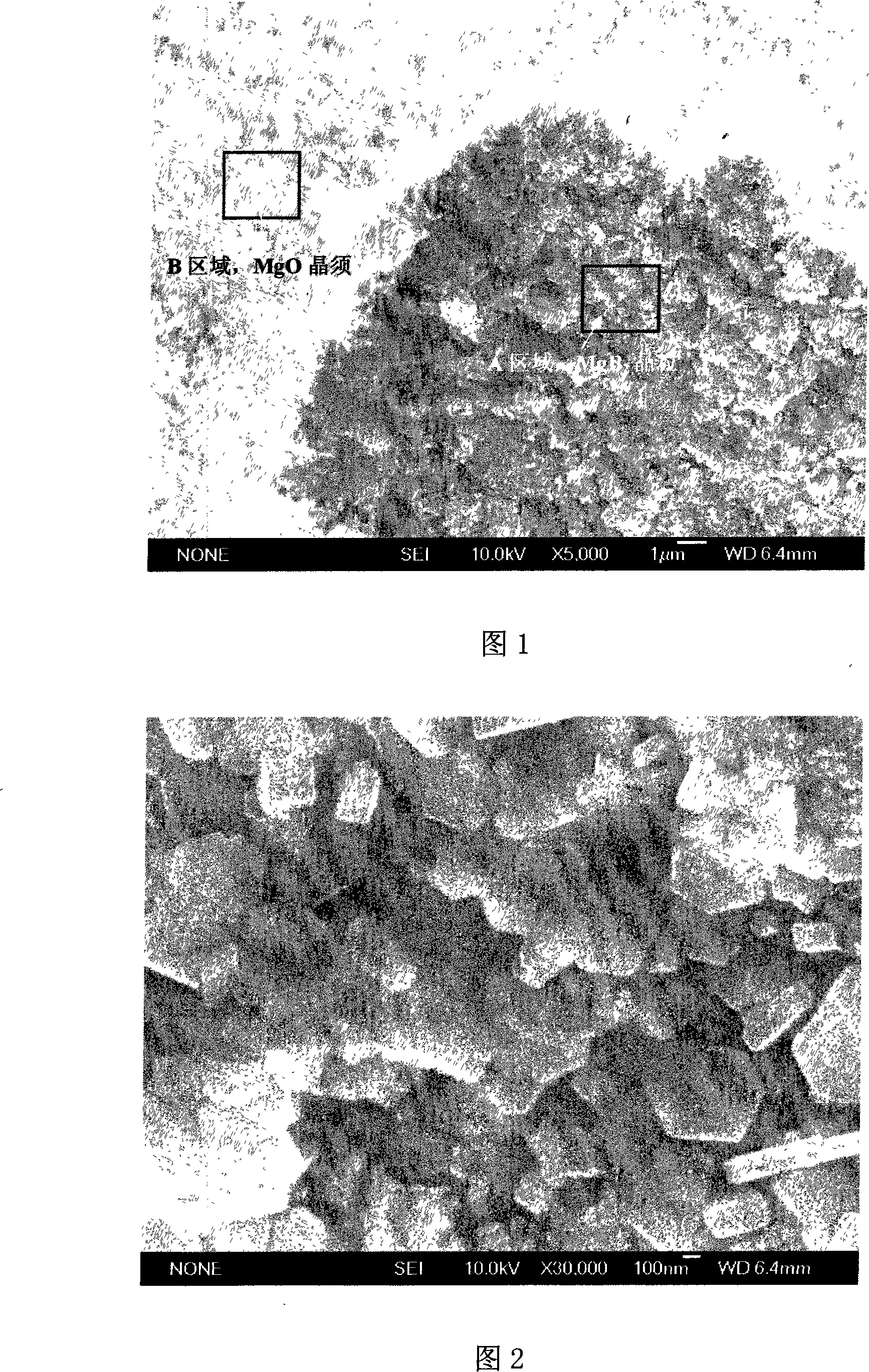

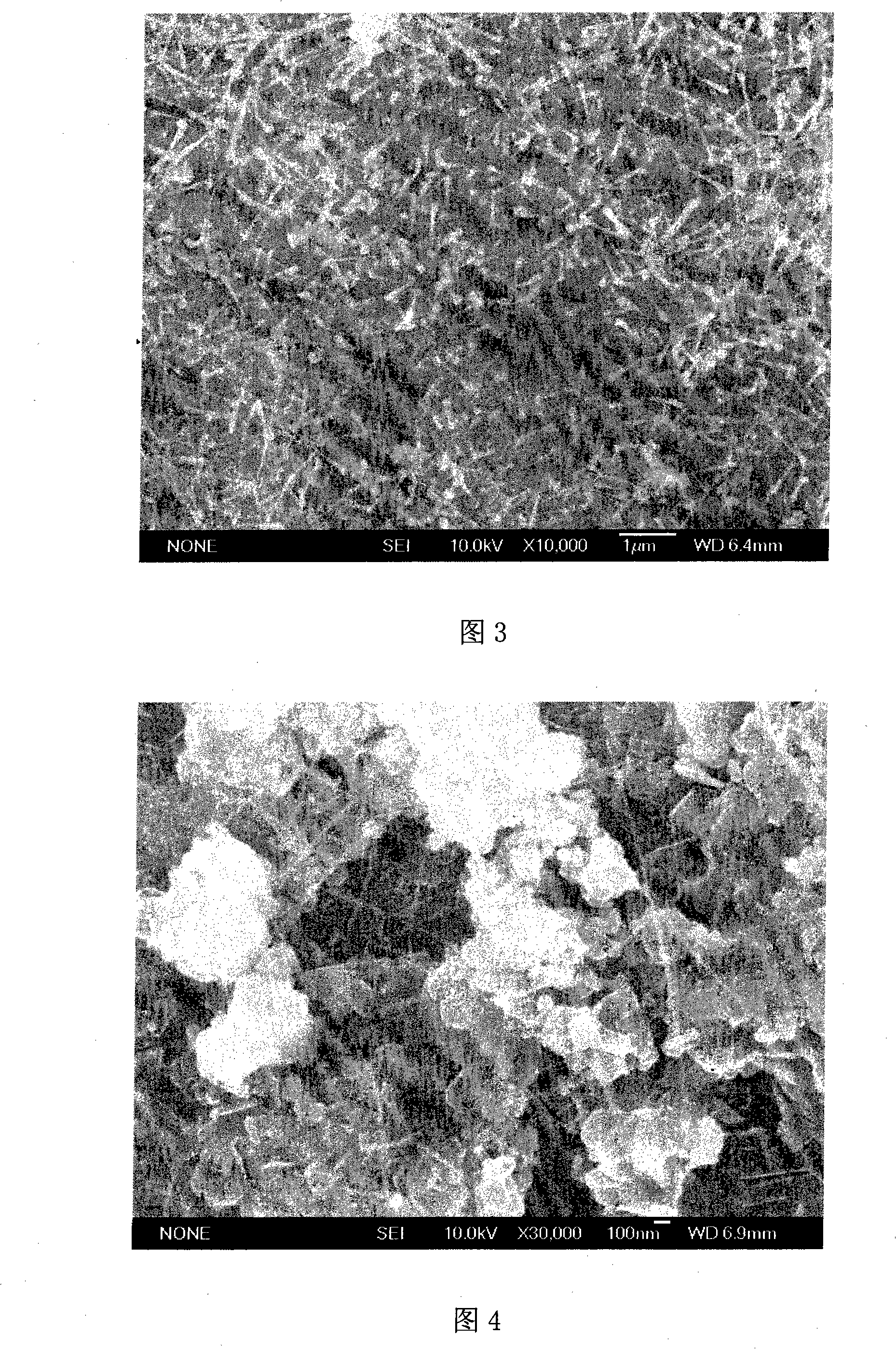

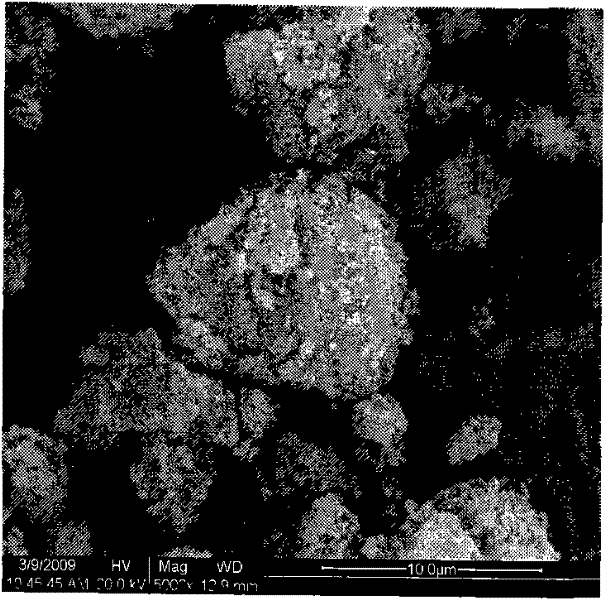

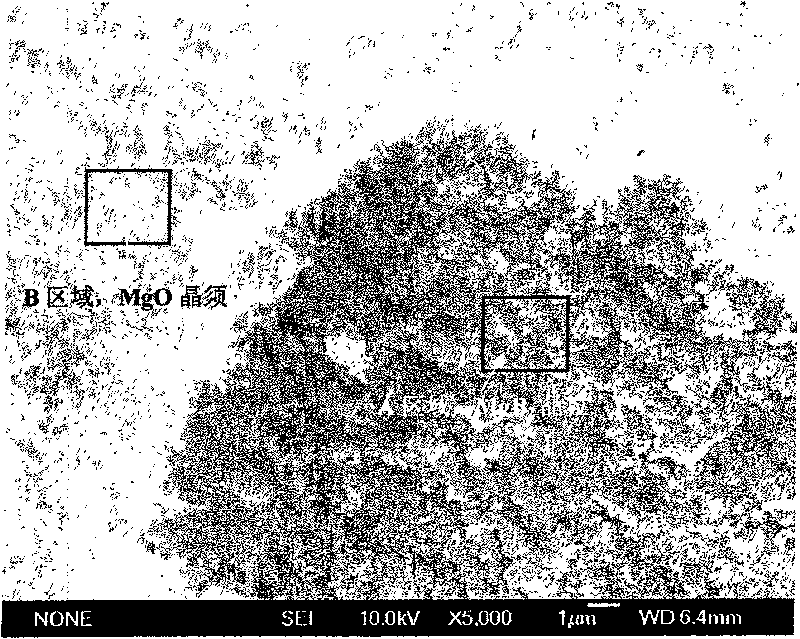

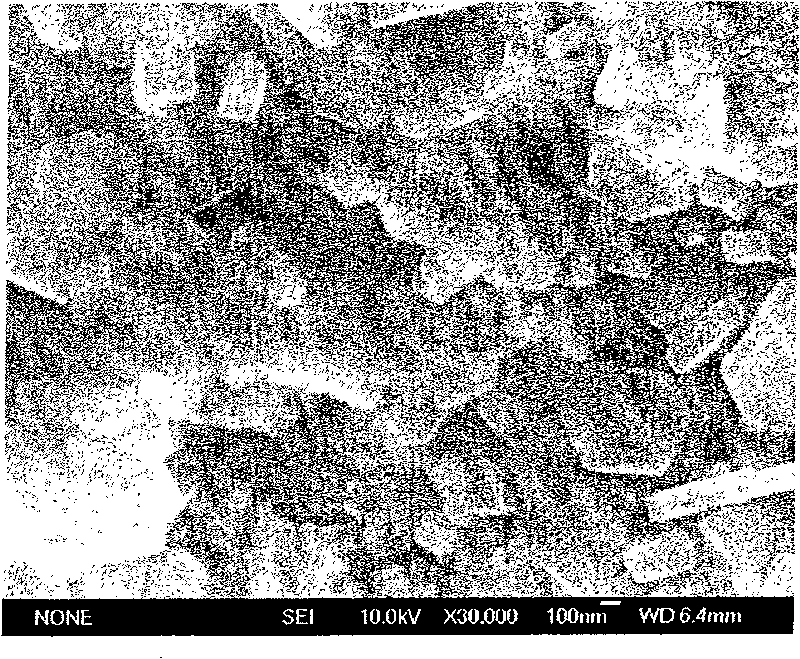

Low-temperature method for manufacturing nano-MgO crystal whisker

InactiveCN101220516AControl supersaturationControl shapePolycrystalline material growthFrom chemically reactive gasesCrucibleRoom temperature

The invention relates to a method for preparing nanometer MgO whiskers at the low temperature and the method is that magnesium powders and amorphous boron powders are mixed according to atomic ratio of MG:B being equal to 1 to 1.5:2 and the mixture is grinded for 30 to 120 minutes for thorough mixing, and after the mixed powders are made into a lump sinter under the pressure of 5 to 10 kg / cm<3> by a press machine, the lump sinter is put into a crucible which is put into a heating zone of an evacuated tubular furnace. The evacuated tubular furnace is sealed, vacuumized to 1 to 10 Pa and filled with argon the oxygen content of which is 2 percent to 5 percent and the flow rate of the mixed gas is 5 to 20 lit. per minute to heat the sample up to 650 to 750 DEG C at the heating rate of 5 to 20 K per minute, and the sample is decreased to the room temperature at the same heating rate after the temperature is kept for 0 to 120 minutes. The surface of the sample forms nanometer MgO whiskers with various appearances and sizes. When reaching 650 DEG C, magnesium evaporates and reacts with the little filled oxygen to produce MgO vapour, and under the lower over-saturation state, MgO whiskers are deposited on a substrate. The method for preparing MgO whiskers needs temperature much lower than the previous and greatly increases the practicality of preparing MgO whiskers.

Owner:TIANJIN UNIV

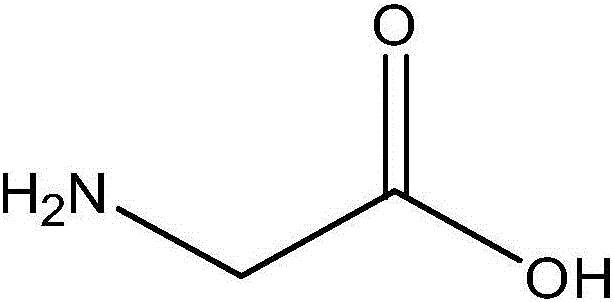

Method for controlling temperature of glycine cooling crystallization crystal point

InactiveCN106442607AOptimizing the crystallization processControl supersaturationInvestigating phase/state changeTemperature controlGlycine solution

The invention belongs to the technical field of chemical crystallization and particularly relates to a method for controlling the temperature of a glycine cooling crystallization crystal point. The method specifically includes the steps that glycine and deionized water are added into a crystallizer according to a certain proportion, a proper additive is added after the materials are completely dissolved, after the additive is completely dissolved, temperature-controlled cooling and crystallization are conducted at a certain stirring speed and a certain cooling speed, and the temperature of the glycine crystal point is observed and recorded. The method for controlling the temperature of the glycine cooling crystallization crystal point can effectively control the supersaturation degree of a glycine solution and control the temperature of the glycine crystal point, and accordingly provides bases for optimizing the glycine crystallization technology.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

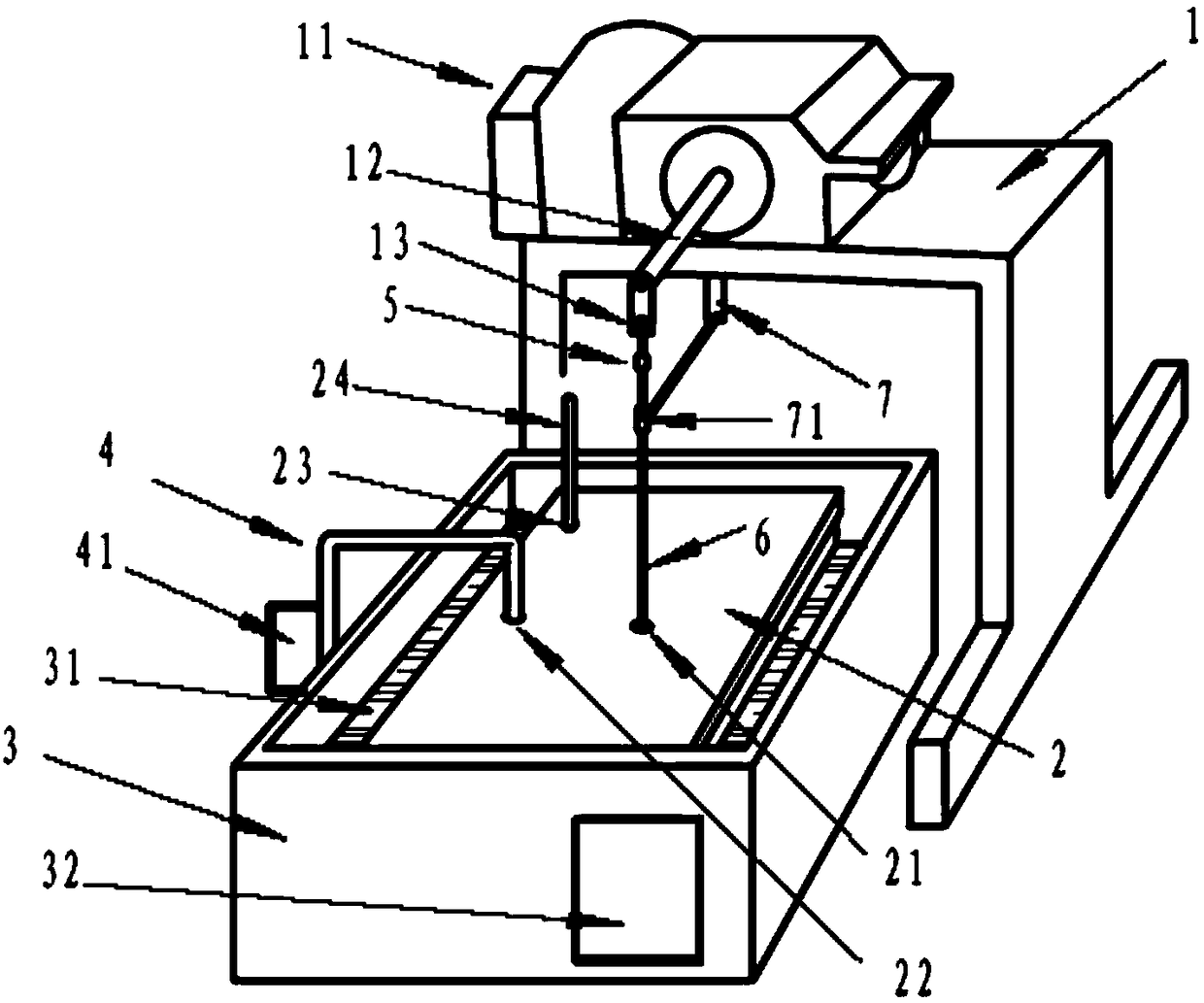

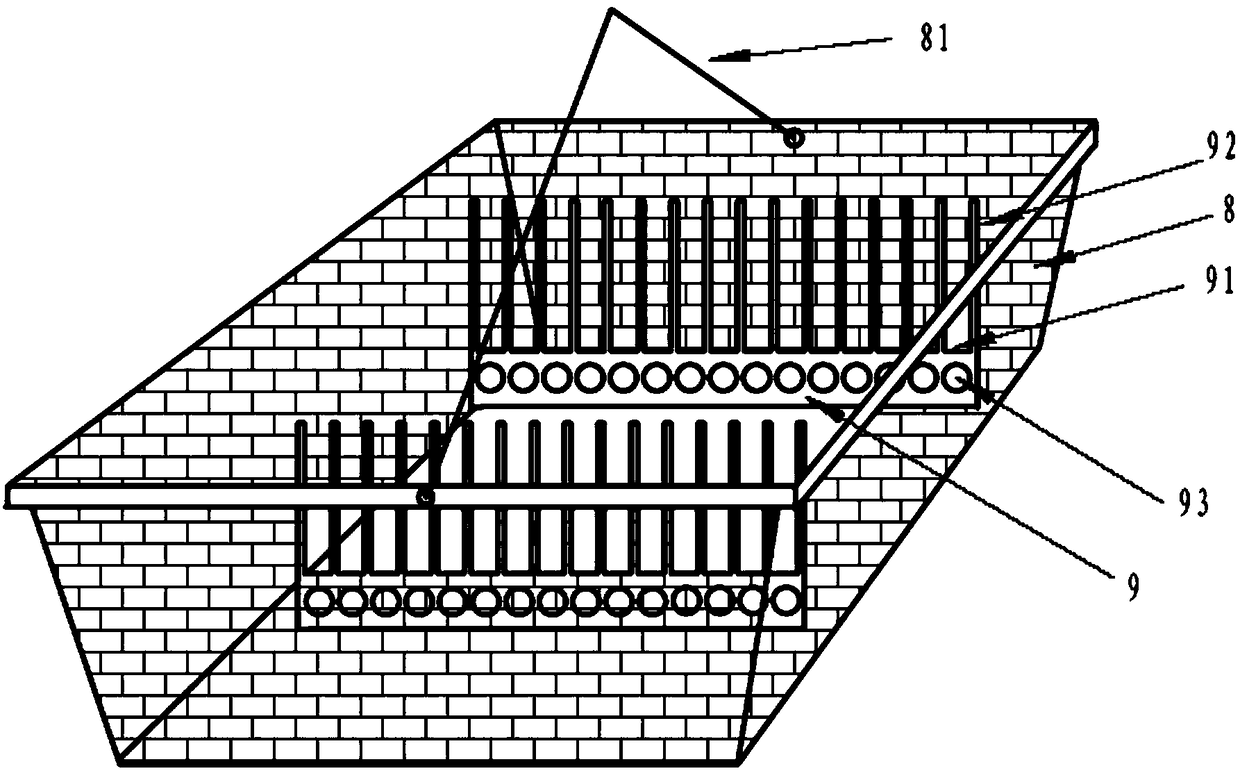

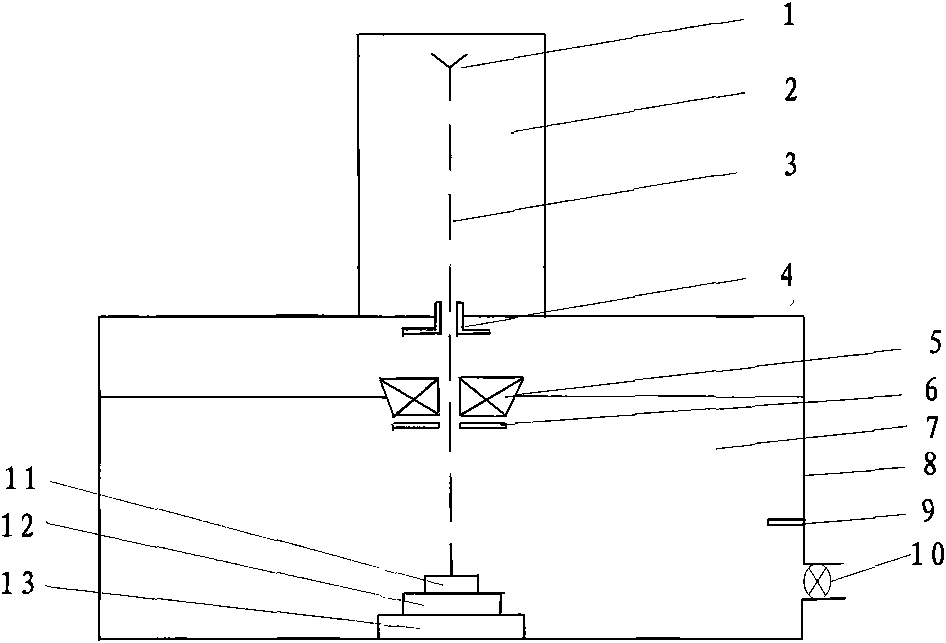

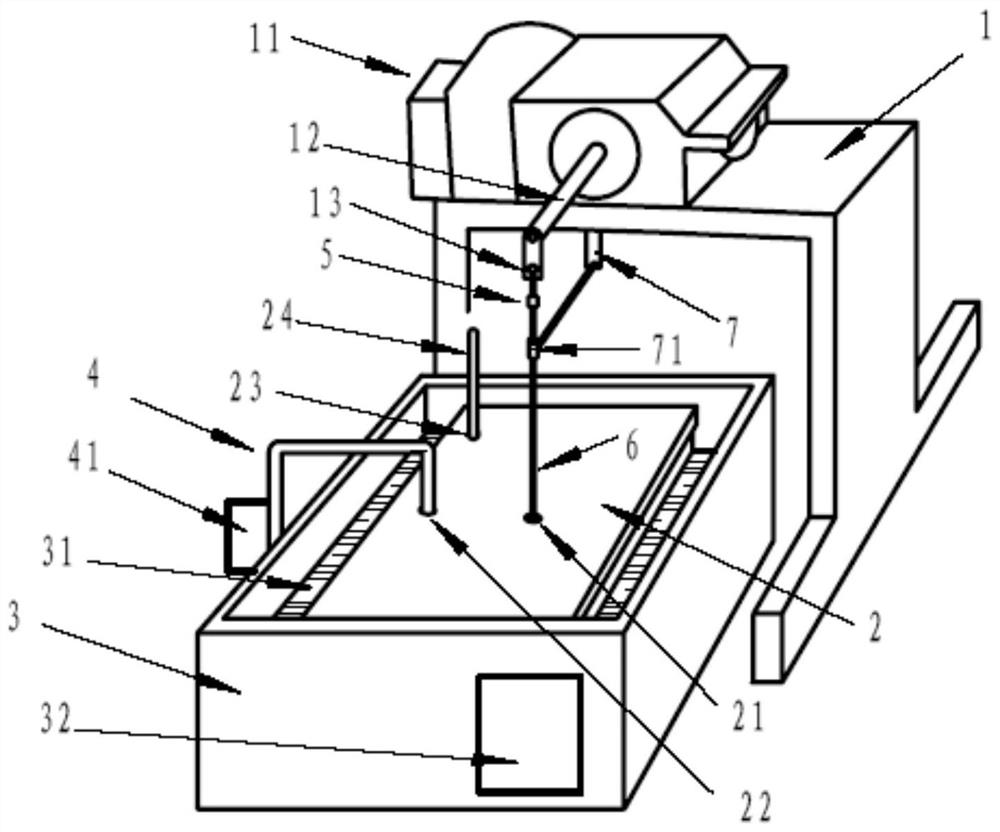

Corrosion device and method for artificial quartz crystal seed chip

ActiveCN109371456AControl supersaturationUniform corrosion ratePolycrystalline material growthFrom normal temperature solutionsTemperature controlWater baths

The invention provides a corrosion device for an artificial quartz crystal seed chip. The corrosion device comprises a seed chip main body stander, a corrosion tank and a water-bath tank, wherein a timer and a rotating shaft with a motor are arranged on the seed chip main body stander, the timer is connected with the rotating shaft, and a traction rod is fixedly arranged on the rotating shaft; a rotating wheel capable of freely rotating is arranged on the traction rod, a traction line is fixedly arranged on the rotating wheel, a traction through hole and a venting pipe hole are formed in the top of the corrosion tank, the corrosion tank is placed in a water bath tank, and the traction line sequentially penetrates through a limiting hole and the traction through hole and is fixedly connected with a lifting rope. The invention further discloses a corrosion method for the artificial quartz crystal seed chip. The artificial quartz crystal seed chip can do a reciprocating motion in corrosion liquid. Temperature control of the corrosion liquid is emphasized, the supersaturation degree of the corrosion liquid is effectively controlled, and the uniform-speed corrosion is guaranteed by virtue of the concentration of the corrosion liquid.

Owner:山东博达光电有限公司

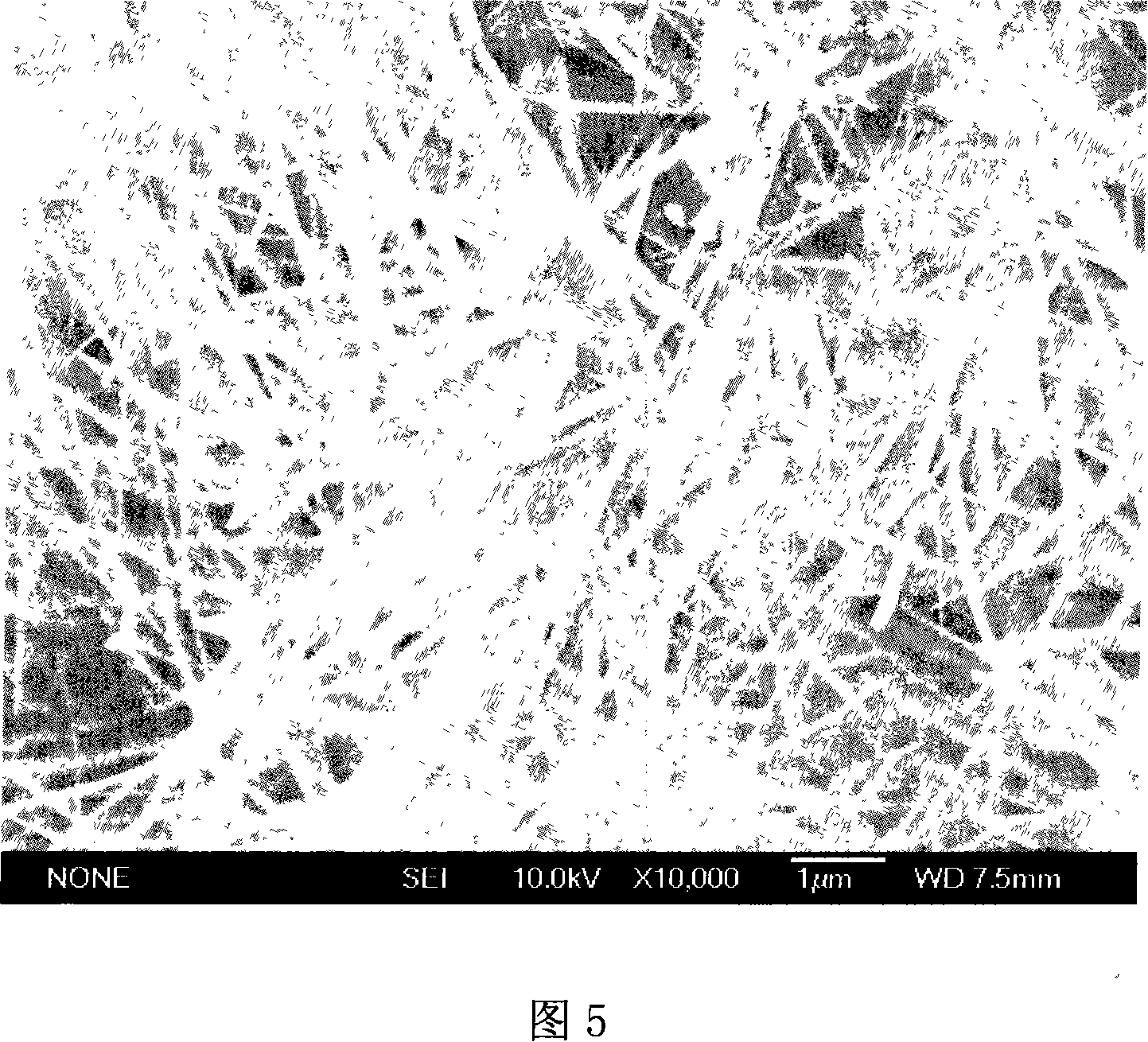

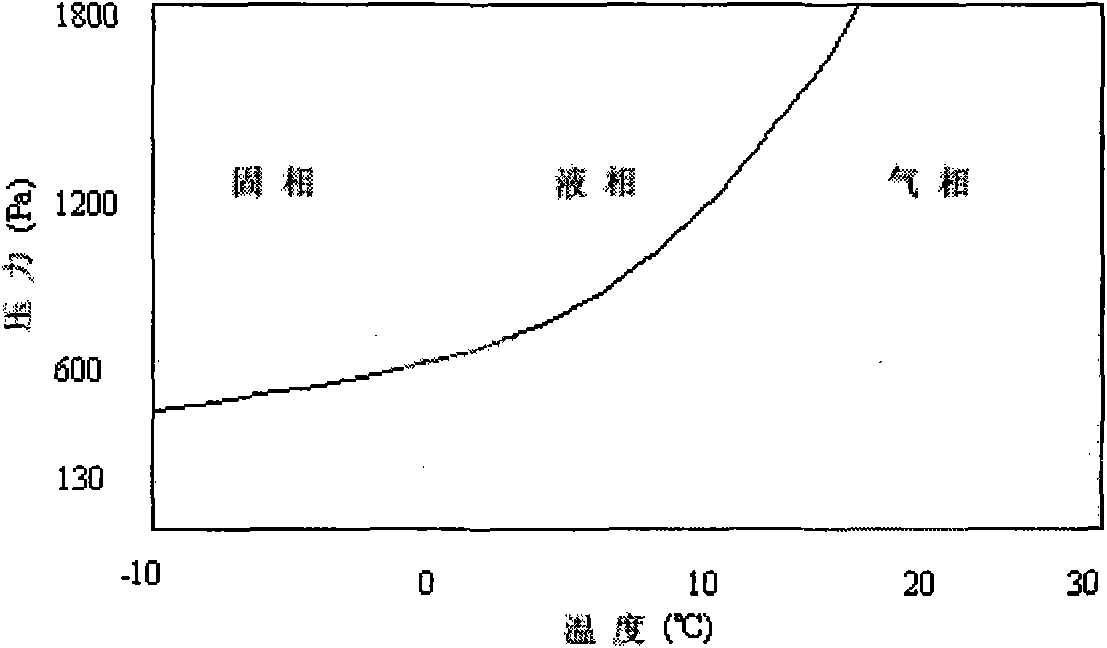

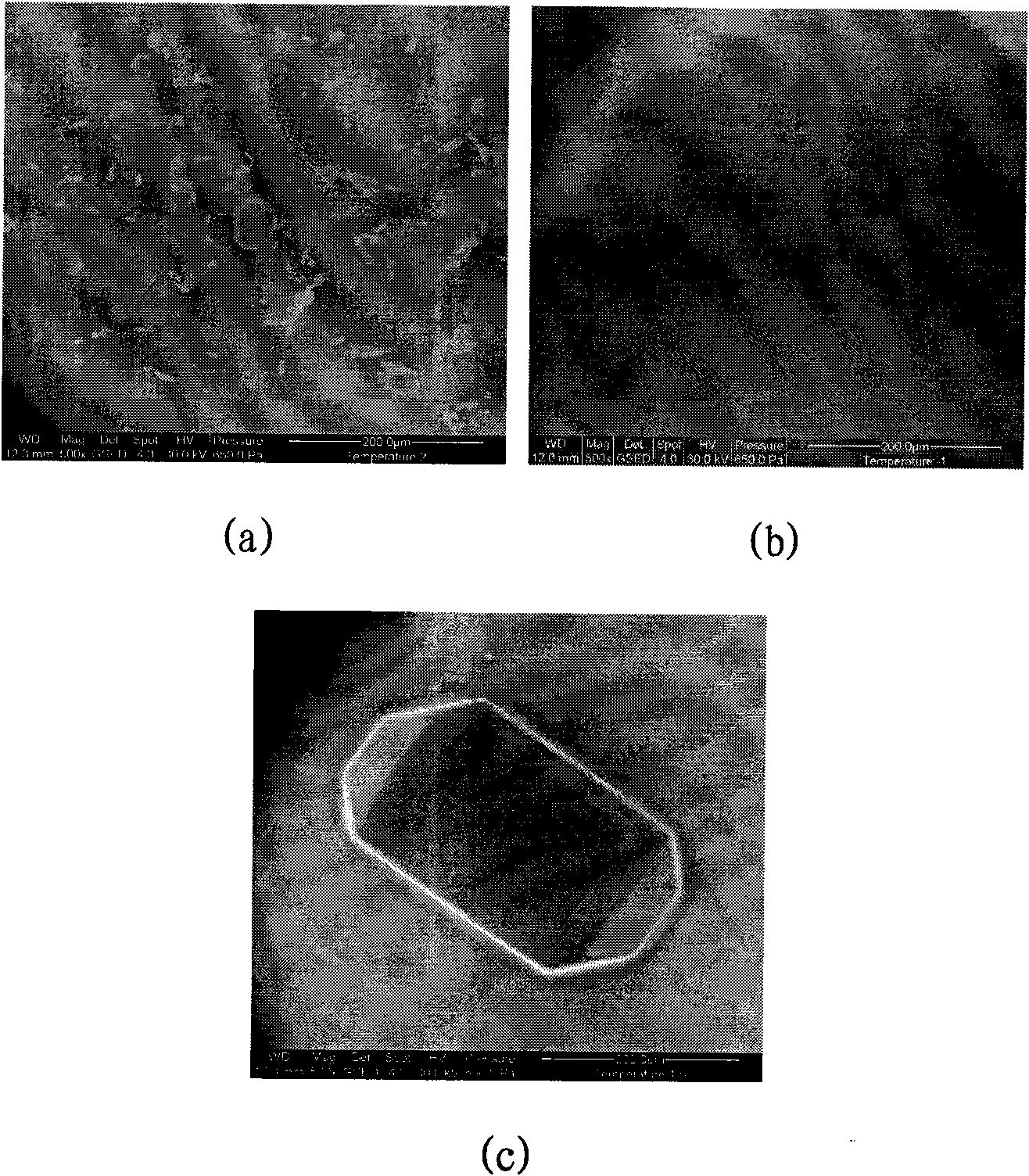

Method for in-situ growth of potassium dihydrogen phosphate single crystal in environmental scanning electronic microscope

InactiveCN101555623AControlled evaporationControl supersaturationPolycrystalline material growthFrom normal temperature solutionsPhosphatePotassium

The invention relates to a method for in-situ growth of potassium dihydrogen phosphate (KDP) single crystal in an environmental scanning electronic microscope (ESEM), belonging to the field of material discipline. The invention applies controllable vacuum environment and temperature changing condition of the ESEM and in-situ grows KDP single crystal and simultaneously in-situ observes the process of dissolving and growing of the KDP. The method prepares the KDP single crystal by the KDP polycrystal powder through controlling water-vapor pressure, relative moisture and the temperature of a sample platform in an ESEM sample chamber; the pressure for dissolving the KDP polycrystal powder is 600 to 670Pa, the temperature is minus 1 to 1 DEG C, and Phi is approximately equal to 100 percent; the pressure for growing the KDP single crystal is 600 to 650Pa, the temperature is 1 to 2.2 DEG C, and Phi is approximately equal to 91 percent to 95 percent. The method is also applicable to grow other water-soluble crystals, and provides methods and conditions for basic problems of dynamically studying microcosmic appearance characteristics and growth mechanism of the water-soluble crystals and the influence of moisture environment to the water-soluble crystals and the like.

Owner:BEIJING UNIV OF TECH

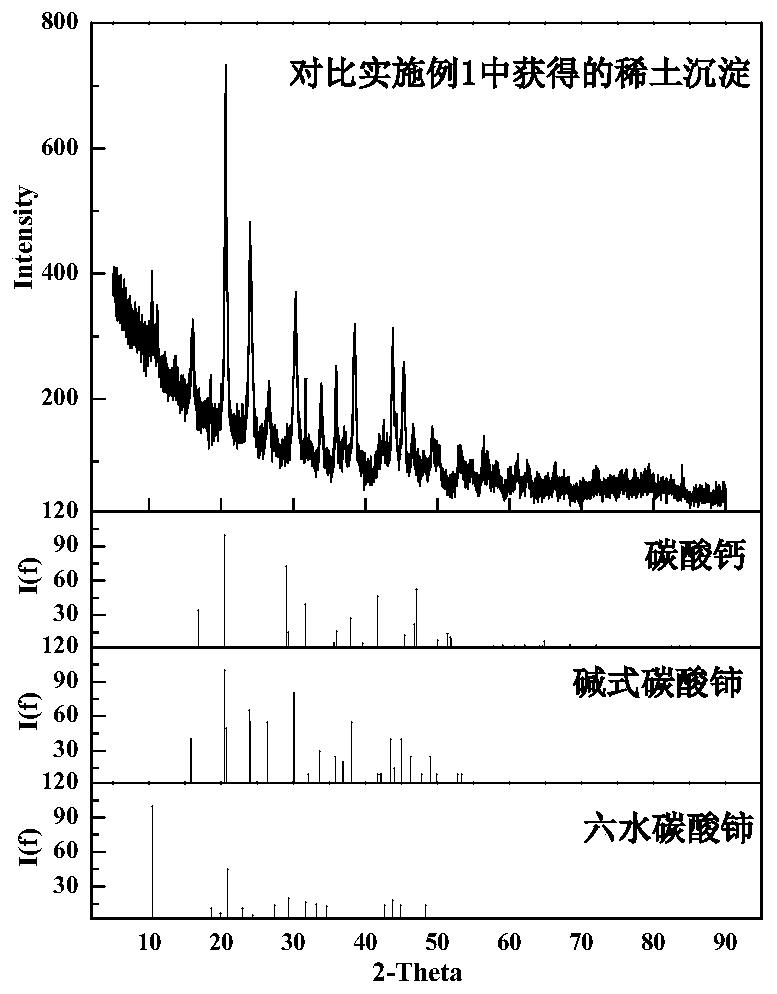

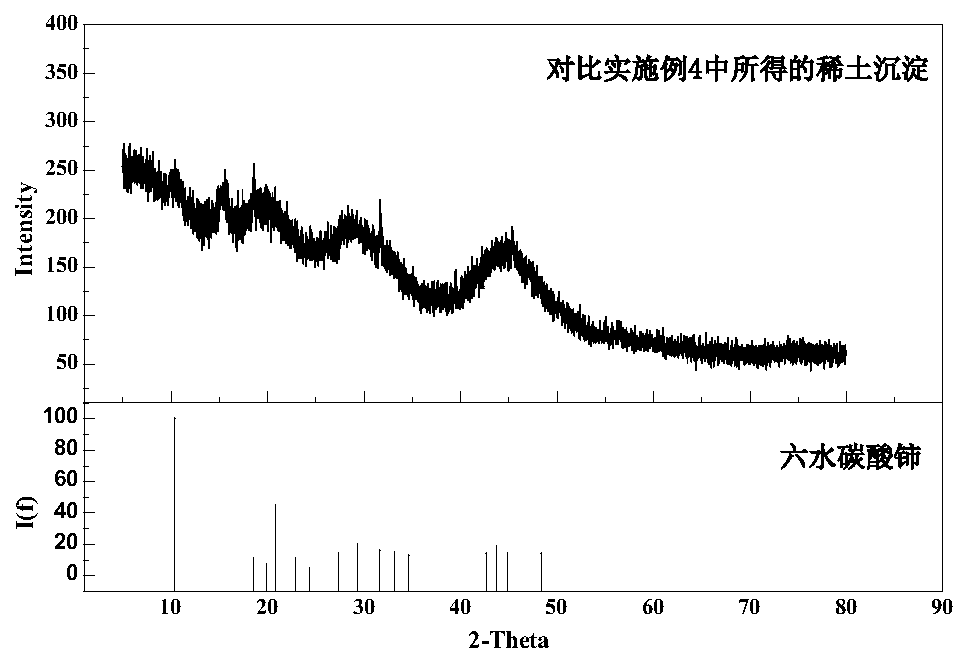

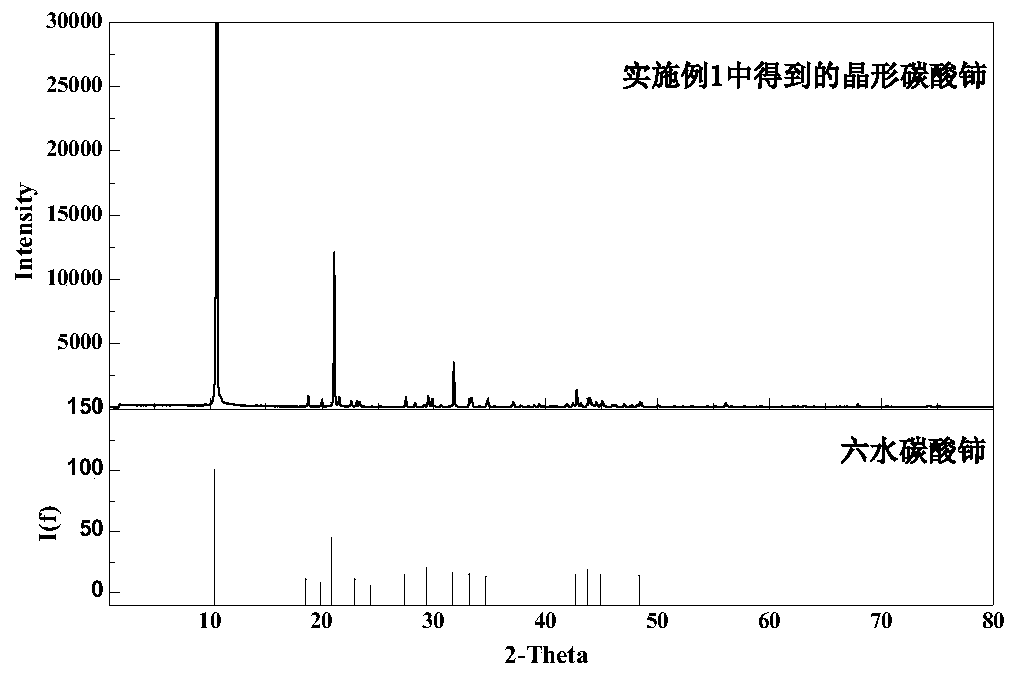

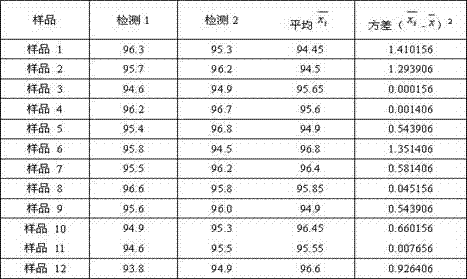

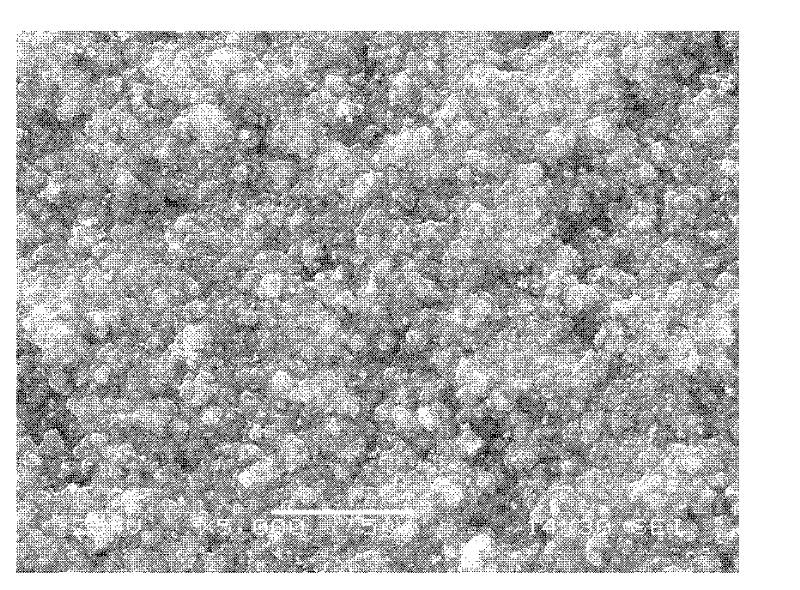

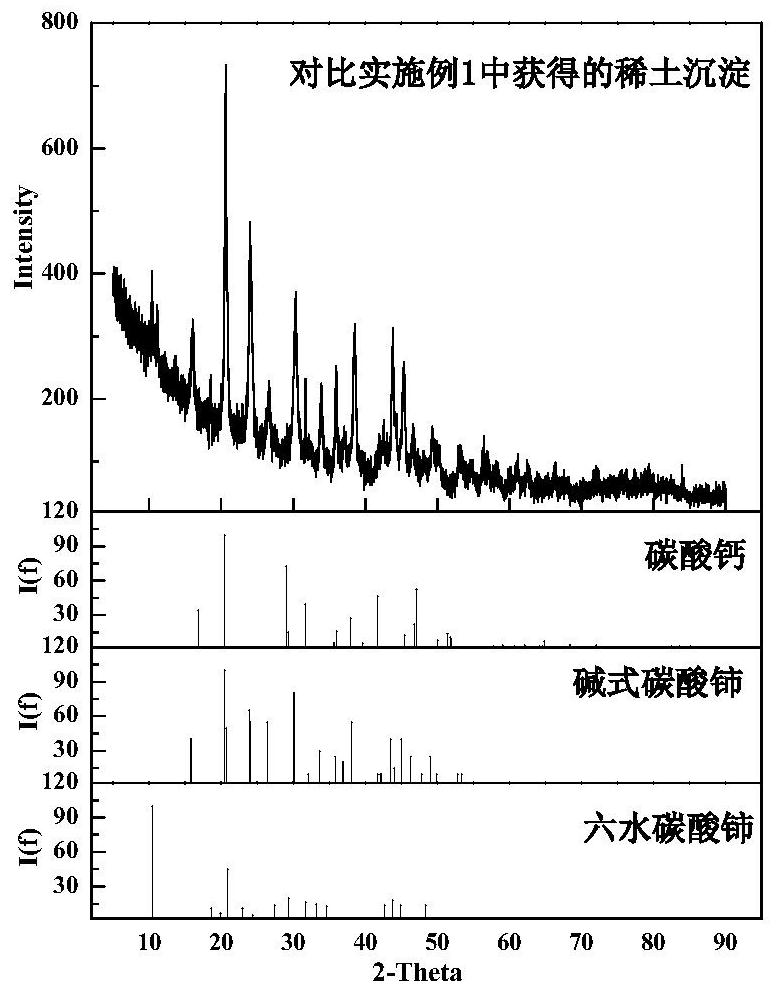

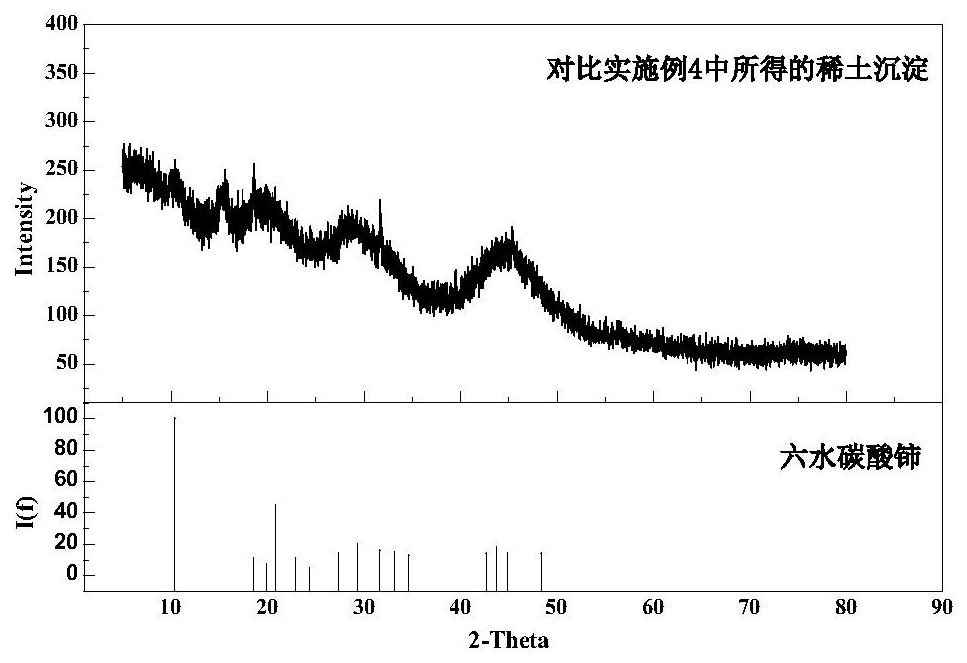

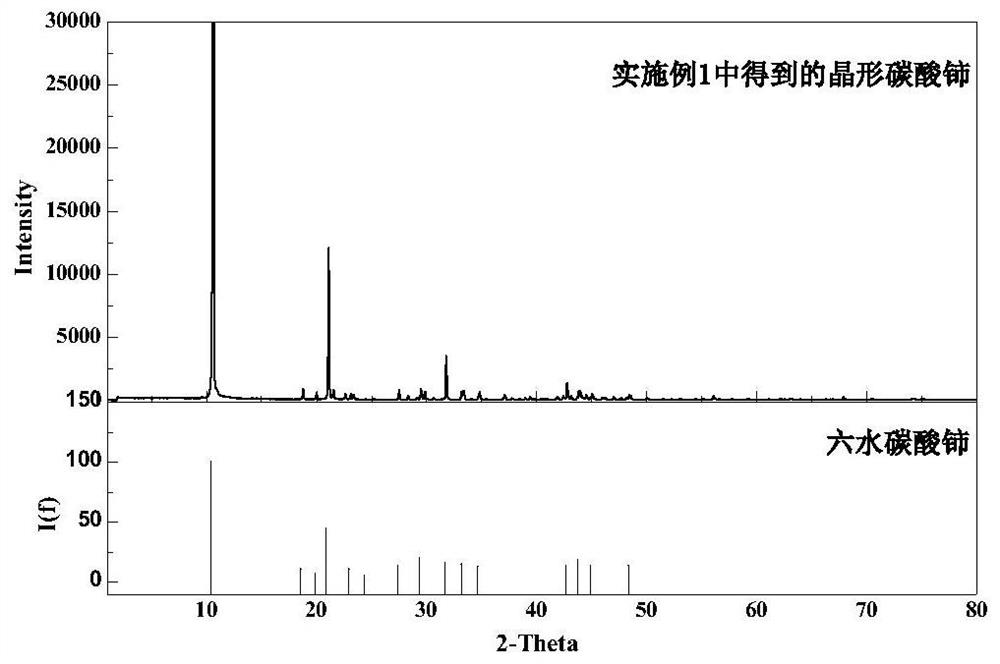

Method for separation of rare earth in calcium-containing rare earth solution by precipitation

ActiveCN111593214AReduced stabilityControl supersaturationProcess efficiency improvementCalcium bicarbonateSupersaturation

The invention discloses a method for separation of rare earth in a calcium-containing rare earth solution by precipitation. The calcium-containing rare earth solution in which the rare earth concentration ranges from 0.1 mol / L to 1.5 mol / L, the calcium ion concentration ranges from 0.1 mol / L to 1.0 mol / L, the molar ratio X of the rare earth and calcium is more than or equal to 0.7 and less than orequal to 8.0 is adopted, the rare earth in the calcium-containing rare earth solution is precipitated by bicarbonate salt, and the conditions such as temperature, pH, feeding speed in the precipitation process are adjusted and controlled according to the size of the molar ratio of the rare earth and the calcium in the solution, and the concentration of bicarbonate in the solution is adjusted to control the stability of calcium bicarbonate and the supersaturation of rare earth carbonate, so that rare earth ions precipitate to form the crystalline rare earth carbonate; and calcium ions form thesoluble calcium bicarbonate, the efficient separation of the rare earth and the calcium in the calcium-containing rare earth solution is achieved, and rare earth oxide with the purity greater than 98% is obtained.

Owner:GANZHOU ZHANHAI IND & TRADING

Domestic ceramic raw material whiteness proficiency testing sample

InactiveCN107064020AEasy to prepareIncrease success rateColor/spectral properties measurementsMicrometerProficiency testing

Provided is a domestic ceramic raw material whiteness proficiency testing sample, and belongs to the technical field of interlaboratory proficiency testing. The proficiency testing sample is prepared from zirconia particles of which the content is bigger than 99% and the average particle size is smaller than 74 micrometers, and is characterized in that the zirconia particles are prepared by adopting a zirconium compound as a precursor and utilizing a chemical precipitation method through zirconium compound hydrolysis-washing-calcinating-grinding, and the whiteness proficiency testing sample is prepared from the zirconia particles through a whiteness uniformity and stability test after pelleting. The domestic ceramic raw material whiteness proficiency testing sample is high in whiteness uniformity and stability, meets the requirements of the proficiency testing sample, makes up the gap of the field of current inland domestic ceramic raw material whiteness proficiency testing, and provides technical support for developing laboratory domestic ceramic raw material whiteness proficiency testing.

Owner:刘胜

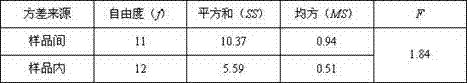

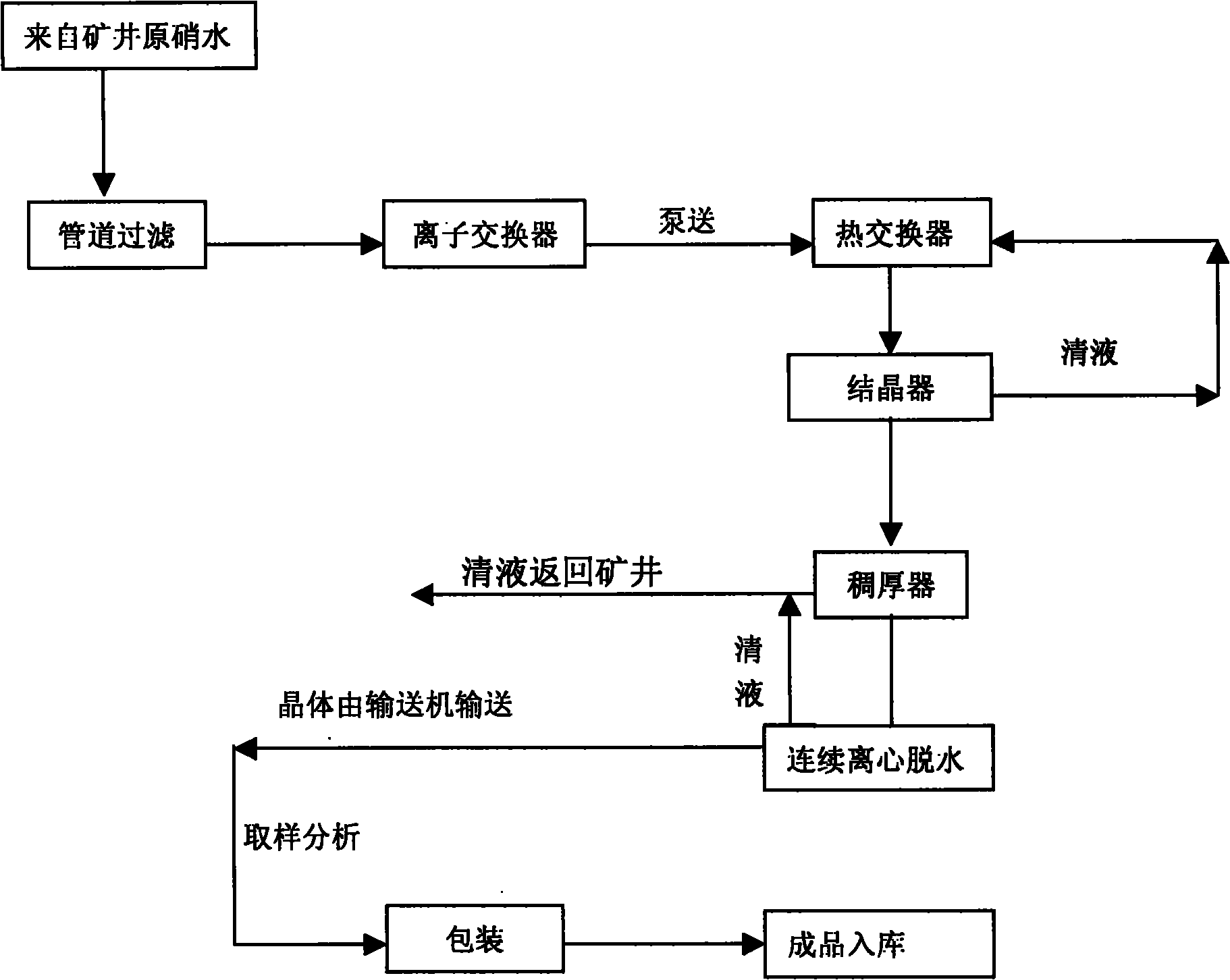

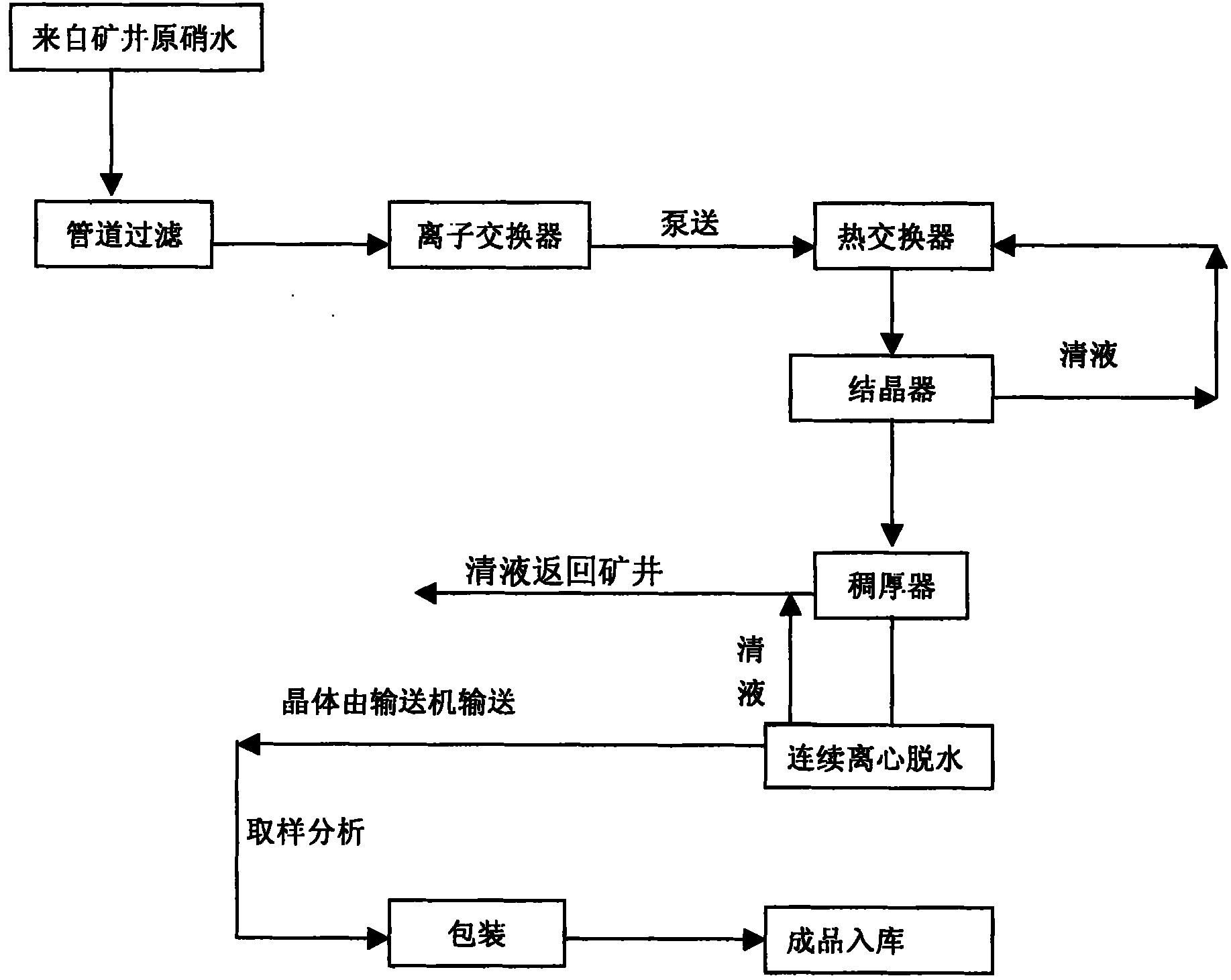

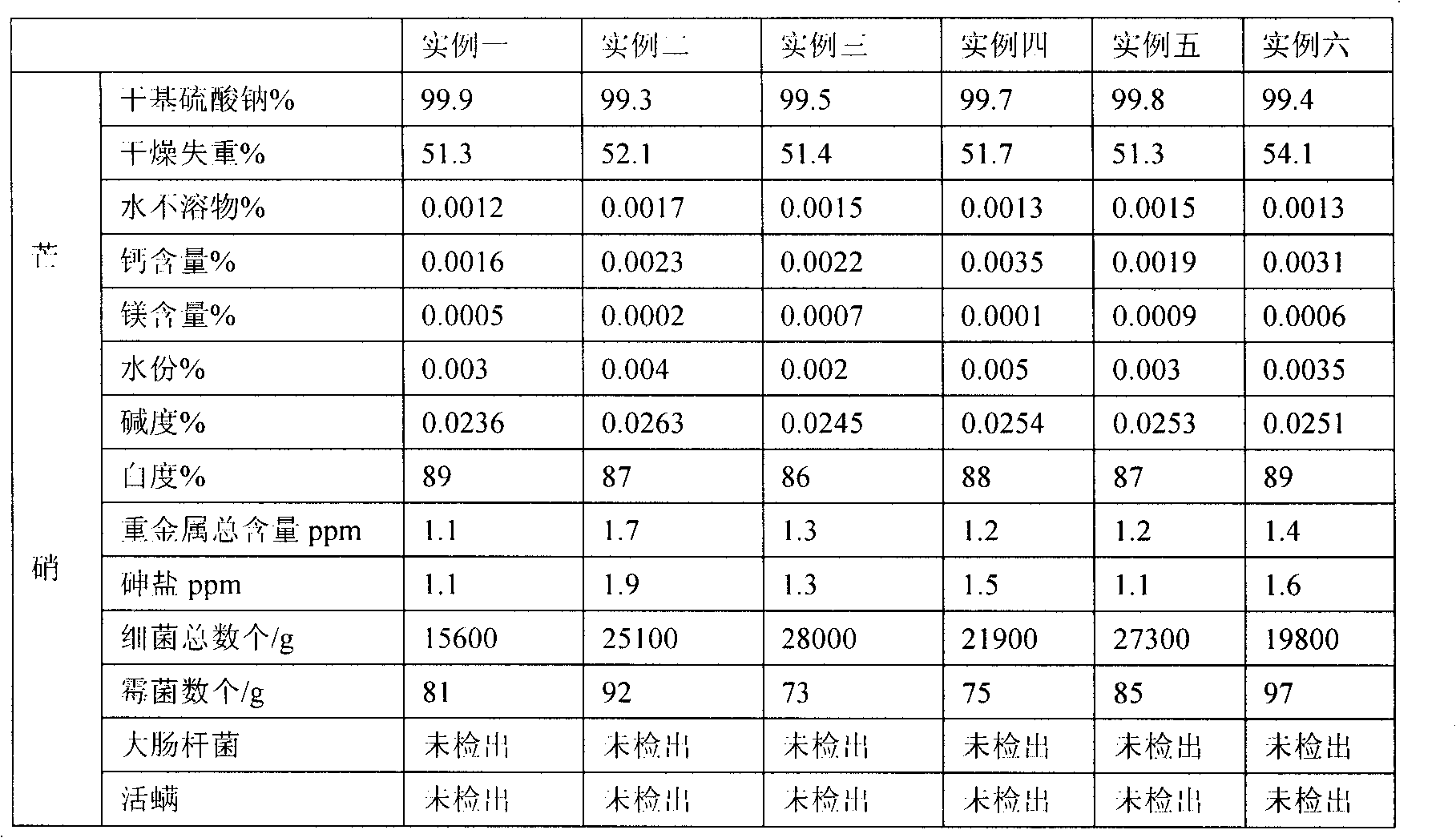

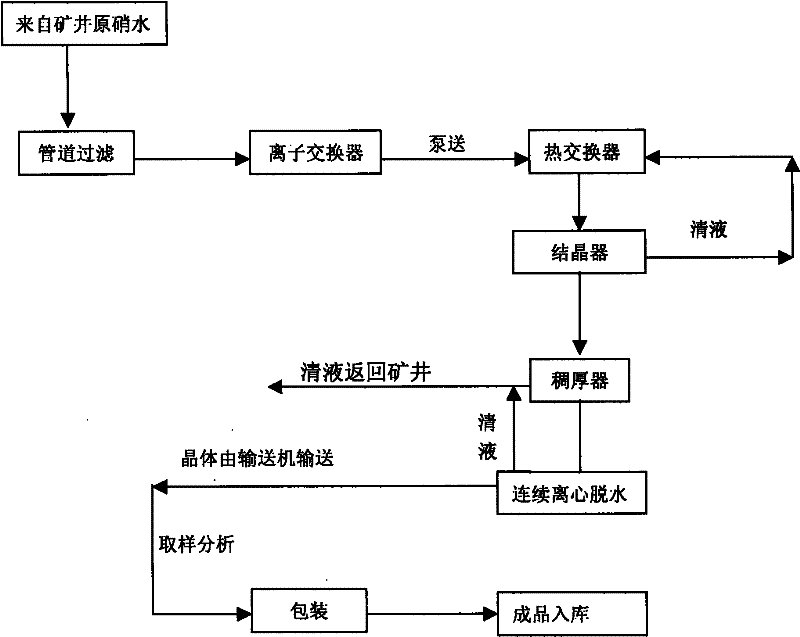

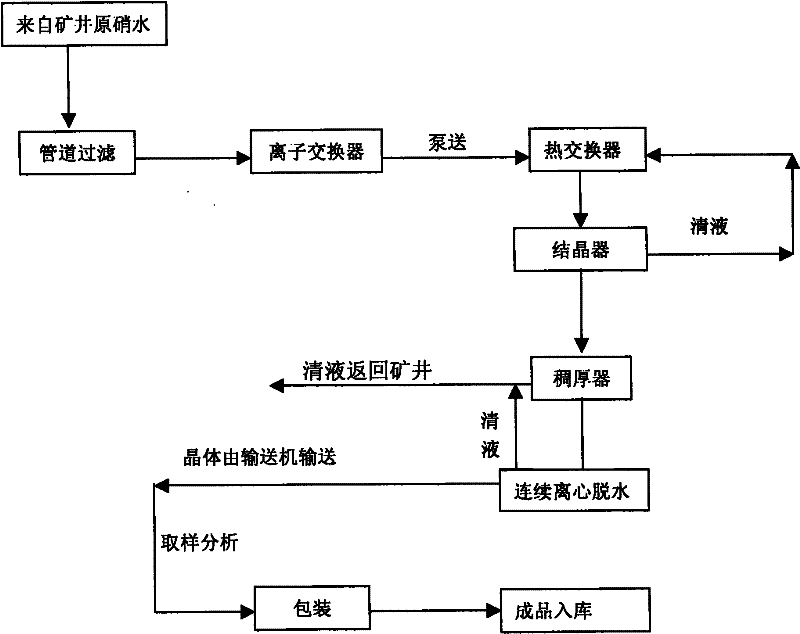

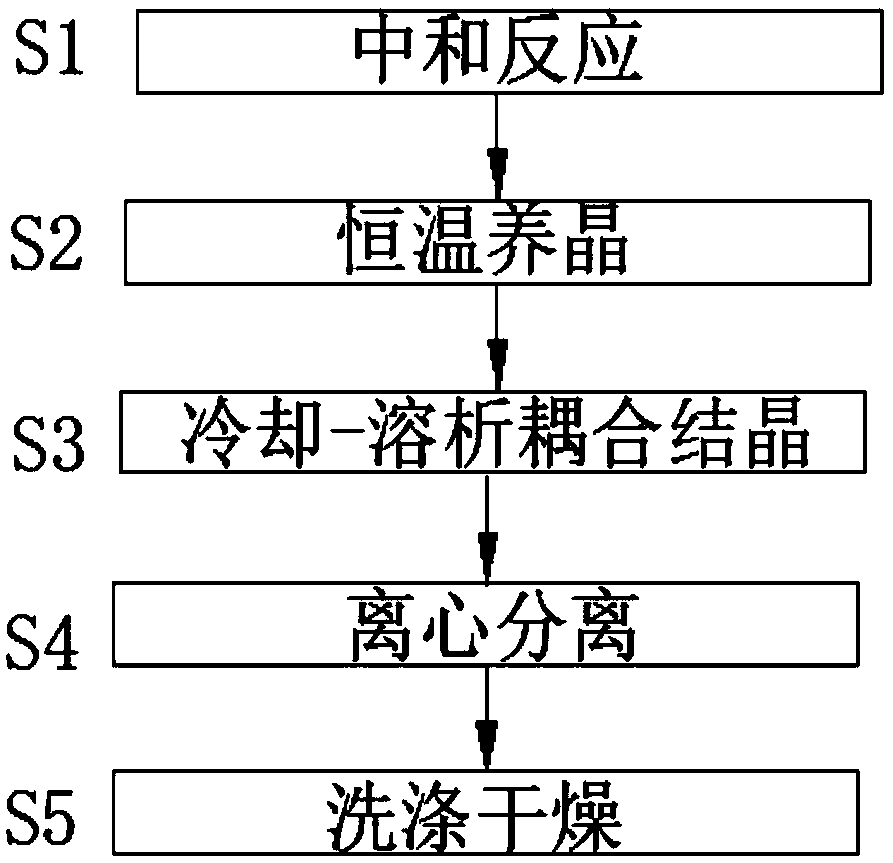

Continuous crystallization manufacturing process of medicinal glauber salt

InactiveCN101928020ALarge and uniform particle sizeControl supersaturationAlkali metal sulfites/sulfatesProcess systemsThree level

The invention discloses a continuous crystallization manufacturing process of medicinal glauber salt, which comprises the following step: removing mechanical impurities of original aqueous glauber salt with a certain concentration transported underground by a three-level pipeline filer under the monitoring of a DCS automatic monitoring system and the adjustment and control of an AK liquid balance flowmeter; refining and purifying by an eight-level ion exchanger to obtain refined aqueous glauber salt with a very low impurity content; introducing into a continuous crystallization process system; carrying out continuous solid-liquid separation by a multistage tandem centrifuge; and finally packing by an automatic packing system to obtain the glauber salt conforming to the pharmaceutical grade of Chinese Pharmacopoeia.

Owner:四川省川眉芒硝有限责任公司

Method for preparing nano catalytic composite materials by utilizing integrating process of ultrasonic-film-anti-solvent method

InactiveCN101863725BEvenly dispersedControllable dispersionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNon solventNano catalyst

The invention relates to a method for preparing nano catalytic composite materials by utilizing an integrating process of an ultrasonic-film-anti-solvent method, comprising the following steps of: (1) the ammonium porchlorate saturated solution preparation process: dissolving ammonium porchlorate into a proper solvent to prepare the ammonium porchlorate saturated solution at certain temperature; (2) the dispersing process of a nano catalyst: uniformly dispersing the nano catalyst into an anti-solvent under ultrasonic action; (3) the preparing process: adding the AP (ammonium porchlorate) saturated solution to a nonsolvent through a film tube under certain pressure, wherein after the anti-solvent carries out desolvation on the solvent, the ammonium porchlorate is separated out and covers on the surfaces of uniformly-dispersed nano particles to form the nano catalytic composite materials; (4) filtering and drying processes: firstly carrying out solid-liquid separation on nano composite particles; and (5) the drying process: drying separated materials at 50-150 DEG C to obtain the nano catalytic composite materials. The nano catalytic composite materials prepared by the method have stable structure, uniform nano catalyst dispersion and controllable particle diameter and appearance.

Owner:NANJING NORMAL UNIVERSITY

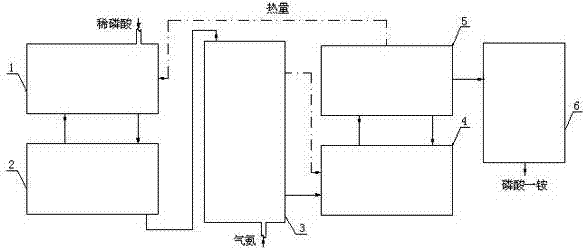

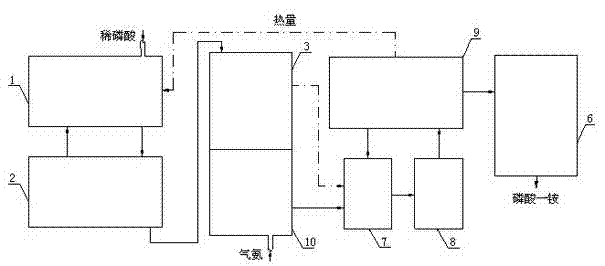

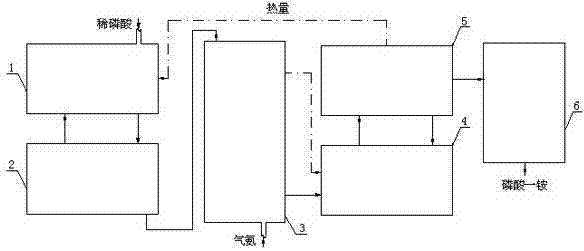

New technology of applying double-effect forced circulation concentration method in production of ammonium phosphate

InactiveCN102020257BReduce in quantityReduce the overall heightPhosphatesThermal energyFluidized bed drying

Owner:GANSU WENGFU CHEM

Low-temperature method for manufacturing nano-MgO crystal whisker

InactiveCN101220516BHigh purityComplete structurePolycrystalline material growthFrom chemically reactive gasesCrucibleRoom temperature

The invention relates to a method for preparing nanometer MgO whiskers at the low temperature and the method is that magnesium powders and amorphous boron powders are mixed according to atomic ratio of MG:B being equal to 1 to 1.5:2 and the mixture is grinded for 30 to 120 minutes for thorough mixing, and after the mixed powders are made into a lump sinter under the pressure of 5 to 10 kg / cm<3> bya press machine, the lump sinter is put into a crucible which is put into a heating zone of an evacuated tubular furnace. The evacuated tubular furnace is sealed, vacuumized to 1 to 10 Pa and filledwith argon the oxygen content of which is 2 percent to 5 percent and the flow rate of the mixed gas is 5 to 20 lit. per minute to heat the sample up to 650 to 750 DEG C at the heating rate of 5 to 20K per minute, and the sample is decreased to the room temperature at the same heating rate after the temperature is kept for 0 to 120 minutes. The surface of the sample forms nanometer MgO whiskers with various appearances and sizes. When reaching 650 DEG C, magnesium evaporates and reacts with the little filled oxygen to produce MgO vapour, and under the lower over-saturation state, MgO whiskersare deposited on a substrate. The method for preparing MgO whiskers needs temperature much lower than the previous and greatly increases the practicality of preparing MgO whiskers.

Owner:TIANJIN UNIV

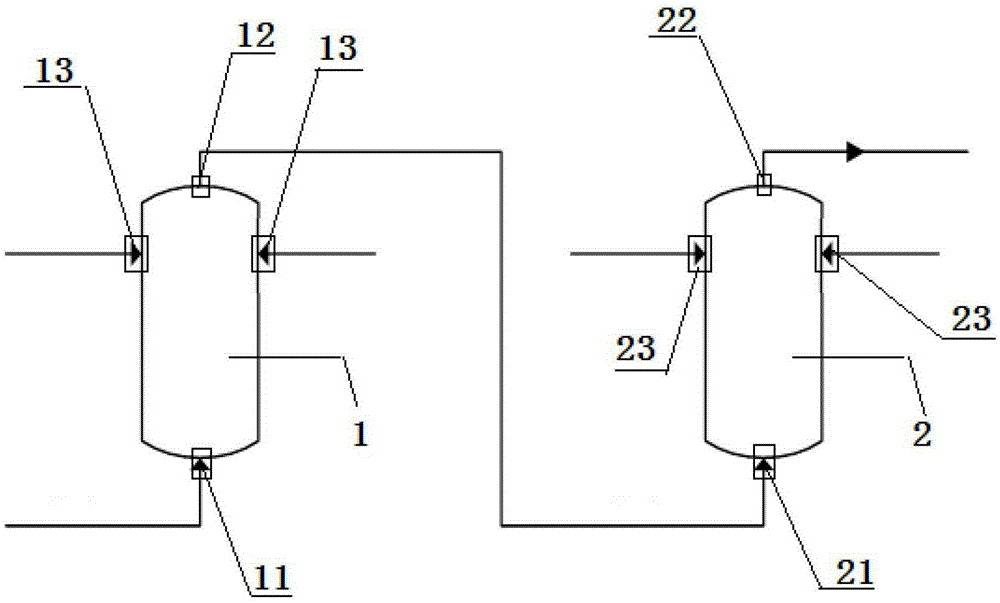

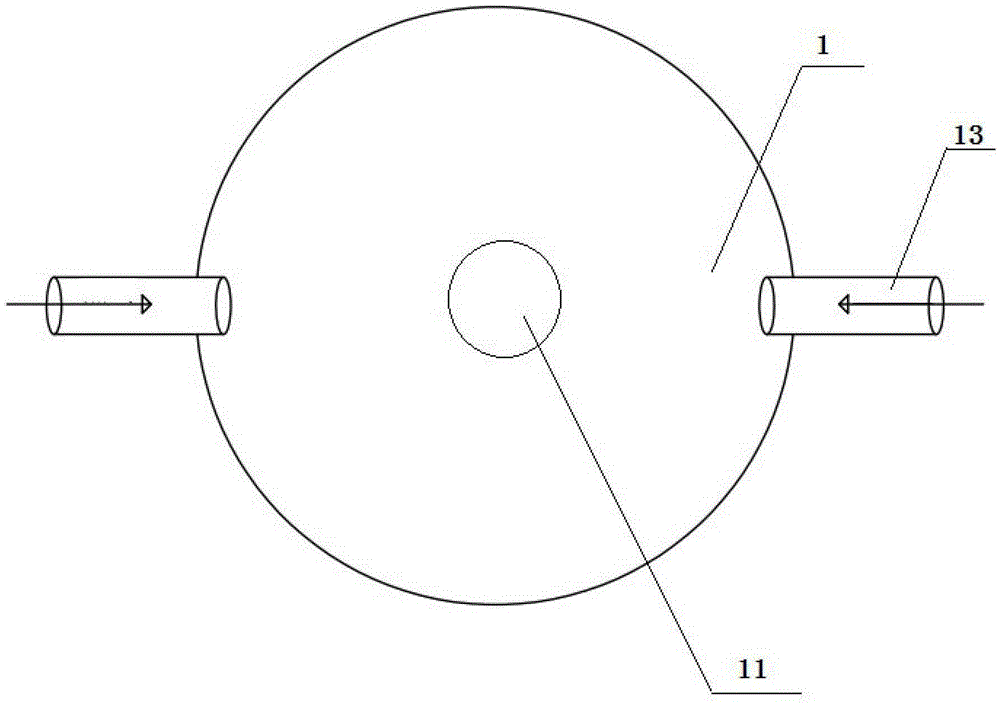

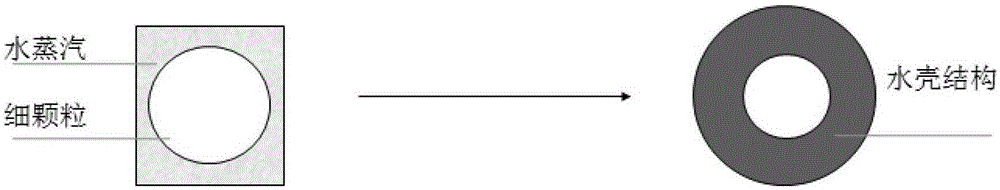

A device for water vapor phase change condensation to promote the removal of PM2.5 fine particles

InactiveCN103230717BControl supersaturationSimple structureUsing liquid separation agentDesorptionFlue gas

The invention provides a device for accelerating desorption of PM2.5 (Particulate Matter 2.5) fine particulate matters by utilizing vapor phase change and condensation. The device comprises a group of desorption towers which are sequentially connected, wherein flue gas inlets are formed in the bottoms of the desorption towers, flue gas outlets are formed in the tops of the desorption towers, and stream inlets are formed in the side walls of the desorption towers. According to the device, the structure is simple, and the cost is low; and by arranging a group of the desorption towers which are sequentially connected, the supersaturation degrees of the desorption towers are effectively controlled, so that the PM2.5 fine particulate matters in the gas are desorbed step by step; and the efficiency is high, and the energy consumption is low.

Owner:SOUTHEAST UNIV

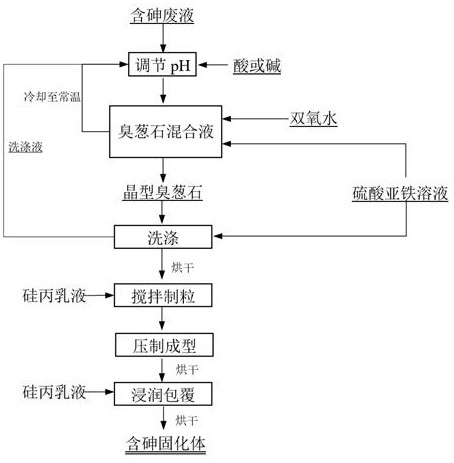

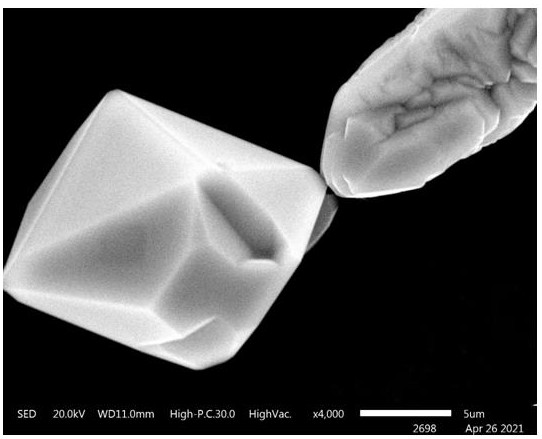

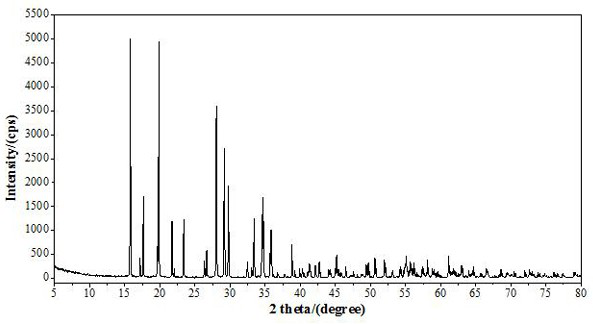

A long-term stabilization treatment method for arsenic-containing waste liquid arsenic

ActiveCN113526563BControl supersaturationReduce spawn rateIron compoundsMicroballoon preparationEnvironmental engineeringScorodite

The invention discloses a long-term stabilization treatment method for arsenic in arsenic-containing waste liquid, which comprises the following steps: (1) mixing arsenic-containing waste liquid with ferrous sulfate solution, adjusting the pH, temperature and oxidation-reduction potential of the mixed liquid, and arsenic-precipitated products Washing and drying to obtain crystalline scorodite; (2) high-speed stirring and granulation of crystalline scorodite and silicon-acrylic emulsion to form primary coated particles with scorodite as the core and silicon-acrylic emulsion as the shell. Press molding in a mold and dry to obtain scorodite core-shell-coated solidified body body; (3) Soak the solidified body body in step (2) in silicon-acrylic emulsion, take it out and dry it, and finally obtain arsenic-containing minerals cured body. The arsenic-containing solidified body obtained by the method has high density, high arsenic content, low arsenic leaching toxicity and good long-term stability.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH

Etching device and etching method of artificial quartz crystal seed wafer

ActiveCN109371456BControl supersaturationUniform corrosion ratePolycrystalline material growthFrom normal temperature solutionsTemperature controlReciprocating motion

The invention provides a corrosion device for an artificial quartz crystal seed chip. The corrosion device comprises a seed chip main body stander, a corrosion tank and a water-bath tank, wherein a timer and a rotating shaft with a motor are arranged on the seed chip main body stander, the timer is connected with the rotating shaft, and a traction rod is fixedly arranged on the rotating shaft; a rotating wheel capable of freely rotating is arranged on the traction rod, a traction line is fixedly arranged on the rotating wheel, a traction through hole and a venting pipe hole are formed in the top of the corrosion tank, the corrosion tank is placed in a water bath tank, and the traction line sequentially penetrates through a limiting hole and the traction through hole and is fixedly connected with a lifting rope. The invention further discloses a corrosion method for the artificial quartz crystal seed chip. The artificial quartz crystal seed chip can do a reciprocating motion in corrosion liquid. Temperature control of the corrosion liquid is emphasized, the supersaturation degree of the corrosion liquid is effectively controlled, and the uniform-speed corrosion is guaranteed by virtue of the concentration of the corrosion liquid.

Owner:山东博达光电有限公司

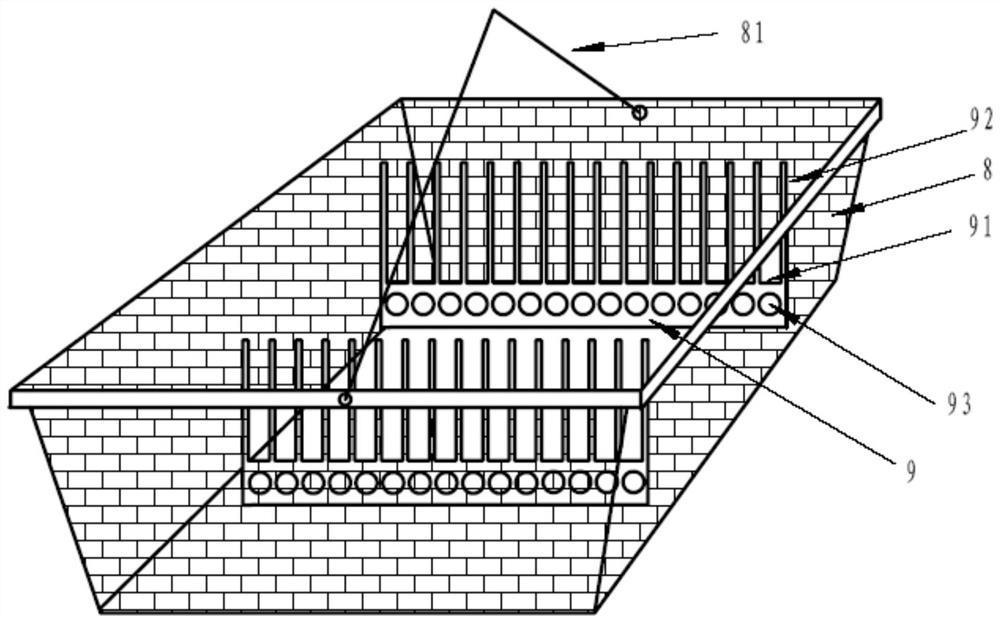

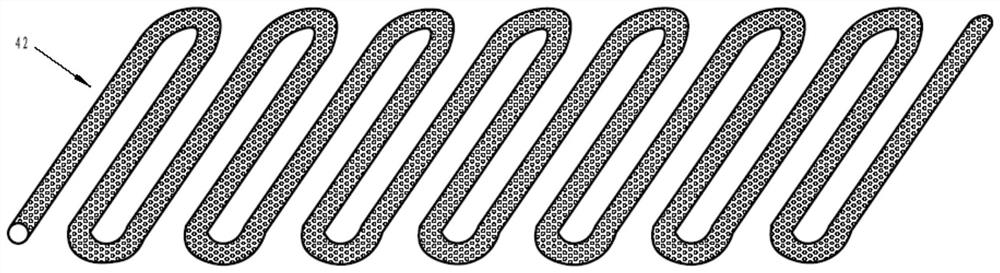

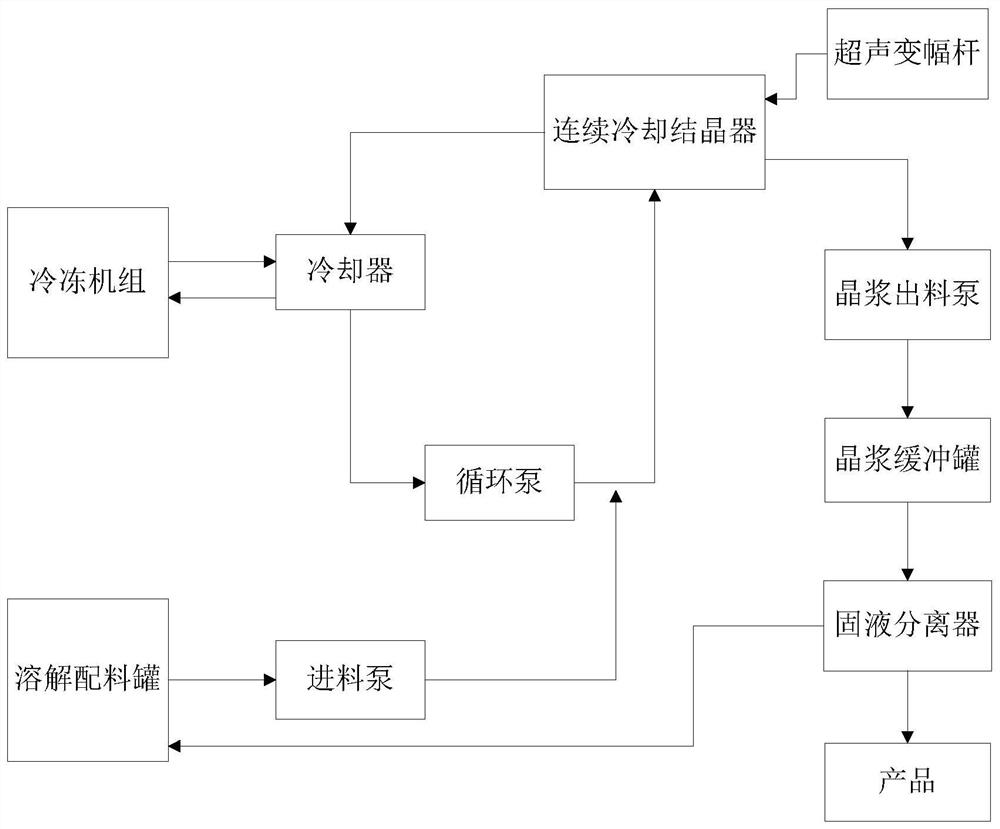

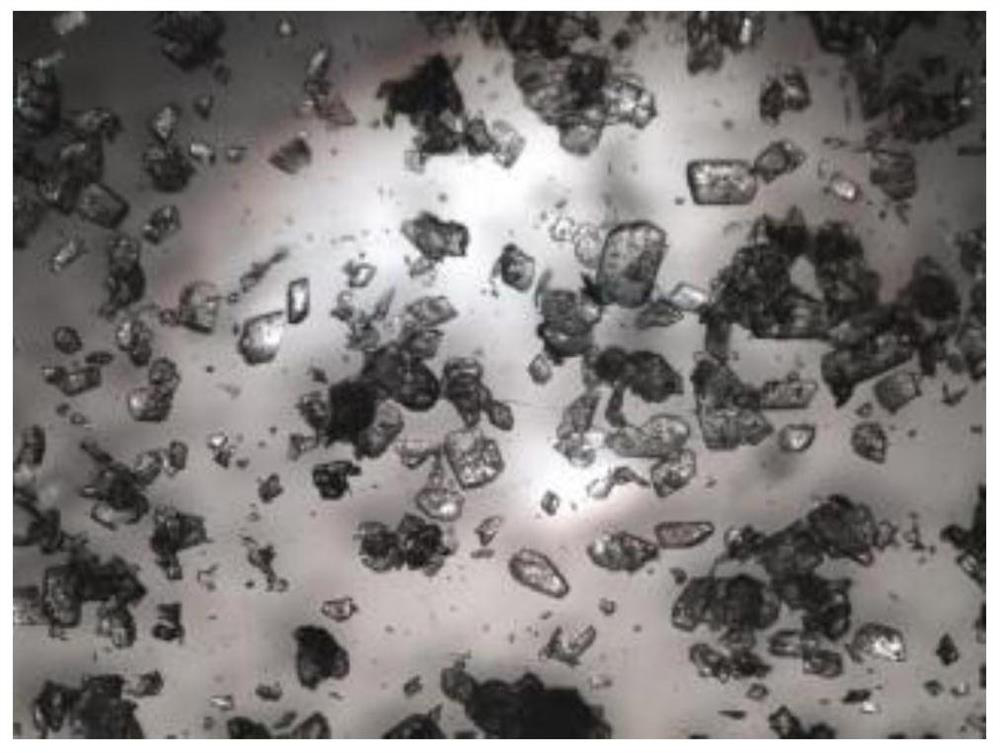

A preparation process and device system for continuous cooling and recrystallization of ethyl carbazole

ActiveCN112250613BUniform particle size distributionControl supersaturationOrganic chemistryAlcohol ethylPhysical chemistry

The invention discloses a preparation process and device system for continuous cooling and crystallization of ethyl carbazole, which solves the problem that floating crystals are prone to appear in the process of preparing ethyl carbazole in the traditional process, resulting in high moisture content of crystals and easy preparation of powdery crystals. question. The invention includes a preparation process of continuous cooling and recrystallization of ethyl carbazole. The ethyl carbazole crude product and ethanol solvent are mixed according to the mass ratio, and after heating and dissolving, the temperature is lowered for the first time, and the solution temperature is reduced to a supercooling degree of 1 ℃~4℃, add ethyl carbazole seed crystals with a particle size of 0.05mm~0.1mm, keep warm, and then lower the temperature to the crystallization temperature for the second time to obtain the mother liquor of continuous crystallization. Ultrasonic treatment is carried out on the pre-configured raw material solution, and the crystallization time is controlled, followed by centrifugation, washing and drying to obtain ethyl carbazole granule products; the above-mentioned preparation process is used to provide the device system. The invention has the advantages of being able to continuously cool and recrystallize to prepare short rod-shaped ethyl carbazole, and at the same time completely avoid the generation of floating crystals.

Owner:CHENGDU CHENGDE CHEM TECH

Surface erosion-resistant composite coating of carbon/carbon composite, preparation method and application thereof

InactiveCN101791883BControl supersaturationActive connectionLayered productsChemical vapor deposition coatingCarbon compositesGas phase

The invention relates to a surface erosion-resistant composite coating of a carbon / carbon composite, which sequentially consists of ZrC0.7 / ZrC1.0 / ZrC1.0+C form outside to inside. The preparation method of the surface erosion-resistant composite coating comprises the following three steps: the preparation of a basal layer ZrC1.0+C, the preparation of a middle layer ZrC1.0 and the preparation of anouter-coating layer ZrC0.7; and is characterized in that in a chemical vapor deposition furnace at normal pressure, zirconium tetrachloride is used as the zirconium source, Ar gas is used as the carrier gas, C3H6, acetylene and methane are respectively used as the carbon source gasses, Ar is used as the diluent, H2 is used as the reducing gas, and the surface erosion-resistant composite coating is obtained by deposition at the temperature of 1100-1300 DEG C. The invention has the advantages of simple process method, convenient operation, single heat, stepwise deposition preparation of the composite coating with gradient-changed carbon contents, firm combination between the coating and the basal body, no penetration crack and interlayer crack, and good coating erosion resistance and thermal shock resistance, can realize the industrialized production, and is applicable to the preparation of the erosion-resistant composite coating of the carbon / carbon composite by the chemical gas-phase permeation or the liquid-phase impregnation process.

Owner:CENT SOUTH UNIV

A method for precipitation and separation of rare earth in calcium-containing rare earth solution

ActiveCN111593214BReduced stabilityControl supersaturationProcess efficiency improvementCalcium bicarbonateSupersaturation

The invention discloses a method for precipitating and separating rare earths in a calcium-containing rare earth solution. Specifically, the concentration of rare earths is 0.1-1.5 mol / L, the concentration of calcium ions is 0.1-1.0 mol / L, and the molar ratio of rare earths to calcium is 0.7≤ The calcium-containing rare earth solution with X≤8.0 is the object, and the rare earth in the calcium-containing rare earth solution is precipitated by bicarbonate, and the conditions such as temperature, pH, and feeding speed during the precipitation process are adjusted and controlled according to the molar ratio of rare earth and calcium in the solution, so that Adjust the concentration of bicarbonate in the solution to control the stability of calcium bicarbonate and the supersaturation of rare earth carbonate, so that rare earth ions precipitate to form crystalline rare earth carbonate, and calcium ions form soluble calcium bicarbonate, so as to realize calcium-containing rare earth solution High-efficiency separation of medium rare earth and calcium, and rare earth oxides with a purity greater than 98%.

Owner:GANZHOU ZHANHAI IND & TRADING

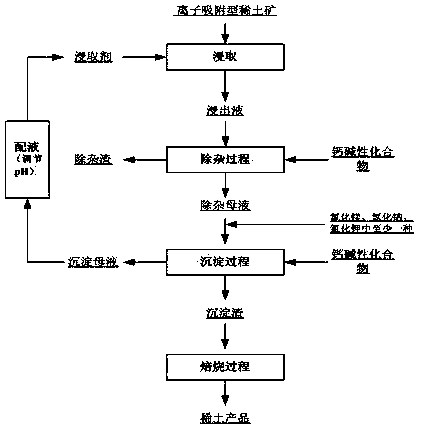

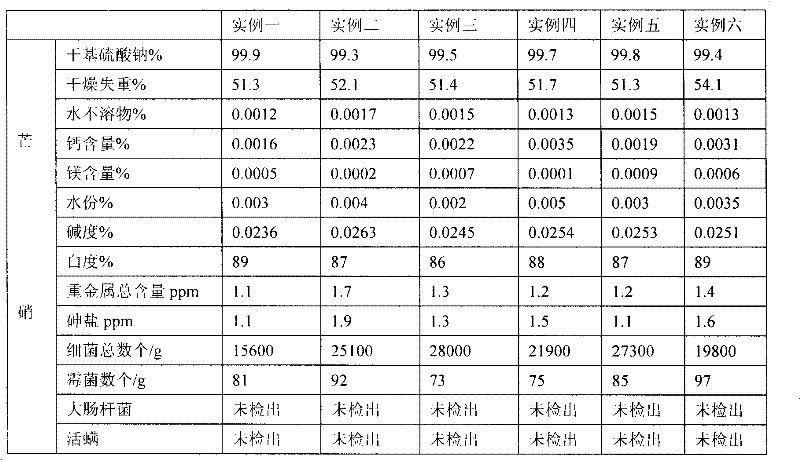

A method for extracting rare earth from ion adsorption type rare earth ore

The invention discloses a method for extracting rare earth from ion adsorption type rare earth ores. The method comprises the following steps: leaching the ion adsorption type rare earth ores by a leaching agent to obtain rare earth leachate; then adding a calcium-alkali compound in the rare earth leachate to remove impurities; adding at least one of magnesium chloride, sodium chloride and potassium chloride in impurity removal mother liquor; and controlling the chloride ion concentration, the temperature and the pH in a precipitation process of the calcium-alkali compound to achieve the purpose of increasing solubility of calcium sulfate and reduce generation of the calcium sulfate in the precipitation process. Meanwhile, under the related conditions of high salinity and the like, the migration speeds of rare earth ions and hydroxyl ions in a precipitation system of the calcium-alkali compound are reduced, the degree of supersaturation of rare earth hydrate is controlled effectively, and crystal precipitates of the rare earth hydrate is facilitated. By the method, ammonia nitrogen pollution is eliminated, formation of the calcium sulfate in the precipitation process of the calcium-alkali compound is reduced, the production cost is reduced, and meanwhile, the product with qualified purity is obtained.

Owner:JIANGXI UNIV OF SCI & TECH

Continuous crystallization manufacturing process of medicinal glauber salt

InactiveCN101928020BLarge and uniform particle sizeControl supersaturationAlkali metal sulfites/sulfatesProcess systemsThree level

The invention discloses a continuous crystallization manufacturing process of medicinal glauber salt, which comprises the following step: removing mechanical impurities of original aqueous glauber salt with a certain concentration transported underground by a three-level pipeline filer under the monitoring of a DCS automatic monitoring system and the adjustment and control of an AK liquid balanceflowmeter; refining and purifying by an eight-level ion exchanger to obtain refined aqueous glauber salt with a very low impurity content; introducing into a continuous crystallization process system; carrying out continuous solid-liquid separation by a multistage tandem centrifuge; and finally packing by an automatic packing system to obtain the glauber salt conforming to the pharmaceutical grade of Chinese Pharmacopoeia.

Owner:四川省川眉芒硝有限责任公司

A method for recovering rare earth and aluminum from ion adsorption type rare earth ore

The invention discloses a method for recycling rare earth and aluminum from ion adsorption type rare earth ores. The method comprises the following steps: leaching the ion adsorption type rare earth ores by a leaching agent to obtain rare earth leachate; then adding at least one of magnesium chloride, sodium chloride and potassium chloride in the leachate; and controlling the chloride ion concentration, the temperature and the pH in a precipitation process of a calcium-alkali compound to achieve the purpose of increasing solubility of calcium sulfate and reduce generation of the calcium sulfate in the precipitation process. Meanwhile, under the related conditions of high salinity and the like, the migration speeds of rare earth ions and hydroxyl ions in a precipitation system of calcium oxide are reduced, the degree of supersaturation of rare earth hydrate is controlled effectively, and crystal precipitates of the rare earth hydrate is facilitated. By the method, ammonia nitrogen pollution is eliminated, the rare earth recycling rate is increased, and aluminum resources are recycled comprehensively. Meanwhile, formation of calcium sulfate in the precipitation process of the calcium oxide is reduced, the production cost is reduced, and meanwhile, the product with the qualified purity is obtained. An impurity removal process does not exist in the method, and therefore, loss of rare earth in the impurity removal process can be avoided.

Owner:JIANGXI UNIV OF SCI & TECH

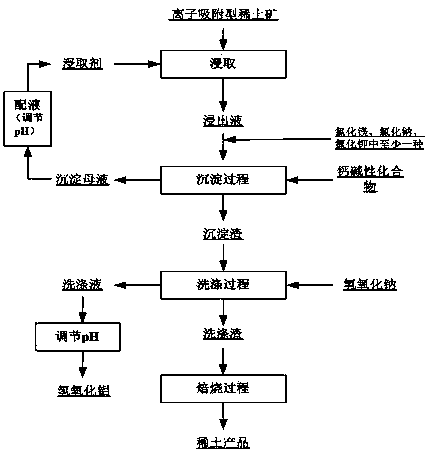

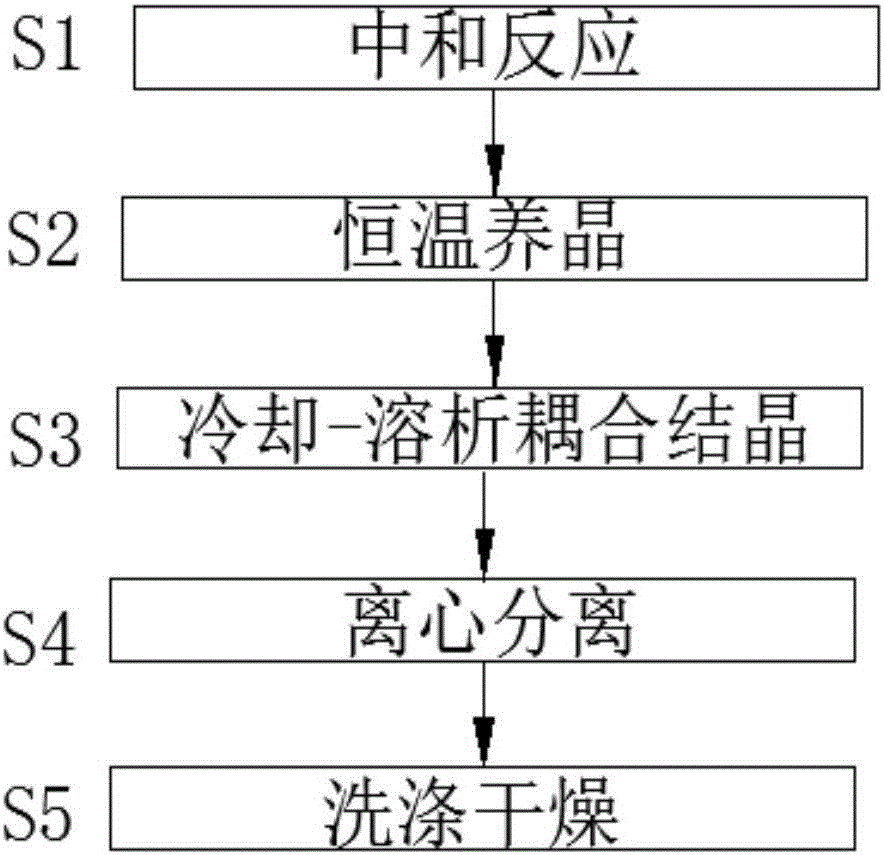

A kind of crystallization method of vitamin C sodium

The invention discloses a crystallization method of sodium ascorbate. A high-purity and large-granularity sodium ascorbate crystal product is prepared by a cooling crystallization and dilution crystallization coupling method through regulation and control of crystallization conditions. The method comprises the following specific technical steps: adding vitamin C and sodium bicarbonate into water; heating to 50 to 60 DEG C to carry out a neutralization reaction; filtering reaction completion liquid through an organic filter membrane, and adding a sodium ascorbate seed crystal; growing the crystal for 1 to 1.5 hours; lowering the temperature by 20 to 30 DEG C to perform first-stage cooling crystallization; raising the temperature by 20 to 30 DEG C, and adding methanol to perform first-stage heating dilution crystallization; performing second-stage cooling crystallization, second-stage heating dilution crystallization and third-stage cooling crystallization; performing centrifugal separation; washing a sodium ascorbate crystal filter cake; performing vacuum drying to obtain a sodium ascorbate crystal product. The crystallization method has high yield, and the obtained sodium ascorbate crystal product has high purity, homogeneous granularity and large crystal main granularity.

Owner:自然资源部天津海水淡化与综合利用研究所

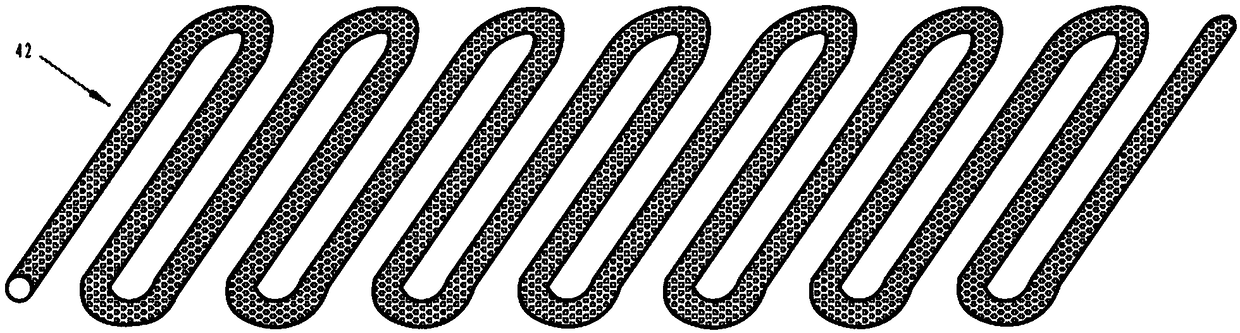

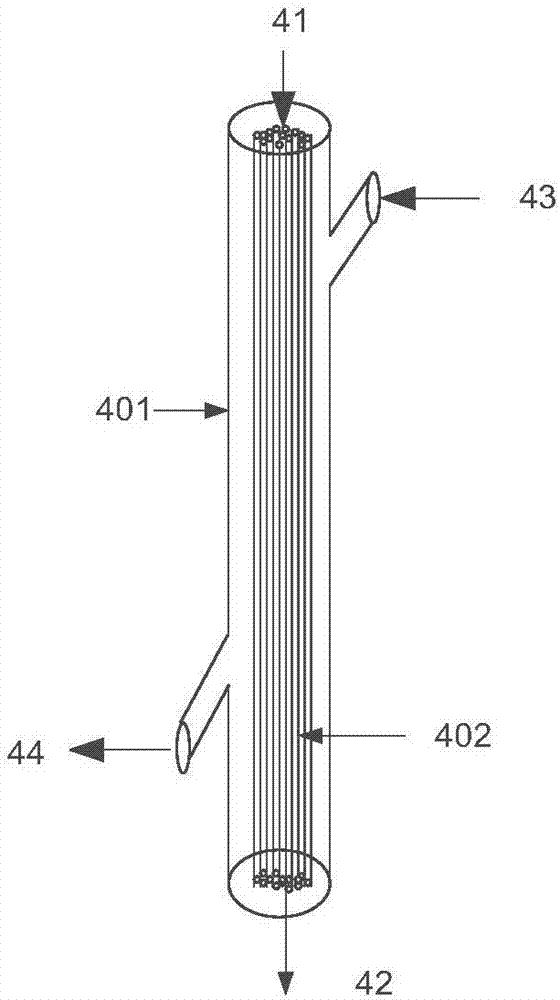

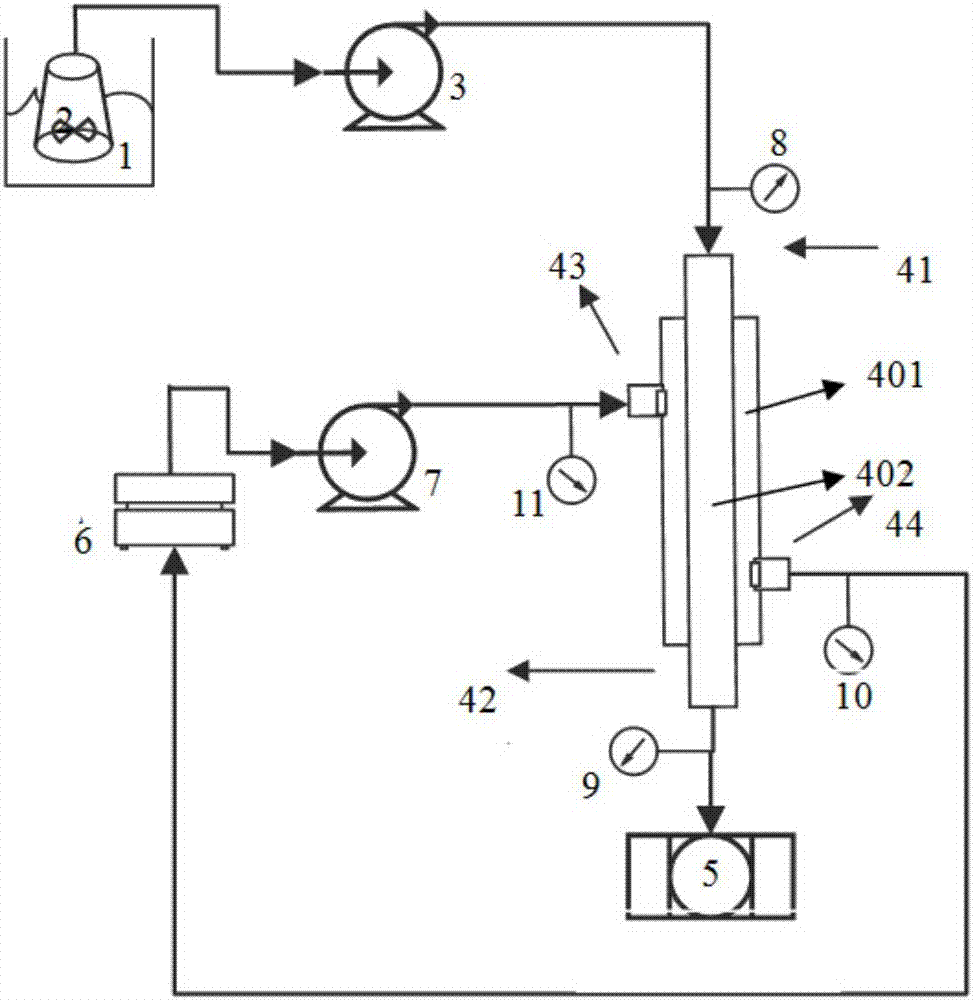

Method for preparing acrylic resin coated nano-drug by solid wall fiber pipe bundle crystallizer

InactiveCN106890132AControl supersaturationHigh thermal conductivityOrganic active ingredientsPharmaceutical delivery mechanismWater bathsPeristaltic pump

The invention provides a method for preparing an acrylic resin coated nano-drug by a solid wall fiber pipe bundle crystallizer and relates to nano-drug preparation. A water bath device, a dissolving drug bottle, two peristaltic pumps, the fiber pipe bundle crystallizer, a vacuum filtration system and a refrigerator are arranged; the dissolving drug bottle is arranged in the water bath device, an inner pipe and an outer pipe are arranged on the fiber pipe bundle crystallizer, the dissolving drug bottle is connected with an inlet of the first peristaltic pump, an outlet of the first peristaltic pump is connected with an inlet of the inner pipe of the fiber pipe bundle crystallizer, an outlet of the inner pipe of the fiber pipe bundle crystallizer is connected with the vacuum filtration system, an outlet of the outer pipe of the fiber pipe bundle crystallizer is connected with an inlet of the second peristaltic pump, an outlet of the second peristaltic pump is connected with an inlet of the outer pipe of the fiber pipe bundle crystallizer, and the inner pipe of the fiber pipe bundle crystallizer is formed by micron size hollow solid wall fiber pipe bundles. The method comprises the steps of preparation of the fiber pipe bundle crystallizer: single bundles of micron size hollow solid wall fiber pipe bundles are cut and put into a sleeve, and the fiber pipe bundle crystallizer is formed; preparation of the nano-drug and coating of acrylic resin; and postprocessing.

Owner:XIAMEN UNIV

A kind of preparation method of fibrous basic magnesium sulfate whisker

ActiveCN103789819BHigh crystallinitySlow down the dissolution ratePolycrystalline material growthFrom normal temperature solutionsMagnesium Sulfate whiskersWhiskers

The invention relates to the preparation field of chemical industrial materials, and particularly relates to a preparation method of a fibrous alkali magnesium sulfate whisker. The preparation method of the fibrous alkali magnesium sulfate whisker comprises the following steps: (1) preparing a magnesium sulfate solution by using MgSO4.7H2O, stirring and adding NaOH granular caustic soda, aging for 2-24 hours at the temperature of 25 to 100 DEG C to obtain a slurry; (2) transferring the slurry obtained in the step (1) into a hydrothermal reactor, wherein the filling degree is 50-80 percent, adding 0.5-5 percent of seed crystal according to the mass of the NaOH granular caustic soda, uniformly stirring, and reacting the slurry for 2-12 hours at the temperature of 130-180 DEG C; (3) cooling after finishing the reaction of the step (2), filtering, washing and drying a obtained white turbid liquid to obtain the fibrous alkali magnesium sulfate whisker. According to the preparation method, the seed crystal is added into the reaction slurry, alkali magnesium sulfate is easily subjected to nucleus formation growth, and the preparation concentration of the reaction slurry can be relatively high; the whisker nucleation time is reduced, and the whisker growth time also can be shortened.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A kind of method prolonging the shelf-life of thiourea dioxide product

InactiveCN103588688BExtended shelf lifeCrystal surface smoothOrganic chemistryPhysical chemistrySaturated aqueous solution

Owner:WUHAN UNIV OF SCI & TECH

Crystallization method of sodium ascorbate

The invention discloses a crystallization method of sodium ascorbate. A high-purity and large-granularity sodium ascorbate crystal product is prepared by a cooling crystallization and dilution crystallization coupling method through regulation and control of crystallization conditions. The method comprises the following specific technical steps: adding vitamin C and sodium bicarbonate into water; heating to 50 to 60 DEG C to carry out a neutralization reaction; filtering reaction completion liquid through an organic filter membrane, and adding a sodium ascorbate seed crystal; growing the crystal for 1 to 1.5 hours; lowering the temperature by 20 to 30 DEG C to perform first-stage cooling crystallization; raising the temperature by 20 to 30 DEG C, and adding methanol to perform first-stage heating dilution crystallization; performing second-stage cooling crystallization, second-stage heating dilution crystallization and third-stage cooling crystallization; performing centrifugal separation; washing a sodium ascorbate crystal filter cake; performing vacuum drying to obtain a sodium ascorbate crystal product. The crystallization method has high yield, and the obtained sodium ascorbate crystal product has high purity, homogeneous granularity and large crystal main granularity.

Owner:自然资源部天津海水淡化与综合利用研究所

A kind of wet-process phosphoric acid prepares tripotassium phosphate method

InactiveCN105217591BReduce consumptionGuaranteed purityPhosphorus compoundsSulfate radicalsPhosphate

Owner:GUIZHOU KAILIN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com