Patents

Literature

1100 results about "Magnetic liquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

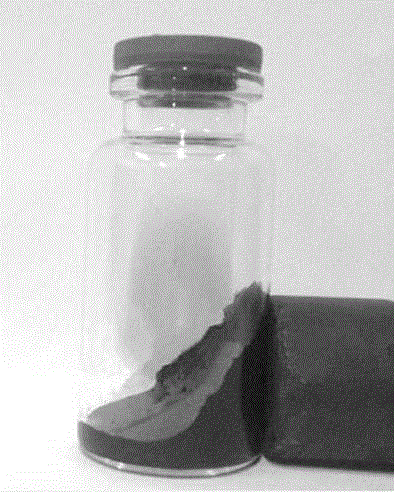

Magnetic fluid is a fluid that is attracted to a magnet, just like iron. In the 1960s, NASA developed magnetic fluid as part of the space program. magnetic fluid has three main constituents: ferromagnetic particles such as magnetite and composite ferrite, a surfactant, and a base liquid such as water or oil.

Method of manufacturing hexagonal ferrite magnetic powder, magnetic recording medium and method of manufacturing the same

ActiveUS20120244387A1Good dispersionReduce dispersion loadMagnetic materials for record carriersIron organic compoundsMagnetic liquidsSolvent

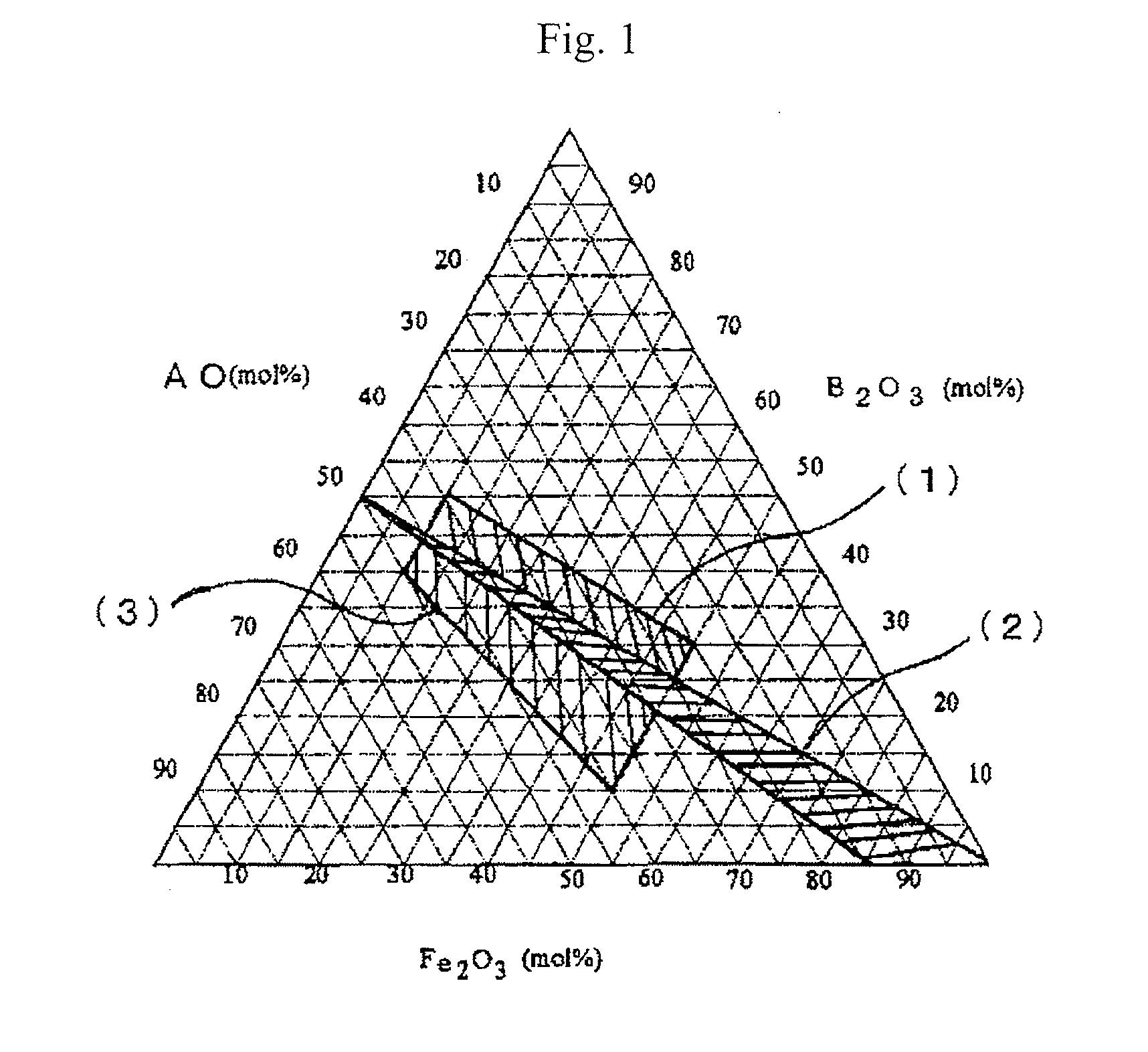

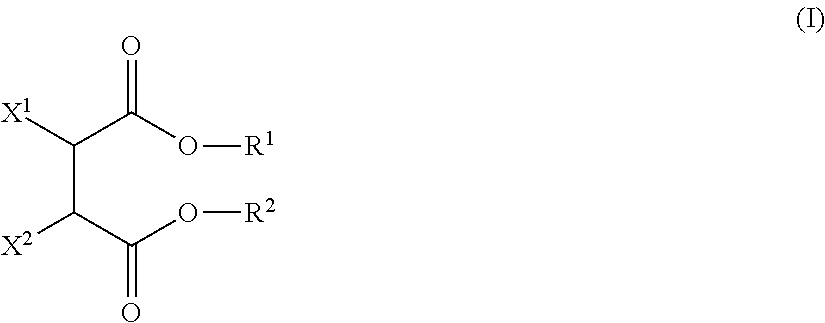

An aspect of the present invention relates to a method of manufacturing hexagonal ferrite magnetic powder. The method of manufacturing hexagonal ferrite magnetic powder comprises wet processing hexagonal ferrite magnetic particles obtained following acid treatment in a water-based solvent to prepare an aqueous magnetic liquid satisfying relation (1) relative to an isoelectric point of the hexagonal ferrite magnetic particles: pH0−pH*≧2.5, wherein, pH0 denotes the isoelectric point of the hexagonal ferrite magnetic particles and pH* denotes a pH of the aqueous magnetic liquid, which is a value of equal to or greater than 2.0, adding a surface-modifying agent comprising an alkyl group and a functional group that becomes an anionic group in the aqueous magnetic liquid to the aqueous magnetic liquid to subject the hexagonal ferrite magnetic particles to a surface-modifying treatment, and removing the water-based solvent following the surface-modifying treatment to obtain hexagonal ferrite magnetic particles.

Owner:FUJIFILM CORP

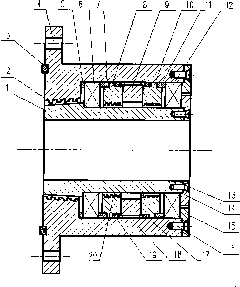

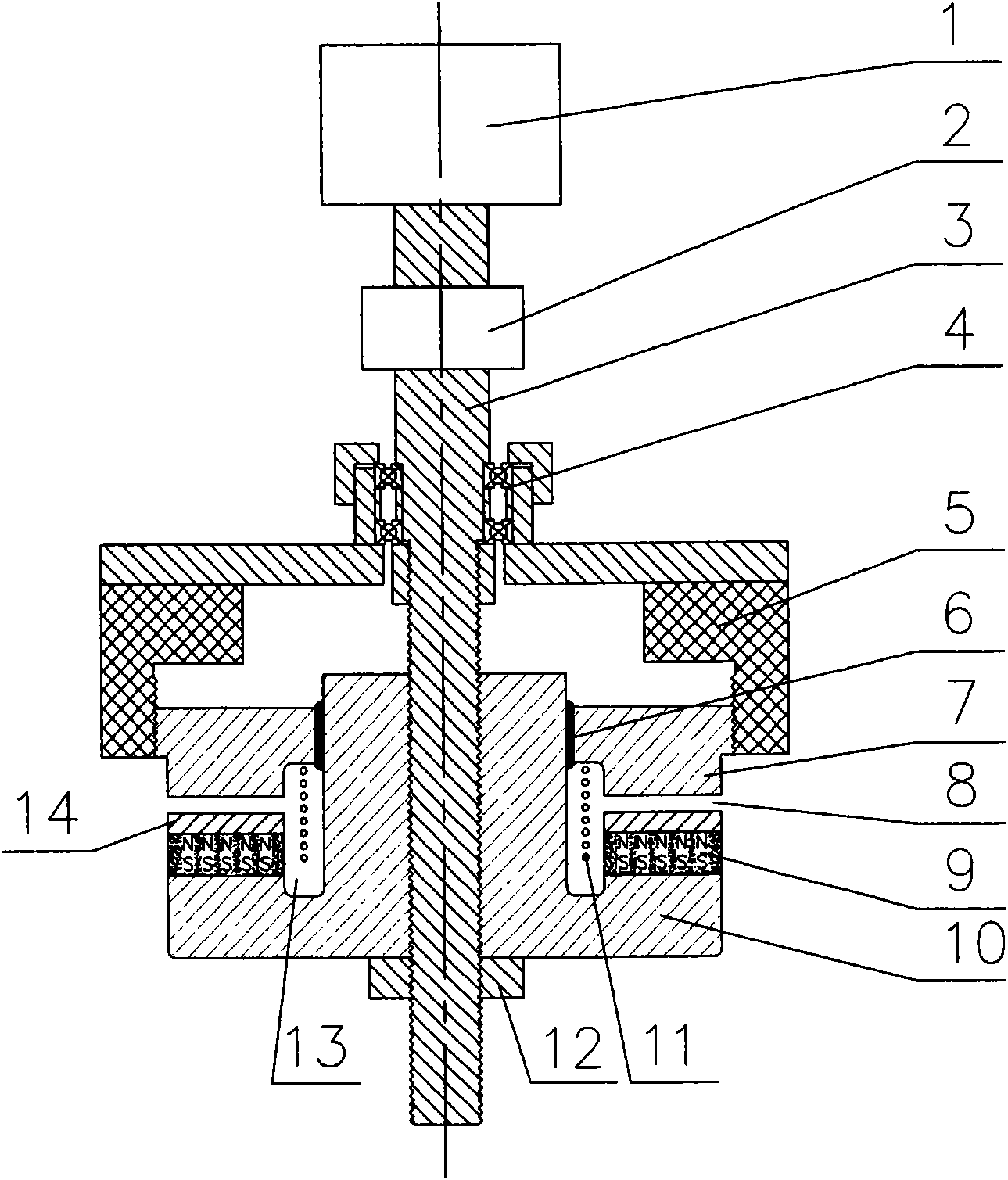

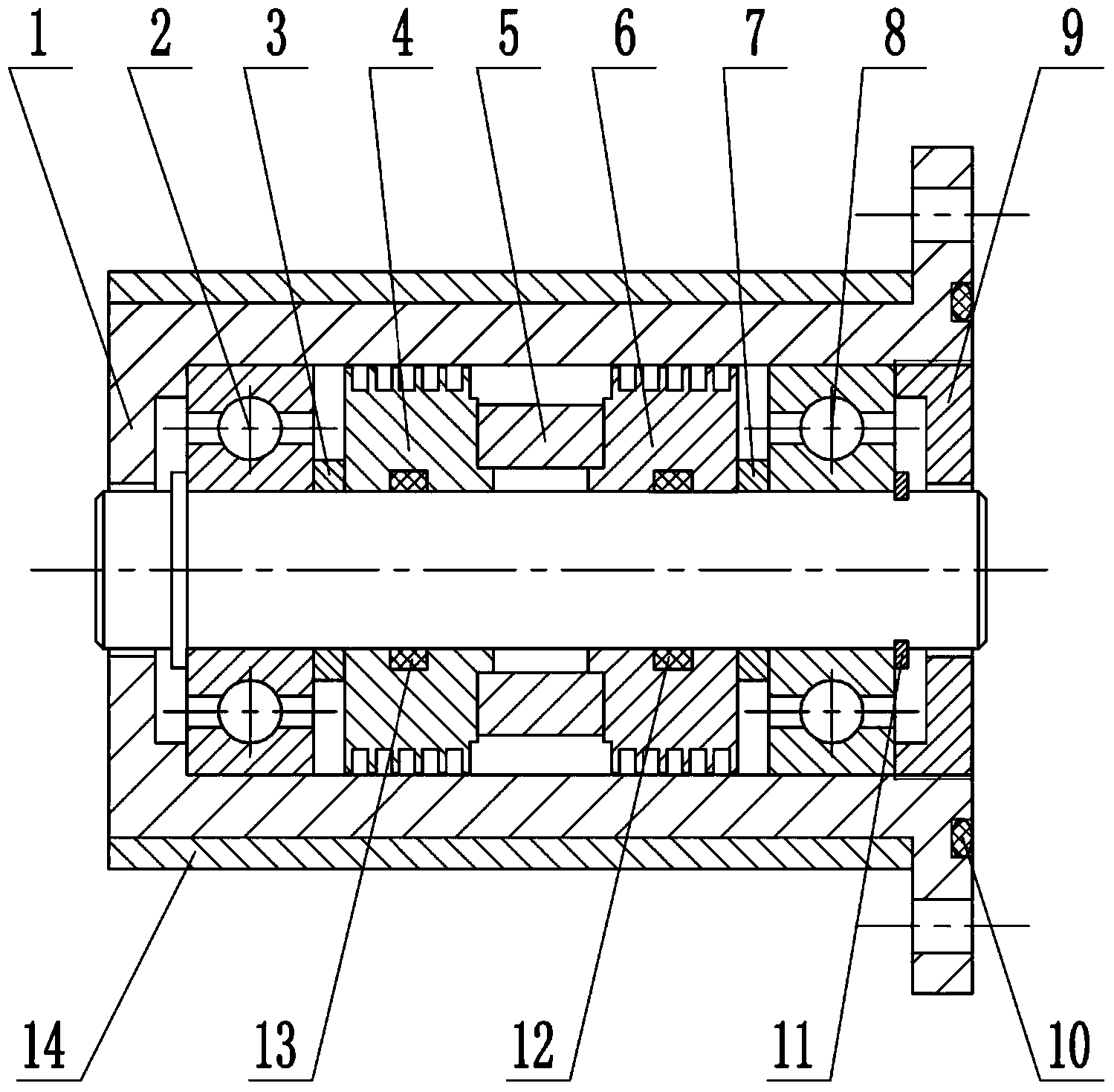

Magnetic fluid damping device

InactiveCN102032304ASolution to short lifeReduce frequencyMagnetic springsEngineeringMagnetic liquids

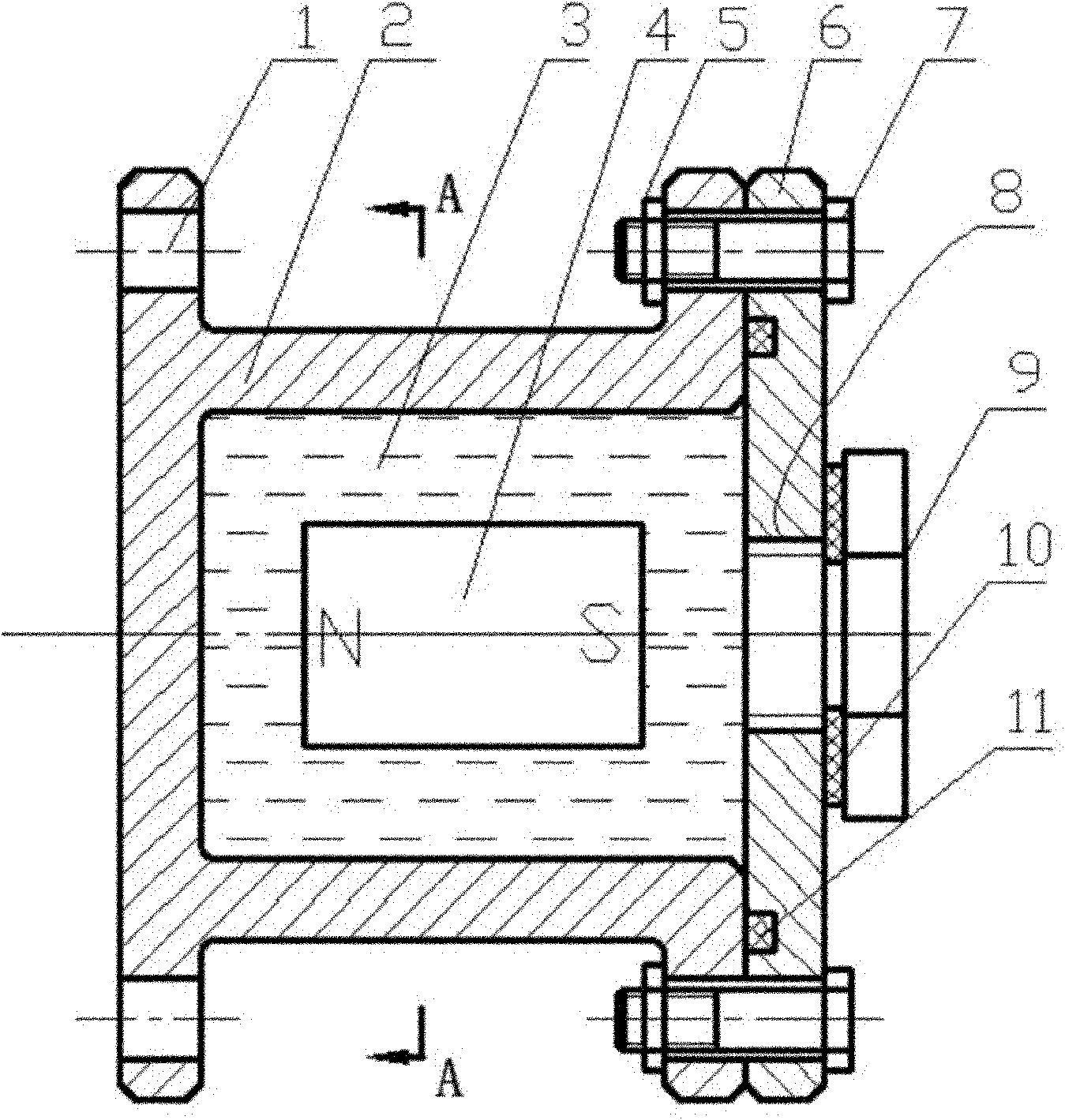

The invention relates to a magnetic fluid damping device, which is suitable for damping long objects in spacecrafts and solves the problem of the damping of the long objects in the spacecrafts. The device comprises a non-magnetic shell (2), magnetic liquid (3), a permanent magnet (4), a nut (5), an end cover (6), a bolt (7), a screw (9), a sealing gasket (10) and an O-shaped seal ring (11). The parts are connected in a way that: the permanent magnet (4) is arranged in the non-magnetic shell (2); the end cover (6) with the O-shaped seal ring (11) is fixed to one end of the non-magnetic shell (2) by the bolt (7) and the nut (5); the magnetic liquid (3) is filled into the non-magnetic shell (2) by a threaded hole (8); and the non-magnetic shell (2) is sealed by the screw (9) and the sealing gasket (10). The device is sensitive to inertia force, can perform damping on the vibration with the characteristics of low frequency, small displacement and low accelerated speed, and has long service life and simple assembly method.

Owner:BEIJING JIAOTONG UNIV

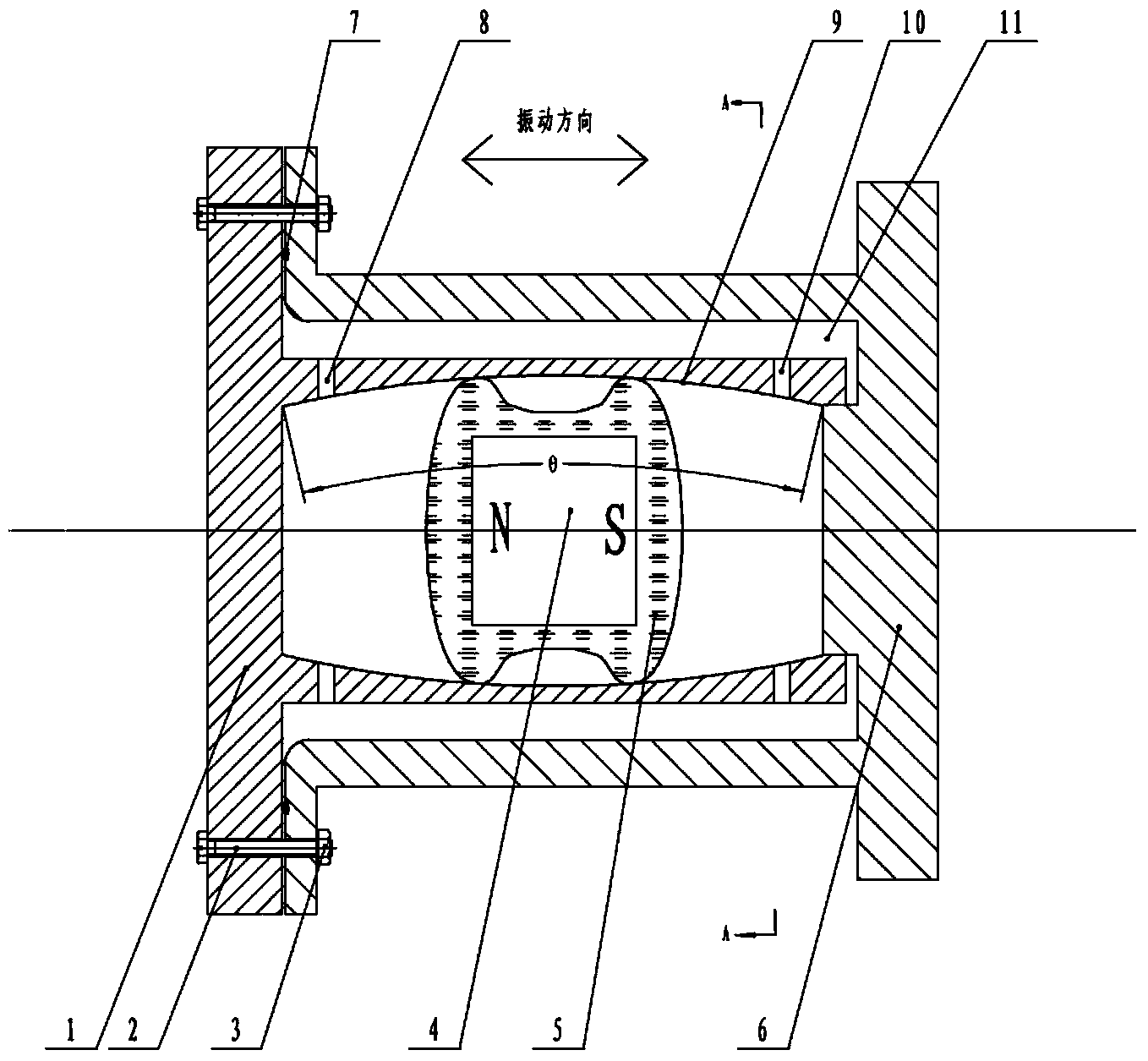

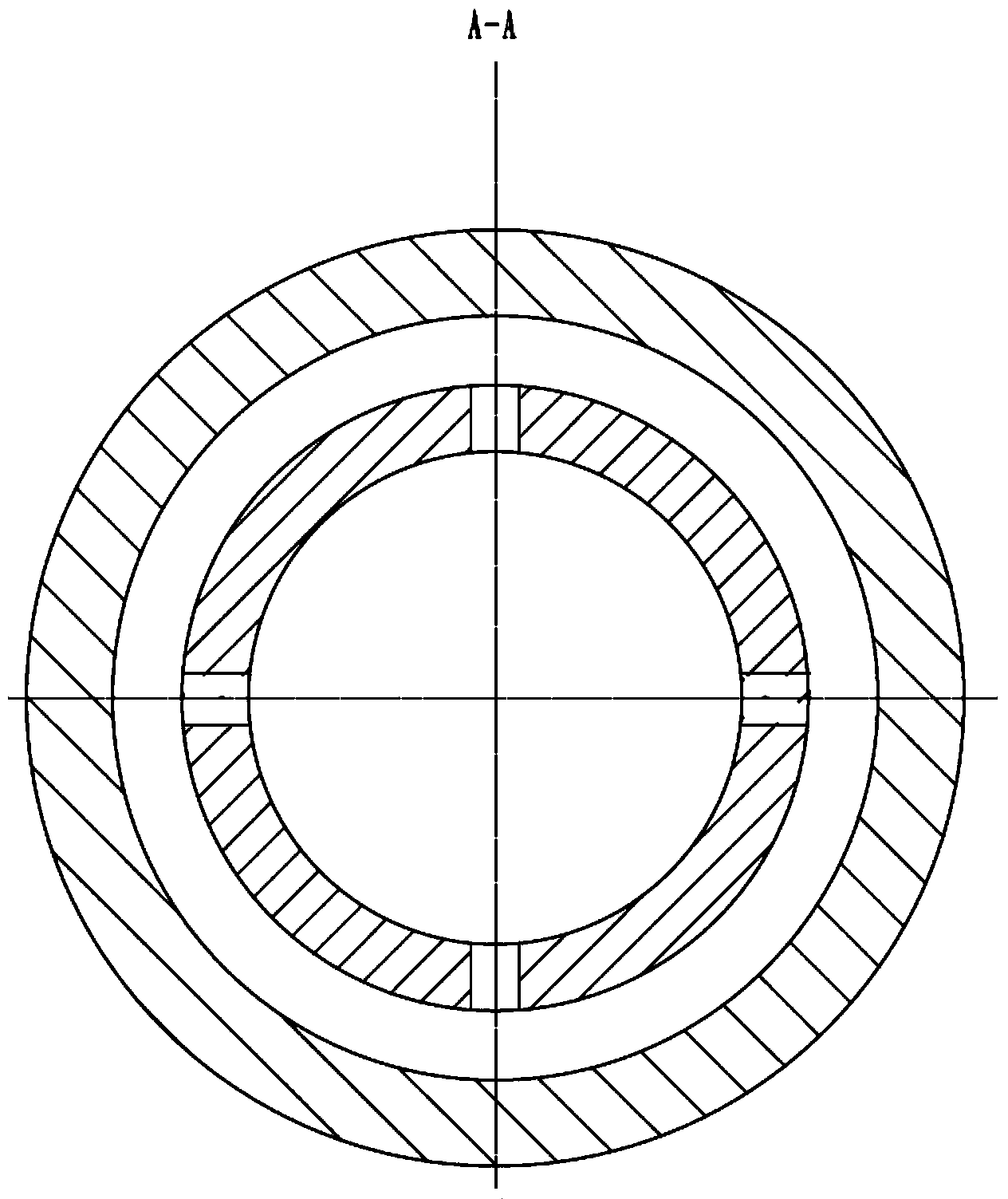

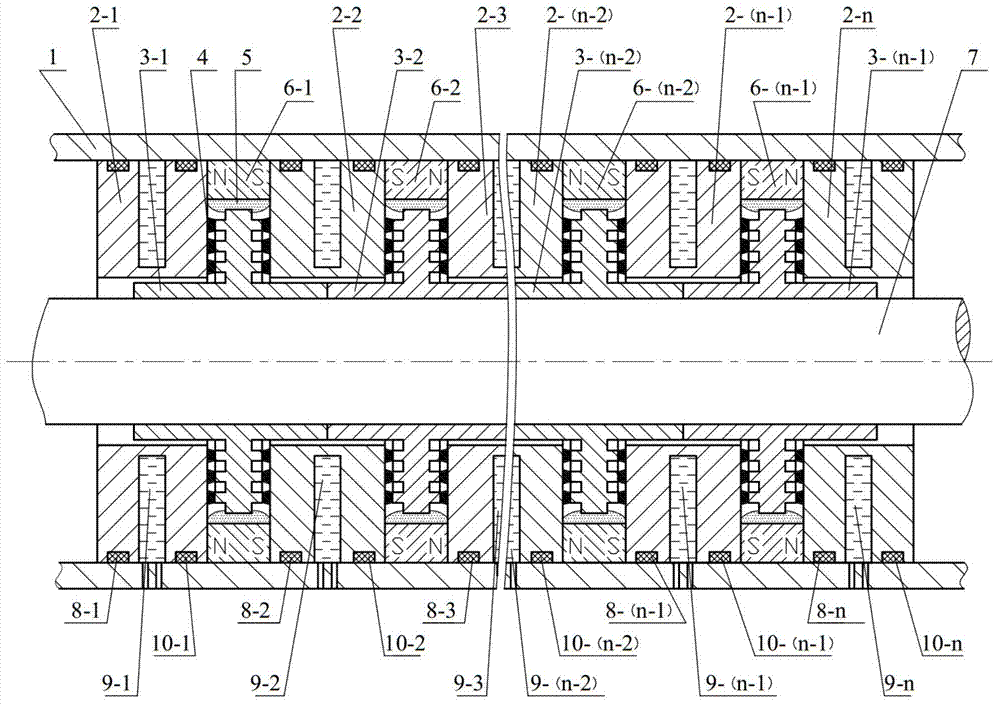

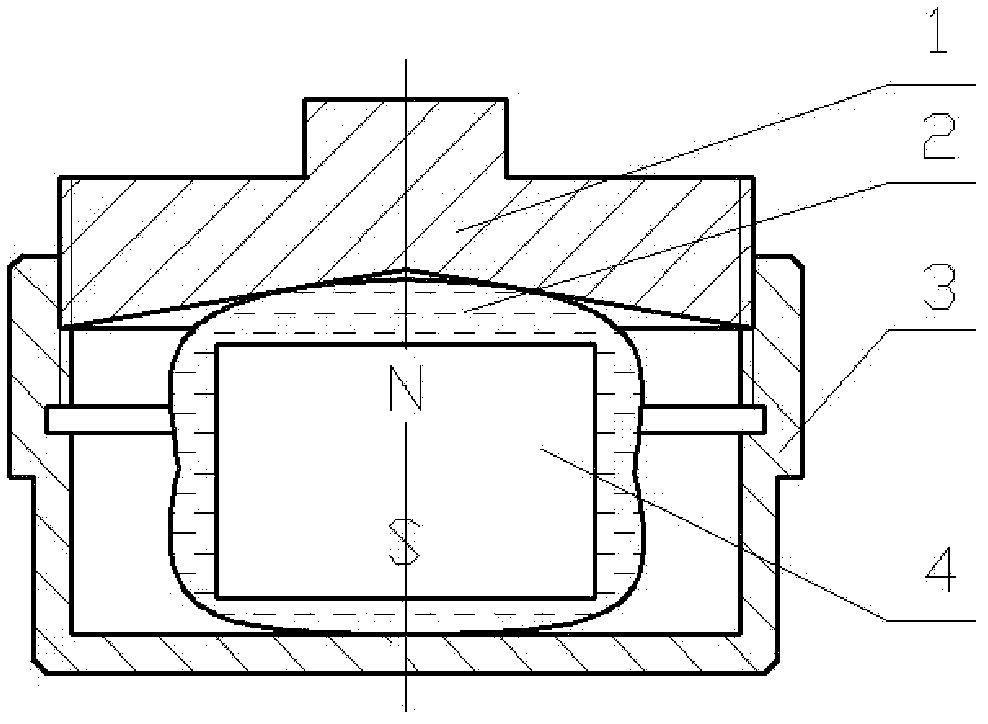

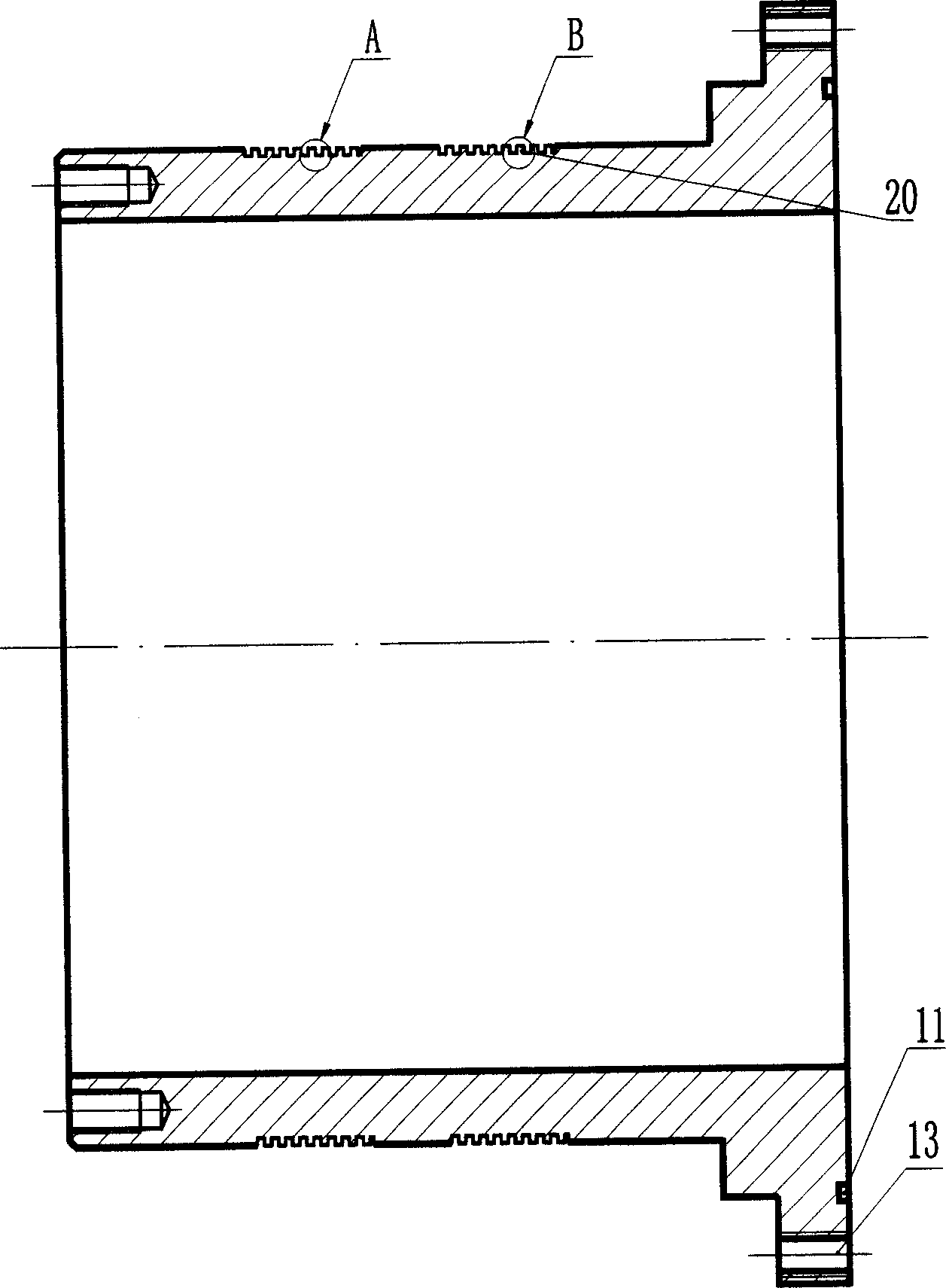

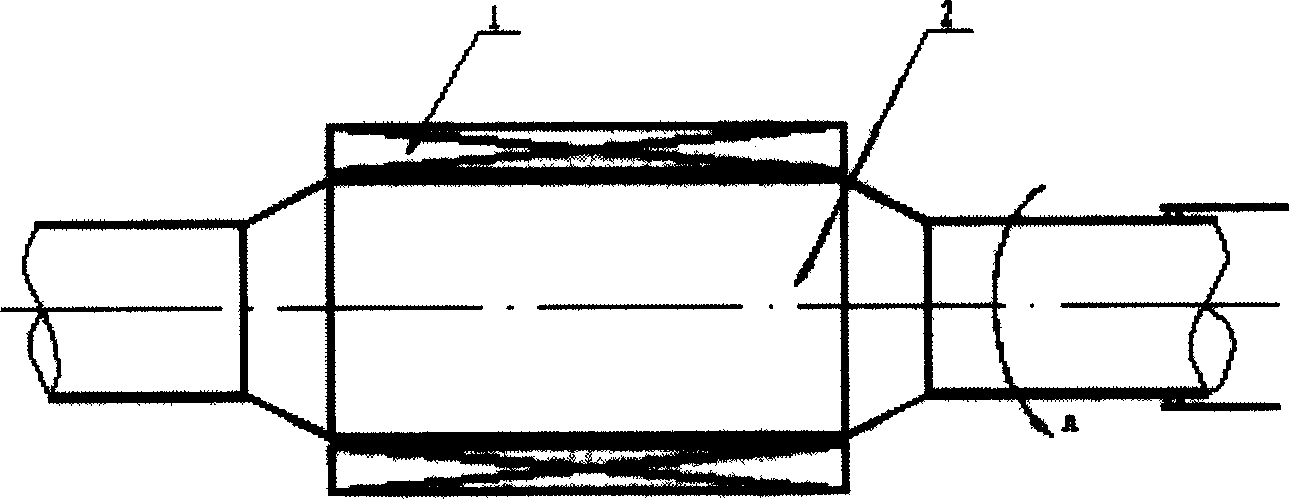

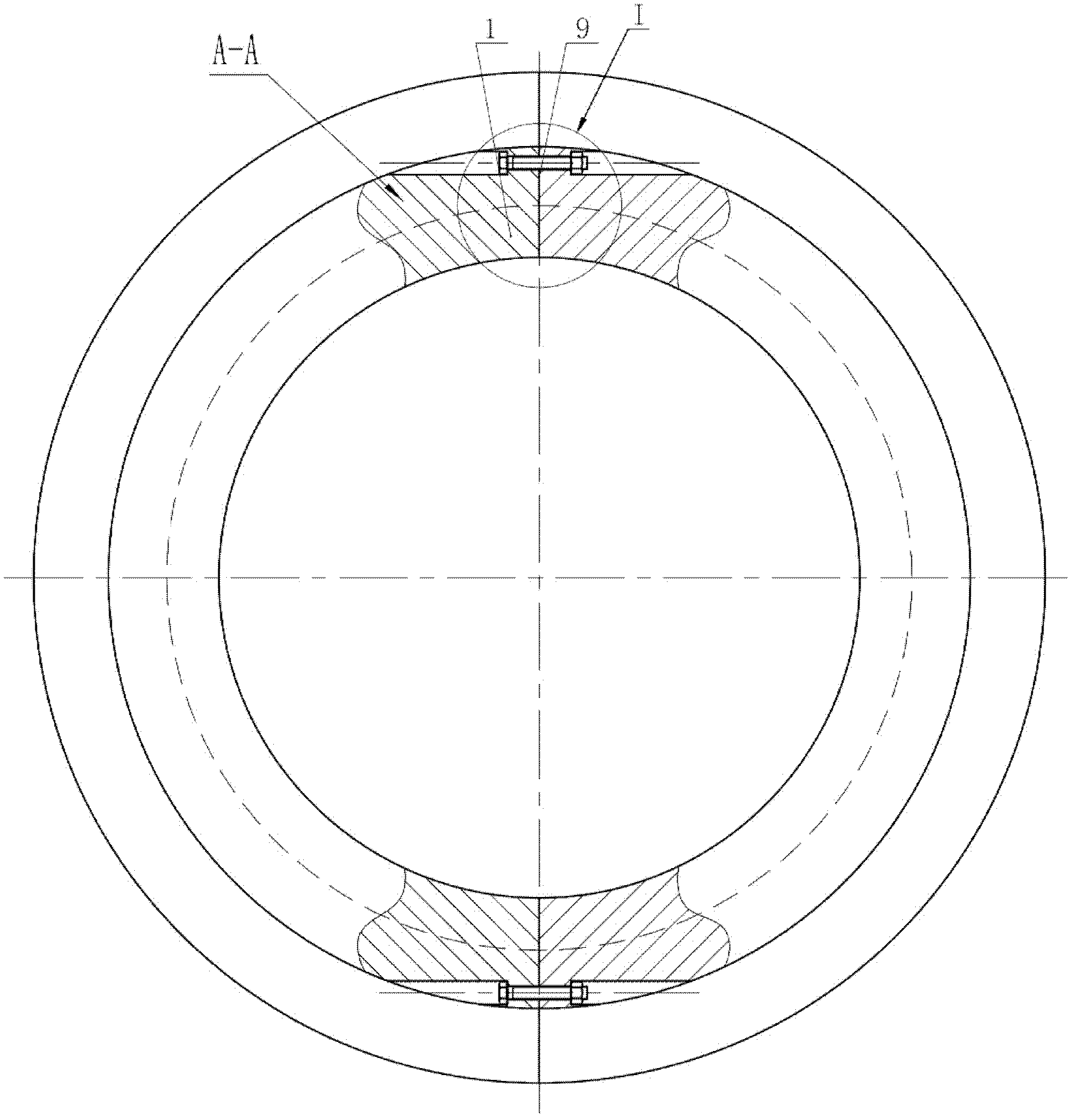

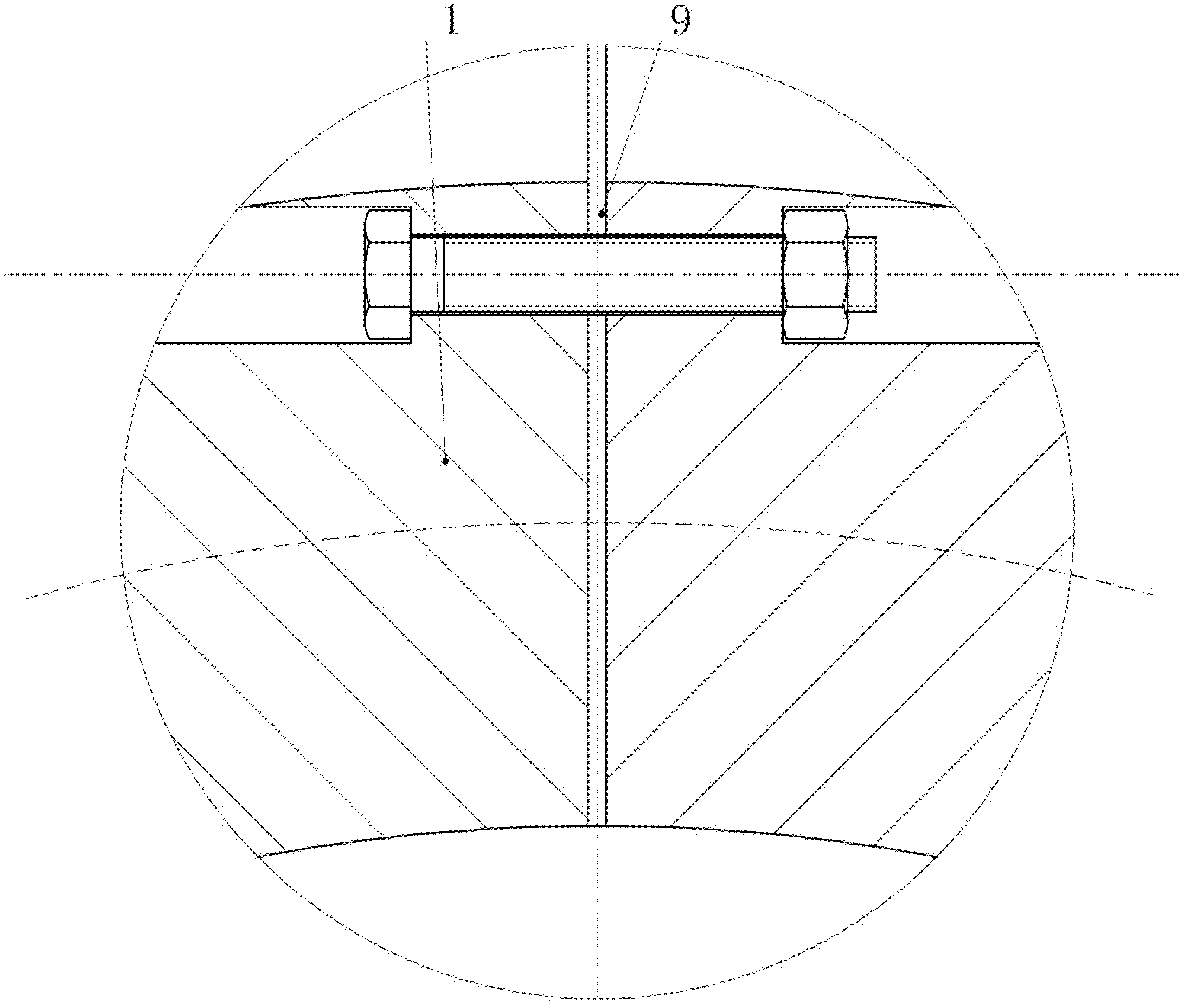

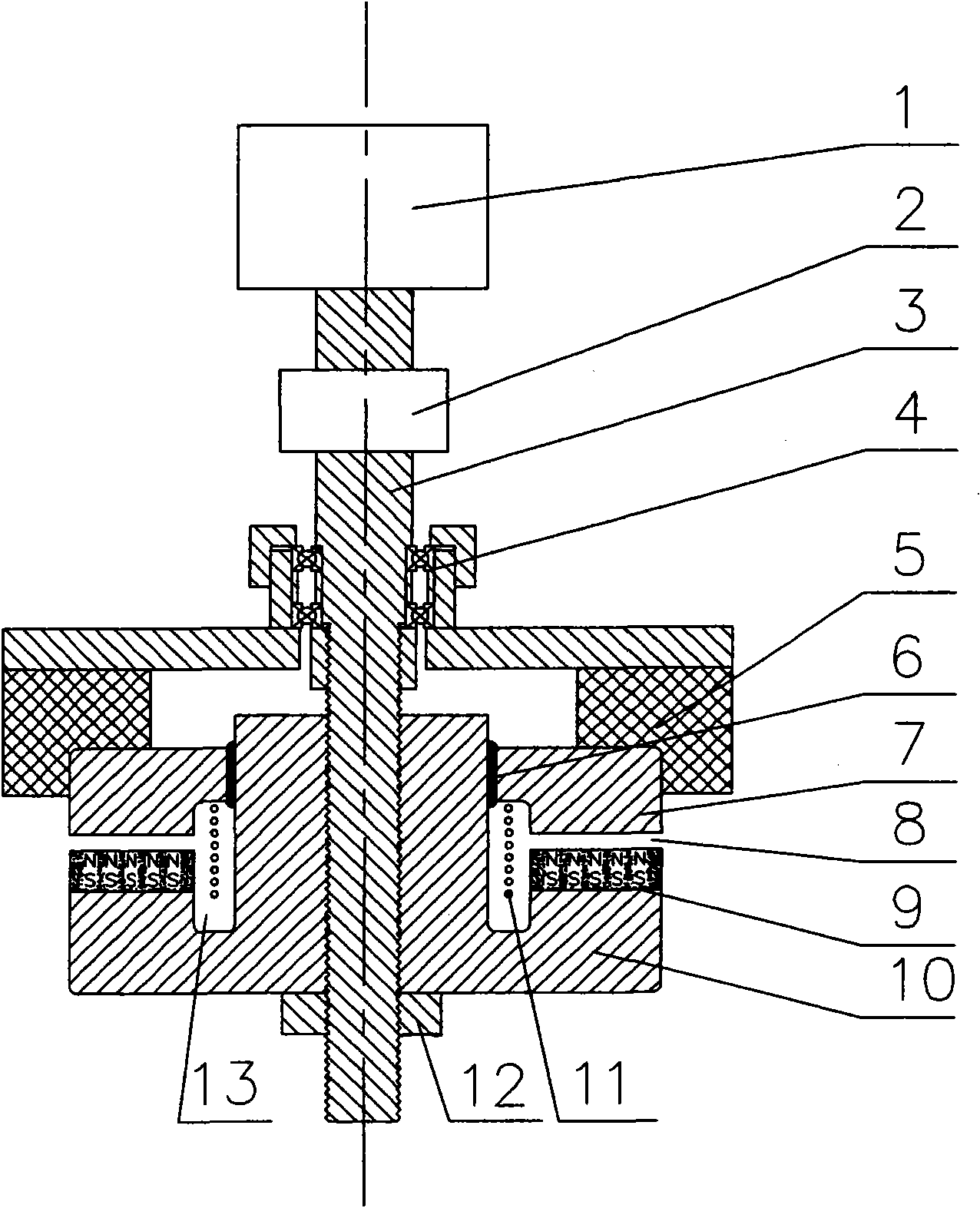

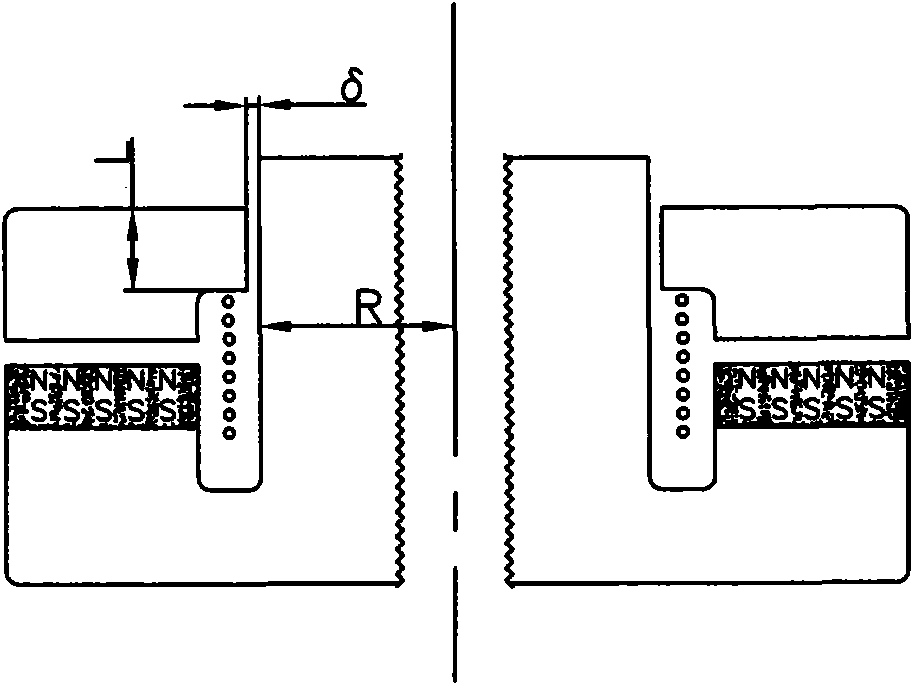

Magnetic liquid damping shock absorber with arc-shaped inner wall axial section

InactiveCN104074903ALittle elasticityIncreased viscous frictionMagnetic springsMagnetic liquidsEngineering

The invention discloses a magnetic liquid damping shock absorber with an arc-shaped inner wall axial section, which is suitable for shock absorption for a long object in a spacecraft. The device comprises a non-magnetic-conducting shell (1), a bolt (2), a nut (3), a permanent magnet (4), a magnetic liquid (5), a non-magnetic housing (6), an O-shaped ring (7), air hole (8), a shell inner wall surface (9) with an arc-shaped inner wall axial section, an air hole (10) and an interlayer air gap (11), wherein connection among the various portions above is as follows: the permanent magnet (4) is installed in the non-magnetic-conducting shell (1), the magnetic liquid is coated on the permanent magnet (4), and the non-magnetic housing (6) and the non-magnetic-conducting shell (1) are sealed by the O-shaped ring (7), and rigidly connected by the bolt (2) and the nut (3); the inner wall axial section of the non-magnetic-conducting shell (1) is arc-shaped, and the corresponding central angle theta is 1-15 degrees. The device is quite sensitive to an inertia force, and capable of carrying out effective shock absorption on shock with the characteristics of a low frequency, a small displacement and a low accelerated speed.

Owner:BEIJING JIAOTONG UNIV

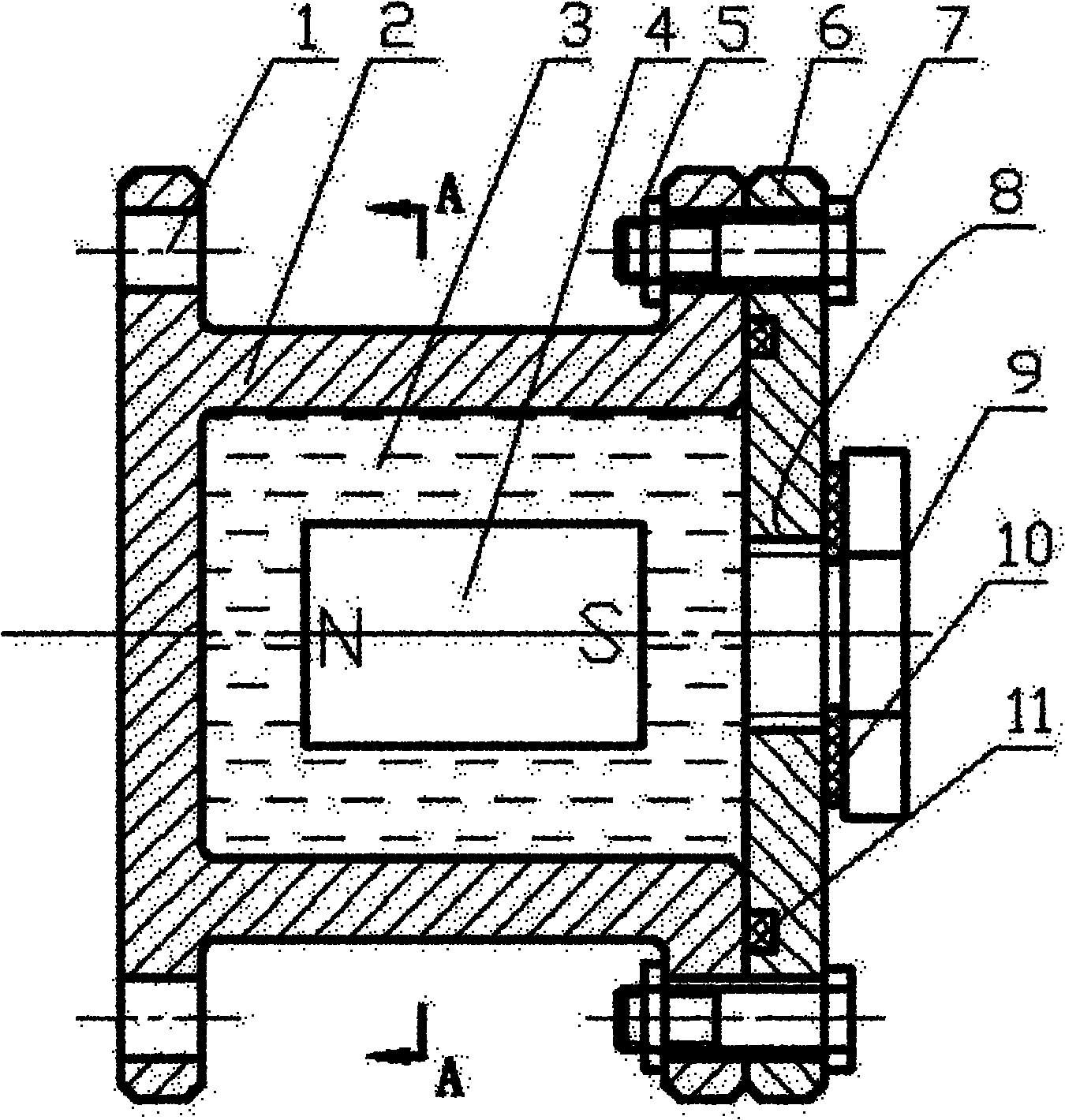

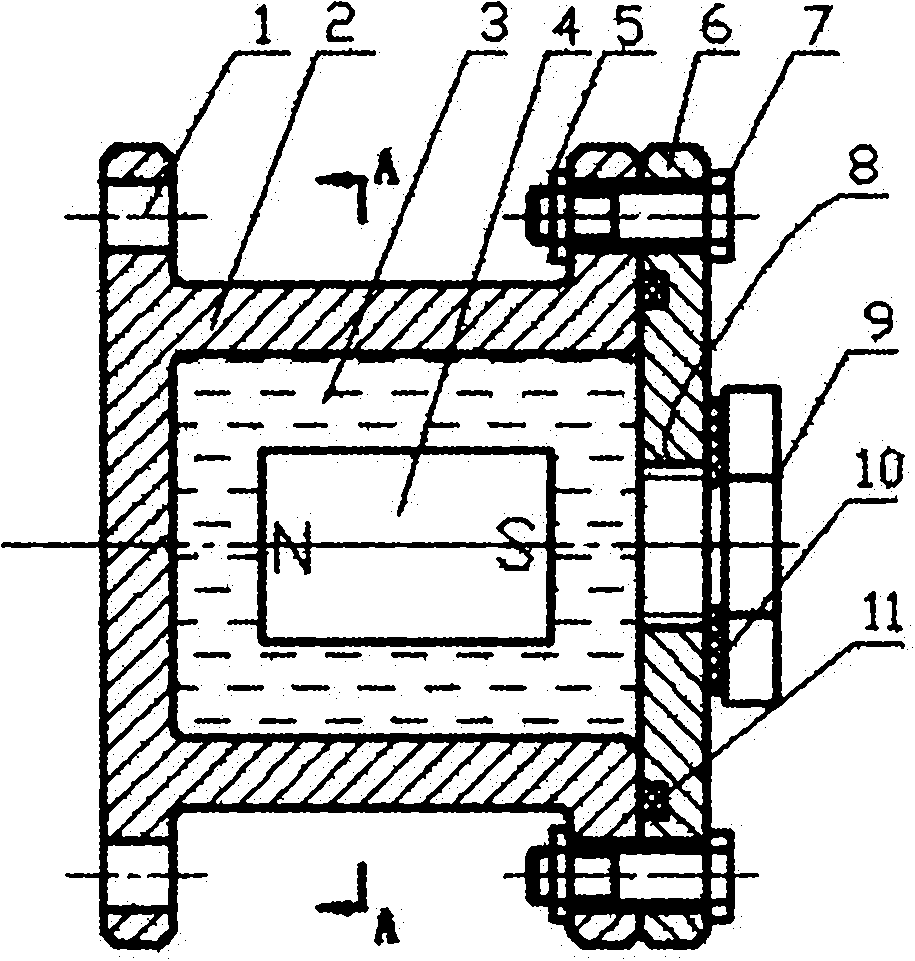

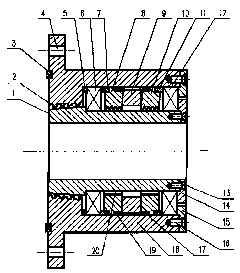

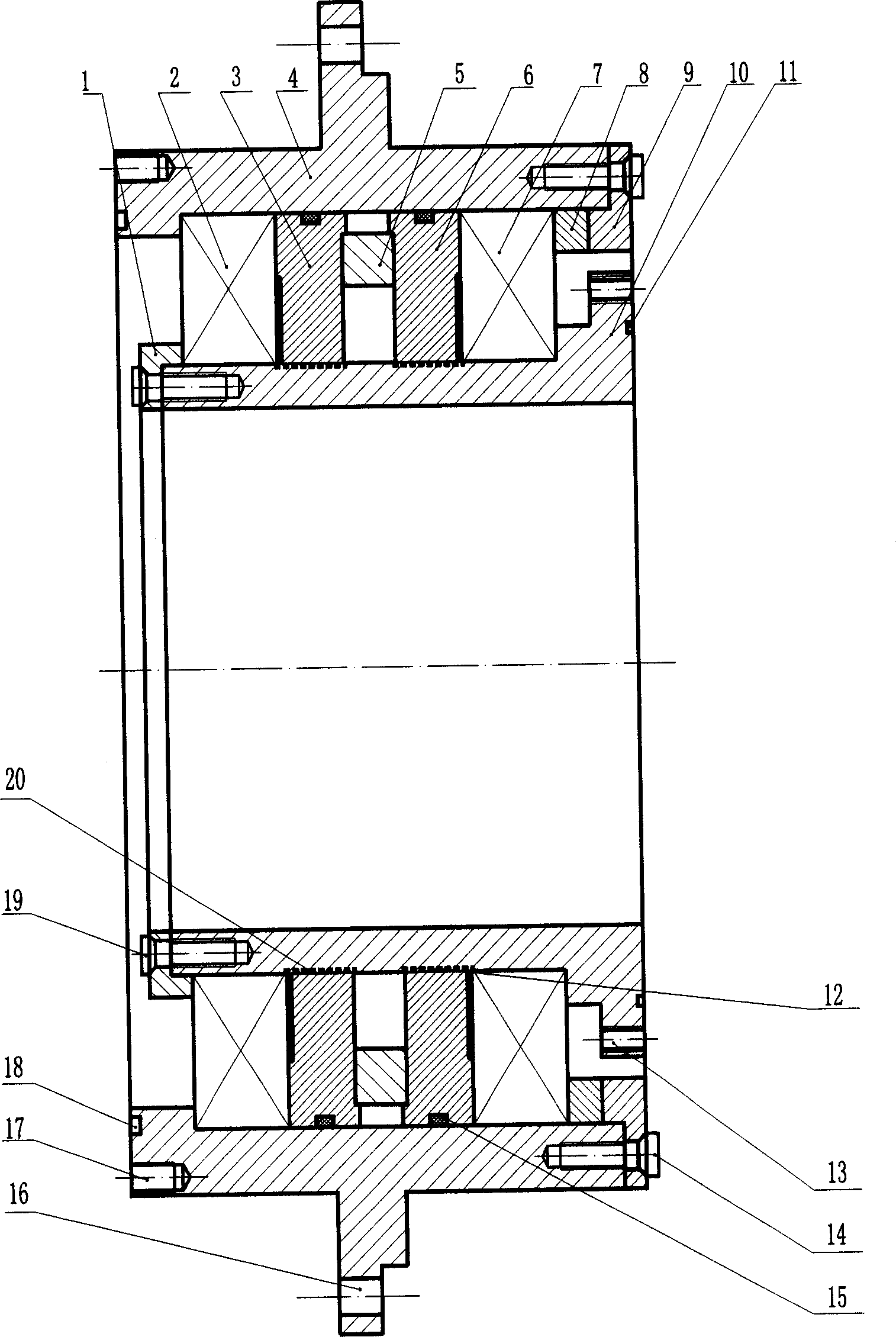

Magnetic liquid damping device

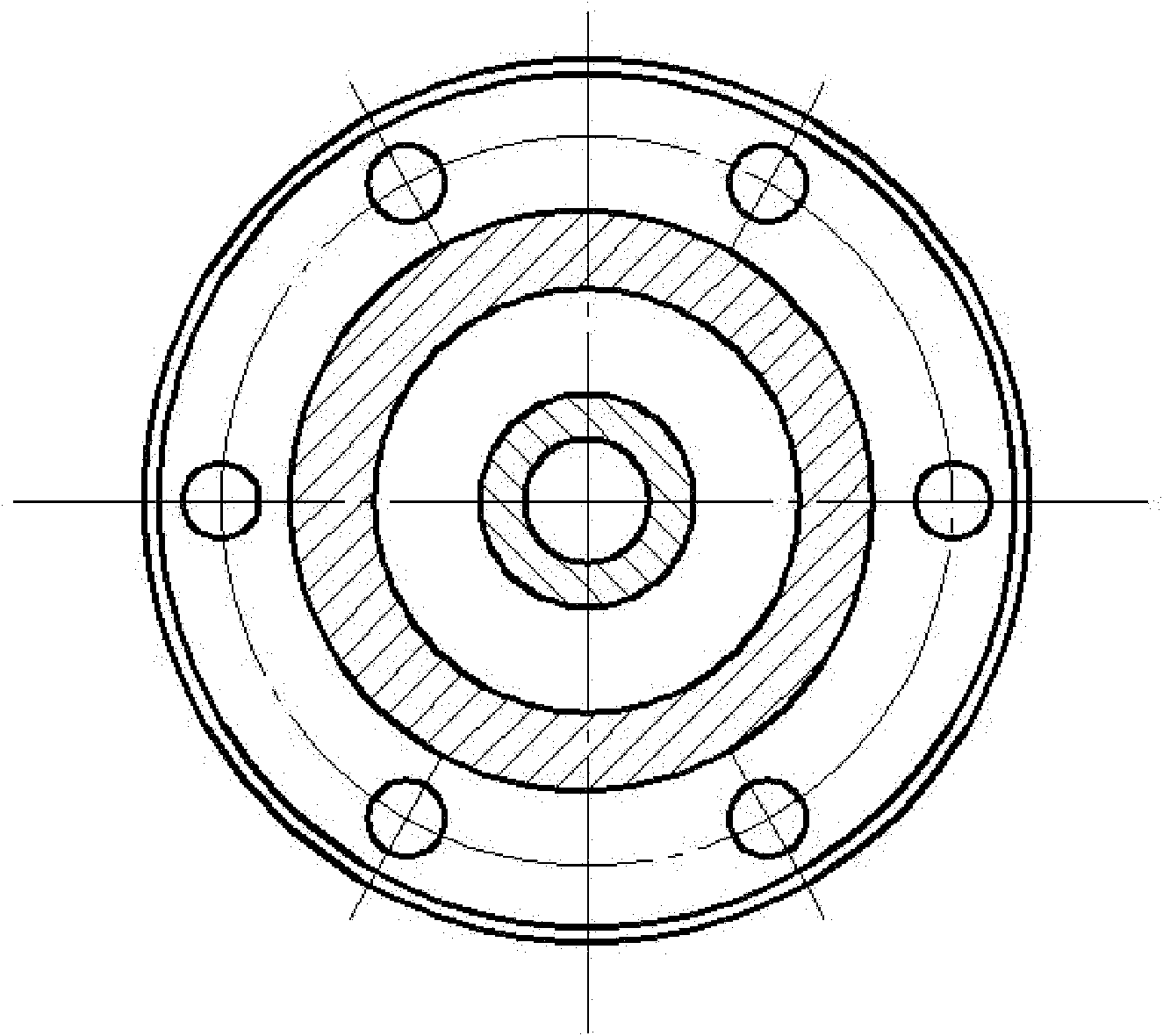

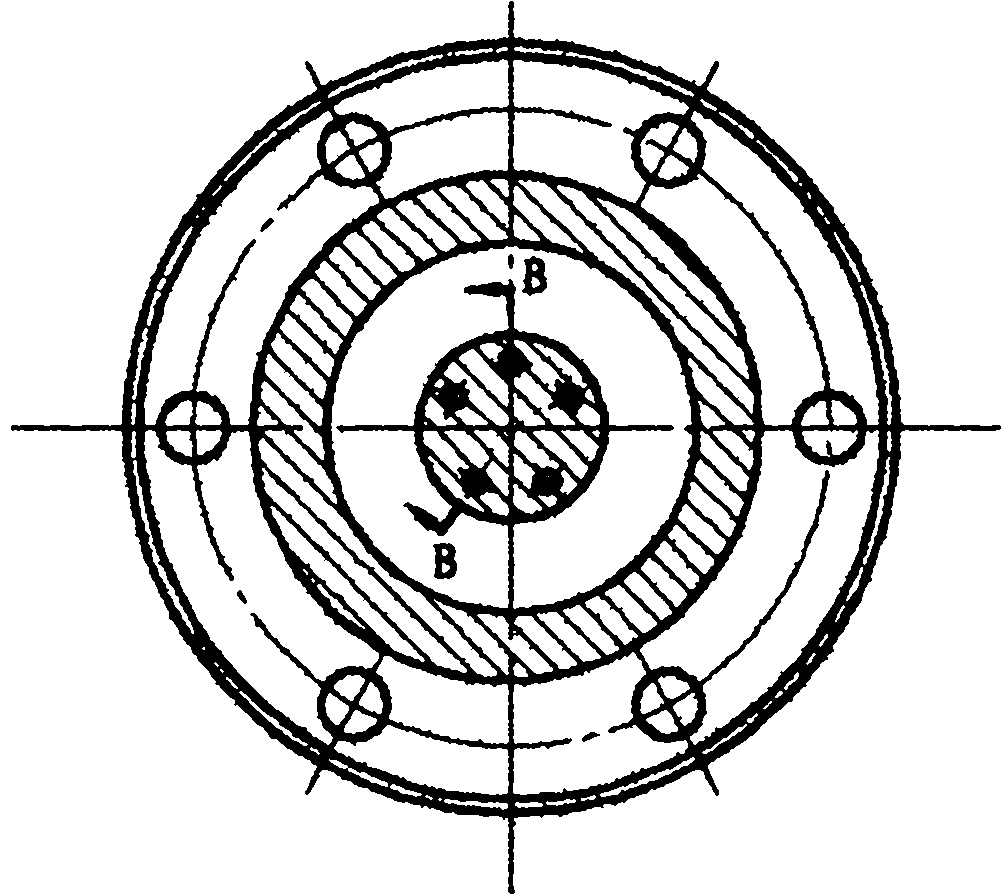

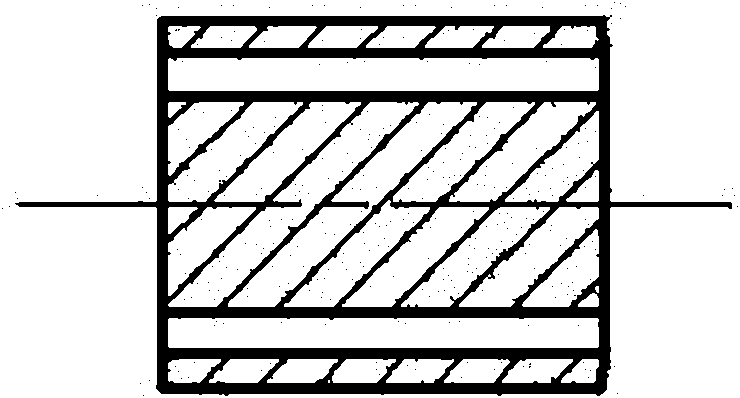

InactiveCN102042359AStrong magnetismIncrease the friction surfaceMagnetic springsMagnetic liquidsMagnet

The invention discloses a magnetic liquid damping device, relates to a damping device and aims to solving the damping problem of a longer object in a spacecraft. The device consists of a non-magnetic conducting shell (2), magnetic liquid (3), a permanent magnet (4), a nut (5), an end cover (6), a bolt (7), a screw (9), a sealing gasket (10) and an O-shaped seal ring (11), wherein the parts are connected together; the permanent magnet (4) is arranged in the cavity of the non-magnetic conducting shell (2); the end cover (6) with the O-shaped seal ring (11) is fixed on one end of the non-magnetic conducting shell (2) through the bolt (7) and the nut (5); the magnetic liquid (3) is filled in the cavity of the non-magnetic conducting shell (2) through a screwed hole (8); the screw (9) and the sealing gasket (10) are used for sealing; the permanent magnet (4) is a cylinder; and 4-8 through holes are distributed in the cylinder axially. The device disclosed by the invention has good damping effect.

Owner:BEIJING JIAOTONG UNIV

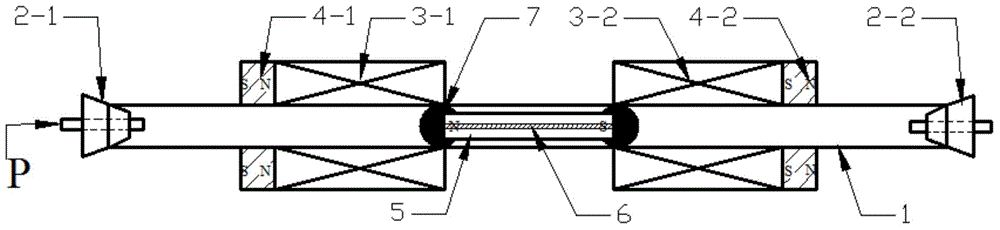

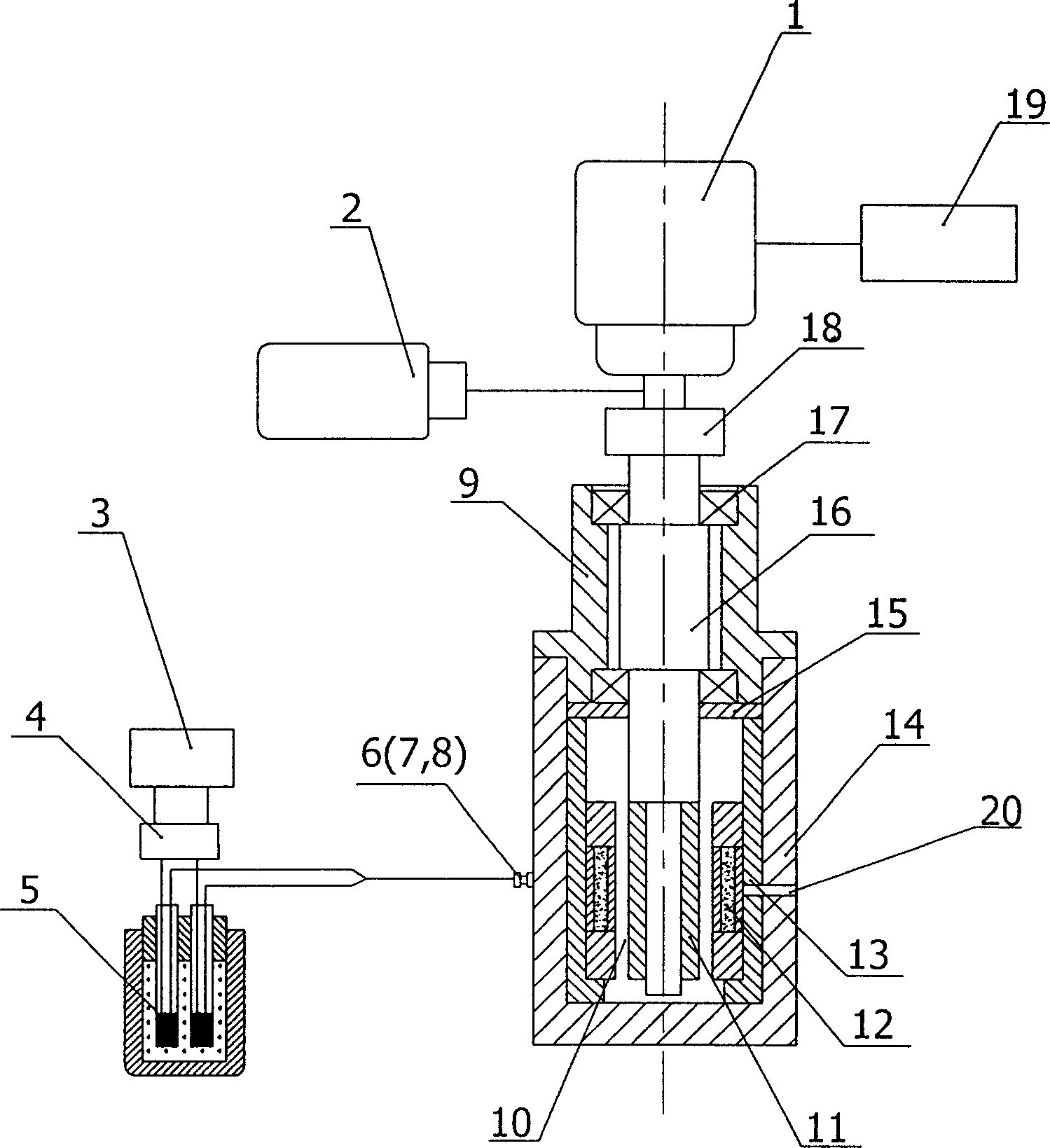

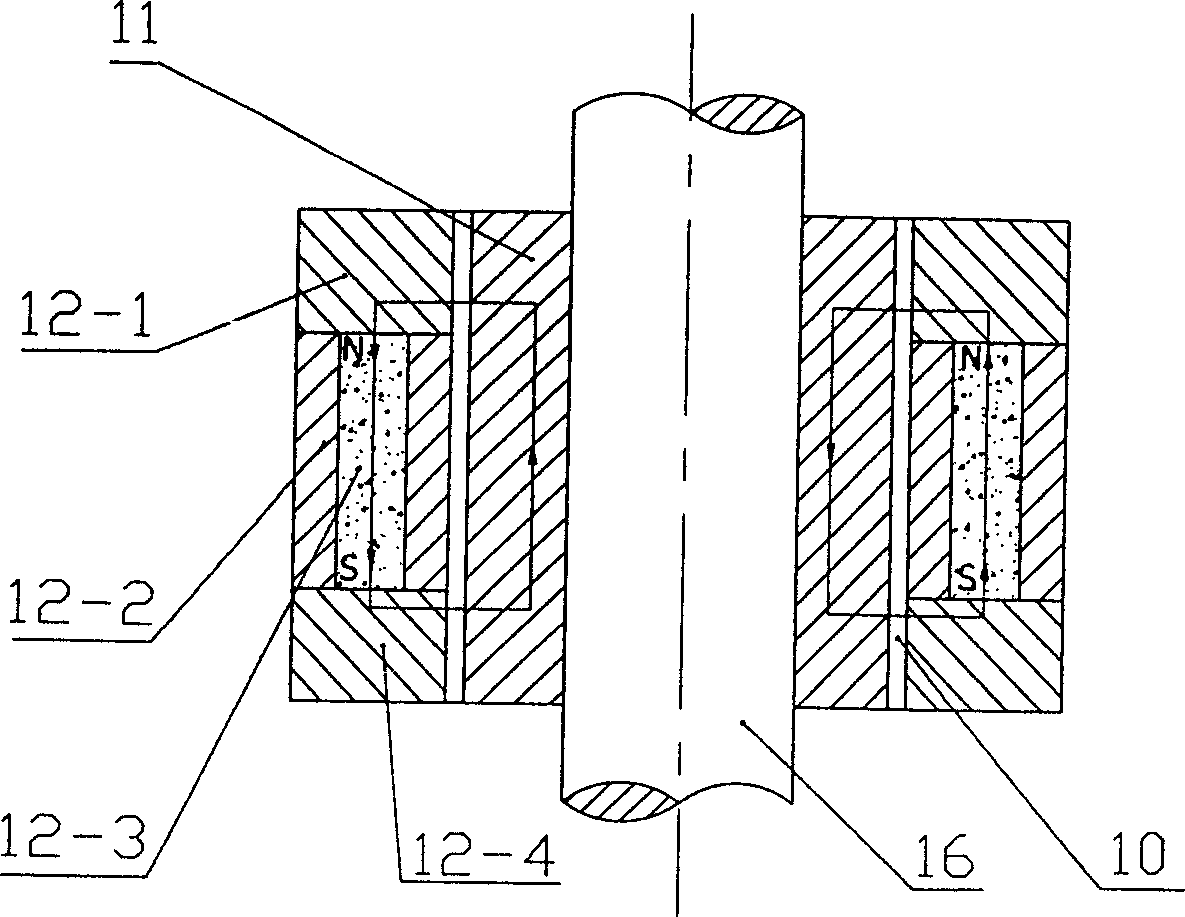

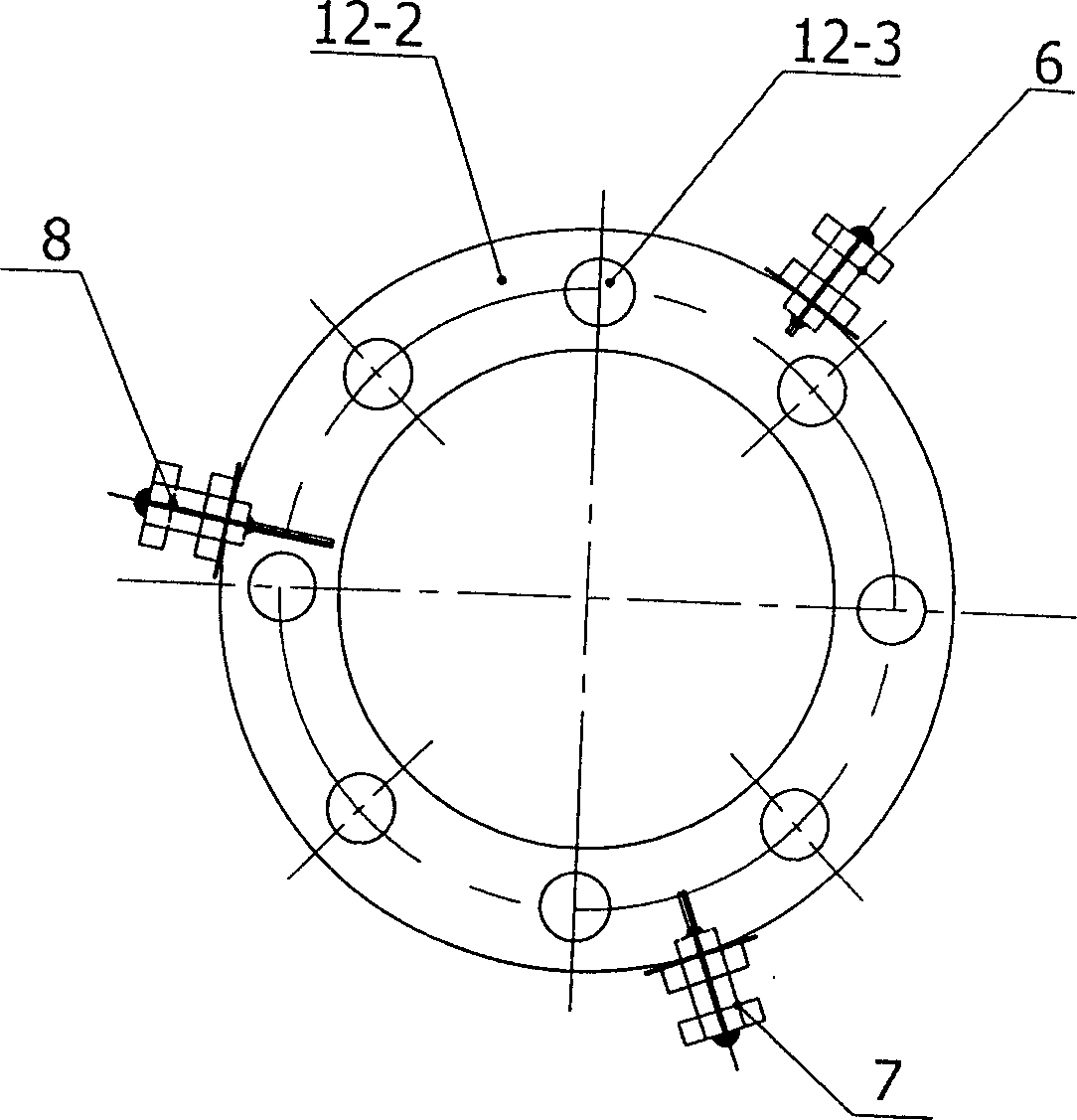

Magnetic liquid acceleration sensor

InactiveCN103149384AHigh sensitivityImprove stabilityAcceleration measurementSpeed/acceleration/shock instrument detailsMagnetic liquidsMagnet

The invention discloses a magnetic liquid acceleration sensor, belonging to the technical field of inertia sensors and solving the problems that the weight is heavy, the measuring range is short, the sensor fails due to the fact that magnet is demagnetized because of long-time use and the stability of the sensor is reduced due to the fact that magnetic particles are aggregated because of long-time work failure in a traditional magnetic liquid acceleration sensor are solved. A cylindrical magnet (5) of the magnetic liquid acceleration sensor is a rubber magnet; the cylindrical magnet (5) is placed in a casing (2); magnetic liquid is filled into the casing (2) and is attached to two axial ends of the cylindrical magnet and enables the cylindrical magnet to suspend; a left end cover (1) and a right end cover (6) are respectively in threaded connection with two ends of the casing; a first coil (3) and a second coil (4) are respectively wound in two annular grooves of the casing; the first coil is connected with the second coil in a differential manner; the diameter of an inner cavity of the casing is reduced from the center to the left side and the right side; a taper angle is 2 alpha; the lateral surface of the inner cavity of the casing takes an axis as a symmetrical shaft; and a first groove and a second groove are formed along the axis.

Owner:BEIJING JIAOTONG UNIV

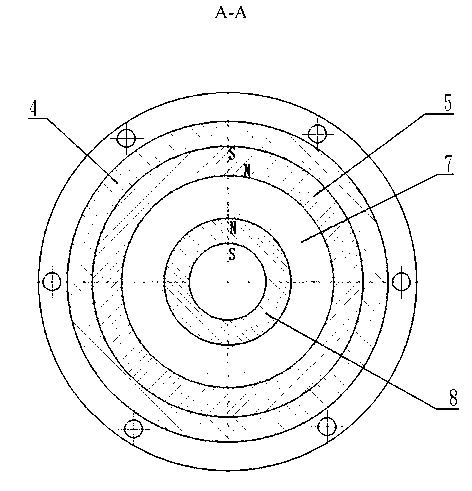

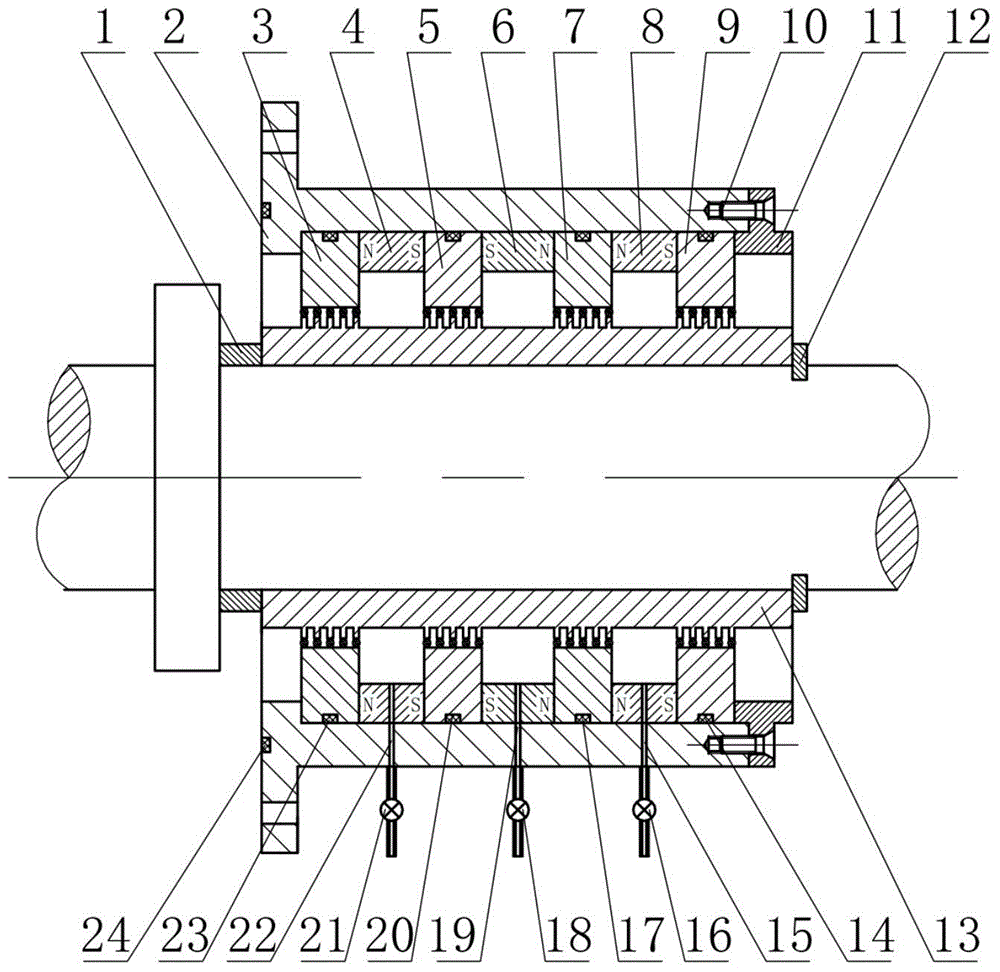

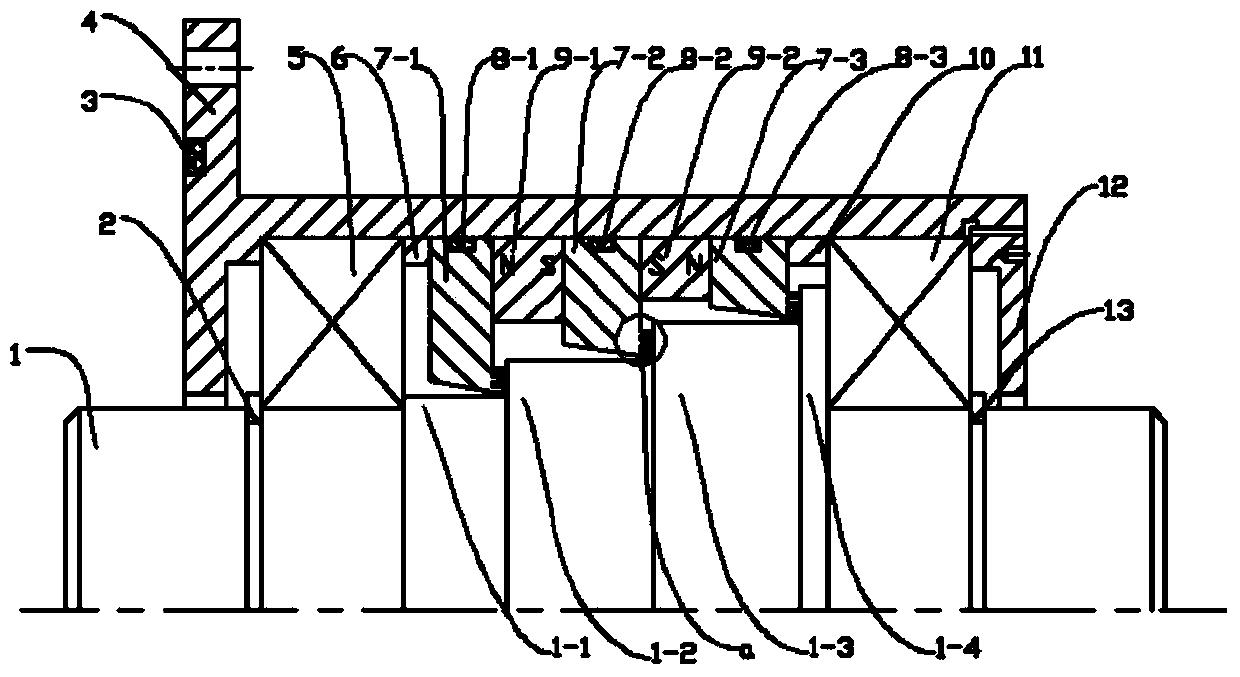

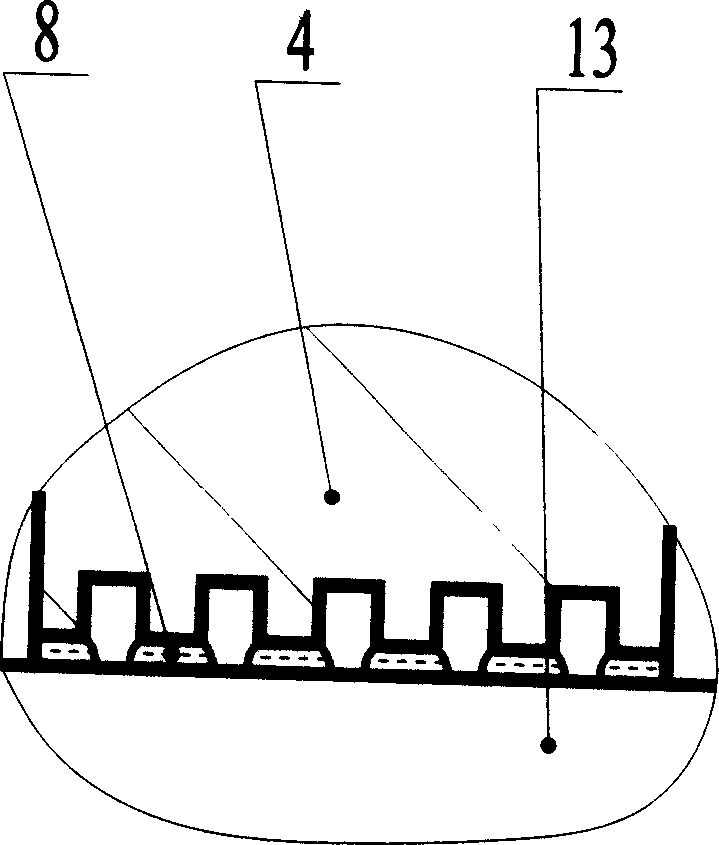

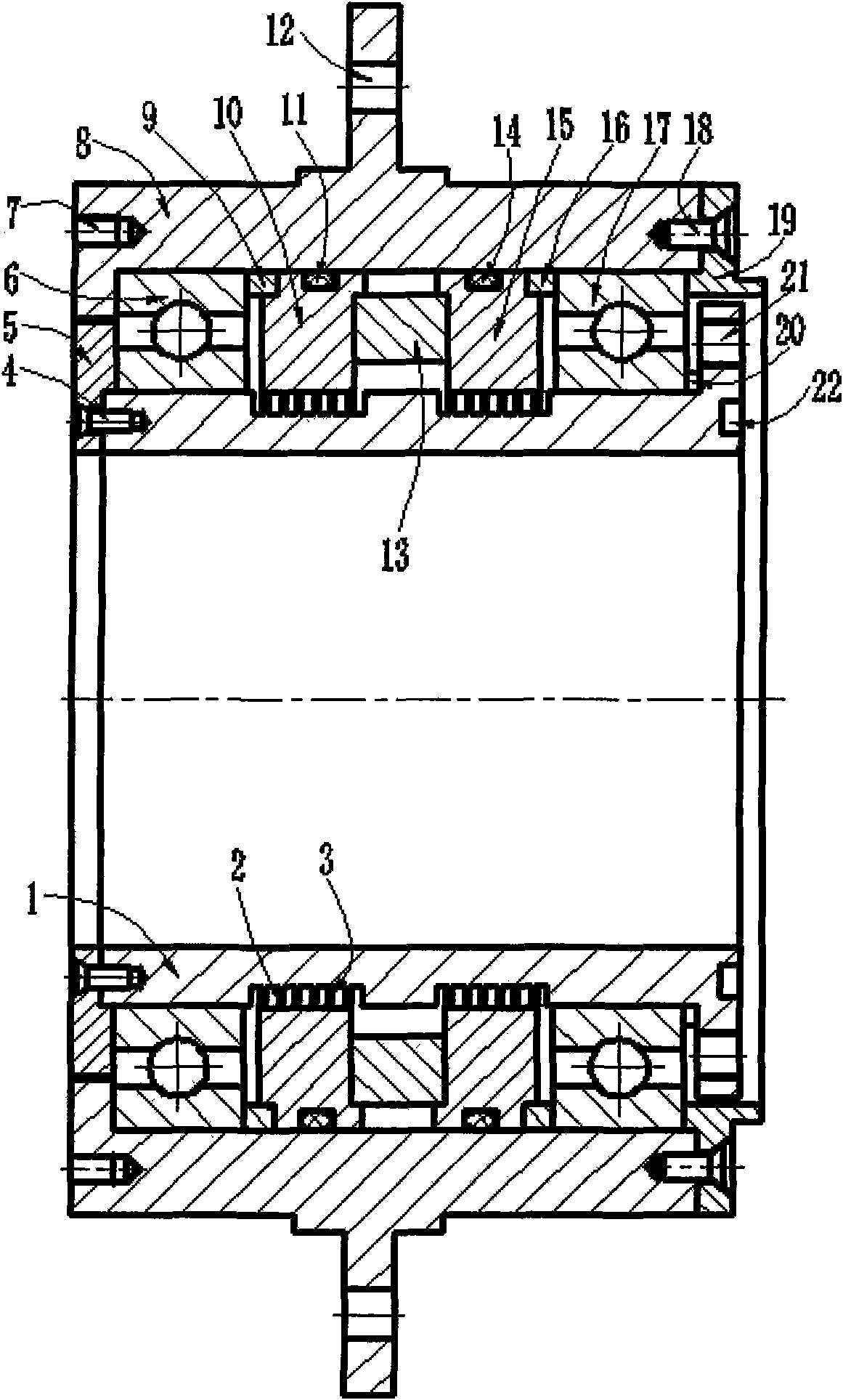

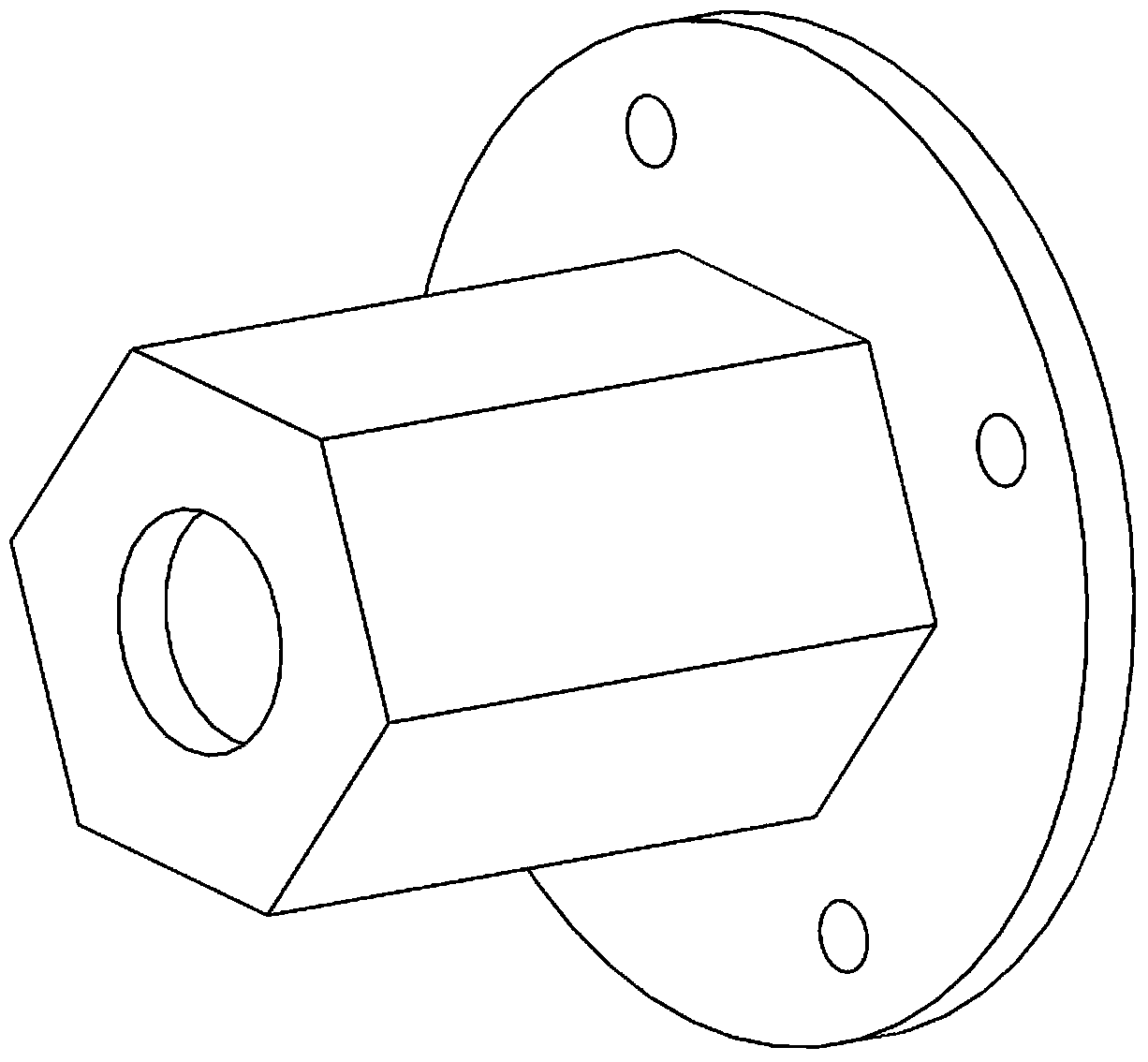

Cooling groove and centrifugal combined magnetic liquid rotating and sealing device

InactiveCN103574041AReduce the temperatureAvoid the problem of excessive centrifugal forceEngine sealsMagnetic liquidsEngineering

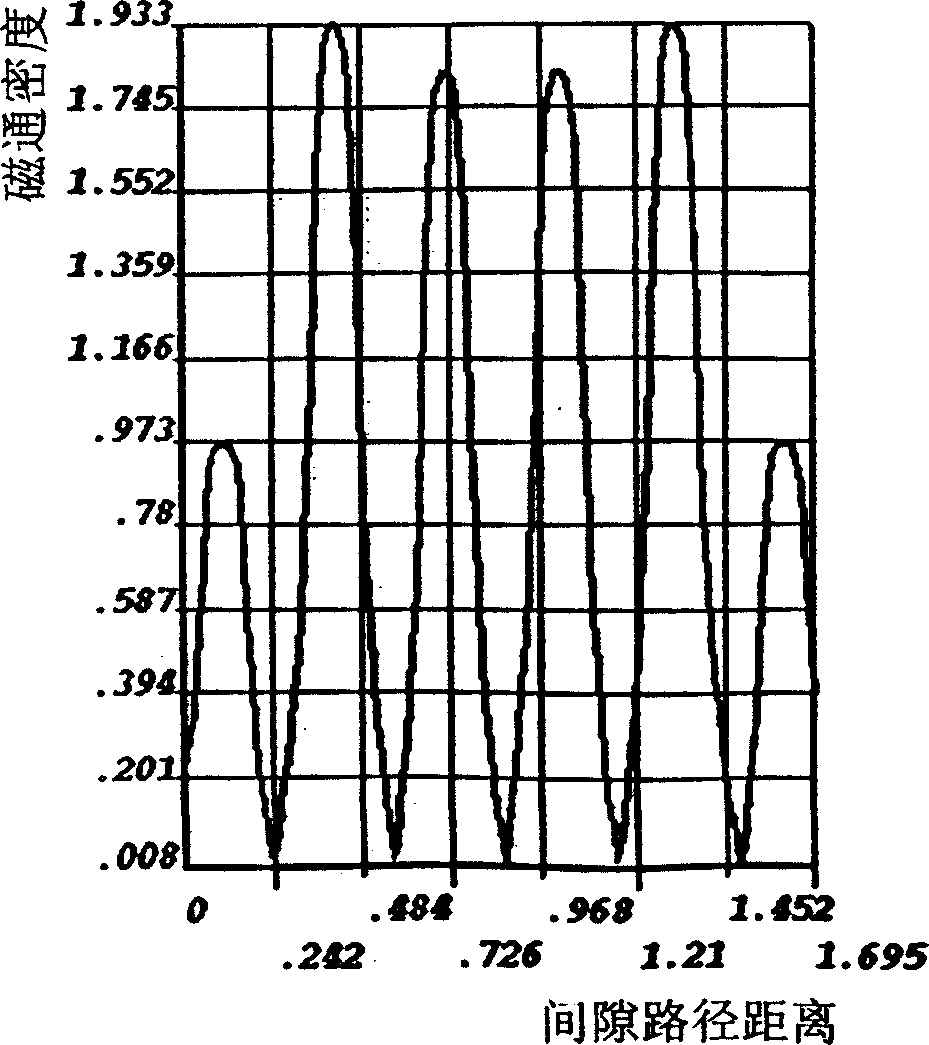

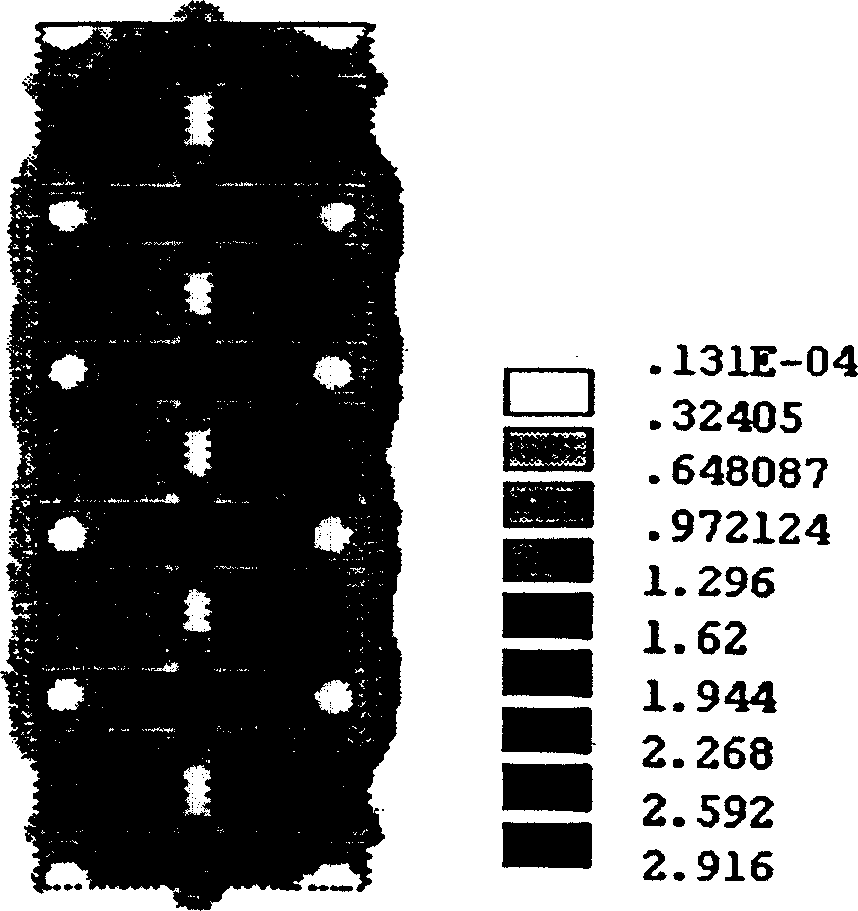

The invention discloses a cooling groove and centrifugal combined magnetic liquid rotating and sealing device and belongs to the field of mechanical engineering sealing. The cooling groove and centrifugal combined magnetic liquid rotating and sealing device solves the invalidation problem caused by the reasons that the temperature of magnetic liquid is excessively high, centrifugal force exerted on the magnetic liquid is excessively large when an existing magnetic liquid sealing device is applied to occasions with large diameters and high revolving speeds. The cooling groove and centrifugal combined magnetic liquid rotating and sealing device comprises parts such as a shell, a pole shoe, a left rubber sealing ring, a right rubber sealing ring, the magnetic liquid, a coolant, a permanent magnet and an axial sleeve. According to the magnetic liquid sealing device, due to the fact that pole teeth are machined on a boss of the shaft sleeve and a cooling groove is formed in the pole shoe, and affection on the magnetic liquid by the centrifugal force and the temperature is lowered.

Owner:BEIJING JIAOTONG UNIV

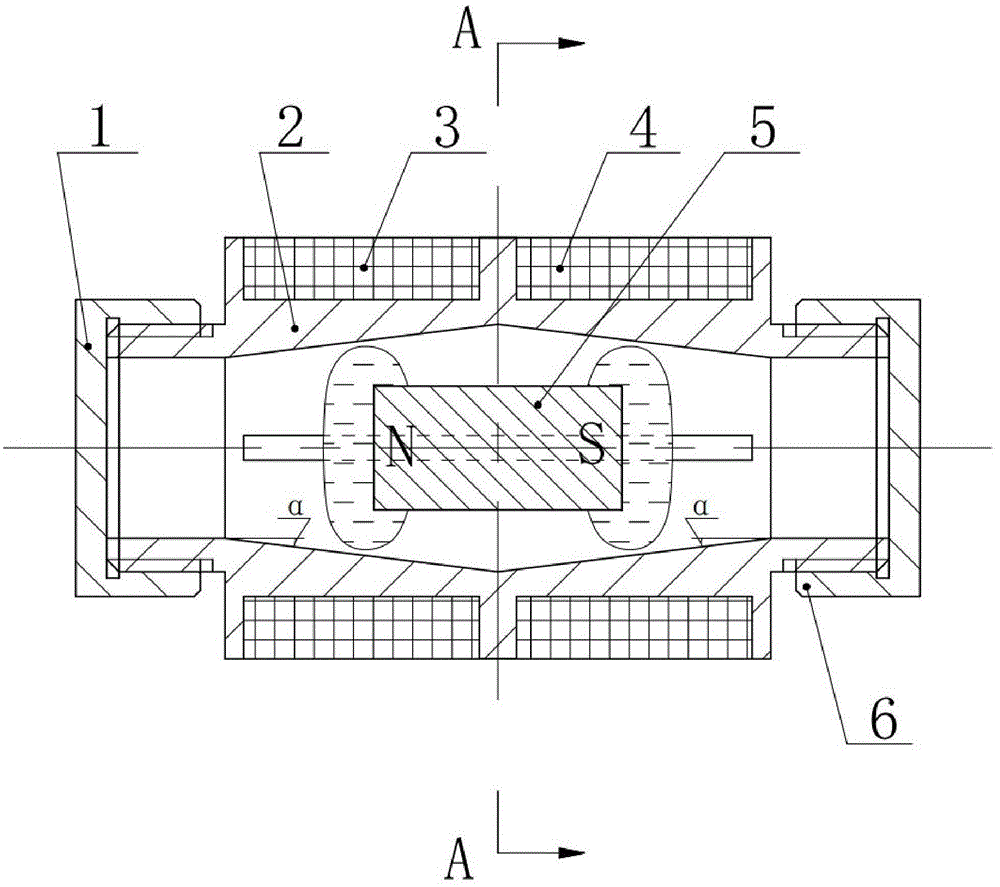

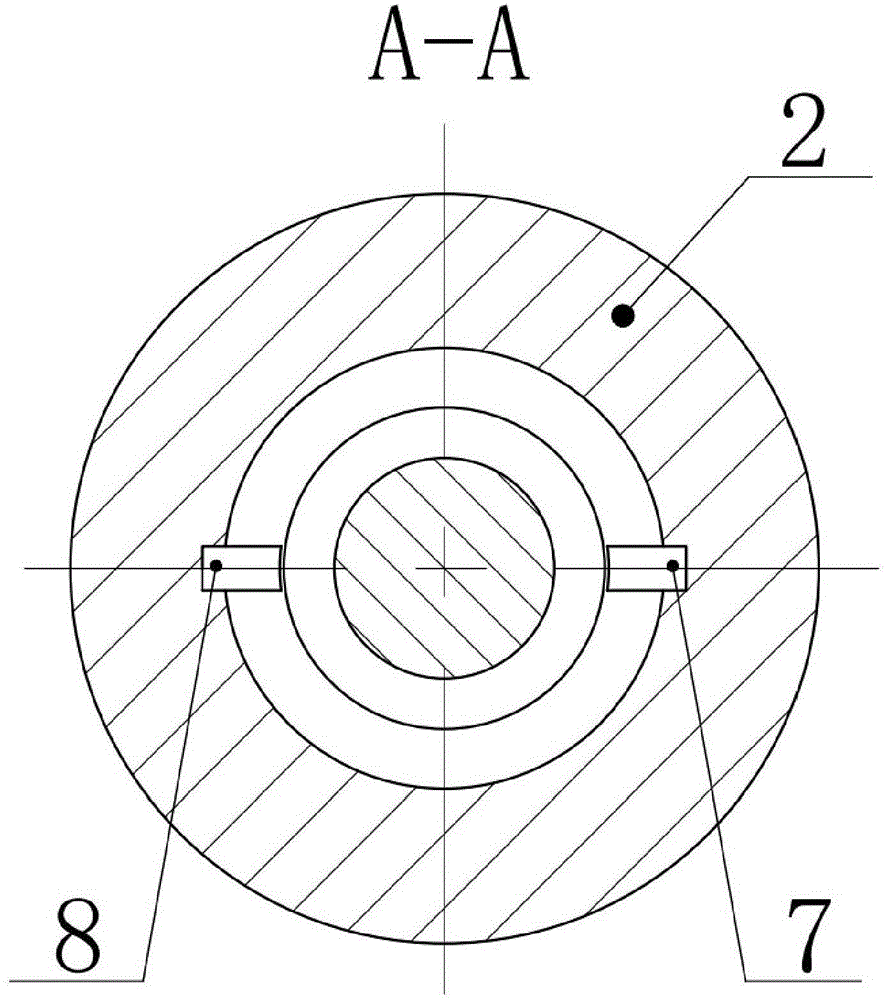

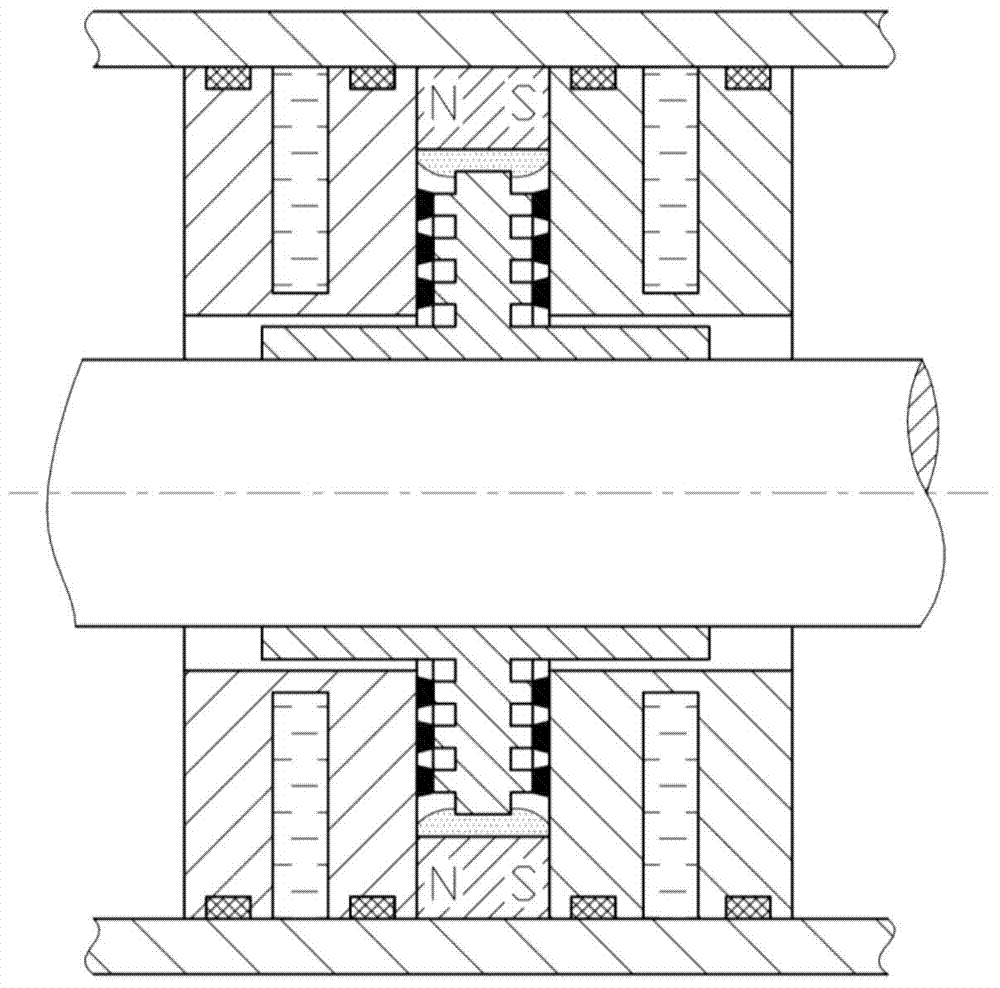

Magnetic liquid damping vibration attenuating device

InactiveCN103122965AAvoid collisionImprove vibration damping effectNon-rotating vibration suppressionWedge angleMagnetic liquids

A magnetic liquid damping vibration attenuating device belongs to the mechanical engineering vibration field, is suitable for vibration attenuating of long objects, and solves the problem that service life of a permanent magnet is shortened and vibration attenuating performance is affected due to the collision of the inner wall of an existing magnetic liquid damping vibration attenuator shell and the permanent magnet. The magnetic liquid damping vibration attenuating device is characterized in that a first annular permanent magnet is adhered to the inner wall of a shell by gum to form the inner wall of an vibration attenuator; the diameter of the first annular permanent magnet equals to the diameter of the inner wall of the shell; the depth of the shell equals to the height of the first annular permanent magnet; wedge angle gaskets are installed on the bottom of the shell, V-shaped included angles are placed upwards, and a second annular permanent magnet adhered to magnetic liquid is arranged in the shell; both the first annular permanent magnet and the second annular permanent magnet are magnetized along the radial direction, and the magnetizing directions of the first annular permanent magnet and the second annular permanent magnet are opposite; and an O-shaped rubber sealing ring is embedded in a groove which is placed on an opening end surface of the shell, and an end cover and the shell are tightly connected together through a bolt and a nut. The magnetic liquid damping vibration attenuating device is simple, reliable, obvious in vibration attenuating effect, and long in service life.

Owner:BEIJING JIAOTONG UNIV

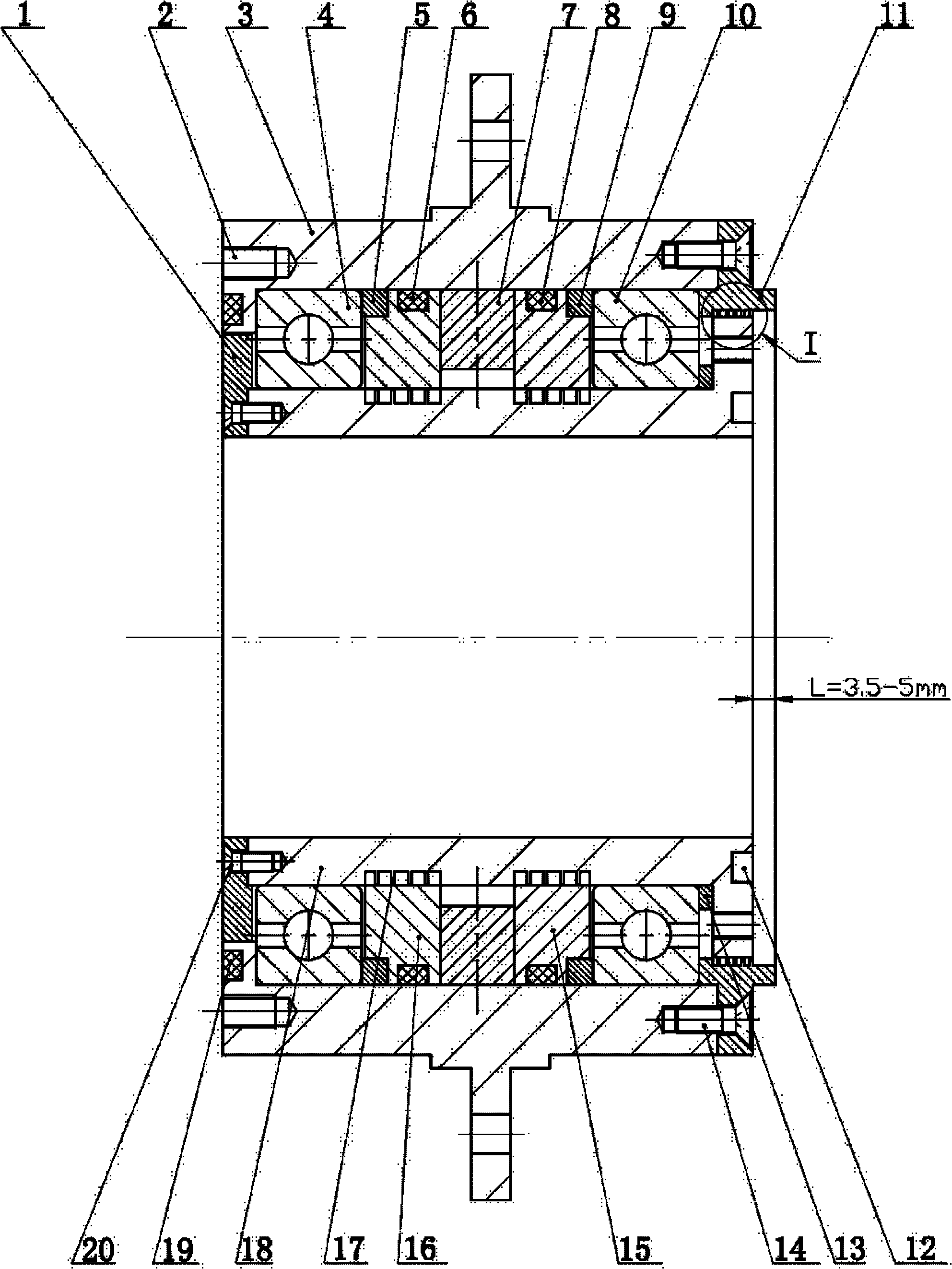

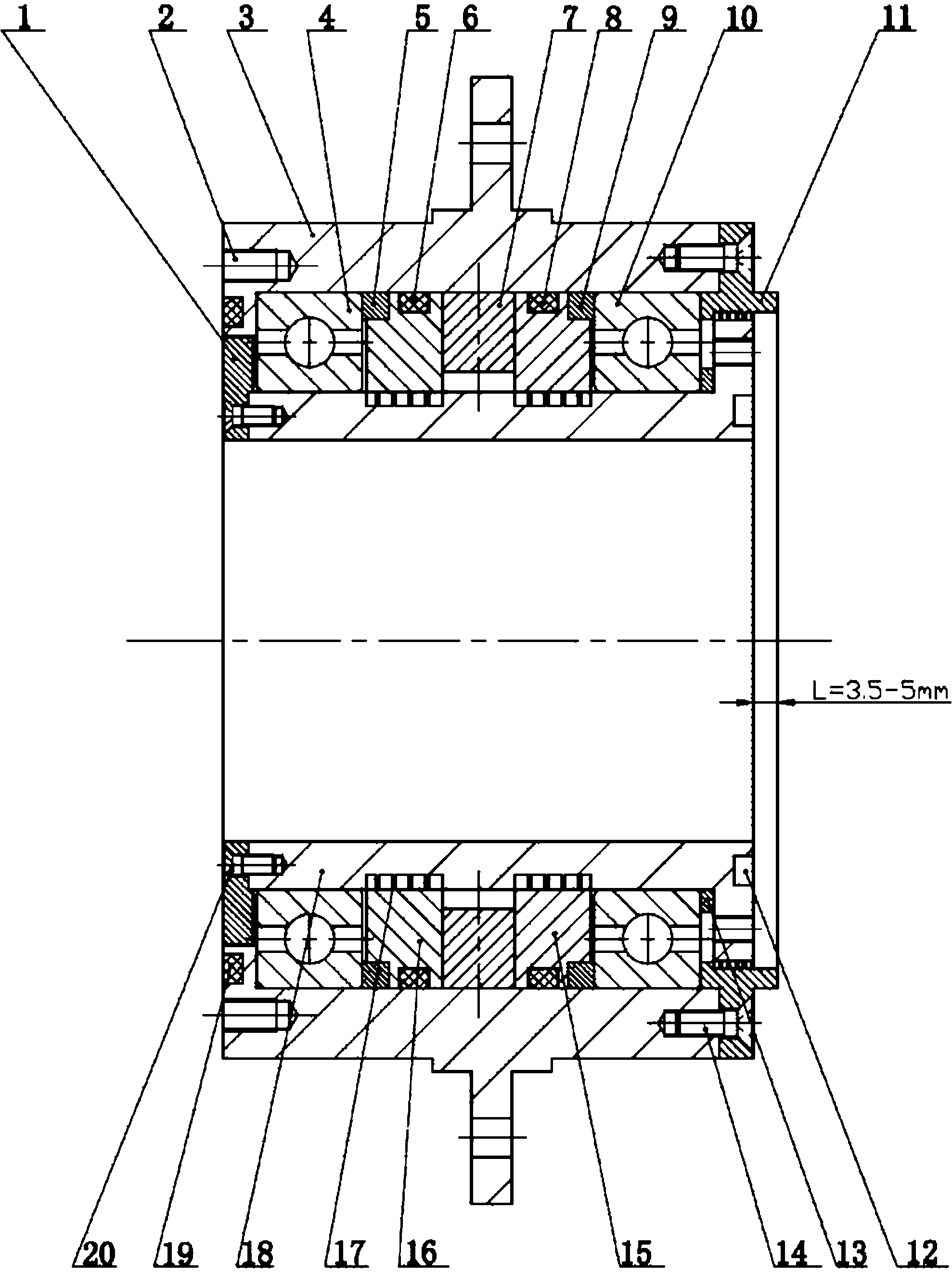

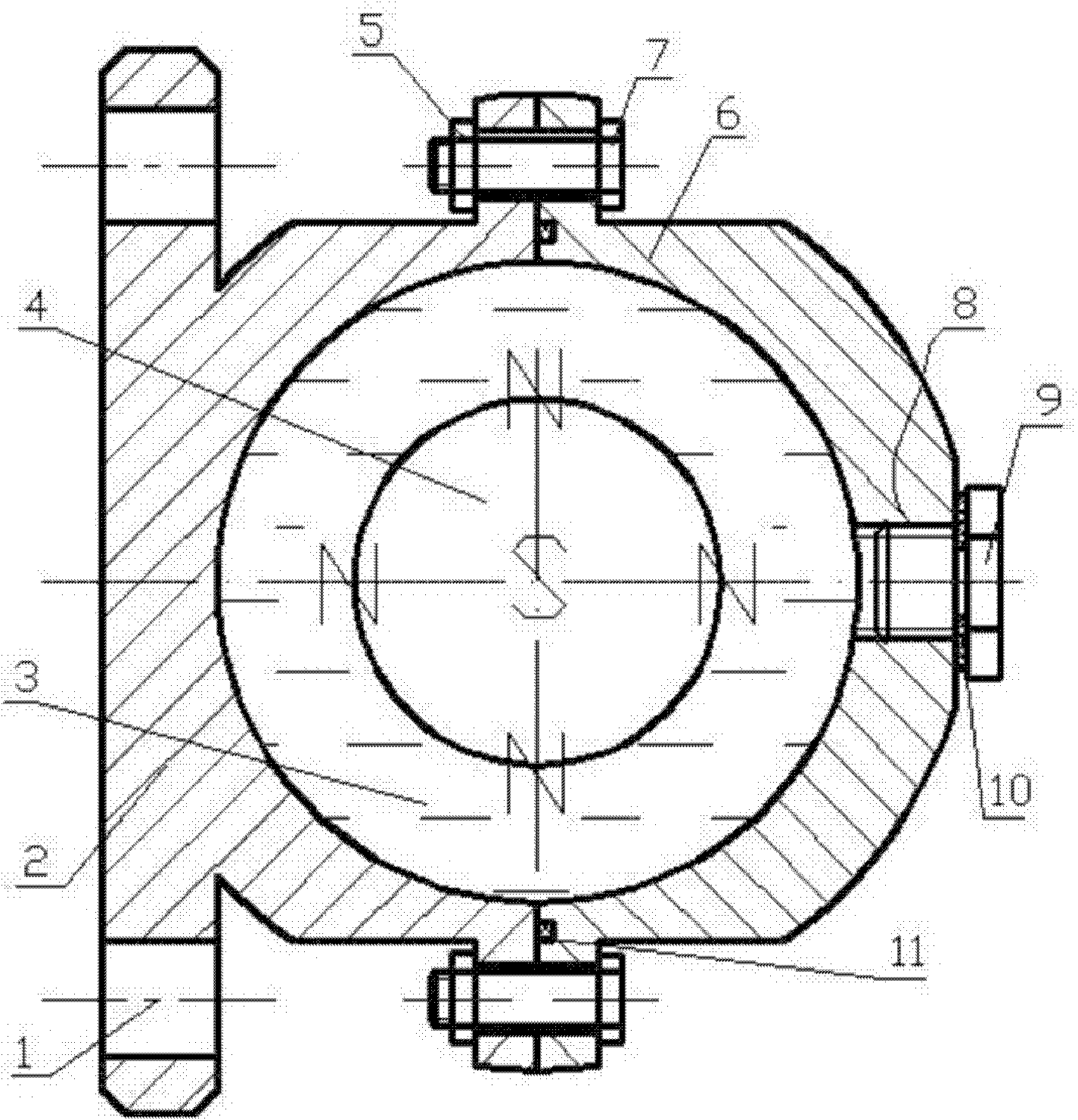

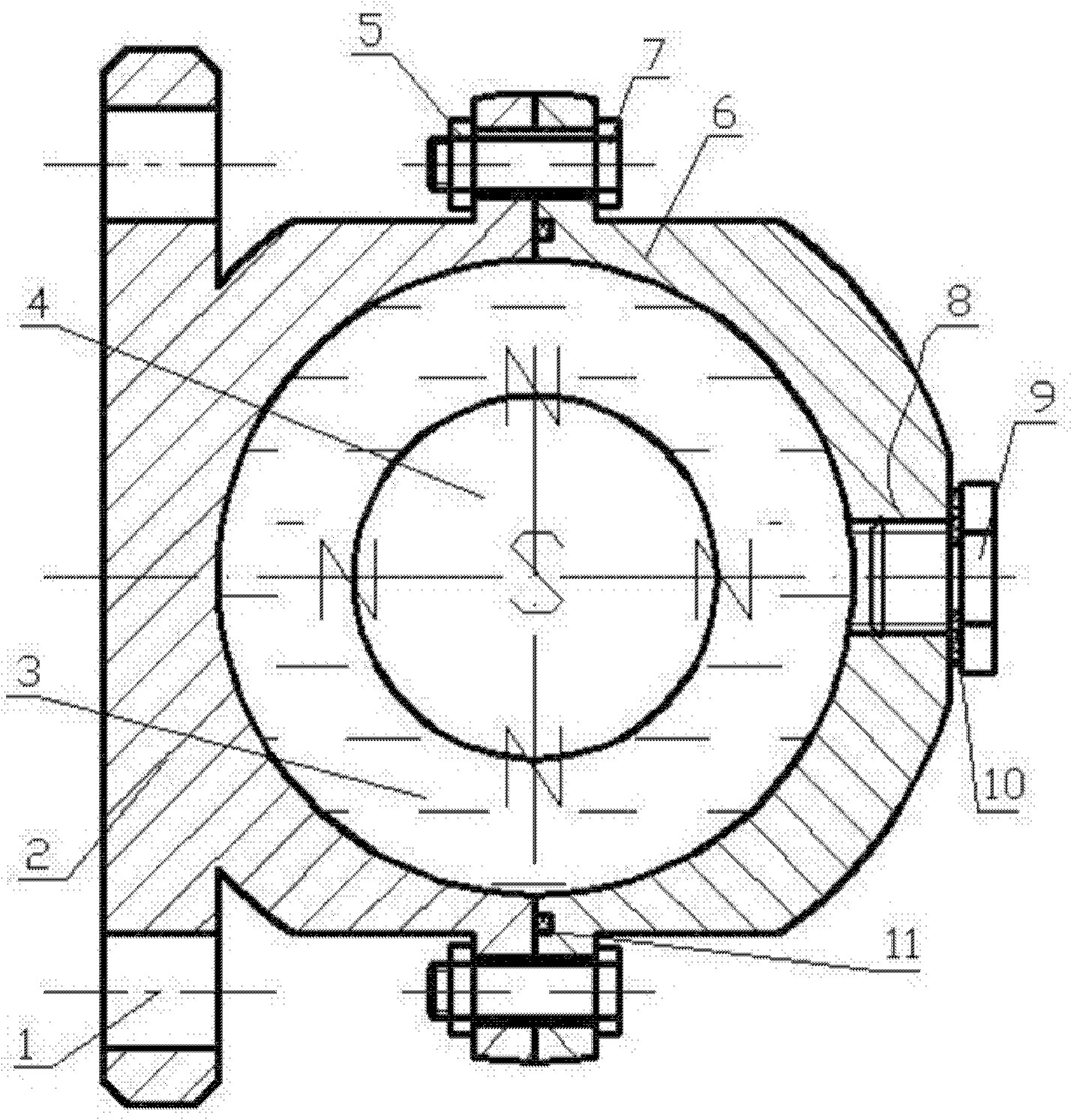

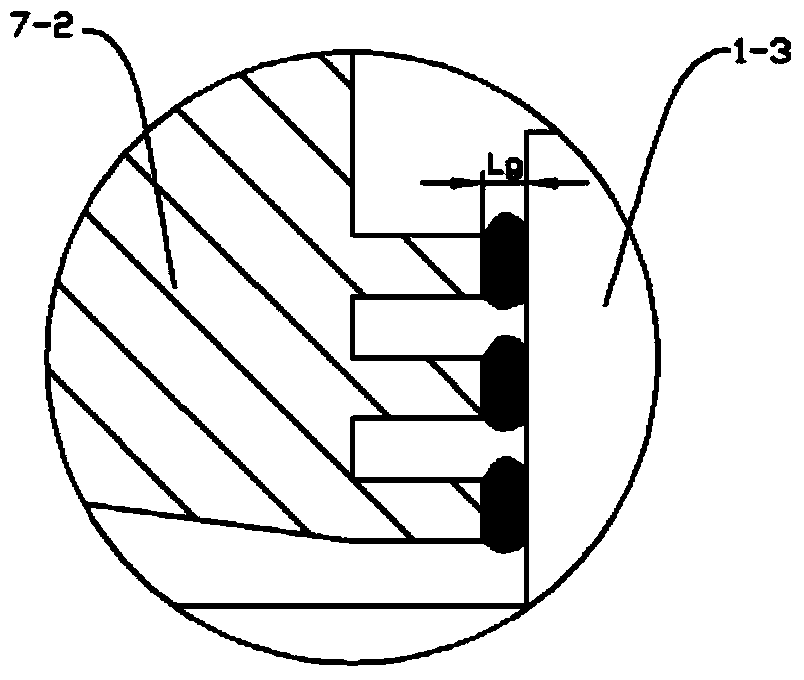

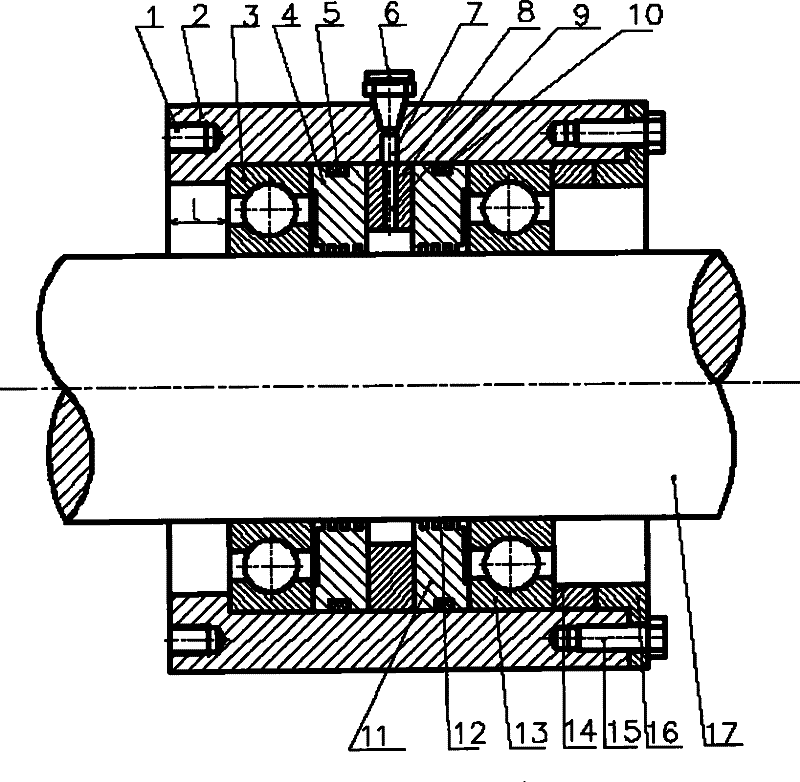

Rotary sealing device for magnetic liquid

The invention relates to a rotary sealing device for a magnetic liquid, belonging to the field of mechanical engineering sealing. By means of the rotary sealing device, the problem that rainy water and dust can enter a right bearing along an end cover to produce rust on a sealing element to influence sealing performance of the traditional sealing device at the atmospheric environment under the condition of horizontal installation is solved. The device is characterized in that a left rolling bearing, a first non-magnetic ring, a left pole shoe with a rubber seal ring, a permanent magnet, a right pole shoe with a rubber seal ring, a second non-magnetic ring and a right rolling bearing abuts against the right side face of an inner bore boss of an outer shell in sequence and connected with threads on the outer shell through screws, and an end cover is fixed on the outer shell; the magnetic liquid is injected; a shaft sleeve for installing an adjusting spacer is loaded into an inner bore of the ; and a retainer ring is clung to the left end face of the shaft sleeve, and the retainer ring and the shaft sleeve are axially fixed by using the screws. A labyrinth spiral sealing groove is arranged on an inner bore of the end cover, and the clearance between the labyrinth spiral sealing groove and the shaft sleeve is 0.4 mm; and the distance L between the right end face of the end cover and the right end face of the shaft sleeve equals to 3.5-5 mm. The device has the advantages of simpleness in assembly, dust prevention, water prevention and long service life.

Owner:BEIJING JIAOTONG UNIV

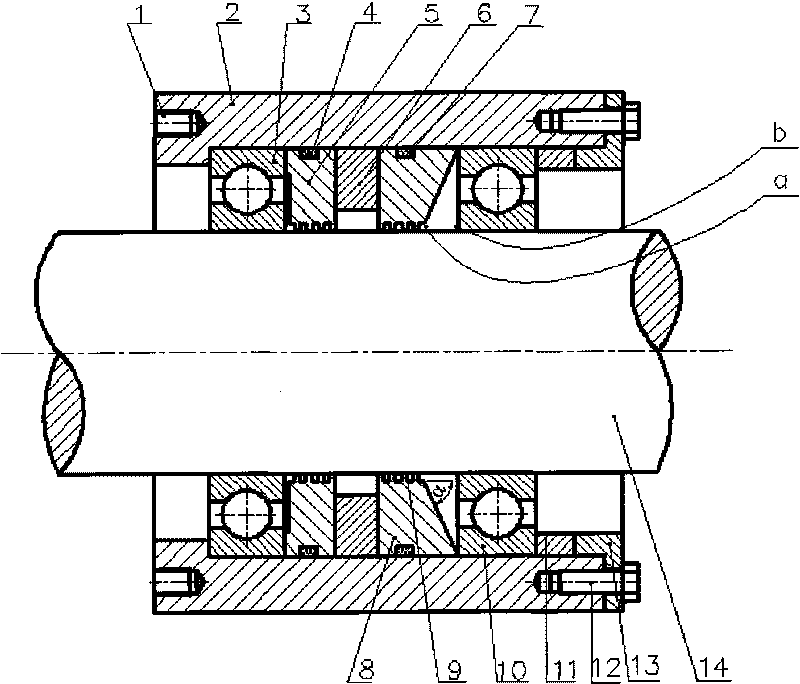

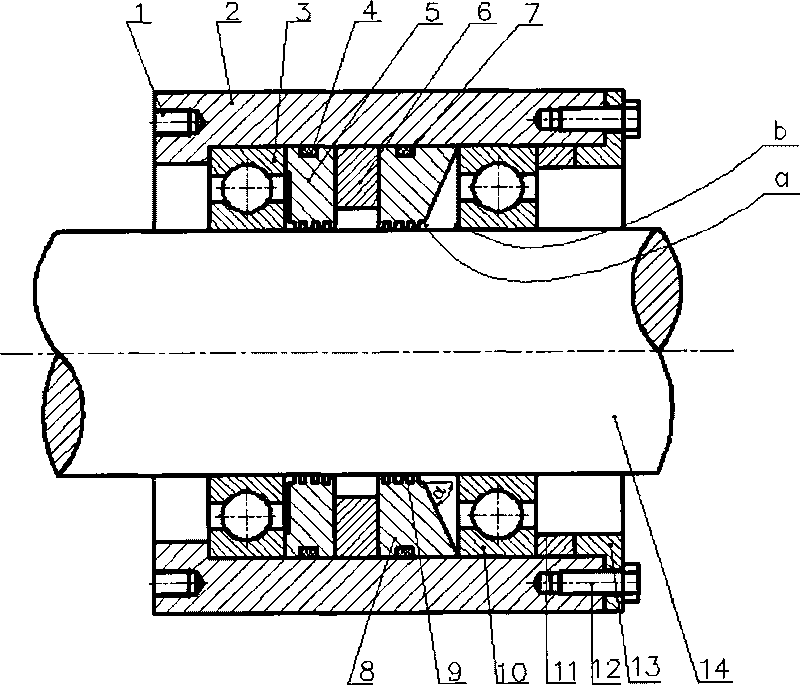

Rotation shaft combined sealing device

InactiveCN101799075AThe installation accuracy is up toEasy to installEngine sealsEngineeringMagnetic liquids

Owner:BEIJING JIAOTONG UNIV

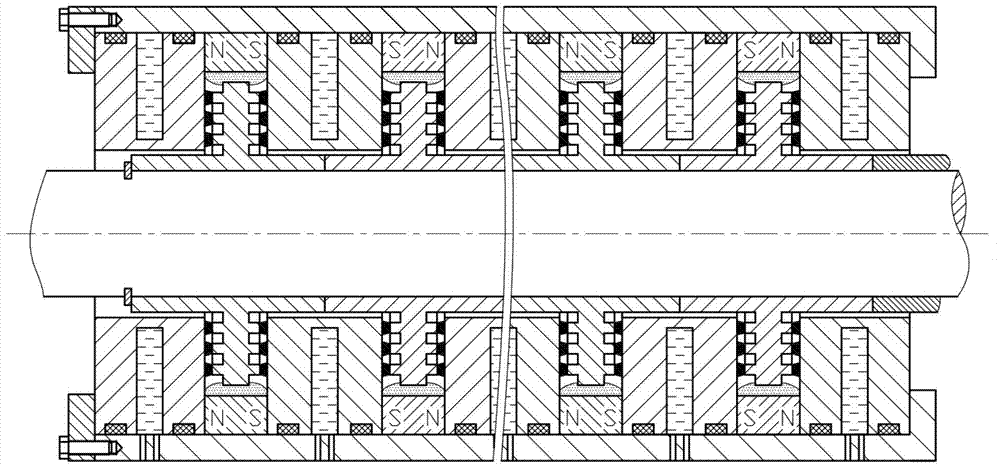

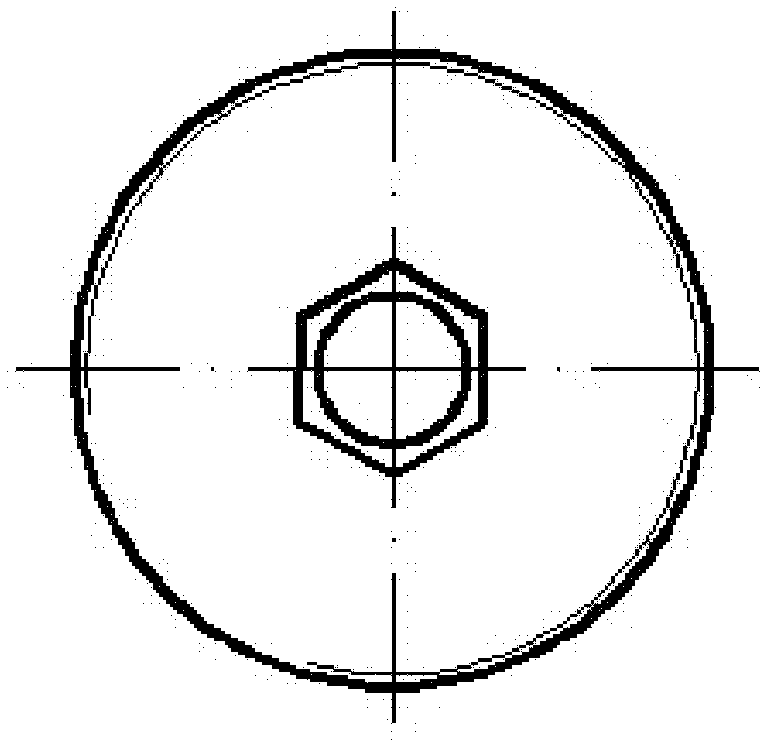

Magnetic liquid damping vibration attenuating device

InactiveCN102494070AWith damping effectGood vibration reduction effectMagnetic springsVibration attenuationEngineering

The invention discloses a magnetic liquid damping vibration attenuating device which is suitable for vibration attenuation for longer objects in a spacecraft and used for solving the problem of vibration attenuation in the spacecraft. The device comprises a non-magnet conductive shell (2), magnetic liquid (3), a permanent magnet (4), nuts (5), an end cover (6), bolts (7), screws (9), a sealing gasket (10) and an O-shaped sealing ring (11); the parts are connected as follows: the permanent magnet (4) is arranged in a cavity of the non-magnet conductive shell (2); the end cover (6) with the O-shaped sealing ring (11) is fixed on the end surface of the open end of the non-magnet conductive shell (2) by using the bolts (7) and the nuts (5); the cavity of the non-magnet conductive shell is full of magnetic liquid through a threaded hole and is sealed by using the screws and the sealing gasket. A cavity formed by the non-magnet conductive shell (2) and the end cover (6) is a ball-shaped cavity. The non-magnet conductive shell (2) and the permanent magnet (4) adopted by the device are in circular ball shapes, therefore, the magnetic liquid damping vibration attenuating device can be used for attenuating the vibration in any direction and good in vibration attenuating effect.

Owner:BEIJING JIAOTONG UNIV

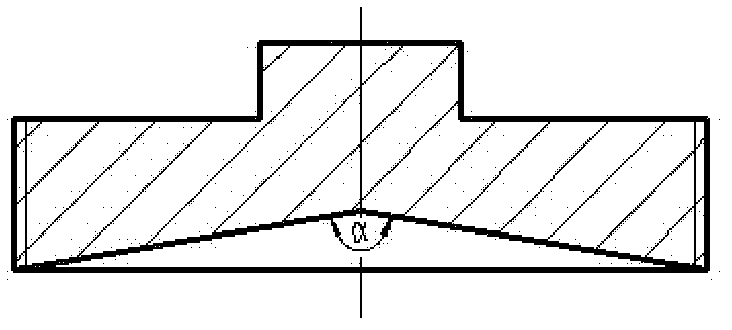

Magnetic liquid damping vibration attenuation device

InactiveCN102213285AGood vibration reduction effectMagnetic springsVibration attenuationMagnetic liquids

The invention discloses a magnetic liquid damping vibration attenuation device which is suitable for longer object vibration attenuation in a spacecraft and can be used for solving the vibration attenuation problem of longer object vibration attenuation in the spacecraft. The magnetic liquid damping vibration attenuation device comprises an end closure (1), a magnetic liquid (2), a non-magnetic-conductive shell (3) and a permanent magnet (4), wherein the permanent magnet (4) is installed in the cavity of the non-magnetic-conductive shell (3), the magnetic liquid (2) is injected into the cavity of the non-magnetic-conductive shell (3) and the end closure (1) is used for sealing. The device is very sensitive to the inertia force, the adopted end closure (1) with threads is provided with a taper angle, the taper angle is 140degrees -170degrees, the depth of the end closure screwed into the non-magnetic-conductive shell (3) can be adjusted so as to regulate the pressure applied to the magnetic liquid by the end closure (1), the permanent magnet is a cylinder, the vibration attenuation effect is good for the vibration with low frequency, small displacement and small acceleration characteristics.

Owner:BEIJING JIAOTONG UNIV

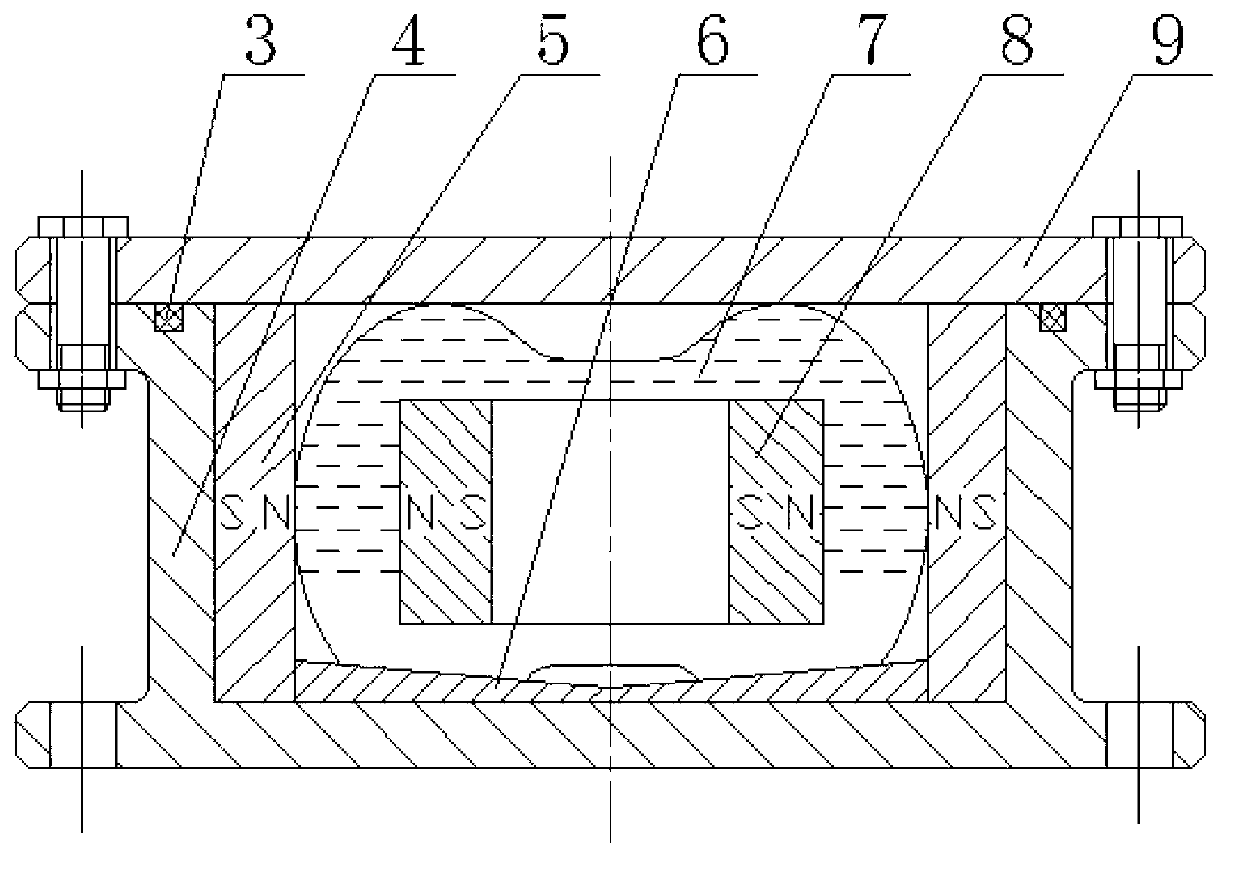

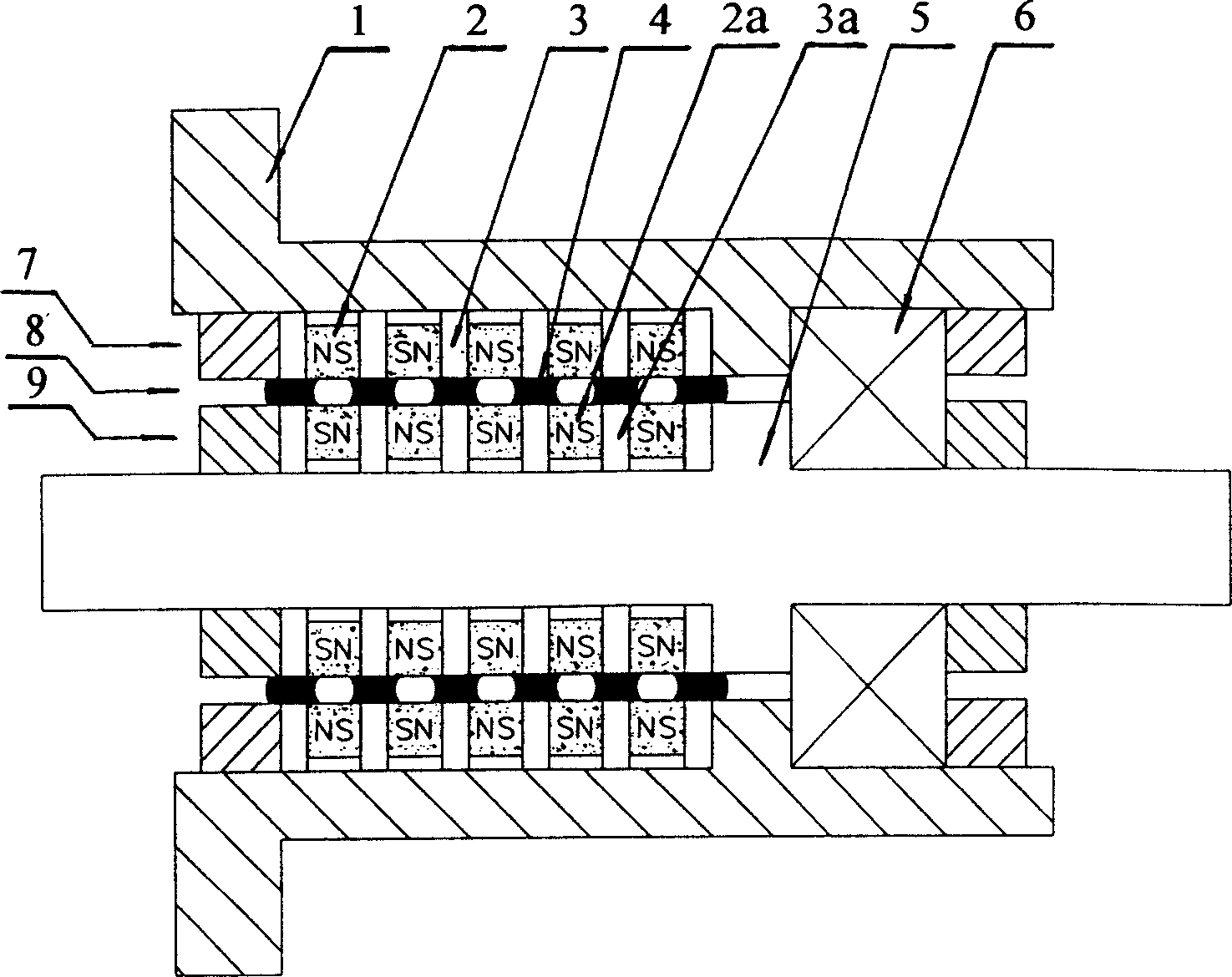

Magnetic liquid sealing device

A sealing device with magnetic liquid is prepared as forming magnetic pole ring by jacketing and superposing external and internal magnetic pole rings or by butt-joint and superposing top and bottom magnetic pole rings, setting adjacent and near permanent magnetic ring used for forming said magnetic pole ring to be at opposite polarity, sealing and erecting dual-superposed magnetic pole rings separately between coaxial gyrorotors to form seal gap for filling in magnetic liquid to realize magnetic liquid seal.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

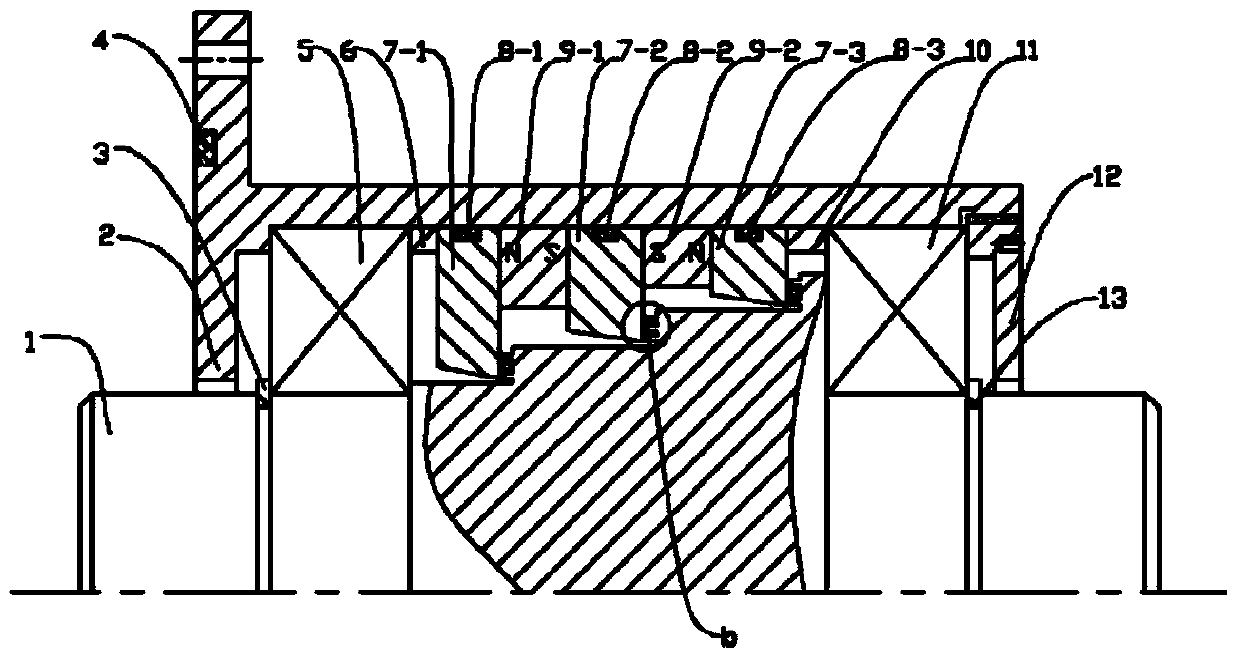

Inflatable magnetic liquid rotating seal device

The invention discloses an inflatable magnetic liquid rotating seal device, belongs to the field of mechanical engineering seal and solves the potential safety hazard problem caused by gas leakage when the existing magnetic liquid seal device is used for sealing high-hazardous gas, i.e., hydrogen, under a complicated working condition. The device comprises a shell, pole shoes, rubber seal rings, magnetic liquid, permanent magnets, a shaft sleeve, a check ring, a gasket, air pressure control valves and other parts. According to the magnetic liquid seal device, a cavity between the inner diameter of the first permanent magnet and the outer diameter of the shaft sleeve is vacuumized, CO2 or inert gas is filled in a cavity between the inner diameter of the second permanent magnet and the outer diameter of the shaft sleeve, and a cavity between the inner diameter of the third permanent magnet and the outer diameter of the shaft sleeve is vacuumized, so that hazardous gas, especially explosive gas, cannot be in direct contact with air, and potential safety hazard problems can be solved.

Owner:BEIJING JIAOTONG UNIV

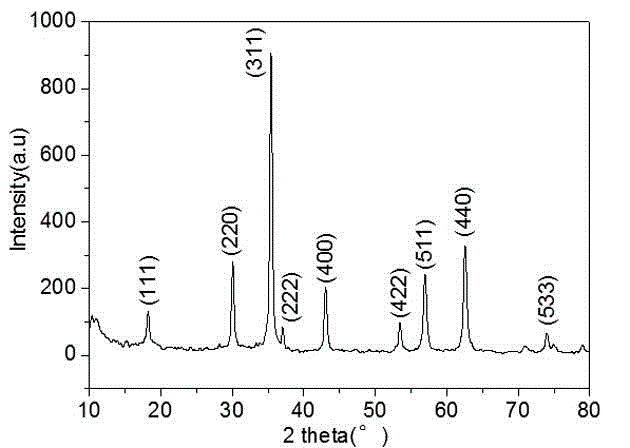

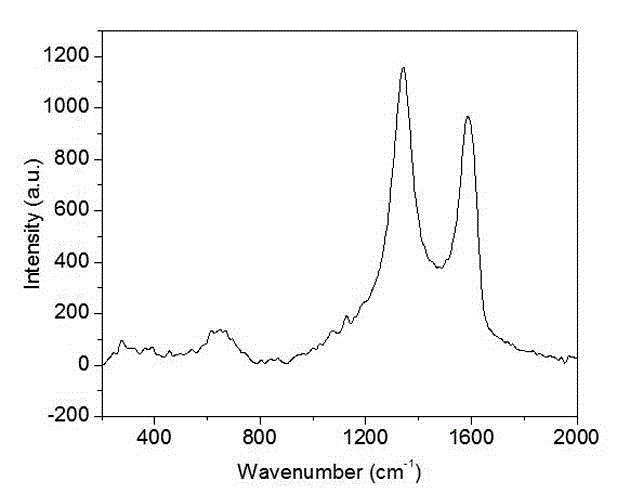

Graphene @Fe3O4 compound water base magnetorheological fluid and preparation method thereof

The invention relates to the field of intelligent magnetic materials and in particular relates to a graphene @Fe3O4 compound water base magnetorheological fluid and a preparation method thereof, solving the problems that existing magnetorheological fluids are easy to settle and the stability and magnetorheological effects of the magnetorheological fluids are difficult to optimize at the same time. The preparation method comprises the following steps: preparing a Fe3O4 water base magnetic fluid with FeCl2.4H2O and FeCl3.6H2O; sequentially adding concentrated sulfuric acid, potassium permanganate and hydrogen peroxide to natural flake graphite and sodium nitrate to prepare graphite oxide; and then carrying out ultrasonic dispersion on home-made graphite oxide to prepare graphene oxide, finally adding a surfactant, the Fe3O4 water base magnetic fluid and a reducing agent to graphene oxide, washing the solution with deionized water until the solution is neutral, and then dispersing graphene @Fe3O4 compound magnetic particles in the deionized water to undergo ultrasonic dispersion, removing the precipitates and taking the supernatant, namely the stable graphene @Fe3O4 compound water base magnetorheological fluid, wherein the magnetic particles are graphene @Fe3O4 and account for 5-35wt% of the whole. The method has the advantages of good stability, low zero field viscosity, high shear strain and wide operating temperature range.

Owner:ZHONGBEI UNIV

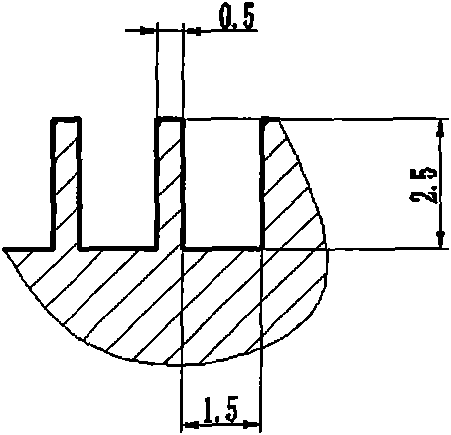

Low-temperature large diameter magnetic liquid sealing arrangement

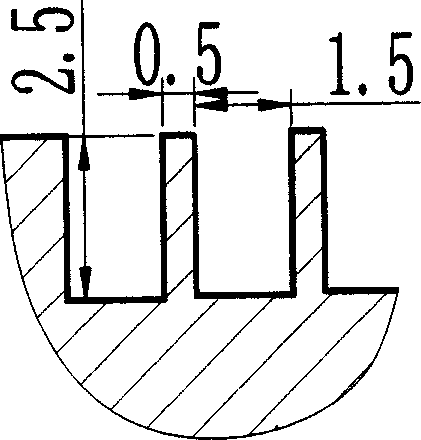

The invention is a low-temperature large-diameter magnetic liquid sealing device, including: small-end cover, jacket, shaft case, bearing, pole boot, PM, magnetic liquid, rubber seal ring, adjusting pad and big-end cover. The shaft case is installed inside the bearings, pole boots and PM, the small-end cover is fixed on the shaft case by bolt; the seal teeth holding magnetic liquid are designed on the outer cylindrical surface of the shaft case; the shape parameters of the seal teeth: width 0.5mm and height 2.5mm. The carrier liquid of the magnetic liquid is high-grade kerosene, silicate or diester, where the size of the magnetic particles is less than 5 nm. The device can implement sealing of shaft diameter greater than 160mm at -40 deg.C and reduce torque, the leakage rate lower than 10 to the power -11 palíñcu 3 / s, the service life long and the assembling method simple.

Owner:BEIJING JIAODA INNOVATION TECH CENT

Preparing method of nano-magnetic polymer composite microsphere

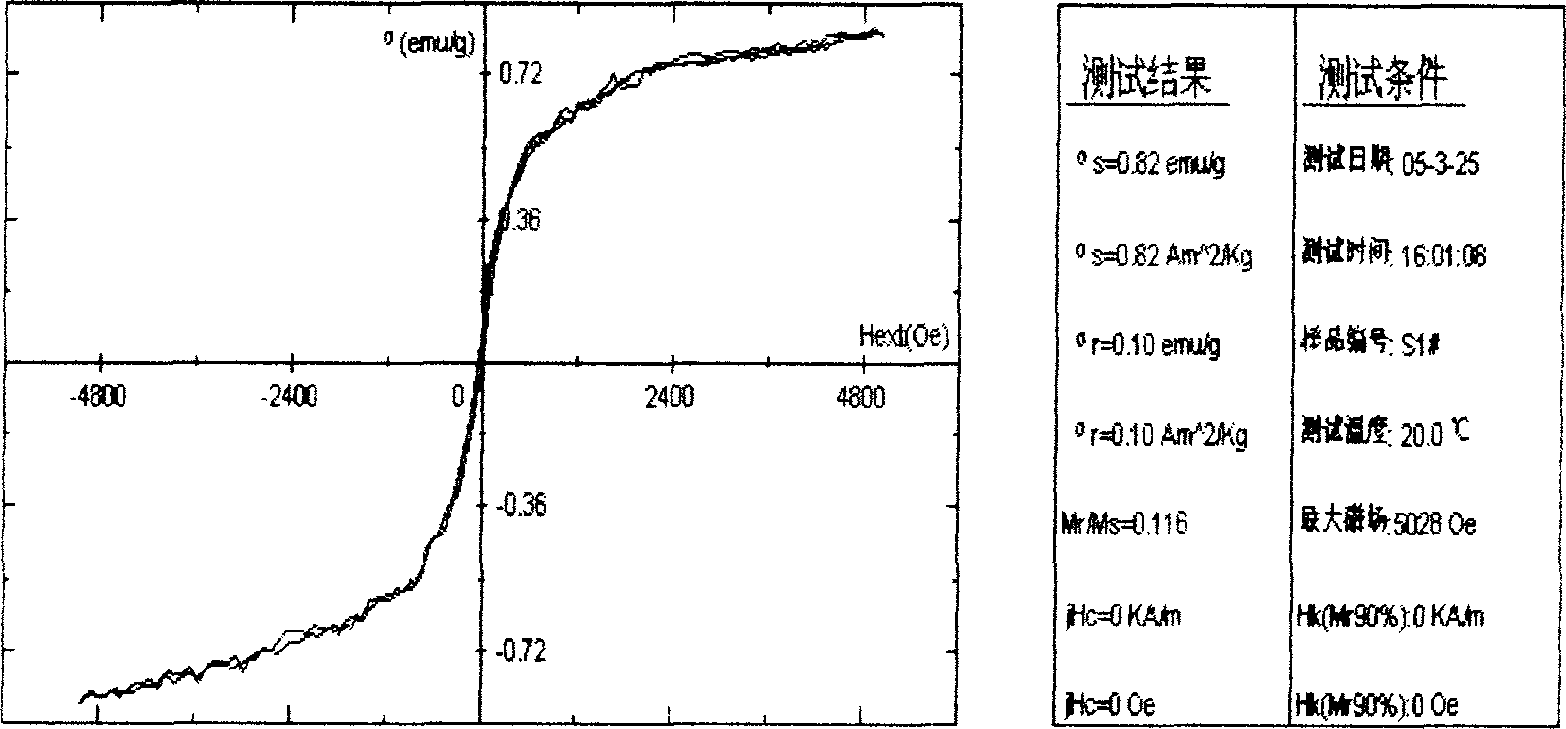

ActiveCN102142310ASuperparamagneticStrong magnetic responseInorganic material magnetismOrganic/organic-metallic materials magnetismPeroxydisulfateSuperparamagnetism

The invention relates to a preparing method ofa nano-magnetic polymer composite microsphere, which comprises the following steps: preparing a hydrophilic Fe3O4 magnetic liquid particle by using a chemical co-precipitation method; dissolving initiating agents and emulsifying agents by weight part into ionized water to prepare water phase, adding the hydrophilic Fe3O4 magnetic liquid particle and adding a monomer to obtain nano-magnetic seed emulsion through polymerization; dissolving initiating agents by weight part into ionized water, adding the nano-magnetic seed emulsion and then adding a monomer to obtain nano-magnetic polymer composite microsphere emulsion through polymerization; the emulsifying agents are sodium lauryl sulfate, sodium dodecyl sulfate or sodium dodecyl benzene sulfonate; the initiating agents are potassium peroxydisulfate, ammonium persulphate or sodium peroxydisulfate; the initiating agents are potassium peroxydisulfate, ammonium persulphate or sodium peroxydisulfate; the hydrophobic monomer is styrene or methyl methacrylate or a mixture of the styrene and the methyl methacrylate; the nano-magnetic polymer composite microspheres prepared by adopting a seed emulsion polymerization method have the superparamagnetism, have stronger magnetic responsiveness, have no uncoated magnetic particle and contain magnetic polymer microspheres and are narrow to distribute.

Owner:PETROCHINA CO LTD

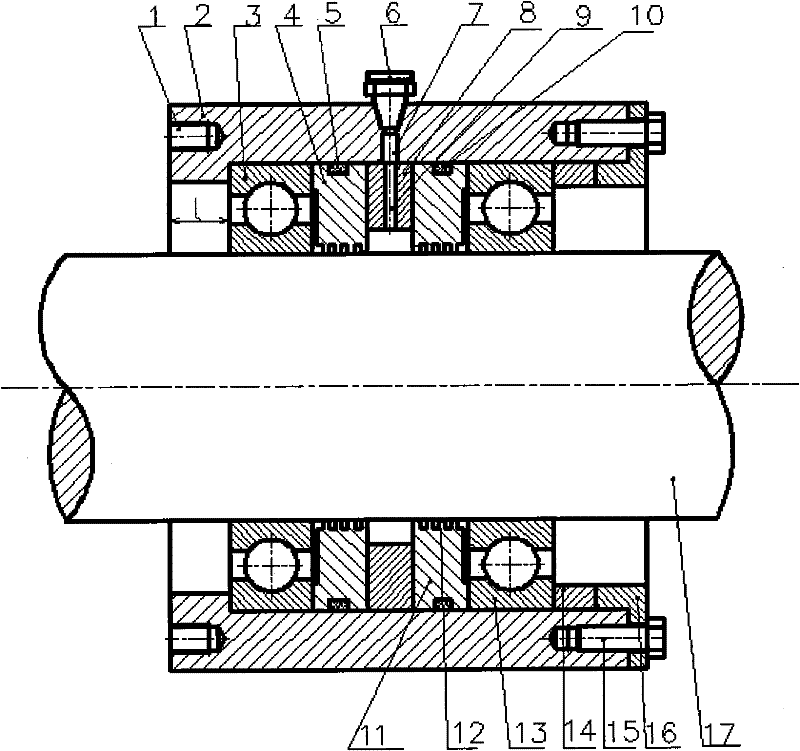

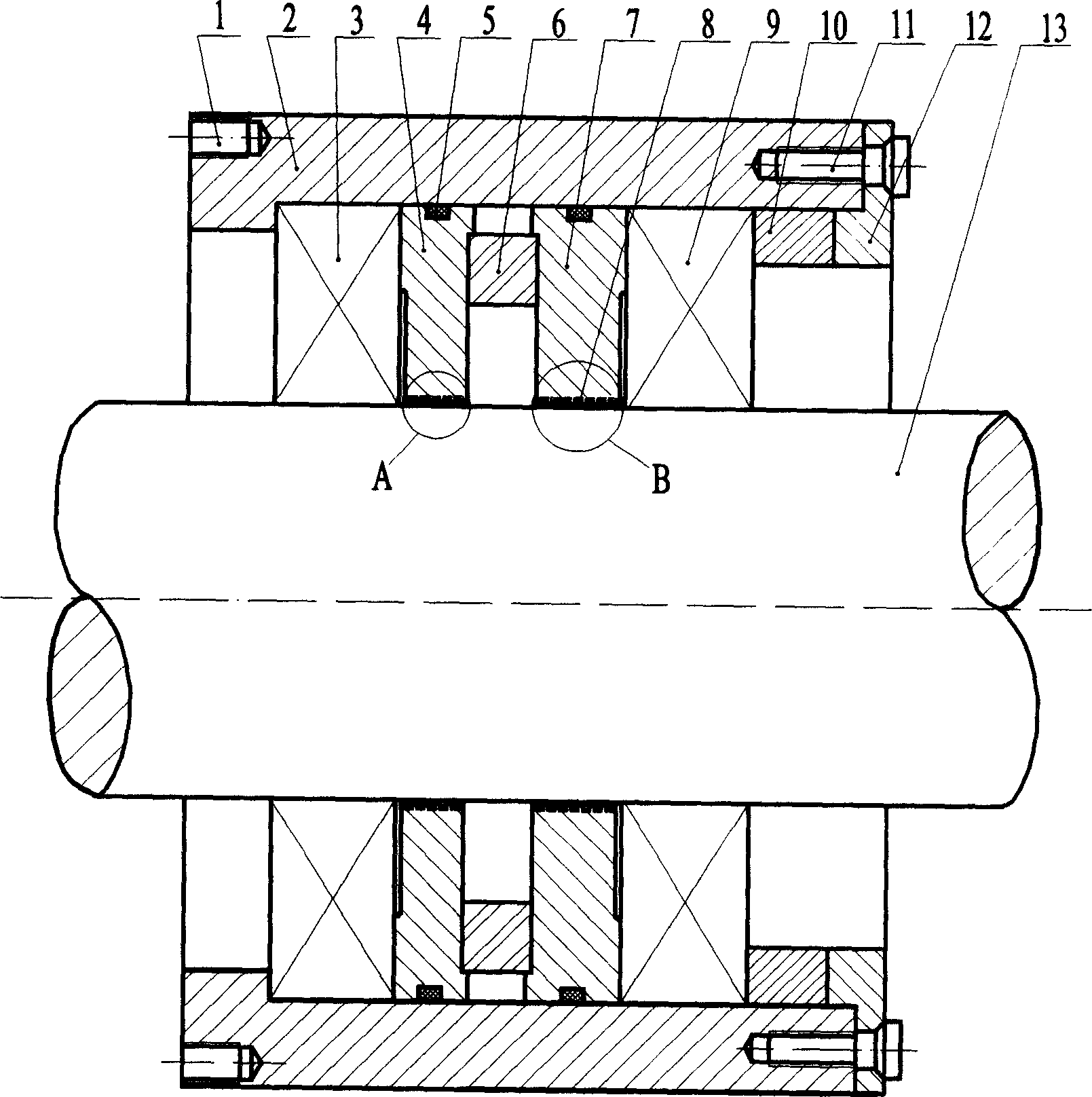

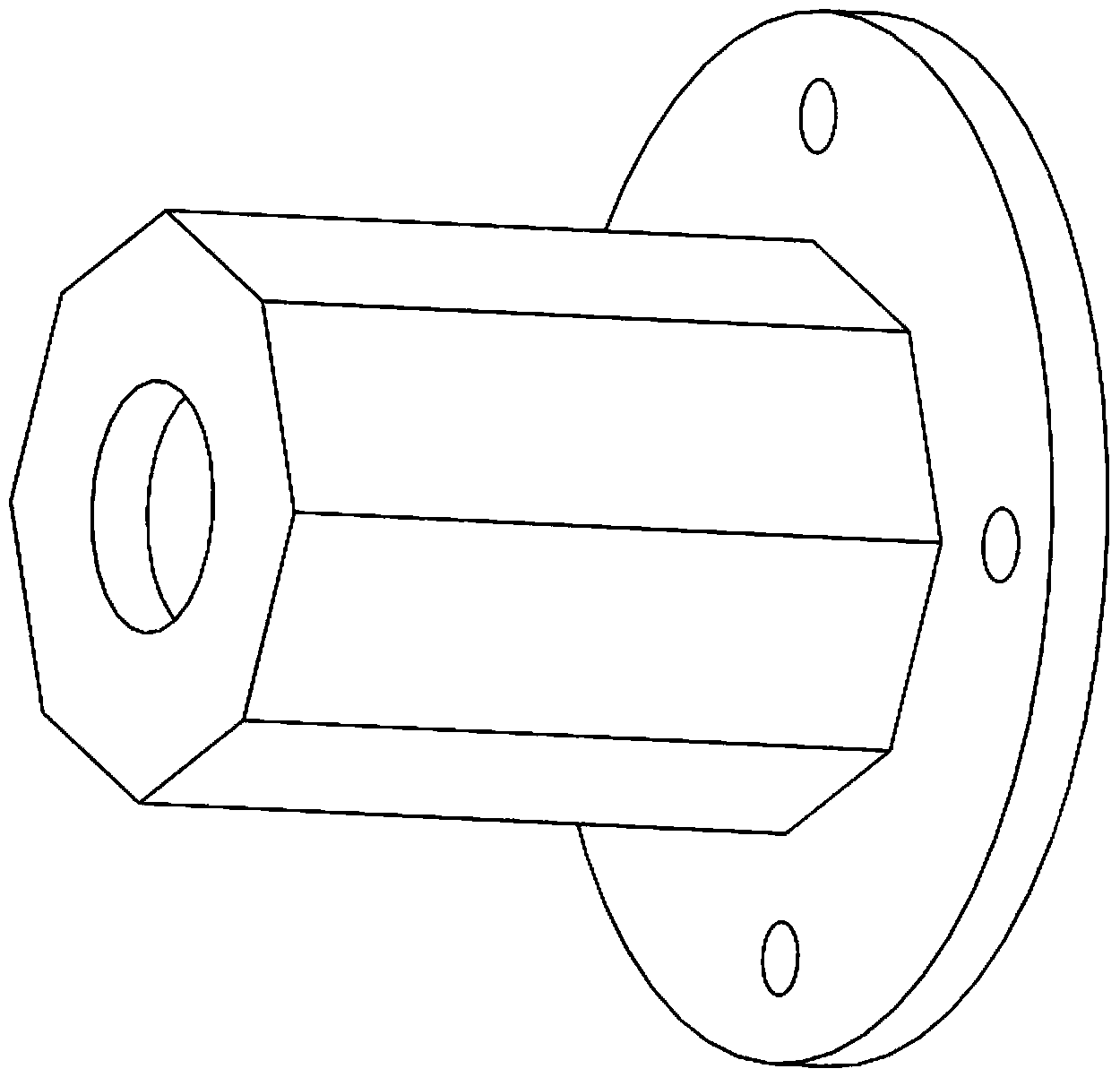

Sealing device for improving sealing anti-pressure capability and sealing reliability of magnetic liquid

InactiveCN103498939AOvercome the shortcomings of low sealing pressure resistanceImprove pressure resistanceEngine sealsMagnetic liquidsEngineering

The invention provides a sealing device for improving the sealing anti-pressure capability and the sealing reliability of magnetic liquid, and belongs to sealing devices of rotating shafts. The problems that large-gap sealing is low in anti-pressure capability and poor in reliability are solved. A shaft of the sealing device is a step shaft, the right side face of a first pole shoe, the right side face of a second pole shoe and the right side face of a third pole shoe, or shaft shoulders of steps from the second to the fourth are provided with pole teeth, the axial gap widths of the pole shoes and the shaft shoulders are smaller than the radial gap widths between the pole shoes and the step shaft, and the sealing device for improving the sealing anti-pressure capability and the sealing reliability of the magnetic liquid is achieved. The defect that the large-gap magnetic liquid is low in sealing anti-pressure capability is overcome, the transformation from an axial drainage channel to a radial drainage channel is achieved, the sealing anti-pressure capability and the sealing reliability of the magnetic liquid under the condition of large gaps are improved, and the safety working range is widened. Therefore, the sealing device is an ideal sealing device for solving the problems of being low in large-gap sealing anti-pressure capability and poor in reliability.

Owner:BEIJING JIAOTONG UNIV

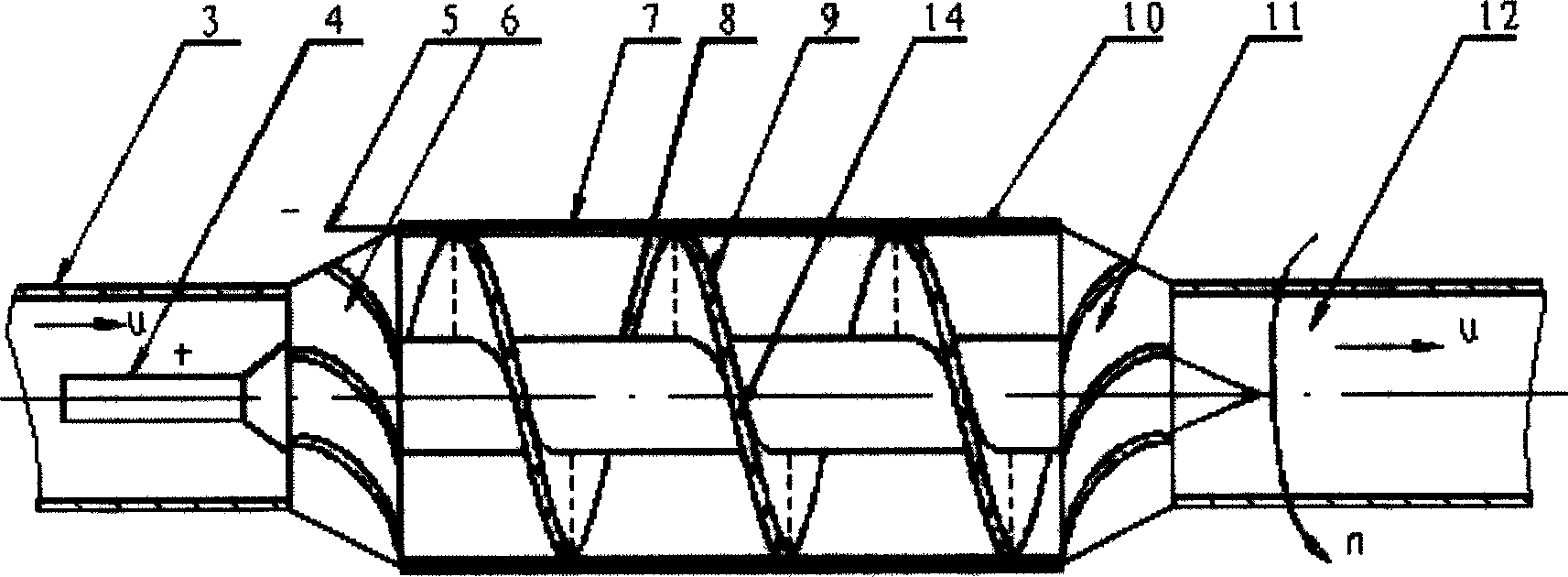

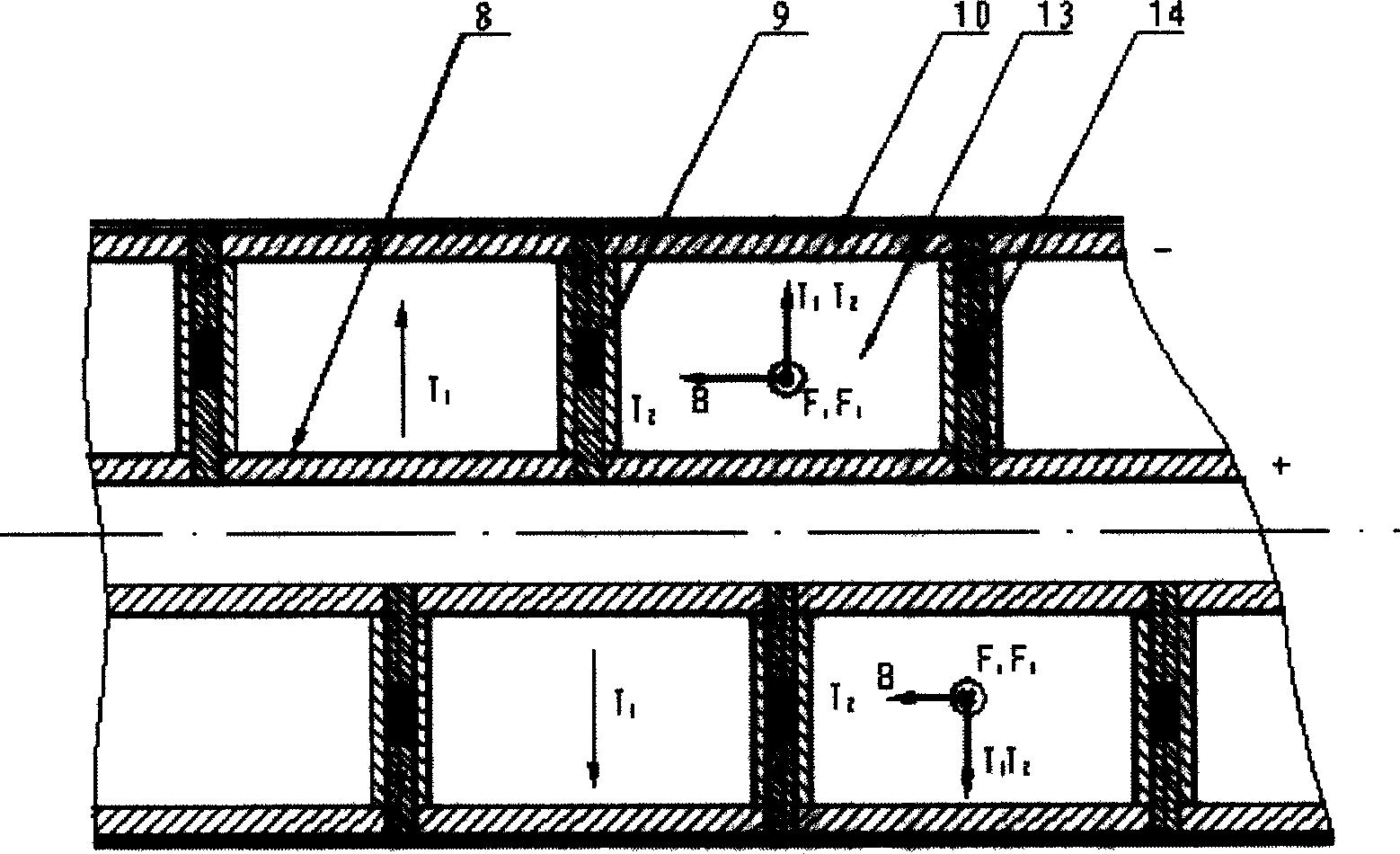

Superconductive magnetic fluid marine propeller

InactiveCN1629036AShorten speedImprove efficiencyPropulsion power plantsPropulsive elementsPower flowPropeller

This invention relates to a superconduct magnetic liquids ship pushing device, which comprises the superconduct screw tube magnet and rotary magnetic liquids pushing channel, wherein, the superconduct screw tube magnet generates the even axle magnetic field in its central working area. There is located with one round metal electrode in the working round pipe of the magnetic liquids and with the round pipe metal outer cylinder as another electrode. There is a screw flow guiding pads between the metal outer electrode and central round electrode. There are distributed with several radial metal conductive bars and current control parts in the length direction of the screw guiding pad, which are connected to the above two electrodes through the conductive bars.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

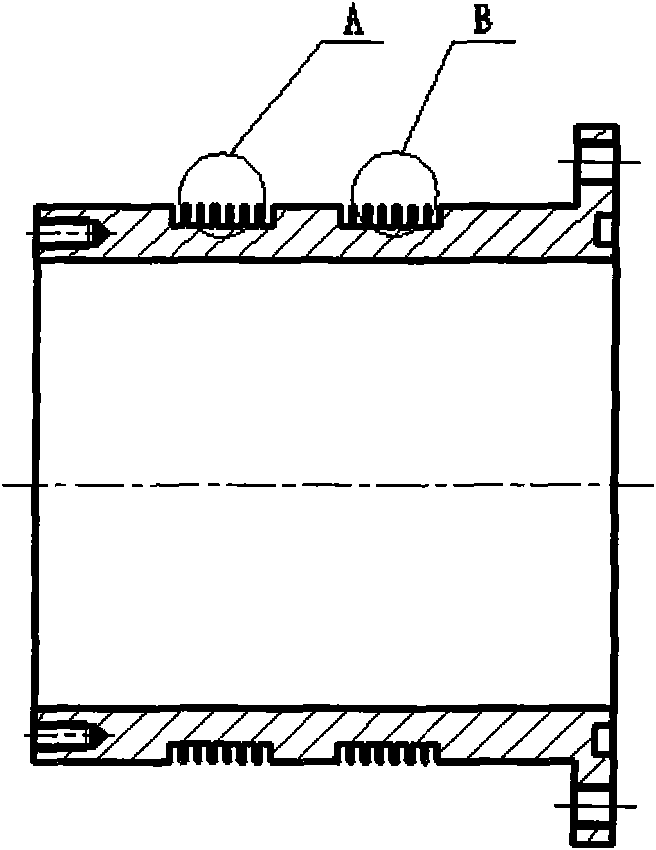

Sealing device with evenly distributed magnetic liquid

The invention relates to a sealing device with evenly distributed magnetic liquid, which belongs to the sealing field of mechanical engineering. The sealing device comprises a sealing assembly formed by installing a left bearing, a left pole shoe with a rubber sealing ring, a permanent magnet, a right pole shoe with a rubber sealing ring and a right bearing together. The space between the internal surface of the permanent magnet and the external surface of an axle is between 5 mm and the height of pole teeth to ensure that magnetic liquid successfully inflows into the clearance between the pole teeth and the axle under the action of magnetic field force, the width center of the permanent magnet is radially provided with a through hole, a through hole with tapered threads is arranged on the position of a casing, the width between the through hole and the left surface is l plus the width of the left bearing plus the width of the left pole shoe with the rubber sealing ring plus half of the width of the permanent magnet, a pipe head is connected in the through hole with tapered threads, and the sealing assembly is filled with air to ensure each pole tooth of the pole shoe to be distributed with the magnetic liquid, thereby the compressive resistance of the device is improved, and the service life of the device is prolonged.

Owner:BEIJING JIAOTONG UNIV

Magnetic liquid sealing device with self-cleaning function

InactiveCN101737499AImprove sealingSeal applicableEngine sealsForeign matterHigh magnetic field strength

The invention discloses a magnetic liquid sealing device with a self-cleaning function, which belongs to the technical field of mechanical engineering sealing and comprises a shell (2), a left bearing (3), a left pole shoe (5) with a rubber seal ring, a permanent magnet (6), a right pole shoe (8) with a rubber seal ring, a right bearing (10), an adjusting gasket (11), a flange disk (13) and a shaft (14). The right end face of the right pole shoe and an axle line form an angle alpha of 10 to 80 degrees to change the shape of the right pole shoe and the magnetic field strength, so that the magnetic field strength on the side a of the right pole shoe is higher than that on the side b. According to Bernoullis equation, the pressure of the granules entering a magnetic liquid from outside on the side with high magnetic field strength is higher that on the side with low magnetic field strength, namely the pressure on the side a is more than that on the side b. The system generates a repulsive force to outside foreign materials so as to fulfil the aim of self cleaning.

Owner:BEIJING JIAOTONG UNIV

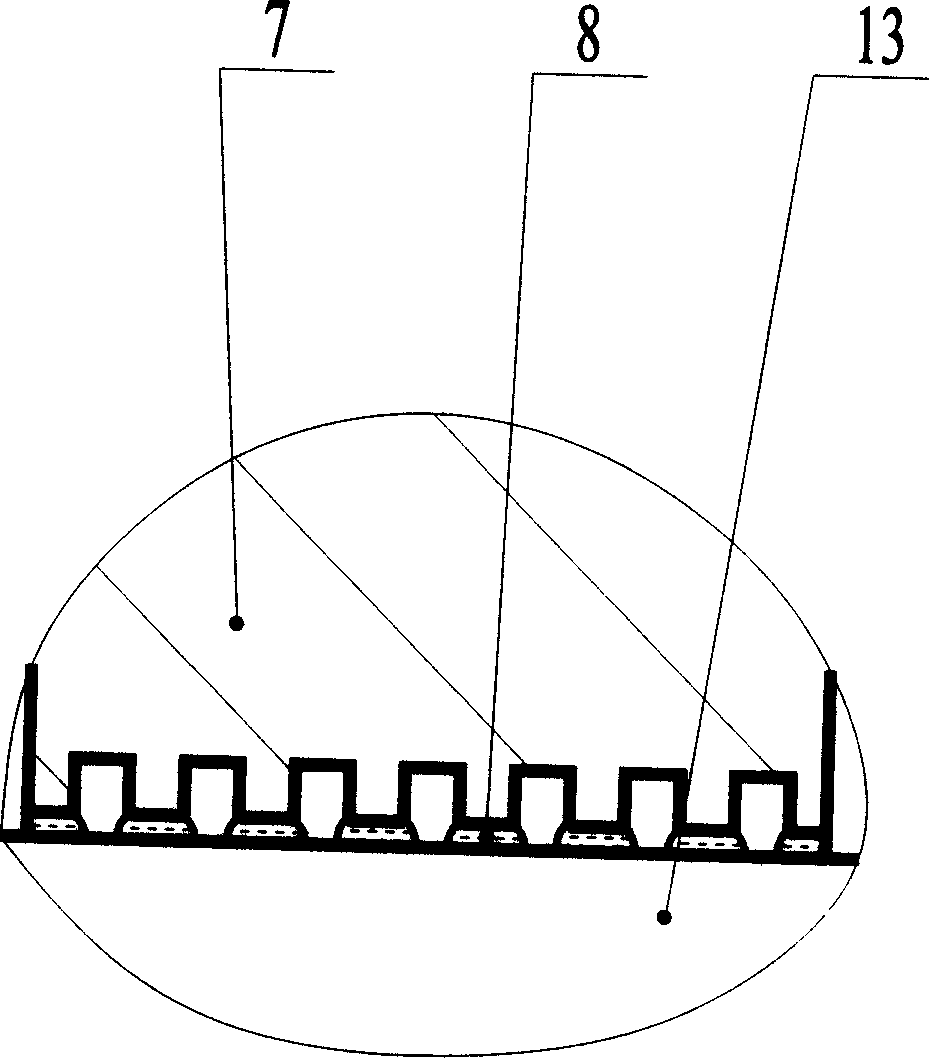

Sealing device with uniformly distributed magnetic liquid

InactiveCN1546890ASave axial space sizeImprove pressure resistanceEngine sealsMagnetic liquidsEngineering

The invention is a kind of sealing device whose magnetism liquid is distributed evenly, the device includes: a cover, a bearing, a rubber sealing ring, a magnet, polar shoe, magnetism liquid, nut, adjusting cushion, frank plat, shaft. The grades of the polar teeth of the two polar shoes are different, the teeth quantity of the polar shoe 4 is less than teeth quantity of the polar shoe 7, ensures each teeth on the polar shoe is covered by magnetism liquid, thus upgrades the pressure resisting ability of the device. The pressure durable ability is high, the lifespan is long, and the assembly is not changed. The application range is enlarged.

Owner:BEIJING JIAODA INNOVATION TECH CENT

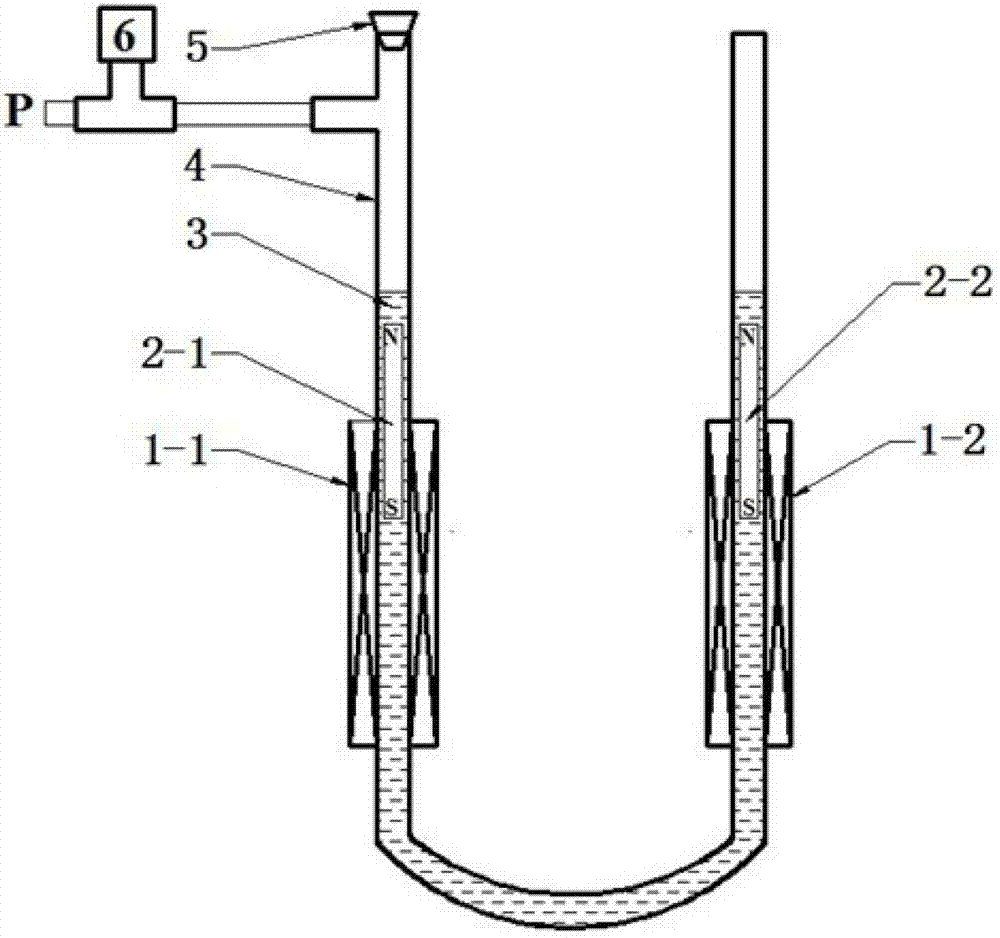

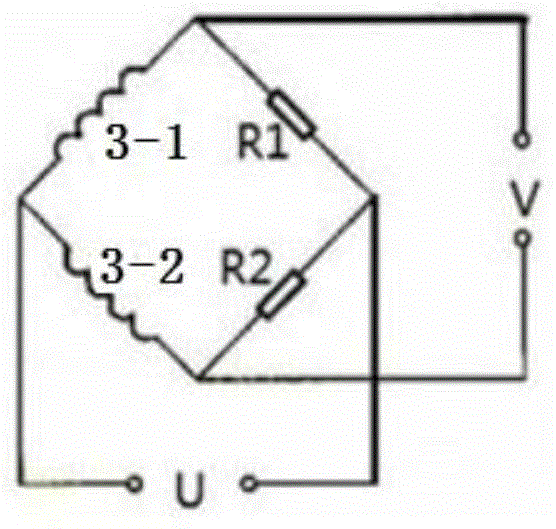

High-sensitivity magnetic liquid micro-pressure difference sensor

InactiveCN103162896AHigh sensitivityThe voltage signal is obviousPressure difference measurement between multiple valvesCopper wireVoltmeter

A high-sensitivity magnetic liquid micro-pressure difference sensor is applicable to the field of micro-pressure measurement and comprises a left arm coil (1-1), a right arm coil (1-2), a first permanent magnet (2-1), a second permanent magnet (2-2), magnetic liquid (3), a U-shaped organic glass tube (4), a rubber plug (5), a pressure gauge (6), a first slide rheostat (R1), a second slide rheostat (R2), an alternating current power supply (U) and a voltmeter (V). Copper wires are uniformly and symmetrically wound on two arms of a U-shaped tube, serially connected with the first slide rheostat (R1) and the second slide rheostat (R2) and then parallelly connected to two ends of the alternating current power supply. The magnetic liquid is poured into the U-shaped tube, two magnets are placed into two arm tubes of the U-shaped tube, the rubber plug is plugged into the U-shaped tube, and an open end of a left arm of the U-shaped tube is connected with a pressure source P and the pressure gauge. Under the action of micro-pressure, the permanent magnets move in the U-shaped tube along with the magnetic liquid, and the sensitivity of the magnetic liquid micro-pressure difference sensor is greatly improved under remarkable differential action as magnetic conductivity of the permanent magnets is far higher than that of the magnetic liquid.

Owner:BEIJING JIAOTONG UNIV

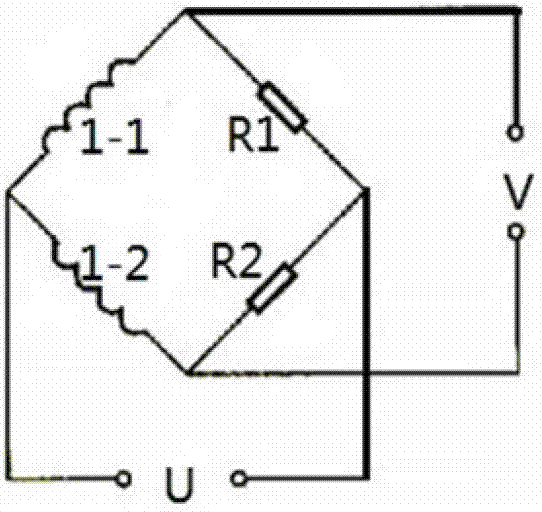

Magnetic-liquid micro differential pressure sensor

InactiveCN103604558AReduce volumeStrong signalPressure difference measurement between multiple valvesDifferential pressureCopper wire

A magnetic-liquid micro differential pressure sensor is suitable for the field of micro pressure measuring. The magnetic-liquid micro differential pressure sensor comprises an organic glass tube (1), a left rubber plug (2-1), a right rubber plug (2-2), a left coil (3-1), a right coil (3-2), a left ring magnet (4), a right ring magnet (4-2), a hollow permanent magnet (5), an iron core (6), magnetic liquid (7), a first constant-value resistor (R1), a second constant-value resistor (R2), an alternating current power supply (U) and a voltmeter (V). Enamelled copper wires are wound around the left side and the right side of the organic glass tube (1), the magnetic liquid (7) is injected after a composite magnetic core is added, the left end of one coil and the right end of the other coil are sleeved with the ring magnets respectively, it should be guaranteed that the dotted terminals of the ring magnets and the composite magnetic core are opposite and used for providing restoring force, and finally the rubber plugs are inserted. The left end is connected with a pressure source (P), the right end is connected with the atmosphere, and a bridge circuit is formed by the two coils and the two resistors (R1 and R2) having the same value; when micro pressure acts, the composite magnetic core moves in the tube, and obvious voltage values are output.

Owner:BEIJING JIAOTONG UNIV

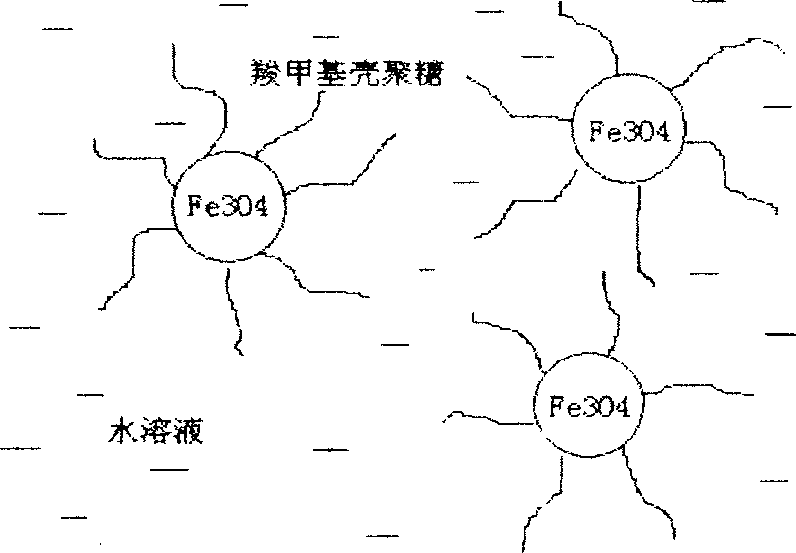

Water-based magnetic liquid and method for making same

InactiveCN1702782AFirmly connectedRich chitin resourcesMagnetic liquidsInductances/transformers/magnets manufactureState of artWater based

This invention relates to water base Fe3O4 magnetic liquid process and provides one water base magnetizing liquid and its process method. This invention adopts shell chitose ramification of CM-sephadex-C25 as surface activity agent to synthesize the Fe3O4 water base magnetizing liquid.

Owner:SUN YAT SEN UNIV

Magnetic liquid apparent viscosity tester and testing method thereof

This invention relates to magnetic liquid surface viscosity test meter and its method, which adopts adjustable magnetic stator and rotor axis with high conductive magnetic cover matched with temperature measurement device and non-contact speed meter. The device is located with high conductive magnetic cover and adjustable permanent magnetic iron stator with liquid gap and the temperature measurement device and the stators are located with multiple heat couple through rotation axis moving in the stators and adopt direct current constant torque motor speed changes to test torque and adopts imbedded magnetic to control added magnetic field with the magnetic field direction vertical to the shearing surface to realize the magnetic flow viscosity testing.

Owner:CHINA UNIV OF MINING & TECH

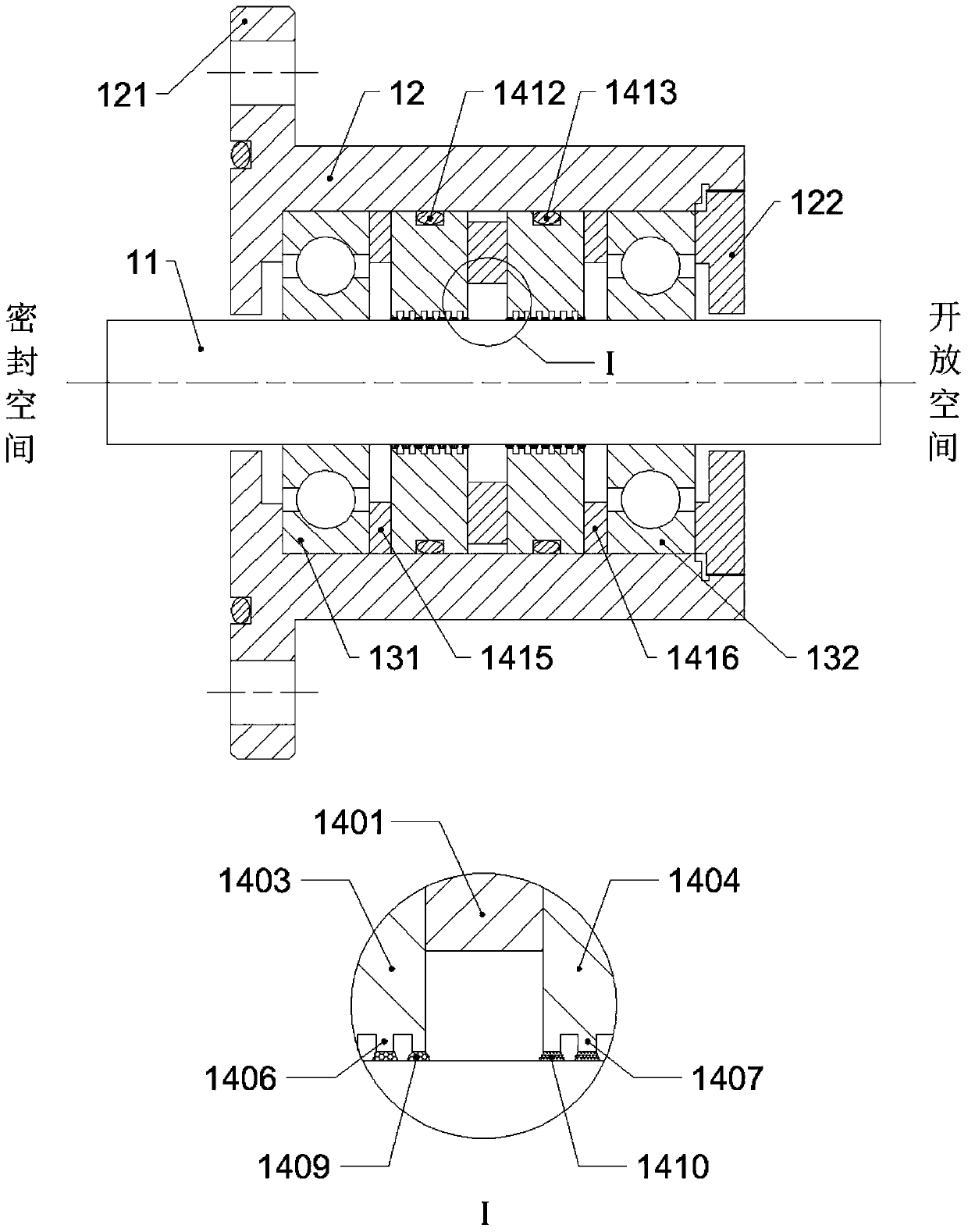

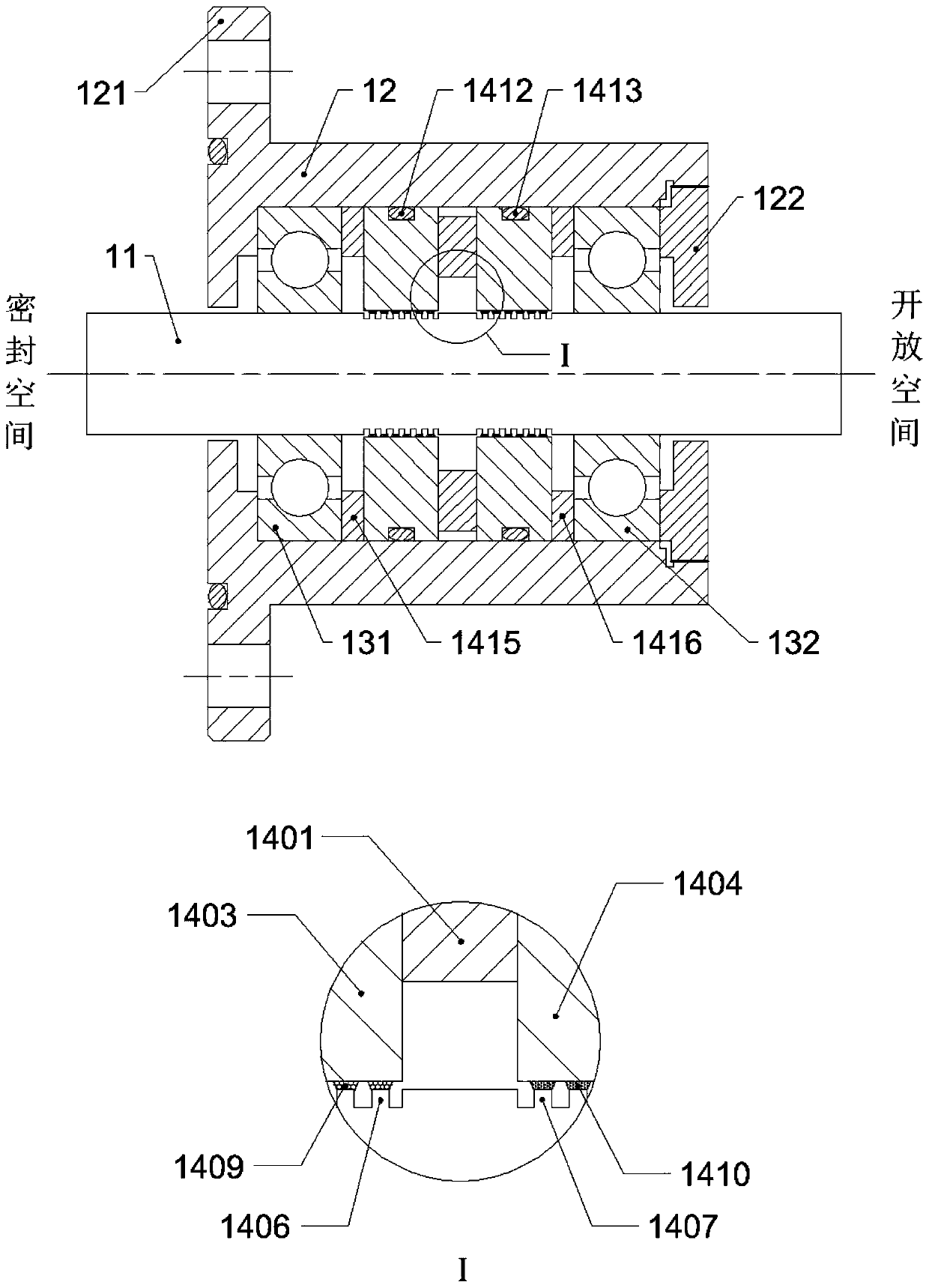

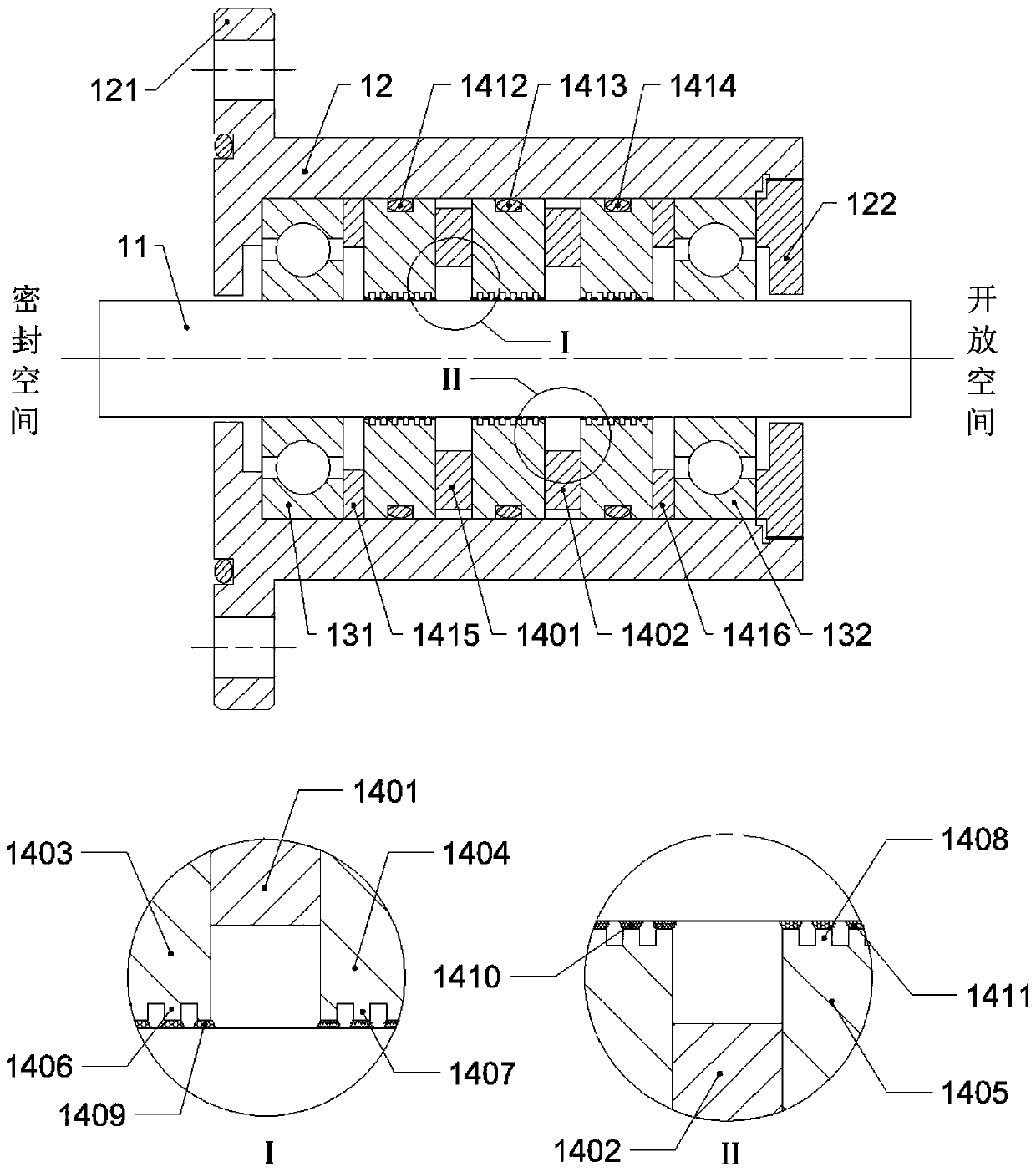

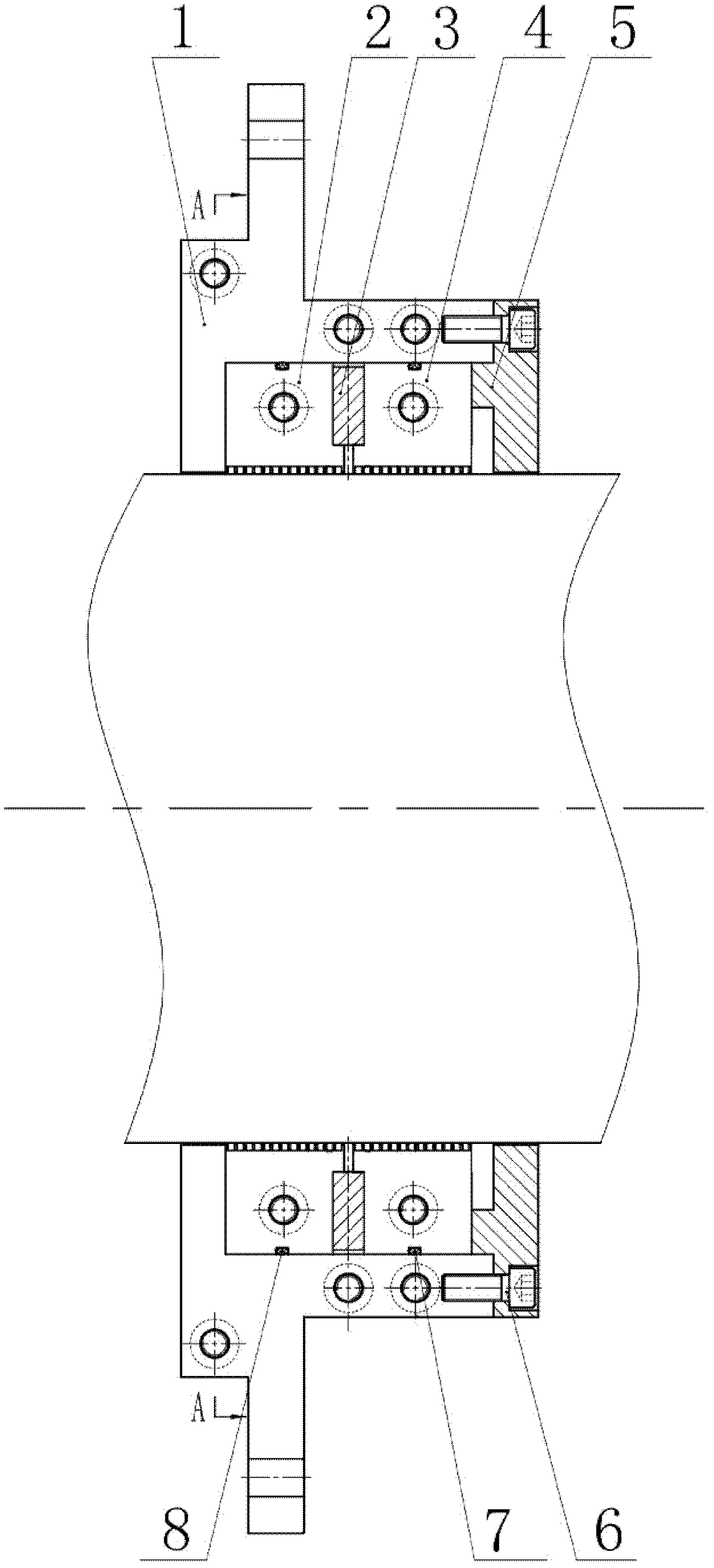

Magnetic liquid sealing device with wide temperature applicability

The invention discloses a magnetic liquid sealing device with wide temperature applicability. The magnetic liquid sealing device comprises a rotating shaft (11), a shell (12), a bearing part (13) anda magnetic liquid sealing part (14); magnetic liquid A (1409 and 1411) is fluorocarbon-based or ester-based magnetic liquid, and magnetic liquid B (1410) is kerosene-based or engine oil-based magneticliquid; the magnetic liquid A (1409) is injected into pole teeth (1406) corresponding to pole shoes (1403) adjacent to a sealing space, and the magnetic liquid B (1410) is injected into at least onestage of pole teeth (1407 and 1408) corresponding to the other pole shoes (1404 and 1405). With the structure, the magnetic liquid sealing device has a low rotational torque under a working conditionof low temperature and low evaporation under a working condition of high temperature; and according to the magnetic liquid sealing device, the pollution caused by the evaporation of the magnetic liquid to the sealing space is effectively prevented, the evaporation loss of the magnetic liquid is also reduced due to the reduction of the evaporation amount of the magnetic liquid, and the maintenancecycle and service life of the magnetic liquid sealing device are indirectly prolonged.

Owner:BEIJING JIAOTONG UNIV

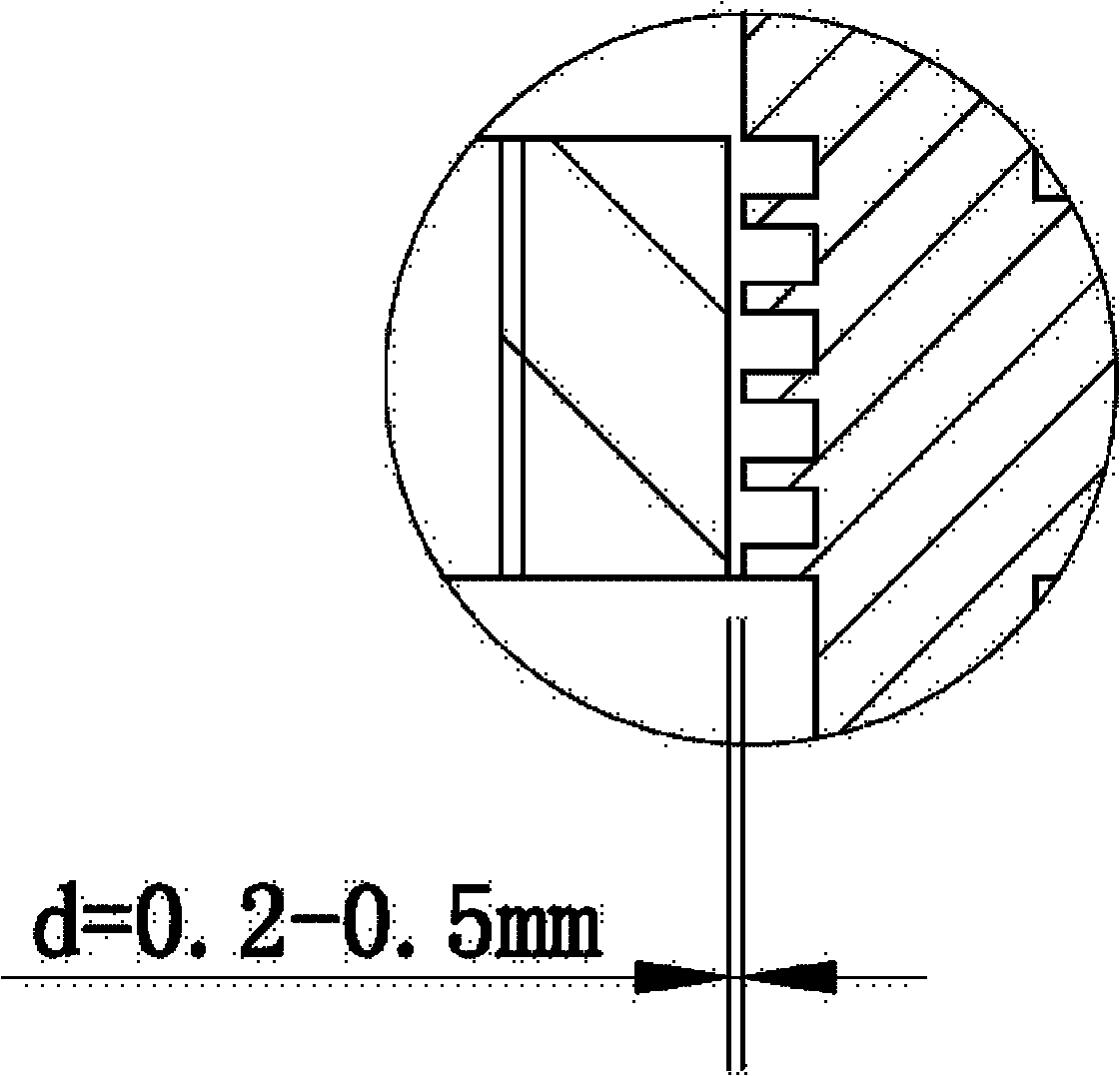

Sealing method for split type magnetic liquid sealing device

InactiveCN102537366AIntegrity guaranteedGuaranteed sealing performanceEngine sealsMagnetic liquidsSealant

A sealing method for split type magnetic liquid sealing device belongs to the field of mechanical engineering sealing, and solves the problems that as the present large-diameter magnetic liquid rotation sealing device applies sealant at the jointed surface of a two-flap structure, the redundant sealant is extruded out after installation and remains on pole teeth at the inner circles of pole shoes, and uneven application influences the sealing performance at the same time. The sealing method is realized as follows: a stainless steel sheet is heated and kept at a temperature between 300 DEG C and 35 DEG C; the stainless steel sheet is stuck into a clearance between a sealing shaft and the pole teeth of the pole shoes; the stainless steel starts from a point at the jointed clearance between two half-pole shoes, and moves along the circumferences of the half-pole shoes to return the start point, so that the sealant extruded from the jointed surfaces of the pole shoes is vaporized; the thickness of the stainless steel sheet is smaller than the clearance between the sealing shaft and the pole teeth of the pole shoes, so as to enable the stainless steel sheet to stick into the clearance; a medical injector is used for sucking magnetic liquid at the jointed clearance between the two half-casings of the split type magnetic liquid sealing device, and the injector starts from a point at the jointed clearance, and continuously injects the magnetic liquid along the circumferences till returning the start point.

Owner:BEIJING JIAOTONG UNIV

Method and device for testing magnetic viscosity of magnetic liquid

The invention relates to a method and a device for testing magnetic viscosity of magnetic liquid, and the method comprises the following steps: taking a permanent magnet as a magnetic source, and restricting the continuous adjustment of a magnetic field to adjust a magnetic conductive rotating ring to adjust a radial adjustable gap up and down along a rotating shaft, thereby achieving the regulation of magnetic reluctance and magnetic flux of a magnetic loop; and further adjusting the strength of the magnetic field applied on a magnetic liquid material sample, starting a speed-regulating motor, then driving the magnetic conductive rotating ring to rotate through the rotating shaft, leading the magnetic liquid to be acted by shearing, converting to rotational torque and rotational angular speed, measuring the magnetic flux on the magnetic loop through a magnetic fluxmeter and finally calculating the magnetic viscosity and magnetic flux density according to a formula. The testing device comprises the speed-regulating motor, a torque and rotational speed sensor, the rotating shaft, a non-magnetic centering component, a magnetic conductive stationary ring, the magnetic conductive rotating ring, a permanent magnetic ring and the like, wherein the magnetic conductive stationary ring, the permanent magnetic ring and the magnetic conducive rotting ring form the magnetic loop with a constant gap and the adjustable gap, and the constant gap is used for forming the uniform magnetic field for restricting the material sample and applying the shearing force on the material sample. The method and the device can accurately determine the critical working magnetic field, realize the measurement of the low-temperature magnetic viscosity, and provide a basis for optimal design of devices for sealing, damping vibration attenuation and the like, and has the advantages of no impacts on the temperature of the sample, convenient use, small power consumption and the like.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Low-temperature and small-diameter magnetic fluid seal device

The invention relates to a low-temperature and small-diameter magnetic fluid seal device which has the structure that a first bearing (6), a first magnetic isolating ring (9), a first pole shoe (10) provided with an O-shaped seal ring, a permanent magnet (13), a second pole shoe (15) provided with an O-shaped seal ring, a second magnetic isolating ring (16) and a second bearing (17) are sequentially installed by tightly attaching a boss of an outer sleeve (8); a large end cover (19) is fixed to the outer sleeve by a screw, and the second bearing is tightly pressed; the magnetic liquid is injected, and a magnetic conducting sleeve (1) provided with an adjusting spacer (20) is installed into inner holes of the assembled bearings and the pole shoes and fixed by a screw (4) and a small end cover (5). The tooth shape parameters of seal teeth on the outer column surface of the magnetic conducting sleeve comprise the tooth width of 0.5mm, the tooth height of 2.5mm and the groove width of 1.5mm. The first magnetic isolating ring is installed between the first bearing and the first pole shoe; and the second magnetic isolating ring is installed between the second bearing and the second pole shoe. The invention solves the problem of the seal of magnetic liquid under the conditions of low temperature and small diameter.

Owner:BEIJING JIAOTONG UNIV

Peltier cooling type magnetic liquid sealing device

InactiveCN103925371AEasy to control temperatureAvoid seal failureEngine sealsMagnetic liquidsExtreme temperature

The invention discloses a Peltier cooling type magnetic liquid sealing device, and belongs to the field of mechanical engineering sealing. The Peltier cooling type magnetic liquid sealing device solves the problem that when an existing magnetic liquid sealing device is used in the extreme temperature occasions, the temperature of magnetic liquid in the sealing gaps is excessively high or low, so that sealing fails. The Peltier cooling type magnetic liquid sealing device comprises a case (1), a left bearing (2), a left magnetism isolation ring (3), a left pole shoe (4), a permanent magnet (5), a right pole shoe (6), a right magnetism isolation ring (7), a right bearing (8), an end cover (9), a sealing ring (10), a clamping spring (11), a right sealing ring (12), a left sealing ring (13) and a Peltier part (14). The Peltier part (14) is installed on the outer surface of the regular polygonal case (1) so that the temperature of the magnetic liquid in the sealing gaps can be controlled, and the problem that when the existing magnetic liquid sealing device is used in the extreme temperature occasions, the temperature of the magnetic liquid in the sealing gaps is excessively high or low, so that sealing fails is effectively solved.

Owner:BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com