Magnetic liquid damping vibration attenuating device

A magnetic liquid and vibration damping device technology, applied in vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of collision, decrease in the service life of the vibration damping device, and affect the vibration damping performance, so as to prevent the impact and increase the vibration damping effect. , Improve the effect of vibration damping performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in conjunction with accompanying drawing:

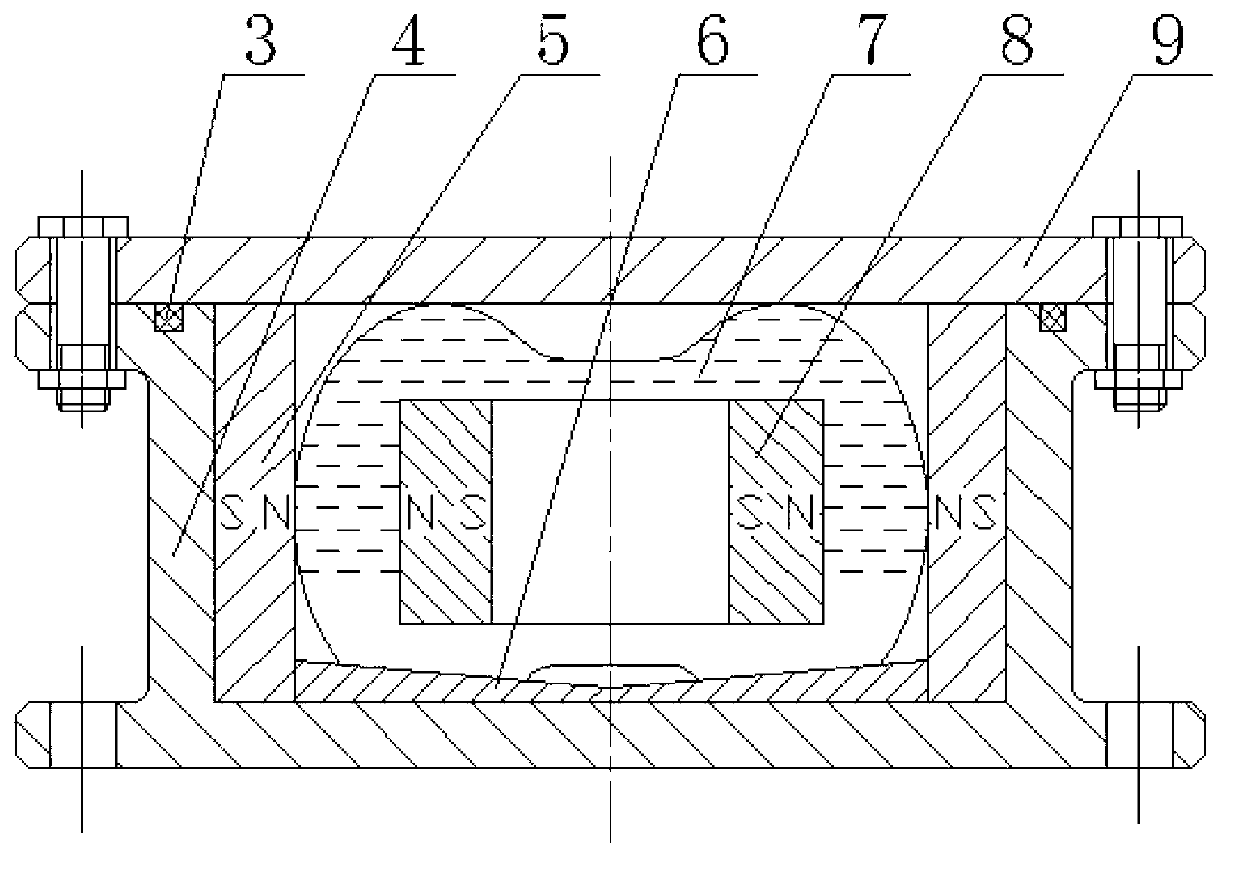

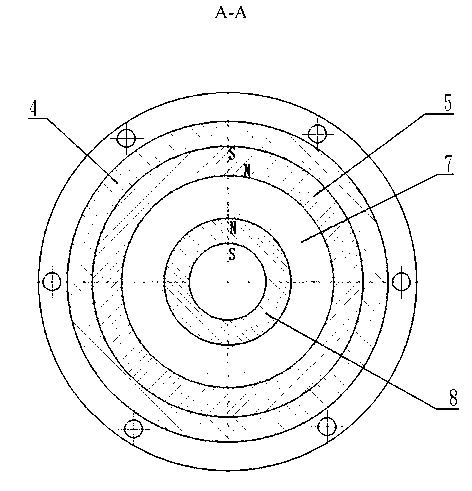

[0018] A magnetic liquid damping vibration reduction device, such as figure 1 , 2, the vibration damping device includes: O-shaped rubber seal ring 3, housing 4, the first annular permanent magnet 5, wedge angle gasket 6, magnetic liquid 7, the second annular permanent magnet 8, end cap 9.

[0019] Glue the first annular permanent magnet 5 on the inner wall of the housing 4 to form the inner wall of the shock absorber; the diameter of the outer circle of the first annular permanent magnet 5 is equal to the diameter of the inner wall of the housing 4; the depth of the housing 4 Equal to the height of the first annular permanent magnet 5.

[0020] Place the wedge gasket 6 on the bottom of the housing 4 with its V-shaped angle facing upwards, and place the second ring-shaped permanent magnet 8 adsorbed with the magnetic liquid 7 in the housing 4 .

[0021] The first ring-shaped pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| V-shaped angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com