Formula of environment-friendly flame-retardant chloroprene rubber

A chloroprene rubber and formula technology, which is applied in the field of environmentally friendly and flame retardant chloroprene rubber formulations, can solve problems such as secondary hazards and endangering life safety.

Active Publication Date: 2010-08-25

TIANJIN PENGYI GRP CO LTD

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the usual chloroprene rubber flame retardant formulations in China mostly use halogen-containing flame retardants such as bromine-containing flame retardants and chlorine-based flame retardants. Fire will produce a large amount of toxic and corrosive hydrogen halide gas, causing secondary hazards, which are usually more serious than those caused by combustion, seriously endangering people's lives

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

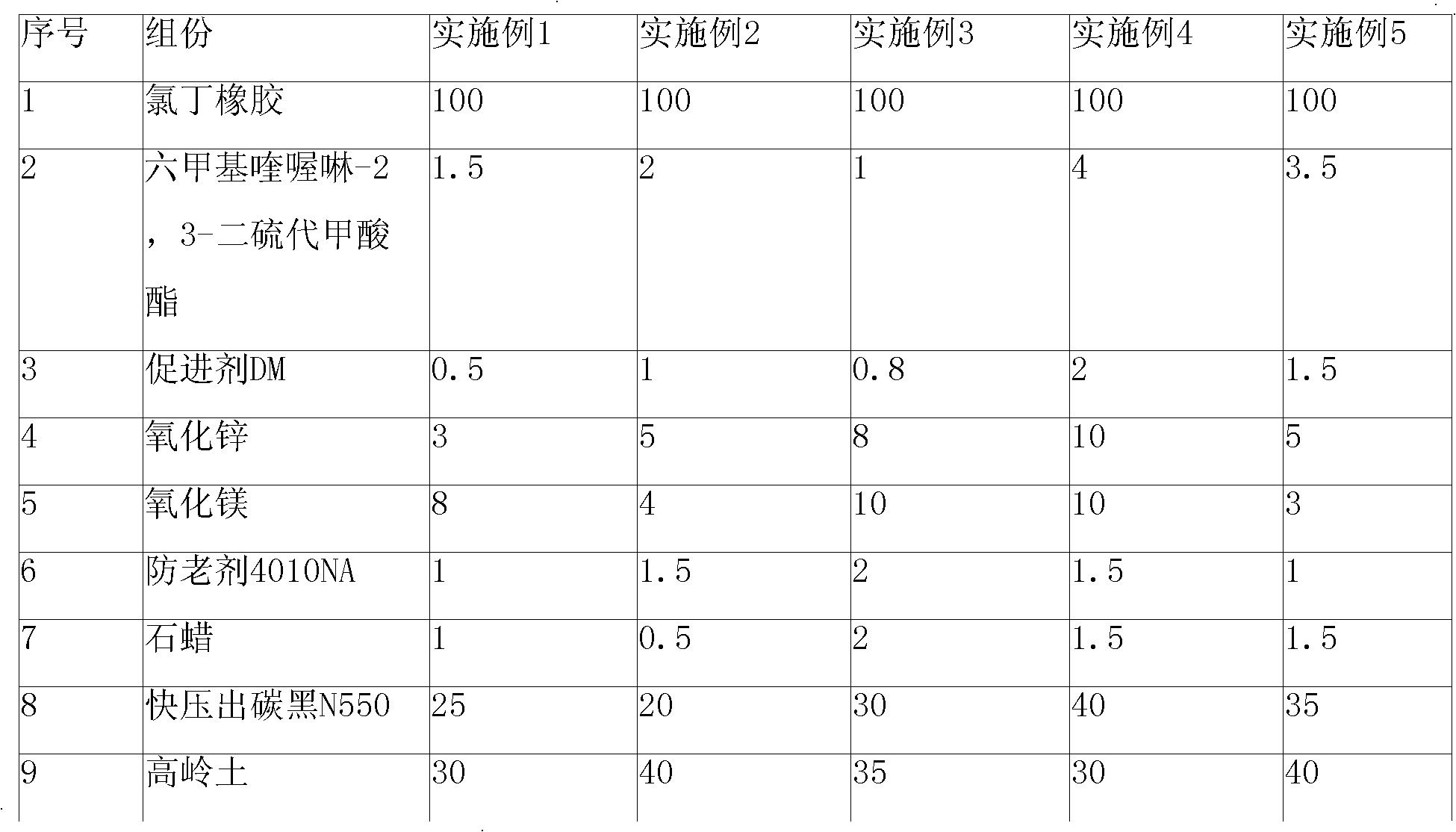

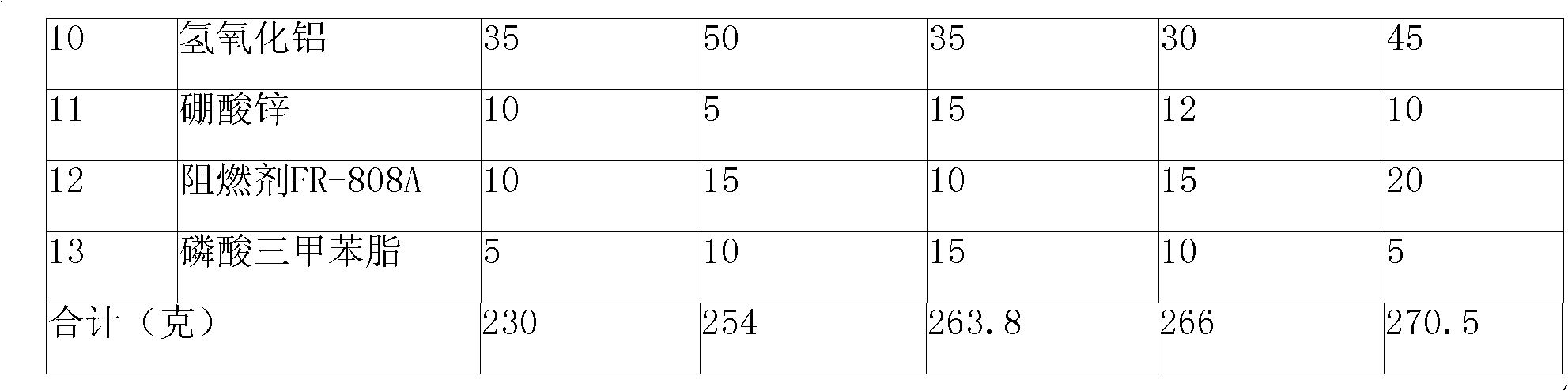

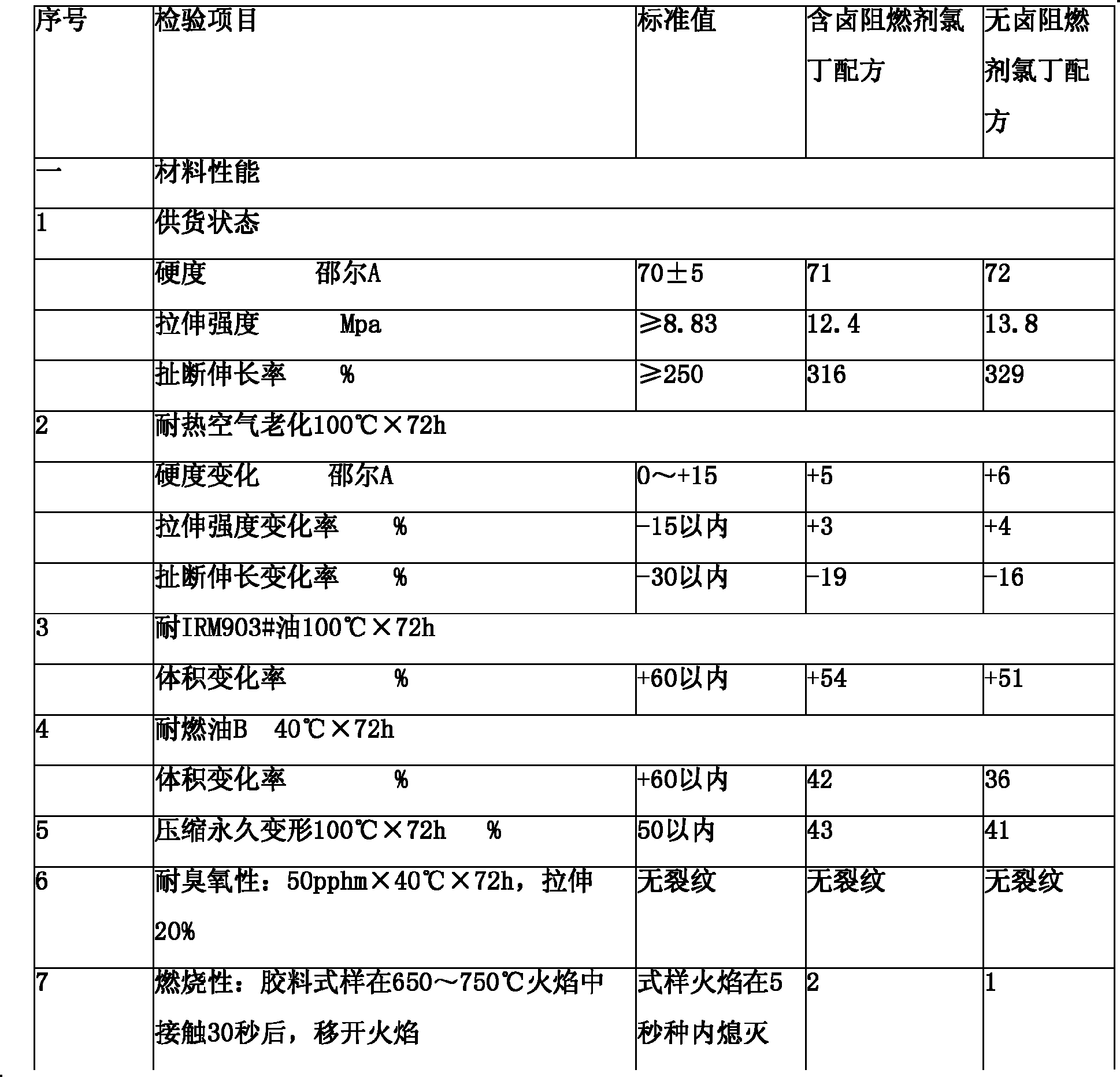

The invention relates to the formula of environment-friendly flame-retardant chloroprene rubber. The flame-retardant chloroprene rubber, according to the formula thereof, comprises the following components by weight part: 100 parts of chloroprene rubber, 1 to 4 parts of hexamethyl-quinoxaline-2,3-dithioformate, 1 to 2 parts of DM as accelerator, 3 to 10 parts of zinc oxide, 3 to 10 parts of magnesium oxide, 1 to 2 parts of 4010NA as anti-ager, 0.5 to 2 parts of paraffin, 20 to 40 parts of FEF (fast-extruding furnace) carbon black (N550), 30 to 40 parts of kaolin, 30 to 50 parts of aluminum hydroxide, 5 to 15 parts of zinc borate, 10 to 20 parts of FR-808A and 5 to 15 parts of tricresyl phosphate. According to the comparative analysis on the performance of the chloroprene formula using halogen-containing flame retardant and the chloroprene rubber formula using halogen-free flame retardant, the performance of the formula using the halogen-free flame retardant in the invention can fully satisfy the requirements of standards, thus substituting for the chloroprene formula using the halogen-containing flame retardant; and based on the chloroprene rubber formula, the invention can meet the requirements of the flame-retardant application, and the materials of the formula are environment friendly and safe for human bodies.

Description

Technical field The invention relates to the technical field of rubber formulations, in particular to an environmentally friendly flame-retardant neoprene formulation. Background technique With the enhancement of environmental protection awareness, the safety and environmental protection requirements of the rubber materials used are getting higher and higher. At present, the usual domestic neoprene flame retardant formulations mostly use halogen-containing flame retardants such as bromine-containing flame retardants and chlorine-based flame retardants. Although the use of such flame retardants can meet good flame retardant effects, once it occurs Fires will produce a large amount of toxic and corrosive hydrogen halide gas, causing secondary hazards. The hazards are usually more serious than the consequences of burning, which seriously endanger people's lives. Summary of the invention The purpose of the present invention is mainly to solve the toxic and harmful problem of flam...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L11/00C08K13/02C08K3/22C08K5/378C08K3/34C08K3/38C08K5/523

Inventor 张洪起王金财

Owner TIANJIN PENGYI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com