Magnetic liquid sealing device with wide temperature applicability

A technology of magnetic liquid and sealing device, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of low rotational torque and low evaporation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the improvement made by the present invention compared with the prior art, three specific implementation modes of the present invention will be described in detail below.

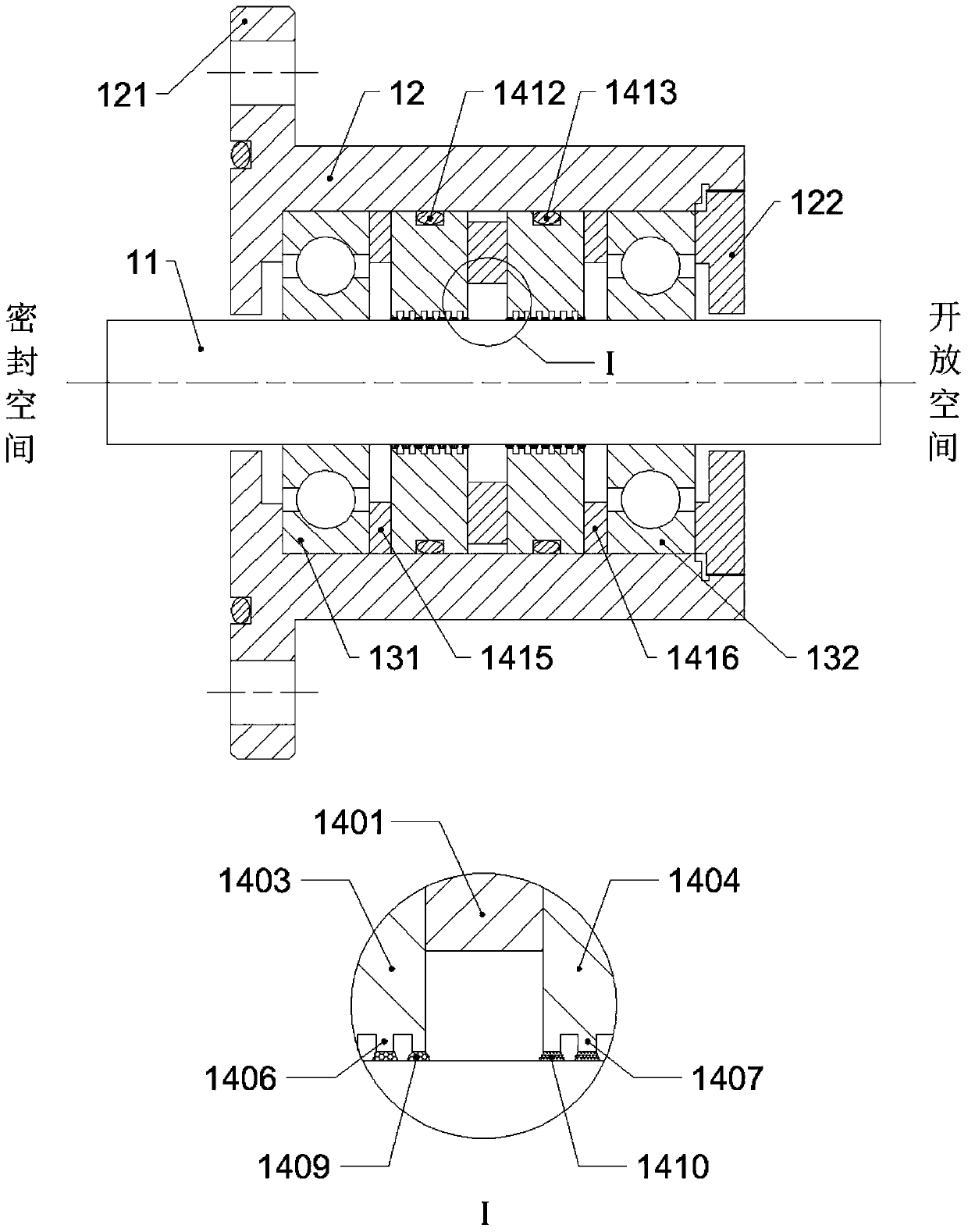

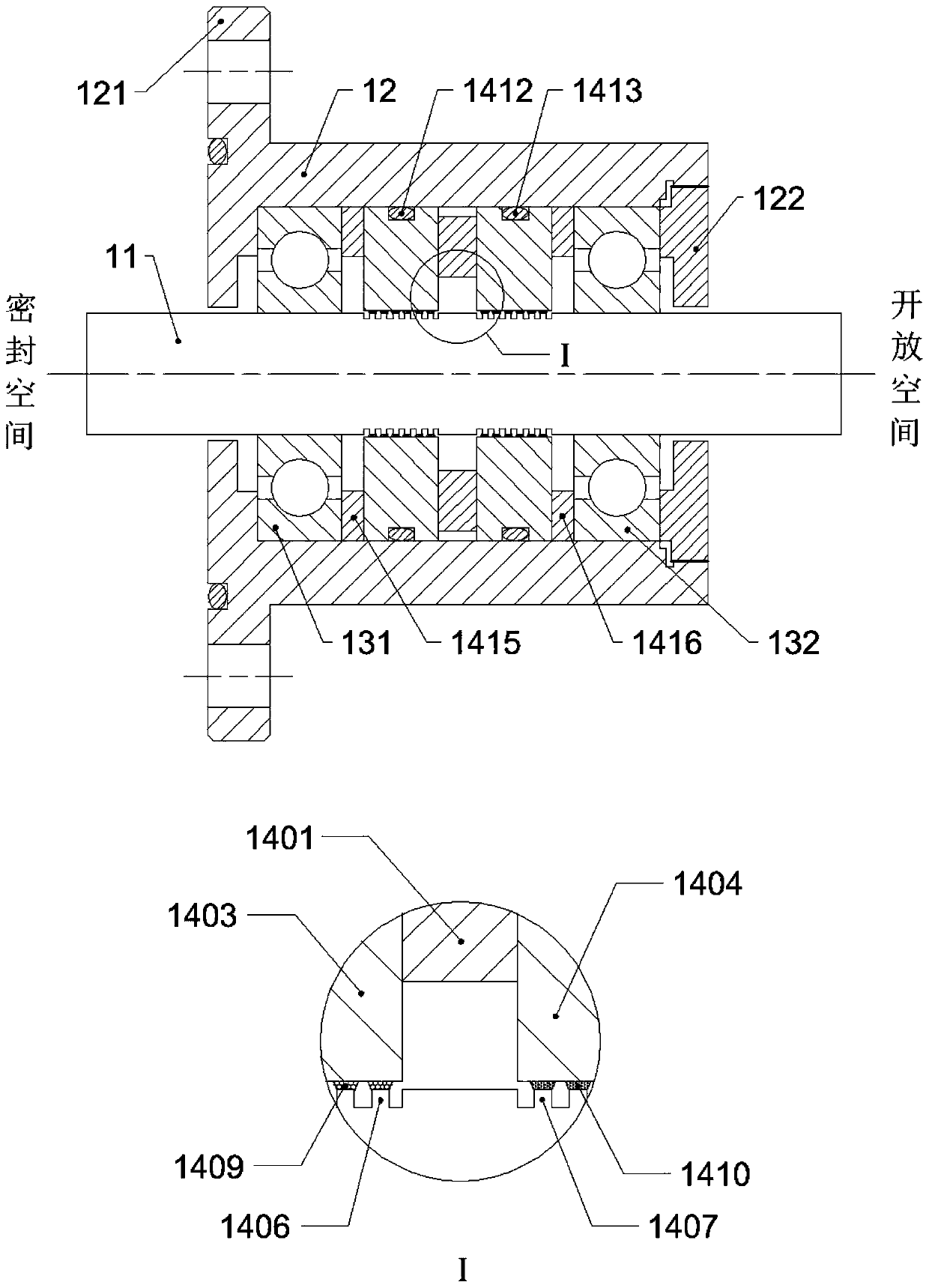

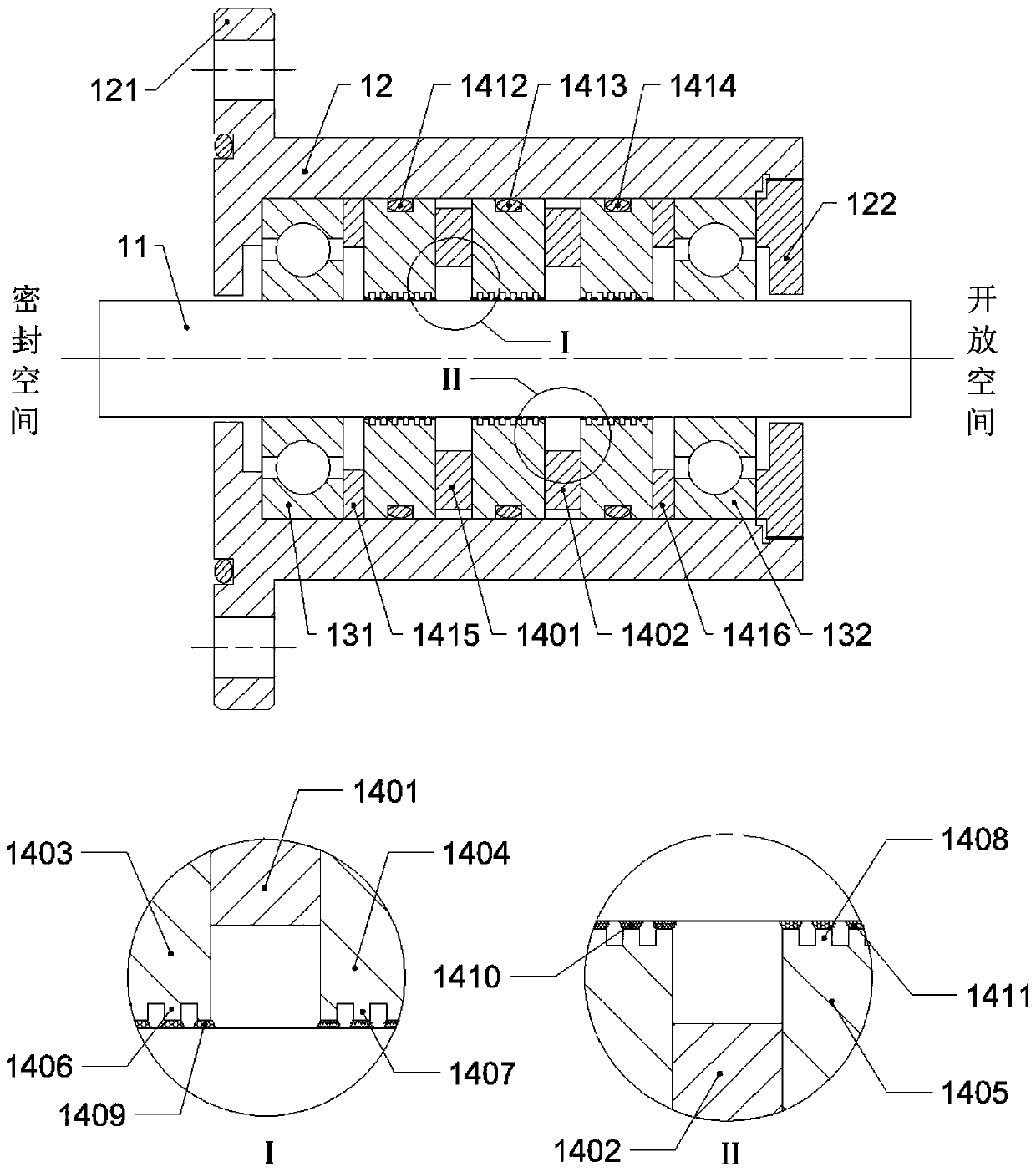

[0015] like figure 1 In the shown first embodiment of the present invention, the magnetic liquid sealing device 1 with wide temperature applicability includes: a rotating shaft 11 , a casing 12 , a bearing part 13 , and a magnetic liquid sealing part 14 . The shell 12 is made of non-magnetic material, and the shell 12 is provided with a flange assembly 121 . An end cap 122 is installed at the end of the shell 12, and the end cap 122 is screwed to the shell 12. The bearings 131 and 132 of the bearing part 13 are installed in the casing 12 , and the rotating shaft 11 cooperates with the bearing part 13 and penetrates through the casing 12 along the axial direction of the casing 12 . The magnetic liquid sealing part 14 is composed of a permanent magnet 1401, pole shoes 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com