Conductive heating functional coating and preparation method

A functional coating, electrical and thermal conductivity technology, applied in conductive coatings, anti-corrosion coatings, coatings, etc., to achieve good electrical and thermal conductivity, improve electrical conductivity, and reduce the effect of adding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

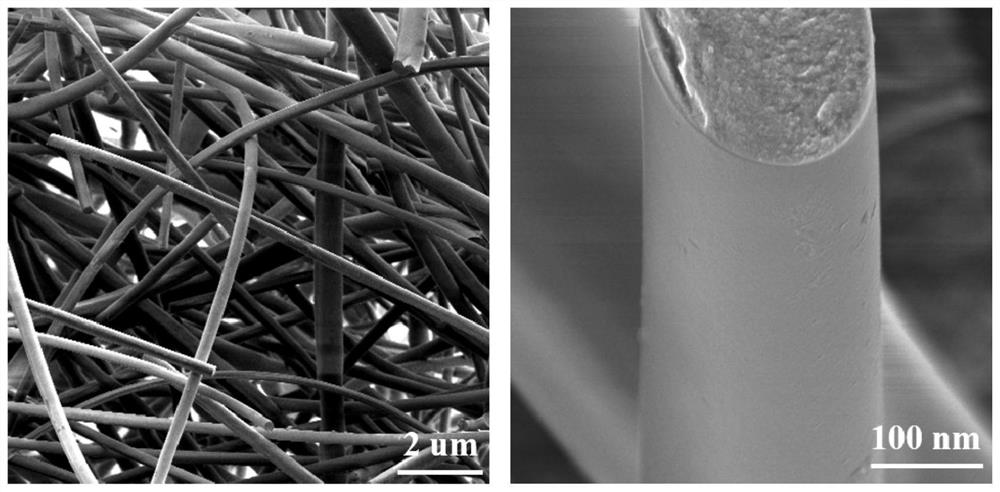

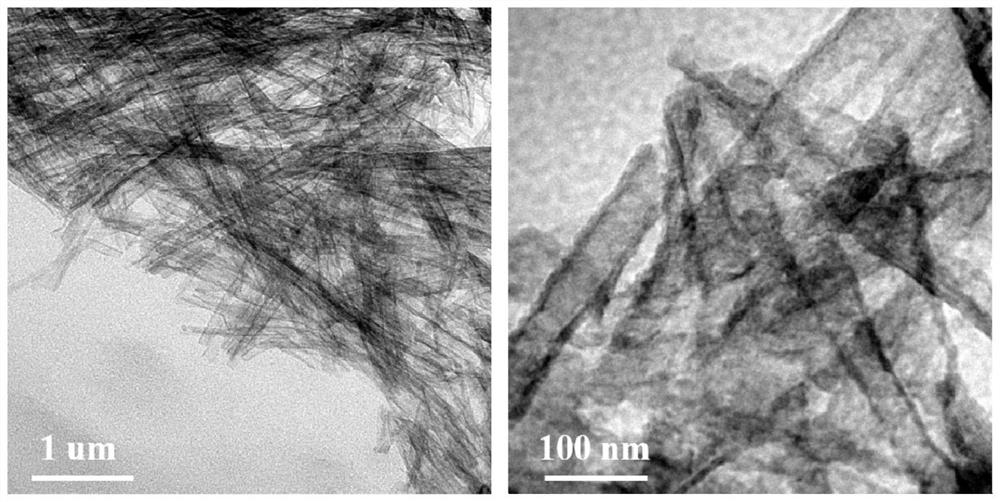

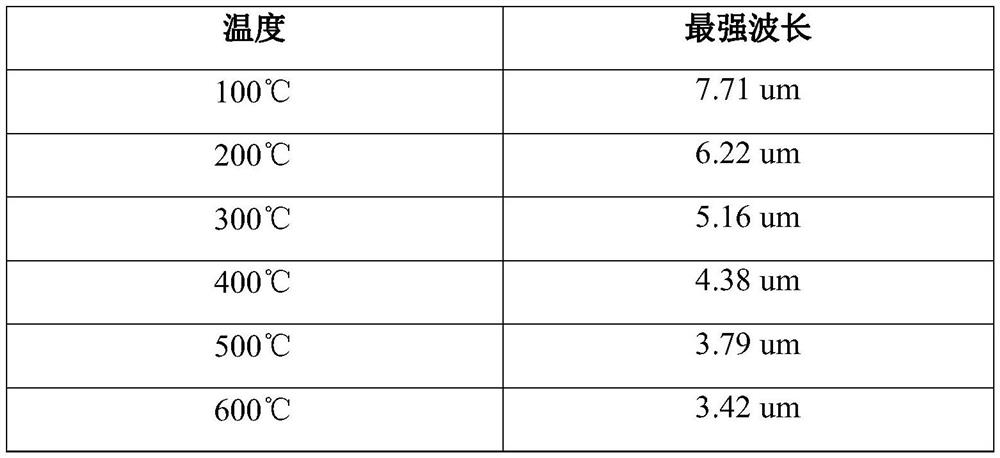

Image

Examples

Embodiment 1

[0028] (1) Add 1g of tin tetrachloride pentahydrate and 0.1g of antimony trichloride to the hydrochloric acid solution with a mass fraction of 15%, and stir until dissolved to obtain a mixed solution of tin and antimony. The concentration of tin tetrachloride pentahydrate in hydrochloric acid is 1g / L;

[0029] (2) Disperse 5g of TiN powder and 1g of graphite-phase carbon nitride in deionized water, add tin-antimony mixed solution and ammonia water dropwise while stirring under heating conditions, until the pH is 3, keep warm for 40 minutes after the addition, come over, and wash , and dry to obtain the conductive and thermally conductive filler, which is ready for use.

[0030] (3) 20g of titanium dioxide, 16g of talcum powder, 14g of diatomaceous earth, 5g of bentonite, and 45g of silicon dioxide are mixed to obtain 100g of pigments and fillers;

[0031] (4) In parts by weight, weigh 100 parts of deionized water, 100 parts of silicone modified water-based acrylate emulsion (...

Embodiment 2

[0034] (1) Add 1g tin tetrachloride pentahydrate, 0.2g antimony trichloride in mass fraction 15% hydrochloric acid solution, after stirring to dissolving, obtain tin-antimony mixed solution, the concentration of tin tetrachloride pentahydrate in hydrochloric acid is: 1.5g / L;

[0035] (2) Disperse 6g of TiN powder and 1g of graphitic carbon nitride in deionized water, add the mixed solution of tin and antimony and ammonia water dropwise while stirring under heating conditions, until the pH is 3, keep the reaction for 50min after the addition, come over, and wash , and dry to obtain the conductive and thermally conductive filler, which is ready for use.

[0036] (3) 18g of titanium dioxide, 20g of talc, 12g of diatomaceous earth, 10g of bentonite, 40g of silicon dioxide, mixed to obtain 100g of pigments and fillers;

[0037] (4) In parts by weight, weigh 100 parts of deionized water, 60 parts of silicone-modified acrylic emulsion (solid content 40%), 10 parts of conductive and ...

Embodiment 3

[0040] (1) Add 1g of tin tetrachloride pentahydrate and 0.1g of antimony trichloride to the hydrochloric acid solution with a mass fraction of 15%, and stir until dissolved to obtain a mixed solution of tin and antimony. The concentration of tin tetrachloride pentahydrate in hydrochloric acid is 1g / L;

[0041] (2) Disperse 8g of TiN powder and 1g of graphite-phase carbon nitride in deionized water, add tin-antimony mixed solution and ammonia water dropwise while stirring under heating conditions, until the pH is 3, keep warm for 50min after the addition, and wash , and dry to obtain the conductive and thermally conductive filler, which is ready for use.

[0042] (3) 15g of titanium dioxide, 20g of talcum powder, 10g of diatomaceous earth, 10g of bentonite, and 45g of silicon dioxide are mixed to obtain 100g of pigments and fillers;

[0043] (4) In parts by weight, weigh 100 parts of deionized water, 80 parts of silicone-modified acrylic emulsion (solid content 40%), 10 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com