Patents

Literature

84results about How to "Low flash point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

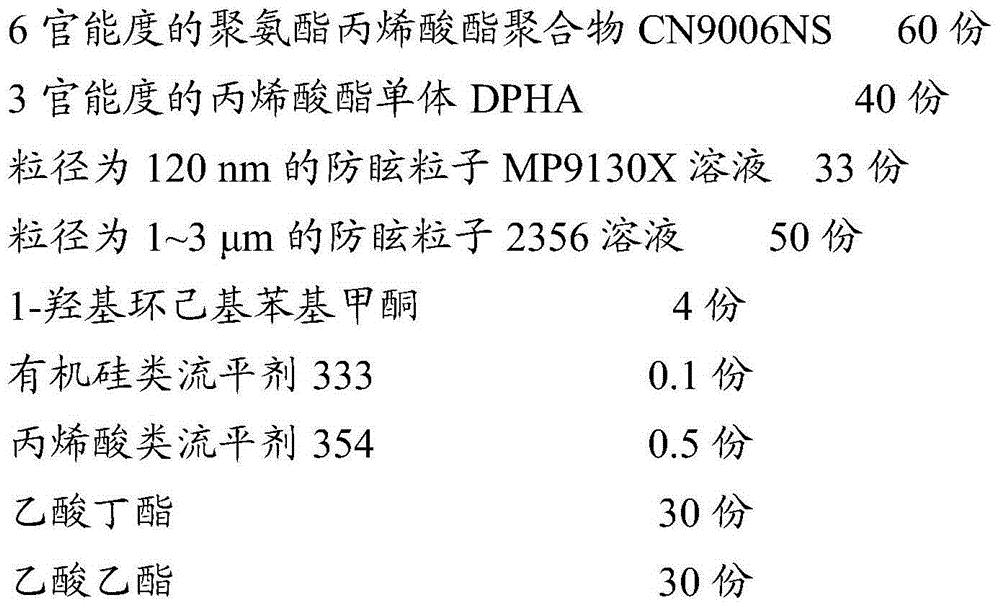

Anti-dazzle coating and anti-dazzle hardening film

ActiveCN104817951AImprove flash pointLow flash pointPolyurea/polyurethane coatingsOptical elementsOrganic solventUrethane acrylate

The invention provides an anti-dazzle coating and an anti-dazzle hardening film. The anti-dazzle coating comprises the following components in parts by weight: 60-80 parts of polyurethane acrylate polymer with six degrees of functionality or above, 20-40 parts of acrylate monomer with six degrees of functionality or above, 10-15 parts of anti-dazzle particles with particle size of less than or equal to 500nm, 5-10 parts of anti-dazzle particles with particle size of 1-3mu m, 4-8 parts of a photoinitiator, 0.1-1 part of an organosilicone levelling agent, 0.5-1 part of an acrylic acid levelling agent and 40-80 parts of an organic solvent. The anti-dazzle coating provided by the invention is used for preparing an anti-dazzle hard coating film; two types of anti-dazzle particles different in particle size are used together so that the prepared anti-dazzle hard coating film has excellent properties of low flash point and high definition; in addition, the anti-dazzle hard coating film further has excellent levelling property so that the flash point of the anti-dazzle hardening film can be lowered further.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Electrolyte of lithium-ion secondary battery

InactiveCN102082295AExtended low temperature operating rangeReduce contentSecondary cells servicing/maintenanceOrganic solventPhysical chemistry

The invention discloses an electrolyte of a lithium-ion secondary battery, which adopts fluoro-carbonate, high molecular weight chain carbonate and N, N-dimethyl trifluoro ethyl amide as cosolvent, and an organboron compound as an enhanced conductivity additive, and also contains film forming additive vinylene carbonate, 1,3-propyl sultone and a non-aqueous organic solvent in which lithium salt is dissolved. The battery assembled by using the electrolyte has good charging performance and discharging performance at low temperature, and the flame retardant property of the electrolyte is remarkably improved as the fluoro-carbonate is added.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Engine fuels

InactiveUSRE37629E1Low flash pointEasy to igniteSolid fuelsLiquid carbonaceous fuelsAlcoholAliphatic hydrocarbon

Owner:WILKINS JR JOE S

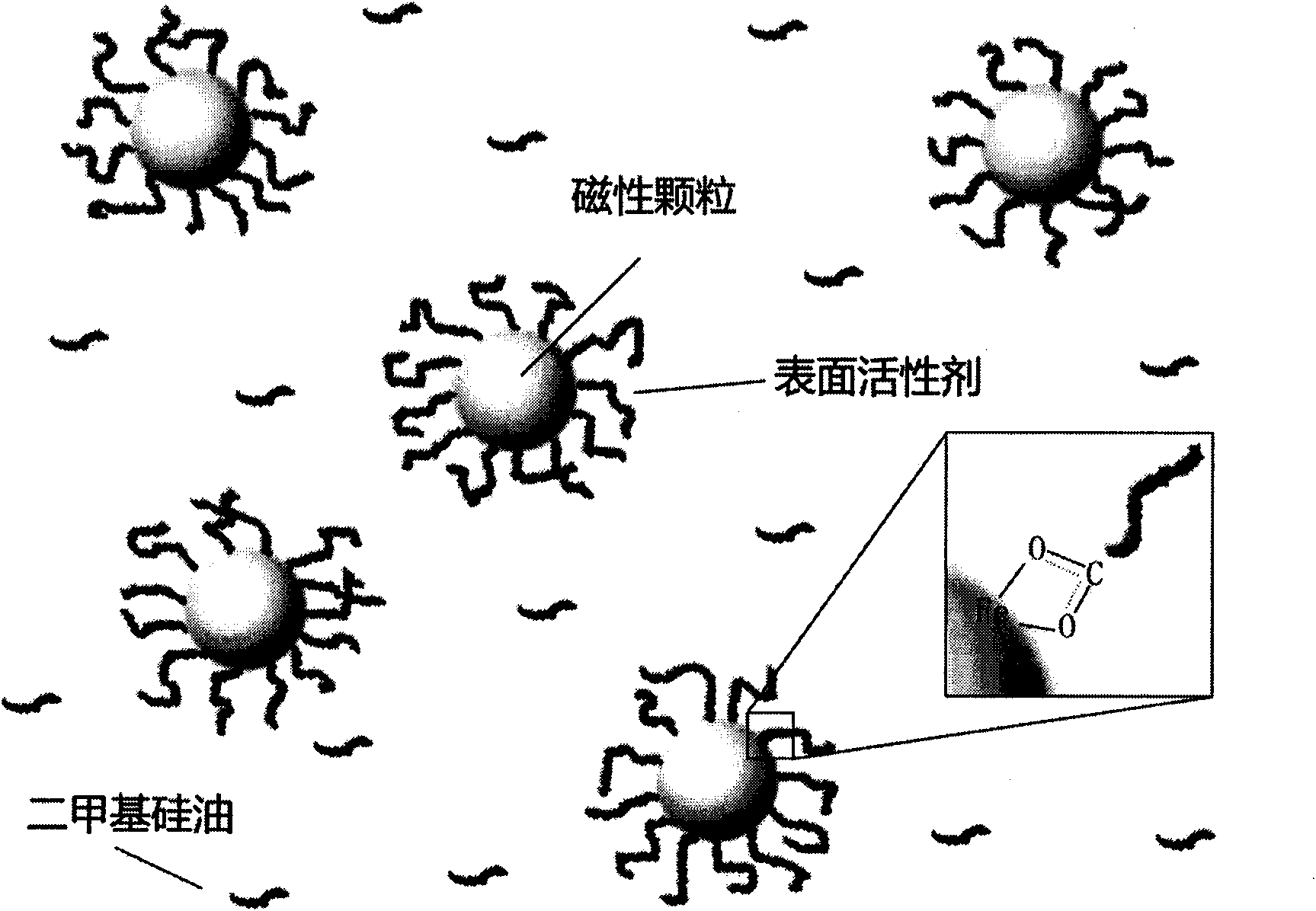

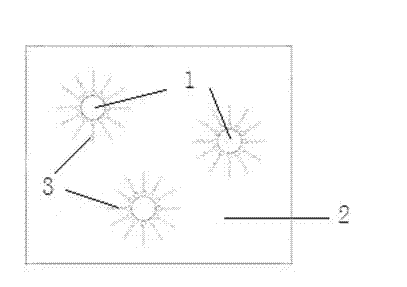

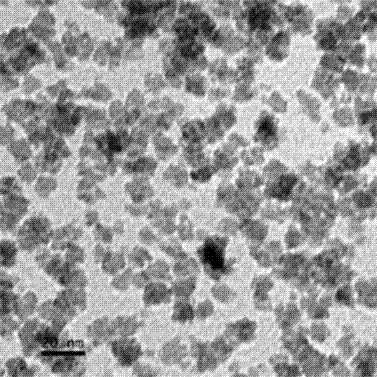

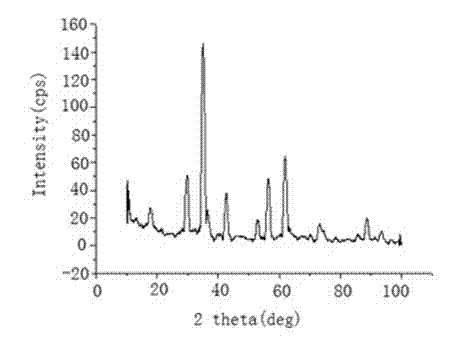

Oxidation resistant dimethyl silicon oil based magnetic fluid and preparation method thereof

InactiveCN101599335ASmall viscosity-temperature coefficientLow compression resistanceMagnetic liquidsOrganic/organic-metallic materials magnetismMethylene DichlorideMagnetic liquids

The invention provides oxidation resistant dimethyl silicon oil based magnetic fluid and a preparation method thereof; the dimethyl silicon oil based magnetic fluid is prepared by nano-magnetic particles, a surface modifier and carrier fluid, and the carrier fluid is the dimethyl silicon oil. The preparation method of the dimethyl silicon oil based magnetic fluid comprises the following steps: preparing the nano-magnetic particles; treating the nano-magnetic particles in an activated way; preparing the nano-magnetic particles which are modified by the surface modifier; adding the modified nano-magnetic particles which are purified into methylene dichloride, dispersing and filtering the mixture to obtain the methylene dichloride based magnetic fluid; adding the magnetic fluid into the dimethyl silicon oil to be stirred and dispersed, heating the mixture and maintaining the temperature between 50 and 90 DEG C, separating and precipitating the mixture to obtain the dimethyl silicon oil based magnetic fluid. The dimethyl silicon oil based magnetic fluid in the invention has the advantages of high stability, low temperature resistance and high temperature resistance. The preparation method is simple, high in efficiency and low in requirement on equipments, thus being easy to be applied in various fields and having wide application prospect.

Owner:SUN YAT SEN UNIV

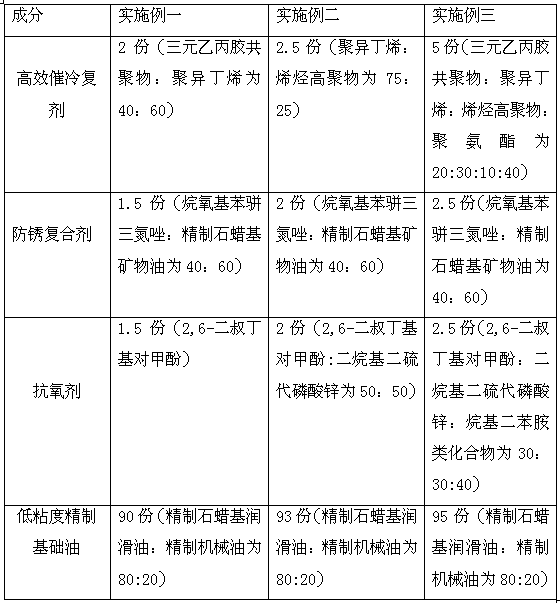

Special lubricating oil of bearing bush of supporting roller of rotary kiln and manufacturing method thereof

The invention discloses special lubricating oil of a bearing bush of a supporting roller of a rotary kiln and a manufacturing method thereof. The special lubricating oil contains the following components according to the content by mass percent: 49 to 69 percent of liquid paraffin chlorination and condensation synthetic oil, 15 to 35 percent of poly-alpha-alkene synthetic oil, 0.5 to 1.5 percent of tackifier, 2 to 4 percent of nano colloid molybdenum disulphide powder, 3.5 to 5.5 percent of organic molybdenum complex additive, 2.5 to 4.5 percent of borate complex additive, 1 to 3 percent of additive T406, 0.4 to 0.6 percent of antioxidant T203, 0.7 to 0.9 percent of antioxidant T531 and 0.6 to 0.8 percent of antioxidant T512. The invention has the favorable performances of extreme-pressure resistance, abrasion resistance, high-temperature resistance, water sprinkling resistance and oxidation resistance, can fully act as the functions of repairing the wire drawing of the bearing bush, decreasing the abrasion and lowering the temperature of the bearing bush, prolongs the use period of the bearing bush of the supporting roller and realizes the aims of energy saving and consumption reduction.

Owner:洛阳正本润滑材料有限公司 +1

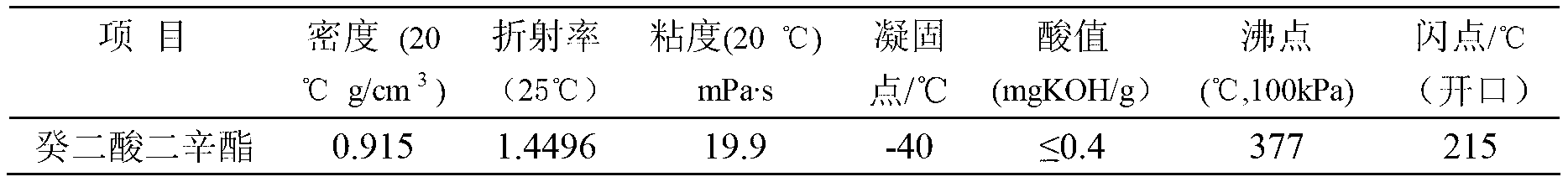

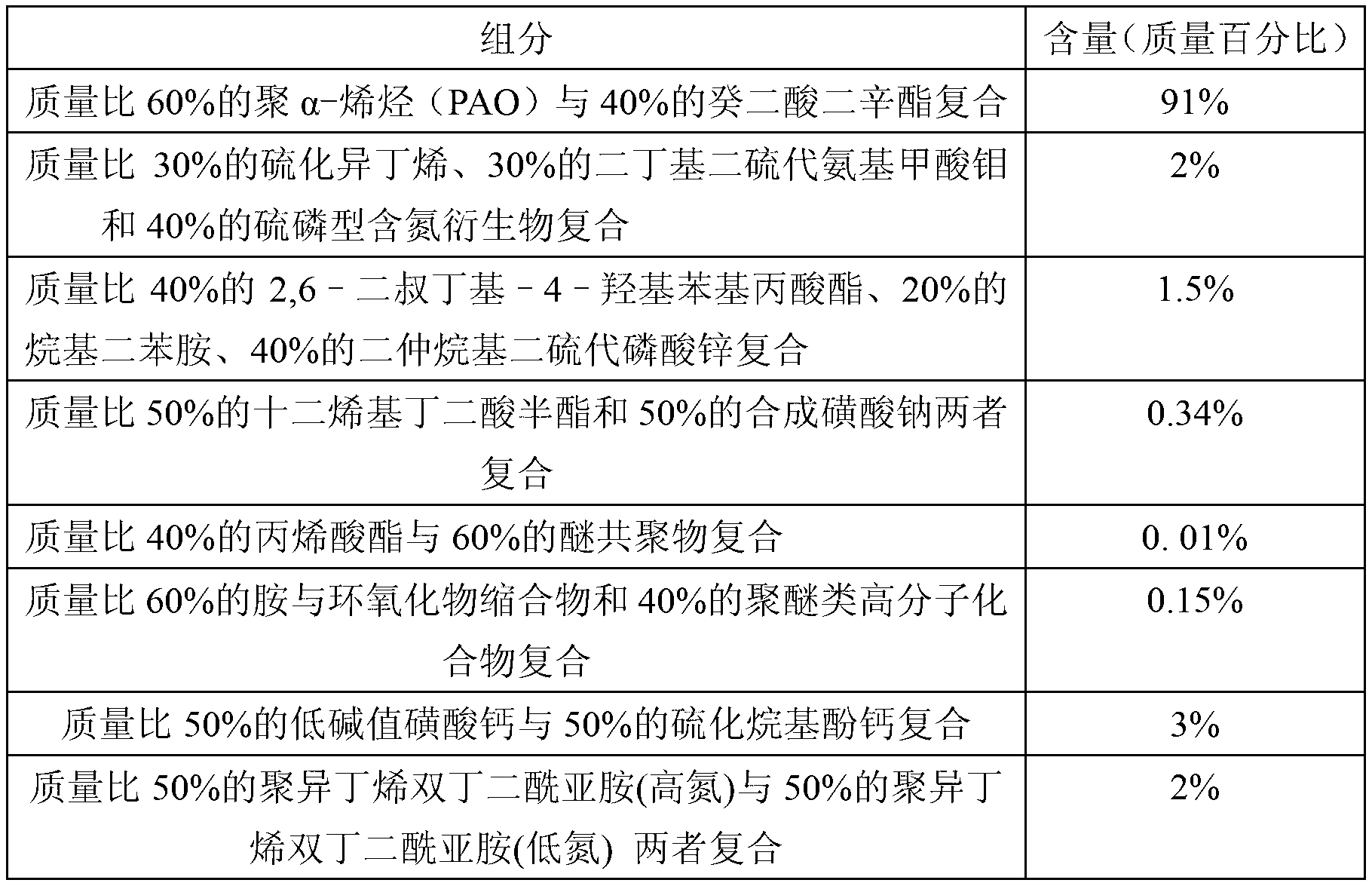

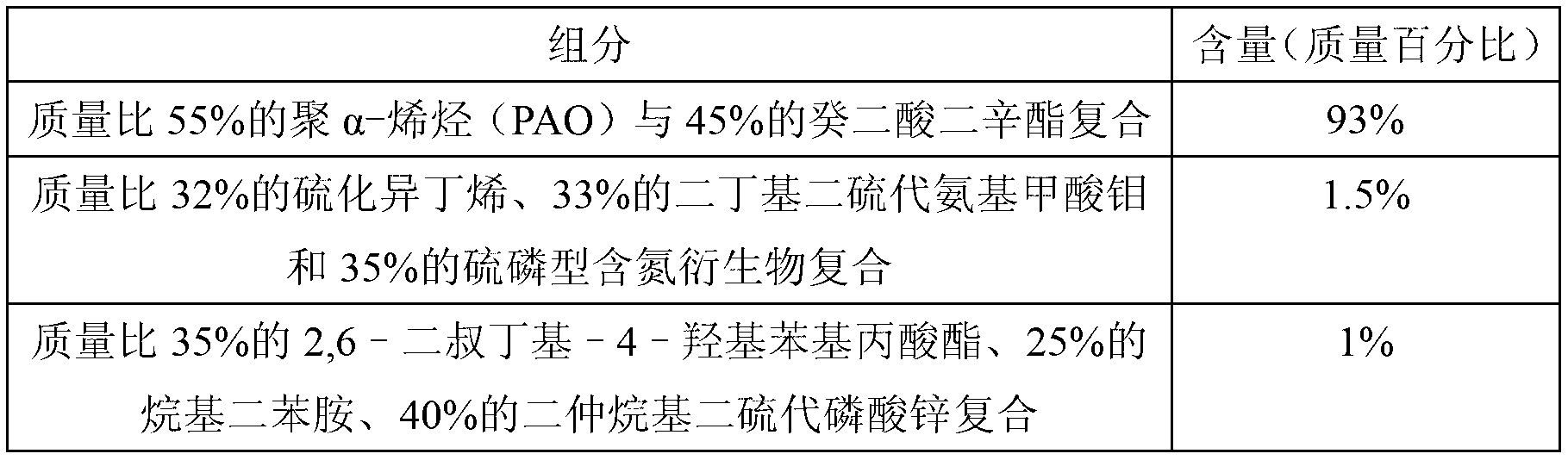

Environmentally-friendly energy-saving-type heavy loading screw compressor oil

ActiveCN103194301AGood low viscosityLow volatilityLubricant compositionLubricationEnvironmentally friendly

The invention provides environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil comprises 90-95% of composite base oil and 10%-5% of other additives in percentage by weight. Poly Alpha-Olefins (PAO) and dioctyl sebacate are compounded to serve as the base oil of the environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention has the advantages of good operating characteristics, long service life and good biodegradability and also has effects of improving the efficiency of a screw compressor, reducing the abrasion and corrosion of a screw, effectively prolong the service life and the oil draining period of the screw compressor and meeting the requirements under special service conditions. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention is not only suitable for the requirements of various middle-heavy loading screw compressors under service conditions, and but also can meet the lubrication, cooling and sealing requirements of the middle-heavy loading sliding vane compressors.

Owner:GUANGXI UNIV

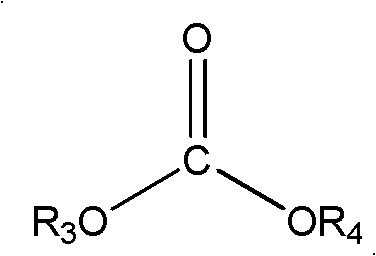

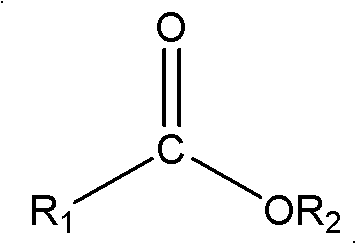

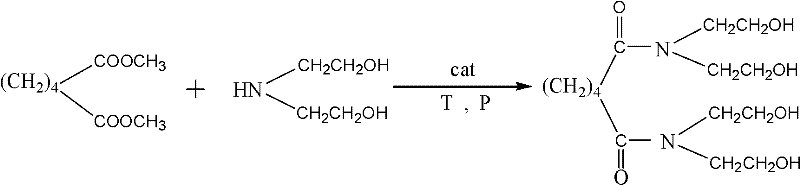

Preparation technique of beta-hydroxyalkylamide

ActiveCN102633667ASuppress generationPurificationOrganic compound preparationCarboxylic acid amides preparationAlcoholAfter treatment

The invention relates to a preparation technique of beta-hydroxyalkylamide, which comprises the following steps: (a) proportionally adding diethanolamine and an alkaline catalyst into a reaction kettle, evacuating until the pressure in the kettle reaches 0.005-0.01MPa, and controlling the temperature at 50-80 DEG C; (b) dropwisely adding dimethyl adipate within 3 hours to carry out ammonolysis reaction, and evaporating to remove alcohol emitted in the reaction process; (c) after finishing dropwisely adding the dimethyl adipate, heating the reaction kettle to the high temperature of 105-120 DEG C to react for 2-4 hours, cooling to 75-95 DEG C to react for 0.5-2 hours, and keeping the viscosity of the product at 800-1000CPS; and (d) after the reaction finishes, carrying out after-treatment (crystallizing, centrifugalizing and drying) on the crude product. The mol ratio of dimethyl adipate to diethanolamine is 1:(1.8-4); the alkaline catalyst is selected from NaOH, KOH, CH3ONa and CH3ONa / NaOH; the alkaline catalyst accounts for 2-6 wt% of the dimethyl adipate; the crystallizing solvent is a mixed solvent in which the ratio of methanol to ethyl acetate is 1:(2-9); and the consumption of the crystallizing solvent is 1.5-4 times of HAA by weight. The invention can effectively enhance the purity of the product and inhibit the generation of side reactions.

Owner:HUANGSHAN HUAHUI TECH

Electrolyte of flame-retarded lithium ion battery

ActiveCN102082296AExcellent non-flammabilityHigh viscositySecondary cells servicing/maintenanceBenzeneOrganic solvent

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

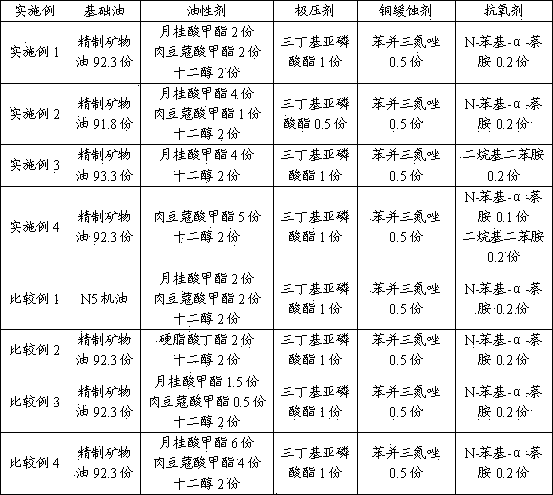

Oil composition for copper foil rolling and uses thereof

InactiveCN104342247AGood lubricating and cooling effectImprove anti-corrosion and anti-rust performanceWork treatment devicesMetal rolling arrangementsPhosphoric Acid EstersEngineering

The invention relates to an oil composition for copper foil rolling and uses thereof, mainly overcoming the problems of the prior art, namely poor lubrication performance, much oil mist and poor low-temperature annealing detergency. The oil composition adopts a mixture comprising following components by weight: a) 90-98 parts of base oil; b) 1-10 parts of an oiliness agent; c) 0.5-4 parts of an extreme pressure agent; d) 0.05-1 part of a copper corrosion inhibitor; and e) 0.05-1 part of an antioxidant, wherein the base oil is selected from purified narrow-fraction dearomatization solvent oil; the oiliness agent is selected from C12-C14 fatty acid methyl ester and C10-C14 alcohol; the extreme pressure agent is selected from tributylphosphite; the copper corrosion inhibitor is selected from benzotriazole and derivatives thereof; and the antioxidant is at least one of N-phenyl-alpha-naphthylamine or dialkyldiphenylamine. By adoption of the abovementioned technical scheme, the problems are solved well, and the oil composition can be used for process lubrication in a copper foil cold-rolling process.

Owner:CHINA PETROLEUM & CHEM CORP

Cleaning composition comprising cationic surfactants, chelant, and an alcohol solvent mixture

InactiveUS7045492B2Low flash pointReduce the possibilityInorganic/elemental detergent compounding agentsCationic surface-active compoundsEthylenediamineSolvent

A cleaning composition for treating and removing residue containing hydrocarbons and other flammable substances uses a mixture of one or more cleaning members containing quaternary salts, a chelator and a dispersant, mixed with water. The preferred cleaning members are tetradecyltrimethylammonium bromide, tetrasodium ethylenediaminetetraacetic acid, benzethonium hydrochloride and 2-butoxyethanol. The chelator is tetrasodium salt ethylenediamine of tetraacetic acid, and the dispersant is polyvinyl alcohol. Optionally, the cleaner contains ethanol and isopropyl alcohol.

Owner:JENEVEIN EARL

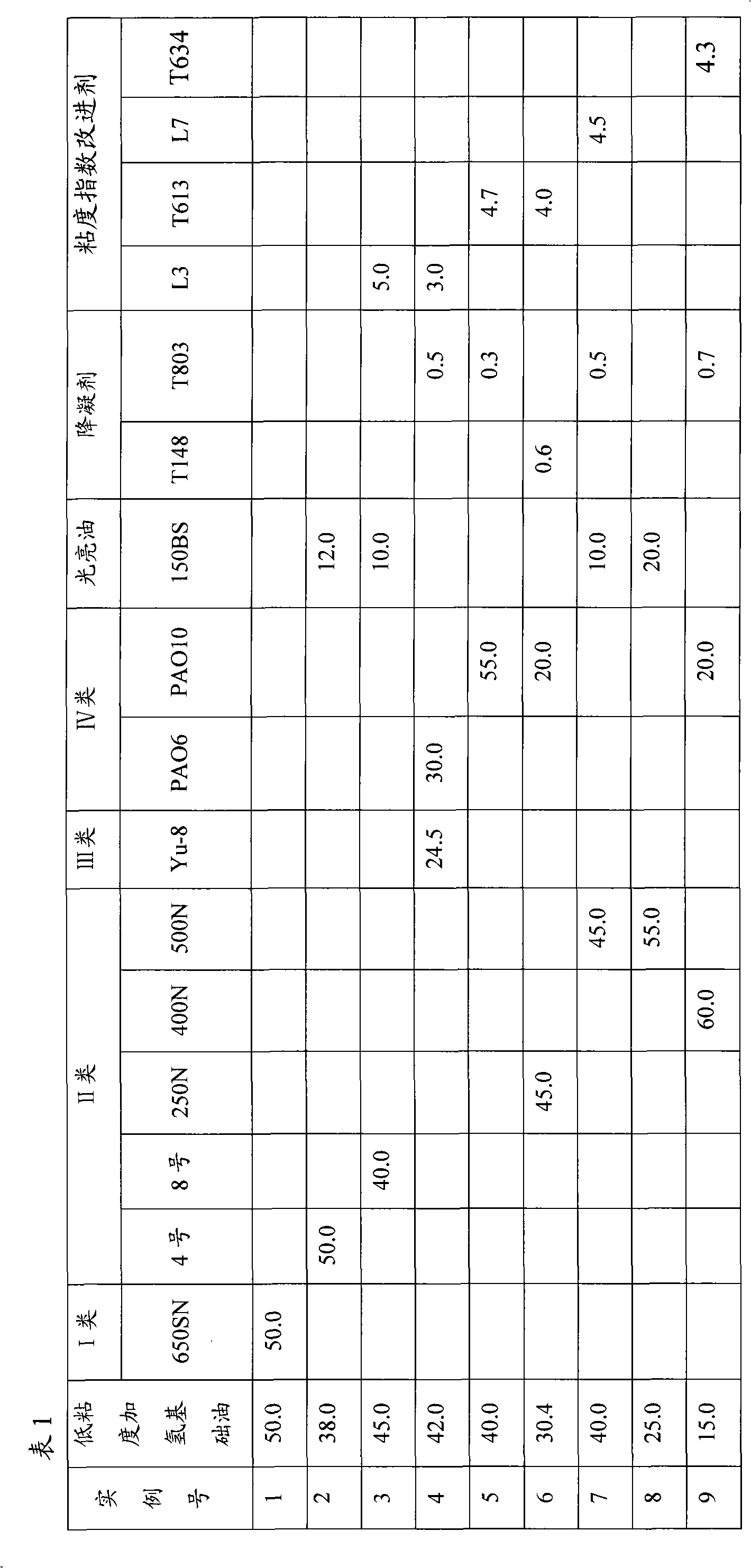

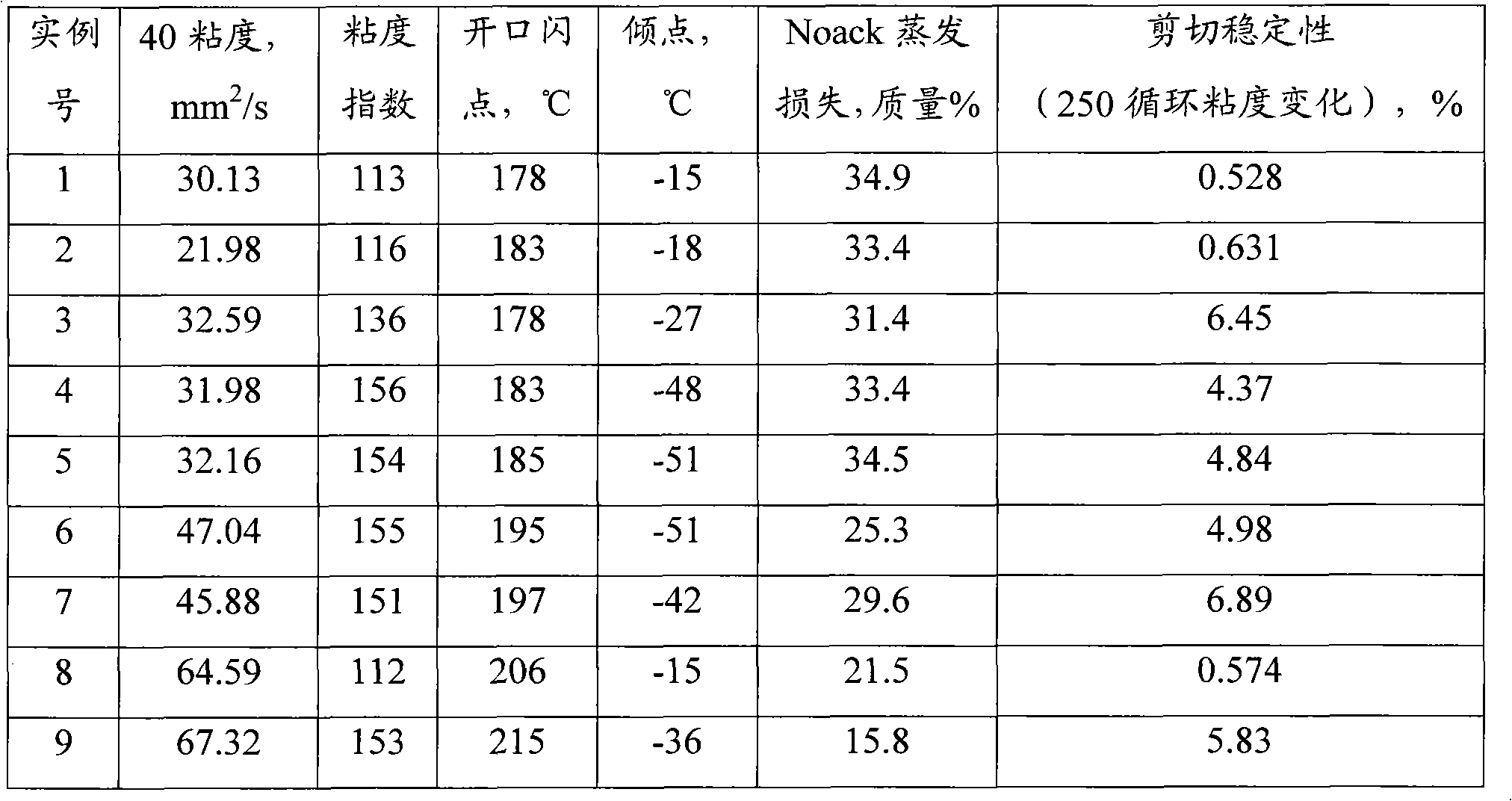

Lubricating oil base oil composition

The invention relates to lubricating oil base oil composition. The lubricating oil base oil composition comprises 10 to 80 mass percent of low-viscosity hydrogenated base oil and 20 to 90 mass percent of lubricating oil base oil, wherein the viscosity of the low-viscosity hydrogenated base oil at the temperature of 100 DEG C is 1.5 to 3.0 mm<2> / s; the low-viscosity hydrogenated base oil comprises less than 40 mass percent of alkane, more than 60 mass percent of total cycloalkane, less than 0.2 mass percent of arene and less than 0.05 mass percent of sulfur; the lubricating oil base oil is selected from one of or composition of any two or more of I type, II type, III type, IV type, V type and bright oil. The base oil composition is the high-quality lubricating oil base oil with the technical indexes such as viscosity index, volatility and the like meeting the requirement of the lubricating oil specification, and is applicable to the base oil of hydraulic oil, transmission liquid and internal combustion engine oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Repairing material for color asphalt pavement, and preparation method thereof

The invention discloses a repairing material for a color asphalt pavement, and a preparation method thereof, wherein the repairing material comprises, by mass, 10-22% of a petroleum resin, 35-50% of acompatibilizer, 2-9% of a polymer, 15-50% of a viscosity reducing agent, 0.05-1.0% of a vulcanizing agent, 0.1-1.5% of an anti-aging agent, and 0.05-1.0% of an activator. According to the present invention, the repairing material has advantages of excellent high-temperature performance, excellent low-temperature performance, good stability, high softening point, strong adhesion, high low-temperature elongation rate and high low-temperature ductility, can be stored at room temperature for more than one year, and can be well mixed with color pigments at a room temperature so as to effectively repair the color asphalt pavement with small-area damage after the mixing.

Owner:CHINA PETROLEUM & CHEM CORP +1

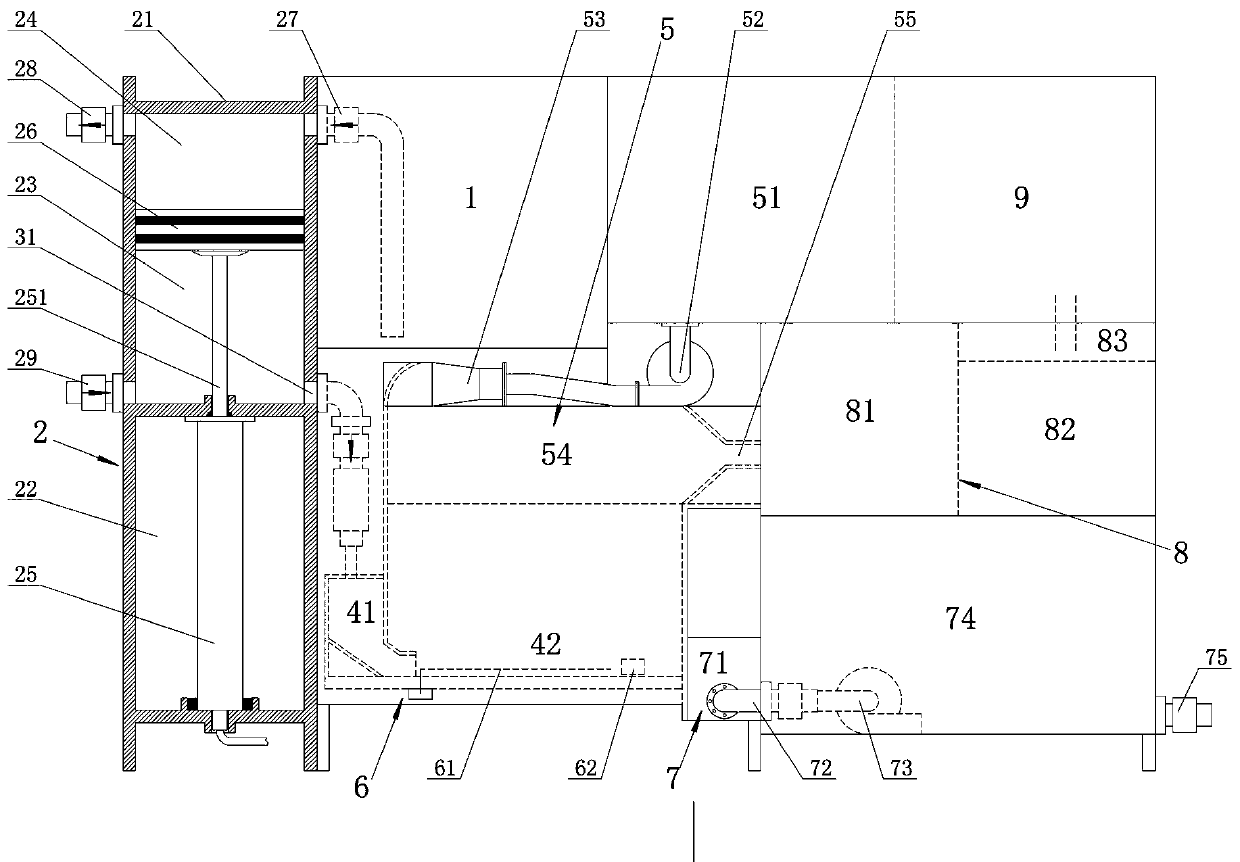

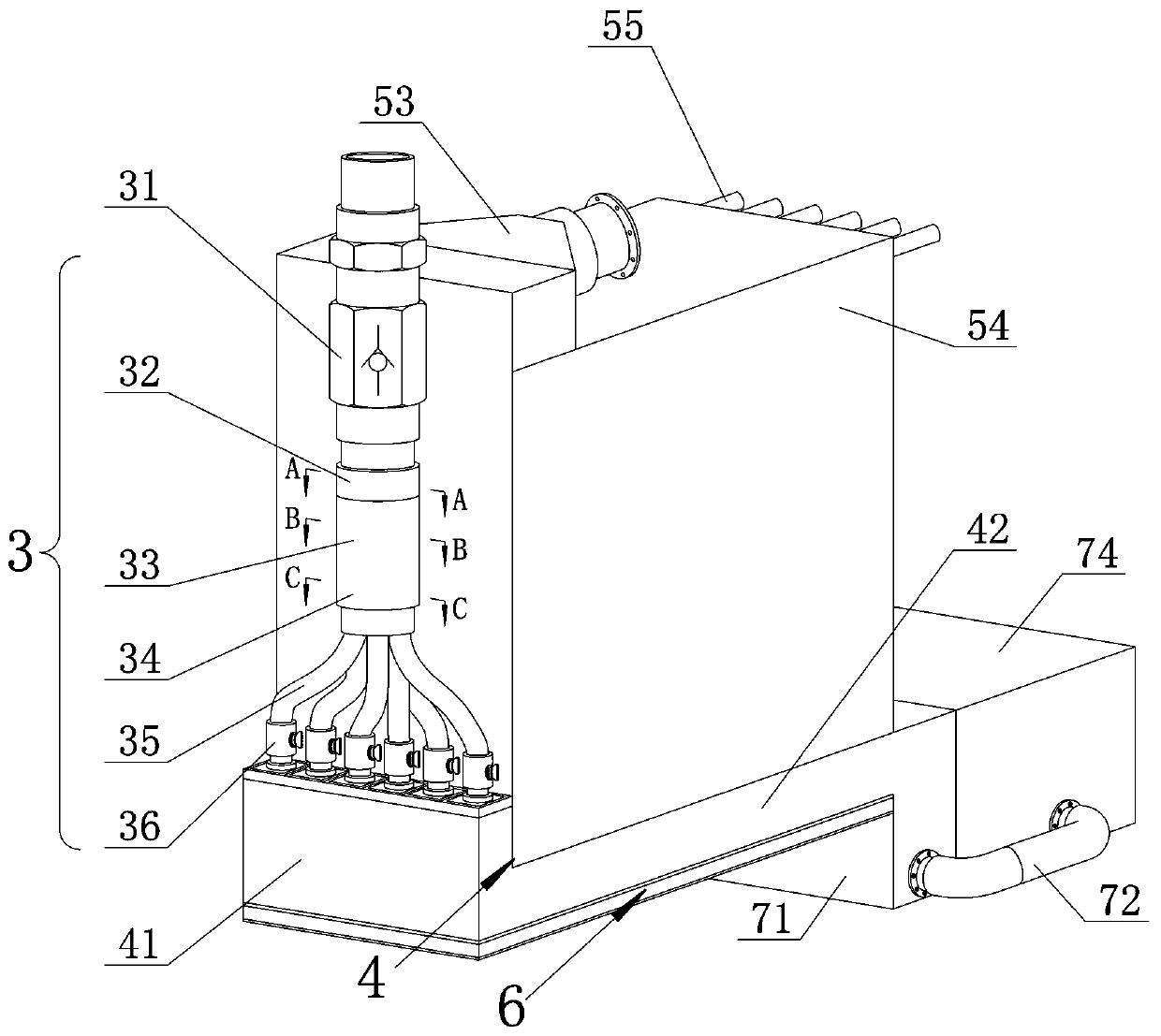

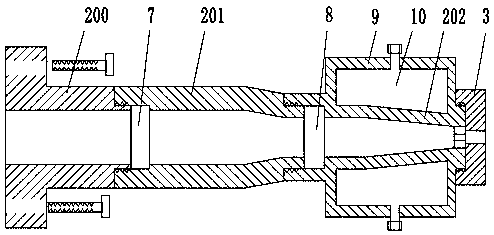

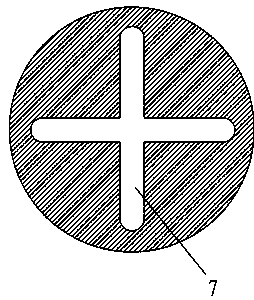

Power grid transformer oil safety detection equipment

ActiveCN110879268AHigh degree of processingStable oil levelComponent separationTemperature controlPower grid

The invention discloses power grid transformer oil safety detection equipment, which comprises a compensation oil storage tank, an oil change mechanism, a distribution mechanism, a heat treatment mechanism, a carrier gas circulation mechanism, a temperature control mechanism, a waste oil recovery mechanism and a gas detection mechanism. An interlayer is arranged in the middle of a cylinder to forman independent driving chamber located on the lower portion and an independent sampling and supplementing oil chamber located on the upper portion. An electric driving mechanism is installed in the driving chamber, a push rod of the electric driving mechanism extends into the sampling and supplementing oil chamber and is provided with a piston, and the piston divides the sampling and supplementing oil chamber into a lower sampling oil chamber and an upper supplementing oil chamber. After sampled oil of the same batch is divided into a plurality of equal parts, emphasized detection is carriedout on different equal parts. Temperature control mechanisms located in different flat grooves can be arranged differently. The purpose of achieving the maximum detection degree is achieved accordingto the separation performance of different gases. Unimpeded butt joint of sampled oil treatment and a carrier gas channel can be achieved. The operability of fault gas detection is improved, and the detection precision is improved.

Owner:河南展丰工程技术咨询有限公司

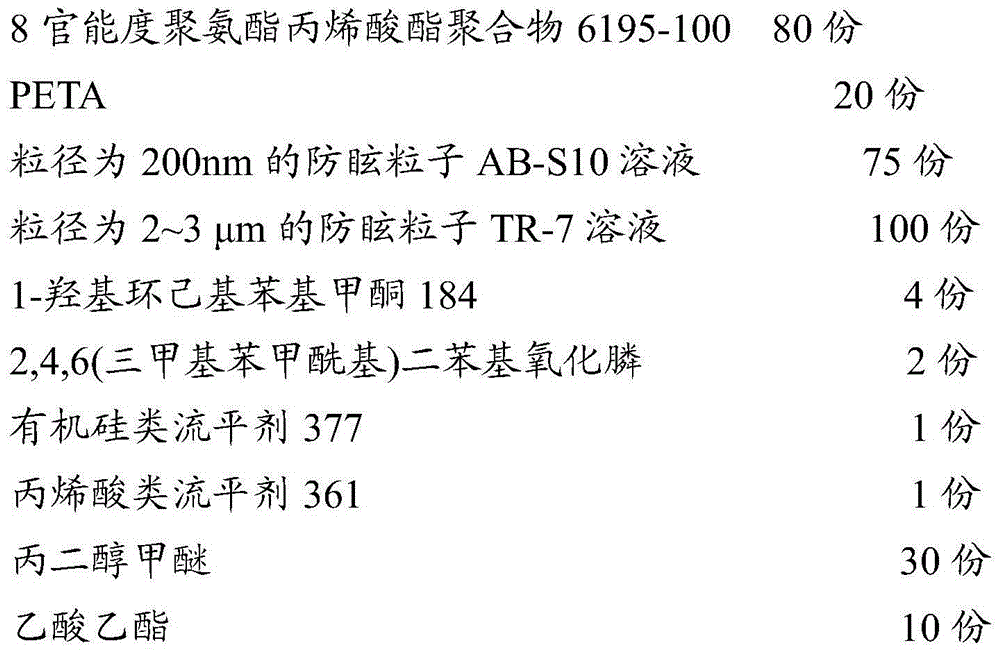

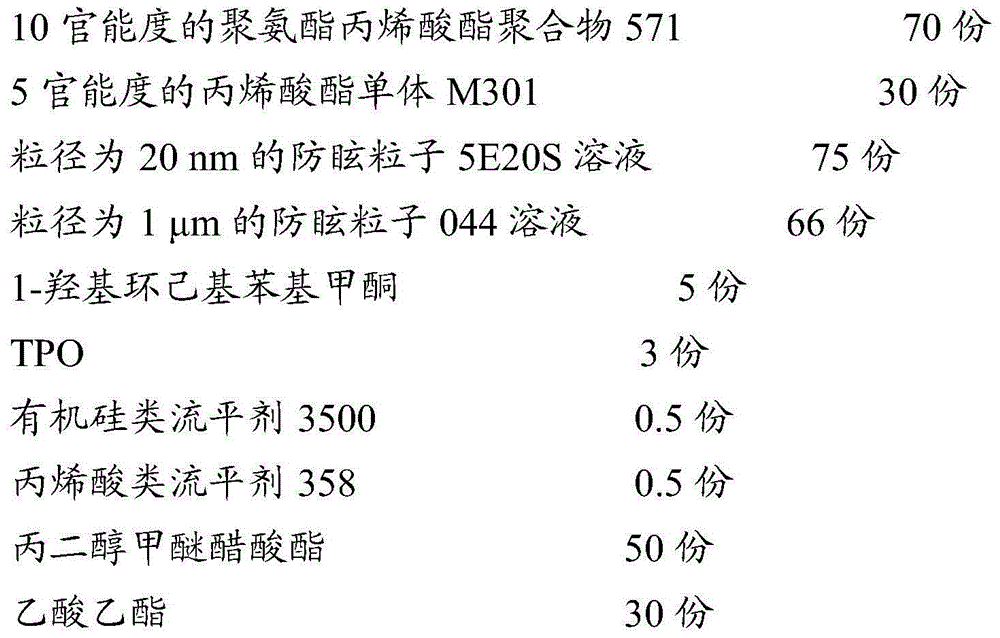

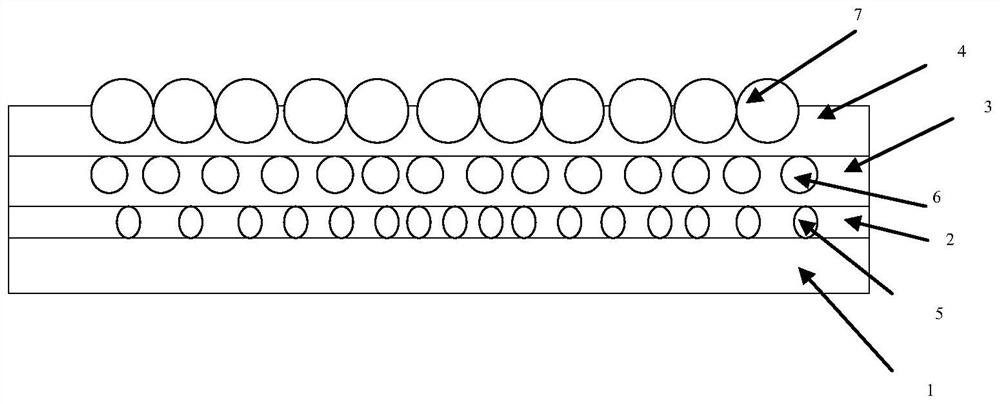

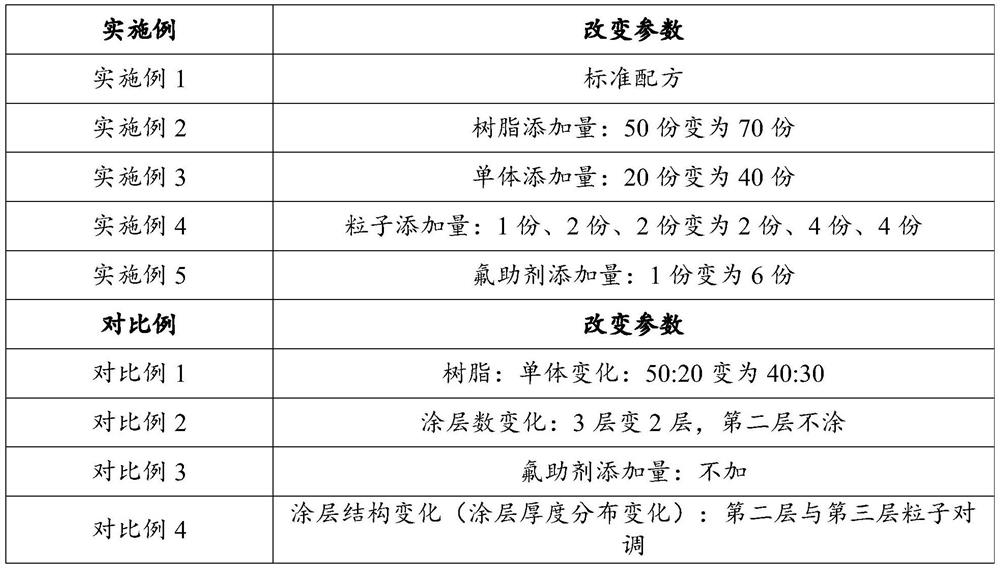

Anti-glare film with high wear resistance and low flash point

ActiveCN112327394AGood compatibilityWill not cause differences in strength or weaknessDiffusing elementsPolyurea/polyurethane coatingsRefractive indexHigh wear resistance

The invention discloses an anti-glare film with high wear resistance and a low flash point. The anti-glare film comprises a base material, and a first anti-glare coating, a second anti-glare coating and a third anti-glare coating which are sequentially coated on the base material; the first anti-glare coating, the second anti-glare coating and the third anti-glare coating respectively contain first anti-glare particles, second anti-glare particles and third anti-glare particles, the particle sizes of the first anti-glare particles, the second anti-glare particles and the third anti-glare particles are sequentially increased, the particle size difference of the first anti-glare particles and the second anti-glare particles is 0.5-5 [mu]m, the particle size difference between the second anti-glare particles and the third anti-glare particles is 1-7 [mu]m; and the first anti-glare particles, the second anti-glare particles and the third anti-glare particles are all organic particles, andthe refractive index difference between the first anti-glare particles, the second anti-glare particles and the resin in the corresponding coatings is less than 0.1. The anti-glare film provided by the invention has excellent properties of low flash point and high definition, and also has excellent wear resistance.

Owner:NUOVO FILM SUZHOU CHINA INC

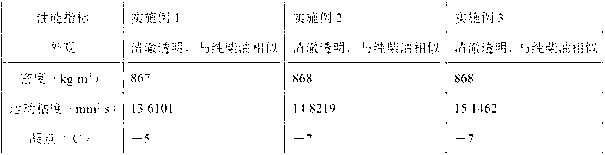

Preparation method of water-alcohol mixed base micro-emulsified diesel oil

InactiveCN103074130AAppearance is clear and transparentLow flash pointLiquid carbonaceous fuelsIsobutyl alcoholChemistry

The invention discloses a preparation method of water-alcohol mixed base micro-emulsified diesel oil. The micro-emulsified diesel oil is prepared through emulsification by taking diesel oil, methanol and water as basic materials, and taking oleic acid, stearic acid, a surfactant, isooctyl alcohol, isobutyl alcohol, n-amyl alcohol, ethyl acetate, triethanolamine and the like as assistants. The micro-emulsified diesel oil is clear and transparent in appearance, and similar to pure diesel oil; the density is 867-869kg / m<3>; the kinematic viscosity is 13.6241-15.4780mm<2> / s; and a condensation point is between -7.5 DEG C and -5 DEG C. The micro-emulsified diesel oil is longer in quality guarantee period, can be stably stored for over 3 months, is low in assistant consumption, low in toxicity, simple in preparation method, mild in technological condition and low in cost, has small harms to a human body and an environment, and facilitates industrial production.

Owner:NORTHWEST NORMAL UNIVERSITY

Bio-based additive for asphalt

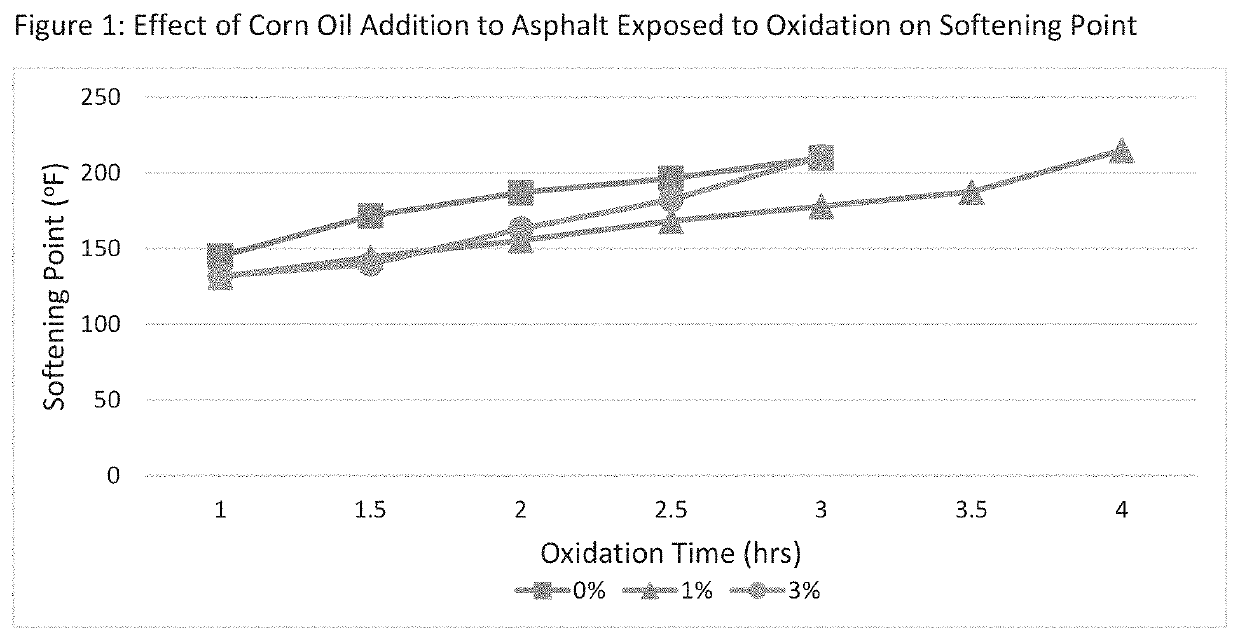

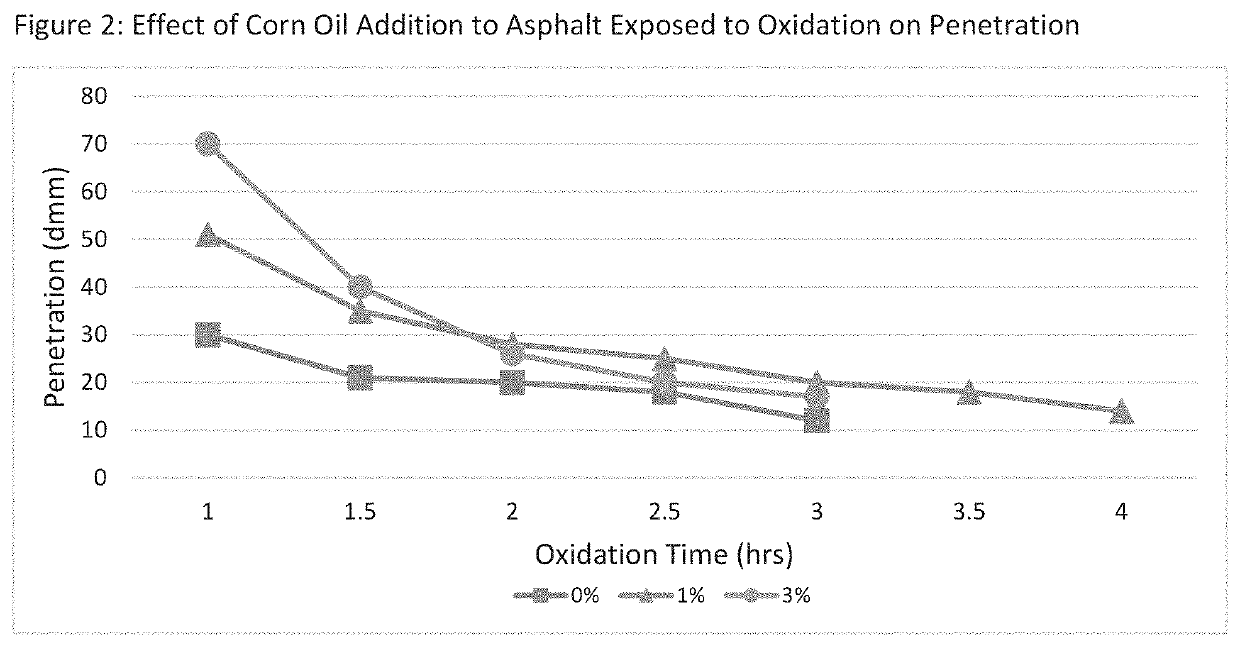

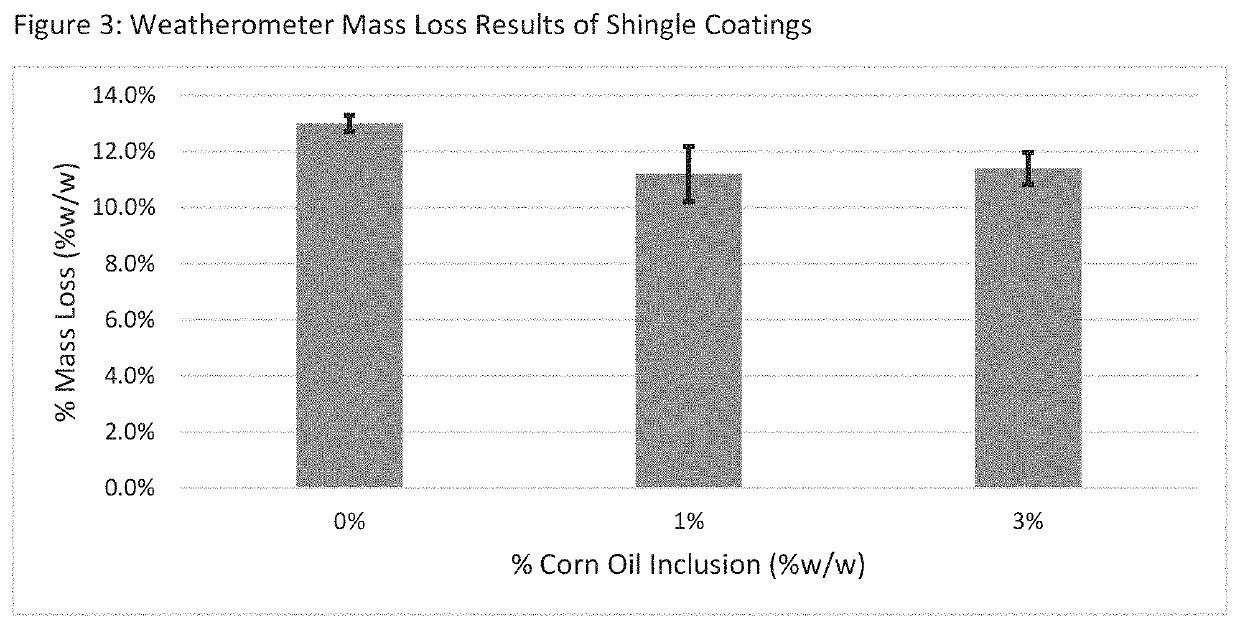

ActiveUS20200131403A1Reduce viscosityLow viscosityRoof covering using tiles/slatesBituminous coatingsPolymer chemistryAsphalt

Compositions comprising asphalt and corn oil are provided, as are the shingles made using the compositions, methods for making the compositions, and methods for making the shingles. The compositions comprise mixtures of asphalt and corn oil, and the mixtures are oxidized to attain desirable properties.

Owner:POET RES INC

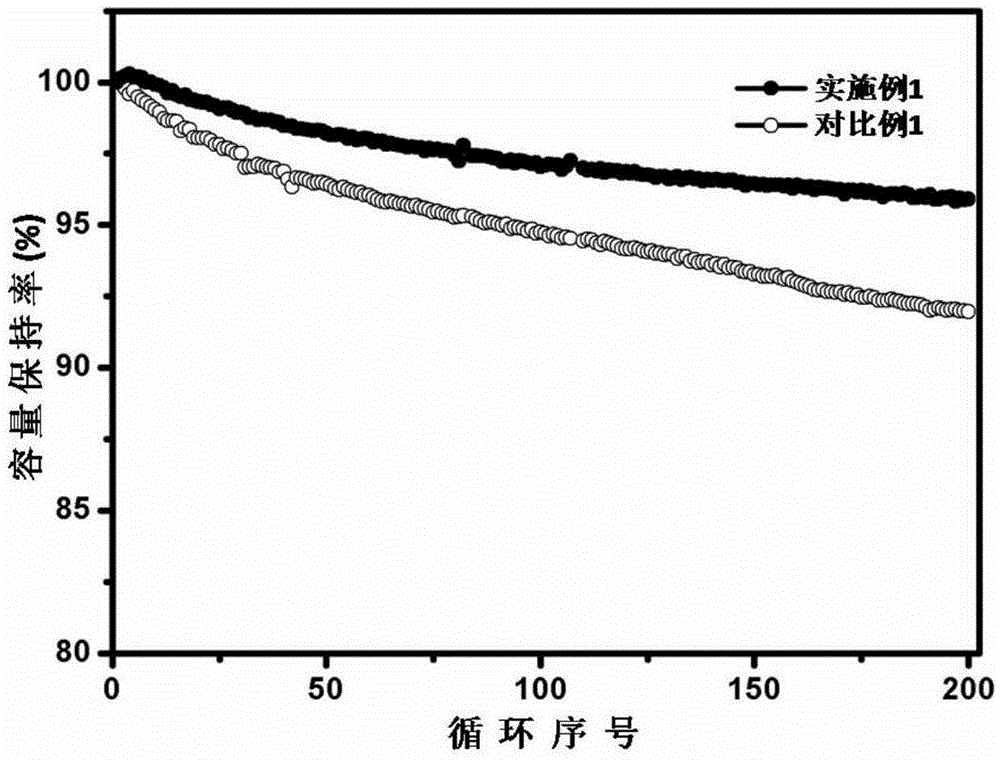

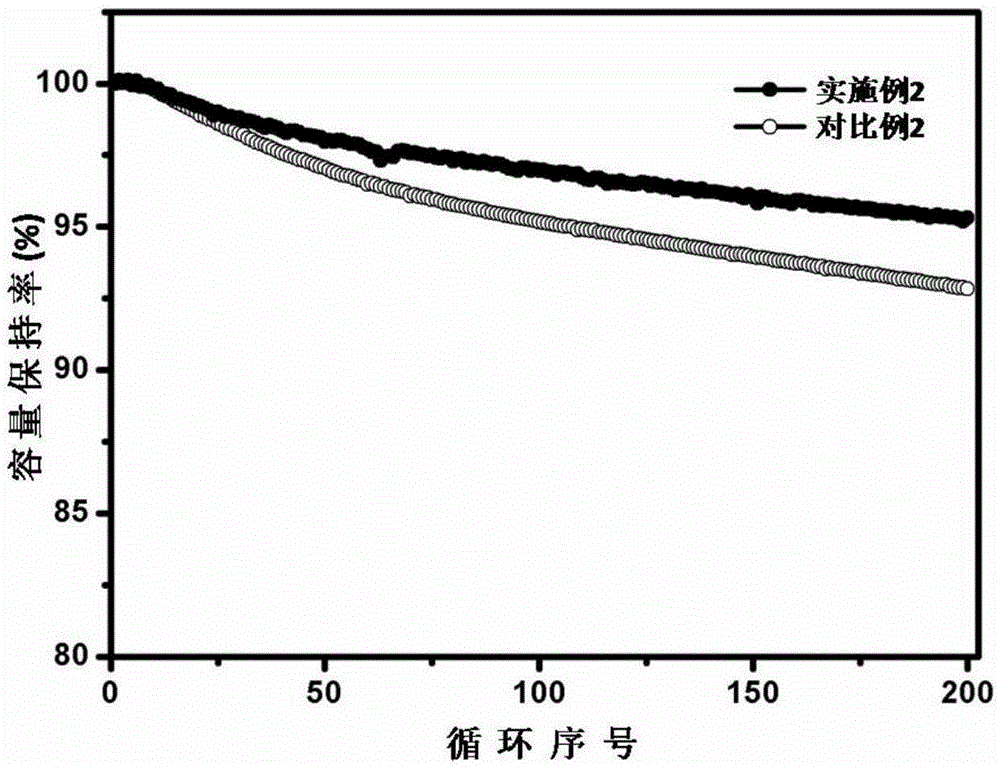

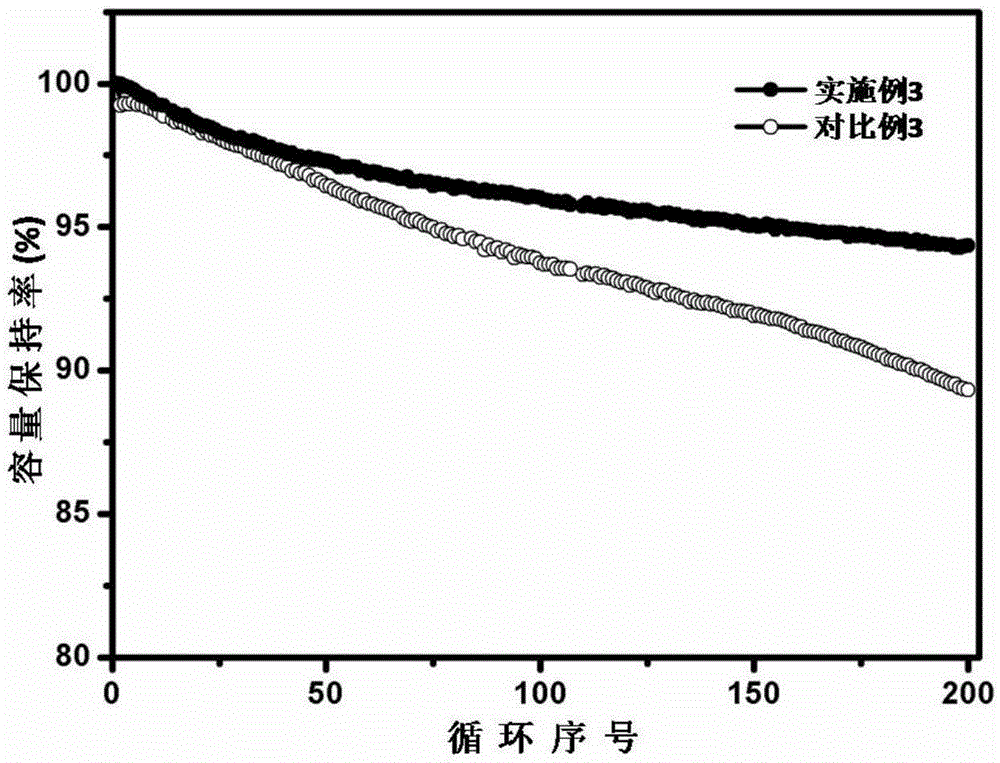

Lithium-ion battery electrolyte and lithium-ion battery containing electrolyte

InactiveCN105428716AGood gas productionReduce gas productionSecondary cellsOrganic electrolytesOrganic solventPhosphate

The invention discloses lithium-ion battery electrolyte. The electrolyte comprises LiPF6, a non-aqueous organic solvent and additives, wherein the additives comprise fluoroalkenyl phosphate compounds and LiBOB, the structural general formula of the fluoroalkenyl phosphate compounds is the general formula I or the general formula II shown in the specification; according to the general formula, when R1 represents alkyl with 1-5 carbon atoms, R2 represents fluoroalkenyl, and when R1 represents fluoroalkyl, R2 represents any one of alkenyl with 2-5 carbon atoms and fluoroalkenyl with 2-5 carbon atoms. The flammability of the lithium-ion battery electrolyte is low, the gas production capacity of the lithium-ion battery prepared from the electrolyte is small in the charging and discharging processes, and the battery can be effectively prevented from expanding and has excellent high-temperature cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

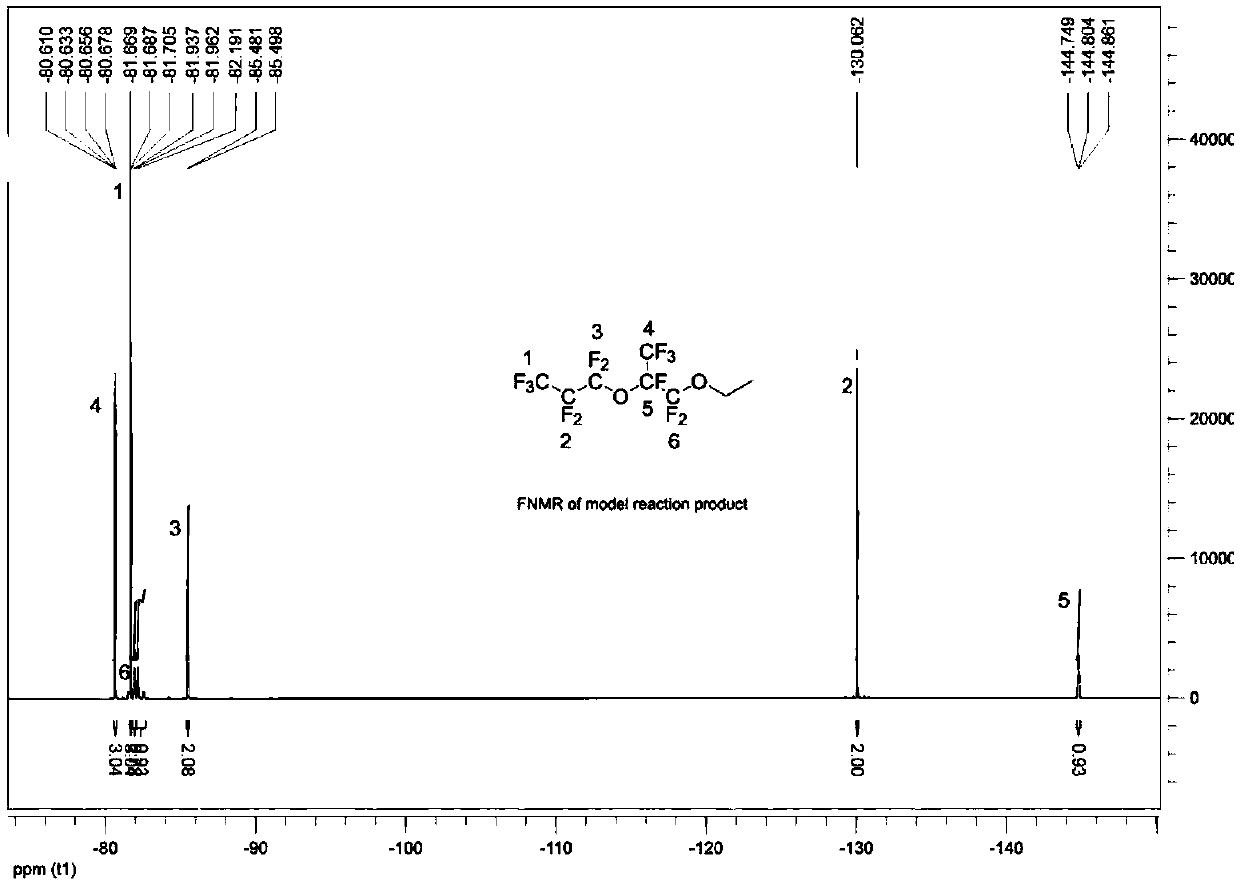

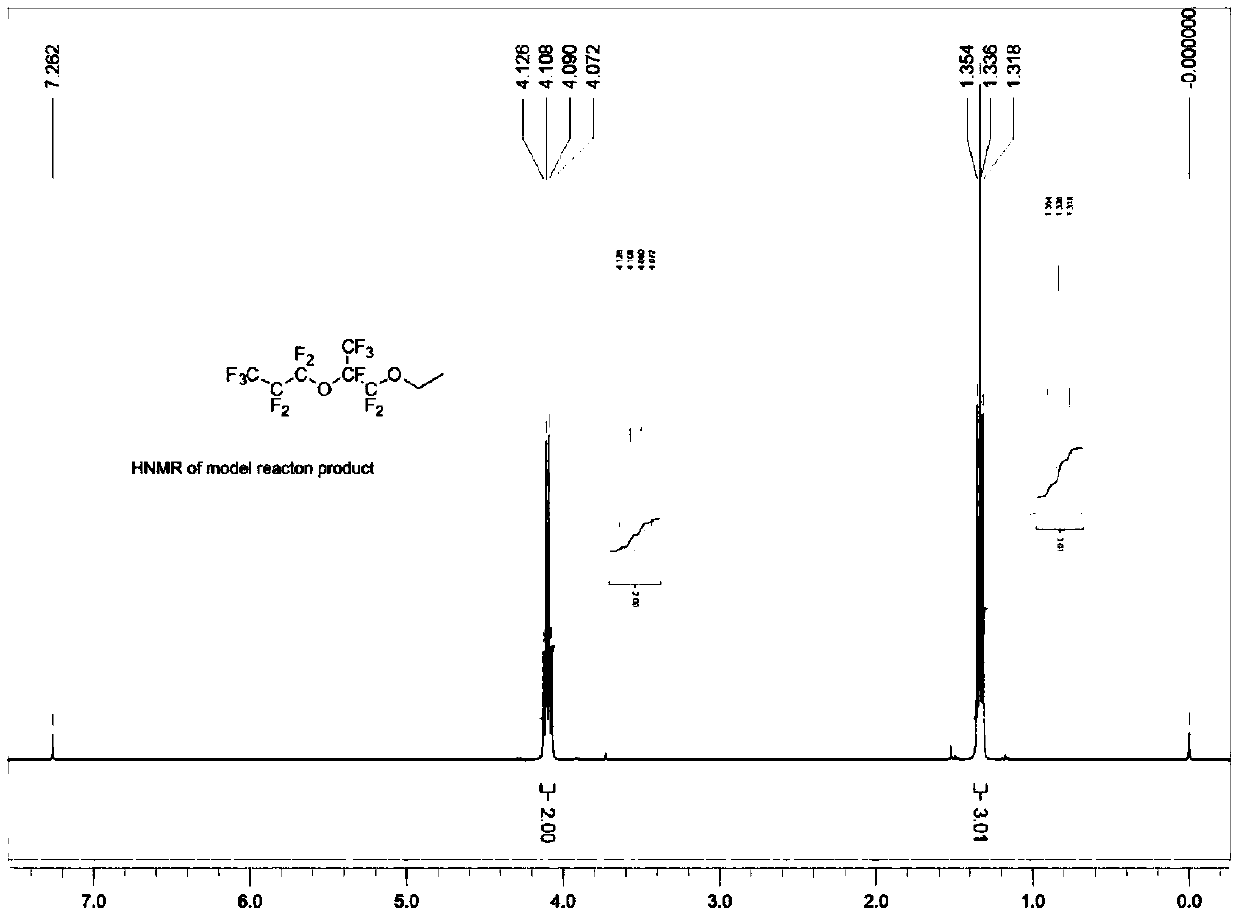

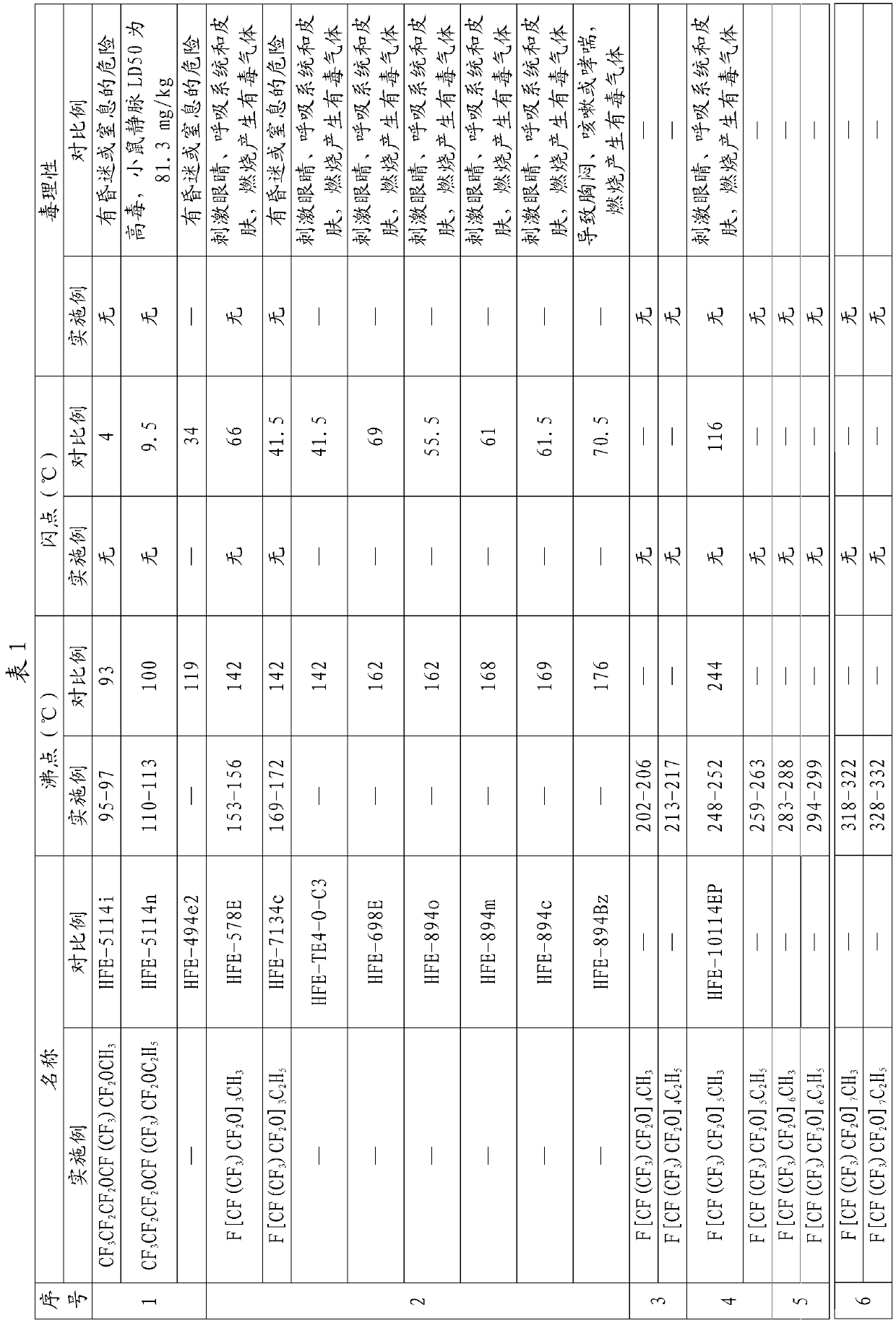

Hydrofluoroether compound and preparation method and application thereof

ActiveCN109608312AHydrophobicChemically inertHeat-exchange elementsNon-surface-active detergent solventsHalogenHydrofluoroether

The invention belongs to the field of hydrofluoroethers, in particular to a hydrofluoroether compound and a preparation method and an application thereof. The hydrofluoroether compound is representedby that follow formula: F [CF(CF3)CF2O]<x>-R<H>; where x = 2-7; RH=CH3, C2H5, n-C3H7 or i-C3H7. The hydrofluoroether compound provided by the invention only contains fluorine, the only halogen element, does not contain ozone-destructive substances, and is an environmentally friendly non-flammable heat transfer agent, a solvent and a cleaning agent.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

Electrolyte of flame-retarded lithium ion battery

ActiveCN102082296BExcellent non-flammabilityHigh viscositySecondary cells servicing/maintenanceBenzeneOrganic solvent

The invention relates to the technical field of electrolyte of flame-retarded lithium ion batteries, in particular to electrolyte of a flame-retarded lithium ion battery. The electrolyte comprises a lithium salt and an organic solvent, and is characterized in that three flame-retarded additives are also added into the electrolyte, wherein the three flame-retarded additives comprise fluoro-carbonate as a first additive, fluoro-benzene as a second additive and a nitrogenous and fluoride bearing organic compound as a third additive. By adopting the technical scheme, the fluoro-carbonate FEC is added into the existing electrolyte system to increase the viscosity of the electrolyte system to a certain extent so that the flash point of the electrolyte system is reduced; the additive fluoro-benzene with comparatively stable electrochemical properties is added to increase the noninflammability of the electrolyte to a certain extent and simultaneously ensure that the viscosity of the electrolyte system is moderate; and the nitrogenous and fluoride bearing organic compound is added to increase the noninflammability of the electrolyte on the basis of guaranteeing the electrochemical properties of the electrolyte.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

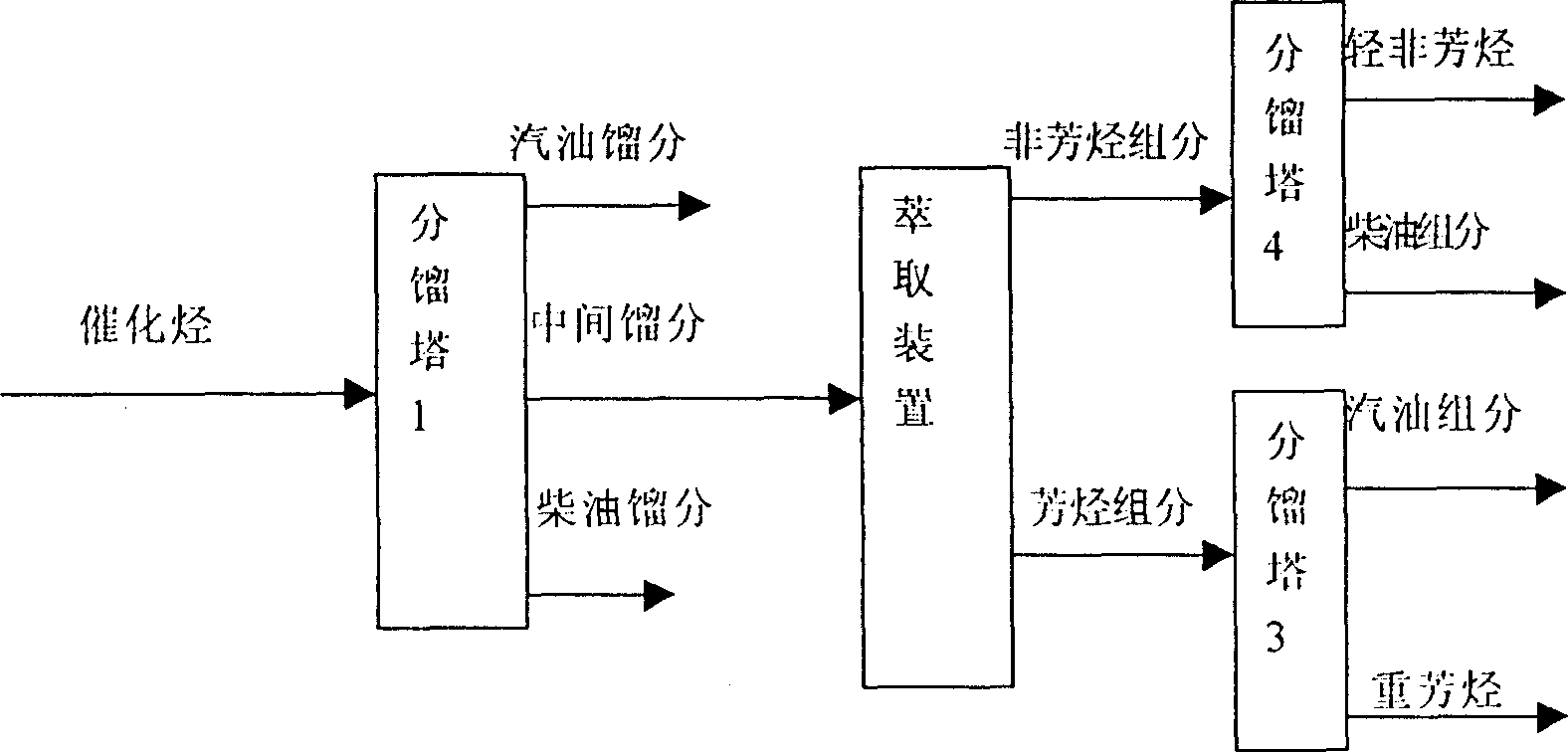

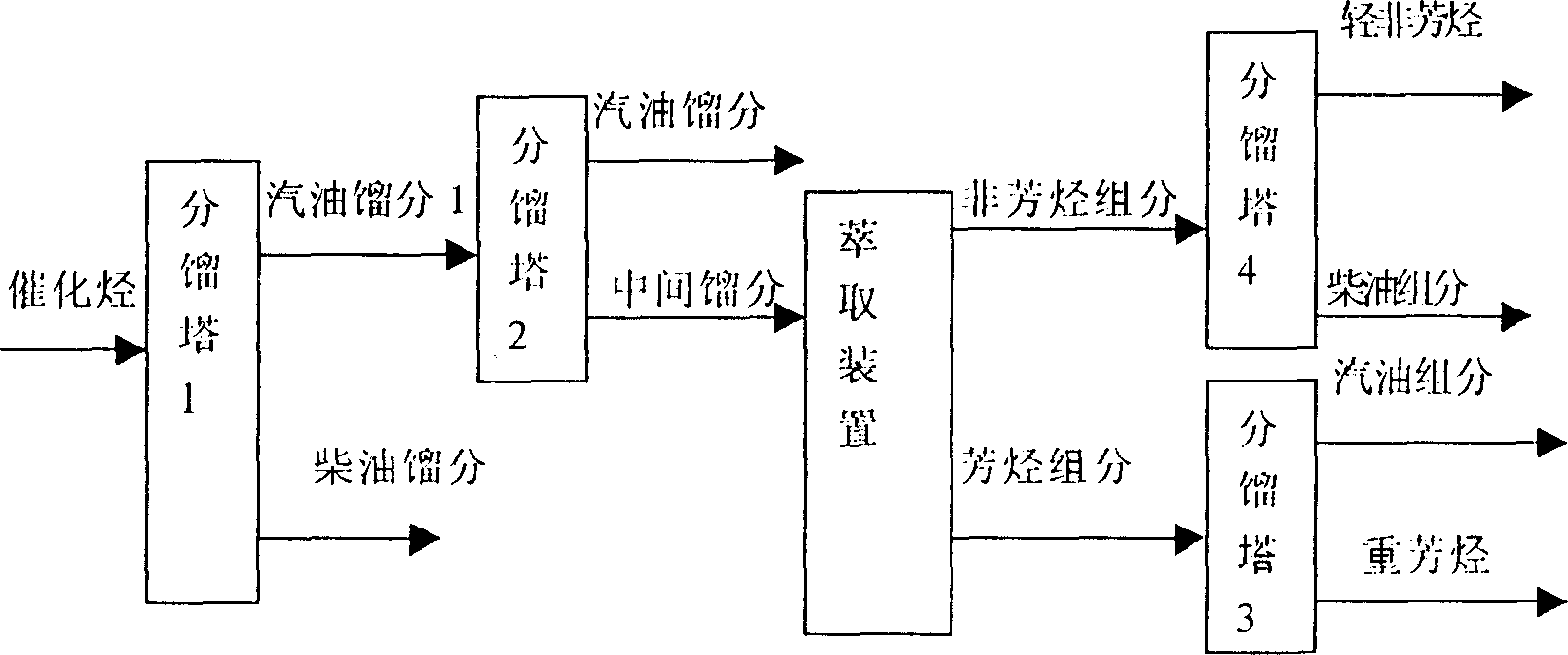

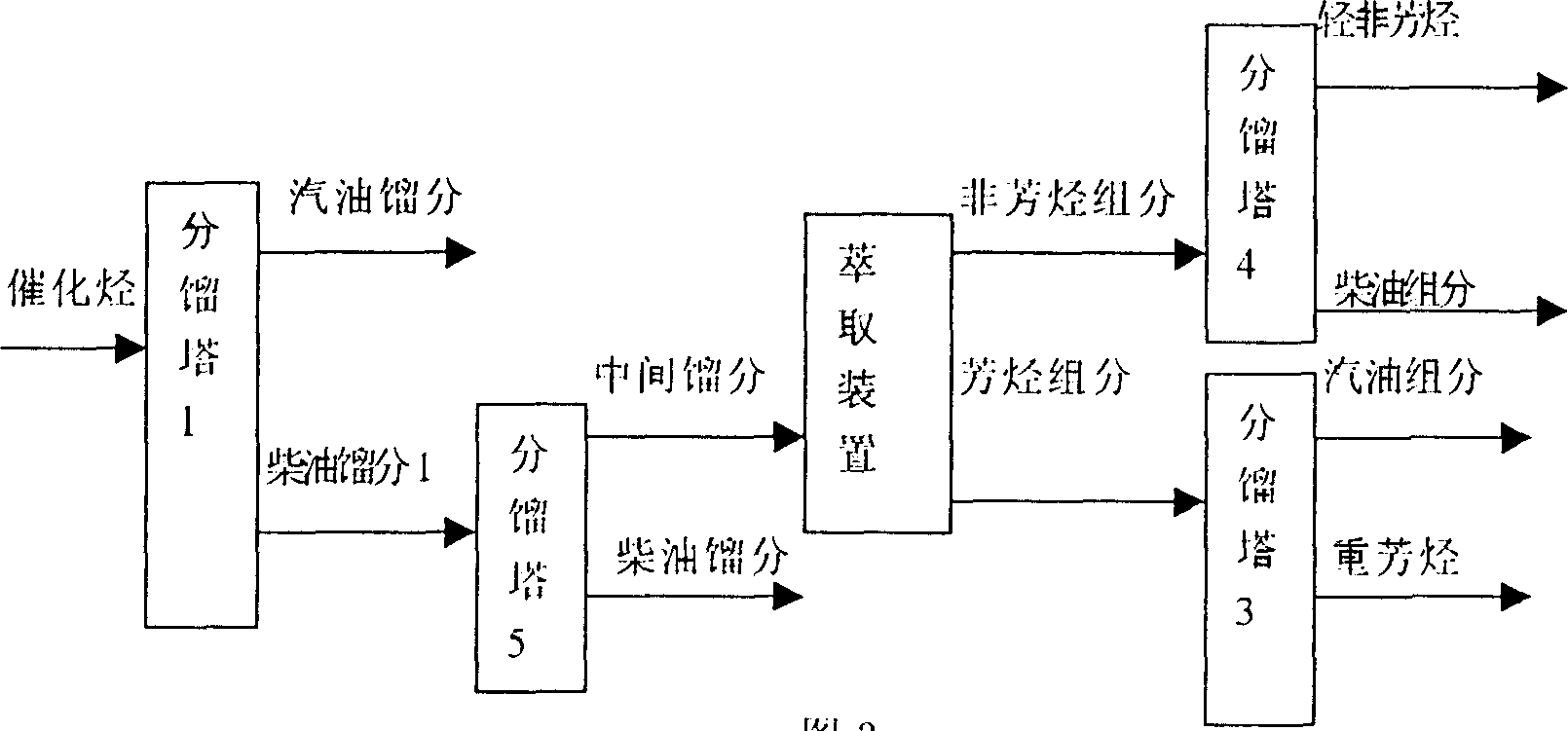

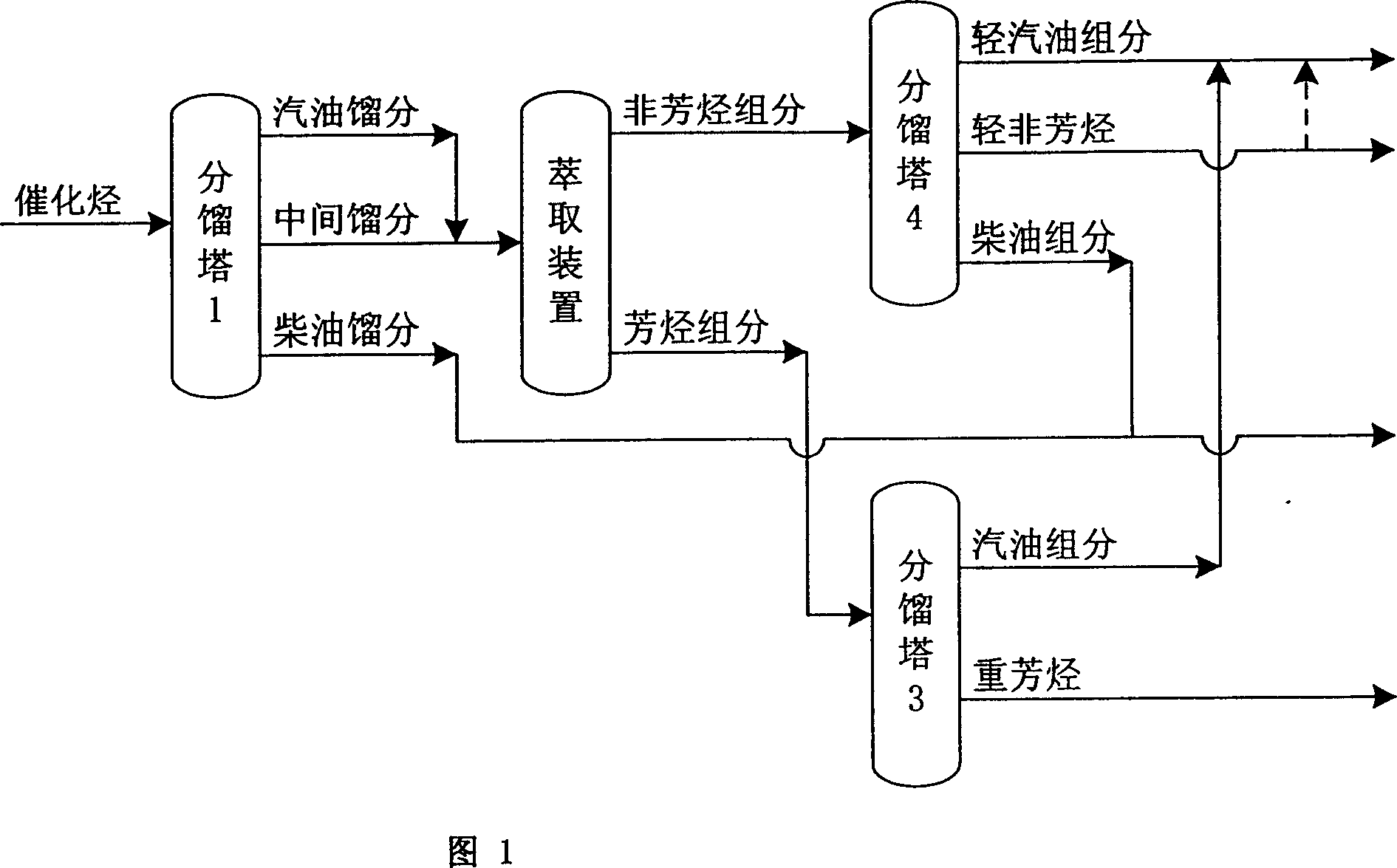

Catalytic hydrocarbon reforming treatment method

InactiveCN1295302CQuality improvementSave construction investmentHydrocarbon distillationCatalytic naphtha reformingGasolineOctane

The present invention discloses a catalytic hydrocarbon recombination treatment method, which includes: making the catalytic hydrocarbon pass through catalytic main fractionator to implement fractionation to obtain gasoline fraction and diesel oil fraction, adding an intermediate fraction, making said described intermediate fraction undergo the process of aromatic hydrocarbon extraction treatment to obtain aromatic hydrocarbon component and non-aromatic hydrocarbon component; fractionating aromatic hydrocarbon component and mixing the obtained high octane value gasoline component with the gasoline fraction to raise the octane value of gasoline; fractionating non-aromatic hydrocarbon component and mixing the obtained diesel oil component and diesel oil fraction to raise diesel oil yield and its cetane value.

Owner:BEIJING GRAND GOLDEN BRIGHT ENG & TECH

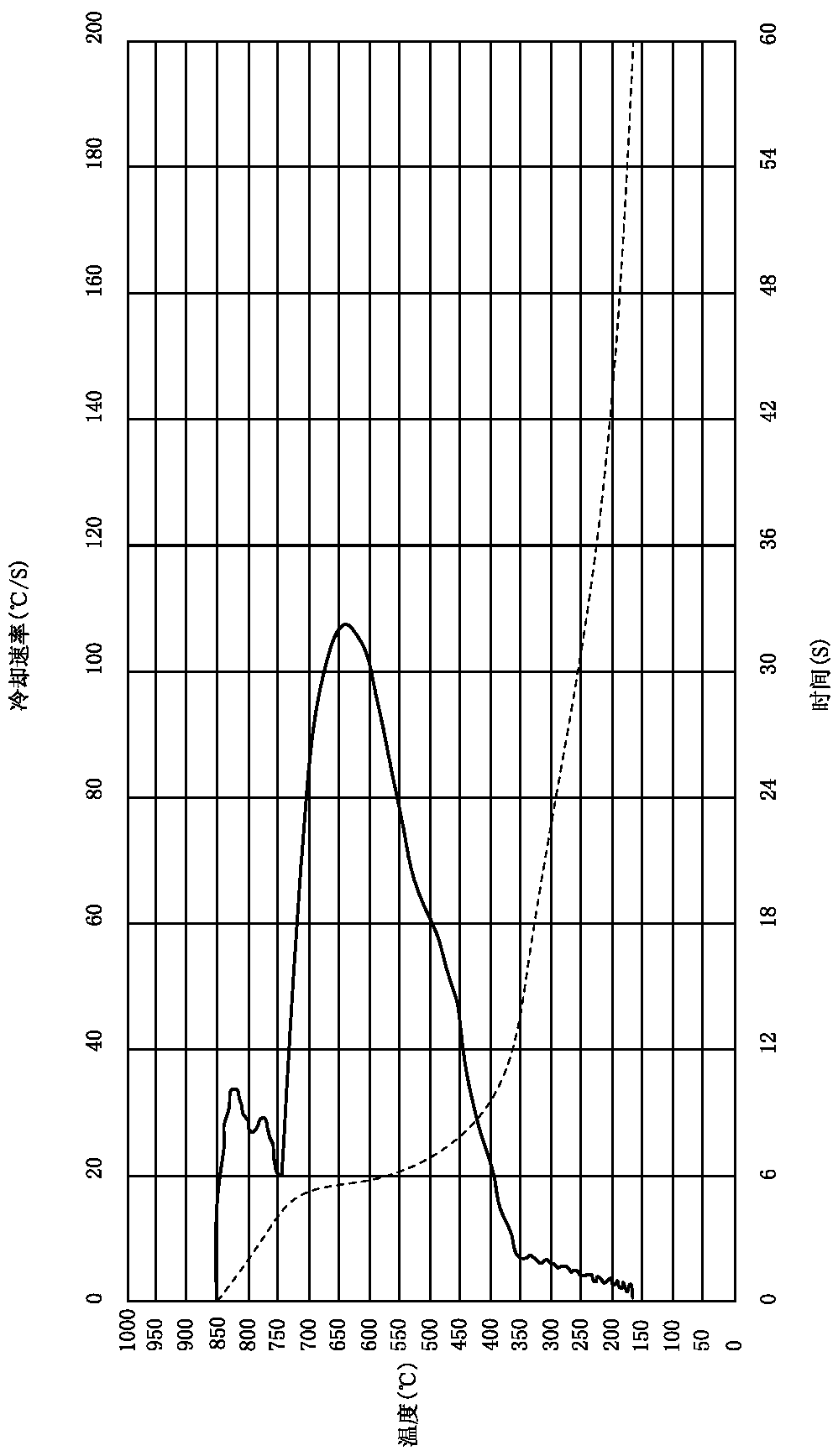

Automobile leaf spring free quenching technology

InactiveCN108676978AImprove quenching qualityEfficient productionFurnace typesQuenching agentsQuenchingOverburden pressure

The invention discloses an automobile leaf spring free quenching technology, and belongs to the technical field of leaf spring machining heat treatment technologies. The automobile leaf spring free quenching technology is characterized by comprising the following steps that firstly, reeds are heated to 860 DEG C-920 DEG C in a stepping type quenching heating furnace, and heat preservation is conducted for 20-25 min; secondly, the reeds are sorted and discharged out of a furnace according to the lengths, wherein the lengths are smaller than or equal to 700 mm, are 700-900 mm, are 900-1,300 mm and are larger than or equal to 1,300 mm correspondingly; thirdly, after the reeds are moved to a forming platform through a robot, chain type overburden pressure forming is adopted; and fourthly, rapid quenching oil is set in a quenching oil groove, the forming platform is used for directly conveying the reeds into the quenching oil groove in a free state, the reeds are quenched within 30 s from furnace discharging to oil entry. According to the automobile leaf spring free quenching technology, the reed quenching quality can be improved while efficient production is achieved.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

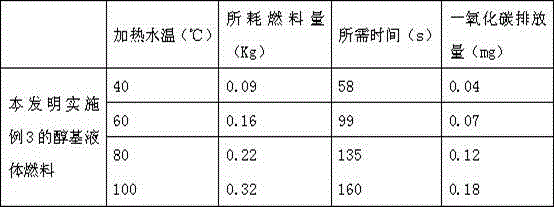

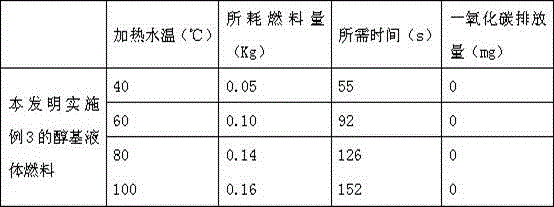

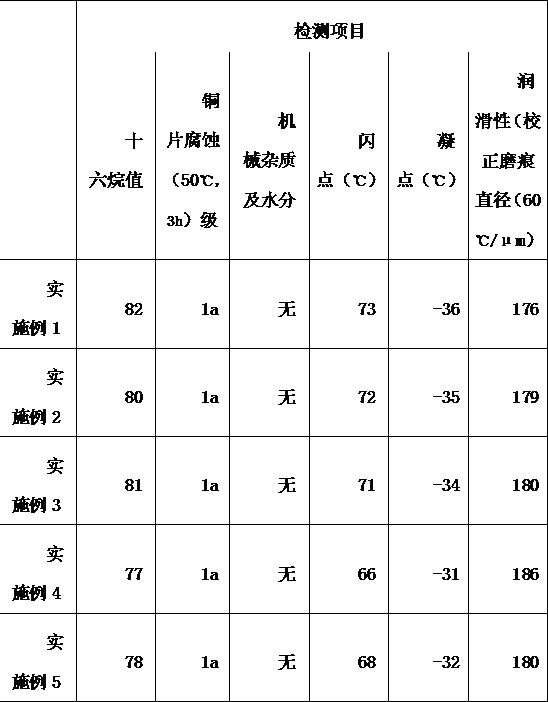

Alcohol-based liquid fuel

InactiveCN106753605AReduce sulfur contentReduce wear rateLiquid carbonaceous fuelsFuel additivesAlcoholJatropha

The invention relates to alcohol-based liquid fuel. The fuel comprises the following raw materials in parts by weight: 80 to 85 parts of methyl alcohol, 5 to 10 parts of water, 1 to 2 parts of petrol, 1 to 3 parts of sodium hydroxide, 1 to 3 parts of castor oil, 3 to 8 parts of jatropha carcas fruit oil, 2 to 5 parts of edible oil, 1 to 3 parts of essence, 1 to 5 parts of industrial salt, and 1 to 5 parts of ethyl alcohol. The fuel has the characteristics that the fuel does not produce poisonous gas when being burnt and is odor-free; the fuel can be completely burnt, the heat value produced through burning is high, the flash point of the fuel can be reduced, the fuel can be easily ignited, can be completely burnt, does not produce poisonous gas, and is low in cost, economical and practical, and green and environmental-friendly.

Owner:吴良善 +2

Industrial heavy oil stain cleaning agent and preparation method thereof

InactiveCN110257189AGood rust protectionLow flash pointOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsCleansing AgentsSolvent

The invention discloses an industrial heavy oil stain cleaning agent and a preparation method thereof. The cleaning agent comprises following components in percentage by weight: 70.0 to 90.0% of aromatic hydrocarbon free solvent oil (D80); 1.0 to 10.0% of a Mannich base cleaning agent (RF1202); 1.0 to 5.0% of vinyl succinate (T747A), and 5.0 to 10.0% of methyl nylon acid. The cleaning agent can remove impurities on the surface of mechanical parts and metal parts such as oil stains, grease, dirt, metal chips, dust, and the like; the cleaning effect is good, the physical and chemical properties are good; moreover, the cleaning agent does not have pungent smell, is harmless to human body, and is noncorrosive; hands can contact with the cleaning agent directly, and the cleaning agent will not damage human body or equipment.

Owner:张娟娟

Fischer-Tropsch synthesis liquid wax environment-friendly biofuel and preparation process thereof

The invention relates to the technical field of fuels, and particularly relates to a Fischer-Tropsch synthesis liquid wax environment-friendly biofuel and a preparation process thereof. The Fischer-Tropsch synthesis liquid wax environment-friendly biofuel comprises the following components: 55%-75% of industrial white oil; 2%-5% of biodiesel; 17%-30% of Fischer-Tropsch synthesis liquid wax; and 2%-5% of an additive. The invention solves the problems that the existing biofuel is short in storage life and cannot be stored for a long time (generally 6-30 days), easy to be layered and low in flashpoint; according to the present invention, with the synergistic cooperation of industrial white oil, biodiesel, Fischer-Tropsch synthesis liquid wax and additives, the prepared biofuel has characteristics of good power performance, no layering after long-term storage, low corrosivity, low cost, energy saving, environmental protection, and good application prospect.

Owner:河南坤清生物能源科技有限公司

Anisotropic rubber material and preparation method thereof

The invention discloses an anisotropic rubber material and a preparation method thereof. The anisotropic rubber material comprises the following components in parts by weight: 100 parts of raw rubber,5-30 parts of white carbon black, 1-5 parts of hydroxyl silicone oil, 2-10 parts of silica powder, 5-50 parts of short fibers, 1-5 parts of a silane coupling agent, 2-8 parts of a diluent and 0.5-5 parts of a cross-linking agent. The short fibers are axially oriented along the extruded sealing strip, so that the extruded rubber material has anisotropism, tensile deformation is prevented in the axial direction of the rubber strip, high elasticity of the rubber material is kept in the vertical direction of the rubber strip, and the problem of stretching of a common rubber sealing strip in the assembling process can be effectively solved. And meanwhile, compared with an extruded rubber strip containing a continuous framework material, the production process is simple, and the extrusion continuity is good.

Owner:PINGHU ALLIED IND

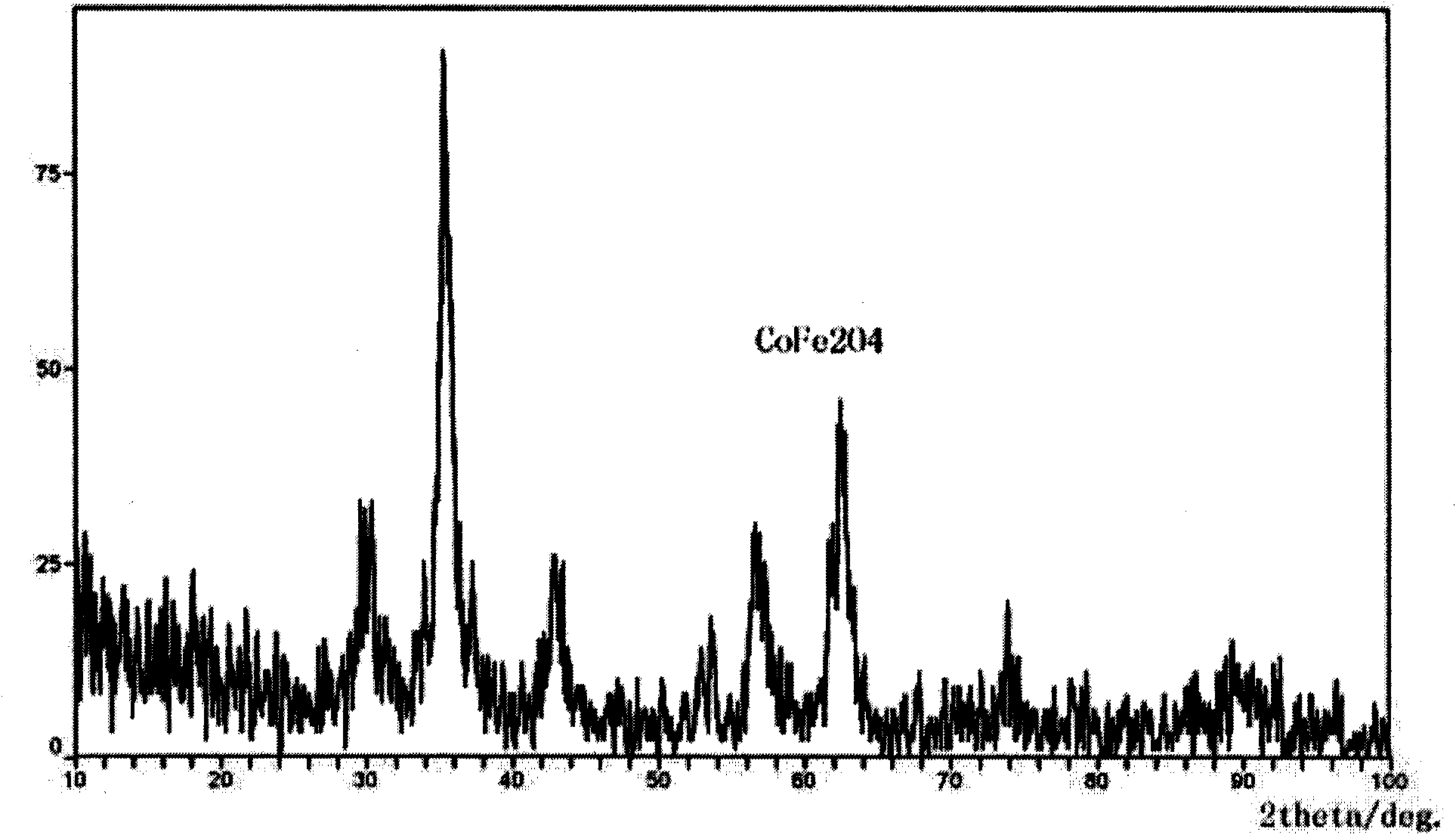

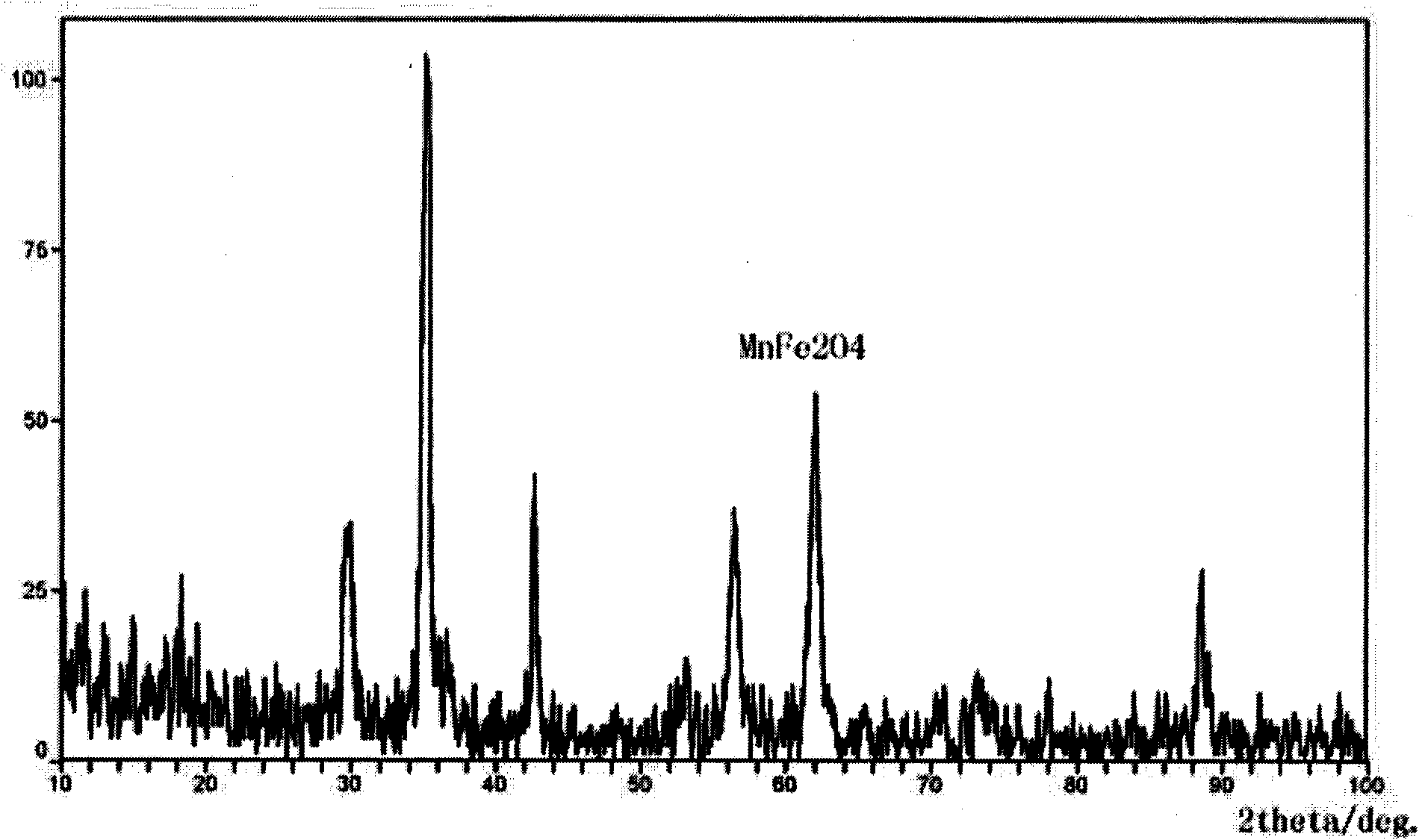

Magnetic liquid based on oxidation-resistant alpha olefin synthetic oil and preparation method thereof

InactiveCN103177839AStrong oxidation abilityStrong magnetic propertiesMagnetic liquidsOxidation resistantMagnetic liquids

The invention relates to the field of nanoscale science and technology, and discloses magnetic liquid based on oxidation-resistant alpha olefin synthetic oil and a preparation method of the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil. The magnetic liquid comprises magnetic nano-particles, surfactants and carrier liquid, and is characterized in that the magnetic nano-particles are ferrite-class magnetic particles DxM1-xFe2O4, wherein the D and the M are Co, Mn, Ni, Mg or Zn, and x=0-1, and the carrier liquid is the alpha olefin synthetic oil or mixed oil with the alpha olefin synthetic oil and other basic oil. According to the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil and the preparation method of the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil, the DxM1-xFe2O4 magenetic particles are small in particle diameter, overcome the defects that existing magnetic liquid is poor in oxidation resistance and stability, and the like, are good in oxidation resistance, good in modification effect, and are capable of being dispersed in the carrier liquid, and good magnetic performance can be kept for a long time under a high-temperature environment. The preparation method of the magnetic liquid based on the oxidation-resistant alpha olefin synthetic oil is simple in operation, high in production efficiency, and low in requirement on equipment, and has good application prospects.

Owner:SUN YAT SEN UNIV

Method for preparing environmentally-friendly chlorinated plasticizer from waste grease, and product produced therethrough

ActiveCN109971551AGood compatibilityHigh plasticizing efficiencyFatty oils/acids recovery from wasteFatty acid esterificationPlasticizerEthyl Chloride

The invention discloses a method for preparing an environmentally-friendly chlorinated plasticizer from waste grease. The method comprises the following steps: the waste grease, used as a raw material, and methanol undergo esterification and ester exchange to obtain a high-condensation point fatty acid methyl ester mainly containing saturated fatty acid methyl ester; and the high-condensation point saturated fatty acid methyl ester is post-treated under the action of a catalyst in the presence of introduced chlorine to obtain chloro fatty acid methyl ester. The environmentally-friendly chlorofatty acid methyl ester plasticizer prepared by the method of the invention has a good plasticizing effect, and makes PVC products have the advantages of difficult oil effusion, low condensation point, low price and good quality. The method has the advantages of simple preparation process, and suitableness for industrial production.

Owner:FUJIAN MINGZHOU ENVIRONMENTAL PROTECTION DEV

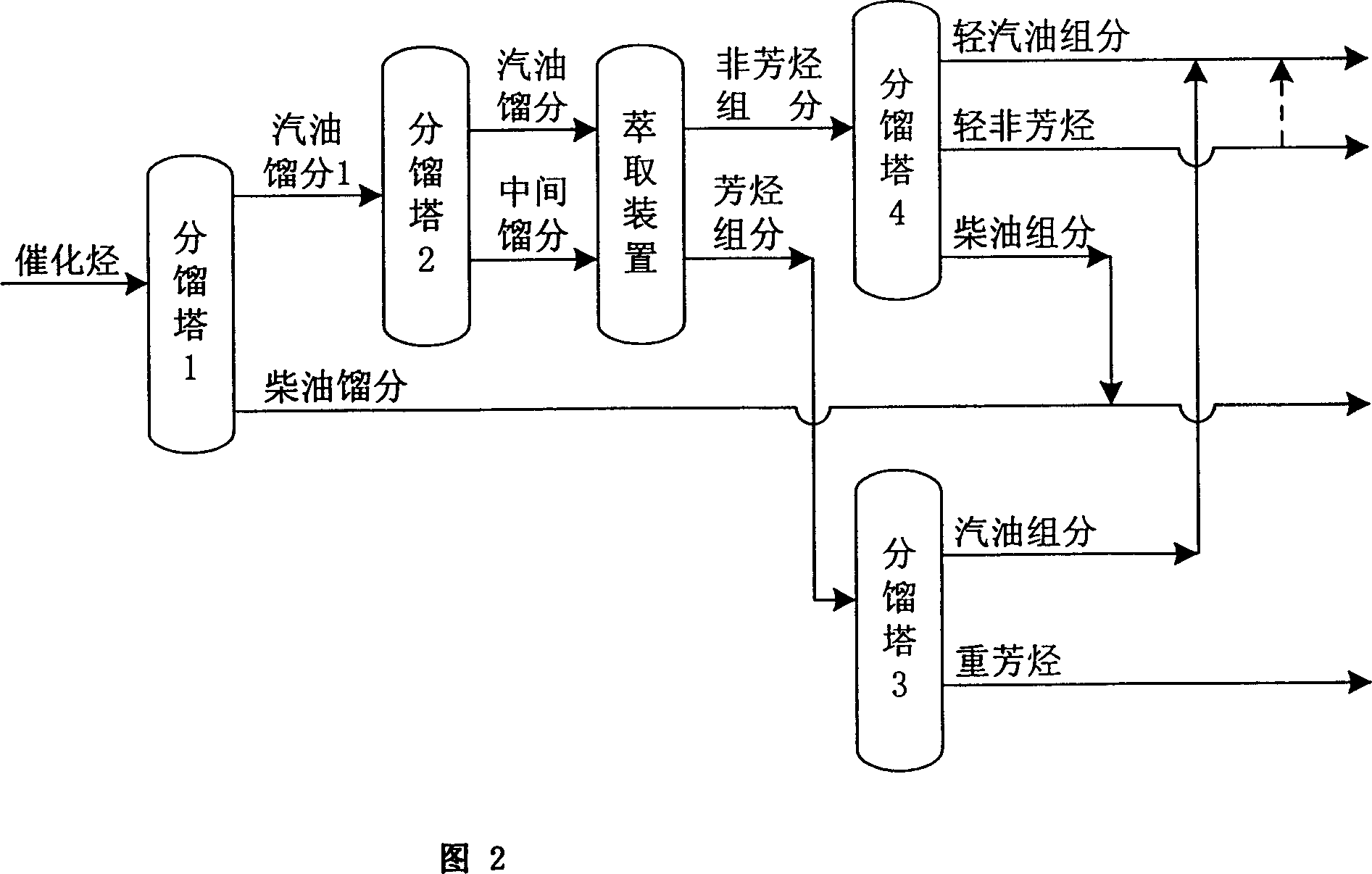

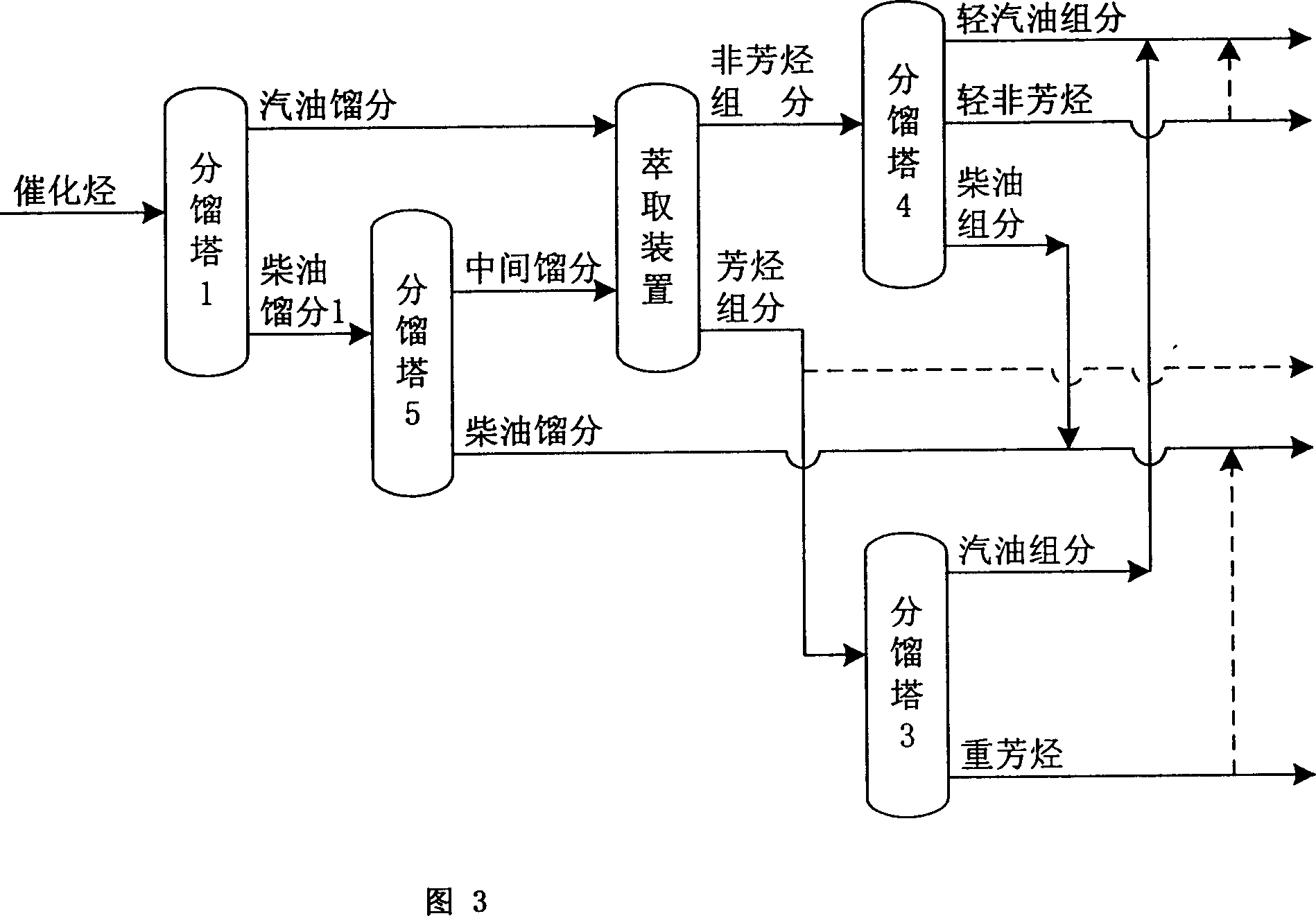

Catalytic hydrocarbon recombinant treating method

InactiveCN1309802CHigh aromatic contentLow flash pointHydrocarbon distillationCatalytic naphtha reformingGasolineAromatic hydrocarbon

A recombination of catalytic aromatic hydrocarbons is carried out by: fractionating them into gasoline fraction, diesel fuel fraction and intermediate distillate through catalysis main dephlegmator, extracting intermediate distillate and gasoline fraction to separate aromatic parts from no-aromatic parts, obtaining high-octane number gasoline oil from aromatic parts mixed with gasoline fraction to increase octane level of gasoline oil and diesel fuel fraction from no-aromatic parts mixed with previous diesel fuel fraction to increase crop and cetane number of diesel fuel. It needs less investment and materials are not limited, and can also increase variety of products.

Owner:丁冉峰

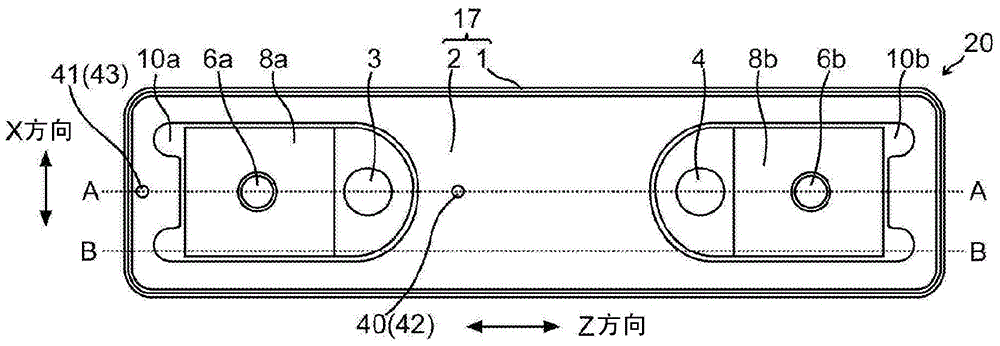

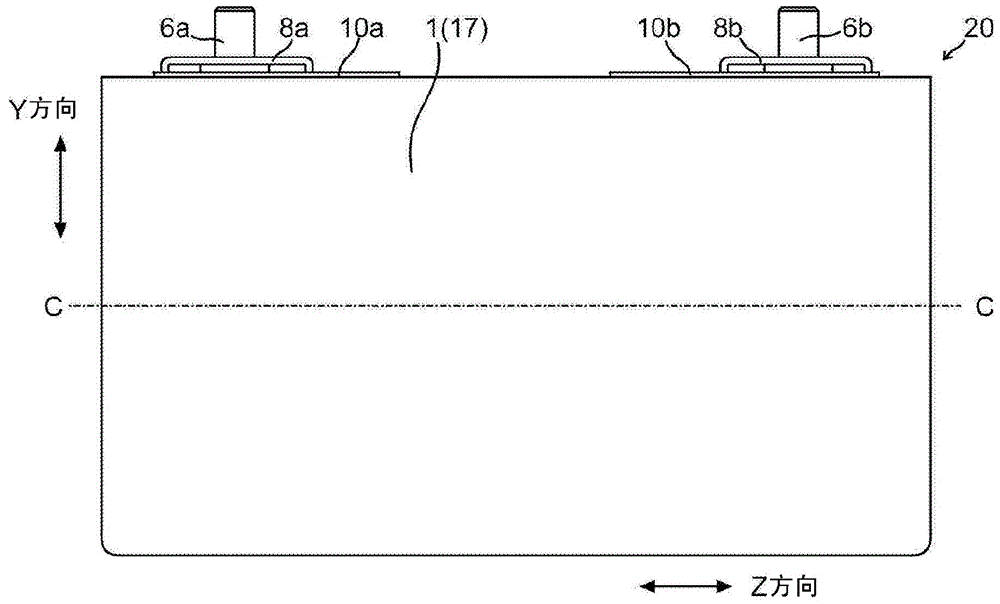

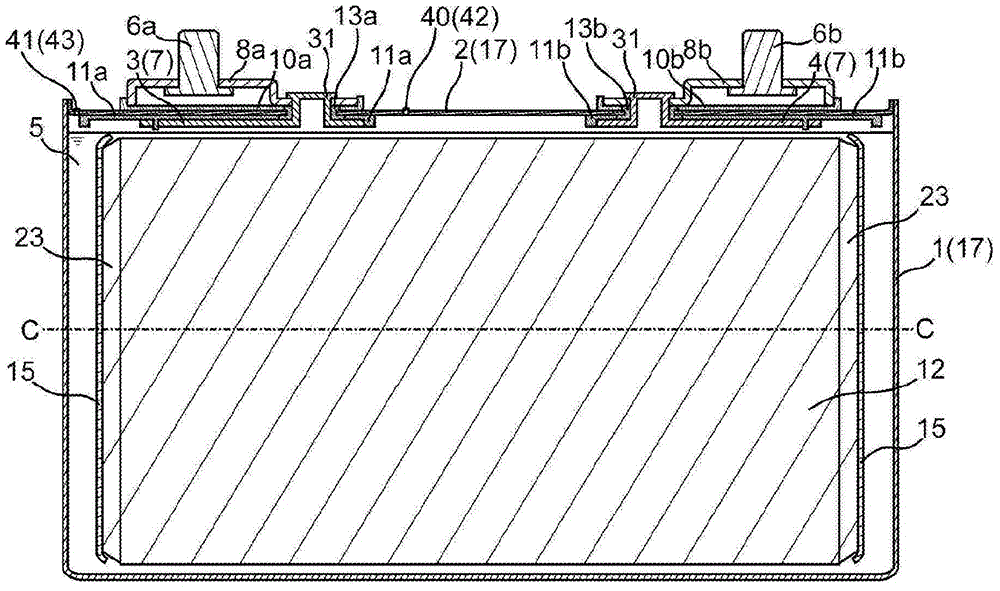

Method for producing non-aqueous electrolyte secondary battery

ActiveCN104871362AEasy to moveLow flash pointCell electrodesFinal product manufactureEngineeringFire retardant

This method for producing a non-aqueous electrolyte secondary battery comprises: a step for introducing, into an outer casing, an electrode body that has a folded structure or a wound structure and in which a positive electrode including a positive-electrode active material and a negative electrode including a negative-electrode active material are stacked with a separator sandwiched therebetween; a step for introducing, into said outer casing, a non-aqueous electrolyte that does not include a flame retardant; a step for performing charging by applying a voltage between said positive electrode and said negative electrode that have been introduced into said outer casing; a step for introducing a flame retardant into said outer casing; and a step for sealing said outer casing. Said method is characterized in that said charging step is a step for performing charging in a state where the surface of said positive-electrode active material and the surface of said negative-electrode active material are in contact with said non-aqueous electrolyte that substantially does not include a flame retardant.

Owner:ELIIY POWER

Method of using waste grease to prepare epoxy plasticizer and product thereof

ActiveCN109970688AGood compatibilityHigh plasticizing efficiencyOrganic chemistryFatty acid esterificationEpoxyPtru catalyst

The invention discloses a method of utilizing waste kitchen grease to prepare an epoxy plasticizer and a product thereof. The method comprises following steps: carrying out freezing fractionation on waste grease to remove saturated grease that is helpless to epoxidation; carrying out esterification reactions between waste grease and alcohols under the catalytic action of a solid acid to reduce theacid value; and finally adding formic acid and hydrogen peroxide to carry out epoxidation reactions. The prepared epoxy plasticizer has the advantages of good plasticization effect, high flash point,and little thermal weight loss, and the PVC product is resistant to oil precipitation. The preparation technology is simple and is suitable for industrial production.

Owner:浙江嘉澳环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com