Oil-resistant low-temperature-resistant weather-proof rubber sealing material and preparation method and application thereof

A technology of rubber sealing and low temperature resistance, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems that do not involve low temperature resistance, oil resistance, ozone resistance and compression permanent deformation resistance, and achieve easy industrial promotion, good oil resistance, Good oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

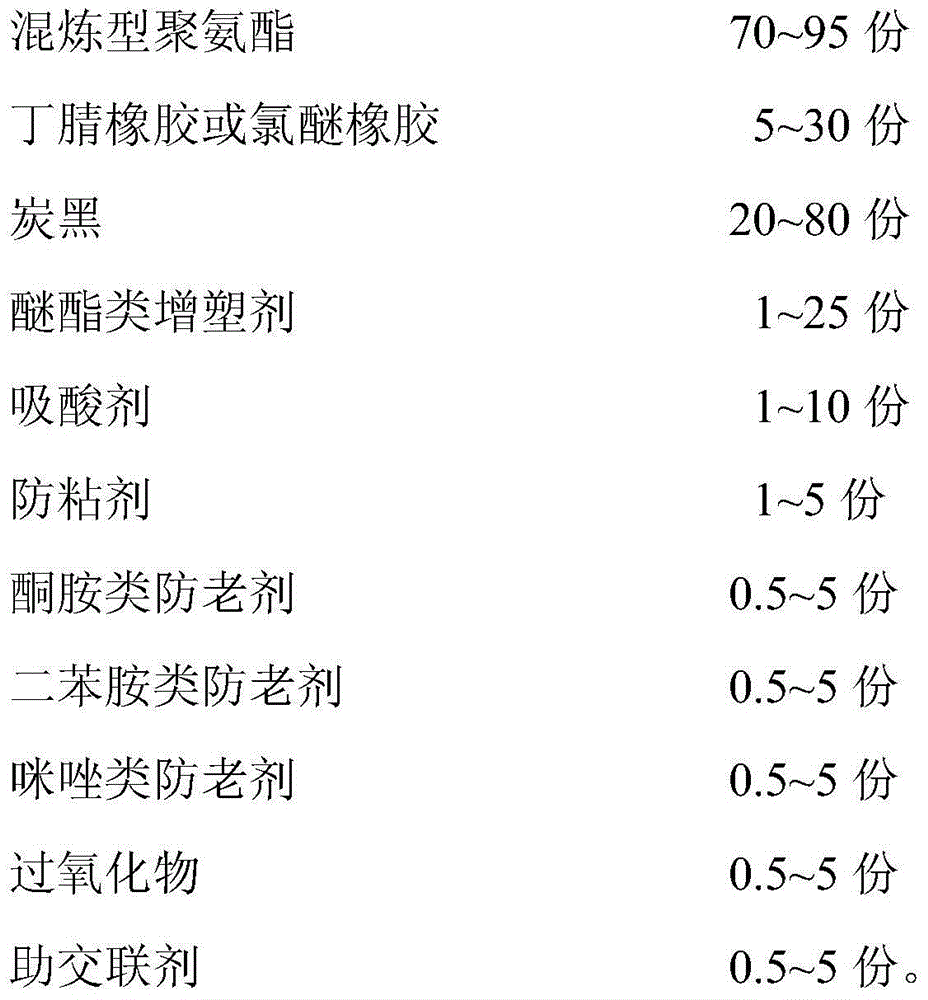

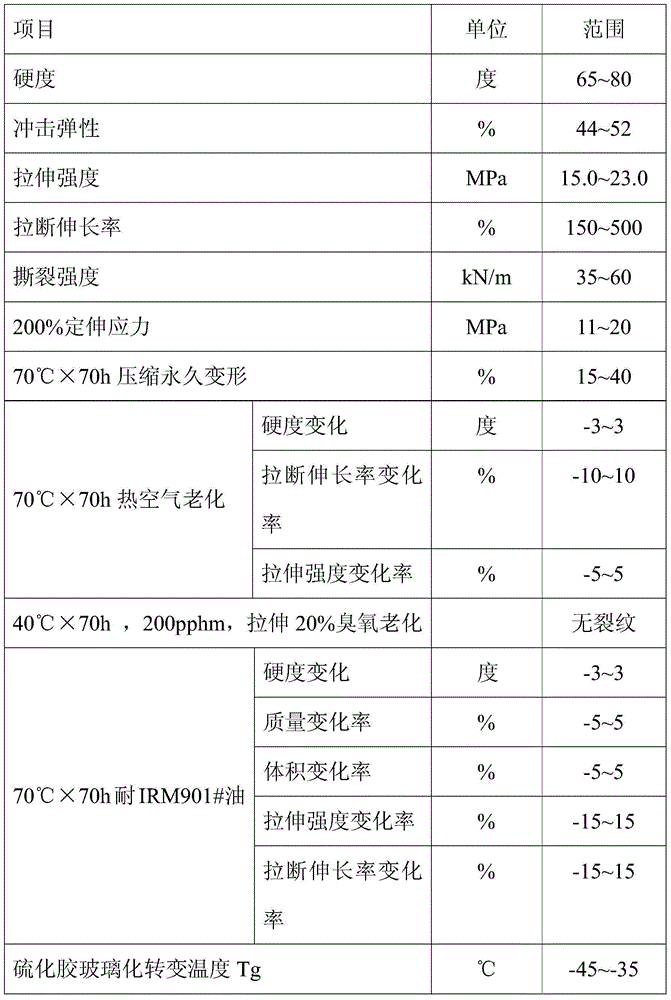

Method used

Image

Examples

Embodiment 1

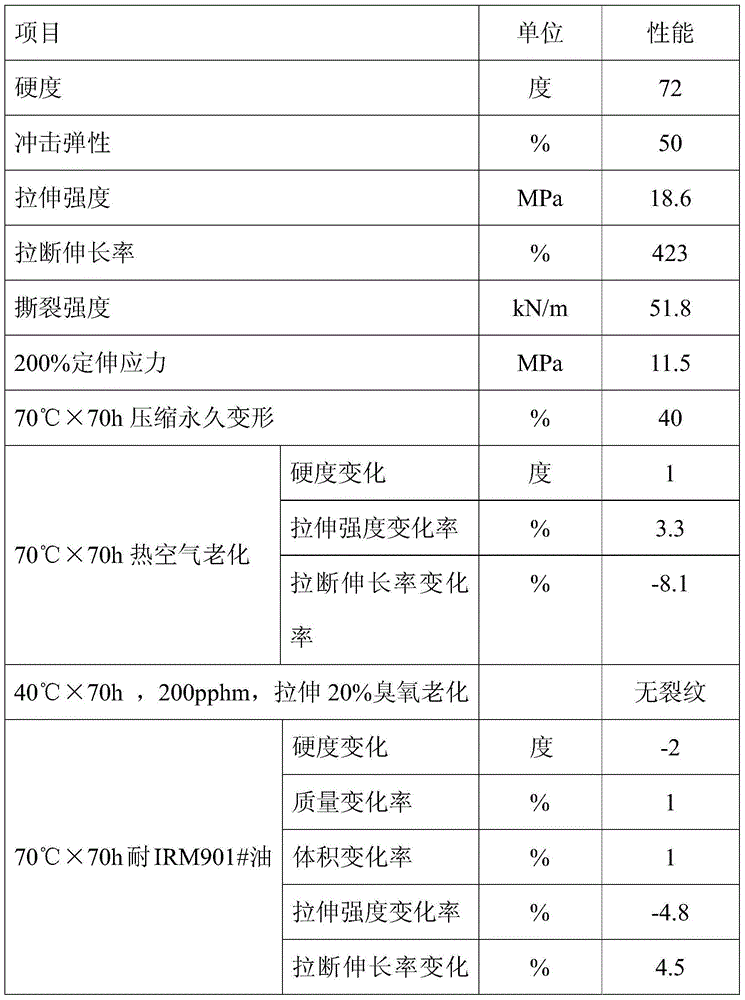

[0043] The oil-resistant, low-temperature and weather-resistant rubber sealing material formula of table 2 embodiment 1

[0044] Polyether Mixable Polyurethane

90

Nitrile rubber NBR1846

5

N660 General Purpose Carbon Black

60

Plasticizer TP95 (di(butoxyethoxyethyl) adipate)

5

0.5

Antisticking agent IM-1 (fatty acid calcium soap)

1.5

Antiaging agent RD (2,2,4-trimethyl-1,2-dihydroquinoline polymer)

1.5

Antiaging agent 445 (diphenylamine substituted derivatives)

0.5

Antiaging Agent MB (2-Mercaptobenzimidazole)

0.5

DCP (dicumyl peroxide)

1.5

R153D (1,2-polybutadiene)

3

[0045] According to the formula shown in the above table 2, the raw materials are mixed on the open mill to obtain the rubber compound, and the mixing method is as follows:

[0046] (1) Pass the polyether type mixing type polyurethane thin pass 7 to 10 times, and the nitrile...

Embodiment 2

[0053] The oil-resistant, low-temperature and weather-resistant rubber sealing material formula of table 4 embodiment 2

[0054] Polyether Mixable Polyurethane

80

Nitrile rubber NBR1846

20

N660 General Purpose Carbon Black

60

Plasticizer TP95 (di(butoxyethoxyethyl) adipate)

5

0.5

Antisticking agent IM-1 (fatty acid calcium soap)

1.5

Antiaging agent RD (2,2,4-trimethyl-1,2-dihydroquinoline polymer)

1.5

Antiaging agent 445 (diphenylamine substituted derivatives)

0.5

Antiaging Agent MB (2-Mercaptobenzimidazole)

0.5

DCP (dicumyl peroxide)

1.5

R153D (1,2-polybutadiene)

3

[0055] According to the formula shown in the above table 4, the raw materials are mixed on an open mill to obtain a rubber compound, and the mixing method is as follows:

[0056] (1) Pass the polyether type mixing type polyurethane thin pass 7 to 10 times, and the nitrile r...

Embodiment 3

[0062] The oil-resistant, low-temperature and weather-resistant rubber sealing material formula of table 6 embodiment 3

[0063] Polyether Mixable Polyurethane

70

Nitrile rubber NBR1846

30

N660 General Purpose Carbon Black

60

Plasticizer TP95 (di(butoxyethoxyethyl) adipate)

5

0.5

Antisticking agent IM-1 (fatty acid calcium soap)

1.5

Antiaging agent RD (2,2,4-trimethyl-1,2-dihydroquinoline polymer)

1.5

Antiaging agent 445 (diphenylamine substituted derivatives)

0.5

Antiaging Agent MB (2-Mercaptobenzimidazole)

0.5

DCP (dicumyl peroxide)

1.5

R153D (1,2-polybutadiene)

3

[0064] According to the formula shown in the above table 6, the raw materials are mixed on an open mill to obtain a rubber compound, and the mixing method is as follows:

[0065] (1) Pass the polyether type mixing type polyurethane thin pass 7 to 10 times, and the nitrile r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com