Patents

Literature

807 results about "Tricresyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tricresyl phosphate, abbreviated TCP, is an organophosphate compound that is used as a plasticizer and diverse other applications. It is a toxic substance that causes neuropathy through ingestion, and has been the cause of several mass poisonings in history. It is a colourless, viscous liquid, although commercial samples are typically yellow. It is virtually insoluble in water.

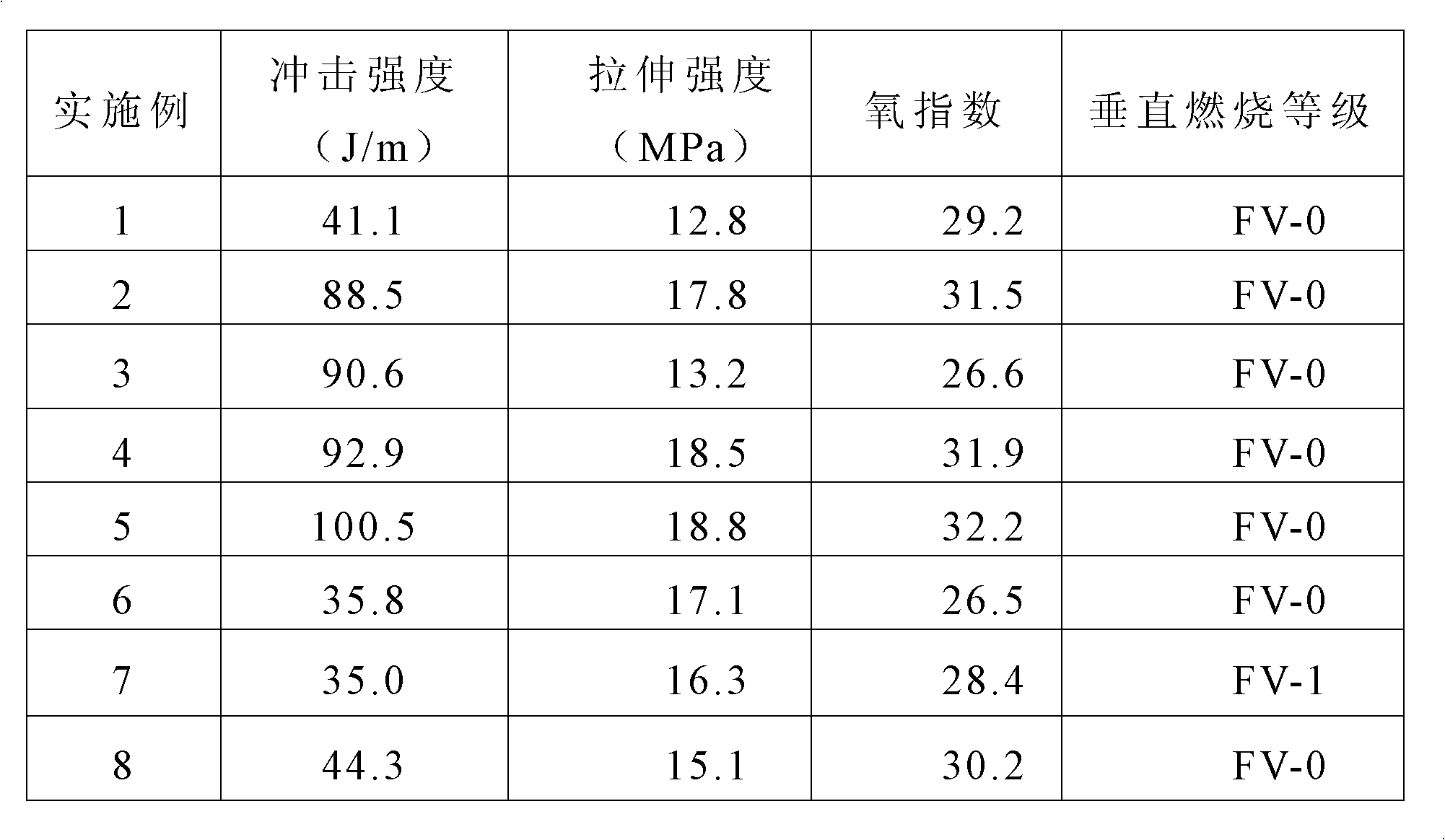

Magnesium hydroxide composite flame retardant material and preparation method thereof

The invention discloses a magnesium hydroxide flame-retardant composite material and a preparation method thereof. The flame-retardant material comprises the following components in parts by weight: 20-100 parts of high polymer, 40-80 parts of magnesium hydroxide and 5-20 parts of toughening agent, wherein the high polymer is one or more of polyethylene, polyvinyl chloride, polypropylene, polystyrene, polyamide, polyformaldehyde, rubber or nylon; and the toughening agent is one or more of dioctyl phthalate, poly(ethylene-octene) elastomer, tricresyl phosphate, styrene-butadiene-styrene block copolymer, hydrogenated styrene-butadiene-styrene block copolymer or styrene-isoprene-styrene block copolymer. Practice proves that the magnesium hydroxide flame-retardant composite material has the advantages of strong shock resistance, high tensile strength and high oxygen index. The preparation method of the composite material is simple in operation, has low cost and high production efficiency,and can be widely used in the field of engineering plastics.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Ester type fire-resistant hydraulic fluid and preparation method thereof

InactiveCN103013635AInhibition of catalytic oxidationImprove stabilityLubricant compositionPhosphoric acidTriazole derivatives

The invention relates to an ester type fire-resistant hydraulic fluid. The hydraulic fluid comprises the following raw materials by weight percent: 95-99% of base oil, 1.0-5.0% of diphenol propane, 0.005% of dimethylsilicone fluid or dimethylsilicone grease, 0.05% of tricresyl phosphate, 0.1% of benzotriazole, 100 parts per million (PPM) demulsifying agent T1001 or LZ5957 and 0.2-0.3% of triazole derivative, thiadiazole derivative, N-salicylidene ethylamine, N, N'-bis(salicylidene)ethylenediamine, N, N'-bis(salicylidene)propylene diamine or ethylenediamine tetraacetic acid. A preparation method of the ester type fire-resistant hydraulic fluid comprises the following steps of sufficiently and evenly stirring various materials at room temperature according to a formula, and then filtering. The ester type fire-resistant hydraulic fluid has the beneficial effects that the high temperature use performance of the product is greatly improved, the service life of a hydraulic system and the oil changing period of oils are prolonged, and the ester type fire-resistant hydraulic fluid has a good flame-retardant effect and is safe to use. The preparation method has the advantages that operation is convenient, technology and equipment are simple, energy consumption is low, cost is low, and the like.

Owner:ANLU AOSEN PETROCHEM

High-expansion fireproof sealant and preparation thereof

ActiveCN101302420AImprove sealingSmall volume shrinkageNon-macromolecular adhesive additivesOther chemical processesFire resistanceSealant

The invention discloses high intumescent fire stopping mastic and a method for preparing the same. The mastic is prepared by taking acrylate emulsion (or elastic styrene-acrylate emulsion), polybutene (or polyisobutylene), glycol, emulsifying agent and tritolyl phosphate as base materials with addition of certain auxiliary materials. The preparation method is as follows: the base materials are added into a reaction kettle according to certain mass portion, stirred, slowly heated and insulated for a period of time, and transferred into a colloid stirrer; auxiliary materials such as ammonium polyphosphates, flame-retarding aluminum hydroxide, flame-retarding zinc borates, calcium carbonates, expandable graphite, iron oxide red and glass fibers are gradually added into the mixture under the condition of stirring; and the process of stirring is continued until a colloid is uniform. The fire stopping mastic prepared by adoption of the method can be quickly carbonized and expanded to 5 to 8 times of the prior volume in case of fire, and can not fall off; the strength and the heat insulation after solidification are good, and the fire resistance is very good; and the adhesion is strong and the elasticity is good. The high intumescent fire stopping mastic and the method are particularly suitable for fire compartmentation of various penetrating penetration assemblies such as cables, cable bridges, pipes and so on.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Weatherproof and wear-resisting cable sheath material

InactiveCN104231600AImprove wear resistanceImprove mechanical propertiesInsulated cablesInsulated conductorsEpoxyCopper oxide

The invention discloses a weatherproof and wear-resisting cable sheath material which comprises the following raw materials in parts by weight: 40-60 parts of thermoplastic polyurethane elastomer, 20-30 parts of chloroprene rubber, 20-30 parts of chlorinated polyethylene, 30-45 parts of nano-titanium dioxide / graphene oxide, 10-15 parts of modified nano talcum powder, 20-35 parts of coupling-agent-modified attapulgite, 3-5 parts of activated zinc oxide, 4-9 parts of stearic acid, 10-18 parts of expansible graphite, 3-7 parts of copper oxide, 5-12 parts of ferric oxide, 5-9 parts of coupling-agent-modified ammonium polyphosphate, 3-6 parts of sulfur, 2-3.5 parts of tricresyl phosphate, 0.5-2 parts of oxidic polyethylene, 3.5-4.5 parts of an accelerant TMDT, 2-5 parts of an anti-aging agent, 1-2.8 parts of epoxy flaxseed oil and 1-1.8 parts of triethyl O-acetylcitrate. The weatherproof and wear-resisting cable sheath pipe has the advantages of good weather resistance, high wear resistance, good mechanical property and long service life.

Owner:无为县华祥电缆材料有限公司

Polypropylene hollow fiber ultrafiltration membrane coated with polymer composite coating

ActiveCN105080361AImprove antibacterial propertiesHigh strengthAntifouling/underwater paintsUltrafiltrationEpoxyFiber

The invention relates to a polypropylene hollow fiber ultrafiltration membrane coated with a polymer composite coating. The polypropylene hollow fiber ultrafiltration membrane comprises a water inlet surface and a water outlet surface which are respectively coated with a coating; the coating on the water inlet surface comprises the following raw materials: tricresyl phosphate, dioctyl phthalate, a modified polysiloxane polymer, polyether-ether-ketone (PEEK), methenamine and the like; and the coating on the water outlet surface comprises the following raw materials: allyl polyoxy alkyl epoxy ether, pentaerythritol, polyethylene glycol lauric acid diester, polyoxyethylene alkylamine, nano silver and the like. The polypropylene hollow fiber ultrafiltration membrane is capable of increasing the retention rate for macromolecular organic matter and emulsified oil, so that the COD removal rate of sewage is greatly increased, the electrostatic effect on the surface of the membrane is changed, the adsorption for contaminants of the surface of the membrane is prevented, the membrane can be continuously used for a long time under the condition of high membrane flux, and the service life of the membrane is prolonged. The addition of the nano silver effectively improves the antibacterial mildew properties of the membrane.

Owner:广州市纳清环保科技有限公司

PET (polyethylene glycol terephthalate) fiber/polyacrylonitrile fiber composite sound absorbing cotton and preparation method of PET fiber/polyacrylonitrile fiber composite sound absorbing cotton

InactiveCN102965847AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesPolymer scienceAntioxidant

The invention discloses PET (polyethylene glycol terephthalate) fiber / polyacrylonitrile fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of polyacrylonitrile fibers, 10 to 15 parts of emulsifying agents OP-20, 5 to 10 parts of peregal O-15, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SEBS (styrene ethylene butylene styrene), 15 to 20 parts of calcined clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of diisooctyl phthalate, 4 to 6 parts of tricresyl phosphate, 2 to 3 parts of polyethylene wax, 1 to 2 parts of vinyl (beta-methoxyethoxy) trisilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of dimethyl dimercapto isooctyl acetate tin, 0.5 to 1.5 parts of anti-aging agents ODA (octyl decyl adipate) and 1 to 2 parts of antioxidants 1035. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Flame-proof ABS factory formula and its production method

InactiveCN1765985AImprove flame retardant performanceIncreased melt flow ratePolymer scienceDecabromobiphenyl ether

The invention relates to product formula and preparation method of a flame-proof ABS. Wherein, the formula comprises mainly: ABS resin, antimony trioxide, decabromodiphenyl oxide, coupling-treated aluminum hydroxide, anti-oxidant 168, tricresyl phosphate, chlorinated polyethylene (CPE), polyvinyl chloride (PVC), EBS, magnesium stearate, SBS, nano-SiO2, and zinc borate. The preparation method comprises: mixing the ABS resin and tricresyl phosphate in high-speed mixer, adding other materials; putting into double screw extruder; cooling, granulating, screening, drying, and packaging. This product has well properties with low cost.

Owner:王崇高

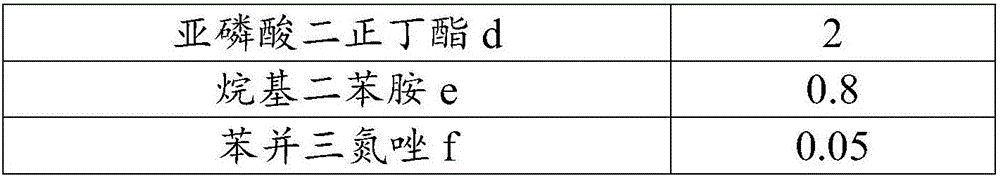

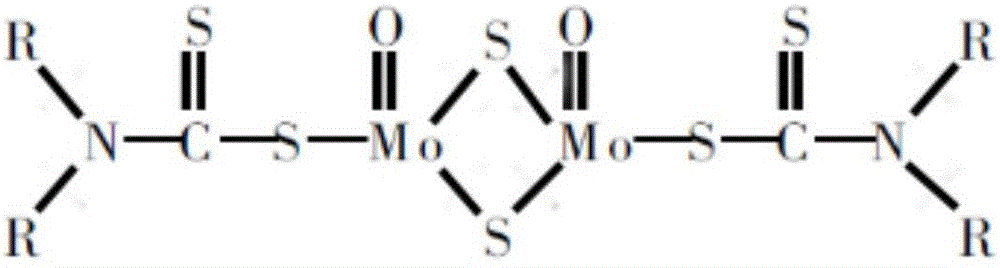

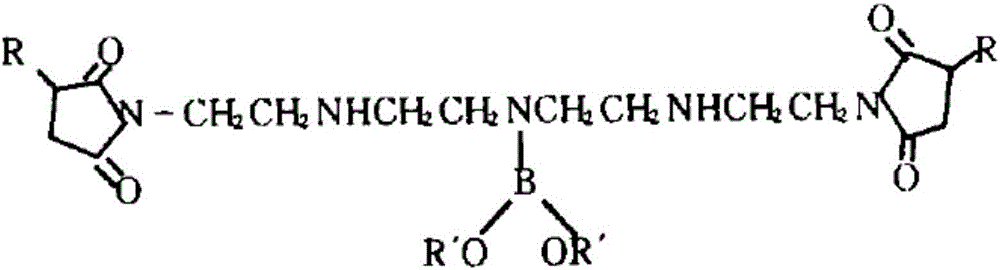

Ash-free anti-wear hydraulic lubricating oil composition and preparation method thereof

InactiveCN107760418AImprove antioxidant capacityImprove anti-wear performanceLubricant compositionAntioxidantPhosphate

The invention discloses an ash-free anti-wear hydraulic lubricating oil composition and a preparation method thereof. The ash-free anti-wear hydraulic lubricating oil composition consists of the following components in percentage by weight: 0.1-5.0% of an extreme pressure anti-wear reagent, 0.05-2.00% of an antioxidant, 0.01-0.5% of a metal deactivating agent, 0.05-0.1% of an anti-rusting agent, 0.03-0.06% of an emulsification resistant agent, 0.001-0.01% of an anti-foam agent, 0.2-6.5% of a viscosity index improver and 92.0-98.6% of basic oil, wherein the extreme pressure anti-wear reagent issulfurized isobutylene, di-n-butyl phosphate, tricresyl phosphate, phosphorothioate and amino salt derivatives thereof, phosphate and amino salt derivatives thereof, or a mixture of any combination of the components. The preparation method comprises the following steps: putting the antioxidant, the extreme pressure anti-wear reagent, the anti-rusting agent, the metal deactivating agent, the anti-foam agent, the emulsification resistant agent and the viscosity index improver respectively into the basic oil, or mixing additives to prepare a concentrated substance, heating and mixing the concentrated substance with the basic oil at a mixing temperature between 40-90 DEG C for 1-6 hours, and filtering. The ash-free anti-wear hydraulic lubricating oil composition disclosed by the invention isexcellent in high-temperature oxidation resistance, high-pressure wearing resistance and extreme pressure resistance, and specification indexes of GB11118.1 and ISO11158-2009 can be met.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

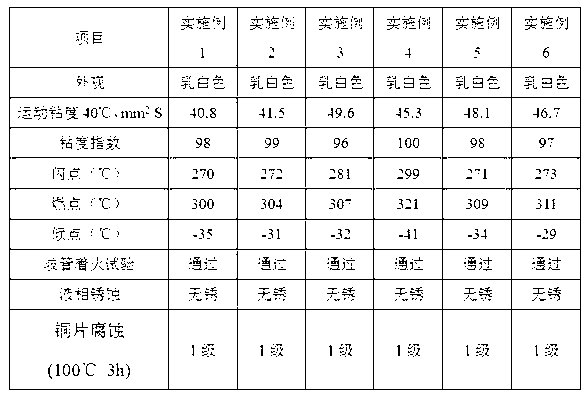

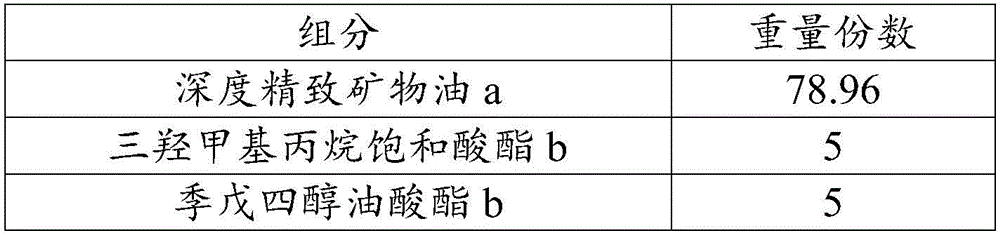

Cold rolling emulsified oil for copper and copper alloy and method for manufacturing same

InactiveCN101307270AHigh surface finishLong period of anti-corrosionAdditivesBase-materialsAlkaneOleic Acid Triglyceride

The invention belongs to the lubricant field, in particular relating to copper and copper alloy cold rolling emulsifying oil with good stability and a manufacturing method thereof. The compositions by weight percentage are as follows: 60 to 70 percent of neutral machine oil, 4 to 6 percent of palm oil, 3 to 6 percent of sulfurized castor oil, 6 to 9 percent of Arlacel-80, 4 to 7 percent of Tween-60, 1 to 3 percent of oleic acid, 1 to 2 percent of trolamine, 3 to 6 percent of sodium alkane sulfoate with 35 to 45 percent of active matter, 1 to 3 percent of tricresyl phosphate, and 0.01 to 0.1 percent of benzotriazole. The emulsifying oil is produced through the method of stepping, adding and stirring, and heating. When the emulsifying oil is diluted into emulsified liquid with a volume concentration between 1 and 8 percent by water, the emulsified liquid can be directly used for machining processes such as cold rolling of sheet materials and belt materials and the drawing of rod materials of copper and copper alloy and so on. The emulsifying oil has high product surface finish, long anti-corrosion period, good cleanliness of annealing surfaces, no toxicity, no pungent smell, convenient operation, and low cost.

Owner:UNIV OF SCI & TECH BEIJING

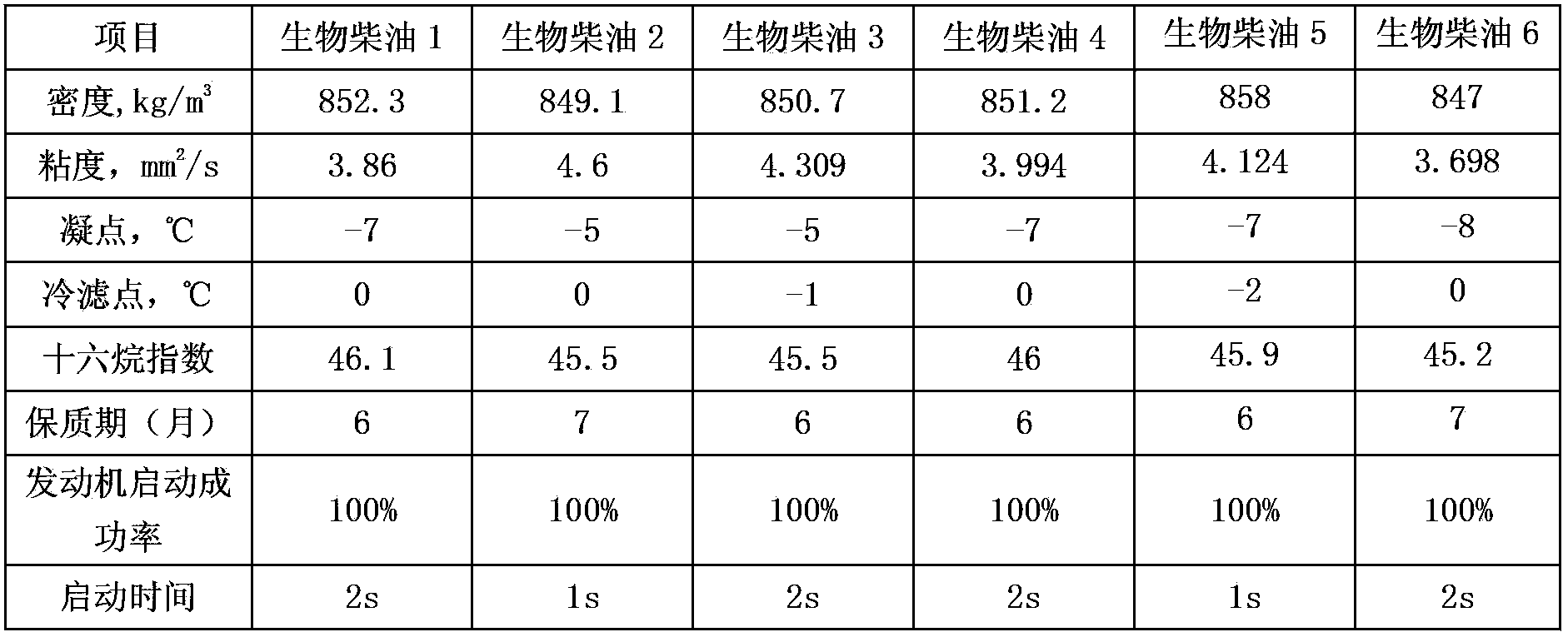

Biodiesel and preparation method thereof

InactiveCN103509611APowerfulHigh calorific valueBiofuelsLiquid carbonaceous fuelsIsobutanolAntioxidant

The invention discloses a biodiesel and a preparation method thereof. The biodiesel comprises a methanol-based fuel, an additive, and common fossil diesel. The additive is prepared from a pH value buffering pair composed of sodium petroleum sulfonate and barium petroleum sulfonate, isobutanol, tricresyl phosphate, dimethyl carbonate, an organic solvent, isooctyl nitrate, co-emulsifying dispersing agent and an antioxidant according to a certain process method. The biodiesel prepared with the method provided by the invention has the advantages of high cetane number, high flash point, low corrosion, low emission, and low cost. The biodiesel can be used for replacing common diesel in the fields such as boilers, vehicles and vessels. The biodiesel has substantial energy-saving and emission-reducing effects.

Owner:东莞恒量新能源科技有限公司 +1

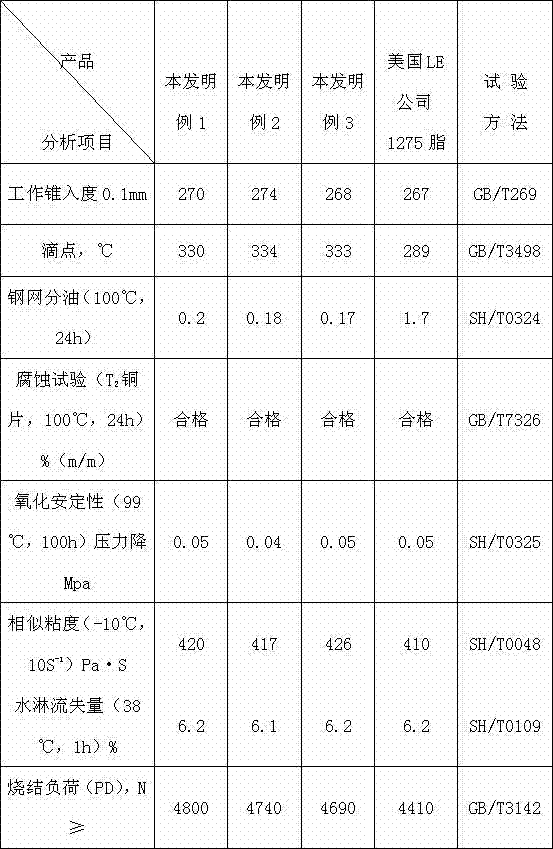

1206 lubricating grease

InactiveCN103897781AEnhanced pumpabilityGood reversibilityLubricant compositionBenzoic acidPhosphoric acid

The invention relates to a 1206 lubricating grease, comprising the following components by weight percent: 2-4% of aluminum isopropoxide, 4-6% of aminated bentonite, 3-5% of stearic acid, 1-3% of benzoic acid, 37-41% of viscous oil in refined naphthenic base, 29-43% of viscous oil in refined paraffin base, 1-3% of zinc dialkyl dithiophosphate, 1.6-2.9% of triazole fatty acid ammonium salt, 0.1-0.5% of a triazole derivative, 0.8-1.8% of tricresyl phosphate, 1.2-5% of polyisobutene and 0.7-1% of ethyl carbamate. Compared with the prior art, the 1206 lubricating grease is high in dropping point, large in sintering load data and relatively good in compression and wear resistance, and the more outstanding feature is as follows: the steel mesh is excellent in oil dividing, the embodiment 3 is 1 / 10 of the 1275 grease of LE company of America, and the embodiment 1 is not greater than 1 / 8; obviously, the pollution in the operation is smaller, the resource can be saved more, and the operation period of the equipment can be prolonged.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

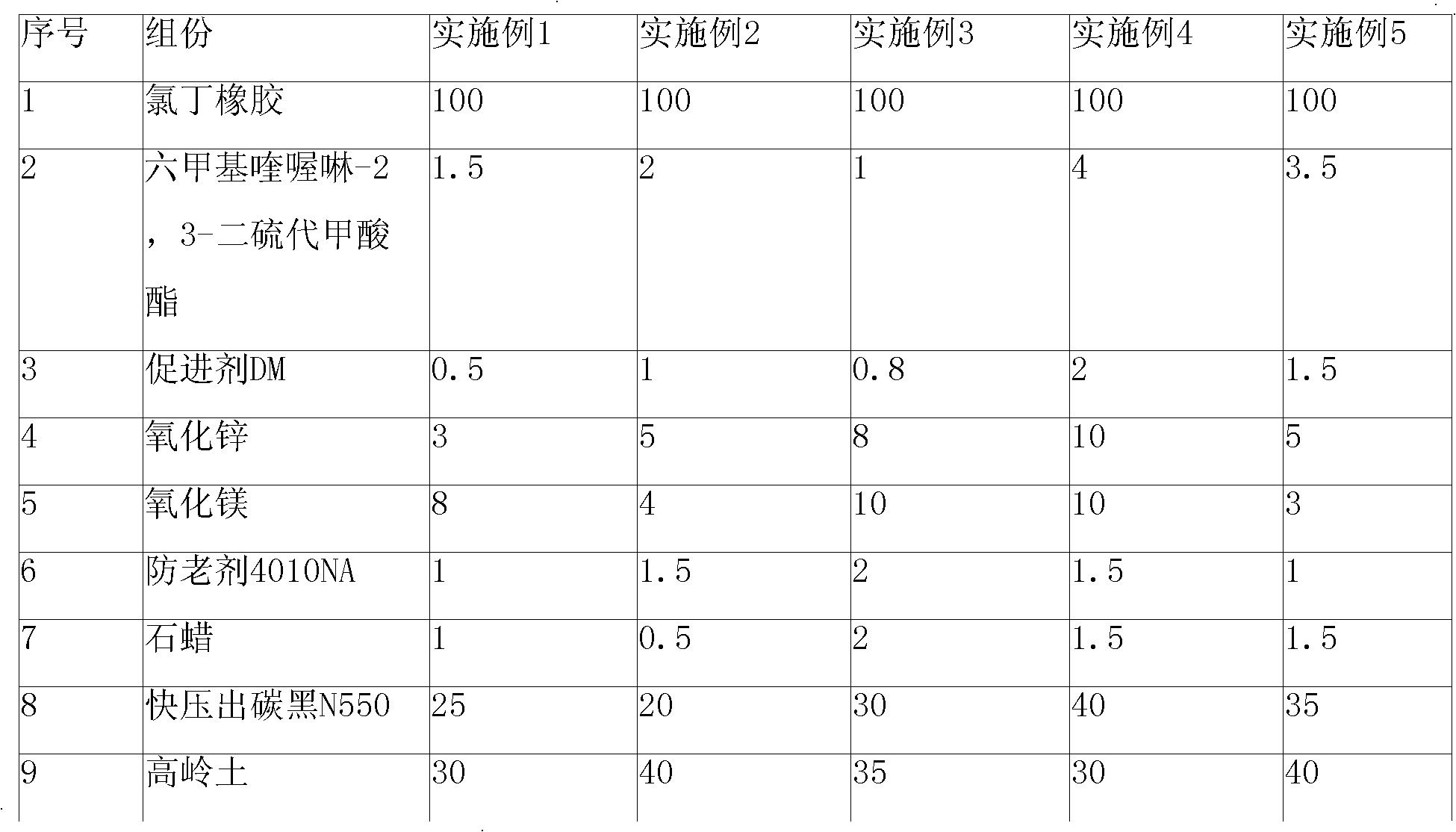

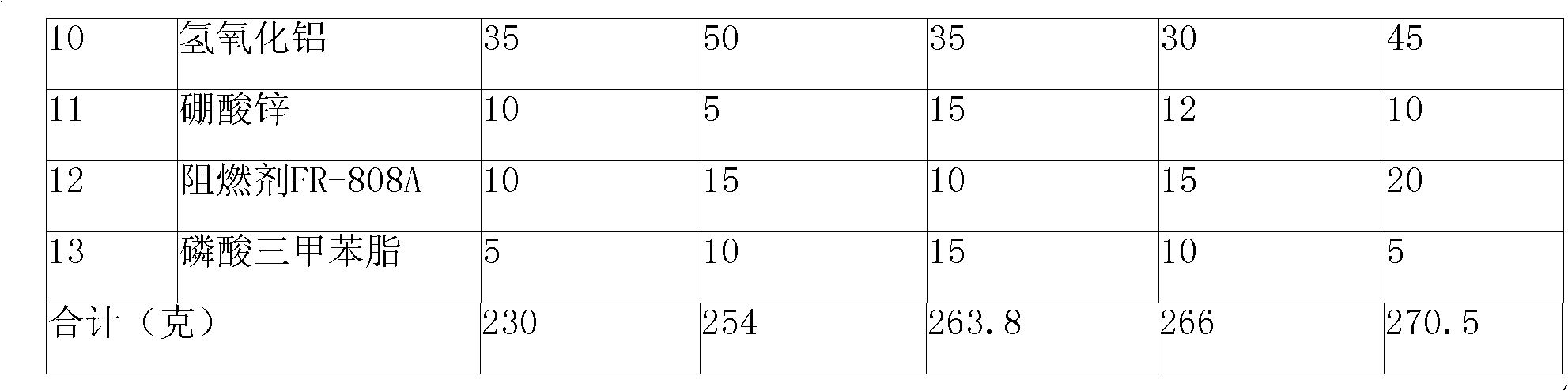

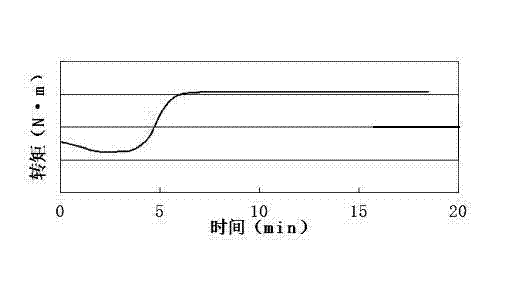

Formula of environment-friendly flame-retardant chloroprene rubber

The invention relates to the formula of environment-friendly flame-retardant chloroprene rubber. The flame-retardant chloroprene rubber, according to the formula thereof, comprises the following components by weight part: 100 parts of chloroprene rubber, 1 to 4 parts of hexamethyl-quinoxaline-2,3-dithioformate, 1 to 2 parts of DM as accelerator, 3 to 10 parts of zinc oxide, 3 to 10 parts of magnesium oxide, 1 to 2 parts of 4010NA as anti-ager, 0.5 to 2 parts of paraffin, 20 to 40 parts of FEF (fast-extruding furnace) carbon black (N550), 30 to 40 parts of kaolin, 30 to 50 parts of aluminum hydroxide, 5 to 15 parts of zinc borate, 10 to 20 parts of FR-808A and 5 to 15 parts of tricresyl phosphate. According to the comparative analysis on the performance of the chloroprene formula using halogen-containing flame retardant and the chloroprene rubber formula using halogen-free flame retardant, the performance of the formula using the halogen-free flame retardant in the invention can fully satisfy the requirements of standards, thus substituting for the chloroprene formula using the halogen-containing flame retardant; and based on the chloroprene rubber formula, the invention can meet the requirements of the flame-retardant application, and the materials of the formula are environment friendly and safe for human bodies.

Owner:TIANJIN PENGYI GRP CO LTD

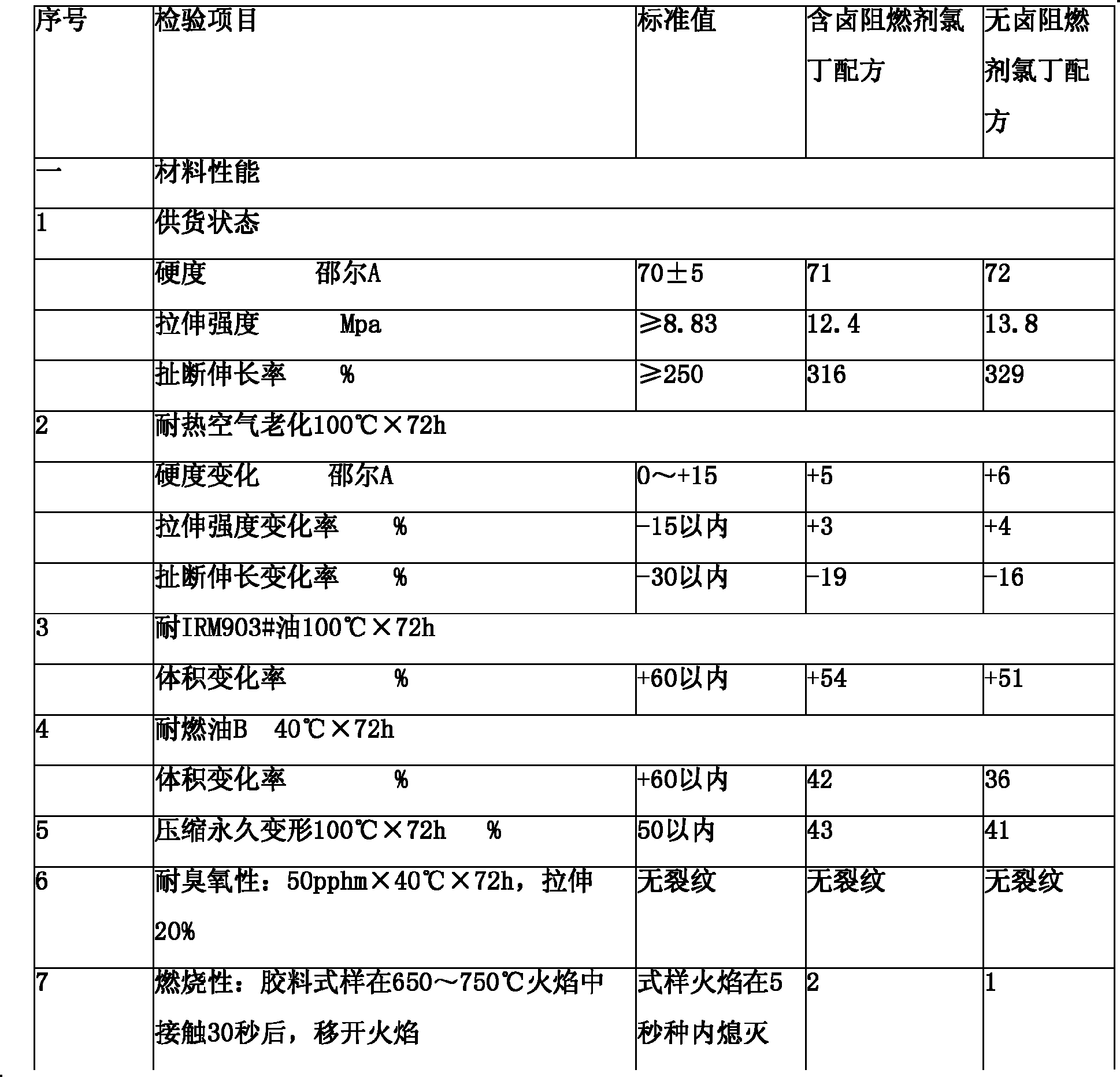

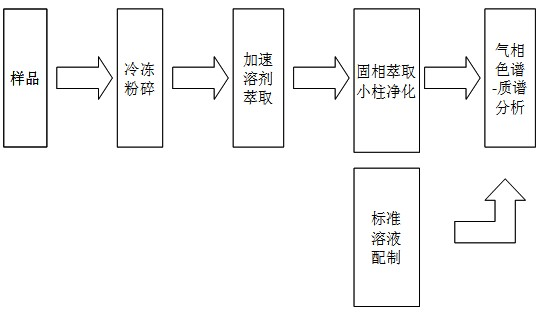

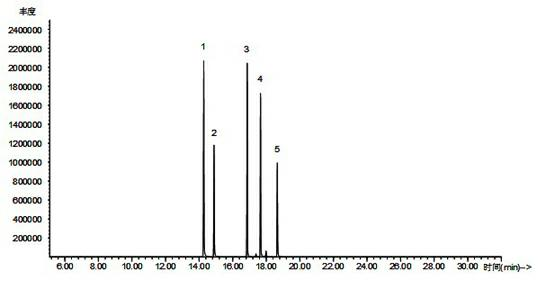

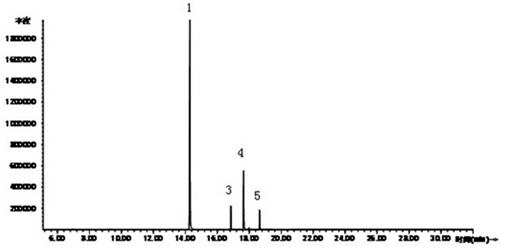

Determination method for content of tricresyl phosphate flame retardants in rubber parts of electronic and electrical products

The invention discloses a method for detecting the content of a triocresyl phosphate fire retardant of a rubber part of an electrical or electronic product. The method comprises the following steps of: (1) sample preparation; (2) extraction of the triocresyl phosphate fire retardant: adding heavy metal powder into the sample, uniformly mixing and performing accelerated solvent extraction so as to obtain extract; (3) extract purification: uniformly mixing the extract and an interior label, transferring to a small solid phase extraction column, eluting by using a mixed solvent, collecting and concentrating eluent so as to obtain the purified extract; and (4) measurment of the triocresyl phosphate fire retardant: measuring the purified extract and the triocresyl phosphate mixed standard solution containing the interior label by using a gas chromatography-mass spectrometer, and performing data processing and quantitative analysis to obtain the content of the triocresyl phosphate fire retardant. By the method, interference impurities in the rubber can be eliminated effectively, triocresyl phosphate can be extracted fully, the purification degree is high, the detection sensitivity is high and the sample measurement cost is low.

Owner:广东德威检验认证有限公司

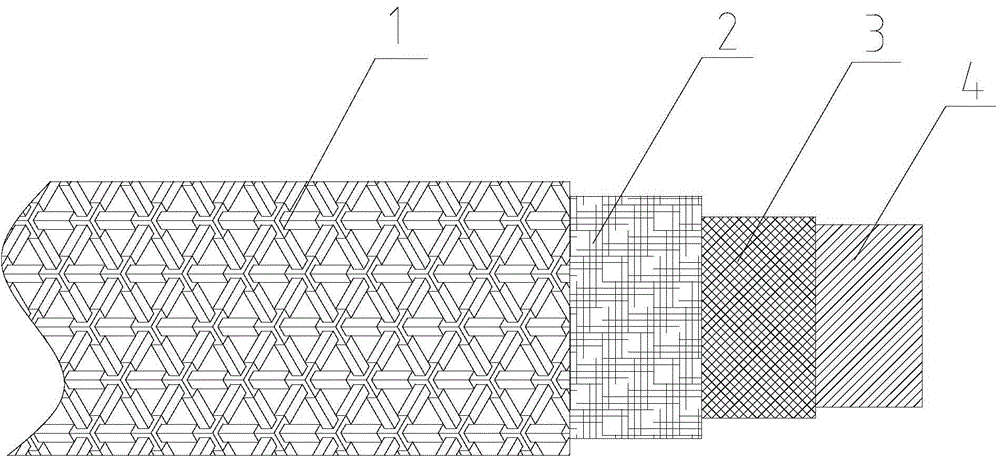

Heat-resistant and oil-resistant rubber hose

InactiveCN104976446AHigh temperature resistantWith pressureFlexible pipesRubber materialPolymer science

The invention provides a heat-resistant and oil-resistant rubber hose. The heat-resistant and oil-resistant rubber hose comprises an outer rubber layer, an inner rubber layer and a framework layer located between the outer rubber layer and the inner rubber layer. The inner rubber layer is composed of, by mass, 100 parts of hydrogenated acrylonitrile butadiene rubber, 30-40 parts of semi-reinforcing carbon black, 20-30 parts of fast extruding furnace black, 15 parts of white carbon black, 5-10 parts of tricresyl phosphate, 0.5-1.5 parts of stearic acid, 1-3 parts of 2,2'-diurethane dimethacrylate-(4-methyl-6-tert-butylphenol), 1-2 parts of polyethylene glycol 4000, 4-6 parts of activated zinc oxide, 0.5-2 parts of accelerant DM, 0.8 part of vulcanizing agent dicumyl peroxide, 1 part of sulphur, 2-3 parts of assistant crosslinker triallylisocyanurate. The heat-resistant and oil-resistant rubber hose further comprises a middle rubber layer. The middle rubber layer is composed of, by mass, 90-110 parts of rubber, 0.5-1.5 parts of active agent, 10-12 parts of vulcanizing agent, 1-2 parts of accelerant, 32-48 parts of reinforcing agent, 16-24 parts of plasticizer, 2-3 parts of anti-aging agent and 20-30 parts of binding agent. By the adoption of the optimum rubber material formula, the heat-resistant and oil-resistant rubber hose has the excellent advantage of being resistant to high temperature, oil, pressure and deflection.

Owner:青岛橡六胶管有限公司

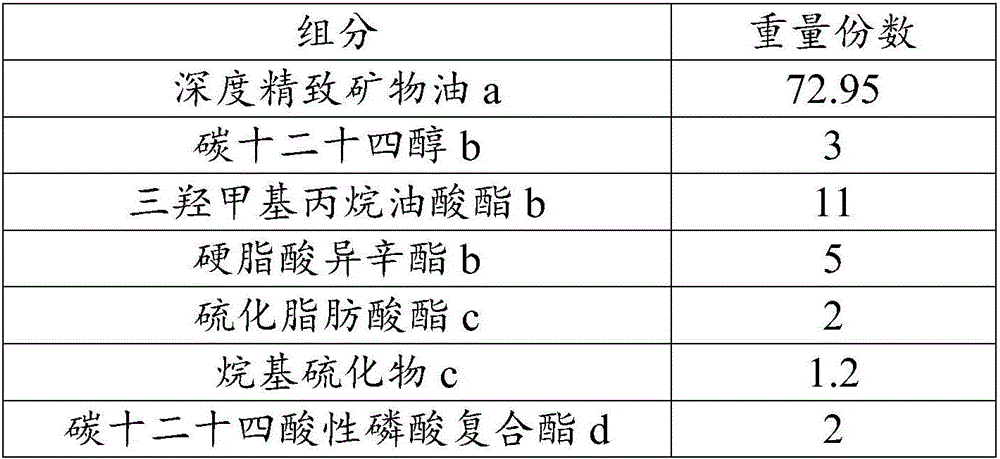

High-lubricating rolling oil composition and application thereof

ActiveCN106318568AImprove the lubrication effectMeet lubrication needsLubricant compositionPhosphateButylated hydroxytoluene

The invention relates to a high-lubricating rolling oil composition and application thereof. The composition is prepared from 40-90 parts of highly refined mineral oil, 10-30 parts of carbon dodecanol tetradecyl alcohol, isotridecyl alcohol, n-octanol, pentaerythritol oleate, trimethylolpropane trioleate, diisooctyl phthalate, 2-ethylhexyl palmitate, isooctyl stearate, methyl palmitate or butyl stearate, 1-5 parts of ZDTP, octadecyl zinc dithiophosphate, sulfurized olefin, sulfide aliphatic acid ester, sulfurized animal oil, alkyl sulfide or sulfur phosphorus molybdenum, 0.5-5 parts of amine thiophosphate, isooctyl acidic phosphate octadecylamine, tricresyl phosphate, tributyl phosphate, dibutyl phosphate and carbon-12 to carbon-14 acid phosphate compound ester, 0.1-5 parts of 2,6-butylated hydroxytoluene, N-phenyl naphthylamine, thioether phenol or alkyl diphenylamine and 0.01-2 parts of 1H-benzotriazole, thiadiazole derivative and benzotriazole.

Owner:CHINA PETROLEUM & CHEM CORP

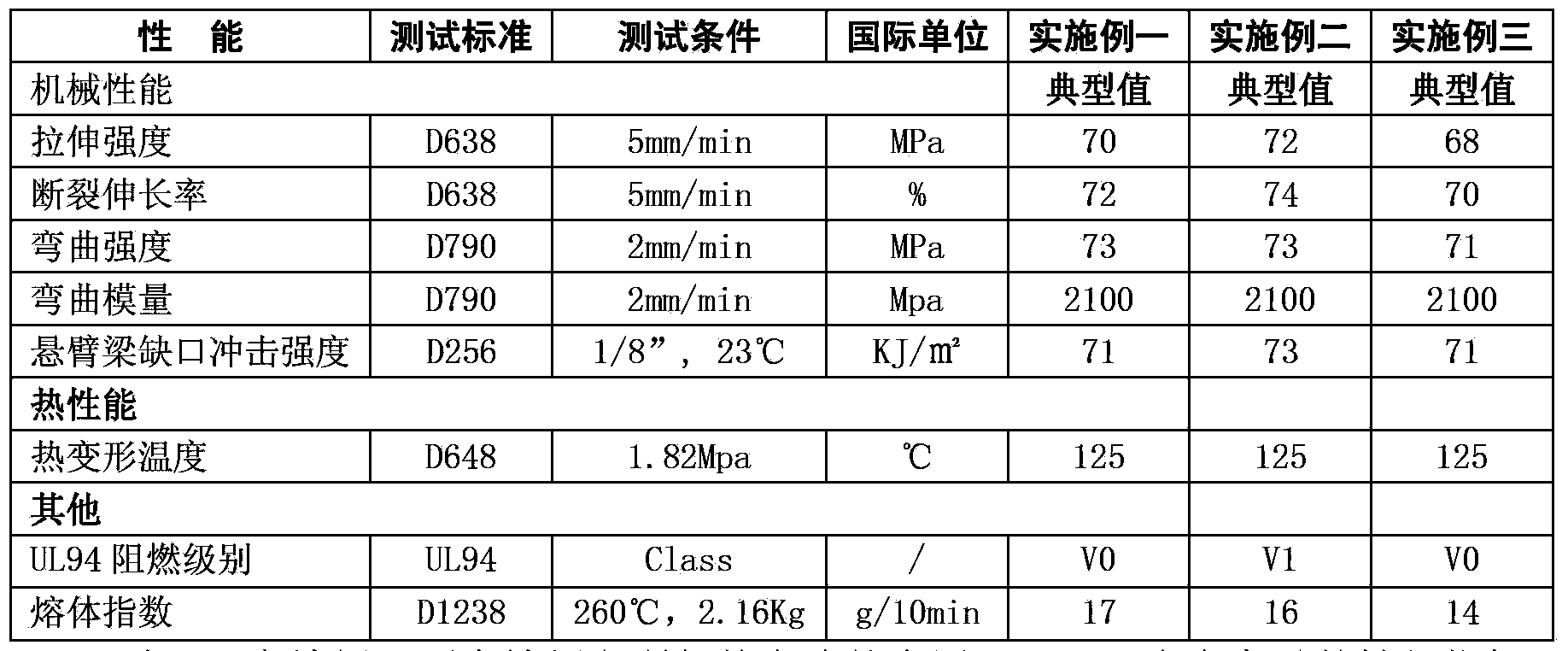

High-toughness heat-resisting ABS resin

The invention belongs to the technical field of chemical industry and relates to a production formula of a high-toughness heat-resisting ABS resin and a preparation method thereof, the formula comprises ABS resin powder, antioxidant 168, antioxidant 1010, tritolyl phosphate, magnesium stearate, nano-silicon dioxide (Nano-SiO2), polycarbonate resin (PC) and polyurethane resin. The preparation method according to the invention comprises the steps: uniformly mixing the ABS resin powder and the tritolyl phosphate in a high-speed mixer, sequentially adding the rest materials in the formula into the high-speed mixer, uniformly mixing and then feeding the materials into a double screw extruder, and obtaining the high-toughness heat-resisting ABS resin by water-cooling, granulating, sieving, drying and packaging the materials extruded out of the double screw extruder. The resin has the characteristics of good heat resistance, high impact strength, excellent toughness and low production cost.

Owner:王崇高

Fuel oil blending additive and preparation method thereof

InactiveCN103509615APowerfulHigh calorific valueLiquid carbonaceous fuelsFuel additivesFuel oilCold filter plugging point

The invention provides an additive for blending fuel oil. The additive comprises an emulsifier formed by complexing a Span-series emulsifier and a Tween-series (or OP-10) emulsifier, a pH value buffering pair formed by combination of sodium petroleum sulfonate and barium petroleum sulfonate, tricresyl phosphate, isooctyl nitrate, a co-emulsifying dispersing agent, an antioxidant, isobutyl alcohol and an organic solvent. The additive is prepared according to certain content and a certain preparation method. The additive can be used for blending methanol, methanol-oleic acid mixture, and other methanol modified complex into a biological fuel oil, and can be used for further blending biodiesel. The blended biological fuel oil and the biodiesel have the advantages of high cetane number, high flash point, low pour point, low cold filter plugging point, low corrosivity, low emission, and low cost.

Owner:刘粤荣 +1

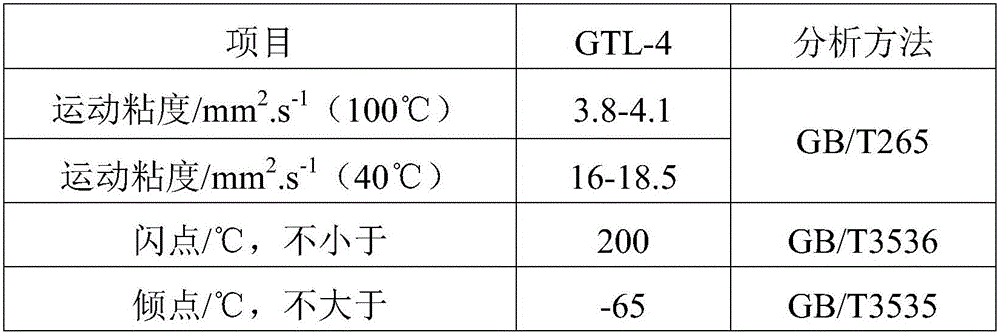

Energy-saving engineering machinery hydraulic oil with high viscosity index and ultralow temperature

ActiveCN105695057AMeet the needs of normal operationModerate kinematic viscosityLubricant compositionFatty amineHigh pressure

The invention discloses energy-saving engineering machinery hydraulic oil with a high viscosity index and an ultralow temperature. The energy-saving engineering machinery hydraulic oil is composed of, by weight, 0.1-1 part of tricresyl phosphate, 0.5-1.5 parts of an antiwear agent, 3-7 parts of benzene triazole fatty amine, 1-5 parts of ethylene glycol oleate, 70-90 parts of viscosity index improvers, 1-3 parts of purification dispersant, 1-3 parts of antioxygen, 2-4 parts of 4, 4'-di-iso-octyldiphenylamine, 3-9 parts of pour point depressant, 0.01-0.05 part of an anti-foaming agent and 800-1000 parts of base oil. According to the energy-saving engineering machinery hydraulic oil, an ash-free extreme pressure antiwear additive agent is adopted for complex formulation, applicability is wider, abrasion resistance is better, efficiency is higher, and lubrication of a plunger pump of a hydraulic transmission system with high power and high pressure can be effectively met; preferably, compatibility between an oiliness agent and the antiwear agent with the base oil is good, and lubrication guarantee can be provided in time in different work stages; equipment can operate steadily, pressure transfer is even, frication is lowered, abrasion is reduced, temperature rise is low, heat dissipation is high in speed, the power loss is lowered, energy consumption is saved, and the oil exchange cycle is prolonged.

Owner:北京雅士科莱恩石油化工有限公司

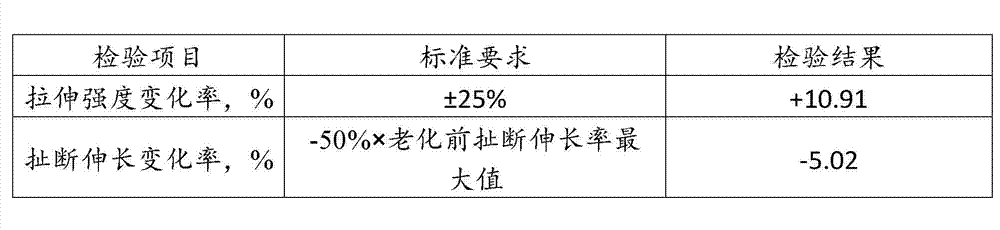

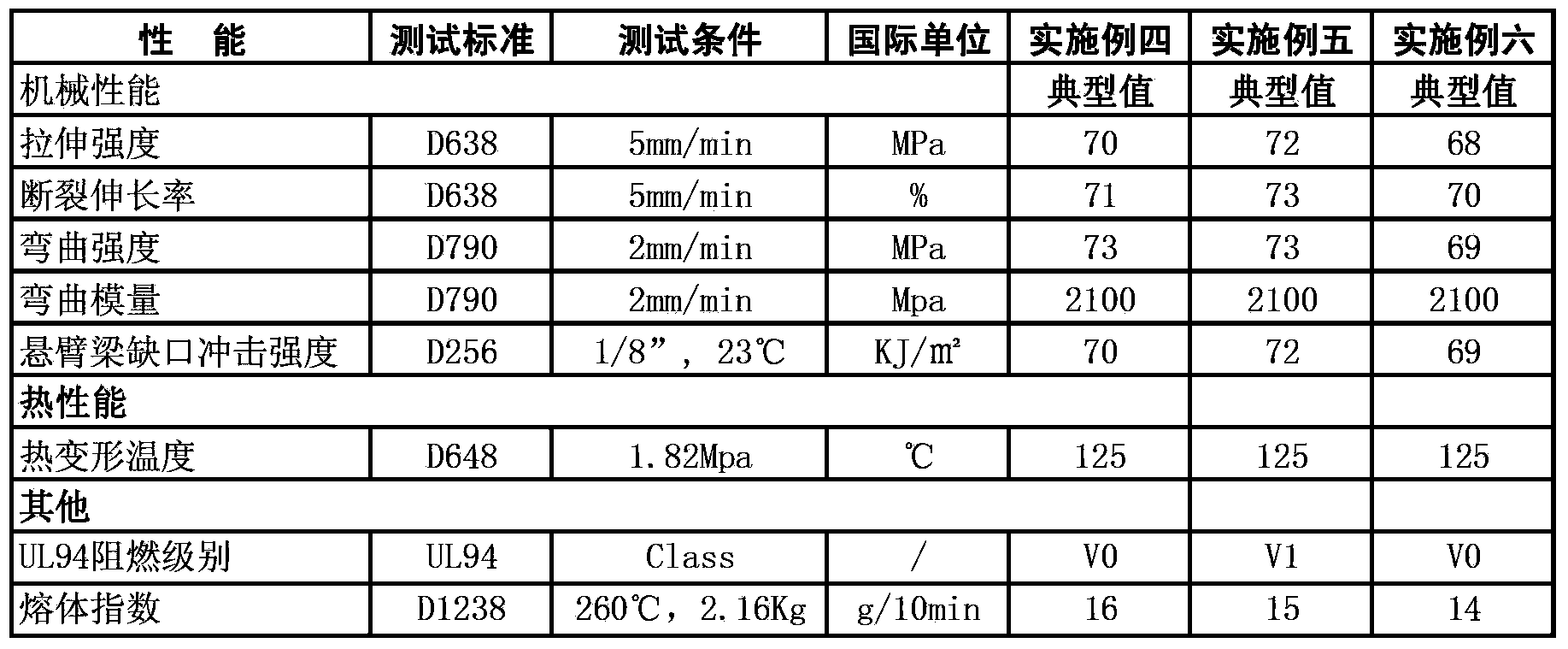

Seismic isolation rubber bearing protective rubber composite with good anti-aging performance

The invention relates to a seismic isolation rubber bearing protective rubber composite with a good anti-aging performance, relating to the technical field of rubber products. The seismic isolation rubber bearing protective rubber composite comprises the following components according to parts by weight: 40-60 parts of natural rubber, 40-60 parts of ethylene propylene diene monomer, 35-45 parts of high abrasion furnace black N330, 3-8 parts of zinc oxide, 1.5-2.5 parts of stearic acid, 0.8-1.5 parts of insoluble sulfur, 0.5-3.5 parts of accelerant CZ, 1-2 parts of antiager 616, 1-2 parts of antiager phosphite ester, 5-10 parts of softener tricresyl phosphate, 5-7 parts of softener paroline 100, 3-5 parts of softener coumarone, 1-3 parts of coupling reagent Si-69, and 0.2-0.5 parts of anti-reversion agent wk-901. A rubber composite, which has good flame retardance, thermostability and relative physical and mechanical properties as well as environment-friendly and nontoxic addition agent and the anti-aging performance of which can meet the designed service life requirement of a structure, is provided for the seismic isolation rubber bearing protective rubber.

Owner:YUNNAN QUAKESAFE SEISMIC ISOLATION TECH

Zirconium oxide-loaded silicone air filtration paper and preparation method thereof

ActiveCN102888785AImprove adsorption capacityImprove filtering effectFiltration separationInorganic compound additionAir filtrationFiber

The invention discloses zirconium oxide-loaded silicone air filtration paper and a preparation method thereof. The air filtration paper comprises the following raw materials in part by weight: 70 to 80 parts of wood pulp, 20 to 30 parts of jute pulp, 10 to 20 parts of ceramic fiber, 2 to 5 parts of modified silicone, 1 to 3 parts of nano calcium carbonate, 2 to 4 parts of activated carbon, 1 to 2 parts of nano aluminium oxide, 0.5 to 0.8 part of ammonium polyphosphate, 2 to 3 parts of acrylic latex, 1 to 2 parts of polyethylene glycol, 0.5 to 1 part of tricresyl phosphate, 0.5 to 1 part of anilmomethyl triethoxy silane, 0.4 to 0.8 part of sodium lauryl sulfate and 2 to 5 parts of modified polyethyleneimine. The prepared filtration paper has the advantages of high water permeability, filtration accuracy, bursting strength and tensile strength, large filtration area, high temperature resistance and the like, the maximum aperture is small, and the filtration efficiency reaches 99.98 percent; and the filtration paper has a stable performance index under the working conditions of normal temperature and high temperature and has relatively good heat resistance and filtration effects.

Owner:ANHUI PHOENIX INT CO LTD

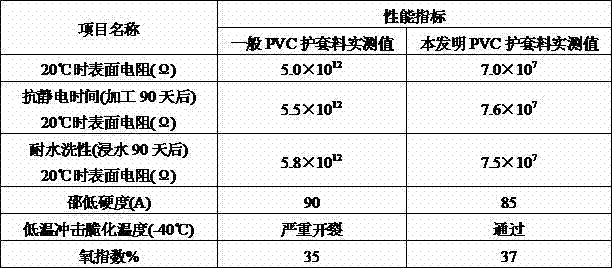

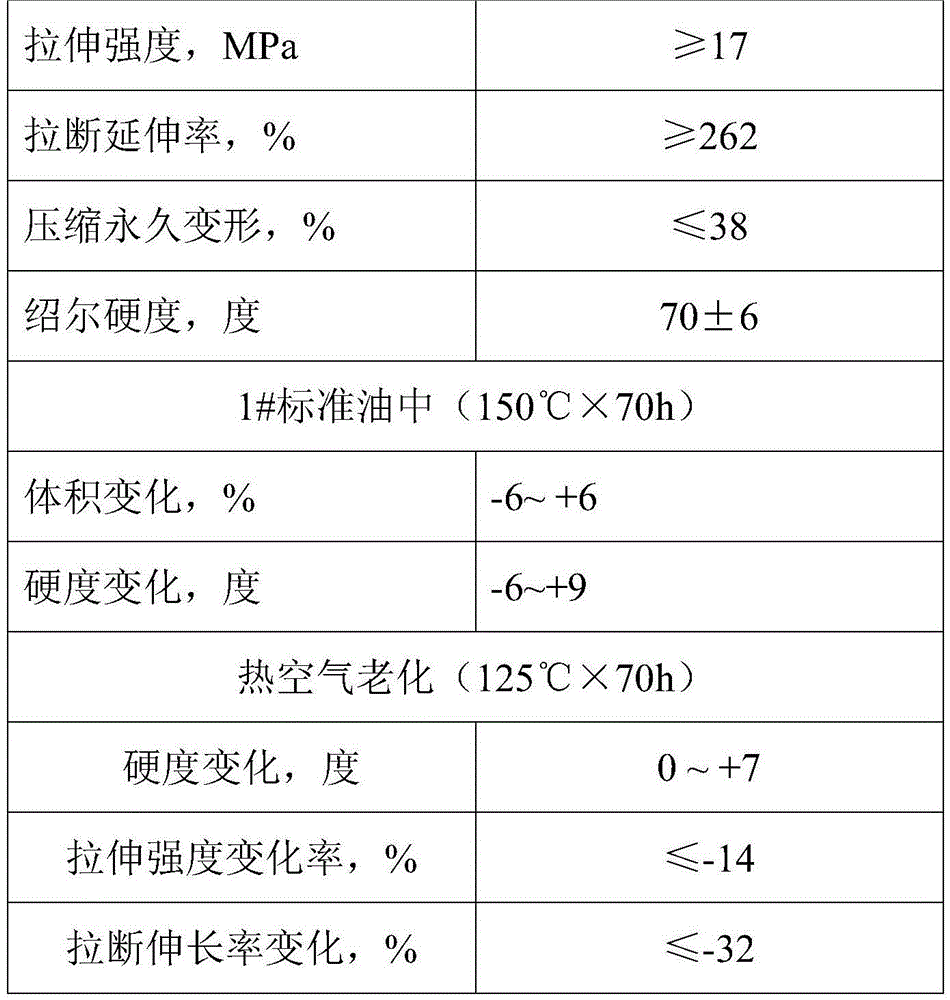

Cold-resistant flame-retardant anti-static polyvinyl chloride sheathing material for coal mine cable

ActiveCN103113692ALower surface resistance valueImprove antistatic performanceInsulated cablesInsulated conductorsPhosphatePolyvinyl chloride

The invention discloses a cold-resistance flame-retardant anti-static polyvinyl chloride sheathing material for coal mine cable; the sheathing material is characterized by consisting of the following raw materials: polyvinyl chloride resin SG3, tri(2-chloroethyl) phosphate, an anti-static agent, dioctyl sebacate, dioctyl phthalate, tricresyl phosphate, antimonous oxide, zinc borate, tribasic lead sulfate, bibasic lead sulfate, light calcium carbonate, bisphenol A, 2-mercapto benzimidazole, vinyl tri(beta-methoxyl ethyoxyl) silane, accelerant TMTD and modified asbestos powder; the polyvinyl chloride sheathing cable material provided by the invention has the following characteristics of being low in surface resistance value and high in anti-static property; by adopting the compound high-concentration anti-static agent consisting of TCEP (trichloroethyl phosphate), quaternary ammonium salt cationic surface active agent and nonionic surface active agent, the excellent anti-static synergistic effect can be brought; the surface resistance value of the sheathing material is no higher than 108ohms, and thus the sheathing material has excellent anti-static property.

Owner:安徽龙庵电缆集团有限公司

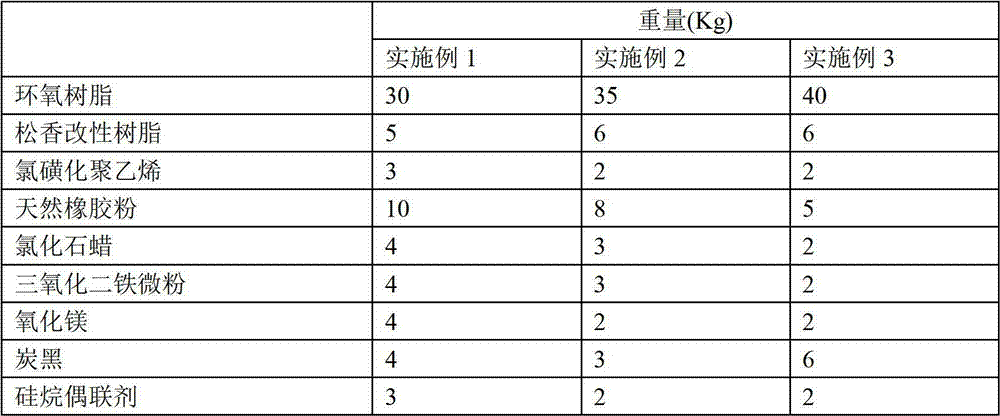

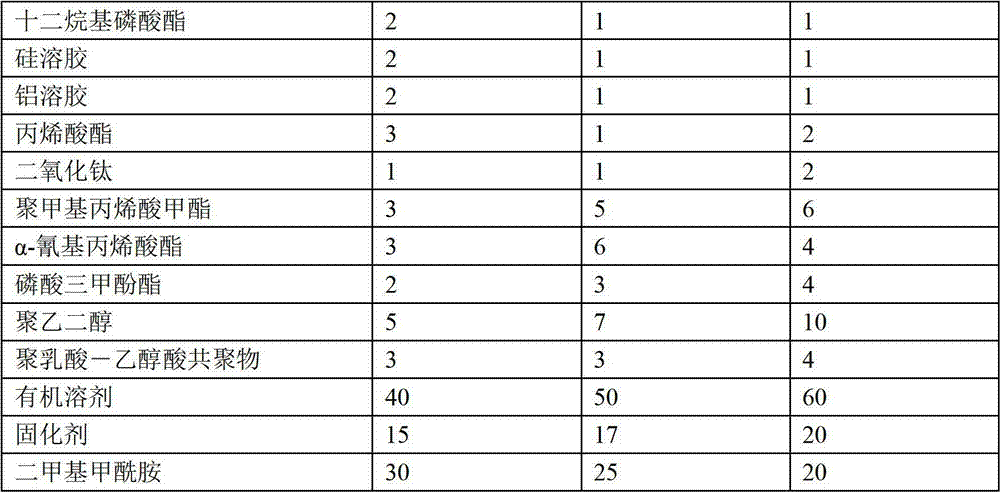

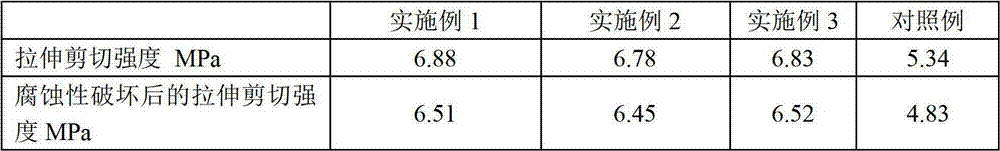

Epoxy resin adhesive for bonding fluororubber and metal

InactiveCN102876242AHigh bonding strengthNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePhosphatePolyethylene glycol

The invention provides an epoxy resin adhesive for bonding fluororubber and metal. The adhesive comprises component A and component B. The component A comprises the following materials by weight: 30-40 parts of epoxy resin, 5-6 parts of rosin-modified resin, 2-3 parts of chlorosulfonated polyethylene, 5-10 parts of natural rubber powder, 2-4 parts of chlorinated paraffin, 2-4 parts of ferric oxide micropowder, 2-4 parts of magnesia, 3-6 parts of carbon black, 2-3 parts of a silane coupling agent, 1-2 parts of dodecyl phosphate, 1-2 parts of silica sol, 1-2 parts of alumina sol, 1-3 parts of acrylate, 1-2 parts of titanium dioxide, 3-6 parts of polymethyl methacrylate, 3-6 parts of alpha-cyanoacrylate, 2-4 parts of tricresyl phosphate, 5-10 parts of polyethylene glycol, 3-4 parts of poly(lactic acid-co-glycolic acid), and 40-60 parts of organic solvent. The component B comprises the following materials by weight: 15-20 parts of a curing agent, and 20-30 parts of dimethyl formamide.

Owner:上海拜高高分子材料有限公司

Method for preparing flame-retardant fabric finishing agent

InactiveCN103790006AExcellent flame retardant effectGood flame retardancyFibre treatmentAmezinium methyl sulfateFire resistance

The invention discloses a method for preparing a flame-retardant fabric finishing agent. The method comprises the following steps: (1) grinding 2-3 weight parts of diammonium hydrogen phosphate, 15-17 weight parts of borax, 8-9 weight parts of trimethylol tripolyamide , 2-3 weight parts of tetrakis hydroxyethyl phosphorus chloride and 6-7 weight parts of sodium silicate, and uniformly mixing; (2) simultaneously adding 2-3 weight parts of dodecyl trimethyl ammonium sulfate, 5-6 weight parts of magnesium chloride, 150-180 weight parts of deionized water and 10-15 weight parts of tricresyl phosphate, finishing batching within 15-20 minutes, and uniformly stirring and mixing at the temperature of 60-65 DEG C; and (3) cooling to room temperature, sequentially adding 2-3 weight parts of hydroxypropyl methyl cellulose, 12-14 weight parts of triethanolamine and 8-9 weight parts of urea, uniformly stirring and mixing to obtain the flame-retardant fabric finishing agent. The invention provides a method for preparing the flame-retardant fabric finishing agent, and the fabric finished by the flame-retardant fabric finishing agent has high fire resistance and hidden combustion property, can prevent molten drops and is resistant to washing and dry cleaning.

Owner:CHANGSHU YAOU IMPORTS & EXPORTS TRADE

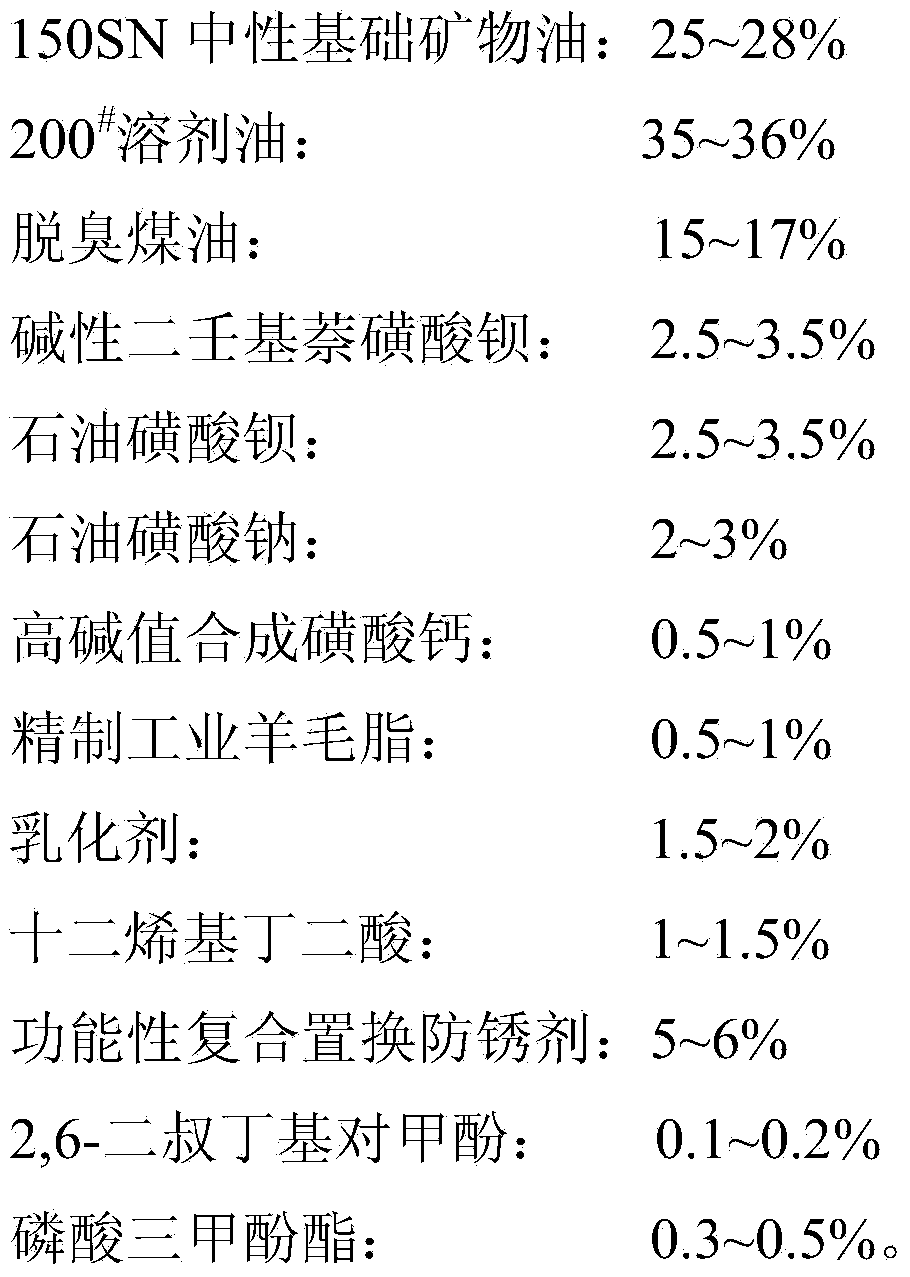

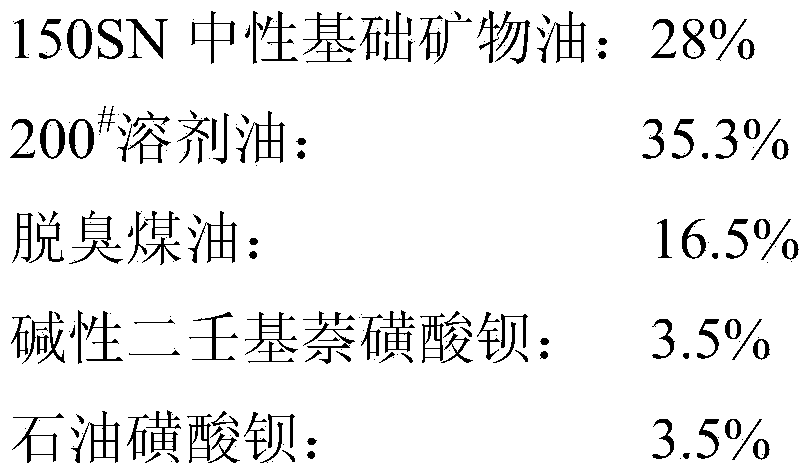

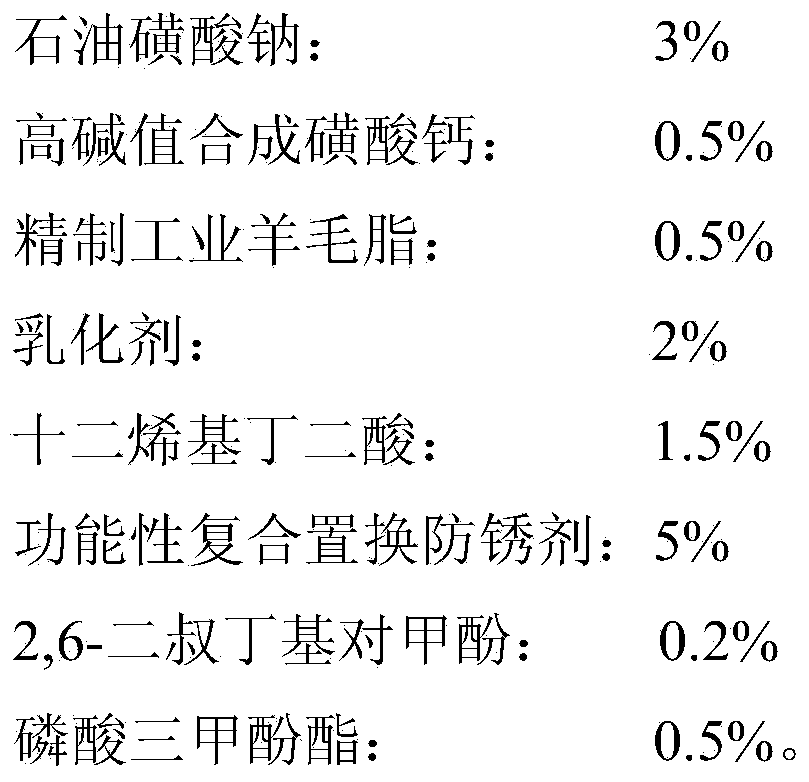

Film-cleaning anti-rust oil for automobile connecting rod, preparation method therefor and applications

ActiveCN103525527ALow kinematic viscosityOvercome the problem of unpacking and cleaningLubricant compositionKeroseneButylated hydroxytoluene

The invention discloses a kind of film-cleaning anti-rust oil for an automobile connecting rod, a preparation method therefor and applications. The anti-rust is prepared from 150SN neutral base mineral oil, 200#solvent naphtha, deodorized kerosene, alkaline barium dinonyl naphthalene sulfonate, petroleum barium sulfonate, petroleum sodium sulfonate, synthesized calcium sulfonate with high base number, refined industrial lanolin, emulsifiers, dodecenyl succinic acid, functional composite displacement antirust agents, 2,6-butylated hydroxytoluene and tricresyl phosphate. The anti-rust oil can form a layer of protection coating on a material surface, the coating has strong compactness, good adhesion, is naturally quick-drying and in a half hard film state, and has atmosphere corrosion resistance, excellent moisture resistance and salt mist resistance, and the anti-rust life can reach above one year. The anti-rust effects are good. The anti-rust oil can completely meet anti-rust quality technical requirements of users during processes of production-manufacturing, transportation, storage and the like.

Owner:GUANGZHOU YUEHUI METAL MACHINERY PROTECTION TECH

Furan resin self-hardening sand for casting and preparation method thereof

The invention discloses furan resin self-hardening sand for casting and a preparation method thereof. The furan resin self-hardening sand is prepared from the following raw materials in parts by weight: 20-30 parts of fresh sand, 70-80 parts of old sand, 1-1.5 parts of self-hardening furan resin, 10-15 parts of phosphoric acid, 8-12 parts of p-toluenesulfonic acid, 5-10 parts of ethyl sulfate, 0.5-1.5 parts of N-2-(amino ethyl group)-3-aminopropyl trimethoxy silane, 4-8 parts of tricresyl phosphate, 3-6 parts of waste syrup, 2-4 parts of activated carbon, 3-5 parts of sepiolite, 4-6 parts of zeolite, 5-10 parts of dibutyl phthalate, 2-3 parts of sodium alginate, 3-5 parts of butyl stearate and 4-6 parts of composite powder. The furan resin self-hardening sand has the advantages of being non-toxic, high in strength, small in smell, low in gas evolution and thermal expansivity, good in gas permeability and collapsibility, proper in viscosity, smooth and clean in surface, easy to clean and the like. The prepared casting is high in degree of precision and good in surface quality. The furan resin self-hardening sand is suitable for casting various cast steels, cast iron and non-ferrous castings.

Owner:TONGLING JINGWEI FLUID SCI & TECH

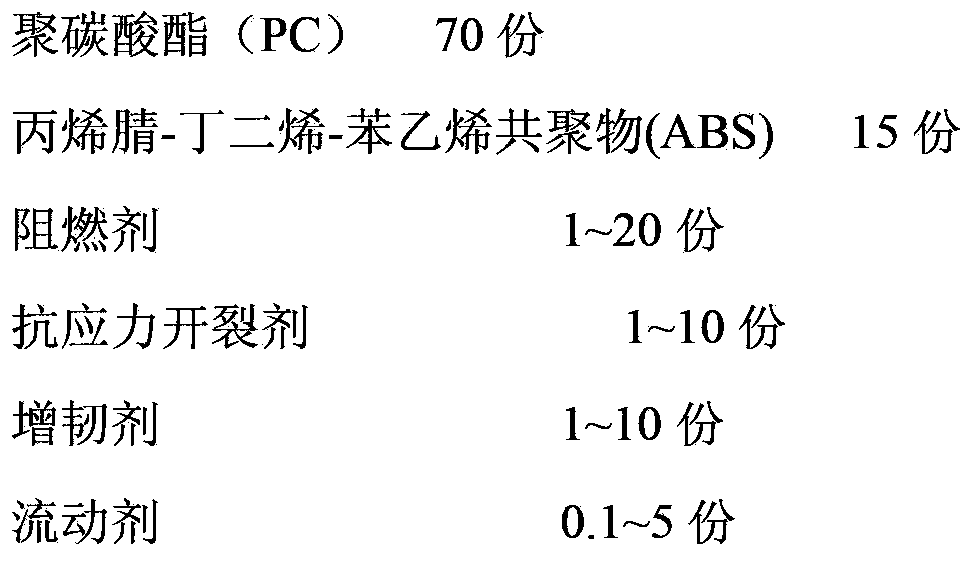

PC-ABS alloy for computer housing

A PC-ABS (Acrylonitrile Butadiene Styrene) alloy for a computer housing is characterized by comprising the following constitutes in parts by weight: 70 parts of PC polycarbonate, 15 parts of ABS copolymer, 1-20 parts of flame retardant, 1-10 parts of stress cracking resisting agent, 1-10 parts of flexibilizer, 0.1-5 parts of flowable agent, wherein the flame retardant is at least one selected from triphenyl phosphate, tricresyl phosphate, bisphenol A diphosphonate cresyl diphenyl phosphate; the stress cracking resisting agent is at least one selected from ethyl- hydrogenised nitrile-acrylate ternary co-polymerized graft, and acrylic acid grafted polyolefin elastomer copolymer; the flexibilizer is at least one selected from ethylene-octane copolymer, ethylene-butane copolymer, ethylene-propene copolymer, and phenethylene-butadiene copolymer. The PC- ABS alloy improves gap impact strength performance and reduces complexity of the operation control.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

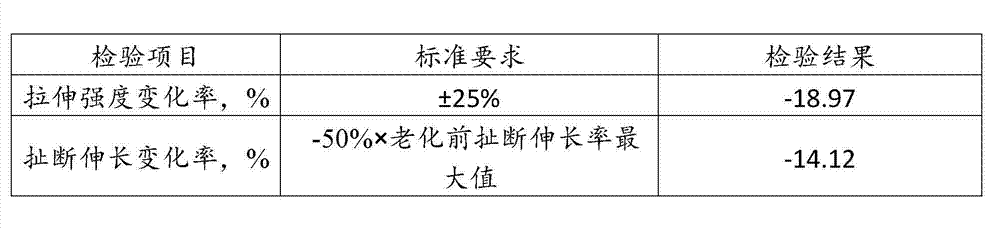

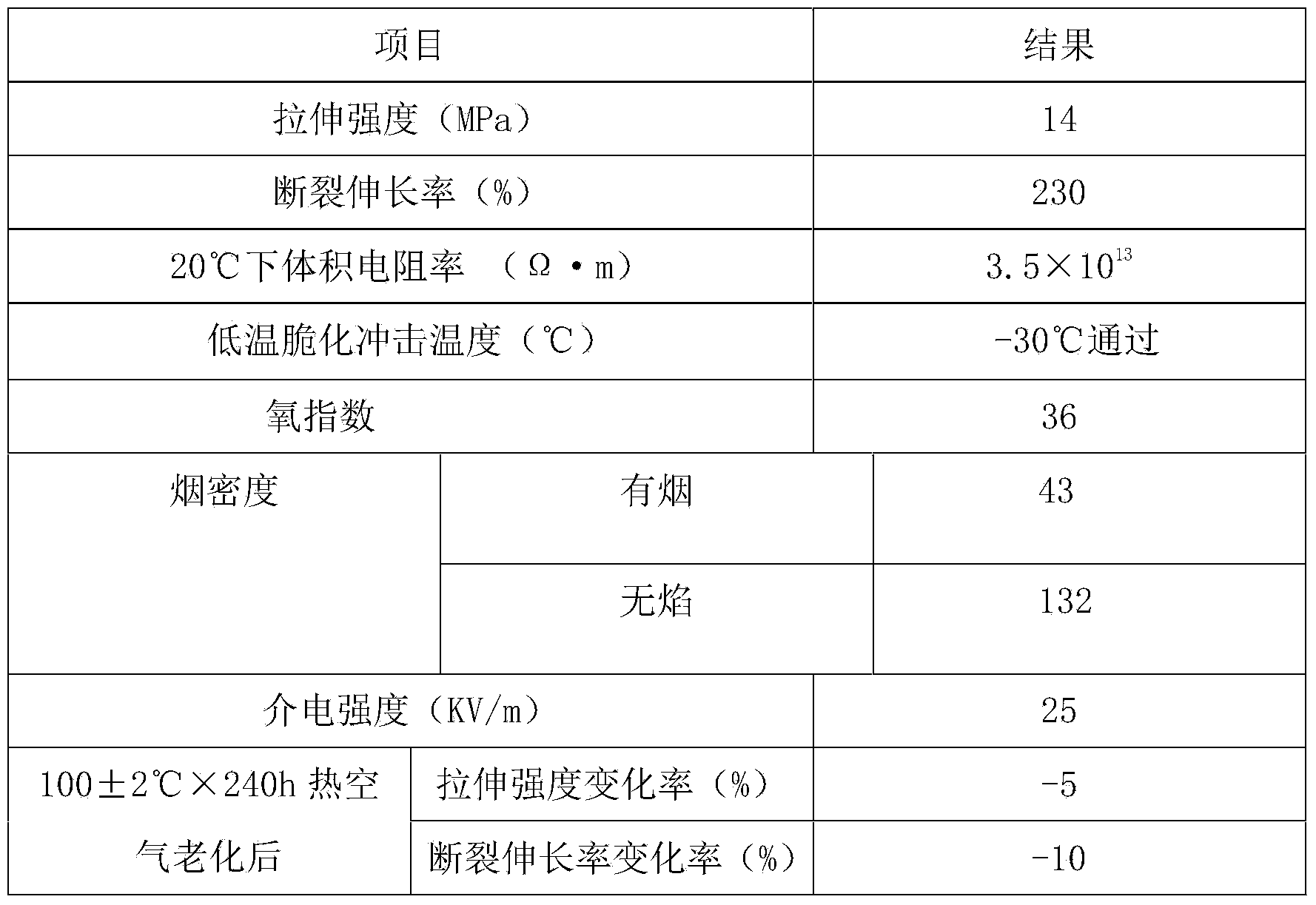

Heat-resisting oil-resisting rubber material for automotive pipes

The invention discloses a heat-resisting oil-resisting rubber material for automotive pipes. The rubber material is prepared from the following raw materials in parts by weight: 50-65 parts of NRB26 nitrile rubber, 20-25 parts of NRB18 nitrile rubber, 2-10 parts of common rubber, 18-20 parts of white carbon black, 0-1 part of aluminium oxide, 8-10 parts of nanometer talcum powder, 2-5 parts of vulcanizing agent, 0.5-1.2 parts of zinc oxide, 1-3 parts of tricresyl phosphate, 0.5-2 parts of oxidized polyethylene, 2-3 parts of accelerant TMDT, 2-5 parts of antiager, 0.2-1.2 parts of accelerant Na-22, 0.2-0.5 parts of epoxy linseed oil, 0.2-0.5 parts of acetyl triethyl citrate and 1.0-1.5 parts of microcrystalline wax. The rubber material disclosed by the invention has excellent mechanical strength, heat resistance and oil resistance and is suitable for preparing automotive rubber pipes with good comprehensive properties.

Owner:安徽宁国尚鼎橡塑制品有限公司

Preparation and application of isobutylcyanoacrylate medical adhesive

The present invention provides a medical adhesive which has the advantages of short adhesion time, good flexibility of adhesive layer, sufficient hemostasis, high adhesion strength and short break-off time. The invention is characterized in that the medical adhesive is manufactured by the following inventive formula and technique, wherein the inventive formula is as follows: 30-75 parts of alpha-isobutyl cyanoacetate by weight, 3.5-23.5 parts of formaldehyde by weight, 0.15-1.55 parts of polymerization inhibitor by weight, 0.1-15.5 parts of pH adjusting agent by weight, and 0.5-19.3 parts of stabilizing agent. The inventive technique comprises the following steps: executing polycondensation reaction with alpha-isobutyl cyanoacetate, formaldehyde and hexa-hydrogen pyridine as pH adjusting agent, executing suction-filtering to the product after water cleaning, and vacuum drying; adding the material which is executed with vacuum drying in a fractionating flask, then adding phosphoric acid as pH adjusting agent, tricresyl phosphate as stabilizing agent and hydrochinone as polymerization inhibitor, mixing to uniform, installing a capillary tube of SO2 protective gas, starting depolymerization, distilling, collecting the component with constant boiling point, and packaging or pouring-in. The medical adhesive can be applied to the aspects of medicine, health-care, beauty treatment, daily life, etc.

Owner:孙丽华

Flame-retardant polyethylene cable material capable of preventing mould

ActiveCN103509228AWith anti-mold functionWeather resistantInsulatorsZinc hydroxideLinear low-density polyethylene

The invention provides a flame-retardant polyethylene cable material capable of preventing mould. The flame-retardant polyethylene cable material is prepared with the following components and raw materials by weight: 50-60 parts of high-density polyethylene, 30-45 parts of linear low-density polyethylene, 10-15 parts of polyester resin, 8-10 parts of organic silicon resin, 2-3 parts of simethicone, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 1-2 parts of barium sulfate, 5-6 parts of dolomite, 6-8 parts of attapulgite, 4-6 parts of celestite, 10-12 parts of zinc hydroxide, 10-15 parts of triammonium phosphate, 10-12 parts of tricresyl phosphate (TCP), 6-8 parts of poly(1,2-propylene glycol adipate), 1-2 parts of sophora flavescens alcohol extract, 0.5-0.6 parts of zanthoxylum oil, 1-2 parts of OBPA (10,10'-oxybisphenoxarsine) mould inhibitor, 1-1.5 parts of PVC (polyvinyl chloride) processing agent ACR-401 (acrylate plastic modifier), and 10-15 parts of modified filler. The cable wire has good antibacterial property, and the characteristics of weather resistance, low smoke, ageing resistance, flame retardation and so on.

Owner:蚌埠尚维知识产权运营有限公司

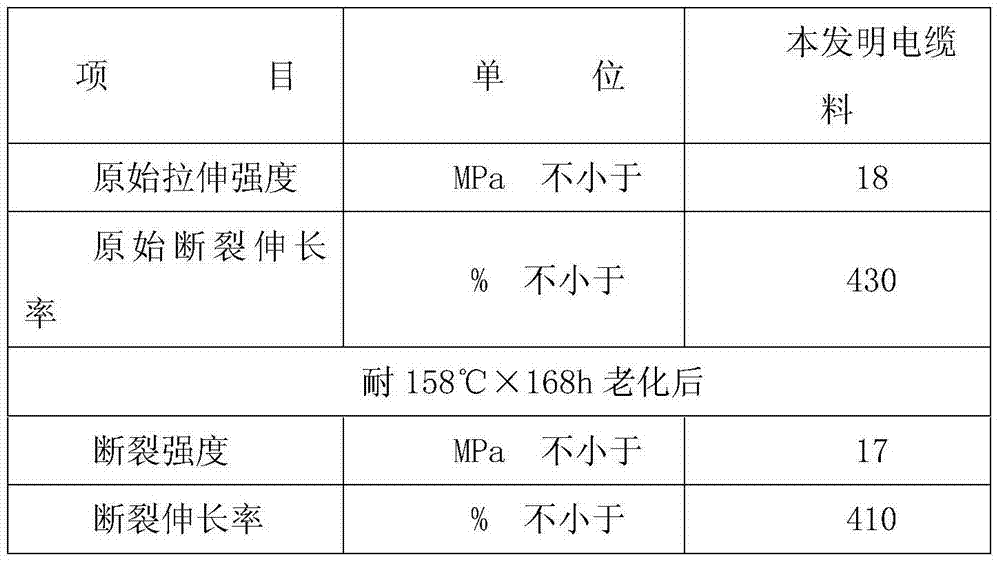

Polyethylene cable insulation material and preparation method thereof

InactiveCN103937071AReduce manufacturing costIncrease productivityPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

A disclosed polyethylene cable insulation material is characterized by being prepared from the following raw materials in parts by weight: 55-60 parts of high-density polyethylene, 13-16 parts of linear low-density polyethylene, 5-7 parts of PE wax, 16-19 parts of diatomite, 23-26 parts of high-wear-resistance carbon black N330, 1-2 parts of promoter TMTM, 1-2 parts of antiaging agent ODA, 14-16 parts of glyceryl trioleate, 2-3 parts of zinc stearate, 2-3 parts of tricresyl phosphate, 1-2 parts of silane coupling agent KH550, 10-12 parts of epoxidized linseed oil and 6-8 parts of an auxiliary agent. By utilizing high-density resin as a base material, the cable insulation material is smooth in surface and relatively good in fluidity, the production technology is simple, easy and practicable, the production efficiency is high, the cable insulation material is good in effect and capable of replacing imported products, and the cable production cost is reduced also.

Owner:MAANSHAN JIAYUAN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com