Preparation technique of beta-hydroxyalkylamide

A hydroxyalkylamide and preparation technology, which is applied in the field of powder coating curing agent, can solve the problems of increasing solvent consumption, post-processing steps, and reducing product purity, and achieve the effects of improving the crystallization effect, optimizing the crystallization process, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

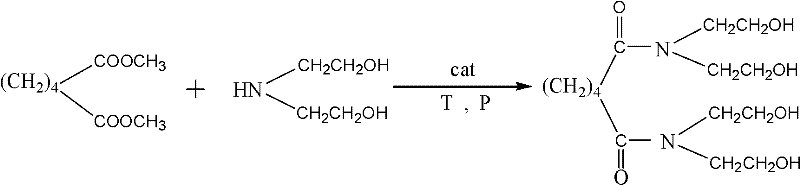

[0021] Embodiment 1: the preparation of HAA

[0022] Add 742Kg diethanolamine (7.06Kmol) and 18KgKOH (accounting for 3% of the mass of dimethyl adipate) into the reactor, heat the mixture to 50°C with stirring, and extract the gas in the kettle until the pressure in the kettle reaches 0.005MPa. Add 600Kg dimethyl adipate (3.4Kmol) dropwise into the reaction kettle, and add dimethyl adipate in 2 hours, then heat to high temperature section 105°C for 2 hours, then lower the temperature to 75-80°C React for 1 hour to keep the product at a viscosity of 800CPS. Finally, add the mixed solvent of 694L methanol / 2776L ethyl acetate to the crude product to crystallize at 5-10°C for 4-6h, then centrifuge and dry in an oven at 70-85°C for 13-16h to obtain 1084Kg HAA product.

Embodiment 2

[0023] Embodiment 2: 643Kg diethanolamine (6.12Kmol) and 12KgCH 3 ONa (accounting for 2% of the dimethyl adipate quality) is added in the reactor, and the mixture is heated to 65°C with stirring, and after the gas in the still is taken out until the pressure in the still reaches 0.01MPa, 600Kg dimethyl adipate ( 3.4Kmol) was added dropwise into the reactor, and dimethyl adipate was added in 1.5 hours, then heated to a high temperature section of 120°C for 1.5h, and then lowered to 95°C for 0.5h to keep the product at 930CPS under viscosity. Finally, the crude product was crystallized at 5-10°C for 4-6h by adding a mixed solvent of 685L methanol / 1369L ethyl acetate, then centrifuged and dried in an oven at 70-85°C for 13-16h to obtain 1082Kg HAA product.

Embodiment 3

[0024] Embodiment 3: 1428Kg diethanolamine (13.6Kmol) and 36KgNaOH (accounting for 6% of the dimethyl adipate quality) are added in the reactor, and the mixture is heated to 70°C with stirring, and the gas in the kettle is extracted until the pressure in the kettle reaches After 0.01MPa, add 600Kg dimethyl adipate (3.4Kmol) dropwise into the reaction kettle, and add dimethyl adipate in 3 hours, then heat it to the high temperature section at about 105°C for 1.5 hours, and then lower it The temperature was raised to 85° C. for 2 hours to keep the product at a viscosity of 940 CPS. Add 549L methanol / 4934L ethyl acetate mixed solvent to the crude product to crystallize at 5-10°C for 4-6h, then centrifuge and dry in an oven at 70-85°C for 13-16h to obtain 1083Kg HAA product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com