Magnesium hydroxide composite flame retardant material and preparation method thereof

A magnesium hydroxide and composite flame-retardant technology, which is applied in the field of inorganic flame-retardant materials, can solve the problems of high cost and achieve the effects of low cost, high production efficiency and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

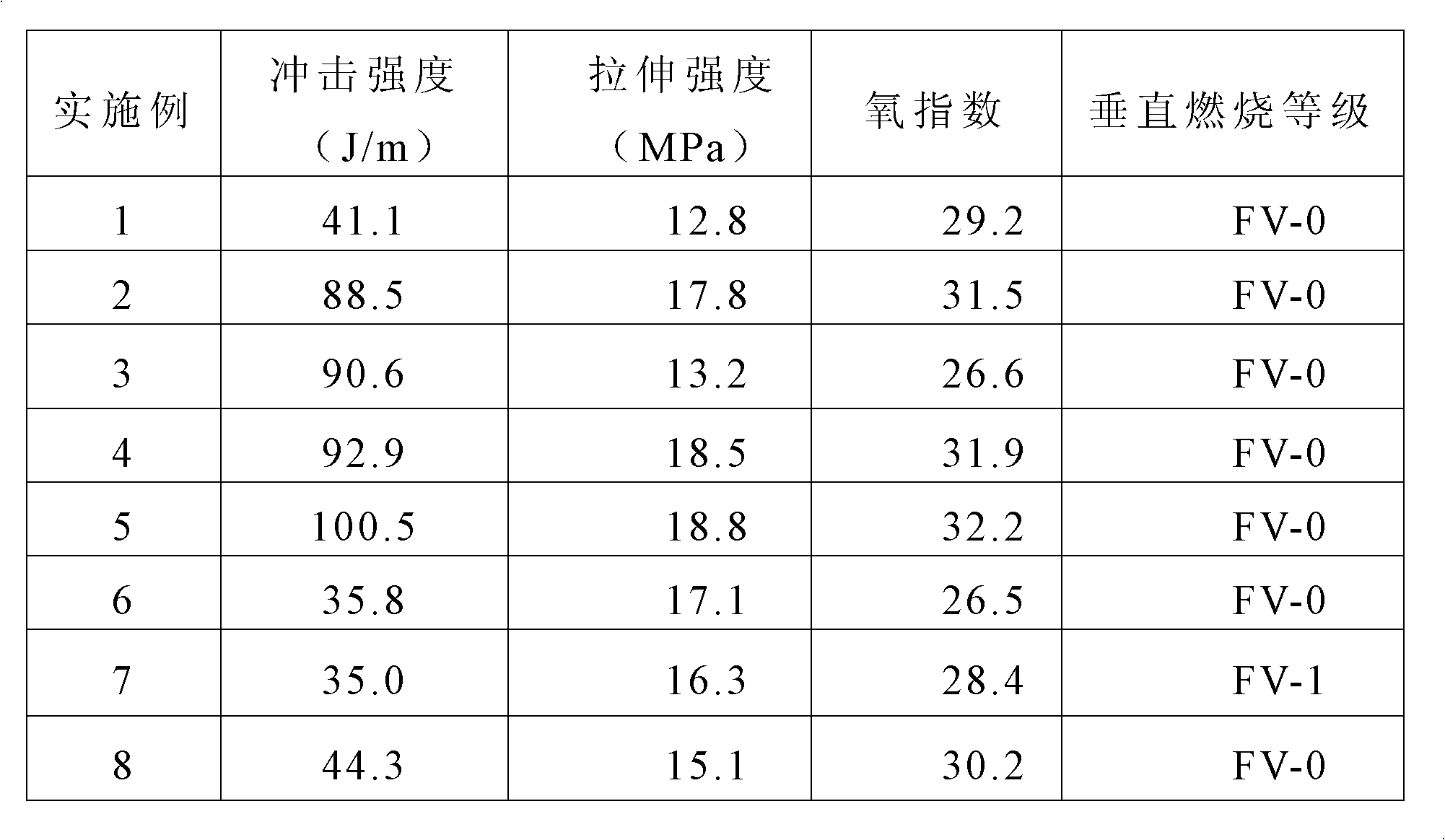

Examples

Embodiment 1

[0022] A magnesium hydroxide composite flame retardant material, comprising the following components in parts by weight: 70 parts of polypropylene, 40 parts of modified magnesium hydroxide, and 15 parts of polyethylene octene elastomer.

Embodiment 2

[0024] A magnesium hydroxide composite flame-retardant material, comprising the following components in parts by weight: 100 parts of polyvinyl chloride, 45 parts of magnesium hydroxide, 10 parts of dioctyl phthalate, 10 parts of tricresyl phosphate, and 1 part of zinc oxide .

Embodiment 3

[0026] A magnesium hydroxide composite flame retardant material, comprising the following components in parts by weight: 60 parts of polypropylene, 40 parts of modified magnesium hydroxide in the form of flakes, 10 parts of dioctyl phthalate, polyethylene octene 10 parts of elastomer, 1 part of zinc oxide, 2 parts of zinc borate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com