High-sensitivity magnetic liquid micro-pressure difference sensor

A micro differential pressure sensor, magnetic liquid technology, applied in pressure difference measurement between multiple valves, measurement of fluid pressure, instruments, etc., can solve the problems of low sensitivity and easy to produce errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described with accompanying drawing as specific embodiment:

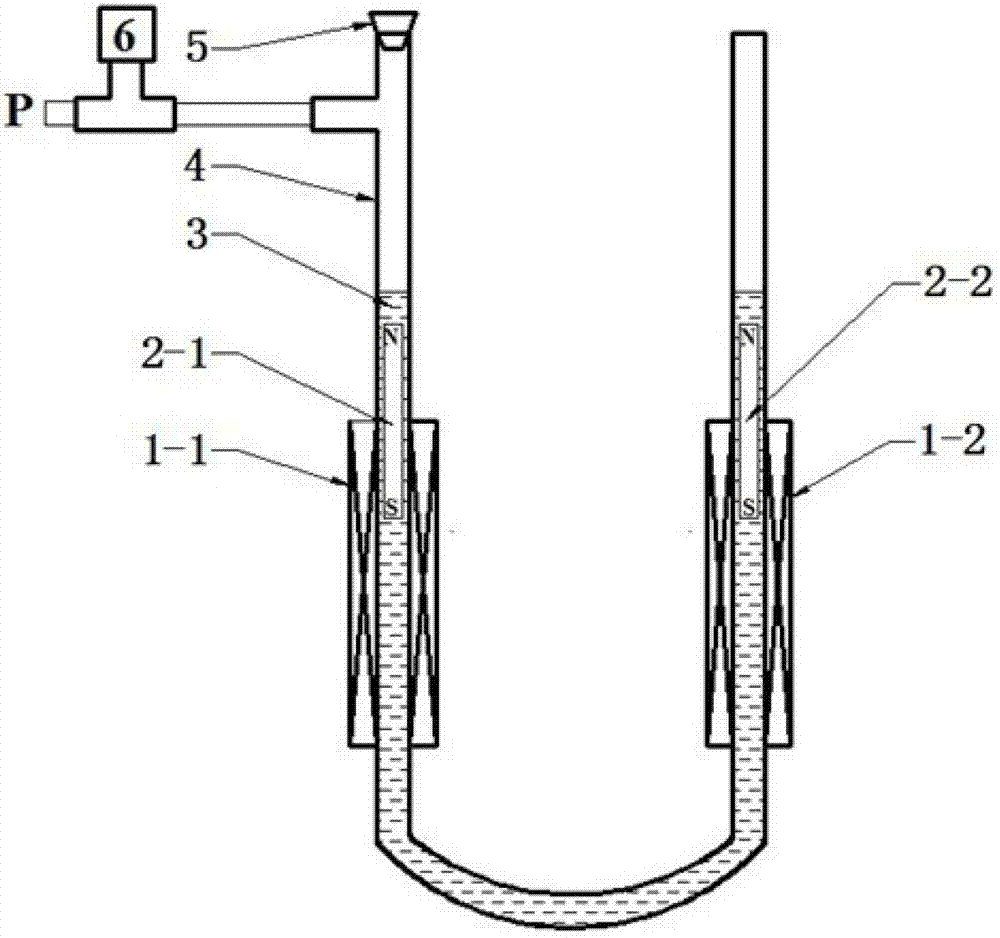

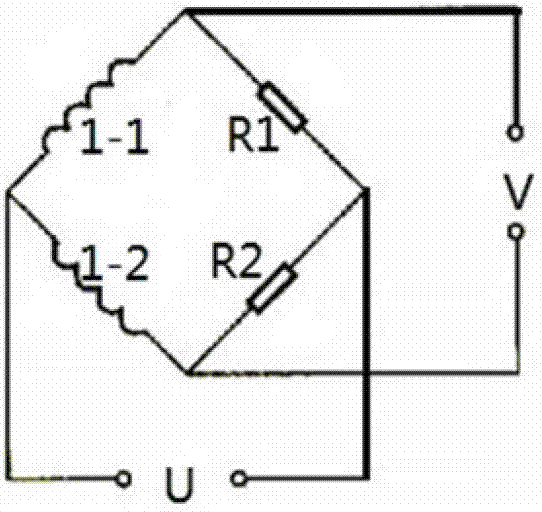

[0018] A magnetic liquid micro pressure difference sensor with high sensitivity, the device includes: a left arm coil 1-1, a right arm coil 1-2, a first permanent magnet 2-1, a second permanent magnet 2-2, a magnetic liquid 3, U-shaped plexiglass tube 4, rubber plug 5, pressure gauge 6, first sliding rheostat R1, second sliding rheostat R2, AC power supply U and voltmeter V.

[0019] The high-strength enamelled copper wire is wound on the two arms of the U-shaped plexiglass tube evenly, symmetrically, and with equal turns to form the left arm coil 1-1 and the right arm coil 1-2, which are injected into the U-shaped plexiglass tube 4 The magnetic liquid 3 and the rubber stopper 5 are plugged in the upper opening of the left arm of the U-shaped plexiglass tube 4, and the side opening end of the left arm of the U-shaped plexiglass tube 4 is connected with the pressure source...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com