Heat-resisting oil-resisting rubber material for automotive pipes

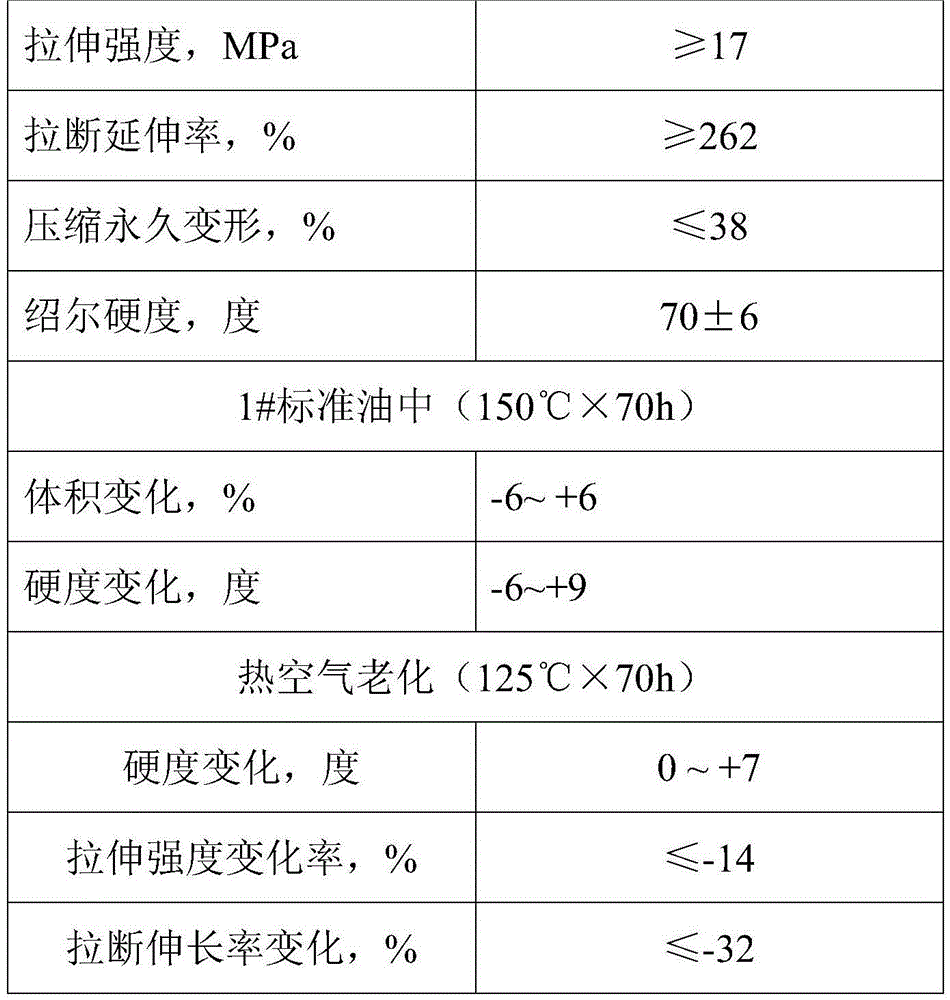

A technology of oil-resistant rubber and pipe fittings, applied in the field of rubber, can solve the problems of poor heat resistance and oil resistance, waste of automotive rubber pipe fittings, cracked and sticky surfaces, etc., to improve compatibility, eliminate gaps, and compress permanent deformation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The heat-resistant and oil-resistant rubber material for automobile pipe fittings of the present invention, its preparation comprises the following steps:

[0036] S1, take each raw material by the weight and number ratio of embodiment 1 in table 2;

[0037] S2. Turn on the open mill, raise the temperature to 31°C, set the roller distance to 0.4mm, add the NRB26 nitrile rubber, NRB18 nitrile rubber, and shared rubber weighed in S1 to the open mill at the same time, and masticate for 19 minutes and then row Glue, tamping, pressing, tableting, cooling to room temperature, and then park for 2.5 hours to obtain a plasticized rubber;

[0038] S3. Raise the temperature of the mill to 35°C, adjust the roller distance to 0.6 mm, add the primary masticated rubber obtained in S2, and after masticating for 14 minutes, discharge the rubber, pound, compress, release, cool to room temperature, and park for 3.3 h to obtain secondary plasticizing rubber;

[0039] S4, raise the temper...

Embodiment 2

[0042] The heat-resistant and oil-resistant rubber material for automobile pipe fittings of the present invention, its preparation comprises the following steps:

[0043] S1, take each raw material by the weight and number ratio of embodiment 2 in table 2;

[0044] S2. Turn on the open mill, raise the temperature to 35°C, set the roller distance to 0.7 mm, add the NRB26 nitrile rubber, NRB18 nitrile rubber, and common rubber weighed in S1 to the open mill at the same time, and masticate for 17 minutes and then row Glue, tamping, pressing, tableting, cooling to room temperature, and then park for 2.9 hours to obtain a plasticized rubber;

[0045] S3. Raise the temperature of the mill to 39°C, adjust the roller distance to 0.8 mm, add the primary masticated rubber obtained in S2, and after masticating for 13 minutes, discharge, pound, tablet, and then cool to room temperature and park for 3.8 h to obtain secondary plasticizing rubber;

[0046] S4, raise the temperature of the ...

Embodiment 3

[0049] The heat-resistant and oil-resistant rubber material for automobile pipe fittings of the present invention, its preparation comprises the following steps:

[0050] S1, take each raw material by the weight and number ratio of embodiment 3 in table 2;

[0051] S2. Turn on the open mill, raise the temperature to 33°C, set the roller distance to 0.6mm, add the NRB26 nitrile rubber, NRB18 nitrile rubber, and common rubber weighed in S1 to the open mill at the same time, and masticate for 15 minutes and then row Glue, tamping, pressing, tableting, cooling to room temperature, and then park for 2.2 hours to obtain a plasticized rubber;

[0052] S3. Raise the temperature of the mill to 37°C, adjust the roller distance to 0.9 mm, add the primary masticated rubber obtained in S2, and after masticating for 11 minutes, discharge, pound, tablet, and then stop for 3.5 minutes after cooling to room temperature. h gets two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com