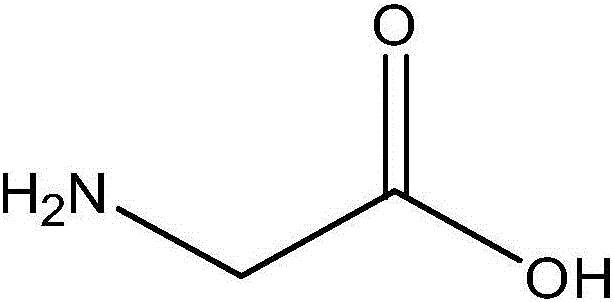

Method for controlling temperature of glycine cooling crystallization crystal point

A technology of crystallization point temperature and cooling crystallization, which is applied in the investigation stage/state change, etc., can solve the problems of high equipment requirements, lower process yield, and small adjustable range, and achieve the effect of easy preparation and optimized process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh glycine and deionized water with a mass ratio of 1:2, place them in a crystallizer, raise the temperature to 80°C, keep constant temperature and stir thoroughly, after glycine is completely dissolved, add 1-(4-sulfopropyl ) butyl-pyridine bisulfate, after it is completely dissolved, set the stirring speed to 200r / min, start cooling at a cooling rate of 15°C / min, and measure the crystal point temperature to be 46.5°C.

Embodiment 2

[0027] Weigh glycine and deionized water with a mass ratio of 1:2, place them in a crystallizer, raise the temperature to 80°C, keep the temperature constant and stir thoroughly, after the glycine is completely dissolved, add 0.5% of the solute mass of alkyl glycoside, and wait for it to completely dissolve Finally, the stirring speed was set to 400r / min, and the temperature was lowered at a cooling rate of 3°C / min, and the temperature of the crystal point was measured to be 52.3°C.

Embodiment 3

[0029] Weigh glycine and deionized water with a mass ratio of 1:2, place them in a crystallizer, raise the temperature to 80°C, keep the temperature constant and stir thoroughly, after the glycine is completely dissolved, add 0.5% of the solute mass of alkyl glycoside, and wait for it to completely dissolve Finally, the stirring speed was set to 800r / min, and the temperature was lowered at a cooling rate of 3°C / min, and the crystal point temperature was measured to be 60.3°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com