Cold-resistant cable sheath material as well as preparation method and application thereof

A cable sheathing and cold-resistant technology, which is used in insulated cables, cables, circuits, etc., to achieve the effects of simple preparation process, excellent torsion resistance, and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

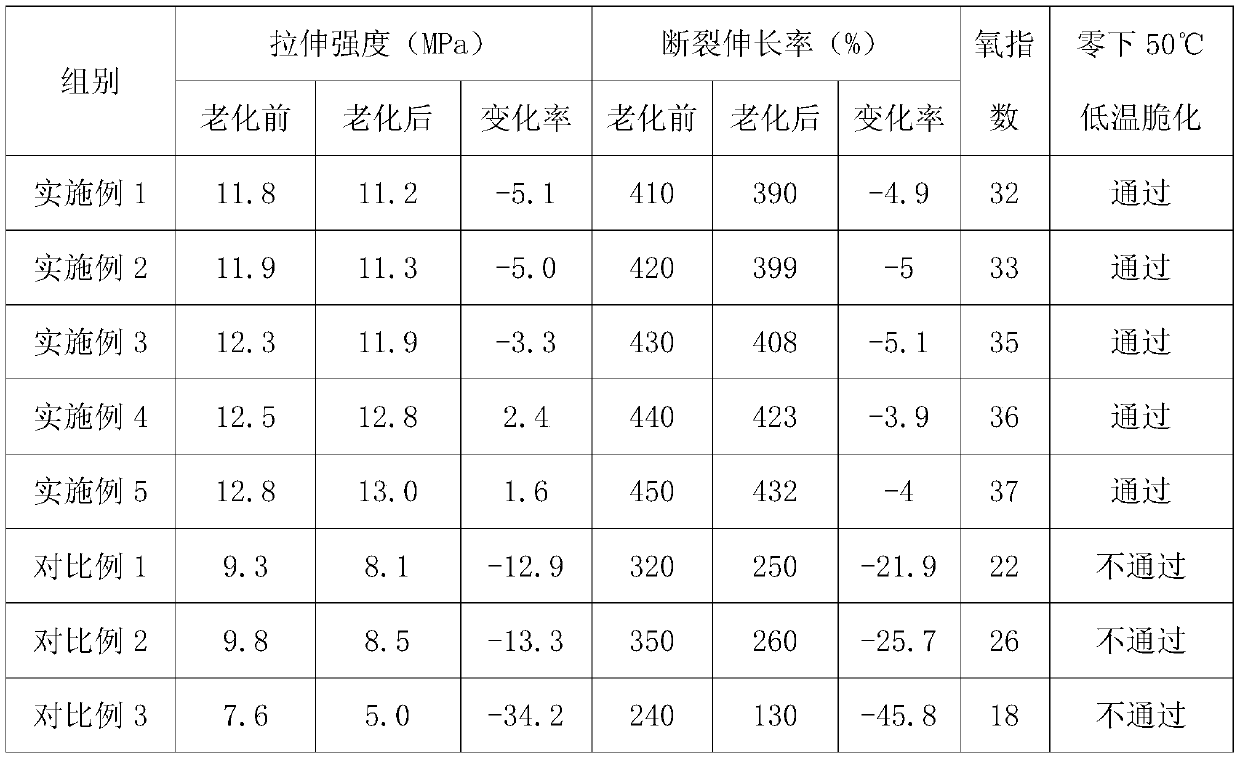

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a cold-resistant cable sheath material is composed of the following raw materials in parts by weight: 72 parts of EPDM rubber, 8 parts of sisal hemp, 13 parts of fish scale powder, 20 parts of dimer fatty acid, phthalate 35 parts of diisobutyl formate.

[0018] Treatment of sisal: Wash and dry the sisal, crush it through a 100-mesh sieve, then add anhydrous ethanol 3 times its mass, seal and stir at 60°C for 30 minutes, then put it into a microwave reactor for microwave treatment, heat Reaction at 140°C for 2 hours; after drying, the treated sisal is obtained. Treatment of fish scale powder: Wash and dry the fish scales, crush them through a 100-mesh sieve, then add anhydrous ethanol 4 times its mass, and perform ultrasonic treatment twice, with a power of 900W, and each ultrasonic treatment time is 35min. After treatment and drying, the treated fish scale powder is obtained. Mix EPDM rubber with dimer fatty acid, raise the ...

Embodiment 2

[0020] In the embodiment of the present invention, a cold-resistant cable sheath material is composed of the following raw materials in parts by weight: 80 parts of EPDM rubber, 15 parts of sisal hemp, 18 parts of fish scale powder, 26 parts of dimer fatty acid, phthalate 46 parts of diisobutyl formate.

[0021] Treatment of sisal: Wash and dry sisal, crush it through a 120-mesh sieve, then add absolute ethanol 4 times its mass, seal and stir at 65°C for 40 minutes, then put it into a microwave reactor for microwave treatment, heat Reaction at 150°C for 3 hours; after drying, the treated sisal is obtained. Treatment of fish scale powder: Wash and dry the fish scales, crush them through a 120-mesh sieve, then add anhydrous ethanol with 5 times its mass, and perform ultrasonic treatment for 3 times. The ultrasonic treatment power is 1000W. After treatment and drying, the treated fish scale powder is obtained. Mix EPDM rubber with dimerized fatty acid, raise the temperature to ...

Embodiment 3

[0023] In the embodiment of the present invention, a cold-resistant cable sheath material is composed of the following raw materials in parts by weight: 74 parts of EPDM rubber, 10 parts of sisal hemp, 14 parts of fish scale powder, 22 parts of dimer fatty acid, phthalate 38 parts of diisobutyl formate.

[0024] Treatment of sisal: Wash and dry the sisal, crush it through a 120-mesh sieve, then add anhydrous ethanol 3.5 times its mass, seal and stir at 62°C for 35 minutes, then put it into a microwave reactor for microwave treatment, heat Reaction at 145°C for 2.5 hours; after drying, the treated sisal is obtained. Treatment of fish scale powder: Wash and dry the fish scales, crush them through a 120-mesh sieve, then add 4.5 times the mass of absolute ethanol, and perform ultrasonic treatment for 3 times with a power of 1000W, and each ultrasonic treatment time is 40min. After treatment and drying, the treated fish scale powder is obtained. Mix EPDM rubber with dimer fatty a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com