High-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material, and preparation method and applications thereof

A rubber material, electrical and thermal conductivity technology, applied in the field of modified rubber, can solve the problems of poor weather resistance, poor oil resistance, decreased mechanical properties, etc., and achieve air aging resistance, excellent mechanical properties, oil resistance, and good heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

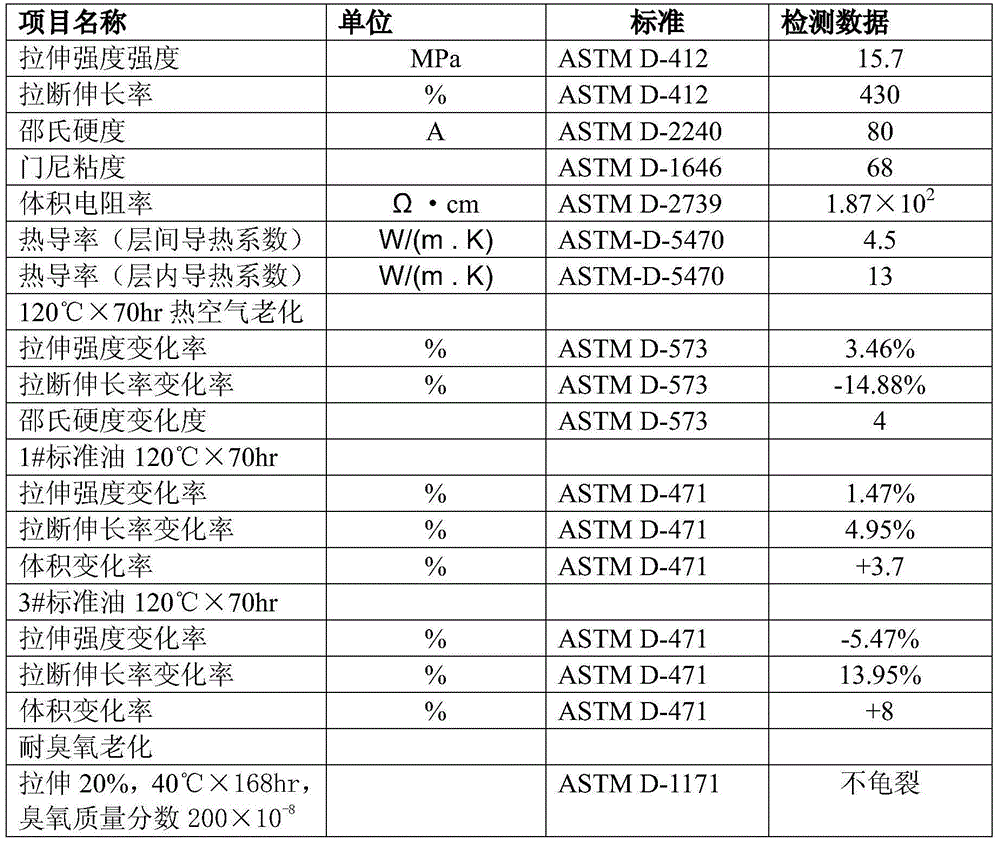

Embodiment 1

[0053]1. Dissolve 20.3g of nickel nitrate and 17.9g of magnesium nitrate in 100ml of absolute ethanol to prepare a mixed catalyst precursor solution, and prepare a 1:1 mixed solution of 0.7mol / L of nickel nitrate and magnesium nitrate. Apply the prepared precursor solution evenly on the copper sheet substrate, and let it dry naturally;

[0054] 2. After winding the tin wire, place it under the substrate and put it on the deposition table in the chamber of the DC plasma chemical vapor deposition equipment. Close the vacuum chamber and turn on the vacuum pump to evacuate. When the pump pressure is less than 0.1pa, pass argon and hydrogen into the vacuum chamber. The flow rates of argon and hydrogen are 4L / min and 10L / min respectively, start the DC arc, adjust the arc current to 120A, adjust the exhaust valve and the vacuum chamber control valve, so that the pressure in the vacuum chamber is stabilized at 3000Pa, react for 8min, and obtain Ni / MgO catalyst;

[0055] 3. Under th...

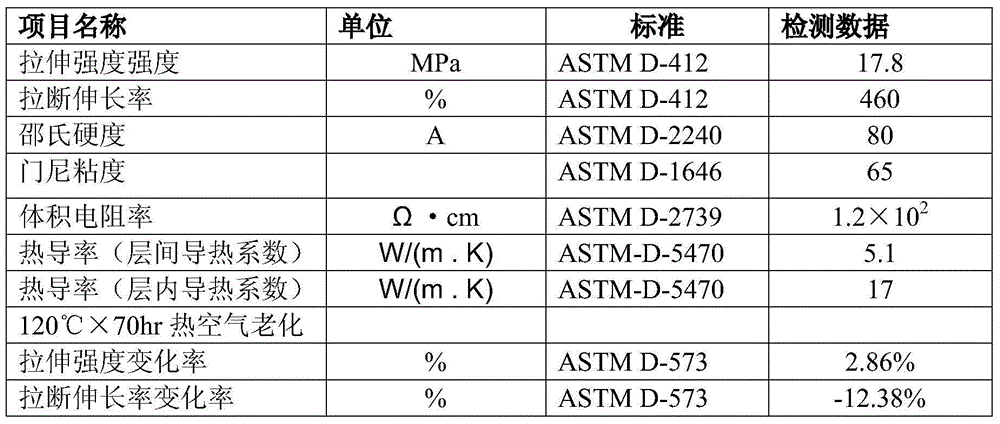

Embodiment 2

[0068] 1. The preparation and surface treatment of modified carbon nanotubes, graphene and aluminum nitride are the same as steps 1 to 6 in Example 1.

[0069] 2. Add 100g of chlorosulfonated polyethylene pellets to 600ml of water, add 2g of sodium polymethacrylate and 0.5g of NP-9 and stir to form a suspension, add 30g of the prepared surface-modified graphene powder, and 0.2% initiator BPO, the closed vessel was heated to 120°C, the pressure was raised to 0.3MPa, and the reaction was performed for 2 hours. The temperature was lowered to 70°C, washed with water, and then centrifuged and dried to obtain a graphene-modified basic rubber material, which was used for later use;

[0070] 3. Put 500g of graphene-modified chlorosulfonated polyethylene powder into a 90°C high-speed mixer, and then add 80g of modified carbon nanotubes prepared before, 80g of surface-treated aluminum nitride powder, 20g of oxidized Magnesium and 120g DOA are subjected to high mixing modification. Afte...

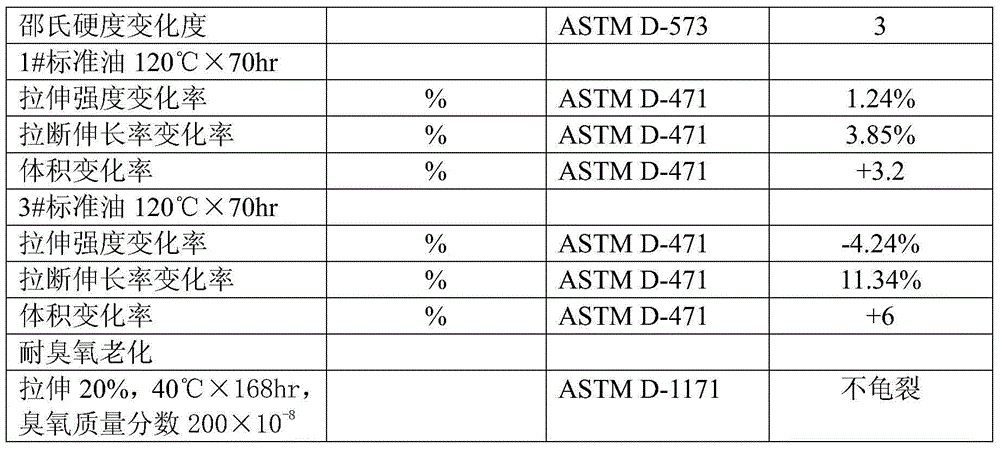

Embodiment 3

[0078] 1. The preparation and surface treatment of modified carbon nanotubes, graphene and aluminum nitride are the same as steps 1 to 6 in Example 1.

[0079] 2. Add 70g of chlorinated polyethylene powder to 600ml of water, add 2g of sodium polymethacrylate and 0.5g of NP-9 and stir to form a suspension, add 30g of liquid neoprene and 30g of the prepared surface-modified graphene powder, and 0.2% initiator BPO, the closed vessel was heated to 125°C, the pressure was raised to 0.3MPa, and the reaction was carried out for 2 hours. The temperature was lowered to 70°C, washed with water, and then centrifuged and dried to obtain a graphene-modified basic rubber material, which was used for later use;

[0080] 3. Put 500g of graphene-modified chlorinated polyethylene and chloroprene rubber mixed powder into a high-speed mixer at 80°C, and then add 100g of modified carbon nanotubes prepared before, 100g of surface-treated nitriding Aluminum powder, 20g magnesium oxide and 160g DOA ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com