High-lubricating rolling oil composition and application thereof

A technology for lubricating rolling and oil composition, which is applied in the direction of lubricating composition and petroleum industry, and can solve problems such as rolling mill vibration, plate surface scratches, rolling oil lubrication performance is not enough to meet the lubrication needs of multi-roll continuous rolling units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

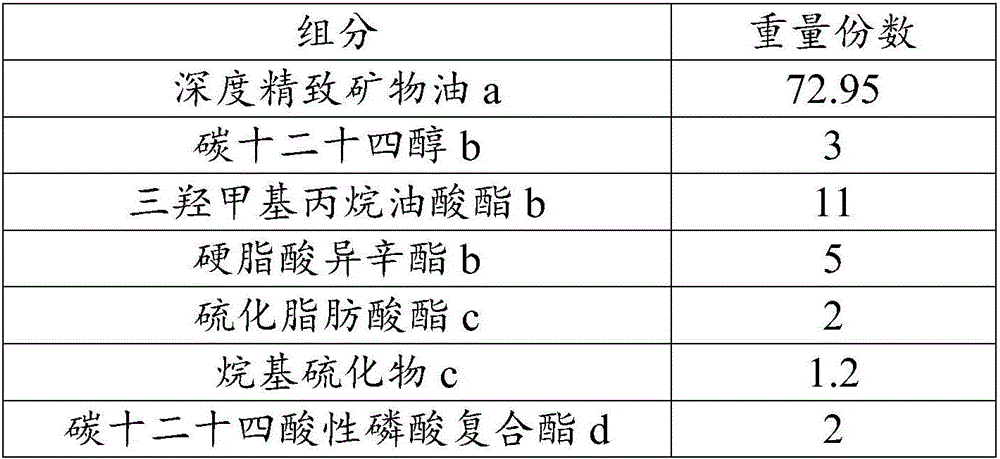

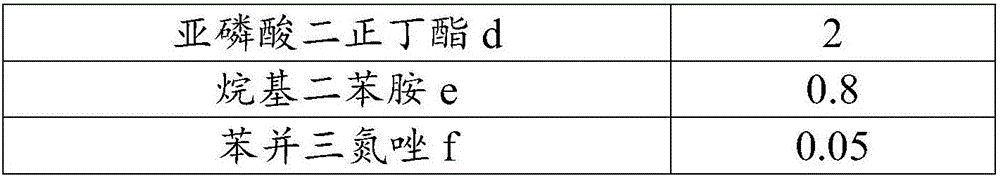

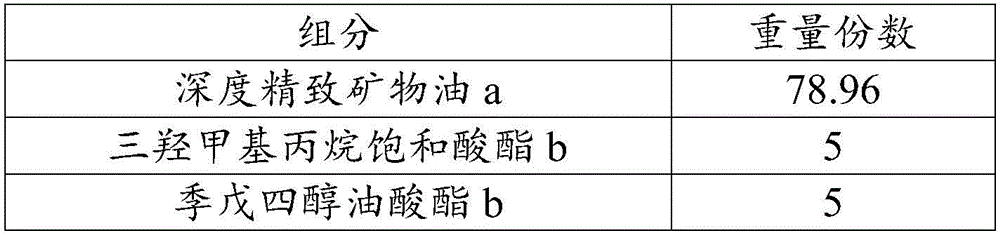

Examples

Embodiment 1~6

[0029] Heat component a) to 45-50°C, add the required amount of components b)-f) sequentially while stirring, and stir thoroughly. After 1.5 hours, stop heating and stir fully. After 0.5 hours, stop stirring and let stand Filter and fill after 1.5 hours.

Embodiment 1

[0031] components parts by weight Deep Refined Mineral Oil a 74.98 trimethylolpropane oleate b 15 Diisooctyl phthalate b 5 Dialkyl dithiophosphate zinc salt c 0.5 sulfurized fatty acid ester c 1.5 tricresyl phosphate d 1 tributyl phosphate d 0.5 Di-n-butyl phosphite d 1 2,6-di-tert-butyl-p-cresole 0.5 Benzotriazole octadecylamine saltf 0.02

Embodiment 2

[0033] components parts by weight Deep Refined Mineral Oil a 73.96 pentaerythritol oleate b 15 Isooctyl palmitate b 5 Sulfurized olefin c 1 zinc octadecyl thiophosphate c 0.5 Amine phosphorothioate d 1 Isooctyl acid phosphate octadecylamine salt d 1.5 tributyl phosphate d 1.5 N-phenyl-α-naphthylaminee 0.5 Thiadiazole Derivativesf 0.04

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com