Lubricating compositions

A technology for lubricating compositions and ionic liquids, applied in the directions of lubricating compositions, petroleum industry, etc., can solve problems such as reducing sludge accumulation or reducing coking in lubricating compositions that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-18 and comparative example A

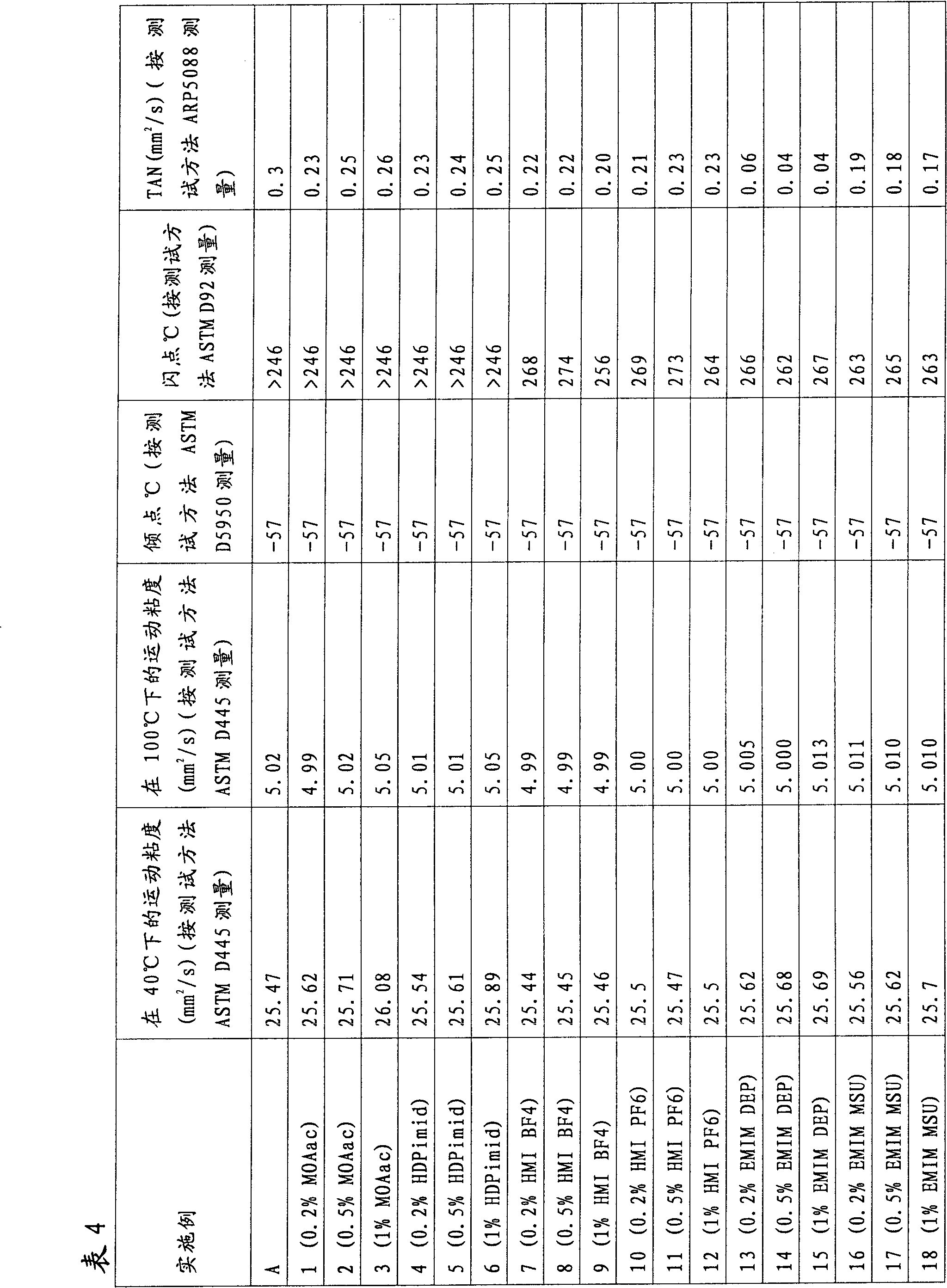

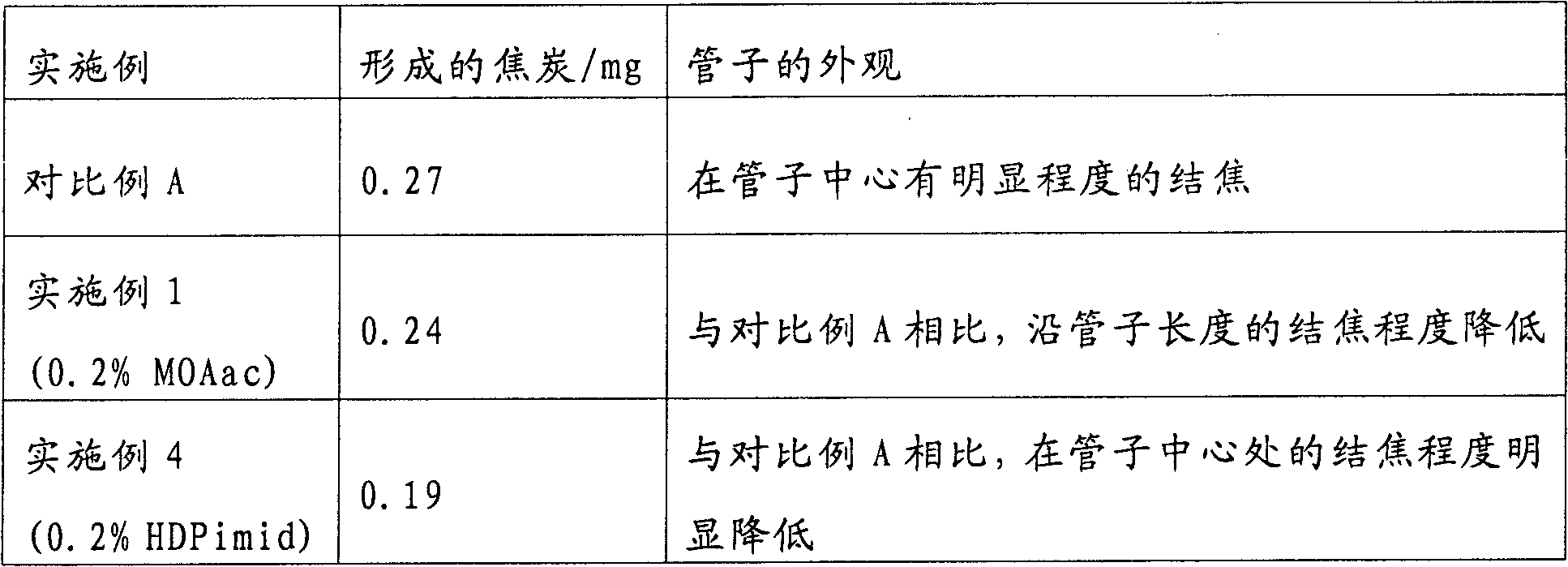

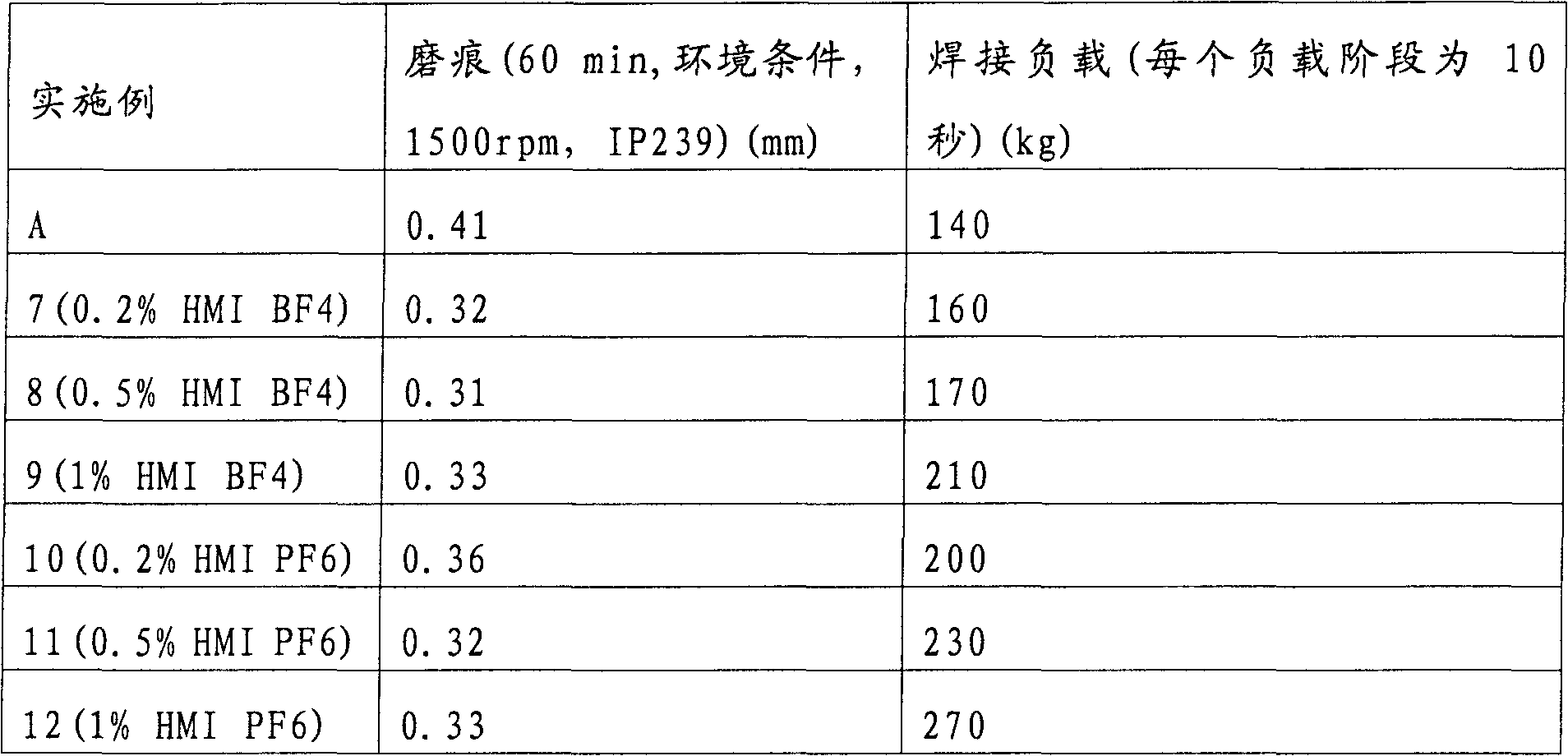

[0071]The turbine engine oils of Examples 1-18 and Comparative Example A were prepared by blending the base oils and additives shown in Tables 1-3 below.

[0072] The amounts in Tables 1-3 are expressed in wt% based on the total weight of the fully formulated formulation.

[0073] The base oil used in the formulations of Tables 1-3 was a 5 cSt pentaerythritol ester, further containing tricresyl phosphate anti-wear additives, tolyltriazole preservatives, dicarboxylic acid preservatives, dioctyl diphenylamine (DODPA) and Aryldiphenylamine as diphenylamine (DPA) antioxidant component, p-tert-octylphenyl-α-naphthylamine as phenyl-α-naphthalene (PANA) antioxidant component, and polysiloxane defoamer. The viscosity of pentaerythritol ester at 100°C is 5mm 2 / s, and the maximum viscosity at -40°C is 13,000mm 2 / s. Additionally, pentaerythritol esters have a maximum pour point of -54°C and a minimum flash point of 246°C.

[0074] Table 1

[0075]

Comparative example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com