Patents

Literature

112 results about "Diisobutyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

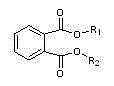

Diisobutyl phthalate (DIBP) is prepared by esterification process of isobutanol and phthalic anhydride. Its structural formula is C₆H₄(COOCH₂CH(CH₃)₂)₂. DIBP is an odorless plasticizer and has excellent heat and light stability. It is the lowest cost plasticizer for cellulose nitrate. DIBP has lower density and freezing point than the related compound dibutyl phthalate (DBP). Othewise, it has similar properties DBP and can often be used as a substitute for it. Its refractive index is 1.488–1.492 (at 20 °C, D).

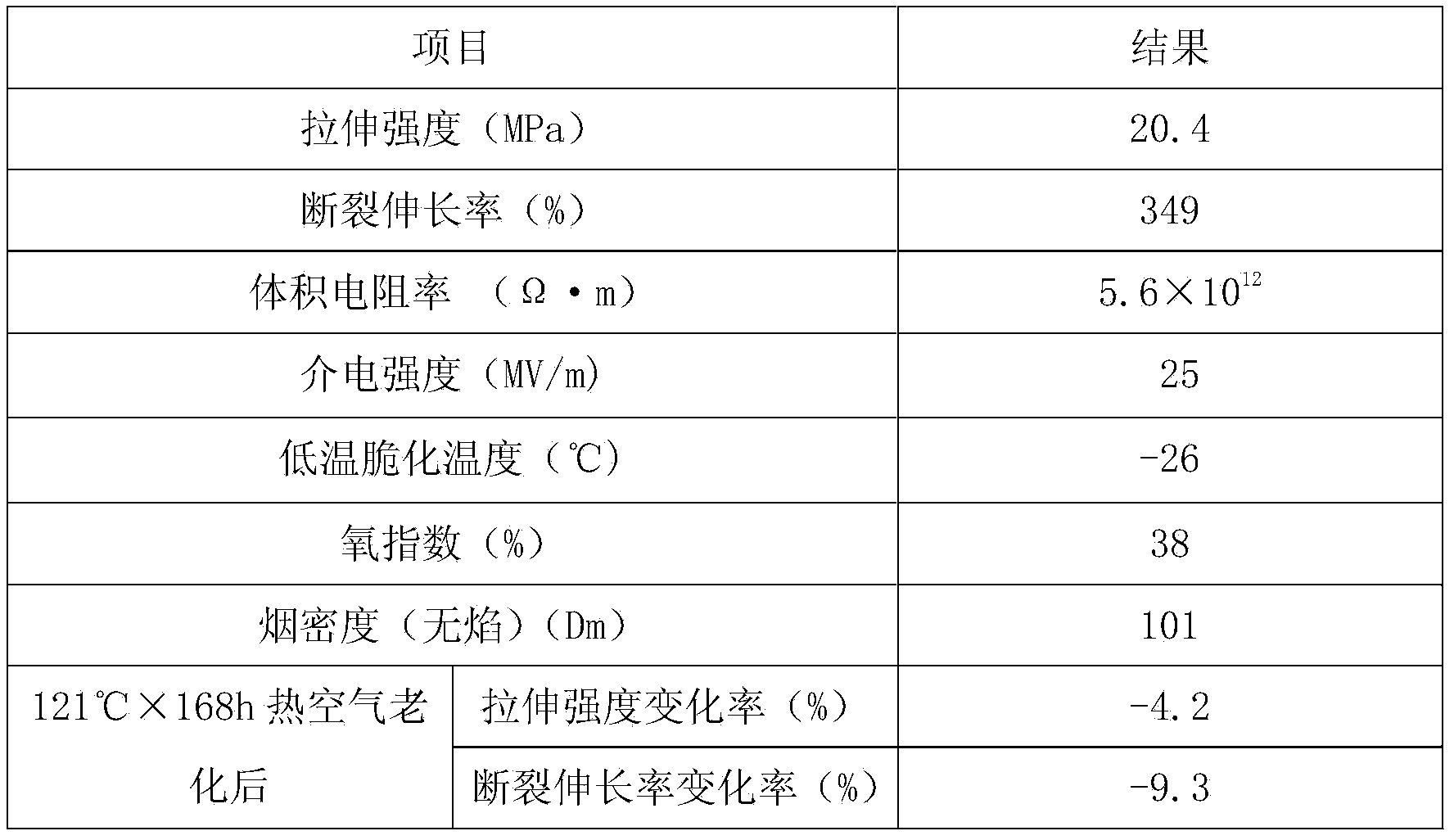

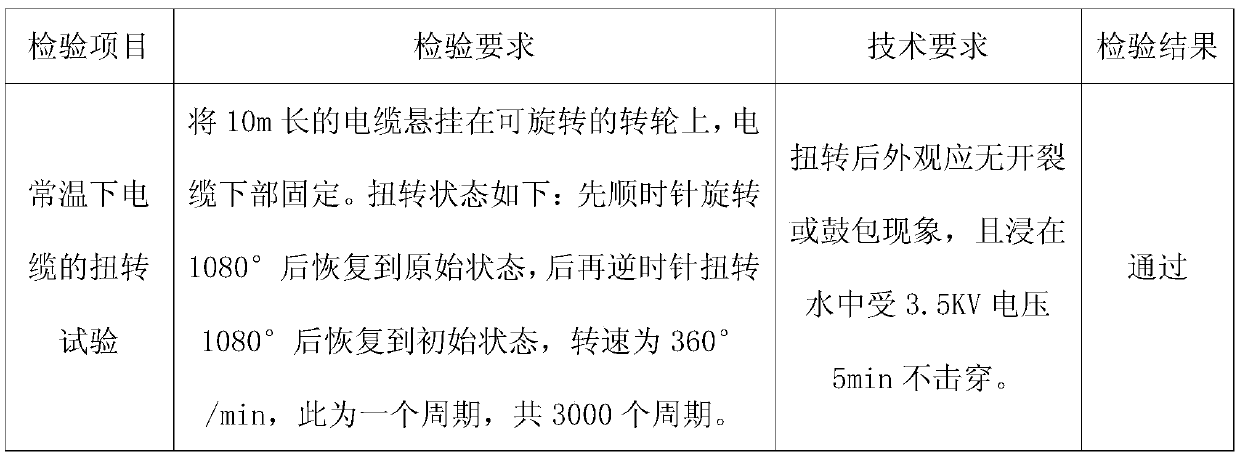

Sheath material for signal controlling cable and preparation method thereof

ActiveCN103524843ANo deformationNot brokenPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneControl signal

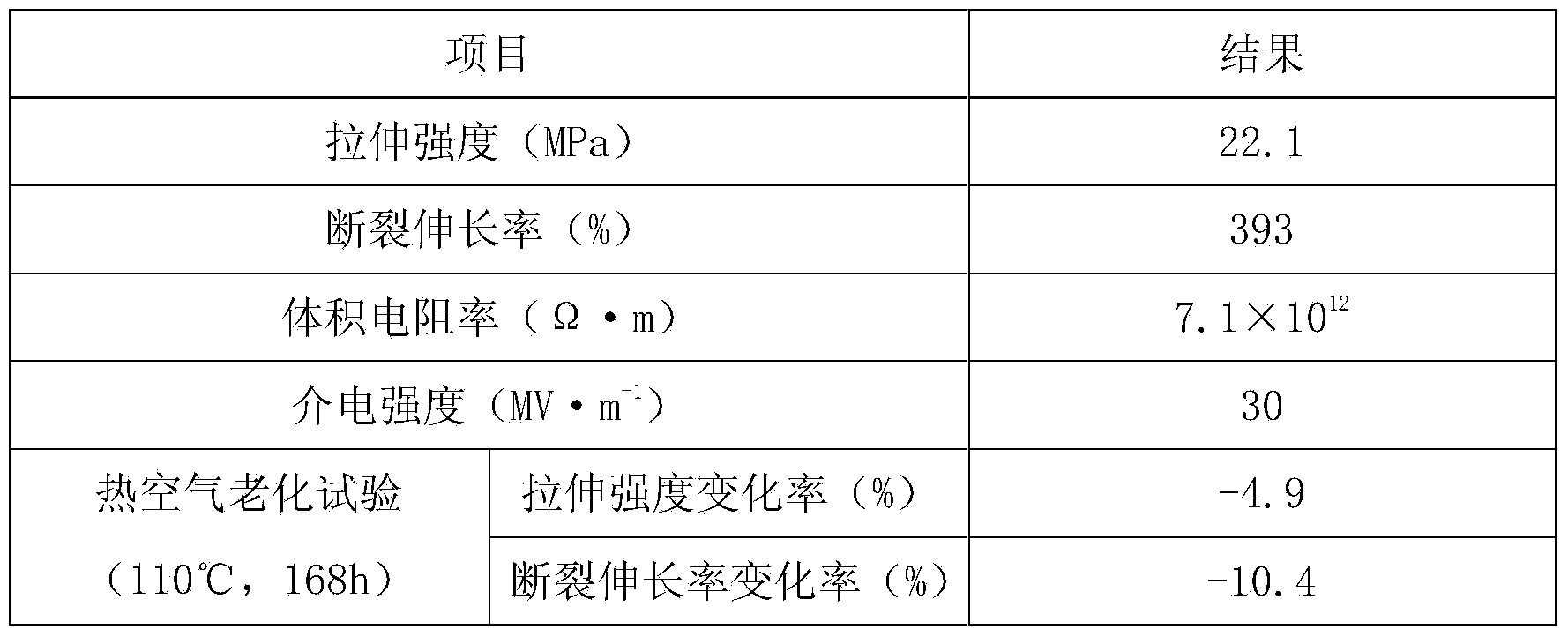

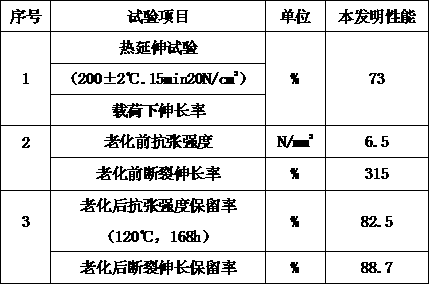

The invention discloses a sheath material for a signal controlling cable and a preparation method thereof. The sheath material comprises the following raw materials in parts by weight: 65-75 parts of low density polyethylene, 20-30 parts of SG-3 type polyvinyl chloride, 15-25 parts of styrene butadiene rubber, 5-10 parts of HIPS, 10-15 parts of nano calcium carbonate, 8-12 parts of nano kaolin, 5-10 parts of an ultrafine mica powder, 3-6 parts of naphthenic oil, 2-3 parts of sulfur, 1-2 parts of an accelerant M, 1-2 parts of zinc oxide, 3-4 parts of stearic acid, 4-8 parts of phenolic resin, 2-3 parts of an anti-aging agent 1010, 0.5-1 part of tert-butyl peroxybenzoate, 3-5 parts of oxidized polyethylene wax, 4-6 parts of rosin pentaerythrityl ester, 1-2 parts of an accelerant TMTD, 5-10 parts of diisobutyl phthalate, 8-12 parts of dioctyl nylon acid ester, 3-6 parts of a composite filler. The sheath material has good high and low temperature resistance and high tensile strength, also has excellent abrasion resistance, acid and alkali resistance, oil resistance, ozone aging resistance, and ultraviolet radiation resistance, extends the service life of a sheath to a great extent, and widens the application scope.

Owner:滁州三界外信息科技有限公司

Polyvinyl chloride tube containing modified attapulgite and preparing method thereof

The invention discloses a polyvinyl chloride (PVC) tube containing modified attapulgite and a preparing method thereof. The PVC tube containing the modified attapulgite is composed of raw materials comprising, based on the weight part ratio, 65-70 parts of SG-7 type PVC resin, 40-45 parts of high density polyethylene, 1-3 parts of poly-4-methyl-1-pentene, 2-4 parts of methyl methacrylate-butadiene-styrene terpolymer, 1.3-1.8 parts of alkylphenol ethoxylates, 2-3 parts of modified attapulgite, 25-30 parts of light calcium carbonate, 1-1.5 parts of dimethyl dimercapto acetic acid ethylhexyl acrylate stannum, 1.3-1.8 parts of diisobutyl phthalate, 0.9-1.1 parts of fungacetin, 1-2 parts of zinc sulfide and 0.4-0.6 part of methyl triethoxysilane. According to the PVC tube containing the modified attapulgite and the preparing method, a formulation is further optimized, the composition of the modified attapulgite is added in the formulation, and therefore dispersion of inorganic fillers is promoted and fluidity of PVC fusant is improved during the manufacturing process of the PVC tube, and furthermore tensile strength and breaking elongation are improved, toughness is good and hardness is low. In addition, the preparing method is simple and effectively applied to every walk of life.

Owner:ANHUI HAINA SICHUAN PLASTICS TECH

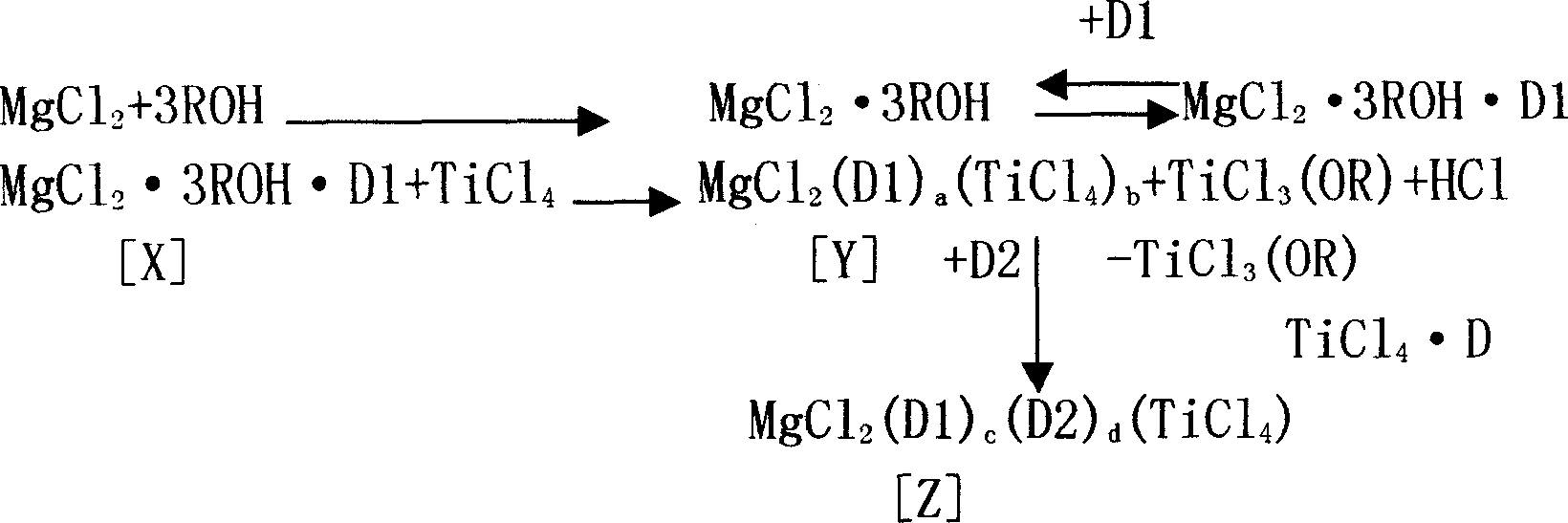

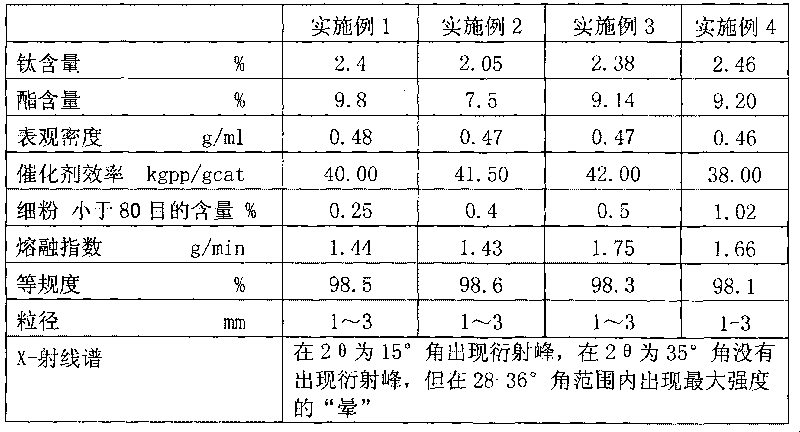

Catalyst for propylene polymerization and its preparation method

The present invention relates to catalyst, and is especially one kind of catalyst for propylene polymerization and its preparation process. The catalyst materials include MgCl2, solvent oil, isooctanol, titanate, acid anhydride, TiCl4, diisobutyl phthalate, toluene and hexane in certain molar proportion. The preparation process of the catalyst includes the following steps: 1. adding anhydrous MgCl2, No. 200 solvent oil and isooctanol into reaction bottle; stirring and heating; and adding tetrabutyl titanate and phthalic anhydride to prepare homogeneous solution; and 2. dropping the solution into glass reactor holding mixture of TiCl4 and refined toluene and adding diisobutyl phthalate.

Owner:LIAONING DINGJIDE PETROCHEM

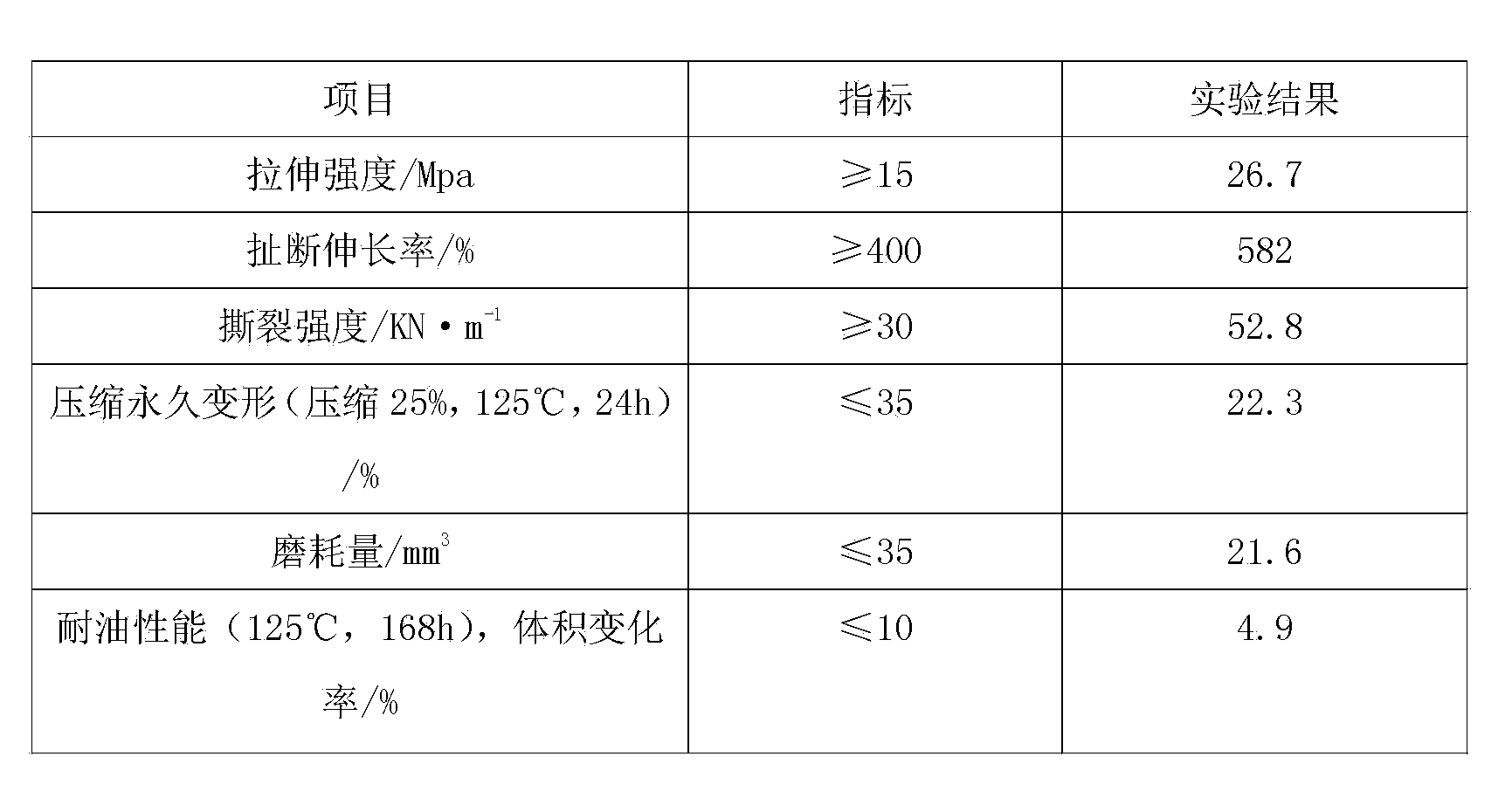

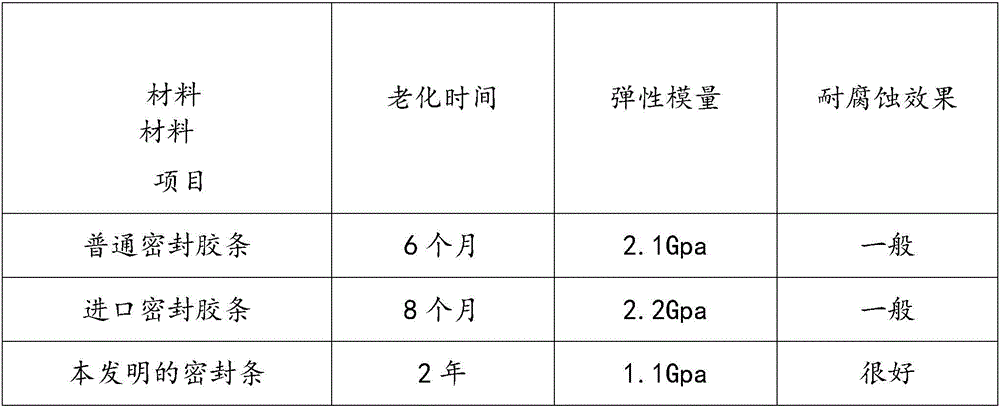

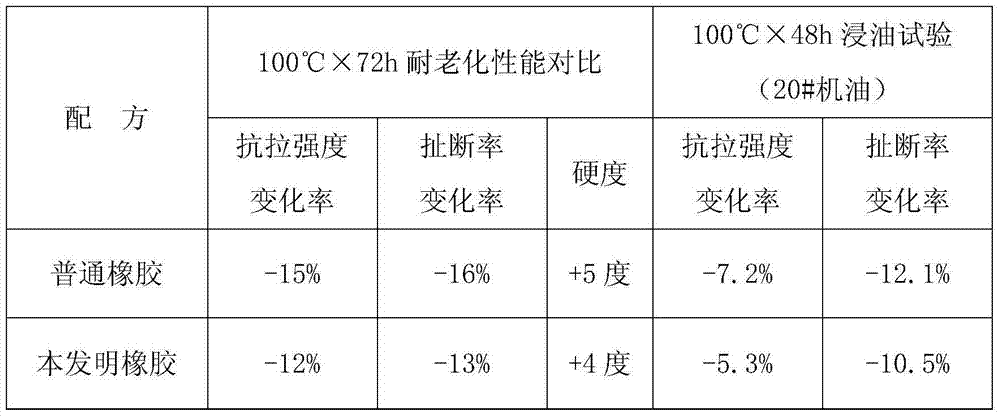

Fluorosilicone rubber/chloroprene rubber sealing gasket for high-temperature oil pump and preparation method thereof

The invention discloses a fluorosilicone rubber / chloroprene rubber sealing gasket for a high-temperature oil pump and a preparation method thereof. The sealing gasket is prepared from fluorosilicone rubber, chloroprene rubber, polyvinylidene chloride, diisobutyl phthalate, wollastonite powder, zinc oxide, magnesium oxide, nano aluminum oxide, dibutyltin dilaurate, nano titanium dioxide, dicumyl peroxide, modified nano-diamond, acetylene black, ammonium polyphosphate, magnesium hydroxide and other raw materials. The sealing gasket has excellent high-temperature resistance, can work at the temperature of 250-300 DEG C for a long time, has quite small mechanical strength and quite small volume changes, and has reliable sealing performance; and the sealing gasket has good corrosion resistance, is resistant to various media, has good air impermeability, is suitable for oil, water, gas, chemical media or other mixed media and the like, and realize effective sealing functions on oil, water, air, coal gas and various chemical media.

Owner:ANHUI TIANMA PUMP VALVE GROUP

Process for preparing polyolefin alloy

Owner:ZHEJIANG UNIV

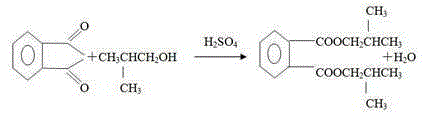

Method for improving thermal stability of dibutyl/diisobutyl phthalate

ActiveCN102219688AImproves intrinsic thermal stabilityImprove thermal stabilityOrganic compound preparationCarboxylic acid esters preparationOrganic synthesisPolyvinyl chloride

The invention provides a method for r improving thermal stability of dibutyl / diisobutyl phthalate, and belongs to the technical fields of fine organic synthesis and application and machine shaping of macromolecular new materials. The method which improves the intrinsic thermal stability of plasticizers of dibutyl phthalate and diisobutyl phthalate by an inorganic carbonate heat treatment is characterized in that: protonic acid, such as sulfuric acid, is adopted to serve as an esterifying catalyst, coarse ester is thermally decomposed by anhydrous solid carbonates in a reaction system prepared through esterifying synthesis of benzoic anhydrides and n-butyl alcohol or isobutyl alcohol, the catalyst and byproducts generated in the reaction process are effectively removed, coloring byproducts in the esterifying reaction system can be effectively removed, the effect of improving the product stability is achieved, and the requirement on thermal treatment of polyvinyl chloride (PVC) products is met; compared with the conventional production methods, the method has the advantages that: process wastewater is reduced by two-thirds, the production period is shortened, and the aims of energy conservation and emission reduction are fulfilled.

Owner:JIANGNAN UNIV +1

Chlorosulfonated polyethylene cable sheath material and preparation method thereof

InactiveCN103265764AImprove aging resistanceImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesPolymer scienceSilanes

The invention discloses a chlorosulfonated polyethylene cable sheath material and a preparation method thereof. The cable sheath material comprises the following raw materials: chlorosulfonated polyethylene, impact-resistant polystyrene, nano calcium carbonate, siliceous rock powder, modified zinc borate, ethyl carbamate, an accelerant CZ, a silane coupling agent KH550, epoxidized butyl stearate, thiodipropionate, alkylphenol polyoxyethylene and diisobutyl phthalate. By taking the chlorosulfonated polyethylene as a main material, the cable sheath material is excellent in aging resistance, heat resistance, low-temperature resistance, oil resistance and electrical-insulation resistance. By taking the nano calcium carbonate as a reinforcing agent and modifying the zinc borate serving as a fire retardant, the fire resistance of the cable sheath is improved greatly, so that the cable sheath is obvious in fire resistance.

Owner:ANHUI CHANGYUAN ZHIHAO ELECTRIC POWER SCI & TECH

Nano vermiculite modified composite sound absorbing material and preparation method thereof

The invention discloses a nano vermiculite modified composite sound absorbing material. The material is prepared from the following raw materials in parts by weight: 100-120 parts of barite powder, 50-60 parts of ceramsite, 40-50 parts of nano vermiculite, 80-90 parts of polyvinyl acetate emulsion, 55-65 parts of modified tree ashes, 15-20 parts of aluminium hydroxide, 20-30 parts of polybenzimidazole fibers, 10-20 parts of nanocarbon, 20-30 parts of EVA (ethylene-vinyl acetate copolymer), 15-20 parts of CPE (chlorinated polyethylene), 5-10 parts of HIPS (high impact polystyrene), 5-8 parts of diisobutyl phthalate, 4-6 parts of decabromodiphenyl ether, 2-3 parts of zinc stearate and 1-2 parts of tribasic lead sulfate. The material has the beneficial effects that the problem of developing and researching the sound absorbing material urgently is solved and the novel sound absorbing material which meets the requirements, can stand the tests of harsh environments and has the advantages of high tensile strength, high elongation, high breaking strength, good sound absorbing effect and the like is prepared.

Owner:芜湖跃飞新型吸音材料股份有限公司

Quickly-vitrified fire resisting cable material

The invention provides a quickly-vitrified fire resisting cable material. The fire resisting cable material is prepared from the following raw materials in parts by weight: 40-50 parts of ethylene-vinyl acetate copolymer, 30-40 parts of polyethylene, 20-35 parts of natural rubber, 30-40 parts of butadiene styrene rubber, 4-6 parts of a compatilizer, 1-2 parts of zinc oxide, 20-30 parts of argil, 10-15 parts of kaolin, 5-6 parts of medical stone, 6-7 parts of garnet, 1-2 parts of 3-aminopropyl trimethoxy silane, 3-4 parts of rapeseed oil, 1-2 parts of pentaerythritol, 1-2 parts of melamine cyanurate, 1-2 parts of molybdenum trioxide, 4-6 parts of ammonium molybdate, 1-2 parts of copper oxide, 1-2 parts of polytetrafluoroethylene micropowder, 10-12 parts of DIBP (diisobutyl phthalate), 6-8 parts of tributyl acetocitrate, 2-4 parts of epoxyoctyl stearate, 1-2 parts of a crosslinking agent TAIC (triallyl isocyanurate), 1-2 parts of ferrocene, and 12-15 parts of a modified filler. The fire resisting cable material is high in fire resistance. At high temperature, the fire resisting cable material can be quickly vitrified to protect the normal use of a cable. Meanhwile, the fire resisting cable material is environment-friendly and high in weather resistance.

Owner:北京福斯机械有限公司

Environment-friendly textile pigment and preparation method thereof

The invention discloses an environment-friendly textile pigment and a preparation method thereof. The pigment is prepared from the following raw materials in parts by weight: 50.0-70.0 parts of styrene-acrylate emulsion, 10.0-20.0 parts of polyvinyl acetate emulsion, 10.0-20.0 parts of ethylene vinyl acetate copolymer emulsion, 0.2-3.0 parts of fumed silica, 0.5-3.0 parts of a polyurethane thickening agent, 2.0-3.0 parts of a film coalescing agent TXIB, 2.0-8.0 parts of glycerol, 5.0-15.0 parts of diisobutyl phthalate, 2.0-3.0 parts of phenoxyethanol, 5.0-15.0 parts of a pigment, 2.0-15.0 parts of calcium carbonate, 0.2-3.0 parts of a coupling agent KH-560, 5.0-15.0 parts of a foaming pigment, 5.0-15.0 parts of a luminous pigment, 5.0-15.0 parts of glitter powder and 0.2-3.0 parts of an emulsifying agent OP-10. The pigment can be quickly dried and has good adhesive force.

Owner:JIANGSU XINGDA STATIONERY GRP

Anti-aging non-woven fabric and preparation method thereof

InactiveCN103696139AHigh tensile strengthIncrease elasticitySynthetic resin layered productsNon-woven fabricsUltravioletOyster shells

The invention relates to anti-aging non-woven fabric, which consists of a top surface layer, a back surface layer and a fiber cotton layer, wherein the fiber cotton layer is clamped and arranged between the top surface layer and the back surface layer, the top surface layer and the back surface layer are made of non-woven fabric materials, and the non-woven fabric is prepared from the following ingredients in parts by weight by a melt blowing method: 100 parts of homopolymerization isotactic polypropylene, 2 to 3 parts of glass fiber, 1 to 2 parts of PP-g-MAH compatilizers, 1 to 2 parts of hydroxyethyl cellulose, 3 to 4 parts of rutile titanium dioxide, 12 to 15 parts of diisobutyl phthalate, 2 to 3 parts of 2,2-di(2-thienyl)glycolic acid methyl ester, 1 to 2 parts of anti-aging agents RD, 2 to 3 parts of calcium citrate, 12 to 15 parts of oyster shells, 1 to 2 parts of perilla leaves, 2 to 3 parts of plum blossoms, 1 to 2 parts of borneol, 1 to 2 parts of luffa stems and 4 to 5 parts of auxiliary agents. The anti-aging non-woven fabric has the advantages that the rutile titanium dioxide is used so that the characteristics of ultraviolet ray resistance, widespread aging resistance, bright color and pollution difficulty are realized; harmful gas and peculiar smell can be adsorbed, and higher pulling-up intensity, higher bending elastic modulus and higher impact intensity are realized.

Owner:芜湖跃飞新型吸音材料股份有限公司

Efficient low-smoke composite antiflaming polyvinyl chloride (PVC) cable material and preparation method thereof

ActiveCN103627116AImprove flame retardant performanceHigh smoke suppression effectPlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideAntimony trioxide

The invention discloses an efficient low-smoke composite antiflaming polyvinyl chloride (PVC) cable material and a preparation method thereof. The cable material comprises the following raw materials in parts by weight: 80-100 parts of SG-4 PVC resin, 0-20 parts of MBS resin, 10-15 parts of diisobutyl phthalate, 0.5-1 part of lead phosphite, dibasic, 2-3 parts of lead stearate, 15-20 parts of isopropylate triphenyl phosphate, 8-12 parts of chlorcosane, 5-10 parts of activated calcium carbonate, 4-8 parts of zinc stannate, 1-2 parts of a titanate coupling agent TMC-TTS, 10-15 parts of antimonous oxide, 3-5 parts of ferrocene, 2-4 parts of potassium titanate whisker, 4-8 parts of mica powder, and 3-6 parts of composite filler. According to the invention, through the mutual synergistic effect of isopropylate triphenyl phosphate, zinc stannate, antimonous oxide and ferrocene, the fire resistance and smoke abatement property of the cable material are improved, the situation that the cable material has excellent physical and mechanical properties and electrical property is ensured, and the application reliability of the PVC cable material is improved.

Owner:立宝莱科技股份有限公司

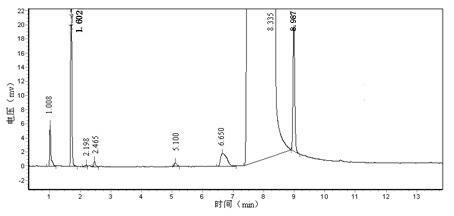

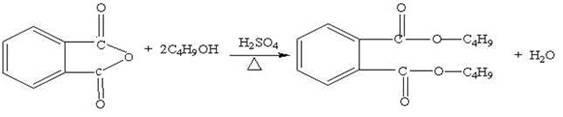

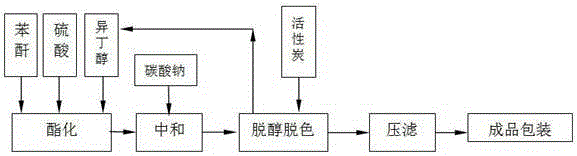

Preparation method of diisobutyl phthalate

InactiveCN105237394AEasy to recycleThe control method is simple and convenientOrganic compound preparationCarboxylic acid esters preparationIsobutanolFiltration

The invention discloses a preparation method of diisobutyl phthalate. The method comprises the following steps: 1, early stage preparation; 2, esterification reaction; 3, neutralization reaction; 4, dealcoholysis and decolorizing reaction; and 5, press filtration and packaging. In the above technical scheme, phthalic anhydride and isobutanol undergo a reaction with concentrated sulfuric acid as a catalyst to synthesize the diisobutyl phthalate plasticizer. The method has the advantages of simple and controllable process, high reaction efficiency, no byproducts, high output, good economic benefit, short reaction cycle, mild reaction conditions, good industrial application values, satisfactory recycling of wastewater and waste residues, and raw material saving.

Owner:DANYANG CITY AUX CHEM PLANT

Capsaicin-containing non-woven fabric material for sound-absorbing cotton

InactiveCN103709499AEvenly dispersedHigh strengthSynthetic resin layered productsNon-woven fabricsEggshellToluene diisocyanate

The invention relates to a non-woven fabric material, and specifically relates to a capsaicin-containing non-woven fabric material for sound-absorbing cotton. The non-woven fabric material is prepared from the following raw materials in parts by weight: 100 parts of isotatic polypropylene, 1-2 parts of anti-oxidant 1010, 2-3 parts of toluene diisocyanate, 1-2 parts of fatty alcohol polyoxyethylene ether, 2-3 parts of nanometer calcium carbonate, 1-2 parts of capsaicin, 6-9 parts of double fourteen-carbon alcohol ester, 12-15 parts of diisobutyl phthalate, 1-2 parts of eggshell powder, 1-2 parts of aluminum sulfate, 2-3 parts of cortex mori, 1-2 parts of peucedanum praeruptorum, 1-2 parts of tussilago farfara and 4-5 parts of an auxiliary agent. The non-woven fabric material has the toughening and reinforcing effects and the sound-absorbing and noise-reducing effects because of contained raw materials such as nanometer calcium carbonate, eggshell powder, Chinese herbal medicine vegetable fibre and the like; additionally, the non-woven fabric material is prolonged in service life because of the insect-preventing bacterium-preventing efficacy possessed by capsaicin; and sound-absorbing cotton can be prepared by performing multilayer stacking on the non-woven fabric material, the technology is simple and the application potential is huge.

Owner:芜湖跃飞新型吸音材料股份有限公司

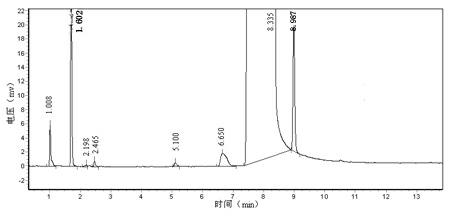

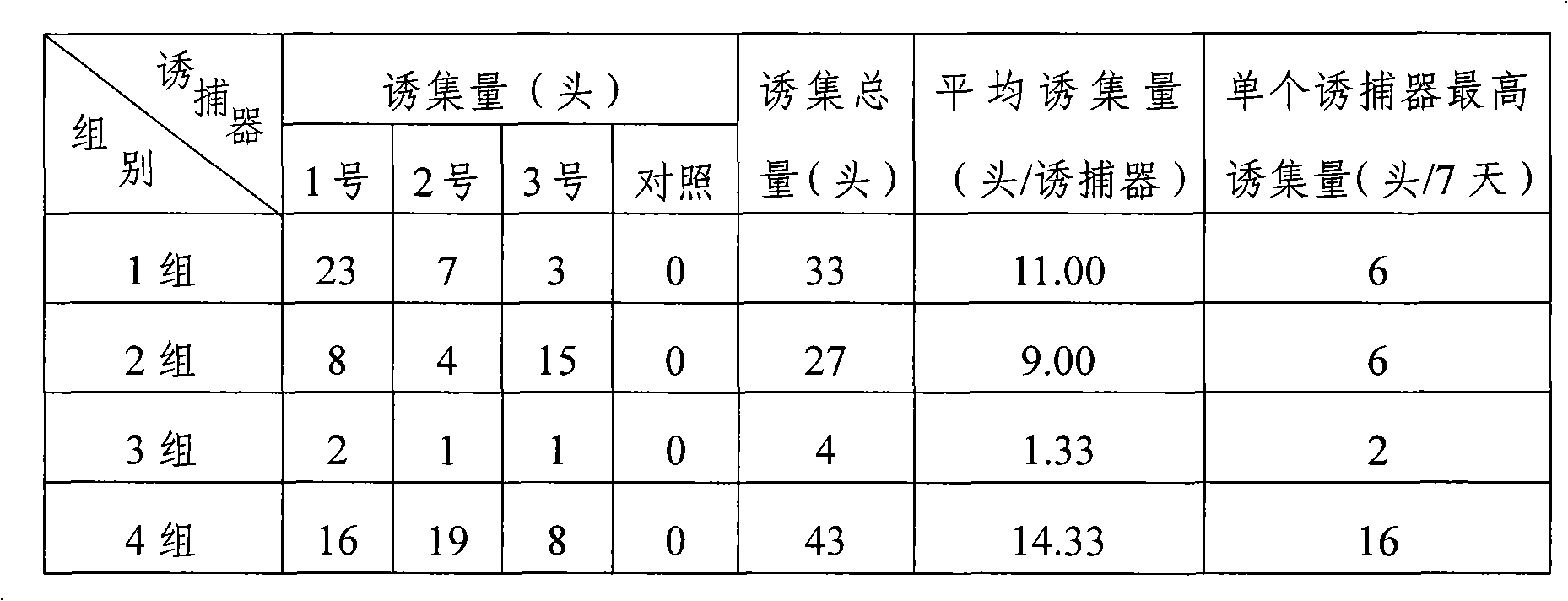

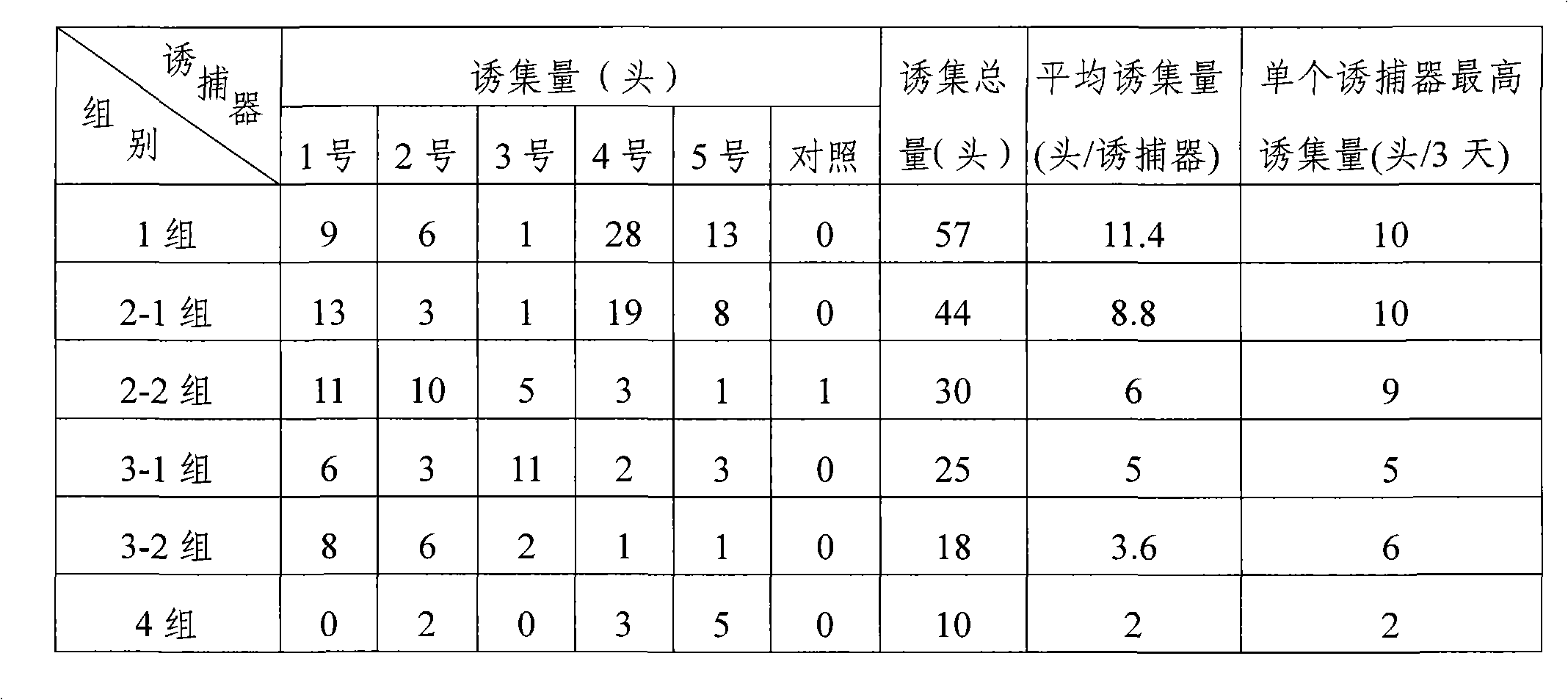

Caragana microphylla chlorophorus attractant and application thereof

InactiveCN101946767AHigh sensitivityStrong specificityBiocidePest attractantsSocial benefitsAdditive ingredient

The invention relates to a caragana microphylla chlorophorus attractant for monitoring and trapping caragana microphylla chlorophorus which is a serious stem boring pest to caragana microphylla, and an application thereof. The attractant can entrap female adults and male adults of the caragana microphylla chlorophorus without pollution conveniently and efficiently. The main components of the attractant are selected from isophorone, dibutyl phthalate or diisobutyl phthalate. The attractant provided by the invention is beneficial to protecting natural enemies of longhorned beetles when being used for no matter monitoring and reporting pest situation or using a trapping method to directly prevent and control the caragana microphylla chlorophorus, so as to protect beneficial insects and remove harmful insects, thereby improving the effect on protecting and controlling the caragana microphylla chlorophorus. In addition, the use amount of chemical pesticides can be reduced, thus reducing pollution, protecting environment, and generating obvious social benefits and ecological benefits.

Owner:BEIJING FORESTRY UNIVERSITY

Treating agent for papermaking sewage

InactiveCN106082369ANothing producedQuick responseWater/sewage treatmentWaste water treatment from plant processingSucrosePhosphate

Owner:虞永华

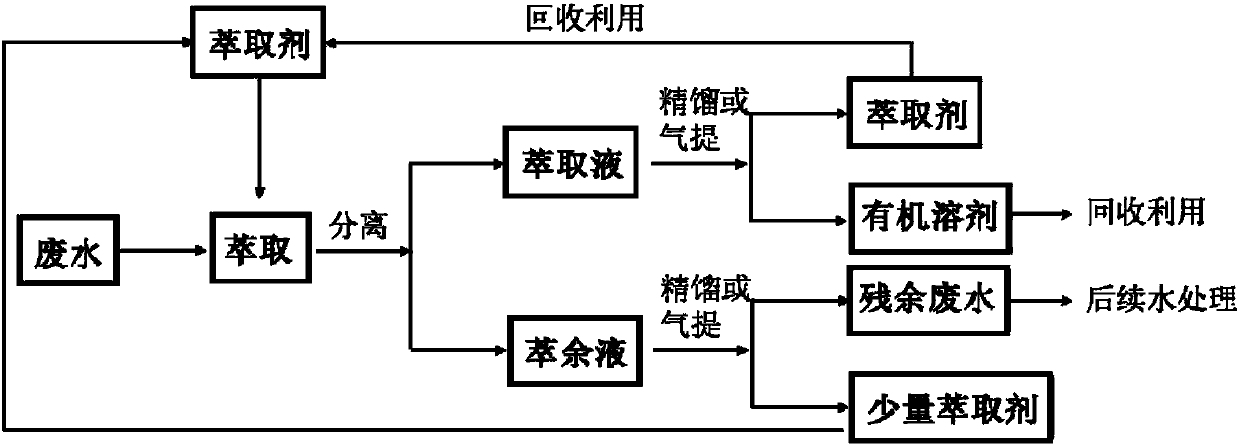

Method for recovering organic solvent from maleic anhydride wastewater

InactiveCN106698575AReduce consumptionReduce the difficulty of biochemistryWater contaminantsWater/sewage treatment by extractionDibutyl sebacateOrganic solvent

Owner:PEKING PUYUAN INST FOR ADVANCED MATERIALS & TECH

Recombinant bacteria for producing carboxylesterase and application thereof

ActiveCN109943515AImprove degradation rateEfficient degradationBacteriaHydrolasesHeterologousEscherichia coli

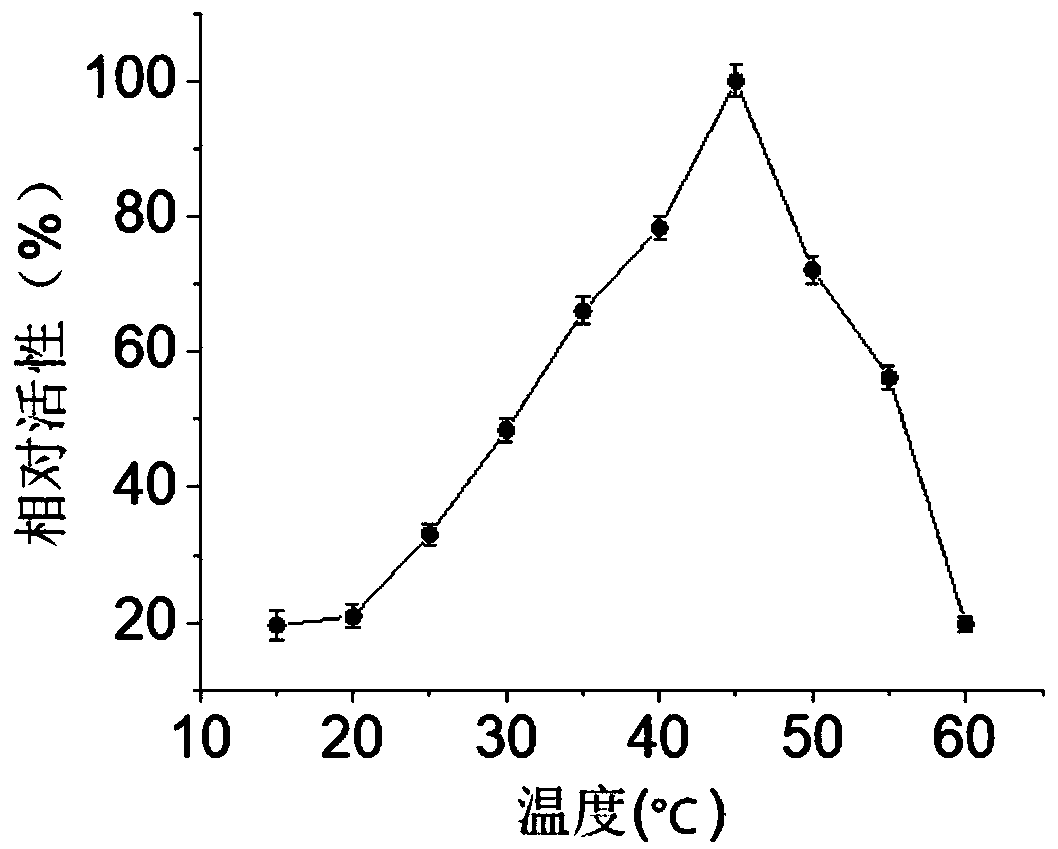

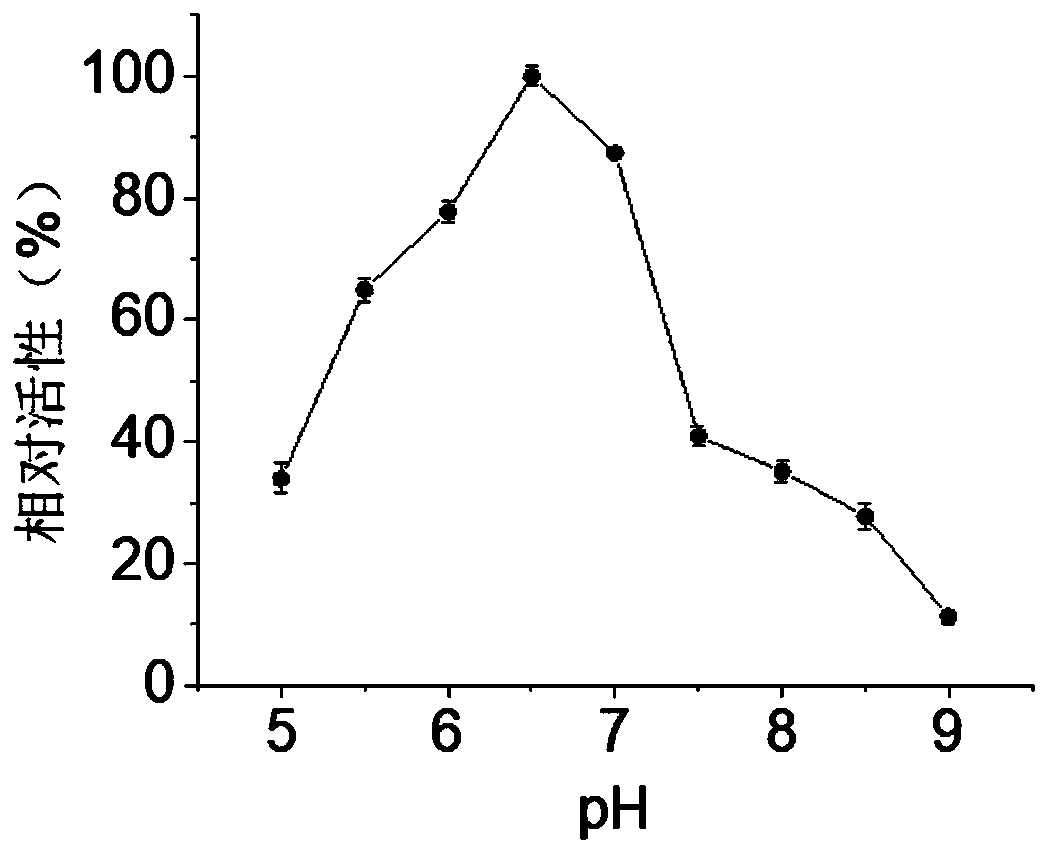

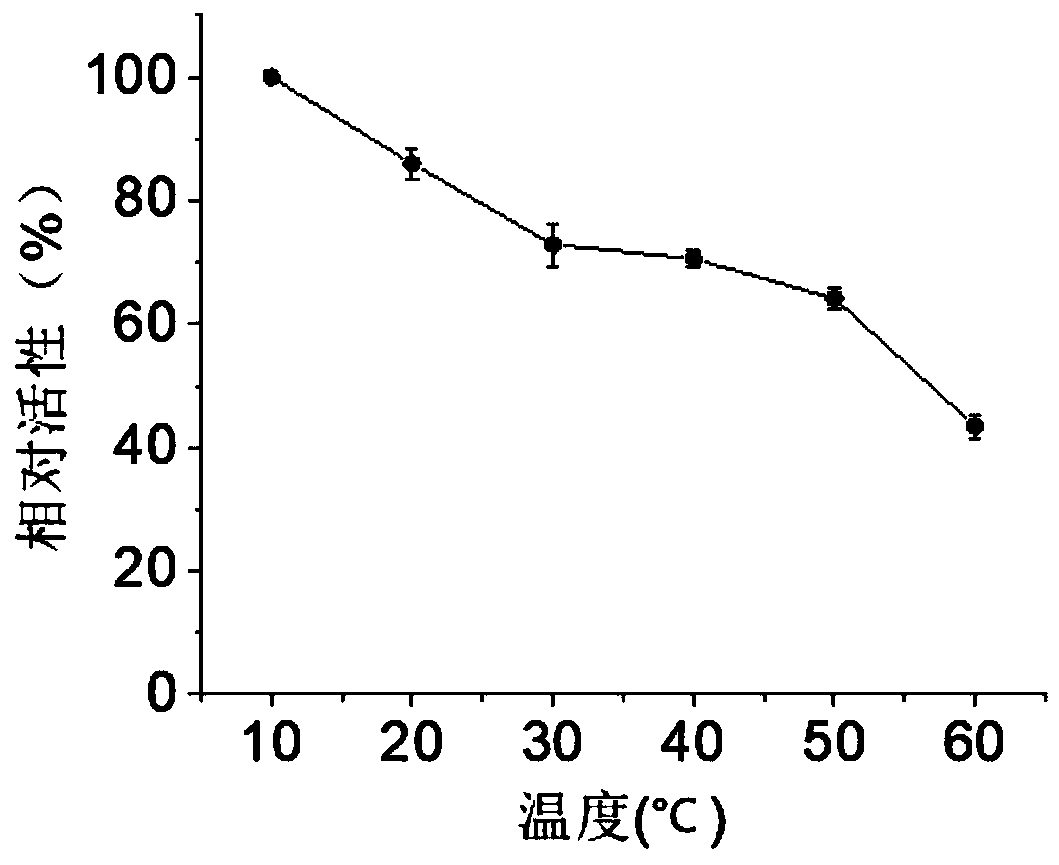

The invention discloses recombinant bacteria for producing carboxylesterase and application thereof, and belongs to the field of enzyme engineering. The carboxylesterase BaCEs02 with the amino acid sequence shown in SEQ ID NO.1 is heterologously expressed in escherichia coli, wherein the enzyme activity of 1-naphthyl acetate and 2-naphthyl acetate being substrates in crude enzyme liquid is 13831.8U / L and 8135.9 U / L. The degradation rates of carboxylesterase BaCEs02 pure enzyme liquid obtained after purification for phthalic acid ester (diethyl phthalate or dibutyl phthalate or diisobutyl phthalate) reach up to 92.2%, 95.6% and 87.3% respectively. A method for efficiently degrading a plasticizer phthalic acid ester is provided.

Owner:JIANGNAN UNIV

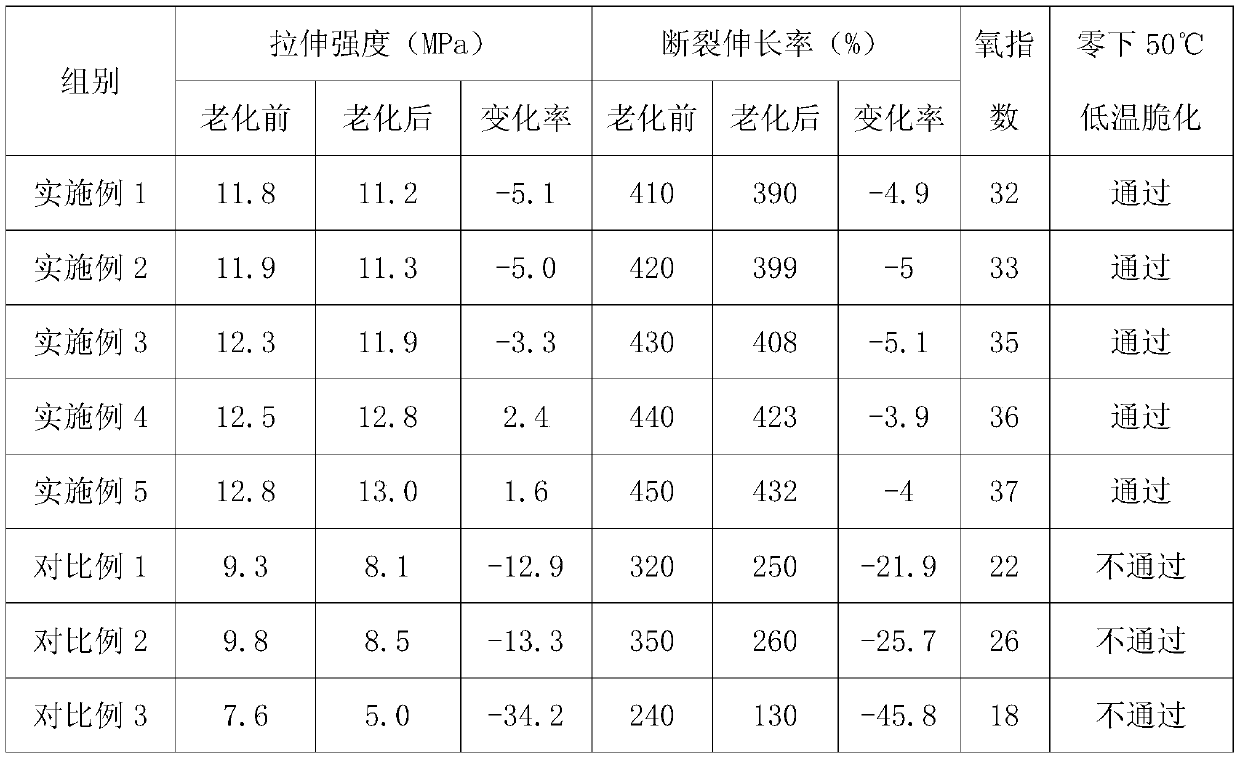

Low-temperature resistant nitrile butadiene rubber material and preparation method thereof

InactiveCN106009108AImprove wear resistanceImprove low temperature resistanceRubber materialSodium Bentonite

The invention discloses a low-temperature resistant nitrile butadiene rubber material which is prepared from the following raw materials in parts by weight: 40-50 parts of nitrile butadiene rubber, 15-20 parts of natural rubber, 20-30 parts of silicone rubber, 18-22 parts of PVC, 50-60 parts of reinforcing carbon black, 3-5 parts of anti-aging agent, 10-15 parts of bentonite, 5-8 parts of zeolite powder, 7-10 parts of stearic acid, 4-6 parts of diisobutyl phthalate, 2-3 parts of paraffin, 6-10 parts of chlorinated polyethylene, 2-4 parts of diisobutyl phthalate, 1-3 parts of sulfur and 2-4 parts of DTDM. The invention also discloses a preparation method of the low-temperature resistant nitrile butadiene rubber material. The preparation method disclosed by the invention is simple; and the prepared rubber material has perfect aging resistance and low-temperature resistance and can be used in an environment of -45 DEG C while the oil resistance and wear resistance are good, and the service life is greatly prolonged.

Owner:郭庆平

Modified terpolymer EP rubber containing cable sheath material and preparation method thereof

The invention discloses a modified terpolymer EP rubber containing cable sheath material and preparation method thereof, and the product comprises the following raw materials: modified terpolymer EP rubber, hydrogenated butadiene-acrylonitrile rubber, blast furnace slag, zeolite molecular sieve, aluminium carbide, promoter 808, promoter CZ, N-(beta-aminoethyl)-gamma-aminopropyl trimethoxysilane (triethoxysilane), barium ricinoleic acid, anti-oxidant 1010, diisobutyl phthalate and phosphate ester; the invention employs modified terpolymer EP rubber as main material, and the terpolymer EP rubber is modified, thereby the product has the characteristics of low-smoke, halogen free, flame retardation, high mechanical strength and high insulation resistor, moreover, the product has good elasticity and flexibility, simultaneously the nanometer attapulgite in the raw material is used as strengthening agent, and nanometer level titanium dioxide and aluminium carbide are used as filling materials.

Owner:东莞桥梓周氏电业有限公司

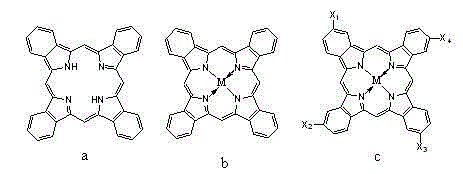

Preparation method of iron phthalocyanine

InactiveCN104311565ASimple reaction conditionsProduction environmental protectionOrganic chemistrySynthesis methodsIron phthalocyanine

The invention discloses a preparation method of iron phthalocyanine, and relates to a preparation method of a compound, the method uses ferrous metal salt, phthalic anhydride and urea as raw materials, phthalic acid ester as a solvent, ammonium molybdate as a catalyst, and ammonium chloride as a catalyst aid, and a solvent synthesis method is used. The synthetic method comprises two stages: (1) reacting for 0.5-2 h at 120 to 140 DEG C; and (2) reacting for 2-8 h at 180 to 240 DEG C. The reaction solvent is the phthalic acid ester such as dioctyl phthalate which is greener and more environmentally friendly compared with a traditional solvent such as paranitrotoluene and trichlorobenzene, the high yield of the reaction proves that the method is effective in industrialization. Through use of the dioctyl phthalate (DOP) as the green solvent, reaction condition is improved, the whole production process is more environmentally friendly, by use of the dioctyl phthalate (DOP) as the solvent, a higher yield is ensured, and at the same time, the dioctyl phthalate can also be recycled.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for preparing spherical catalyst for propylene polymerization

The invention relates to a method for preparing a spherical catalyst for propylene polymerization. The adopted technical scheme comprises the following steps of: adding white oil and silicone oil to a reaction kettle, throwing magnesium chloride and alcohol, the mole ratio of which is 1:2.8-3.0, into the reaction kettle and melting; transferring to a reaction kettle cooled to -30 DEG C after melting, to which hexane is added in advance, wherein the final temperature does not exceed 0 DEG C; performing pumping filtration and washing to obtain a spherical carrier; adding the spherical carrier to a stirred kettle holding the hexane, cooling to -10--20 DEG C, and then slowly dropping to a reaction kettle cooled to -10- -15 DEG C wherein the reaction kettle holds titanium tetrachloride for loading titanium; controlling the kettle pressure and heating to 40 DEG C; adding diisobutyl phthalate and heating to 100-105 DEG C; and controlling the kettle pressure, keeping the constant temperature for 1.5 hours, suction filtering, then adding titanium tetrachloride for washing; heating to 120 DEG C, keeping the constant temperature for 1.5 hours, and then washing until the filtrate does not contain chloride ions. The method is simple, saves raw materials, reduces production cost and is friendly to environment; and the prepared catalyst has even particles.

Owner:LIAONING DINGJIDE PETROCHEM

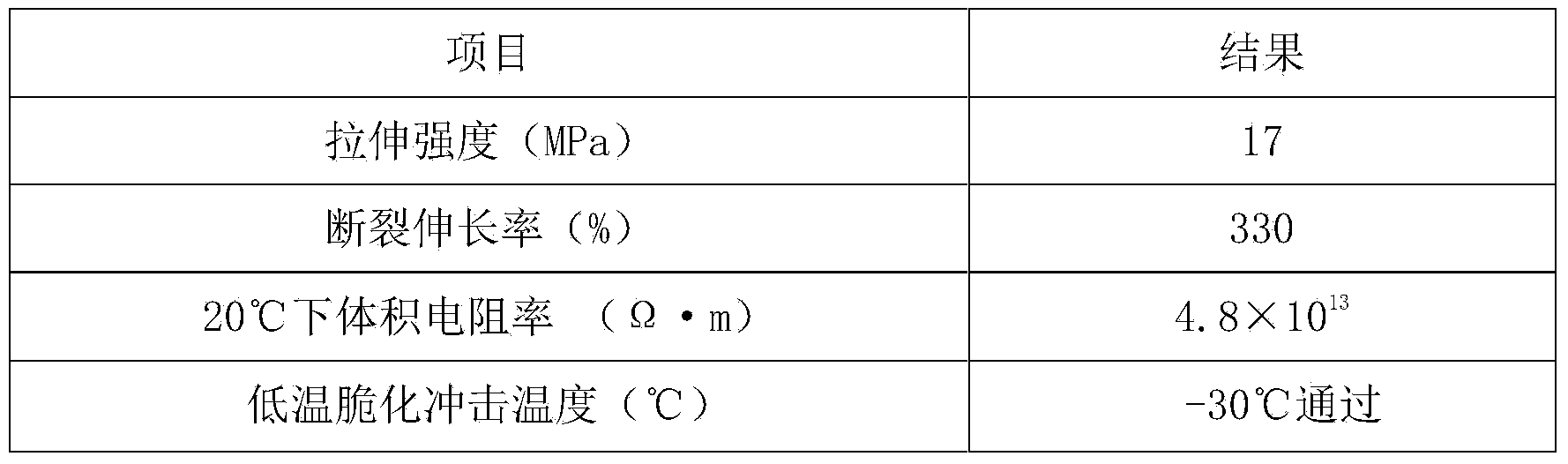

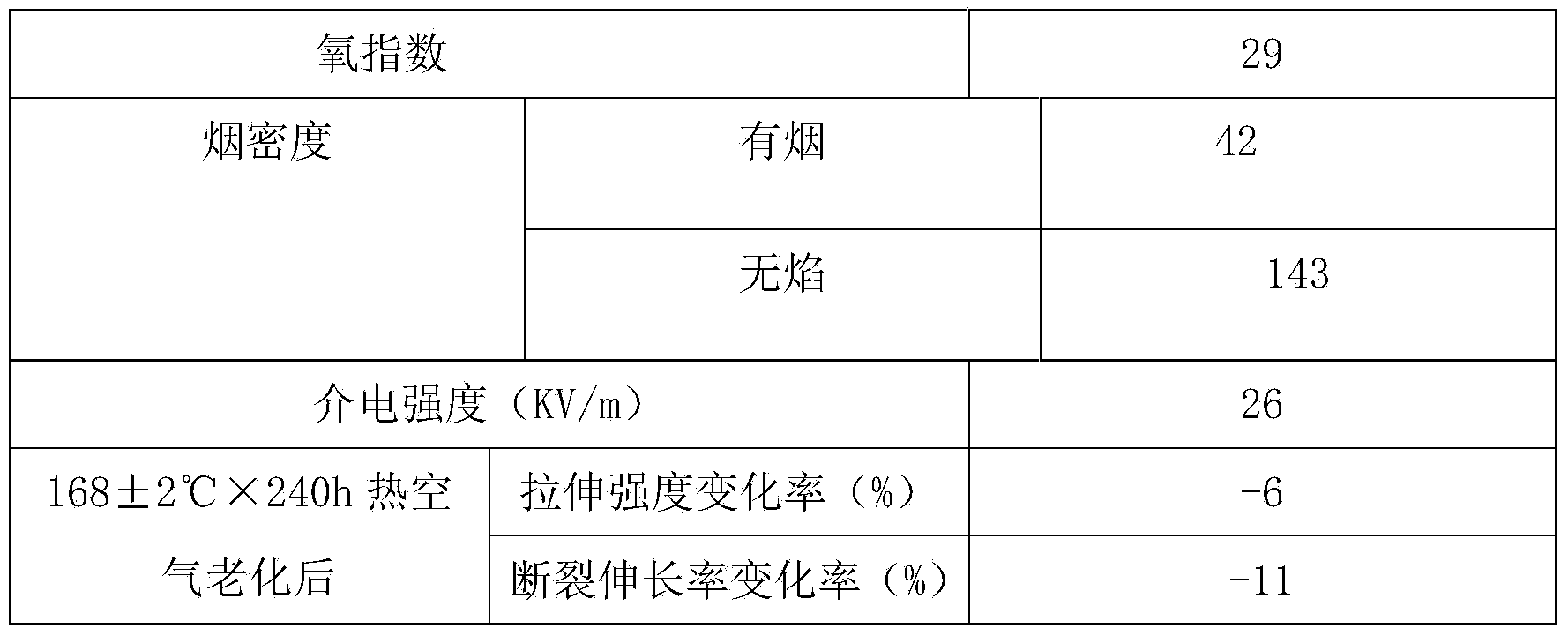

Cold-resistant cable sheath material as well as preparation method and application thereof

InactiveCN105504542AImprove low temperature resistanceImprove flame retardant performanceRubber insulatorsInsulated cablesAnhydrous ethanolMicrowave

The invention discloses a cold-resistant cable sheath material as well as a preparation method and application thereof. The cold-resistant cable sheath material consists of the following raw materials in parts by weight: 72-80 parts of ethylene propylene diene monomer, 8-15 parts of sisal, 13-18 parts of fish scale powder, 20-26 parts of dimer fatty acid, and 35-46 parts of diisobutyl phthalate. The preparation method comprises the following steps: drying and crushing the sisal, adding anhydrous ethanol, and carrying out sealed treatment and microwave drying to obtain treated sisal; drying and crushing fish scales, adding anhydrous ethanol, and carrying out ultrasonic treatment and drying to obtain treated fish scale powder; and mixing ethylene propylene diene monomer with dimer fatty acid, carrying out ultrasonic vibration treatment, adding diisobutyl phthalate, and carrying out heat treatment on the treated sisal and the treated fish scale powder to obtain the cold-resistant cable sheath material. The cold-resistant cable sheath material disclosed by the invention has the advantages of excellent low-temperature resistance, flame-retardant performance and torsion resistance, has simple raw materials and a simple preparation process, and is suitable for cables in cold areas.

Owner:YUYAO YUNHUAN ORIENT ELECTRONICS CO LTD

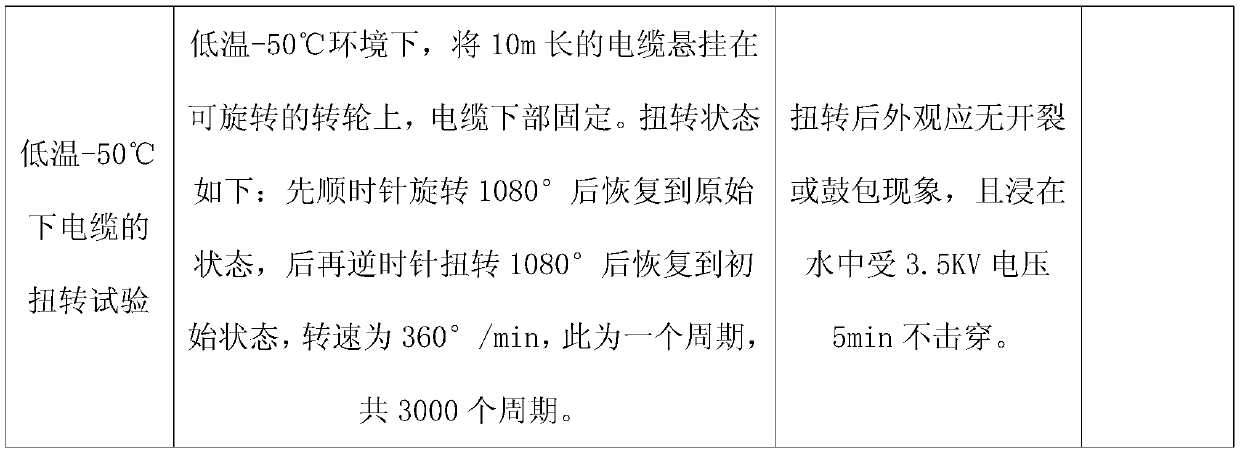

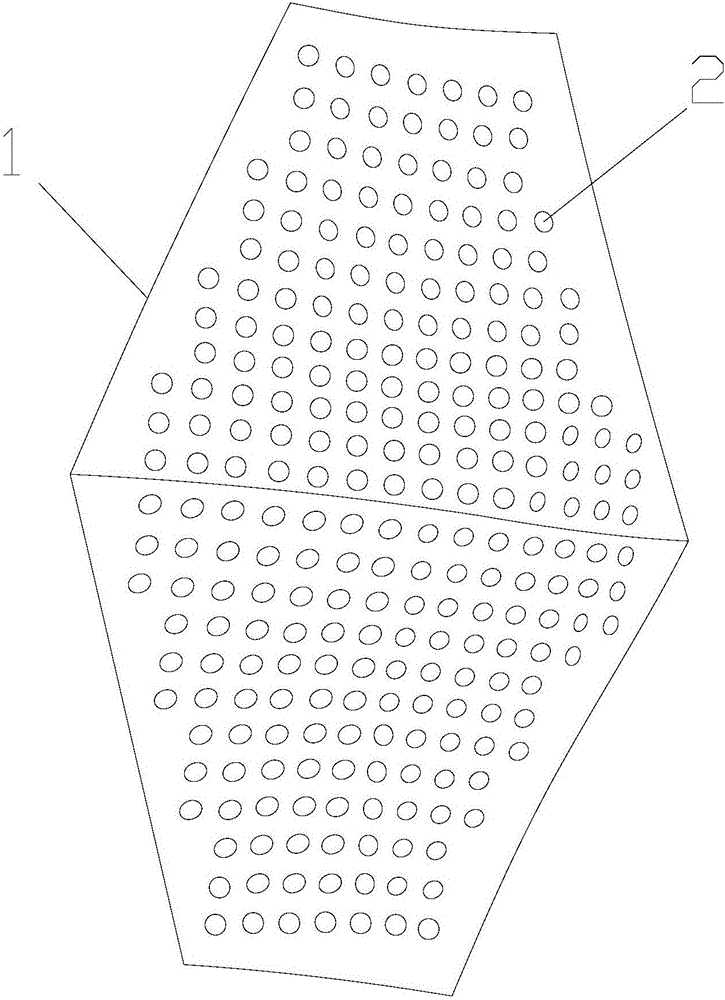

Negative ion mask inner liner and preparation method thereof

The invention discloses a negative ion mask inner liner, which comprises a body, wherein the body is in a hexagonal shape; through holes are uniformly distributed in the surface of the body; the through holes are in round arrangement; the body is prepared from the following materials in parts by weight: 22 to 25 parts of coral fossil, 48 to 50 parts of tourmaline, 25 to 30 parts of lanthanum oxalate, 13 to 15 parts of dysprosium carbonate, 8 to 12 parts of rubber latex, 3 to 8 parts of polyethylene glycol terephthalate, 9 to 15 parts of polycarbonate, 13 to 18 parts of polymethacrylate, 6 to 8 parts of epoxidized soybean oil, 7 to 14 parts of calcium carbonate, 3 to 8 parts of magnesium carbonate, 12 to 16 parts of diphenylethene, 17 to 20 parts of diisobutyl phthalate, 8 to 10 parts of diethyl phthalate, 21 to 26 parts of para-phenylene diamine, 10 to 15 parts of polylactic acid and 8 to 14 parts of polycaprolactone. The negative ion mask inner liner has the advantages that negative ions can be generated; the immunity can be improved; the service life of the material is long; the tensile strength of the material is high.

Owner:ZHEJIANG XINGYUAN BIOTECH CO LTD

Volatile solvent type antirust oil and preparation method thereof

The invention discloses a kind of volatile solvent type antirust oil and a preparation method thereof, and aims to provides a kind of volatile solvent type antirust oil, which has stable properties, a strong salt smog resistance property, and an excellent antirust property. To achieve the goals mentioned above, the volatile solvent type antirust oil is composed of petroleum antirust agent, dodecenylsuccinic acid ester, triazole, diisobutyl phthalate, long carbon chain alkanolamide, high carbon oxidized aliphatic ester, mineral base oil, and solvent oil.

Owner:修建东

Heat-resistant crack-resistant organic glass and preparation method thereof

InactiveCN107057254AIncrease steric hindranceImprove molecular weightEthyl hydroxybenzoateMethacrylate

The invention discloses heat-resistant crack-resistant organic glass and a preparation method thereof; the heat-resistant crack-resistant organic glass comprises, by weight, methyl methacrylate, polycyclic norbornene methacrylate, butanediol diacrylate, epoxidized soybean oil acrylate, an impact modifier, 1-dodecanethiol, polyacrylamide, rubber particles, poly(butyl acrylate), nylon terpolymer, rare earth, azobisisobutyronitrile, dicumyl peroxide, diisobutyl phthalate, and ethyl 4-hydroxybenzoate. The heat-resistant crack-resistant organic glass and the preparation method thereof are provided herein; the organic glass has high glass transition temperature, good heat resistance and good mechanical properties, rarely cracks and has good economic benefit.

Owner:蚌埠承永玻璃制品有限公司

Sealing rubber strip for automobile window and preparation method of sealing rubber strip

The invention discloses a sealing rubber strip for an automobile window. The sealing rubber strip is made of the following materials in parts by weight: 22-26 parts of polyvinyl chloride, 40-45 parts of ethylene-propylene-diene-terpolymer rubber, 6-10 parts of paraffin, 7-11 parts of poly propadiene siloxane, 12-15 parts of tert-Butylhydroquinone, 18-20 parts of diisobutyl phthalate, 9-14 parts of sulfydryl acid ester, 8-12 parts of lauryl alcohol polyoxyethylene, 6-12 parts of sodium fluosilicate, 2-4 parts of coal gangue, 15-20 parts of carbon black, 2-3 parts of trichlorofluoromethane, 4-8 parts of sodium alcohol ether sulfate, 6-11 parts of aluminum borate crystal whisker, 12-14 parts of silicic acid hydrate, 9-15 parts of sodium antimonate, 3-8 parts of diisopropylamine and 7-11 parts of glyceryl tristearate. The sealing rubber strip of the automobile window is provided with bubbles inside and is good in elasticity, good in corrosion resistance and aging resistance, and long in service life.

Owner:芜湖天鸿汽车零部件有限公司

High-strength fluorine rubber gasket material and preparation method thereof

The invention discloses a high-strength fluorine rubber gasket material. The high-strength fluorine rubber gasket material is characterized by being prepared from the following raw materials in parts by weight: 75-80 parts of fluororubber, 20-24 parts of carbon black, 2-3 parts of 2.5-dimethyl-2.5 bi(tertiary butyl peroxyl) hexane, 4-5 parts of triallyl isocyanurate, 10-12 parts of diisobutyl phthalate, 2-3 parts of aluminium stearate, 1-2 parts of sulphur, 2-3 parts of zinc oxide, 3-4 parts of vaseline, 14-18 parts of butyl rubber (BBK232), 3-5 parts of glycerinum triacetate, 20-25 parts of bauxite powder, 10-15 parts of carbon black N339, 1-2 parts of a titanate coupling agent TMC-TTS, 0.8-1.2 parts of an accelerant Na-22, and 10-12 parts of modified attapulgite. The modified attapulgite is added in the high-strength fluorine rubber gasket material, so that the processing property of a sizing material is improved. The high-strength fluorine rubber gasket material has the advantages of high strength, good oil resistance, pressure resistance and sealing performance, simple process and low cost.

Owner:马鞍山市中澜橡塑制品有限公司

Prepn process of anticorrosive metal paint

InactiveCN1847335AStrong adhesionWon't fall offLiquid surface applicatorsConjugated diene hydrocarbon coatingsPolymer scienceWater resistant

The present invention provides the preparation process of anticorrosive metal paint. The anticorrosive metal paint is prepared with n-butyl alcohol 22-54 weight portions, 200#solvent oil 18-26 weight portions, diisobutyl phthalate 3-8 weight portions, phenolic resin 4-6 weight portions and butadiene styrene rubber 2-4 weight portions. The preparation process includes the following steps: throwing n-butyl alcohol and 200# solvent oil into reactor with stirrer and stirring for 10 min; adding diisobutyl phthalate and phenolic resin and stirring at 1500-2400 rpm for 1.5-2 hr; adding butadiene styrene rubber and raising the rotation speed to 3600-4000 rpm for high speed shearing for 1 hr; and finally filtering and packing. The paint can form protecting film fast, and the protecting film is acid and alkali resistant, water resistant, high in adhesion and weather resistant.

Owner:邹文和

High-efficient ceramic binding agent

InactiveCN104212390ACuring at room temperatureHigh bonding strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPotassiumPotassium hydrogen phthalate

The invention discloses a high-efficient ceramic binding agent which is composed of following raw materials including 2-3 parts of silicon powder, 3-5 parts of diatom ooze, 6-8 parts of mica powder, 9-12 parts of bentonite, 5-10 parts of magnesium oxide, 10-12 parts of barium sulfate, 3-6 parts of calcium carbonate, 4-8 parts of calcium oxide, 2-6 parts of tetraethoxysilane, 3-5 parts of vinyltrimethoxysilane, 1-3 parts of aminopropyltriethoxysilane, 3-5 parts of 2-bromoisobutyryl bromide, 6-10 parts of diethylene triamine pentamethylene phosphonic acid, 3-5 parts of pentamethyldiethylenetriamine, 5-8 parts of diisobutyl phthalate, 3-5 parts of 2-methyl-2-propanol, 4-6 parts of potassium biphthalate, 100-120 parts of phenol-formaldehyde resin and 50-80 parts of petroleum resin. The high-efficient ceramic binding agent is used for binding and repairing of a ceramic product, can cure at normal temperature, is high in binding strength, and is acid-resistant, alkali-resistant and corrosion-resistant.

Owner:黄惠娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com