Flame-retardant warm edge spacer bar, flame-retardant composite material used thereby, and preparation method of flame-retardant composite material

A flame retardant composite material, warm edge spacer technology, applied in building components, buildings, parallel glass structures, etc., can solve the problems of large filling amount of inorganic flame retardants, poor thermal stability, strong volatility, etc. Flame retardant effect, high thermal stability, the effect of promoting carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

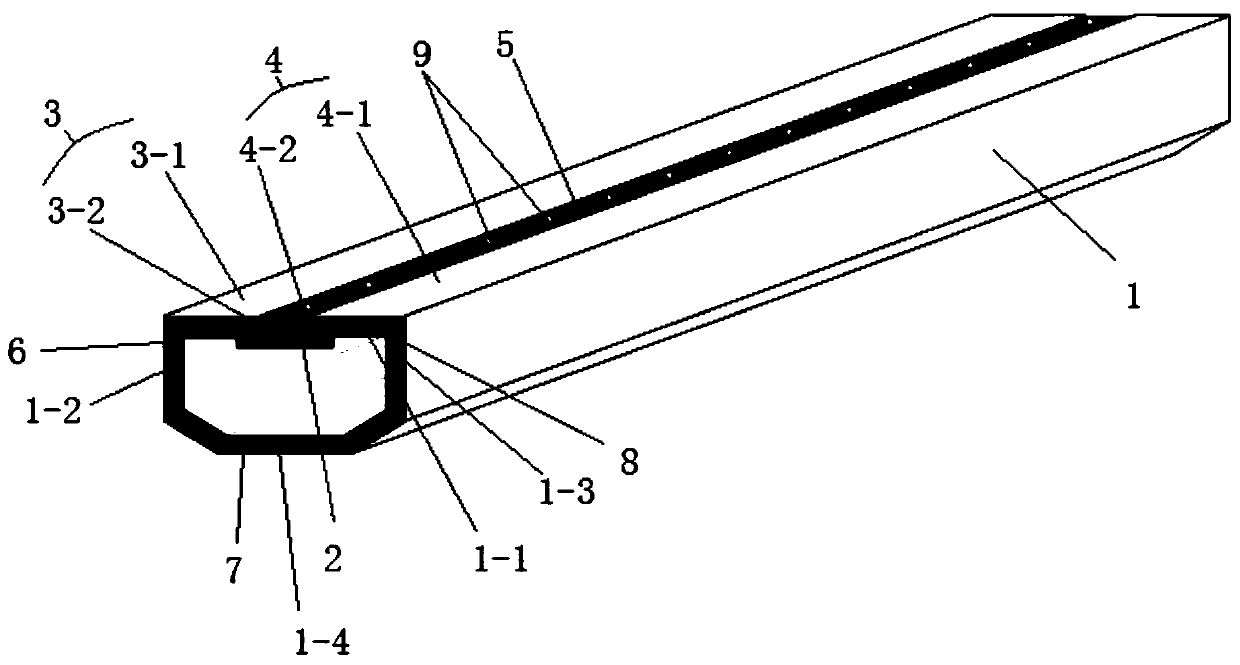

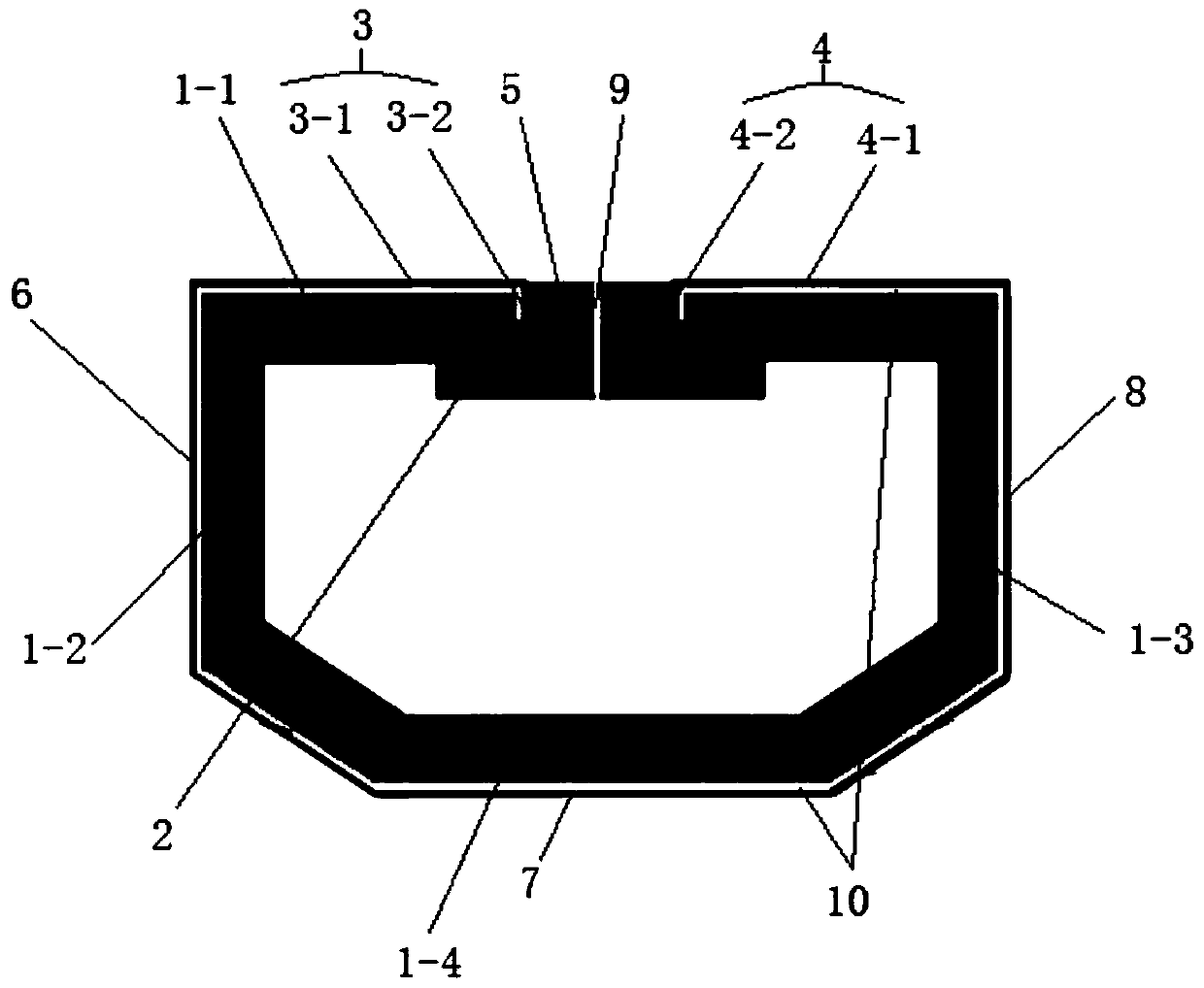

[0038] refer to Figure 1-Figure 2 , a flame-retardant warm-edge spacer for insulating glass, the spacer includes a flame-retardant composite frame with a "mouth"-shaped cross section, and an upper plate of the "mouth"-shaped flame-retardant composite frame 1 The lower surface of 1-1 is provided with a rectangular flame-retardant composite material reinforcing body 2 protruding toward the inside of the frame and arranged along the length direction of the upper plate body 1-1, and the axial length of the rectangular flame-retardant composite material reinforcing body 2 The axial length of the flame-retardant composite material frame 1 in the shape of "口" is equal to that of the rectangular flame-retardant composite material reinforcement body 2 and the flame-retardant composite material frame body 1 in the shape of "口". The left and right sides of the upper surface of the upper plate body 1-1 of the flame-retardant composite material frame body 1 in the shape of "口" are respect...

Embodiment 2

[0059] The difference from Example 1 is that

[0060] The flame retardant composite material used in the flame retardant warm edge composite spacer includes polymer resin, resin modifier, inorganic flame retardant powder, smoke suppressant, polymer dispersant, plasticizer, and auxiliary agent. The polymer resin is ABS, resin modifier is pentaerythritol stearate, smoke suppressant is Al(OH) 3 , the plasticizer is dibutyl phthalate.

[0061] Each of the above-mentioned ingredients is composed of the following parts by weight:

[0062]

[0063] Wherein, the polymer dispersant in the flame-retardant composite material is silicone-modified epoxy resin.

[0064] The auxiliary agent is silane coupling agent KH550 and UV antiaging agent.

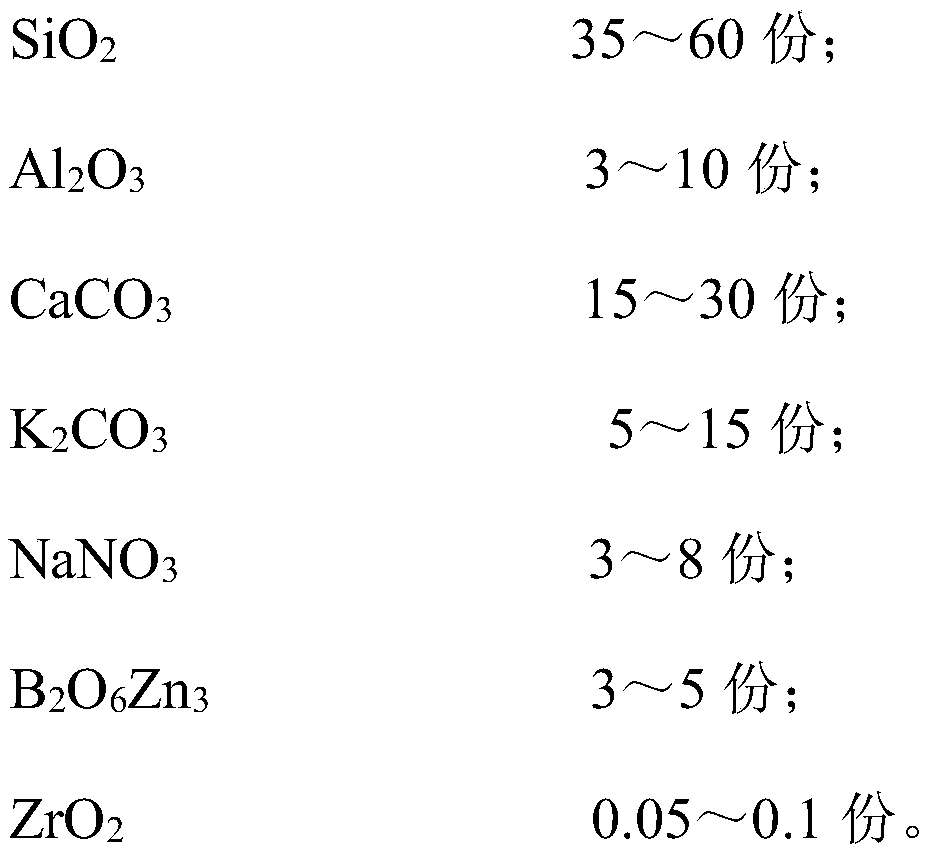

[0065] Inorganic flame retardant powder in the flame retardant composite material includes:

[0066]

[0067] The preparation method in the flame-retardant composite material, the method comprising:

[0068] Step 1. Preparation of inorgan...

Embodiment 3

[0076] The difference from Example 1 is that

[0077] The polymer resin is polyketone POK, the resin modifier is glycidyl methacrylate, the plasticizer is diisobutyl phthalate, and the smoke suppressant is Mg(OH) 2 .

[0078] The flame retardant composite material includes the following raw materials, which are composed in parts by weight:

[0079]

[0080] Wherein, the polymer dispersant in the flame-retardant composite material is silicone-modified epoxy resin.

[0081] The auxiliary agent is silane coupling agent KH550 and UV antiaging agent.

[0082] The inorganic flame retardant powder in the flame retardant composite material includes according to parts by weight:

[0083]

[0084]

[0085] The preparation method in the flame-retardant composite material, the method comprising:

[0086] Step 1. Preparation of inorganic flame retardant powder: according to the proportion, take the inorganic silicon and aluminum components except B 2 o 6 Zn 3Stir the other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com