Sealing device for improving sealing anti-pressure capability and sealing reliability of magnetic liquid

A technology of pressure resistance and magnetic liquid, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of seal failure, large seal pressure resistance, reduction, etc., to expand the safe working range, easy to install, improve The effect of withstand voltage capability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

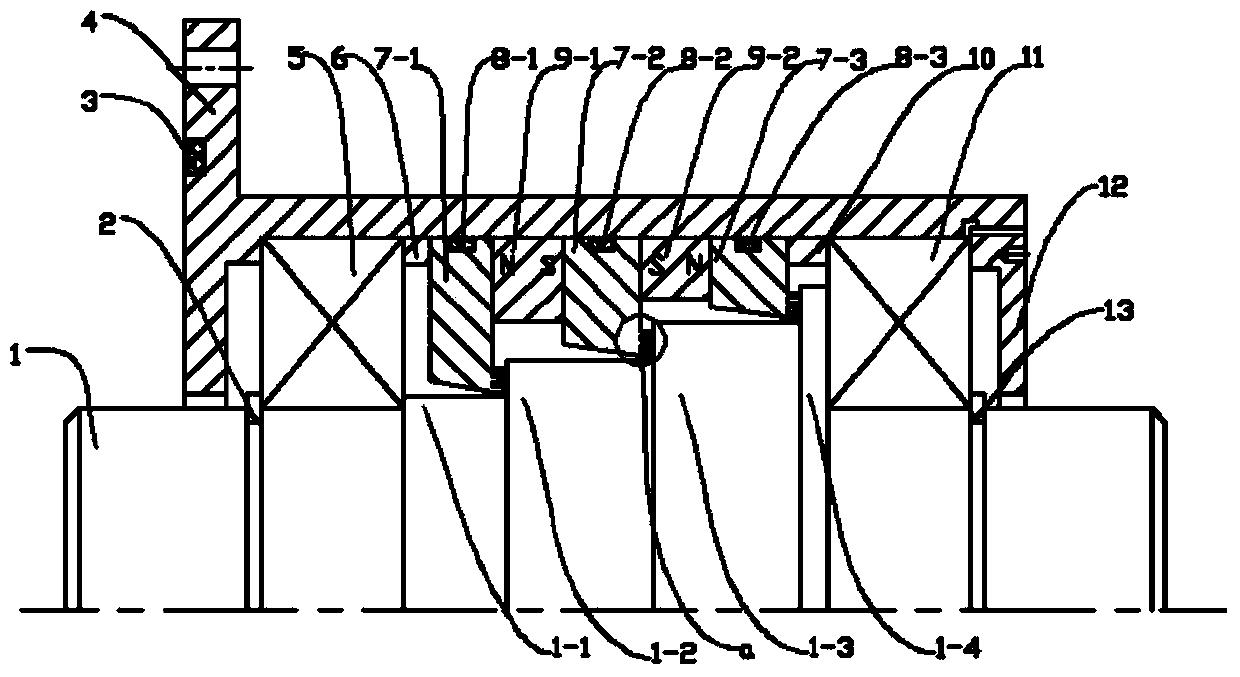

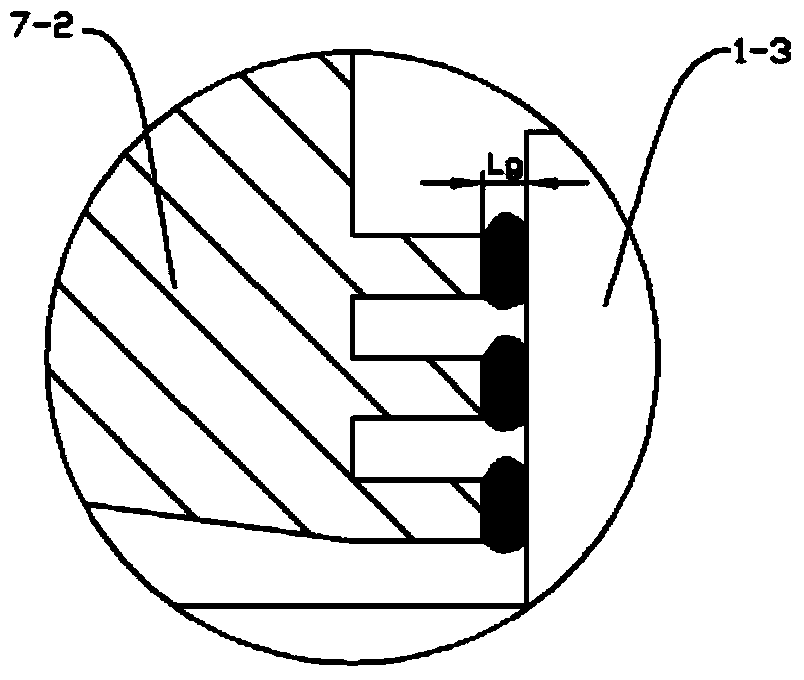

[0025] A sealing device that improves the pressure resistance and sealing reliability of magnetic liquid seals, such as figure 1 As shown, the sealing device includes: shaft 1, housing 2, first and second magnetic isolation rings 6, 10, first to third pole shoes 7-1, 7-2, 7-3, first to third Rubber rings 8-1, 8-2, 8-3, first and second permanent magnets 9-1 and 9-2, first and second bearings 5 and 11, end caps 12, first and second retaining springs 3, 13.

[0026] The shaft 1 is a stepped shaft, and the material of the stepped shaft is 2cr13 stainless steel.

[0027] The material of the shell 2 is non-magnetic stainless steel.

[0028] The material of the first to third pole pieces 7-1, 7-2, 7-3 is 2cr13 stainless steel.

[0029] The materials of the first and second permanent magnets 9-1 and 9-2 are all NdFeB materials.

[0030] Pole teeth are processed on the right sides of the first pole piece, the second pole piece and the third pole piece, and the number of pole tee...

Embodiment approach 2

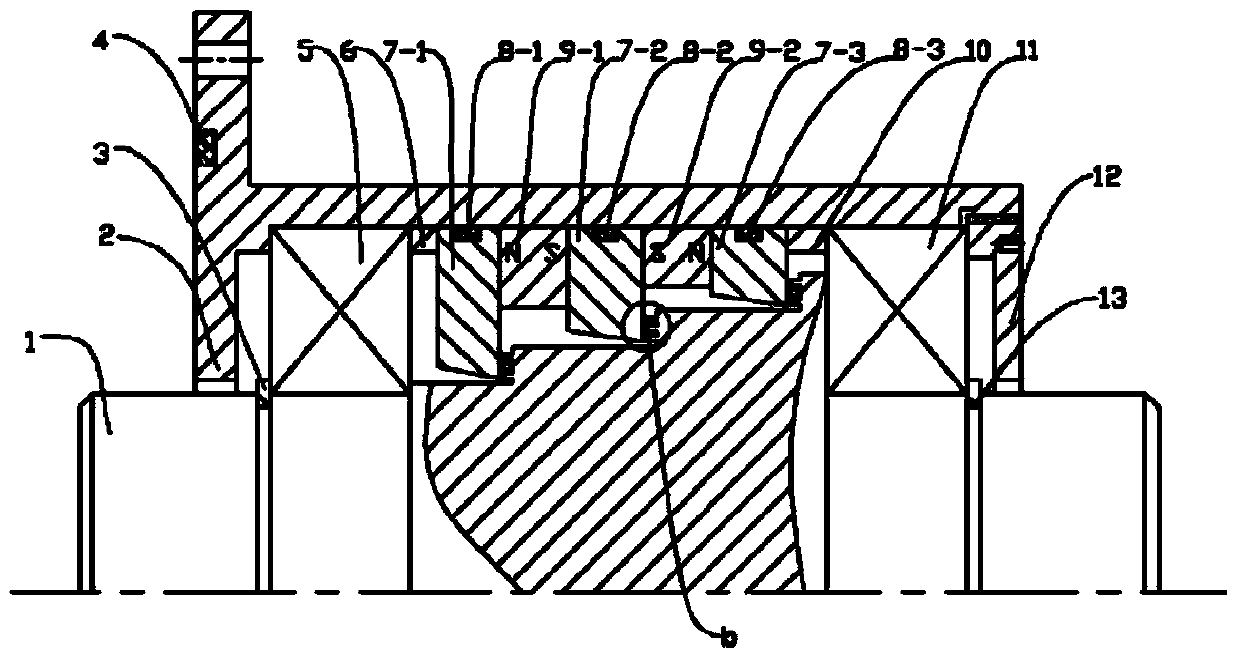

[0044] A sealing device that improves the pressure resistance and sealing reliability of magnetic liquid seals, such as image 3 As shown, the sealing device includes: shaft 1, housing 2, first and second magnetic isolation rings 6, 10, first to third pole shoes 7-1, 7-2, 7-3, first to third Rubber rings 8-1, 8-2, 8-3, first and second permanent magnets 9-1 and 9-2, first and second bearings 5 and 11, end caps 12, first and second retaining springs 3, 13.

[0045] The shaft 1 is a stepped shaft, and the material of the stepped shaft is 2cr13 stainless steel.

[0046] The material of the shell 2 is non-magnetic stainless steel.

[0047] The material of the first to third pole pieces 7-1, 7-2, 7-3 is 2cr13 stainless steel.

[0048] The materials of the first and second permanent magnets 9-1 and 9-2 are all NdFeB materials.

[0049] Pole teeth are processed on the right sides of the first pole piece, the second pole piece and the third pole piece, and the number of pole tee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com